Page 1

SERVICE MANUAL

VIDEO CASSETTE RECORDER

HR-J3008UM/J4008UM

Regarding service information other than these sections, refer to the HR-A37U service manual (No.82836).

Also, be sure to note important safety precautions provided in the service manual.

SPECIFICATIONS

GENERAL

Power requirement : AC 110 V – 220 Vd, 50 Hz/60 Hz

Power consumption

Power on : 14 W

Power off : 2.0 W

Temperature

Operating : 5°C to 40°C

Storage : –20°C to 60°C

Operating position : Horizontal only

Dimensions (W x H x D) : 360 mm x 94 mm x 247 mm

Weight : 3.0 kg

Format : VHS NTSC standard

Maximum recording time

SP : 210 min. with ST-210 video cassette

EP : 630 min. with ST-210 video cassette

VIDEO/AUDIO

Signal system : NTSC-type color signal and EIA

Recording/Playback

system

Signal-to-noise ratio : 45 dB

Horizontal resolution : 230 lines

Frequency range : 70 Hz to 10,000 Hz

Input/Output : RCA connectors (IN x 1, OUT x 1)

(The specifications shown pertain specifically to the model HR-J4008UM)

monochrome signal, 525 lines/

60 fields

: DA-4 (Double Azimuth) head helical

scan system

TUNER

Tuning system : Frequency-synthesized tuner

Channel coverage

VHF : Channels 2–13

UHF : Channels 14–69

CATV : 113 Channels

RF output : Channel 3 or 4 (switchable; preset to

Channel 3 when shipped) 75 ohms,

unbalanced

TIMER

Clock reference : Quartz

Program capacity : 1-year programmable timer/

8 programs

Memory backup time : Approx. 6 months

Estimated figure based on supplied

fresh battery; actual performance may

differ.

ACCESSORIES

Provided accessories : RF cable (F-type),

Lithium battery CR2025,

Infrared remote control unit,

“AA” battery x 2,

Conversion plug

Specifications shown are for SP mode unless specified otherwise.

E. & O.E. Design and specifications subject to change without

notice.

No.82852

April 2001

Page 2

TABLE OF CONTENTS

Section Title Page Section Title Page

DIFFERENT TABLE ........................................................................... 1 to 2

2. MECHANISM ADJUSTMENT

2.1 Before starting repair and adjustment...........................................2-1

2.1.1Precautions ...................................................................................2-1

2.1.2Checking for proper mechanical operations .................................2-1

2.1.3Manually removing the cassette tape ...........................................2-1

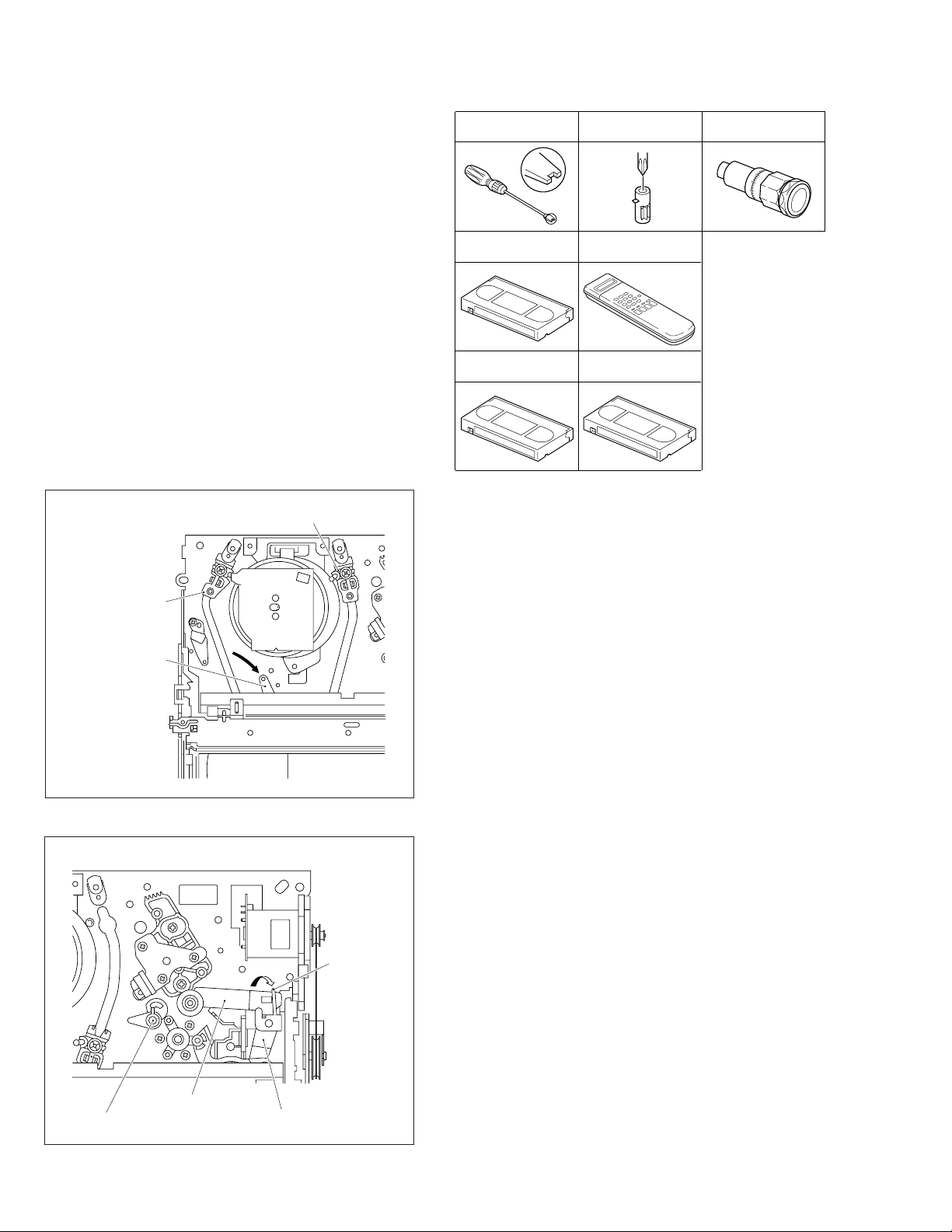

2.1.4Jigs and tools required for adjustment ..........................................2-2

2.1.5Maintenance and inspection .........................................................2-3

2.2 Replacement of major parts..........................................................2-6

2.2.1Before starting disassembling

2.2.2How to set the “Mechanism assembling mode” ............................2-6

2.2.3Cassette holder assembly ............................................................2-6

2.2.4Pinch roller arm assembly ............................................................2-8

2.2.5Guide arm assembly and press lever assembly ...........................2-8

2.2.6A/C head .......................................................................................2-8

2.2.7Loading motor ...............................................................................2-8

2.2.8Capstan motor ..............................................................................2-9

2.2.9Pole base assembly (supply or take-up side) ...............................2-9

2.2.10 Rotary encoder .....................................................................2-10

2.2.11 Clutch unit .............................................................................2-10

2.2.12 Change lever assembly,direct gear,clutch gear

2.2.13 Link lever............................................................................... 2-11

2.2.14 Cassette gear,control cam and worm gear ........................... 2-11

2.2.15 Control plate.......................................................................... 2-11

2.2.16 Loading arm gear (supply or take-up side)

2.2.17 Take-up lever,take-up head and control plate guide ............. 2-13

2.2.18 Capstan brake assembly ......................................................2-13

2.2.19 Sub brake assembly (take-up side) ......................................2-13

2.2.20 Main brake assembly (take-up side),

(Phase matching between mechanical parts) .........................2-6

and coupling gear .................................................................2-10

and loading arm gear shaft ................................................... 2-12

2.2.21 Tension brake assembly, reel disk (supply side)

2.2.22 Idler lever, idler arm assembly ..............................................2-14

2.2.23 Stator assembly ....................................................................2-14

2.2.24 Rotor assembly .....................................................................2-14

2.2.25 Upper drum assembly...........................................................2-15

2.3 Compatibility adjustment.............................................................2-16

2.3.1FM waveform linearity .................................................................2-16

2.3.2Height and tilt of the A/C head ....................................................2-17

2.3.3A/C head phase (X-value) ..........................................................2-17

2.3.4Standard tracking preset.............................................................2-18

2.3.5Tension pole position ..................................................................2-18

4. CHARTS AND DIAGRAMS

4.1 MAIN (SYSCOM) AND LT BATTERY

4.2 MAIN CIRCUIT BOARD

4.3 MAIN CIRCUIT BOARD

5. PARTS LIST

5.1 PACKING AND ACCESSORY ASSEMBL Y <M1> ........................ 5-1

5.2 FINAL ASSEMBL Y <M2>.............................................................. 5-2

5.3 MECHANISM ASSEMBLY <M4>.................................................. 5-4

5.4 ELECTRICAL PARTS LIST ..........................................................5-6

reel disk (take-up side) and

main brake assembly (supply side).......................................2-13

and tension arm assembly ....................................................2-14

SCHEMATIC DIAGRAMS.......................................................4-1

(MAIN PWB LPB10130-001C) [HR-J4008UM].............................4-3

(MAIN PWB LPB10130-001D) [HR-J3008UM].............................4-5

MAIN BOARD ASSEMBLY <03> ..................................................5-6

A/C HEAD BOARD ASSEMBLY <12>. .......................................5-10

LOADING MOTOR BOARD ASSEMBLY <55> ..........................5-10

LT BATTERY BOARD ASSEMBLY <93>

[HR-J4008UM] .......................................................................510

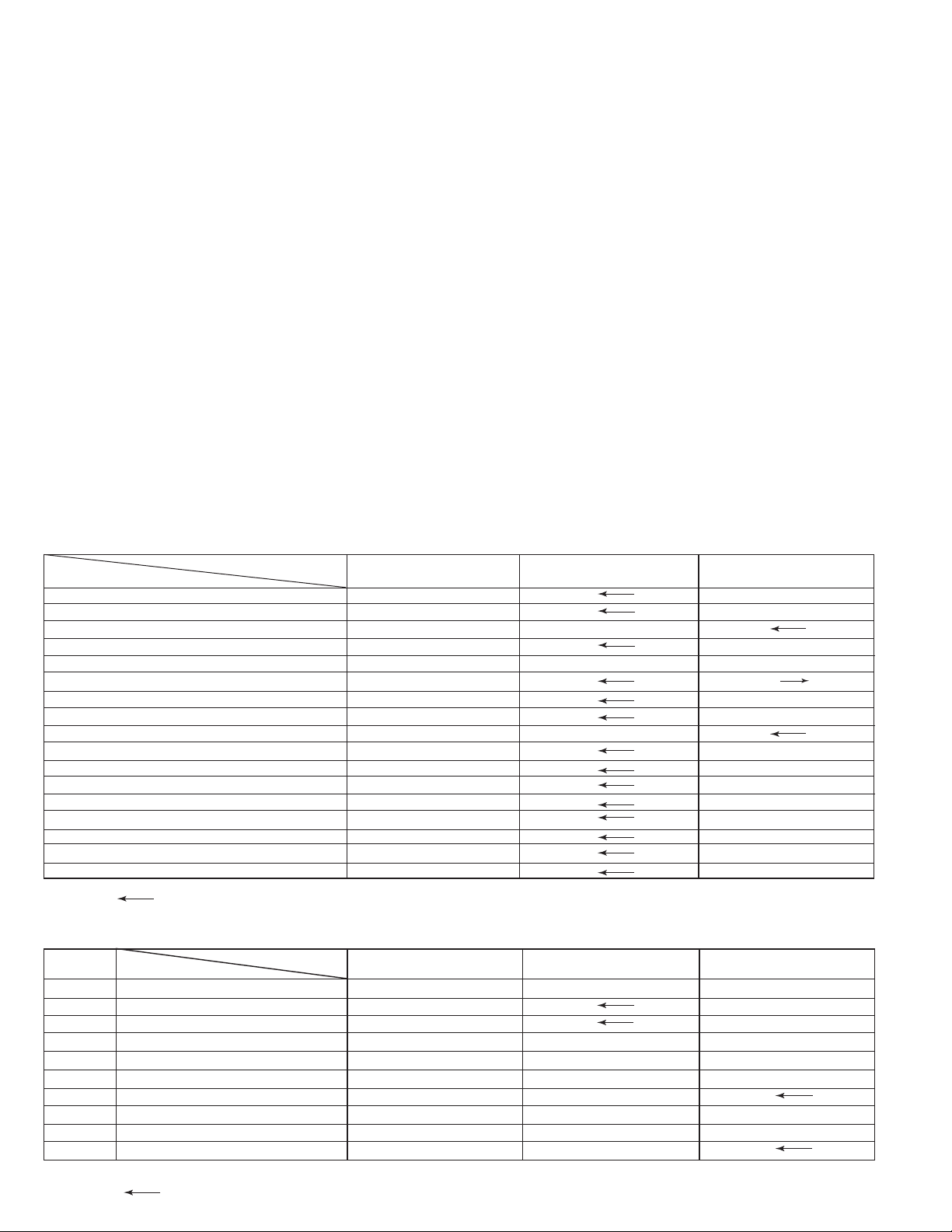

The following table indicate main different points between models HR-A37U,HR-J3008UM and HR-J4008UM.

ITEM

MODEL

HR-A37U

HR-J3008UM

HR-J4008UM

POWER VOLTAGE 120V, 60HZ 110-220V, 50/60HZ

POWER PLUG UL, CSA SASO

COSMETIC/COLOR MOLD-DARK GRAY PAINT-Pure SILVER

RCU TYPE / COLOR U1 / MOLD BLACK E1 / PAINT SILVER

INSTRUCTION / LANGUAGE 1 SHEET / ENG YES / SPA YES / SPA, ENG

PLUG ADAPTER NOT USED SASO CEE

LITHIUM BATTERY NOT USED CR2025

HEAD CLEANER NOT USED USED

SHUTTLE SERCH(LATCH) SP

X7, EPX21 SPX7, EPX21(X21)

B.E.S.T. PICTURE AUTO PICTURE A.V. CALIBRATION

AUTO CH PRESET USED (P&P) USED

BACKUP TIME NOT USED 6 MONTHS(LI BATT.)

TIMER PROGRAM BACKUP

PERMANENT PROGRAM

NOT USED

SUMMER TIME ADJUST USED NOT USED

AUTO CLOCK / JUST CLOCK USED NOT USED

REC RESUME NOT USED USED

LANGUAGE[INITIAL] [ENG], SPA, FRE [SPA], ENG

Note: Mark is same as left.

The following table indicate main different points between models HR-A37U,HR-J3008UM and HR-J4008UM.

PACKING AND ACCESSORY ASSEMBLY <M1>

!

REF

NO.

ITEM

MODEL

HR-A37U

HR-J3008UM

HR-J4008UM

301 PACKING CASE LP30836-006A LP30836-017A LP30836-015B

306 REMOTE CONTROL UNIT LP20878-001A

306A COVER(BATTERY) LP40610-001A

LP20878-002A

LP40610-002A

! 309 LITHIUM BATTERY ––– ––– PECA0903

! 310 INST. BOOK(EN) LPT0497-001A ––– LPT0533-001A

! 310 INST. BOOK(SP) ––– LPT0532-001A LPT0533-002A

311 POLY BAG ––– QPC02503530P

! 313 CONVERSION PLUG ––– ––– PEMC1012

317 REGIST. CARD BT-51020-2 ––– –––

320 CONNECTION SHEET ––– PU36560-2

Note: Mark ––– is not used.

Mark is same as left.

1

Page 3

FINAL ASSEMBL Y<M2>

!

REF

NO.

ITEM

MODEL

HR-A37U

HR-J3008UM

HR-J4008UM

! 501 FRONT PANELASSEMBLY * LP10348-004D LP10348-009F LP10348-008F

501A CASSETTE DOOR * LP20977-002C LP20977-008C

501C DISPLAY WINDOW LP20976-004A LP20976-009A LP20976-008A

! 502 TOP COVER LP10352-002A LP10352-008A

503 SCREW,X2,TOP COVER(SIDE) QYTDSF3010M QYTDSF3010R

! 511 BOTTOM CHASSIS * LP10350-003D LP10350-004D LP10350-005D

! 517 POWER CORD ––– ––– QMP73J0-170

518 CLEANER ASSEMBLY ––– ––– LP40369-001D

518A CLEANER ROLLER ––– ––– PQ46418-1-2

518B CLEANER ––– ––– PQ46419-1-2

518C CLEANER ARM ––– ––– LP30407-001D

520 CAP ––– ––– LP30336-001A

531 SCREW,REAR ––– ––– QYTDSF3010M

532 SCREW,TERMINAL BOARD

MAIN BOARD ASSEMBLY<03>

REF

!

NO.

PW1 MAIN BOARD ASSEMBLY * LPA10130-02D1

LITHIUM BATTERY BOARD ASSEMBLY<93>

REF

!

NO.

! PW4

ITEM

ITEM

LITHIUM BATTERY BOARD ASSEMBLY

MODEL

MODEL

––– ––– QYTDSF3010Z

HR-A37U

HR-A37U

––– ––– LPA10130-01A4

HR-J3008UM

HR-J3008UM

HR-J4008UM

LPA10130-05B1

HR-J4008UM

Note : Mark ––– is not used.

Mark

Mark * reference model was also changed.

is same as left.

2

Page 4

SECTION 2

MECHANISM ADJUSTMENT

2.1 Before starting repair and adjustment

2.1.1 Precautions

(1) Unplug the power cord plug of the VCR before using your

soldering iron.

(2) Take care not to cause any damage to the conductor

wires when plugging and unplugging the connectors.

(3) Do not randomly handle the parts without identifying

where the trouble is.

(4) Exercise enough care not to damage the lugs, etc. dur-

ing the repair work.

(5) When reattaching the front panel assembly, make sure

that the door opener of the cassette holder assembly is

lowered in position prior to the reinstallation. (See SECTION 1 DISASSEMBLY.)

(6) When using the Jig RCU, it is required to set the VCR to

the Jig RCU mode (the mode in which codes from the

Jig RCU can be received). (See SECTION 1 DISASSEMBLY.)

Loading motor

2.1.2 Checking for proper mechanical operations

Enter the mechanism service mode when you want to operate the mechanism when no cassette is loaded. (See SECTION 1 DISASSEMBLY.)

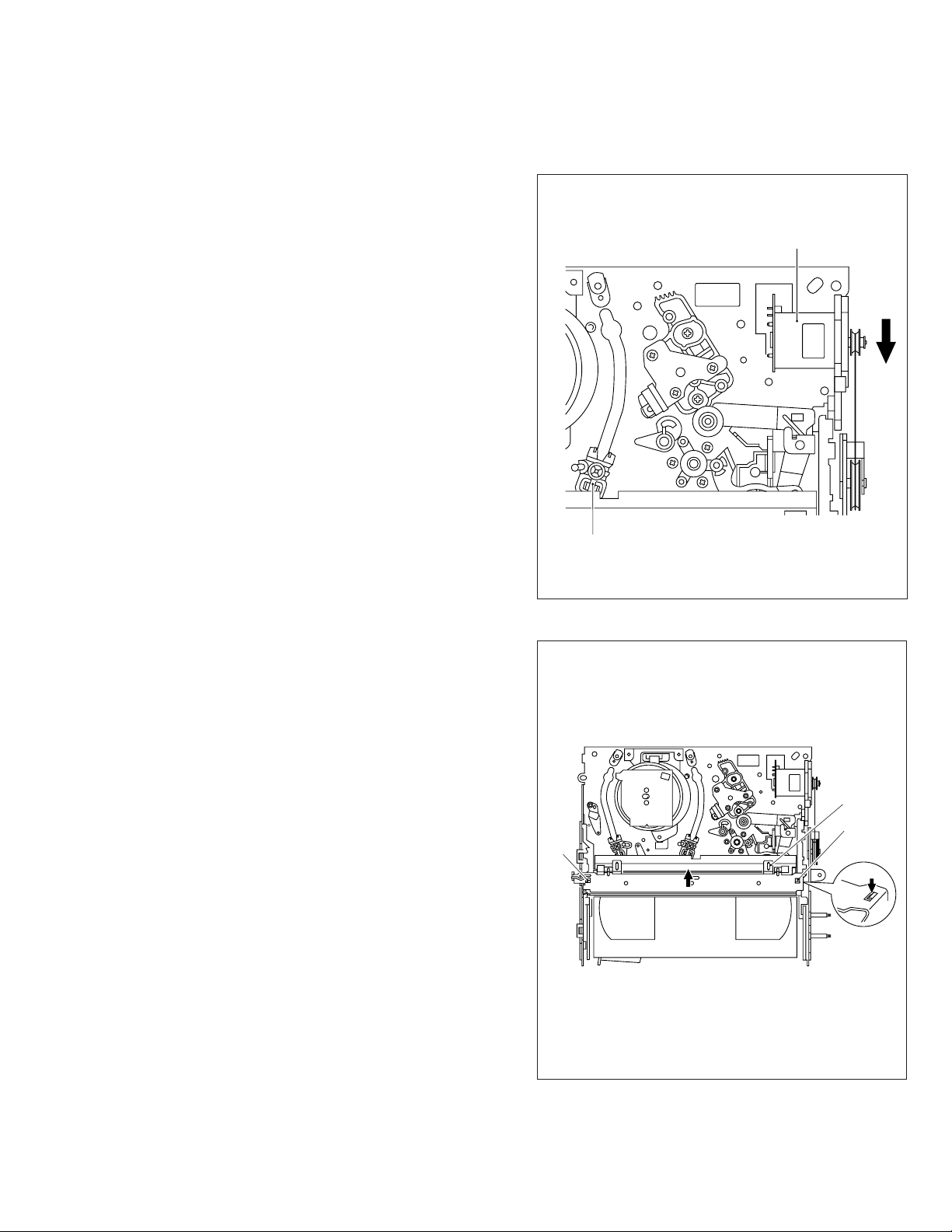

2.1.3 Manually removing the cassette tape

1. In case of electrical failures

If you cannot remove the cassette tape which is loaded because of any electrical failure, manually remove it by taking

the following steps.

(1) Unplug the power cord plug from the power outlet.

(2) Refer to the disassembly procedure and perform the dis-

assembly of the major parts before removing the drum

assembly.

(3) Unload the pole base assembly by manually turning the

loading motor of the mechanism assembly toward the

front. In doing so, hold the tape by the hand to keep the

slack away from any grease. (See Fig.2-1-3a.)

(4) Bring the pole base assembly to a pause when it reaches

the position where it is hidden behind the cassette tape.

(5) Move the top guide toward the drum while holding down

the lug (A) of the bracket retaining the top guide. Likewise hold part (B) down and remove the top guide.

Section (C) of the top guide is then brought under the

cassette lid. Then remove the top guide by pressing the

whole cassette tape down. (See Fig.2-1-3b.)

(6) Remove the cassette tape by holding both the slackened

tape and the cassette lid.

(7) Take up the slack of the tape into the cassette. This com-

pletes removal of the cassette tape.

Note:

• For the disassembly procedure of the major parts and

details of the precautions to be taken, see “SECTION

1 DISASSEMBLY”.

Pole base assembly

Fig. 2-1-3a

(C)

(A)

(B)

Press

Fig. 2-1-3b

2-1

Page 5

2. In case of mechanical failure

If you cannot remove the cassette tape which is loaded because of any mechanical failure, manually remove it by taking the following steps.

(1) Unplug the power cable and remove the top cover, front

panel assembly and others so that the mechanism assembly is visible. (See SECTION 1 DASASSEMBLY.)

(2) While keeping the tension arm assembly of the mecha-

nism assembly free from tension, pull the tape on the pole

base assembly (supply or take-up side) out of the guide

roller. (See Fig.2-1-3c.)

(3) Take the spring of the pinch roller arm assembly off the

hook of the press lever assembly, and detach it from the

tape. (See Fig.2-1-3d.)

(4) In the same way as in the electrical failure instructions in

2.1.3-1(5), remove the top guide.

(5) Raise the cassette tape cover. By keeping it in that posi-

tion, draw out the cassette tape case from the cassette

holder and take out the tape.

(6) By hanging the pinch roller arm assembly spring back

on the hook, take up the slack of the tape into the cassette.

Pole base assembly (take-up side)

2.1.4 Jigs and tools required for adjustment

Roller driver

PTU94002

Back tension cassette gauge

PUJ48076-2

Alignment tape

(SP, stairstep, NTSC)

MHP

A/C head positioning tool

PTU94010

Jig RCU

PTU94023B

Alignment tape

(EP, stairstep, NTSC)

MHP-L

Torque gauge

PUJ48075-2

Pole base assembly

(supply side)

Tension arm assembly

Fig. 2-1-3c

Take the spring

off the hook, and

detach it from the

tape.

Guide pole guard

2-2

Pinch roller arm assembly

Press lever assembly

Fig. 2-1-3d

Page 6

2.1.5 Maintenance and inspection

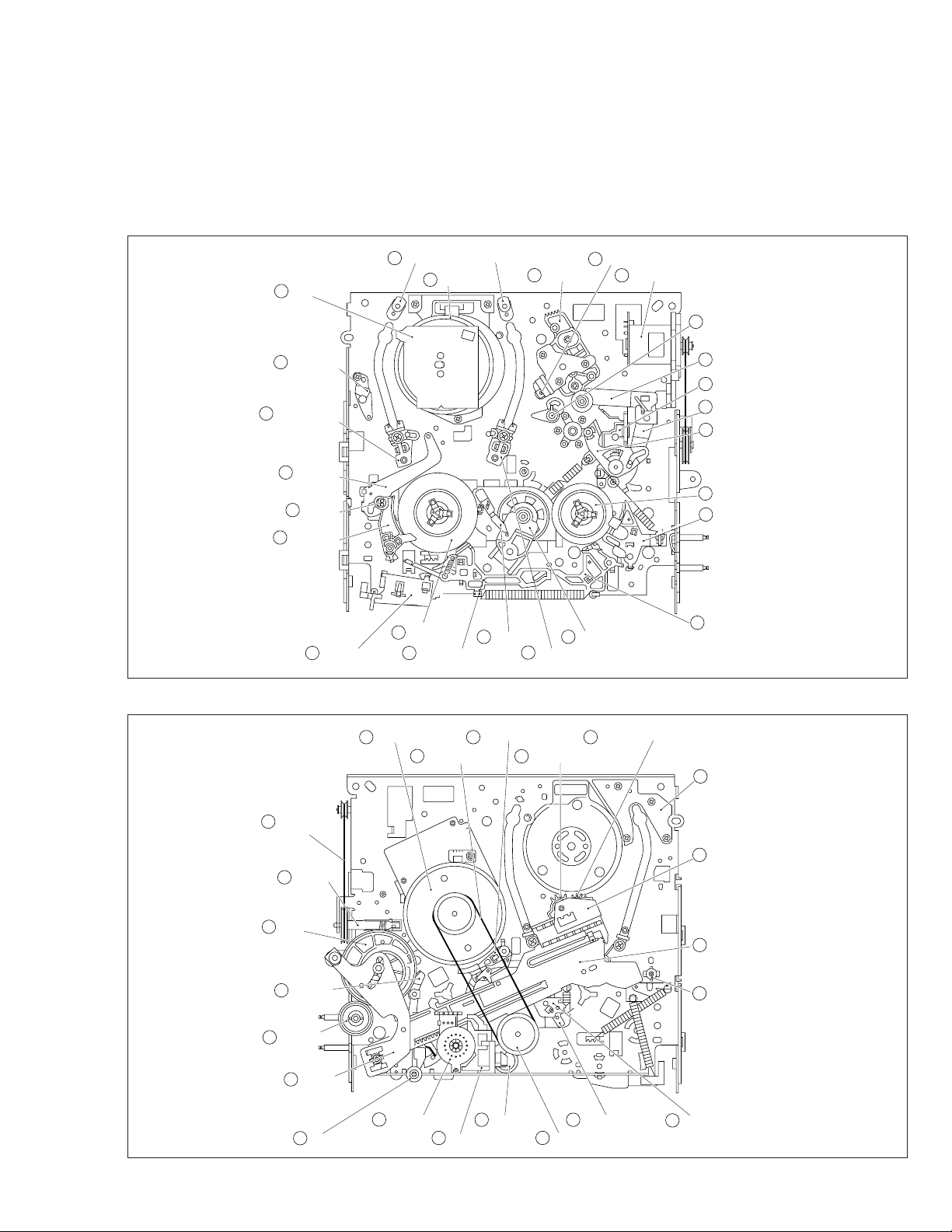

1. Location of major mechanical parts

In this chapter, the two mechanism speeds are described by comparing the speeds of the standard type and the high-speed

FF/REW type.

It is possible to distinguish between these two types of mechanism by the diameters of their capstan pulleys.

The capstan pulley diameter for the standard type is approx. 32 mm.

The capstan pulley diameter for the high-speed FF/REW type is approx. 43 mm.

For information on the different parts used in the two mechanism types, please refer to the “Replacement of major parts”.

UV catcher2 (supply and take-up side)

Stator assembly

T2

Full erase head

T26

Pole base assembly

T25

(supply side)

Tension arm

T24

assembly

Adjust pin

T23

Tension brake

T22

assembly

T1

T5 T7

T3

Drum assembly

Head base

T6

A/C head

Loading motor

Guide pole guard

T8

Pinch roller arm

T9

assembly

Lid guide

T10

Press lever

T11

assembly

Guide arm

T12

assembly

Reel disk

T13

(take-up side)

Sub brake assembly

T14

(take-up side)

Belt

B22

(loading motor)

B21

Control cam

B20

B19

Cassette gear

B18

Worm gear

Brake lever

Rec safety lever

B1

Reel disk

T20

(supply side)

Main brake assembly

(supply side)

Idler lever

T17T19T21

Idler arm assembly

T16T18

Pole base assembly (take-up side)

Fig. 2-1-5a Mechanism assembly top side

Capstan motor

B2

Capstan brake assembly

B3 B5

Belt (capstan)

Loading arm gear (take-up side)

B4

Loading arm gear (supply side)

Main brake assembly

T15

(take-up side)

Plate

B6

(supply side)

Control

B7

bracket1

Control plate

B8

Tension arm

B9

bearing

Link lever

B17

Rotary encoder guide

B16

Rotary encoder

B15

B14

Direct gear

B13

Change lever assembly

B12

B10

Clutch unit

Take-up head

Fig. 2-1-5b Mechanism assembly bottom side

Take-up lever

B11

2-3

Page 7

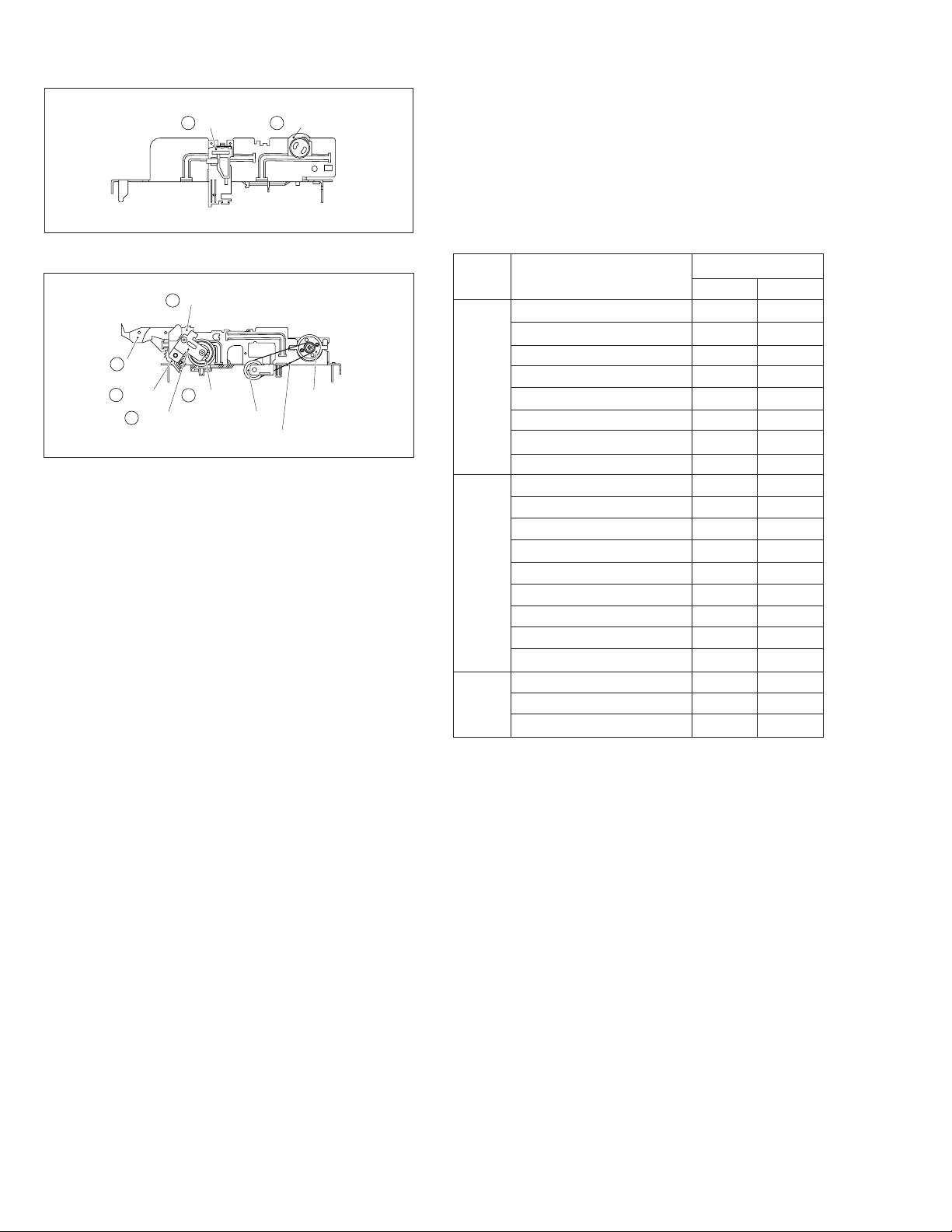

Guide rail Roller cam assembly

L2L1

Fig. 2-1-5c Mechanism assembly left side

R1

Opener guide

Door

R2

opener

Drive gear

R3

Cassette housing bracket

R4

R5

Limit gear

Loading motor

Worm gear

Belt (loading motor)

Fig. 2-1-5d Mechanism assembly right side

2. Cleaning

Regular cleaning of the transport system parts is desirable

but practically impossible. So make it a rule to carry out cleaning of the tape transport system whenever the machine is

serviced.

When the video head, tape guide and/or brush get soiled,

the playback picture may appear inferior or at worst disappear, resulting in possible tape damage.

(1) When cleaning the upper drum (especially the video

head), soak a piece of closely woven cloth or Kimu-wipe

with alcohol and while holding the cloth onto the upper

drum by the fingers, turn the upper drum

counterclockwise.

Note:

• Absolutely avoid sweeping the upper drum vertically

as this will cause damage to the video head.

(2) To clean the parts of the tape transport system other than

the upper drum, use a piece of closely woven cloth or a

cotton swab soaked with alcohol.

(3) After cleaning, make sure that the cleaned parts are com-

pletely dry before using the video tape.

3. Lubrication

With no need for periodical lubrication, you have only to lubricate new parts after replacement. If any oil or grease on

contact parts is soiled, wipe it off and newly lubricate the

parts.

Note:

• See the “mechanism assembly” diagram of the parts

list for the lubricating or greasing spots, and for the

types of oil or grease to be used.

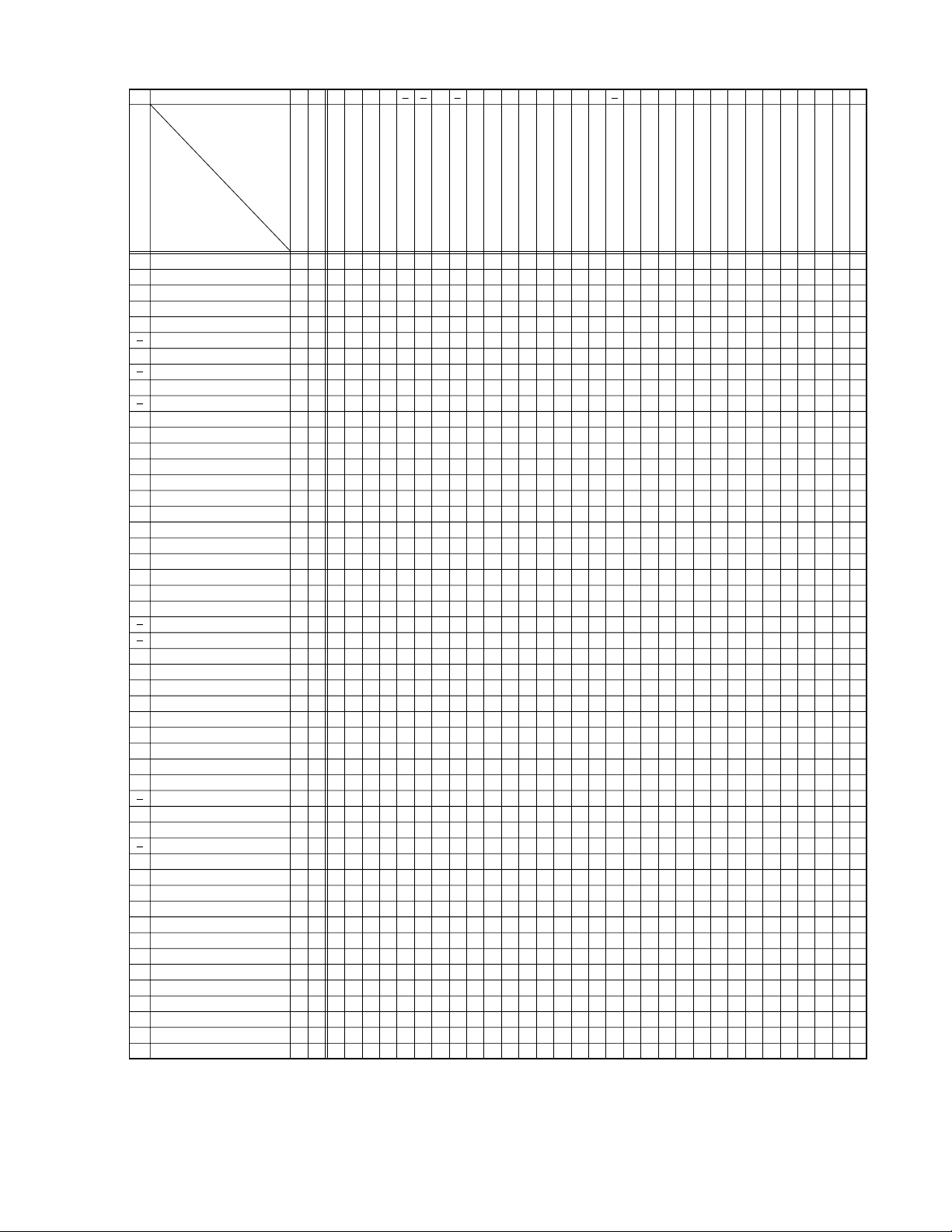

4. Suggested servicing schedule for main components

The following table indicates the suggested period for such

service measures as cleaning,lubrication and replacement.

In practice, the indicated periods will vary widely according

to environmental and usage conditions.However, the indicated components should be inspected when a set is brought

for service and the maintenance work performed if necessary. Also note that rubber parts may deform in time,even if

the set is not used.

System Parts Name

Upper drum assembly

A/C head

Lower drum assembly

Pinch roller arm assembly

Full erase head

Tension arm assembly

Capstan motor (Shaft)

Guide arm assembly

Capstan motor

Capstan brake assembly

Main brake assembly

Belt (Capstan)

Belt (Loading motor)

Loading motor

Clutch unit

Worm gear

Control plate

Brush

Tension brake assembly

Other Drive Tape transport

Rotary encoder

: Cleaning

¤

: Inspection or replacement if necessary

R

Operation Hours

~1000H ~2000H

¤R R

¤R ¤R

¤¤R

¤¤

¤¤

¤¤

¤¤

¤¤

R

R

R

RR

R

R

R

R

R

¤R ¤R

RR

R

Table 2-1-5a

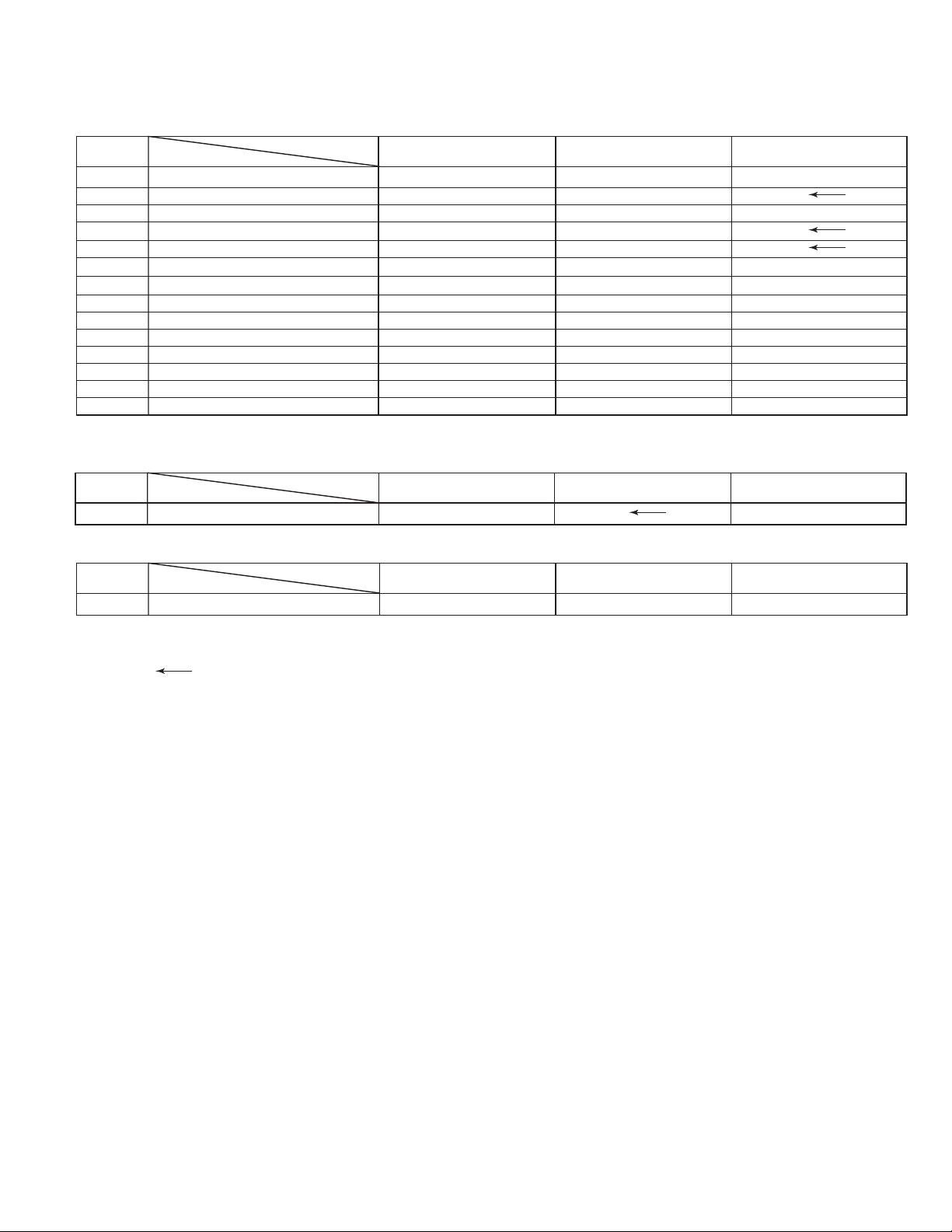

5. Disassembling procedure table

The following table indicates the order in which parts are removed for replacement. To replace parts, remove them in

the order of 1 to 18 as shown in the table. To install them,

reverse the removal sequence.

The symbols and numbers preceding the individual part

names represent the numbers in the “Location of major mechanical parts” table. Also, the “T”, “B”, and “T/B” on the right

of each part name shows that the particular part is removed

from the front, from the back, and from both sides of the

mechanism, respectively.

2-4

Page 8

R4 R1 R3 T9 T12 T11 B15 B12 B14 B13 B17 B21 B7 B8 B5 B4 B11 T14 T15 T13 T22 T24 T18 B1 9

Symbols and numbers

Removal parts

(Reference items)

Replacement parts

Symbols and numbers

2.2.3 Guide rail T 1

L2

2.2.3 Roller cam assembly T 1

R4

2.2.3 Cassette housing bracket T 1

R1

2.2.3 Opener guide T 2

R2

2.2.3 Door opener T 3

2.2.3 Relay gear T 3

R5

2.2.3 Limit gear T 3

2.2.3 Cassette holder assembly T 6

R3

2.2.3 Drive gear T 4

2.2.3 Drive arm T 8

T9

2.2.4 Pinch roller arm assembly T 1

T12

2.2.5 Guide arm assembly T 1

T11

2.2.5 Press lever assembly T 3

T6

2.2.6 A/C head T 1

T7

2.2.7 Loading motor T 1

B1

2.2.8 Capstan motor T/B 1

T1

2.2.9 UV catcher2 T 1

T17

Pole base assembly (take-up side)

2.2.9

T25

Pole base assembly (supply side)

2.2.9

B15

2.2.10 Rotary encoder B 1

B12

2.2.11 Clutch unit B 1

B14

2.2.12 Change lever assembly B 3

B13

2.2.12 Direct gear B 4

2.2.12 Coupling gear B 5

2.2.12 Clutch gear B 6

B17

2.2.13 Link lever B 1

2.2.14 Cassette gear B 2

B18

B20

2.2.14 Control cam B 2

B21

2.2.14 Worm gear B 1

T10

- Lid guide T/B 5

B7

2.2.15Control bracket1 B 1

2.2.15Control plate B 6

B8

B5

2.2.16Loading arm gear (supply side) B 7

B4

Loading arm gear (take-up side)

2.2.16

2.2.16Loading arm gear shaft B 9

2.2.17Take-up lever T/B 7

B11

B10

2.2.17Take-up head T/B 8

2.2.17Control plate guide T/B 8

B3

2.2.18Capstan brake assembly T/B 7

T14

Sub brake assembly(take-up side)

2.2.19

T15

Main brake assembly(take-up side)

2.2.20

T19

Main brake assembly(supply side)

2.2.20

T13

2.2.20Reel disk (take-up side) T/B 16

T22

2.2.21Tension brake assembly T/B 9

T20

2.2.21Reel disk (supply side) T/B 10

T24

2.2.21Tension arm assembly T/B 10

B9

2.2.21Tension arm bearing T/B 10

T18

2.2.22Idler lever T/B 17

T16

2.2.22Idler arm assembly T/B 18

B19

- Brake lever (

B16

- Rotary encoder guide T/B 19

1

) T/B 18

*

L1L1L2

Number of removal steps

Guide rail

Roller cam assembly

Cassette housing bracket

Opener guide

112

12

12

12 3

3

4 5

5 6

Relay gear

6 7

Front (T)/Back (B) of mechanism

1 2 3 4 5

12

T/B 2

T/B 2

B8

T/B 15

1 2 3 4

T/B 16

1 2 3 4 5 6 7 8

T/B 9

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

Cassette holder assembly

Drive gear

7

Table 2-1-5b

Note:

• The parts with marked (

nisms (standard type or high-speed FF/REW type).

1: Uses the standard type mechanism only.

*

2: Uses the high-speed FF/REW type mechanism only.

*

) have different types of mecha-

*

T1

Drive arm

Pinch roller arm assembly

Guide arm assembly

Press lever assembly

UV catcher2

Rotary encoder

Clutch unit

Change lever assembly

Direct gear

1

2

1

1

1

2

12

3

12

3

1 2 3 4 5

12

3 4

1 2 3 4

1 2 3 4 5

1 2 3 4 5 6

1 2 3 4 5 6 7

1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

8

9 10 11 12 13 14

9 10 11 12 13 14 15

9 10 11 12 13 14 15

9 10 11 12 13 14 15 16

9 10 11 12 13 14 15 16 17

9 10 11 12 13 14 15 16 17

9 10 11 12 13 14 15 16 17 18

4

Clutch gear

Link lever

Worm gear

Control bracket1

Control plate

Loading arm gear (supply side)

Loading arm gear (take-up side)

1

1

5

6

7

8

)

1

*

(

Take-up lever

Sub brake assembly (take-up side)

Main brake assembly (take-up side)

Reel disk (take-up side)

Tension brake assembly

Tension arm assembly

Idler lever

Brake lever

7

7

9

9

9

2-5

Page 9

2.2 Replacement of major parts

2.2.1 Before starting disassembling (Phase matching between mechanical parts)

The mechanism of this unit is closely linked with the rotary

encoder and system controller circuits.

Since the system controller detects the status of mechanical operation in response to phases of the rotary encoder

(internal switch positions), the mechanism may not operate

properly unless such parts as the rotary encoder, control

plate, loading arm gear, control cam, cassette gear, limit gear,

relay gear and drive gear are installed in their correct positions.

Especially, this model is not provided with any cassette housing assembly, so that cassette loading and unloading must

be accomplished by operation of the cassette holder assembly. The latter is in turn driven by such parts as the drive

gear, relay gear and limit gear. Exercise enough care, therefore, to have the phases of all this gear matching one another. (For information on phase matching of the mechanism,

see the instructions on how to install individual parts.)

This unit is provided with a mechanism assembly mode. It is

therefore necessary to enter this mode for assembling and

disassembling procedures.

This mode is usually not in use, manually set it when it is

required.

2.2.3 Cassette holder assembly

1. How to remove

(1) Remove the guide rail and roller cam assembly. (See

Fig.2-2-3a.)

(3 lugs on the guide rail and one lug on the roller cam

assembly)

Guide rail

Lugs

Roller cam

assembly

Lug

Lug

Fig. 2-2-3a

(2) Remove the two slit washers and remove the cassette

housing bracket. (See Fig.2-2-3b.)

(3) Remove the opener guide, spring(A), door opener, relay

gear and limit gear. (See Fig.2-2-3b.)

2.2.2 How to set the “Mechanism assembling mode”

Remove the mechanism assembly and place it bottom side

up. (See SECTION 1 DISASSEMBLY.) Turn the worm gear

toward the front so that the guide hole of the control cam is

brought into alignment with the hole at the mechanism assembly chassis. This position renders the mechanism assembling mode operational. Make sure that the control plate is

located in alignment with the mark E. (See Fig.2-2-2a.)

Worm gear

Chassis hole

Guide hole

Control cam

Limit gear

Spring(A)

Opener guide

Relay gear

Door opener

Cassette housing bracket

Slit washers

Fig. 2-2-3b

(4) While swinging the lock levers (R) and (L) of the cassette

holder assembly toward the front, slide the cassette

holder assembly until its legs come to where the guide

rail and the roller cam assembly have been removed (so

that the drive arm is upright). (See Fig.2-2-3c.)

Lock lever (L)

Cassette holder assembly

Drive arm

(Upright)

2-6

Control plate

Fig. 2-2-2a

Mark E

Leg Legs

Fig. 2-2-3c

Page 10

While holding the left side of the cassette holder, lift the

(5)

cassette holder assembly so that the three legs on the

left side are all released. Then pull the legs (A) and (B)

on the right side out of the rail and also pull up the leg(C).

(See Fig.2-2-3d and Fig.2-2-3e.)

(6) Draw out the drive gear, and remove the drive arm.

Cassette holder assembly

Fig. 2-2-3d

Cassette holder assembly

(A)

2. How to install (Phase matching)

(1) Insert the section (A) of the drive arm into the section (B)

of the main deck.

(2) Insert the section (1) of the drive gear into the round hole,

and the section (2) into the square hole on the drive arm.

(See Fig.2-2-3f.)

(3) Hold the drive arm upright and fit the leg (C) on the right

side of the cassette holder assembly into the groove. (See

Fig.2-2-3g.)

(4) While swinging the lock lever (R) of the cassette holder

assembly toward the front, put the legs (A) and (B) into

the rail. (See Fig.2-2-3g.)

(5) Drop the three legs on the left side of the cassette holder

assembly into the groove at one time. (See Fig.2-2-3h.)

(6) Slide the whole cassette holder assembly toward the front

to bring it to the eject end position.

(7) Install the limit gear so that the notch on the outer cir-

cumference of the limit gear is brought into alignment with

the guide hole on the main deck. (See Fig.2-2-3i.)

(8) Install so that the notch on the periphery of the relay gear

is aligned with the notch of the main deck and that hole

A of the relay gear is aligned with the hole A of the limit

gear and that hole B of the relay gear is aligned with the

hole B of the drive gear. (See Fig.2-2-3i.)

(9) Install the door opener, opener guide, spring(A) and cas-

sette housing bracket and fasten the two slit washers.

Cassette holder assembly

Fig. 2-2-3e

Main deck right side

Drive arm

Hole

(C)

Lock lever (R)

(A)

(B)

(B)

Drive arm

Drive arm

(C)

Fig. 2-2-3g

Cassette holder assembly

Hole

Drive gear

(1)

(2)

(A)

Fig. 2-2-3f

(B)

Fig. 2-2-3h

2-7

Page 11

Relay gear

B

Guide holeNotches Notch

2.2.6 A/C head

1. How to remove

(1) Remove the two screws (A) and remove the A/C head

together with the head base.

(2) When replacing only the A/C head, remove the three

screws (B) while controlling the compression spring.

Head base

B

AA

Drive gear Limit gear

Fig. 2-2-3i

2.2.4 Pinch roller arm assembly

1. How to remove

(1) Remove the spring from the hook of the press lever as-

sembly.

(2) Remove the slit washer and remove the pinch roller seat

2. (See Fig.2-2-4a.)

(3) Remove the pinch roller arm assembly by pulling it up.

Slit washer

Pinch roller seat2

Spring

Pinch roller arm

Press lever assembly

Pinch roller arm assembly

assembly

Fig. 2-2-4a

2.2.5 Guide arm assembly and press lever assembly

1. How to remove

(1) Remove the spring and expand the lug of the lid guide in

the arrow-indicated direction. Then remove the guide arm

assembly by pulling it up.

(2) Remove the press lever assembly by pulling it up. (See

Fig.2-2-5a.)

Screws(A)

A/C head

Fig. 2-2-6a

Screws(B)

A/C head

Compression

A/C head board

assembly

Head base

springs

Fig. 2-2-6b

2. How to install

(1) To make the post-installation adjustment easier, set the

temporary level as indicated in Fig.2-2-6c. Also make sure

that the screw center (centre) is brought into alignment

with the center (centre) position of the slot.

A/C head

12.4 mm

Head base

Screw

2-8

Tension

spring

LugLid guide

Fig. 2-2-5a

Press lever

assembly

Guide arm

assembly

Head base

A/C head

Fig. 2-2-6c

2.2.7 Loading motor

1. How to remove

(1) Remove the belt wound around the worm gear.

(2) Open the two lugs of the motor guide and remove the

loading motor, loading motor board assembly and motor

guide altogether by pulling them up.

(3) When replacing the loading motor board assembly, take

care with the orientation of the loading motor. (Install so

that the loading motor label faces upward.)

(4) When the motor pulley has been replaced, choose the

fitting dimension as indicated in Fig.2-2-7a.

Page 12

Loading motor board assembly

Loading motor

Lugs

Motor guide

6.5 ± 0.2 mm

LABEL

Motor pulley

Worm gear

Belt

Fig. 2-2-7a

2.2.8 Capstan motor

1. How to remove

(1) Remove the belt (capstan) on the mechanism assembly

back side.

(2) Remove the three screws (A) and remove the capstan

motor.

Screws(A)

Screw(A)

Capstan motor

Belt

Fig. 2-2-8a

Spacer

Spacer

2. How to install (Centering the mounting position)

When the capstan motor has once been removed and then

reinstalled out of the initial correct position in the rotational

direction, the capstan motor current may be unstable during

operation in high or low temperatures. This may result in

greater Wow & Flutter and occasionally in power breakdown

because of current over - load. Install the capstan motor while

following the procedure given below.

(The capstan motor is centrally located when the unit is

shipped from the factory.)

(1) Provisionally tighten the three screws (A) securing the

capstan motor.

(2) Install the mechanism assembly to which the capstan

motor is provisionally fastened on the bottom chassis

which incorporates the Main board assembly. (No need

to tighten the screws for mounting the mechanism.)

Make sure that all the connectors for the mechanism assembly and the Main board assembly are correctly installed as indicated in Fig. 2-2-8b.

(3) Making sure that the connector for the capstan motor is

correctly mounted, and securely tighten the three screws

(A).

Note:

• When the capstan motor has been replaced with a new

one, perform recording in the EP(or LP) mode for at

least 2 minutes at normal temperatures immediately before starting the FF/REW or SEARCH operations (Aging).

2.2.9 Pole base assembly (supply or take-up side)

1. How to remove

(1) Remove the UV catcher 2 on the removal side by loos-

ening the screw (A).

(2) Remove the pole base assembly on the supply side from

the mechanism assembly by loosening the screw (B) on

the mechanism assembly back side and sliding the pole

base assembly toward the UV catcher 2.

(3) As for the pole base assembly on the take-up side, turn

the pulley of the loading motor to lower the cassette

holder because the screw (B) is hidden under the control plate. (See the “Procedures for Lowering the Cassette

holder assembly” of 1.3 DISASSEMBLY/ASSEMBLY

METHOD.) Further turn the motor pulley to move the cassette holder until the screw (B) is no longer under the control plate (in the half-loading position). Then remove it as

done for the supply side by removing the screw (B).

Note:

• After reinstalling the Pole base assembly and the UV

catcher2, be sure to perform compatibility adjustment.

Fig. 2-2-8b

Connector for

the capstan motor

Screw(A)

UV catcher2

Screw(A)

UV catcher2

Screw(B)

Fig. 2-2-9a

2-9

Page 13

2.2.10 Rotary encoder

1. How to remove

(1) Remove the screw (A) and remove the rotary encoder

by pulling it up. (See Fig. 2-2-10a.)

Rotary encoder (Front side)

Screw(A)

Guide marks

2.2.12 Change lever assembly, direct gear, clutch gear and coupling gear

1. How to remove

(1) Release the two lugs of the rotary encoder guide in the

arrow-indicated direction and remove the change lever

assembly.

(2) Remove the slit washer retaining the direct gear and re-

move the latter.

Take care so as not to lose the washer and spring. (See

Fig.2-2-12a.)

Rotary encoder (Back side)

Positioning pin of the rotary encoder

Fig. 2-2-10a

Mark E

Shaft of the rotary encoder guide

Control plate

Fig. 2-2-10b

2. How to install (Phase matching)

(1) Make sure that the mark E of the control plate is in align-

ment with the mark

of the loading arm gear shaft and

bring the guide marks on the rotary encoder into alignment as indicated in Fig.2-2-10a. (See Fig. 2-2-10a and

Fig. 2-2-10b.)

(2) Turn over the rotary encoder with its guide marks kept in

alignment and install it by fitting on the shaft of the rotary

encoder guide and the positioning pin.

(3) Tighten the screw (A) to complete the installation.

2.2.11 Clutch unit

(1) Remove the belt wound around the capstan motor and

the clutch unit.

(2) Remove the slit washer and remove the clutch unit.

Change lever

assembly

Spring(B)

Lugs

Note:

• The parts with marked (

speed FF/REW type).

1 : Uses the standard type mechanism only.

*

2:

Uses the high-speed FF/REW type mechanism only.

*

Slit washer

Washer (*1)

Spacer

Direct gear

Spring(A)

Position the projecting

side down.

) have different types of mechanisms (standard type or high-

*

Coupling gear

Spring (C)

Clutch gear

Spacer

Fig. 2-2-12a

2. How to install

(1) Install the clutch gear, spring (A), spring (C), direct gear,

spacer and others to the individual shafts of the main

deck, and finally the slit washer. (See Fig.2-2-12a.)

(2) Let the spring (B) drops into the rotary encoder guide hole

and install the change lever assembly.(Take care not to

mistake a direction of the spring.) The point is to slightly

lift the clutch gear and catch it from the both sides with

the assembly. (See Fig.2-2-12b.)

Rotary encoder guide

Spring(B)

Change lever assembly

Coupling gear

2-10

Belt

Clutch unit

Fig. 2-2-11a

Slit washer

Main deck Main deck

Fig. 2-2-12b

Page 14

2.2.13 Link lever

1. How to remove

(1) Remove the two slit washers.

(2) Remove the link lever by lifting it from the shaft retained

by the slit washers. Then swing the link lever

counterclockwise and remove it from the locking section

of the control plate.

Slit washers

2.2.14 Cassette gear, control cam and worm gear

1. How to remove

(1) Remove the control cam by lifting it.

(2) Open the two lugs of the cassette gear outward and pull

the latter off.

(3) Remove the belt wound around the worm gear and the

loading motor.

(4) Open the lug of the lid guide outward and remove the

worm gear.

Link lever

Locking section of the

control plate

Fig. 2-2-13a

2. How to install (Phase matching)

(1) Slide the control plate so that its mark E is aligned with

the mark

on the loading arm gear shaft. (See Fig.2-2-

13b.)

(2) Rotate the worm gear until the guide hole of the control

cam is aligned exactly with the guide hole of the main

deck. (See Fig.2-2-13c.)

(3) Insert the link lever into the locking section of the control

plate. (See Fig.2-2-13a.)

(4) Rotate the link lever clockwise so that it is installed on

the shafts in the center (centre) and on the left of the control cam.

(5) Fasten the slit washers at these two points.

Loading motor

Belt

Lug

Worm gear

Lugs

Cassette gear

Lid guide

Control cam

Fig. 2-2-14a

2.2.15 Control plate

1. How to remove

(1) Remove the screw (A) retaining the control bracket 1 and

remove the latter.

(2) Slide the control plate as indicated by the arrow and re-

move the control plate. (See Fig.2-2-15a.)

Shaft of the rotary encoder guide

Fig. 2-2-13b

Worm gear

Main deck

guide hole

Control cam

guide hole

Cassette gear

Fig. 2-2-13c

Control plate

Control cam

Mark E

Screw(A)

Control

bracket1

Control

plate

Fig. 2-2-15a

2. How to install (Phase matching)

(1) Adjust the position of the idler arm assembly pin as indi-

cated in Fig.2-2-15b (to the left of center (centre) of the

R section).

(2) Bring the guide hole of the take-up lever into alignment

with the hole at the control plate guide and fix the position by inserting a 1.5 mm hexagonal wrench.

2-11

Page 15

(3) Install the control plate so that the section A of the load-

ing arm gear shaft fits into the hole (A) of the control plate,

the section B of the control plate guide into the hole (B),

and the control plate comes under the section C of the

rotary encoder guide and the section D of the loading arm

gear shaft while press-fit the pole base assmebly (supply side) as indicated by the arrow. It is important that

the tension arm assembly shaft is positioned closer toward you than the control plate. (See Fig.2-2-15c.)

(4) Make sure that the mark E of the control plate is in align-

ment with the mark

of the loading arm gear shaft. (See

Fig.2-2-15c.)

(5) Pull off the hexagonal wrench for positioning.

(3) Turn the loading arm gear (take-up side) clockwise so

that the notch of the loading arm gear (take-up side) is

in alignment with the projection of the loading arm gear

shaft and lift it.

Likewise, turn the loading arm counterclockwise so that

the notch is in alignment with the projection and remove

the loading arm gear (take-up side). (See Fig.2-2-16a and

Fig. 2-2-16b.)

(4) When removing the loading arm gear shaft, be sure of

first removing the screw retaining the drum assembly (on

the back side of the loading arm gear shaft). Then remove the screw (C) and remove the loading arm gear

shaft by sliding it.

Idler arm assembly

pin

R section

Guide hole of the

control plate guide

Section D

1.5mm hexagonal wrench

Fig. 2-2-15b

Section A

Section D

Hole A

Pressfit

Take-up lever

Insert

Pole base assembly

(supply side)

Section A

Hole A

Pole base assembly

(take-up side)

Screw(B)

Torsion arm

Loading arm gear

(take-up side)

Projection B

Guide marks

Projection A

Pole base assembly

(supply side)

Screw(A)

Loading arm gear

(supply side)

Fig. 2-2-16a

Loading arm gear shaft

Loading arm gear (take-up side)

Notch

Screw(C)

Loading arm gear shaft

Section C

Section C

Section B

Hole B

Hole B

Section B

Control plate

Tension arm assembly

shaft

Fig. 2-2-15c

2.2.16 Loading arm gear (supply or take-up side) and loading arm gear shaft

1. How to remove

(1) Remove the loading arm gear (supply side) by loosen-

ing the screw (A). (See Fig. 2-2-16a.)

(2) Remove the screw (B) and remove the torsion arm from

the pole base assembly (take-up side). (See Fig.2-2-16a.)

2-12

Fig. 2-2-16b

2. How to install

(1) Align the notch of the loading arm gear (take-up side) to

the projection B of the loading arm gear shaft and slip it

over. Then rotate it clockwise for alignment with the projection A and slip it down to the bottom. (See Fig.2-216b.)

(2) Then turn the loading arm gear (take-up side)

counterclockwise. Hang the torsion arm on the pole base

assembly (take-up side) and tighten the screw (B).

(3) Install the loading arm gear (supply side) so that the guide

mark of the loading arm gear (take-up side) is in alignment with the guide mark of the loading arm gear (supply side). Then hang the torsion arm on the pole base

assembly (supply side) and tighten the screw (A). (See

Fig.2-2-16a.)

Page 16

2.2.17 Take-up lever, take-up head and control plate guide

(1) Remove the spring of the take-up lever from the main

deck.

(2) Remove the lug (A) of the take-up lever from the main

deck and pull out the take-up lever and the take-up head

together.

(3) Remove the screw (A).

(4) Align the idler arm assembly pin in the center (centre) of

the R section of the control plate guide, remove the con-

trol plate guide lugs (B) and (C) from the main deck, and

remove the control plate guide.

Idler arm assembly pin

Lug(C)

Screw(A)

Take-up lever

Take-up head

Lug(A)

Lug(B)

Control plate guide

Fig. 2-2-17a

2.2.18 Capstan brake assembly

1. How to remove

(1) Move the lug (A) of the capstan brake assembly in the

arrow-indicated direction so that it comes into alignment

with the notch of the main deck. (See Fig. 2-2-18a.)

(2) Remove the lug (B) of the capstan brake assembly from

the main deck and remove the capstan brake assembly.

Spring

Sub brake

Lug(A)

Lug(B)

assembly

(take-up side)

Lug(C)

Fig. 2-2-19a

2.2.20 Main brake assembly (take-up side), reel disk (take-up side) and main brake assembly (supply side)

1. How to remove

(1) Move the main brake assembly (take-up side) in the ar-

row-indicated direction and remove the reel disk (takeup side).

Remove the spring attached to the main brake assembly.

(2)

(3) Remove the lug (A) of the main brake assembly (take-

up side) and pull out the lug (B) after bringing it into alignment with the main deck notch.

(4) Remove the lugs (C), (D) and (E) of the main brake as-

sembly (supply side) from the main deck and pull them

off. (See Fig.2-2-20a.)

(5) When installing the main brake assembly (take-up side),

slide the brake lever in the direction as indicated by the

arrow to prevent it from hitting the projection of the main

brake assembly (take-up side). (See Fig.2-2-20b.)

Main brake assembly

(supply side)

Reel disk

(take-up side)

Main brake assembly

(take-up side)

Lug(B)

Lug(A)

Capstan brake assembly

Fig. 2-2-18a

2.2.19 Sub brake assembly (take-up side)

1. How to remove

(1) Remove the spring attached to the lid guide and sub

brake assembly (take-up side).

(2) Bring the lug (A) of the sub brake assembly (take-up side)

into alignment with the notch of the main deck.

(3) Remove the lugs (B) and (C) of the sub brake assembly

(take-up side) from the main deck and remove the sub

brake assembly (take-up side).

Lug(B)

Lug(C)

Lug(D)

SpringLug(E)

Lug(A)

Notch

Fig. 2-2-20a

1)

(

*

Brake

lever

Note:

• The parts with marked ( *) have different types of mechanisms (standard type

or high-speed FF/REW type).

1 : Uses the standard type mechanism only.

*

Rotary encoder guide

Projection of the main

brake assembly

(take-up side)

Fig. 2-2-20b

2-13

Page 17

2.2.21 Tension brake assembly, reel disk (supply side) and tension arm assembly

1. How to remove

(1) Remove the three lugs of the tension brake assembly

from the main deck and pull them off.

(2) Remove the reel disk (supply side) by loosening in the

arrow-indicated direction the main brake assembly (supply side).

(3) Remove the tension spring on the back of the main deck.

Then release the lug of the tension arm bearing in the

arrow-indicated direction and draw out the tension arm

assembly. (See Fig. 2-2-21a.)

Lug of the tension

arm bearing

Tension arm

assembly

Reel disk

(supply side)

2.2.23 Stator assembly

(1) Remove the flat cable.

(2) Remove the two screws (A), (B) and remove the lug wire.

(3) Remove the stator assembly by lifting in the arrow-indi-

cated direction. (Take care that the brush spring does not

jump out.)

Notes:

• Be careful not to lose the brush and spring.

• There are some models that do not use the lug wire.

Refer to the parts list for these models.

• When tightening the screw (B), place the caulked part

of the lug terminal near to the shaft of the drum and

then tighten it.

• After installation, be sure to perform the switching

point adjustment according to the electrical adjustment

procedure.

Tension brake

assembly

Lugs

Tension spring Main brake assembly

(supply side)

Fig. 2-2-21a

2.2.22 Idler lever, idler arm assembly

1. How to remove

(1) Remove the lug of the idler lever from the main deck and

remove the hook fitted in the idler arm assembly hole by

lifting it.

(2) Remove the slit washer and pull out the idler arm assem-

bly.

Lug Idler lever

Hook

Idler arm

assembly

Slit washer

Screw (A)

Stator assembly

Screw (B)

Lug wire

(Note)

Drum

shaft

Flat cable

(Take care not to mix up the

polar faces when installing.)

Lug wire

Screw (A)

Fig. 2-2-23a

2.2.24 Rotor assembly

1. How to remove

(1) Remove the stator assembly.

(2) Remove the two screws (B) and remove the rotor assem-

bly.

2. How to install

(1) Match the phases of the upper drum assembly and the

rotor assembly as indicated in Fig.2-2-24a.

(2) Place the upper drum assembly hole (a) over the rotor

assembly holes (b) (with three holes to be aligned) and

tighten the two screws (B). (See Fig.2-2-24a.)

Screws (B)

Hole(a)

2-14

Fig. 2-2-22a

Screw holes

Upper drum

assembly

Rotor assembly

Fig. 2-2-24a

The hole is not in

line but is offset

toward the right.

Hole(b)

Page 18

2.2.25 Upper drum assembly Notes:

• To replace the upper drum assembly only may not be

possible with some models. For upper drum assembly replacement, refer to the parts list. (When the parts

number of the upper drum assembly is not listed on

the parts list, then this cannot be replaced.)

• When replacement is required, control the up- down

movement of the brush. Never apply grease.

• When replacing the upper drum assembly, replace it

the together with the washer.

1. How to remove

(1) Remove the stator assembly and rotor assembly.

(2) Loosen the screw of the collar assembly using a 1.5 mm

hexagonal wrench and remove the collar assembly. Also

remove the brush, spring and cap at one time.

(3) Remove the upper drum assembly and remove the

washer using tweezers.

Lower drum assembly

Coil parts

Upper drum assembly

Fig. 2-2-25b

Spring

Brush

Upper drum

assembly

Washer

Collar

assembly

Loosen

Cap

Shaft

1.5 mm

hexagonal wrench

Lower drum assembly

Fig. 2-2-25a

2. How to install

(1) Clean the coil parts of the lower drum assembly and the

newly installed upper drum assembly with an air brush

in advance. (See Fig.2-2-25b.)

(2) Install a new washer and upper drum assembly on the

drum shaft. (See Fig.2-2-25a.)

(3) Install the cap to the upper drum assembly.

(4) Position the collar assembly as indicated in Fig.2-2-25c

while controlling its up- down movement.

(5) Secure the collar assembly in position with a hexagonal

wrench while pressing its top with the fingers.

(6) After installation, gently turn the upper drum assembly

with your hand to make sure that it turns normally. Then

install the brush and the spring.

(7) Install the rotor assembly and stator assembly according

to Fig 2-2-23a and 2-2-24a.

(8) When installation is complete, clean the upper drum as-

sembly and lower drum assembly and carry out the fol-

lowing adjustments.

• PB switching point adjustment

• Slow tracking adjustment

• Compatibility adjustment (Be sure to check for compatibility for the EP (or LP) mode.)

Upper drum

assembly

Collar

assembly

Fig. 2-2-25c

Press

Fig. 2-2-25d

Collar

assembly

Tighten

2-15

Page 19

2.3 Compatibility adjustment Notes:

• Although compatibility adjustment is very important,

it is not necessary to perform this as part of the normal servicing work. It will be required when you have

replaced the A/C head, drum assembly or any part of

the tape transport system.

• To avoid any damage to the alignment tape while performing the compatibility adjustment, get a separate

cassette tape (for recording and play back) ready to

be used for checking the initial tape running behavior.

• Unless otherwise specified, all measuring points and

adjustment parts are located on the Main board.

• When using the Jig RCU, it is required to set the VCR

to the Jig RCU mode (the mode in which codes from

the Jig RCU can be received). (See SECTION 1 DISASSEMBLY.)

Jig RCU

[Data transmitting method]

Depress the “ ” ( 3 ) button

after the data code is set.

pole base assembly (supply or take-up side).

(7) Unload the cassette tape once, play back the alignment

tape (A1) again and confirm the V.PB FM waveform.

(8) After adjustment, confirm that the tape wrinkling does not

occur at the roller upper or lower limits. (See Fig. 2-31d.)

[Perform adjustment step (9) only for the models

equipped with SP mode and EP (or LP) mode.]

(9) Repeat steps (1) to (8) by using the alignment tape (A2).

CUSTOM CODE

43: A CODE

53: B CODE

DATA CODE

INITIAL MODE

Fig. 2-3a Jig RCU [PTU94023B]

2.3.1 FM waveform linearity

Signal (A1) •

(A2) •

Mode (B) • PB

Equipment (C) • Oscilloscope

Measuring point (D) • TP106 (PB. FM)

External trigger (E) • TP111 (D.FF)

Adjustment part (F) • Guide roller [Mechanism assembly]

Specified value (G) • Flat V.PB FM waveform

Adjustment tool (H)

Alignment tape(SP, stairstep, NTSC) [MHP]

Alignment tape(EP, stairstep, NTSC) [MHP-L]

• Roller driver [PTU94002]

(1) Play back the alignment tape (A1).

(2) Apply the external trigger signal to D.FF (E), to observe

the V.PB FM waveform at the measuring point (D).

(3) Set the VCR to the manual tracking mode.

(4) Make sure that there is no significant level drop of the

V.PB FM waveform caused by the tracking operation, with

its generally parallel and linear variation ensured. Per-

form the following adjustments when required. (See Fig.

2-3-1a.)

(5) Reduce the V.PB FM waveform by the tracking opera-

tion. If a drop in level is found on the left side, turn the

guide roller of the pole base assembly (supply side) with

the roller driver to make the V.PB FM waveform linear.

If a drop in level is on the right side, likewise turn the guide

roller of the pole base assembly (take-up side) with the

roller driver to make it linear. (See Fig. 2-3-1c.)

(6) Make sure that the V.PB FM waveform varies in parallel

and linearly with the tracking operation again. When re-

quired, perform fine-adjustment of the guide roller of the

Max level

Proper waveform variation

Improper waveform variation

Fig. 2-3-1a

Roller driver

Fig. 2-3-1b

Min level

Guide roller (supply side)

2-16

Page 20

A

B

waveform by turning the screws (1), (2) and (3) little by

little until both waveforms reach maximum. The screw (1)

and (3) are for adjustment of tilt and the screw (2) for azimuth.

(4) Adjust the AUDIO OUT waveform and Control pulse

Level drop at the guide roller (supply side)

C

Level drop at the guide roller (take-up side)

• Proper waveform variation: Always flat

• Improper waveform variation:

Higher Lower

Fig. 2-3-1c

Improper

(a) Guide roller

Head base

A/C head

(2)

(3)

(1)

AUDIO OUT

CTL. P

D

Fig. 2-3-2a

2.3.3 A/C head phase (X-value)

Proper

Signal (A1) •

Mode (B) • PB

Equipment (C) • Oscilloscope

Measuring point (D) • TP106 (PB. FM)

External trigger (E) • TP111 (D.FF)

Adjustment part (F) •

Specified value (G) • Maximum V.PB FM waveform

Adjustment tool (H) • A/C head positioning tool [PTU94010]

Alignment tape(SP, stairstep, NTSC) [MHP]

A/C head base [Mechanism assembly]

(b) Guide pole

Fig. 2-3-1d

2.3.2 Height and tilt of the A/C head Note:

• Set a temporary level of the height of the A/C head in

advance to make the adjustment easier after the A/C

head has been replaced. (See Fig.2-2-6c.)

Signal (A) •

Mode (B) • PB

Equipment (C) • Oscilloscope

Measuring point (D1)

(D2) •TP4001 (CTL. P)

External trigger (E) • TP111 (D.FF)

Adjustment part (F) • A/C head [Mechanism assembly]

Specified value (G) • Maximum waveform

Alignment tape(SP, stairstep, NTSC) [MHP]

• AUDIO OUT terminal

(1) Play back the alignment tape (A).

(2) Apply the external trigger signal to D.FF (E), to observe

the AUDIO OUT waveform and Control pulse waveform

at the measuring points (D1) and (D2) in the ALT mode.

(3) Set the VCR to the manual tracking mode.

(1) Play back the alignment tape (A1).

(2) Apply the external trigger signal to D.FF (E), to observe

the V.PB FM waveform at the measuring point (D).

(3) Set the VCR to the manual tracking mode.

(4) Loosen the screws (4) and (5), then set the A/C head

positioning tool to the innermost projected part of the A/

C head. (See Fig. 2-3-3a.)

(5) Turn the A/C head positioning tool fully toward the cap-

stan. Then turn it back gradually toward the drum and

stop on the second peak point position of the V.PB FM

waveform output level. Then tighten the screws (4) and

(5).

(6) Perform the tracking operation and make sure that the

V.PB FM waveform is at its maximum.

If it is not at maximum, loosen the screws (4) and (5),

and turn the A/C head positioning tool to bring the A/C

head to a position, around where the waveform reaches

its maximum for the first time. Then tighten the screws

(4) and (5).

2-17

Page 21

[Perform adjustment steps (7) to (10) only for 2 Head

models equipped with LP mode.]

(7) Then play back the alignment tape (A2).

(8) Set the VCR to the manual tracking mode.

(9) Perform the tracking operation and make sure that the

V.PB FM waveform is at its maximum.

(10)

If it is not at maximum, loosen the screws (4) and (5),

and turn the A/C head positioning tool to bring the A/C

head to a position, around where the waveform reaches

its maximum for the first time. Then tighten the screws

(4) and (5).

Note:

• After adjusting, always perform the confirmation and

re-adjustment of the item 2.3.4.

Toward the drum

A/C head positioning tool

To the drum

A/C head

Toward the capstan

Head base

Screw

Screw

To the capstan

(4)

(5)

Fig. 2-3-3a

Alignment tape

[SP, stairstep]

played with the

SP head

Alignment tape

[EP(LP), stairstep]

played with the

EP(LP) head

(4) Set the VCR to the Auto adjust mode by transmitting the

code (F) twice from the Jig RCU. When the VCR enters

the stop mode, the adjustment is completed.

(5) If the VCR enters the eject mode, perform adjustment for

the audio control head phase (X-value) again.

2.3.5 Tension pole position

Signal (A) • Back tension cassette gauge

Mode (B) • PB

Adjustment part (F) • Adjust pin [Mechansim assembly]

Specified value (G)

[PUJ48076-2]

• 25 - 51 gf•cm (2.45 – 5 × 10

-3

Nm]

(1) Play back the back tension cassette gauge (A).

(2) Check that the indicated value on the left side gauge is

within the specified value (G).

(3) If the indicated value is not within the specified value (G),

perform the adjustment in a following procedure.

1) Set the VCR to the mechanism service mode. (See

SECTION 1 DISASSEMBLY.)

2) Set the VCR to the play back mode and adjust by turning adjustment pin to align the tension arm assembly

edge with the main deck hole (A) on the right edge

marker. (See Fig. 2-3-5a)

Tension arm

assembly

Hole (A)

Marker

Edge

Waveform output

X-value adjustment point

Drum side Control head position Capstan side

Maximum

Fig. 2-3-3b

2.3.4 Standard tracking preset

Signal (A) •

Mode (B) • PB ¥ Auto adjust

Equipment (C) • Oscilloscope

Measuring point (D) • TP106 (PB. FM)

External trigger (E) • TP111 (D.FF)

Adjustment part (F) • Jig RCU: Code “50”

Specified value (G)

Adjustment tool (H)

Alignment tape(EP, stairstep, NTSC) [MHP-L]

• STOP mode

(Maximum V.PB FM waveform)

• Jig RCU [PTU94023B]

(1) Play back the alignment tape (A).

(2) Apply the external trigger signal to D.FF (E), to observe

the V.PB FM waveform at the measuring point (D).

(3) Confirm that the automatic tracking operation is com-

pleted.

0.5 mm

Tension arm assembly

Tension brake assembly

Adjust pin

Fig. 2-3-5a

2-18

Page 22

Mechanism Timing Chart

Mechanism mode

Control plate mark

Rotary encoder

Control cam angle

EJECT

END

E U CI

HIGH

C CH

LOW

HIGH

B CH

LOW

HIGH

A CH

LOW

0

CASS-

UP

69 136 370 412.

CASS-INS

FF/REW

FR

230

STOP

ST

264.

REV

R

7

318.

7

SLOW/STILLPPLAY

SL

42

Rotary encoder

angle

Pole base

Pinch roller

Guide arm

Tension arm

Main brake S

Main brake T

Sub brake S

Sub brake T

Capstan brake

Direct gear

Change lever 2

Idler position

Take-up lever

Rec safety switch

Operation mode

HALF PRESS

CONTACT

ON PLAY

ON REV

CONTACT

(C-INS)

HALF REV

HALF FF/REW

CONTACT

CONTACT

IN FF/REW

OUT PLAY

SUPPLY

CENTER

TAKE-UP

READY

RESET

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

0

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

20 42.652.

6

6

114.

150.4167.8178.

8

207.2218.2240.2251.

Timer REC

(drum at stop)

POWER OFF

(cassette loaded)

standby

STOP

2

Backspace Slow FOR

Search REW

Slow REW

293.2304.2320.4335

REC pause

Search FF

STOP

(

drum

REC

in motion)

2-19

Page 23

Page 24

VICTOR COMPANY OF JAPAN, LIMITED

VIDEO DIVISION

S40894

Printed in Japan

Loading...

Loading...