Page 1

SERVICE MANUAL

CORDLESS FM STEREO HEADPHONES

HA-W500RF (EG)/(EK)

Specifications

HA-W500RF (EG)/(EK)

Contents

Specifications ------------ Front cover

1. Disassembly ------------------------- 3

2. Schematic Diagram ---------------- 4

3. Measurement Condition --------- 5

4. Print Circuit Board ----------------- 5

5. Wiring Diagram --------------------- 7

6. Block View Inside IC -------------- 7

7. Block Diagram ---------------------- 8

8. Electric Parts List ------------------ 8

9. Exploded view ----------------------- 9

10 .Mechanical Parts List ------------ 9

11. Packing Method ------------------ 10

12. Packing Materials Parts List - 10

13. Accessories List ----------------- 10

General Specifications

System : Radio Frequency (UHF stereo)

Modulation : Frequency modulation

Carrier frequency : 863-865 MHz

Usable area

(distance to reach) : Approx. 100m (328 ft) : using

JVC measurements systems

Frequency response : 30 Hz-15,000 Hz

Distortion : Less than 4 % (at 1 kHz)

Transmitter (J22121-001)

Power requirements : DC 9 V (with the exclusive AC

adaptor J47126-001(EG Model)

/J47127-001(EK Model))

Audio input ter minal : 3.5 mm dia. stereo mini plug

Input impedance : 25 k

Reference input level : 300 mV

Dimensions : 100(W) x 100(D) x 106(H) mm

(3-15/16" x 3-15/16" x 4-3/16")

(Including antenna)

: 115

Mass

(4.1 oz)

(Without connection cord and AC

adaptor)

Headphones (HA-W500RF)

Power requirements : Rechargeable

Ni-Cd batter y (1.2 V) x 2

Battery running time : 20 hours

(When charged for 24 hours)

Mass : 280

Provided Accessories

Instructions x 1

AC adaptor x 1

Connection cord x 1 (3.5 mm dia. stereo mini jack-

Plug adaptor x 1 (converts 3.5 mm dia. stereo

(9.9 oz)

(With installed rechargeable

Ni-Cd batter y x 2)

RCA pin plug x 2 : 0.1 m (0.3 ft))

mini plug to a 6.3 mm dia. standar d

stereo phone plug)

* Design and specifications subject to change without notice.

COPYRIGHT 2002 VICTOR COMPANY OF JAPAN, LTD.

No.70270

Sep. 2002

Page 2

HA-W500RF (EG)/(EK)

Safety Precautions

1. This design of this product contains special hardware and many circuits and components specially

for safety purposes. For continued protection, no changes should be made to the original design

unless authorized in writing by the manufacturer. Replacement parts must be identical to those

used in the original circuits. Services should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of

the product should not be made. Any design alterations or additions will void the manufacturer`s

warranty and will further relieve the manufacture of responsibility for personal injury or property

damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics.

These characteristics are often not evident from visual inspection nor can the protection afforded

by them necessarily be obtained by using replacement components rated for higher voltage,

wattage, etc. Replacement parts which have these special safety characteristics are identified in

the Parts List of Service Manual. Electrical components having such features are identified by

shading on the schematics and by ( ) on the Parts List in the Service Manual. The use of a

substitute replacement which does not have the same safety characteristics as the recommended

replacement parts shown in the Parts List of Service Manual may create shock, fire, or other

hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the

like to be separated from live parts, high temperature parts, moving parts and/or sharp edges

for the prevention of electric shock and fire hazard. When service is required, the original lead

routing and dress should be observed, and it should be confirmed that they have been returned

to normal, after re-assembling.

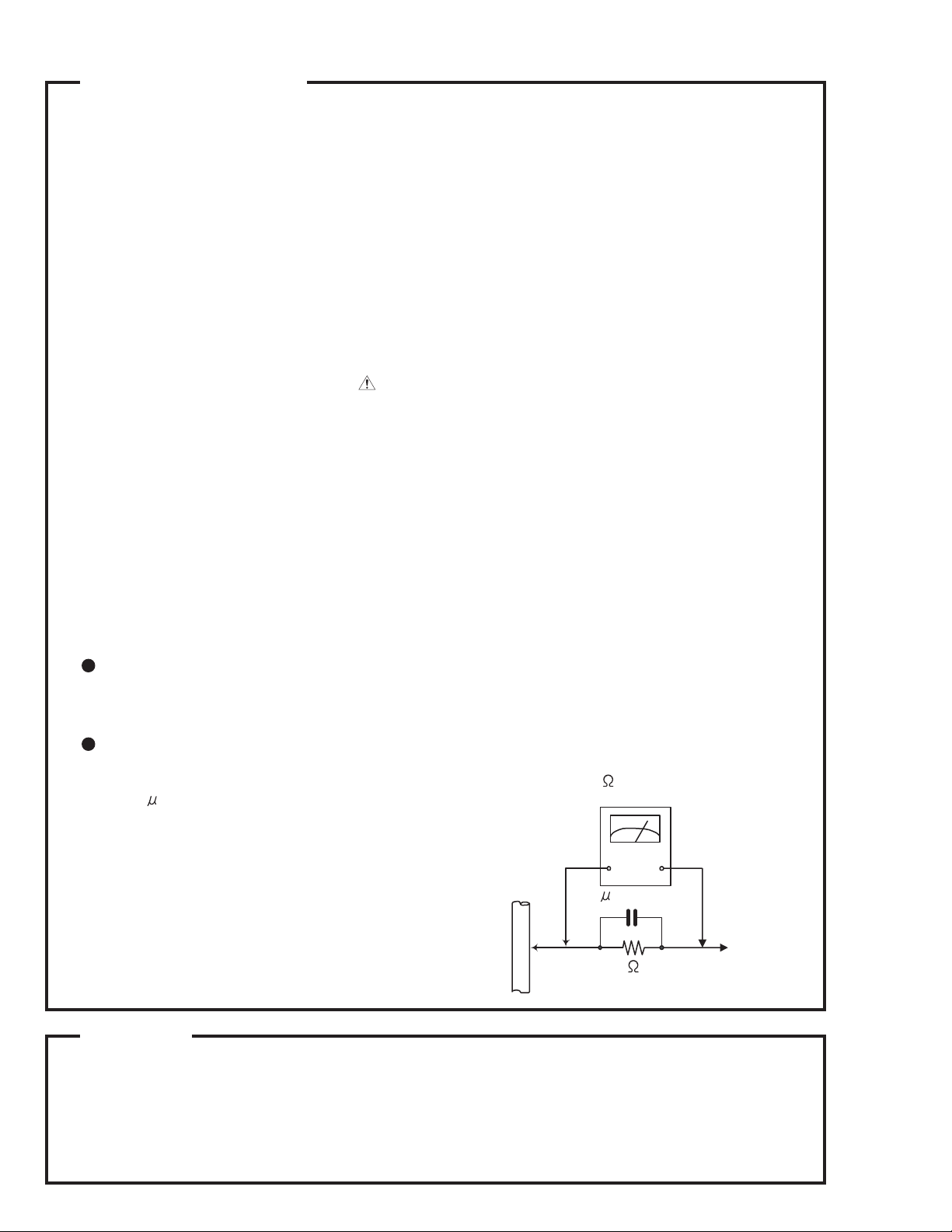

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts

of the product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control

shafts, etc.) to be sure the product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure

the leakage current from each exposed metal parts of the cabinet , particularly any exposed

metal part having a return path to the chassis, to a known good earth ground. Any leakage

current must not exceed 0.5mA AC (r.m.s.)

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms

per volt or more sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by

a 0.15 F AC-type capacitor between an exposed

metal part and a known good earth ground.

Measure the AC voltage across the resistor with the

AC voltmeter.

Move the resistor connection to eachexposed metal

part, particularly any exposed metal part having a

return path to the chassis, and meausre the AC

voltage across the resistor. Now, reverse the plug in

the AC outlet and repeat each measurement. voltage

measured Any must not exceed 0.75 V AC (r.m.s.).

This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

Warning

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

2 (No.70270)

Page 3

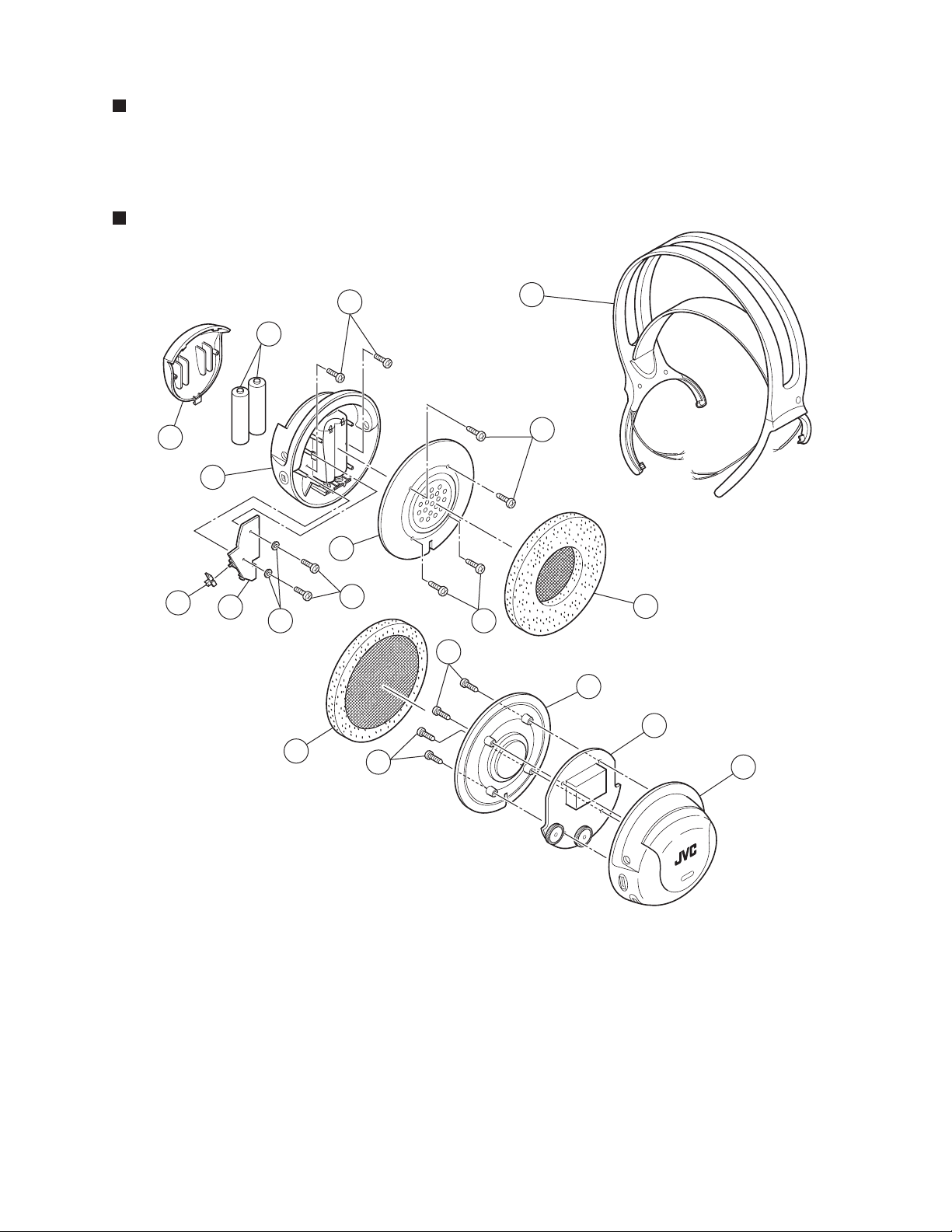

1.Disassembly

Transmitter

In case of some problems arise in this transmitter unit,

have to change the transmitter unit itself, due to avoid

the law of radio regulation.

Receiver(Headphones)

HA-W500RF (EG)/(EK)

L

10

9

11

12

2

8

7

6

1

5

4

4

15

R

4

1

4

3

13

R

14

R

1.Remove the ear pad 1 from the driver unit ass'y (L) 2 and (R) 3.

2.Remove the screw 4 and pull up the driver unit ass'y (L) 2 and (R) 3.

3.At channel L. Remove the screw 5 and insulation washer 6, and pull up the charge print circuit board 7.

4.Remove the switch knob 8.

5.Remove the screw 9 and remove the battery door 10 from the housing ass'y (L) 12.

6.Remove the battery 11 from the housing ass'y (L) 12.

7.At channel R. Remove the main print circuit board 13 from the housing (R) 14

8.Remove the wire with solder from the charge and main print circuit board 7 13, then remove the headband

ass'y 15.

(No.70270) 3

Page 4

HA-W500RF (EG)/(EK)

g

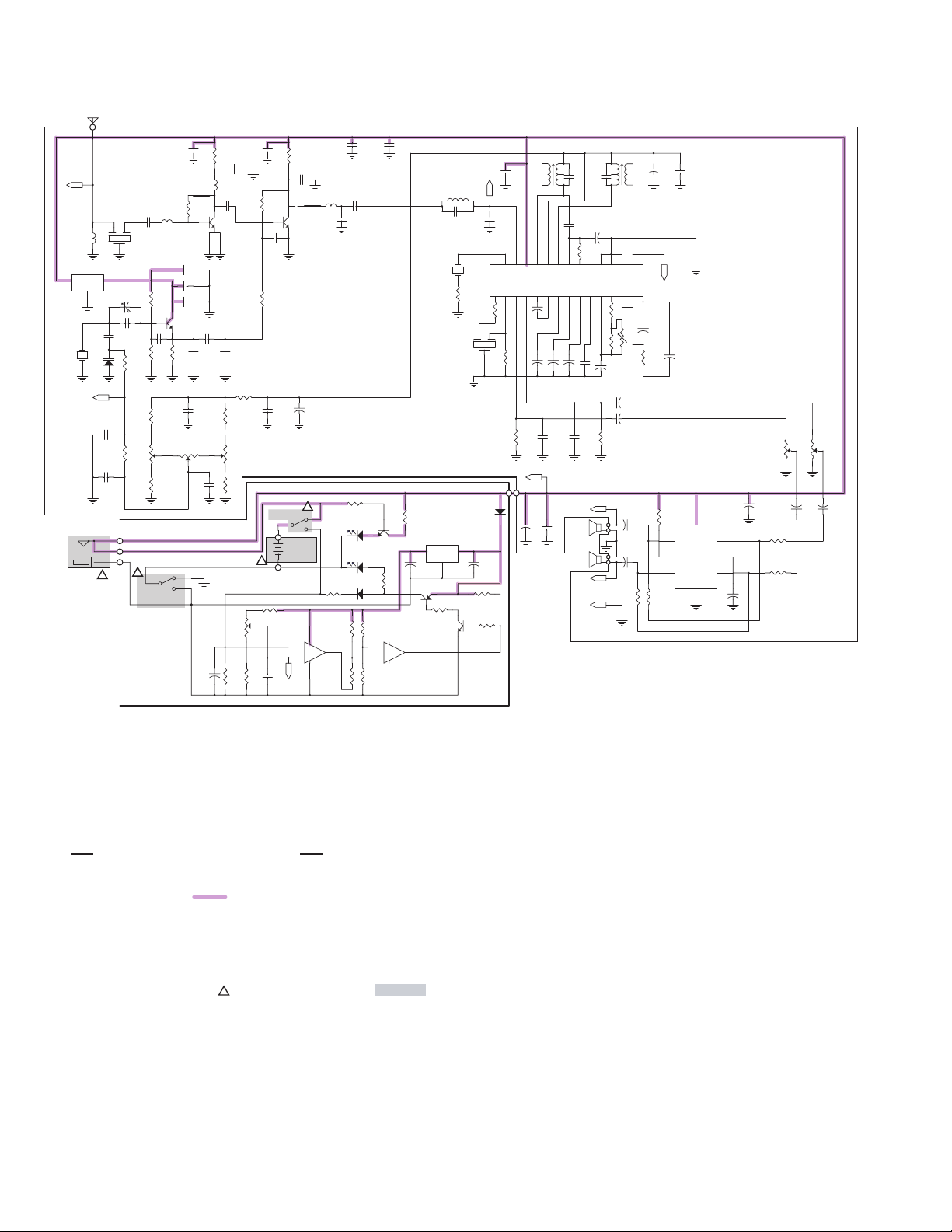

2.Schematic diagram

ANT1

C75

1

Test-1

L3

12nH

IC1 7201-15

3 1

VI VO

GND

2

C1

3p*

X1 C2

D1

V809

Test-10

JX1

CHARGE OUTPUT

TERMINAL

C39

1000p

C48

1000p

!

X4

863MHz

R30

1k

C8

100p

TC1

1.5-3p

C3

5p6

R24

R2

1K

39k

VR4

5k

!

S1a SW SPDT

R50

330

0.01u

L2

C881000p

15nH

C76

9

0

VR2

100k

C5

1u

C52

0.01u

C51

22P

4

R49

27K

C47

1000p

C59

10u

C17

3P*

C46

0.1u

C20

2P(N)

Q9

5508

100p

R28

1k

R27

1k

VR3

5k

R42

50

R40

1M

C78

1p

R29

100

K

L1

15nH

R1

18k

Q1

50

R4

3P*

47

R25

1k

R26

1k

C80

0.01u

R53

27K

C77

1p

R56

0

C45

0.1u

VR3 795.1Mhz

VR4 791.5Mhz

+

BATTERY

-

!

82K

R46

R41

C73

0.1u

75k

Test-11

R54

330

C874p

C81

0.01U

Q11

5508

2.4V

3

2

+

S1bSW SPDT

C44

10u

!

84

+

-

L9

15nH

C83

10p

*

N750

ON

OFF

R37300

R38

100k

IC4A

LM393 or

NJM2903M

1

R39

68k

C41

C19

1u

0.001u

C84

0.01u

Q8

R35

100k

R36

100k

R18

10

R13

1k5

IC4B

84

LM393 or

5

NJM2903M

+

6

-

7

R47 18k

3904

D2A RED

D2B GREEN

D3 4148 Q68550

C60

47u

X3

10.7M

IC5

78L06

L8

0.33uh

R11

100

GND

2

R434k7

Q7

3904

C53

56P

X2

10.7MHz

31

VIVO

C61

10u

Test-3

R12

330

4148

R4510k

R4410k

C21

12p

C49

10

Test-6

Test-7

C22

12

7p

+

R14

100K

15 29

813 9

C30

0.01U

R16

3k3

11

C31

10U

T2

p

C25

+

+

C24

C23

10U

0.1U

Test-1 High RF in

C72

4U7

2

35

6

+

+

Test-3 Low RF in

Test-5 R out

Test-6 L out

Test-7 GND

Test-8 VCC

Test-9 STEREO

Test-10 VT

TEST-11 REF V

VR1b

100k

C38

C36

100u

+

2U2

R19

2k7

R20

2k7

VR1a

100k

+

C37

2U2

4U7

3020

17

Test-9

1

27

R34

2k2

C32

+

0.47u

R33

+

2

2K

R22

27k

R21

100K

1

7

C33

4U7

OUT1

OUT2

8

BY PASSMUTE

4

Rout

Lout

IC3

LM4809

VCC

IN1

IN2

GND

R32

3K3

C54

2u2

+

+

C55

2u2

C73

220u

(C74)

C32

220u

R23

27k

VR5

5K

+

+

T1

C40

1u

C10

10p

21 4

18

26

722

IC2

CXA1538M

216 28

6233

5

25

+

C27

1U

R31

2K2

R15

3k3

D4

C34

0.015u

+

C26

1U

Test-8

C43

220u

+

+

+

C28

C29

4U7

33U

C35

0.015u

Test-5

C42

0.1u

SPK1

32ohm

Rout

SPK2

32ohm

Lout

Use of Circuit Diagram

Notes:

1. The thick line ( ) is the B (+) power supply.

2. This circuit diagram is the r eference diagram. Cir cuits and constans ar e subject to change without notice for

improvement.

3. Values printed in r ed show the voltares of each section measur ed by the tester (inter nal resistance 20 kOhms/V),

with the power switch ON.

4. Parts marked with (in the shaded area ) are safety parts.When replacing these, be sure to use only the

nated parts to ensure safety.

desi

4 (No.70270)

!

Page 5

3.Measurement Condition

HA-W500RF (EG)/(EK)

AC IN

Transmitter Receiver (Headphones)

4.Print Circuit Board

Receiver (Headphones)

CHARGE P. C. BOARD

Reference input signal :1kHz 300mVp-p sine wave

Hedaphone volume control : MAX

Distance : 1m (3.28ft)

shows the B(+) power supply

shows the ground

shows others.

Surface

TOP

Back side

(No.70270) 5

Page 6

HA-W500RF (EG)/(EK)

4.Print Circuit Board

Receiver (Headphones)

MAIN P.C.BOARD

TOP

Surface

shows the B(+) power supply

shows the ground

shows others.

D

C

B

A

1234

Back side

Receiver (Headphones)

MAIN P.C.B. LOCATION

Symbol

ICs

IC2

IC3

IC4

IC5

Transistors

Q6

Q7

Q8

Filters

X2

X3

Diodes

D2

D3

D4

Resistors

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

6 (No.70270)

Location

2B

2A

CHG.PCB

CHG.PCB

CHG.PCB

CHG.PCB

CHG.PCB

3C

2B

CHG.PCB

CHG.PCB

CHG.PCB

Symbol

R11

R12

R13

R14

R15

R16

R17

R18

R19

R20

R21

R22

R23

R24

R25

R26

R27

R28

R29

R30

R31

R32

R33

R34

R35

R36

Location

Resistors Resistors

1B

CHG.PCB

2B

3B

3B

CHG.PCB

2A

2A

2A

3A

2A

3D

4C

4C

4C

4C

3D

3C

2B

2B

2B

CHG.PCB

CHG.PCB

Symbol

R37

R38

R39

R40

R41

R42

R43

R44

R45

R46

R47

R48

R49

R50

VR1

VR2

VR3

VR4

VR5

JP1

JP2

JP3

JP4

Capacitors

C21

C22

Location

CHG.PCB

CHG.PCB

CHG.PCB

CHG.PCB

CHG.PCB

CHG.PCB

CHG.PCB

CHG.PCB

CHG.PCB

CHG.PCB

CHG.PCB

3A

4B

4C

4C

1B

1C

3D

3D

1B

2C

Symbol

C23

C24

C25

C26

C27

C28

C29

C30

C31

C32

C33

C34

C35

C36

C37

C38

C39

C40

C41

C42

C43

C44

C45

C46

C47

C48

Location

Capacitors Capacitors

1C

1C

1B

3B

3B

2B

3B

3C

1B

2B

3B

3B

3B

3A

3A

2A

3D

2D

2D

4D

4C

3C

4B

3D

Symbol

C49

C50

C51

C52

C53

C54

C55

C59

C60

C61

C72

C73

C74

T1

T2

L8

Location

2B

2C

3B

3A

CHG.PCB

CHG.PCB

CHG.PCB

2A

3A

2A

Coils

1B

2C

2C

Page 7

5.Wiring Diagram

Inside of the housing (R)

Antenna

Black

lead

Inside of the

head band

ass'y

HA-W500RF (EG)/(EK)

Inside of the housing (L)

Red lead

Ni-Cd

Battery

Black lead

Speaker

Red lead

(Rch)

Blue lead

6.Block View Inside IC

PLL LPF1

PILOT DET LPF2

PILOT DET LPF2

ST IND/VCO CHECK

Rch OUT

Lch OUT

Vcc

RIPPLE FILTER

AGC AFC 1

AGC AFC 2

GND

TUNE IND

FM IF IN

AM IF IN

BAND SELECT

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

RX:IC2

CXA1538M

GND

30

PLL LPF2

29

MPX REG

28

VCO

27

FM DISCRI

26

MUTE

25

AM OSC

24

AFC

23

FM OSC

22

REG

21

FM RF

20

AM RF IN

19

FM RF IN

18

FE GND

17

FM/AM FE OUT

16

Natural shielded lead

Red shielded lead

Green shielded lead

Natural shielded lead

Output 1

Input 1

Bypass

Output 1

-Input 1

+Input 1

Inside of the

head band ass'y

1

2

3

4

GND

LM4809

1

2

3

4

GND

NJM2903M

RX:IC3

RX:IC4

LM393

Green

shielded lead

Natural shielded lead

8

Vcc

7

Output 2

6

Input 2

5

Shutdown

8

Vcc

7

Output 2

6

-Input 2

5

+Input 2

Speaker

(Lch)

(No.70270) 7

Page 8

HA-W500RF (EG)/(EK)

7.Block Diagram

Receiver (Headphones)

ANT

TUNING

VT

UHF

Ni-Cd Battery

(1.2V) x 2

ANT

POWER

SW1

MODULE

ON

OFF

ON

OFF

IF

VB

FILTER

POWER INDICATOR

LED RED

VR2

COMPARATOR

IC4:LM393

NJM2903

-

22 20

OSC RF

5

Rch

18

RF IN

7

FM STEREO RADIO

IC2:CXA1538M

13

16

CHARGE INDICATOR

LED GREEN

AF OUT

6

Lch

AF OUT

DISCRIFE OUTIF INVcc

26

CHARGE INPUT

VOLUME

VR1

2

HEADPHONE

6

IC3:LM4809

AMP

8

1

Rch OUT

7

Lch OUT

4

8.Electric Parts List

Transmitter

A Item No. Parts No. Parts Name Description

A

In case of some problem arise in this transmitter unit, have to change the transmitter unit

itself, due to avoid the law of radio regulation.

Parts marked (A ) ave safety parts. When replacing, be sure to use the specified one.

Receiver (Headphones)

A Item No. Parts No. Parts Name Description

A J22133-001 Main P.C.B Ass'y Adjusted

J22134-001 Charge P.C.B Ass'y

D2 J47138-001 LED Power and charge Indicator

VR1 J47139-001 Variable Resistor Volume control, 100 k X 2

VR2 J47140-001 Variable Resistor Tuning control, 100 k X 1

A SW1 J47145-001 Power Switch Slide

A JK1 J47141-001 Charge Jack

Parts marked (A ) are safety parts. When replacing, be sure to use the specified one.

J22121-001 Transmitter Unit

8 (No.70270)

Page 9

9.Exploded View

Receiver(Headphones)

HA-W500RF (EG)/(EK)

L

4

2

7

Charge P.C.B. Ass'y

11

9

10

5

11

10

10

8

10

R

1

R

8

6

Main P.C.B. Ass'y

3

10.Mechanical Parts List

Receiver(Headphones)

A Item No. Parts No. Parts Name Q'ty Description

1 J34073-001 Headband Ass'y 1 with connecting wir e

2 J34074-001 Housing(L) Ass'y 1 with battery terminal

3 J34075-001 Housing(R) Ass'y 1

4 J34076-001 Battery Door 1

5 J34077-001 Driver Unit(L) Ass'y 1

6 J34078-001 Driver Unit(R) Ass'y 1

7 J47146-001 Swihch knob 1

8 J47144-001 Ear Pad 2

9 J46514-001

10 QYSPSPU1411M Screw 8

11 QYSPSFT1403M Screw 4

Parts marked ( A ) are safety parts. When replacing, be sur e to use the specifide one.

Rechargeable Ni-Cd batteries

1

R

with protector

with protector

2pcs/pack

(No.70270) 9

Page 10

HA-W500RF (EG)/(EK)

11.Packing Method

8

1

4

3

5

10

12

2

9

7

6

12.Packing Materials Parts List

A Item No. Parts No. Parts Name Q'ty Description

1 J22110-001 Packing case 1 for (EG) model

1 J22110-002 Packing case 1 for (EK) model

2 J22135-001 Packing Holder 1

3 J47142-001 Sub Packing Holder 1

4 QPA01202005 Poly Bag 1 for transmitter

5 QPA01506005 Poly Bag 1 for receiver(headphones)

6 QPA00500805 Poly Bag 1 for connection cord

7 QPA01202005 Poly Bag 1 for AC Adaptor

Parts marked ( A ) are safety parts. When replacing, be sur e to use the specifide one.

13.Accessories List

A Item No. Parts No. Parts Name Q'ty Description

A 8 J5500-114A Instructions 1 for (EG) model

A 8 J5500-115A Instructions 1 for (EK) model

9 BT-54008-4

A 10 J47126-001 AC Adaptor 1 for (EG) model

A 10 J47127-001 AC Adaptor 1 for (EK) model

11 J47143-001 Connection cor d 1

12 J46517-001 Plug adaptor 1

European Guarantee Certificate

11

1

Parts marked ( A ) are safety parts. When replacing, be sur e to use the specifide one.

10 (No.70270)

Page 11

< MEMO >

HA-W500RF (EG)/(EK)

(No.70270) 11

Page 12

HA-W500RF (EG)/(EK)

VICTOR COMPANY OF JAPAN, LIMITED

COMMUNICATION NETWORK BUSINESS UNIT

AV & MULTIMEDIA COMPANY 1644, Shimotsuruma, Yamato, Kanagawa 242-8514, Japan

No.70270

Printed in Japan

200209

Loading...

Loading...