Page 1

SERVICE MANUAL

HD MEMORY CARD CAMERA RECORDER

HC047<Rev.001>20132SERVICE MANUAL

GY-HM600U, GY-HM600E,

GY-HM650U, GY-HM650E

E

D

O

C

E

M

I

T

COPYRIGHT © 2013 JVC KENWOOD Corporation

Note :

Lead free solder used in the board (material : Sn, Ag, In, Bi, melting point : 227 Centigrade)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.1 SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3.1 Center frame section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3.2 L Side cover assembly section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3.3 R Side cover assembly section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

3.4 Handle assembly section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

4.1 Instruments required for adjustment and the setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

4.2 Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

5 TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

5.1 Service menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

5.2 How to update the firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

COPYRIGHT © 2013 JVC KENWOOD Corporation

No.HC047<Rev.001>

2013/2

Page 2

SPECIFICATION

General

Power DC 12 V

Power consumption Approx. 10.2 W

Mass Approx. 2.4 kg (with battery) Approx. 2.5 kg (with battery)

Allowable operating temperature 0 °C to 40 °C (32 °F to 104 °F)

Allowable operating humidity 30 %RH to 80 %RH

Allowable storage temperature -20 °C to 50 °C (-4 °F to 122 °F)

Terminal Sec tion

[HD/SD SDI] output terminal (480i or 576i:Downconverted 720p/1080i: embedded audio), BNC (unbalanced)

[INPUT1/INPUT2] terminal

[AUX] terminal -22dBu, 10 kΩ, 3.5 mm stereo mini jack (unbalanced)

[AV] terminal 4-pin 3.5 mm mini jack

[HEADPHONE] terminal 3.5 mm mini jack (stereo) x 1

[REMOTE] terminal 2.5 mm wired remote control Ø2.5 mm mini jack (stereo)

[USB] terminal Mini USB-B type, USB 2.0, miniB, slave function (mass storage

[TC] terminal

Lens Section

Lens Fujinon F1.6, 23x, f=4.1 mm to 94.3 mm (35 mm conversion: 29 mm to 667 mm)

Filter diameter Ø72 mm

Camera Section

Image pickup device 1/3-inch Progressive CMOS

Color separation prism F1.6, 3-color separation prism

Sync system Internal sync (built-in SSG)

Optical filter OFF, 1/4, 1/16, 1/64

Gain -6dB, -3dB, 0dB, 3dB, 6dB, 9dB, 12dB, 15dB, 18dB, 21dB, 24dB, Lolux (30dB, 36dB), ALC

Electronic shutter 1/6 to 1/10000, EEI

Variable frame Rate 2/30-60/30fps, 2/25-50/25fps, 2/24-60/24fps

LCD monitor 3.5-inch LCD, 16:9 920K pixels

Viewfinder 0.45-inch LCOS, 1.22 Mpixels (852 x 480 x 3)

Storage Section

Supported media SDHC/SDXC

Slots x 2

Video/Audio

Recording time Approx. 25 minutes (8 GB SD card, 35 Mbps, VBR mode)

HD mode (MOV / MP4 / MXF: MPEG2)

HD mode (AVCHD)

HD mode (MOV: H.264)

SD mode (MOV: H.264)

Web mode (MOV: H.264)

Accessories

HD-SDI Compliant with SMPTE 292 M

SD-SDI Compliant with SMPTE 259 M

[MIC] -50 dBu, 3 kΩ, XLR (balanced), +48 V output (phantom power supply)

[LINE] +4 dBu, 10 kΩ, XLR (balanced)

Video signal 1.0 V (p-p)

Audio signal -8 dBu (during reference level input), 1 kΩ (unbalanced)

[DEVICE] - Mini USB-B type, USB 2.0, miniB, slave function (mass storage class) only

[HOST] - USB-A type, USB2.0, network connection function only

[IN] 1.0 V(p-p) to 4.0 V(p-p) high impedance

[OUT] 2.0 ± 1.0 V(p-p) low impedance

Video recording file format

Video: HQ mode MPEG-2 Long GOP VBR, 35 Mbps (Max) MP@HL, 1920x1080/59.94i, 29.97p, 23.98p, 50i, 25p 1440x1080/59.94i, 50i 1280x720/59.94p, 29.97p,

Video: SP mode MPEG-2 Long GOP CBR, 18.3 Mbps MP@HL (720p)/25 Mbps MP@H14 (1080i) 1440x1080/59.94i, 50i 1280x720/59.94p, 50p

Video recording file format

Video: HQ mode MPEG-4 AVC/H.264, 24 Mbps (Max) 1920x1080/59.94i, 50i

Video: SP mode MPEG-4 AVC/H.264, 17 Mbps 1920x1080/59.94i, 50i

Audio Dolby Digital 2ch, 48 kHz/16 Bit, 256 kbps

Video recording file format

Video - MPEG-4 AVC/H.264, 35 Mbps (Max) 1920x1080/59.94i, 23.98p, 50i

Audio - LPCM 2ch, 48 kHz/16 Bit

Video recording file format

Video MPEG-4 AVC/H.264, 8 Mbps 720x480/59.94i (U model only), 720x576/50i (E model only)

Audio LPCM 2ch, 48 kHz/16 Bit

Video recording file format

Video - MPEG-4 AVC/H.264, 1.2 Mbps 480x270/29.97p, 23.98p, 25p

Audio - µ-law 2ch, 16 kHz

(during recording with backlight set to [STANDARD] while the viewfinder is in use)

class) only

QuickTime File Format (For Final Cut Pro)/MP4 File Format QuickTime File Format (For Final Cut Pro)/MP4 File Format/ MXF File Format

23.98p, 50p, 25p

AVCHD File Format

- QuickTime File Format

QuickTime File Format

- QuickTime File Format

Warranty Card (U model only), Instructions, CDROM, AC Adapter, Power Cord (U model: 1, E model: 2), Battery, AV Cable, Clamp Filter, Wire Clamp,

Large Eyecup

GY-HM600U, GY-HM600E GY-HM650U, GY-HM650E

Approx. 13.0 W

(during recording with backlight set to [STANDARD] while the viewfinder is in

use)

-

1-2 (No.HC047<Rev.001>)

Page 3

SECTION 1

r

PRECAUTION

1.1 SAFETY PRECAUTIONS

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes of the countries in which they are to be

sold.However,in order to maintain such compliance, it is equally

important to implement the following precautions when a set is

being serviced.

1.1.1 Precautions during Servicing

(1) Locations requiring special caution are denoted by labels

and inscriptions on the cabinet, chassis and certain parts of

the product.When performing service, be sure to read and

comply with these and other cautionary notices appearing

in the operation and service manuals.

(2) Parts identified by the symbol and shaded ( ) parts

are critical for safety.

Replace only with specified part numbers.

NOTE :

Parts in this category also include those specified to

comply with X-ray emission standards for products

using cathode ray tubes and those specified for

compliance with various regulations regarding spurious radiation emission.

(3) Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

(4) Use specified internal wiring. Note especially:

• Wires covered with PVC tubing

• Double insulated wires

• High voltage leads

(5) Use specified insulating materials for hazardous live parts.

Note especially:

• Insulation Tape

• PVC tubing

•Spacers

• Insulation sheets for transistors

• Barrier

(6) When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

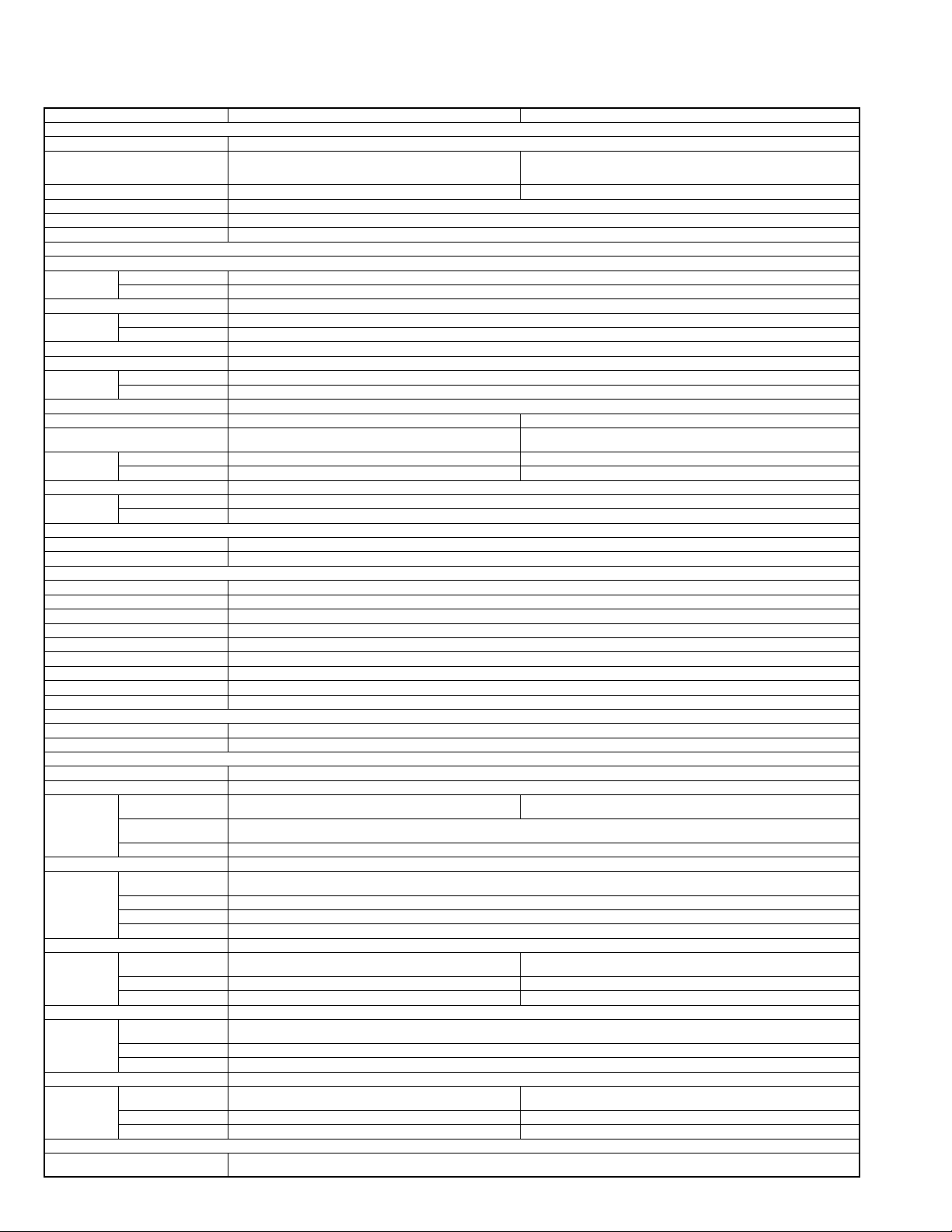

Fig.1-1-1

(7) Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

(8) Check that replaced wires do not contact sharp edged or

pointed parts.

(9) When a power cord has been replaced, check that 10-15

kg of force in any direction will not loosen it.

Power cord

cathode ray tubes and other parts with only the specified

parts. Under no circumstances attempt to modify these circuits.Unauthorized modification can increase the high voltage value and cause X-ray emission from the cathode ray

tube.

(12) Crimp type wire connector In such cases as when replac-

ing the power transformer in sets where the connections

between the power cord and power trans former primary

lead wires are performed using crimp type connectors, if

replacing the connectors is unavoidable, in order to prevent

safety hazards, perform carefully and precisely according

to the following steps.

• Connector part number :E03830-001

• Required tool : Connector crimping tool of the proper

type which will not damage insulated parts.

• Replacement procedure

a) Remove the old connector by cutting the wires at a

point close to the connector.Important : Do not reuse a connector (discard it).

cut close to connector

Fig.1-1-3

b) Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

15 mm

Fig.1-1-4

c) Align the lengths of the wires to be connected. In-

sert the wires fully into the connector.

Metal sleeve

Connector

Fig.1-1-5

d) As shown in Fig.1-1-6, use the crimping tool to

crimp the metal sleeve at the center position. Be

sure to crimp fully to the complete closure of the

tool.

1

.2

2.0

5.5

5

Crimping tool

Fig.1-1-6

e) Check the four points noted in Fig.1-1-7.

Not easily pulled free

Crimped at approx. cente

of metal sleeve

Fig.1-1-2

(10) Also check areas surrounding repaired locations.

(11) Products using cathode ray tubes (CRTs) In regard to such

products, the cathode ray tubes themselves, the high voltage circuits, and related circuits are specified for compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the

Conductors extended

Wire insulation recessed

more than 4 mm

Fig.1-1-7

(13) Battery replacement caution notice.

CAUTION RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO THE

INSTRUCTIONS.

(No.HC047<Rev.001>)1-3

Page 4

1.1.2 Safety Check after Servicing

Examine the area surrounding the repaired location for damage

or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following

tests and confirm the specified values in order to verify compliance with safety standards.

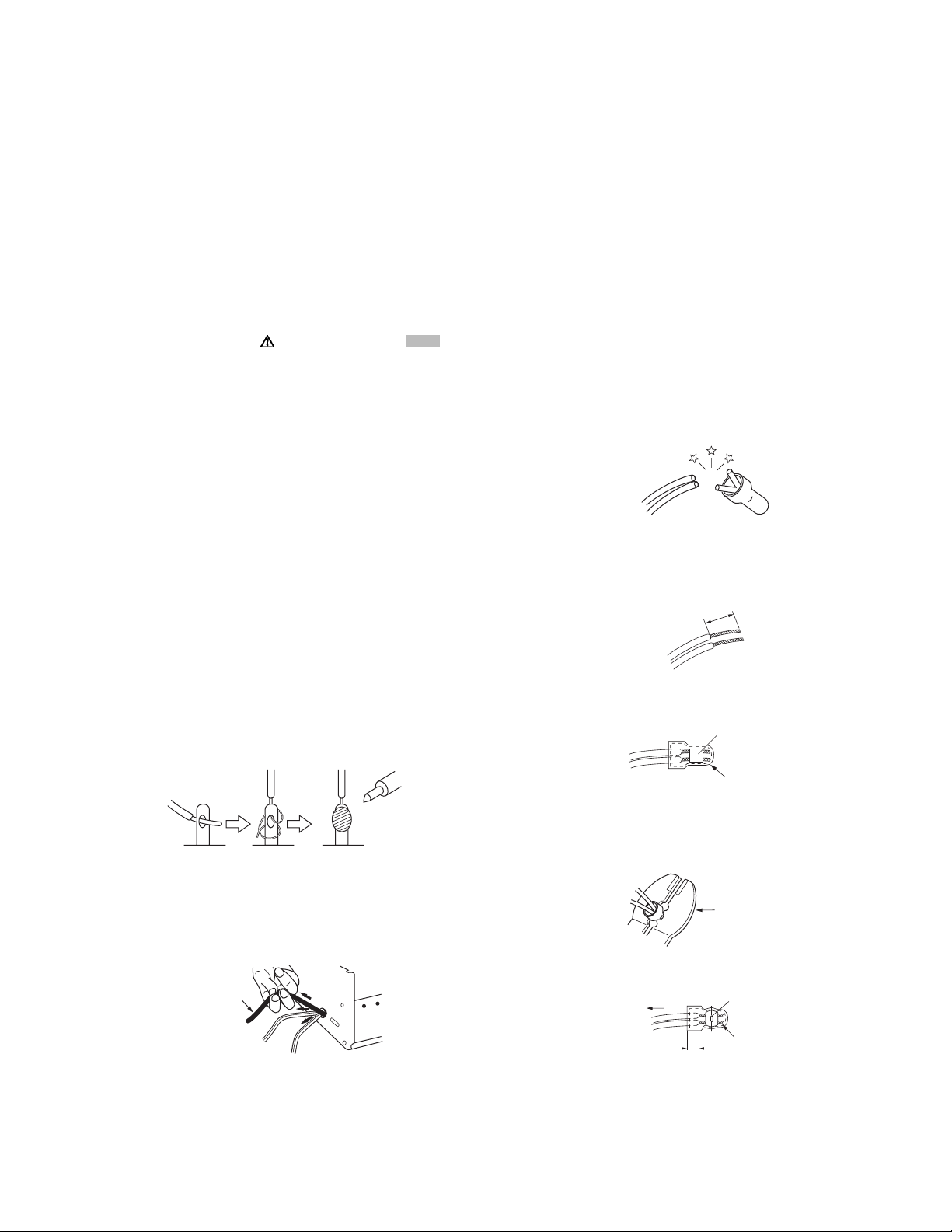

(1) Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed

parts of the set (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).See table 1 below.

(2) Dielectric strength test

Confirm specified dielectric strength or greater between

power cord plug prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone

jacks, etc.). See Fig.1-1-11 below.

(3) Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d') between soldered terminals, and between terminals and surrounding metallic

parts. See Fig.1-1-11 below.

d

Chassis

d'

Power cord

primary wire

Fig.1-1-8

(4) Leakage current test

Confirm specified or lower leakage current between earth

ground/power cord plug prongs and externally exposed accessible parts (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON) Insert load Z between

earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure

across both terminals of load Z. See Fig.1-1-9 and following Fig.1-1-12.

ab

Externally

exposed

accessible part

Z

V

c

A

Fig.1-1-9

(5) Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between

earth pin in AC inlet and externally exposed accessible

parts (Video in, Video out, Audio in, Audio out or Fixing

screw etc.).Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and

exposed accessible parts. See Fig.1-1-10 and grounding

specifications.

AC inlet

Earth pin

Exposed accessible part

Milli ohm meter

Grounding Specifications

Region

USA & Canada

Europe & Australia

Grounding Impedance (Z

Z 0.1 ohm

Z 0.5 ohm

)

Fig.1-1-10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Insulation Resistance (R

R 1 M /500 V DC

1 M R 12 M /500 V DC

R 10 M /500 V DC

)

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 minute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(

Class

(

Class

Clearance Distance (d), (d'

d, d' 3 mm

d, d' 4 mm

d, d' 3.2 mm

d 4 m m

)

d' 8 m m (Power cord

d' 6 m m (Primary wire

)

Fig.1-1-11

AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Load Z

1

0.15

1.5

2

50

Leakage Current (i)

i 1 mA rms

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

a, b, c

Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

Other terminals

Fig.1-1-12

NOTE :

These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

)

)

)

1-4 (No.HC047<Rev.001>)

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

SECTION 3

DISASSEMBLY

3.1 Center frame section

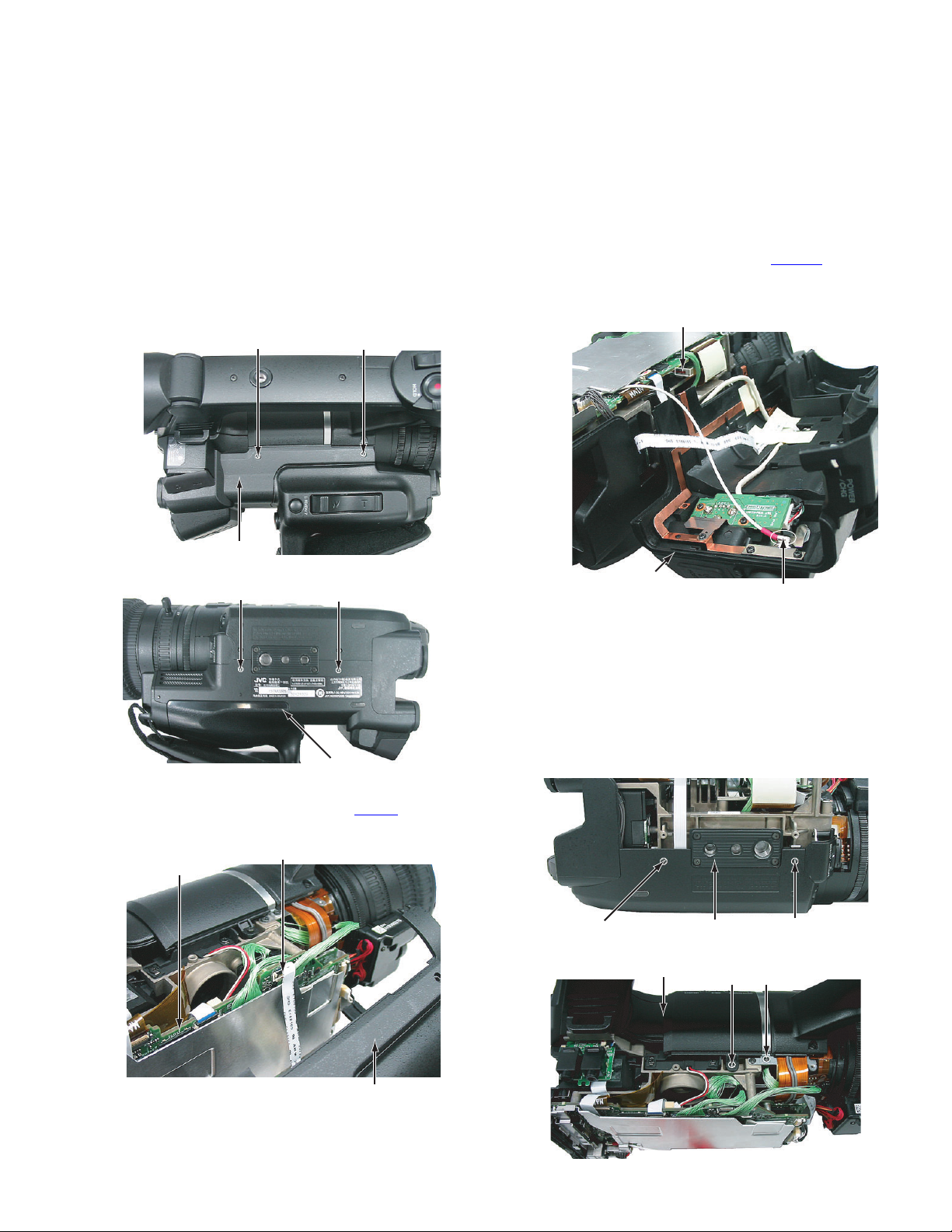

3.1.1 Removing the L side cover assembly (See Figure 1, 2,

3 and 4)

(1) Remove the four screws A attaching the L side cover as-

sembly, and then open the L side cover assembly.

A

L Side cover assembly

Fig.1

AA

L Side cover assembly

Fig.2

(2) Pull out the wire from the connector CN210

board.

CN210

MAIN Board

A

on the MAIN

(3) Pull out the wire from the SDI terminal.

(4) Pull out the wire from the connector CN3112

WORK board, and then remove the L side cover assembly

(only GY-HM650).

CN3112

L Side cover assembly

Fig.4

3.1.2 Removing the R side cover assembly (See Figure 5, 6,

7 and 8)

• Remove the L side cover assembly.

(1) Remove the four screws B and the one screw C attaching

the R side cover assembly.

Screw B: Short Screw C: Long

(2) Remove the two screws D attaching the handle cover (R)

and then remove the handle cover (R).

SDI Terminal

on the NET-

L Side cover assembly

Fig.3

BBR Side cover assembly

Fig.5

R Side cover assembly

BB

Fig.6

(No.HC047<Rev.001>)1-5

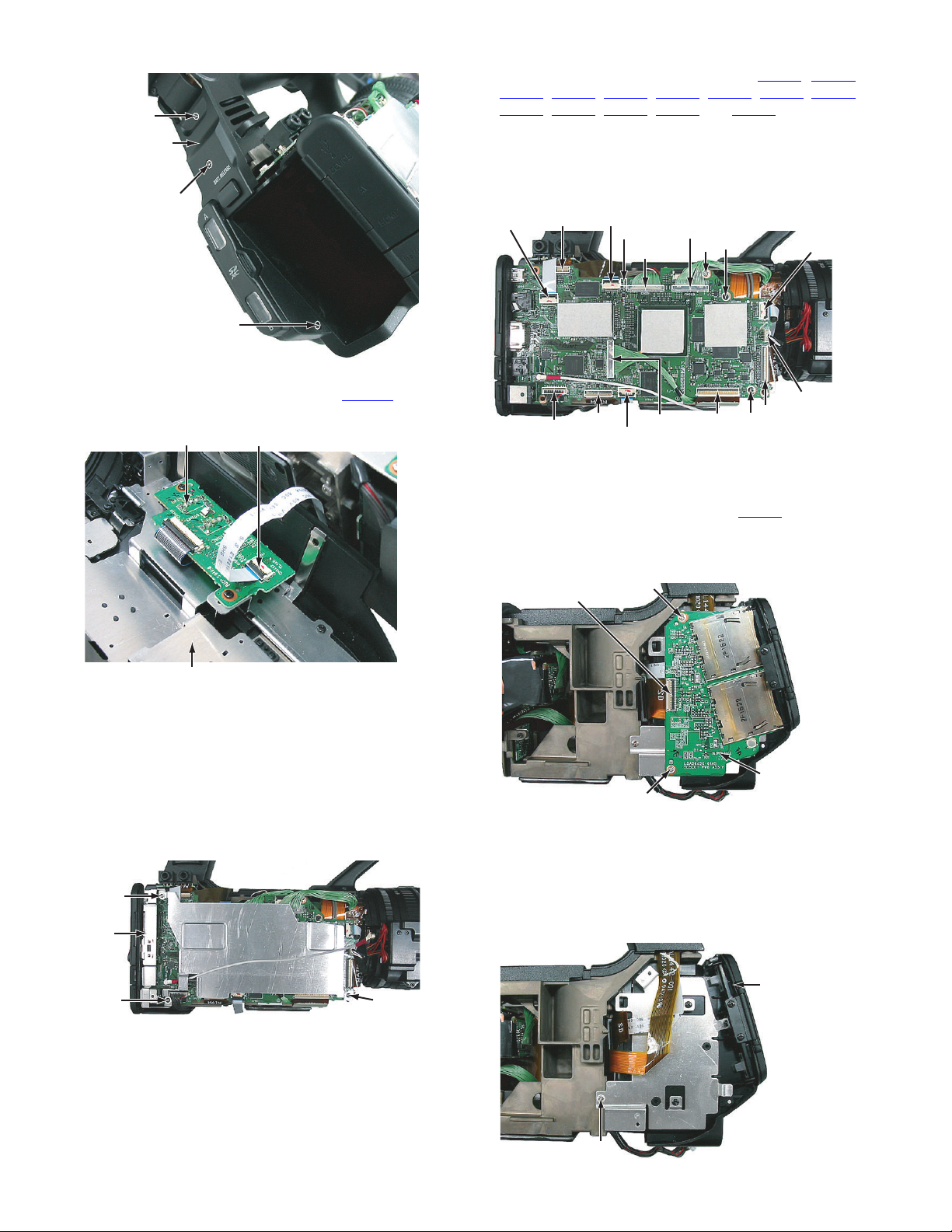

Page 6

D

Heat sink plate

MAIN Board

Handle cover (R)

(2) Pull out the wires from the connectors CN203

, CN214, CN208, CN213, CN209, CN212, CN202,

CN207

CN204

, CN205, CN206, CN215 and CN216 on the MAIN

, CN201,

board.

(3) Remove the one screw F attaching the MAIN board, and

then remove the MAIN board.

(4) Remove the two screws G, and then remove the NET-

D

WORK board (only GY-HM650).

CN214

CN208

CN207

CN215

CN201

CN203

G

H

CN216

C

Fig.7

(3) Pull out the FFC wire from the connector CN1412 on the

GAIN board, and then remove the R side cover assembly.

GAIN Board CN1412

R Side cover assembly

Fig.8

3.1.3 Removing the MAIN board and NETWORK board (See

Figure 9 and 10)

• Remove the L side cover assembly.

(1) Remove the three screws E attaching the bracket (DCIN)

and heat sink plate, and then remove the bracket (DCIN)

and heat sink plate.

• When attaching the bracket (DCIN) and heat sink plate,

a bracket (DCIN) is under a heat sink plate.

E

Bracket

(DCIN)

Heat sink plate

Heat sink plate

EE

Fig.9

MAIN Board

MAIN Board

CN206

CN205

CN213

CN209

CN212

CN202

CN204

G

Fig.10

3.1.4 Removing the SDSLOT board (See Figure 11)

• Remove the R side cover assembly.

(1) Pull out the wire from the connector CN809

on the SD-

SLOT board.

(2) Remove the two screws H attaching the SDSLOT board,

and then remove the SDSLOT board.

CN809

H

SDSLOT

H

Board

Fig.11

3.1.5 Removing the rear assembly (See Figure 12 and 13)

• Remove the L side cover assembly and R side cover assembly

etc, .

(1) Remove the one screw J and the five screws K attaching

the rear assembly, and then remove the rear assembly.

Screw J: Silver Screw K: Black

Rear

assembly

1-6 (No.HC047<Rev.001>)

J

Fig.12

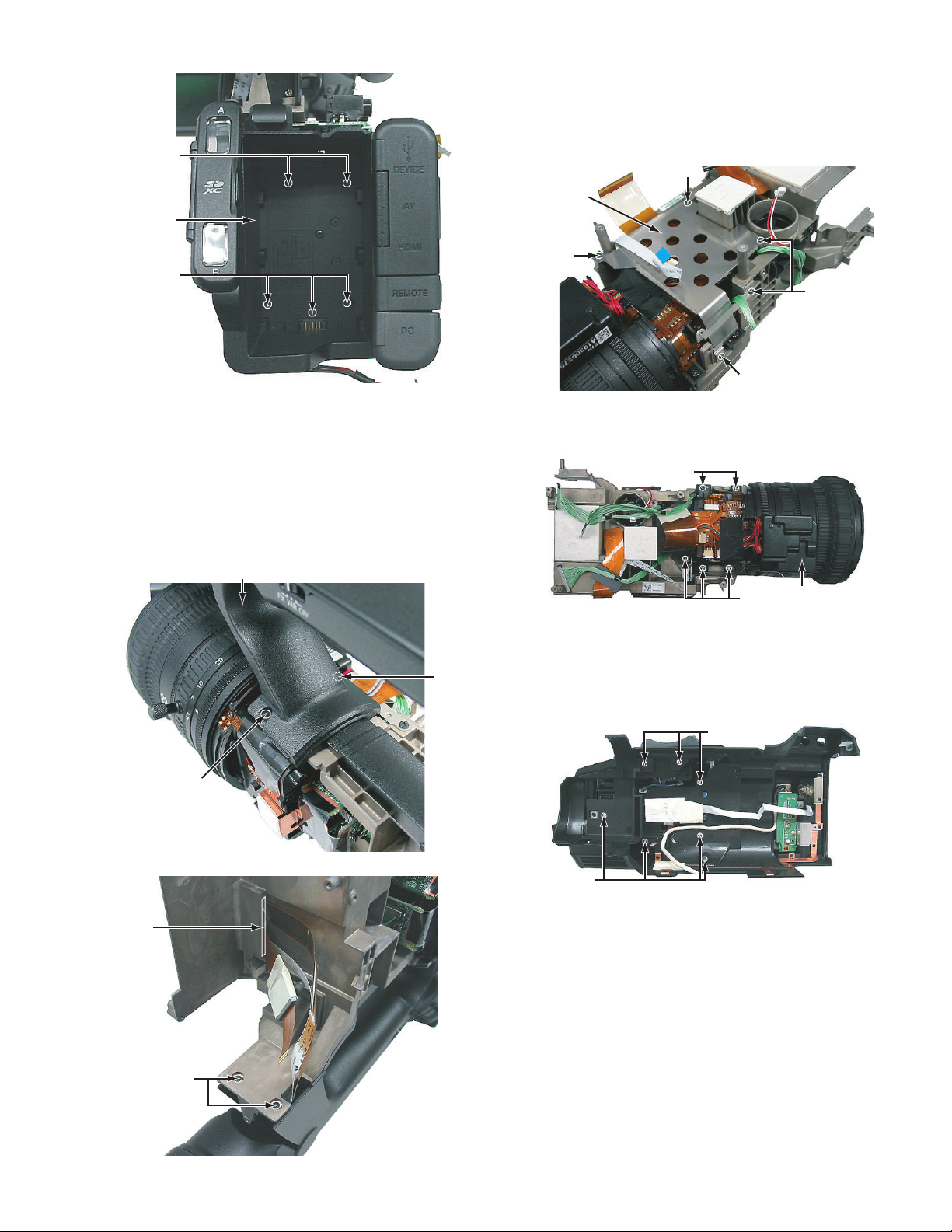

Page 7

Rear

assembly

3.1.7 Removing the lens unit (See Figure 16 and 17)

• Remove the L side cover assembly and R side cover assembly

etc, .

(1) Remove the five screws M attaching the board bracket,

K

and then remove the board bracket.

Board

M

bracket

M

K

M

Fig.13

3.1.6 Removing the handle assembly (See Figure 14 and

15)

• Remove the L side cover assembly and R side cover assembly

etc, .

(1) Remove the four screws L attaching the handle assembly,

and then remove the handle assembly.

• When attaching the handle assembly, let two wires from

VF pass to the slit of a frame.

Handle assembly

L

L

M

Fig.16

(2) Remove the five screws N attaching the lens unit, and then

remove the lens unit.

N

Lens unit

N

Fig.17

3.2 L Side cover assembly section

3.2.1 Removing the Grip cover assembly (See Figure 1)

(1) Remove the seven screws A attaching the grip cover as-

sembly, and then remove the grip cover assembly.

A

Slit

Fig.14

A

Fig.1

L

Fig.15

(No.HC047<Rev.001>)1-7

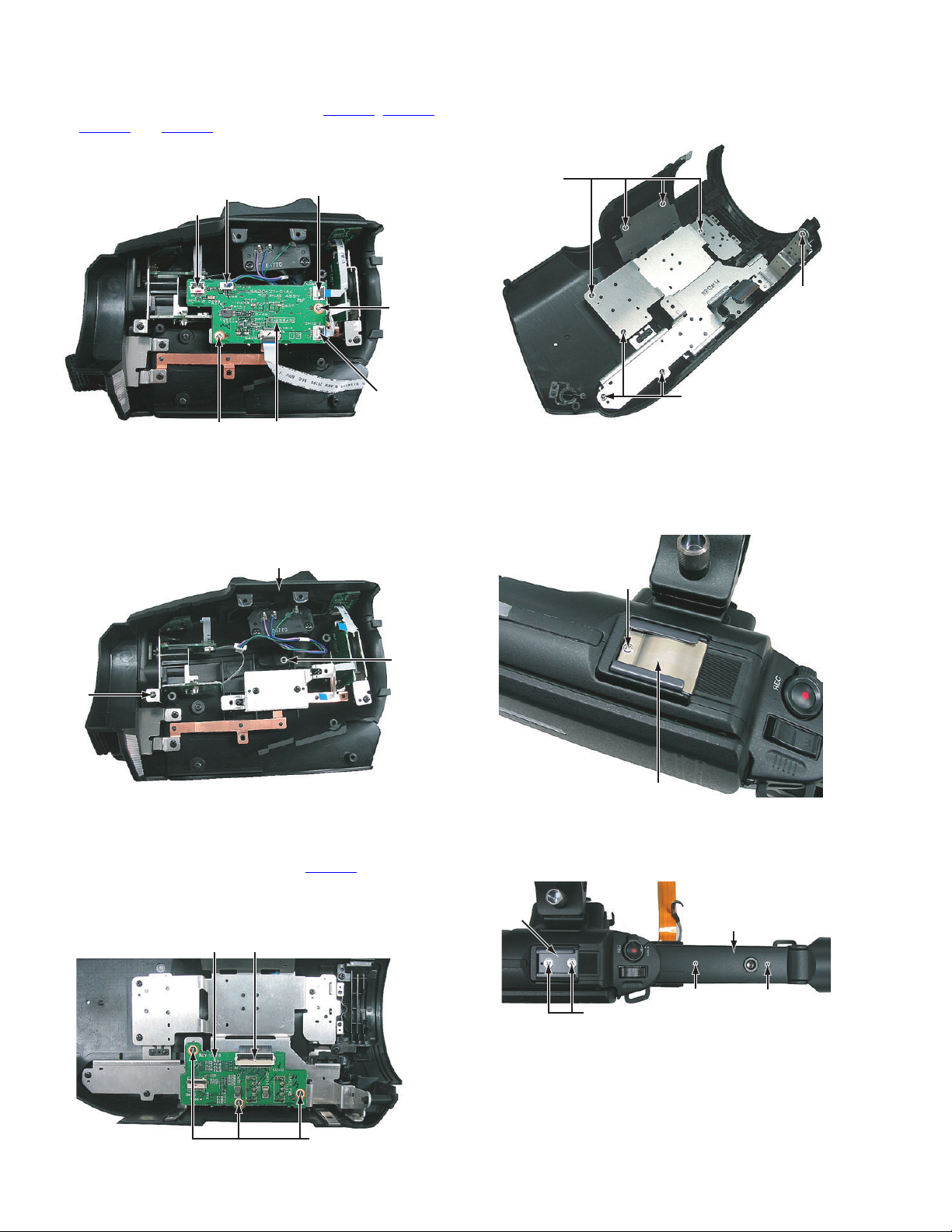

Page 8

3.2.2 Removing the TC board (See Figure 2)

R OPE Unit

• Remove teh grip cover assembly.

(1) Pull out the wires from the connectors CN1212

CN1213

(2) Remove the two screws B attaching the TC board, and

then remove the TC board.

and CN1214 on the TC board.

CN1213

CN1211

, CN1211,

CN1214

B

3.3.2 Removing the R OPE unit (See Figure 2)

• Remove the GAIN board.

(1) Remove the eight screws B attaching the R OPE unit, and

then remove the R OPE unit.

B

R OPE Unit

R OPE Unit

B

CN1212

B TC Board

Fig.2

3.2.3 Removing the seesaw assembly (See Figure 3)

• Remove the grip cover assembly and TC board.

(1) Remove the two screws C attaching the seesaw assembly,

and then remove the seesaw assembly.

Seesaw assembly

C

C

Fig.3

3.3 R Side cover assembly section

3.3.1 Removing the GAIN board (See Figure 1)

(1) Pull out the wire from the connector CN1413

board.

(2) Remove the three screws A attaching the GAIN board, and

then remove the GAIN board.

on the GAIN

CN1413GAIN Board

B

Fig.2

3.4 Handle assembly section

3.4.1 Removing the handle cover T (See Figure 1, 2 and 3)

(1) Remove the one screw A attaching the shoe spring, and

then remove the shoe spring.

A

Shoe spring

Fig.1

(2) Remove the two screws B attaching the shoe, and then re-

move the shoe.

(3) Remove the two screws C attaching the handle cover T.

Shoe

Handle cover T

1-8 (No.HC047<Rev.001>)

B

CC

Fig.2

A

Fig.1

Page 9

(4) Pull out the FFC wire from the connector CN405 on the

HANDLE board, and then remove the handle cover T.

3.4.3 Removing the VF unit (See Figure 7, 8 and 9)

• Remove the handle cover T.

(1) Remove the four screws F attaching the ACC base, and

then remove the ACC base.

F

CN405

HANDLE Board

Fig.3

3.4.2 Removing the GPS and HANDLE board (See Figure 4,

5 and 6)

• Remove the handle cover T.

(1) Remove the one screw D attaching the GPS. (only GY-

HM650)

D

GPS

Fig.4

(2) Remove the three screws E attaching the bracket and

HANDLE board.

E

ACC Bace

(2) Remove the four screws G attaching the VF unit, and then

remove the VF unit.

F

Fig.7

VF Unit

G

Fig.8

VF Unit

G

G

HANDLE Board

Fig.5

(3) Pull out the wire from the connector CN407

DLE board, and then remove the GPS and HANDLE board.

on the HAN-

HANDLE Board

CN407

Fig.6

Fig.9

3.4.4 Removing the XLR board (See Figure 10, 11, 12 and

13)

• Remove the handle cover T.

(1) Remove the six screws H attaching the XLR cover.

H

XLR Cover

H

Fig.10

(No.HC047<Rev.001>)1-9

Page 10

(2) Remove the one screw L attaching the FFC, and then pull

H

out the wire from the connector CN1806

(3) Remove the two screws M attaching the hinge, and then

remove the monitor assembly.

CN1806

M

.

Monitor

assembly

H

Fig.11

(2) Pull out the wires from the connectors CN506

on the XLR board.

and CN503

CN506

CN503

Fig.12

(3) Remove the four screws J attaching the terminal, and then

remove the XLR board.

L

M

Fig.15

(4) Remove the one screw N, and then remove the front guard.

(5) Remove the six screws P and the one screw Q attaching

the OPE cover, and then remove the OPE cover.

Front guard

P

N

P

P

Q

AVR Board

P

PP

Fig.16

(6) Remove the two screws R attaching the volume knob, and

then remove the volume knob.

• When attaching the volume knob, turn in the direction of

an arrow, and attach so that “0” becomes a position of a

figure.

R

J

Fig.13

3.4.5 Removing the monitor assembly and AVR board (See

Figure 14, 15, 16, 17 and 18)

(1) Remove the two screws K attaching the joint cover, and

then remove the joint cover and hinge cover.

K Joint cover

Hinge

cover

K

Fig.14

1-10 (No.HC047<Rev.001>)

"0"

Fig.17

Page 11

(7) Pull out the wires from the connectors CN301, CN305 and

on the AVR board.

CN302

(8) Remove the six screws S attaching the AVR board, and

then remove the AVR board.

CN305S

S

CN302

CN301

S

S

AVR Board

S

S

Fig.18

(No.HC047<Rev.001>)1-11

Page 12

SECTION 4

ADJUSTMENT

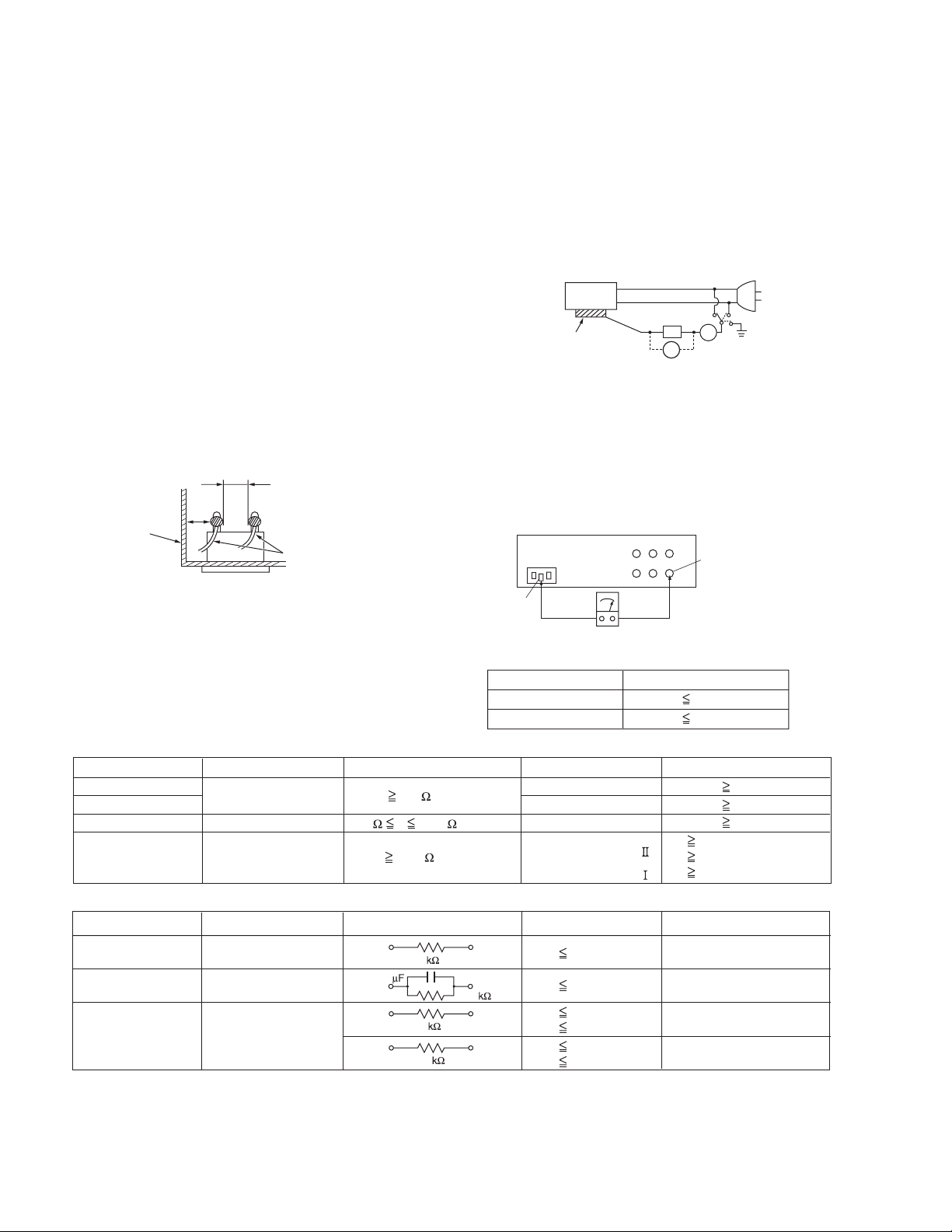

4.1 Instruments required for adjustment and the setup

4.1.1 Measuring instruments required for adjustment

Instrument Condition Instrument Condition

PC (Windows) With an RS-232C compliant serial

communication port.

Color TV monitor Supporting HD(1080/60i), with an

HDMI input.

Oscilloscope 100 MHz or higher (300 MHz is recom-

mended), calibrated instrument.

Signal generator Output level change is possible.

(1kHz, 300Hz)

Digital volt meter Calibrated instrument. Thermometer, Color thermometer, Illuminometer

4.1.2 Jigs and tools required for adjustment

Audio tester Calibrated instrument.

Speaker ----------

DC power source 12V/1.7A or more, power source for light box.

AC adapter Used as a power source for the unit.

(Accessory)

Adjustment software

PC cable Focus chart

QAM0099-002 YTU92001-018

Download from JS-NET

HM6xx_Adjust.exe

(.NET framework 4.0 required)

Light source INF adjustment lens

White chart

(Collimator)

The halogen lamp of 3000K,

YTU92001E 88.9% of reflectance

2600lx

4.1.3 Set up for adjustment

(1) Connect appropriate measuring instruments, jigs, and tools required for the adjustment item.

Color TV monitor

Oscilloscope

Light source

1-12 (No.HC047<Rev.001>)

Focus chart

75 resistor for termination

Collimator

Video signal

To AUX

terminal

PC Cable

Page 13

4.2 Adjustment

The adjustment for this model is a special adjustment using a PC. Use the adjustment software (HM6xx_Adjust.exe) for adjustment.

(1) Preparation of SD card for adjustment

This camera can be changed to adjustment mode by using SD card for adjustment.

The SD card for adjustment has a file named PROJECT.ADJ in a root directory.

4.2.1 Installation of adjustment software

(1) Download adjustment software (HM6xx_Adjust.exe) from JS-NET, and store it in the arbitrary place in your PC.

4.2.2 The operation method

(1) Connect PC cable (QAM0099-002) to PC and a camera (AUX terminal).

(2) The screen as shown below will be displayed when launching the adjustment software.

(3) Set up a serial port.

(4) Operate the adjustment software by switching tabs according to the contents of adjustment.

4.2.2.1 ADJ Tab

If ADJ tab is chosen, the tab according to the adjustment item will appear.

(No.HC047<Rev.001>)1-13

Page 14

(1) Composite tab

This is used for Composite signal adjustment. By operating each slide bar, each value can be changed, and by pressing the

[READ] button, the current preset value is acquirable.

(2) ZOOM MR Tab

This is used for Zoom ring adjustment. After pressing the [START] button, adjust by operating the Zoom ring, according to the

instruction.

• For FOCUS MR tab, ZOOM VR tab, and Z Tracking tab, adjust each article according to the instruction respectively. FOCUS

MR tab for Focus ring adjustment, ZOOM VR tab for Zoom potentiometer adjustment, and Z Tracking tab for Zoom tracking

adjustment.

(3) OIS Drv tab

This is used for OIS adjustment. After pressing the [START] button, adjust by rocking a camera, according to the instruction.

1-14 (No.HC047<Rev.001>)

Page 15

(4) Ingain tab

This is used for Ingain adjustment. The adjustment is automatically performed when pressing the [START] button.

(5) AF Filter tab

This is used for AF Filter adjustment. The adjustment needs to be performed under the condition of ND 1/16 and ND 1/64.

It is automatically performed under each condition when pressing each [START] button.

(6) BPD Tab

This is used for White Blemish adjustment. The adjustment is automatically performed when pressing the [START] button.

(7) Audio tab

This is used for audio adjustment.

(No.HC047<Rev.001>)1-15

Page 16

4.2.2.2 EEP Tab

It is used when reading and writing the data of EEPROM which each microcomputer (CC, BE, IF) has managed.

• For example, when reading the data of EEPROM which BE microcomputer has managed, input an address to read into the Adrs

colummn on the left side of the [READ] button of BE Write, and press the [READ] button.

• When writing data to EEPROM which BE microcomputer has managed, input an address to write into the Adrs column on the left

side of the [Write] button of BE Write, and the data to write into the Data column, and then press the [Write] button.

• Also for the EEPROM which CC microcomputer and IF microcomputer have managed, it is the same as that of BE microcomputer.

4.2.2.3 SETTING1 Tab and SETTING2 Tab

This is used for setting parameters to the camera. Input a parameter to set to the camera into a relevant column, respectively, and

then press the relevant [Write] button.

4.2.2.4 OTHERS Tab

Each reset is assigned here and it is frequently-used.

NOTE:

Other tabs are not used.

1-16 (No.HC047<Rev.001>)

Page 17

4.2.3 Preparation

When the camera is in the adjustment mode, the red “P” letter can be seen at the top of the LCD screen, and this mode is retained

until ALL Reset is performed with the adjustment software, even if shutting off the camera.

(1) Insert the SD card for adjustment into slot B, and remove it after flashing slot B indicator.

(2) Connect a JLIP cable to an AUX terminal of the camera.

(3) When the clock setting screen of the camera is displayed, press the [SET] button of the camera to skip it.

(4) Choose an OTHERS tab, press the [0x01] button of the MENU Reset to reset the menu.

(5) In the case of the "U" model, Master Black is set to "-3". You need to set this to "0" for adjustment. the procedure is as follows;

Choose EEP tab, input 7 into Adrs column of the BE Write, input 32 into Data column and then press the [Write] button.

4.2.4 Camera adjustment

No. Adjustment

item

1 Composite

analog output

CGAIN

60Hz U

2 Composite

analog output

YGAIN

60Hz U

3 Composite

analog output

YGAIN

60Hz I

Adjustment

type

Manual adjustment

Manual adjustment

Manual adjustment

Jig Signal Adjustment

Oscilloscope

Oscilloscope

Oscilloscope

Built-in

color bar

Built-in

color bar

Built-in

color bar

point

Composite

output

Composite

output

Composite

output

standard Adjustment

value range

0.286V 0-255 112

1.0V 0-255 162

1.0V 0-255 175

Adjustment

default value

(0x70)

(0xA2)

(0xAF)

Procedure

(1) Set Record Format to 1920 x 1080,

60i(HQ) or 1440 x 1080, 60i(HQ), if it

has not been set so. Choose SETTING1

tab, input 0 into the "Video Format

Change" column and then press the

[Write] button.

(2) Set SETUP to ON, if it has not been set

so. Choose SETTING1 tab, input 1 into

the "Composite Setup On/Off" column

and then press the [Write] button.

(3) Choose ADJ tab -> Composite tab,

press the [Read] button of the CGAIN

60HZ U.

(4) Adjust the value to the standard by oper-

ating the slider of the CGAIN 60HZ U,

with observing the wave form on the oscilloscope.

(1) Set Record Format to 1920 x 1080,

60i(HQ) or 1440 x 1080, 60i(HQ), if it

has not been set so. Choose SETTING1

tab, input 0 into the "Video Format

Change" column and then press the

[Write] button.

(2) Set SETUP to ON, if it has not been set

so. Choose SETTING1 tab, input 1 into

the "Composite Setup On/Off" column

and then press the [Write] button.

(3) Choose ADJ tab -> Composite tab,

press the [Read] button of the YGAIN

60HZ U.

(4) Adjust the value to the standard by oper-

ating the slider of the YGAIN 60HZ U,

with observing the wave form on the oscilloscope.

(1) Set Record Format to 1920 x 1080,

60i(HQ) or 1440 x 1080, 60i(HQ), if it

has not been set so. Choose SETTING1

tab, input 0 into the "Video Format

Change" column and then press the

[Write] button.

(2) Set SETUP to OFF, if it has not been set

so. Choose SETTING1 tab, input 0 into

the "Composite Setup On/Off" column

and then press the [Write] button.

(3) Choose ADJ tab -> Composite tab,

press the [Read] button of the YGAIN

60HZ I.

(4) Adjust the value to the standard by oper-

ating the slider of the YGAIN 60HZ I,

with observing the wave form on the oscilloscope.

(No.HC047<Rev.001>)1-17

Page 18

No. Adjustment

item

4

Composite

analog output

CGAIN

50Hz E

5 Composite

analog output

YGAIN

50Hz E

6 ZOOM Ring

MR

(Perform

before "8.

ZOOM Ring

TELE/WIDE

potentiometer" adjustment)

7 FOCUS

Ring MR

(Perform

before "8.

ZOOM Ring

TELE/WIDE

potentiometer" adjustment)

8 ZOOM ring

TELE/WIDE

potentiometer

9 ZOOM

Tracking

Adjustment

type

Manual adjustment

Manual adjustment

Semiauto

adjustment

Semiauto

adjustment

Semiauto

adjustment

Automatic

adjustment

Jig Signal Adjustment

Oscilloscope

Oscilloscope

Built-in

color bar

Built-in

color bar

point

Composite

output

Composite

output

standard Adjustment

value range

0.30V 0-255 113

1.0V 0-255 171

Adjustment

default value

(0x71)

(0xAB)

Procedure

(1) Set Record Format to 1920 x 1080,

50i(HQ) or 1440 x 1080, 50i(HQ), if it

has not been set so. Choose SETTING1

tab, input 1 into the "Video Format

Change" column and then press the

[Write] button.

(2) Choose ADJ tab -> Composite tab,

press the [Read] button of the CGAIN

50HZ E.

(3) Adjust the value to the standard by oper-

ating the slider of the CGAIN 50HZ E,

with observing the wave form on the oscilloscope.

(1) Set Record Format to 1920 x 1080,

50i(HQ) or 1440 x 1080, 50i(HQ), if it

has not been set so. Choose SETTING1

tab, input 1 into the "Video Format

Change" column and then press the

[Write] button.

(2) Choose ADJ tab -> Composite tab,

press the [Read] button of the YGAIN

50HZ E.

(3) Adjust the value to the standard by oper-

ating the slider of the YGAIN 50HZ E,

with observing the wave form on the oscilloscope.

-- (1) Choose ADJ tab -> ZOOM MR tab,

press the [START] button.

(2) After pressing the [START] button, turn

the ZOOM ring quickly clockwise and

counterclockwise alternately by hand.

(3) It will be completed when displayed as

Complete.

- - (1) Choose ADJ tab -> FOCUS MR tab,

press the [START] button.

(2) After pressing the [START] button, turn

the FOCUS ring quickly clockwise and

counterclockwise alternately by hand.

(3) It will be completed when displayed as

Complete.

-- (1) Set the ZOOM ring to the TELE end.

(2) Choose ADJ tab -> ZOOM VR tab, press

the [START] button.

(3) After pressing the [START] button, turn

the ZOOM ring slowly to the WIDE end

by hand.

(4) It will be completed when displayed as

Complete.

Collimator

LED

lighting

- (1) Attach the Collimeter to the Lens.

(2) Check the illumination is 19±3Lux.

(3) Choose ADJ tab -> Z Tracking tab,

press the [START] button.

(4) It will be completed when displayed as

Complete.

1-18 (No.HC047<Rev.001>)

Page 19

No. Adjustment

item

Adjustment

type

10 OIS Drive Automatic

adjustment

INGAIN and

11

ANALOGGAIN

AF Filter ND

12

1/16

AF Filter ND

13

1/64

White blem-

14

ish

Automatic

adjustment

Semiauto

adjustment

Semiauto

adjustment

Automatic

adjustment

Jig Signal Adjustment

point

--

Mini

studio

Mini

studio

Mini

studio

White

chart

White

chart

White

chart

- - (IRIS

CLOSE)

standard Adjustment

value range

Adjustment

default value

Procedure

(1) Choose ADJ tab -> OIS Drv tab,

press the [START] button.

(2) After pressing the [START] button,

adjust so that the shake of a monitor

screen comes to minimum, while vibrating a camera by hand.

(3) It will be completed when displayed

as Complete.

(1) Prepare an adjustment environ-

ment of 3000K (Mini studio or

something).

(2) Set Record Format to 1920 x 1080,

24p(HQ), if it has not been set so.

Choose SETTING1 tab, input 4 into

the "Video Format Change" column

and then press the [Write] button.

(3) Choose ADJ tab -> Ingain tab,

press the [START] button.

(4) It will be completed when displayed

as Complete.

(1) Set ND filter to the 1/16 position.

(2) Set Record Format to 1920 x 1080,

60i(HQ) or 1440 x 1080, 60i(HQ), if

it has not been set so. Choose

SETTING1 tab, input 0 into the "Video Format Change" column and

then press the [Write] button.

(3) Choose ADJ tab -> AF Filter tab,

press the [START] button of ND 1/

16.

(4) It will be completed when displayed

as Complete.

(1) Set ND filter to the 1/64 position.

(2) Set Record Format to 1920 x 1080,

60i(HQ) or 1440 x 1080, 60i(HQ), if

it has not been set so. Choose

SETTING1 tab, input 0 into the "Video Format Change" column and

then press the [Write] button.

(3) Choose ADJ tab -> AF Filter tab,

press the [START] button of ND 1/

64.

(4) It will be completed when displayed

as Complete.

(1) Wait about 30 minutes for pre-heat-

ing the camera.

(2) Set Record Format to 1920 x 1080,

60i(HQ) or 1440 x 1080, 60i(HQ), if

it has not been set so. Choose

SETTING1 tab, input 0 into the "Video Format Change" column and

then press the [Write] button.

(3) Choose ADJ tab -> BPD tab, press

the [START].

(4) It will be completed when displayed

as Complete.

(No.HC047<Rev.001>)1-19

Page 20

4.2.5 Audio adjustment

Perform this adjustment only when you change a microphone.

No. Adjustment

item

1 AUDIO XLR

Level

INPUT1

LINE Level

2 AUDIO XLR

Level

INPUT1

MIC Level

3 AUDIO XLR

Level

INPUT2

LINE Level

4 AUDIO XLR

Level

INPUT2

MIC Level

5 AUDIO

Built-in microphone

Adjustment

type

Manual adjustment

Manual adjustment

Manual adjustment

Manual adjustment

Manual adjustment

Jig Signal Adjustment

Audio

signal

generator

Audio

signal

generator

Audio

signal

generator

Audio

signal

generator

2CH

Audio

Analyzer,

Sound

source,

Speaker

1kHz

(+4dBu)

1kHz

(-50dBu)

1kHz

(+4dBu)

1kHz

(-50dBu)

300Hz

(400 to

700mV)

point

ADC DATA -20dBFS

ADC DATA -20dBFS

ADC DATA -20dBFS

ADC DATA -20dBFS

LINE OUT Rch=Lch ±8 (1) Set both CH1 INPUT SELECT and CH2

standard Adjustment

(3277 as

decimal

value)

(3277 as

decimal

value)

(3277 as

decimal

value)

(3277 as

decimal

value)

value range

±8 (1) Switch XLR1 input to LINE.

±8 (1) Switch XLR1 input to MIC.

±8 (1) Switch XLR2 input to LINE.

±8 (1) Switch XLR2 input to MIC.

Adjustment

default value

Procedure

(2) Choose ADJ tab -> Audio tab, press the

[Read] button of XLR LINE1 LEV.

(3) Adjust by operating the slider so that the

on-screen level meter indication comes

to -20dB.

(2) Choose ADJ tab -> Audio tab, press the

[Read] button of XLR MIC1 LEV.

(3) Adjust by operating the slider so that the

on-screen level meter indication comes

to -20dB.

(2) Choose ADJ tab -> Audio tab, press the

[Read] button of XLR LINE2 LEV.

(3) Adjust by operating the slider so that the

on-screen level meter indication comes

to -20dB.

(2) Choose ADJ tab -> Audio tab, press the

[Read] button of XLR MIC2 LEV.

(3) Adjust by operating the slider so that the

on-screen level meter indication comes

to -20dB.

INPUT SELECT to INT.

(2) Put a camera so that a built-in micro-

phone faces straight to the speaker,

apart 20 cm or more from each other.

(3) Output the 300Hz sine wave from the

speaker. Adjust the audio output level of

the speaker so that the audio output

comes to 400 ~ 700 mVrms.

(4) Choose ADJ tab -> Audio tab, press the

[Read] button of MIC BALANCE.

(5) Adjust by operating the slider so that the

value differences between Lch Eva Val

and Rch Eva Val are minimized.

1-20 (No.HC047<Rev.001>)

Page 21

SECTION 5

TROUBLE SHOOTING

5.1 Service menus

5.1.1 Modes required in servicing

While holding down the specified button (FOCUS ONE PUSH

AUTO), press the [MENU] button to display the first layer menu

of the service menu hierarchy. The items in the first layer vary according to the specified button being held when the [MENU] button is pressed. (Characters are displayed on LCD monitor screen

or View finder.)

MENU Item Contents

Advanced Function Camera settings, Blemish detect etc.

Service Function Test signal, Battery voltage settings etc.

DIP SW DIP SW Menu

Hour Meter Hour meter indication

Others All reset

5.1.2 Service menu Display

(1) While holding down the [FOCUS ONE PUSH AUTO] but-

ton, and then press the [USER1] + [USER2] + [MENU] buttons.

(2) And in the state which has pressed [FOCUS ONE PUSH

AUTO] button, a press on [USER3]+[MENU] button will display Service menu. (Pressing a [FOCUS ONE PUSH AUTO] button is continued to the last.)

5.1.4 Advanced Function menu operation

(1) Refer to 5.1.2 to display the Service menu.

(2) Select the [Advanced Function...], then press the [Set] but-

ton or the [Cross-Shaped] button (right).

(3) Advanced Function menu is displayed.

(4) Select the item to be changed, then press the [Set] button

or the [Cross-Shaped] button (right).

(5) A choice screen is displayed. Press the [Cross-Shaped]

buttons (up/down) to change the parameter.

(6) Press the [Set] button to set the parameter. A choice

screen closes.

(7) If the [CANCEL] button or the [Cross-Shaped] button (left)

is pressed, it will return to the layer on one and will end a

setup.

NOTE:

• To cancel the parameter setting change, press the

[CANCEL] button or the [Cross-Shaped] button (left)

while the choice screen is displaying.

5.1.3 Operation in the first layer of the service menu

(1) The first layer of each service menu is displayed.

(2) Press the [Cross-Shaped] buttons to select the item.

(3) Press the [Set] button or the [Cross-Shaped] button (right)

to select the item.

NOTE:

• During recording, the service menu does not start up.

• To go back to the upper layer, press the [CANCEL]

button or the [Cross-Shaped] button (left).

• To cancel the service menu, press the [MENU] button.

(No.HC047<Rev.001>)1-21

Page 22

Item Parameter

Pixel Compen

Det (FA) *1

FAW Sensitivity Slow

Silent Zoom Off ZOOM speed is not late.

AF Mode (Does

not function.)

AF Sensitivity

(Does not function.)

AF Frequency

(Does not function.)

AF M.O.D (Does

not function.)01

C.Rec Audio

Fade

Loop Rec Off No LOOP REC.

SDI Out.. Refer to the 5.1.5

Cancel Does not execute blemish detec-

tion.

Execute Executes blemish detection.

Sets the response speed of the

Midle

Fast

On ZOOM speed is slow.

0-255 The operational mode (evaluation

0

1

2

0

1

2

5

10

20

Off No AUDIO FADE in STBY↔REC.

On AUDIO FADE in STBY↔REC.

On Endless LOOP REC.

FAW control.

It is not quiet.

It becomes quiet.

area) of AF is changed.

The sensitivity of AF is changed.

The frequency of AF filter is

changed.

The shortest object distance of AF

is changed.

Refer to 5.1.4 Advanced Function Menu because the operations

are almost the same.

Item Parameter

OutType Consumer The bit in the CONSUMER mode of

AES/EBU is added to a SDI output.

Pro The bit in the PROFESSIONAL

mode of AES/EBU is added to a

SDI output.

LTC Off Does not add the LTC data on SDI

output.

On Adds the LTC data on SDI output.

VITC Off Does not add the VITC data on SDI

output.

On Adds the VITC data on SDI output.

Audio Off Does not add the audio data and TC

data on SDI output.

On Adds the audio data and TC data on

SDI output.

(Bold is the factory setting.)

5.1.6 Service Function menu operation

(1) Refer to 5.1.2 to display the Service menu.

(2) Select the [Service Function...], and then press the [Set]

button or the [Cross-Shaped] button (right).

(3) The Service Function menu is displayed.

(Bold is the factory setting.)

*1 Available only when the Camera Resolution setting is

1920x1080, and the Frame & Bit Rate setting is 60i(HQ) or

50i(HQ). Except them, it becomes a gray display and execution

is impossible.

5.1.5 SDI Out menu operation

(1) Open the Advanced Function menu, select the [SDI Out...],

and then press the [Set] button or the [Cross-Shaped] button (right).

(2) The SDI Out menu is displayed.

1-22 (No.HC047<Rev.001>)

Page 23

Refer to 5.1.4 Advanced Function Menu because the operations

are almost the same.

Item Parameter

Pixel Compen

*1

Test Signal Off No output test signal.

DC Shutdown

BATT Shutdown

BATT Alarm 6.6V Display voltage of battery alarm is set

Off Does not correct the detected white

blemish.

On Corrects the detected white blemish.

Check Light up the pixels which are the de-

tected white blemish.

FPGA1 Outputs FPGA1 signal.

1 to 32

FB1 Outputs FB1 signal.

1 to 5

FPGA2 Outputs FPGA2 signal.

LCD/VF Bars, Check Field A, Check

Field B

FB2 Outputs FB2 signal.

1 to 5

10.4V Shutdown voltage is set up at 0.1V

step at the time of DC power supply

use. (10.0V to 12.0V)

6.3V Shutdown voltage is set up at 0.1V

step at the time of battery use. (6.3V

to 7.2V)

up at 0.1V step at the time of battery

use. (6.3V to 7.2V)

(Bold is the factory setting.)

*1 This mode is automatically set to ON when the power is turned

ON. The OFF mode is enabled only after it is set to OFF on this

screen until the power is turned OFF.

5.1.7 DIP SW Menu Operation

(1) Refer to 5.1.2 to display the Service menu.

(2) Select the [DIP SW...], and then press the [Set] button or

the [Cross-Shaped] button (right).

(3) The DIP SW is displayed.

NOTE:

ALL DIP switches are factory use only. These DIP switches

are not used for repair or maintenance. Therefore all DIP

Switch settings which are shown below should not be

changed. And do not forget to return to the initial position, if

setting was changed.

Refer to 5.1.4 Advanced Function Menu because the operations

are almost the same.

Item Parameter

DIP SW ALL

RESET

DIP SW 0-15 DIP SW 0 to 15 OFF Change prohibited.

DIP SW 16-23 DIP SW 16 to 23 OFF Change prohibited.

DIP SW 24-31 DIP SW 24 to 31 OFF Change prohibited.

DIP SW 32-47 DIP SW 32 to 47 OFF Change prohibited.

DIP SW 48-63 DIP SW 48 to 63 OFF Change prohibited.

CANCEL Cancel to reset all DIPSW

settings.

EXECUTE Execute to reset all DIPSW

settings.

(Bold is the factory setting.)

(No.HC047<Rev.001>)1-23

Page 24

5.1.8 Hour Meter menu operation

(1) Refer to 5.1.2 to display the Service menu.

(2) Select the [Hour Meter...], and then press the [Set] button

or the [Cross-Shaped] button (right).

(3) The Hour Meter menu is displayed.

Refer to 5.1.4 Advanced Function Menu because the operations

are almost the same.

Item Parameter

Power 000000 Displays the power hour meter.

Reset Resets the power hour meter.

Fan 000000 Displays the fan hour meter.

Reset Resets the fan hour meter.

Slot Eject 000000 Displays the slot A and B eject count.

Reset Resets the slot A and B eject count.

5.1.9 Others menu operation

(1) Refer to 5.1.2 to display the Service menu.

(2) Select the [Others...], and then press the [Set] button or the

[Cross-Shaped] button (right).

(3) The Others menu is displayed.

Refer to 5.1.4 Advanced Function Menu because the operations

are almost the same.

Item Parameter

ALL

Cancel Standard setting.

Reset

Reset Resets all EEP-ROM data to default settings

except adjustment data and hour meter data.

(Bold is the factory setting.)

5.2 How to update the firmware

NOTE:

• The update should connect both of battery with an AC adaptor.

• Remove the USB cable, HDMI cable, component cable and

A/V OUT cable.

• Do not turn OFF the power during the update.

• Update time is about 3 minutes.

5.2.1 Preparation (Copy the firmware to SD/SDHC memory

card)

NOTE:

• Please do not use the SDHC memory card for record.

• Format the SD memory card on the GY-HM600/650 if formatting is required.

(1) Download the update file from download site and unzip it to

a PC. (It unzip, when a file is double-clicked.)

(2) Insert the SD/SDHC memory card to the PC and confirm

that no file is in the SD/SDHC memory card. If there are

some files, delete them.

(3) Copy the unzipped update file to the SD/SDHC memory

card. Check that the directory in SD card is as follows.

\\PRIVATE\JVC\GY-HM600 (In case of GY-HM650, \\PRIVATE\JVC\GY-HM650)

5.2.2 Update procedure

(1) Check that the power switch is come by OFF. While press-

ing the [FOCUS PUSH AUTO] and [MENU/THUMB (side)]

buttons, turn ON the power.

The version of the present firmware is displayed on VF.

NOTE:

Nothing is displayed on LCD.

VF screen

1-24 (No.HC047<Rev.001>)

Firmware Update

Current Version: Vxxxx

Please Plug AC and Battery.

(2) Insert the SD/SDHC memory card into the card slot B. (Can

not be updated with slot A.)

Page 25

(3) The updating is started automatically, after the SD/SDHC

memory card was inserted.

• A progress bar is displayed on VF during update.

• SLOT A LED goes out and SLOT B LED carries out red

blink irregularly.

VF screen

5.2.4 Update error

When update cannot be performed by a certain cause, it is displayed to VF as "Update Error !".

SLOT A LED and SLOT B LED blink by turns.

VF screen

Updating

Don't Turn Power Off

(4) After update is completed, it is displayed on VF as "Com-

plete". (Update time is about 3 minutes.)

SLOT A LED and SLOT B LED carry out green blink simultaneously slowly.

VF screen

...

Firmware Update

Complete

(5) Remove the SD/SDHC memory card.

(6) Update is ended. Remove an AC adaptor and a battery.

Turn OFF the power and turn it ON again.

5.2.3 When update cannot be performed

When update cannot be performed by a certain cause, it is displayed to VF as "Update can't be Executed !".

SLOT A LED and SLOT B LED blink by turns.

Update Error !

In this case, there is possibility of failure of apparatus.

VF screen

Update can't be Executed !

In this case, check whether an update file is a thing of an applicable model.

(No.HC047<Rev.001>)1-25

Page 26

JVC KENWOOD Corporation

Professional Systems Business Group, Business Solution Div.

(No.HC047<Rev.001>)

Printed in Japan

VSE

Loading...

Loading...