Page 1

SERVICE MANUAL

DV CAMCORDER

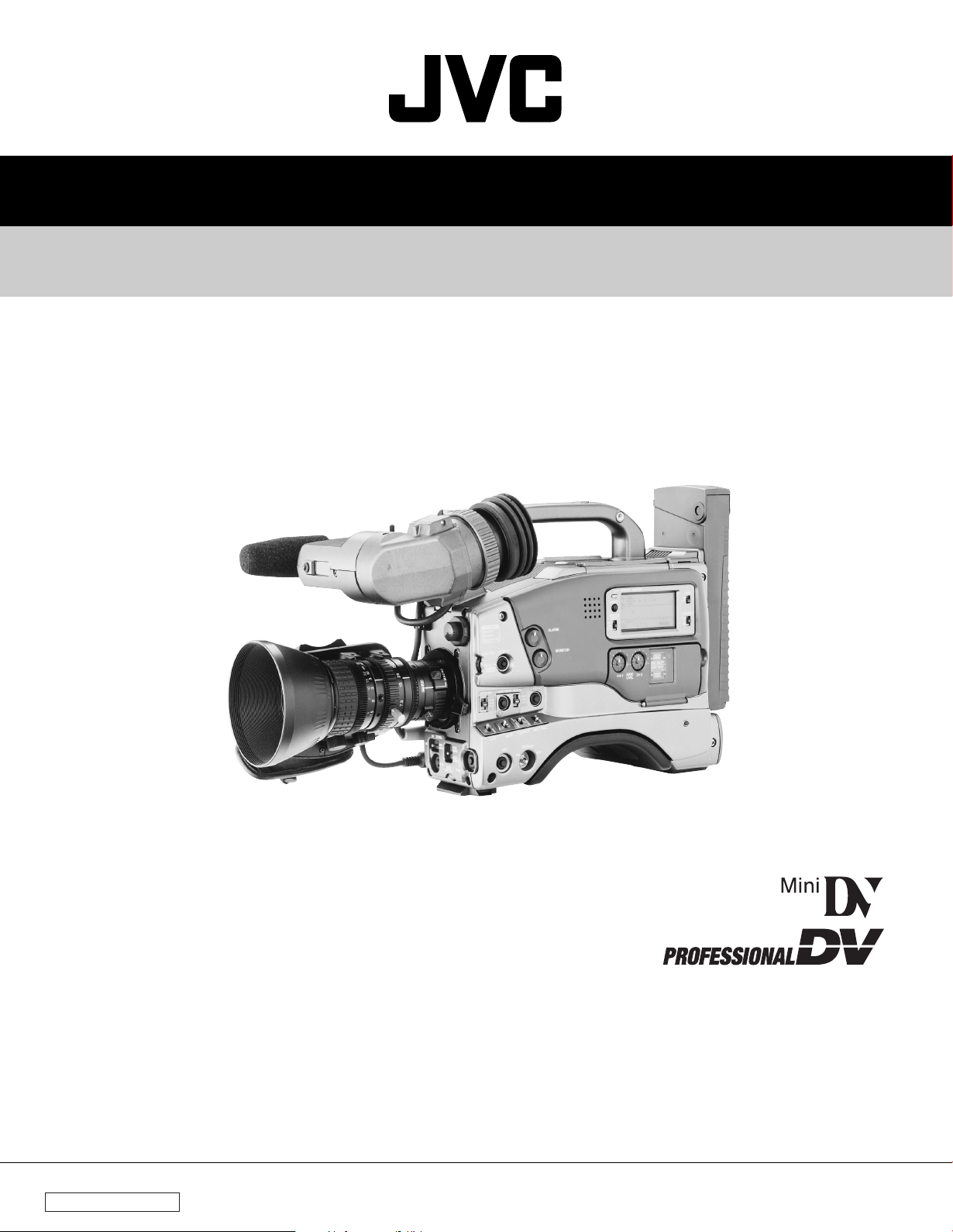

GY-DV500U/GY-DV500E

100% recycled paper

The photo shows the GY-DV500 DV camcorder with an optional lens and viewfinder.

COPYRIGHT © 1999 VICTOR COMPANY OF JAPAN, LTD.

No. 60125

November 1999

Page 2

TABLE OF CONTENTS

Section Title Page Section Title Page

Important Safety Precautions

INSTRUCTIONS

SECTION 1 SERVICE CAUTIONS AND DISASSEMBLY

1.1

RESETTING THE POWER CIRCUIT PROTECTION BREAKER ...........

1.2 REMOVING THE EXTERIOR COVERS ..................................... 1-1

1.3 LAYOUTS OF THE MAJOR BOARDS ..................................... 1-2

1.4 REMOVING THE OPTICAL BLOCK ASSEMBLY AND THE

OPTICAL FILTER ASSEMBLY .................................................. 1-3

1.5 REMOVING MAJOR BOARDS FROM THE CAMERA ............. 1-4

1.6 REMOVING THE MAJOR BOARDS FROM THE VCR ............. 1-6

1.7 DISASSEMBLY OF THE VCR UNIT ..........................................1-8

1.8 TAPE EJECTION IN CASE OF EMERGENCY .........................1-10

1.9 CAUTION FOR REPLACING THE DV MAIN BOARD AND VIDEO

SYSCON BOARD ................................................................... 1-12

1.10 FUNCTIONS OF INTERNAL SWITCHES ............................... 1-13

1.11 MODES REQUIRED IN SERVICING ...................................... 1-14

1.12 CHANGING THE COLOR MATRIX SETTING ........................ 1-16

1.13 SERVICE MENU .................................................................... 1-18

1.14 ALARM DETECTION METHODS .......................................... 1-22

1.15 BATTERY POWER DETECTION METHODS ......................... 1-23

1.16 WARNING CODES ................................................................ 1-23

1.17 ANALYSIS OF BLOCK NOISE (SYMPTOMS: POOR VIDEO,

ABSCNCE OF AUDIO) .......................................................... 1-26

1-1

SECTION 2 MECHANISM ADJUSTMENTS

2.1 BERORE ADJUSTMENTS ........................................................ 2-1

2.2 BASICS OF MECHANISM DISASSAMBLY/ASSEMBLY .......... 2-2

2.3 MECHANISM TIMIN CHART ................................................... 2-4

2.4 MAINTENANCE AND INSPECTION OF MAJOR PARTS .......... 2-5

2.5 PERIODICAL MAINTENANCE .................................................. 2-8

2.6 DISASSEMBLY/ASSEMBLY OF MECHANISM ASSEMBLY ..... 2-9

2.7 REPLACEMENT OF MAJOR PARTS ...................................... 2-12

2.8

CONFIRMATION AND ADJUSTMENT OF MECHANISM PHASES........2-27

2.9 MECHANISM DISASSEMBLY/ASSEMBLY SHEET ................ 2-28

2.10 DISASSEMBLY PROCEDURE LIST .......................................2-30

2.11 TORQUE ADJUSTMENTS .................................................... 2-31

2.12 COMPATIBILITY ADJUSTMENT ........................................... 2-32

SECTION 3 ELECTRICAL ADJUSTMENTS

3.1 FLOWCHART OF ELECTRICAL ADJUSTMENTS .................... 3-1

3.2 FUNCTIONS REQUIRED FOR ADJUSTMENTS, SETUP .......... 3-2

3.3 STANDARD SETUP .................................................................. 3-3

3.4 ADJUSTMENT MENU ..............................................................3-3

3.5 CAMERA ADJUSTMENTS ....................................................... 3-5

3.6 VCR ADJUSTMENTS ............................................................. 3-11

3.7 DV ADJUSTMENTS (USING ADJUSTMENT SOFTWARE) .... 3-14

SECTION 4 CHARTS AND DIAGRAMS

4.1 INDEX TO PAGES OF MAIN BOARDS AND CIRCUIT BOARD

LOCATION................................................................................ 4-3

4.2 OVERALL WIRING DIAGRAM (1/2) ......................................... 4-4

• OVERALL WIRING DIAGRAM (2/2) ......................................... 4-5

4.3 ISB/ISG/ISR SCHEMATIC DIAGRAM

4.4 ISB/ISG/ISR CIRCUIT BOARD .................................................. 4-7

4.5 TG(Timing Generator) SCHEMATIC DIAGRAM 14................. 4-8

4.6 TG CIRCUIT BOARD ................................................................ 4-9

4.7 CAM1(CAMera 1) SCHEMATIC DIAGRAM (1/2) 15............ 4-10

• CAM1 SCHEMATIC DIAGRAM (2/2) 15............................... 4-11

4.8 CAM1 CIRCUIT BOARD .........................................................4-12

4.9 CAM2(CAMera 2) SCHEMATIC DIAGRAM (1/3) 16............ 4-14

• CAM2 SCHEMATIC DIAGRAM (2/3) 16............................... 4-15

• CAM2 SCHEMATIC DIAGRAM (3/3)16................................ 4-16

4.10 CAM2 CIRCUIT BOARD ........................................................ 4-17

4.11 PS(Power Supply)1,

PS2 SCHEMATIC DIAGRAM (1/2)

• PS1, PS2 SCHEMATIC DIAGRAM (2/2)

4.12 PS1, PS2 CIRCUIT BOARD ................................................... 4-21

4.13 IF(InterFace), ROM(Read Only Memory)

SCHEMATIC DIAGRAM

4.14 IF, ROM CIRCUIT BOARD ..................................................... 4-23

4.15 SWRU, JOG SCHEMATIC DIAGRAM

4.16 SWF, SWRM, SWRB, SWPW, MIC, BNC SCHEMATIC DIA-

GRAM

4.17 SWRU, JOG, SWF, SWRM, SWRB, SWPW, MIC, BNC, FL

4.18 VIDEO/SYSCON SCHEMATIC DIAGRAM (1/2) 31............. 4-27

• VIDEO/SYSCON SCHEMATIC DIAGRAM (2/2) 31............. 4-28

4.19 VIDEO/SYSCON CIRCUIT BOARD ........................................ 4-29

4.20 AUDIO/LCD SCHEMATIC DIAGRAM (1/2) 32.................... 4-30

• AUDIO/LCD SCHEMATIC DIAGRAM (2/2) 32.................... 4-31

4.21 AUDIO/LCD CIRCUIT BOARD .............................................. 4-32

• AUDIO/LCD CIRCUIT BOARD

4.22 REG(REGulater) SCHEMATIC DIAGRAM 33..................... 4-34

4.23 REG CIRCUIT BOARD........................................................... 4-35

4.24 MOTHER SCHEMATIC DIAGRAM 34............................... 4-36

4.25 MOTHER, AU JUNK CIRCUIT BOARD ................................. 4-37

4.26 AU JUNK SCHEMATIC DIAGRAM 39............................... 4-38

4.27

4.28 CONNECT, REMOTE, XLR, EAR.J, SEN1, SENS2 SCHEMATIC

4.29 OPE, PWR JUNC, CONNECT, REMOTE, XLR, EAR.J, SEN1,

4.30 VTR UNIT OVERALL WIRING DIAGRAM ............................. 4-42

4.31 DV MAIN SCHEMATIC DIAGRAM (1/7) 10........................ 4-43

• DV MAIN SCHEMATIC DIAGRAM (2/7) 10........................ 4-44

• DV MAIN SCHEMATIC DIAGRAM (3/7) 10........................ 4-45

• DV MAIN SCHEMATIC DIAGRAM (4/7) 10........................ 4-46

• DV MAIN SCHEMATIC DIAGRAM (5/7) 10........................ 4-47

• DV MAIN SCHEMATIC DIAGRAM (6/7) 10........................ 4-48

• DV MAIN SCHEMATIC DIAGRAM (7/7) 10........................ 4-49

4.32 DV MAIN CIRCUIT BOARD ................................................... 4-50

• DV MAIN CIRCUIT BOARD (FOR SERIAL No.⳯⳯⳯⳯0332

4.33 PR & MDA SCHEMATIC DIAGRAM (1/2) 01...................... 4-52

• PR(Pre Rec) & MDA(Motor Drive Amp.) SCHEMATIC DIAGRAM

23/ 24/ 25/ 26/ 27/ 28

CIRCUIT BOARD ................................................................... 4-26

(FOR SERIAL No.⳯⳯⳯⳯0732 AND AFTER OF GY-DV500U,⳯⳯⳯⳯0840

AND AFTER OF GY-500E) ........................................................................... 4-32-2

PWR JUNC, OPE(OPEration) SCHEMATIC DIAGRAM

DIAGRAM

SENS2 CIRCUIT BOARD ....................................................... 4-41

AND AFTER OF GY-DV500U, ⳯⳯⳯⳯0545 AND AFTER OF GY-

DV500E) ............................................................................ 4-50-2

(2/2) 01............................................................................... 4-53

42/ 38/ 40/ 43/ 36/ 37

21/ 19

11/ 12/ 13

17/ 18

17/ 18

....................................... 4-22

22/ 20

................................ 4-25

.......................... 4-40

.............. 4-6

......................... 4-19

................. 4-20

................... 4-24

41/ 35

..... 4-39

Page 3

4.34 PR & MDA CIRCUIT BOARD ................................................ 4-54

4.35 ROM, CONN. SCHEMATIC DIAGRAM

4.36 DCDC SCHEMATIC DIAGRAM 02..................................... 4-56

4.37 DCDC, ROM, CONN. CIRCUIT BOARD ................................ 4-57

4.38 IS &TG BLOCK DIAGRAM (G channel) ................................. 4-58

4.39 CAM1 BOARD BLOCK DIAGRAM ........................................ 4-59

4.40 CAM2 BOARD BLOCK DIAGRAM ........................................ 4-60

4.41 IF, SWF, SWRU BLOCK DAIGRAM .......................................4-61

4.42 SYSCON BLOCK DIAGRAM ................................................. 4-62

4.43 LCD BLOCK DIAGRAM......................................................... 4-63

4.44 VIDEO BLOCK DIAGRAM ..................................................... 4-64

4.45 REG BLOCK DIAGRAM ........................................................ 4-64

4.46 AUDIO BLOCK DIAGRAM .................................................... 4-65

4.47 DV BLOCK DIAGRAM 1/2 ..................................................... 4-66

• DV BLOCK DIAGRAM 2/2 .....................................................4-67

4.48 IC BLOCK DIAGRAM ........................................................... 4-68

03/ 04

................. 4-55

SECTION 5 EXPLODED VIEW AND PARTS LIST

5.1 CAMERA HEAD ASSEMBLY M1............................................ 5-3

5.2 CABINET ASSEMBLY M2....................................................... 5-4

5.3 RIGHT SIDE COVER ASSEMBLY M3...................................... 5-7

5.4 CHASSIS ASSEMBLY M4....................................................... 5-8

5.5 VTR UNIT ASSEMBLY M5.................................................... 5-11

5.6 MECHANISM ASSEMBLY M6.............................................. 5-12

SECTION 6 ELECTRICAL PARTS LIST

6.1 PR & MDA BOARD ASSEMBLY PARTS LIST 01................... 6-2

6.2 DCDC BOARD ASSEMBLY PARTS LIST 02.......................... 6-3

6.3 ROM BOARD ASSEMBLY PARTS LIST 03............................ 6-4

6.4 CONN. BOARD ASSEMBLY PARTS LIST 04......................... 6-4

6.5 DV MAIN BOARD ASSEMBLY PARTS LIST 10..................... 6-5

6.6 ISB BOARD ASSEMBLY PARTS LIST 11............................ 6-11

6.7 ISG BOARD ASSEMBLY PARTS LIST 12............................. 6-11

6.8 ISR BOARD ASSEMBLY PARTS LISTT 13........................... 6-12

6.9 TG BOARD ASSEMBLY PARTS LISTT 14........................... 6-12

6.10 CAM1 BOARD ASSEMBLY PARTS LIST 15....................... 6-13

6.11 CAM2 BOARD ASSEMBLY PARTS LIST 16....................... 6-17

6.12 PS1 BOARD ASSEMBLY PARTS LIST 17........................... 6-21

6.13 PS2 BOARD ASSEMBLY PARTS LIST 18........................... 6-21

6.14 ROM BOARD ASSEMBLY PARTS LIST 19......................... 6-22

6.15 JOG BOARD ASSEMBLY PARTS LIST 20.......................... 6-22

6.16 IF BOARD ASSEMBLY PARTS LIST 21.............................. 6-23

6.17 SWRU BOARD ASSEMBLY PARTS LIST 22...................... 6-23

6.18 SWF BOARD ASSEMBLY PARTS LIST 23......................... 6-24

6.19 SWRM BOARD ASSEMBLY PARTS LIST 24...................... 6-24

6.20 SWRB BOARD ASSEMBLY PARTS LIST 25....................... 6-24

6.21 SWPW BOARD ASSEMBLY PARTS LIST 26...................... 6-24

6.22 MIC BOARD ASSEMBLY PARTS LIST 27.......................... 6-25

6.23 BNC BOARD ASSEMBLY PARTS LIST 28.......................... 6-25

6.24 VIDEO/SYSCON BOARD ASSEMBLY PARTS LIST 31....... 6-25

6.25 AUDIO/LCD BOARD ASSEMBLY PARTS LIST 32.............. 6-28

6.26 REG BOARD ASSEMBLY PARTS LIST 33.......................... 6-31

6.27 MOTHER BOARD ASSEMBLY PARTS LIST 34.................. 6-33

6.28 OPE BOARD ASSEMBLY PARTS LIST 35.......................... 6-33

6.29 SEN1 BOARD ASSEMBLY PARTS LIST 36........................ 6-33

6.30 SENS2 BOARD ASSEMBLY PARTS LIST 37...................... 6-33

6.31 REMOTE BOARD ASSEMBLY PARTS LIST 38.................. 6-33

6.32 AU JUNK BOARD ASSEMBLY PARTS LIST 39.................. 6-34

6.33 XLR BOARD ASSEMBLY PARTS LIST 40........................... 6-35

6.34 PWR JUNC BOARD ASSEMBLY PARTS LIST 41............... 6-35

6.35 CONNECT BOARD ASSEMBLY PARTS LIST 42................ 6-35

6.36 EAR.J BOARD ASSEMBLY PARTS LIST 43....................... 6-35

SECTION 7 PACKING

7.1 PACKING ASSEMBLY M7....................................................... 7-1

7.2 FACTORY SETTING OF SWITCH AND VR ...............................7-2

SECTION 8 DESCRIPTION OF NEW CIRCUITRY

8.1 OUTLINE OF DV ....................................................................... 8-1

8.2 MAJOR SIGNAL PROCESSING OPERATIONS OF DV ............ 8-6

8.3 VIDEO/AUDIO SIGNAL PROCESSING IN RECORDING

CIRCUITRY ............................................................................... 8-7

VIDEO/AUDIO SIGNAL PROCESSING IN PLAYBACK CIRCUITRY ..

8.4

8.5 CAPSTAN SERVO................................................................... 8-20

8.6 DRUM SERVO ........................................................................ 8-22

8-18

SECTION 9 CIRCUIT DESCRIPTION

9.1 CAMERA HEAD CIRCUITRY .................................................... 9-1

9.2 DVC CIRCUIT ........................................................................... 9-4

9.3 MECHANISM OPERATION DESCRIPTION ............................ 9-20

9.4 EXPLANATION OF NEW FUNCTIONS ................................... 9-26

Page 4

Important Safety Precautions

Connector

Metal sleeve

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes

of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the

following precautions when a set is being serviced.

Precautions during Servicing

1. Locations requiring special caution are denoted by labels and

inscriptions on the cabinet, chassis and certain parts of the

product. When performing service, be sure to read and comply with these and other cautionary notices appearing in the

operation and service manuals.

2. Parts identified by the

critical for safety.

Replace only with specified part numbers.

Note: Parts in this category also include those specified to com-

ply with X-ray emission standards for products using

cathode ray tubes and those specified for compliance

with various regulations regarding spurious radiation

emission.

3. Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

4. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

5. Use specified insulating materials for hazardous live parts.

Note especially:

1) Insulation Tape 3) Spacers 5) Barrier

2) PVC tubing 4) Insulation sheets for transistors

6. When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

symbol and shaded ( ) parts are

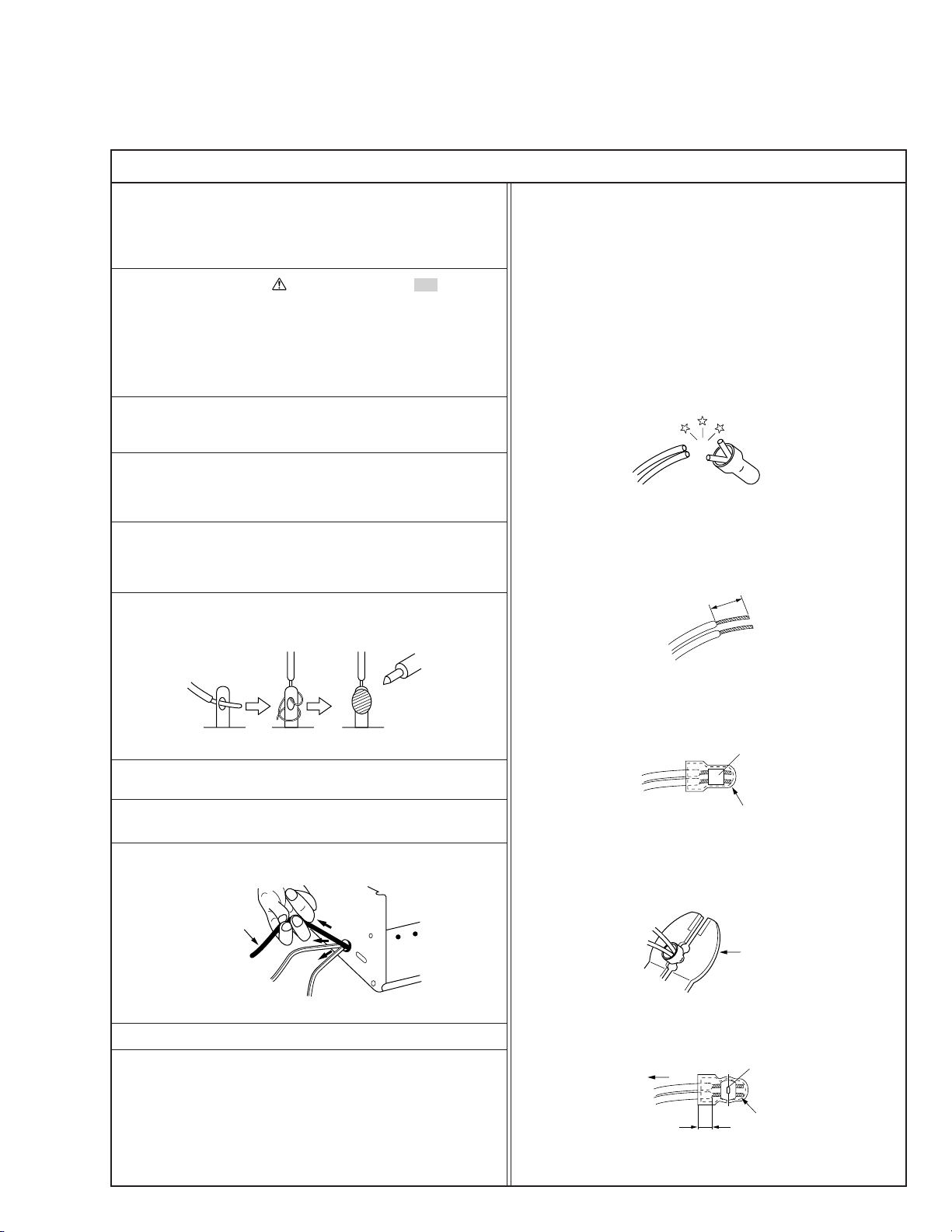

12. Crimp type wire connector

In such cases as when replacing the power transformer in sets

where the connections between the power cord and power

transformer primary lead wires are performed using crimp type

connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely

according to the following steps.

1) Connector part number : E03830-001

2) Required tool : Connector crimping tool of the proper type

which will not damage insulated parts.

3) Replacement procedure

(1) Remove the old connector by cutting the wires at a point

close to the connector.

Important : Do not reuse a connector (discard it).

cut close to connector

Fig.3

(2) Strip about 15 mm of the insulation from the ends of

the wires. If the wires are stranded, twist the strands to

avoid frayed conductors.

15 mm

7. Observe that wires do not contact heat producing parts

8. Check that replaced wires do not contact sharp edged or

9. When a power cord has been replaced, check that 10-15 kg of

10. Also check areas surrounding repaired locations.

11. Products using cathode ray tubes (CRTs)

Fig.1

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

pointed parts.

force in any direction will not loosen it.

Power cord

Fig.2

In regard to such products, the cathode ray tubes themselves,

the high voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the cathode ray tubes and other parts with only the specified parts.

Under no circumstances attempt to modify these circuits.

Unauthorized modification can increase the high voltage value

and cause X-ray emission from the cathode ray tube.

Fig.4

(3) Align the lengths of the wires to be connected. Insert

the wires fully into the connector.

Fig.5

(4) As shown in Fig.6, use the crimping tool to crimp the

metal sleeve at the center position. Be sure to crimp fully

to the complete closure of the tool.

1.25

2.0

5.5

Fig.6

(5) Check the four points noted in Fig.7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Fig.7

Crimping tool

Crimped at approx. center

of metal sleeve

Conductors extended

1

Page 5

p

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety standards.

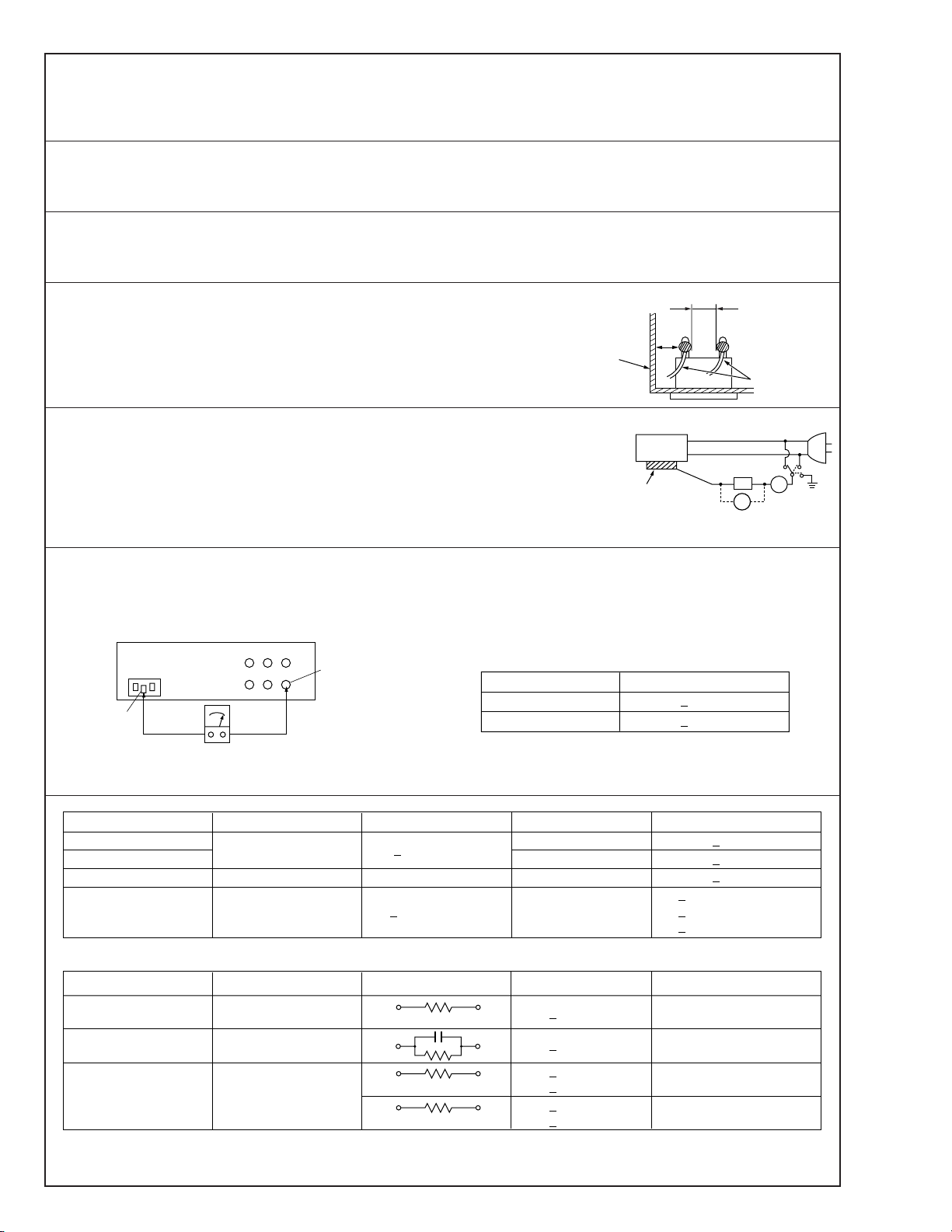

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and

externally exposed parts of the set (RF terminals, antenna terminals, video and audio input

and output terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed

accessible parts of the set (RF terminals, antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

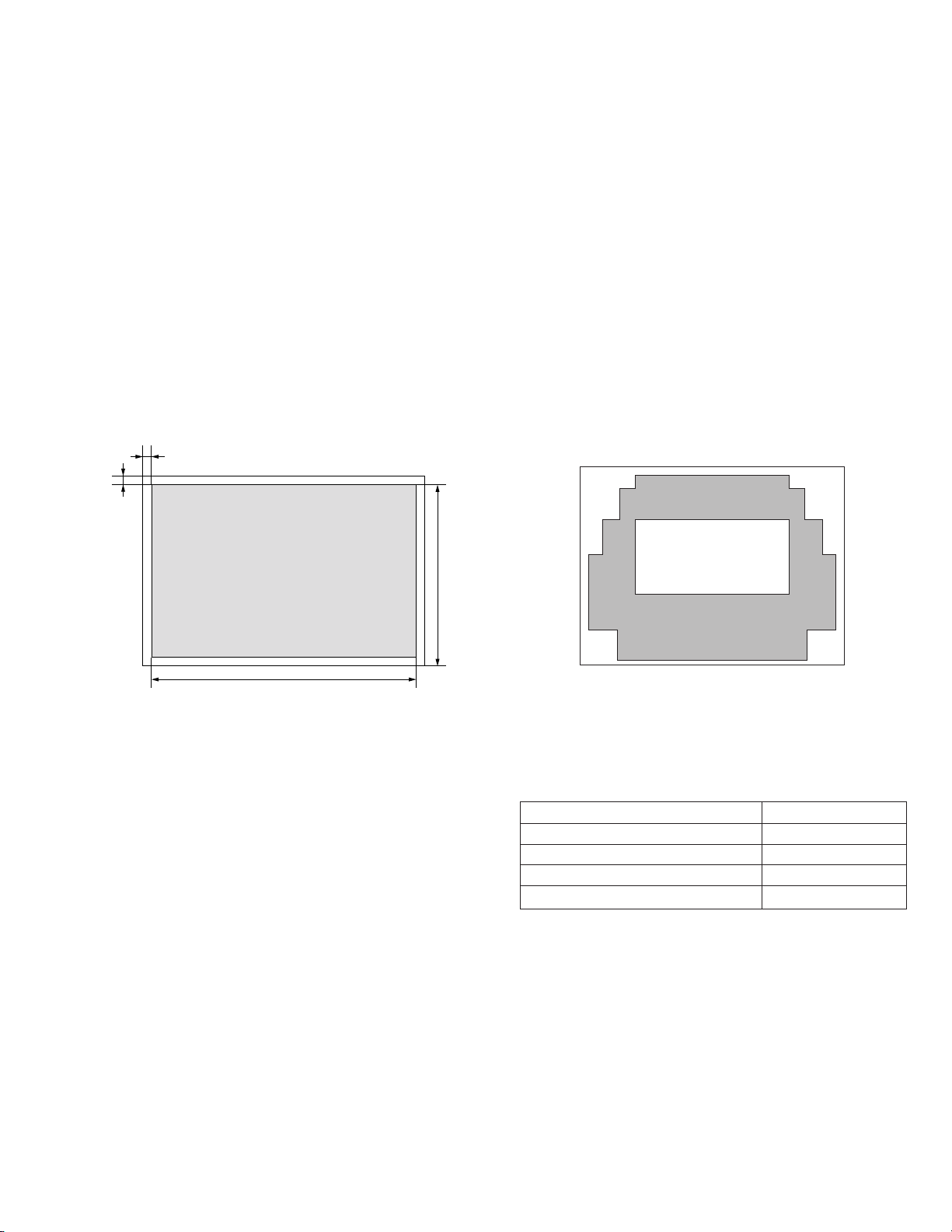

3. Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d’) between soldered terminals, and between terminals and surrounding metallic parts. See table 1

below.

Chassis

Fig. 8

4. Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure across both terminals of load Z. See figure 9 and

following table 2.

5. Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin in AC inlet and externally exposed accessible parts (Video in,

Video out, Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and exposed accessible parts. See figure 10 and grounding specifications.

AC inlet

Earth pin

Exposed accessible part

Grounding Specifications

Region

USA & Canada

Europe & Australia

Externally

exposed

accessible

Grounding Impedance (Z)

d

d'

art

≤

Z 0.1 ohm

≤

Z 0.5 ohm

Power cord,

primary wire

Z

V

Fig. 9

ab

c

A

Milli ohm meter

Fig. 10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Note: These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

Region

Japan R 1 MΩ/500 V DC

USA & Canada

Europe & Australia R 10 MΩ/500 V DC

Region Load Z

Japan

USA & Canada

Europe & Australia

Table 2 Leakage current specifications for each region

Insulation Resistance (R)

≤

–

≤

Table 1 Specifications for each region

1 kΩ

0.15 µF

1.5 kΩ

2 kΩ

50 kΩ

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 miute

AC 900 V 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

i 1 mA rms Exposed accessible parts

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

≤

≤

≤

≤

≤

≤

(Class 2)

(Class 1)

Clearance Distance (d), (d')

≤

d, d' 3 mm

≤

d, d' 4 mm

≤

d, d' 3.2 mm

≤

d 4 mm

≤

d' 8 mm (Power cord)

≤

d' 6 mm (Primary wire)

a, b, cLeakage Current (i)AC Line Voltage

Exposed accessible parts

Antenna earth terminals

Other terminals

2

Page 6

2

2

4

SECTION 1

1

SERVICE CAUTIONS AND DISASSEMBLY

1.1 RESETTING THE POWER CIRCUIT PROTECTION

BREAKER

This unit employs a power circuit protection breaker in place of

a fuse to disconnect from the main power and to thus protect

the internal circuitry from damage caused by any current overload. The power can be re-connected by resetting the breaker.

To prevent any complications resulting from the failure, check the cause of the shutdown and repair it

before resetting the circuit breaker.

(1) Switch OFF the POWER of this unit as well as that of any

equipment supplying power to it.

(2) The circuit breaker

Press the BREAK button to re-connect the power line.

is located below the VCR at the rear.

Å

1.2.2 Opening the Right Side Cover

(1) Loosen the 4 screws

Fig. 1-2-2(1) Opening the Right Side Cover

(2) Flip open the right side cover toward the front.

2

.

Å

Fig. 1-1 Position of the Circuit Breaker

1.2 REMOVING THE EXTERIOR COVERS

1.2.1 Removing the Left Side Cover

(1) Open the cassette door by pressing the EJECT switch.

(2) Loosen the 4 screws

Cassette cover

and remove the left side cover.

1

3

EJECT switch

1

Fig. 1-2-2(2) View of the Opened Right Side Cover

1.2.3 Removing the Bottom Cover

(1) Remove the left side cover (see section 1.2.1).

(2) Remove the 2 screws

Fig. 1-1).

(3) Remove the 4 screws

and remove the shoulder pads (see

3

and remove the bottom cover.

4

Fig. 1-2-1 Removing the Left Side Cover

Fig. 1-2-3 Removing the Bottom Cover

4

1-1

Page 7

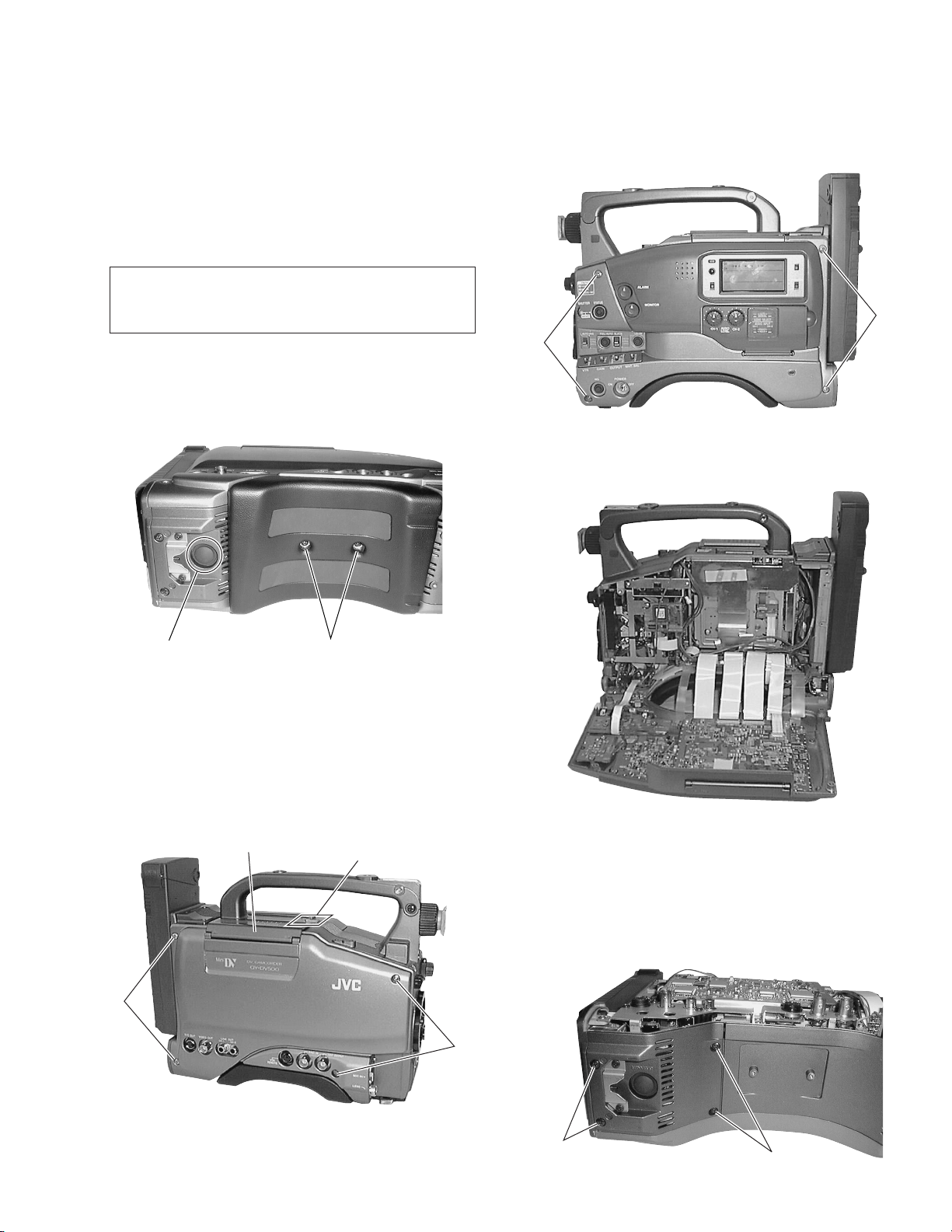

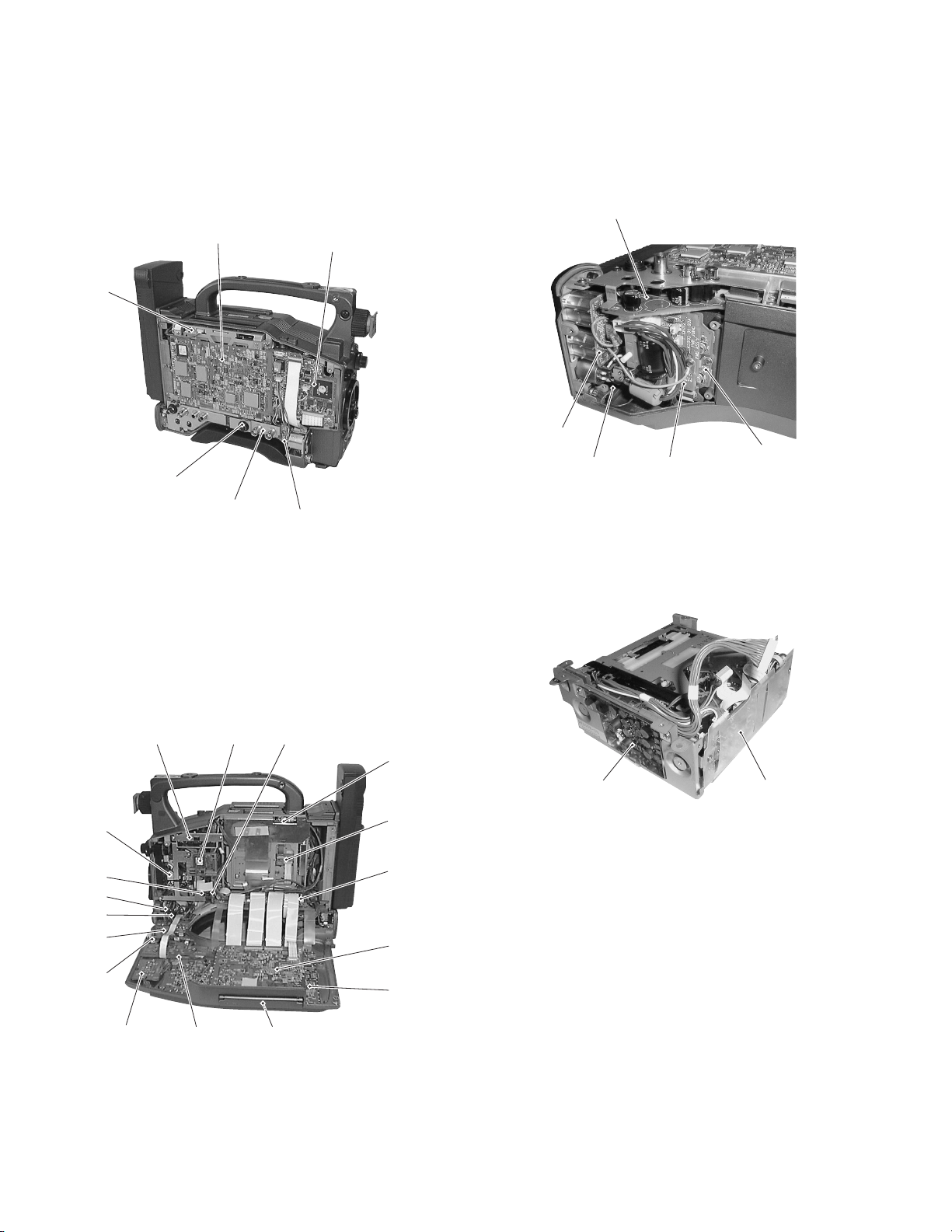

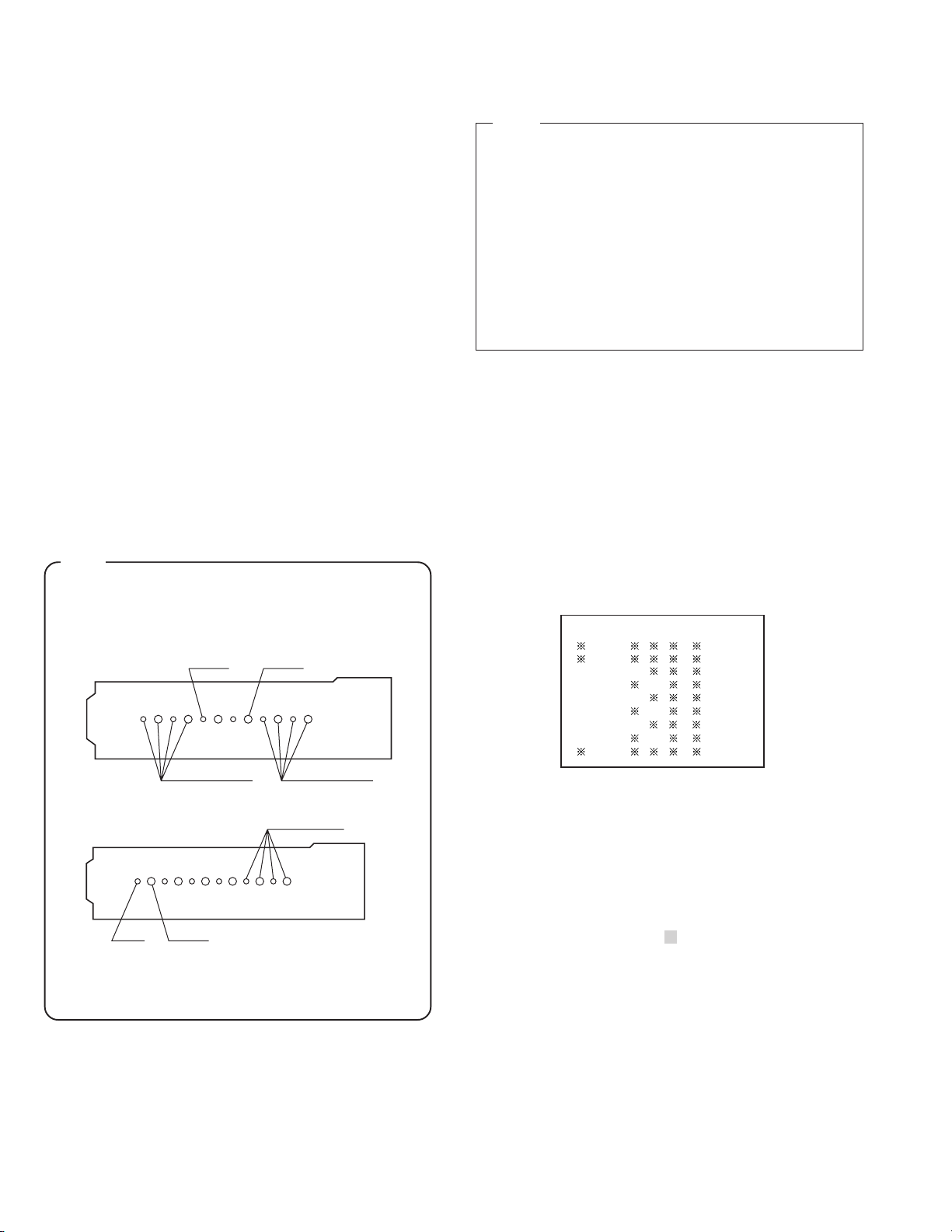

1.3 LAYOUTS OF THE MAJOR BOARDS

On the side of the left-hand side cover

03ROM

10DV MAIN

37SENS2

38REMOTE

28BNC

27MIC

16CAM2

On the side of the bottom cover

42CONNECT

40XLR

43EAR.J

41PWR JUNC

VCR section

39AU JUNK

On the side of the right-hand side cover

19ROM 15CAM1

35OPE 22SWRU 20JOG

11ISB

12ISG

13ISR

14TG

23SWF

21IF

25SWPB

26SWPW

24SWRM

17PS1, 18PS2

36SEN1

04CONN.

34MOTHER

31VIDEO/SYSCON

32AUDIO/LCD

02DCDC

01PR & MDA

1-2

Page 8

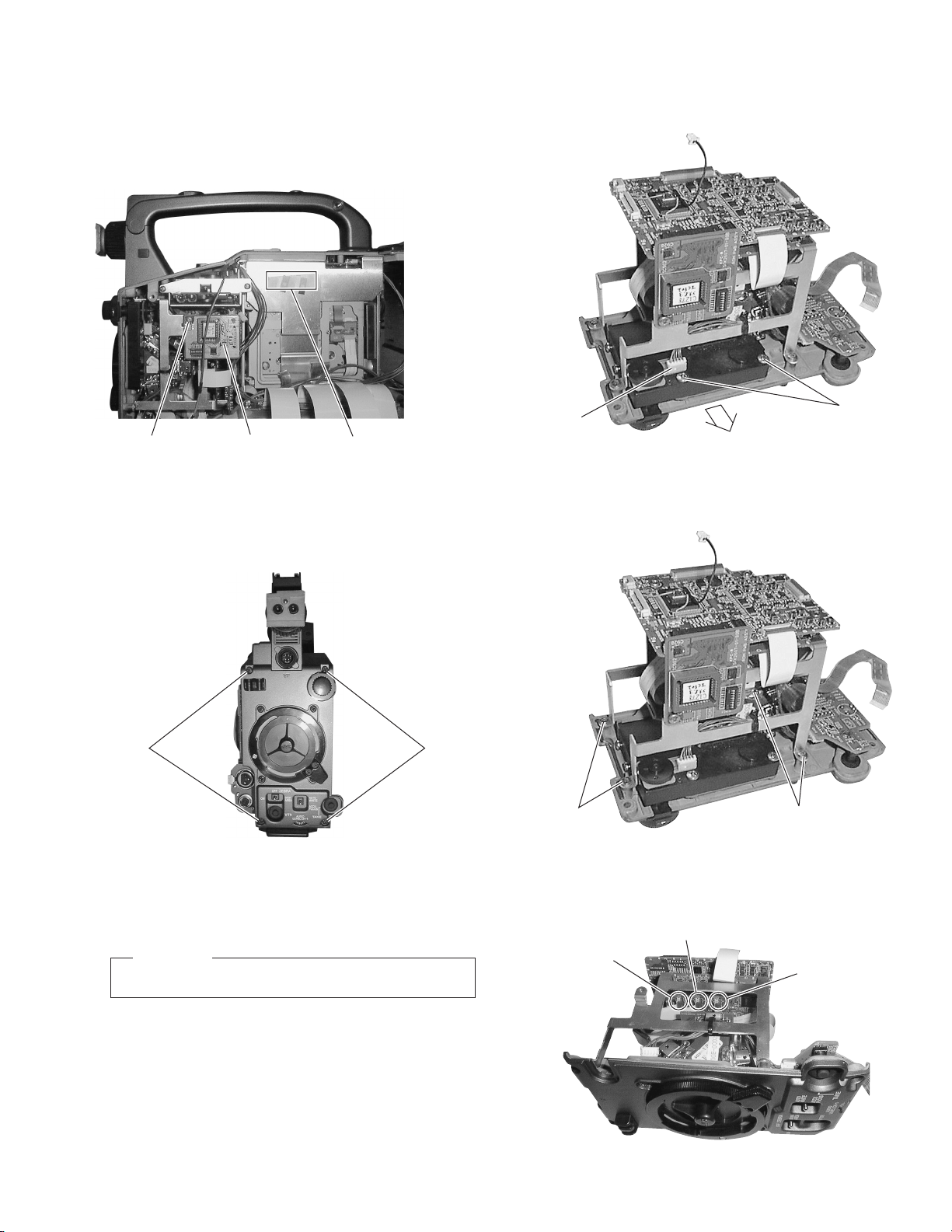

1.4 REMOVING THE OPTICAL BLOCK ASSEMBLY AND

2

3

Å

THE OPTICAL FILTER ASSEMBLY

(1) Remove the right side cover (see section 1.2.2).

(2) Remove the screw

retaining the ROM board.

1

(5) Loosen the 2 screws

(6) Remove the optical filter assembly in the direction of the

arrow.

and remove the connector Å.

3

1

(3) Remove the 4 screws

ROM board

Fig. 1-4-1

.

2

S.S.F. ID label

for VIDEO/SYSCON board

2

Fig. 1-4-2

(4) Pull out the optical block assembly and the front panel to-

gether toward the front.

CAUTION

Be careful not to damage the boards or the FC cables.

Fig. 1-4-3

(7) Remove the 4 screws

board mounting brackets.

4

(8) Flip open CN11, CN12 and CN13 and unplug the flexible

cables.

CN11

and remove the TG board and CP

4

4

Fig. 1-4-4(1)

CN12

CN13

Fig. 1-4-4(2)

1-3

Page 9

(9) Remove the 4 screws

sembly from the front panel.

and separate the optical block as-

5

55

Fig. 1-4-5

NOTES

• The CCDs are bonded precisely to the prism. In case of

trouble with a CCD, it is not possible to replace an individual CCD, but the entire optical block assembly should

be replaced.

• The optical block assembly supplied as a service part

(SCM1049-N0A (NTSC)/P0A (PAL)) is not equipped with the

DR board. When replacing the optical block assembly, attach the surrounding PC boards to the new assembly before mounting it in the camera.

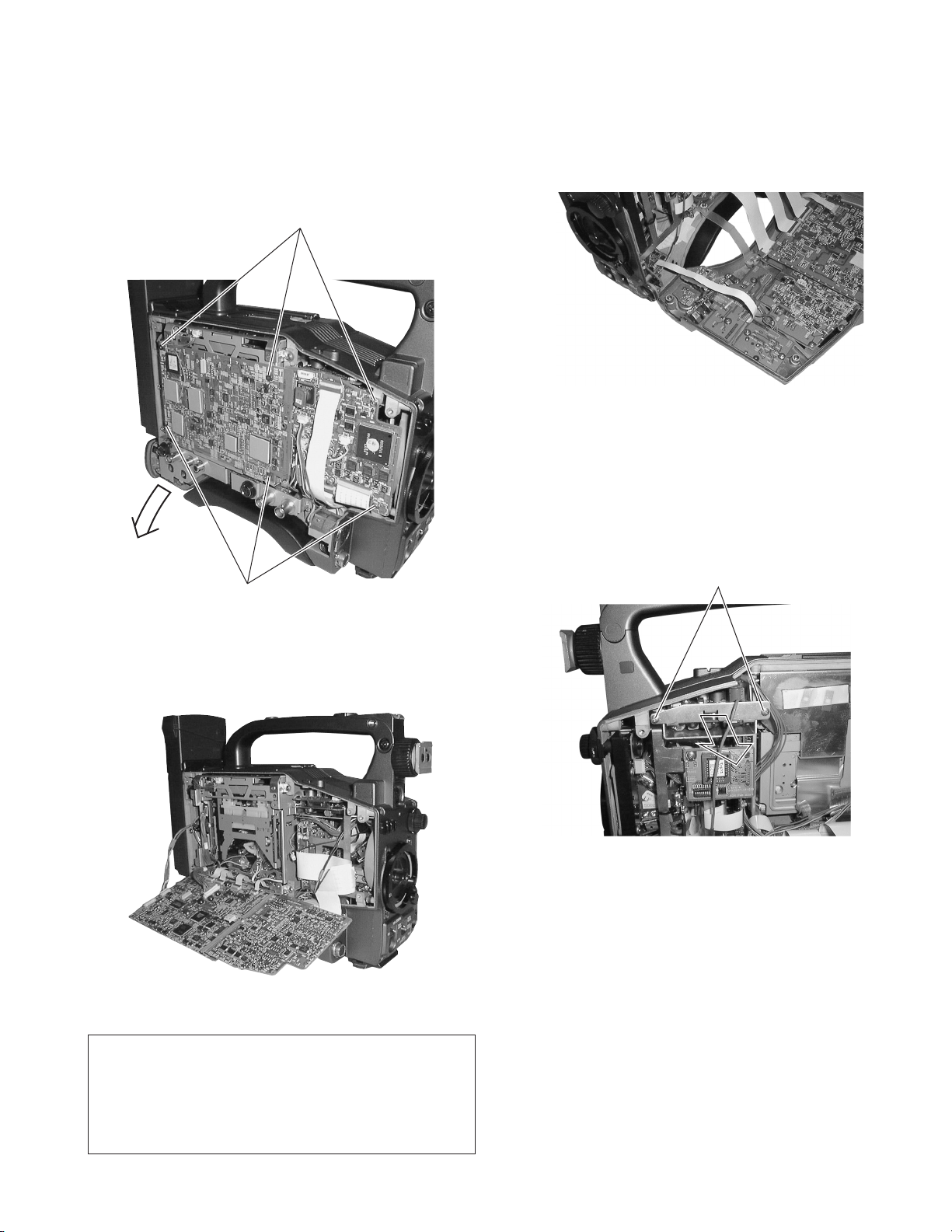

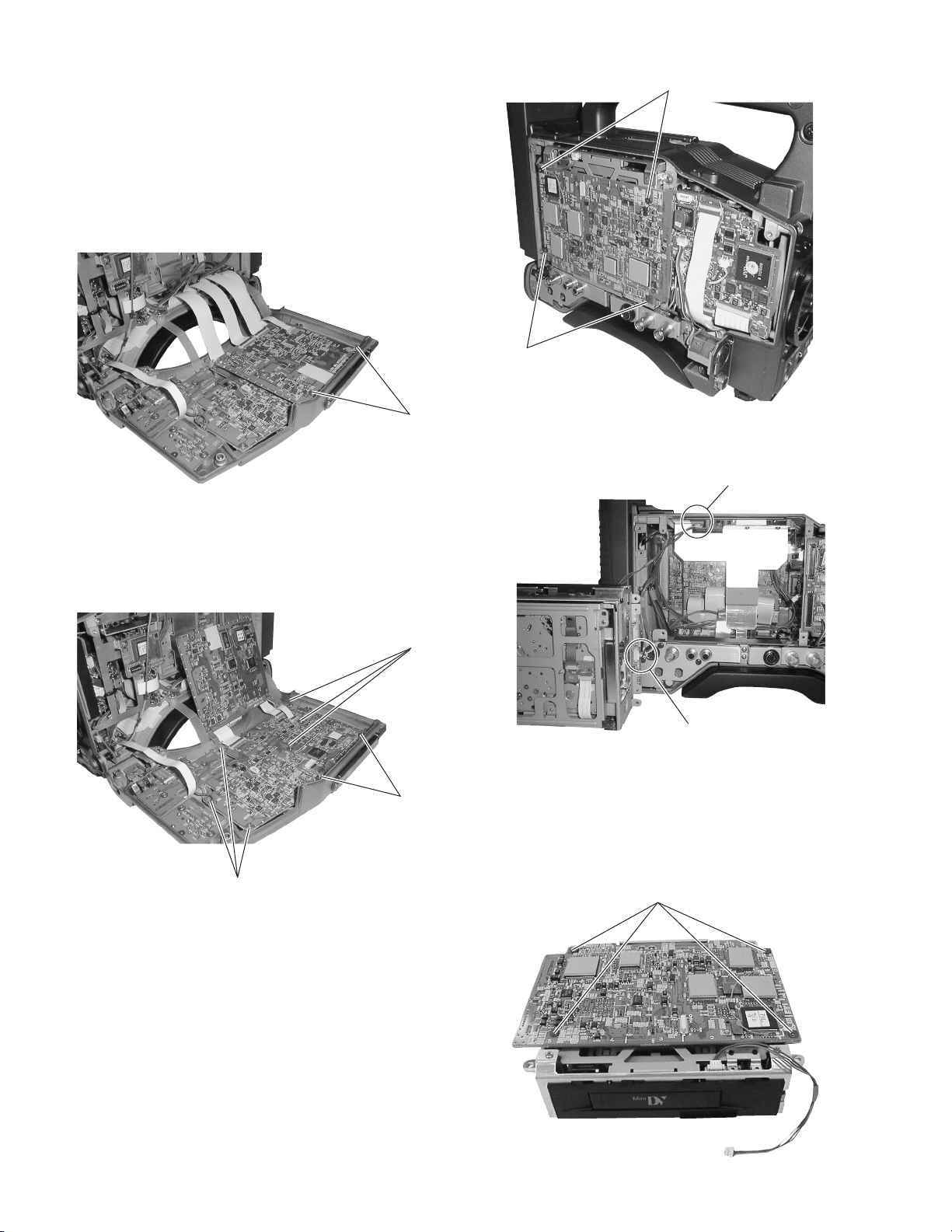

1.5 REMOVING MAJOR BOARDS FROM THE

CAMERA

1.5.1 Removing the CP and TG Boards.

(1) Remove the right side cover (see section 1.2.2).

(2) Remove the 4 screws retaining the front panel (see section

1.4.3).

(3) Pull out the optical block assembly and the front panel to-

gether toward the front.

(4) Remove the screw retaining the ROM board. Now the ROM

board can be removed.

(5) Remove the 4 screws

. Now the CP board can be removed.

1

1

1

Fig. 1-5-1(1)

Fig. 1-4-6 Optical Block Assembly for Servicing

CAUTION

When mounting the optical block assembly in the camera,

take care of the positioning of the wire assembly. A malfunction may occur if a wire is somehow caught up.

(6) Remove the CP board, then remove the 4 stud screws 4.

Now the TG board is disengaged from the stay.

(7) Unplug the flexible cables connecting the IS boards and the

TG board. Now the TG board can be removed.

4

Fig. 1-5-1(2)

1-4

Page 10

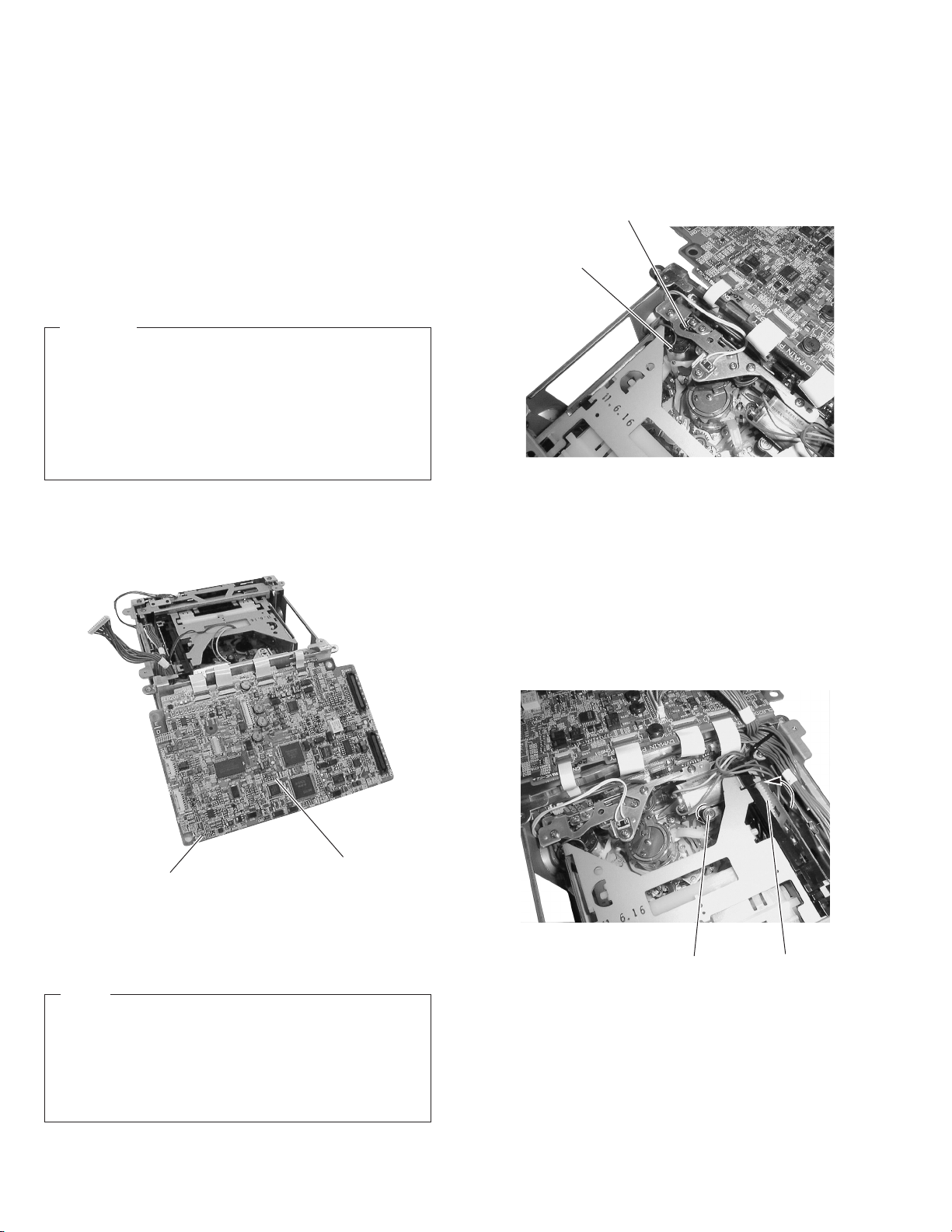

1.5.2 Removing the CAM1 Board

(1) Remove the left side cover (section 1.2.1).

(2) Remove the 6 screws

(3) The DV MAIN board on the VCR side and the CAM2 board

are connected by a board-to-board connector. Open the two

boards together in the direction of the arrow.

2

.

2

1.5.3 Removing the SW Boards

(1) Open the right side cover (see section 1.2.2).

(2) The JOG, SWRU, SWRM, SWPW and SWRB boards are

attached on the right side cover. Remove them as required.

Fig. 1-5-3

1.5.4 Removing the PS 1 & 2 board.

(1) Open the right side cover (see section 1.2.2).

(2) Remove the 2 screws

(3) Pull out the PS 1 & 2 board, along the guide rail in the direc-

tion of the arrow.

retaining the PS 1 & 2 board.

3

2

Fig. 1-5-2(1)

(4) The opened boards can be secured by fitting them into the

notches on the VCR side frame as shown in the figure.

Fig. 1-5-2(2)

3

Fig. 1-5-4

The operation of the VCR can be confirmed when the

circuit boards are tilted.

When the circuit boards are tilted, take care that the

electrical circuitry on each board is not short-circuited

by the BNC connector located below the board.

1-5

Page 11

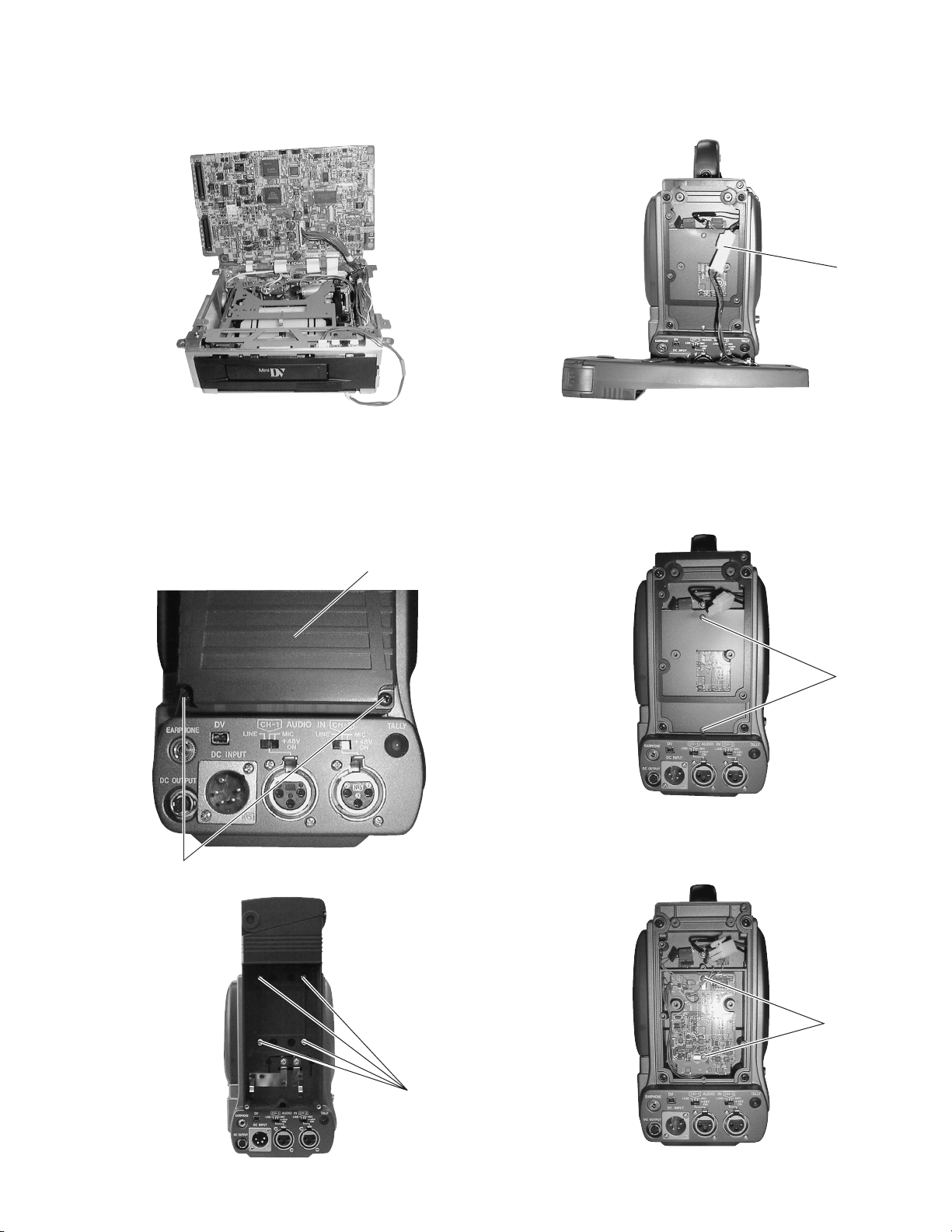

1.6 REMOVING THE MAJOR BOARDS FROM THE VCR

1.6.1 Removing the VIDEO/SYSCON Board and Audio/

LCD Board

(1) Open the right side cover (see section 1.2.2).

The VIDEO/SYSCON board is clamped to the right side cover.

(2) Remove the 2 screws

can be removed.

. Now the VIDEO/SYSCON board

1

4

4

1

Fig. 1-6-1(1)

(3) After removing the VIDEO/SYSCON board, remove the 6

screws

be removed.

and 2 studs 3. Now the AUDIO/LCD board can

2

2

3

2

Fig. 1-6-1(2)

Fig. 1-6-2(1)

(4) Remove the EJECT switch wire

.

ı

and power supply wire

Å

Å

ı

Fig. 1-6-2(2)

1.6.3 Removing the DV MAIN Board

(1) Remove the VCR unit (see section 1.6.2).

(2) Remove the 4 screws

(3) Now the DV MAIN board can be removed.

5

.

5

1.6.2 Removing the VCR Unit

(1) Remove the left side cover (see section 1.2.1).

(2) Remove the 4 screws

(3) Pull out the VCR unit gently in the direction of the arrow. As

the VCR unit is connected to the CAM2 board with a boardto-board connector, disconnect it gently.

1-6

4

.

Fig. 1-6-3(1)

Page 12

(4) After removing the DV MAIN board, leave it standing up by

fitting it into the notches on the unit frame, as shown in the

figure.

(3) Unplug the power cable that supplies power from the bat-

tery case to the main unit, from the connector

Ç

.

Ç

Fig. 1-6-3(2)

1.6.4 Removing the Battery Case

(1) Remove the 2 screws 1 and remove the rear cover of the

battery case.

(2) Remove the 4 screws

the main unit.

and remove the battery case from

2

Rear cover

1

Fig. 1-6-4(1)

Fig. 1-6-4(3)

1.6.5 Removing the REG Board

(1) Remove the battery case (see section 1.6.4).

(2) Remove the 2 screws

(3) Remove the 2 screws

and remove the panel.

3

Fig. 1-6-5(1)

and remove the REG board.

4

3

Fig. 1-6-4(2)

4

2

Fig. 1-6-5(2)

1-7

Page 13

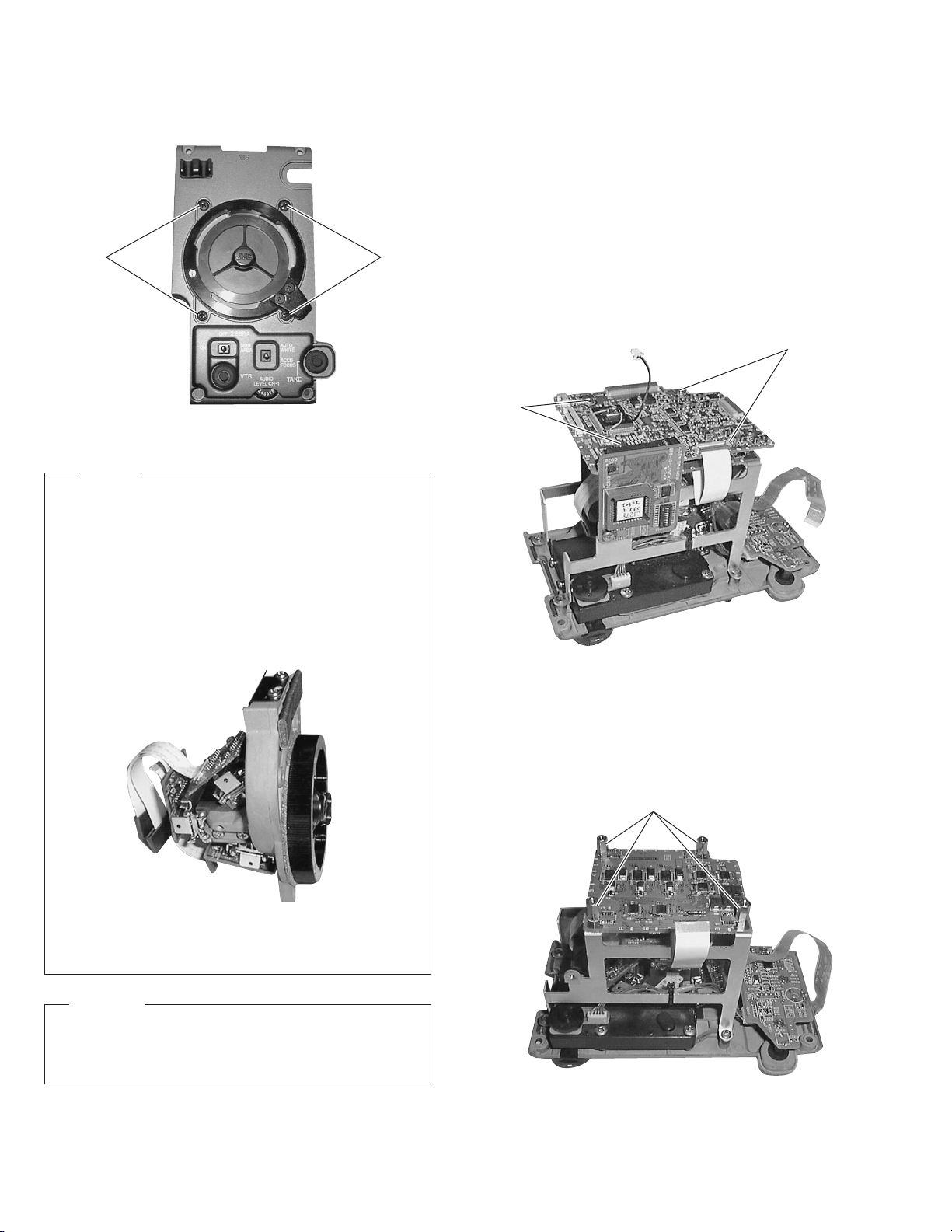

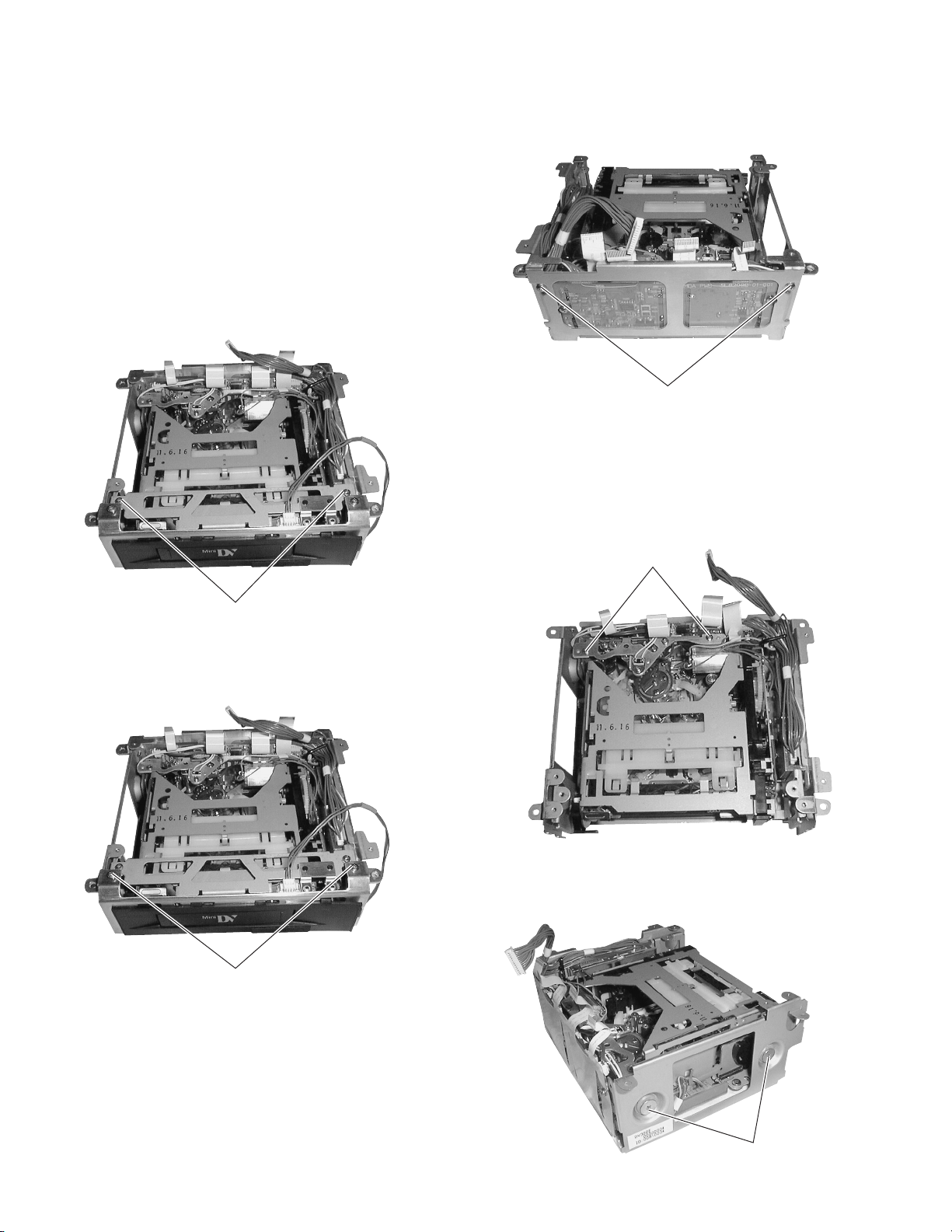

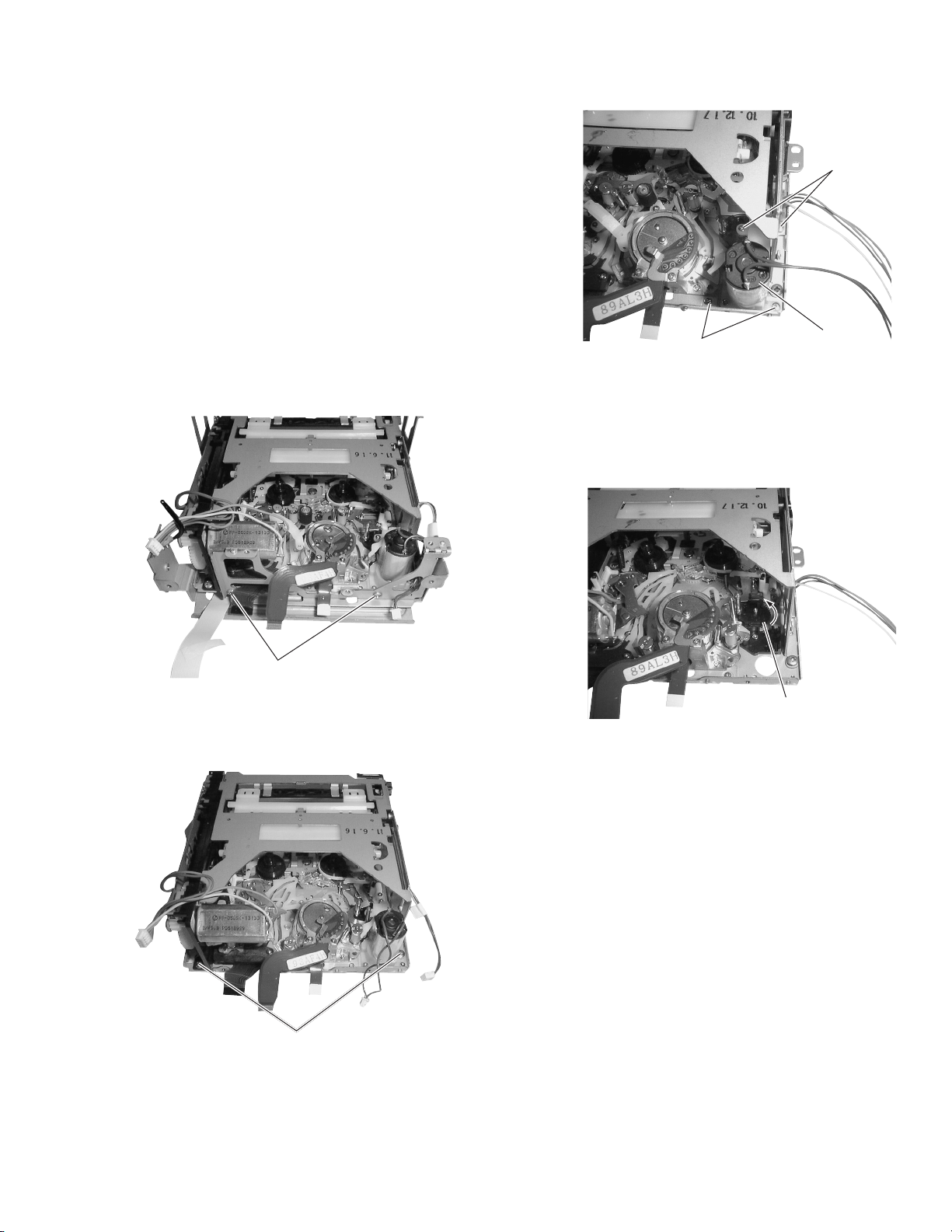

1.7 DISASSEMBLY OF THE VCR UNIT

The mechanism unit incorporated in the unit can be disassembled as described below. Note that the following description

deals only with the method of removing the mechanism unit

from the VCR unit.

1.7.1 Disassembling the Front Part of the Unit

(1) Remove the VCR unit from the camera (see section 1.6.2).

(2) Remove the DV MAIN board (see section 1.6.3).

(3) Remove the 2 screws

cover. The cover of the cassette insertion slot will come out

together with it.

and remove the stay on the front

1

1.7.2 Disassembling the Rear Part of the Unit

(1) Remove the 2 screws

and remove the rear side stay.

3

3

Fig. 1-7-2(1)

(4) Remove the 2 screws

1

Fig. 1-7-1(1)

and remove the front stay.

2

(2) Remove the 2 screws

During this operation, be careful not to apply excessive force

to the wire that is connected between the active head cleaner

assembly and CN609 on the PR & MDA boards.

and remove the active head cleaner.

4

4

Fig. 1-7-2(2)

(3) Remove the 2 screws

and remove the side stays.

5

1-8

2

Fig. 1-7-1(2)

5

Fig. 1-7-2(3)

Page 14

(4) Insulators (blue) are attached to the retaining screws. Be

sure to attach the insulators when re-assembling the side

stays.

(5) The side stays to both sides are attached in the same way.

Remove the 2 screws

and remove the side stays.

6

6

Fig. 1-7-3

6

Fig. 1-7-2(4)

(6) After removing the rear stays and side stays (left and right),

remove the 2 screws 7 then remove the PR & MDA board.

When removing the PR & MDA boards, be careful not to

damage the wires and FFCs connecting them to the deck

assembly housing motor and power supply board.

7

Fig. 1-7-2(5)

1.7.4 Removing the Mechanism Unit

(1) Remove the 3 screws 8. This allows the mechanism unit

to be removed from the stays When it is required to disassemble the mechanism unit itself, see SECTION 2.

8

Fig. 1-7-4(1)

(2) When the remove the mechanism unit completely, also re-

move the connector

from the rear.

Å

1.7.3 Removing the Cassette Housing Assembly

(1) Remove the 2 screws

assembly.

and remove the cassette housing

6

Å

Fig. 1-7-4(2)

1-9

Page 15

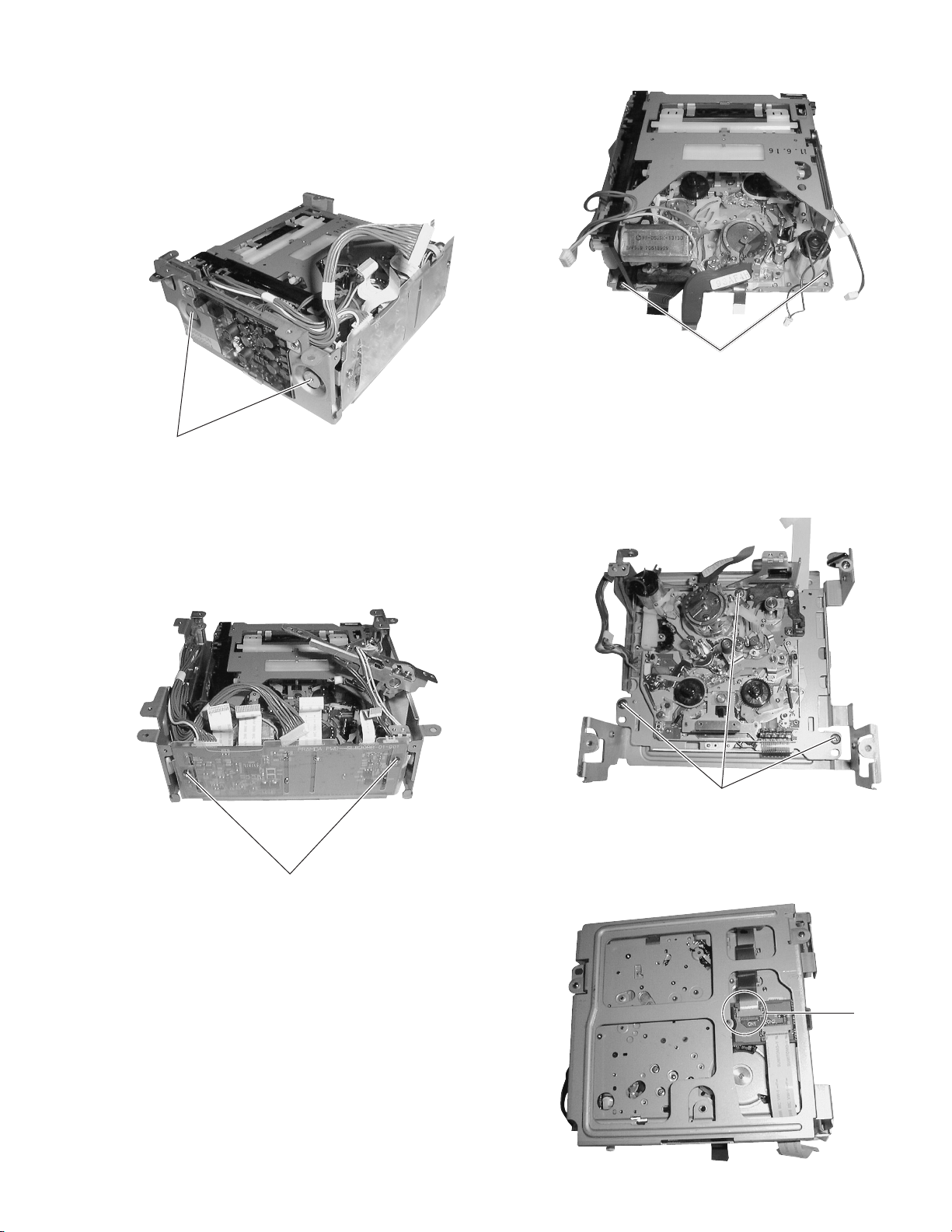

1.8 TAPE EJECTION IN CASE OF EMERGENCY

When the cassette tape cannot be ejected normally, take it out

by the following methods.

1.8.1 Tape Ejection Using Forced Eject Mode

(Short-circuiting of Internal TP)

GY-DV500 is provided with a compulsory eject mode for use in

case the button operations are not accepted due to a malfunction of the mechanism control circuitry. When an attempted

operation of the operation buttons is not accepted, set the compulsory eject mode as described below before removing the

tape.

CAUTION

䡲 This mode is effective only when the electrical and me-

chanical systems of the mechanism unit are normal and a

tape ejection operation is not accepted due to a problem

of the electrical system.

䡲 If there is a problem in the mechanical system of the unit,

this mode may be ineffective. If compulsory ejection is performed in such a case, the tape could be damaged or cut.

(1) Remove the left side cover (see section 1.2.1).

(2) With the power supply on, short-circuit TP107 on the DV

MAIN board with the GND using a wire, etc.

(3) Forced ejection is activated to eject the tape.

(3) Apply 3 V DC to the electrodes at the top of the loading

motor (red wire to + pole, brown wire to - pole) to unload

the tape. Unload it little by little because it could be damaged or contaminated by grease if the pole base assemblies

are returned completely beyond the position of the tape.

Brown wire

Red wire

Fig. 1-8-2(1)

(4) If the tape slackens, take it up by rotating the shaft at the

top of the capstan motor in the direction of the arrow using

a sharp-tipped object (chip IC replacement tool, etc.).

(5) Repeat steps (3) and (4) above until the tape is taken up

completely.

(6) After confirming that the tape has been taken up completely,

rotate the gear of the cassette housing assembly in the direction of the arrow in order to eject the cassette tape.

TP107

DV MAIN board

Fig. 1-8-1

1.8.2 Tape Ejection without Using the Forced Eject Mode

Activate the loading motor by applying DC voltage to its two

terminals.

NOTE

When a forced ejection is not accepted because the loaded

cassette tape cannot be ejected due to a fault in the electrical system or because of some problem in the mechanism

unit, eject the tape by using the following procedure.

However, as this mode drives the loading motor, it assumes

that the mechanical system is operating normally.

(1) Turn off the power supply to the unit.

(2) Flip open the DV MAIN board to expose the mechanism

(see section 1.6.3).

1-10

Shaft

Fig. 1-8-2(2)

Gear

Page 16

1.8.3 Manual Tape Ejection

If the loading motor cannot be run by the procedure outlined in

section 1.8.2, the mechanism may be defective. When the loading motor is defective, remove the tape as described below.

(1) Remove the mechanism unit from the main unit. See sec-

tion 1.6.2 for the removal method.

(2) After removing the mechanism unit, remove the DV MAIN

board (see section 1.6.3).

(3) Remove the 2 screws and remove the active head cleaner

assembly (see section 1.7.2).

(4) Remove the side cover to easy operation (see section 1.7.2).

(5) Remove the 2 screws and remove the rear panel from the

side of the PR & MDA board.

Carefully unplug the wires so as not to damage them, then

remove the PR & MDA board (see section 1.7.2).

3

3

Fig. 1-8-3(3)

(9) Unload the pole base assemblies by rotating the gear shown

in the figure in the direction of the arrow.

Loading motor

(6) Remove the 2 screws

stay.

(7) Loosen the 2 screws

rated freely.

(8) Remove the 4 screws

1

Fig. 1-8-3(1)

and remove the active head cleaner

1

2

Fig. 1-8-3(2)

so that the cassette housing is sepa-

2

and remove the loading motor.

3

Gear

Fig. 1-8-3(4)

(10) The pole base assemblies should be unloaded little by lit-

tle. If they are returned completely beyond the position of

the tape, the tape may slacken and become damaged or

stained by grease.

(11) If the tape slackens, take it up by rotating the shaft on the

top of the capstan motor in the direction of the arrow using a sharp-tipped object (chip IC replacement tool, etc.)

(see section 1.8.2-(4)).

(12) Repeat steps (9) and (10) above until the tape is taken up

completely.

(13) After confirming that the tape has been taken up com-

pletely, tighten the cassette housing retaining screws which

were loosened in step (6).

(14) Attach and clamp the cassette housing again, then rotate

the gear of the housing assembly in the direction of the

arrow to eject the cassette tape in the same way as in

section 1.8.2-(6).

1-11

Page 17

1.9 CAUTION FOR REPLACING THE DV MAIN BOARD

AND VIDEO SYSCON BOARD

When the DV MAIN board or VIDEO SYSCON board has been

replaced for servicing, be sure to enforce the following items.

1.9.1 DV MAIN Board

[A] About the ID Management Label

Each VCR unit carries an ID label in compliance with IEEE1394

showing the unique ID assigned on the production line.

(See the following figure for the label position.)

When replacing the DV MAIN board, remove the ID management label that was provided originally with the unit from the

defective board and attach it in the same position to the new

board.

DV MAIN board

[B] Load EEPROM Internal Data

The EEPROM provided with the new board for replacement

contains no data, while the EEPROM originally provided with

the VCR unit contains the IEEE1394 ID data as well as all adjustment data written in the assembly and adjustments written on

the production line. This means that the new VCR unit will not

function if the new EEPROM is used in the condition in which it

is delivered.

When replacing the DV MAIN board, load the internal data of

the EEPROM on the original board to the EEPROM of the new

board.

(1) How to use original EEPROM to new DV MAIN board.

Remove the EEPROM from the original DV MAIN board,

and attach the chip to the new board.

(2) How to write data from the original board to the new

EEPROM

How to load all parameters in EEPROM on original board to

new EEPROM by using the adjustment software.

(For details, see section 3.7.13)

(3) In case of original EEPROM on the original DV MAIN board

was broken.

Load the default data before making adjustments with the

adjustment software, write the data in the new EEPROM,

then make adjustments by following the adjustment procedures. (See section 3.7.12 for details.)

And then, input the ID number on the original board to new

EEPROM by using the adjustment software. (See section

3.7.13 for details.)

ID Label

Fig. 1-9-1

1.9.2 VIDEO SYSCON Board

[A] Transporting of IC407 (EEPROM) Data

When the SSF function is used, the cassette number recorded

on tape (see section 9.4.1) has the model ID code appended to

it. The model ID code is written in IC407 (EEPROM). However,

as the new EEPROM mounted on the new replacement circuit

board does not have the ID code written into it, the SSF function cannot work normally (the model ID code should be written

in IC407 for the correct operation of the SSF function).

Nevertheless, no means is provided for transporting the model

ID code from the original EEPROM to the new EEPROM. Therefore, it is recommended to remove the original IC from the original board and mount it on the new board.

[B] ID Management Label

An ID management label is attached to the camera head. For

the position, see Fig. 1-4-1.

1-12

Page 18

1.10 FUNCTIONS OF INTERNAL SWITCHES

1.10.1 DIP Switch S901 on ROM Board

Symbol ShipmentFunctionNameNo.

1 Adjustment mode Adjustment mode ON/OFF OFF

2 Check mode Check mode ON/OFF OFF

3 Not used OFF

S901

4 Character mixing TEST OUT character display ON/OFF OFF

5 Not used OFF

6 Color matrix adjustment Color matrix adjustment mode ON/OFF OFF

7 Setup (NTSC model only) ON (0% setup)/ OFF (7.5% setup) OFF

8 Function setting Initial setting of camera functions OFF

Table 1-10-1

(1) Adjustment mode (S901-1)

Set S901-1 to ON to initiate the camera electrical adjustment mode.

For details, see section 3.3.

(2) Check mode (S901-2)

Set S901-2 to ON to display the camera’s check mode screen

on the viewfinder.

In this mode, the auto white balance and auto iris control

data in the microcomputer controlling the camera can be

viewed and checked. (This mode is not used for adjustments

but is intended to simply allow the checking of control values and their functions.)

R-G

–

B-G

R GAIN LEVEL

B GAIN LEVEL

PEAK

APL

NAM ERROR

GAIN ∗dB

CHECK MODE

–

: ∗

: ∗

: ∗

: ∗

: ∗

: ∗

: ∗

: ∗

Fig. 1-10-1(1)

R-G/B-G

Shows the data on the R/G/B signals input to the CPU for

use in white balance control in terms of R-G and B-G. The

values are variable between -127 and 128.

These values approach 0 if the white balance circuit is activated by capturing a non-color image such as a gray scale.

R GAIN LEVEL/B GAIN LEVEL

Show the levels of the R and B channel white balance control signals.

These values are variable between 0 and 255.

The R value tends to decrease and the B value tends to

increase under low color temperatures (reddish lighting), and

the R value tends to increase and the B value tends to decrease under high color temperatures (bluish lighting).

PEAK

Shows the peak hold value of the video signal in a vertical

scanning period.

APL

Shows the average picture signal level.

NAM ERROR

Shows the NAM value used in the auto iris control.

The value is variable between -127 and 128.

The value approaches 0 when the auto iris control approaches

the optimum level.

GAIN

Shows the electrical gain value set with the GAIN switch on

the right-hand side of the unit.

Shows “ALC” in the full auto-shooting mode.

1-13

Page 19

(3) Character mixing (S901-4)

Set S901-4 to ON to superimpose the same characters as

those displayed on the viewfinder-screen in the output signal from the TEST OUT terminal. This is a convenient facility

for adjustment because the adjustment menu and screen

can be displayed on an external monitor.

(4) Color-matrix adjustment (S901-6)

Set S901-6 to ON to view the color-matrix adjustment-mode

screen on the

Viewfinder-screen.

This mode makes it possible to set color-matrix parameters

in details (see section 1.12).

* Note that the color-matrix adjustment is not a normal adjust-

ment item. It is usually not required to adjust the color-matrix because this has been set to the optimum level before

shipment.

* In case a color-matrix adjustment becomes necessary be-

cause of a user’s request, it should be performed in accordance with the description in section 1.2.

(5) Setup (S901-7): NTSC only

Set S901-7 to ON or OFF to select whether or not the output signal setup is included in the TEST OUT and MONITOR

OUT terminals output.

(Note that the signal recorded onto tape is not affected by

the position of this switch. The signal is always recorded

without the setup information.)

As changing the position of this switch does not alter the

signal level, it is not necessary to re-adjust the signal recording according to the position of this switch. This switch is

effective only on the camera video output. With the video

signal obtained by playing back a previously recorded tape,

whether the setup is included or not can be selected with

the item “SETUP” in the Service Menu (see section 1.13.3).

(6) Function setting (S901-8)

This switch is used to set the functions shown in Table 1-91(2).

This switch is usually used to switch the defaults of the domestic and export-oriented models.

S901-8

Function

GAIN

V. SCAN

ALC GAIN

L

M

H

OFF ON

0 dB

6 dB

9 dB

60.1 to 251.3

0 to + 18 dB

NTSC

60.1 to 2067.0

0 to + 18 dB

0 dB

9 dB

18 dB

PAL

Do not care

0 dB

9 dB

18 dB

50.1 to 2053.6

0 to + 18 dB

1.11 MODES REQUIRED IN SERVICING

1.11.1 Camera Service Menu

The CAMERA SERVICE MENU can be displayed on the viewfinder screen by setting the [POWER] switch to ON while tilting

the AUTO WHITE/ACCU FOCUS switch upward (toward AUTO

WHITE).

— — — CAMERA SERVICE MENU — — —

Cxxxx V

CCD CORRECT : ON

ERROR DETECT START

WHITE CLIP LEVEL : 108%

END

∗. ∗∗

<U>

Fig. 1-11-1

Select an item by turning the SHUTTER dial, and push the SHUTTER dial to select or set it.

Cxxxx V∗.∗∗<U>

This item displays the version number of the camer control software (IC902 on ROM board).

* The Character “U” after the Version No. indicates that U

version software is running. When “E” is shown here, the

software for E version is running.

CAUTION

Also be sure to reset the system after replacing IC902

(ROM) on the ROM board. See section 1.11.2, “System

Reset”.

CCD CORRECT (ON/OFF)

This item sets whether white blemish due to CCD is to be corrected or not.

To correct : ON

Do not correct : OFF

The factory shipment condition is ON. Even when OFF is selected with this menu, it is temporary and the correction status

(ON) is recalled automatically the next time the power is turned

on.

NOTE

• To correct any white blemish interference produced after

the factory shipment, perform the “ERROR DETECT

START” described on the next page. Be sure to warm up

the camera by leaving it on for more than 2 hours before

performing the “ERROR DETECT START”.

Table 1-9-1(2)

* The L/M/H positions of GAIN can also be set individually

using the [CAMERA MENU].

1-14

• The white blemish correction is performed with the lens

iris closed or with the lens cap on. In normal use, the lens

iris closes automatically when performing a white blemish

correction. However in a case when the lens cable is disconnected and the lens iris cannot be closed, “ERROR DETECT FAIL” will be displayed on the viewfinder and the

white blemish correction cannot be executed. Before performing the white blemish correction again, be sure to first

close the lens.

Page 20

ERROR DETECT START

When this item is selected and the SHUTTER dial is pushed,

the white blemish detection for correcting CCD white blemish

starts automatically.

The following messages are displayed on the viewfinder screen

during detection.

1.11.2 System Reset

While pushing the [SHUTTER] dial, press the [POWER] switch

to ON. This resets the system and initializes the menu set items

to their default values.

The following description shows items that are initialized to the

defaults by a system reset and those that are not.

ERROR DETECT EXECUTING

↓

ERROR DETECT END

After the completion of error detection, the camera is automatically set to the white blemish correction ON condition.

The following types of white blemish can be corrected.

(1) White blemish correction target area

5%

5%

Correction target area

90%

1.11.3 Resetting DSP Data

While pushing the [SHUTTER] dial and [STATUS] switch tilted

toward “SKIN AREA”, press the [POWER] switch to ON. This

resets the internal setting data (color matrix setting data) in the

DSP to the default setting.

1.11.4 Displaying Auto Iris Area Gate

While holding the [AUTO WHITE/ACCU FOCUS] switch down

(toward ACCU FOCUS), press the [POWER] switch to ON. The

area gate for the auto iris control is displayed in the viewfinder

screen.

90%

Fig. 1-11-2

(2) Details of correctable white blemishes

䡲 White blemishes at luminance levels of 30 mV or more

can be corrected. The total number of white blemishes

that can be corrected is up to 7 for the R, G and B signals.

䡲 Even when there are 2 white blemishes on a single scan-

ning line, both of them can be corrected. (However, when

they are adjacent, the results of a correction appear inferior to those of the results of the correction of a single

white blemish. These results are due to the correction characteristics themselves.)

WHITE CLIP

The white clip level of the through-camera composite output

signal that is output at TEST OUT can be selected from the following 2 values:

100% or 108% (shipment setting)

Fig. 1-11-3

1.11.5 List of Servicing Switches (Camera)

The following table that shows the switches described above is

for use in servicing. Use this table as a reference in servicing.

Switch Operation Result

[AUTO WHITE] + [POWER] ON Service menu display

[SHUTTER] + [POWER] ON System reset

[STATUS] + [SHUTTER] + [POWER] ON

[ACCU FOCUS] + [POWER] ON Area gate display

DSP data reset

Table 1-11-4

1-15

Page 21

1.11.6 EEPROM in Camera

IC905 on the CAM1 board is an electrically erasable/rewritable

EEPROM. It stores the following data.

䡲 Camera adjustment data set in the adjustment mode.

䡲 Settings in [CAMERA MENU].

䡲 White blemish position coordinate data for use in white blem-

ish correction.

䡲 Auto white balance control data (A/B).

䡲 Camera status at the last power OFF (positions of non-lock

type switches, etc.).

Therefore, when retention of the above data becomes impossible due to a failure in the EEPROM or over the 1 million times of

rewrite count, the EEPROM should be replaced with a new one

and the data should then be re-set in it.

1.11.7 Tripod base

See the KA-510U servide manual NO. 60065 for servicing.

The tripod is not exactly same as KA-510U. See note for the

difference.

Note

These 1/4 and 3/8 inch fixing tripod holes are not

povided for the KA-510U.

1.12 CHANGING THE COLOR MATRIX SETTING

NOTE

The color reproduction properties of the color-matrix circuit

built into the DSP can be re-set by varying the values of 9

parameters. However, as these parameters have been set at

the factory to the default values based on detailed studies of

the product development process, it is usually not recommended to alter them. Note that this adjustment is not a

normal electrical adjustment item.

Should a re-adjustment of the color matrix (a color reproducibility change) be required as a result of a user request, etc.,

this should be performed only after studying and understanding the details of the following instructions.

1.12.1 Setting the Color Matrix

Preparation

The color matrix setting requires a color chart for use as a

reference for color reproduction and a vectorscope. As we

do not specify a color chart for this purpose, discuss the

matter with any user requesting a custom setting and use a

color chart to be agreed by the user.

Adjustment

The color-matrix circuit can be set using menus displayed

on the screen (the viewfinder-screen or the test out screen).

Front

Front

Accessory

KA-510U

2–3/8"

Not provided

4–3/8"4–1/4"

2–1/4"

Not provided

Not provided

Rear

Rear

MODE : M3 M2 M1 DATA

R (R-G) :

R (R-B) :

G+(G-R) : X

G–(G-R) : X

G+(G-B) : X

G–(G-B) : X

B+(B-G) : X

B–(B-G) : X

B (B-R) :

Fig. 1-12-1

Use the following procedure.

(1) Remove the right side cover (see section 1.3.1)

(2) Set DIP switch S901-6 on the ROM board to ON to display

the color-matrix setting menu on both the viewfinder and

testout screens.

(3) Move the cursor (mark of “

”) to the desired item by using

the [SHUTTER] dial.

(4) When the cursor set on the desired item, pushing the [SHUT-

TER] dial causes the selected item to blink. (This is the status of the value adjustment.)

(5) When the adjustment value is blinking, rotating the [SHUT-

TER] dial varies the adjustment value. The available adjustment values are “M3”, “M2”, “M1” which is 0 or 1, and

“DATA” which is between 0 and 31.

1-16

Page 22

M3

0 : Active

1 : Inactive

M2

0 : Active

1 : Inactive

M1

0 : Increase

1 : Decrease

DATA

0 – 31

MODE

R±(R-G)

R±(R-B)

G+(G-R)

G–(G-R)

G+(G-B)

G–(G-B)

B+(B-G)

B–(B-G)

B±(B-R)

M3

M3

M2

M2

M2

M2

M3

M3

M3

M3

M3

M2

0 or 1

0 or 1

0 or 1

0 or 1

0 or 1

0 or 1

0 or 1

0 or 1

0 or 1

0 or 1

0 or 1

0 or 1

0 or 1

0 or 1

0 or 1

0 or 1

0 or 1

0 or 1

0 or 1

0 or 1

0 or 1

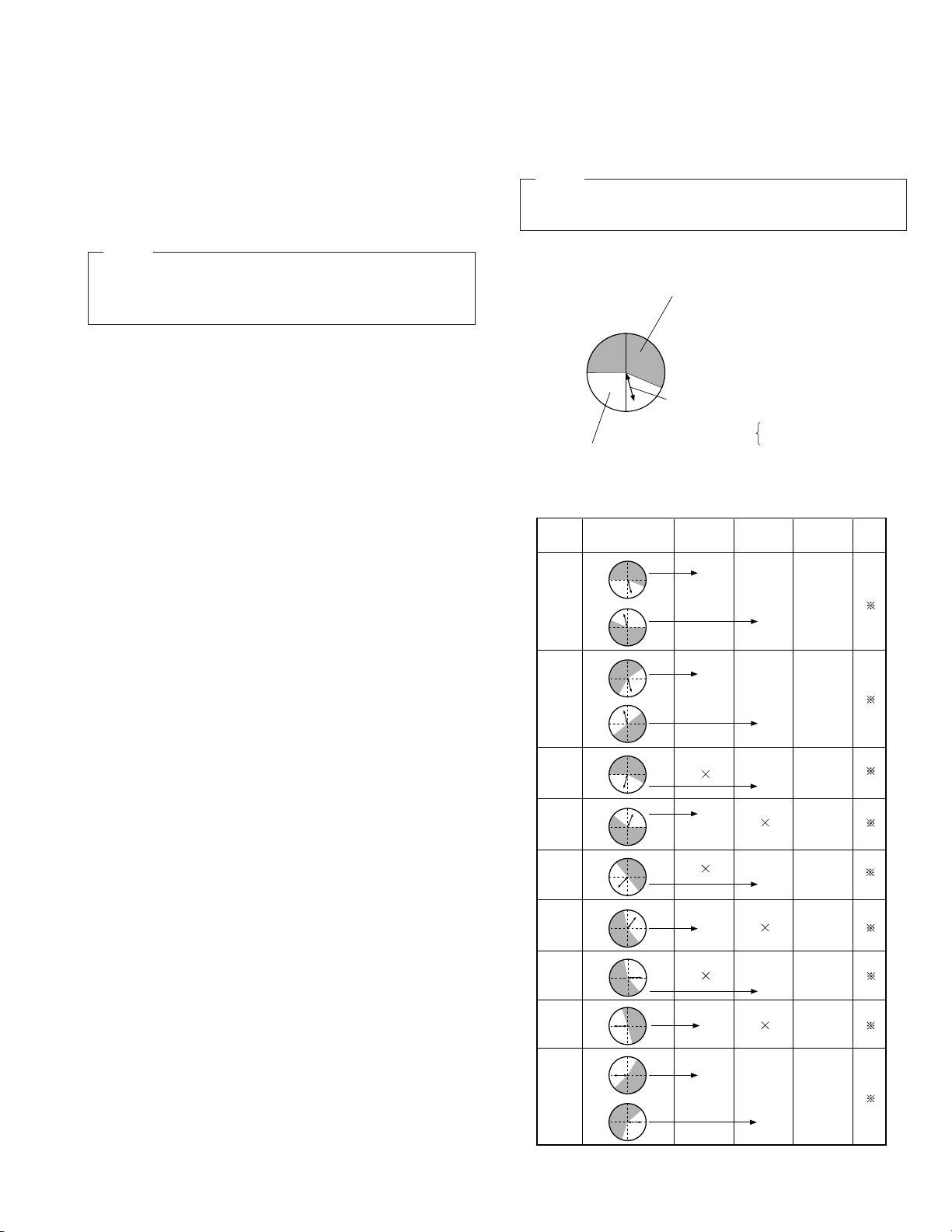

Active Area

Graph display

(6) Set DIP switch S901-6 on the ROM board to OFF. The color-

Inactive area:

Represents a vector area

that is not affected by a

currently selected setting

item.

M1 = 0: Increasing trend

M1 = 1: Decreasing trend

Color signal increase/decrease trend:

The increase or decrease trend can be

selected with M1.

Active area:

Represents the vector area that is affected

by a currently selected setting item.

(The area can be selected with M3 or M2

depending on the item.)

matrix setting menu is canceled and the normal screen appears again.

NOTE

The settings are stored and reflected every time a value in

an item is changed. The setting values marked “X” do not

need to be changed.

1.12.2 Details of Setting Items

As described above, the color matrix setting consists of varying

12 items using 9 parameters. The following table shows a comparison of the setting items.

NOTE

The model diagrams in the table may be interpreted as follows.

NOTE

If the [STATUS] switch is pressed during the value of some

adjustment item is blinking, all of the data being set is reset

to the default values.

(Example)

This diagram represents the display area of the vectorscope.

Table 1-12-1

1-17

Page 23

1.13 SERVICE MENU

1.13.1 Operation Method

When the [MENU] button is pressed, the setup menu appears on the viewfinder screen to allow the user to perform setups. (For the

contents of the setup menu, refer to page 66 of the instruction manual). Then, with the setup menu displayed, press the [MENU]

button while holding down the [LOG] button to display the service menu.

To change a menu setting value, press the [DATA SET] button. The viewfinder screen and counter display show the blinking “DATA

SET” indicators and the set returns to normal mode.

To return to the setup menu, turn the power off and then on again.

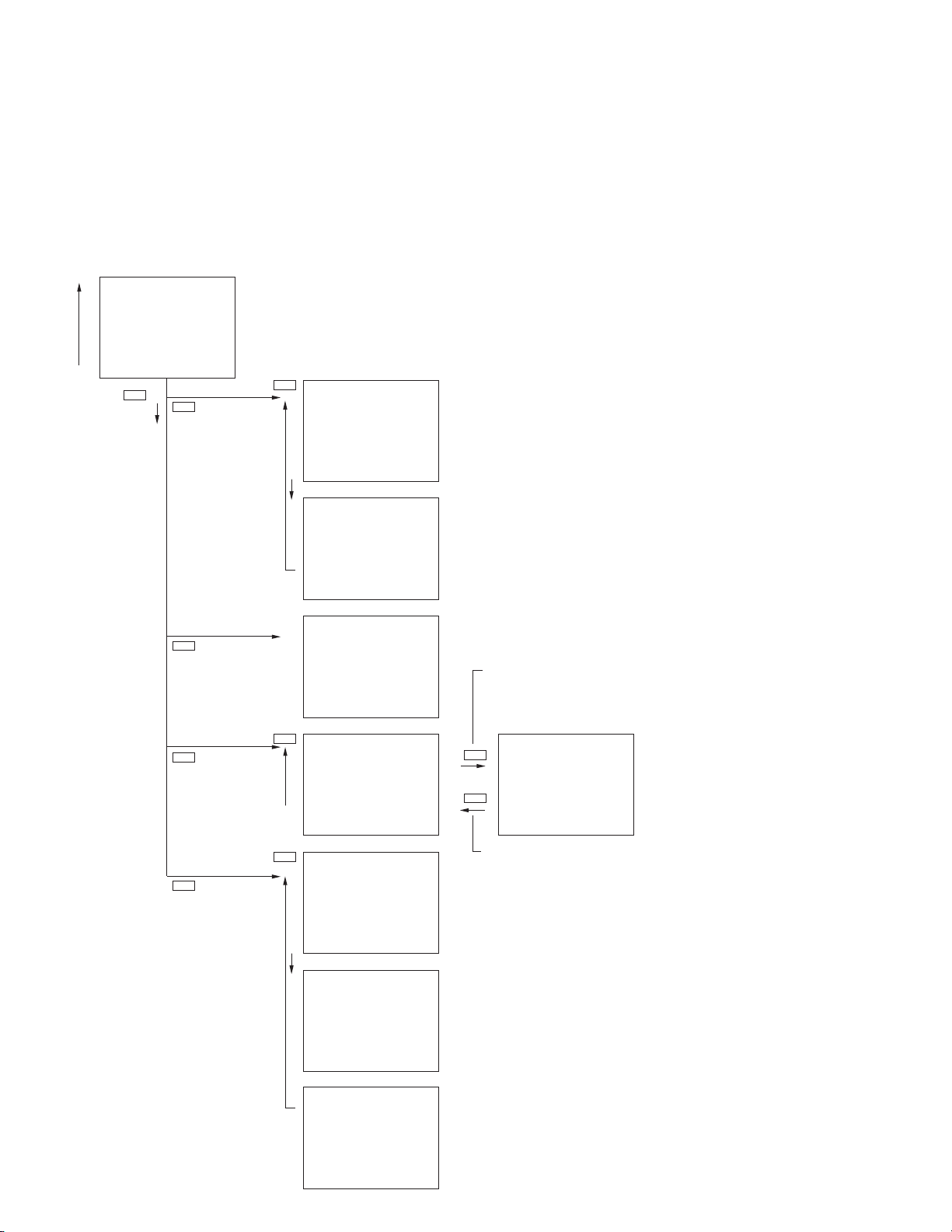

1.13.2 Configuration of the Service Menu (Displayed on the Viewfinder Screen)

GROUP

↓

→

:

SERVO/SYSTE

000

↓

100 :VIDEO

↓

20 0 : AUDI O

↓

300 :SYSTE

↓

↓

↓

↓

↓

↓

↓

→

↓

M

400 :TI

500 :ONSCREEN

700 :DI P S

HM: HOURMETER

RV :ROMVERSI ON

:

ERROR HI STORY

EH

OT:OTHERS

GROUP

M

E CODE

W

HOUR METER

SERECT

M

Initial display of the service menu.

Select an item with the [GROUP] button and press the [SELECT] button

to go to a lower hierarchical level.

ITEM

( HOURMETER)

↓

↓

↓

↓

↓

↓

↓

↓

M

DH : DRU

TH : TOTAL DR

PH : PO

CH : CAP HOUR

LD : LOADI NG T I

EJ : EJECT T I

HC : HEAD CREANI NG T I

FR : F

HOURMETER

M

W

ER HOURMETER

M

( HOURMETER)

M

ES

W

D/REV T IMES

HOURMETER

ETER

M

ES

000000H

000000H

000000H

000000H

000000

000000

M

ES

000000

000000

Hour meter data can be checked.

See section 1.13.4.

ROM VERSION

SERECT

ERROR HISTORY

SERECT

OTHERS

SERECT

(RO

M

VERSI ON)

SY : SYSCON RO

LT :LCD/TC RO

US : UNI T SY S RO

U

M

:UNITMSD ROMVER.

ITEM

ITEM

→

←

(ERROR HISTORY)

↓

1:ERR7101

CAP

M

↓

2:ERR7101

↓

3:ERR7101

↓

4:ERR7101

↓

MS:MEM

↓

ML:MEM

↓

M I:MEM

↓

EC : ERROR HI S TORY CL EAR

↓

LCD:LCD/KEY T EST

↓

DHC : DRU

↓

CHC: CAP H.M. C LEAR

↓

LTC:LOADING TIMES CLEAR

↓

ETC: EJECT T IMES CL EAR

↓

HTC :H . CLEAN TIMES CLEAR

FTC:F

OTOR FA I L URE

CAP

M

OTOR FA I L URE

CAP

M

OTOR FA I L URE

CAP

M

OTOR FA I L URE

(OTHERS)

ORY SWSAVE

ORY SWLOAD

ORY SWINITIALIZE

(OTHERS)

MH.M

(OTHERS)

W

D/REV T IMES C LEAR

M

VER.

M

VER.

M

VER.

.CLEAR

ROM version data can be checked.

See section 1.13.5 .

01

01

01

01

Error history of the 4 most recent errors can be

checked.

Pressing the [SELECT] switch in this screen

displays the mechanism information of each

error.

(MECHANI SMSWINFO.)

SELECT

(

M

ODE) REC

→

REC PAUSE

(EDCD) HLH

( HOUS ) O F F ( CASS ) ON

(SAFE ) OF F

(BGIN)OFF (END)ON

MENU

(RE

M

) OOHOOM

(P.T

M

) OOOOOOH

(TEMP) 60~

See sections 1.13.5 and 1.13.6.

The set-up menu contents can be saved, loaded or initialized

OFF

and the hour meter data can be reset.

OFF

See section 1.13.8.

After switching an item from OFF to ON using [SELECT],

OFF

execute the selected item by pressing [DATA SET]. It is not

OFF

possible to execute more than one item simultaneously.

OFF

When an item is switched ON, other items are switched OFF.

OFF

OFF

OFF

OFF

OFF

OFF

1-18

Page 24

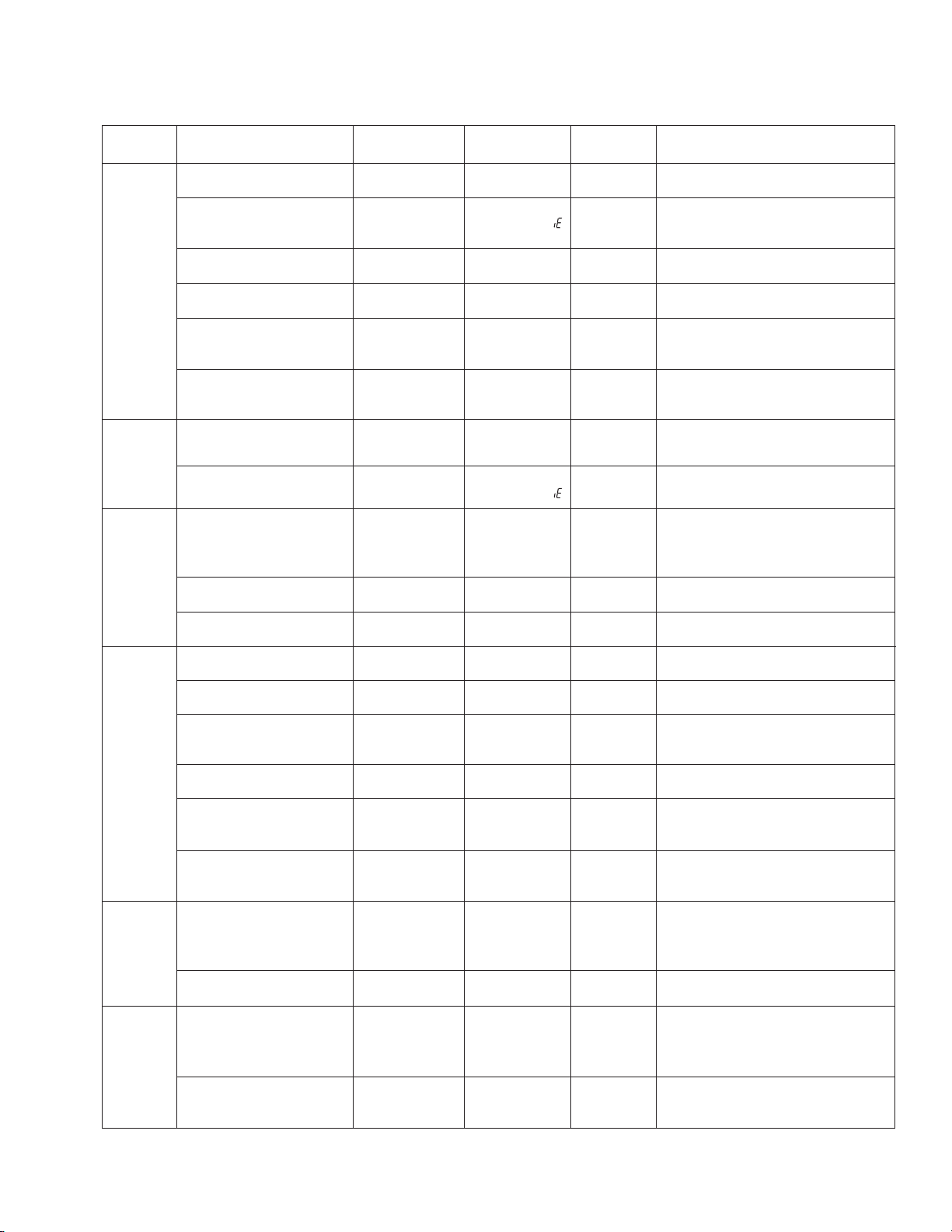

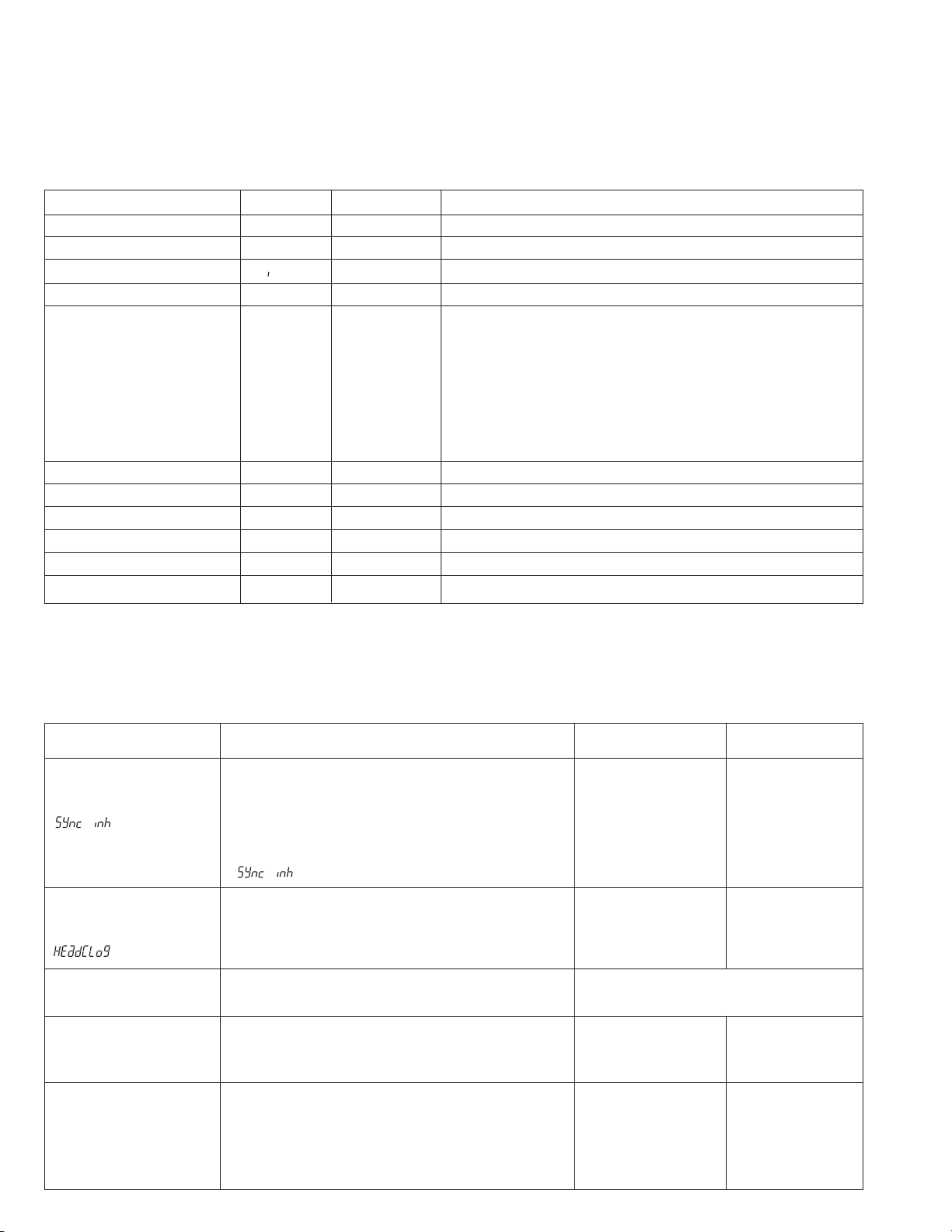

1.13.3 Contents of Service Menu

Group Item Settings Counter Display

000

SERVO/

SYSTEM

002: OPERATION LOCK

050: REMOTE SELECT

ON

OFF

LOCAL

002 01

U

RSL Lc

IEEE1394

RS232C

080: BATTERY SHUTDOWN V

10.5 – 11.0V

BE 105

(0.1V step)

081: BATTERY ALARM V

082: BACK TALLY MODE

10.5 – 12.0 V

(0.1V step)

BLINK

BA 110

U

RT D BL

OFF

ON

083: FRONT TALLY MODE

BLINK

083 03

ON

100

VIDEO

125: SET UP

(Only U-ver.)

126: INPUT SELECT

OFF

ON

CAMERA

125 00

VD c

IEEE1394

200

AUDIO

244: LOW CUT

OFF

CH1

LcTF OF

CH2

245: SAMPLING RATE

CH1&CH2

32K

U

SPL 48

48K

246: FRONT VOLUME ENABLE

DISABLE

FRVL OF

ENABLE

300

SYSTEM

303: WARNING DISABLE

305: REC REPEAT

ENABLE

DISABLE

OFF

303 00

305 00

ON

306: LONG PAUSE DISABLE

ENABLE

306 00

DISABLE

307: LONG PAUSE TIME

3MIN

LGPT 03

30MIN

396: BATTERY TYPE

12V

BATT 12

13.2V

14.4V

398: SSF MODE

OFF

55F OF

CUE MODE

MARK MODE

400

TIME CODE

500

ON

SCREEN

406: USERS BIT GROUP

416: NON DROP/DROP

(Only U-ver.)

515: CALENDAR SELECT

516: DISPLAY SELECT

NOT SPECIFIED

ISO CHAR

UNASSIGNED1

UNASSIGNED2

DROP

NON DROP

JAPAN

USA

EUROPE

TC

40B 00

TcG DF

515 00

DSP Tc

CLOCK

00

23

OFF

ON

01

01

02

ON

32

01

01

01

30

13

14

cU

01

02

03

01

02

ON

01

NF

cL

U

R

Factory Default

OFF

LOCAL

10.5V

11.0V

BLINK

BLINK

ON

U

CAMERA

OFF

48K

ENABLE

ENABLE

OFF

ENABLE

30MIN

12V

CUE MODE

NOT

SPECIFIED

DROP

U-ver: USA

E-ver: EUROPE

TC

Description

Operation lock setting.

User setup menu (Refer to page 68 of

the instruction manual.)

Battery empty detection voltage setting.

Battery alarm detection voltage setting.

User setup menu (Refer to page 68 of

the instruction manual.)

Select the front tarry

BLINK: Blinking

ON: Lighting

Select the setup of MONITOR OUT in playback mode.

ON: Setup added.

OFF: No setup.

Input signal selection

User setup menu (Only U-ver.) (Refer to

page 68 of the instruction manual.)

User setup menu (Refer to page 68 of

the instruction manual.)

User setup menu (Refer to page 68 of

the instruction manual.)

User setup menu (Refer to page 68 of

the instruction manual.)

ENABLE: Warning enabled.

DISABLE: Warning disabled.

OFF: REC Full Repeat enabled.

ON: REC Full Repeat disabled.

ENABLE: Long pause is canceled after specified period of time (set using Menu 307).

DISABLE: Long pause is not canceled.

User setup menu (Refer to page 68 of

the instruction manual.)

User setup menu (Refer to page 68 of

the instruction manual.)

User setup menu (Refer to page 68 of

the instruction manual.)

User bit’s binary group flag setting

User setup menu (Refer to page 68 of

the instruction manual.)

Calendar display format selection.

JAPAN: Year/Month/Day

USA: Month/Day/Year

EUROPE: Day/Month/Year

User setup menu (Refer to page 68 of

the instruction manual.)

1-19

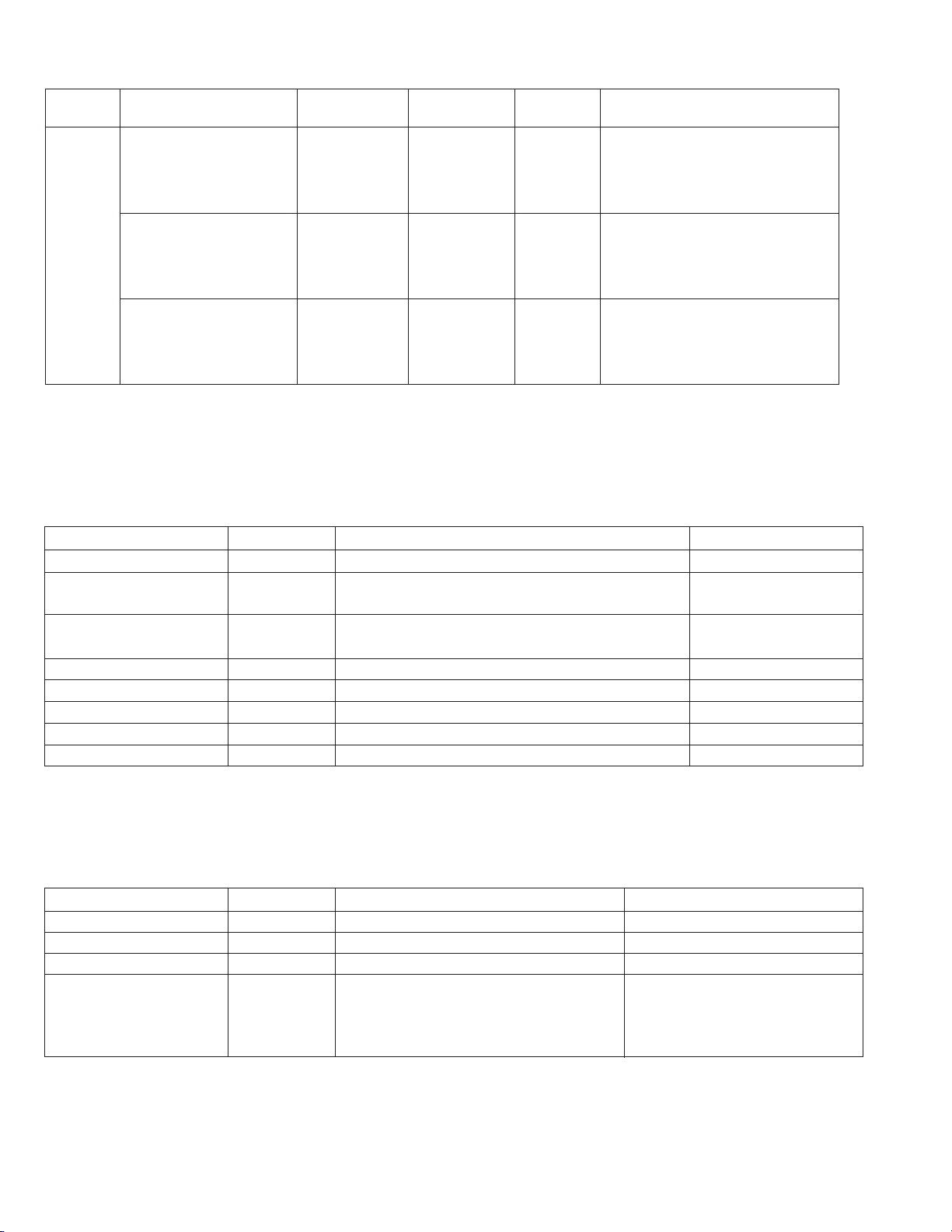

Page 25

Group Item Settings Counter Display

Factory Default

Description

700

DIP SW

Operations are not accepted when the cassette cover is open. Therefore, DIP switch-0 and -1 can be used in checking the operation when the

side cover is open or in the compatibility adjustment.

700: DIP SWITCH-0

701: DIP SWITCH-1

702: DIP SWITCH-2

to to

715: DIP SWITCH-15

OFF

ON

OFF

ON

OFF

ON

700 00

701 00

702 00

715 00

01

01

01

01

OFF

OFF

All OFF

Operate LED display switching

OFF: Blinks in amber when the cassette

cover is opened.

ON: Extinguished when the cassette

cover is opened.

OFF: Other operations than ejection are

inhibited when the cassette cover is

opened.

ON: Operations are valid even when the

cassette cover is opened.

Switching inhibited. Must be set to OFF.

1.13.4 HOUR METER

This screen allows the data of hour meters to be checked.

Item

DRUM HOUR METER

TOTAL DRM HOUR METER

Counter Display

DH∗∗∗∗∗∗

TH∗∗∗∗∗∗

Description

Displays the drum rotation hours.

Displays the total drum rotation hours. This data can-

Max. Display Hours/Count

999999H

999999H

not be reset.

POWER HOUR METER

PH∗∗∗∗∗∗

Displays the power ON hours. This data cannot be re-

999999H

set.

CAP HOUR METER

LOADING TIMES

EJECT TIMES

HEAD CLEANING TIMES

FWD/REV TIMES

cH∗∗∗∗∗∗

LH∗∗∗∗∗∗

EJ∗∗∗∗∗∗

Hc∗∗∗∗∗∗

FR∗∗∗∗∗∗

Displays the capstan motor rotation hours.

Displays the loading count.

Display the ejection count.

Displays the active cleaning head operation count.

Displays the forward or reverse operation count

999999H

999999TIMES

999999TIMES

999999TIMES

999999TIMES

∗∗∗∗∗∗ are the figures of time (or count).

1.13.5 ROM VERSION

This screen allows the ROM versions to be checked.

Item

SYSCON ROM VER. Video/Sys-con board IC403 PLSL1063-V1-**

LCD/TC ROM VER. Audio/LCD board IC601 UPD78P058BT***

UNIT SYS ROM VER. DV MAIN board IC101 MN102F1617HL-**

UNIT MSD ROM VER. DV MAIN board IC401 M31020EAVP-***

Counter Display

SY ∗∗

LT ∗∗

US ∗∗

U

U ∗∗

Board Name Symbol No. Remark

ROM board IC1 M27W102-80N6-**

(The MSD CPU program is written in

IC401 and ROM board IC1.)

(The ROM version No. of PAL begins

with “80”.)

∗∗ is the version number.

1-20

Page 26

1.13.6 ERROR HISTORY

This screen allows the history of the 4 most recent errors to be checked.

Error code

( ER ROR H I ST ORY )

Latest warning

Warning before the latest

Warning before the above

1: ERR7101

CAP

2: ERR7101

CAP

3: ERR7101

CAP

4: ERR7101

CAP

M

OTOR FA I L URE

M

OTOR FA I L URE

M

OTOR FA I L URE

M

OTOR FA I L URE

Warning before the above

1.13.7 MECHANISM SW INFO

This screen allows the mechanism mode at each error to be displayed.

Error message

(MECHANISMSWINFO. )

(MODE ) R E C

→

(EDCD) HLH

( HOUS ) O F F ( CA SS ) ON

( SAFE) OF F

(BGIN)OFF (END)ON

(RE

(P.T

(TEMP) HIGH

REC PAUSE

M

) OOHOOM

M

) OOOOOOH

Display

Item

(MODE)

(ECOD)

(HOUS)

(CASS)

(SAFE)

(BGIN)

(END)

Description

Mode at the moment of VCR error & mode immediately before.

Rotary encoder output.

Cassette housing switch status.

Cassette switch status.

REC safety switch status.

Tape begin sensor status.

Tape end sensor status.

Input Pin

—

DV MAIN board

IC401

Pin 44 → CAM0

Pin 45 → CAM1

Pin 46 → CAM2

DV MAIN board

IC401 pin 27

DV MAIN board

IC401 pin 32

DV MAIN board

IC401 pin 47

DV MAIN board

IC401 pin 126

DV MAIN board

IC401 pin 125

Display

PLAY, STILL, REC, REC PAUSE, NO CASSETTE, EJECT,

STNDBY-ON, FF, REW, SHTL, STILL, SHTL X10, SHTL X-10

Shows H or L according to the mechanism position.

Rotary encoder terminal

(ENCD) H L H

CAM0 CAM1 CAM2

ON : Housing inserted/ejected status

OFF : Housing operating status

ON : Cassette tape inserted

OFF : Cassette tape not inserted or during insertion /ejec-

tion

ON : Non-recordable tape inserted, cassette tape not in-

serted or during insertion /ejection

OFF : Recordable tape inserted

ON : Tape leader section detected

OFF : Magnetic tape section detected

ON : Tape leader section detected

OFF : Magnetic tape section detected

(REM)

(P.TM)

(TEMP)

Remaining tape at the moment of

error.

POWER HOUR METER data at

the moment of error.

Set’s internal temperature at the

moment of error

—

—

DV MAIN board

IC101 pin 75

Remaining tape time

POWER HOUR METER time

UNDER : under 10°C

NORMAL : 10 to 40°C

HIGH : 40 to 60°C

OVER : over 60°C

1-21

Page 27

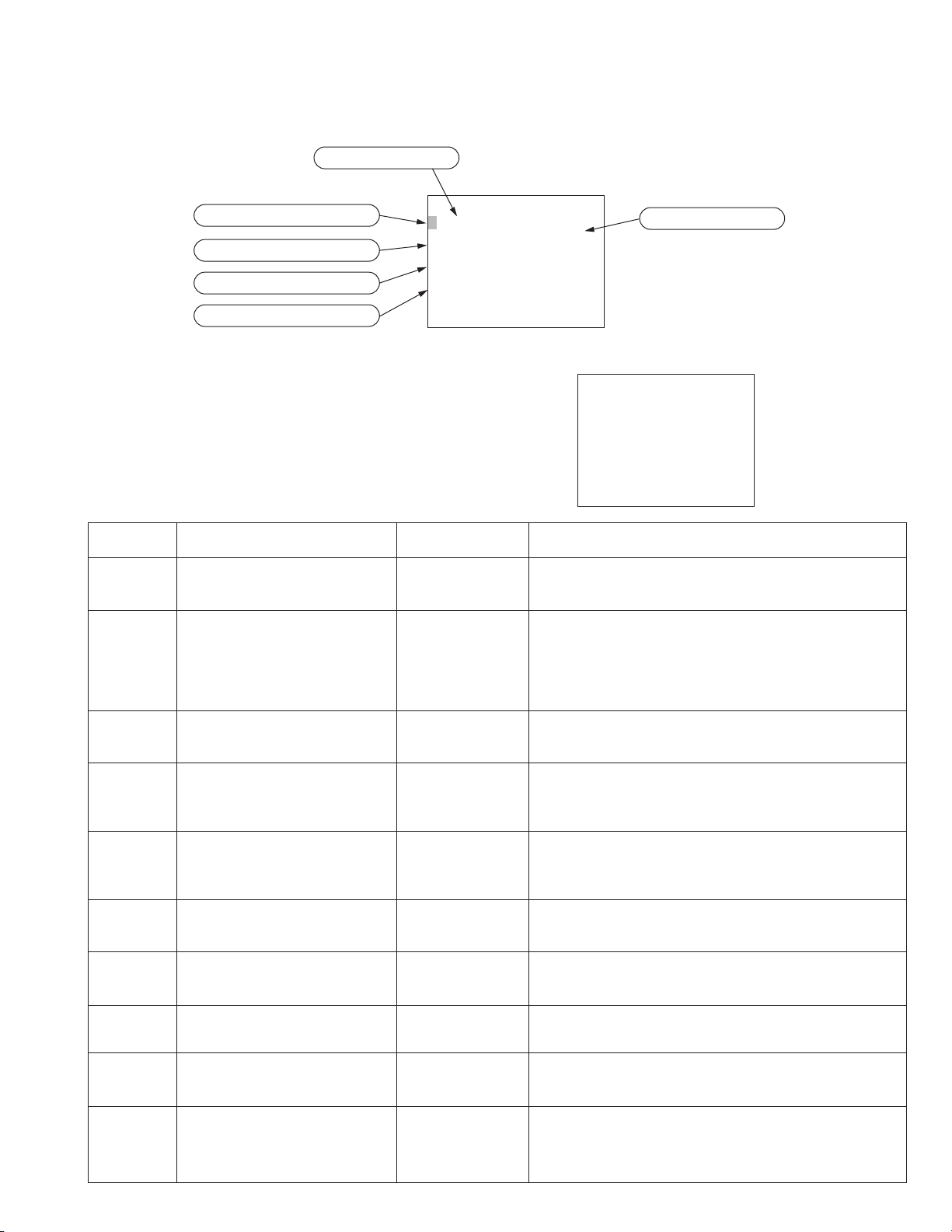

1.13.8 OTHERS

This screen allows the setup menu to be saved temporarily, loaded or initialized.

To execute an item, switch it from “OFF” (displayed as “00”) to “ON” (displayed as “01”) with the [SELECT] button, then press the

[DATA SET] button (excluding hour meter). As switching an item “ON” switches other items automatically “OFF”, it is not possible to

execute more than one item simultaneously.

Item

MEMORY SW SAVE

MEMORY SW LOAD

MEMORY SW INITIALIZE

ERROR HISTORY CLEAR

LCD/KEY TEST

DRUM H.M. CLEAR

CAP H.M. CLEAR

LOADING TIMES CLEAR

EJECT TIMES CLEAR

H. CLEAN TIMES CLEAR

FWD/REV TIMES CLEAR

Counter Display

U

S00

U

L00

U

Ec 00

LcD 00

DHc 00

cHc 00

L7c 00

E7c 00

H7c 00

F7c 00

1.14 ALARM DETECTION METHODS

Factory Default

00

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Description

Saves the data set with the setup menu.

Loads the data set for the setup menu.

Initializes the setup menu data to the factory defaults.

Clears the error history.

Checks the lighting of operation key LEDs.

After changing the setting to “START”, press the [DATA SET] but-

ton. The viewfinder screen and LCD display show “PERFORM”

and the key test mode is set. In this mode pressing an operation

key, lights the corresponding LED but does not cause the VCR to

operate. To exit from the key test mode, change the setting to

“STOP” and press the [DATA SET] button. The viewfinder screen

and LCD shows “PERFORM” and the normal mode is reset.

Resets the drum hour meter.

Resets the capstan hour meter.

Resets the loading count.

Resets the ejection count.

Resets the head cleaning count.

Resets the forward/reverse operation count

The unit incorporates the alarm display function, which notifies the user of the VCR status, remaining tape and remaining battery

power. For the contents of the alarm display, see page 86 of the instruction manual. This section describes the methods applied for

alarm detection.

Item

Servo lock error

“SERVO”

(Counter display)

Head clog

“RF”

(Counter display)

Dew condensation

When the drum rotation phase is deviated by more than

10 or when the capstan motor rotation speed is deviated by more than 20%.The alarm sound is generated

in REC mode. The alarm display only appears in the

PLAY mode.

When external sync input signal SYNC IN is disturbed,

“

” (sync inhbit) is displayed.

Measures the error rate during playback or quick review with RET button and displays “HEAD CLOG”

when the viterbi is ON and exceeds 2000 (total).

When dew warning occurs with the VCR.

Description

Status After Detection

Same mode is

maintained.

Detection Method

The MSD microcomputer

detects the drum rotation

phase from the phase error

between the TSR and HID

signals. The capstan motor

rotation speed is detected

based on the CAP FG signal.

Same mode is

maintained.

—

See error code “0201 DEW” in 1.16.

“DEW”

Lithium battery exhaustion

“Li”

When the built-in lithium battery for the timecode

backup is exhausted or not installed.

Same mode is

maintained.

Decrease in the

battery voltage

below 2.6 V.

Remaining battery

When the remaining battery power is low.

• Battery nearly empty:

Operation is maintained.

Detects the voltage

at system controller

pin 62.

• Battery empty: Operation stops automatically.

1-22

Page 28

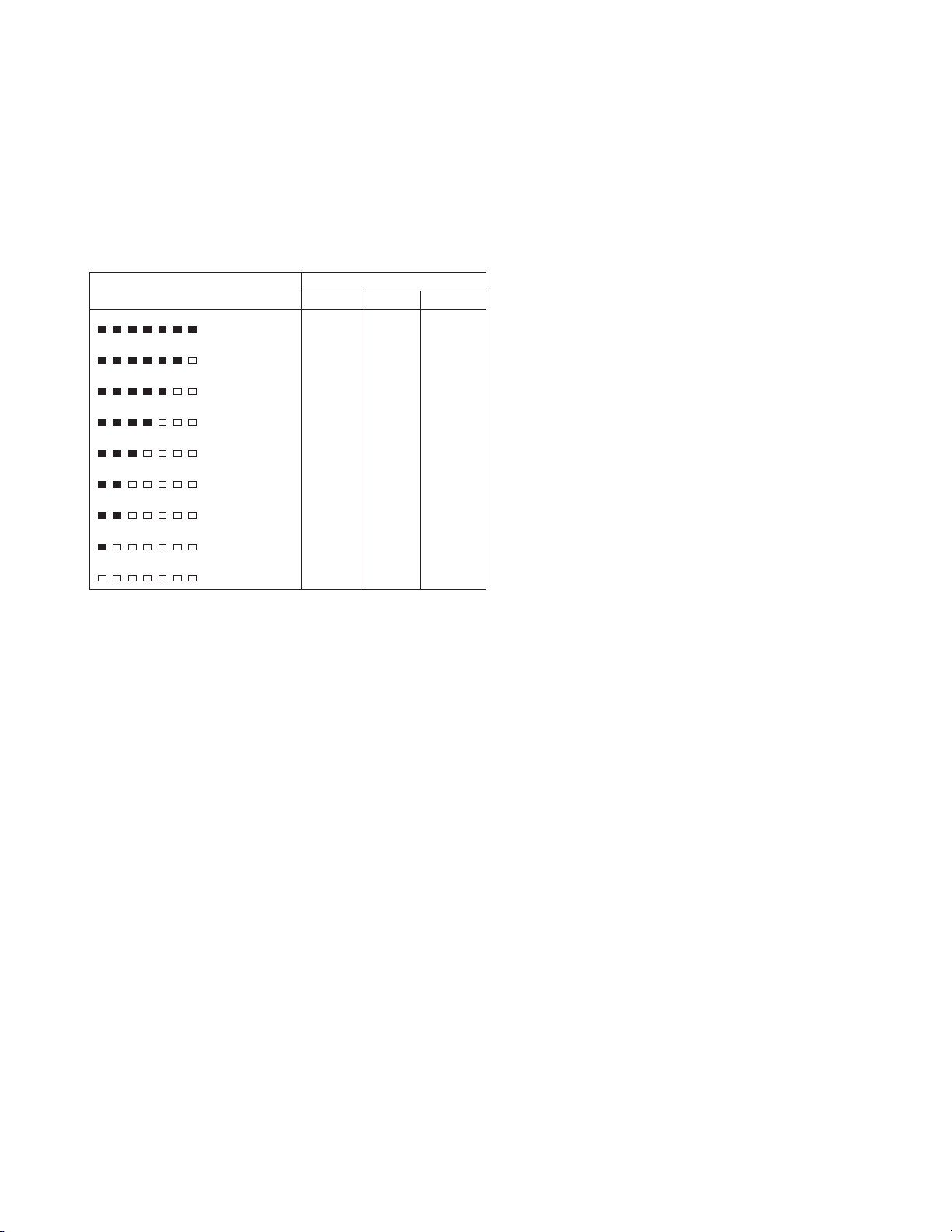

1.15 BATTERY POWER DETECTION METHODS

1.16 WARNING CODES

The battery voltage is detected to display the remaining power

on the LCD. Since the detection voltage is variable depending

on the 12 V/13.2 V/14.4 V battery types, correct settings should

be made with the setup menu.

Detection voltage and remaining battery display

12V

Battery Type

13.2V

3.9V –

13.2V – 13.8V

13.0V – 13.1V

12.8V – 12.9V

12.4V – 12.7V

12.3V

11.6V – 12.2V

10.6V – 11.5V

– 10.5V

14.4V

15.1V –

14.4V – 15.0V

14.2V – 14.3V

13.9V – 14.1V

13.6V – 13.8V

13.4V – 13.5V

12.6V – 13.3V

10.6V – 12.5V

– 10.5V

EFBATT

EFBATT

EFBATT

EFBATT

EFBATT

EFBATT

EFBATT

EFBATT

EFBATT

Display

(“F” off)

(“F” off)

(“F” off)

(“F” off)

(“F” off)

(“F” off, “BATT” blinking)

(Segment blinking)

(“F” off, “BATT” blinking)

(Segment blinking)

(“F” off, “BATT” blinking)

(Segments off)

12.6V –

12.0V – 12.5V

11.8V – 11.9V

11.6V – 11.7V

11.3V – 11.5V

11.2V

11.0V – 11.1V

10.6V – 10.9V

– 10.5V

If a problem occurs during operation, the unit diagnoses the

cause by itself, provides a warning through the “warning LED”

and “buzzer”, and displays the diagnosis results in the counter

display.

[LCD counter]

Error display appears. (∗∗∗∗ is the error code.)

ERR-∗∗∗∗

[Warning LED]

The red LED blinks (at about 4 Hz).

[Buzzer]

Generates a continuous tone. However, the tone is intermittent

(at about 4 Hz) in case of dew alarm.

0201 Condensation

•VCR operation

In save mode:

· If a cassette is loaded, enters the AUTO OFF mode.

· If a cassette is not loaded, the warning LED lights

and the SAVE mode is maintained.

In other modes:

· If a cassette is loaded, the AUTO OFF mode is ini-

tiated.

· If a cassette is not loaded, the warning LED lights

and the drum rotates. An operation is accepted after any condensation has evaporated.

•Cause : Condensation of moisture.

•Detection method : Check the voltage at the pin 124 of

IC401.

DEW ON : 2.4 V or more

DEW OFF : 1.8 V or less

0601 WRONG CASSETTE TYPE

•VCR operation : The AUTO OFF mode is initiated.

•Cause : A wrong type of cassette for the

computer is inserted.

•Detection method : An error in the cassette type is detected (at pins 117, 118 and 119 of

IC401) after the insertion is completed.

3200 LOADING INCOMPLETE

•VCR operation : The AUTO OFF mode is initiated.

•Cause : Malfunction of the loading motor,

rotary encoder or mechanism.

•Detection method : The rotary encoder output is

checked (at pins 44, 45 and 46 of

IC401) and an error is detected

when loading has not completed in

4 seconds.

1-23

Page 29

3300 UNLOADING INCOMPLETE

•VCR operation : After the first unloading error, the

cassette is loaded temporarily, then

unloading is retried. If the retry fails

again, the AUTO OFF mode is initiated.

•Cause : Malfunction of the loading motor,

rotary encoder or mechanism.

•Detection method : The rotary encoder output is

checked (at pins 44, 45 and 46 of

IC401) and an error is detected

when unloading has not completed

in 4 seconds.