Page 1

SECTION 8

DESCRIPTION OF NEW CIRCUITRY

8.1 OUTLINE OF DV

8.1.1 Features of DV

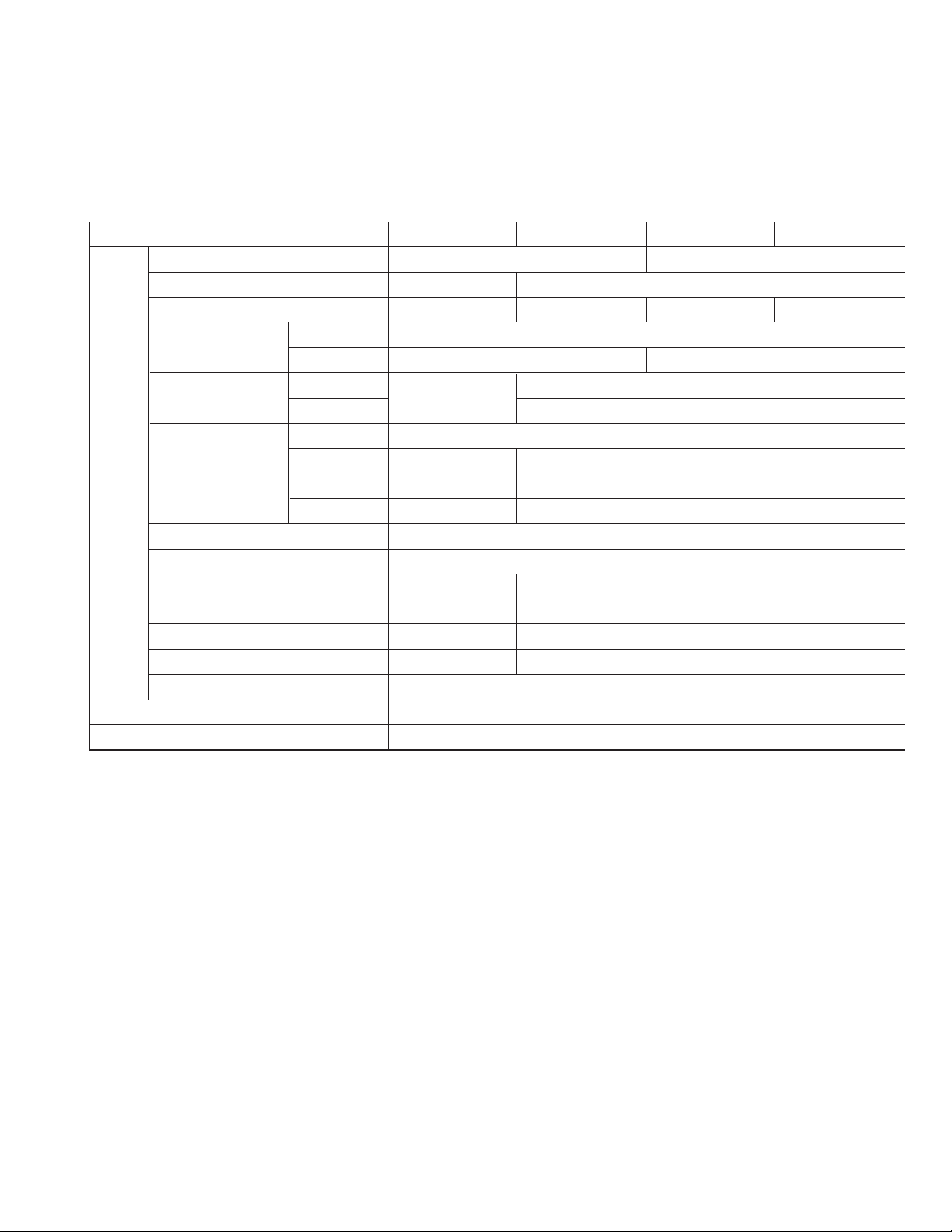

Table 8-1-1 outlines comparisons between DV and other digital VCR formats.

D9 (Digital S) DVC Pro DV CAM DV

Material MP ME

Tape

Sampling frequency

(MHz)

Sampling rate

Width (inch) 1/2 1/4

Track pitch (µm) 20

Y 13.5

R-Y/B-Y 6.75 3.375

NTSC

PAL

4 : 2 : 2

18 15 10

4 : 1 : 1

4 : 2 : 0 (Line Sequential)

Video

Audio

Error correction code

Modulation method

As shown in the above table, the major specifications of the DV

are almost identical to the D9 (Digital S).

Differences lie only in the tape used, sampling rate and number

of executed pixels.

Samples per line

TV lines per frame

Quantization bits

Compression method

Compression

Sampling frequency (kHz)

Quantization bits

Channels

Compression

Y 720

R-Y/B-Y 360 180 : NTSC,360 : PAL

NTSC

PAL

Table 8-1-1 Comparison of Digital VCR Formats

482

578

1/3.3

48

16

4

480

576 : Y , 288 : R-Y/B-Y

8

In-frame DCT

1/5

48(32)

16(12)

2(4)

Non compressed

Reed-Solomon integration code

SI-NRZI , 24/25

(A) Video signal

High video quality thanks to the 4:1:1 (*4:2:0) component digital recording.

(Note) Descriptions marked * in the text and figures are PAL

data.

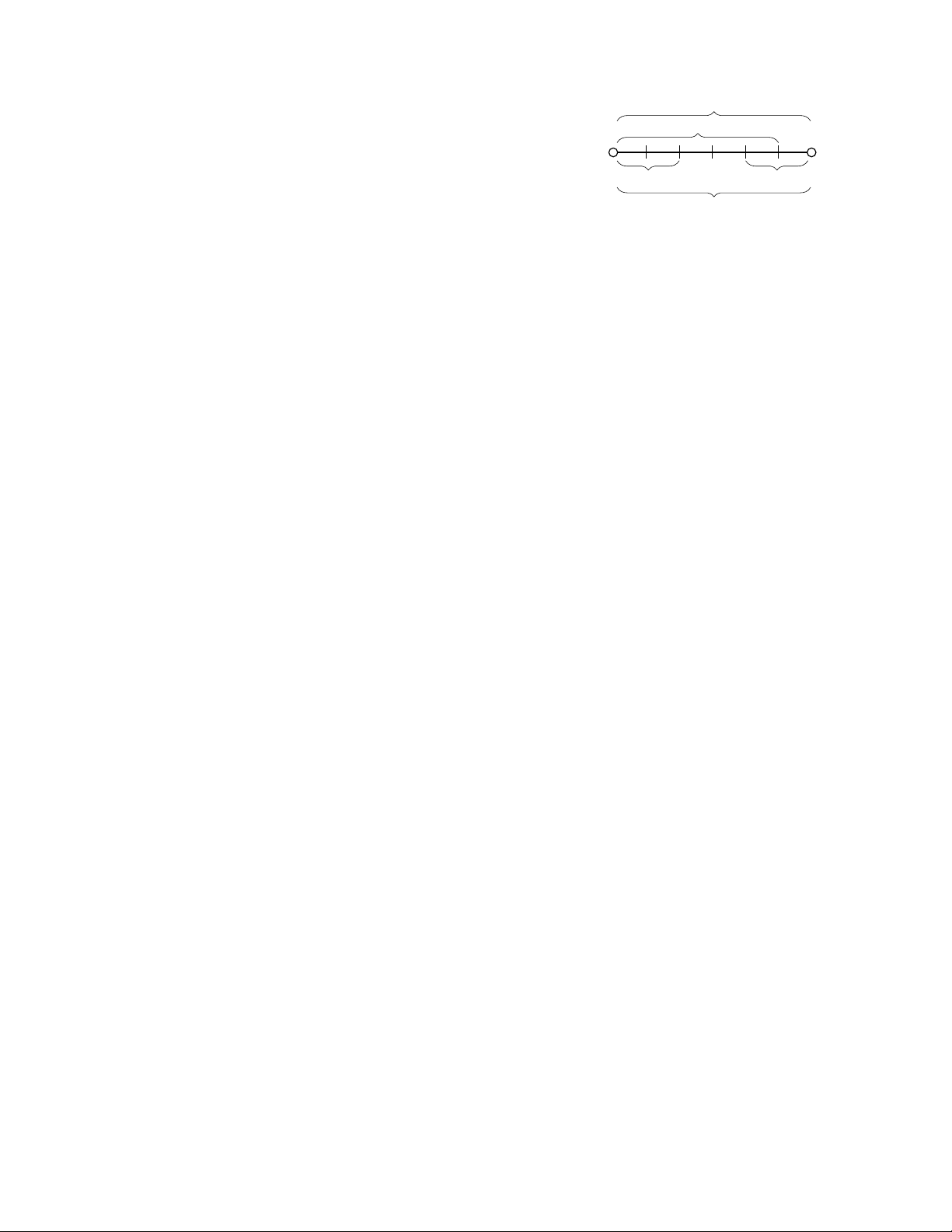

• Luminance signal

The Y signal is sampled at 13.5 MHz so the Y signal bandwidth

is about half the sampling frequency, or 6.75 MHz. This provides better resolution than S-VHS and current TV broadcasting

(Y bandwidth of about 4.5 MHz).

8-1

Page 2

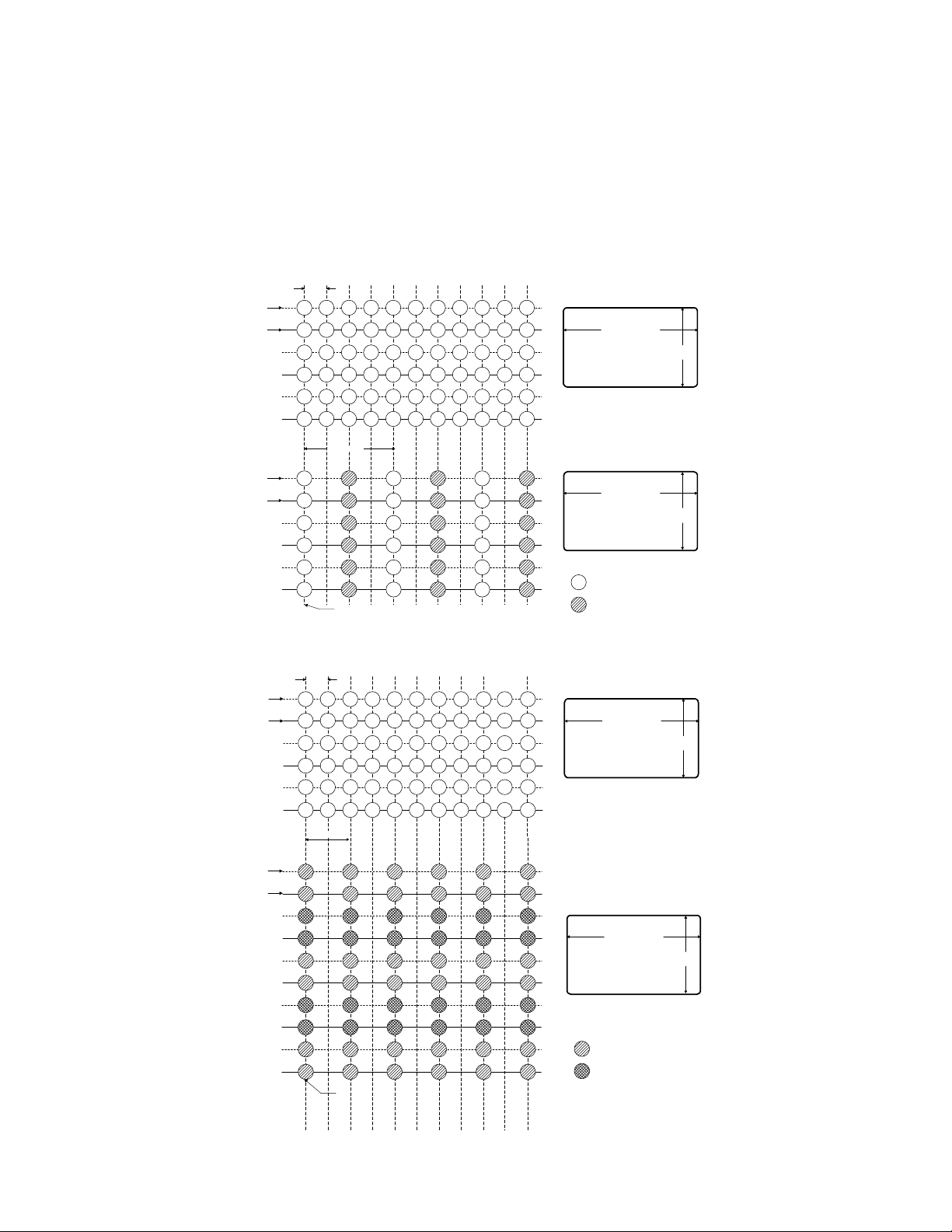

• Chrominance signal

By recording the chrominance signal in a form divided into color

difference signals R-Y and B-Y (component recording method),

recording with excellent color reproduction and little color blur

is achieved.

MHz

Y Signal

First effective line

in each field

Colour difference

Signal (CR, CB)

First effective line

in each field

1/13.5

MHz

1/3.375

First pixel in the effective period

With VHS, the chrominance signal has been converted into a

lower-frequency signal so that its bandwidth has been limited

to 0.5 MHz. The DV has expanded the bandwidth by about 3

times to 1.68 MHz (3.375MHz/2) and records the chrominance

components quite separately from the Y component. The sampling frequency of the R-Y and B-Y signals are 3.375 MHz (*6.75

MHz), which is 1/4 (*1/2) of the Y signal sampling frequency of

13.5 MHz. Based on this ratio, this recording method is referred

to as 4:1:1 (*4:2:0 line sequential) digital component recording.

Line

285

Line

23

Line

286

Line

24

Line

287

Line

25

Line

285

Line

23

Line

286

Line

24

Line

287

Line

25

720 Samples

180 Samples

4:1:1 Sampling

: Effective sample

: Interlaced sample

480 Samples

480 Samples

X2

Y Signal

First effective line

in each field

Colour difference

Signal (CR, CB)

First effective line

in each field

Fig. 8-1-1 4:1:1 Component Digital Recording

MHz

1/13.5

Line

335

Line

23

Line

336

Line

24

Line

337

Line

25

MHz

1/6.75

Line

335

Line

23

Line

336

Line

24

Line

337

Line

25

Line

338

Line

26

Line

339

Line

27

First pixel in the effective period

720 Samples

360 Samples

4:2:0 Sampling

: CR

: CB

576 Samples

288 Samples

X2

8-2

Fig. 8-1-2 *4:2:0 Component Digital Recording

Page 3

(B) Audio signal

The DV format also records the audio digitally. Two recording

formats (48 kHz, 32 kHz) are provided to allow selection according to the purpose. Compatibility with 44.1 kHz sampling is also

provided for use in the reproduction of software tapes.

• 48 kHz, 16-bit high quality stereo mode

This recording mode provides high audio quality equivalent to

the DAT.

Although compression technology is used in video recording,

the audio recording does not use compression.

• 32 kHz, 12-bit mode with a stereo dubbing capability

This mode divides the audio area into two parts and records 12bit stereo audio channels to both of them, or a total of 4 channels. This makes it possible to record 2 audio channels at the

same time as performing video recording and to dub 2 additional audio channels while leaving the original audio channels.

(C) Other features

• Video signal output

The digital signal read out from a tape during playback is fed to

the image memory to arrange the time axis before being output

as the video signal. This makes it possible to reduce wow &

flutter, which may be caused by head rotation irregularities or

tape transport variations.

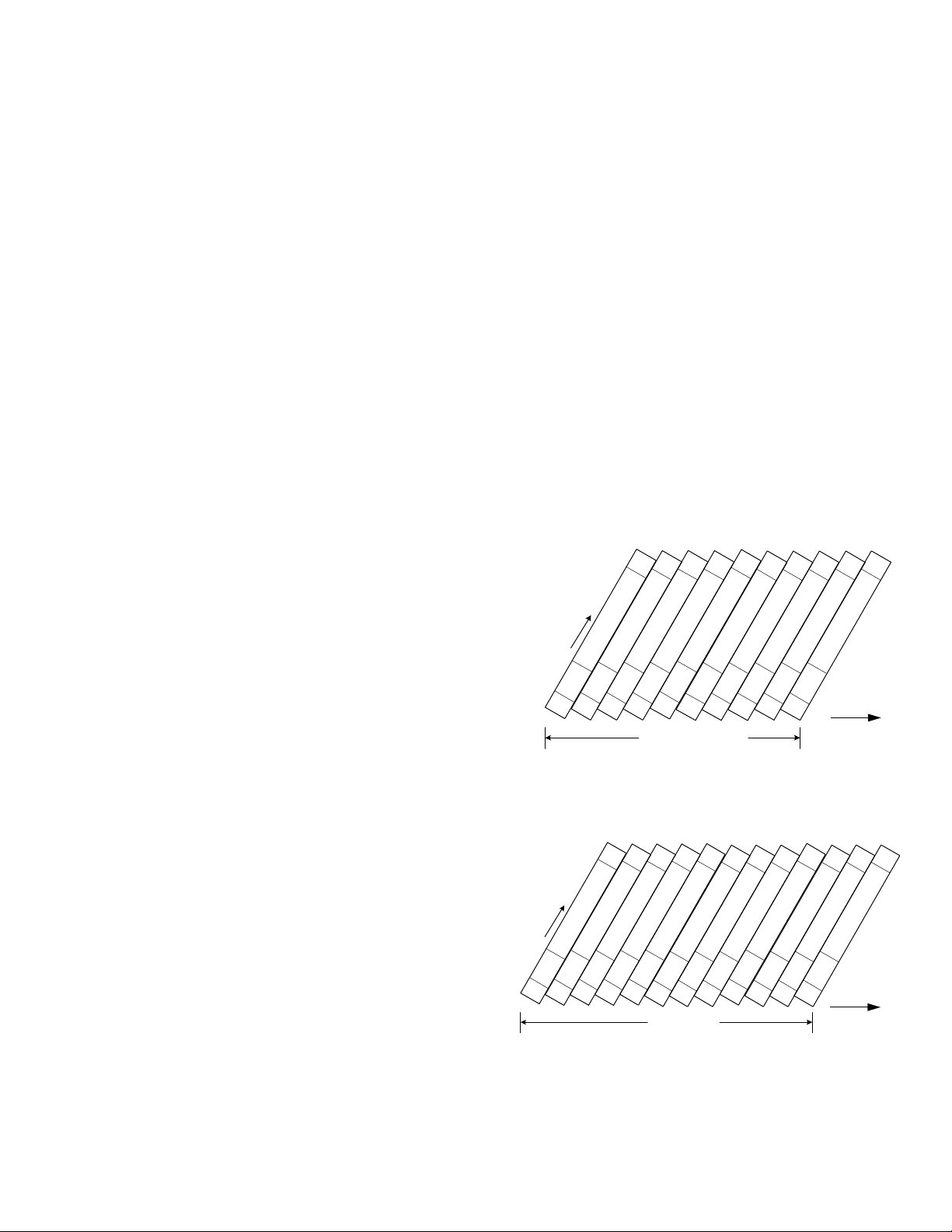

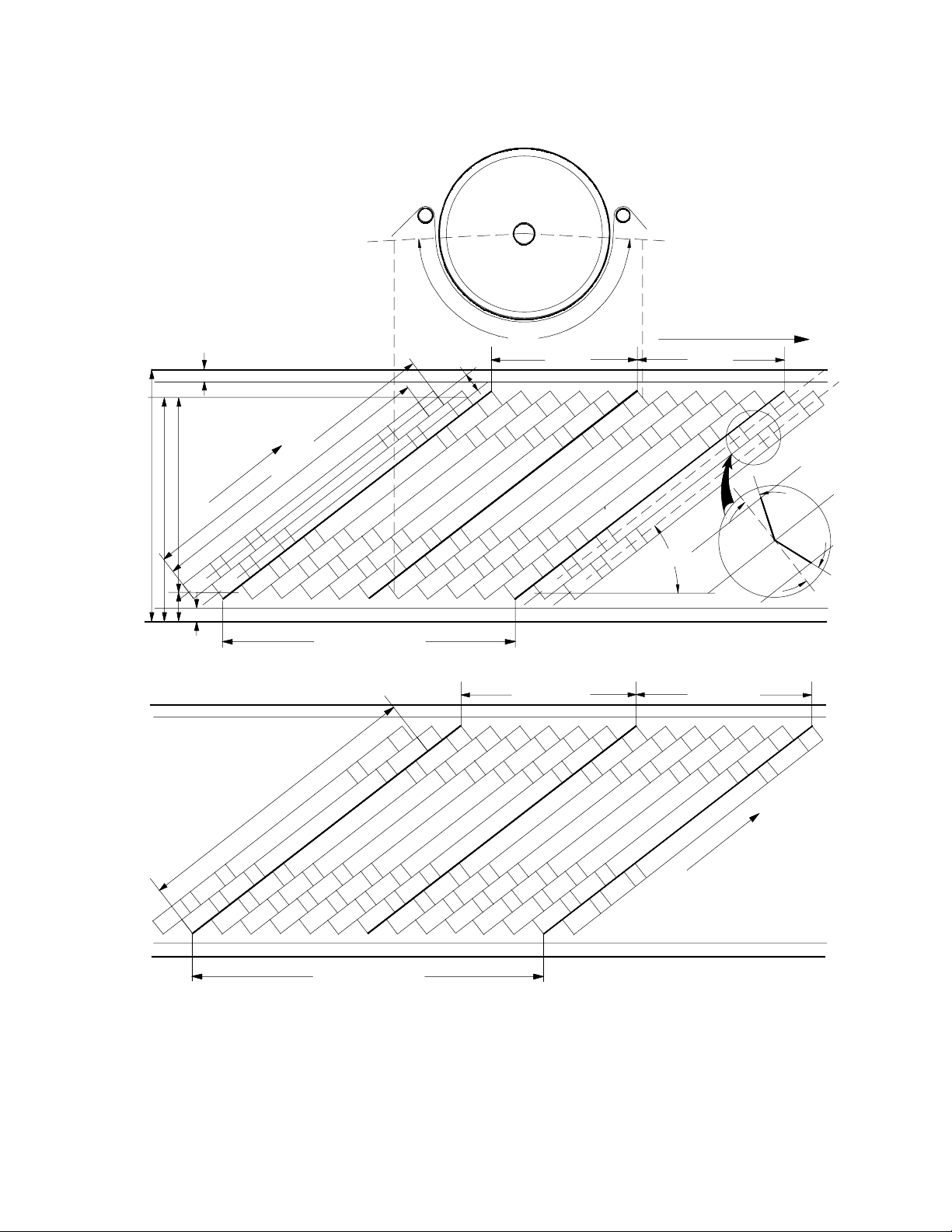

8.1.2 Tape Format of DV

Note) Descriptions marked * in the text and figures are PAL

data.

The DV records the video and audio signals independently, in

the video area and in the audio area respectively. With the video

signal, the data of each frame is divided into 10 tracks (*12 tracks)

before being recorded. Namely, the data of a frame is input to a

memory, divided into 10 (*12), and recorded into 10 tracks (*12

tracks) using a 2-channel head by rotating the drum by 5 turns

(*6 turns) in the period of one frame (33.3 ms/*40 ms) of a

normal NTSC (*PAL) signal. The sub-code area records data including the timecode, recording date, index and absolute track

number, and the ITI area records the reference signal of the

absolute height of track (SSA) ad tracking signals. The DV does

not use the tracking control track. The tracking system of the

DV is called the 3-frequency (F0, F1, F2) digital pilot system,

which records digital pilot signals F0 (0Hz), F1 (465 kHz) or

F2 (697.5 kHz) on every track during recording. When the F0

track is reproduced, the DV controls the tracking servo so that

the crosstalk levels of the pilot signals (F1, F2) in the tracks on

the left and right of the F0 track become identical. The pilot

signals are recorded over all the tracks.

Sub

• Timecode enabling editing

The DV tape has a sub-code area for recording signals for use in

editing. Timecodes are automatically recorded frame by frame

in this area so that the video can later be edited on a per-frame

basis. The sub-code area also includes the recording of index ID

signals, which can be used in search and other operations later.

• AUX data recording information on recording and shooting

The video signal recording area on the tape records the signal

called the AUX data together with the video signal. The AUX

data contains information on the recording date and shooting

conditions such as wide-screen shooting, and is recorded automatically during recording. Parts of the AUX data information

can be displayed on the screen as required. The AUX data on

the record mode, etc. is also recorded in the audio area in a

similar way to the video area.

• Digital interface for digital inputs/outputs (optional)

All track data can be input or output directly without altering the

digital format (IEEE1394 compliant).

DV terminals are provided to enable dubbing and editing using

digital signals.

Video

Head writing

Audio

ITI

F0 F0 F0 F0 F0F1 F2 F1 F1F2

10 tracks/frame

Fig. 8-1-3 NTSC Format DV Tape

Sub

Video

Head writing

Audio

ITI

F0 F0 F0 F0 F0F1 F2 F1 F1F2 F0 F2

12 tracks/frame

Tape travel

Tape travel

Fig. 8-1-4 PAL Format DV Tape

8-3

Page 4

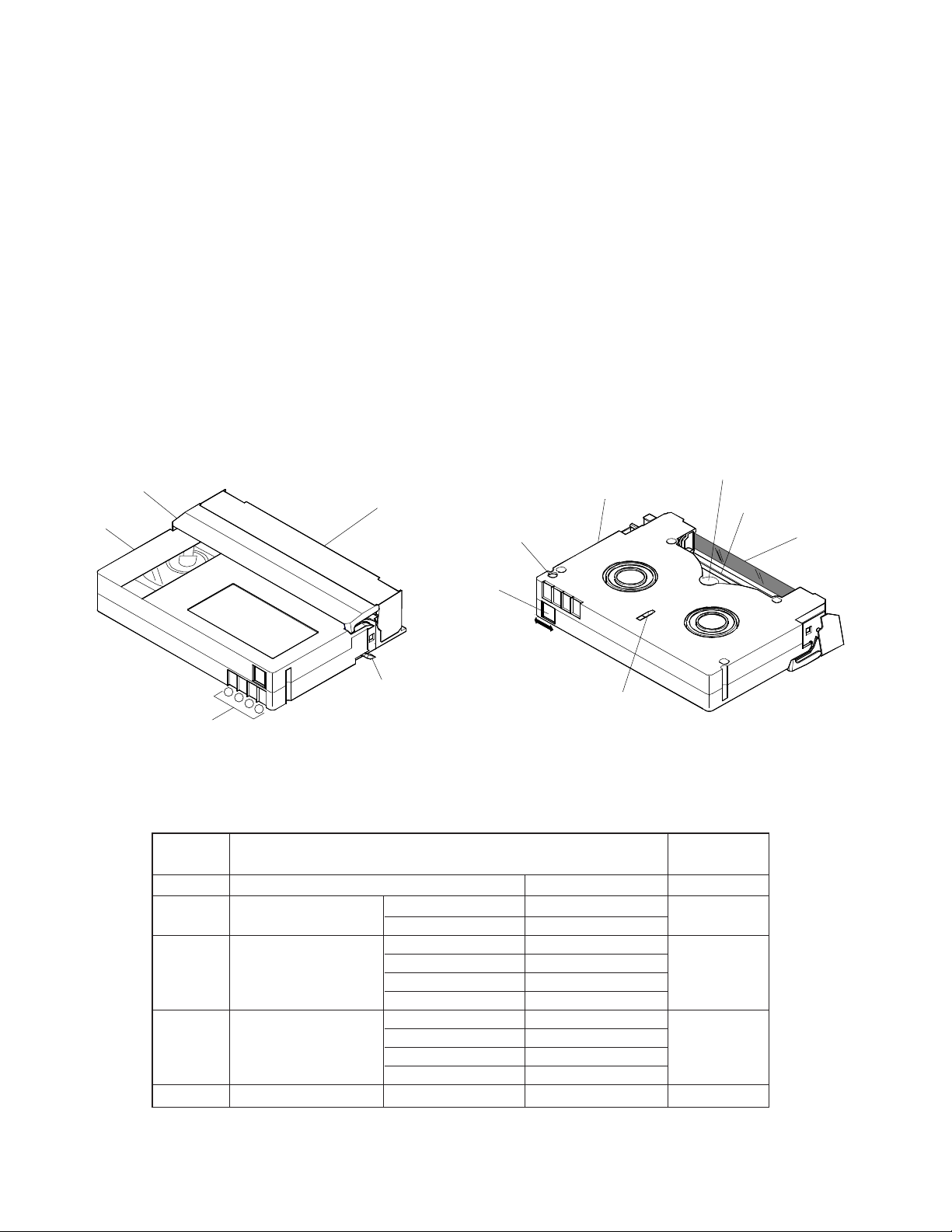

(A) Mini-DV cassette tape

The DV cassette uses metallic magnetic particles so that stable, high-power signals can be obtained from even very thin

tracks. Metal tapes include the metal particle coated (MP) tapes

and metal evaporated (ME) tapes. The Metal tape used with the

DV is the ME tape which features a thin magnetic layer and low

demagnetization.

• ID board and memory-in cassette (MIC)

The DV cassette has 4-contact terminals on the back label side

edge of the shell. These terminals are called the “ID board terminals”, and the values of resistance across the terminals express basic cassette ID (BCID) information such as the tape thickness, tape type and applications. The DV cassette can optionally incorporate a memory for storing the BCID as well as the

content information. In this case, these 4 terminals are used as

the serial communication terminals for the storage and readout

of cassette memory contents.

As described above, the ID board terminals are used in two

ways and the cassettes are available as those with or without

internal memory according to the usage. The GY-DV500 and

BR-DV600 are not avairable with this optional function, so information such as the content information cannot be written or

read even when a cassette with internal memory is used with

them.

All these models do through these terminals is read the BCID of

every cassette.

Upper shell

Top lid

ID board terminal

Terminal

No

1

2

3

4

1

2

3

4

thickness

Tape type

Tape grade

Front lid

Accidental erasure

protection hole

Accidental erasure

protection tab

Open

REC possible : Close

REC impossible: Open

Lid lock

Fig. 8-1-5 External View of Mini-DV Cassette

Contents

Tape

7µm

Reserved

ME

Reserved

For cleaning

MP

For consumer

For professional

Reserved

For PC

–

LED hole

Lower shell

Close

Reel lock

MICID Board

Resistor value Function

Open

1.80kΩ ± 0.09k

VDD

Open

6.80kΩ ± 0.34k

1.80kΩ ± 0.09k

SDA

S/C

Open

6.80kΩ ± 0.34k

1.80kΩ ± 0.09k

SCK

S/C

–

GNDGND

Bottom lid

Tape

8-4

Table 8-1-2 ID Board Terminal Standard

Page 5

(B) Main Standard of DV Tape Format (SD)

θr

Tape travel (Ts)

A ch 1

(ch 1, 2)

Sub

Code

G3

A ch 1

(ch 1, 2)

MRG

α1

α2

174°

A ch 2

(ch 3, 4)

Video

0

F0

Opt. track 2

Video

G1

ITI

9

F2

(PF1)

A ch 2

(ch 3, 4)

G3

Audio

8

F0

Sub

G2

Code

MRG

MRG

Sub

Code

G3

Video

H2

Head motion

Lr (θe)

Wt

H0

(We)

1

0

F2

F0

He

H1

(PF1)

Effective data area (NTSC: 134975 bit)

G2

Audio

G1

ITI

8

9

F0

F1

6

7

F0

F2

1 Frm (Pilot Frm 0)

525/60

ITI

5

F1

Opt. track 1

G1

Video

4

F0

Audio

ITI

Tp

MRG

Sub

Code

G3

G2

G2

Audio

G1

2

3

F2

1

F0

F1

Opt. track 2

MRG

Sub

Code

G3

MRG

Sub

Code

G3

MRG

Sub

Code

G3

MRG

Sub

Code

G3

1

F1

(PF0)

Effective data area (PAL: 134850 bit)

Audio

G1

ITI

0

11

F0

10

F2

F0

Video

G2

9

8

F1

F0

ITI

6

7

F0

F2

G2

G2

Audio

Audio

G1

G1

ITI

3

4

5

F0

F1

2

F2

F0

Video

1

F1

Video

0

F0

G2

Audio

G1

ITI

11

F2

Video

Opt. track 1

1 Frm (Pilot Frm 0)

625/50

(PF0)

Fig. 8-1-6 Main Standard of DV Tape Format (SD) (Track Pattern)

Head motion

8-5

Page 6

8.2

MAJOR SIGNAL PROCESSING OPERATIONS OF DV

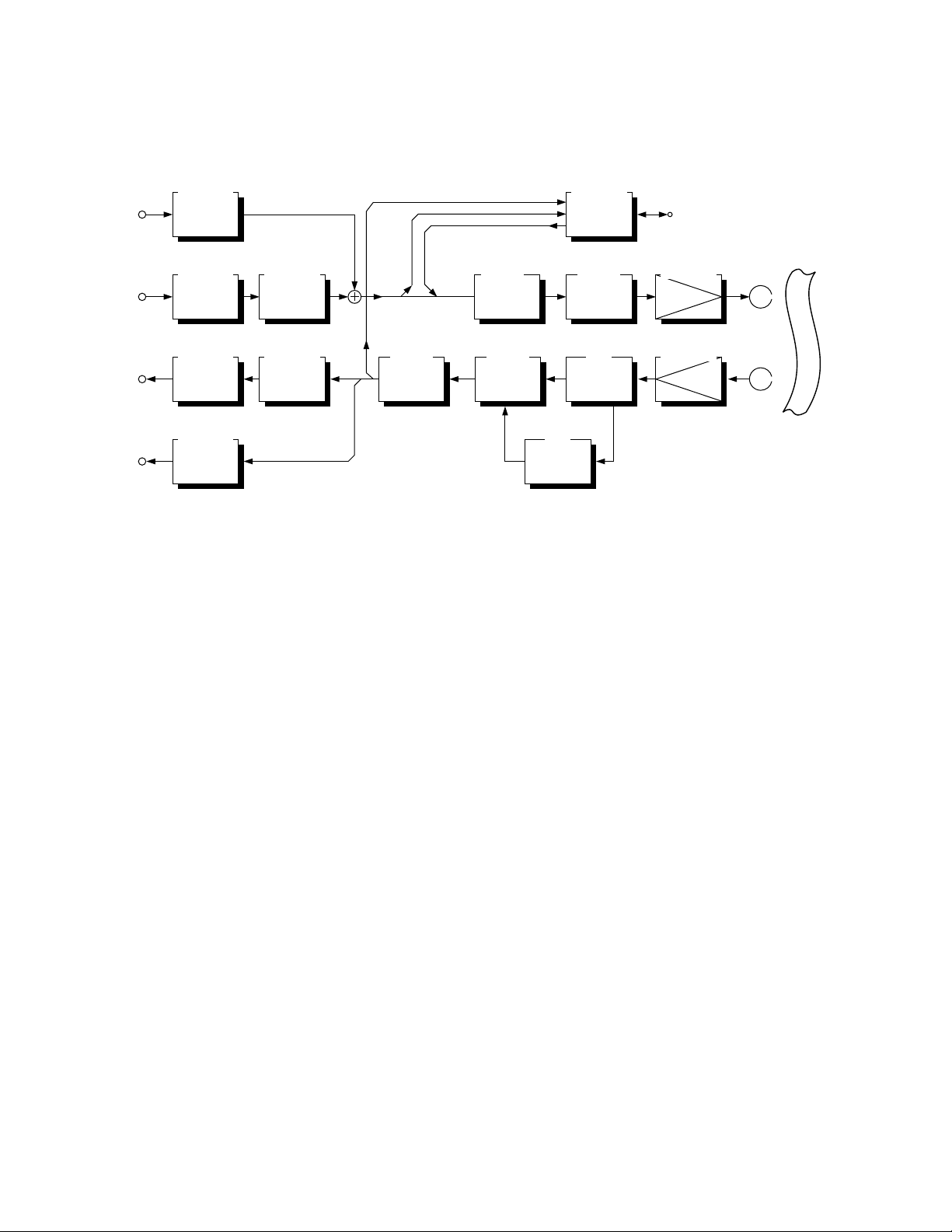

Fig. 8-2-1 shows the basic configuration of the major signal

processing circuitry of the DV in the form of a block diagram.

SHUFFLE

SHUFFLINGAUDIO

VIDEO

VIDEO

AUDIO

SHUFFLE

MACRO BLOCK

SHUFFLING

DESHUF.

DESHUFFLING

DESHUF.

DESHUFFLING

CODING

DCT

VLC

DECODING

I-DCT

VLD

ECC

INNER

OUTER

SHUFFLING

Fig. 8-2-1 Basic Configuration of Major Signal Processing Circuitry of DV

8.2.1 Flow of Video and Audio Signals in Recording Circuitry

The video and audio signal inputs/outputs shown in Fig. 8-2-1

are sampled digital signals.

The input digital video signal is shuffled block by block, so that

deviations in the compression rate of the picture can be prevented. This is achieved by gathering data from various positions in the picture and compressing it. When the video signal is

supplied to the ECC block for error correction later, de-shuffling

is applied to return the data to the original positions in the video

signal. The shuffled video signal is coded. The coding consists

of replacing the image signal in the conversion block composed

of multiple pixels with signals without correlation by means of

discrete cosine transform (DCT).

The DCT operation consists of dividing the picture into blocks

(each composed of 8 x 8 pixels) and obtaining the transform

coefficient, which indicates the amount of components of the

previously determined basic image pattern (64 pixels) in each

block.

The VLC (Variable Length Coding) quantizes the DCT transformed

signal and applies entropy coding to the quantized signal. The

coding technique used here performs Run Length coding first,

then applies Huffman coding.

The audio input signal is also shuffled block by block in the same

way as with the video signal, but the audio signal is not compressed.

The video and audio signals are input to the ECC block, where

error-correcting codes are appended to them. The error-correcting codes use product codes obtained by double coding of the

Reed-Solomon integration codes.

The DCI-R (Digital Channel Interface for Recording) block performs channel coding of the recorded signals. It performs what

IEEE1394

I/F DV TERMINAL

TG

SERVO

DCI-R

SI-NRZI

24/25

Phase &

Amplitude

Compensator

ECC

OUTER

INNER

DESHUFFLING

DCI-P EQ

3 TO 2

1+D

VITERBI

TRACKING

Note : PAL model is not available the signal output.

See note:

REC.AMP. HEAD

PRE-AMP.

HEAD

TAPE

is usually called modulation by transforming a series of digital

data composed of “1” and “0” to match the properties of magnetic recording systems.

8.2.2 Flow of Video and Audio Signals in Playback Circuitry

When a digital VCR plays a recorded signal, the frequency response of the low-frequency and high-frequency components

is degraded. The degradation in the frequency response of the

low-frequency components is because the played signal becomes a differential waveform and a rotary transformer is used.

That in the frequency response of the high-frequency components is caused by the performance of the recording tape itself

and by the gap between the tape and head during recording/

playback.

When a tape in which 1-bit pulses are recorded is played while

the frequency response is degraded, the pulse duration is expanded and intersymbol interference results. The equalizer is

used to suppress the intersymbol interference and reduce code

errors.

The DCI-P (Digital Channel Interface for Playback) block demodulates the signal, which has been coded for recording and turns it

into a signal that can be subjected to error correction.

The ECC (Error Correcting Codes) block corrects errors while

performing shuffling. The audio signal is then de-shuffled and

output. The video signal is sent to the decoding block where

the signal compressed by coding is expanded by means of decoding, and returns to a digital signal. The digital video signal is

then de-shuffled before being output.

8-6

Page 7

8.3 VIDEO/AUDIO SIGNAL PROCESSING IN

RECORDING CIRCUITRY

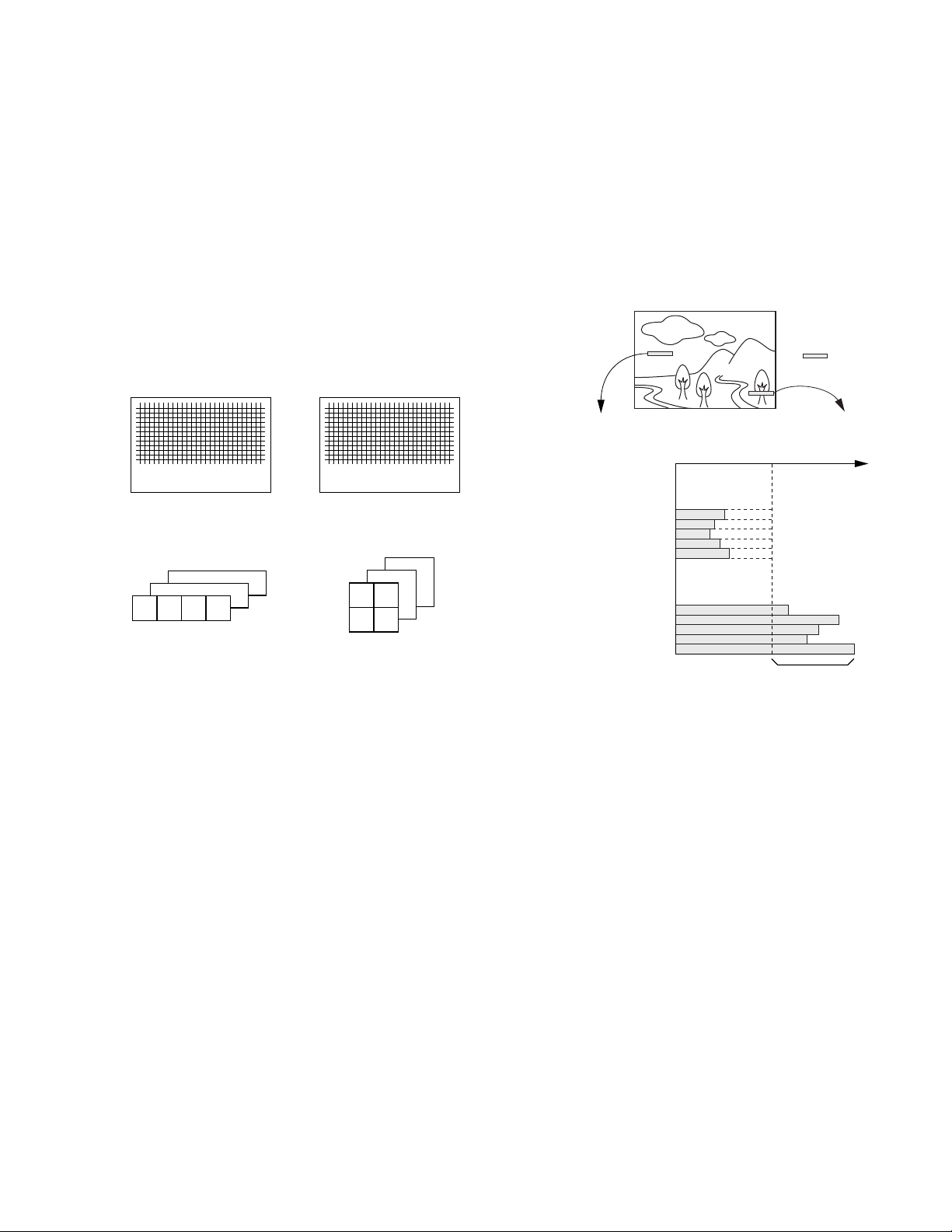

8.3.1 Division into Blocks

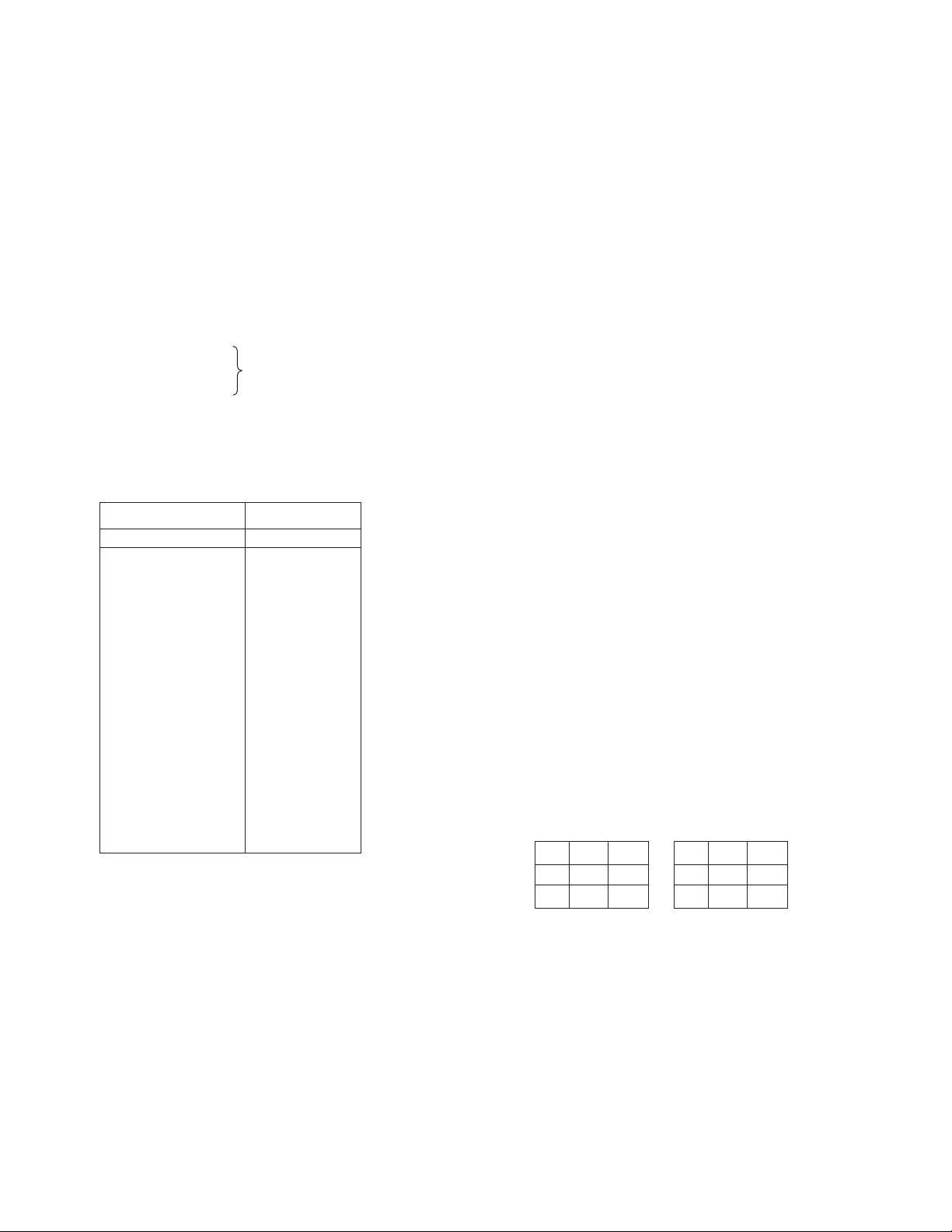

As shown in Fig. 8-3-1, data of each frame is divided into

macroblocks (MBs) (8 x 8 pixels) which are the basis of the DCT

circuitry. Since the luminance signal and two color difference

signals are sampled with different frequencies, 4-luminance signal blocks and each of the color difference signal blocks occupy

the same position and area in the picture. When data of any one

of the 4-luminance signal blocks is lost, the data in other blocks

becomes meaningless. Therefore, the signals of every 6 blocks

are processed as a single processing unit and recorded onto

tape.

(a) With a 525/60 system:

90 (22.5) blocks

(b) With a 625/50 system:

90 (45) blocks

8.3.2 Shuffling (Video)

The 5 macroblocks composing a single video segment is collected from a picture by means of shuffling according to a specified rule.

The objective of shuffling lies in making uniform the quantity of

information that is contained in the 5 macroblocks in a video

segment. The image information of a frame is not usually distributed evenly in the picture, but there are segments with a

large amount of information and those with a small amount of

information as shown in Fig. 8-3-2.

5MB

60 (60)

blocks

Figures inside ( ) are the number of color difference (CR, CB) blocks.

Macroblock

CB

CR

Y

8

8

8 8 8

8

8

Six blocks occupying the same position and

area in the picture form a macroblock.

8

72 (36)

blocks

8

Macroblock

CB

8

R

8

C

Y

8

8

8 8

8

8

Fig. 8-3-1 Division into Blocks, Macroblock

The macroblock is a group composed of the 6 blocks.

The data divided into blocks is processed by the DCT coding as

described later, and the video-recording rate is compressed to

25 Mbps. In fact, however, the data of each frame is compressed

to the specified number of bits, which are recorded onto the

specified number of tracks on tape. Namely, when 25 Mbps is

converted into the number of bits per frame, the following

number of bits are recorded onto 10 (NTSC) or 12 (PAL) tracks:

(25 x 10

(25 x 10

6

)/30 = 833333 bits ............ (NTSC)

6

)/25 = 1000000 bits .......... (PAL)

As seen above, the data in each frame is compressed so as not

to exceed the specified number of bits calculated based on the

video-recording rate. This is referred to as length fixation. Although the length of the data of a frame is fixed so as not to

exceed the calculated number of bits, the actual length fixation

is applied per 5 macroblocks. In other words, the length of the

data of 5 macroblocks is fixed so as not to exceed the following

number of bits:

833333 x 5/1350 = 3086 bits ......... (NTSC)

1000000 x 5/1620 = 3086 bits ....... (PAL)

The 5 macroblocks used as the unit of length fixation is referred

to as a video segment.

Video segment A

(Flat, sky section)

Video segment A

(Few information)

Video segment B

(Much information)

MB1

MB2

MB3

MB4

MB5

MB1

MB2

MB3

MB4

MB5

Length fixation information

Video segment B

(Fine branch section)

Coarse quantization for

reducing the amount of

information

Fig. 8-3-2 Distribution of Information in a Picture

As a result, if the fixed-length data obtained from 5 sequential

macroblocks uses the same number of bits for each macroblock,

distortion due to compression or expansion of data would be

noticeable. This would depend on the screen segments (distortion is less noticeable in the segments with little information

but noticeable in segments with much information). To prevent

this by making the information uniform across the video segments and making distortion less noticeable, shuffling is performed in the picture.

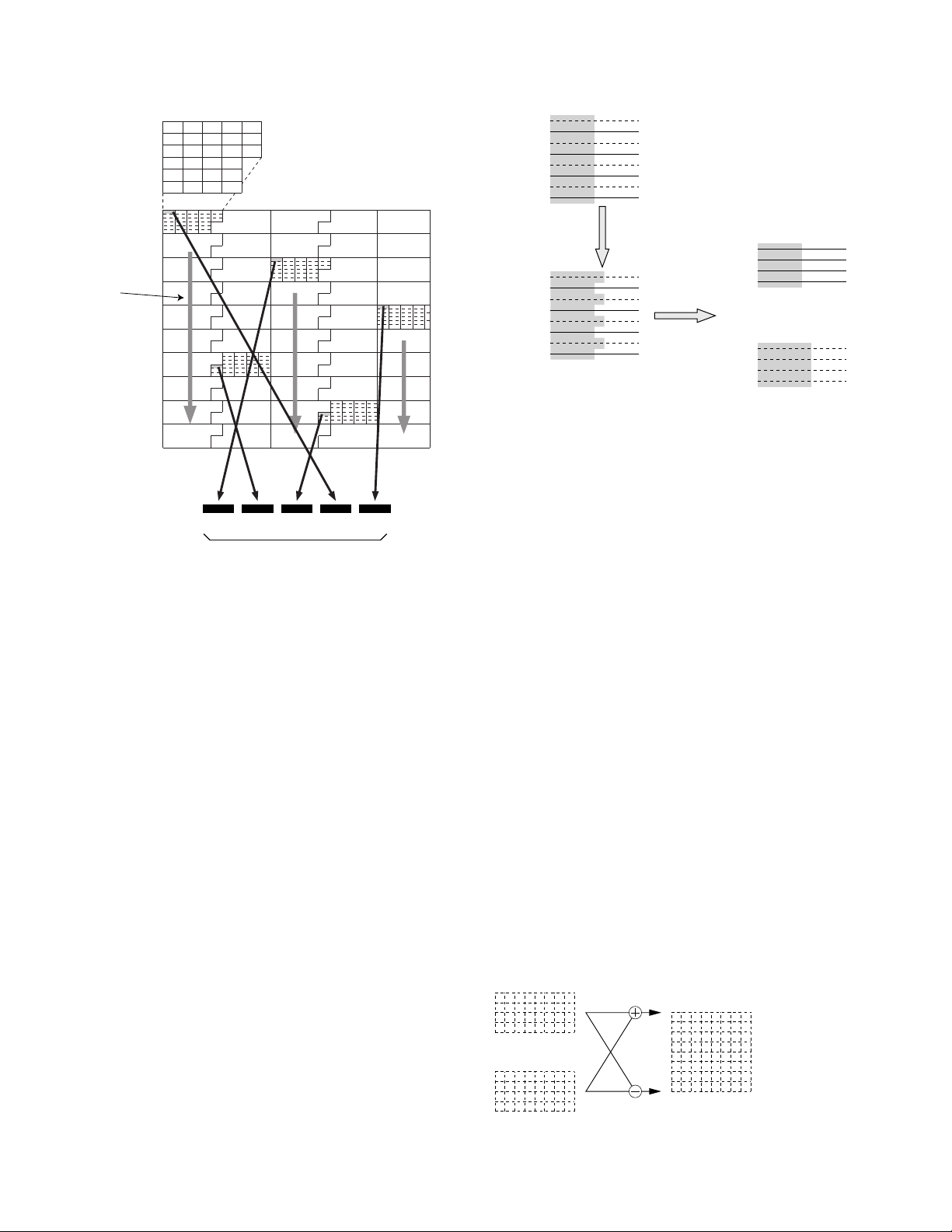

The shuffling is performed based on the rule shown in Fig. 8-3-

3.

Each picture is divided vertically into the same number as the

number of macroblocks in a video segment (5), and divided horizontally into the same number as the number of tracks used to

record the data of 1 frame onto tape (NTSC: 10, PAL: 12).

The blocks divided in this way are referred to as superblocks.

8-7

Page 8

Sequence of MBs in a superblock

No.

0

11

12

23

1

10

2

9

3

8

4

7

5

6

24

13

22

25

14

21

26

15

20

16

19

17

18

8 pixels

2nd Field

1st Field

8 lines

Sequence of

superblocks

Order of shuffling

12 34 5

MB1 MB2 MB3 MB4 MB5

Set at a fixed length of 5 MBs.

Fig. 8-3-3 Shuffling Technique (Example with 525/60)

With shuffling, the first macroblock (No. 0) in each of the 5

superblocks are collected to form a video segment as shown in

Fig. 8-3-3, and the next video segment is formed by collecting

the first macroblocks (No. 1) of the same 5 superblocks. When

all of the macroblocks in the 5 superblocks have been collected,

data collection of the next 5 superblocks starts.

8.3.3 DCT

The video segments formed by shuffling are DCT transformed

per (8 x 8) blocks. There are two DCT transform modes including the stationary mode and the dynamic mode.

(1) Stationary mode (8 x 8 DCT mode)

This is the basic mode, executing (8 x 8) DCT transform to

every (8 x 8) pixels in blocks.

(2) Dynamic mode (2 x 4 x 8 DCT mode)

The (8 x 8) blocks are divided into two (4 x 4) blocks called

fields 1 and 2, and a (4 x 8) DCT transform is applied to every

(4 x 8) pixels.

The following paragraph explains this mode by taking the

case in which an object moves toward the right as an example.

When the object

moves horizontally:

The vertical high-frequency

component increases.

4 lines

(2 x 4 x 8)

4 lines

8 pixels

(1st Field)

8 pixels

(2nd Field)

Fig. 8-3-4 (2 x 4 x 8) DCT Transform in Motion Mode

When the object does not move, the data in the horizontal direction contains the high-frequency component but the data in

the vertical direction contains only the DC current. On the other

hand, when the object moves in the horizontal direction, the

position of the object at the time of 1st field scanning is different from that at the time of 2nd field scanning, so the picture of

the object in a frame appears to have ridged edges. The highfrequency component increases in the vertical direction data as

well as in the horizontal direction data. In such a case, the (8 x 8)

blocks are divided into two pairs of (4 x 8) blocks for fields 1 and

2, and (4 x 8) DCT transform is applied to every (4 x 8) pixels.

This method makes it possible to reduce any increases in the

high-frequency component in the vertical direction data and prevents a drop in the compression rate.

Whether a DCT transform is performed in the stationary mode

or in the dynamic mode is decided by detecting the (8 x 8) blocks

in each video segment by the motion detector circuit located

before the DCT transform circuit.

The data of a block in stationary mode is composed of one DC

component and 63 AC components. But, in dynamic mode each

one of the two (4 x 8) blocks is composed of a DC component

and 31 AC components. To allow the dynamic mode data to be

processed in the same way as the stationary mode data, the

dynamic mode processing calculates the sum and differences

of the factors of the same order and form (8x 8) blocks as shown

in Fig. 8-3-5.

(2 x 4 x 8) DCT factors

8

4

(1st field)

8

4

8

(Sum of factors)

8

(Difference of factors)

8-8

(2nd field)

Fig. 8-3-5 Processing of DCT Transform Factors in Dynamic Mode

Page 9

The above processing allows both the dynamic mode data and

0

0

1

2

4

7

6

5

3

0

0

1

1

2

2

2

1

0

1

1

2

3

2

2

1

1

1

1

2

3

3

2

2

1

1

2

2

3

3

3

2

1

2

2

3

3

3

3

2

2

2

2

3

3

3

3

3

2

2

3

3

3

3

3

3

DC

0

0

1

2

2

1

1

1234567

(8 x 8) DCT

Vertical direction

0

0

1

2

3

0

1

1

2

1

1

2

2

1

2

2

2

1

2

2

3

2

2

3

3

2

3

3

3

3

3

3

3

DC

0

1

1

1234567

(2 x 4 x 8) DCT

Horizontal direction

(Sum)

4

7

6

5

0

2

1

1

1

2

2

1

1

3

2

2

2

3

2

2

2

3

3

2

2

3

3

3

3

3

3

3

0

1

1

0

Vertical direction

(Difference)

Class No. Area No.

0

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

1

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

2

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

3

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

0

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

4

4

4

4

8

8

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

4

4

4

4

8

8

8

8

2

1

1

1

1

1

1

1

1

2

2

2

2

4

4

4

4

8

8

8

8

16

16

3

1

1

1

1

1

1

1

2

2

2

4

4

4

4

8

8

8

8

16

16

16

16

Quantizer No.

Horizontal direction

stationary mode data to be handled as data composed of one

DC component and 63 AC components in the subsequent

quantization processing.

8.3.4 Quantization

(A) Data quantity estimation

After all of the blocks in a video segment have been DCT transformed, the video segment is stored in the buffer. At this time,

the data quantity estimation block selects the quantizer for use

in quantizing the video segment.

With DCT transform, normalization is performed so that the DCT

factors have a 10-bit dynamic range for the 8-bit pixel block. The

DCT factors are divided by an integer called the quantization

step and allocated to a smaller number of bits before being subjected to variable-length coding (VLC). This operation (division)

is referred to as re-quantization, or simply quantization. The

quantization reduces the values of the factors, turning many of

0 in the high frequencies. As the VLC in the subsequent stage

performs code allocation by forming value 0 run lengths and the

non-0 factor after it into a group, so the quantization improves

the coding efficiency. As the VLC consists of simply allocating

codes to factors, the code quantity (number of bits) is controlled by the VLC block.

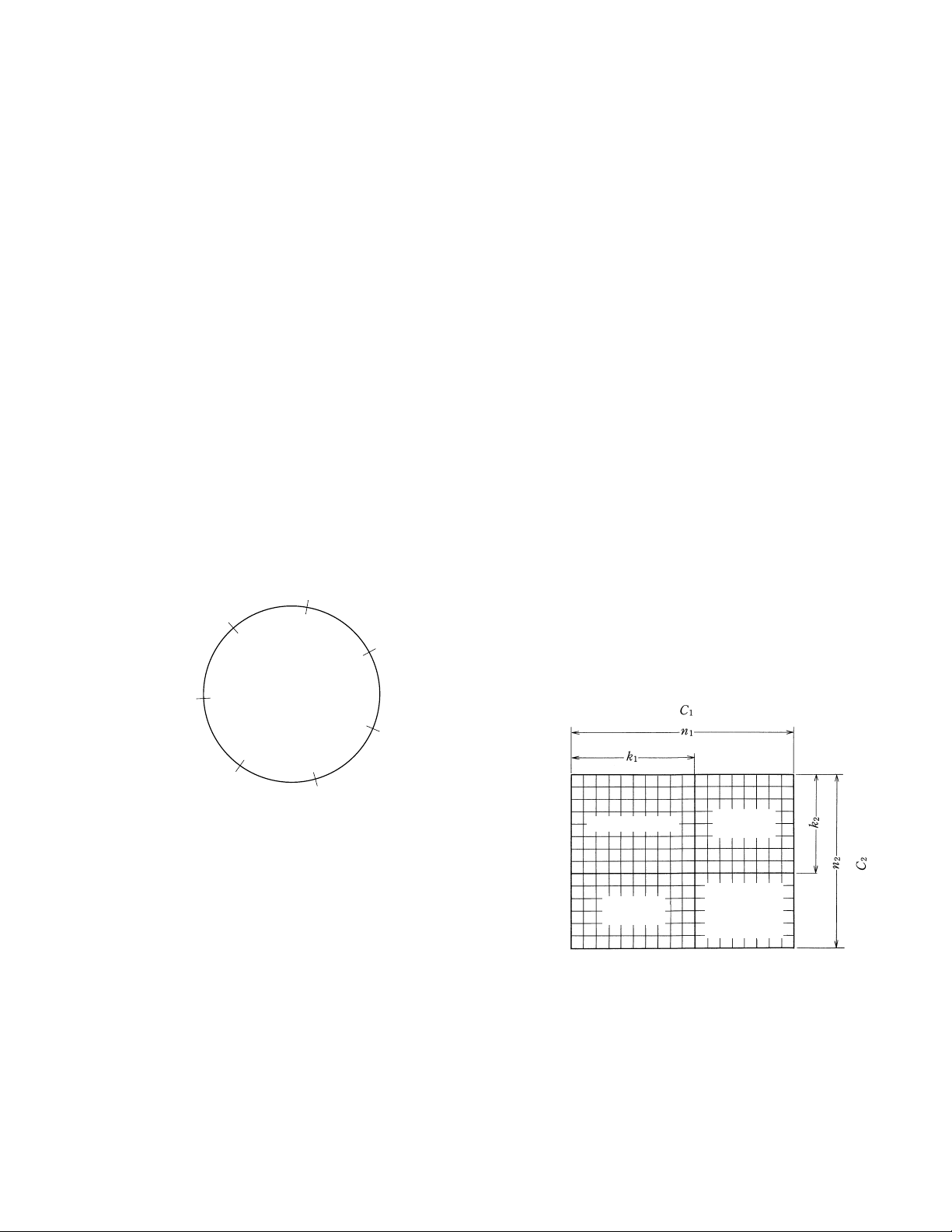

(B) Quantization

Each quantizer is composed of a set of 4 quantization steps as

shown in Fig. 8-3-6, and the factors in a block are divided into 4

areas. The data is quantized in the 4 areas using different

quantization steps. The factors are shifted from low-frequency

factors to high-frequency factors as the area number increases,

so the quantization of high-frequency factors are coarser than

for low-frequency factors. This utilizes the fact that the distortion of high-frequency factors is less noticeable to human vision

even when they are coarsely quantized.

Fig. 8-3-6

(C) Classification

Each block in a video segment is classified into one of 4 classes

before being quantized. The quantization steps of the quantizers

vary depending on the class numbers (see Fig. 8-3-6). Table 8-31 shows the definitions of the 4 classes.

Class No.

0

1

2

3

Block with which quantization distortion after compression is highly noticeable. The absolute value of the AC

factor should not exceed 225.

Block with which quantization distortion after compression is less noticeable than Class 0. The absolute value of

the AC factor should not exceed 225.

Block with which quantization distortion after compression is less noticeable than Class 1. The absolute value of

the AC factor should not exceed 225.

Block with which quantization distortion after compression is little noticeable or the absolute value of the AC

factor exceeds 225.

Definition

Table 8-3-1 Definitions for Classification

8-9

Page 10

The Table 8-3-1 means that a block with a larger class number

has a more approximate degree of definition (activity). The data

in such a block is quantized relatively roughly to compress the

data quantity. Rather approximate quantization of picture areas

with low activity does not cause odd sensations for the human

vision, but approximate quantization of those with high activity

does cause odd sensations. The blocks with low activity in each

segment are quantized as roughly as possible with a reduced

number of allocated bits, unless the odd sensations are not felt.

However, the blocks with high activity are quantized using an

increased number of allocated bits to improve the picture quality experienced by the human vision.

A block containing factors with a larger absolute AC factor than

255 is classified as Class 3, and subjected to an operation called

initial shifting before quantization. This operation divides an AC

factor over 255 by 2 so that errors do not occur in the VLC operation.

Class No.

Initial shifting

Before initial shifting

MSB=1

(ACmax > 255)

After initial shifting

0

Not applied1Not applied2Not applied

9 bits

MSB LSB

1

1-bit shift

01

The value is accommodated within 8 bits.

3

Applied

Fig. 8-3-7 Initial Shifting

While the AC factor before quantization consists of 10 bits, or 9

bits excluding the sign bit, the VLC in the subsequent stage can

codify a non-0 factor value only into an 8-bit code. Initial shifting

is performed to deal with this. As a result, a factor that has a

value in the 9th bit (SMB) (i.e. a factor over 255) can be accommodated in 8 bits and processed by VLC. Fig. 8-3-6 shows that

an increase in the class No. increases the quantization steps in

the same quantizer No. or that quantization of a larger class No.

is more approximate.

Although the quantization steps of Class 2 look less than for

those of Class 3, this is because the Class 3 data has been

subjected to initial shifting before quantization. The actual

quantization steps of Class 3 are more approximate than in those

of Class 2.

8.3.5 VLC

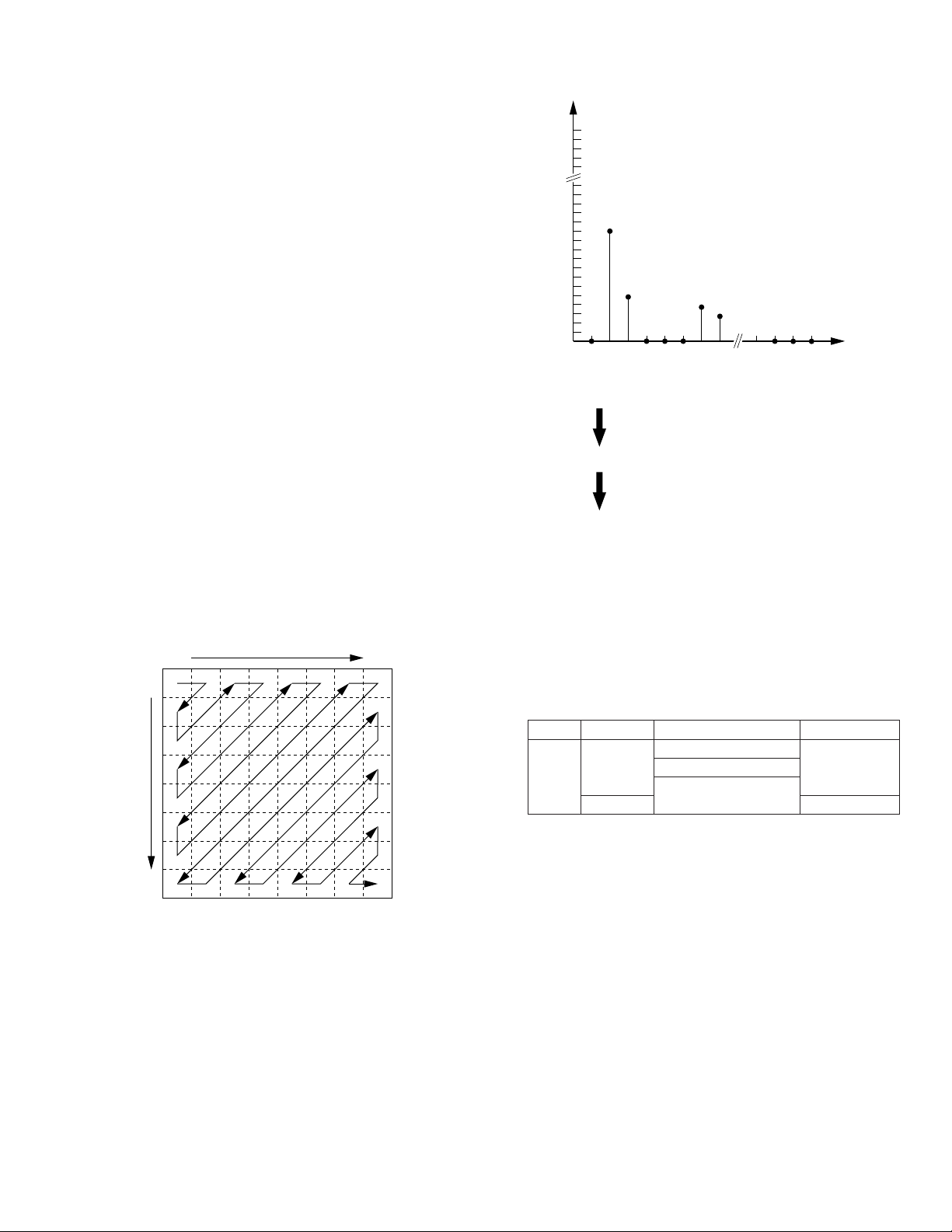

After division into (8 x 8) blocks by DCT transform, the energy

of pixels are concentrated in the DC component and the vertical

and horizontal vertical factors become almost null. To code these

factors, coding uses a technique for varying the code length

according to the incidence of the factors.

This coding technique varying the code length is referred to as

variable length coding (VLC).

(A) Entropy coding

As the VLC achieves efficient coding by allocating short codes

to data with a high DCT factor incidence and long codes to data

with a low incidence, it is sometimes called the entropy coding.

The entropy coding can be expressed with an entropy function.

H = 1 (max.) when Pn = 0.5 (when 0 and 1

both occur at the same probability)

H

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0 0.1

0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

0

P

Fig. 8-3-8 Entropy Function

When VLC approaches the above function, it is regarded as coding with a high compression rate.

(B) Huffman coding

The DV uses Huffman codes to improve the compression efficiency. The Huffman codes determines the minimum average

code length of information with a known incidence probability.

Table 8-3-2 shows the method of construction of Huffman codes.

The symbols in the table should be regarded as the levels of

pixel values.

Symbol Incidence Code Word

1

0.49

2

0.14

3

0.14

4

0.07

5

0.07

6

0.04

7

0.02

8

0.02

9

0.01

Construction Procedure

0

0

1

0

0

1

0

0

0

1

0

1

1

1

1

0

100

101

1

1100

1101

1110

11110

111110

111111

8-10

Table 8-3-2 Construction of Huffman Codes

Page 11

The Huffman coding uses the following procedure.

Mode Channels Sampling Frequency

48 k

44.1 k

32 k

32 k

2

4

48 kHz

44.1 kHz

32 kHz

32 kHz

16-bit linear

12-bit nonlinear

Quantization

(1) Information source symbols 1 to 9 are arranged in the order

of incidence probability.

(2) For the symbol with the lowest incidence and that with the

second-lowest incidence, “0” is allocated to one and “1” is

allocated to the other. (Which of the two symbols is “0” and

which is “1” can be decided arbitrarily.)

(3) Then, the above two symbols are considered to be joined

together as a single symbol. The incidence probability of the

joined symbols should be equal to the sum of the incidence

probabilities of the two symbols before joining.

(4) By considering the joined symbols as new individual sym-

bols, these symbols and other symbols (which should exclude the two symbols which were joined) are rearranged in

the order of incidence probability.

(5) Steps (2) to (4) are repeated until the number of symbols

becomes 1.

(6) The values (0 or 1) allocated to the original symbols in step

(2) are read in the reverse order. The read values form the

code word for the symbols.

255

15

10

5

Factor Value <Absolute Value>

0

1 2 3 4 5 6 61 62 6378

Order of Zigzag Scanning

Factor series = {0, 12, 5, 0, 0, 0, 4, 3,... 0, 0, 0}

Transform into (0 run length + non-0 factor values)

(1, 12), (0, 5), (3, 4), (0, 3)... (EOB)

A Huffman code constructed in this way can be decoded instantaneously because, by following the bits one by one from

the first bit at the time of decoding, the end of a code word can

be determined without referring to the head of the next code

word.

As the VLC used with the DV is based on Huffman coding combined with run length coding, it is called “modified 2-dimensional Huffman coding”.

Horizontal frequency

Vertical frequency

Fig. 8-3-9 Zigzag Scanning of DCT Factors

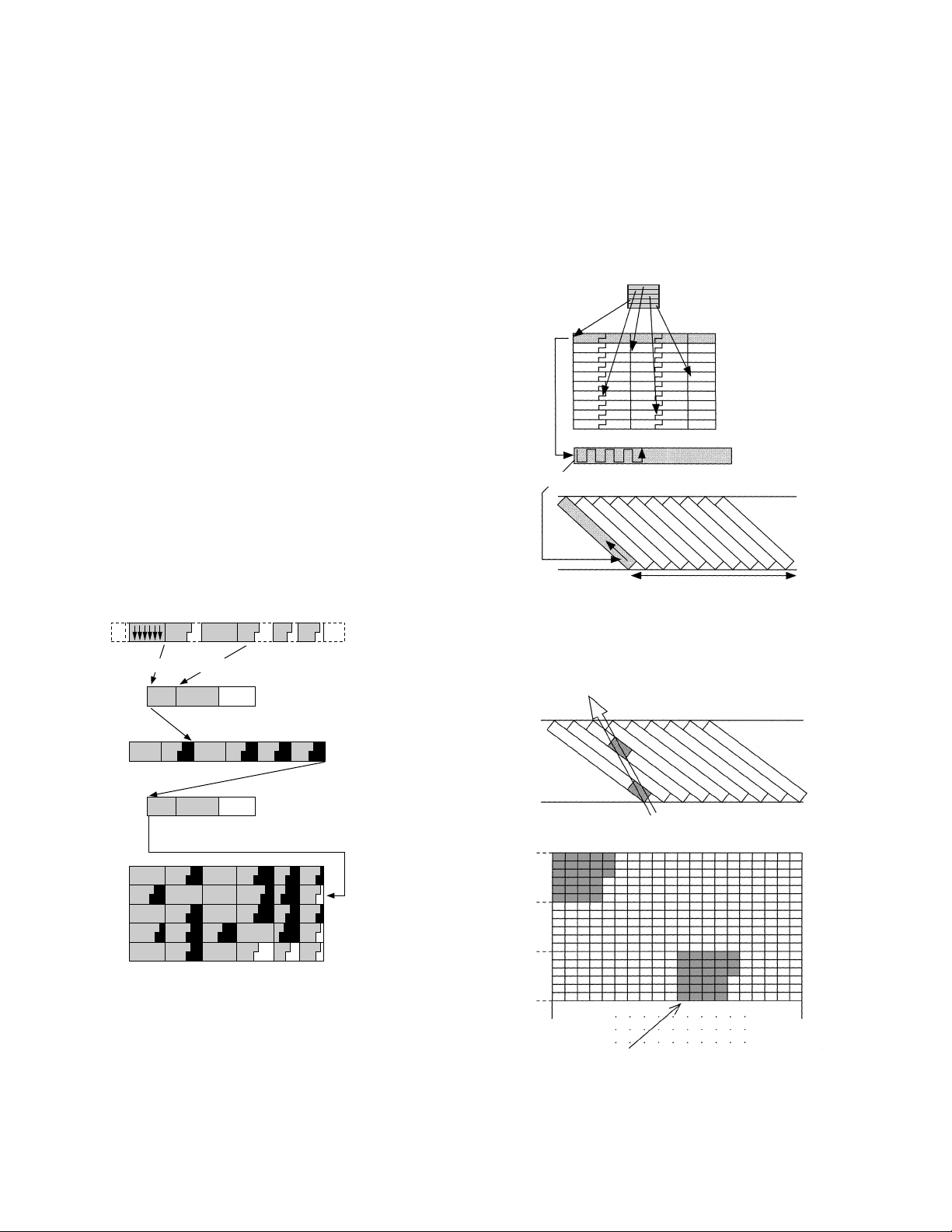

Among the factors transformed by 2D DCT, the 63 AC factors

other than the DC component factor are rearranged by zigzag

scanning as shown in Fig. 8-3-9. When the AC factors are rearranged in the order of scanning, the result is as shown in Fig.

8-3-10, where the scanned factor series is divided into a group

of sequential 0 factors followed by a group of non-0 factors. A

code called the EOB (End Of Block) is appended after the last

non-0 factor scanned.

After the factors are transformed into a group of 0-value run

length and a group of non-0 factor values, a Huffman code table

is compiled according to the incidence probabilities of these

groups and VLC is applied based on this.

VLC

(111011s), (100s), (11011s),... (1110)

s: Sign bit

Fig. 8-3-10 2D Huffman Coding

8.3.6 Shuffling (Audio)

Unlike the video signal, the audio signal is not compressed. It is

subjected only to shuffling as preparation for the ECC.

Table 8-3-3 shows the basic modes of the DV.

Table 8-3-3 Basic Audio Modes

In the 2-channel modes, the quantization is 16-bit linear and the

sampling frequency can be selected from 48 kHz, 44.1 kHz or

32 kHz. One of the 2 channels is recorded in the first 5 tracks of

the 10 tracks of an NTSC frame (first 6 tracks of the 12 tracks of

a PAL frame) after shuffling. Therefore, when an error occurs

with a track, 1/5 (or 1/6) interpolation is applied.

8-11

Page 12

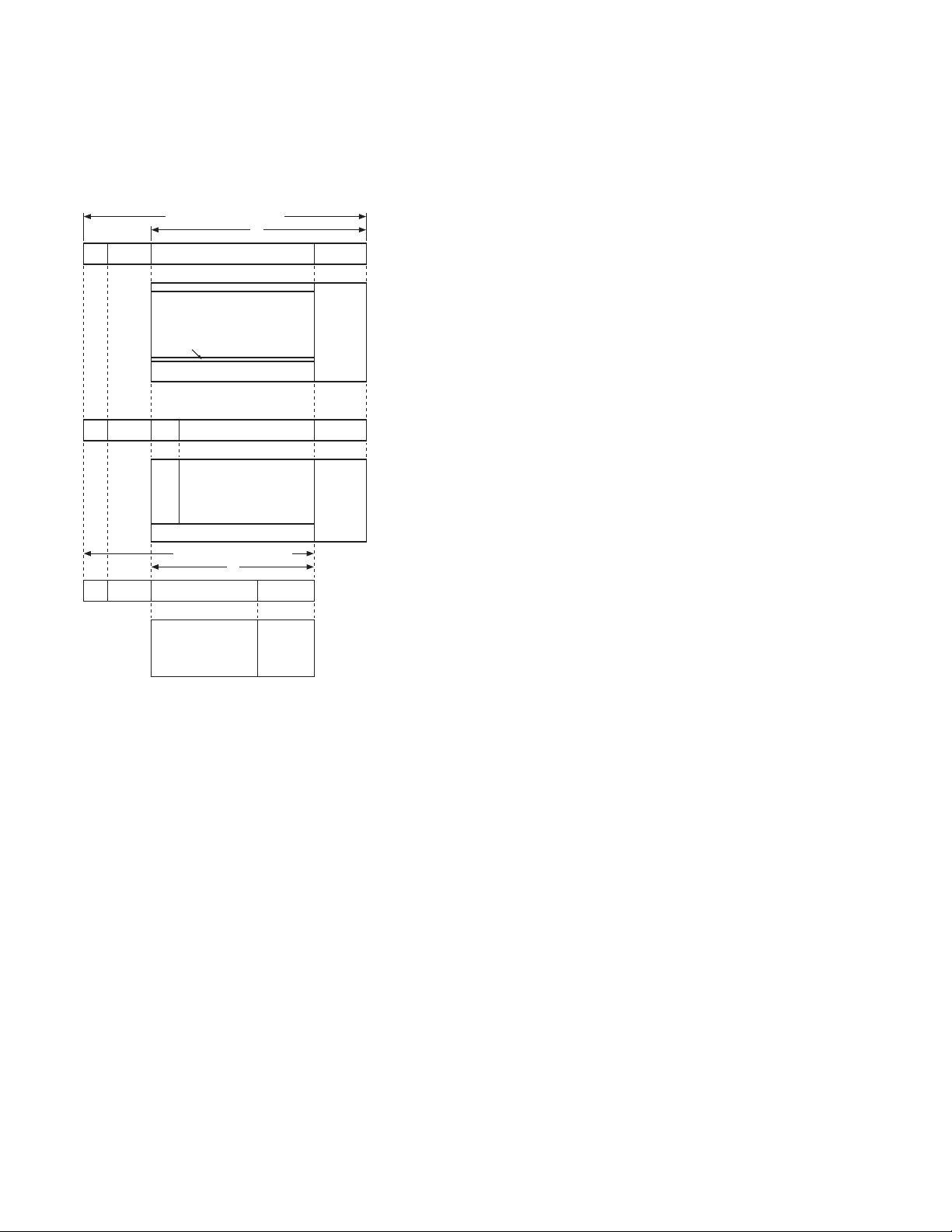

8.3.7 De-shuffling

The compressed video data is recorded on tracks on tape. The

video data recording area of each track is divided into sub-units

called the sync blocks (SBs). The number of SBs where video

data is recorded is 135 per track, and the number of SBs per

frame is:

135 x 10 = 1350 ............................. (NTSC)

130 x 12 = 1620 ............................. (PAL)

These values are equal to the number of macroblocks per frame.

Therefore, the compressed video segment data (5 macroblocks)

is packed into 5 SBs and recorded.

Fig. 8-3-11 shows the packing of video segment data into 5 SBs.

<Step 1>

• The macroblock data is packed into the specified area (fixed

area) on a per-DCT block basis.

• Overflow data is stored in the macroblock memory.

• This step is performed for each macroblock.

<Step 2>

• The data in MB memory is packed in the vacant area of

the same SB.

• Overflow data is stored in the VS (Video Segment) memory.

• This step is performed for each macroblock.

<Step 3>

• The data in theVS memory is packed in the vacant areas

in the 5 macroblocks.

The section corresponding to the data area of each SB(unit) is

divided into the number of DCT blocks per macroblock (fixed

areas) and the data in the DCT blocks is packed in priority in the

fixed areas. When data packed in 5 units is recorded, it is not

recorded in 5 sequential SBs.

After the data in each video segment has been packed in 5 units,

the data is de-shuffled before being recorded. The data of a

frame, composed by the de-shuffling, is recorded sequentially

on the SBs on tape as shown in Fig. 8-3-12.

Data of video segment (5 MBs)

De-shuffling

Track 2

Track 3

Track 4

Track 5

Track 6

Track 7

Track 8

Track 9

De-shuffling memory

Data is recorded on the track in this order.

Track 10

Y block 1

Y block 2

Y block 3

Y block 4

CR block

(14 byte)

(14 byte)

(14 byte)

(14 byte)

(10 byte)

CB block

(10 byte)

5B1 8B

Overflow data is stored in the MB memory. (Step 1)

Data of

MB memory 1

block 1

Data of

block 3

Data in the MB memory is packed in the

vacant areas of the same SB. (Step 2)

Overflow data is stored

VS memory

Data of

MB1

Data of

MB3

in the VS memory.

Data in the VS memory is packed in the vacant

areas in the 5 MBs. (Step 3)

MB1

MB2

MB3

MB4

MB5

Fig. 8-3-11 Packing of Compressed Data in SB

1 frame (10 tracks)

Fig. 8-3-12 De-shuffled Recording (NTSC)

The reason why the shuffled data is not recorded on tape but

de-shuffled before being recorded is to make the picture quality

in variable-speed playback easier to view.

Head

Areas updated per head scan

8-12

Areas forming a group on the picture

are updated simultaneously.

Fig. 8-3-13 Picture Updating in Variable-Speed Playback

Fig. 8-3-13 shows the picture updating by data reproduced during variable-speed playback. The picture is easy to see because

the de-shuffling before recording causes the reproduced data

to form a sequential group.

Page 13

8.3.8 Error Correction

Error correction consists of correcting errors occurring in the

data. For this purpose, data is provided with regularity by adding

redundant parts. The error correction codes are the mathematical systematization of how to add the redundant parts, and the

theory of this is referred to as the coding theory.

(A) Principles of error detection and error correction

With the DV, it may happen that data recorded as “0” is reproduced as “1” or data recorded as “1” is reproduced as “0” due

to thermal noise of the recording/playback amplifier or dust or

scratches on the tape surface. The error correction detects and

corrects such code error produced in the process of recording

or playback.

In the following, the principles of error detection and error correction will be explained by using codes composed by adding a

3-bit redundant part to every 2 bits of data as shown below.

Information part Information part Parity check part

(00) → (00 110)

(01) → (10 101)

(10) → (10 011)

(11) → (11 111)

With the coding theory, the part for data is called the information part, the redundant part is called the parity check part, and

the total of information part and parity check part is called the

code word. The operation of transforming the information part

into code word is referred to as coding.

Let us assume that a code word (00110) corresponding to data

(00) has been recorded and is reproduced with an error in 1 bit

(01110). When the reproduced series is compared with previously defined 4 code words, it may be known that the former

coincides with none of the latter. These are the principles of

error detection.

When the above situation is verified in more detail, it can be

established that the reproduced series (01110) is different by 1

bit from the code word (00110) and by 2 or more bits from other

code words.

The fact that a code word is most similar to the reproduced

series means that the probability that it is the recorded code

word is highest. Therefore, coding errors can be corrected by

considering that the most similar code word to the reproduced

series is the recorded code word. These are the principles of

error correction.

The operation of correcting errors in the reproduced series is

referred to as decoding.

(B) Hamming distance

The error detection and correction capabilities of error correction coding can be defined in terms of the hamming distance

between the code words. The hamming distance is the number

of dissimilar components when two code words are compared

component by component. For example, assuming that code

word (00110) is C

tance dH (C

(11111) is C

1 and code word (01101) is C2, hamming dis-

1, C2) is 3. If code word (10011) is C3 and code word

4, hamming distance dH (C3, C4) becomes 2.

Fig. 8-3-14 shows the scheme of the relationship between the

error detection and correction capabilities and the hamming distance.

Min. hamming distance

Code word

Ci

t

S

Code word

Cj

t

2t+1

Fig. 8-3-14 Expressions of Error Detection and Correction

Capabilities by Hamming Distance

To enable error correction coding, detect all of S or more errors,

the minimum value of the hamming distance between code

words (minimum hamming distance) should be S + 1. This is

because, if the minimum hamming distance is less than S, code

word Ci could be turned into another code word Ci if there are

S error items.

Similarly, to correct t or fewer errors, the minimum hamming

distance between code words should be 2t + 1 or more. This is

because, if the minimum hamming distance is less than 2t, code

word Cj which has a shorter hamming distance than Ci would

exist if t error items occur with Ci. The hamming distances between the code words of the above-mentioned code are:

d

H ((00110), (01101)) = 3

d

H ((00110), (10011)) = 3

d

H ((00110), (11111)) = 3

d

H ((01101), (10011)) = 4

d

H ((01101), (11111)) = 2

d

H ((10011), (11111)) = 2

Therefore, the minimum hamming distance between these code

words is 2. Thus, as the number of errors that can be detected

is:

S = 1 (because S + 1 = 2)

This means that the error of a bit can be detected.

It was described above that the error of a bit in code word (00110)

can be corrected. This is because the minimum hamming distance between only code word (00110) and other code words is

3. Therefore:

t = 1 (because 2t + 1 = 3)

However, correction of error of a bit is not possible with other

code words, with which only error detection is possible.

(C) Simple error correction codes

Examples of simple error correction codes will be described in

the following.

(1) Simple parity check code

The parity check code is composed of a k-bit information

part and 1-bit parity check part. The code with which parity

is selected so that the number of “1” contained in a code

word is an even number is referred to as the even parity

code. That with which parity is selected so that the number

of “1” contained in a code word is an odd number is referred to as the odd parity code. For example, a 3-bit code

may have even parity codes as follows:

(00) → (000)

(01) → (011)

(10) → (101)

(11) → (110)

All of the hamming distances between the 4 code words are 2,

so a 1-bit error occurring in any code word can be detected.

8-13

Page 14

(2) Repetition code

The repetition code consists of n times of repetitions of 1bit information parts, and the number of code words is 2.

For instance, a 3-bit code has two repetition codes as follows:

(0) → (000)

(1) → (111)

The minimum hamming distance between these codes is 2,

so a 1-bit error occurring in a code word can be corrected.

(3) (7, 4) hamming code

The (7, 4) hamming code consists of a 4-bit information part

(i

3, i2, i1, i0) and a 3-bit parity check part (P2, P1, P0) which is

determined according to the following rule.

P0 = i3 + i2 + i0

P1 = i2 + i1 + i0

.... (8.3.1)

P2 = i3 + i2 + i1

In expressions (8.3.1), operators “*” represent exclusive OR,

so 0 + 0 = 0, 0 + 1 = 1, 1 + 0 = 1, and 1 + 1 = 0.

The (7, 4) hamming code has 4 information bits, or 2

4

= 16

code words. Table 8-3-4 shows all of the code words.

Information Part

i

3

i

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

i

2

1

0

0

0

0

1

0

1

0

0

1

0

1

1

1

1

1

0

0

0

0

1

0

1

0

0

1

0

1

1

1

1

1

Parity Check Part

i

P

0

2

0

0

0

1

0

1

0

0

0

1

0

0

0

0

0

1

1

0

1

1

1

1

1

0

1

1

1

0

1

0

1

1

P

P

1

0

0

0

0

1

1

1

1

0

1

0

1

1

0

1

0

0

1

1

1

0

0

0

0

1

0

1

0

0

1

0

1

1

Table 8-3-4 List of Code Words of (7, 4) Hamming Code

This table shows that the minimum hamming distance of the

code is 3 and that a 1-bit error can be corrected.

(4) Basic knowledge on algebra

The examples of error correction codes used in the description of the previous section are beginner-type codes, and

their error detection and correction capabilities are insufficient for application in the DV.

The error correction codes with practical error detection and

correction capabilities for use with the DV are constructed

based on abstract algebra. In the following, the minimum

required knowledge on the algebra for understanding the

error correction will be described. If you want to gain more

knowledge, please also refer to books on mathematics.

(a) Galois field

Here, the term “field” refers to the set of elements with

which the four arithmetical operations of addition, subtraction, multiplication and division can be defined.

The term “field” is used because its functions are working

organically, and have come from German word “Körper”.

For example, a real number or complex number is a field.

However, when the term “field” is used with error correction codes, it does not mean a field with an infinite number

of elements such as a real number, but means a finite field

composed of a finite number of elements.

The “element” is what belongs to a set.

For example, if there is “a” which belongs to set “M”, it is

said, “a is an element of M”. The fact that “a” belongs to

“M” is expressed using a symbol as “a ∈ M2”. “∈“ is the

symbol of the initial letter of “element”. If “a” does not belong to “M”, it is expressed as “a ∉ M”.

A finite field is also called the Galois field, after the French

mathematician Evariste Galois (Oct. 25, 1811 - May 31, 1832)

who created one of the basic algebra theories. A Galois field

composed of P elements is expressed as GF(P).

The simplest Galois field is a GF(2) composed of elements

(0, 1). The addition in GF(2) is defined as exclusive OR and

the multiplication can be defined as multiplication of ordinary integers.

Table 8-3-5 shows the operation tables of GF(2).

0

1

0

0

1

1

1

0

0

1

0

0

1

0

0

1

(a) Addition (b) Multiplication

Table 8-3-5 Operation Tables of GF(2)

8-14

(b) Extension field

The complex number field is created by adding root “i” of

2

“x

+ 1 = 0”, the polynomial which cannot be factorized any

more in a real number field (irreducible polynomial) to a real

number field. In the same way, by adding a root of an irreducible polynomial in Galois field GF(P) to GF(P), it is possible to create a field GF(P

is equal to P

m

which is a P’s power. This operation is re-

m

) where the number of elements

ferred to as a field extension. GF(P) is called the ground field

and GF(P

m

) is called the extension field.

Page 15

For example, assume that there is an irreducible cubic polynomial as follows:

3

x

+ x + 1 = 0,

If there is an extension field GF (2

3

) created by a root of the

above polynomial “α“ to GF (2), “0”, “1” and “α“ are the elements of extension field GF (2

3

). Then, since multiplication should

be definable in a field, all of α‘s powers become the elements

of GF (2

nomial x

3

). As for the α‘s powers, since “α“ is the root of poly-

3

+ x + 1 = 0,

3

α

= α + 1

Therefore, this relationship means the following:

0

α

= 1

1

α

= α

2

2

α

= α

α3 = α + 1

4

α

= (α + 1) α = α2 + α

5

α

= (α2 + α) α = α2 + α1 + 1

6

α

= (α2 + α + 1) α = α2 + 1

7

α

= (α2 +1) α = 1

:

(Repeated)

α‘s power after α

7

are repetitions of the above.

Fig. 8-3-15 shows this relationship from a different viewpoint.

In this figure, since the cycle is closed, α‘s power after α

replaced by values of α

α = α

1 = α

6

or below.

2

α

1

8

α

0

7

α

3

α

7

are

element with a period of 2

m

- 1 to GF(2). The hamming code

is a cyclic code which uses a primitive polynomial as the

generation polynomial, and its parameters are as shown

below.

Code length : n = 2

m

- 1

Information amount : k = n - m

Min. hamming distance : d

MIN = 3

A hamming code with code length of n and information

amount of k is called a (n, k) hamming code. Since the minimum hamming distance is 2, any 1-bit error occurring in the

code word can be corrected.

(7) BCH code

The BCH (Bose-Chauduri-Hocgenghem) code extends the

error correction of a Hamming code to 2 bits or more. The

BCH codes with t-bit correction become the cyclic codes of

code table n with which generation polynomial G(x) is a

minimum-order polynomial having α, α

assuming that α is a primitive root of GF(2

m

2

- 1.

2

,... α2t as the roots,

m

) and that n =

(8) Reed-Solomon code

The BCH code described in above (7) is defined on GF(2).

The Reed-Solomon code is an extension of the above to

m

GF(2

). Its error detection and correction are applied per symbol, which is an element of the extension field.

In general, a Reed-Solomon code with code length of n and

information amount of k is called the (n, k) RS code.

(9) Reed-Solomon product code

Assuming that C

1 is (n1, k1) codes and C2 is (n2, k2) codes,

the product code of them can be obtained by coding k

umns, each composed of k

k

2 rows, each composed of k1 symbols with C1. Fig. 8-3-16

2 symbols, with C2, then coding

shows the construction of product code.

1 col-

4

α

6

α

Fig. 8-3-15 Cycle of GF (2

5

α

3

)

(5) Cyclic code

The cyclic codes are important codes that can be coded or

decoded easily.

The cyclic code has the following properties:

• The sum of arbitrary code words is a code word.

• The series obtained by cyclic shifting of code words be-

comes a code word.

(6) Hamming code

When one of the roots of an irreducible m-order polynomial

in GF(2) is assumed to be α, the maximum period until α‘s

power returns to the original number is 2

m

- 1 (see Fig. 8-3-

15).

An irreducible polynomial which has a root α with which the

period is 2

m

- 1 is called the primitive polynomial, and α in

this polynomial is called a primitive element.

m

GF(2

) is an extension field created by adding a primitive

Information part

C2’s parity

check part

C1’s parity

check part

C2’s parity

check part on

C1’s parity

check part

Fig. 8-3-16 Construction of Product Codes

The C2’s parity check part on C1’s parity check part is identical

to the C1’s parity check part on C2’s parity check part. As a

result, the same product code can be obtained by coding C1

before coding C2. The DV uses the Reed-Solomon product code

obtained by a double coding of the Reed-Solomon code.

8-15

Page 16

8.3.9 Data Structure

Random errors and burst errors due to dropouts on tape occur

with the magnetic recording/playback circuitry of the DV. To deal

with this, the DV records data by turning into sync blocks. Fig.

8-3-17 shows the DV data structure.

23

Sync

ID code

area

ID0,ID1,ID

135

23

Sync

ID code

ID0,ID1,ID

area

23

Sync

ID code

area

ID0,ID1,ID

Sync block length: 90 bytes

2

2

VAUX

1

11

2

9

5

2

12

Outer code parity

5

AAUX

58

AAUX

Outer code parity

Sync block length: 12 bytes

52

Sub-code data

52

Sub-code data

85

77 8

Video data

77 8

VAUX

Video data

72 8

Audio data

72

Audio data

7

Inner code

parity

Inner code

parity

Inner code

parity

Inner code

parity

Inner code

parity

Inner code

parity

4

GF (2

)

8

GF (2

)

8

GF (2

)

Unit: Byte

Fig. 8-3-17 Data Structure

The video and audio uses the same sync block configuration to

reduce the scale of hardware. The video or audio data forms a

sync block together with the sync area, the ID code indicating

the data attributes and the inner code parity.

The byte counts of the sync area and ID code in Fig. 8-3-17 are

the values before the 24/25 conversion (by a converter circuit

which produces digitally the pilot signal for use in tracking during playback). In practice, however, they are 24/25-converted

and become scrambled interleaved NRZI-converted signals before being recorded onto tape. The following 17-bit patterns have

been defined as sync patterns.

• Audio/Video sectors

Sync-D : 00011111111110001

Sync-E : 11100000000001110

MSB LSB

• Sub-code sector

Sync-F : 00000111111111101

Sync-G : 11111000000000010

MSB LSB

The ID code is composed of 3 bytes including two ID bytes and

a parity byte.

The ID bytes of a video or audio sector are:

4 bits of sequence number for indicating the continuity of frame,

4 bits of track pair number indicating the track number, and 8

bits of sync block number indicating the arrangement of sync

blocks in each track.

(1) Error correction in the ID code area

In the ID code area, (12, 8, 3) BCH codes are used for common error correction to the audio, video and sub-code sectors.

The configuration is as shown below.

Primitive polynomial: x4 + x + 1

ID

0:C15 C14 C13 C12 C11 C10 C9 C8

ID1:C7 C6 C5 C4 C3 C2 C1 C0

IDP:P7 P6 P5 P4 P3 P2 P1 P0

MSB LSB

ID-CW

0: C14 C12 C10 C8 C6 C4 C2 C0 P6 P4 P2 P0

ID-CW1: C15 C13 C11 C9 C7 C5 C3 C1 P7 P5 P3 P1

The parity can be expressed as follows.

P

7 =C15 +C11 +C7 +C5

P5 =C15 +C13 +C9 +C5 +C3

P3 =C15 +C13 +C11 +C7 +C3 +C1

P1 =+C13 +C9 +C7 +C1

P6 =C14 +C10 +C6 +C4

P4 =C14 +C12 +C8 +C4 +C2

P2 =C14 +C12 +C10 +C6 +C2 +C0

P0 =+C12 +C8 +C6 +C0

As the contents of ID code have regularity (inertia) between

successive sync blocks, it is also possible to apply only the

error detection.

(2) Error correction in the video and audio areas

The video data and audio data are composed of Reed-Solomon product codes of GF (2

8

) as shown in Fig. 8-3-17. With

internal codes, a common code length is used to reduce the

burden on the hardware.

(a) Inner codes: same video and audio (85, 77)

α : Primitive element

Primitive polynomial : x

Generation polynomial : g = (x + 1)(x + α)(x + α

8

+ x4 + x3 + x2 + 1

2

)...(x + α7)

As 8 bytes of parity are added, up to 4 errors can be corrected.

(b) Outer codes: Video (149, 138), audio (14, 9)

Primitive polynomial: x

8

+ x4 + x3 + x2 + 1

Generation polynomials:

Video g = (x + 1)(x + α)(x + α

Audio g = (x + 1)(x + α)(x + α

2

)...(x + α10)

2

)(x + α3) (x + α4)

As 11 parity bytes are added to the video data, the maximum burst error correction length assuming that all random

errors are corrected by inner code is 85 x 11 = 935 bytes,

which corresponds to correction of error due to a defect of

about 0.3 mm in the widthwise direction of tape.

Similarly, 5 parity bytes are added to the audio data so the

maximum burst error correction is 85 x 5 = 425 bytes, which

corresponds to correction of error due to a defect to about

0.14 mm in the widthwise direction of tape.

8-16

Page 17

(3) Error correction in the sub-code area

Errors in the sub-code area in each track are corrected by

using only the inner codes without using the produce codes.

Multiple write in a frame is adopted to improve the reliability.

Sub-code (14,0) GF(2

Primitive polynomial : x

Generation polynomial : g = (x + 1)(x + α)(x + α

4

) Reed-Solomon code

4

+ x + 1

2

)(x + α3)

8.3.10 DCI

Channel coding of recording signals is to convert the digital information signals composed of “1” and “0” according to the

properties of the magnetic recording/playback circuitry. As the

DV transports tape by means of helical scanning of a rotary drum,

the signal processing of the recording/playback circuitry is subject to the following restrictions.

(1) The signal-to-noise ratio (S/N) in playback should be good.

If the S/N is poor, a large number of random errors make

error correction difficult.

(2) The DC and low-frequency components should be small.

The magnetic recording system has a differential wave type

transfer characteristic and a rotary transformer is used in

signal exchange between the magnetic heads and recording/playback circuitry. Therefore, the DC and low-frequency

components (where signal “1” or “0” continues) cannot be

recorded or reproduced.

(3) The timing clock should be reproduced.

If a stable reproduce clock which is synchronized with the

reproduce signal by shortening successive “1” or “0” of

data, jitter may occur.

To deal with the above restrictions, the DV uses the scrambled

interleaved NRZI technique. This technique is called scrambled

interleaved because the bit series of every other bit are identical to the NRZI system and that two NRZI series are alternating.

It is also called PR4 (Partial Response class IV) or PR(1, 0, -1).

(A) Interleaved NRZI

The interleaved NRZI system has a close frequency charac-

teristic to the characteristic of magnetic recording circuitry

and the technique is used with many digital VCRs.

When there is an isolate pulse, inter-code interference pro-

ducing -1 occurs in 2 bits after it. This technique shapes the

reproduced waveform by utilizing the inter-code interference.

Fig. 8-3-18 shows the process in which the input data series

is reproduced by PR4 through tape transport. When a data

series is input to point A it is converted by the Precoder

after signal processing. The data and frequency spectrum

are as shown by B in the figure after conversion. The data is

then turned into a differential waveform according to the

differentiation property of the magnetic recording/playback

circuitry, and the loss in the high-frequency band is compen-

sated by the equalizer to become waveform C. Then, a sig-

nal delayed by 1 clock and the original signal are mixed to

become waveform D. By applying 3-value detection to con-

vert data “-1” into “1”, output data E which is identical to

the input data can be obtained.

Scrambled data

Input

Input data

REC

Delay by 1 clock

ID point

Reproduce

data

Precoder

Comparator

ID point Reproduce

Fig. 8-3-18 Si-NRZI

This signal flow can be expressed using delay parameter D as

follows.

Precoder : 1/(1 - D

2

)

Reproduce circuitry : 1 - D (Differentiation property)

Decoder : 1 + D

Transfer function : (1/(1 - D

2

) · (1 - D2) = 1

The above shows that the input data and output data are identical also in expressions.

(B) 24/25 conversion

To gain advantage of the compatible playback with track linearity, the DV employs 24/25 conversion which turns the

entire track into pilot signals.

The 24/25 conversion generates the low-frequency pilot component by inserting an extra bit (1 bit) to every 24 bits (3

bytes) of scrambled data series. The run length is set to no

more than 9 and the extra bit is added to the recorded data

series as if supplementing the spectra shown in Fig. 8-3-19.

When the recording rate is 41.85 MHz, f1 is 465 kHz and f2

is 697.5 kHz. The spectra shown in Fig. 8-3-19 are recorded

respectively in tracks F0, F1 and F2 shown in Figs. 8-1-3 and

8-1-4. When the play heads scan track F0 during playback,

pilot components f1 and f2 can be obtained as crosstalk signals from the adjacent tracks so that stable tracking is possible.

Track F0 Track F2Track F1

data

Fig. 8-3-19 Recording Signal Spectra

8-17

Page 18

8.4 VIDEO/AUDIO SIGNAL PROCESSING IN PLAYBACK

CIRCUITRY

For the playback signal processing in the initial stage at the head

amp, equalizer and (1+D), see 8.3.10, “DCI”.

8.4.1 Viterbi Decoding

This section describes the concept of Viterbi decoding.

Viterbi decoding is applicable only to the NRZI series signals.

The decoding process of DV divides an interleaved NRZI series

into two NRZI series and applies Viterbi decoding separately to

each of them, then merges them later on to the original data

series. Fig. 8-4-1 shows the concept of the basic principles of

Viterbi decoding of NRZI series.

Recording signal

Reproduce signal

at detection point

Previous detector

(bit-by-bit)

Viterbi decoder

A/D conversion

A

Error

(V) Soft decision

“1”

1V

Recognition level

“0”

Recognition level

“–1”

Selection of the

correct series

8.4.2 Error Correction

The DV corrects errors by decoding the data that has been coded

using Reed-Solomon product codes. The minimum hamming

distance of the product codes is d

ming distances of C

1 and C2 are d1 and d2, thus up to (d1d2 - 1)/2

1 and d2 if the minimum ham-

errors can be corrected from the principles. Nevertheless, in

fact, the maximum number of correctable errors is variable depending on the decoding technique. One of the decoding techniques is the series decoding technique that decodes C

then decodes C

2. Although this is not the best way from the

1 first

viewpoint of error correction capability, the serial connection of

two decoders C

1 and C2 makes it easy to build the hardware so

it is used by many digital VCRs.

With a digital VCR, compound errors in which random errors

and burst errors are mixed are produced (see Fig. 8-4-2).

Fig. 8-4-2 shows the correction of compound errors by product

codes.

C

1

Recording direction

Pointers

2

C

Fig. 8-4-1 Viterbi Decoding

The differential waveform obtained by playing a NRZI-recorded

tape is defined as the ID point for Viterbi decoding (point D in

Fig. 8-3-18). The signal shown in Fig. 8-4-1 contains random

noise. Previous processes (GR-DV1, etc.) without Viterbi decoding have been applying 3-value detection to this signal. In this

case, errors may occur by judging the level at point A in Fig. 8-41 as “0” while it should be “-1”. This technique is referred to as

hard decision because it uses fixed identification levels.

On the other hand, Viterbi decoding uses a soft decision method.

It first A/D converts the reproduce signal and reads the waveform level. For instance, if “1” is read as +1 V, “0” is read as 0

V, “-1” is read as -1 V and the level is -0.4, this leads to the

judgment that the probability of being 0 is higher than that of

being -1. Therefore, the bit series may be either 10010 or 10-

110.

A decision criterion that “this is the recording/playback of NRZI

series” is thus invoked. The differentiation waveform at the ID

point of the reproduce waveform of NRZI series has the following rule.

The rule is that, when there are two positive-going waveforms,

there is always a negative-going waveform between them. In

other words, there is always “-1” between two “1” in the decoded value. This rule means that bit series 10010 above cannot exist, and bit series10-110 is selected.

As described above, the Viterbi decoding corrects errors by utilizing the rule between bits (redundancy of the NRZI series ).

Burst errorsRandom errors

Fig. 8-4-2 Principles of Erasure Correction

Assume that the signal has been recorded in the direction of

the arrow.

Decoding is applied in the common order, i.e. C

With the C

1 decoding, pointers indicating random or burst er-

1 first, then C2.

rors beyond the correction capability are placed to all of the symbols of the code word containing the errors at the same time as

random error correction. The symbols to which a pointer is attached are referred to as erasure symbols.

This decoding technique utilizing pointers is called the erasure

correction, which features an improved error correction capability compared to the decoding techniques without pointers. In

cases when a code error is ignored during C

ent code from the recorded code may be output by the C

1 decoding, a differ-

2 de-

coding. This erroneous correction is one of the most important

causes of video and audio quality deterioration. To prevent erroneous correction, the C

1 decoding prevents error detection mis-

takes by limiting the number of error corrections. Although the

DV is capable of error correction of 2 symbols, the actual number

of symbols subjected to error correction is limited to 1 by the

RS code in GF(2

ror detection mistake probability to about 1/2

8

). This error correction limitation allows the er-

16

of 2-symbol error correction. The error correction technique used in the C

decoding is variable depending on the number of erasure symbols.

2

8-18

Page 19

(1) When the number of erasure symbols is 1 or less:

In this case, the use of a pointer cannot improve the error

correction capability because only one error can be corrected.

Therefore, the same 1-error correction and 2-error detection

as the C1 decoding are used without using a pointer. An

error that cannot be corrected by this technique is subject

to error concealment, which will be described in section 8.4.3.

(2) When the number of erasure symbols is 2 or more:

Error detection is performed and, if errors are found in the

locations with erasure symbols, error correction is also applied.

If errors are found in other locations than those with erasure

symbols, the data is subjected to error concealment.

(3) When the number of erasure symbols is 3 or more:

In this case, error correction making a full use of the error

correction capability is possible. However, as there is no error detection capability, error detection mistakes during C1

decoding will result in erroneous corrections.

To prevent this, verification is applied to see if each erasure

symbol is right or wrong, and error correction is applied only

when the number of right erasure symbols is no more than

2.

This erasure correction technique is referred to as a 2 out of

3, erasure correction.

When it is identified that code errors are found with all of

the 3 errors, error concealment is applied by judging that

code errors beyond the error correction capability have occurred.

(4) When the number of erasure symbols is 4 or more:

In this case, the erasure correction capability is exceeded so

that error concealment is applied to prevent erroneous correction.

8.4.4 De-shuffling (Audio)

The audio data, which has been shuffled before error correction, is de-shuffled and output as the audio signal.

8.4.5 VLD

The video data that has been shuffled before error correction is

processed by VLD (Variable Length Decoding). This consists of

decoding the signal that has been coded with VLC as described

before.

8.4.6 I-DCT

After VLD, the data is processed by I-DCT (Inverse Discrete

Cosine Transform) to expand the compressed data.

8.4.7 De-shuffling (Video)

The expanded data is de-shuffled to restore the video signal.

8.4.3 Error Concealment

Error concealment is a radically different technology from error

correction.

Error correction technology restores errors to their original states

by utilizing the relationship between the information part and

the parity check part. However, error concealment makes errors less noticeable by complementing errors with the surrounding pixels. This means that error concealment can be applied

only when there is a data correlation. The DV can employ error

concealment because the video and audio signals are correlated

between each other. The error concealment is particularly effective when there is a major scratch on the tape or when the

reproduce error rate in slow, still or high-speed playback is too

high to be handled by the error correction technology.

Error concealment is available by using more than one technique. For easy understanding, the techniques can be regarded

as similar to the blemish compensation of still cameras or the

dropout compensation (DOC) of VHS video.

Specifically, each data item containing an error is replaced with

the data of 1 frame before using a frame memory.

8-19

Page 20

8.5 CAPSTAN SERVO

The rotation speed of the capstan motor is controlled in two

ways; by velocity control or by ATF tracking.

8.5.1 Velocity Control

The capstan motor rotation speed is controlled according to the

CAP FG pulse in the same way as the VHS video.

8.5.2 ATF Tracking

The capstan motor rotation speed is controlled based on pulses

f

0, f1 and f2 that have been added by the 24/25 conversion, so

that the crosstalk components from f

track f

0 is traced.

Head scanning

1 and f2 are identical when

Tape transport

The TREB waveform indicates the CH1 tracking condition (see

Fig. 8-5-3).

f0f2

f1

V

2.4 V

1.5 V

0.6 V