Page 1

SERVICE MANUAL

DIGITAL VIDEO CAMERA

YF009200312

DISASSEMBLY

GR-DX Series

Manual No. Model name

86735 GR-DX25EX,GR-DX25EY,GR-DX25EZ,GR-DX25EK,GR-DX35EX,GR-DX35EY,GR-DX35EZ,GR-DX35EK

86740 GR-DX75EX,GR-DX75EY,GR-DX75EZ,GR-DX75EK,GR-DX95EX,GR-DX95EY,GR-DX95EZ,GR-DX95EK

86751 GR-DX100EX,GR-DX100EY,GR-DX100EZ,GR-DX100EK,GR-DX300EX,GR-DX300EY,GR-DX300EZ,GR-DX300EK

86752 GR-DX45EX,GR-DX45EY,GR-DX45EZ,GR-DX45EK,GR-DX55EX,GR-DX55EY,GR-DX55EZ,GR-DX55EK

86753 GR-DX75AA,GR-DX75AG,GR-DX75AH,GR-DX75AS,GR-DX76AG

86754 GR-DX35AC,GR-DX35AH

86755 GR-DX95AC,GR-DX95AH

86757 GR-DX75US,GR-DX95US

86762 GR-DX106AG

86763 GR-DX300AA,GR-DX300AG

86764 GR-DX300AC,GR-DX300AH

86765 GR-DX75KR,GR-DX95KR

86766 GR-DX300US

GR-DV Series

Manual No. Model name

86734 GR-DV500US,GR-DV800US,GR-DV801US,GR-DV900US

86736 GR-DV4000US

86756 GR-DV4000EX,GR-DV4000EY,GR-DV4000EZ,GR-DV4000EK

86758 GR-DV700EX,GR-DV700EY,GR-DV700EZ,GR-DV700EK

86759 GR-DV500KR,GR-DV700KR,GR-DV800KR,GR-DV900KR,GR-DV4000KR,GR-DV5000KR

86760 GR-DV400EX,GR-DV400EY, GR-DV500EX,GR-DV500EY,GR-DV500EZ

86767 GR-DV4000AG,GR-DV5000AA,GR-DV5000AG

86768 GR-DV500AA,GR-DV500AG,GR-DV500AS,GR-DV900AA,GR-DV900AG

86771 GR-DV700AH,GR-DV900AC,GR-DV4000AC,GR-DV5000AC

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LIMITED

No.YF009

2003/12

Page 2

SECTION 1

DISASSEMBLY (GR-DX Series)

1.1 BEFORE ASSEMBLY AND DISASSEMBLY

1.1.1 Precautions

• Be sure to disconnect the power supply unit prior to mounting

and soldering of parts.

• Prior to removing a component part that needs to disconnect

its connector(s) and its screw(s), first disconnect the wire(s)

from the connector(s), and then remove the screw(s).

• When connecting/disconnecting wires, pay enough attention

not to damage the connectors.

• When inserting the flat wire to the connector, pay attention to

the direction of the flat wire.

• Be careful in removing the parts to which some spacer or

shield is attached for reinforcement or insulation.

• When replacing chip parts (especially IC parts), first remove

the solder completely to prevent peeling of the pattern.

• Tighten screws properly during the procedures. Unless

specified otherwise, tighten screws at a torque of 0.088N

·cm). However, 0.088N·m (0.9kgf·cm) is a value at the

(0.9kgf

time of production. At the time of service, perform the

procedure at a torque 10% less than 0.088N

·m (0.9kgf·cm).

(See "SERVICE NOTE" as for tightening torque.)

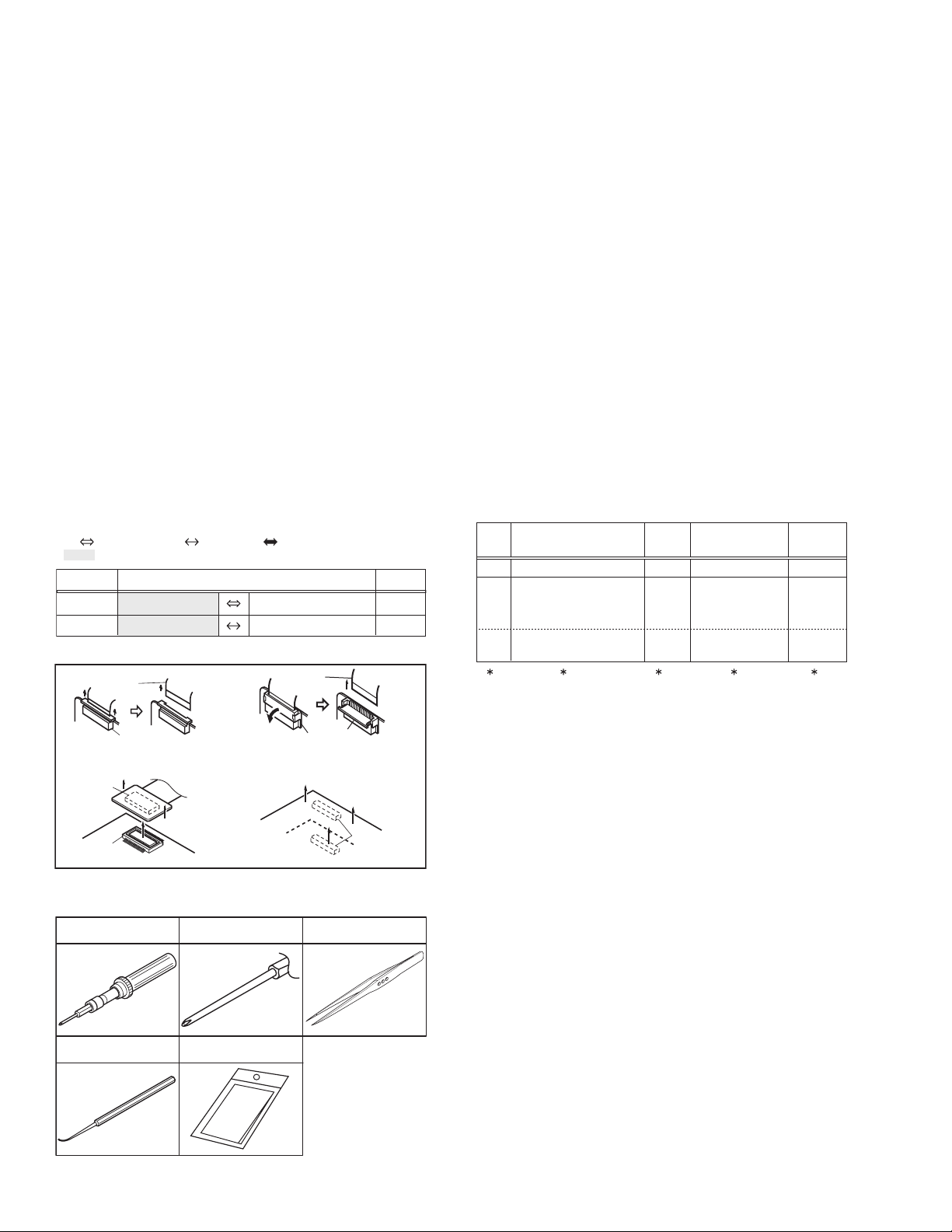

1.1.2 Destination of connectors

Two kinds of double-arrows in connection tables respectively

show kinds of connector/wires.

: Wire: Flat wire : Board to board (B-B)

: The connector of the side to remove

CONN. No. PIN No.CONNECTOR

CN2a

CN2b

MAIN CN101

MAIN CN103

MONI/ BW CN761

MIC CN762

1.1.3 Disconnection of connectors (Wires)

Wire

· Pull both ends of the connector in the arrow

direction, remove the lock and disconnect the flat

wire.

B-B Connector

B-B Connector

· Pull the both ends of the board in the direction of the arrow, and remove the B-B Connector.

FPC Connector

· Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After

removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

Wire

FPC Connector

Lock

B-B Connector

Fig.3-1-1

1.1.4 Tools required for disassembly and assembly

Torque driver

YTU94088

Chip IC replacement jig

PTS40844-2

Bit

YTU94088-003

Cleaning cloth

KSMM-01

Tweezers

P-895

·m

40

2

• Torque driver

Be sure to use to fastening the mechanism and exterior parts

because those parts must strictly be controlled for tightening

torque.

• Bit

This bit is slightly longer than those set in conventional torque

drivers.

• Tweezers

To be used for removing and installing parts and wires.

• Chip IC replacement jig

To be used for replacement of IC.

• Cleaning cloth

Recommended cleaning cloth to wipe down the video heads,

mechanism (tape transport system), optical lens surface.

1.2 ASSEMBLY AND DISASSEMBLY OF MAIN PARTS

1.2.1 Assembly and disassembly

When reassembling, perform the step(s) in reverse order.

STEP

No.

[1]

[2]

[8]

PART

TOP COVER ASSEMBLY

UPPER ASSEMBLY

(Inc. VF ASSEMBLY,

SPEAKER/MONITOR)

VF ASSEMBLY

(∗1) Order of steps in Procedure

When reassembling, preform th e step(s) in the reverseorder.

These numbers are also used as the identification (location)

No. of parts Figures.

(∗2) Part to be removed or installed.

(∗3) Fig. No. showing Procedure or Part Location.

C = CABINET

(∗4) Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped or unsoldered.

S = Screw

L = Lock, Release, Hook

SD = Solder

CN = Connector

[Example]

• 4 (S1a) = Remove four S1a screws.

• 3 (L1a) = Disengage three L1a hooks.

• 2 (SD1a) = Unsolder two SD1a points.

• CN1a = Remove a CN1a connector.

(∗5) Adjustment information for installation.

Fig.

No.

Fig.C1

Fig.C2-1

Fig.C2-2

POINT

S1,2(L1)

S2a,2(S2b),3(S2c)

2(S2d),S2e,S2c

L2,CN2a,b

2(S8),L8,CN8a

( 4) ( 5)( 2) ( 3)( 1)

NOTE

-

-

NOTE 8a

NOTE 8b

1-2 (No.YF009)

Fig.3-1-2

Page 3

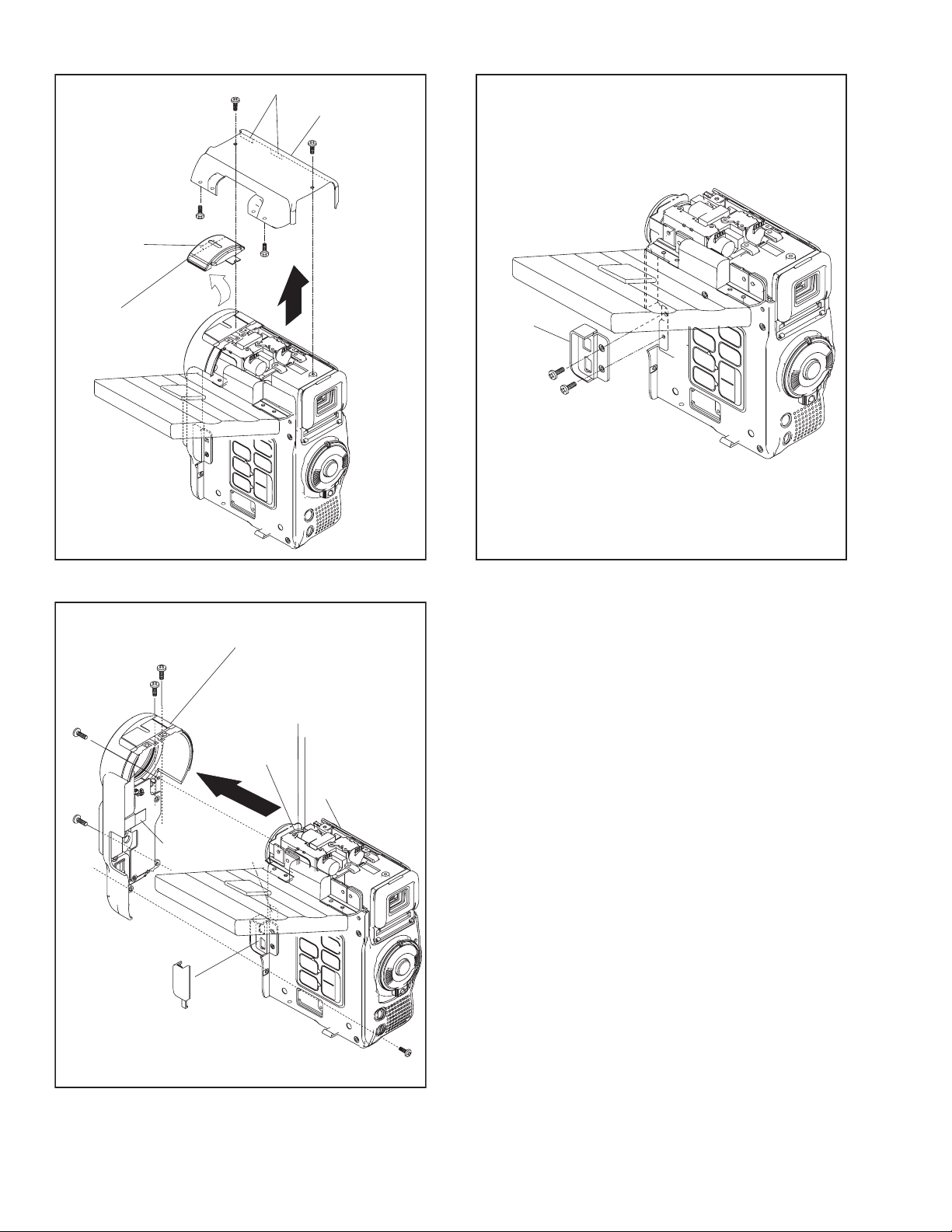

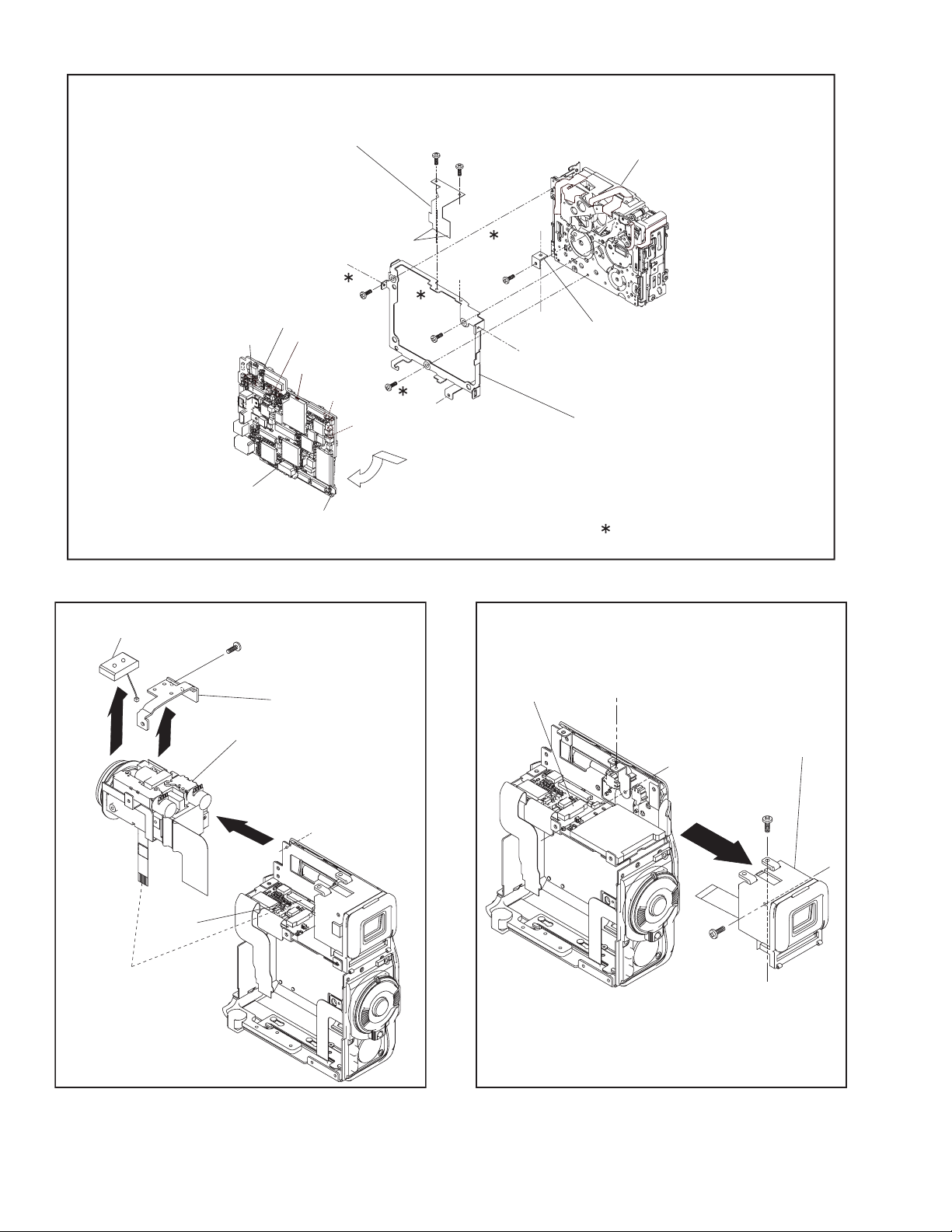

1.2.2 ASSEMBLY/DISASSEMBLY OF CABINET PARTS AND ELECTRICAL PARTS

zDisassembly procedure

Step

Parts Name

No.

[1]

COVER(TOP)

[2]

COVER(MIC)

[3]

FRONT COVER ASSY

[4]

COVER(DV)

[5]

UPPER ASSY

MAIN BOARD ASSY

[6]

/MECHANISM ASSY

/[7]

OP BLOCK ASSY

[8]

/MIC ASSY

/[9]

VF ASSY

[10]

Fig.

No.

(S1a),3(S1b),2(L1)

Fig.C1

L2

Fig.C2

2(S3a),(S3b),(S3c),(S3d),CN3,HOLDER(DV/USB)

Fig.C3

(S4a),(S4b)

Fig.C4

(S5a),(S5b),2(S5c),(S5d),(S5c),

(S5d),(S5e),CN5a,CN5b

CN6a,b,c,d,e,(S6a),3(S6b),2(S6c),

Fig.C5-1

Fig.C5-2

L6a,SHELD PLATE,L6b,CN6f,g,h,i,k,m

(S7a),3(S7b),BKT(PRE/REC),MECHA BKT ASSY

(S8),BKT(TOP),L8,CN8

Fig.C6

Fig.C7

CN10,2(S10)

Point Note

NOTE 3a:

Open the CASSETTE COVER, and remove the two screws

(No.7 and 8).

NOTE3b:

Take care not to cut the FPC and wire.

NOTE3c:

-

-

NOTE3a,b,c

-

NOTE5a,b

NOTE6a,b

-

NOTE8

NOTE10

zDestination of connectors

CN No.

CN3 MAIN CN115 STROBE CN6501 12

CN5a MAIN CN113 MONITOR CN7601 49/45

CN5b MAIN CN112 SUB OPE UNIT - 9

CN6a MAIN CN101 BATT.TERM. - 17

CN6b MAIN CN109 SD CN301 60

CN6c MAIN CN102 CCD - 20

CN6d MAIN CN111 CAMERA OPE UNIT - 11

CN6e MAIN CN114 MIC - 4

CN6f MAIN CN106 SENSOR - 16

CN6g MAIN CN110 HEAD - 8

CN6h MAIN CN103 LOADING MOTOR - 6

CN6j MAIN CN107

CN6k MAIN CN104 DRUM MOTOR - 11

CN6m MAIN CN108 CAPSTAN MOTOR - 18

CN8 SD CN302 OP BLOCK ASSY - 24

CN10 SD CN304 VF BW CN7001 18

Be careful about the HOLDER (DV/USB) because it is

removed together with the FRONT COVER ASSY.

NOTE5a:

Take care not to damage the part.

NOTE5b:

Take care not to cut the FPC.

NOTE6a:

Remove the MIC wire while removing the MAIN BOARD

ASSY.

NOTE6b:

Take care not to cut the FPC.

NOTE8:

Take care not to damage the LENS in OP BLOCK ASSY

and not to cut the FPC.

NOTE10:

Take care not to cut the FPC.

CONNECTOR

ROTARY ENCODER SW

Pin.

No.

- 6

(No.YF009)1-3

Page 4

L2

3

(S1b)

1

(S1a)

L1

[1]

2

(S1b)

4

(S1b)

7

(S3b)

8

(S3c)

[2]

(S3a)

6

5

(S3a)

a

b

NOTE3b

Fig.C1

[3]

NOTE3b

CN3

a

b

CASETTE

COVER

[4]

10

(S4a)

11

(S4b)

Fig.C3

NOTE3a

1-4 (No.YF009)

HOLDER(DV/USB)

NOTE3c

9

(S3d)

Fig.C2

Page 5

CN5a

CN5b

(S5e)

16

(S5d)

19

17

(S5c)

15

(S5c)

(S5c)

Fig.C4

14

18

(S5d)

NOTE5b

[5]

NOTE5a

13

(S5b)

12

(S5a)

(S6b)

NOTE6a

CN6e

CN6b

CN6a

[6]/[7]

23

c

CN6d

20

(S6a)

CN6c

Fig.C5-1

a

21

(S6b)

b

22

(S6b)

(No.YF009)1-5

Page 6

SHIELD PLATE

CN6m

CN6f

CN6k

CN6g

C

27

(S7b)

L6a

24

(S6c)

28

(S7b)

25

(S6c)

d

e

26

(S7a)

[7]

d

e

b

BKT(PRE/REC)

[9]

[6]

NOTE6b

(S8)

a

[8]

30

BKT(TOP)

NOTE8

CN6j

L6b

a

CN6h

29

(S7b)

a

Fig.C5-2

MECHA BKT ASSY

CN10

a

: 0.068N.m(0.7kgf.cm)

NOTE10

[10]

b

31

(S10)

1-6 (No.YF009)

b

CN8

32

(S10)

a

Fig.C6 Fig.C7

Page 7

1.2.3 SERVICE NOTE

[6]/[7]

cm)

.

m (0.7kgf

.

[8] [9]

[2]

[1] [3] [4] [5]

CABINET PARTS AND ELECTRICAL PARTS

Symbol No.

-

C1 C2 C3 C4 C5-1

1 2 3 4 - 5 6 7 8 9 1011121314151617181920212223

Place to stick screw

Removing order of screw

Screw tightening torque

Reference drawing (Fig.No.)

[6]/[7] [10]

CABINET PARTS AND ELECTRICAL PARTS

Symbol No.

-

24 25 26 27 28 29 - 30 31 32

Place to stick screw

Removing order of screw

C7C5-2 C6

cm) : 0.068N

.

m (0.9kgf

.

: 0.088N

1) * : Don't reuse the screw, because screw lock bond was applied to them.

2) Pay careful attention to tightening torque for each screw.

NOTE:

Screw tightening torque

Reference drawing (Fig.No.)

(No.YF009)1-7

Page 8

SECTION 2

DISASSEMBLY (GR-DV Series)

2.1 BEFORE ASSEMBLY AND DISASSEMBLY

2.1.1 Precautions

• Be sure to disconnect the power supply unit prior to mounting

and soldering of parts.

• Prior to removing a component part that needs to disconnect

its connector(s) and its screw(s), first disconnect the wire(s)

from the connector(s), and then remove the screw(s).

• When connecting/disconnecting wires, pay enough attention

not to damage the connectors.

• When inserting the flat wire to the connector, pay attention to

the direction of the flat wire.

• Be careful in removing the parts to which some spacer or

shield is attached for reinforcement or insulation.

• When replacing chip parts (especially IC parts), first remove

the solder completely to prevent peeling of the pattern.

• Tighten screws properly during the procedures. Unless

specified otherwise, tighten screws at a torque of 0.078N

·cm). However, 0.078N·m (0.8kgf·cm) is a value at the

(0.8kgf

time of production. At the time of service, perform the

procedure at a torque 10% less than 0.078N

·m (0.8kgf·cm).

(See "SERVICE NOTE" as for tightening torque.)

2.1.2 Destination of connectors

Two kinds of double-arrows in connection tables respectively

show kinds of connector/wires.

: Wire: Flat wire : Board to board (B-B)

: The connector of the side to remove

CONN. No. PIN No.CONNECTOR

CN2a

CN2b

MAIN CN101

MAIN CN103

MONI/ BW CN761

MIC CN762

2.1.3 Disconnection of connectors (Wires)

Wire

· Pull both ends of the connector in the arrow

direction, remove the lock and disconnect the flat

wire.

B-B Connector

B-B Connector

· Pull the both ends of the board in the direction of the arrow, and remove the B-B Connector.

FPC Connector

· Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After

removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

Wire

FPC Connector

Lock

B-B Connector

Fig.3-1-1

2.1.4 Tools required for disassembly and assembly

Torque driver

YTU94088

Chip IC replacement jig

PTS40844-2

Bit

YTU94088-003

Cleaning cloth

KSMM-01

Tweezers

P-895

·m

40

2

• Torque driver

Be sure to use to fastening the mechanism and exterior parts

because those parts must strictly be controlled for tightening

torque.

• Bit

This bit is slightly longer than those set in conventional torque

drivers.

• Tweezers

To be used for removing and installing parts and wires.

• Chip IC replacement jig

To be used for replacement of IC.

• Cleaning cloth

Recommended cleaning cloth to wipe down the video heads,

mechanism (tape transport system), optical lens surface.

2.2 ASSEMBLY AND DISASSEMBLY OF MAIN PARTS

2.2.1 Assembly and disassembly

When reassembling, perform the step(s) in reverse order.

STEP

No.

[1]

[2]

[8]

PART

TOP COVER ASSEMBLY

UPPER ASSEMBLY

(Inc. VF ASSEMBLY,

SPEAKER/MONITOR)

VF ASSEMBLY

(∗1) Order of steps in Procedure

When reassembling, preform th e step(s) in the reverseorder.

These numbers are also used as the identification (location)

No. of parts Figures.

(∗2) Part to be removed or installed.

(∗3) Fig. No. showing Procedure or Part Location.

C = CABINET

(∗4) Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped or unsoldered.

S = Screw

L = Lock, Release, Hook

SD = Solder

CN = Connector

[Example]

• 4 (S1a) = Remove four S1a screws.

• 3 (L1a) = Disengage three L1a hooks.

• 2 (SD1a) = Unsolder two SD1a points.

• CN1a = Remove a CN1a connector.

(∗5) Adjustment information for installation.

Fig.

No.

Fig.C1

Fig.C2-1

Fig.C2-2

POINT

S1,2(L1)

S2a,2(S2b),3(S2c)

2(S2d),S2e,S2c

L2,CN2a,b

2(S8),L8,CN8a

( 4) ( 5)( 2) ( 3)( 1)

NOTE

-

-

NOTE 8a

NOTE 8b

1-8 (No.YF009)

Fig.3-1-2

Page 9

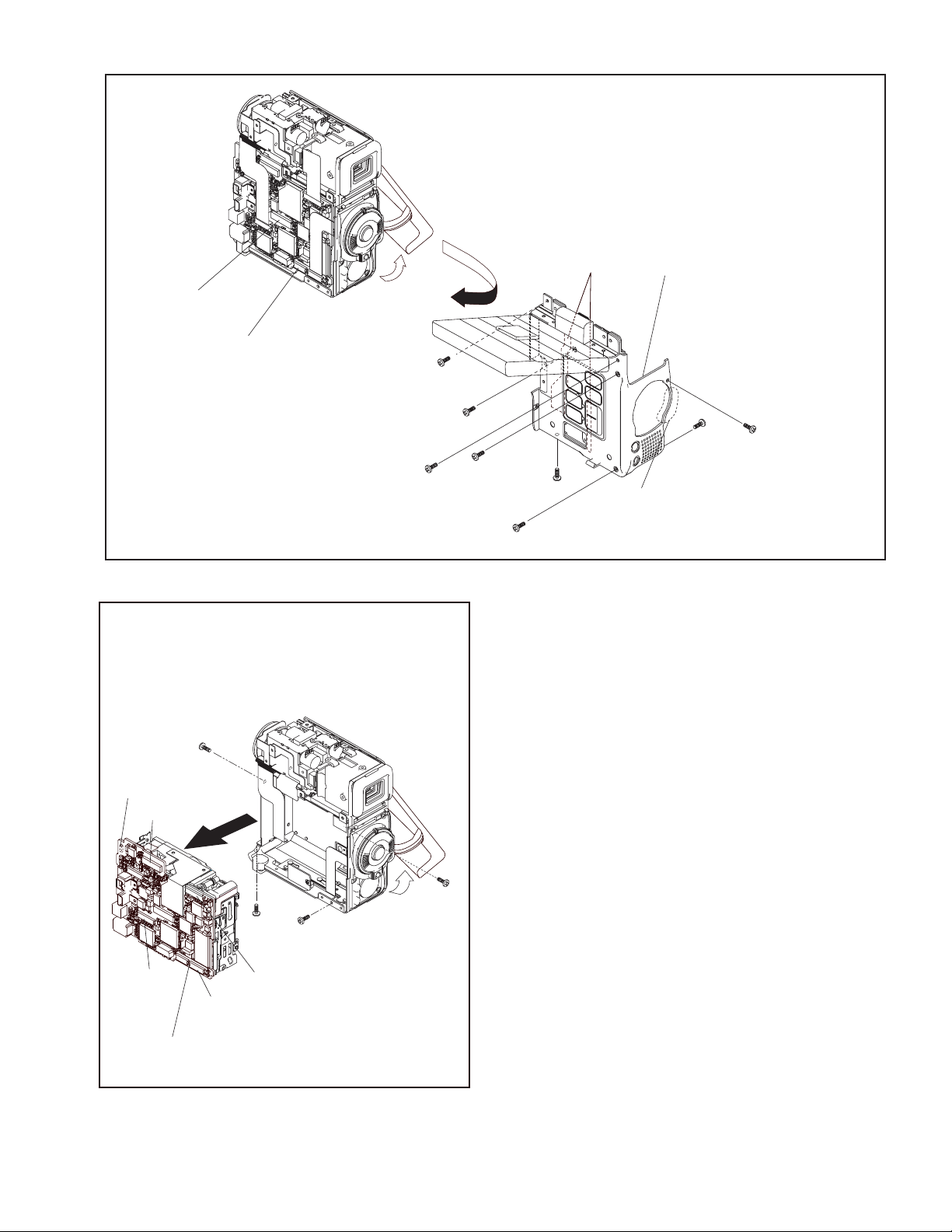

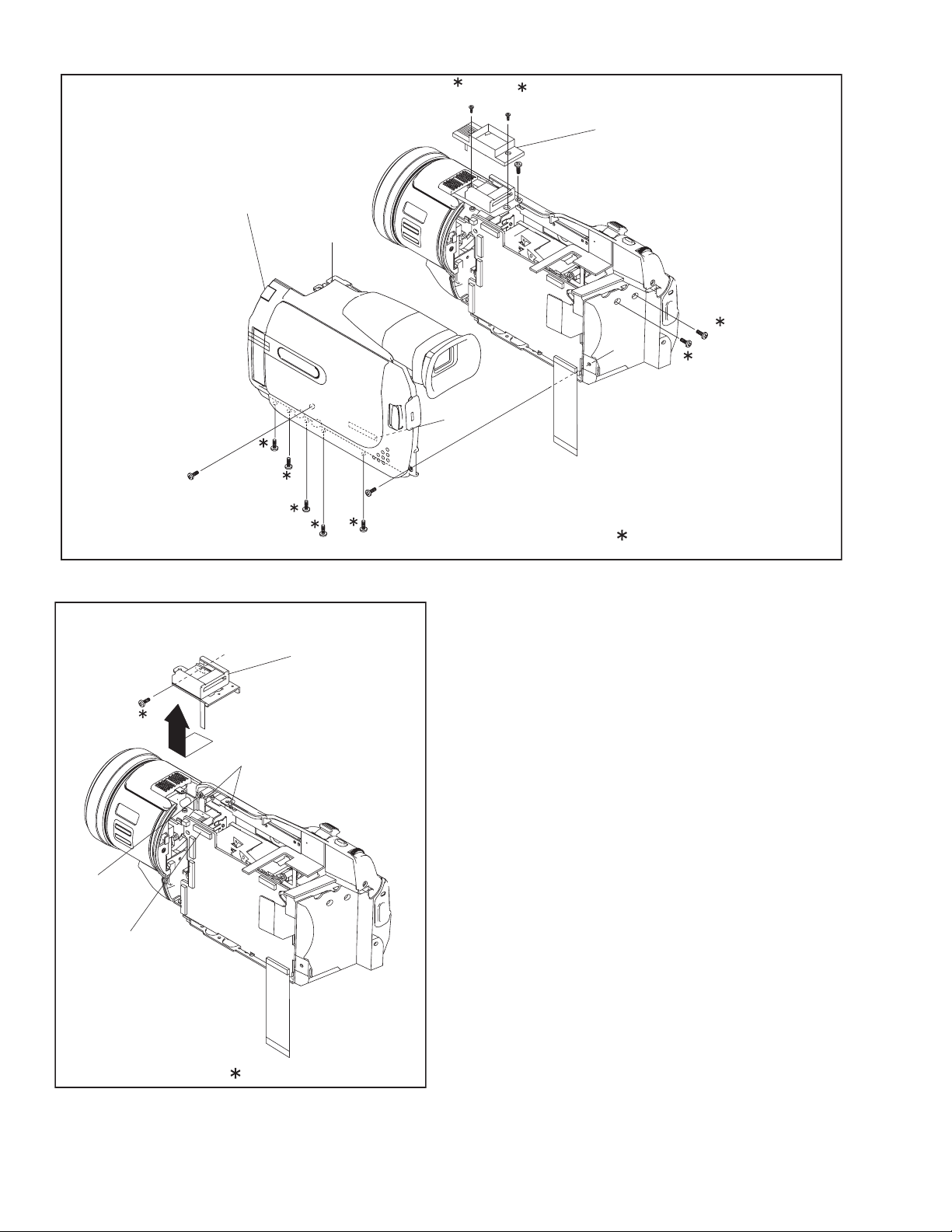

2.2.2 ASSEMBLY/DISASSEMBLY OF CABINET PARTS AND ELECTRICAL PARTS

zDisassembly procedure

Step

No.

[10]

[11]

[12]

[13]

[14]

[15]

Parts Name

[1]

COVER(SHOE) ASSY

/[2]

UPPER ASSY

[3]

SHOE ASSY

[4]

FRONT ASSY

[5]

REAR ASSY

[6]

OP BLOCK ASSY

[7]

BASE

[8]

LOWER CASE ASSY

[9]

MAIN BOARD ASSY

PRE/MDA BOARD ASSY

MECHANISM ASSY

VF ASSY

MONITOR BOARD ASSY

COVER(UPPER)ASSY

MONITOR ASSY

Fig.No.

(S1a),(S1b)

Fig.C1

4(S2a),(S2b),(S2c),2(S2d),2(S2e),CN2

Fig.C2

CN3,S3,2(L3)

Fig.C3

CN4a,CN4b,(S4a),(S4b),(S4c),COVER(JACK)

Fig.C4

CN5,3(S5),COVER(DC)

Fig.C5

CN6a,CN6b,(S6a),(S6b),L6

Fig.C6

2(S7)

CN8a,CN8b,(S8a),3(S8b)

Fig.C7-1

(S9a),(S9b),L9,CN9a,CN9b

/Fig.C7-2

2(S10a),SHIELD COVER(PR),L10a

CN10a,b,c,d,e,f,(S10b),L10b

S(S11),BRACKET(MECHA)

CN12,(S12a),(S12b),L12

Fig.C8

Fig.C9

CN13a,CN13b,(S13a),6(S13b),KNOB(SLIDE)

2(S14)

Fig.C10-1

2(S15a),2(S15b)

Fig.C10-2

Point Note

NOTE2:

Open the MONITOR ASSY.

NOTE4a:

The screw no.16 is under the COVER (JACK).

NOTE4b:

CN4b is contained in only models with strobe function.

NOTE4c:

-

NOTE2

-

NOTE4a,b,c

-

-

-

-

-

-

-

-

NOTE13a,b,c

NOTE14

NOTE15

zDestination of connectors

CONN.

No.

CN2 MAIN CN106 MONITOR CN701 57

CN3 MAIN CN103 SHOE 16

CN4a MAIN CN111 FRONT CN501 30

CN4b MAIN CN109 STROBE CN6501 16

CN5 MAIN CN110 REG CN601 80

CN6a MAIN CN102 CCD - 20

CN6b MAIN CN104 OP BLOCK ASSY - 24

CN8a MAIN CN112 JACK CN201 12

CN8b MAIN CN114 ZOOM DIAL OPE - 16

CN9a MAIN CN108 PRE/MDA CN408 40

CN9b MAIN CN107 PRE/MDA CN401 40

CN10a PRE/MDA CN402 HEAD - 8

CN10b PRE/MDA CN404 DRUM MOTER - 11

CN10c PRE/MDA CN406 SENSOR - 16

CN10d PRE/MDA CN407

CN10e PRE/MDA CN403 LOADING MOTOR - 6

CN10f PRE/MDA CN405 CAPSTAN MOTOR - 18

CN12 MONITOR CN703 VF BL CN801 20/18

CN13a MONITOR CN702 BL

CN13b MONITOR CN704 SPEAKER - 2

After removing the FRONT ASSEMBLY, the OP BLOCK

ASSEMBLY is not covered with anything. Be careful not to

damage the OP BLOCK ASSEMBLY.

NOTE13a:

Take care not to lose the KNOB because the KNOB is

removed together with the MONITOR BOARD ASSY.

NOTE13b:

In attachment procedure, take care not to insert a wire.

NOTE13c:

Prior to removing the MONITOR BOARD ASSY, remove the

memory card.

NOTE14:

Prior to removing the COVER(UPPER)ASSY, close the

MONITOR.

NOTE15:

When removing the MONITOR ASSY, take care not to cut

or damage the FPC.

CONNECTOR

ROTARY ENCODER SW

PIN.

No.

- 6

CN601/CN605

38/21.21

(No.YF009)1-9

Page 10

9

(S2d)

[2]

(S2b)

NOTE2

7

6

(S2a)

5

(S2a)

4

(S2a)

a

3

(S2a)

8

(S2c)

(S1a)

CN2

Fig.C1

1

2

(S1b)

[1]

10

(S2d)

a

11

(S2e)

12

(S2e)

: 0.098N.m(1.0kgf.cm)

b

CN3

13

(S3)

b

L3

[3]

: 0.098N.m(1.0kgf.cm)

Fig.C2

1-10 (No.YF009)

Page 11

[4]

COVER(JACK)

15

(S4b)

16

(S4c)

NOTE4a

a

g

a

CN4b

NOTE4b

14

(S4a)

NOTE4c

CN4a

Fig.C3

[5]

CN5

a

Fig.C4

a

19

(S5)

17

(S5)

18

(S5)

COVER(DC)

(No.YF009)1-11

Page 12

21

(S6b)

[6]

CN6b

20

(S6a)

CN6a

d

L6

[7]

d

a

b

22

(S7)

23

(S7)

Fig.C5 Fig.C6

a

b

27

(S8b)

[8]

26

(S8b)

c

CN8a

d

e

c

d

CN8b

a

b

e

a

b

25

(S8b)

24

(S8a)

[9]/[10]/[11]

Fig.C7-1

1-12 (No.YF009)

Page 13

28

(S9a)

SHIELD COVER(PR)

30

(S10a)

32

(S10b)

CN10c

CN9a

31

(S10a)

CN10f

c

L10a

CN10b

a

a

b

33

(S11)

CN10a

b

34

(S11)

CN10e

L10b

35

(S11)

[11]

BRACKET(MECHA)

29

(S9b)

d

[10]

L9

c

d

[9]

CN10d

CN9b

: 0.068N.m(0.7kgf.cm)

Fig.C7-2

36

(S12a)

CN12

L12

37

(S12b)

[12]

Fig.C8

(No.YF009)1-13

Page 14

39

(S13b)

40

(S13b)

38

(S13a)

44

(S13b)

(S13b)

42

(S13b)

43

CN13a

Fig.C9

KNOB(SLIDE)

NOTE13a

41

(S13b)

CN13b

[13]

NOTE13b NOTE13c

NOTE14

[14]

1-14 (No.YF009)

a

45

(S14)

a

b

Fig.C10-1

b

46

(S14)

Page 15

49

(S15b)

50

(S15b)

[15]

47

(S15a)

48

(S15a)

a

a

NOTE15

b

b

: 0.198N.m(2.0kgf.cm)

Fig.C10-2

(No.YF009)1-15

Page 16

2.2.3 SERVICE NOTE

cm)

.

[8][1] [2]

m (2.0kgf

.

C6 C7-1

[6] [7][5]

[4]

[3]

C4 C5

C3

C2

C1

[13]

[12] [14] [15]

C10-1 C10-2C7-2 C9

C8

cm) : 0.198N

.

m (1.0kgf

.

cm) : 0.098N

.

m (0.7kgf

.

cm) : 0.068N

.

1-16 (No.YF009)

[10] [11]

CABINET PARTS AND ELECTRICAL PARTS

1 2 3 4 5 6 7 8 9 101112131415161718192021222324252627

Symbol No.

Place to stick screw

Removing order of screw

Screw tightening torque

Reference drawing (Fig.No.)

[9]

CABINET PARTS AND ELECTRICAL PARTS

28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50

Symbol No.

Place to stick screw

Removing order of screw

m (0.8kgf

.

: 0.078N

1) * : Don't reuse the screw, because screw lock bond was applied to them.

2) Pay careful attention to tightening torque for each screw.

NOTE:

Screw tightening torque

Reference drawing (Fig.No.)

Page 17

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY CAMCORDER CATEGORY 12, 3-chome, Moriya-cho, kanagawa-ku, Yokohama, kanagawa-prefecture, 221-8528, Japan

(No.YF009)

Printed in Japan

WPC

Loading...

Loading...