Page 1

SERVICE MANUAL

DIGITAL VIDEO CAMERA

VICTOR COMPANY OF JAPAN, LIMITED

VIDEO DIVISION

S40894

GR-DV1800EG/EK,DV2000EG/EK

GR-DV1800EG/EK,DV2000EG/EK

SPECIFICATIONS

For General

No. 86604

Power supply : DC 6.3 } V (Using AC Power Adapter/Charger)

Power consumption

LCD monitor off, viewfinder on : Approx. 4.4 W

LCD monitor on, viewfinder off : Approx. 5.3 W

Dimensions (W x H x D) : 74 mm x 90 mm x 178 mm

Weight : Approx. 660 g (without cassette, memory card and battery)

Operating temperature : 0°C to 40°C

Operating humidity : 35% to 80%

Storage temperature : –20°C to 50°C

Pickup : 1/4" CCD (Progressive Scan)

Lens : F 1.8, f = 3.8 mm to 38 mm, 10:1 power zoom lens

Filter diameter : ø52 mm

LCD monitor : 3.5" diagonally measured, LCD panel/TFT active matrix system

Viewfinder : Electronic viewfinder with 0.44" colour LCD

Speaker : Monaural

For Digital Video Camera

Format : DV format (SD mode)

Signal format : PAL standard

Recording/Playback format : Video: Digital component recording

Cassette : Mini DV cassette

Tape speed : SP: 18.8 mm/s

Maximum recording time : SP: 80 min.

(using 80 min. cassette) LP: 120 min.

For Digital Still Camera

Storage media : SD Memory Card/MultiMediaCard

Compression system : JPEG (compatible)

File size : 3 modes (UXGA: 1600 x 1200 pixels/XGA: 1024 x 768 pixels/

Picture quality : 2 modes (FINE/STANDARD)

Approximate number of storable images

(with the provided MultiMediaCard [8 MB])

FINE : 50 (VGA), 24 (XGA), 10 (UXGA)

STANDARD : 150 (VGA), 72 (XGA), 30 (UXGA)

(with an optional MultiMediaCard [16 MB])

FINE : 100 (VGA), 48 (XGA), 20 (UXGA)

STANDARD : 300 (VGA), 144 (XGA), 60 (UXGA)

DC 7.2 } V (Using battery pack)

(with the LCD monitor closed and the viewfinder pushed back

in, without the lens hood)

Approx. 740 g (incl. cassette, memory card and battery)

: Audio: PCM digital recording, 32 kHz 4-channel (12-bit),

48 kHz 2-channel (16-bit)

LP: 12.5 mm/s

VGA: 640 x 480 pixels)

Camcorder

For Connectors

AV

Video output : 1 V (p-p), 75 Ω, analogue

Video input (GR-DV2000 only) : 0.5 V (p-p) – 2.0 V (p-p), 75 Ω, analogue

Audio output : 308 mV (rms), 1 kΩ, analogue, stereo

Audio input (GR-DV2000 only) : 308 mV (rms), 50 kΩ, analogue, stereo

DV

Output : 4-pin, IEEE 1394 compliant

Input (GR-DV2000 only) : 4-pin, IEEE 1394 compliant

PHONE

Headphone output : ø3.5 mm, stereo

MIC

External microphone input : 459 µV (rms), high impedance unbalanced, ø3.5 mm (stereo)

PRINTER : For an optional video printer equipped with a PRINT DATA

connector

AC power adapter/charger AA-V40EG or AA-V40EK

Power requirement : AC 110 V to 240 V`, 50 Hz/60 Hz

Power consumption : 23 W

Output

Charge : DC 7.2 } , 1.2 A

VTR : DC 6.3 } , 1.8 A

Dimensions (W x H x D) : 68 mm x 38 mm x 110 mm

Weight

AA-V40EG : Approx. 260 g

AA-V40EK : Approx. 340 g

Jack Box CU-V504U

For General

Dimensions (W x H x D) : 37.5 mm x 18.5 mm x 55 mm

Weight : Approx. 30 g

For Connectors

USB : TYPE B

S-VIDEO : Y: 1 V (p-p), 75 Ω, analogue output

EDIT : ø3.5 mm, 2-pole

Specifications shown are for SP mode unless otherwise indicated. E & O.E. Design and specifications

subject to change without notice.

C: 0.29 V (p-p), 75 Ω, analogue output

Printed in Japan

This service manual is printed on 100% recycled paper.

COPYRIGHT © 2001 VICTOR COMPANY OF JAPAN, LTD.

No. 86604

January 2001

Page 2

TABLE OF CONTENTS

Section Title Page Section Title Page

Important Safety Precautions

INSTRUCTIONS

1. DISASSEMBLY

1.1 BEFORE ASSEMBLY AND DISASSEMBLY ......................... 1-1

1.1.1 Precautions..................................................................... 1-1

1.1.2 Assembly and disassembly ............................................ 1-1

1.1.3 Destination of connectors ............................................... 1-1

1.1.4 Disconnection of Connectors (Wires) ............................. 1-1

1.2 JIGS AND TOOLS REQUIRED FOR DISASSEMBLY,

ASSEMBLY AND ADJUSTMENT .......................................... 1-2

1.2.1 Tools required for adjustments ....................................... 1-2

1.3 DISASSEMBLY/ASSEMBLY OF CABINET PARTS AND

BOARD ASSEMBLY .............................................................. 1-2

1.3.1 Disassembly flow chart ................................................... 1-2

1.3.2 Disassembly method ...................................................... 1-3

1.4 E.VF(COLOR) ....................................................................... 1-8

1.4.1. Disassembly/Assembly of the 6 E.VF(COLOR) ............ 1-8

DISASSEMBLY OF THE 7 OP BLOCK AND CCD BOARD ASSEMBLIES

1.5

1.5.1 Precautions..................................................................... 1-9

1.5.2 How to remove ............................................................... 1-9

1.5.3 How to install .................................................................. 1-9

1.5.4 Replacement of Service Repair Parts ............................ 1-9

1.6

DISASSEMBLY/ASSEMBLY OF THE @ MONITOR ASSEMBLY ...

1.6.1 @ Monitor Assembly and Hinge Assembly ................... 1-10

1.7 MANUAL EJECTION OF THE CASSETTE TAPE ................ 1-11

1.8 EMERGENCY DISPLAY ...................................................... 1-12

1.9 SERVICE NOTE .................................................................. 1-13

2. MECHANISM ADJUSTMENT

2.1

PRELIMINARY REMARKS ON ADJUSTMENT AND REPAIR ....

2.1.1 Precautions..................................................................... 2-1

2.1.2 Notes on procedure for disassemby/assembly............... 2-1

2.2 JIGS AND TOOLS REQUIRED FOR DISASSEMBLY,

ASSEMBLY AND ADJUSTMENT .......................................... 2-2

2.2.1 Tools required for adjustments ....................................... 2-2

2.3 DISASSEMBLY/ASSEMBLY OF MECHANISM ASSEMBLY . 2-3

2.3.1 General statement .......................................................... 2-3

2.3.2 Explanation of mechanism mode ................................... 2-3

2.3.3 Mechanism timing chart.................................................. 2-4

2.4 DISASSEMBLING PROCEDURE TABLE ............................. 2-5

2.4.1 Disassembly/assembly ................................................... 2-7

2.4.2 List of procedures for disassembly ............................... 2-13

2.5 CHECKUP AND ADJUSTMENT OF MECHANISM PHASE 2-14

2.6 MECHANISM ADJUSTMENTS ........................................... 2-15

2.6.1 Adjustment of the slide guide plate............................... 2-15

2.6.2

Adjustment of the Tension Arm and Pad Arm Assemblies .

2.6.3 Adjustment of the Slide Lever 2.................................... 2-16

2.7 JIG CONNECTOR CABLE CONNECTION ......................... 2-17

2.8 SERVICE NOTE .................................................................. 2-18

3. ELECTRICAL ADJUSTMENT

3.1 PRECAUTION ....................................................................... 3-1

3.2 SETUP ................................................................................... 3-2

3.3 MONITOR ADJUSTMENT ..................................................... 3-3

3.3.1 PLL (MONI)..................................................................... 3-3

3.4 ELECTRONIC VIEWFINDER (E.VF) ADJUSTMENT ............ 3-3

3.4.1 PLL (VF) ......................................................................... 3-3

1-9

1-10

2-1

2-16

4. CHARTS AND DIAGRAMS

NOTES OF SCHEMATIC DIAGRAM .......................................... 4-1

CIRCUIT BOARD NOTES ........................................................... 4-2

4.1 BOARD INTERCONNECTIONS ........................................... 4-3

4.2 MAIN IF SCHEMATIC DIAGRAM (1/2) ................................. 4-5

4.3 MAIN IF SCHEMATIC DIAGRAM (2/2) ................................. 4-7

4.4 CPU SCHEMATIC DIAGRAM ............................................... 4-9

4.5 MSD CPU SCHEMATIC DIAGRAM .................................... 4-11

4.6 DV MAIN SCHEMATIC DIAGRAM ..................................... 4-13

4.7 V OUT SCHEMATIC DIAGRAM ......................................... 4-15

4.8 ANA IN SCHEMATIC DIAGRAM [GR-DV2000EG/EK] ....... 4-17

4.9 TG/VDR SCHEMATIC DIAGRAM ....................................... 4-19

4.10 CDS/AD SCHEMATIC DIAGRAM .................................... 4-21

4.11 DSP SCHEMATIC DIAGRAM .......................................... 4-23

4.12 OP DRIVE SCHEMATIC DIAGRAM ................................ 4-25

4.13 DSC SCHEMATIC DIAGRAM .......................................... 4-27

4.14 P SHIFT SCHEMATIC DIAGRAM ................................... 4-29

4.15 USB SCHEMATIC DIAGRAM .......................................... 4-31

4.16 DSC IF SCHEMATIC DIAGRAM ..................................... 4-33

4.17 MDA SCHEMATIC DIAGRAM ......................................... 4-35

4.18 PRE/REC SCHEMATIC DIAGRAM ................................. 4-37

4.19 AUDIO SCHEMATIC DIAGRAM ...................................... 4-39

4.20 REG SCHEMATIC DIAGRAM .......................................... 4-41

4.21 MONITOR SCHEMATIC DIAGRAM ................................ 4-43

4.22 JACK SCHEMATIC DIAGRAM ........................................ 4-45

4.23 EJECT AND DECK OPE. SCHEMATIC DIAGRAMS ...... 4-47

4.24 CCD SCHEMATIC DIAGRAM .......................................... 4-48

4.25 ZOOM OPE. UNIT, POWER OPE. UNIT,

SUB OPE. UNIT, MENU SW UNIT AND

FRONT FPC UNIT SCHEMATIC DIAGRAMS ................. 4-49

4.26 MAIN CIRCUIT BOARD ................................................... 4-51

4.27 DSC CIRCUIT BOARD .................................................... 4-57

4.28 PRE/MDA CIRCUIT BOARD ............................................ 4-59

4.29 AUDIO CIRCUIT BOARD................................................. 4-61

4.30 REG CIRCUIT BOARD .................................................... 4-63

4.31 MONITOR CIRCUIT BOARD ........................................... 4-65

4.32 JACK CIRCUIT BOARD ................................................... 4-67

4.33 EJECT AND DECK OPE. CIRCUIT BOARDS ................. 4-69

4.34 CCD CIRCUIT BOARD .................................................... 4-71

4.35 VOLTAGE CHARTS ......................................................... 4-72

4.36 POWER SYSTEM BLOCK DIAGRAM ............................. 4-77

4.37 REGULATOR SYSTEM BLOCK DIAGRAM .................... 4-79

4.38 VIDEO SYSTEM BLOCK DIAGRAM ............................... 4-81

4.39 AUDIO SYSTEM BLOCK DIAGRAM ............................... 4-85

5. PARTS LIST

5.1 PACKING AND ACCESSORY ASSEMBLY <M1> ................ 5-1

5.2 FINAL ASSEMBLY <M2> ...................................................... 5-3

5.3 MECHANISM ASSEMBLY <M3>.......................................... 5-6

5.4 ELECTRONIC VIEWFINDER ASSEMBLY <M4> ................. 5-8

5.5 MONITOR ASSEMBLY <M5> ............................................... 5-9

5.6 ELECTRICAL PARTS LIST ................................................. 5-10

MAIN BOARD ASSEMBLY <01> ............................................. 5-10

DSC BOARD ASSEMBLY <02> .............................................. 5-18

PRE/MDA BOARD ASSEMBLY <03> ..................................... 5-20

AUDIO BOARD ASSEMBLY <04> .......................................... 5-21

REG BOARD ASSEMBLY <05> .............................................. 5-23

MONITOR BOARD ASSEMBLY <06> ..................................... 5-24

JACK BOARD ASSEMBLY <07> ............................................ 5-25

EJECT BOARD ASSEMBLY <08> .......................................... 5-26

DECK OPE. BOARD ASSEMBLY <09> .................................. 5-26

CCD BOARD ASSEMBLY <10> .............................................. 5-26

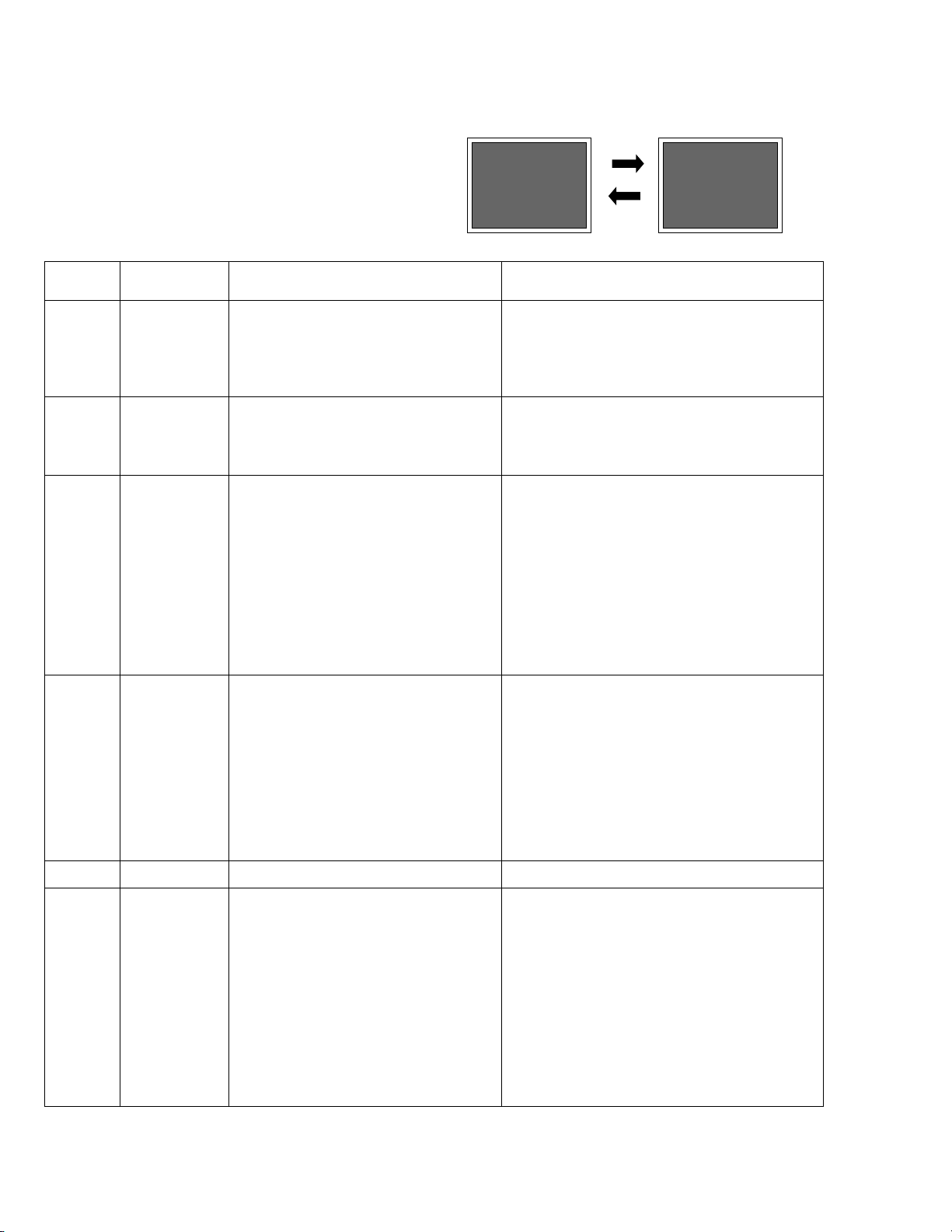

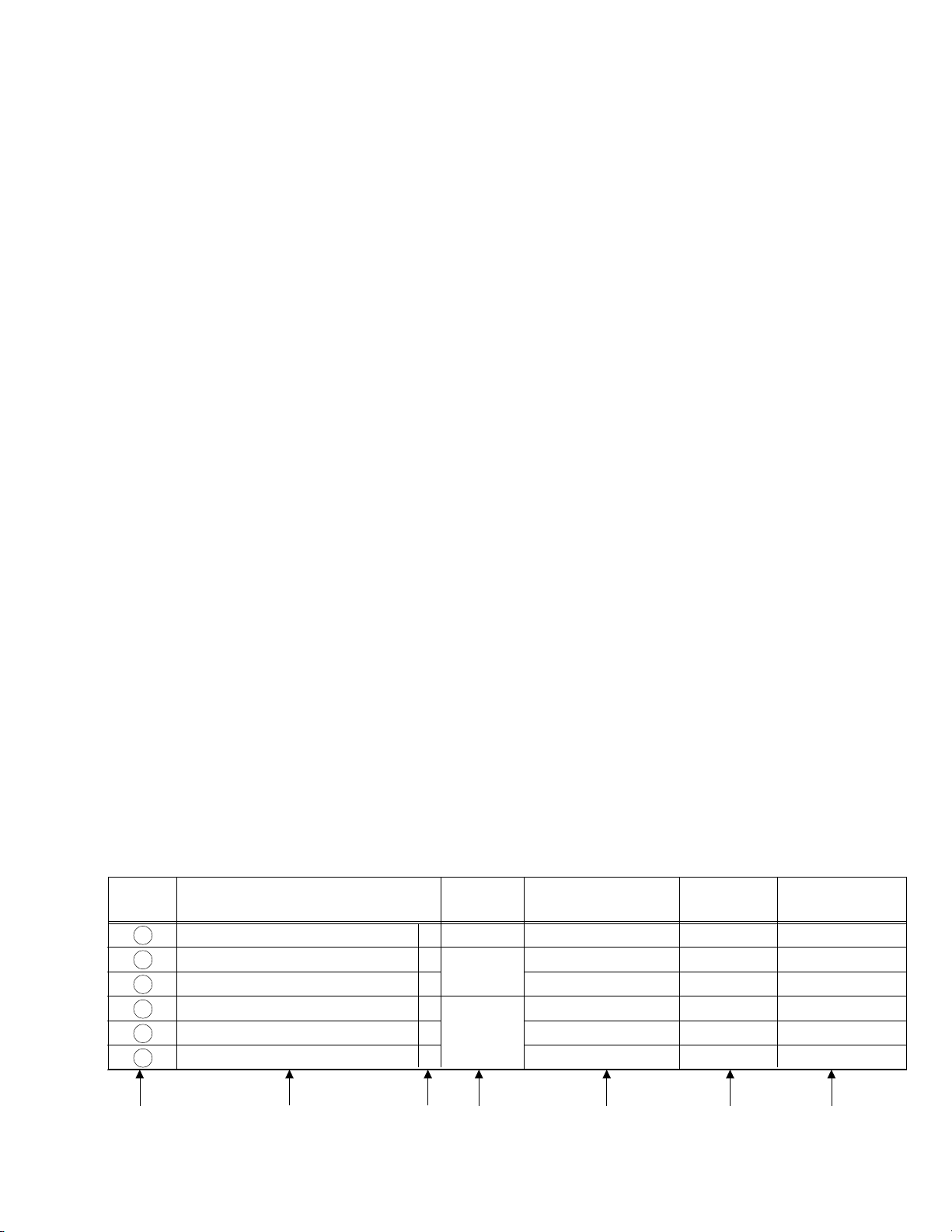

The following table lists the differing points between Models GR-DV1800EG/EK and GR-DV2000EG/EK in this serise.

GR-DV1800EG GR-DV1800EK GR-DV2000EG GR-DV2000EK

AV INPUT NOT USED USED

S INPUT/OUTPUT NOT USED/USED(JACK BOX) USED/USED(JACK BOX)

DV INPUT NOT USED USED

AC ADAPTOR CHARGER AA-V40EG AA-V40EK AA-V40EG AA-V40EK

Page 3

Important Safety Precautions

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes of the

countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the following precautions

when a set is being serviced.

Precautions during Servicing

•

1. Locations requiring special caution are denoted by labels and inscriptions on the cabinet, chassis and certain parts of the product.

When performing service, be sure to read and comply with these

and other cautionary notices appearing in the operation and service manuals.

2. Parts identified by the ! symbol and shaded ( ) parts are

critical for safety.

Replace only with specified part numbers.

Note: Parts in this category also include those specified to com-

ply with X-ray emission standards for products using

cathode ray tubes and those specified for compliance

with various regulations regarding spurious radiation

emission.

3. Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

4. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

5. Use specified insulating materials for hazardous live parts. Note

especially:

1) Insulation Tape 3) Spacers 5) Barrier

2) PVC tubing 4) Insulation sheets for transistors

6. When replacing AC primary side components (transformers, power

cords, noise blocking capacitors, etc.) wrap ends of wires securely

about the terminals before soldering.

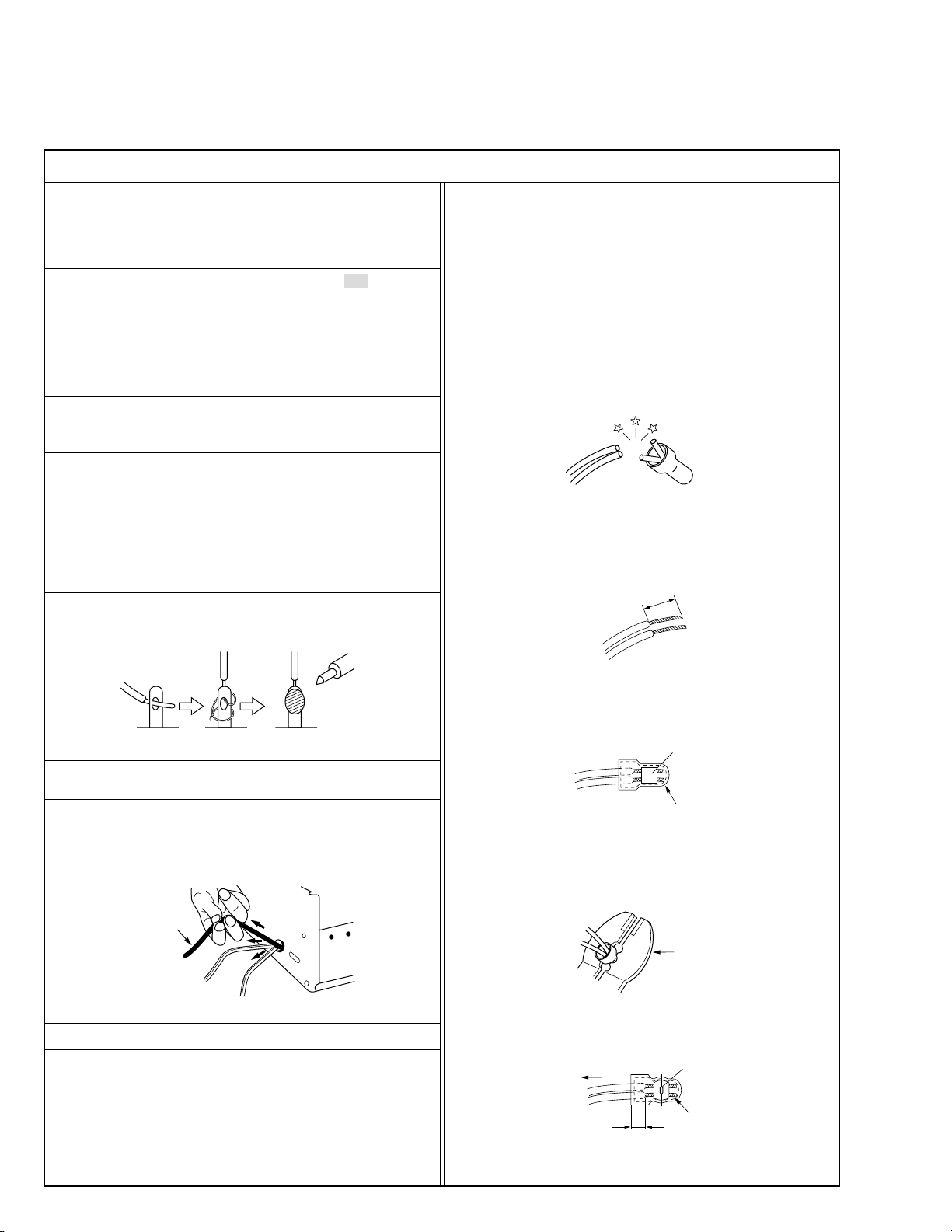

12. Crimp type wire connector

In such cases as when replacing the power transformer in sets

where the connections between the power cord and power transformer primary lead wires are performed using crimp type connectors, if replacing the connectors is unavoidable, in order to prevent

safety hazards, perform carefully and precisely according to the

following steps.

1) Connector part number : E03830-001

2) Required tool : Connector crimping tool of the proper type which

will not damage insulated parts.

3) Replacement procedure

(1) Remove the old connector by cutting the wires at a point

close to the connector.

Important : Do not reuse a connector (discard it).

cut close to connector

Fig.3

(2) Strip about 15 mm of the insulation from the ends of the

wires. If the wires are stranded, twist the strands to avoid

frayed conductors.

15 mm

Fig.1

7. Observe that wires do not contact heat producing parts (heatsinks,

oxide metal film resistors, fusible resistors, etc.)

8. Check that replaced wires do not contact sharp edged or pointed

parts.

9. When a power cord has been replaced, check that 10-15 kg of

force in any direction will not loosen it.

Power cord

Fig.2

10. Also check areas surrounding repaired locations.

11. Products using cathode ray tubes (CRTs)

In regard to such products, the cathode ray tubes themselves, the

high voltage circuits, and related circuits are specified for compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the cathode ray tubes and other parts with only the specified parts. Under

no circumstances attempt to modify these circuits.

Unauthorized modification can increase the high voltage value and

cause X-ray emission from the cathode ray tube.

Fig.4

(3) Align the lengths of the wires to be connected. Insert the

wires fully into the connector.

Metal sleeve

Connector

Fig.5

(4) As shown in Fig.6, use the crimping tool to crimp the metal

sleeve at the center position. Be sure to crimp fully to the

complete closure of the tool.

1

.2

5

2

.0

5

.5

Fig.6

(5) Check the four points noted in Fig.7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Fig.7

Crimping tool

Crimped at approx. center

of metal sleeve

Conductors extended

I

S40888-01

Page 4

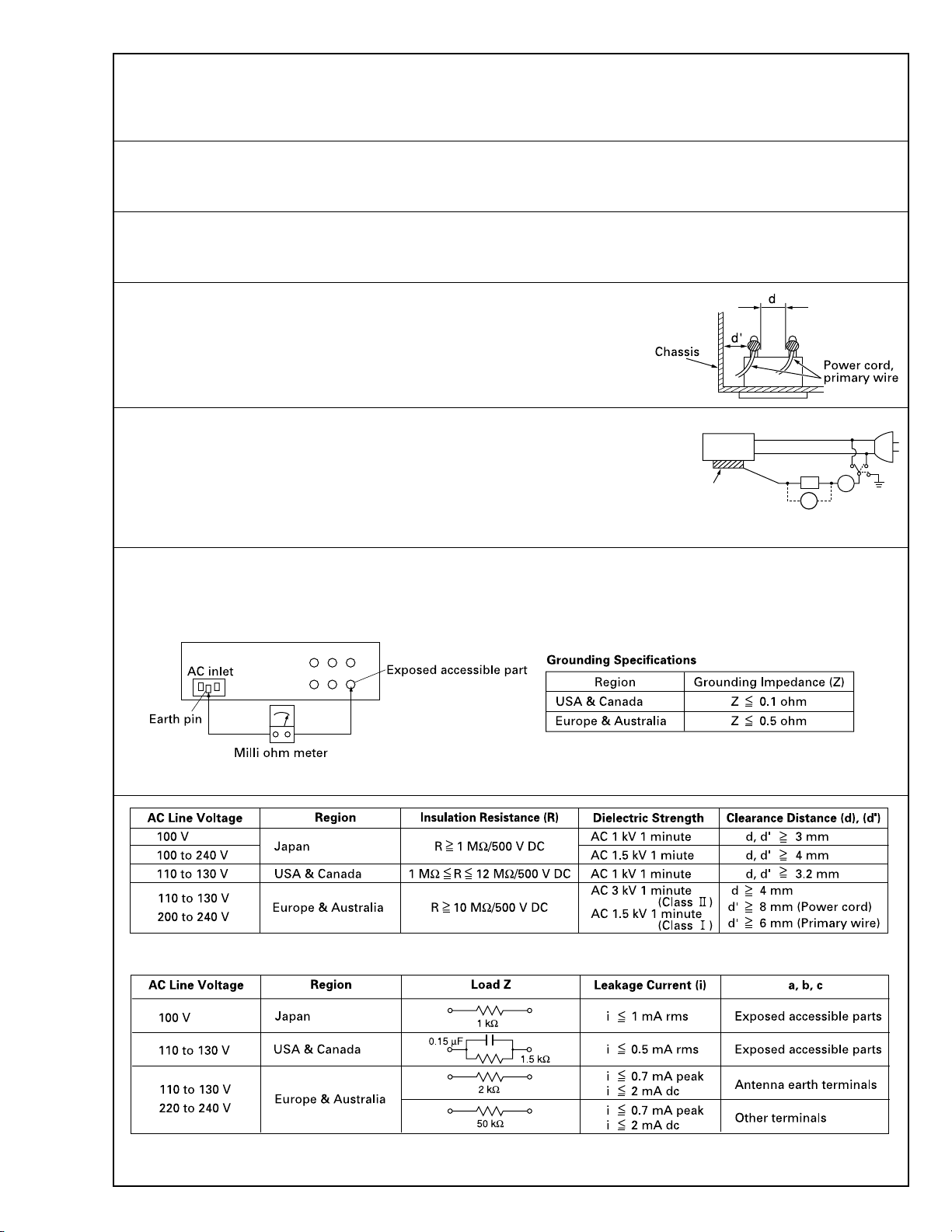

Safety Check after Servicing

•

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been returned

to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety

standards.

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed parts of the set (RF terminals, antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed accessible parts of the set (RF terminals, antenna terminals, video and audio input and output terminals,

microphone jacks, earphone jacks, etc.). See table 1 below.

3. Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d’) between soldered terminals, and between terminals and surrounding metallic parts. See table 1

below.

Fig. 8

4. Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs and

externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and

output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible

parts. Use an AC voltmeter to measure across both terminals of load Z. See figure 9 and following

table 2.

Externally

exposed

accessible part

Fig. 9

Z

V

ab

A

c

5. Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin in AC inlet and externally exposed accessible parts (Video in, Video out,

Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and exposed accessible parts. See figure 10 and grounding specifications.

Fig. 10

Table 1 Specifications for each region

Table 2 Leakage current specifications for each region

Note: These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

II

S40888-01

Page 5

Page 6

SECTION 1

DISASSEMBLY

1.1 BEFORE ASSEMBLY AND DISASSEMBLY

1.1.1 Precautions

1. Be sure to remove the power supply unit prior to mounting and soldering of parts.

2. When removing a component part that needs to disconnect the connector and to remove the screw for removing itself, first disconnect the connecting wire from the

connector and then remove the screw beforehand.

3. When connecting and disconnecting the connectors, be

careful not to damage the wire.

4. Carefully remove and handle the part to which some

spacer or shield is attached for reinforcement or insulation.

5. When replacing chip parts (especially IC parts), desolder

completely first (to prevent peeling of the pattern).

6. Tighten screws properly during the procedures.

Unless specified otherwise, tighten screws at a torque

of 0.069N

•

m(0.7kgf•cm).

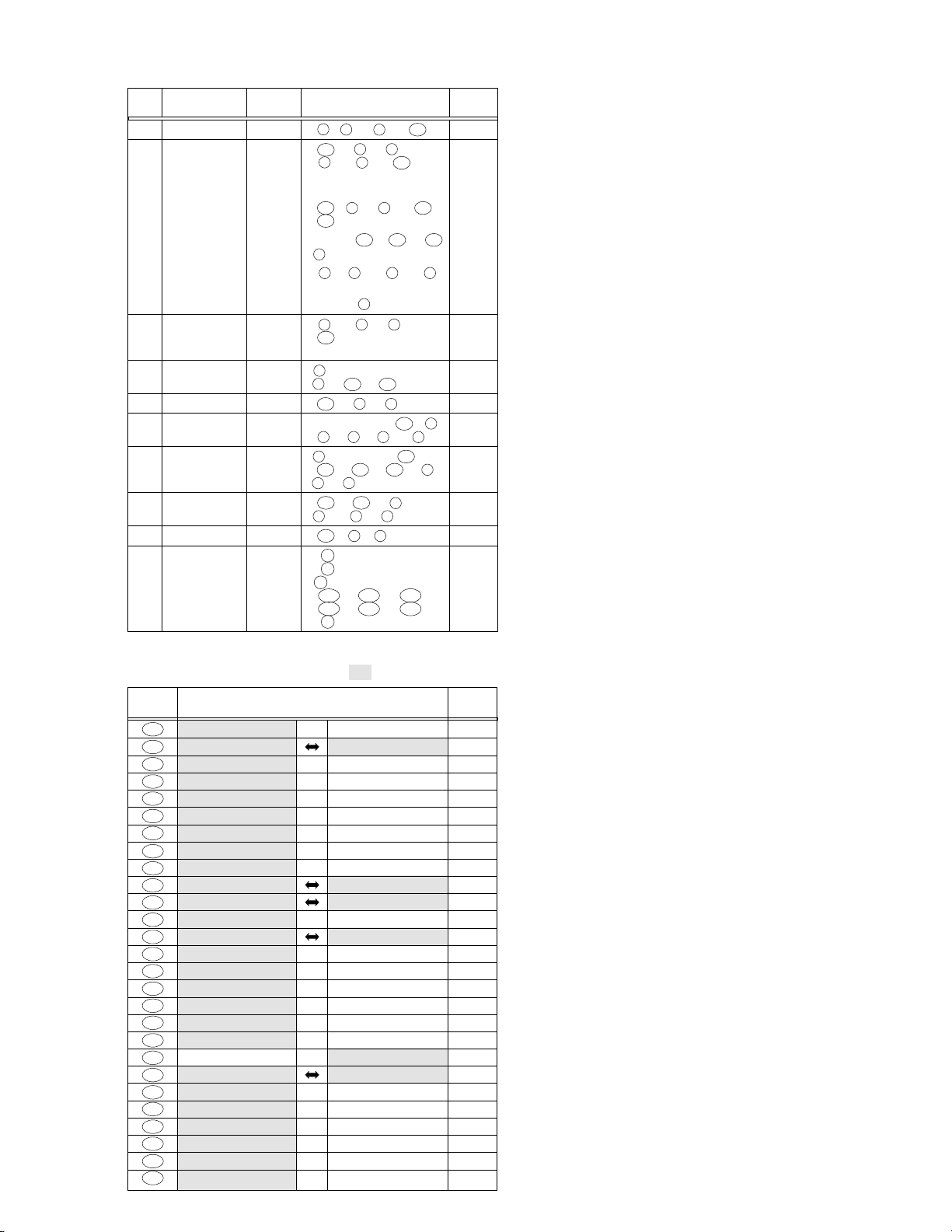

1.1.2 Assembly and disassembly

STEP

No.

1

2

PART

ZOOM OPE UNIT Fig.1-3-1

FRONT COVER Fig.1-3-2 CN 2a ,2(S 2 a),(S 2 b), NOTE2a

ASSY 2(S 2 c),2(S 2 b),CN 2b NOTE2b

Fig.No.

POINT NOTE

3(S 1 ),(L 1 a),4(L 1 b),CN 1a

–

NOTE2c

NOTE2d

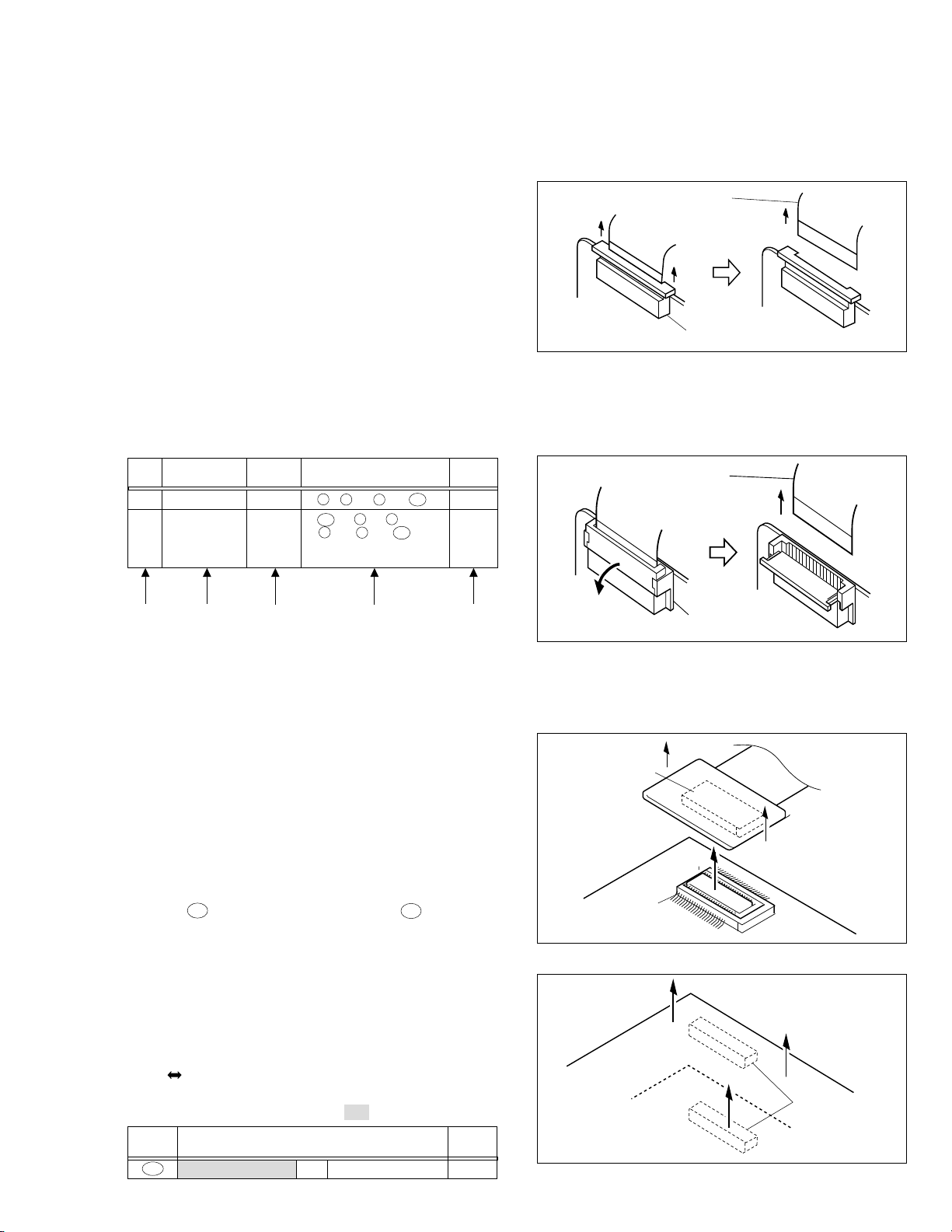

1.1.4 Disconnection of Connectors (Wires)

Connector

Pull both ends of the connector in the arrow direction, remove the lock and disconnect the flat wire.

Flat wire

Connector

Fig. 1-1-1 Connector 1

Extend the locks in the direction of the arrow for unlocking

and then pull out the wire. After removing the wire, immediately restore the locks to their original positions because

the locks are apt to come off the connector.

Flat wire

(1) (2) (3) (4) (5)

(1) Indicate the disassembly steps. When assembling, per-

form in the reverse order of these steps. This number

corresponds to the number in the disassembly diagram.

(2) Indicates the name of disassembly/assembly parts.

(3) Indicates the number in the disassembly diagram.

(4) Indicates parts and points such as screws, washers,

springs which must be removed during disassembly/

assembly.

Symbol Name, Point

S Screw

L Lock, Pawl, Hook

SD Soldering

夡(Others) Connector, Cover, Bracket, etc.

(Example)

• 2 (S1) : Remove the two screws (S1) for removing

the part 1.

• CN 1a : Disconnect the connector 1a .

•SD1 : Unsolder at the point SD1.

(5) Precautions on disassembly/assembly.

1.1.3 Destination of connectors

Note:

Three kinds of double-arrows in connection tables respectively show kinds of connector/wires.

↔ : Wire

⇔ : Flat wire

: Board to Board connector

[Example]

Note:

Remove the parts marked in .

CONN.

No.

1a AUDIO CN203 ⇔ ZOOM OPE – 8

CONNECTOR

Pin No.

Connector

Fig. 1-1-2 Connector 2

B-B connector

Pull the board by both the sides in the direction of the arrow for disconnecting the B-B connector.

Connector

Connector

Fig. 1-1-3 Connector 3

Connector

Fig. 1-1-4 Connector 4

1-1

Page 7

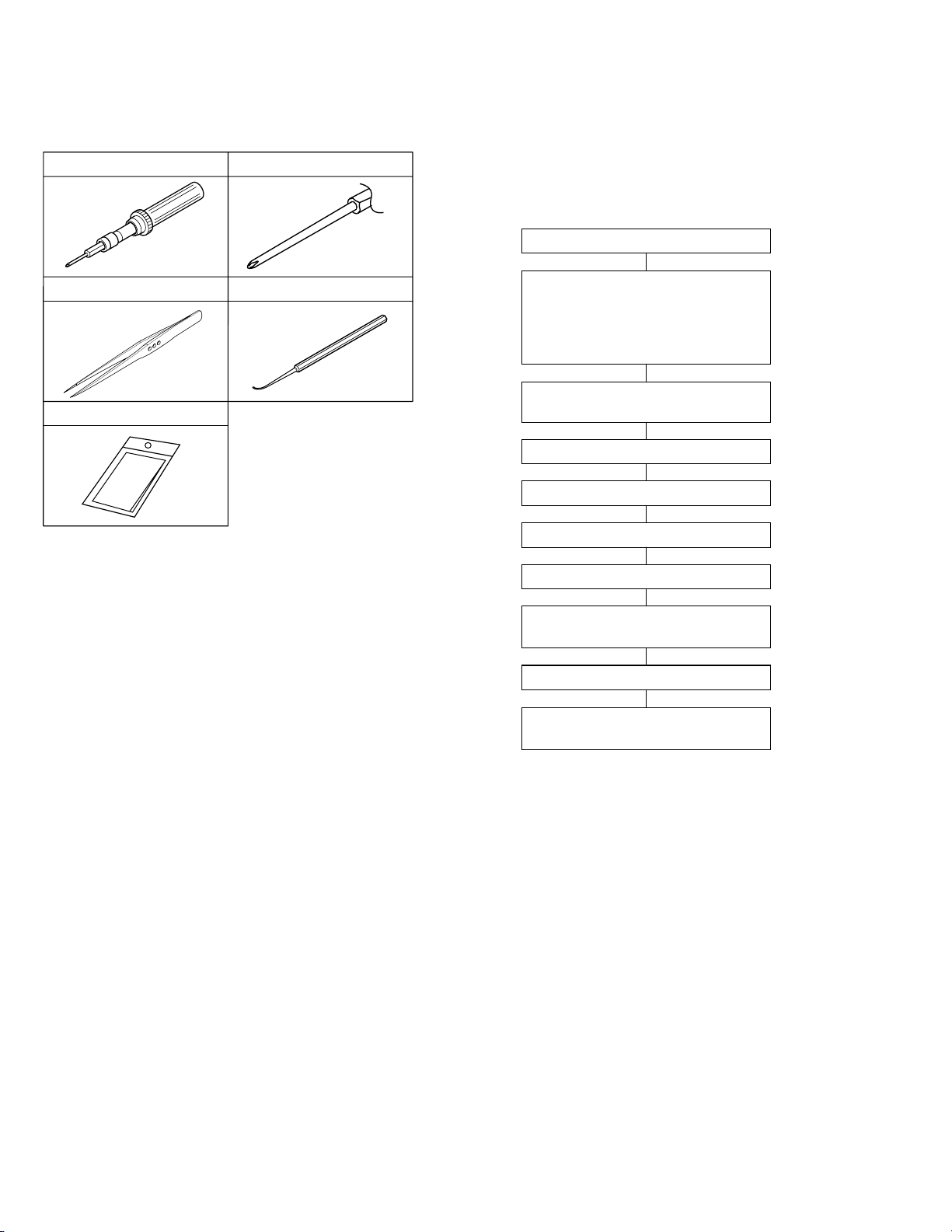

1.2 JIGS AND TOOLS REQUIRED FOR DISASSEMBLY, ASSEMBLY AND ADJUSTMENT

1.2.1 Tools required for adjustments

1

Torque Driver

YTU94088

2

Bit

YTU94088-003

1.3 DISASSEMBLY/ASSEMBLY OF CABINET PARTS AND BOARD ASSEMBLY

1.3.1 Disassembly flow chart

This flowchart indicates the disassembly step for the cabinet parts and board assembly in order to gain access to

item(s) to be serviced. When reassembling, perform the

step(s) in reverse order.

3

5

Tweezers

P-895

Cleaning Cloth

KSMM-01

Chip IC Replacement Jig

4

PTS40844-2

Table 1-2-1

1. Torque driver

Be sure to use to fastening the mechanism and exterior

parts because those parts must strictly be controlled for

tightening torque.

2. Bit

This bit is slightly longer than those set in conventional

torque drivers.

3. Tweezers

To be used for removing and installing parts and wires.

4. Chip IC replacement jig

To be used for adjustment of the camera system.

5. Cleaning cloth

Recommended cleaning cloth to wipe down the video

heads, mechanism (tape transport system), optical lens

surface.

1

2

ZOOM OPE UNIT

FRONT COVER ASSY

(Inc. AUDIO BOARD ASSY,

FRONT FPC UNIT,

MICROPHONE,

SHOE ASSY)

3

4

5

6

7

8

9

0

/

!

UPPER CASE ASSY

(Inc.

MONITOR ASSY)

@

DSC BOARD ASSY

REAR COVER ASSY

E. VF(COLOR)

OP BLOCK ASSY

LOWER CASE ASSY

(Inc.JACK,EJECT BOARD ASSY)

MAIN BOARD ASSY

PRE/MDA BOARD ASSY,

MECHANISM ASSY

Table 1-3-1

1-2

Page 8

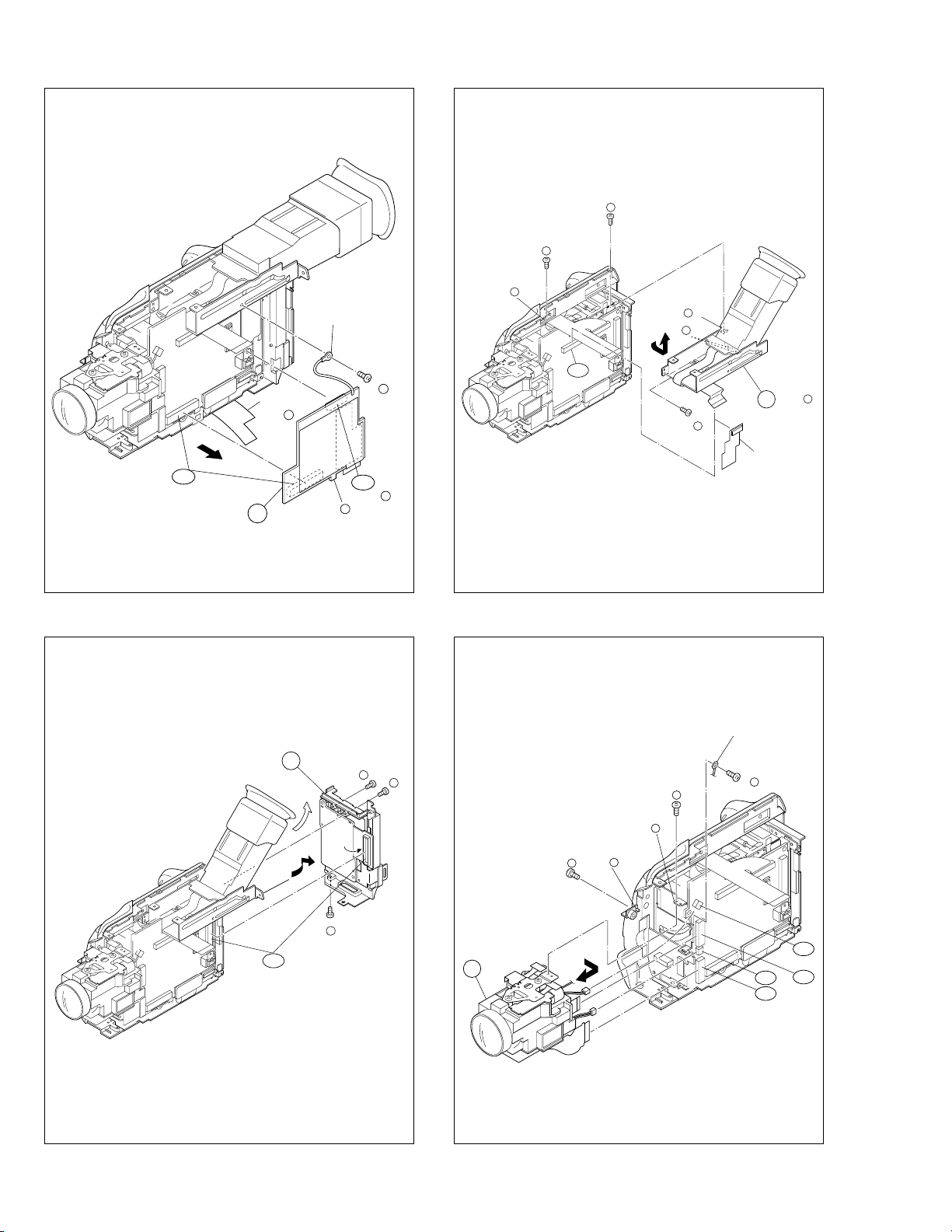

1.3.2 Disassembly method

STEP

No.

1

2

3

4

5

6

7

8

9

0

/ ASSY, 2(S 10 b), NOTE0b

!

PART

ZOOM OPE UNIT Fig.1-3-1

FRONT COVER Fig.1-3-2 CN 2a ,2(S 2 a),(S 2 b), NOTE2a

ASSY 2(S 2 c),2(S 2 b),CN 2b NOTE2b

--------------------------------------------------------

AUDIO BOARD ASSY

-------------- ---------------------------------

FRONT FPC UNIT

--------------------------------------------------------

MICROPHONE Fig.1-3-2c 2(S 2 f),(S 2 g),2(S 2 h),2(L 2 a)

-------------- ---------------------------------

SHOE ASSY SPACER,2(L 2 b) NOTE2j

UPPER CASE ASSY

Inc. MONITOR CN 3a NOTE3b

ASSY NOTE3c

DSC BOARD ASSY

REAR COVER ASSY

E.VF(COLOR) Fig.1-3-6

OP BLOCK ASSY Fig.1-3-7 (S 7 a),LUG WIRE,CN 7a , –

LOWER CASE Fig.1-3-8 CN 8a ,CN 8b ,3(S 8 a), –

ASSY (S 8 b),2(L 8 a),(L 8 b)

MAIN BOARD ASSY

PRE/MDA BOARD

MECHANISM

ASSY CN 10a ,CN 10b ,CN 10c ,

Fig.No.

3(S 1 ),(L 1 a),4(L 1 b),CN 1a

Fig.1-3-2b CN 2c ,(S 2 d),(S 2 e),CN 2d ), NOTE2e

CN 2e ) NOTE2f

SPACER,CN 2f ,CN 2g ,CN 2h ,

(S 2 e)

Fig.1-3-3 3(S 3 a),6(S 3 b),(S 3 c), NOTE3a

Fig.1-3-4 (S 4 ),LUG WIRE,HEAT SINK, NOTE4a

(L 4 ),CN 4a ,CN 4b NOTE4b

Fig.1-3-5 CN 5a ,2(S 5 a),(S 5 b) –

HEAT SINK(MAIN),CN 6a ,(S 6 a),

2(S 6 b),(L 6 a),(L 6 b),2(L 6 c)

CN 7b ,CN 7c ,CN 7d ,2(S 7 b),

(L 7 a),(L 7 b)

Fig.1-3-9 CN 9a ,(S 9 ),(L 9 ) –

Fig.1-3-10 3(S 10 a),BKT(MECHA) ASSY, NOTE0a

(L 10 ),SHIELD COVER(PRE/REC),

CN 10d ,CN 10e ,CN 10f ,

3(S 10 b)

POINT NOTE

Table 1-3-2

Note:

Remove the parts marked in .

CONN.

No.

1a AUDIO CN203 ⇔ ZOOM OPE – 8

2a AUDIO CN201 MAIN CN112 80

2b EJECT CN2421 ⇔ FRONT FPC – 12

2c AUDIO CN202 ⇔ SHOE ASSY – 16

2d AUDIO CN205 ⇔ LENS SHUTTER – 10

2e AUDIO CN204 ↔ MICROPHONE – 3

2f

FRONT FPC UNIT

2g

FRONT FPC UNIT CN2412

2g FRONT FPC UNIT CN2411

3a MAIN CN108 MONITOR – 50

4a DSC CN8401 MAIN CN105 120

4b DSC CN8402 ⇔ JACK CN301 20/45

5a MAIN CN109 REG CN601 80

6a MAIN CN110 ⇔ E.VF(COLOR) CN501 22

7a MAIN CN102 ⇔ CCD – 20

7b MAIN CN101 ↔ CCD – 2

7c MAIN CN103 ↔ OP BLOCK ASSY – 2

7d MAIN CN104 ⇔ OB BLOCK ASSY – 39

8a EJECT CN2422 ⇔ MAIN CN113 13

8b JACK CN301 ⇔ MAIN CN111 24/45

9a MAIN CN106 PRE/MDA CN401 80

10a PRE/MDA CN406 ⇔ SENSOR – 16

10b PRE/MDA CN405 ⇔

10c PRE/MDA CN404 ⇔ DRUM MOTOR – 11

10d PRE/MDA CN402 ⇔ HEAD – 8

10e PRE/MDA CN407 ⇔

10f PRE/MDA CN403 ⇔

CONNECTOR

CN2413 ⇔ FOCUS RING – 6

↔

IR UNIT

⇔

MENU SW UNIT

CAPSTAN .MOTOR

ROTARY ENCODER

LOADING MOTOR

–

–

– 18

– 6

– 6

–

NOTE2c

NOTE2d

–

NOTE2g

NOTE2h

NOTE6

Pin No.

3

6

NOTE 2a:

Open the cassette cover after removing the

screws.

NOTE 2b:

Be careful not to damage the FPC when unplugging it.

NOTE 2c:

As the

result of the above steps, be careful not to damage any of its parts. Take particular care not to

scratch the lens surfaces.

NOTE 2d:

When mounting the parts, set the REC MODE

switch to “video”. Also set the lever to the uppermost position at the same time.

NOTE 2e:

NOTE 2f:

Treat the microphone wire with care.

When mounting, be careful not to damage the

jacks.

NOTE 2g:

When mounting, be careful not to damage the

switches.

NOTE 2h:

When mounting, be careful when handling the

FPC.

NOTE 2j:

When mounting, be careful not to damage the

boss (stud).

NOTE 3a/3b:

NOTE 3c:

For the disassembly of the

bly, see section 1.6, “Disassembly/Assembly of

@

NOTE 4a:

NOTE 4b:

NOTE 6:

NOTE 0a:

NOTE 0b:

Be careful not to damage the CONNECTOR.

Handle the peeled-off heat sink carefully be-

cause it should be reused in the assembly.

For the disassembly of the

1.4, “Disassembly/Assembly of

The FPC of the loading motor should be

mounted by inserting it between the Mechanism

Assembly and the PRE/MDA Board Assembly.

When mounting the shield cover, push down the

FPC of the drum while attaching it.

OP Block Assembly is exposed as a

7

Be sure to confirm the position of the screws.

Monitor Assem-

@

Monitor Assembly”.

E.VF, see section

6

E.VF”.

6

Table 1-3-3

1-3

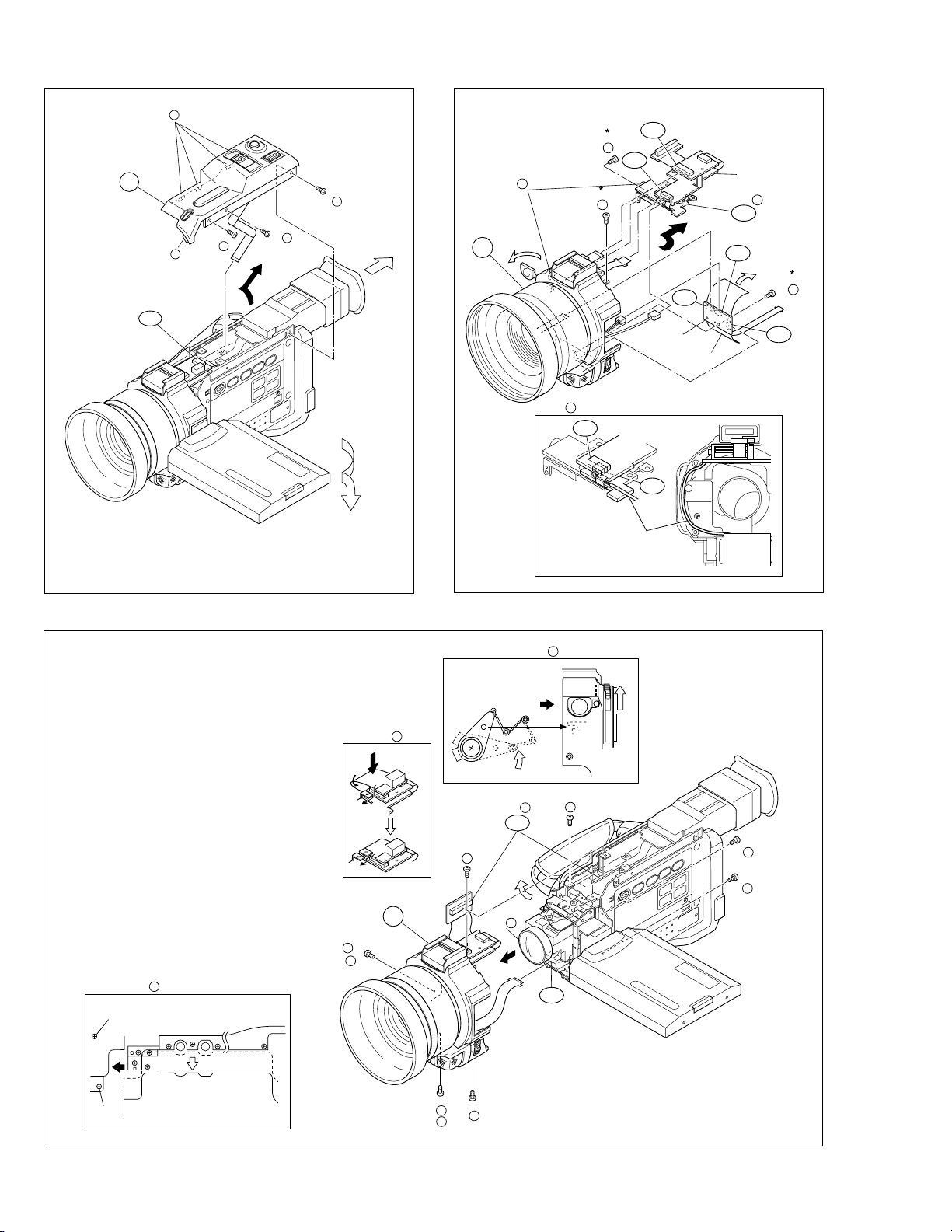

Page 9

(L b)

NOTE f

2

NOTE e

2

NOTE e

WIRE

(MIC)

2

2d

2d

2

2c

2d

2e

2h

2f

2g

12

(S e)

2

13

(S e)

2

SPACER

FRONT FPC

UNIT

AUDIO BOARD

ASSY

11

(S d)

2

*

: 0.078 N•m (0.8 kgf•cm)

1

1

2

(S )

(L a)

1

1

(S )

1

3

(S )

1

1

1a

Fig. 1-3-1

Fig. 1-3-2b

8

7

NOTE a

2

(BOTTOM)

(S b)

NOTE a

6

2

2

NOTE b

2

2

7

(S c)

2

NOTE a

2

4

(S a)

2

(S c)

NOTE b

NOTE c

8

2

NOTE d

2

2a

2

2

(S a)

2b

VIDEO

XGA/VGA

UXGA

5

2

9

(S d)

2

10

(S d)

2

1-4

Fig. 1-3-2a

Page 10

(

)

NOTE g

2

15

(S f)

2

14

(S f)

2

18

(S h)

2

SWITCH

(S g)

17

(S h)

2

16

2

NOTE h

NOTE j

2

(L b)

2

2

SHOE ASSY

: 0.078 N•m (0.8 kgf•cm)

*

15

(S f)

2

16

(S g)

2

17

(S h)

2

18

(S h)

2

14

(S f)

2

(L a)

2

Fig. 1-3-2c

3a

28

(S c)

3

NOTE 3 b

SPACER

3

NOTE g ,

2

SWITCH

27

(S b)

3

h

2

NOTE 3 b

27

28

15

(S f)

2

FPC

NOTE 3 a

22

20

(S a)

3

21

(S a)

3

22

(S b)

3

NOTE 3 a

19

(S a)

3

(BOTTOM)

25

24

23

26

23

(S b)

3

24

(S b)

3

25

S b

3

12

26

(S b)

3

NOTE 3 c

Fig. 1-3-3

1-5

Page 11

LUG WIRE

(L a)

6

34

(S b)

6

35

(S b)

6

(L b)

(L c)

6

6

4a

Fig. 1-3-4

HEAT SINK

(BASE)

NOTE b

4

29

(S )

4

4

6a

NOTE

6

6

33

(S a)

6

HEAT SINK

(MAIN)

4b

NOTE a

(L )

4

4

Fig. 1-3-6

LUG WIRE

5

30

(S a)

5

31

(S a)

5

38

(S b)

7

36

(S a)

7

1-6

Fig. 1-3-5

(L a)

7

37

(L b)

(S b)

32

(S b)

5

5a

7

7

7

7b

7a

7c

7d

Fig. 1-3-7

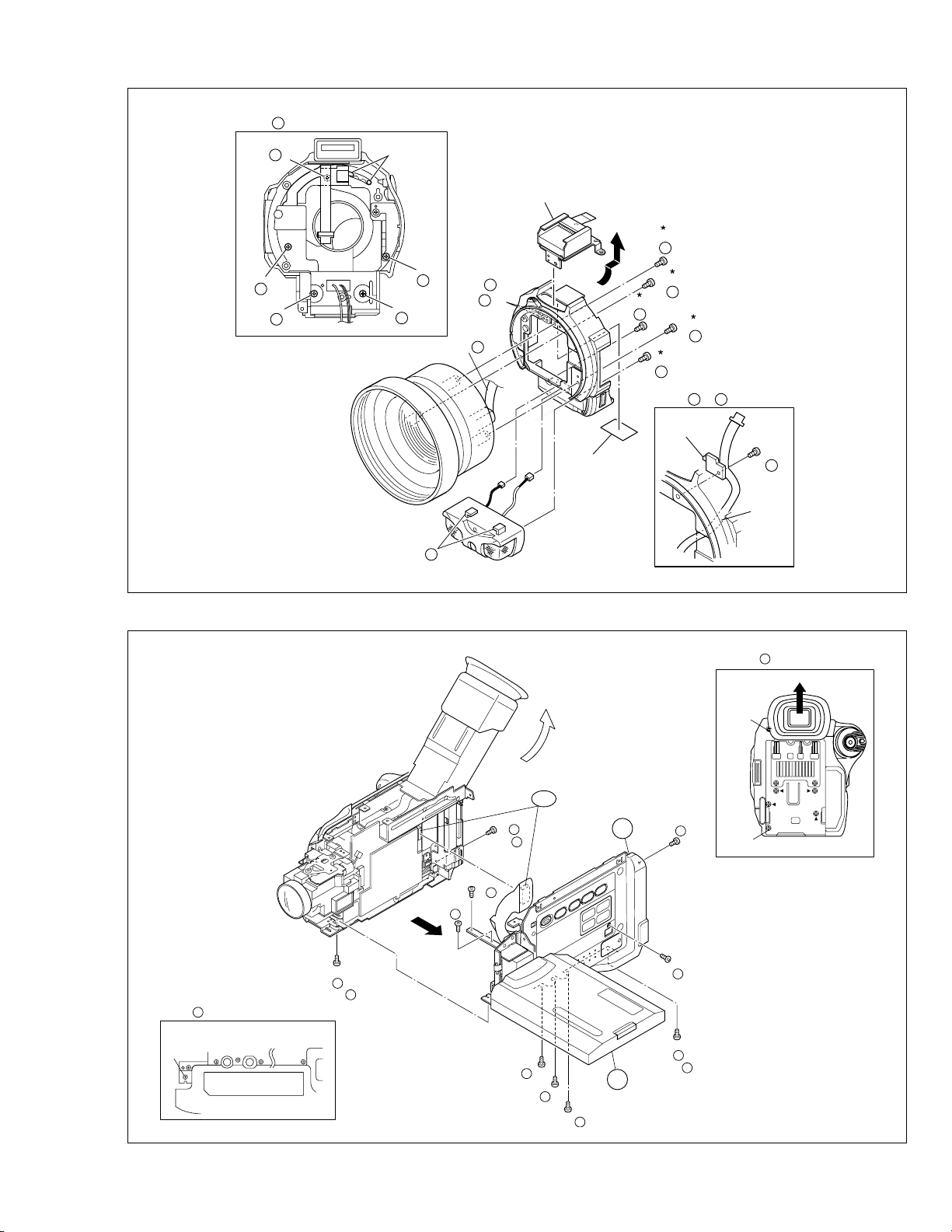

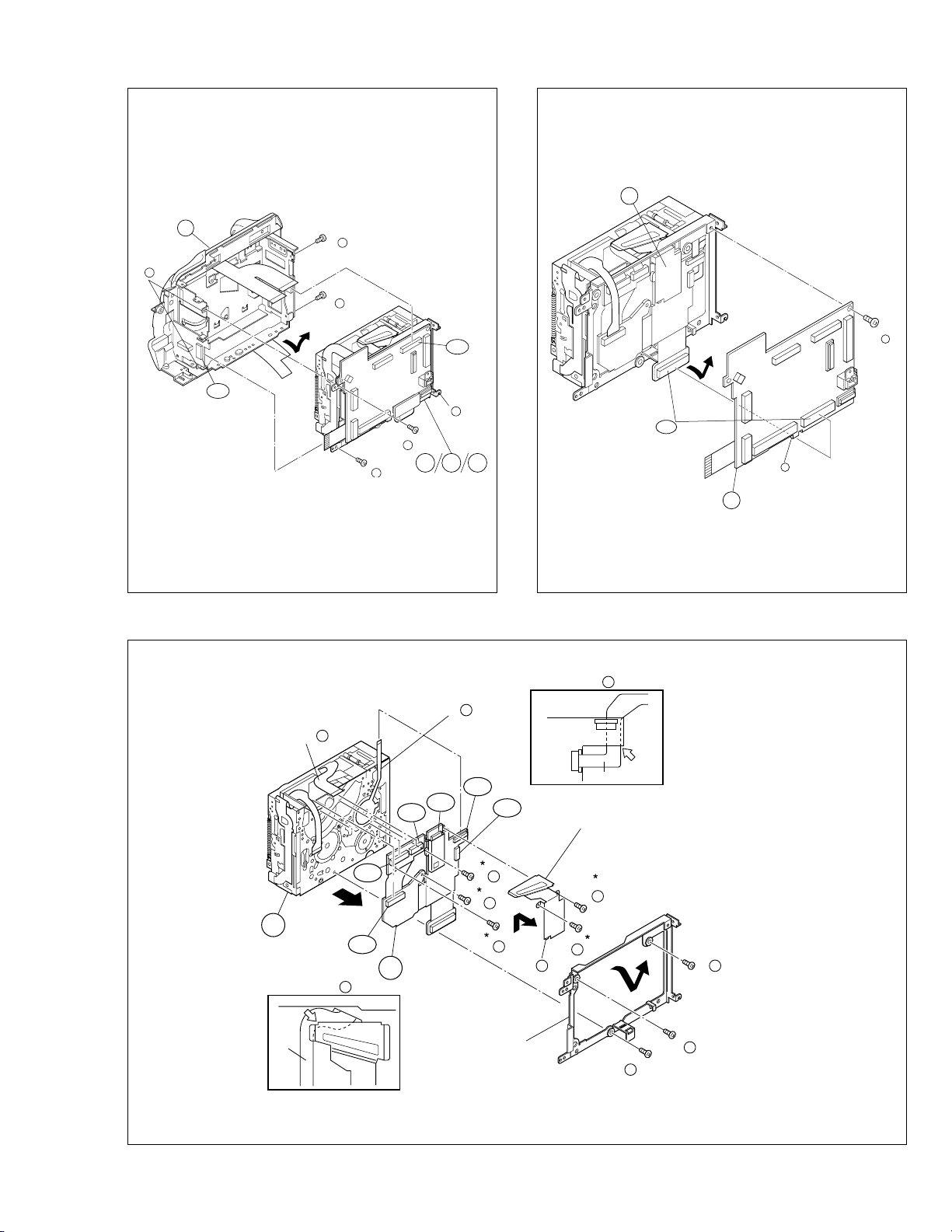

Page 12

(

)

(L a)

9

10

9a

43

(S )

9

(L )

9

8

41

(S a)

8

42

(S b)

8

8b

8a

(L b)

8

39

(S a)

8

40

S a

8

9810 11

Fig. 1-3-8 Fig. 1-3-9

NOTE a

10

NOTE a

10

NOTE b

10

10e

10d

10c

10b

11

10a

51

(S b)

10

49

(S b)

10

50

(S b)

10f

10

10

NOTE b

10

FPC

BKT (MECHA) ASSY

CN407

CN403

FPC

SHIELD COVER (PRE/REC)

47

(S b)

10

48

(S b)

10

(L )

10

45

(S a)

10

46

(S a)

10

44

(S a)

10

: 0.078 N•m (0.8 kgf•cm)

*

Fig. 1-3-10

1-7

Page 13

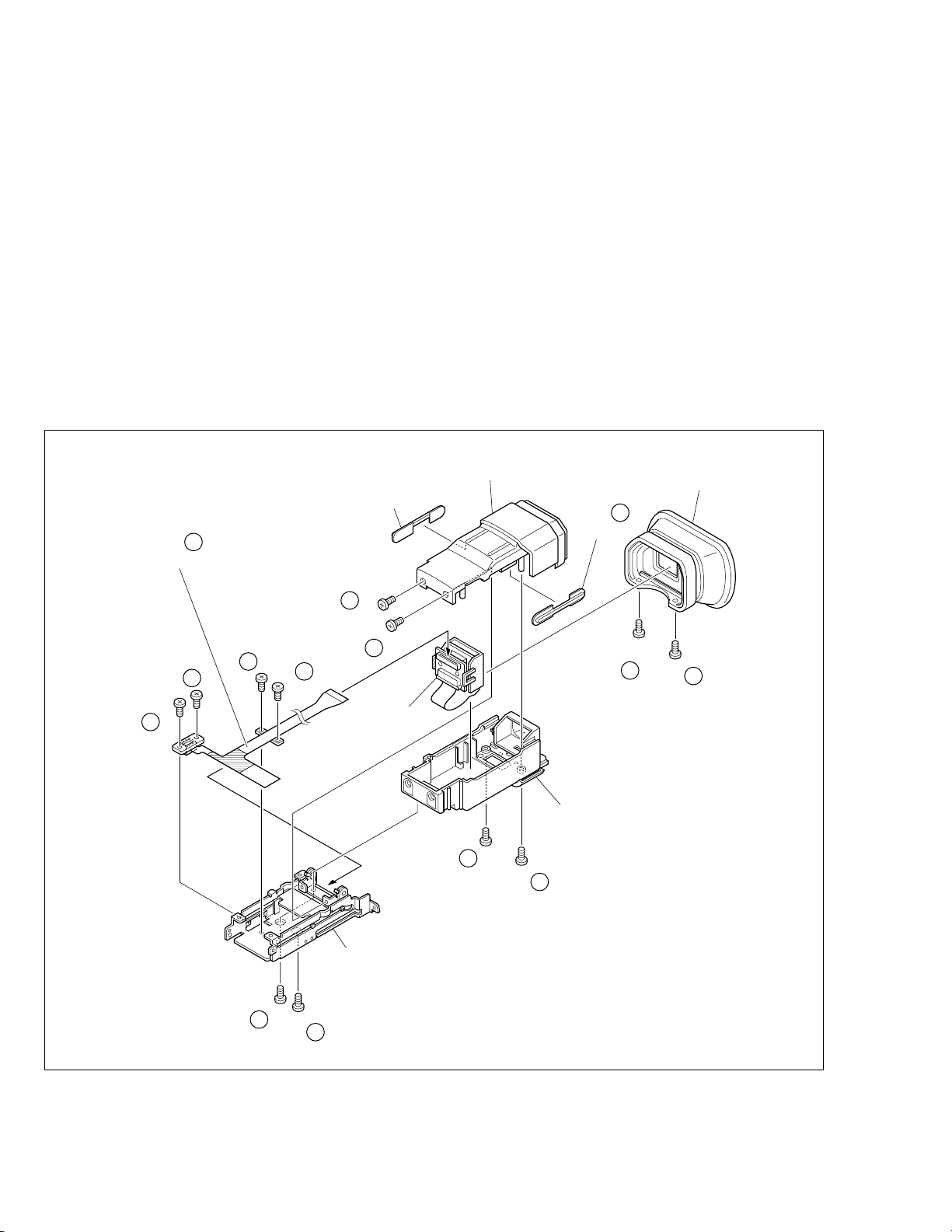

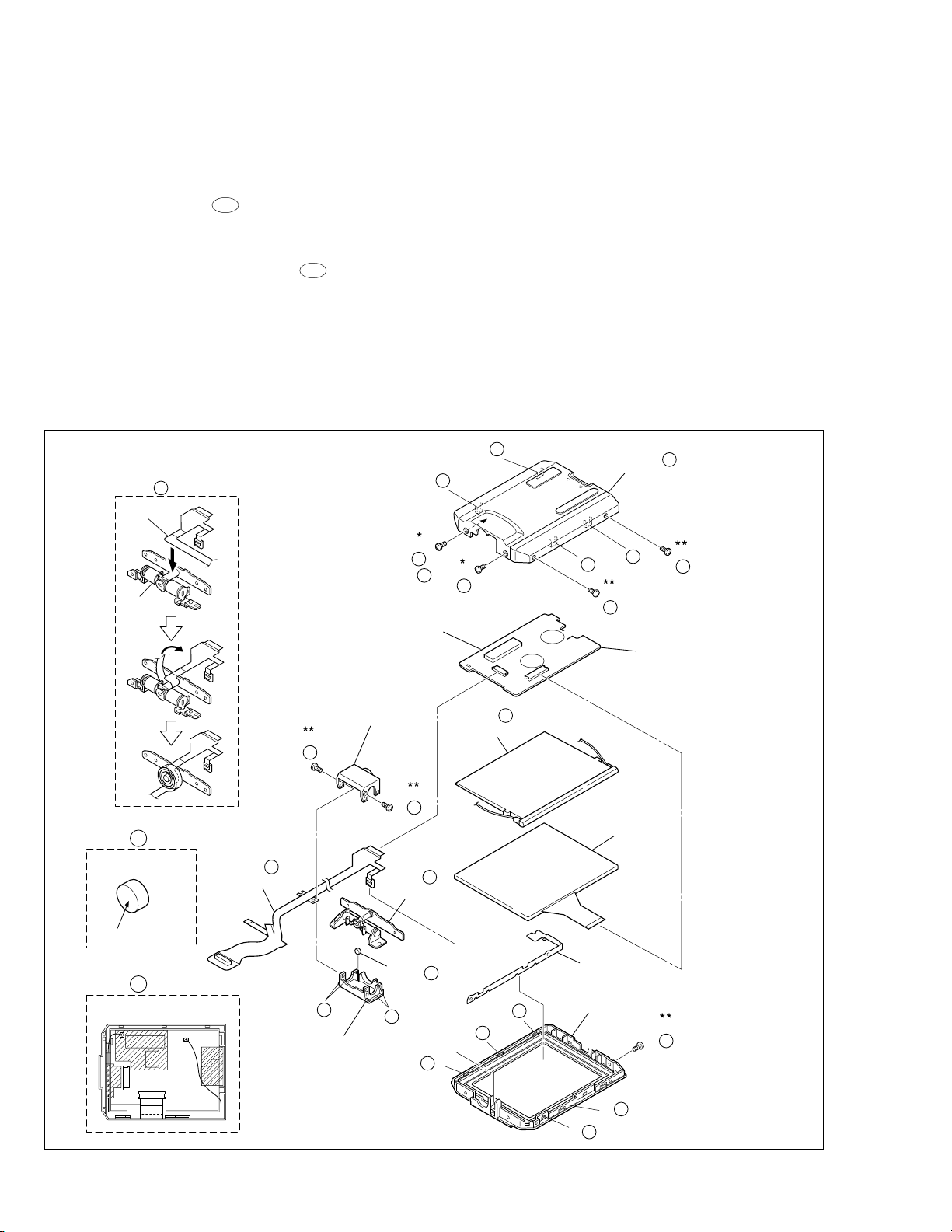

1.46 E.VF(COLOR)

1.4.1. Disassembly/Assembly of the 6 E.VF(COLOR)

1. Remove the 2 screws (1 and 2) and then remove the EYE

CAP.

2. Remove the 2 screws (3 and 4).

3. Pull out the VF assembly and them remove the 4 screws

(5 to 8) to release the FPC ASSY.

4. Remove the 2 screws (9 and 10) then lift the E.VF from

the BRACKET (VF) ASSY and take out the FPC ASSY.

Note

a :

Be careful not to disconnect or break the FPC

6

ASSY wire.

5. Remove the 2 screws (11 and 12) to remove the UPPER

CASE ASSY.

Note

b :

Be careful not to lose any of the parts.

6

6. Remove the LCD UNIT from the BOTTOM CASE ASSY.

NOTE a

FPC ASSY

(S c)

**

5

6

(S c)

**

6

6

6

**

7

6

(S d)

**

8

6

(S d)

**

3

6

(S b)

(S b)

LCD UNIT

**

4

6

RIB

UPPER CASE ASSY

NOTE b

BOTTOM CASE ASSY

**

11

6

(S e)

**

12

6

(S e)

RIB

6

*

1

6

(S a)

EYE CUP

*

2

6

(S a)

1-8

**

9

6

(S e)

BRACKET(VF) ASSY

**

10

6

(S e)

Fig. 1-4-1

: 0.059 N·m (0.6kgf·cm)

*

: 0.078 N·m (0.8kgf·cm)

**

Page 14

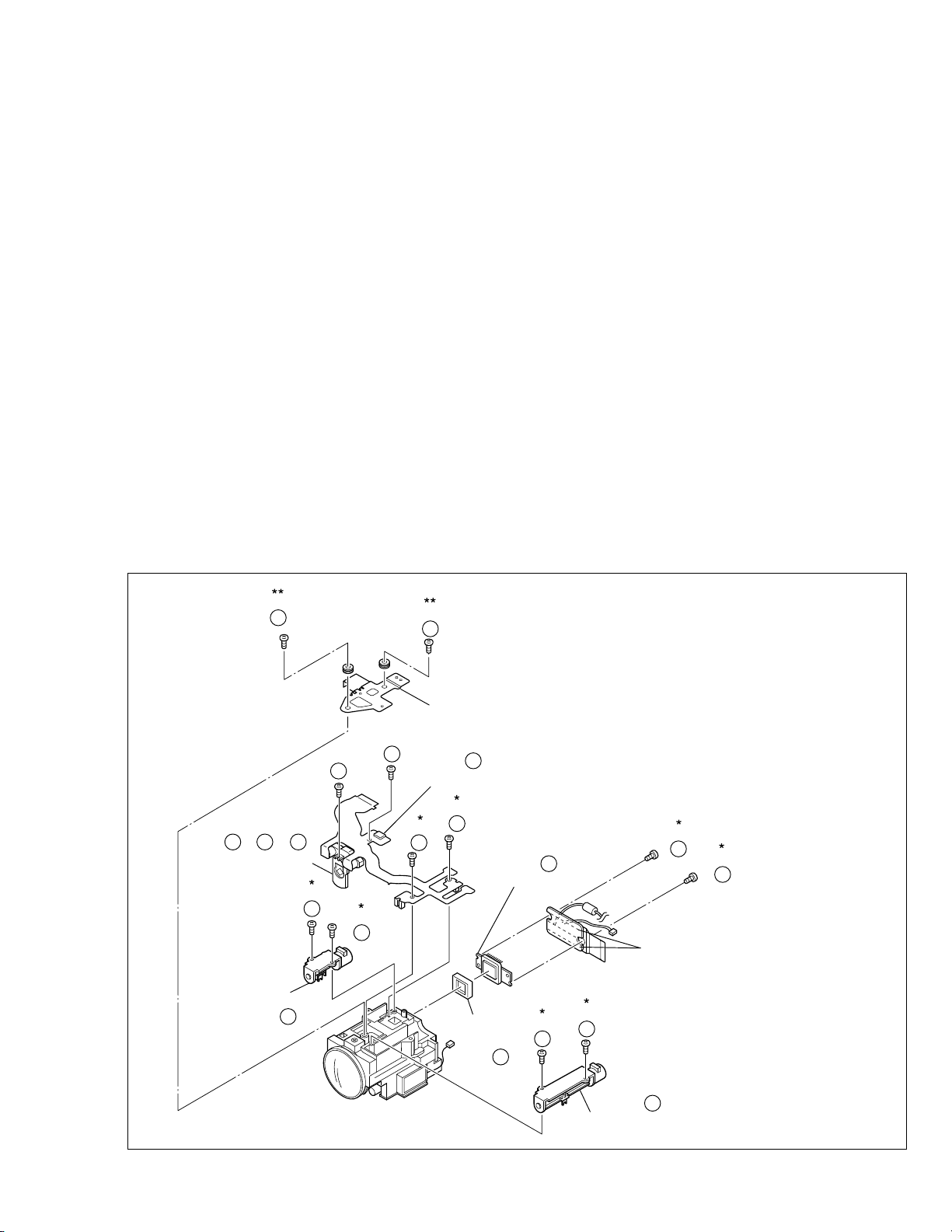

1.5 DISASSEMBLY OF THE 7 OP BLOCK AND CCD BOARD ASSEMBLIES

1.5.1 Precautions

1. Take care in handling the CCD image sensor, optical LPF

and lens components when performing maintenance

etc., especially with regard to surface contamination, attached dust or scratching. If fingerprints are present on

the surface they should be wiped away using either a

silicon paper, clean chamois or the cleaning cloth recommended by the Video Product Division.

2. The CCD image sensor may have been shipped with a

protective sheet attached to the transmitting glass. When

replacing the CCD image sensor, do not peel off this

sheet from the new part until immediately before it is

mounted in the OP Block Assembly.

1.5.3 How to install

1. With the spacer rubbers attached to the CCD base,

mount the CCD base in the OP Block Assembly and

tighten them together using the two screws (1, 2).

2. Mount the CCD Board Assembly and attach solder to

the 16 points (SD1).

1.5.4 Replacement of Service Repair Parts

The service repair parts for the OP Block Assembly are as

listed below.

Before replacement of these parts, remove the bracket (OP

assyembly) as required.

Take special care not to disconnect any of the FPC wires

or cause any damage due to soldering (excessive heating).

1.5.2 How to remove

1. Remove the solder (SD1) from the 16 soldered points

on the CCD Board Assembly and take the assembly out.

2. Remove the two screws (1, 2) and take out the CCD Base

Assembly.

Note

a:

When removing the CCD Base Assembly, be

7

careful not to take out the CCD image sensor together with the spacer rubbers attached to it.

Note 7b:

The CCD image sensor should not be replaced

as a single part but should be replaced together

with the entire CCD Base Assembly.

3

7

(S b)

NOTE 7 c/ 7 d/ 7 e

IRIS MOTOR

UNIT

(S c)

(S c)

9

7

6

7

10

(S c)

(S c)

7

4

7

(S b)

BRACKET (OP) ASSY

5

7

NOTE 7 e

SWITCH

8

7

(S d)

7

7

(S d)

CCD BASE ASSY

1. Focusing motor

2. Zoom motor

3. Iris motor unit

Note

7

Note 7d:

Note 7e:

NOTE 7 b

c:

When replacing the focusing motor or the zoom

motor, solder the FPC at a space of about 1 mm

above the terminal pin.

The iris motor unit includes the FPC Assembly,

switch and two sensors.

Be careful not to damage the switch.

1

7

(S a)

SD1

2

7

(S a)

FOCUS

MOTOR

NOTE 7 c

SPACER

RUBBER

NOTE 7 a

Fig. 1-5-1

11

7

(S c)

12

7

(S c)

NOTE 7 c

ZOOM MOTOR

: 0.118 N·m (1.2kgf·cm)

*

: 0.147 N·m (1.5kgf·cm)

**

1-9

Page 15

1.6 DISASSEMBLY/ASSEMBLY OF THE @ MONITOR

ASSEMBLY

1.6.1

Monitor Assembly and Hinge Assembly

@

1. Remove the four screws (1 to 4), disengage the four

hooks (L@ a to d) in order, and take out the Monitor Cover

Assembly.

2. Unlock the connector ( 12a ) and, while lifting the Hinge

Assembly, unplug and take out the FPC.

3. Remove the screw (5) and take out the bracket (MONI-

TOR CASE).

4. Unplug the FPC from the connector ( 12b ) and take out

the Monitor Board Assembly and the backlight.

5. Remove the LCD module by disengaging the five hooks

(L@ e to j).

6. Remove the two screws (6, 7) and take out the hinge

covers (U, L) by disengaging the four hooks (L@ k, l) at

both sides of each of the hinge covers.

7. Remove the FPC Assembly from the Hinge Assembly.

12

NOTE f,h

FPC ASSY

(S a)

NOTE a

HINGE

ASSY

(MONITOR CASE)

12

(L a)

1

12

12

(S a)

BRACKET

Note

@

a:

Note @b:

Note @c:

Note @d:

Note @e:

Note @f:

Note @g:

Note @h:

12

(L d)

a

2

12

CN 12b

Don't reuse the screw, because screw lock bond

was applied to them.

Be careful not to damage the FPC or the connector when removing the Monitor Cover Assembly.

Be careful not to damage the parts when removing or mounting the Hinge Assembly.

To unplug the FPC, release only the lock of the

connector and remove the FPC together with the

Hinge Assembly.

As the backlight is soldered at two points on the

Monitor Board Assembly, the solder should be removed when disassembling the backlight as a single part.

Take care when handling the FPC.

Be careful not to lose the magnets and attach

them in the correct orientation.

When mounting the FPC Assembly, wrap it around

the Hinge Assembly by 3-1/2 turns.

12

NOTE b

MONITOR COVER ASSY

4

12

(S b)

MONITOR BOARD ASSY

CN 12a

12

(L b)

(S b)

(L c)

3

12

12

12

NOTE g

MARK (BLACK)

12

NOTE e

WIRE RING

12

NOTE d,f

FPC ASSY

**

HINGE COVER(L)

6

12

(S d)

HINGE ASSY

12

(L k)

HINGE COVER(U)

: 0.118 N·m (1.2kgf·cm)

*

: 0.078 N·m (0.8kgf·cm)

(L l)

7

12

(S d)

12

NOTE c

MAGNETS

NOTE 12 g

12

12

(L j)

12

NOTE e

BACK LIGHT

12

(L g)

12

(L h)

LCD MODULE

BRACKET

(MONI CASE)

MONITOR

CASE ASSY

(L e)

12

(L f)

12

5

12

(S c)

1-10

Fig. 1-6-1

Page 16

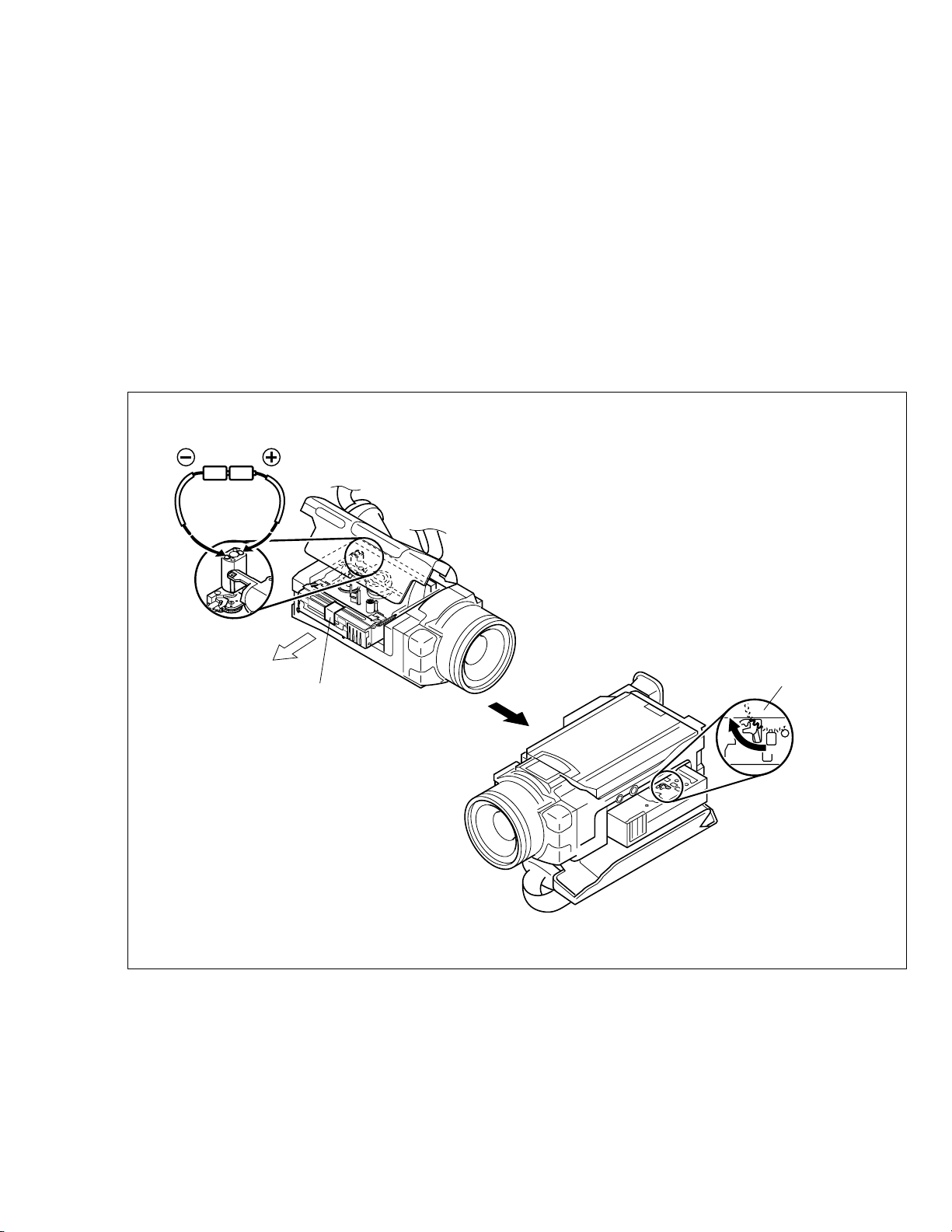

1.7 MANUAL EJECTION OF THE CASSETTE TAPE

Note:

The following procedure describes a simplified method

of ejecting the cassette tape in case it is not possible

to eject it, due to an electrical failure.

Be careful not to damage any of the parts or the tape

when performing repairs or maintenance work.

1. Remove the Power Unit (battery, DC code, etc.) from the

main unit.

2. Open the cassette cover.

3. Attach a piece of PVC tape at the front of the cassette

housing.

Note:

This helps prevent the tape from being damaged when

the Cassette Housing Assembly is moved upward at

the unloading end.

(DC3V)

4. In order to change the mechanism mode at the unloading end apply 3 V, DC to the electrode on the top surface of the Loading Motor Assembly and then set it to

the eject mode.

5. If there is any slack tape in the tape transport system,

wind it inside the cassette tape by turning the Supply

Reel Disk from the backside of the Slide Deck Assembly.

6. Peel off the PVC tape and take out the cassette tape from

the cassette housing.

Note:

Make sure that grease or a similar substance is not

attached to the surface of the tape.

Similarly, also make sure that grease or a similar sub-

stance is not attached on the Mechanism

Assembly.

PVC TAPE

REEL DISK ASSY (SUP)

Fig. 1-7-1

1-11

Page 17

1.8 EMERGENCY DISPLAY

Whenever some abnormal signal is input to the syscon

CPU, an error number (E01, as an example) is displayed

on the LCD monitor or (in the electronic view finder).

In every error status, such the message as shown below

alternately appear over and over.

• In an emergency mode, all operations except turning on/

off the POWER switch are ineffectual.

Example (in case of the error number E01):

UNIT IN

E01

SAFEGUARD MODE

E01

REMOVE AND

REATTACH BATTERY

LCD

display

E01 LOADING

E02 UNLOADING

E03 TU & SUP REEL

E04 DRUM FG

Emergency

mode

FG

Details Possible cause

In the case the encoder position is not shifted

to the next point though the loading motor has

rotated in the loading direction for 4 seconds

or more. This error is defined as [E01].

In the case the encoder position is not shifted

to the next point though the loading motor has

rotated in the unloading direction for 4 seconds or more. This error is defined as [E02].

In the case no REEL FG is produced for 4 seconds or more in the capstan rotation mode after loading was complete, the mechanism

mode is shifted to STOP with the pinch roller

set off.

This error is defined as [E03].

However, no REEL EMG is detected in the

SLOW/STILL mode.

In the case there is no DRUM FG input in the

drum rotation mode for 4 seconds or more.

This error is defined as [E04], and the mechanism mode is shifted to STOP with the pinch

roller set off.

1. The mechanism is locked during mode shift.

2. The mechanism is locked at the mechanism loading end, because the encoder position is skipped

during mechanism mode shift.

3. No power is supplied to the loading MDA.

1. The mechanism is locked during mode shift.

2. The mechanism is locked at the mechanism loading end, because the encoder position is skipped

during mechanism mode shift.

1. The idler gear does not engage with the reel disk

well.

2. Though the idler gear and reel disk are engaged with

each other, the tape is not wound because of overload to the mechanism.

3. No FG pulse is output from the reel sensor.

4. No power is supplied to the reel sensor.

5. Tape transport operation takes place with a cassette

having no tape inside.

6. The tape slackens and no pulse is produced until

the slack is taken up and the tape comes into the

normal status.

1. The drum cannot be started or drum rotation is

stopped because tape transport load is too high.

1) Tape tension is extremely high.

2) The tape is damaged or soiled with grease, etc.

2. The DRUM FG signal is not received by the syscon

CPU.

1) Disconnection in the middle of the signal line.

2) Failure of the DRUM FG pulse generator (hall element).

3. No drum control voltage is supplied to the MDA.

4. No power is supplied to the DRUM MDA.

E05 –

E06 CAPSTAN FG

1-12

– –

In the case no CAPSTAN FG is produced in

the capstan rotation mode for 2 seconds or

more. This error is defined as [E06], and the

mechanism mode is shifted to STOP with the

pinch roller set off.

However, no CAPSTAN EMG is detected in the

STILL/FF/REW mode.

1. The CAPSTAN FG signal is not received by the

syscon CPU.

1) Disconnection in the middle of the signal line.

2) Failure of the CAPSTAN FG pulse generator (MR

element).

2. No capstan control voltage is supplied to the MDA.

3. No power is supplied to the CAPSTAN MDA.

4. The capstan cannot be started or capstan rotation

is stopped because tape transport load is too high.

1) Tape tension is extremely high. (Mechanical

locking)

2) The tape is damaged or soiled with grease, etc.

(Tape tangling occurs, etc.)

Table 1-8-1

(DVC_03)

Page 18

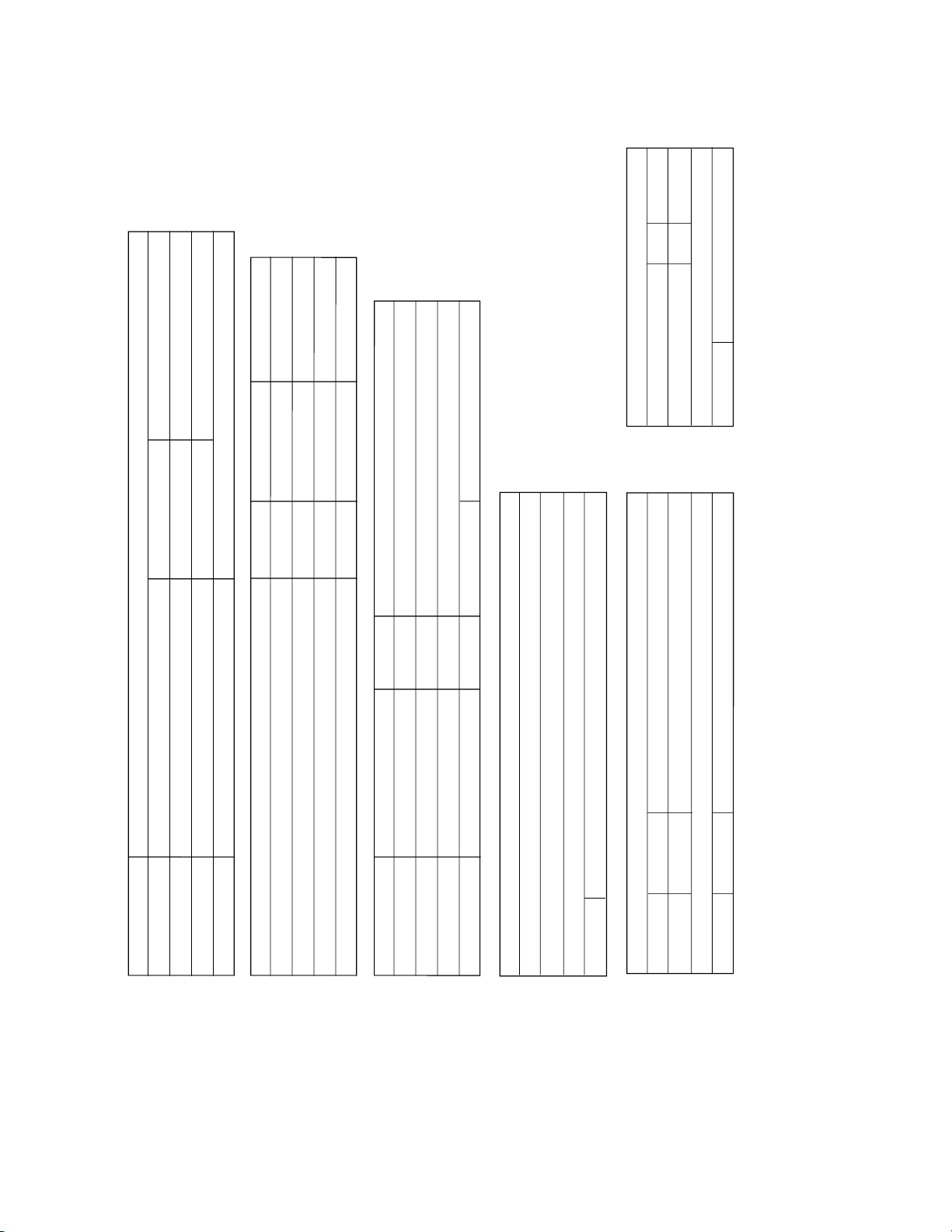

1.9 SERVICE NOTE

1234 5

99 99 9 9 99

6 7 8 9 10 11 12 13 14 15 16 17 18

1

Fig. 1-3-1

Fig. 1-3-2a

Fig. 1-3-2cFig. 1-3-2b

Symbol No.

Removing order of screw

Place to stick screw

Reference drawing

Screw tightening torque

→

→

→

→

Symbol No.

Removing order of screw

Place to stick screw

Reference drawing

Screw tightening torque

→

→

→

→

→

Symbol No.

Removing order of screw

Place to stick screw

Reference drawing

Screw tightening torque

→

→

→

→

→

Removing order of screw

Place to stick screw

Reference drawing

Screw tightening torque

→

→

→

→

12

34 567

MONITOR ASSY

II

7

OP BLOCK ASSY

Fig. 1-5-1

VIV IVIV

12

34

5678

9

10

11 12

< NOTE >

1)

9

;

Don't reuse the screw, because screw lock bond was applied to them.

2) Pay careful attention to tightening torque for each screw.

I

: 0.069N·m (0.7kgf

·cm)

II : 0.078N

·m (0.8kgf·cm)

III : 0.059N

·m (0.6kgf·cm)

IV

: 0.118N·m (1.2kgf

·cm)

V : 0.147N

·m (1.5kgf·cm)

Fig. 1-6-1

→

I

9999

99

III

19 20 21 22 23

99 9 99

24 25 26 27 28 29 30 31 32 33 34 35

3

5

2

64

Fig. 1-3-3

Fig. 1-3-6Fig. 1-3-4 Fig. 1-3-5

IIII

36 37 38 39 40

99

41 42 43 44 45 46 47 48 49 50 51

7

980

@

Fig. 1-3-7

Fig. 1-3-8 Fig. 1-3-9

Fig. 1-3-10

Symbol No.

Removing order of screw

Place to stick screw

Reference drawing

Screw tightening torque

→

→

→

→

→

IIII II

6

Fig. 1-4-1

VF UNIT

III II

12

3

45

6

7

8

9

10

11

12

Table 1-9-1

1-13

Page 19

1-14

Page 20

SECTION 2

MECHANISM ADJUSTMENT

2.1 PRELIMINARY REMARKS ON ADJUSTMENT AND REPAIR

2.1.1 Precautions

1. When fastening parts, pay careful attention to the tight-

ening torque of each screw. Unless otherwise specified,

tighten a screw with the torque of 0.039 N

2. Be sure to disconnect the set from the power supply be-

fore fastening and soldering parts.

3. When disconnecting/connecting wires, be careful not to

get them and their connectors damaged. (Refer to the

Section 1.)

4. When replacing parts, be very careful neither to dam-

age other parts nor to fit wrong parts by mistake.

2.1.2 Notes on procedure for disassemby/assembly

The disassembling procedure table (Table 2-4-1 on page

2-5,a part of the table is shown below for reference)shows

the procedure to disassemble/reassemble mechanism

parts.

Carefully read the following explanation before starting actual disassembling/reassembling work. The item numbers

(circled numbers)in the following explanation correspond

to those appearing under respective columns of the table.

(1) Circled numbers appearing in this column indicate the

order to remove parts. When reassembling, follow these

numbers in the reverse order. Circled numbers in this

column correspond to those appearing in drawings of

this section.

(2) This column shows part names corresponding to circled

numbers in the left column.

(3) The symbol (T or B)appearing in this column shows the

side which the objective part is mounted on.

T =the upper side, B =the lower side

(4) Symbols appearing in this column indicate drawing

numbers.

Step Part Name Fig. Point Note Remarks

•

m (0.4 kgf•cm).

(5) This column indicates parts and points such as screws,

washers,springs,and others to be removed/fitted for disassembling/reassembling the mechanism. Besides such

the parts, this column occasionally indicates working

points.

P = Spring

W = Washer

S = Screw

* = Lock (L),soldering (SD),shield,connector (CN),

etc.

Example • Remove ((W1)=Washer W1.

• **Remove the solder at (SD1)=Point SD1.

• **Disconnect

(6) Numbers in this column represent the numbers of notes

in the text.For example, “1” means “Note 1”.

(For parts that need phase adjustment after reassembling, refer to “2.6 MECHANISM ADJUSTMENTS”.)

(7) This column indicates required after-disassembling/-re-

assembling work such as phase adjustment or mechanism adjustment.

=Connector Å .

Å

NO. PART NAME FIG. POINT NOTE REMARKS

1 CASSETTE HOUSING ASSY T Fig.2-4-3 3(S1),(L1a)-(L1e)

2 UPPER BASE ASSY T Fig.2-4-4 (S2),(L2a),(L2b)

3 DRUM ASSY T (S3a),2(S3b)

4 REEL DISK ASSY(SUP) T Fig.2-4-5 (W4)

5 REEL DISK ASSY(TU) T (W5)

6 REEL COVER ASSY T 2(W6),(S6a),2(S6b)

(1) (2) (3) (4) (5) (6) (7)

NOTE1a,b,c,d

NOTE

2

NOTE3a,b

NOTE4a

NOTE

5

NOTE

6

ADJUSTMENT

ADJUSTMENT

2-1

Page 21

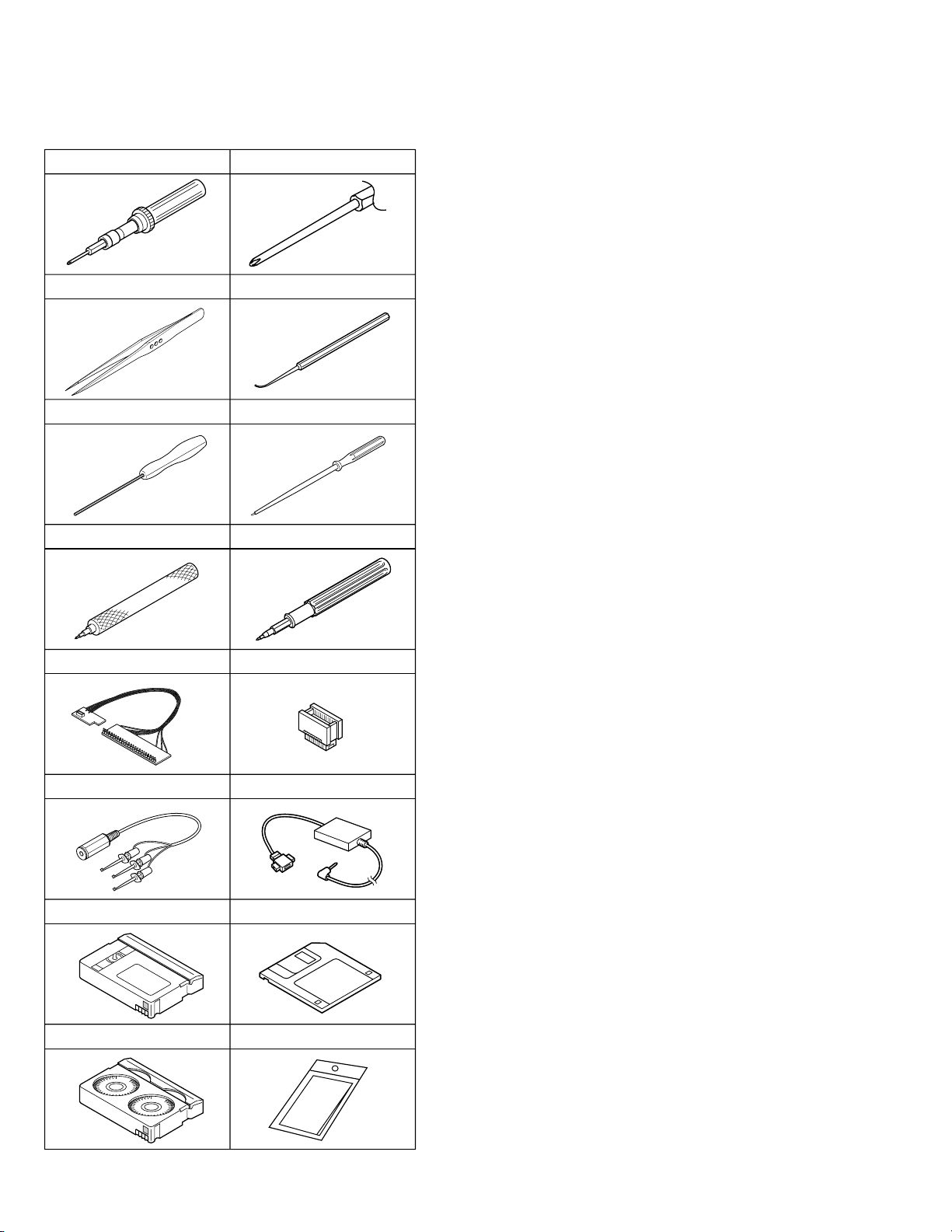

2.2 JIGS AND TOOLS REQUIRED FOR DISASSEMBLY, ASSEMBLY AND ADJUSTMENT

2.2.1 Tools required for adjustments

1

3

5

7

9

11

13

15

Torque Driver

YTU94088

Tweezers

P-895

Guide Driver (Hexagonal)

D-770-1.27

Slit Washer Installation Jig

YTU94121A

Jig Connector cable

YTU93106B

Communication cable

YTU93107A

Alignment Tape

MC-2

Cassette Torque Meter

YTU94151A

2

Chip IC Replacement Jig

4

6

Slit Washer Installation Jig

8

10

12

Service Support System

14

16

Bit

YTU94088-003

PTS40844-2

Adjustment Driver

YTU94028

YTU94121B

Extension connector

YTU94145C-30

PC cable

QAM0099-002

YTU94057-50

Cleaning Cloth

KSMM-01

1. Torque Driver

Be sure to use to fastening the mechanism and exterior

parts because those parts must strictly be controlled for

tightening torque.

2. Bit

This bit is slightly longer than those set in conventional

torque drivers.

3. Tweezers

To be used for removing and installing parts and wires.

4. Chip IC Replacement Jig

To be used for adjustment of the camera system.

5. Guide Driver (Hexagonal)

To be used to turn the guide roller to adjustment of the

linarity of playback envelope.

6. Adjustment Driver

To be used for adjustment.

7. Slit Washer Installation Jig

To be used to install slit washers.

8. Slit Washer Installation Jig (NEW TYPE)

To be used to install slit washers.

9. Jig Connector Cable

Connected to CN107 of the main board and used for

electrical adjustment, etc.

10. Extension Connector

Connect this extension connector to the connector of the

jig connector cable for extending the cable connector.

For supplying the power through the coupler by re-

Note:

moving the cover (for jig), use this extension connector double for connecting the jig connector cable.

11. Communication Cable

Connect the Communication cable between the PC cable and Jig connector cable when performing a PC adjustment.

12. PC Cable

To be used to connect the VideoMovie and a personal

computer with each other when a personal computer is

used for adjustment.

13. Alignment Tape

To be used for check and adjustment of interchangeability of the mechanism.

14. Service Support System

To be used for adjustment with a personal computer.

15. Cassette Torque Meter

This is used to cheek the back tension and play torque

during mechanism adjustment.

When using the cassette torque meter, install the

Note:

service support system software in advance.

•

LED : Forced to ON

•

EJECT SW : OFF (Cancel)

The above setting is required to prevent any tape

damage that may occur because the cassette

torque meter cannot detect the leading/trailing sections of the tape.

16. Cleaning Cloth

Recommended cleaning cloth to wipe down the video

heads, mechanism (tape transport system), optical lens

surface.

2-2

Table 2-2-1

Page 22

2.3 DISASSEMBLY/ASSEMBLY OF MECHANISM AS-

<SUB CAM GEAR>

TOP VIEW BOTTOM VIEW

<C IN mode>

<SHORT FWD mode>

<STOP mode>

<REV mode>

<PLAY mode>

SEMBLY

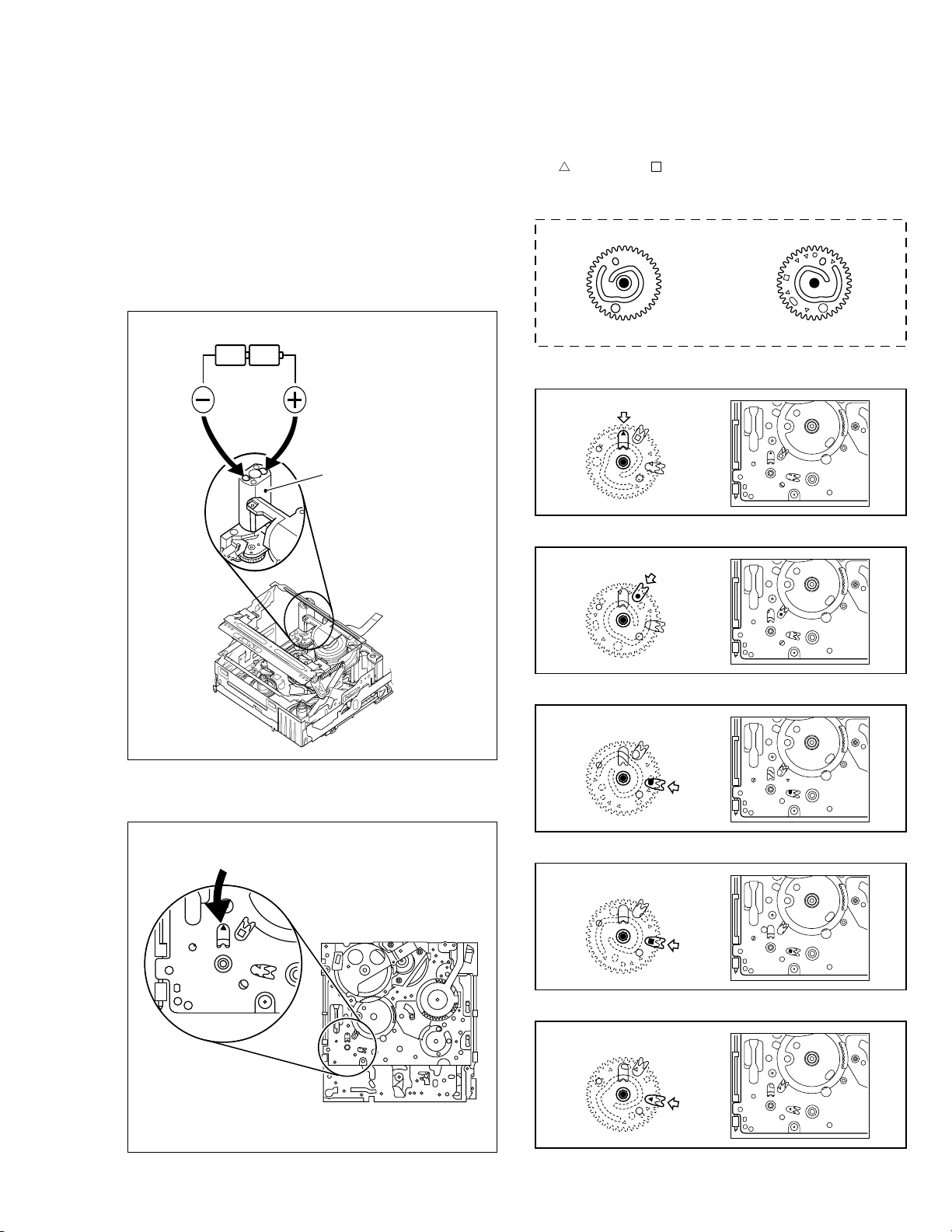

2.3.1 General statement

The mechanism should generally be disassembled/assembled in the C.IN mode (ASSEMBLY mode). (Refer to Fig.

2-3-1,2.)

However, when the mechanism is removed from the main

body, it is set in the STOP mode. Therefore, after the

mechanism is removed from the main body, supply 3 V DC

to the electrode on the top of the loading motor to enter

the mechanism mode into the C,IN mode compulsory.

<Mechanism assembly/Cassette housing assembly>

DC3V

2.3.2 Explanation of mechanism mode

The mechanism mode of this model is classified into five

modes as shown in Table 2-3-1. Each mechanism mode

can be distinguished from others by the relative position

”, “Q”, “Q” “ ” marks on the sub cam gear to the in-

of “

ner or outer protrusion on the main deck.

Refer to Fig. 2-3-3 to 2-3-8 below.

Fig. 2-3-3

<Back side of the mechanism assembly>

C IN mode

LOADING MOTOR

Fig. 2-3-4

Fig. 2-3-5

Fig. 2-3-1

Fig. 2-3-6

Back side of deck

Fig. 2-3-2

Fig. 2-3-7

Fig. 2-3-8

2-3

Page 23

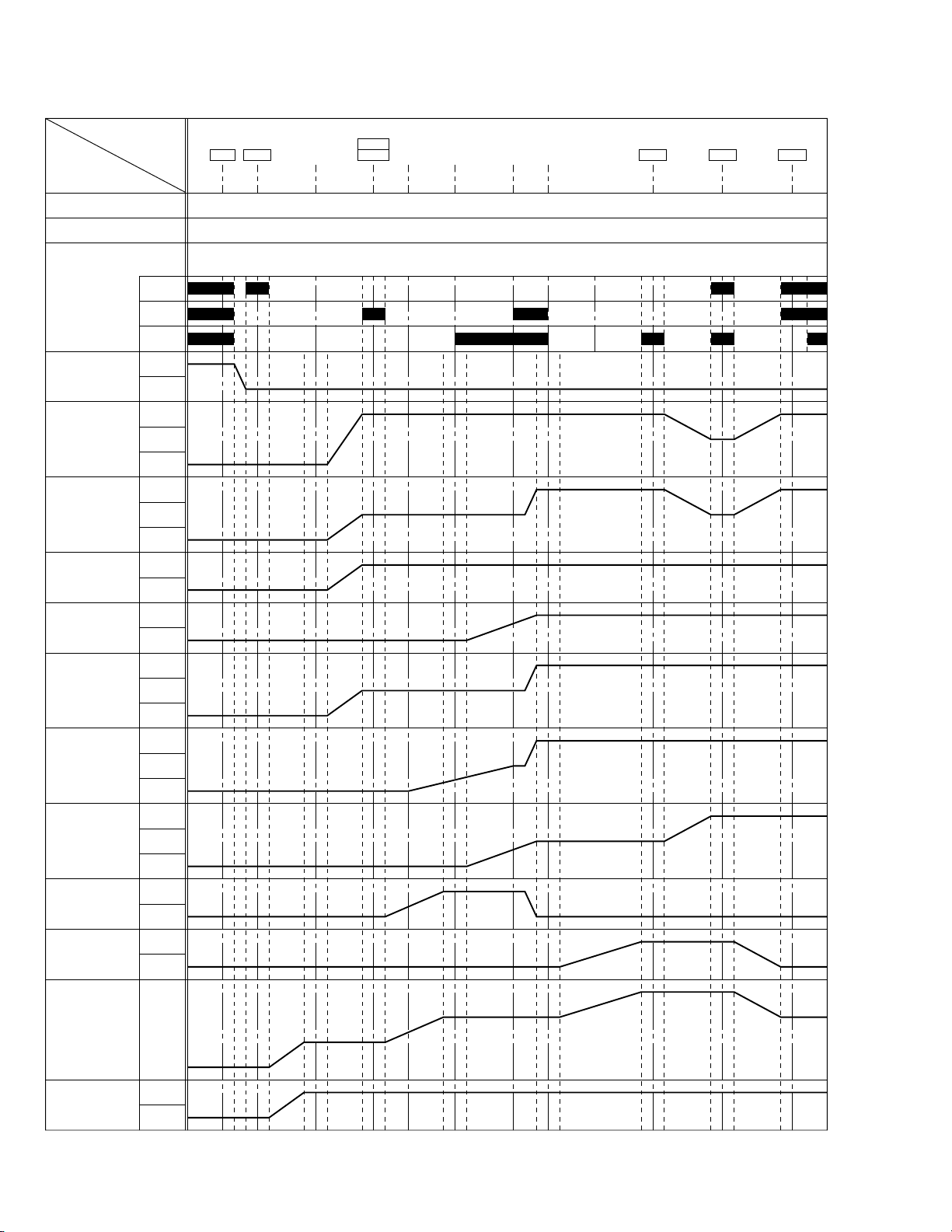

2.3.3 Mechanism timing chart

PARTS

MAIN CAM

SUB CAM

ROTARY

ENCODER

EJECT LEVER

TENSION ARM

TU ARM

SLIDE DECK

BRAKE (S)

BRAKE (T)

MODE

ON

OFF

L. END

LOCK

L. END

OFFPAD ARM

ON

OFF

LOAD

L. END

LOADSUP. L. ARM

L. END

LOADTU. L. ARM

PRESS

LOADP. ROLLER

ON

OFF

ON

OFF

SHORT

EJECT

CAS. IN

-12.40° (22.44°) (69.53°) (80.5°) (150.58°) (153.5°)58.71°0° 177.79° 212.77° 243.94°

-16.97° (30.71°) (95.14°) (110.06°) (206.06°) (210.05°)80.34°0° 243.29° 291.16° 333.82°

-15° (27.14°) (84.08°) (97.35°) (182.10°) (185.63°)71°0°

-13°-3° 3° 68°

a

b

c

UL

UL

UL

UL

UL

UL

R

RELEASE

TU. P. B

START

SLIDE SLIDE

START

TU. P. B

END END

STOP PLAYREVFWD

215°

212° 218°

257.3°

254.3° 260.3°

295°

292° 310°74°

CTL PLATE

RELEASE

LEVER

2-4

C

L

ON

OFF

Table 2-3-1

Page 24

2.4 DISASSEMBLING PROCEDURE TABLE

NO. PART NAME FIG. POINT NOTE REMARKS

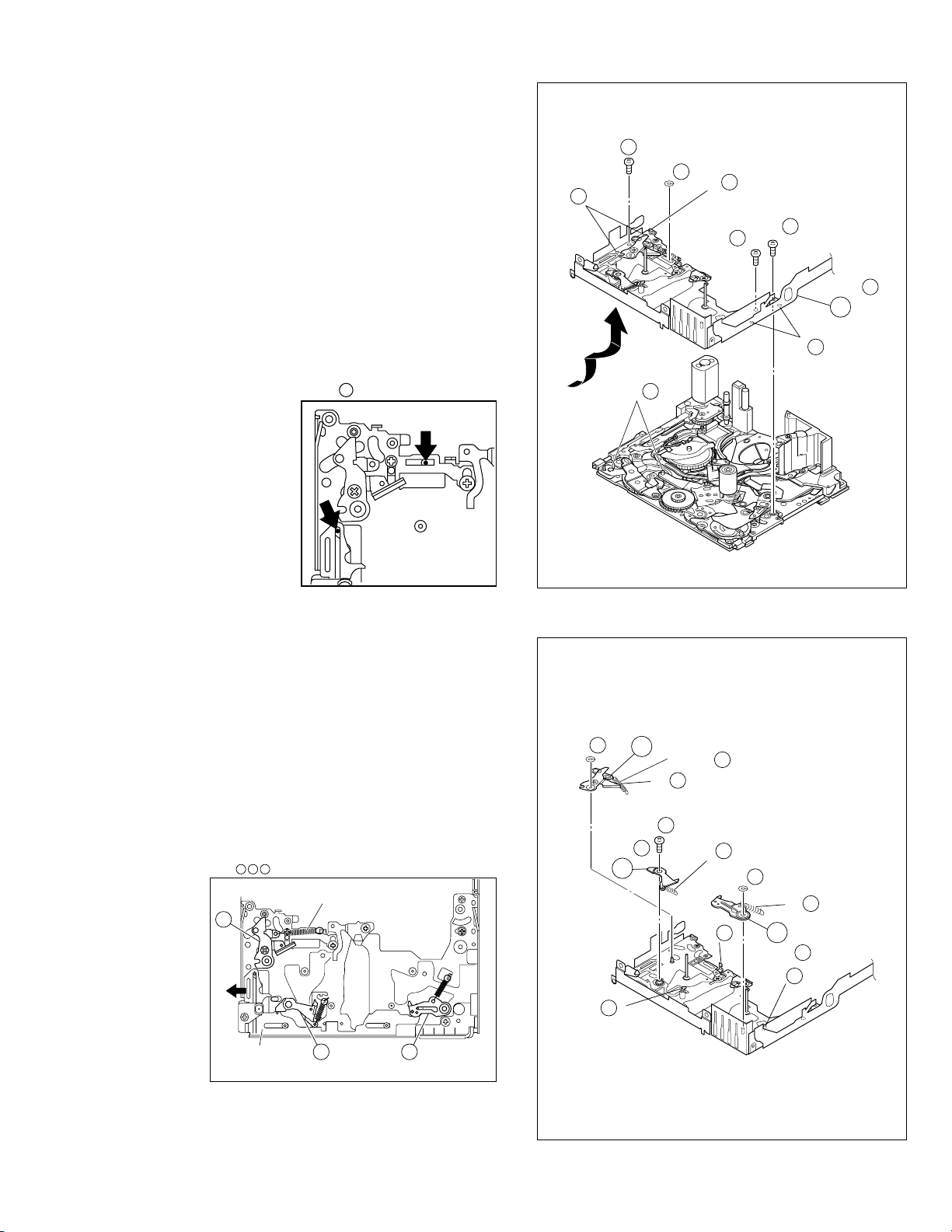

1 CASSETTE HOUSING ASSY T Fig.2-4-3 3(S1),(L1a)-(L1e)

2 UPPER BASE ASSY T Fig.2-4-4 (S2),(L2a),(L2b)

3 DRUM ASSY T (S3a),2(S3b)

4 REEL DISK ASSY(SUP) T Fig.2-4-5 (W4)

5 REEL DISK ASSY(TU) T (W5)

6 REEL COVER ASSY T 2(W6),(S6a),2(S6b)

7 TENSION ARM ASSY T Fig.2-4-6 —

8 SLANT POLE ARM ASSY T —

9 TU ARM ASSY T —

10 SWING ARM ASSY T (S0)

11 SLIDE DECK ASSY T Fig.2-4-7a (W

12 PAD ARM ASSY T Fig.2-4-7b (P@),(L@),(W@)

13 SUP BRAKE ASSY T (P#),(L#),(S#)

14 TU BRAKE ASSY T (P$),(L$),(W$)

15 TENSION CTL LEVER ASSY T Fig.2-4-8 —

16 CENTER GEAR T —

17 PINCH ROLLER ARM F. ASSY T (W&)

18 TENSION CTL PLATE ASSY T —

19 BRAKE CTL LEVER ASSY T —

20 MOTOR BRACKET ASSY T Fig.2-4-9 3(S)),(L)a),2(L)b)

21 GUIDE RAIL ASSY T

22 SLIDE LEVER 2 ASSY T —

23 LOADING PLATE ASSY T (W‹)

24 MODE GEAR T —

25 EJECT LEVER T (Wfi)

26 BASE R ASSY T Fig.2-4-10 (Sfla),(Sflb),2(Lfl)

27 ROTARY ENCODER T 2(S‡)

28 GEAR COVER ASSY T (S°a),2(S°b)

29 MAIN CAM ASSY T —

30 SLIDE ARM ASSY T Fig.2-4-11 —

31 CONNECT GEAR 2 T —

32 SUB CAM ASSY T (S™)

33 CONTROL ARM ASSY T —

34 REEL GEAR 1 T —

35 / 36

36 CAPSTAN MOTOR T (S§)

37 MAIN DECK ASSY T —

DRUM BASE ASSY/ T Fig.2-4-12 3(S∞)

CAPSTAN MOTOR

),2(S!a),(S!b),

!

2(L!a),2(L!b),(L!c)

2(W⁄),(S⁄),2(L⁄a),(L⁄b)

NOTE1a,b,c,d

NOTE

2

NOTE3a,b

NOTE

4

NOTE

5

NOTE

6

NOTE

7

NOTE

8

NOTE

9

NOTE

0

NOTE!a,b

NOTE

@

NOTE

#

NOTE

$

NOTE

%

NOTE

^

NOTE

&

NOTE

*

NOTE

(

NOTE

)

NOTE

⁄

NOTE

¤

NOTE

‹

NOTE

›

NOTE

fi

NOTE

fl

NOTE

‡

—

NOTE

·

NOTE

‚

NOTE

¡

NOTE

™

NOTE

£

NOTE

¢

NOTE∞a,b

NOTE

§

—

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT / 夝

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT / 夝

ADJUSTMENT / 夝

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT / 夝

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

PHASE ADJUSTMENT

PHASE ADJUSTMENT

ADJUSTMENT

PHASE ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

MARK: 夝 After assembly, perform adjustments.

Table 2-4-1

2-5

Page 25

< TOP VIEW >

24 27 2 3 36 3521

17

< BOTTOM VIEW >

20

23

18

8

7

22

12

4

29

19

34

143128161530

13

Fig. 2-4-1

5

36 3 22

26

34

9

10

33

26

6

37

25

32

11

26

32

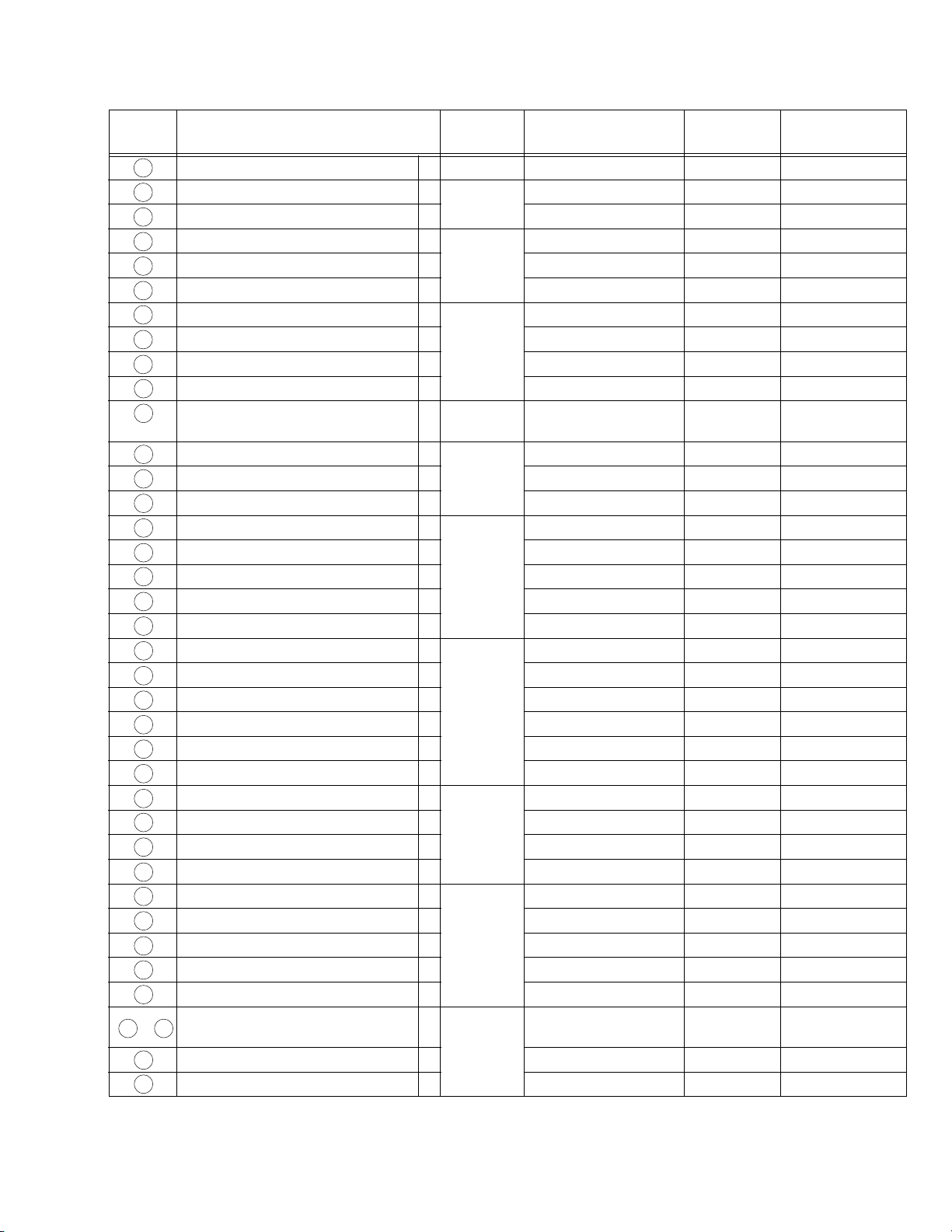

25

31 16 6

Fig. 2-4-2

37

11

27

20

30

18

19

29

30

2-6

Page 26

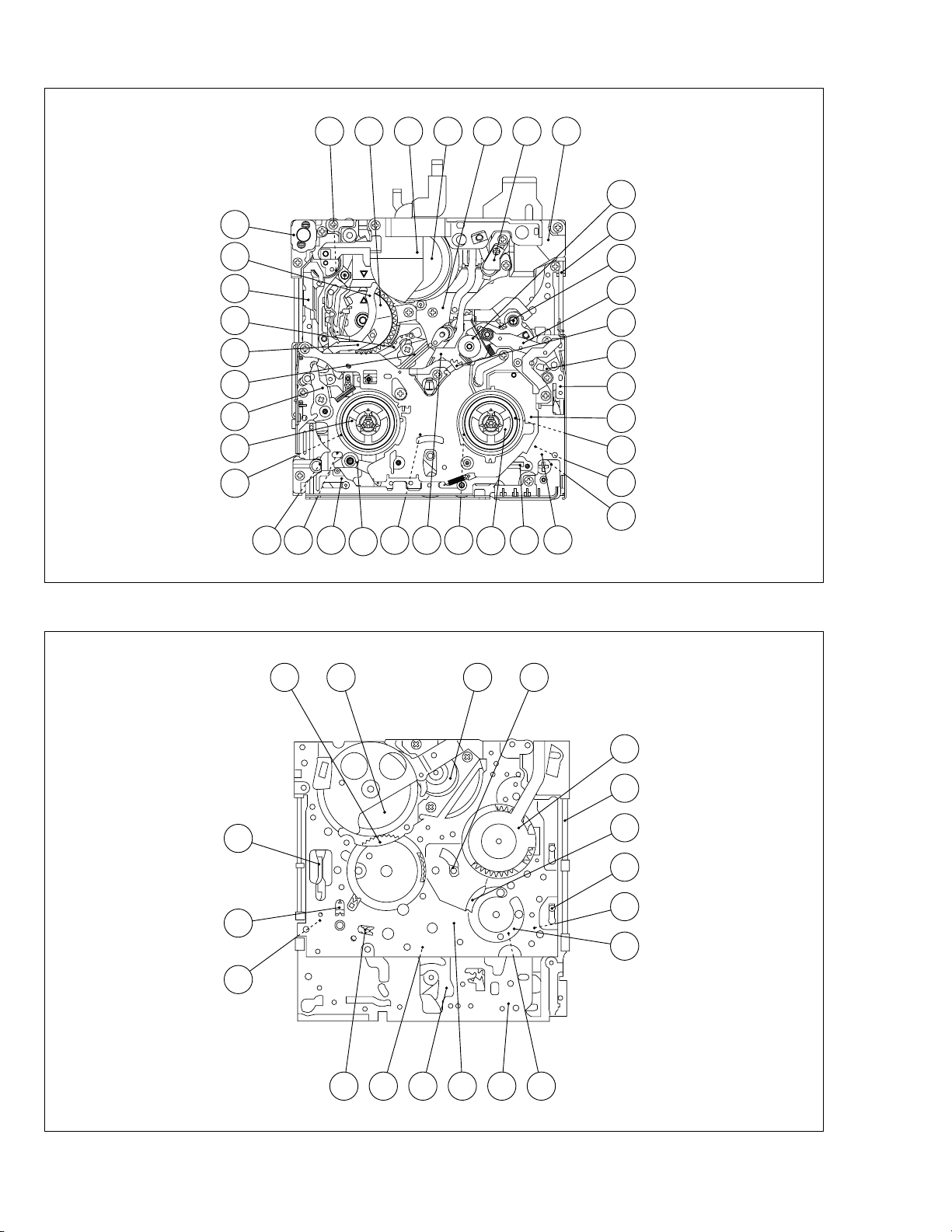

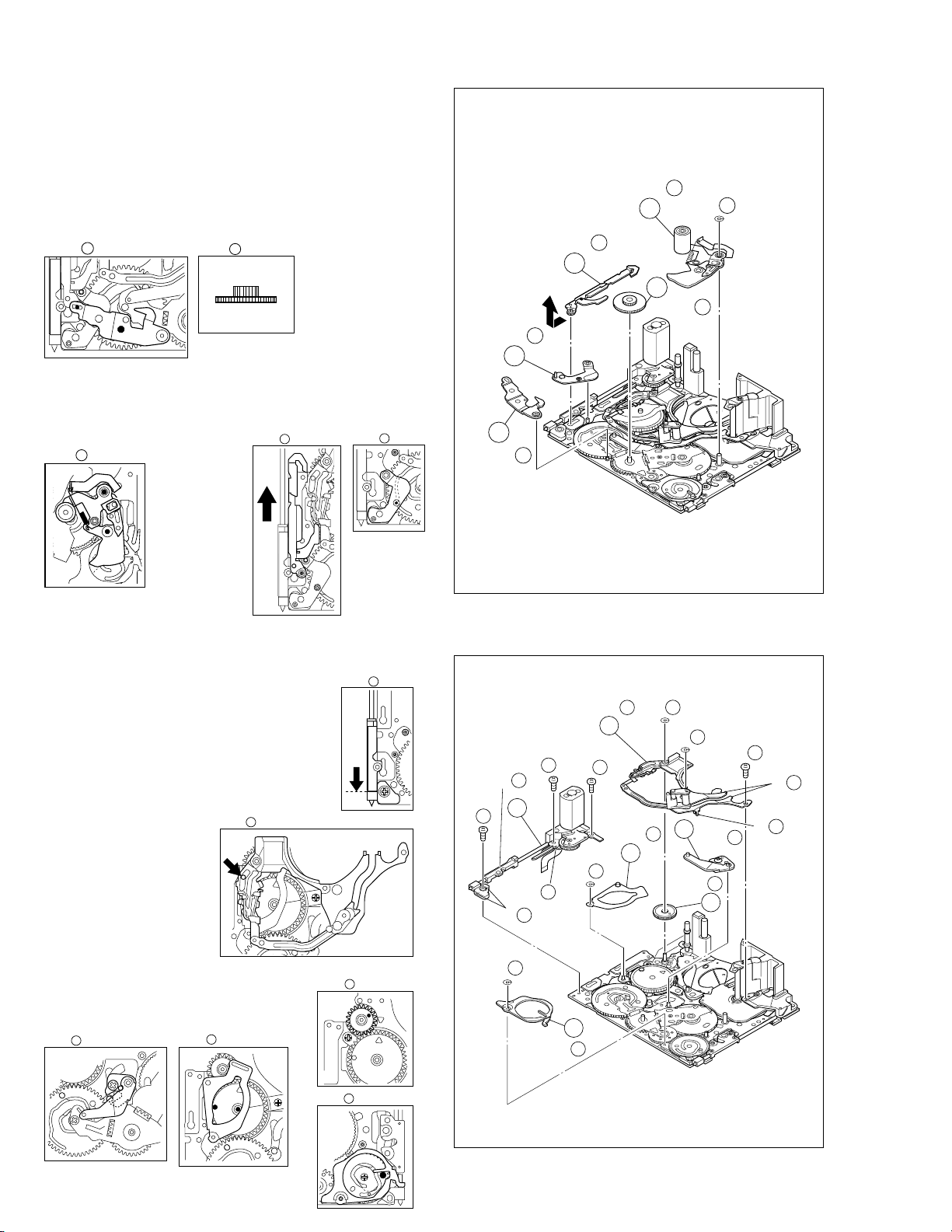

2.4.1 Disassembly/assembly

1

(S )

1

2

(S )

1

1

NOTE d

1

NOTE c

1

NOTE b

1

NOTE a

1

(S )

1

3

(L d)

LOCK

LEVER

1

(L a)

1

(L e)

1

(L c)

1

(L b)

1

NOTE d

1

2

3

(S )

2

4

(S b)

7

3

(S b)

6

3

(S a)

5

3

(L b)

2

(L a)

2

NOTE

2

NOTE

3

NOTE b

3

NOTE

2

a

CASSETTE HOUSING ASSY

1.

1

NOTE1a:

Be careful not to damage any of the

parts during work.

NOTE1b:

Special care is required in mounting.

1

NOTE b

NOTE1c:

NOTE c

When mounting, the CASSETTE

HOUSING ASSY should be attached in the Eject status. Pay

heed to the positions of the LOCK

LEVER and EJECT LEVER during

mounting.

NOTE1d:

When mounting, be sure to locate the

FPC in the gap.

2.

UPPER BASE ASSY

2

DRUM ASSY

3

NOTE

NOTE2:

When mounting, be sure to insert

the FPC reinforcing sheet.

1

EJECT

LEVER

NOTE d

2

LOCK

LEVER

1

Fig. 2-4-3

NOTE3a:

Be mindful of scratches or damage

during work.

NOTE3b:

Be careful not to attach screws incorrectly.

3

NOTE

b

5

7

6

Fig. 2-4-4

2-7

Page 27

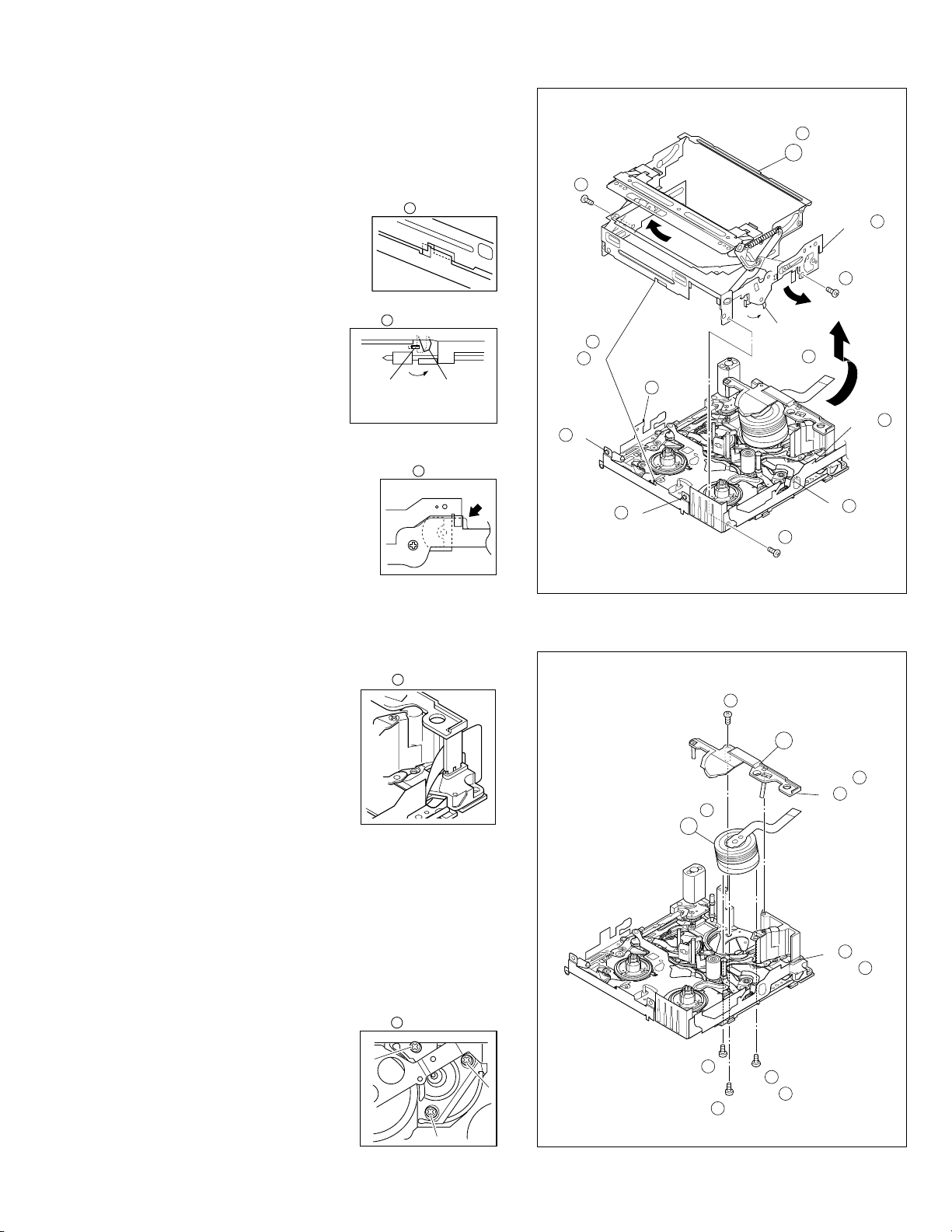

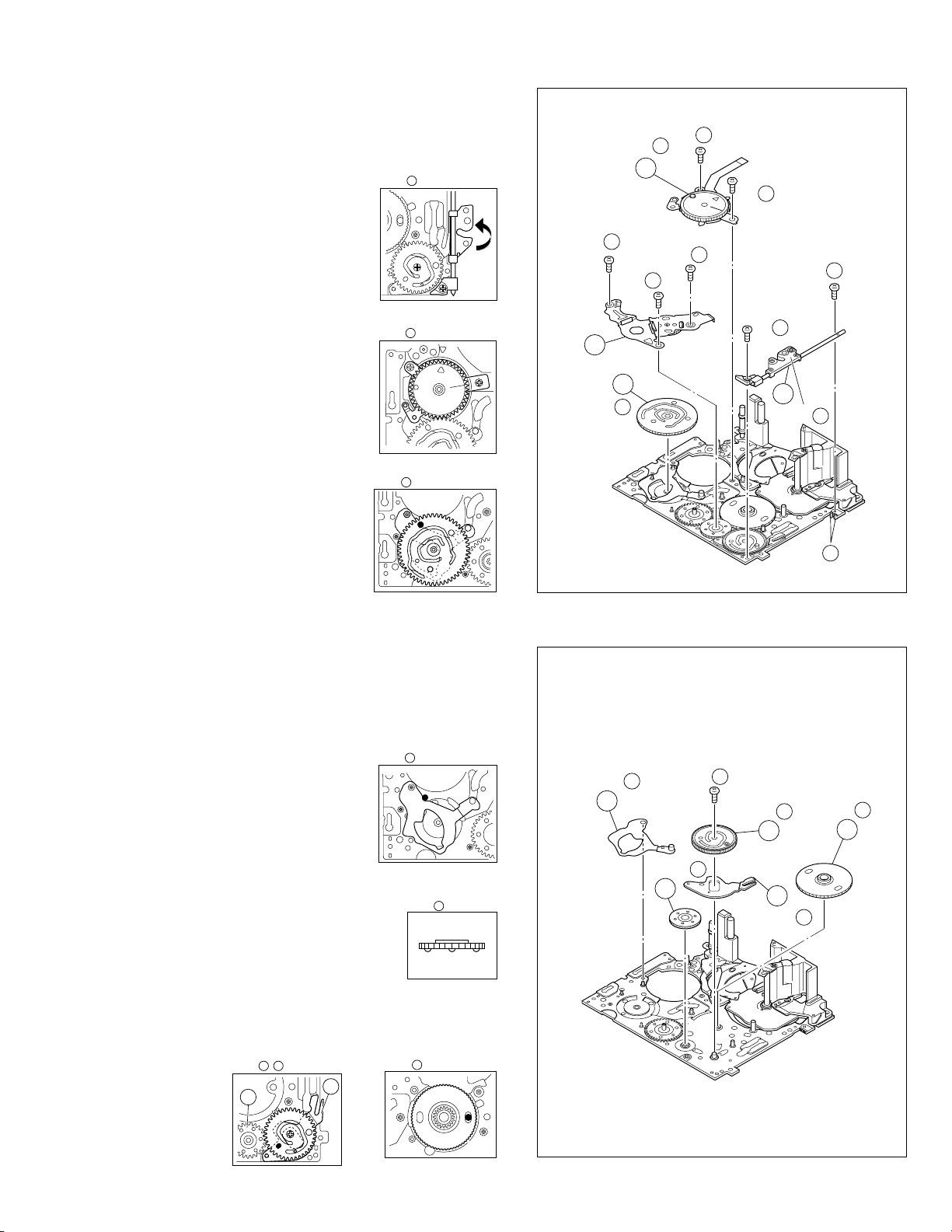

REEL DISK ASSY(SUP)

3.

4

REEL DISK ASSY(TU)

5

REEL COVER ASSY

6

NOTE4:

Be careful not to attach the REEL DISK wrongly. The Supply side can be identified by the white color at the center.

4 5

NOTE5:

Be careful not to attach the

REEL DISK wrongly. The

NOTE ,

REEL DISK ASSY

WHITE

BLACK

Take-up side can be identified by the black color at

the center.

SUP

TU

NOTE6:

Perform the following steps for mounting.

1. Move the RELEASE GUIDE back and align the 2 holes

with the pins.

2. Attach the PINCH ROLLER ARM ASSY by aligning the

positions.

3. Attach the SUB DECK

ASSY by aligning the

positions.

NOTE

6

3

5

2

4. Check that the parts

below them are located in the correct

positions.

4

5. Tighten the 2 screws.

6. Tighten the screw.

7. Attach the 2 SLIT

WASHER parts.

1, 7

RELEASE GUIDE

4

(W )

5

NOTE

4

(W )

4

8

6

5

(S b)

5

10

6

9

6

(S a)

6

(W )

6

(W )

NOTE

(S a)

6

NOTE

6

6

Fig. 2-4-5

4.

TENSION ARM ASSY

7

SLANT POLE ARM ASSY

8

TU ARM ASSY

9

SWING ARM ASSY

0

NOTE7:

When detaching, remove the spring

of the @ PAD ARM ASSY in advance.

Pay attention to the attachment position.

NOTE8:

Be careful not to lose any parts

(such as a spring).

NOTE9:

Pay attention to the

mounting position.

9

NOTE

7

NOTE

SPRING

8

NOTE

SPRING

10

NOTE

TOP SIDE

NOTE

7

NOTE

7

(P )

NOTE

NOTE

7

10

8

NOTE

8

8

10

11

10

(S )

9

9

NOTE0:

When detaching, remove the

screw then remove the SWING

ARM ASSY by pulling it up and

turning it.

2-8

Fig. 2-4-6

Page 28

5.

(W )

11

11

(S b)

14

11

(S a)

12

11

(S a)

13

11

(L b)

11

(L a)

11

(L c)

11

NOTE a

11

NOTE b

11

SLIDE DECK ASSY

!

NOTE!a:

Each of the parts on the SLIDE DECK ASSY can be replaced separately.

When detaching the assembly, if there is no need to replace

any of its parts, remove the SLIDE DECK ASSY as it is.

NOTE!b:

When mounting, pay attention to the positions of the

¤

SLIDE LEVER (2) studs to which the SLIT WASHERS are

attached and the BRAKE CONTROL LEVER ASSY.

When mounting, position the CONTROL PLATE on the left

side.

Pay attention to the position of the SLIDE GUIDE PLATE

during mounting.

11

NOTE

b

6.

PAD ARM ASSY

@

SUP BRAKE ASSY

#

TU BRAKE ASSY

$

NOTE@:

The spring may have already been disengaged when the

8

SLANT POLE ARM ASSY was removed.

NOTES#/$:

When mounting, pay attention to the correct positioning.

Mount the CONTROL PLATE by moving it fully toward the

left side.

12 13 14

NOTE

12

SPRING

CONTROL

PLATE

13 14

12

(W )

NOTE

(L )

13

13

12

(P )

15

(S )

13

NOTE

12

13

Fig. 2-4-7a

12

13

(P )

(W )

12

(L )

14

14

NOTE

(L )

14

(P )

14

14

Fig. 2-4-7b

2-9

Page 29

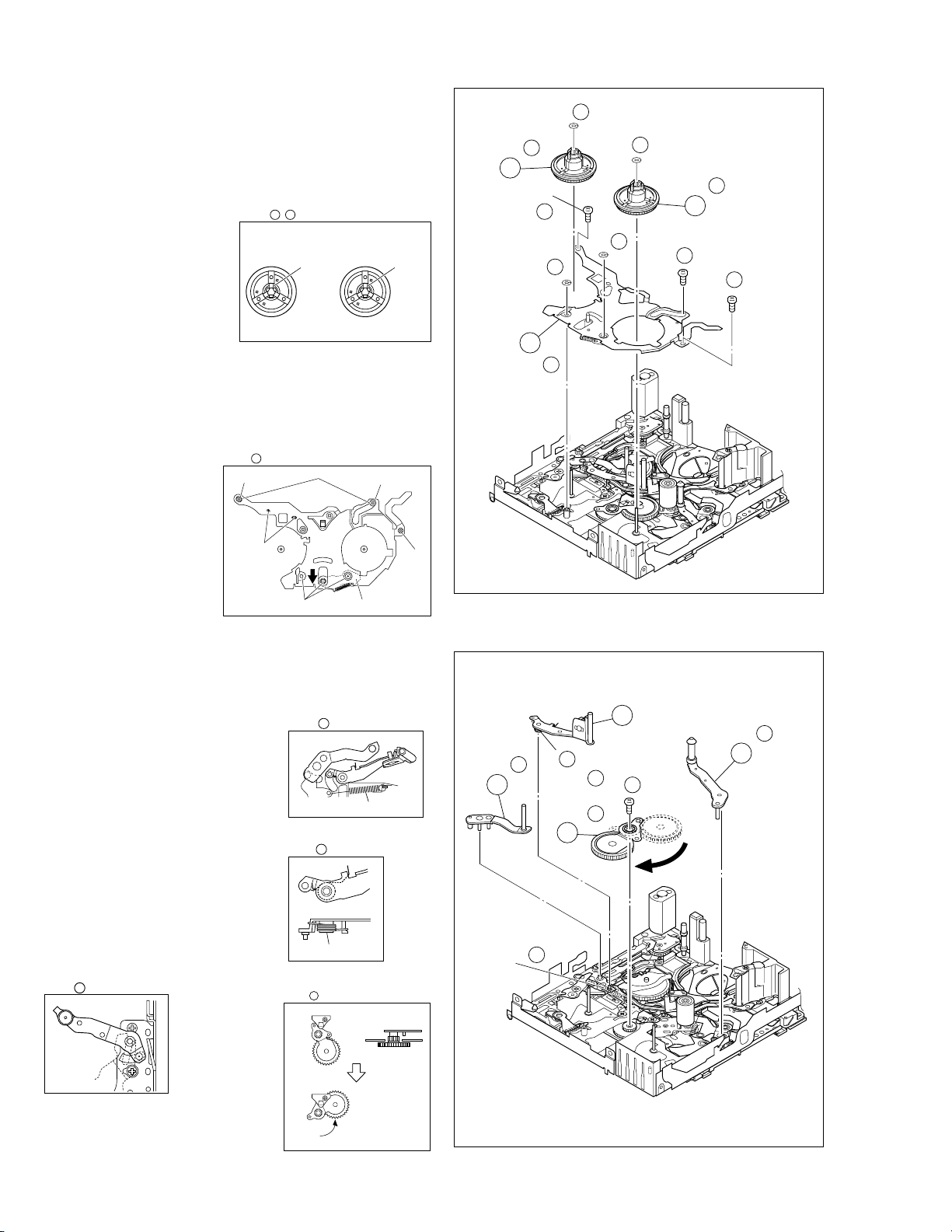

TENSION CTL LEVER ASSY

7.

%

CENTER GEAR

^

PINCH ROLLER ARM F. ASSY

&

TENSION CTL PLATE ASSY

*

BRAKE CTL LEVER ASSY

(

NOTES%/^:

When mounting, pay attention to the correct positioning.

15

NOTE

NOTE

16

(TOP)

(BOTTOM)

NOTES*/(:

When mounting, pay at-

NOTE&:

Take care against grease

attachment during work.

17

NOTE

tention to the correct positioning.

19

NOTE

18

NOTE

NOTE

15

NOTE

19

15

19

NOTE

18

18

NOTE

17

16

17

NOTE

17

(W )

16

MOTOR BRACKET ASSY

8.

)

GUIDE RAIL ASSY

⁄

SLIDE LEVER 2 ASSY

¤

LOADING PLATE ASSY

‹

MODE GEAR

›

EJECT LEVER

fi

NOTE):

When mounting, pay attention to the positioning of the sliding parts.

21

NOTE

NOTE⁄:

When mounting, take care

that no part is allowed to

float or rattle.

NOTES¤/‹/›/fi:

NOTE

When mounting, pay attention to the

correct positioning.

23

NOTE

22

NOTE

NOTE

24

Fig. 2-4-8

20

21

21

21

NOTE

(W )

(W )

23

22

21

NOTE

19

21

(S )

22

(L a)

21

(L b)

21

NOTE

18

20

(S )

20

20

17

20

(S )

NOTE

16

20

(S )

23

23

(L b)

25

(W )

(L a)

20

(W )

20

NOTE

24

24

25

25

NOTE

2-10

NOTE

25

Fig. 2-4-9

Page 30

BASE R ASSY

9.

fl

ROTARY ENCODER

‡

GEAR COVER ASSY

°

MAIN CAM ASSY

·

NOTEfl:

When mounting, fold the sliding

part to the inner side.

NOTE

22

27

(S )

27

NOTE

26

27

23

27

(S )

25

26

28

24

28

(S a)

20

26

(S b)

28

(S b)

(S b)

NOTE‡:

When mounting, pay attention to

the correct positioning and the

FPC layout.

NOTE

·

:

When mounting, pay attention to

the correct positioning.

SLIDE ARM ASSY

10.

‚

CONNECT GEAR 2

¡

SUB CAM ASSY

™

CONTROL ARM ASSY

£

REEL GEAR 1

¢

NOTE

‚

:

When mounting, pay attention to the

correct positioning and the FPC layout.

NOTE

NOTE

NOTE

21

26

27

(S a)

28

29

29

NOTE

29

26

NOTE

26

26

(L )

Fig. 2-4-10

30

30

NOTE

30

27

32

(S )

NOTE

32

32

NOTE

34

34

NOTE¡:

When mounting, pay attention to the position of the front and back.

NOTE

(BOTTOM)

31

(TOP)

NOTES™/£/¢:

When mounting, pay attention to the correct positioning and

the FPC layout.

34

32 33

NOTE /

32

33

NOTE

NOTE

31

31

Fig. 2-4-11

33

NOTE

33

2-11

Page 31

11.

DRUM BASE ASSY

∞

CAPSTAN MOTOR

§

MAIN DECK ASSY

¶

NOTES

∞

a /§:

When detaching, remove them together and then separate

from ∞a.

§

∞

b:

NOTE

When mounting, attach the DRUM BASE ASSY so that the

screw hole is located at the center of the ellipse.

35

NOTE b

35

28

35

(S )

29

35

(S )

31

36

(S )

30

35

(S )

NG

OK

NG

NOTE

36

36

Fig. 2-4-12

37

NOTE

35

a

2-12

(Z27 Ver.1)

Page 32

2.4.2 List of procedures for disassembly

(W )

13

(P )

18

(S )

20

13

13

12

(W )

14

(S )

20

17

12

20

(S b)

8

(P )

14

(W )

14

(P )

14

11

8

2

(S )

12

(P )

16

(S )

1

(W )

4

(S a)

(W )

6

7

(W )

22

(S )

20

18

27

1

4

29

(S )

35

5

3

(S )

35

36

17

2

2

(S )

17

(W )

31

3

35

30

35

(S )

1

1

4

5

(W )

9

6

6

(W )

6

5

8

6

(S a)

(S b)

(S )

9

6

9

21

19

21

28

(S )

35

7

3

(S b)

(S a)

6

3

(S b)

23

27

30

23

(S )

11

10

(S )

(S a)

(S )

23

27

13

11

3

1

34

10

12

11

(S a)

11

21

(W )

22

(W )

(S )

21

25

28

(S b)

15

29

16

31

26

28

(S b)

28

24

28

(S a)

19

24

37

Fig. 2-4-13

20

26

(S a)

26

25

(W )

(S )

25

27

32

32

33

2-13

Page 33

2.5 CHECKUP AND ADJUSTMENT OF MECHANISM PHASE

MODE GEAR

24

Align the MODE GEAR with the Main Deck

Assembly hole.

Note:

The MODE GEAR may

be displaced during the

mechanism operation,

however it can be

checked from the rear

and realigned during

manual assembly.

27

ROTARY ENCODER

Mount the ROTARY ENCODER by aligning its mark ( )

and the mark ( ) of the Main Deck Assembly.

Note:

Be careful when handling the FPC during mounting.

34

REEL GEAR 1

Align the REEL GEAR 1 with

the Main Deck Assembly hole.

Note:

The REEL GEAR 1 may be

displaced during mechanism

operation, however this can

be checked from the rear and

realigned during manual

assembly.

MAIN CAM ASSY/ 30 SLIDE ARM ASSY

29 32

When mounting the SLIDE ARM ASSY align it with the

Main Deck Assembly and MAIN CAM ASSY holes.

Note:

During the mounting procedure, make sure that the 32 .

SUB CAM ASSY is in the correct mounting position.

Fig. 2-5-1

SUB CAM ASSY/ 33 CONTROL ARM ASSY

Mount the SUB CAM ASSY hole to align with the CONTROL

ARM ASSY and Main Deck Assembly holes and then tighten

them all together with a screw.

The screw tightening torque should be 0.039 N•m (0.4 kgf•cm)

Note:

When mounting it, make sure that the 29 MAIN CAM ASSY is

in the correct mounting position.

2-14

Page 34

2.6 MECHANISM ADJUSTMENTS

2.6.1 Adjustment of the slide guide plate

Use Fig. 2-6-1 as the reference unless otherwise specified.

1. Set the PLAY mode.

See Fig. 2-3-8.

2. Loosen the screws A , B ).

3. With the Main Deck Assembly and Slide Deck Assembly pushed inside the unit, tighten the screws ( A , B )

while applying pressure on the slit washers of the slide

guide plate.

The pressure applied should be enough to enable utilization of the rebounding force of the springs.

The tightening torque should be 0.069 N

•

m (0.7 kgf•cm).

4. Check the operation.

Repeat unloading and loading several times and make

sure that these operations can be performed smoothly

without producing rattles.

3

2, 3

SCREW

3

3

3

A

2,3

SCREW

B

3

Fig. 2-6-1

2-15

Page 35

2.6.2 Adjustment of the Tension Arm and Pad Arm Assemblies

Use Fig. 2-6-2 as the reference unless otherwise specified.

1. Set the PLAY mode.

Se Fig. 2-3-8.

2. Loosen the screw A .

3. With the take-up side at the bottom, align the extreme

end of the Tension Arm Assembly with the crossed

grooves on the screw B that retains the Loading Motor

Assembly and then tighten the screw A .

The tightening torque should be 0.069 N

•

m (0.7 kgf•cm).

4. Check the operation.

Repeat unloading and loading several times and make

sure that the Tension Arm Assembly is located within the

normal range.

Note :

With the above checking method, a Torque Meter is not used.

When a Torque meter is used, the following are

the reference values:

2, 3

SCREW

SCREW

A

TENSIOM

ARM ASSY

B

Back Tension : 2.0 to 6.0 g•cm

Play Torque : 8.3 to 12.5 g

•

cm

2.6.3 Adjustment of the Slide Lever 2

Use Fig. 2-6-3 as the reference unless otherwise specified.

1. Set the C IN mode.

See Fig. 2-3-4.

2. Loosen the screw A .

3. Set the Main Deck and Slide Deck Assemblies apart so

that they do not rattle, then tighten the screw A by

screwing it fully toward the Drum Assembly.

The tightening torque should be 0.069 N

•

m (0.7 kgf•cm).

4. Check the operation.

Repeat unloading and loading several times and make

sure that these operations can be performed smoothly

without producing rattles.

2, 3

SCREW

Fig. 2-6-2

3

A

2-16

3

Fig. 2-6-3

Page 36

2.7 JIG CONNECTOR CABLE CONNECTION

Remove one screw (1) first and the cover (JIG) next.

GUIDE ROLLER (TU) ASSY

GUIDE ROLLER (SUP)

ASSY

COMMINICATION CABLE JIG CONNECTOR

to 8 pin

RED

( JLIP_RX )

to 9 pin

( JLIP_TX )

WHITE

to 5 or 23 pin

BLACK

( GND )

JIG CONNECTOR CABLE

COMMUNICATION CABLE

MAIN BOARD ASSY CN107

16

1

17

2

D_REG3V

DJIG.MOD

DJIG_SCL

DJIG.SPT

18

3

19

4

20

5

21

6

MONI_CHG(REC_I)

22

7

CHG_STOP

23

8

24

9

JLIP_RX

PB_CLK

JLIP_TX

25

10

26

ENV_OUT

11

27

12

28

13

PB_VCO

MAIN_VCO

VPPC_5V

AL_3VSYS

29

14

30

15

CJIG_MOD

CJIG_SCK

CJIG_SPT

TDO_F

TDI_F

TCMK

TMS

TRST

GND

SBE

SPA

GND

GND

HID1

ATFI