Page 1

SERVICE MANUAL

DIGITAL VIDEO CAMERA

YF228<Rev.001>20082SERVICE MANUAL

GR-D850UC, GR-D850US,

GR-D870UC, GR-D870US,

GR-D875US

GR-D850UCM,GR-D850USM [M8D523]

GR-D870UCM,GR-D870USM

COPYRIGHT© 2008 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

GR-D875USM [M8D525]

TABLE OF CONTENTS

1 PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

5 TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

COPYRIGHT© 2008 Victor Company of Japan, Limited

No.YF228<Rev.001>

2008/2

Page 2

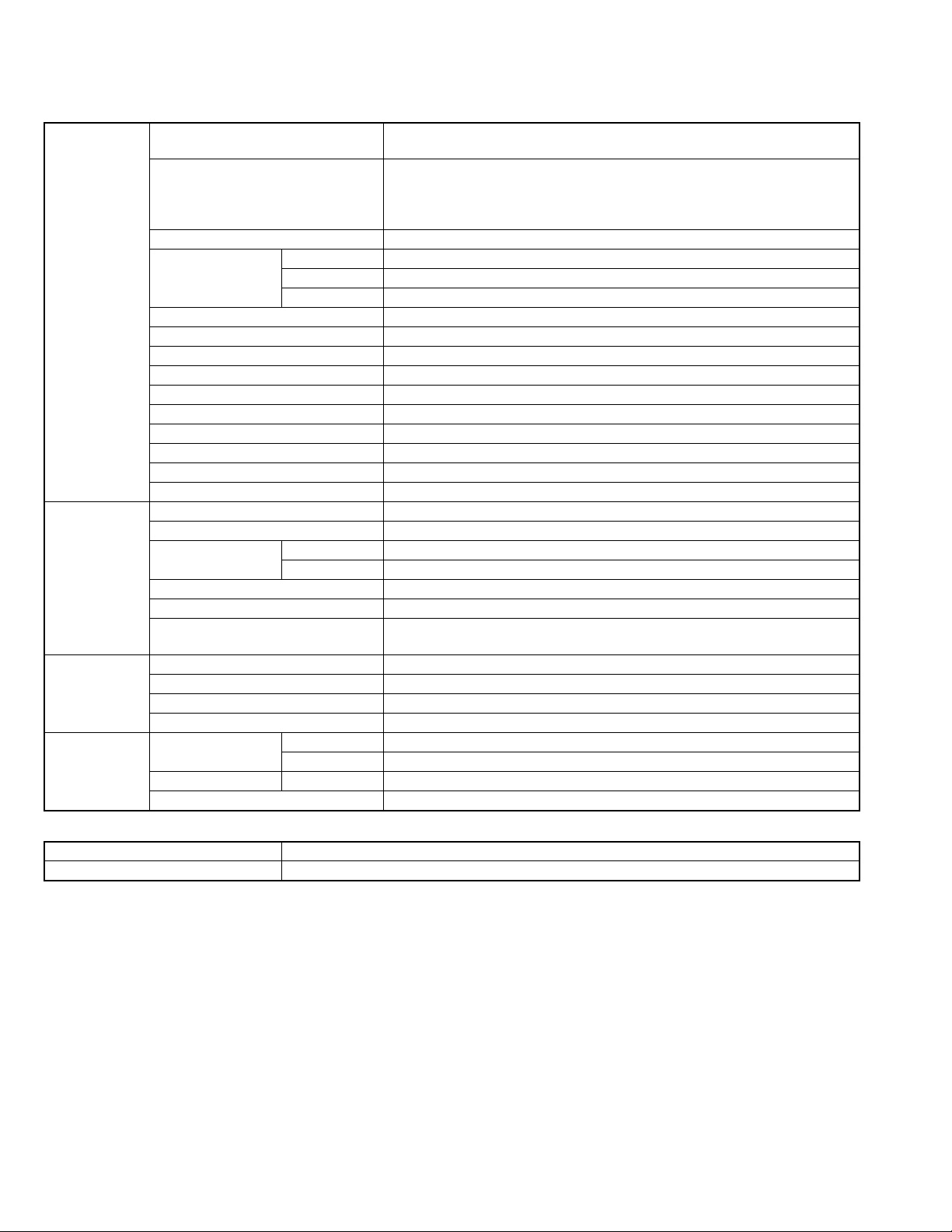

SPECIFICATION

Camcorder

For General Power supply DC 11 V (Using AC Adapter)

DC 7.2 V (Using battery pack)

Power consumption Approx. 2.4 W (2.6 W*) (LCD monitor off, viewfinder on)

Approx. 7.5 W (Maximum; when charging the battery pack)

* Using LED Light

** The LCD Backlight is set to [STANDARD] mode.

Dimensions (W × H × D) 68 mm × 74 mm × 118 mm(2.68" × 2.91" × 4.65")

Weight Approx. 420 g (0.93 lbs) (without battery, cassette and lens cap)

GR-D850 Approx. 485 g (1.07lbs) (incl. battery, cassette and lens cap)

GR-D870 Approx. 490 g (1.08lbs) (incl. battery, cassette and lens cap)

Operating temperature 0°C to 40°C (32°F to 104°F)

Operating humidity 35% to 80%

Storage temperature -20°C to 50°C (-4°F to 122°F)

Pickup 1/6" CCD

Lens F1.8 to 4.0, f=2.2 mm to 77 mm, 35:1 power zoom lens

Filter diameter Ø30.5 mm

LCD monitor 2.7" diagonally measured, LCD panel/TFT active matrix system

Viewfinder Electronic viewfinder with 0.16" color LCD

Speaker Monaural

LED Light Effective distance: 1.5 m (5 ft)

For Digital Video

Camera

For Digital Still

Camera

* GR-D870only

For Connectors AV Video output 1.0 V (p-p), 75Ω, analog

Format DV format (SD mode)

Signal format NTSC standard

Recording/Playback

format

Cassette Mini DV cassette

Tape speed SP: 18.8 mm/s, LP: 12.5 mm/s

Maximum recording time

(using 80 min. cassette)

Storage media SD Memory Card/MultiMediaCard

Compression system JPEG (compatible)

File size Still image : 640 × 480 pixels

Picture quality 2 modes (FINE/STANDARD)

DV Input/output 4-pin, IEEE 1394 compliant

USB Mini USB-B type, USB 1.1 compliant

Video Digital component recording

Audio PCM digital recording, 32 kHz 4-channel (12-BIT), 48 kHz 2-channel (16-BIT)

SP: 80 min., LP: 120 min.

Audio output 300 mV (rms), 1 kΩ, analog, stereo

AC Adapter

Power requirement AC 110 V to 240 V, 50 Hz/60 Hz

Output DC 11 V, 1 A

Specifications shown are for SP mode unless otherwise indicated. E & O.E. Design and specifications subject to change without

notice.

1-2 (No.YF228<Rev.001>)

Page 3

SECTION 1

r

PRECAUTIONS

1.1 SAFTY PRECAUTIONS

Prior to shipment from the factory, JVC products are strictly

inspected to conform with the recognized product safety and

electrical codes of the countries in which they are to be

sold.However,in order to maintain such compliance, it is equally

important to implement the following precautions when a set is

being serviced.

1.1.1 Precautions during Servicing

(1) Locations requiring special caution are denoted by labels

and inscriptions on the cabinet, chassis and certain parts of

the product.When performing service, be sure to read and

comply with these and other cautionary notices appearing

in the operation and service manuals.

(2) Parts identified by the symbol and shaded ( ) parts

are critical for safety.

Replace only with specified part numbers.

NOTE :

Parts in this category also include those specified to

comply with X-ray emission standards for products

using cathode ray tubes and those specified for

compliance with various regulations regarding

spurious radiation emission.

(3) Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as

specified.

(4) Use specified internal wiring. Note especially:

• Wires covered with PVC tubing

• Double insulated wires

• High voltage leads

(5) Use specified insulating materials for hazardous live parts.

Note especially:

• Insulation Tape

• PVC tubing

•Spacers

• Insulation sheets for transistors

•Barrier

(6) When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

emission. Consequently, when servicing these products,

replace the cathode ray tubes and other parts with only the

specified parts. Under no circumstances attempt to modify

these circuits.Unauthorized modification can increase the

high voltage value and cause X-ray emission from the

cathode ray tube.

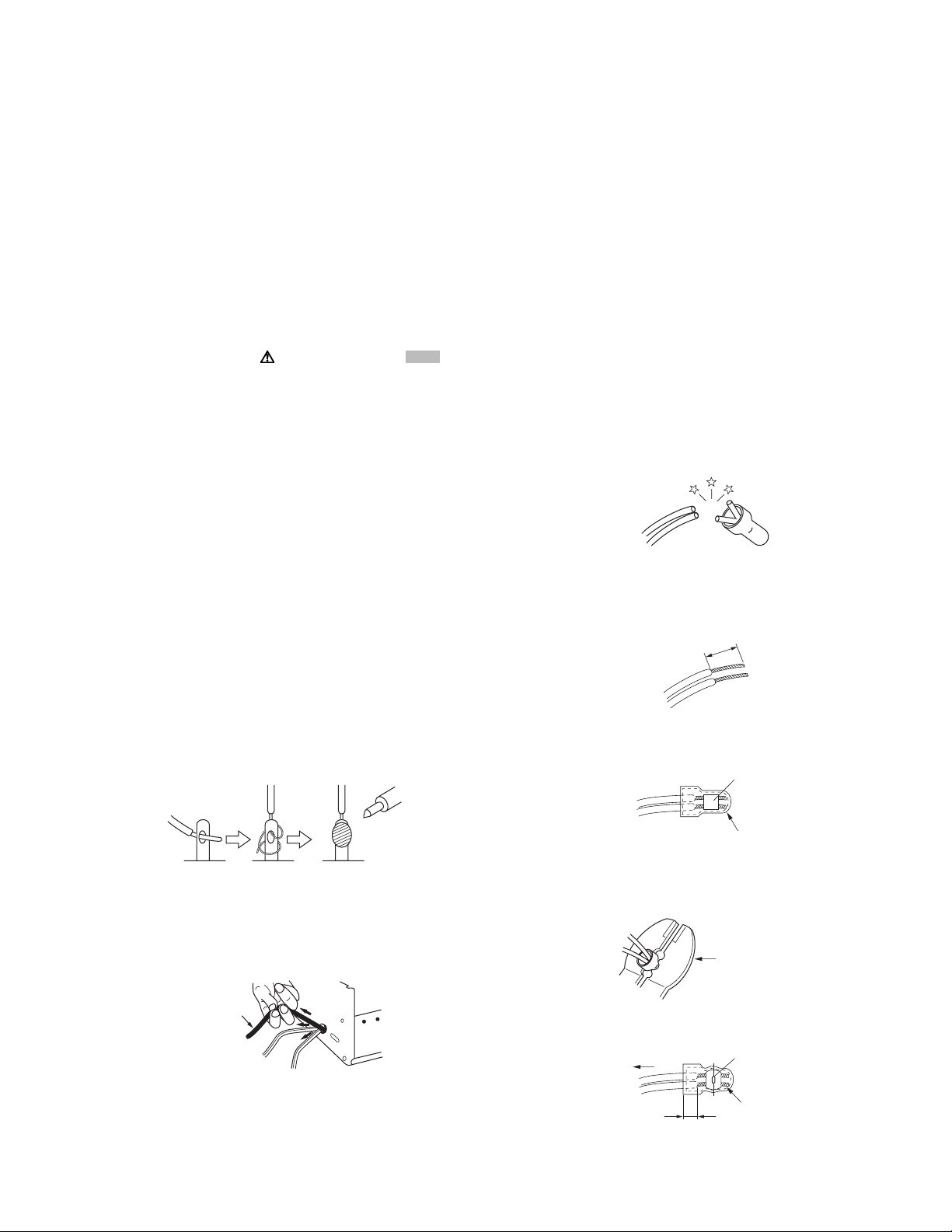

(12) Crimp type wire connectorIn such cases as when replacing

the power transformer in sets where the connections

between the power cord and power trans former primary

lead wires are performed using crimp type connectors, if

replacing the connectors is unavoidable, in order to prevent

safety hazards, perform carefully and precisely according

to the following steps.

• Connector part number :E03830-001

• Required tool : Connector crimping tool of the proper

type which will not damage insulated parts.

• Replacement procedure

a) Remove the old connector by cutting the wires at a

point close to the connector.Important : Do not

reuse a connector (discard it).

cut close to connector

Fig.1-1-3

b) Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

15 mm

Fig.1-1-4

c) Align the lengths of the wires to be connected.

Insert the wires fully into the connector.

Metal sleeve

Fig.1-1-1

(7) Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

(8) Check that replaced wires do not contact sharp edged or

pointed parts.

(9) When a power cord has been replaced, check that 10-15

kg of force in any direction will not loosen it.

Power cord

Fig.1-1-2

(10) Also check areas surrounding repaired locations.

(11) Products using cathode ray tubes (CRTs)In regard to such

products, the cathode ray tubes themselves, the high

voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray

Connector

Fig.1-1-5

d) As shown in Fig.1-1-6, use the crimping tool to crimp

the metal sleeve at the center position. Be sure to

crimp fully to the complete closure of the tool.

1.2

5

2.0

5.5

Crimping tool

Fig.1-1-6

e) Check the four points noted in Fig.1-1-7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Crimped at approx. cente

of metal sleeve

Conductors extended

Fig.1-1-7

(No.YF228<Rev.001>)1-3

Page 4

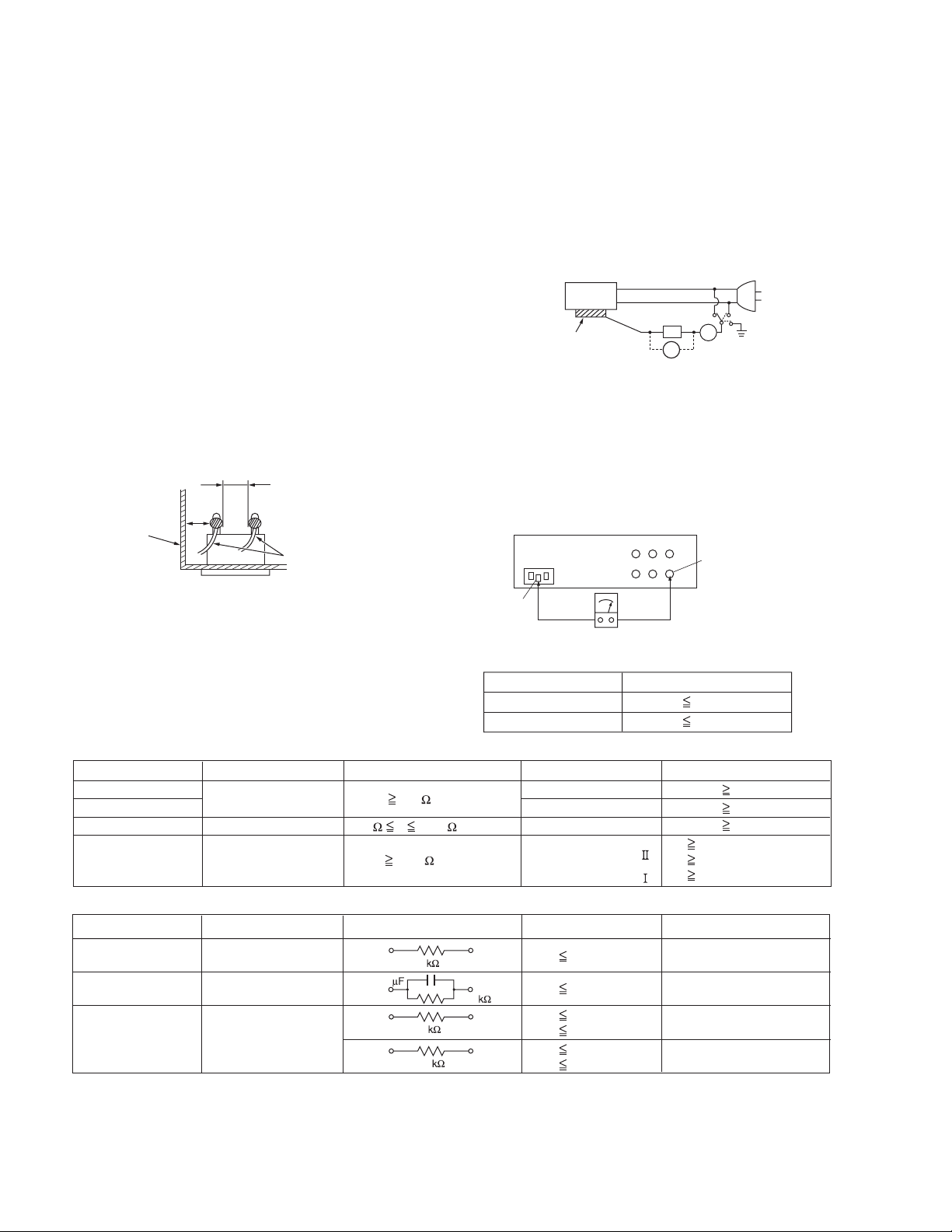

1.1.2 Safety Check after Servicing

Examine the area surrounding the repaired location for damage

or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following

tests and confirm the specified values in order to verify

compliance with safety standards.

(1) Insulation resistance test

Confirm the specified insulation resistance or greater

between power cord plug prongs and externally exposed

parts of the set (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks,

earphone jacks, etc.).See table 1 below.

(2) Dielectric strength test

Confirm specified dielectric strength or greater between

power cord plug prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone

jacks, etc.). See Fig.1-1-11 below.

(3) Clearance distance

When replacing primary circuit components, confirm

specified clearance distance (d), (d') between soldered

terminals, and between terminals and surrounding metallic

parts. See Fig.1-1-11 below.

d

d'

Chassis

Power cord

primary wire

Fig.1-1-8

(4) Leakage current test

Confirm specified or lower leakage current between earth

ground/power cord plug prongs and externally exposed

accessible parts (RF terminals, antenna terminals, video

and audio input and output terminals, microphone jacks,

earphone jacks, etc.).

Measuring Method : (Power ON)Insert load Z between

earth ground/power cord plug prongs and externally

exposed accessible parts. Use an AC voltmeter to

measure across both terminals of load Z. See Fig.1-1-9

and following Fig.1-1-12.

ab

Externally

exposed

accessible part

Z

V

c

A

Fig.1-1-9

(5) Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between

earth pin in AC inlet and externally exposed accessible

parts (Video in, Video out, Audio in, Audio out or Fixing

screw etc.).Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and

exposed accessible parts. See Fig.1-1-10 and grounding

specifications.

AC inlet

Earth pin

Exposed accessible part

MIlli ohm meter

Grounding Specifications

Region

USA & Canada

Europe & Australia

Grounding Impedance (Z

Z 0.1 ohm

Z 0.5 ohm

)

Fig.1-1-10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Insulation Resistance (R

R 1 M /500 V DC

1 M R 12 M /500 V DC

R 10 M /500 V DC

)

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 minute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(

Class

(

Class

Clearance Distance (d), (d'

d, d' 3 mm

d, d' 4 mm

d, d' 3.2 mm

d 4 m m

)

d' 8 m m (Power cord

d' 6 m m (Primary wire

)

Fig.1-1-11

AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Load Z

1

0.15

1.5

2

50

Leakage Current (i)

i 1 mA rms

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

a, b, c

Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

Other terminals

Fig.1-1-12

NOTE :

These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

)

)

)

1-4 (No.YF228<Rev.001>)

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

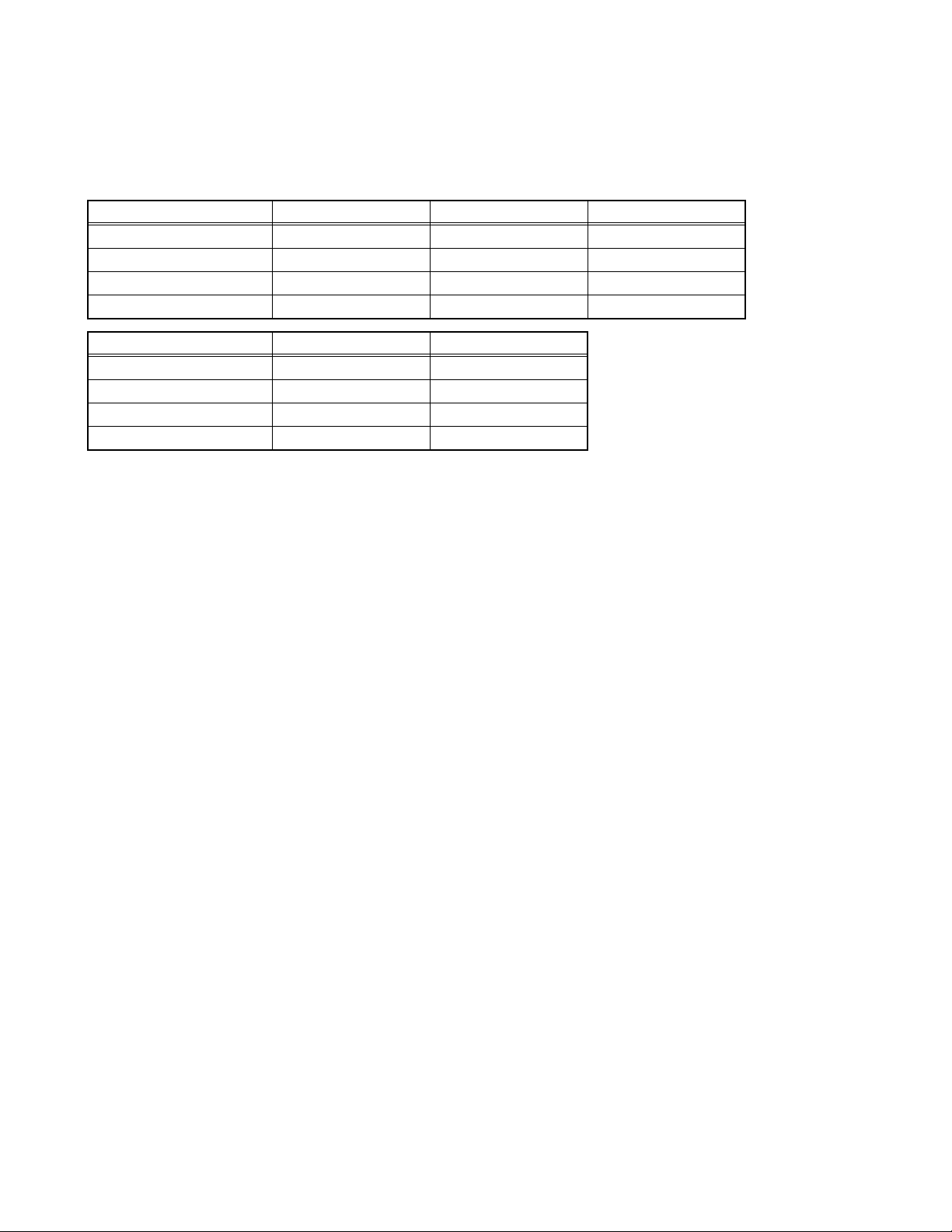

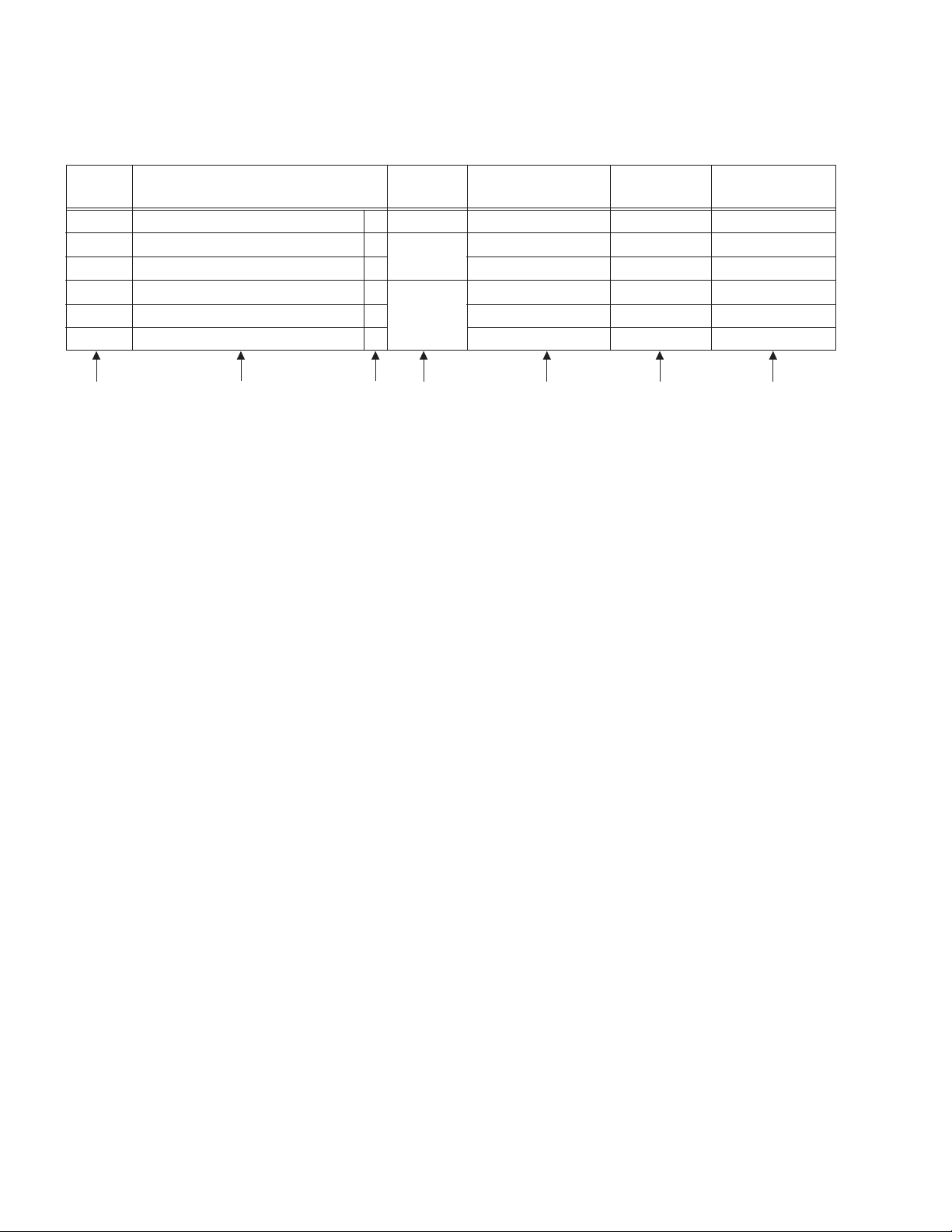

2.1 DIFFERENCE LIST

The following table indicate main different points between models GR-D850UC, GR-D850US, GR-D870UC, GR-D870US,

and GR-D875US.

MODEL NAME GR-D850UC GR-D850US GR-D870UC

DSC

CD-ROM NO NO YES

USB CABLE/TERMINAL NO NO YES

REMOTE CONTROL UNIT NO NO NO

MODEL NAME GR-D870US GR-D875US

DSC

CD-ROM YES YES

USB CABLE/TERMINAL YES YES

REMOTE CONTROL UNIT NO YES(RM-V740US)

NO NO YES

YES YES

(No.YF228<Rev.001>)1-5

Page 6

SECTION 3

DISASSEMBLY

3.1 BEFORE ASSEMBLY AND DISASSEMBLY

3.1.1 Precautions

• Be sure to disconnect the power supply unit prior to mounting

and soldering of parts.

• Prior to removing a component part that needs to disconnect

its connector(s) and its screw(s), first disconnect the wire(s)

from the connector(s), and then remove the screw(s).

• When connecting/disconnecting wires, pay enough attention

not to damage the connectors.

• When inserting the flat wire to the connector, pay attention to

the direction of the flat wire.

• Be careful in removing the parts to which some spacer or

shield is attached for reinforcement or insulation.

• When replacing chip parts (especially IC parts), first remove

the solder completely to prevent peeling of the pattern.

• Tighten screws properly during the procedures. Unless

otherwise specified, tighten screws at a torque of 0.088N

·cm). However, as this is a required value at the time of

(0.9kgf

·m

production, use the value as a measuring stick when

proceeding repair services. (See "SERVICE NOTE(1)" as for

tightening torque.)

3.1.2 Destination of connectors

Two kinds of double-arrows in connection tables respectively

show kinds of connector/wires.

: Wire: Flat wire : Board to board (B-B)

: The connector of the side to remove

CONN. No. PIN No.CONNECTOR

CN2a

CN2b

MAIN CN101

MAIN CN103

MONI BW CN761

MINI BW CN762

40

10

3.1.3 Disconnection of connectors (Wires)

Wire

· Pull both ends of the connector in the arrow

direction, remove the lock and disconnect the flat

wire.

· Pull the both ends of the board in the direction

of the arrow, and remove the B-B Connector.

· Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After

removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

B-B Connector

B-B Connector

· Pull the both ends of the board in the direction of the arrow, and remove the B-B Connector.

FPC Connector

Wire

FPC Connector

Wire

Lock

FPC Connector

· Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After

removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

· Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After

removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

Wire

FPC Connector

Wire

FPC Connector

Lock

Lock

Lock

B-B Connector

Fig.3-1-1

3.1.4 Tools required for disassembly and assembly

Torque driver

YTU94088

Chip IC replacement jig

PTS40844-2

Bit

YTU94088-003

Cleaning cloth

KSMM-01

Tweezers

P-895

Fig.3-1-2

• Torque driver

Be sure to use to fastening the mechanism and exterior parts because those parts must strictly be controlled for tightening torque.

• Bit

This bit is slightly longer than those set in conventional torque

drivers.

• Tweezers

To be used for removing and installing parts and wires.

• Chip IC replacement jig

To be used for replacement of IC.

• Cleaning cloth

Recommended cleaning cloth to wipe down the video heads,

mechanism (tape transport system), optical lens surface.

3.2 ASSEMBLY AND DISASSEMBLY OF MAIN PARTS

3.2.1 Assembly and disassembly

When reassembling, perform the step(s) in reverse order.

STEP

No.

[1]

[2]

PART

TOP COVER ASSY

UPPER ASSY

(Inc. VF ASSY,

SPEAKER/MONITOR)

[8]

E.VF UNIT(B/W)

(∗1) Order of steps in Procedure

When reassembling, preform the step(s) in the reverseorder.

These numbers are also used as the identification (location)

No. of parts Figures.

(∗2) Part to be removed or installed.

(∗3) Fig. No. showing Procedure or Part Location.

(∗4) Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped or unsoldered.

S = Screw L = Lock, Release, Hook

SD = Solder CN = Connector

[Example]

• 4 (S1a) = Remove 4 S1a screws.

• 3 (L1a) = Disengage 3 L1a hooks.

• 2 (SD1a) = Unsolder 2 SD1a points.

• CN1a = Remove a CN1a connector.

(∗5) Adjustment information for installation.

Fig.

No.

4(S1a), 3(L1a),CN1a

C1

(S2a),2(S2b),3(S2c)

C2-1

2(SD1a),

L2,CN2a,b

2(S8),L8,CN8a

C2-2

POINT

( 4) ( 5)( 2) ( 3)( 1)

NOTE

-

-

NOTE 8

1-6 (No.YF228<Rev.001>)

Page 7

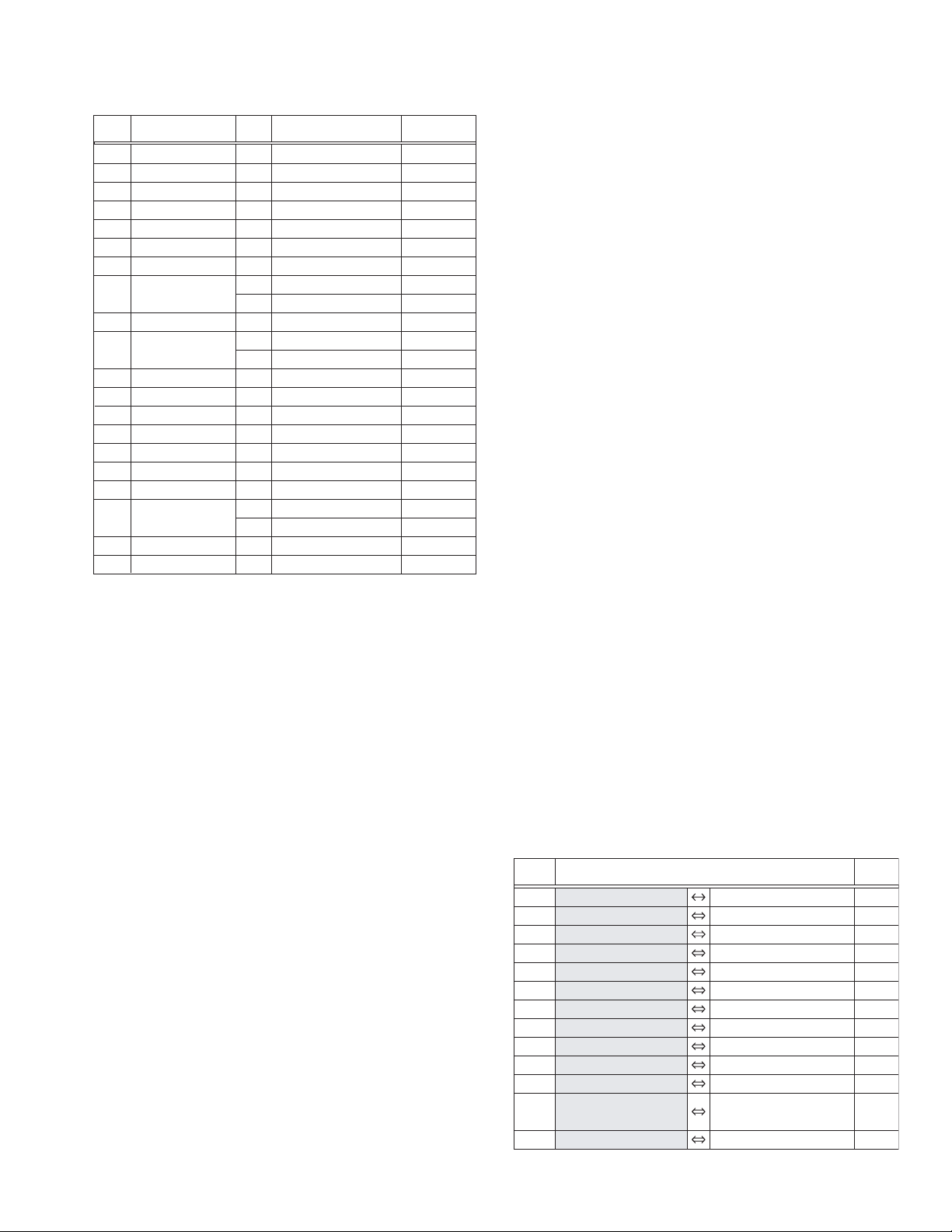

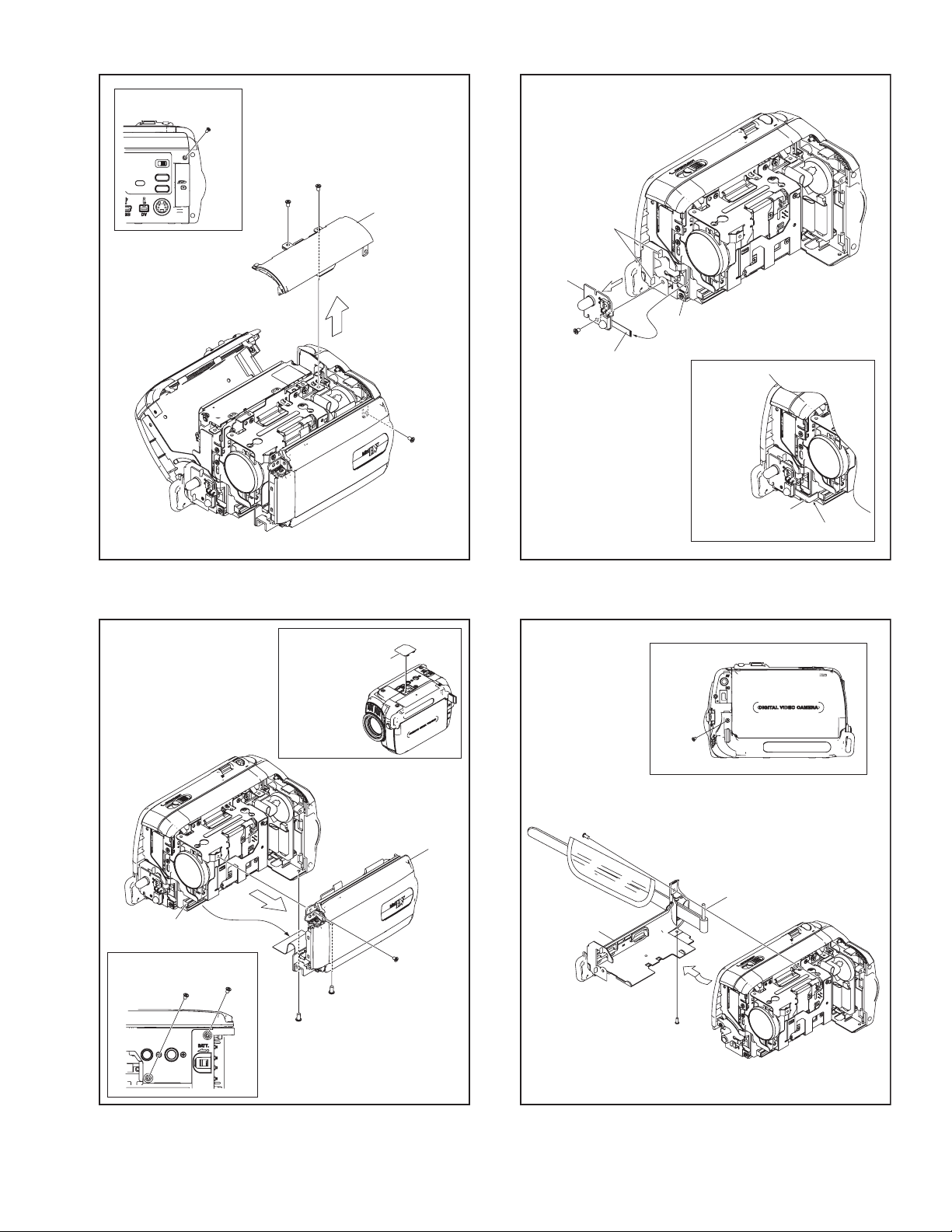

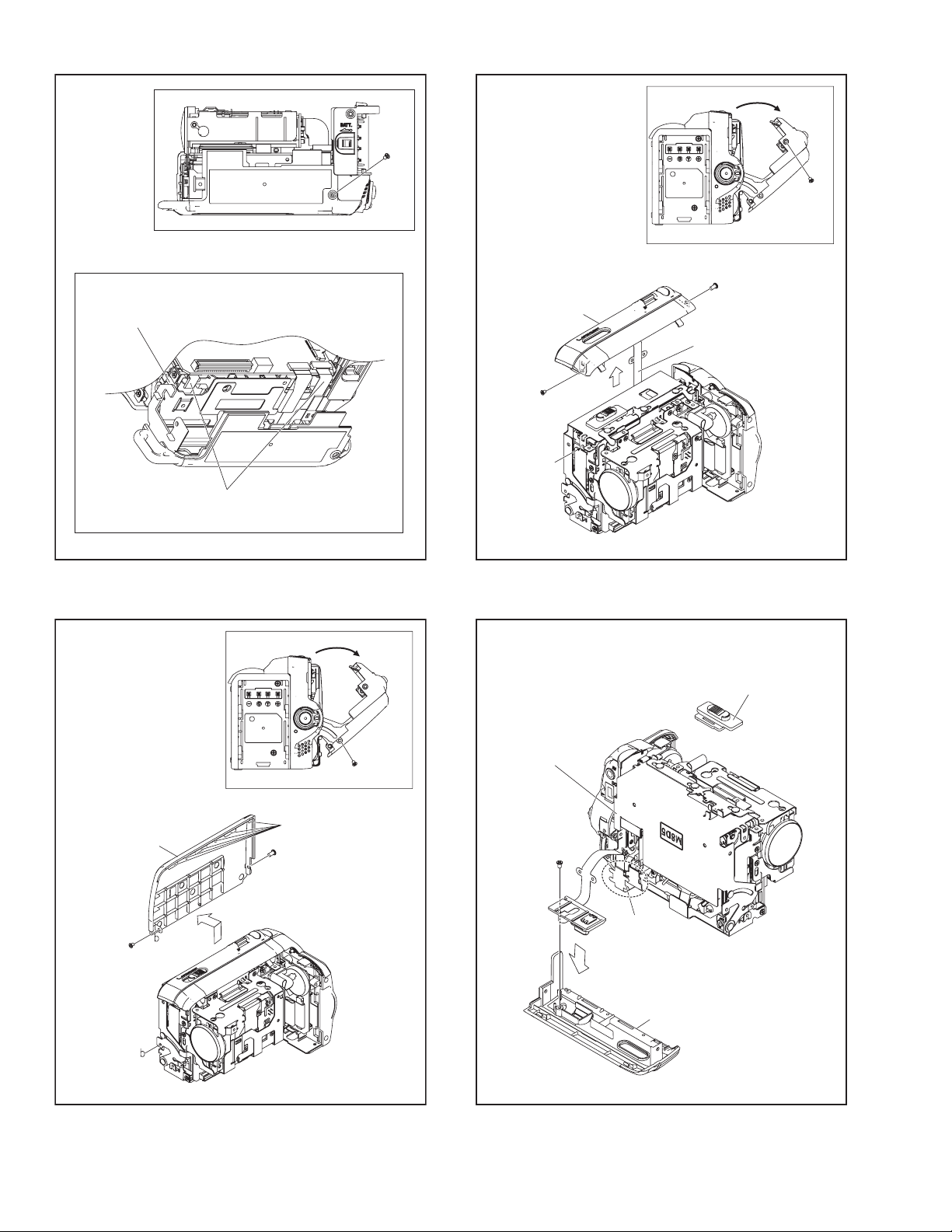

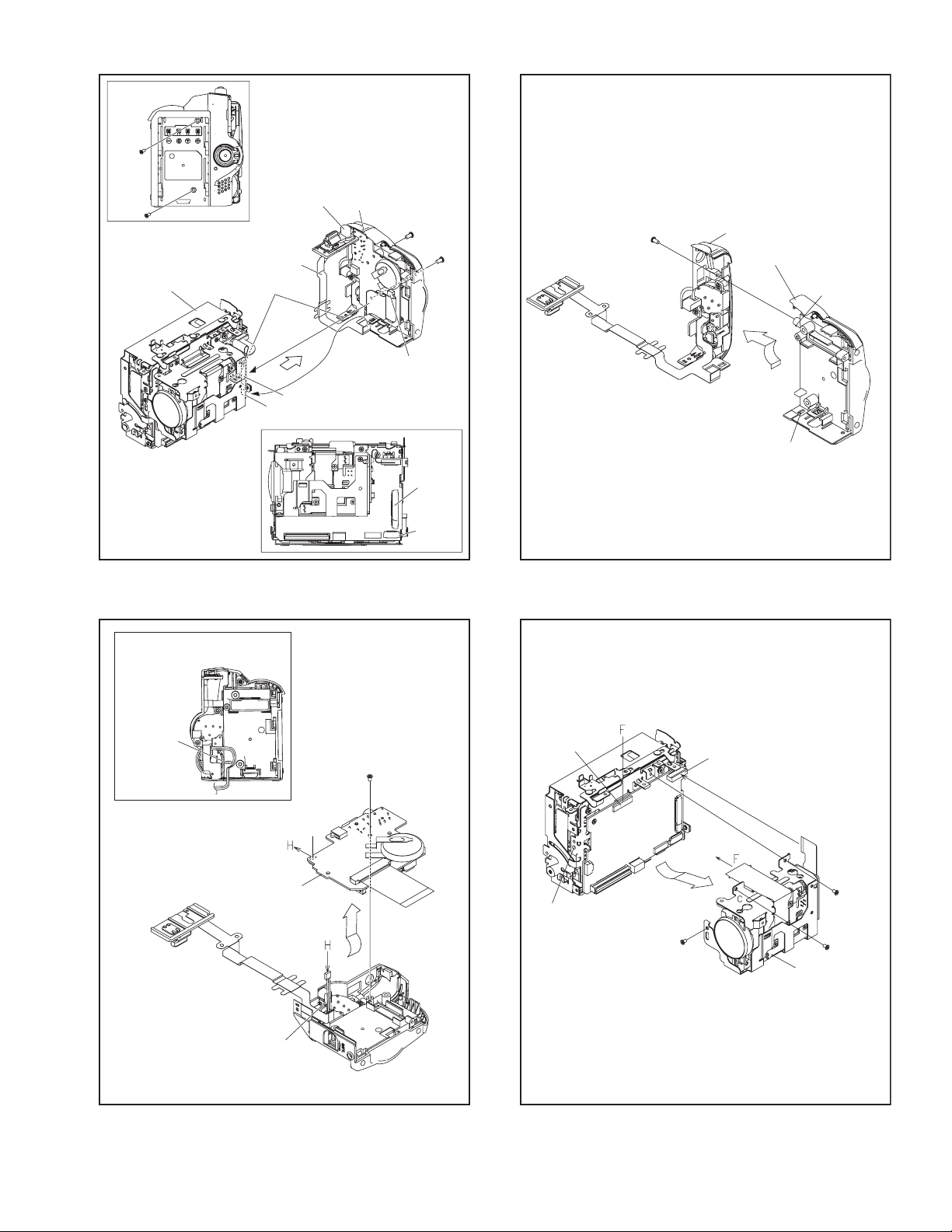

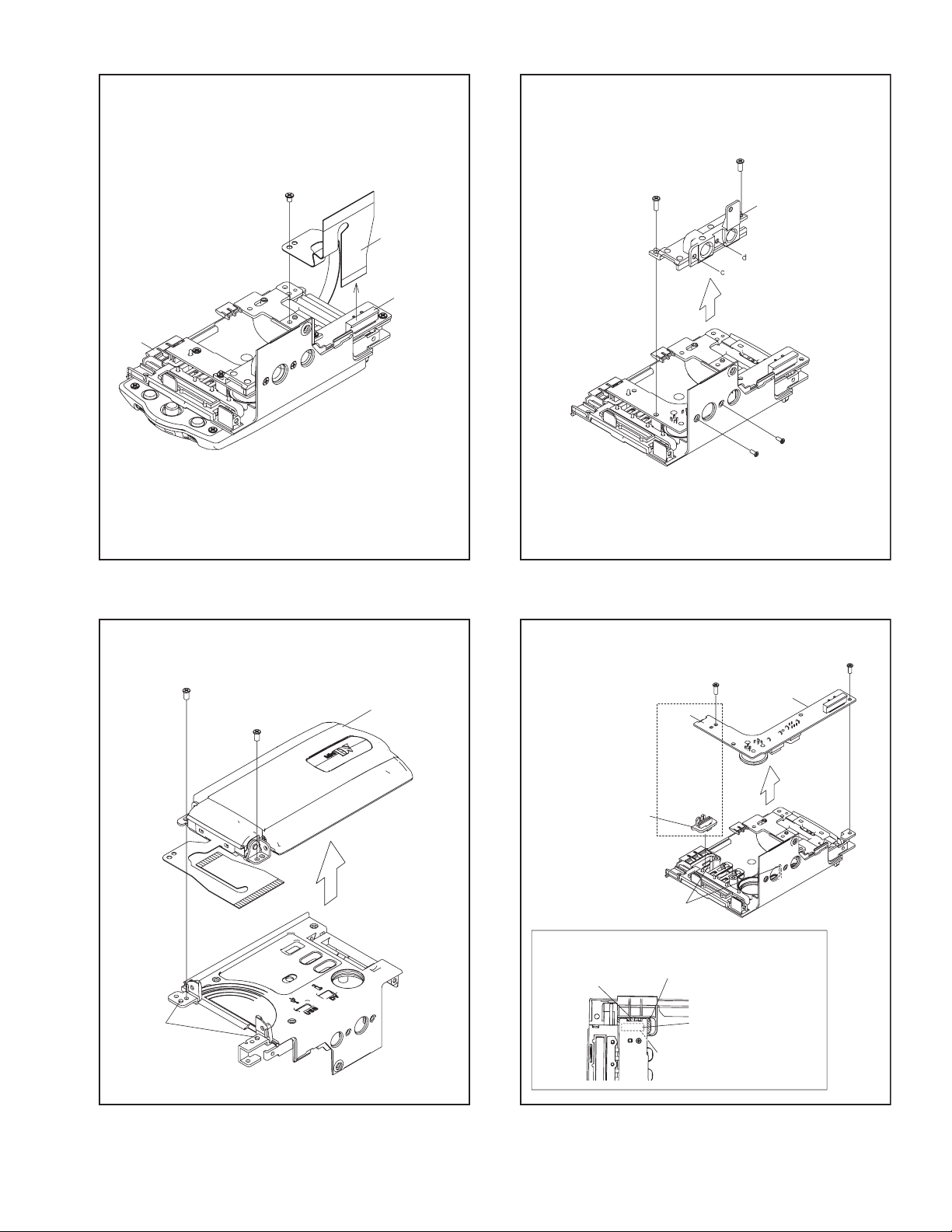

3.2.2 Assembly/Dissambly of cabinet parts and electrical parts

zDisassembly procedure

STEP

PART NAME

No.

[1]

COVER(LAST)

[2]

LOWER CASE(FRO) ASSY

[3]

FRONT CAVER ASSY

[4]

MIC

[5]

TOP COVER ASSY

[6]

UPPER ASSY

[7]

FRONT BOARD ASSY

[8]

LOWER CASE ASSY

[9]

CASSETTE COVER(SIDE)

[10]

CASSETTE COVER(TOP)

[11]

REAR ASSY

[12]

REAR BOARD ASSY

[13]

LOWER CASE(P) ASSY

[14]

OP BLOCK ASSY

[15]

ARM ASSY

[16]

MAIN BOARD ASSY

[17]

MECHANISM ASSY

[18]

MONITOR ASSY

[19]

TRIPOD(BASE)

[20]

JACK BOARD ASSY

Fig.

No.

3-2-1

3-2-2

3-2-3

3-2-4

3-2-5

3-2-6

3-2-7

3-2-8A

3-2-8B

3-2-9

3-2-10A

3-2-10B

3-2-11

3-2-12

3-2-13

3-2-14

3-2-15

3-2-16A

3-2-17

3-2-18A

3-2-18B

3-2-19

3-2-20

POINT NOTE

GRIP BELT,2(S1),L1a,b

3(S2)

2(S3a),S3b,CN3

S4

S5a,2(S5b)

COVER(JIG),S6a,b,c,CN6

S7,2(L7),CN7

S8a,b

-

2(S9),6(L9)

2(S10a)

S10b

2(S11),L11a,b,CN11a,b

S12,CN12

S13,L13a,b

CN14a,3(S14),L14,CN14b

4(S15),L15

CN16a,b,c,d,e,L16a,b

4(S17)

S18a,CN18

2(S18b),2(L18)

S19a,3(S19b)

S20a,b,2(L20)

NOTE1

-

NOTE3

NOTE4

-

NOTE6a,b

NOTE7

NOTE8a

NOTE8b

-

NOTE10a

NOTE10b,c

NOTE11a,b

NOTE12

NOTE13a,b

NOTE14a,b

NOTE15a,b

NOTE16

-

NOTE18a

NOTE18b

-

NOTE20a,b

NOTE1:

Pull out the GRIP BELT from the HOOK first as it interferes

with the procedure.

NOTE3:

When attaching, be careful with the wiring.

After connecting the wire to the connector, locate the wire

behind the FPC.

NOTE4:

When attaching, be careful with the wiring (MIC).

NOTE6a:

When removing, remove the COVER (JIG) first.

NOTE6b:

Please refer to Fig.3-2-18A and the following procedure for

removing the UPPER ASSY.

NOET7:

When attaching, be careful with the wiring.

NOTE8a:

During the procedure, be careful in handling the parts.

When the LOWER CASE ASSY is removed, the SHAFT

may come off.

NOTE8b:

When attaching, be careful with the FPC.

NOET10a:

During the procedure, be careful in handling the parts.

Be careful in handling the FPC as the switch connected to the

FPC is screwed on the back of the CASSETTE COVER (TOP).

NOET10b:

Be careful not to lose the KNOB (EJECT), or remove the

KNOB (EJECT) during the following procedures as it is easily

comes off when the CASSETTE COVER (TOP) is removed.

NOET10c:

When removing, carefully peel off and release the FPC as it

sticks to the ARM ASSY.

NOTE11a:

When attaching, be careful with the FPC.

NOTE11b:

When attaching, close the ARM ASSY.

When attaching, be careful with the wiring.

NOTE12:

When attaching, be careful with the wiring.

NOTE13a:

When removing, remove the screw (No.27) located under

the COVER (JACK) first.

NOTE13b:

When removing, be careful not to damage the HOOK (L13b).

NOTE14a:

When removing, the brackets are attached to the OP

BLOCK ASSY. During the procedure, remove the brackets

if necessary.

NOTE14b:

Refer to 3.2.3 Assembly/Disambly of [14] OP BLOCK ASSY/

CCD BOARD ASSYof OP BLOCK ASSY.

NOTE15a:

When removing, remove the 4 screws (No.31-34), and then

release the HOOK.

NOTE15b:

During the procedure, be careful with the grease applied to

the both sides.

NOTE16:

When attaching, be careful with the FPC.

NOTE18a:

Pay special attention in handling the removed UPPER

ASSY as the FPC is unstable.

NOTE18b:

Refer to 3.2.4 Disassembly of [18] MONITOR ASSY of

MONITOR ASSY.

NOTE20a:

When removing, be careful in handling the KNOB (SLIDE)

as they may come off.

NOTE20b:

When attaching, make sure that the LEVER of the SW interlocks with the KNOB (SLIDE).

zDestination of connectors

CN.

No.

CONNECTOR

PIN

No.

CN3 MAIN CN2601 MIC - 4

CN6 MAIN CN103

JACK/MONITOR

CN401/CN7002 50/24,28

CN7 MAIN CN108 FRONT CN801 8

CN11a MAIN CN101/CN106

CN11b MAIN CN105

REAR

CN501/CN504 40/32

POWER/ZOOM UNIT

- 12

CN14a MAIN CN4201 CCD CN5001 20

CN14b MAIN CN4901 OP BLOCK ASSY

- 25

CN16a MAIN CN1604 SENSOR - 16

CN16b MAIN CN1603 CAPSTAN MOTOR

- 18

CN16c MAIN CN1602 DRUM MOTOR - 11

CN16d MAIN CN3501 HEAD - 8

CN16e MAIN CN1601

/ROTARY ENCODER

LOADING MOTOR

8

-

CN18 JACK CN401 MONITOR CN7002 24

(No.YF228<Rev.001>)1-7

Page 8

1

(S1)

2

(S1)

[1]

7

(S3a)

6

(S3a)

NOTE3

GRIP BELT

NOTE1

HOOK

Fig.3-2-1

L1a

L1b

[3]

8

(S3b)

CN3

NOTE3

Fig.3-2-3

FPC

WIRE

6

(S3a)

7

(S3a)

8

(S3b)

[2]

5

(S2)

3

(S2)

4

(S2)

Fig.3-2-2

3

(S2)

[4]

NOTE4

WIRE(MIC)

9

(S4)

PLATE(MIC)

NOTE4

Slot WIRE(MIC) between

these bosses.

BOSS

Fig.3-2-4

1-8 (No.YF228<Rev.001>)

Page 9

10

(S5a)

11

(S5b)

12

(S5b)

[5]

L7

[7]

Fig.3-2-5

NOTE6a

COVER(JIG)

10

(S5a)

16

(S7)

FPC

NOTE7

CN7

NOTE7

FPC

Dress FPC as shown in figure.

Fig.3-2-7

17

(S8a)

CN6

(S6b)

14

13

(S6a)

13

(S6a)

Fig.3-2-6

14

(S6b)

NOTE6b

[6]

15

(S6c)

17

(S8a)

NOTE8a

SHAFT

[8]

18

(S8b)

Fig.3-2-8A

(No.YF228<Rev.001>)1-9

Page 10

NOTE8b

Ensure this part of LOWER CASE is on top of FRAME ASSY.

18

(S8b)

21

(S10a)

21

(S10a)

[10]

NOTE10a

FPC

Fold the MECHA FPC towards LOWER SIDE

when attaching LOWER CASE ASSY.

Fig.3-2-8B

L9

[9]

19

(S9)

19

(S9)

22

(S10a)

c

c

ARM ASSY

23

(S10b)

Fig.3-2-10A

KNOB(EJECT)

NOTE10b

20

(S9)

1-10 (No.YF228<Rev.001>)

Fig.3-2-9

FPC

NOTE10c

[10]

Fig.3-2-10B

Page 11

24

(S11)

25

(S11)

ARM ASSY

NOTE11a

FPC

L11b

CN11a

CN11b

Fig.3-2-11

[11]

L11a

24

(S11)

(S11)

SW(EJECT)

NOTE11b

CN11a

CN11b

25

27

(S13)

NOTE13a

[13]

Fig.3-2-13

REAR COVER

ASSY

NOTE13b

L13b

L13a

NOTE12

BOSS

[12]

WIRE

NOTE12

CN12

26

(S12)

CN14b

L14

30

(S14)

CN14a

29

(S14)

28

(S14)

[14]

NOTE14a,b

Fig.3-2-12

Fig.3-2-14

(No.YF228<Rev.001>)1-11

Page 12

NOTE15a

[15]

31

(S15)

NOTE16

33

(S15)

34

(S15)

g

32

(S15)

33

(S15)

34

(S15)

NOTE15b

35

(S16)

Fig.3-2-15

NOTE16

[16]

CN16e

g

A

CN16d

CN16a

B

C

CN16c

L16b

E

D

CN16b

L15

CN16a

(S17)

CN16b CN16c CN16d CN16e

Fig.3-2-16B

39

(S17)

36

37

(S17)

38

(S17)

AA

L16a

1-12 (No.YF228<Rev.001>)

E E

C

BB

Fig.3-2-16A

FRAME ASSY

HOOK

DD

[17]

Fig.3-2-17

Page 13

[18]

40

(S18a)

NOTE18a

FPC

CN18

43

(S19a)

44

(S19b)

(S19b)

[19]

45

46

(S19b)

L18

41

(S18b)

Fig.3-2-18A

42

(S18b)

NOTE18b

[18]

NOTE20b

NOTE20a

KNOB(SLIDE)

NOTE20b

LEVER

Fig.3-2-19

47

(S20a)

SW

L20

KNOB(SLIDE)

JACK

BOARD ASSY

48

(S20b)

[20]

Fig.3-2-18B

SW

Fig.3-2-20

(No.YF228<Rev.001>)1-13

Page 14

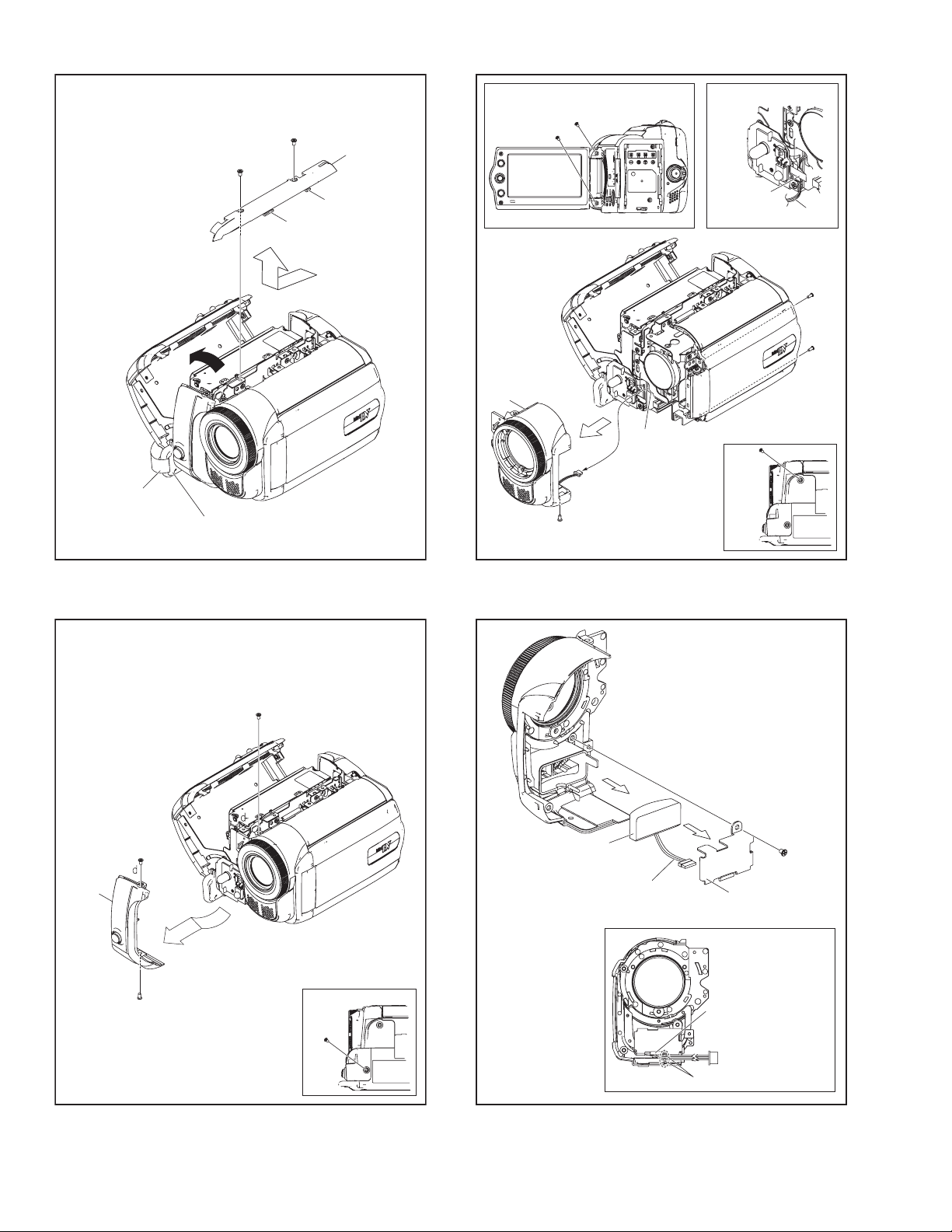

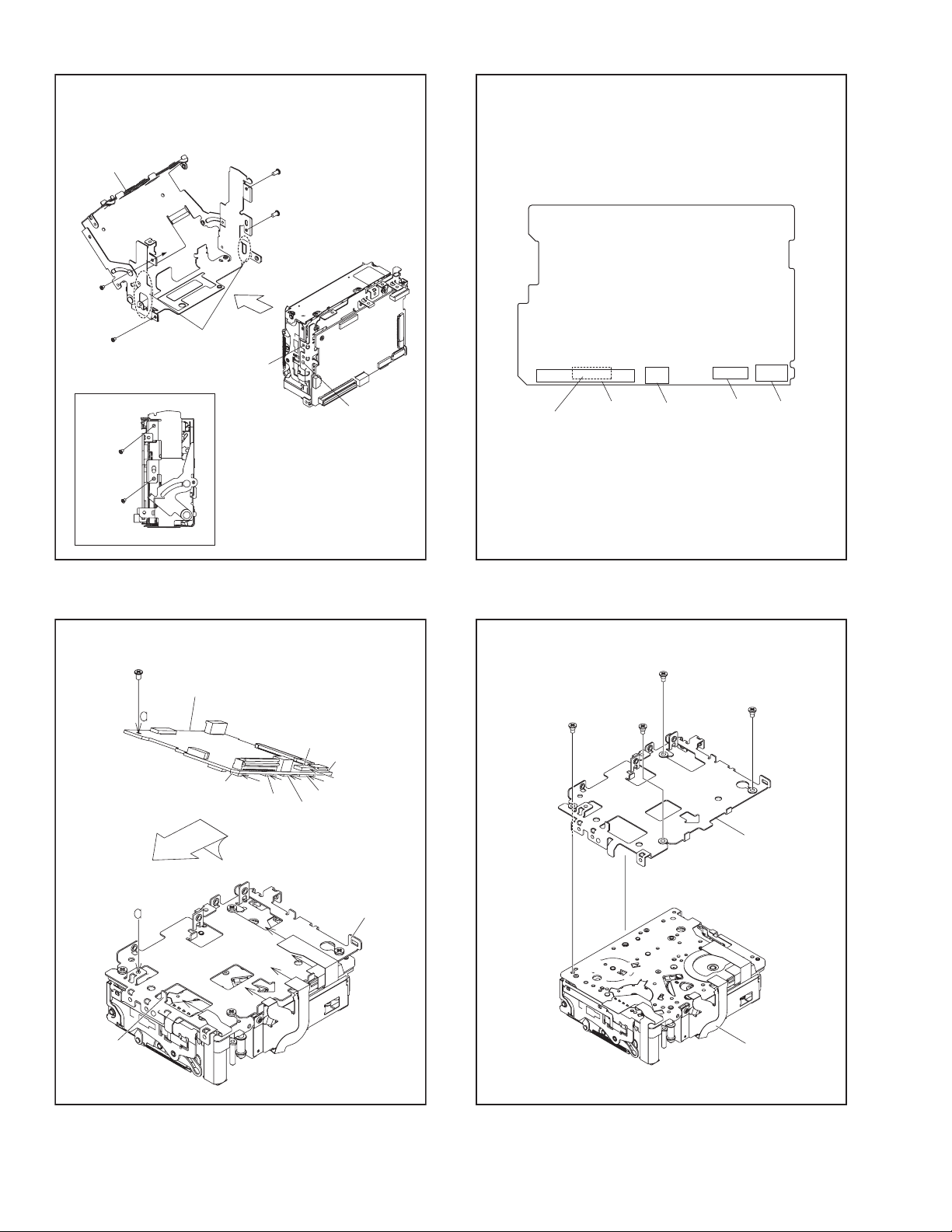

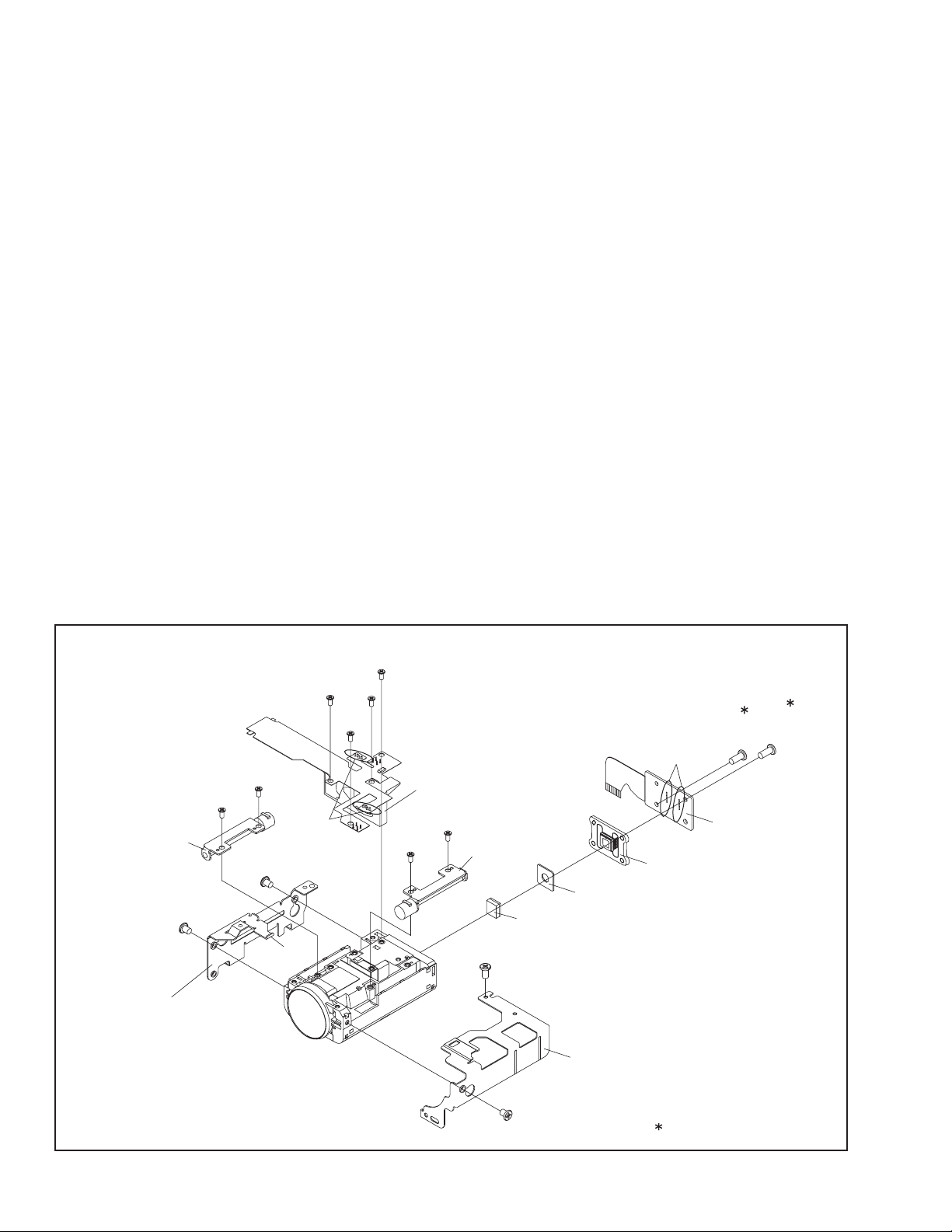

3.2.3 Assembly/Disambly of [14] OP BLOCK ASSY/CCD BOARD ASSY

zPrecautions

(1) Be careful in handling the CCD IMAGE SENSOR, OPTI-

CAL LPF and the LENS components. Pay special attention not to soil or damage the surfaces., especially with

regard to surface contamination, attached dust or

scratching. If fingerprints are present on the surface they

should be wiped away using either a silicon paper, clean

chamois or the cleaning cloth.

(2) The CCD IMAGE SENSOR may have been shipped with

a protective sheet attached to the transmitting glass.

When replacing the CCD IMAGE SENSOR, do not peel

off this sheet from the new part until immediately before

it is mounted in the OP BLOCK ASSY.

(3) As the CUSHION(OP) protects the OP BLOCK ASSY

from scratches or damages, leave the CUSHION as

long as it does not interfere with the procedure.

zDisassembly of OP BLOCK ASSEMBLY / CCD BOARD AS-

SEMBLY

(1) Unsolder the fourteen soldered points (SD11a) of the

CCD BOARD ASSY.

(2) Remove the two screws (1,2), and then remove the CCD

BOARD ASSY and the CCD BASE ASSY.

NOTE11a:

When removing the CCD BASE ASSY, be careful in

handling as the CCD IMAGE SENSOR may be removed together with the SHEET and the OP LPF attached.

NOTE11\b:

Replace the CCD IMAGE SENSOR as a CCD BASE

ASSY, not as a single part replacement.

zAssembly of OP BLOCK ASSEMBLY / CCD BOARD AS-

SEMBLY

(1) Set the OPTICAL LPF first, and then the SHEET to the

(2) Attach the CCD BASE ASSY first, then the CCD BASE

(3) Solder the 14 points (SD11a) on the CCD BOARD AS-

zReplacement of service repair parts

The service repair parts for the OP BLOCK ASSY are as listed

below.

When replacing the parts, remove the BKT OP (1) and (2) first

if necessary.

When replacing parts, be careful not to cut the FPCs or damage any parts by soldering (excessive heat).

(1) FOCUS MOTOR UNIT

(2) ZOOM MOTOR UNIT

(3) AUTO IRIS UNIT

NOTE 13e:

When replacing the FOCUS MOTOR UNIT or the ZOOM

MOTOR UNIT, solder the FPC at a space of about 0.5 mm

above the terminal pin.

NOTE 13f:

The IRIS MOTOR UNIT includes the FPC ASSY and two

sensors.

OP BLOCK ASSY.

NOTE11c:

Be careful with the attachment direction of the OP

LPF.

ASSY so that the SHEET stays in place, and then tighten

with the two screws (1, 2).

SY.

ZOOM MOTOR

UNIT

5

(S14c)

BKT OP(2) ASSY

9

(S14d)

10

(S14d)

6

(S14c)

HOOK

11

(S14d)

SD14b

13

(S14d)

12

(S14d)

14

(S14d)

(S14d)

NOTE14d

AUTO IRIS

UNIT

8

(S14d)

7

FOCUS MOTOR

UNIT

OP LPF

3

(S14c)

NOTE14c

SD14a

CCD BASE ASSY

NOTE14a,b

SHIEET

BKT OP(1) ASSY

1

(S14a)

CCD BOARD

ASSY

2

(S14a)

1-14 (No.YF228<Rev.001>)

Fig.3-2-21

4

(S14c)

:0.147 N・m (1.5kgf・cm)

Page 15

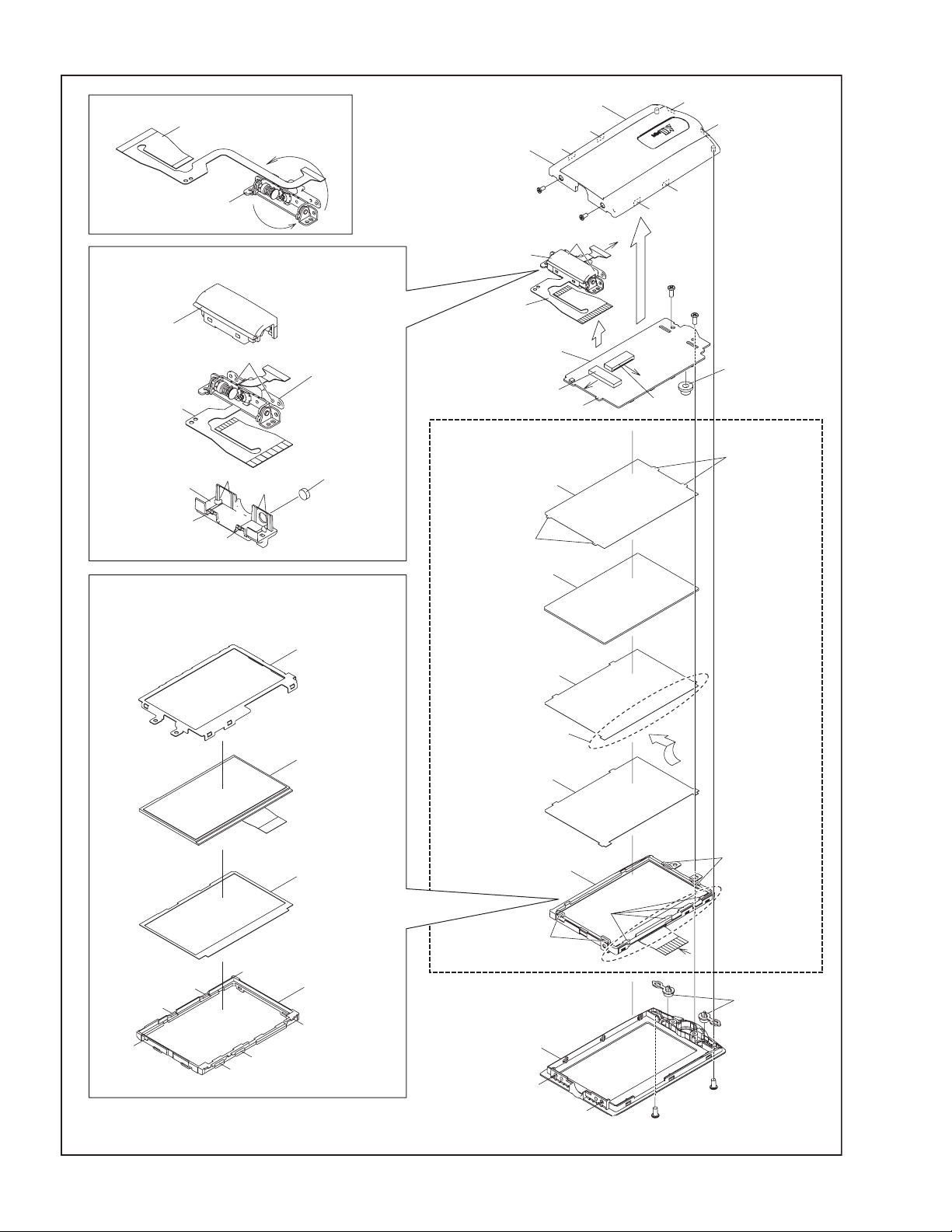

3.2.4 Disassembly of [18] MONITOR ASSY

zCAUTIONS

(1) During the procedure, be careful in handling the LCD

MODULE and other parts. Pay special attention not to

damage or soil the monitor screen.

If fingerprints are left on the screen, wipe them with clean

chamois leather or a cleaning cloth.

zRemoving MONITOR ASSEMBLY

(1) Remove the 2 screws (1 and 2).

(2) Turn the HINGE UNIT ASSY 90º, and remove the two

screws (3 and 4).

(3) Remove the MONITOR COVER ASSY by removing the

6 hooks (L18a-f).

(4) Release the lock of the connector (CN18a), and remove

the HINGE UNIT by lifting it up.

NOTE18a:

During the procedure, be careful in handling the FPC.

(5) Release the lock of the connector (CN18b), and pull out

the FPC.

(6) Remove the 2 screws (5 and 6), and remove the MONI-

TOR BOARD ASSY .

NOTE18b:

Be careful in handling as the parts located below may

be misaligned or removed when the MONITOR

BOARD ASSY is removed.

Attach the MONITOR BOARD ASSY by lifting up the

MONITOR CASE as the KNOB (CURSOR) that is attached to the BOARD sticks out toward the LCD

screen.

NOTE18c:

When replacing the MONITOR CASE or when there is

no need to replace individual parts in the MONITOR

CASE, remove the whole parts from the SHEET

(M.REF) to the LCD SA as a unit.

(7) Remove the SHEET (M.REF), LIGHT GUIDE, SHEET

(M/DIFF), and the SHEET(BEF)1.

NOTE18d:

When attaching, insert one side of the SHEET (M/

DIFF) under the LCD CASE RIB.

NOTE18e:

When attaching, insert each tab on both sides of the

SHEET (M.REF) into the LCD CASE notch.

(8) Remove the SHIELD CASE(MONI), LCD MODULE,

SHEET(COVER) and the LCD CASE.

NOTE18f:

During the procedure, handle the 4 parts (SHIELD

CASE(MONI), LCD MODULE, SHEET(COVER)) together.

zRemoving HINGE UNIT ASSEMBLY

(1) While removing the 6 HOOKs (L18t-w) from one side

and then from the other side, remove the HINGE COVER (U).

NOTE18g:

Be careful in handling the HINGE ASSY as grease is

applied inside.

(2) Remove the HINGE COVER(L).

(3) Remove the MAGNET.

NOTE18h:

During the procedure, be careful in handling the mag-

net.

When attaching, set the negative pole outside as

shown in the figure. Be careful when removing as

there is no marking.

NOTE18j:

During the procedure, be careful in handling the FPC.

NOTE18k:

The FPC is rolled around the axis of rotation of the

HINGE ASSY 2.5 rounds (2.5times).

The connecting side to the MONITOR BOARD ASSY

is placed inside.

(No.YF228<Rev.001>)1-15

Page 16

FPC

LIB

NOTE18d

HINGE ASSY

<HINGE UNIT ASSY>

H.COVER(U)

L18g

NOTE18j

FPC

H.COVER(L)

L18v

L18w

NOTE18k

NOTE18g

HINGE UNIT

NOTE18h

MAGNET

MONITOR COVER

ASSY

3

(S18b)

NOTE18g

HINGE UNIT

ASSY

FPC

NOTE18a

MONITOR

BOARD ASSY

CN18a

NOTE18c

SHEET

(M.REF)

L18a

a

4

(S18b)

L18g

L18h

[18]

L18b

L18f

L18e

L18d

b

C

C

L18c

5

(S18c)

B

CN18b

6

(S18c)

KNOB

(CURSOR)

L18j

NOTE18e

L18t

NOTE18f

<LCD SA>

L18s

L18r

L18q

L18u

SHILD CASE

(MONI)

LCD MODULE

SHEET(COVER)

L18t

LCD CASE

L18p

L18n

L18m

NOTE18e

L18k

LIGHT GUIDE

SHEET

(M/DIFF)

NOTE18d

SHEET

(BEF)1

NOTE18f

LCD SA

NOTE18e

MONITOR CASE

a

NOTE18d

NOTE18d

LIB

LIB

b

(S18a)

NOTE18e

B

BUTTON

(MONI)

NOTE18b

1

2

(S18a)

1-16 (No.YF228<Rev.001>)

Fig.3-2-22

Page 17

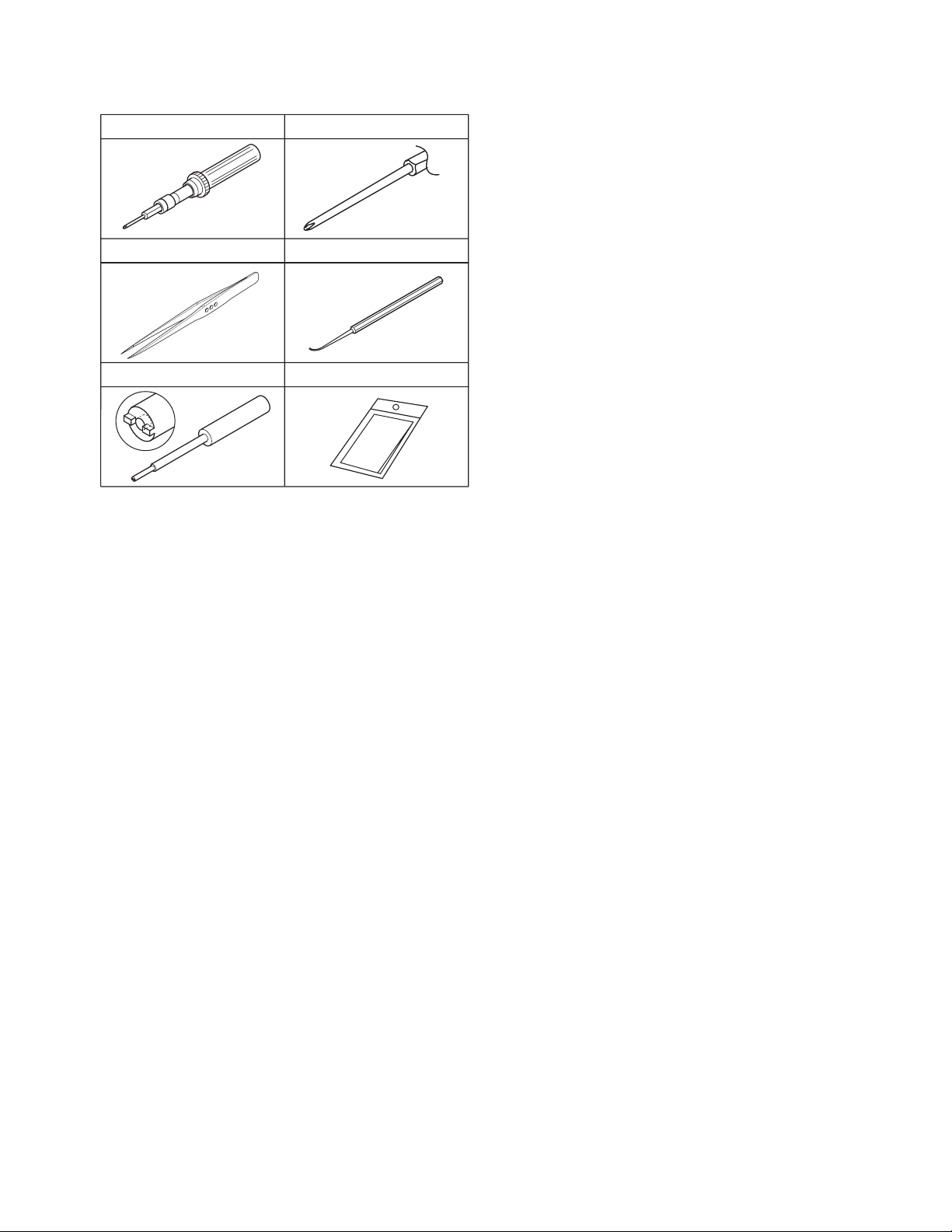

3.3 DVC MECHANISM

3.3.1 TOOLS REQUIRED FOR ADJUSTMENTS

1.

Torque driver

YTU94088

2.

Bit

YTU94088-003

1. Torque driver

Be sure to use to fastening the mechanism and exterior parts

because those parts must strictly be controlled for tightening

torque.

Torque setting value of torque driver is limited. At the values

over the maximum torque setting value, fasten a screw manually not to damage the screw thread.

3.

Tweezers

P-895

Chip IC replacement jig

4.

PTS40844-2

2. Bit

This bit is slightly longer than those set in conventional torque

drivers.

3. Tweezers

To be used for removing and installing parts and wires.

4. Chip IC replacement jig

5.

Guide driver

YTU94148A-1

6.

Cleaning cloth

KSMM-01

To be used for replacement of part.

5.Guide driver

To be used for the height adjustment such as the guide rollers.

6. Cleaning cloth

Recommended cleaning cloth to wipe down the video heads,

mechanism (tape transport system), optical lens surface.

3.3.2 Precautions

(1) When fastening parts, pay careful attention to the tightening torque of each screw. Unless otherwise specified, tighten a screw

with the torque of 0.055 N

·m (0.56 kgf·cm).

(2) Be sure to disconnect the set from the power supply before fastening and soldering parts.

(3) When disconnecting/connecting wires, be careful not to get them and their connectors damaged.

(4) When replacing parts, be very careful neither to damage other parts nor to fit wrong parts by mistake.

(No.YF228<Rev.001>)1-17

Page 18

3.3.3 Notes on procedure for disassembly/assembly

The DISASSEMBLY PROCEDURE TABLE shows the procedure to disassemble/reassemble mechanism parts.

Carefully read the following explanation before starting actual disassembling/reassembling work. The item numbers(circled numbers)in the following explanation correspond to those appearing under respective columns of the table.

Example

NO. PART NAME FIG. POINT NOTE REMARKS

[1]

[2]

[3]

[4]

[5]

[6]

*1 *2 *3 *4 *5 *6 *7

*1 Numbers appearing in this column indicate the order to re-

move parts. When reassembling, follow these numbers in

the reverse order. Circled numbers in this column correspond to those appearing in drawings of this section.

*2 This column shows part names corresponding to numbers

in the left column.

*3 The symbol (T or B)appearing in this column shows the

side which the objective part is mounted on.

T =the upper side, B =the lower side

*4 Symbols appearing in this column indicate drawing num-

bers.

*5 This column indicates parts and points such as screws,

washers,springs,and others to be removed/fitted for disassembling/reassembling the mechanism. Besides such the

parts, this column occasionally indicates working points.

P= Spring

W = Washer

S= Screw

* = Lock (L),soldering (SD),shield,connector (CN),etc.

CASSETTE HOUSING ASSY T Fig.2-4-3 3(S1),(L1a)-(L1e)

UPPER BASE ASSY T Fig.2-4-4 (S2),(L2a),(L2b)

DRUM ASSY T (S3a),2(S3b)

REEL DISK ASSY(SUP) T Fig.2-4-5 (W4)

REEL DISK ASSY(TU) T

REEL COVER ASSY T

(W5a),(W5b),(W5c)

(W6),(S6a),2(S6b)

*6 Numbers in this column represent the numbers of notes in

the text.

(For parts that need phase adjustment after reassembling,

refer to “MECHANISM ADJUSTMENTS”.)

*7 This column indicates required after-disassembling/-reas-

sembling work such as phase adjustment or mechanism

adjustment.

NOTE 1 a,b,c,d

NOTE 2

NOTE 3 a,b

NOTE 4 a

NOTE 5 a,b

NOTE 6

ADJUSTMENT

ADJUSTMENT

Example

• Remove (W1)=Washer W1.

• Remove the solder at (SD1)=Point SD1.

• Disconnect A = Connector A.

1-18 (No.YF228<Rev.001>)

Page 19

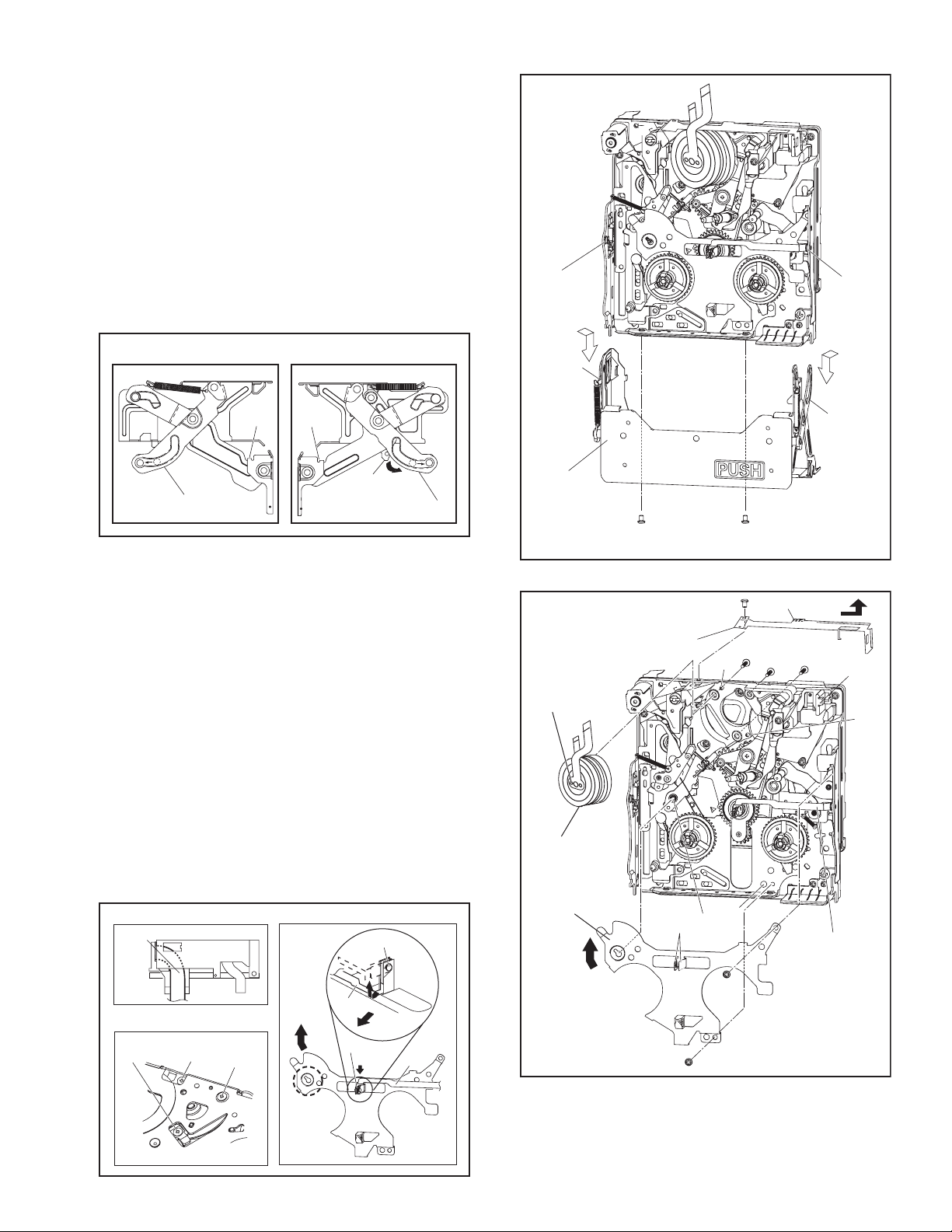

3.3.4 DISASSEMBLY AND ASSEMBLY OF MECHANISM ASSEMBLY

Half Panch

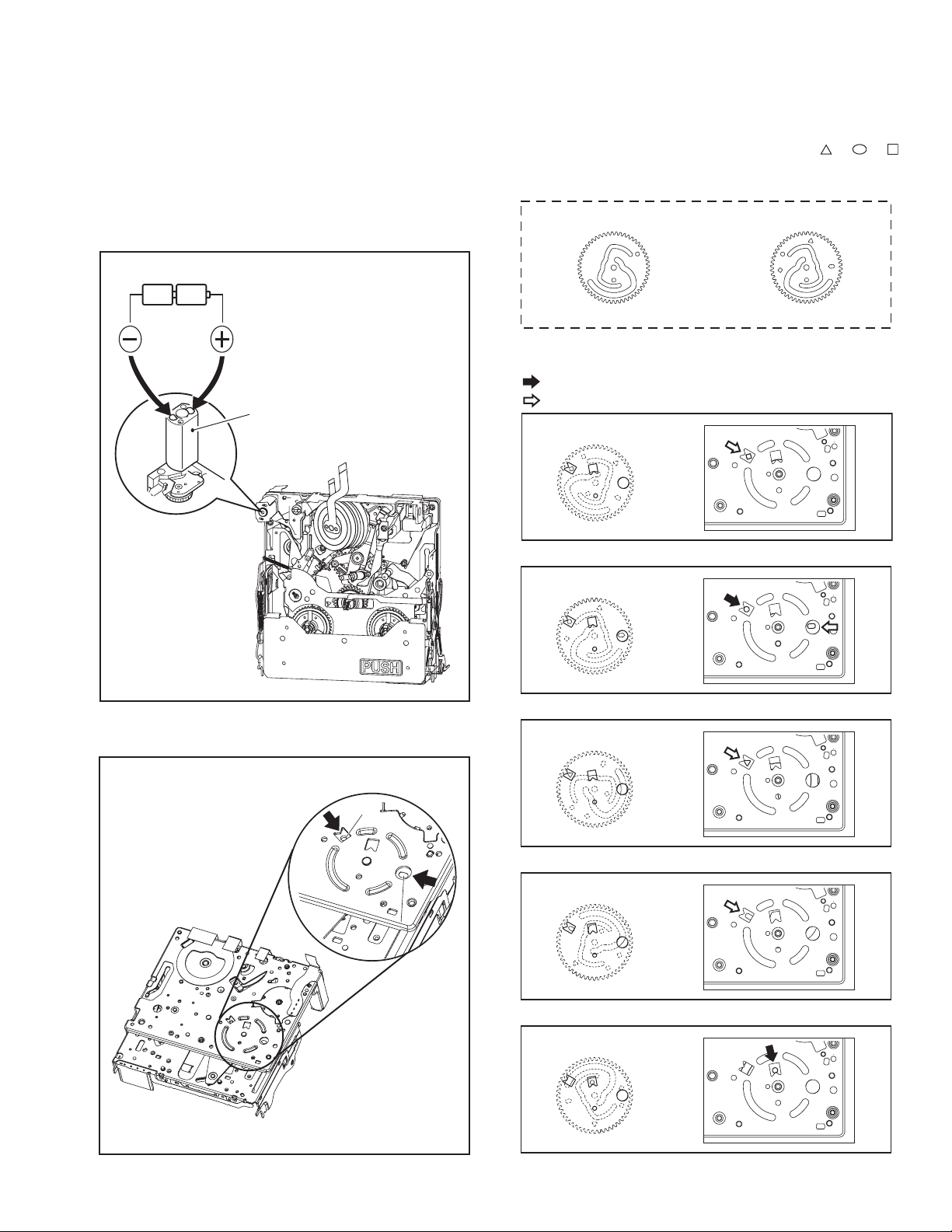

3.3.4.1 General statement

The mechanism should be disassembled/assembled in the

CASS IN mode (ASSEMBLY mode). (Refer to Fig. 3-3-2,3-3-5.)

When the mechanism assembly is removed from the main body,

it is generally set in the STOP mode.

After the mechanism assembly is removed from the main body,

it is required to forcibly supply 3V DC to the LOADING MOTOR

to unload, and then set the CASS IN mode.

<Mechanism assembly/Cassette housing assembly>

3.3.4.2 Mechanism modes

The mechanism mode of this model is classified into five modes

as shown in Fig. 3-3-9. Each mechanism mode can be distinguished from others by the relative position of “ ”, “ ”, “ ”

marks on the sub cam gear to the inner or outer protrusion on the

main deck. Refer to Fig. 3-3-3 to 3-3-8 below.

DC3V

<Confirmation of mode>

LOADING MOTOR

<MAIN CAM GEAR>

TOP VIEW BOTTOM VIEW

Fig.3-3-3

:HOLE(Penetration)

:Half Panch

<EJECT mode>

Fig.3-3-1

<Back side of the mechanism assembly>

CASS INOQFG

HOLE

Half Panch

Half Panch

Fig.3-3-4

<CASS IN mode>

Fig.3-3-5

<SHORT FF mode>

Fig.3-3-6

<STOP mode>

Back side of deck

Fig.3-3-2

Fig.3-3-7

<PLAY mode>

Fig.3-3-8

(No.YF228<Rev.001>)1-19

Page 20

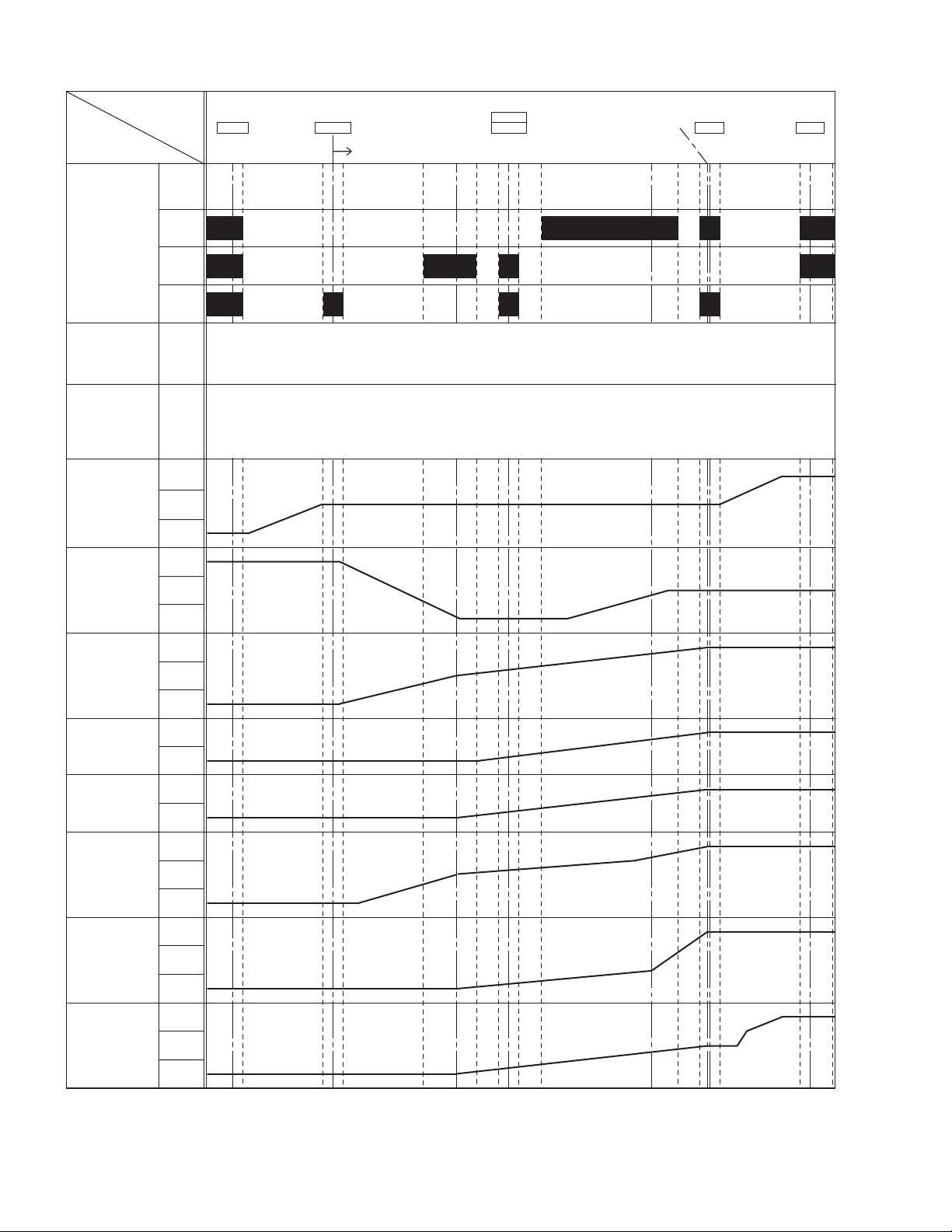

3.3.4.3 Mechanism timing chart

PARTS

ROTARY

ENCODER

MAIN CAM

SUB CAM

PRESS ARM

T.C. PLATE

MODE

-69.2

a

b

c

PRESS

OFF

EJECT

OFF1

OFF2

EJECT CAS. IN

o

-68.4

o

-54.7

(-50

(-65

-40

o

)

-52

o

)

-49.2

o

o

o

o

-6.5

o

-46.3

-5.5

o

0

3.4

TU. P. B

END

182.8

SLIDE

END

187.8

STOP PLAYFWD

o

244.5

254.5

273.6

o

260

o

o

274.5

o

190

(200o)

o

247

(260o)

o

o

205.3

o

o

o

210.8

199.8

o

150

(149o)(126.9o)

o

195

(193.8o)(164.9o)

o

210.5

o

SHORT

SLIDE

49.3

o

START

(49.1

(63.8

o

78.3

90.3o101.3o113.3

o

)

o

)

95.8

70

91

o

o

o

o

CCW

o

o

o

5.5

o

0

o

0

o

TENSION ARM

T5 ARM

SLIDE DECK

S1 ARM

POLE BASE

PINCH ROLLER

ON

LO2

LO1

UL

ON

OFF

LO

UL

PRESS

LO

UL

PRESS

LO

UL

PRESS

SLIDE

OFF

3.4

o

69

o

67.2

o

o

79.6

o

67.2

o

67.2

o

14

o

67.2

o

67.2

127.8

o

o

204

o

204

o

204

o

164.2

TOUCH

173.6

TOUCH

o

204

o

204

o

o

244.5

o

225.5

o

220.2

TOUCH

o

204

Fig.3-3-9

1-20 (No.YF228<Rev.001>)

Page 21

3.3.5 DISASSEMBLY PROCEDURE TABLE

MARK: # After assembly, perform adjustments.

NO. PART NAME FIG. POINT NOTE REMARKS

[1] HOUSING ASSY T 3-3-10 2(S1),L1a,b,c,d NOTE1a,b ADJUSTMENT

[2] DRUM PROTECTOR T 3-3-11 S2,L2a,b NOTE2

[3] DRUM ASSY T 3-3-11 3(S3),L3a,b NOTE3a,b #

[4] REEL COVER ASSY T 3-3-11 2(S4),2(L4a),L4b,c NOTE4

[5] IDLER ARM ASSY T 3-3-12 - -

[6] T5 ARM ASSY T 3-3-12 L6a,b NOTE6a,b ADJUSTMENT

[7] TENSION ARM ASSY T 3-3-12 L7a,S7,L7b,2(L7c) NOTE7a,b,c ADJUSTMENT/#

[8] S1 ARM ASSY T 3-3-13 L8 NOTE8 ADJUSTMENT

[9] SLIDE GUIDE PLATE T 3-3-13 S9,L9 NOTE9a,b ADJUSTMENT/#

[10] GUIDE PLATE T 3-3-13 S10,L10 - ADJUSTMENT

[11] SLIDE DECK ASSY T 3-3-14A 2(L11a),3(L11b),2(L11c) NOTE11a,b ADJUSTMENT/#

[12] CASSETTE GUIDE T 3-3-14B S12,2(L12) -

[13] PINCH ROLLER ARM ASSY T 3-3-14B L13 NOTE13a,b,c

[14] REEL DISK ASSY (SUP) T 3-3-14B L14 NOTE14a,b

[15] REEL DISK ASSY (TU) T 3-3-14B L15 NOTE15a,b,c

[16] BRAKE PLATE T 3-3-14B - NOTE16 ADJUSTMENT

[17] T. C. PLATE ASSY T 3-3-15 L17,SLIDE COLLAR1 NOTE17

[18] DRUM BASE T 3-3-15 3(S18),L18a,2(L18b) NOTE18

[19] DRIVE ARM ASSY T 3-3-15 L19,SLIDE COLLAR2 NOTE19a,b ADJUSTMENT

[20] GUIDE RAIL ASSY T 3-3-16 S20 NOTE20 ADJUSTMENT/#

[21] T5 CATCHER T 3-3-16 S21,L21 -

[22] CAPSTAN MOTOR T 3-3-16 2(S22) NOTE22

[23] REEL PULLEY T 3-3-16 - -

[24] CENTER GEAR T 3-3-16 - -

[25] MOTOR BRACKET ASSY T 3-3-17 S25 NOTE25a,b,c

[26] BELT GUIDE T 3-3-17 S26,2(L26) -

[27] GEAR COVER T 3-3-17 3(S27),L27a,b,c,d NOTE27 ADJUSTMENT

[28] PRESS ARM ASSY T 3-3-17 L28 NOTE28 ADJUSTMENT

[29] SUB CAM T 3-3-18 - NOTE29 PHASE ADJUSTMENT

[30] CONNECT GEAR T 3-3-18 - NOTE30

[31] MAIN CAM T 3-3-18 - NOTE31 PHASE ADJUSTMENT

[32] ROTARY ENCODER T 3-3-19 L32 NOTE32 PHASE ADJUSTMENT

[33] LOADING GEAR 1 T 3-3-19 - -

[34] GUIDE ROLLER (S) ASSY T 3-3-19 - NOTE34a,b #

[35] COMPRESSION SPRING T 3-3-19 - NOTE35

[36] MAIN DECK ASSY T 3-3-19 - - #

[ 1 ]

(No.YF228<Rev.001>)1-21

Page 22

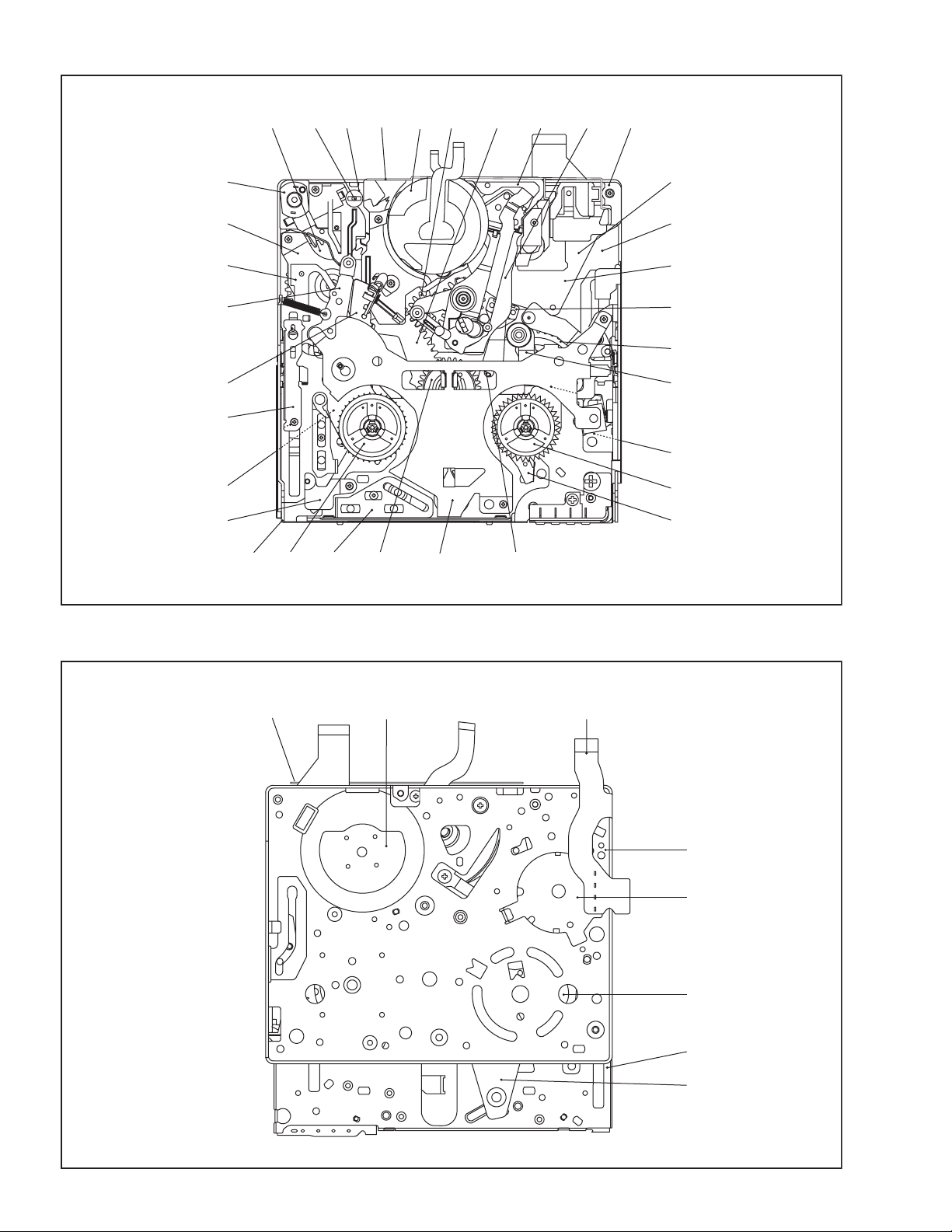

< TOP VIEW >

[34] [35] [ 3 ]

[ 2 ][32] [33] [19] [18] [20] [21]

[25]

[27]

[17]

[ 7 ]

[ 8 ]

[10]

[31]

[12]

[22]

[36]

[ 6 ]

[26]

[29]

[30]

[28]

[15]

[16]

[14][11] [ 9 ] [ 5 ] [ 4 ] [30]

< BOTTOM VIEW >

[25][22][ 2 ]

[36]

[32]

[31]

[11]

[19]

1-22 (No.YF228<Rev.001>)

Page 23

3.3.6 DISASSEMBLY/ASSEMBLY

3.3.6.1 [1] HOUSING ASSY

NOTE1a:

When disassembling/ assembling the MECHANISM ASSY,

make sure to remove the HOUSING ASSY.

When removing the HOUSING ASSY, make sure to bring the

HOUSING ASSY up either by changing the mechanism mode

to the EJECT mode, or by moving the EJECT LEVER to the direction as indicated by the arrow.

During the procedure, make sure to return to the CASS IN

mode if the mode was changed.

NOTE1b:

Be careful not to damage the LEFT ARM2,RIGHT ARM2 during work.

<NOTE1a,b>

L1a L1b

L1c

LEFT

ARM2

NOTE1b

L1d

RIGHT

ARM2

NOTE1b

EJECT

LEFT ARM2

3.3.6.2 [2] DRUM PROTECTOR

[3] DRUM ASSY

[4] REEL COVER ASSY

NOTE2:

During the procedure, be careful in handling the FPC.

NOTE3a:

When removing, carefully hold the top center of the DRUM

ASSY with fingers otherwise it may possibly fall off.

NOTE3b:

Pay extra attention to the soil, dust and scratch on the surface.

During the procedure, be careful not to cut/ damage the FPC.

NOTE4:

During the procedure, remove the LED from the REEL COVER

ASSY first to set the FPC free, remove the two screws (7, 8),

then remove the REEL COVER ASSY by sliding it to the direction as indicated by the arrow.

During the procedure, be careful in handling the FPC.

LEVER

RIGHT ARM2

<NOTE2> <NOTE4>

FPC

LED

[ 1 ]

NOTE1a

NOTE3a

[3]

NOTE3b

[4]

1

(S1)

NOTE2

Fig.3-3-10

[2]

L4c

L4a

3

(S2)

L3a

L4b

2

(S1)

4

(S3)

L2a

5

(S3)

6

(S3)

L2b

L3b

FPC

NOTE4

<NOTE3a>

6

(S3)

(S3)

< bottom side >

7

FPC

DRUM

5

4

(S3)

LED

SIDE

FPC

8

(S4)

(S4)

Fig.3-3-11

(No.YF228<Rev.001>)1-23

Page 24

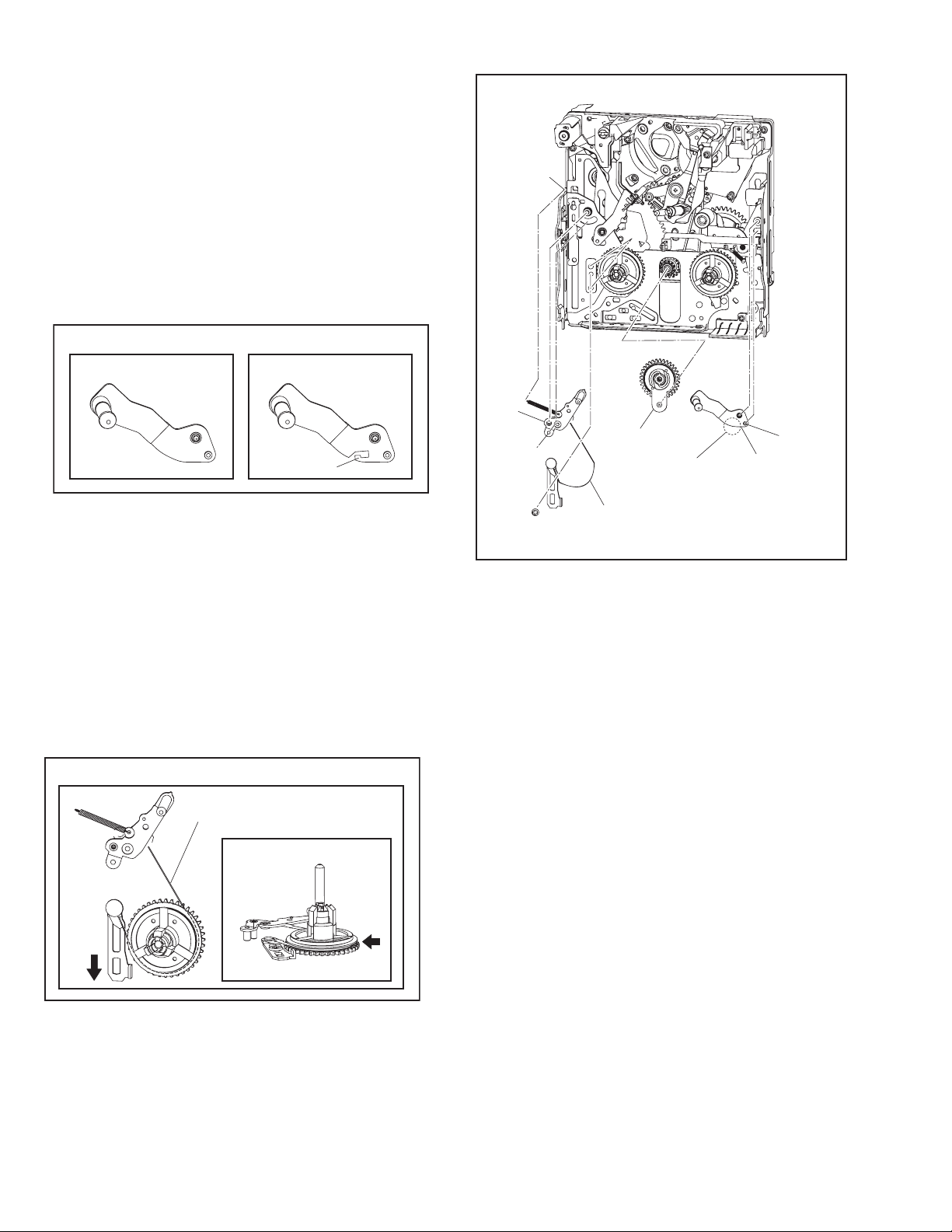

3.3.6.3 [5] IDLER ARM ASSY

L7c

[6] T5 ARM ASSY

[7] TENSION ARM ASSY

NOTE6a:

There are two types of the T5 ARM ASSY. They are different

in shape. The old type is without a hook and the new type is

with a hook.

When an old type is replaced by a new type, replace the

PINCH ROLLER ARM ASSY at the same time as the proper

combination of the parts is required.

When removing, remove the spring from the hook first if there

is a hook.

NOTE6b:

When mounting, pay attention to the correct positioning.

<NOTE6a>

< OLD TYPE > < NEW TYPE >

[7]

L7a

L7c

L7c

L6a

NOTE7a:

During the procedure, be careful in handling the TENSION

BAND.

NOTE7b:

When mounting, attach the TENSION BAND along the groove

of the gear.

NOTE7c:

When mounting, pay attention to the correct positioning.

When mounting, attach the TENSION ARM ASSY with the

plate moved to the direction as indicated by the arrow.

If the plate is moved to the other direction, the TENSION

BAND may break during the operation check as there is too

much tension.

After the mounting, adjust the TENSION ARM ASSY.

<NOTE7b,c>

< TOP >

TENSION BAND

< FRONT >

L7b

(S7)

[5]

NOTE6a

L6b

[6]

NOTE6b

9

TENSION BAND

NOTE7a

Fig.3-3-12

1-24 (No.YF228<Rev.001>)

Page 25

3.3.6.4 [8] S1 ARM ASSY

[9] SLIDE GUIDE PLATE

[10] GUIDE PLATE

NOTE8:

When mounting, pay attention to the correct positioning.

NOTE9a:

When mounting, pay attention to the correct positioning.

NOTE9b:

After attachment, adjust the SLIDE GUIDE PLATE.

L10

[10]

3.3.6.5 [11] SLIDE DECK ASSY

NOTE11a:

When removing, set the FPC free first.

During the procedure, be careful not to cut the FPC.

NOTE11b:

During the procedure, be careful in handling.

<NOTE11a>

L11c

T5 CATCHER

L11a

FPC

(S10)

[11]

11

L8

L11b

L9

[8]

NOTE8

Fig.3-3-13

L11b

FPC

10

(S9)

NOTE9a,b

NOTE11a

[9]

L11a

Fig.3-3-14A

L11c

NOTE11b

MIC SW

(No.YF228<Rev.001>)1-25

Page 26

3.3.6.6 [12]CASSETTE GUIDE

[13] PINCH ROLLER ASSY

[14] REEL DISK ASSY (SUP)

[15] REEL DISK ASSY (TU)

[16] BRAKE PLATE

NOTE13a:

The spring attachment differs according to the types of the T5 ARM

ASSY. The spring is attached either to the hook of the SLIDE

DECK ASSY or to the hook of the T5 ARM ASSY. When an old

type is replaced by a new type, replace the T5 ARM ASSY at the

same time as the proper combination of the parts is required.

When removing, remove the spring only when the spring is attached to the SLIDE DECK ASSY.

Be careful when attaching as the spring has been removed if

it was attached to the T5 ARM ASSY.

NOTE13b:

During the procedure, be careful in handling.

Pay extra attention to the soil, dust and scratch on the ROLLER.

NOTE13c:

Be sure to place this part beneath the SLIDE DECK ASSY.

<NOTE13a>

< OLD TYPE > < NEW TYPE >

12

(S12)

L12

NOTE13b

[13]

NOTE13a

TENSION

SPRING

NOTE13c

[12]

L13

L15L14

L14,L15

L13

NOTE14a:

When removing, be careful not to damage or open too much

the hook as there is only one hook in a narrow part.

NOTE14b:

Be careful not to attach the REEL DISK wrongly. The Supply

side can be identified by the white color at the center.

NOTE 15a:

When removing, be careful not to damage or open too much

the hook as there is only one hook in a narrow part.

NOTE 15b:

Be careful not to attach the REEL DISK wrongly. The Take-up

side can be identified by the black color at the center.

NOTE 15c:

When removing the REEL DISK ASSY, be careful in handling

as the BRAKE PLATE which is located under the REEL DISK

ASSY becomes free.

NOTE 16:

During the procedure, be careful in handling.

WHITE

[14]

BLACK

[16]

Fig.3-3-14B

[15]

NOTE15a,bNOTE16NOTE14a,b

1-26 (No.YF228<Rev.001>)

Page 27

3.3.6.7 [17] T. C. PLATE ASSY

[18] DRUM BASE

[19] DRIVE ARM ASSY

NOTE17:

During the procedure, be careful not to lose the SLIDE

COLLAR1.

NOTE19a:

When mounting, pay attention to the correct positioning.

NOTE19b:

During the procedure, be careful not to lose the SLIDE

COLLAR2.

<NOTE19a>

L18a

(S18)

14

(S18)

[17]

[18]

L18b

13

L18a

15

(S18)

NOTE17

SLIDE COLLAR1

L17

SLIDE COLLAR2

NOTE19b

L19

3.3.6.8 [20] GUIDE RAIL ASSY

[21] T5CATCHER

[22] CAPSTAN MOTOR

[23] REEL PULLEY

[24] CENTER GEAR

NOTE20:

When mounting, pay attention to the correct positioning.

NOTE22:

When attaching the BELT, place the BELT inside the BELT

GUIDE and roll up around the REEL PULLEY.

<NOTE22><NOTE20>

BELT GUIDE

REEL

PULLEY

[21]

L21

17

(S21)

NOTE22

(S22)

19

(S22)

BELT

L19

18

[19]

NOTE19a

Fig.3-3-15

[22]

16

(S20)

[20]

NOTE20

Fig.3-3-16

[24]

(No.YF228<Rev.001>)1-27

[23]

Page 28

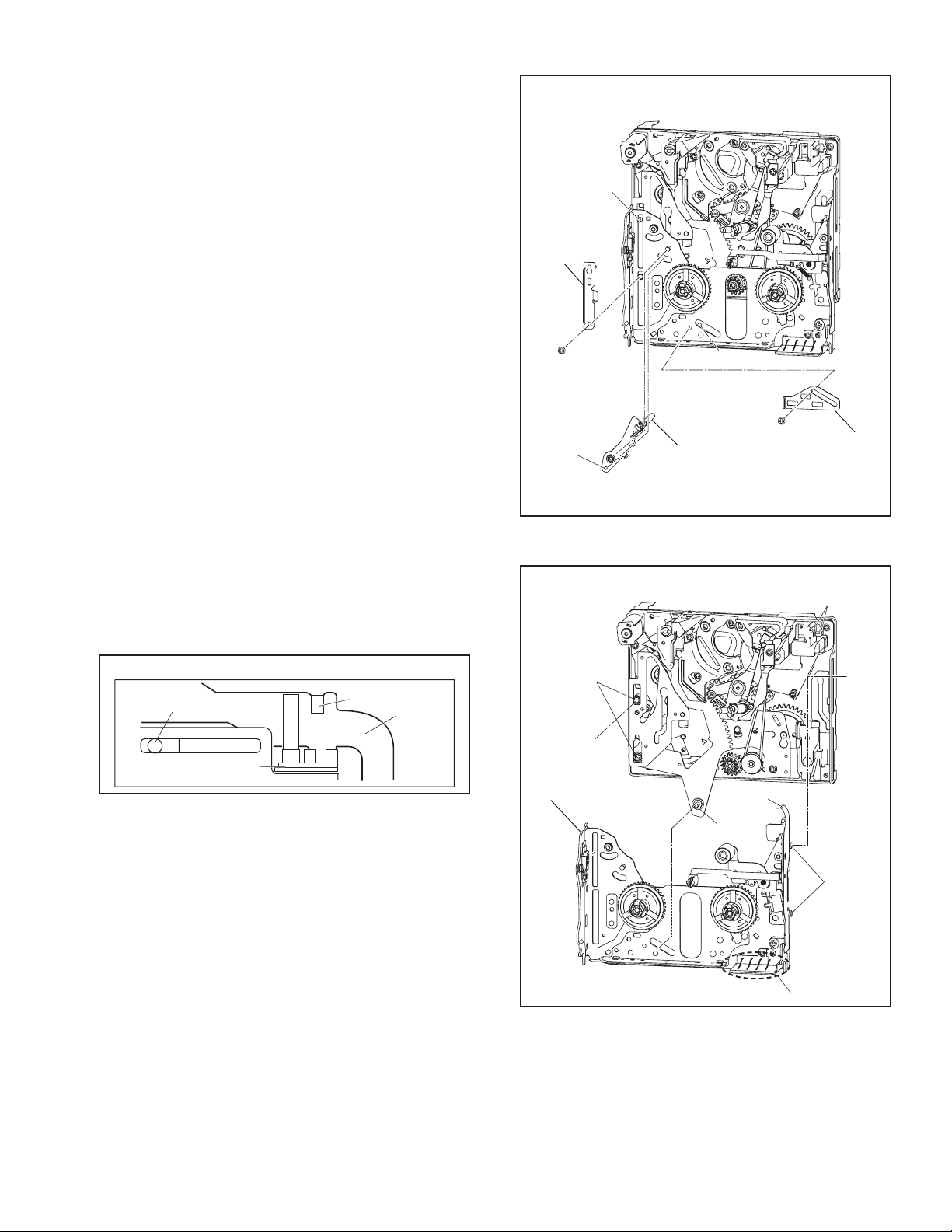

3.3.6.9 [25] MOTOR BRACKET ASSY

[26] BELT GUIDE

[27] GEAR COVER

[28] PRESS ARM ASSY

NOTE25a:

When disassembling, remove the four solder points (SD25) on

the ROTARY ENCODER as the MOTOR BRACKET ASSY

and the ROTARY ENCODER are soldered together to one

FPC.

NOTE25b:

During the procedure, be careful in handling the FPC. Pay attention not to leave finger prints etc. on the surface of the DEW

sensor.

NOTE25c:

During the procedure, be careful with the WORM WHEEL

which is attached inside.

When mounting, attach the WORM WHEEL to the MOTOR

BRACKET ASSY before mounting to the MECHANISM DECK

ASSY.

NOTE27:

When removing, remove the three screws (22-24), turn the

GEAR COVER anticlockwise by lifting up the parts with broken

lines.

Remove L27b,c and slide the GEAR COVER by sliding to the

direction shown with arrows.

When mounting, pay attention to the correct positioning.

NOTE28:

When mounting, pay attention to the correct positioning.

NOTE25a,b,c

[25]

20

(S25)

DEW SENSOR

NOTE25b

22

(S27)

23

(S27)

[27]

NOTE27

[26]

24

(S27)

L26

21

(S26)

Fig.3-3-17

NOTE25c

WORM WHEEL

L27d

L27c

L27b

L28

L27a

[28]

NOTE28

<NOTE25a> <NOTE25c>

FPC

SD25

BOTTOM

SIDE

<NOTE27>

L27cL27d

GEAR COVER

L27b

L27a

MOTOR

BRACKET

SIDE

PRESS

ARM

ASSY

1-28 (No.YF228<Rev.001>)

Page 29

3.3.6.10 [29] SUB CAM

[30] CONNECT GEAR

[31] MAIN CAM

NOTE29:

When mounting, pay attention to the correct positioning.

NOTE30:

When mounting, make sure to confirm the correct positioning

of the MAIN CAM, the SUB CAM, and the left and right GEAR

before attachment. Although the positioning adjustment of the

CONNECT GEAR itself is not necessary, the alignment of the

left and right GEARs is very important.

NOTE31:

When mounting, pay attention to the correct positioning.

<NOTE30>

NOTE31

NOTE31

[31]

LOADING

GEAR

MAIN CAM

[30]

SUB

CAM

<NOTE29><NOTE31>

[29]

NOTE29

Fig.3-3-18

(No.YF228<Rev.001>)1-29

Page 30

3.3.6.11 [32] ROTARY ENCODER

[33] LOADING GEAR 1

[34] GUIDE ROLLER (S) ASSY

[35] COMPRESSION SPRING

[36] MAIN DECK ASSY

NOTE32:

When mounting, pay attention to the correct positioning.

<NOTE32> <NOTE34b>

17.1mm

NOTE34a,b

[34]

NOTE35

[35]

[36]

L32

NOTE34a:

During the procedure, be careful in handling.

Pay extra attention to the soil, dust and scratch on the ROLLER.

NOTE34b:

Be sure to perform rough adjustment if the height of the GUIDE

ROLLER (S) ASSY has been adjusted during the procedure.

Otherwise the tape will be damaged when it is run.

For the rough adjustment, fully tighten up the GUIDE ROLLER

(S) ASSY clockwise then rewind it 1.5 revolutions.

The guide measurement for the height is 17.1mm.

NOTE35:

During the procedure,be caraful not to lose any parts.

[32]

NOTE32

[33]

Fig.3-3-19

1-30 (No.YF228<Rev.001>)

Page 31

3.3.7 Mechanism adjustment

TENSION ARM

ASSY

3.3.7.1 SLIDE GUIDE PLATE adjustment

This adjustment is required when the SLIDE DECK ASSEMBLY

is removed from the MAIN DECK ASSEMBLY.

The adjustment is also required when the SLIDE GUIDE PLATE

is removed.

Refer to the Fig3-3-20Aunless otherwise instructed.

Adjustment procedure

(1) Set the PLAY mode while the HOUSING ASSEMBLY is

removed. Refer to the Fig. 3-3-8.

(2) Loosen the screw A.

(3) Press both the MAIN DECK ASSEMBLY/ SLIDE DECK

ASSEMBLY inward with an even power from both left

and right. Fully pull up the SLIDE GUIDE PLATE to the

left and tighten the screw A.

NOTE:

When pressing the SLIDE DECK ASSEMBLY, press

near the screw hole for the HOUSING ASSEMBLY attachment. Avoid pressing the sensor as it is fragile.

NOTE:

The tightening torque is 0.078N•m(0.8kgf•cm)

(4) Perform an operation check.

NOTE:

Repeat the operation check of unloading/ loading to

confirm the smooth and steady slide movement without any jam or rattle.

(1) Set the Play mode while the Housing Assembly is re-

moved. Refer to the Fig. 3-3-8.

(2) Loosen the screw B.

(3) Slide the Guide Plate up and down to set the tip of the

Tension Arm Assembly to the edge of the screw groove,

and tighten the screw B.

• The tightening torque is 0.049N•m(0.5kgf•cm)

(4) Perform an operation check.

NOTE:

Repeat loading and unloading, and make sure to

check that the top of the TENSION ARM and the edge

match properly when observed from the straight

above.

NOTE:

The adjustable range is ±0.25mm from the edge.

<NOTE>

0.5mm

EDGE

MAIN DECK ASSY

SENSOR

SLIDE

GUIDE

PLATE

Screw A

TENSION ARM

TENSION ARM

MAIN DECK ASSY

TENSION

ARM

ASSY

EDGE

( 0.25mm)

ASSY

ASSY

SENSOR

Screw B

Fig.3-3-20A

3.3.7.2 Tension Arm Assembly adjustment

This adjustment is required when the Tension Arm Assembly is

replaced.

Refer to the Fig.3-3-20Bunless otherwise instructed.

Adjustment procedure

Fig.3-3-20B

(No.YF228<Rev.001>)1-31

Page 32

3.3.8 REMARKS

3.3.8.1 Cleaning

(1) For cleaning of the upper drum (particularly video heads),

use fine-woven cotton cloth with alcohol soaks through. Do

not move the cloth but turn the upper drum counterclockwise.

NOTE:

Make sure not to move the cloth in the vertical direction

to the video head, since it may cause damage of the video

heads.

(2) For cleaning of parts of the tape transport system except

the upper drum, use fine-woven cotton cloth or cotton swab

soaked alcohol.

(3) After cleaning, confirm that the cleaned parts are complete-

ly dry before loading the deck with cassette tape.

3.3.8.2 Applying oil and grease

(1) Periodical oiling and greasing are not required but should

be done to new parts when replacing. If oil and grease on

the other parts of the other party are old and dirty, wipe

them clean and apply new oil or grease.

(2) For parts and points to apply oil and grease, refer to the

PARTS LIST.

Fig.3-3-21 specifies oil and grease to be used.

(3) When oiling, clean the objective parts with alcohol first and

apply one or two drop(s) of oil. Too much oiling causes rotary parts to slip because of oil leakage.

Classification Part No. Symbol in drawing

Grease KYODO-SH-JB AA

Oil YTU94027 BB

Grease

JVS-306U CC

specifies oil and grease to be used

Fig.3-3-21

1-32 (No.YF228<Rev.001>)

Page 33

SECTION 4

ADJUSTMENT

4.1 PREPARATION

4.1.1 Precaution

Camera system and deck system of this model are specially

adjusted by using PC.

However, if parts such as the following are replaced, an

adjustment is required. The adjustment must be performed in a

Service Center equipped with the concerned facilities.

• EEP ROM (IC1005 of MAIN board)

• OP BLOCK ASSEMBLY

• MONITOR ASSEMBLY

In the event of malfunction with electrical circuits, first find a

defective portion with the aid of proper test instruments as shown

in the following electrical adjustment procedure, and then

commence necessary repair/ replacement/adjustment.

• In observing chip TP, use IC clips, etc. to avoid any stress.

Prior to replacement of chip parts (especially IC), remove the

solder completely to prevent peeling of the pattern.

• Use a patch cord if necessary. As for a patch cord, see the

BOARD INTERCONNECTIONS.

• Since connectors are fragile, carefully handle them in

disconnecting and connecting the FPC.

4.1.2 REQUIRED TEST EQUIPMENT

• Personal computer (for Windows)

• Color TV monitor

• Oscilloscope (dual-trace type, observable 100MHz or higher

frequency). The one observable 300 MHz or higher frequency

is recommended.

• Digital voltmeter

• DC power supply or AC adapter

• Frequency counter (with threshold level adjuster)

4.1.3 Tools required for adjustment

Torque Driver

YTU94088

Chip IC Replacement Jig

PTS40844-2

INF Adjustment Lens

YTU92001B

Light box Assembly

YTU93096B

Focus Chart

YTU92001-018

INF Adjustment Lens Holder

Bit

YTU94088-003

Cleaning Cloth

KSMM-01

YTU94087

Gray Scale Chart

YTU94133A

Alignment Tape

MC-1

Tweezers

P-895

Guide Driver

YTU94148A-1

Mini Stand

YTU93108

Color Bar Chart

YTU94133C

Service Support System

YTU94057-107

PC Cable

QAM0099-002

Jig Connector Cable

YTU93082J

Charing Battery Adjuatment Jig

Communication Cable

YTU93112A

YTU93111-1

• Torque driver

Be sure to use to fastening the mechanism and exterior parts

because those parts must strictly be controlled for tightening

torque.

• Bit

This bit is slightly longer than those set in conventional torque

drivers.

• Tweezers

To be used for removing and installing parts and wires.

(No.YF228<Rev.001>)1-33

Page 34

• Chip IC replacement jig

To be used for adjustment of the camera system.

• Cleaning cloth

Recommended the Cleaning cloth to wipe down the video

heads, mechanism (tape transport system), optical lens surface.

• Guide driver

To be used to turn the guide roller to adjustment of the linarity

of playback envelope.

• INF adjustment lens

To be used for adjustment of the camera system. For the

usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

• INF adjustment lens holder

To be used together with the Camera stand for operating the

Videocamera in the stripped-down condition such as the status without the exterior parts or for using commodities that are

not yet conformable to the interchangeable ring. For the usage

of the INF lens holder, refer to the Service Bulletin No. YA-SB-

10035.

• Mini stand

To be used together with the INF adjustment lens holder. For

the usage of the Mini stand, refer to the Service Bulletin No.

YA-SB-10035.

• Light box assembly

To be used for adjustment of the camera system. For the

usage of the Light box assembly, refer to the Service Bulletin

No. YA-SB-10035.

• Gray scale chart

To be used for adjustment of the camera system. For the

usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

• Color bar chart

To be used for adjustment of the camera system. For the

usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

• Focus chart

To be used for adjustment of the camera system. For the

usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

• Alignment tape

To be used for check and adjustment of interchangeability of

the mechanism.

• Service support system

To be used for adjustment with a personal computer. Software

can be downloaded also from JS-net.

• PC cable

To be used to connect the Videocamera and a personal computer

with each other when a personal computer issued for adjustment.

• Communication cable

Connect the Communication cable between the PC cable and

Jig connector cable when performing a PC adjustment.

• Jig connector cable

Connected to JIG CONNECTOR of the main board and used

for electrical adjustment, etc.

• Charging Battery Adjustment Jig

This Jig is used for the adjustment of the camcorders that have

Main Body battery charging function.

4.2 JIG CONNECTOR CABLE CONNECTION

4.2.1 Connection procedure

Remove the COVER(JIG), and remove the COVER(ADJ).

GUIDE ROLLER (TU)

GUIDE ROLLER (SUP)

JIG CONNECTOR

CABLE

COMMUNICATION

CABLE

JIG CONNECTOR

TO AL_2.8VSYS

TO IF_RX

TO IF_TX

TO GND

BLUE

RED

WHITE

BLACK

COVER(JIG)

JIG CONNECTOR

COMMUNICATION

CABLE

Fig.4-2-2

RS232C

COM PORT

PC CABLE

TO ENV_OUT

TO HID

COVER(ADJ)

JIG CONNECTOR

CABLE

SERVICE SUPPORT SYSTEM

MENU

PERSONAL COMPUTER

OSCILLOSCOPEJIG CONNECTOR

1-34 (No.YF228<Rev.001>)

Page 35

Jig connector diagrams

ENV_OUT GND

KENTO2

IRU

ATFI

MVD

JIG CONNECTOR CABLE (YTU93082J)

MAIN CN102

612

11

10

9

8

7

KENTO

5

AL_2.8VSYS

4

IF_RXIF_TX

3

HID

2

1

GND

Fig.4-2-3

JIG CONN. BOARD

(PIN NO.)

GND

1

HID

2

GND

3

IF_RX

4

AL_2.8VSYS

5

KENTO

6

MVD

7

ATFI

8

ENV_OUT

9

IF_TX

10

IRU

11

KENTO2

12

4.3 MECHANISM COMPATIBILITY ADJUSTMENT

4.3.1 Tape pattern adjustment

NOTE:

Prior to the adjustment, remove the CASS.COVER.

(1) Play back the compatibility adjustment tape.

While triggering the HID, observe the waveform of ENV_OUT.

(2)

(3) Set the manual tracking mode (ATF OFF).

(4) Confirm that the waveform is entirely parallel and straight,

and free from remarkable level-down, through the tracking

operation.

Make the confirmation as follows if necessary.

If level-down is observed on the left hand side of the waveform,

(5)

straighten the level by turning the GUIDE ROLLER (SUP).

If level-down is observed on the right hand side of the waveform, straighten the level by turning the GUIDE ROLLER (TU).

(6) After the adjustment, try the unloading motion once, and

confirm that the waveform is flat when the tape has been

played back again.

(7) Play back the self-recording.

(8) Confirm that the waveform is flat.

Flatten the waveform.

4.4 ELECTRICAL ADJUSTMENT

Electrical adjustment is performed by using a personal computer

and software for SERVICE SUPPORT SYSTEM. Read

README.TXT file to use the software properly.

As for the connection of cables, see "4.2 JIG CONNECTOR

CABLE CONNECTION".

Misalignment of guide

roller height on the

supply side

ENV_OUT

HID

Misalignment of guide roller

height on the take-up side

Fig.4-3-1

Fig.4-3-2

(No.YF228<Rev.001>)1-35

Page 36

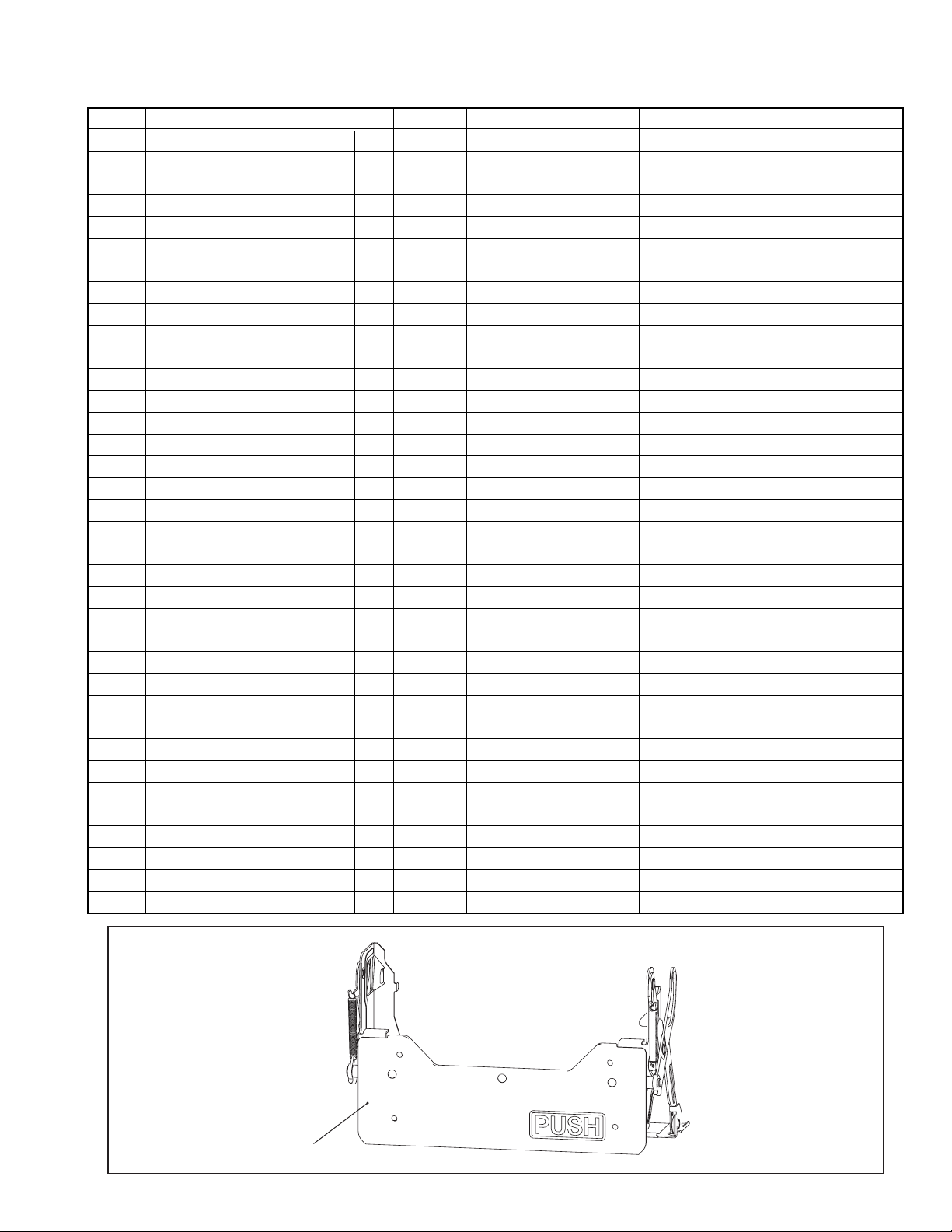

5.1 SERVICE NOTE(1)

SECTION 5

TROUBLE SHOOTING

3-2-12 3-2-13

aa

3-2-8 3-2-9 3-2-10A 3-2-11

3-2-4 3-2-7

3-2-3 3-2-5 3-2-6

3-2-23-2-1

3-2-18A3-2-16A 3-2-18B

3-2-15 3-2-19 3-2-203-2-17

aab

[18]

[11]

a

3-2-22

1 2 3 4 5 6

ac

3-2-21

[1] [2] [4][3] [5] [6] [9] [10] [11] [12] [13][7] [8]

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27

CABINET PARTS AND ELECTRICAL PARTS(1)

Symbol No.

Removing order of screw

1-36 (No.YF228<Rev.001>)

[14] [15] [16] [17] [18] [19] [20]

28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

CABINET PARTS AND ELECTRICAL PARTS(2)

Symbol No.

Place to stick screw

Screw tightening torque

Reference drawing (Fig.No.)

Removing order of screw

3-2-14

1 2 3 4 5 6 7 8 9 10 11 12 13 14

[11]OP BLOCK ASSY/CCD BOARD ASSY [18]MONITOR ASSY

Symbol No.

Place to stick screw

Screw tightening torque

Reference drawing (Fig.No.)

Removing order of screw

Place to stick screw

Screw tightening torque

Reference drawing (Fig.No.)

NOTE:

㧝)㧖and㧖㧖 (This mark shows where to attach the screws) : Do not reuse the screws because the screw lock bond was applied to prevent the screws from loosening.

Prepare the specified screws and use them in place of the removed screws.

㧞)Tightening torque for the screws

There are setting limits of the torque value for the torque driver. If the value exceeds the setting value, take it as a rough measurement (reference value),

and tighten the screw manually.

The specified torque value is a recommended value of the initial assembly. Therefore, set the value below the specified torque value in the assembling procedure.

a㧦 0.088N㨯m (0.9kgf㨯cm)ޓޓb㧦 0.078N㨯m (0.8kgf㨯cm)ޓޓc㧦 0.147N㨯m (1.5kgf㨯cm)

Be careful not to break either the screws or the screw holes.

Page 37

5.2 EMERGENCY DISPLAY

When any abnormal signal is input to the syscon CPU, an error

number is displayed on the LCD monitor. (Shown as examples

01 and 03)

In every error status, the relevant messages as shown in the examples keep appearing alternately.

Proceed with the operation following the messages.

Example (in case of the error number 01):

UNIT IN

SAFEGUARD MODE

01

REMOVE AND REATTACH

BATTERY OR DC PLUG

Example (in case of the error number 03):

01

UNIT IN

SAFEGUARD MODE

03

LCD display Emergencymode Details Possible cause

01 LOADING In the case the encoder position is not

shifted to the next point though the

loading motor has rotated in the

loading direction for 4 seconds or

more. This error is defined as [01].

02 UNLOADING In the case the encoder position is not

shifted to the next point though the

loading motor has rotated in the

unloading direction for 4 seconds or

1. The mechanism is locked during mode shift.

2. The mechanism is locked at the mechanism loading end,

because the encoder position is skipped during mechanism

mode shift.

3. No power is supplied to the loading MDA.

1. The mechanism is locked during mode shift.

2. The mechanism is locked at the mechanism loading end,

because the encoder position is skipped during mechanism

mode shift.

more. This error is defined as [02].

03 REEL FG(TU & SUP) In the case no REEL FG is produced

for seconds shown in the table below

or more in the capstan rotation mode

after loading was complete, the

mechanism mode is shifted to STOP

with the pinch roller set off. This error

is defined as [03].However, no REEL

EMG is detected in the SLW/STILL

mode.

1. The idler gear does not engage with the reel disk well.

2. Though the idler gear and reel disk are engaged with each

other, the tape is not wound because of overload to the

mechanism.

3. No FG pulse is output from the reel sensor.

4. No power is supplied to the reel sensor.

5. Tape transport operation takes place with a cassette having

no tape inside.

6. The tape slackens and no pulse is produced until the slack

is taken up and the tape comes into the normal status.

REEL(SUP) REEL(TU)

PB/REC

S-FWD

S-REW

FF

REW

04 DRUM FG In the case there is no DRUM FG

input in the drum rotation mode for 4

seconds or more. This error is defined

as [04], and the mechanism mode is

shifted to STOP with the pinch roller

set off.

3 SEC

3 SEC

0.3 SEC

3 SEC

0.1 SEC

3 SEC

0.3 SEC

3 SEC

0.1 SEC

3 SEC

1. The drum cannot be started or drum rotation is stopped

because tape transport load is too high.

1) Tape tension is extremely high.

2) The tape is damaged or soiled with grease, etc.

2. The DRUM FG signal is not received by the syscon CPU.

1) Disconnection in the middle of the signal line.

2) Failure of the DRUM FG pulse generator (hall element).

3. No drum control voltage is supplied to the MDA.

4. No power is supplied to the DRUM MDA.

05 - - -

06 CAPSTAN FG In the case no CAPSTAN FG is

produced in the capstan rotation

mode for 2 seconds or more. This

error is defined as [06], and the

mechanism mode is shifted to STOP

with the pinch roller set off.However,

no CAPSTAN EMG is detected in the

STILL/FF/REW mode.

1. The CAPSTAN FG signal is not received by the syscon

CPU.

1) Disconnection in the middle of the signal line.

2) Failure of the CAPSTAN FG pulse generator (MR

element).

2. No capstan control voltage is supplied to the MDA.

3. The capstan cannot be started or capstan rotation is

stopped because tape transport load is too high.

1) Tape tension is extremely high. (Mechanical locking)

2) The tape is damaged or soiled with grease, etc. (Tape

tangling occurs, etc.)

Fig.5-3-1

EJECT AND

REINSERT TAPE

03

(No.YF228<Rev.001>)1-37

Page 38

5.3 TAKING OUT CASSETTE TAPE

If the tape cannot be taken out due to electrical failure, take

out the tape in the following procedure.

Please note that following is a simplified method.

Removing the cabinet parts before taking out the tape is recommended for easy tape removal considering the workability and reliability.

(1) Remove the Power Unit (battery or DC code) from the set.

(2) Remove a cover (ADJ).

NOTE

For more efficient operation, loosen and move the grip

belt prior to the procedure (2).

(3) Open the CASSETTE COVER till it is completely opened

and fixed.

(4) Attach a PVC TAPE as shown in the figure.

NOTE

Be careful of cassette tape damage caused because the

CASSETTE HOUSING ASSEMBLY is moved upward at

the unloading end (EJECT mode).

(5) To set the SLIDE DECK ASSEMBLY to the unloading end,

apply DC 3V to the electrode (terminal) on the top surface

of the LOADING MOTOR ASSEMBLY that is seen through

a hole under the cover removed in the procedure (2).

NOTE

Be careful not to attach grease or a similar substance to

the surface of the cassette tape on the tape transport

system.

(6) Wind the cassette tape by directly turning the CENTER

GEAR from the backside of the SLIDE DECK ASSEMBLY

by using a sharp tool (Chip IC replacement jig).

(7) Confirm that the cassette tape is completely wound, and

then peel off the PVC TAPE from the CASSETTE HOUSING ASSEMBLY and take out the cassette tape.

NOTE

To confirm that the cassette tape is completely wound,

confirm that one REEL DISK ASSEMBLY (SUP) rotates

as you rotate the other REEL DISK ASSEMBLY (TU).

(8) Make sure that grease or a similar substance is not at-

tached to the surface of the tape taken out in the procedure

(7). Similarly, also make sure that grease or a similar substance is not attached on the MECHANISM ASSEMBLY,

especially the tape transport system.

COVER(ADJ)

CASS.COVER

TAPE

CENTER GEAR

(DC3V)

LOADING MOTOR

GRIP BELT

CASS.HOUSEING ASSY

SLIDE DECK ASSY

CHIP IC

REPLACEMENT JIG

TAPE

Fig.5-2-1

1-38 (No.YF228<Rev.001>)

Page 39

5.4 SERVICE NOTE

Use the following chart to manage mechanism parts that are removed for disassembling the mechanism.

[1]

HOUSING ASSY DRUM ASSY

3-3-11

[4]

REEL COVER ASSY

IDLER ARM ASSY T5 ARM ASSY

[5] [6]

DRUM PROTECTOR

[2]

[3]

(NEW TYPE)(OLD TYPE)

or

[7]

3-3-11 3-3-10

[8]

S1 ARM ASSY

[11] [13] [14]

SLIDE DECK ASSY PINCH ROLLER

[9]

SLIDE GUIDE PLATE GUIDE PLATE

3-3-12

TENSION ARM ASSY

[10]

ASSY

[12]

3-3-14B

REEL DISK ASSY

(SUP : WHITE)

CASSETTE

GUIDE

3-3-14A 3-3-13

Fig.5-4-1

3-3-14B

(TU : BLACK)

REEL DISK ASSY

[15] [16]

BRAKE PLATE

(No.YF228<Rev.001>)1-39

Page 40

T.C.PLATE ASSY GUIDE RAIL

[17] [20]

SLIDE

COLLAR1

ASSY

[22]

CAPSTAN MOTOR REEL PULLEY

[23]

[18]

3-3-15

[19]

DRUM ASSY

DRIVE ARM ASSY

SLIDE

COLLAR2

3-3-163-3-17

[21]

T5 CATCHER

MOTOR

[25] [27] [28]

BRACKET ASSY

WORM

WHEEL

[26]

BELT GUIDE

GEAR COVER PRESS ARM

[24]

CENTER GEAR

ASSY

[29]

[30]

3-3-18

[31]

SUB CAM ROTARY

CONNECT GEAR

MAIN CAM

[32] [33]

ENCODER

[36]

MAIN DECK ASSY

3-3-19

Fig.5-4-2

LOADING

GEAR1

[34]