Page 1

SERVICE MANUAL

SPECIFICATIONS

DIGITAL STILL CAMERA

GC-QX3U

STILL CAMERA

Dimensions

Power consumption

Weight

Power source

Flash

Recommended distance for flash

LCD screen

Storage media

CCD

Recording pixels

Focal distance

Lens

Video

Recording format

Sensitivity

Iris value (F value)

Exposure control

Exposure compensation

Minimum subject distance

Light measurement system

Shutter type

Shutter speed

White balance

Focus

: 108 (W) mm x 64 (H) mm x 57 (D) mm

(4-5/16" x 2-9/16" x 2-1/4")

: 4.0 W (when the LCD screen is off)

5.6 W (when the LCD screen is on)

: Approx. 290 g (0.64 lbs)

(without a Memory card and battery)

: DC 5 V

: Built-in,

Auto/red-eye prevention/forced/disabled

: 2.3 m to 5.2 m

: 2.0 inch, cool polysilicon TFT, 200,000 pixels

: SmartMedia

: 3.34 million pixels (3.24 million valid pixels),

1/1.8" square pixels, primary color filter,

interlace scan CCD

: 2032 x 1536 (TIFF 9.5MB, FINE 1MB, STD 700KB)

1024 x 768 (TIFF 2.4MB, FINE 500KB, STD 300KB)

640 x 480 (TIFF 980KB, FINE 150KB, STD 80KB)

: 7.5 mm to 17.5 mm

(equivalent to 37mm to 86 mm on a 35 mm still camera)

: 2.3X optical zoom lens

: 160 x 120, 20 seconds (80KB – 200KB) JVC original

: Exif Ver. 2.1 (DCF compliant), TIFF (Uncompressed),

DPOF-compatible

: 80/160/320 (ISO compliant)

: F2.8/3.8, 5.6, 8, 11

: Program AE, iris priority AE

: +/–2EV (0.5EV steps)

: Approx. 2 cm to 50 cm (in Macro mode)

: Multi, spot

: Electronic shutter

: Auto (Program AE: 1/8 – 1/750, Iris priority AE: 1/4 – 1/750)

: Auto/Manual (

: Auto/Manual

TM

3.3V (up to 64MB)

, , , MWB)

Self timer

Photo quality

Number of storable photos

(with an 8MB Memory card,

STANDARD/FINE/NO COMP.)

Battery

Printer connector

VIDEO output connector

Digital output connector

: 1 second, 8 seconds

: 3 modes (STANDARD/FINE/NO COMP.)

: 2032 x 1536: approx. 10/8/0

1024 x 768: approx. 43/32/3

640 x 480: approx. 87/65/9

: Lithium ion battery

: Output for optional printer

: Two-pole plug, 3.5 mm diameter (NTSC)

: Mini-USB connector

AC Power Adapter/Charger AA-V37

Power requirement

U.S.A. and Canada

Other countries

Power consumption

Output

Charge

Camera

Operating temperature

Dimensions

Weight

E. & O. E. Design and specifications subject to change without notice.

: AC 120 V`, 60 Hz

: AC 110 V – 240 V`, 50 Hz/60 Hz

: 23 W

: DC 3.6 V

: DC 5.0 V

:0°C to 40°C (32°F to 104°C)

[when charging: 10°C to 35°C (50°F to 95°F)]

: 68 (W) mm x 38 (H) mm x 110 (D) mm

(2-11/16" x 1-1/2" x 4-3/8")

: Approx. 230 g (0.51 lbs) (without a DC cord)

, 0.77 A

, 1.5 A

No.86564

June 2000

Page 2

TABLE OF CONTENTS

Section Title Page Section Title Page

Important Safety Precautions

1. DISASSEMBLY

1.1 BEFORE ASSEMBLY AND DISASSEMBLY .................... 1-1

1.1.1 Precautions ................................................................. 1-1

1.1.2 Assembly and disassembly ......................................... 1-1

1.1.3 Disconnection of Connectors (Wires) ......................... 1-2

TOOL AND EQUIPMENTS REQUIRED FOR ADJUSTMENTS .

1.2

1-2

1.2.1 Tools required for adjustments ................................... 1-2

1.3 DISASSEMBLY /ASSEMBLY OF CABINET PARTS ......... 1-2

1.3.1 Disassembly flow chart ............................................... 1-2

1.3.2 Disassembly method ( I ) ............................................ 1-3

1.3.3 Disassembly method ( II ) <OP UNIT> ....................... 1-6

1.3.4 OP BLOCK Lens compositison ................................... 1-7

1.4 IC BLOCK DIAGRAM ...................................................... 1-8

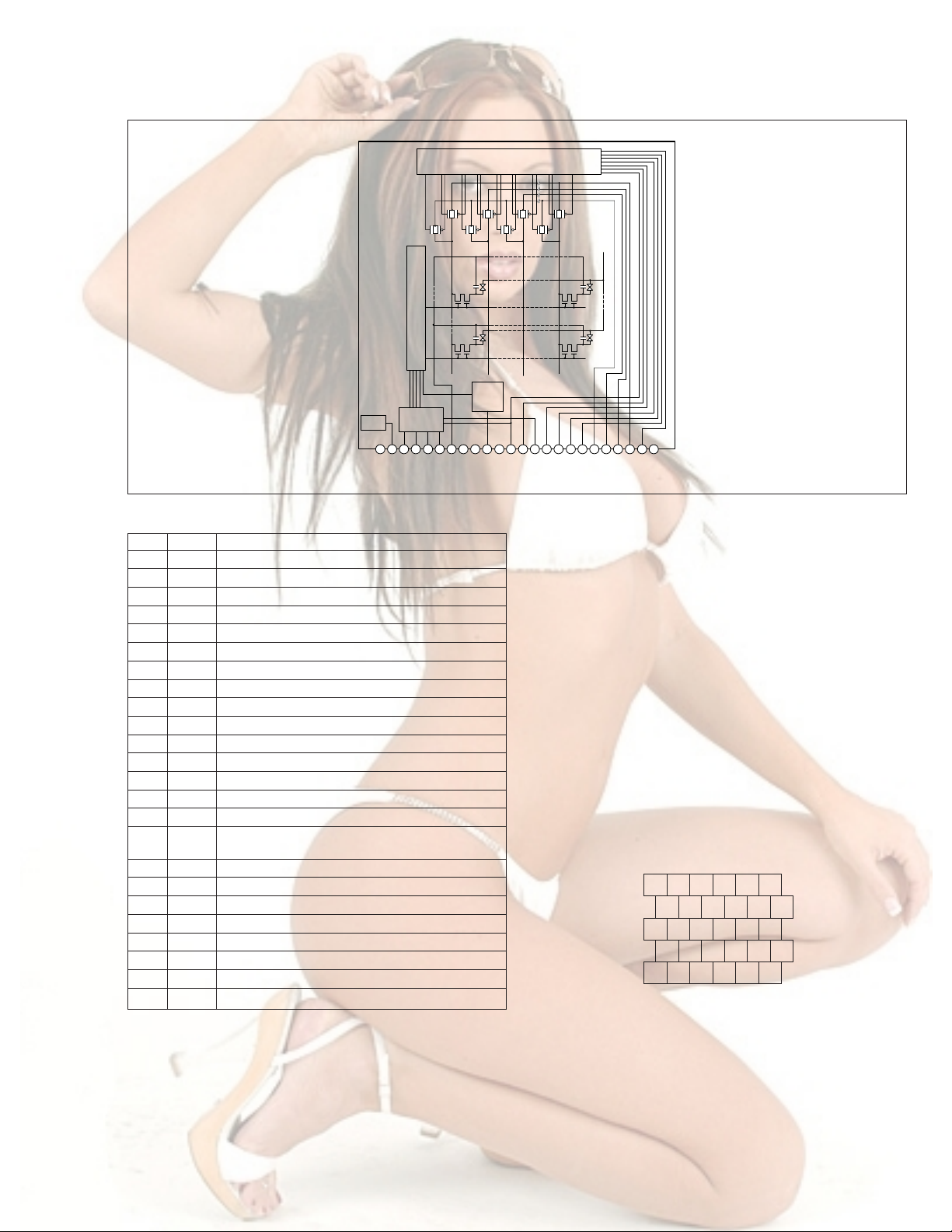

1.4.1 IC 1002 (CXD2497R) ................................................... 1-8

1.4.2 IC 2001 (CDS/AGL) ..................................................... 1-9

1.4.3 IC 7302 (CXA3268AR)) .............................................. 1-10

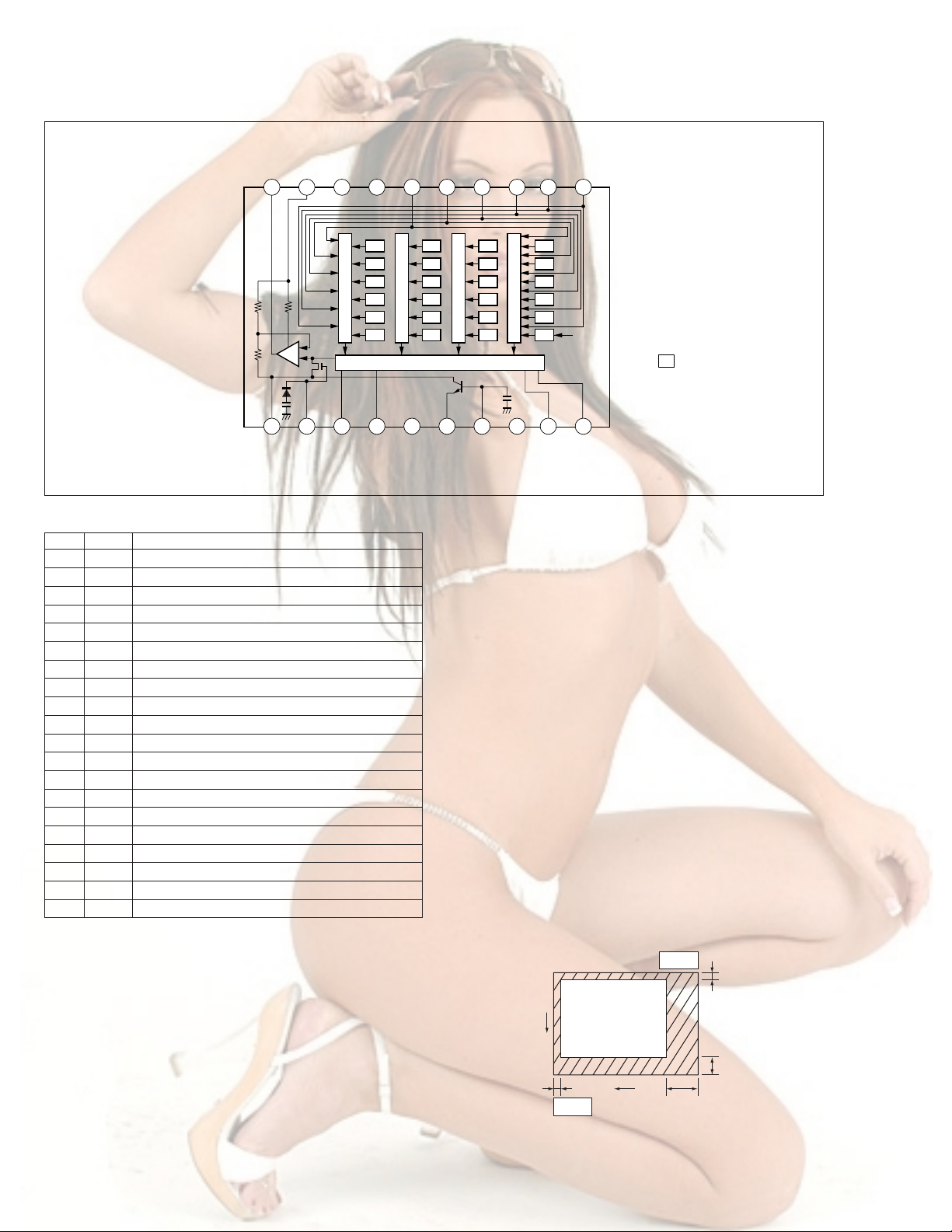

1.4.4 LCD (ACX301AK) ...................................................... 1-11

1.4.5 CCD (ICX262AQ) ....................................................... 1-12

2. ELECTRICAL ADJUSTMENT

2.1 ELECTRICAL ADJUSTMENT .......................................... 2-1

2.1.1 Precautions ................................................................. 2-1

Test instruments required for electrical adjustment .............

2.1.2

2-1

2.1.3 Required test equiqment ............................................ 2-1

2.1.4 Setup (LCD ADJUSTMENT) ........................................ 2-1

2.1.5 Setup (CCD ADJUSTMENT) ....................................... 2-2

2.2 Setup with patch cords and jig connector cables............ 2-3

4. PARTS LIST

4.1 PACKING AND ACCESSORY ASSEMBLY <M1> ........... 4-1

4.2 OP BLOCK ASSEMBLY <M3> ........................................ 4-2

4.3 FINAL ASSEMBLY <M2> .............................................. 4-3

4.4 ELECTRICAL PARTS LIST ............................................... 4-6

MAlN BOARD ASSEMBLY <01> .................................... 4-6

CCD BOARD ASSEMBLY <02> .................................... 4-11

MONI REG BOARD ASSEMBLY <03> ......................... 4-12

JACK BOARD ASSEMBLY <04> .................................. 4-14

STOROBE FLASH BOARD ASSEMBLY <05> .............. 4-15

5. AC POWER ADAPTER (AA-V37U)

5.1 CABINET ASSEMBLY <MA> .......................................... 5-1

5.2 SCHEMATIC DIAGRAM .................................................. 5-2

5.3 CIRCUIT BOARD ............................................................. 5-4

5.4 ELECTRICAL PARTS LIST ............................................... 5-5

MAIN AND TERMINAL BOARD ASSEMBLY <91> ........ 5-5

3. CHARTS AND DIAGRAMS

NOTES OF SCHEMATIC DIAGRAM ........................................ 3-1

CIRCUIT BOARD NOTES ......................................................... 3-2

3.1 BOARD INTERCONNECTIONS ....................................... 3-3

3.2 MAIN (SYSCON) SCHEMATIC DIAGRAM ...................... 3-5

3.3 MAIN (DSP96) SCHEMATIC DIAGRAM.......................... 3-7

3.4 MAIN (DSP97) SCHEMATIC DIAGRAM.......................... 3-9

3.5 MAIN (G/A JCY0148) AND

MAIN (SD SUB) SCHEMATIC DIAGRAM........... 3-11

3.6 MAIN (F/Z MDA) AND

MAIN (IRIS) SCHEMATIC DIAGRAM ................. 3-12

3.7 MAIN (CDS AGC A/D AND ARM ROM)

SCHEMATIC DIAGRAM ..................................... 3-13

3.8 MAIN (STROBE CONTROL AND STROBE FLASH)

SCHEMATIC DIAGRAM ..................................... 3-14

3.9 CCD SCHEMATIC DIAGRAM........................................ 3-15

3.10 MONI REG (MONITOR) SCHEMATIC DIAGRAM ......... 3-16

3.11 MONITOR REG (DC/DC) SCHEMATIC DIAGRAM........ 3-17

JACK (VIDEO OUT/USB/PRINTER/DC JACK) AND

3.12

MONITOR BACK LIGHT SCHEMATIC DIAGRAM .....

3-19

3.13 VOLTAGE CHARTS........................................................ 3-20

3.14 MAIN CIRCUIT BOARD (YB10282-01-05) ..................... 3-23

3.15 MAIN CIRCUIT BOARD (YB10282-01-06) ..................... 3-29

3.16 MONITOR REG CIRCUIT BOARD (YB10283-01-02) ..... 3-35

3.17 MONITOR REG CIRCUIT BOARD (YB10283-01-04) ..... 3-37

3.18 JACK CIRCUIT BOARD (YB10283-01-02) ..................... 3-39

3.19 JACK CIRCUIT BOARD (YB10283-01-04) ..................... 3-41

3.20 CCD CIRCUIT BOARD (YB10283-01-02) ....................... 3-43

3.21 CCD CIRCUIT BOARD (YB10283-01-04) ....................... 3-44

STOROBE FLASH CIRCUIT BOARD (YB10283-01-02) ......

3.22

3.23

STOROBE FLASH CIRCUIT BOARD (YB10283-01-04) ......

3-45

3-46

3.24 OVER ALL BLOCK DIAGRAM....................................... 3-47

3.25 POWER SUPPLY BLOCK DIAGRAM ............................ 3-49

3.26 OP BLOCK SCHEMATIC DIAGRAM <REFERENCE> .. 3-51

3.27 OPERATION UINT

SCHEMATIC DIAGRAM <REFERENCE>.......... 3-52

SOFTWARE SECTION FOR Windows

Operating Environment

The host computer that runs the Windows

operating environment must satisfy the following

conditions.

USB Driver

®

1. Microsoft

2. Available USB port

3. CD-ROM drive

Video Player

1. CPU: Intel

2. Microsoft

3. Display capability of 65,536 colors or more

4. CD-ROM drive

5. Minimum RAM requirement: 32MB

6. Minimum hard disk space requirement: 1MB

* The system requirements information is not a

* Microsoft

* Intel

* Other trademarks are property of their respective

* If you use Windows

Windows® 98/Windows® 98 Second

Edition, pre-installed

®

Pentium® 200MHz class or higher

®

Windows® 95/Windows® 98

guarantee that provided software applications will

work on all personal computers meeting those

requirements.

®

, Windows® are either registered

trademarks or trademarks of Microsoft corporation

in United States and/or other countries.

®

, Pentium® are registered trademarks of Intel

corporation.

owners.

which does not have a USB port, use an optional

flash path, conversion card adapter, etc. For

details on the operating environment of these

devices, contact the dealers or manufacturers.

®

95 or a personal computer

®

®

SOFTWARE SECTION FOR Macintosh

Operating Environment

The host computer that runs the Macintosh

operating environment must satisfy the following

conditions.

USB Driver

1. USB-compatible computer (iMac™, iBook™,

Power Mac™ G3/G4, Power Book™ G3, etc.)

2. Mac OS 8.5.1/Mac OS 8.6/Mac OS 9.0

JVC Video Decoder

1. Power PC 603e/120MHz or faster

2. Mac OS 7.6.1 or later

3. QuickTime 3.0 or later

4. Minimum RAM requirement: 32MB

5. Minimum hard disk space requirement: 1MB

®

* Macintosh

* Other trademarks are property of their

* If you use Macintosh

is a registered trademark of Apple

Computer.

owners.

port, use an optional flash path, conversion

adapter, etc. For details on the operating en

ment of these devices, contact the dealers or

manufacturers.

®

which does not have a

®

®

Page 3

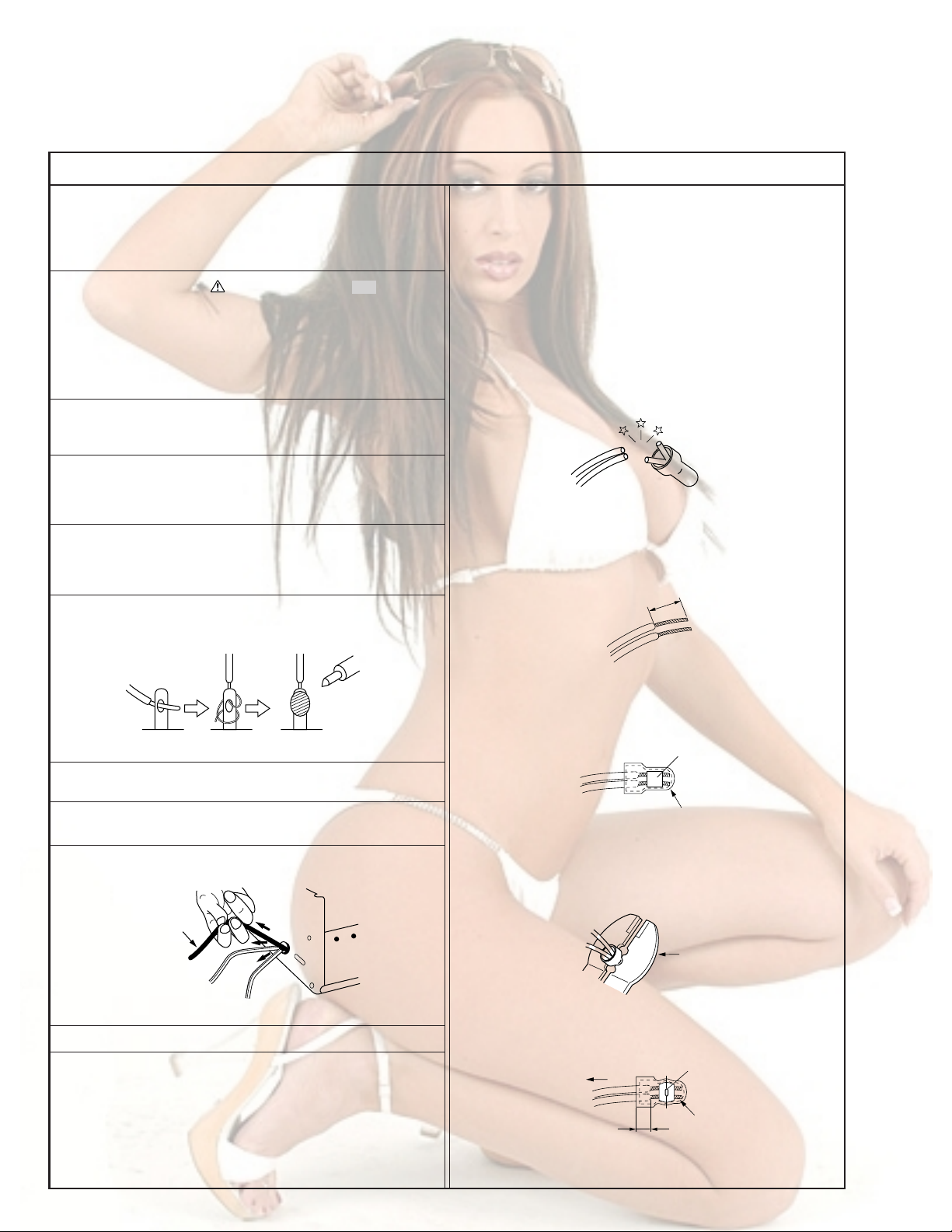

Important Safety Precautions

cut close to connector

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes

of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the

following precautions when a set is being serviced.

v

Precautions during Servicing

1. Locations requiring special caution are denoted by labels and

inscriptions on the cabinet, chassis and certain parts of the

product. When performing service, be sure to read and comply with these and other cautionary notices appearing in the

operation and service manuals.

2. Parts identified by the

critical for safety.

Replace only with specified part numbers.

Note: Parts in this category also include those specified to com-

ply with X-ray emission standards for products using

cathode ray tubes and those specified for compliance

with various regulations regarding spurious radiation

emission.

3. Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

4. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

5. Use specified insulating materials for hazardous live parts.

Note especially:

1) Insulation Tape 3) Spacers 5) Barrier

2) PVC tubing 4) Insulation sheets for transistors

6. When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

symbol and shaded ( ) parts are

12. Crimp type wire connector

In such cases as when replacing the power transformer in sets

where the connections between the power cord and power

transformer primary lead wires are performed using crimp type

connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely

according to the following steps.

1) Connector part number : E03830-001

2) Required tool : Connector crimping tool of the proper type

which will not damage insulated parts.

3) Replacement procedure

(1) Remove the old connector by cutting the wires at a point

close to the connector.

Important : Do not reuse a connector (discard it).

Fig.3

(2) Strip about 15 mm of the insulation from the ends of

the wires. If the wires are stranded, twist the strands to

avoid frayed conductors.

15 mm

Fig.1

7. Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

8. Check that replaced wires do not contact sharp edged or

pointed parts.

9. When a power cord has been replaced, check that 10-15 kg of

force in any direction will not loosen it.

Power cord

Fig.2

10. Also check areas surrounding repaired locations.

11. Products using cathode ray tubes (CRTs)

In regard to such products, the cathode ray tubes themselves,

the high voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the cathode ray tubes and other parts with only the specified parts.

Under no circumstances attempt to modify these circuits.

Unauthorized modification can increase the high voltage value

and cause X-ray emission from the cathode ray tube.

Fig.4

(3) Align the lengths of the wires to be connected. Insert

the wires fully into the connector.

Metal sleeve

Connector

Fig.5

(4) As shown in Fig.6, use the crimping tool to crimp the

metal sleeve at the center position. Be sure to crimp fully

to the complete closure of the tool.

1.25

2.0

5.5

Fig.6

(5) Check the four points noted in Fig.7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Fig.7

Crimping tool

Crimped at approx. center

of metal sleeve

Conductors extended

1

S40888-01

Page 4

v

d'

d

Chassis

Power cord,

primary wire

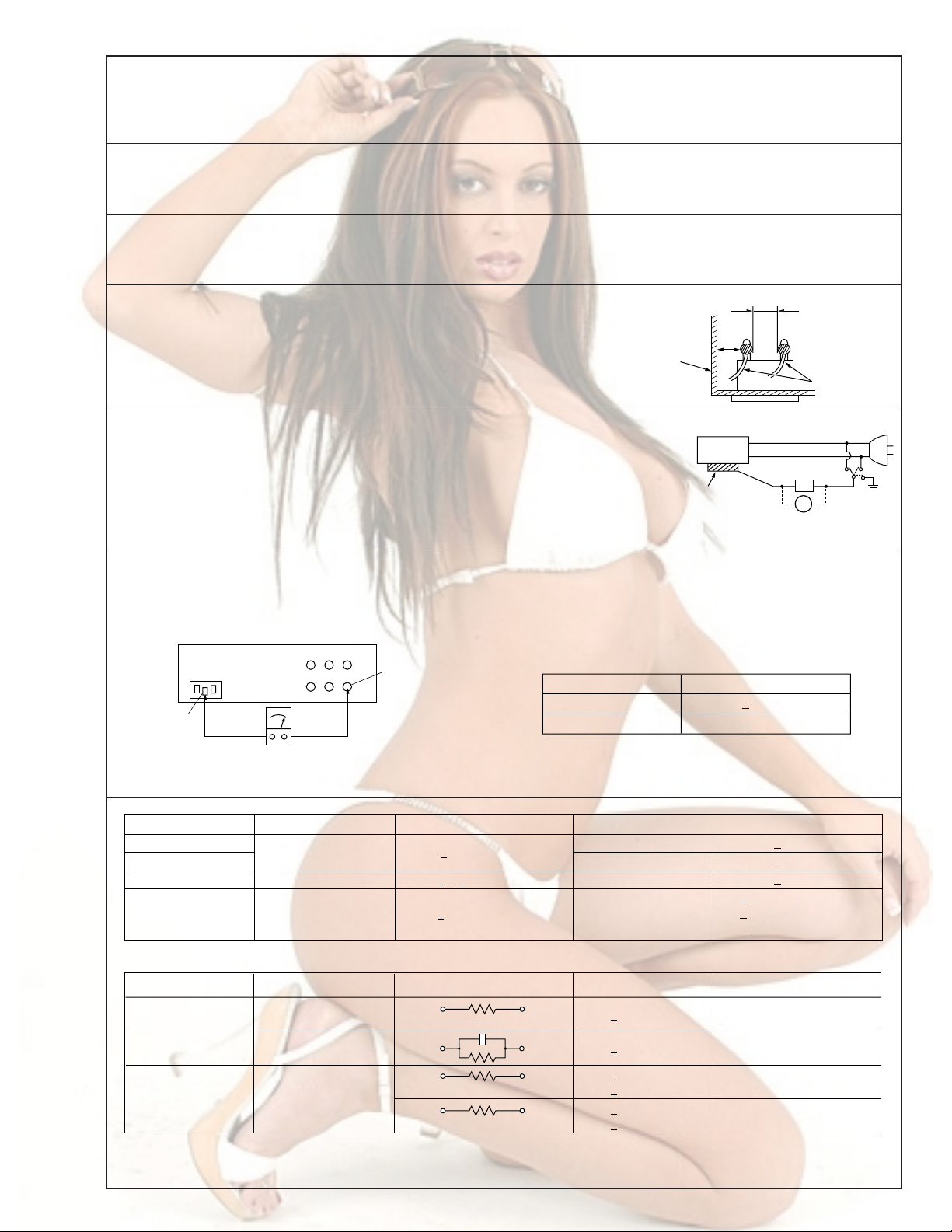

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety standards.

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and

externally exposed parts of the set (RF terminals, antenna terminals, video and audio input

and output terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed

accessible parts of the set (RF terminals, antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

3. Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d’) between soldered terminals, and between terminals and surrounding metallic parts. See table 1

below.

Fig. 8

4. Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure across both terminals of load Z. See figure 9 and

following table 2.

Externally

exposed

accessible part

Z

V

Fig. 9

ab

c

5. Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin in AC inlet and externally exposed accessible parts (Video in,

Video out, Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and exposed accessible parts. See figure 10 and grounding specifications.

AC inlet

Earth pin

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Exposed accessible part

Milli ohm meter

Fig. 10

Region

Japan

USA & Canada

Europe & Australia R 10 MΩ/500 V DC

Region Load Z

Insulation Resistance (R)

≤

R 1 MΩ/500 V DC

≥≥

1 MΩ R 12 MΩ/500 V DC

≤

Table 1 Specifications for each region

Grounding Specifications

Region

USA & Canada

Europe & Australia

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 miute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(Class 2)

(Class 1)

Grounding Impedance (Z)

≤

Z 0.1 ohm

≤

Z 0.5 ohm

Clearance Distance (d), (d')

≤

d, d' 3 mm

≤

d, d' 4 mm

≤

d, d' 3.2 mm

≤

d 4 mm

≤

d' 8 mm (Power cord)

≤

d' 6 mm (Primary wire)

a, b, cLeakage Current (i)AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Note: These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

Japan

USA & Canada

Europe & Australia

Table 2 Leakage current specifications for each region

1 kΩ

0.15 µF

1.5 kΩ

2 kΩ

50 kΩ

2

≤

i 1 mA rms Exposed accessible parts

≤

i 0.5 mA rms

≤

i 0.7 mA peak

≤

i 2 mA dc

≤

i 0.7 mA peak

≤

i 2 mA dc

Exposed accessible parts

Antenna earth terminals

Other terminals

S40888-01

Page 5

Page 6

SECTION 1

DISASSEMBLY

1.1 BEFORE ASSEMBLY AND DISASSEMBLY

1.1.1 Precautions

1. Be sure to remove the power supply unit prior to mounting and soldering of parts.

2. When connecting and disconnecting the connectors, be

careful not to damage the wire.

3. When replacing chip parts (especially IC parts), desolder

completely first (to prevent peeling of the pattern).

4. Tighten screws properly during the procedures.

Unless specified otherwise, tighten screws at a torque

of 0.1N•m (1.0 kgf•cm).

CAUTION!!

RISK OF ELECTRIC SHOCK

When disassembling the unit, electric hazards may

occur in some cases if the capacitor for strobe

emission (STROBE board C6512) has been charged.

Therefore be also very careful when performing repairs

and inspections.

It is recommended that operations be carried out after

waiting for more than ten minutes with the power

supply removed or after discharging the capacitor

forcibly.

Discharge the capacitor according to <NOTE 2> on

Page 1-3.

C6512 is located behind the STROBE board.

PRECAUTIONS ON HANDLING

THE LITHIUM SECONDARY BATTERY

This unit is equipped with a coin type lithium secondary

battery.

Improper handling of this battery may cause heat to

be generated, damage, fires, or leakage. Always follow

the precautions below.

1 Do not short-circuit, disassemble, distort, nor heat

the battery.

2 Load the battery with its + and - poles connected

correctly.

3 Do not solder the battery itself.

4 When replacing parts, also refer to the numbers

listed in the Parts List of the manual.

5 Do not store the battery in direct sunlight and hot

and humid places.

6 When replacing the battery, handle it with care and

do not attempt to hold it with tweezers as it may

short-circuit.

7 When disposing the battery, wind tape around the

terminal to insulate the battery, and dispose the

battery according to the method prescribed.

1.1.2 Assembly and disassembly

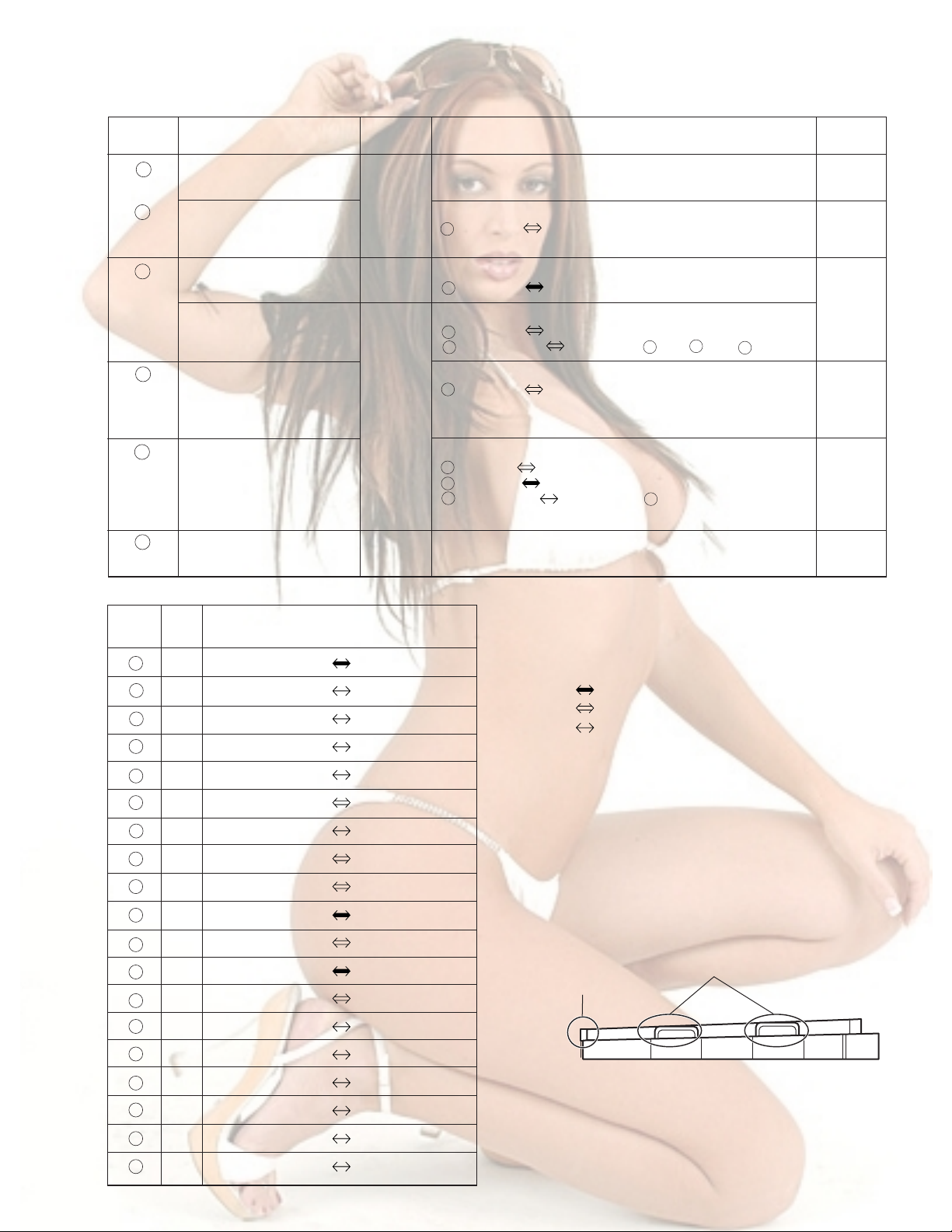

STEP

PART NAME

1 FRONT CASE Remove screws

REAR CASE

2 OPERATION UNIT Remove the Connector Remove screws NOTE 1

FIG.

NO.

Fig

1-2-1

r MAIN CN4001 OPERATION UNIT

Remove the TOP COVER 2 (115)

POINT

2(115), 3(156), 4(114), 1(116)

3 (116)

(1) (2) (3) (4) (5)

(1) : Indicate the disassembly steps. When assembling,

perform in the reverse order of these steps. This

number corresponds to the number in the disassem-

bly diagram.

(2) : Indicates the name of disassembly/assembly parts.

(3) : Indicates the number in the disassembly diagram.

(4) : Indicates parts and points such as screws, washers,

springs which must be removed during disassembly/

assembly.

Lock (L), soldering (SD), shield, connector, etc.

The encircled numbers indicate the order for disas-

Note:

sembling the cabinet parts.

The screw numbers indicate the disassembling order.

:Wire

:Flat wire

:Board to Bord Connector

[Example]

• (115) = Remove the parts No 115 screw.

• (SD1) = Desoldering at the point SD1.

• a = Disconnect the connector/ML a .

(5) : Precautions on disassembly/assembly.

NOTE

1-1

Page 7

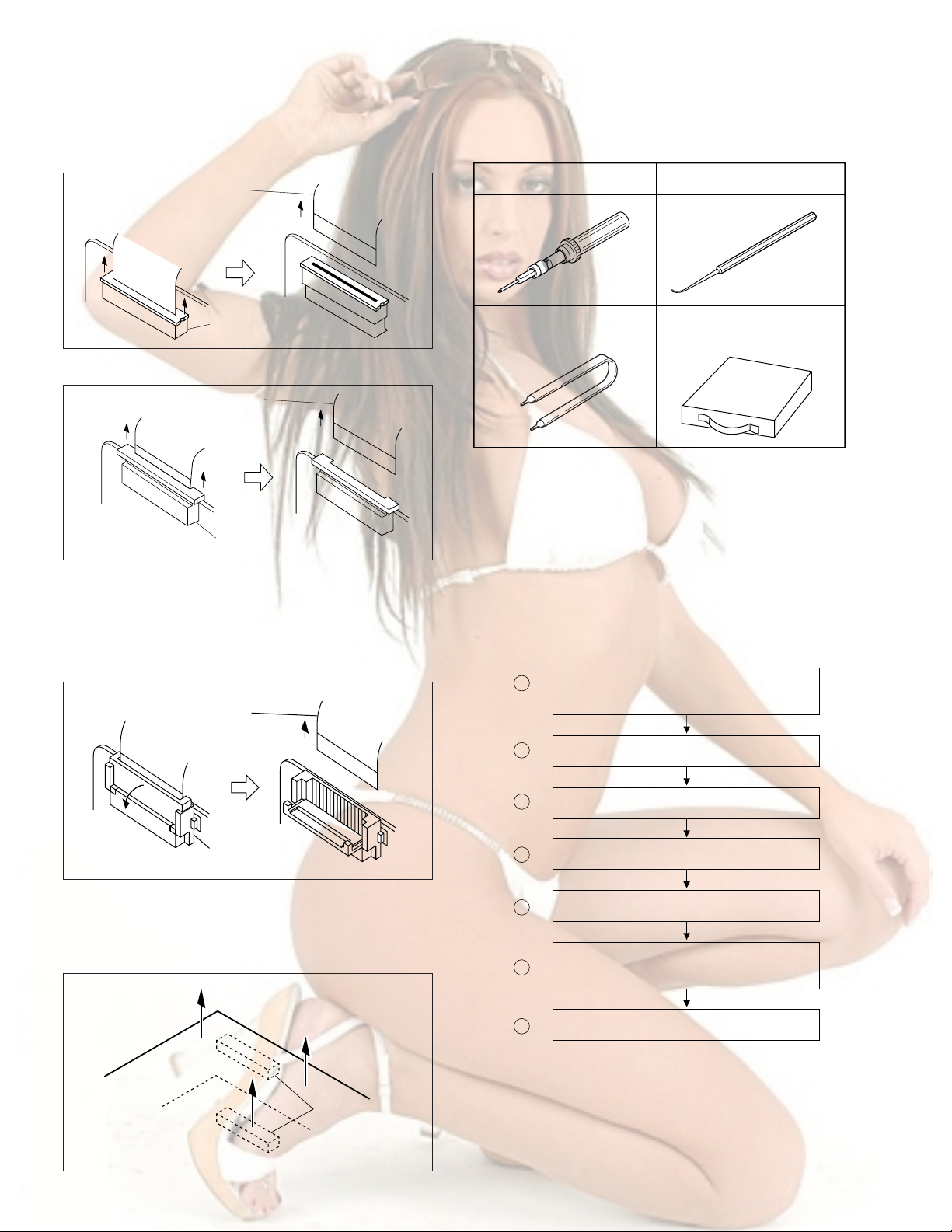

1.1.3 Disconnection of Connectors (Wires)

Connector

Pull both ends of the connector in the arrow direction, remove the lock and disconnect the flat wire.

Flat wire

1.2 TOOLS AND EQUIPMENTS REQUIRED FOR

ADJUSTMENTS

1.2.1 Tools required for adjustments

12

Torque driver

YTU94088

Clip IC replacement jig

PTS40844-2

Connector 1

Fig. 1-1-1 Connector 1

Flat wire

Connector 2

Fig. 1-1-2 Connector 2

Extend the locks in the direction of the arrow for unlocking

and then pull out the wire. After removing the wire,

immediately restore the locks to their original positions

because the locks are apt to come off the connector.

Flat wire

Connector catcher

34

YTU94036A

Soldering kit

YTU96016B

1.3 DISASSEMBLY/ASSEMBLY OF CABINET PARTS

1.3.1 Disassembly flow chart

The following flow chart shows the steps for disassembling

the cabinet parts. To assemble, perform the steps of the flow

chart in the reverse order.

The encircled numbers indicate the order for disas-

Note:

sembling the cabinet parts.

The screw numbers indicate the disassembling order.

1

FRONT CASE

REAR CASE

2

OPERATION UNIT

Connector 3

Fig. 1-1-3 Connector 3

B-B connector

Pull the board by both the sides in the direction of the arrow

for disconnecting the B-B connector.

Connector 4

Fig. 1-1-4 Connector 4

1-2

3

4

5

6

7

STROBE BOARD ASSEMBLY

JACK BOARD ASSEMBLY

LCD MODULE

MAIN BOARD ASSEMBLY

MONI/REG BOARD ASSEMBLY

OP UNIT

Page 8

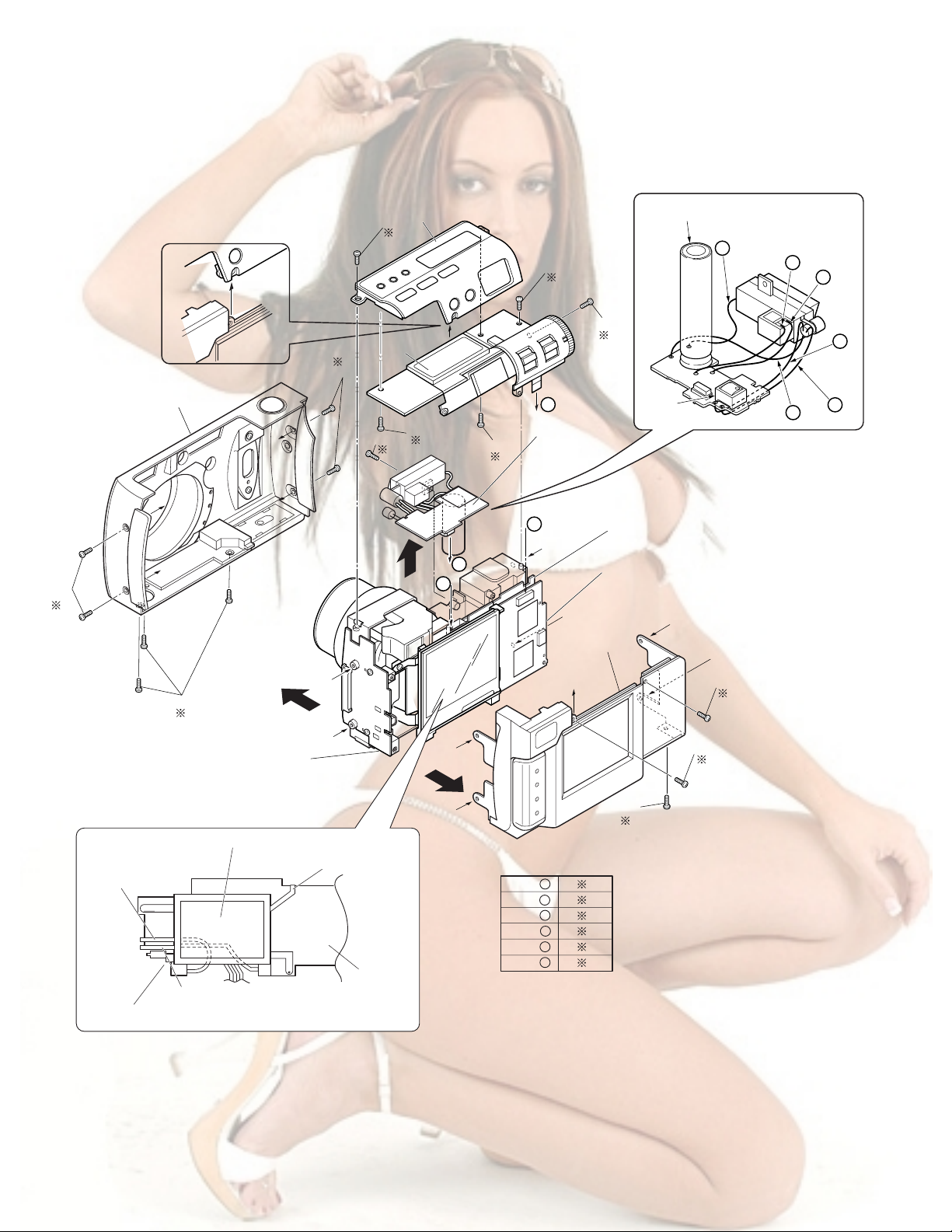

1.3.2 Disassembly method ( I )

no

slippege

4 sprts locked

STEP

1 FRONT CASE Remove screws

REAR CASE 2 (115), 3 (156), 4 (157), 1 (154)

2 OPERATION UNIT Remove the Connector Remove screws Note 1

3 STROBE BOARD ASSEMBLY Remove the Connector Remove screw Note 1

JACK BOARD ASSEMBLY Remove the Connector Remove screws

4 LCD MODULE Remove the Connector Remove screws Note 1

5 MAIN BOARD ASSEMBLY Remove the Connector Note 1

MONI/REG BOARD ASSEMBLY Remove the PWB HOLDER Remove screws 2 (114) Note 1

6 OP UNIT Remove from the Frame Assy Remove screws 3 (117)

PART NAME

Fig

1-3-1

Fig

1-3-1

Fig

1-3-2

Fig

1-3-3

r MAIN CN4001

Remove the TOP COVER 2 (115)

n MAIN CN6601

p MAIN CN5501

m LCD MODULE (BL)

k MAIN CN3002

Remove from the Frame Assy

Remove from the LCD Holder Note 4

h MAIN CN501

c MAIN CN3001

d MON/REG TL9001

OPERATION UNIT 3 (116)

STROBE CN6501 1 (114) Note 2

JACK CN101 2 (114)

LCD MODULE (LCD) 2 (114)

OP UNIT

MON/REG CN9001

Frame Assy d (SD1)

POINTFIG. NO.

JACK CN701 e (SD3), f (SD4), g (SD5)

NOTE

Note 3

CONNEC- NO.OF

TOR/HL PINS

c

80 MAIN Board CN3001

d

e

g

h

k

m 2 JACK Board CN701

n

p 38 MAIN Board CN5501

q

s

u

v

w

x

1 MONI/REG Board TL9001

1 JACK Board TP3

f 1 JACK Board TP2

1 JACK Board TP1

22 MAIN Board CN501

j

2 MAIN Board CN502

24 MAIN Board CN3002

14 MAIN Board CN6601

28 MAIN Board CN2001

r 12 MAIN Board CN4001

STROBE UNIT WIRE (ORANGE)

1

t

STROBE UNIT WIRE (BROWN)

1

1 STROBE UNIT WIRE (RED)

STROBE UNIT WIRE (BLACK)

1

1

STROBE UNIT WIRE (Red, Thin wire) STROBE Board J6505 (Through hole)

STROBE UNIT WIRE (BLACK, Thin wire)

1

CONNECTION

MONI/REG Board CN9001

MAIN FRAME (RED)

MAIN FRAME (BROWN)

MONI/REG Board J9001 (BLACK)

MONI/REG Board J9002 (RED)

OP UNIT

OP UNIT

LCD MODULE (LCD)

LCD MODULE (BL)

STROBE Board CN6501

JACK Board CN101

CCD Board CN1001

OPERATION UNIT

STROBE Board J6501 (Through hole)

STROBE Board J6502 (Through hole)

STROBE Board J6503 (Through hole)

STROBE Board J6504 (Through hole)

STROBE Board J6506 (Through hole)

Note 1

Destination of connectors.

Note:

Three kinds of double-arrows in connection tables

respectively show kinds of connector/wires.

: Board to Board connector

: Flat wire

: Wire

Note 2

Be careful from electric shock hazard because the capacitor

(C6512) for the strobe is exposed. Be sure to positively discharge the capacitor if it is energized by short-circuiting a

resistor (10 - 22 k ) connected at both capacitor terminals.

Please be very careful when doing this job.

Note 3

Make sure that there is no slippage between the LCD panel

and the backlight, the four spots are locked with hooks

securely, and the sheet is placed in the correct direction.

Note 4

Both the stripe pattern and the non-slippage (notch) on the

sheet surface are to be in the direction as illustrated.

1-3

Page 9

116

110

C6512

2

s

116

2

u

v

157

116

2

L6501

x

w

t

153

111

D

1

155

r

2

STROBE

BOARD ASSY

< 05 >

G

114

115

2

3

115

H

E

r

G

F

n

n

1

E

114

1

JACK BOARD ASSY

< 04 >

F

E

MONI/REG BOARD ASSY

< 02 >

MAIN BOARD ASSY

< 01 >

H

152

D

G

H

154

1

156

1

1-4

LCDMODULE + BRAKLIGHT

WHITE WIRE

RED WIRE

LEFT LOW FOOT

HOLDER (LCD)

MAIN PWB

F

Fig.1-3-1

Remove screw marks

STEP 1

STEP 2

STEP 3

STEP 4

STEP 5

STEP 6

1

2

3

4

5

6

157

1

Page 10

Pass this through the inside of the boss.

d

101

117

6

MONI/REG BOARD ASSY

< 02 >

(SD1)

d

B

103

MAIN BOARD ASSY

< 01 >

c

114

6

117

A

p

3

F

m

e

(SD3)

f

(SD4)

g

(SD5)

JACK BOARD ASSY

< 04 >

C

e

OP BLOCK ASSY

<M3>

(SD2)

107B

107C

f

g

CCD BOARD ASSY

< 03 >

q

p

j

h

113

C

107A

106

114

5

A

108

105

109

h

q

j

B

114

4

k

104

114

5

107

m

k

Fig.1-3-2

1-5

Page 11

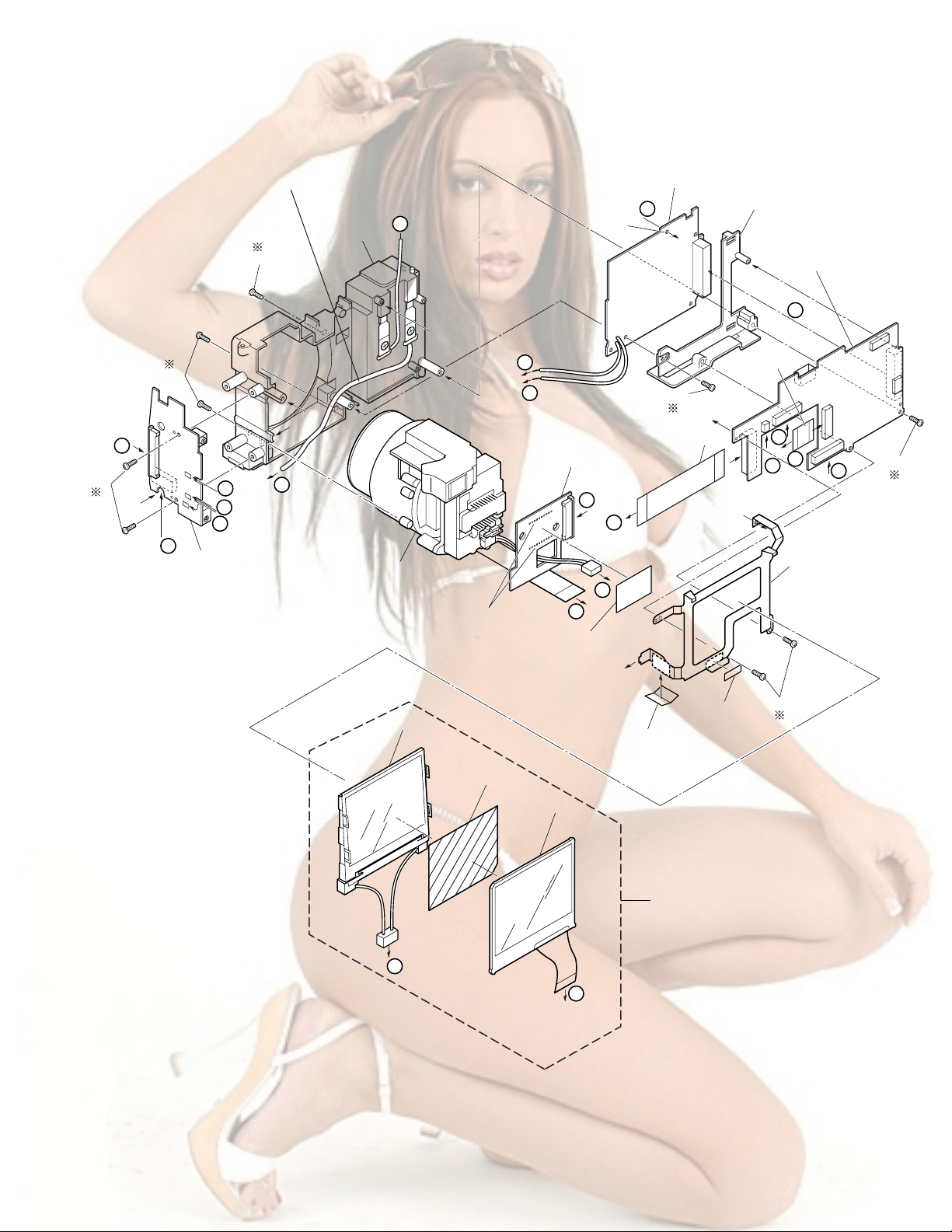

1.3.3 Disassembly method ( II ) <OP Unit>

STEP POINT

PART NAME

NOTE

1 OP Block ASSEMBLY Remove screws 3 (208)

2 COVER

Remove screws 3 (206),2 (207),

CCD BASE ASSEMBLY 1 (236)

SPACER Remove screws 3(206),2(207).

SET PLATE Remove the CCD Board Assy

20(SD1)

3 TILT FRAME Remove the SET RING Note 1

RATCH GEAR 2 (231) Note 2

MAIN PIN Note 3

4 RATCH MAGNET Remove Screws Note 4

NUT ASSEMBLY 3 (237),1 (236)

RATCH PIECE

Note 1

Turn and fix the set ring and make sure that the convex marks

are identical.

Note 2

Make sure that the torsion spring is in the groove of the

latch gear.

Note 3

Turn the latch gear clockwise ( ) and position it so that

the toothless portion comes to the level that is as high as

the main frame.

NOTE2

NOTE3

Note 4

Never move the setscrew in the

center of the nut assembly!

1

208

208

Remove screw marks

STEP 1

STEP 2

STEP 4

1

2

4

203

206

206

2

2

232

229

228

237

4

227

202

225

226

224

223

231

Fig. 1-3-3

221

234

234

236

222

230

4

233

204

237

231

4

SET SCREW

205

CCD Board Assembly

S2

207

SD1

1-6

Page 12

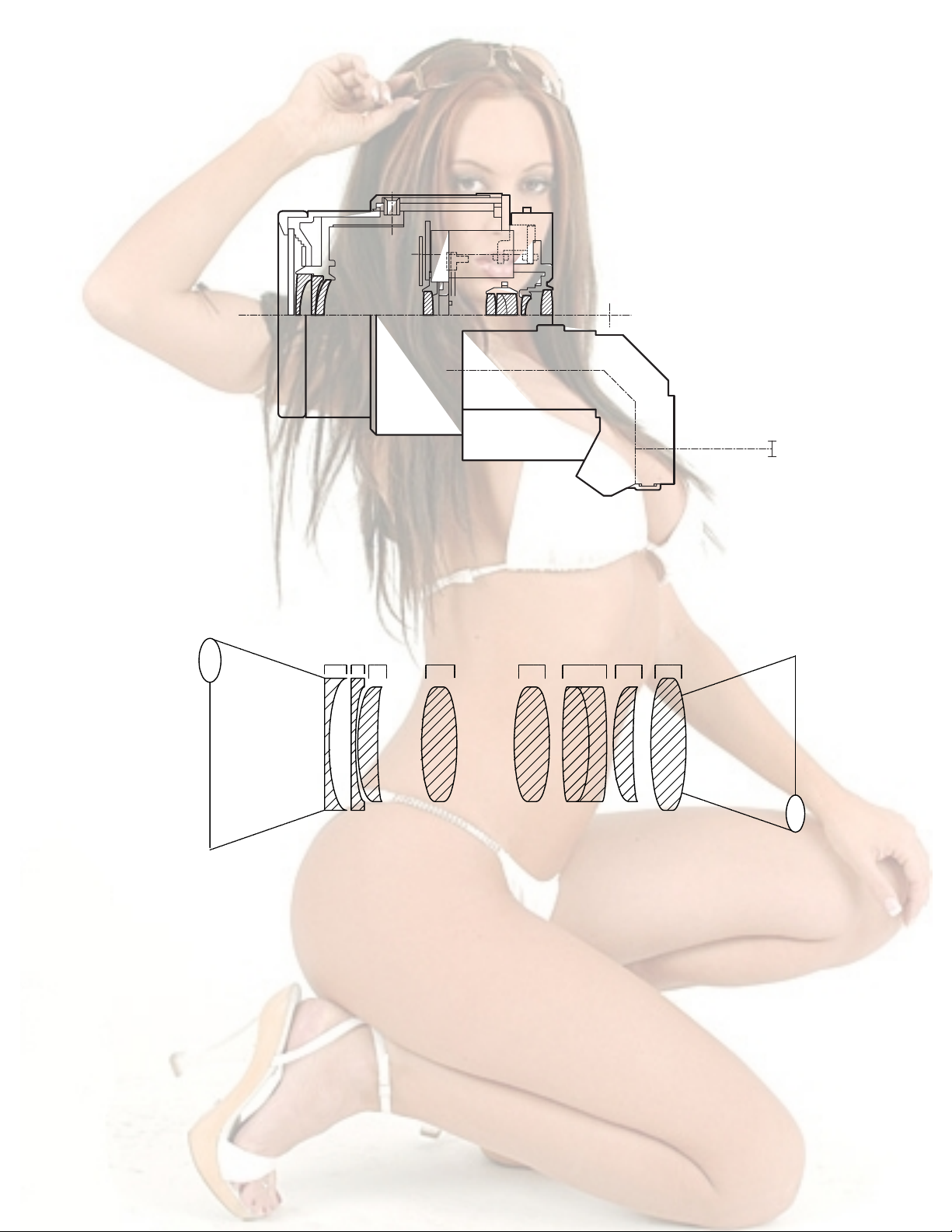

1.3.4 OP BLOK Lens Compositison

Fig. 1-3-4 Composition of GC-QX3U Lens (8-group 9-element lens composition)

2GROUP

1GROUP

3GROUP 4GROUP 5GROUP 6GROUP 7GROUP8GROUP

123 4 5 6 87 9

1.2.3...Condensing and focal length

Subject Image

5.6.7...Focal adjustment

7.8.9...Correction or compensation

Fig. 1-3-5 8-group-9-piece lens composition

1-7

Page 13

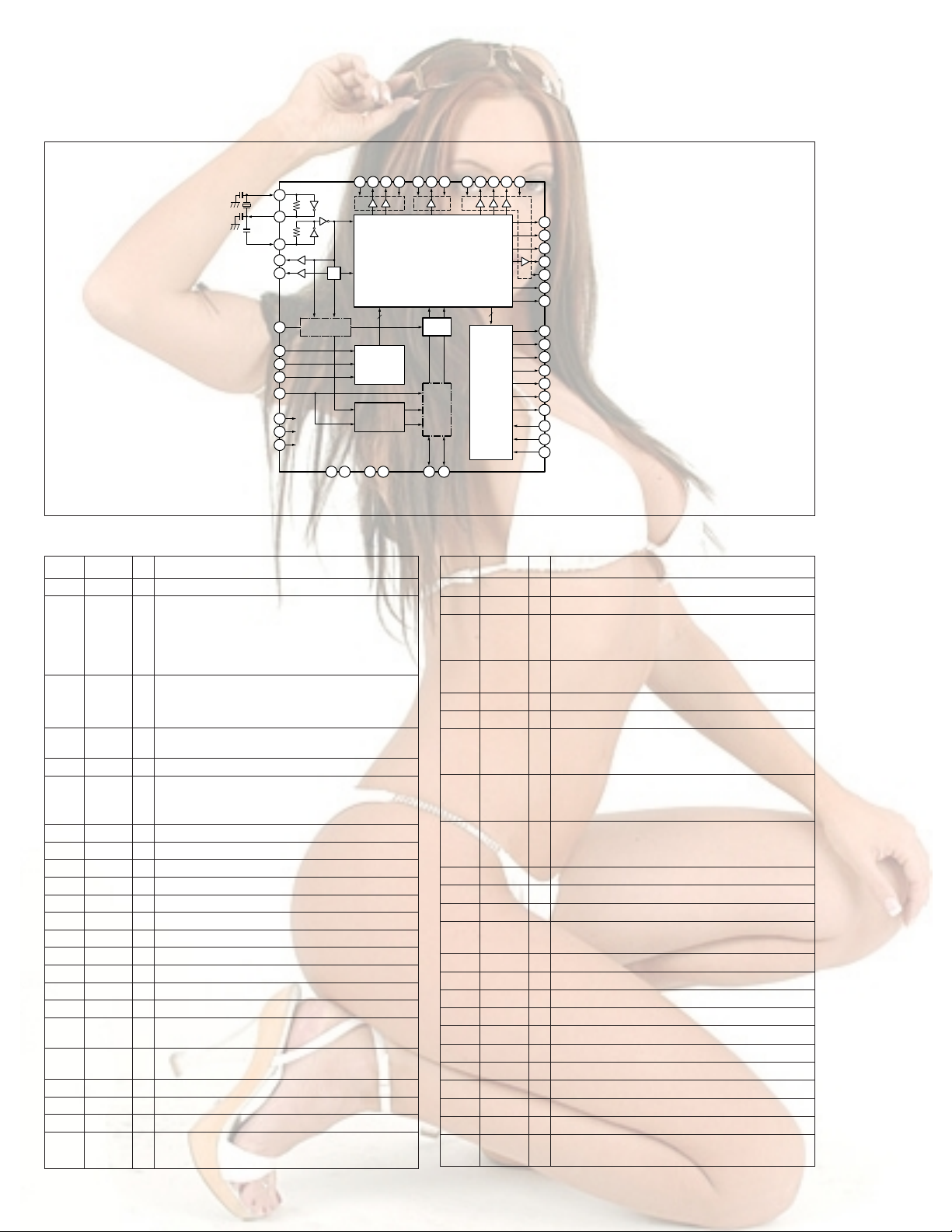

1.4 IC BLOCK DIAGRAM

1.4.1 IC 1002 (CXD2497R)

3

DD

V

OSCI

28

OSCO

27

CKI

26

25

CKO

MCKO

SNCSL

SSI

SCK

SEN

SSGSL

RST

TEST1

TEST2

30

3

31

32

33

6

2

37

48

Selctor

1/2

Register

SSG

1

5

1

SS

DD

DD

V

V

V

Pin Descriptions

Pin No. Pin Name I/O Description

1VSS1 - GND

2 RST I System reset input terminal H: Reset released L: Reset

activated

(Should be activated at power ON, normally.)

(Schmitt trigger input/without protection diode on power

supply side)

3 SNCSL I Sync system switching control input terminal

(with pull-down resistor)

H: CKI sync L: MCKO sync

4 ID O Line identification pulse output terminal in the vertical

direction

5 WEN O Memory write timing pulse output terminal

6 SSGSL I Built-in SSG enable input terminal (with pull-down

resistor)

H: Built-in SSG is effective. L: External sync is effective.

7VDD1 - 3.3V power (for common logic section)

8VDD2 - 3.3V power (for RG terminal)

9 RG O Reset gate pulse output terminal for CCD

10 VSS2 - GND

11 VSS3 - GND

12 H1 O Clock output terminal for CCD horizontal register

13 H2 O Clock output terminal for CCD horizontal register

14 VDD3 - 3.3V to 5.0V power (for H1 and H2 terminals)

15 VDD4 - 3.3V power (for CDS system terminals)

16 XSHP O CCD pre-charge level sample/hold pulse output terminal

17 XSHD O CCD data level sample/hold pulse output terminal

18 XRS O Sample/hold pulse output terminal for phase matching in

analog-to-digital conversion

19 PBLK O Pulse output terminal for pulse cleaning during

horizontal and vertical blanking period

20 CLPDM O Pulse output terminal for CCD dummy signal clamping

21 VSS4 - GND

22 OBCLP O Pulse output terminal for CCD optical black signal

23 ADCLK O Clock output terminal for analog-to-digital conversion IC

Logical phase is adjustable with the serial interface data

H1H2V

11

5

SS

V

2

3

DD

SS

RG

V

Pulse Generator

Latch

35361297

HD

2

SS

V

Selector

34

VD

4

DD

V

XSHP

V Driver

XSHD

181716151098 21131214

XRS

4

SS

V

19

PBLK

CLPDM

20

22

OBCLP

23

ADCLK

24

V

SS

5

4

ID

5

WEN

41

V1A

43

V1B

39

V2

44

V3A

46

V3B

40

V4

47

SUB

VH

42

VM

38

VL

45

24 VSS5 - GND

25 CKO O Inverter output terminal

26 CKI I Inverter input terminal

27 OSCO O Inverter output terminal for oscillation (If not used,

should be opened or connected to GND through a

capacitor.)

28 OSCI I Inverter input terminal for oscillation (If not used, should

be fixed to "Low".)

29 VDD5 - 3.3V power (for common logic section)

30 MCKO O System clock output terminal for signal processing IC

31 SSI I Serial interface data input terminal for setting each IC

mode (Schmitt trigger input/without protection diode on

power supply side)

32 SCK I Serial interface clock input terminal for setting each IC

mode (Schmitt trigger input/without protection diode on

power supply side)

33 SEN I Serial interface strobe input terminal for setting each IC

mode (Schmitt trigger input/without protection diode on

power supply side)

34 VD I/O Vertical sync signal input/output terminal

35 HD I/O Horizontal sync signal input/output terminal

36 VSS6 - GND

37 TEST1 I IC test terminal 1 with pull-down resistor (Should be

fixed to GND normally.)

38 VM - GND (for vertical drivers)

39 V2 O Clock output terminal for CCD vertical register

40 V4 O Clock output terminal for CCD vertical register

41 V1A O Clock output terminal for CCD vertical register

42 VH - 15.0V power (for vertical drivers)

43 V1B O Clock output terminal for CCD vertical register

44 V3A O Clock output terminal for CCD vertical register

45 VL - -7.5V power (for vertical drivers)

46 V3B O Clock output terminal for CCD vertical register

47 SUB O Pulse output terminal for CCD electronic shutter

48 TEST2 I IC test terminal 2 with pull-down resistor (Should be

fixed to GND normally.)

1-8

Page 14

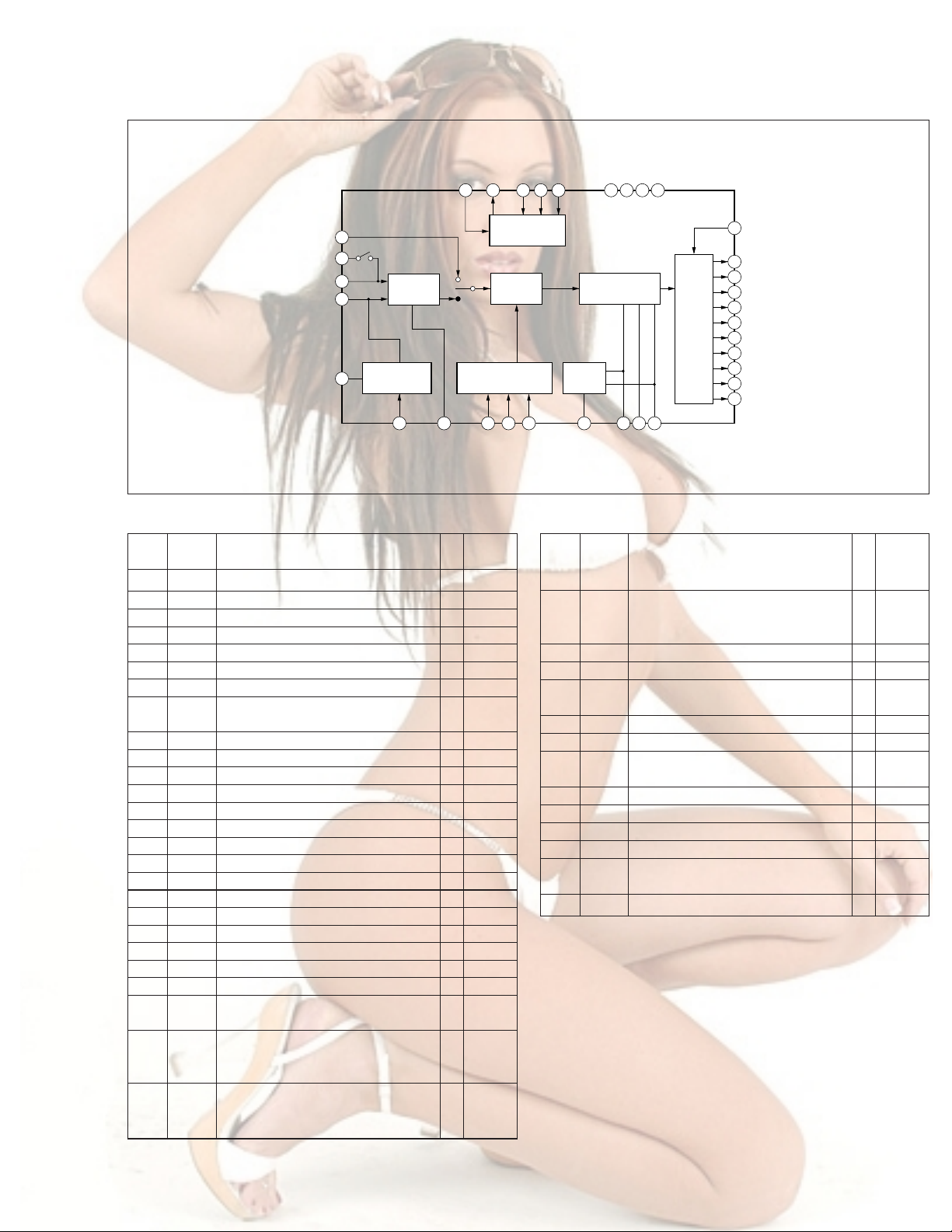

1.4.2 IC 2001 (CDS/AGL)

OADSW

OADCLK

13 16 18 19

21

ADCLK

SPBLK

SPSIG

41

AVDDDVDD

46

AVSS

DVSS

40

48

27

ADCIN

25

CDSSW

26

CDSIN

BLKSH

BLKFB

28

29

CDS PGA

DC offset

compensatory

17

20

OBP

PBLK

Pin Descriptions

Pin No. Pin Name Description I/O

Analog (A) or

1 NC No internal connection - 2 D0 Digital output terminal (LSB) O D

3-10 D1-D8 Digital output terminals O D

11 D9 Digital output terminal (MSB) O D

12 NC No internal connection - 13 OADCLK Latch clock output terminal for D0 to D9 O D

14 DVSS Digital GND (0V) - D

15 DV

DD Power for digital 3.0V system - D

(Should be connected to AVDD outside the IC.)

16 ADCLK Analog-to-digital conversion clock input terminal I D

17 OBP Optical black pulse input terminal I D

18 SPBLK Black level sampling clock input terminal I D

19 SPSIG Signal level sampling clock input terminal I D

20 PBLK Pre-blanking signal input terminal I D

21 OADSW OADCLK enable input terminal I D

22 AVSS Analog GND (0V) - A

23 AVDD Power for analog 3.0V system - A

24 NC No internal connection - 25 CDSSW Signal level sampling output terminal O A

26 CDSIN CDS input terminal I A

27 ADCIN ADC input terminal I A

28 BLKSH Black level sample/hold terminal - A

29 BLKFB Black level feedback terminal - A

30 AVSS Analog GND (0V) - A

31 AV

DD Power for analog 3.0V system - A

(Should be connected to DVDD outside the IC.)

32 VRT Reference voltage terminal 3 - A

(Ceramic capacitor of 0.1µF or more should be

connected between this terminal and AVss.)

33 VRB Reference voltage terminal 2 - A

(Ceramic capacitor of 0.1µF or more should be

connected between this terminal and AVss.)

Serial

Interface

44

SCK

Digital (D)

TIMING

gen

43CS45

SDATA

Bias

Occurrence

35

BIAS

10bit

ADC

33

Output

32

34

VRT

VRB

VRM

Latch

circuit

42 OEB

11 D9

10 D8

9D7

8D6

7D5

6D4

5D3

4D2

3D1

D0

2

34 VRM Reference voltage terminal 1 - A

(Ceramic capacitor of 0.1µF or more should

be connected between this terminal and AVss.)

35 BIAS Internal bias terminal - A

(A 24-Kohm resistor should be connected

between this terminal and AVss.)

36 NC No internal connection - 37 AVSS Analog GND (0V) - A

DD Power for analog 3.0V system - A

38 AV

(Should be connected to DVDD outside the IC.)

39 NC No internal connection - 40 AVSS Analog GND (0V) - A

41 AVDD Power for analog 3.0V system - A

(Should be connected to DVDD outside the IC.)

42 OEB Digital output enable control input terminal I D

43 CS Serial interface control input terminal I D

44 SCK Serial clock input terminal I D

45 SDATA Serial data input terminal I D

46 DV

DD Power for digital 3.0V system - D

(Should be connected to AVDD outside the IC.)

47,48 DV

SS Digital GND - D

1-9

Page 15

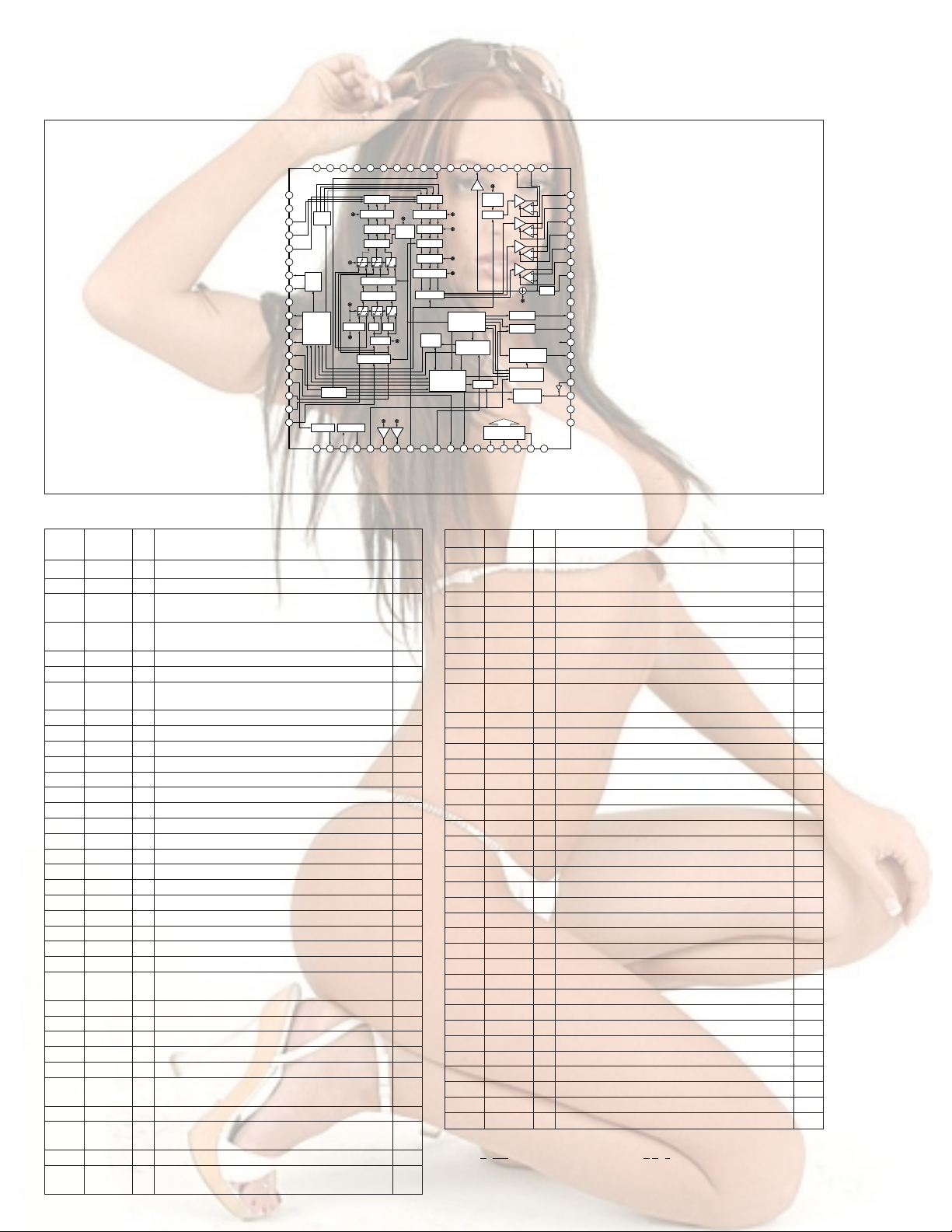

1.4.3 IC 7302 (CXA3268AR)

VSSVSSTST10

TST9

51 38 37

V

SSVSS

+3.0V

55

V

TST11

OSD B

OSD R

OSD G

HCK1

HCK2

VCC1

FIL IN

B/B-Y

R/R-Y

DD

56

S/H

GEN

57

58

59

60

NC

61

HCK

GEN

62

+3.0V

63

64

HST

HCOUNTER

HPULSE

65

EN

GEN

66

VCK

67

VST

67

RGT

69

70

71

G/Y

72

H.FILTER SYNC SEP

SS

V

SS

V

MODE

FIL OUT

MODE

PIC-G

PIC-F

CONT

SYNC IN

OSD RGB

CONTRAST

GR

CLAM[P

SYNC OUT

Pin Descriptions

Pin No. Pin Name I/O Description

1 Vss - GND terminal for digital 3.0V system

2 FIL OUT O H filter output terminal (for internal sync separator use)

3 SYNC IN I Sync input terminal for sync separator circuit

(for internal sync separator use)

4

SYNC OUT

O Sync output terminal for sync separator circuit

(for internal sync separator use)

5

CSYNC/HD

I CSYNC/horizontal sync signal input terminal

6 DA OUT O DAC output terminal

7 REF O Level shifter circuit reference voltage output terminal for

LCD panel

8 F ADJ O f0 adjust resistor connecting terminal for TRAP

9 GND1 - GND terminal for analog 3.0V system

10 VD I Vertical sync signal input terminal

11 DWN O Up/Down switching signal output terminal

12 WIDE O 16:9 wide display switching pulse output terminal

13 TST1 - Test terminal (Should be opened.)

14 SCK I Serial clock input terminal

15 SEN I Serial load input terminal

16 SDAT I Serial data input terminal

17 R INJECT O Resistor connecting terminal for serial block current control

18 VSS - GND terminal for digital 3.0V system

19 VDD - Power for digital 3.0V system

20 VDD - Power for digital 3.0V system

21 CKO O Oscillation cell output terminal

22 CKI I Oscillation cell input terminal

23 Vss - GND terminal for digital 3.0V system

24 RPD O Phase comparison output terminal

25 XCLR I Capacitor connecting terminal for power-on reset (for

timing generating system)

26 VDO O VDO pulse output terminal

27 HDO O HDO pulse output terminal

28 TST2 - Test terminal (Should be connected to GND.)

29 GND2 - GND terminal for analog 12.0V system

30 SIG.C I DC voltage adjust terminal for R, G, B and PSIG outputs

31 B DC DET O Capacitor connecting terminal for B signal's DC voltage

feedback circuit

32 B OUT O B signal output terminal

33 R DC DET O Capacitor connecting terminal for R signal's DC voltage

feedback circuit

34 R OUT O R signal output terminal

35 G DC DET O Capacitor connecting terminal for G signal's DC voltage

feedback circuit

1-10

TST8

TRAP

LPF

CLAMP

MATRIX

DL1PICTURE

HUE

SYNC/HD

TST7

DL1

COLOR

DA

Buf Buf

DA OUT

FILTER

FILTER

B

BGR

HUE

CLP

REF

Input

TST6

LPF

BIAS

REF

Res.

L

H

TST5NCPOF

S/H

USER-BRIGHT

GAMMAM

CLAMP

BLK-LIM

SUB-BRIGHT

POL SW

PULSE

ELM

V COUNTER

GND1

F ADJ

GND1

U-GRT

γ1γ2

WHITLIM

SUB-CONT R

SUB-CONT B

BLKLIM

SUB-BRT R

SUB-BRT B

VD

TST4

GND3

COUNTER

V CONTROL

V POSITION

DWN

GND3

COM

Buf

PLL

V SEP

TST1

WIDE

3

CC

V

+12.0V +12.0V

PSIGBRT

PSIGBRIGHT

POL SW

S/P CONV

REGISTER DAC

SCK

TST3

394041424344454647484950525354

Buf

Buf

Buf

Buf

COM-DC

HDO GEN

VDO GEN

COMPARATOR

HSYNC DET

H SKEW DET

CLK

1615141312111098765321 4 17 18

SEN

PSIG OUT

PHASE

CK

CONTROL

SDAT

2

CC

PSIG DC DET

V

SIG.C

MCK

V

SS

SS

V

R INJECT

+3.0V

+3.0V

GND2

V

36

G OUT

35

G DC OUT

34

R OUT

33

R DC DET

32

B OUT

31

B DC DET

30

SIG. C

29

GND2

28

TST2

27

HDO

26

VFO

25

XCLR

24

RPD

23

SS

SS

V

22

CKI

21

CKO

20

DD

V

19

V

DD

36 G OUT O G signal output terminal

37 VCC2 - Power for analog 12.0V system

38 PSIG DC O Capacitor connecting terminal for G signal's DC voltage

DET feedback circuit

39 PSIG OUT O PSIG output terminal

40 TST3 - Test terminal (Should be opened.)

41 VCC3 - Power for analog 12.0V system COM (CS)

42 COM O

Common electrode voltage output terminal (CS) for LCD panel

43 GND3 - GND terminal for analog 12.0V system COM (CS)

44 TST4 - Test terminal (Should be opened.)

45 POF O LCD panel power ON/OFF terminal

(Open, if this function is not used.)

46 NC - No internal connection

47 TST5 - Test terminal (Should be connected to GND.)

48 TST6 - Test terminal (Should be connected to GND.)

49 TST7 - Test terminal (Should be opened.)

50 TST8 - Test terminal (Should be opened.)

51 TST9 - Test terminal (Should be opened.)

52 TST10 - Test terminal (Should be opened.)

53 VSS - GND terminal for digital 3.0V system

54 VSS - GND terminal for digital 3.0V system

55 VDD - Power for digital 3.0V system

56 TST11 - Test terminal (Should be connected to GND.)

57 OSD B I OSD B input terminal

58 OSD R I OSD R input terminal

59 OSD G I OSD G input terminal

60 NC - No internal connection

61 HCK1 O H clock pulse 1 output terminal

62 HCK2 O H clock pulse 2 output terminal

63 VCC1 - Power for analog 3.0V system

64 HST O H start pulse output terminal

65 EN O EN pulse output terminal

66 VCK O V clock pulse output terminal

67 VST O V start pulse output terminal

68 RGT O Right/Left switching signal output terminal

69 FIL IN I H FILTER input terminal (for internal sync separator use)

70 B/B-Y I B/B-Y signal input terminal

71 G/Y I G/Y signal input terminal

72 R/R-Y I R/R-Y signal input terminal

DOWN SCAN and UP SCAN RGT: RIGHT SCAN and LEFT SCAN

* DWN:

H: Pull-up resistor incorporated L: Pull-down resistor incorporated

Page 16

1.4.4 LCD (ACX301AK)

BGRBRG

RBGRGB

RBGRGB

BGRBRG

RBGRGB

V shift register

COM

V Level shifter

Electrode

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

TESTL

Pin Descriptions

Pin No. Pin Name Description

1 TESTL Panel testing terminal (Should be opened.)

2 COM Common electrode voltage input terminal for panel

3 VST Start pulse input terminal for V shift register drive

4 VCK Clock input terminal for V shift register drive

5 EN Enable signal input terminal for gate select pulse

6 DWN Drive direction signal input terminal for V shift register

7VVDD Power for V driver

8VSS GND for H and V drivers

9HVDD Power for H driver

10 VSSG Negative voltage setting terminal for V driver

11 TEST2 Connected to GND through a 1-Mohm resistor in the panel

12 WIDE Pulse input terminal for 16:9 mode

13 HST Start pulse input terminal for H shift register drive

14 REF Level shifter circuit reference voltage input terminal

15 TEST Panel testing terminal (Should be opened.)

16 Cext/Rext Power input terminal for setting H shift register drive time

constant

17 HCK2 Clock input terminal for H shift register drive

18 HCK1 Clock input terminal for H shift register drive

19 PSIG Uniformity improving signal input terminal

20 GREEN Video signal (G) input terminal for the panel

21 RED Video signal (R) input terminal for the panel

22 BLUE Video signal (B) input terminal for the panel

23 RGT Drive direction signal input terminal for H shift register

24 TESTR Panel testing terminal (Should be opened.)

COM

EN

VST

VCK

H Level shifter & Shift register

Negative

Voltage

Occurence

Circuit

VSS

DWN

VVDD

HVDD

COM

LCCs

HST

VSSQ

TEST2

WIDE

REF

TEST

HCK2

Cext/Rext

HCK1

PSIG

GREEN

RED

BLUE

RTG

TESTR

Features

• Device Structure

- Active matrix panel with internal driver using lowtemperature polysilicon transistors

- Pixels

Total dots: 896 (H) x 230 (V) =206,080

Display dots: 880 (H) x 228 (V) =200,640 (2.0 in.)

• Total dots: 200,000 dots 5.1cm diagonal (2.0 in.)

• Horizontal resolution: 440 TV scanning lines

• Light permeability: 5.6% (standard)

• Smooth screen image with RGB delta array

• NTSC/PAL compatible

• High image quality internal circuitry

• 16:9 screen display function

• Low-reflection screen display processing assures easy

viewing even outdoors

• Anti-grime display

Delta array

1-11

Page 17

1.4.5 CCD (ICX262AQ)

OUT

V

GND

TEST

10

9

8

Gb

Gb

Gb

Vertical register

11

12

13

ØRG

Ø2

H

DD

V

Pin Descriptions

Pin No. Pin Name Description

1Vø4 Vertical register transfer clock

2Vø3A Vertical register transfer clock

3Vø3B Vertical register transfer clock

4Vø2 Vertical register transfer clock

5Vø1A Vertical register transfer clock

6Vø3B Vertical register transfer clock

7 TEST Test terminal*

8 TEST Test terminal*

1

1

9 GND GND

10 VOUT Signal output

11 VDD Circuit power

12 øRG Reset gate clock

13 Hø2 Horizontal register transfer clock

14 Hø1 Horizontal register transfer clock

15 GND GND

16 øSUB PCB clock

17 CSUB PCB bias*

2

18 VL Protection transistor bias

19 Hø1 Horizontal register transfer clock

20 V

ø2 Horizontal register transfer clock

*1: Terminal should be opened.

*2: A 0.1µF capacitor should be connected between the pin and GND, since the

DC bias is generated inside the CCD.

Ø1B

TEST

V

7

6

B

R

R

R

14

Gr

B

Gr

B

Gr

Horizontal register

15

Ø1

H

GND

Ø1A

Ø2

Ø3B

Ø3A

Ø4

V

V

2

1

(NOTE)

(NOTE)

19

20

Ø1

Ø2

H

H

: Photo Sensor

5

16

V

ØSUB

V

V

4

3

Gb

R

Gb

R

Gb

Gb

17

SUB

C

B

Gr

B

Gr

B

Gr

18

L

V

Features

• Field period readout system

• Interline CCD image sensor

• Total number of pixels: 2140 (H) x 1560 (V) approx. 3340k

pixels

• Number of effective pixels: 2088 (H) x 1550 (V) approx.

3240k pixels

• Effective number of pixels: 2080 (H) x 1542 (V) approx.

3210k pixels (1.18in)

• Chip size: 8.10mm (H) x 6.64mm (V)

• Unit cell size: 3.45m␣ m (H) x 3.45m␣ m (V)

• Optical black:

Horizontal (H) direction : front 4 pixels, rear 48 pixels

Vertical (V) direction : front 8 pixels, rear 2 pixels

• Number of dummy bits: Horizontal 28 Vertical 1 (even fields

only)

• Square pixels

• Horizontal drive frequency: 18kHz

• RGB basic color mosaic on-chip color filter

• High sensitivity

• Cyclic, variable speed shutter

• Excellent anti-blooming characteristics

1pin

2

1-12

V

4

11pin

H

48

Optical black wiring diagram

(Top View)

8

Page 18

SECTION 2

910

Light box assembly

YTU93096A

Gray scale chart

YTU94133A

Cleaning cloth

KSMM-01

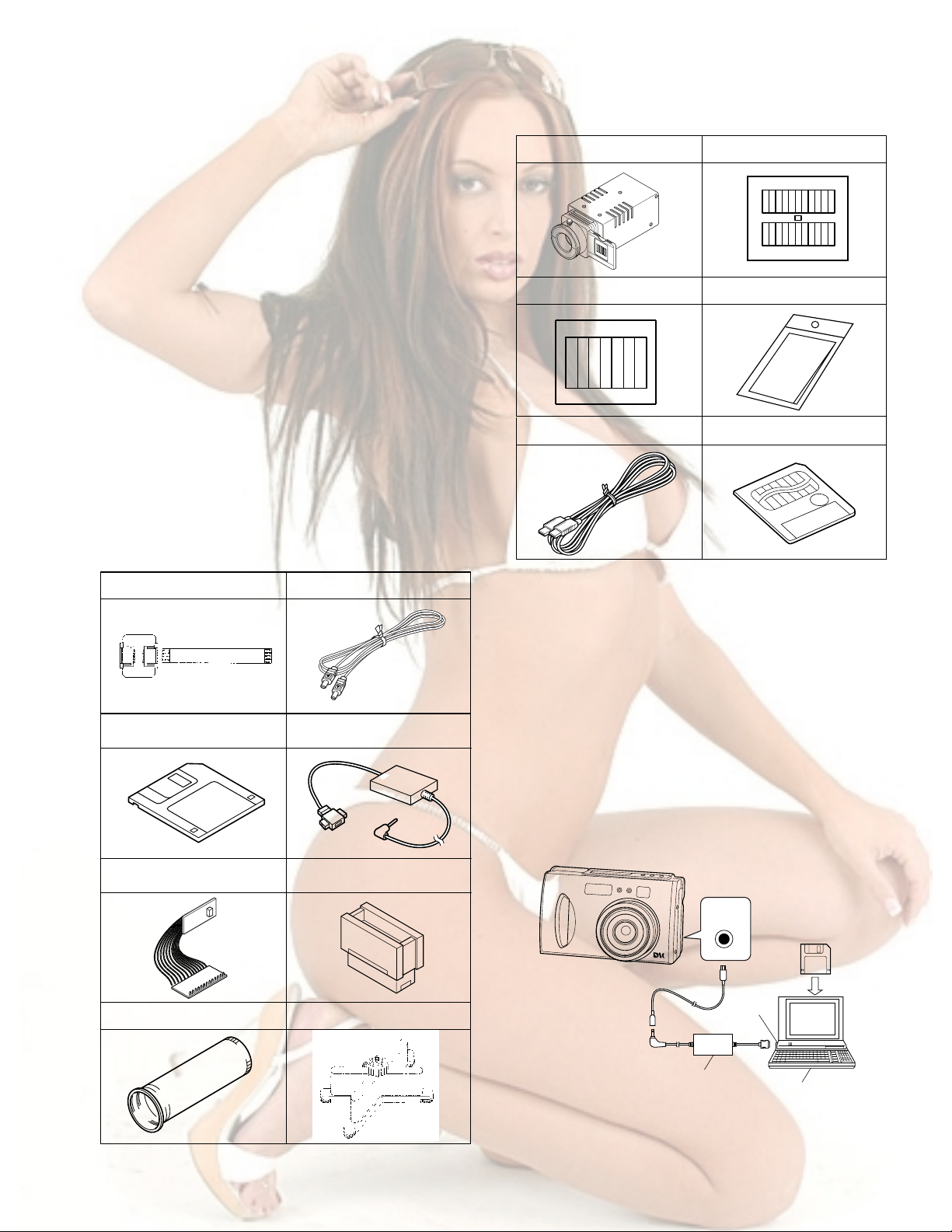

11

Color bar chart

YTU94133C

12

Smart media card

16MB

13

USB

QAM0252-001

14

ELECTRICAL ADJUSTMENT

2.1 ELECTRICAL ADJUSTMENT

2.1.1 Precautions

Both the camera section and deck section of this model

are designed and manufactured to be adjustment-free.

However, if both or either of the following parts is replaced,

it needs special adjustment with a personal computer at a

JVC service equipment after the part replacement

• OP block assembly

• EEPROM (on the MAIN board)

When there is some trouble in the electric circuit, it is required

to detect the faulty part with specified test instruments first

and then to proceed to repair, replacement and adjustment.

1. When cheking a signal at a chip test point, be sure to use

an IC clip or the like not to apply any stress to the test point.

When replacing a chip part (IC in particular), completely

remove solder chips from it and its periphery before

proceeding to part replacement (in order to avoid exfoliation

of the pattern).

2. Carefully disconnect/connect connectors because they

are apt to get damaged.

2.1.2 Test instruments required for electrical

adjustment

12

34

5

Patch cord

YTU93099A

Service support system

YTU94057-47

Jig connector cable

YTU93091B

Jig connector cable

YTU93102A

QAM0099-002

Extension connector

6

PC cable

YTU94145A

2.1.3 Required test equipment

1. Color TV monitor.

2. AC power adapter (AA-V37 or equivalent)

3. Oscilloscope (dual-trace type, for more than 20 MHz).

4. Digital voltmeter

5. Frequency counter (with threshold level adjuster)

6. Personal computer

2.1.4 Setup (LCD ADJUSTMENT)

Setup for electrical adjustment with personal computer

Note 1:

As a general rule for adjustment with a personal

computer, connect a personal computer to its

PRINTER terminal.

Note 2:

Use DC cord to supply the power.

PRINTER

Service support system

YTU94057-47

INF adjustment lens

78

YTU92001B

Camera stand

YTU93079

RS-232C

PC cable

QAM0099-002

port

MENU

Personal computer

Fig. 2-1-1 Setup for electrical adjustment with

personal computer (I)

2-1

Page 19

Extension connector

Note) It is needs to connect

the extension

double for use the DC

cord(coupler)

Jig connector cable

(YTU93091B)

Fig. 2-1-2 Setup for electrical adjustment with

personal computer (II)

connector

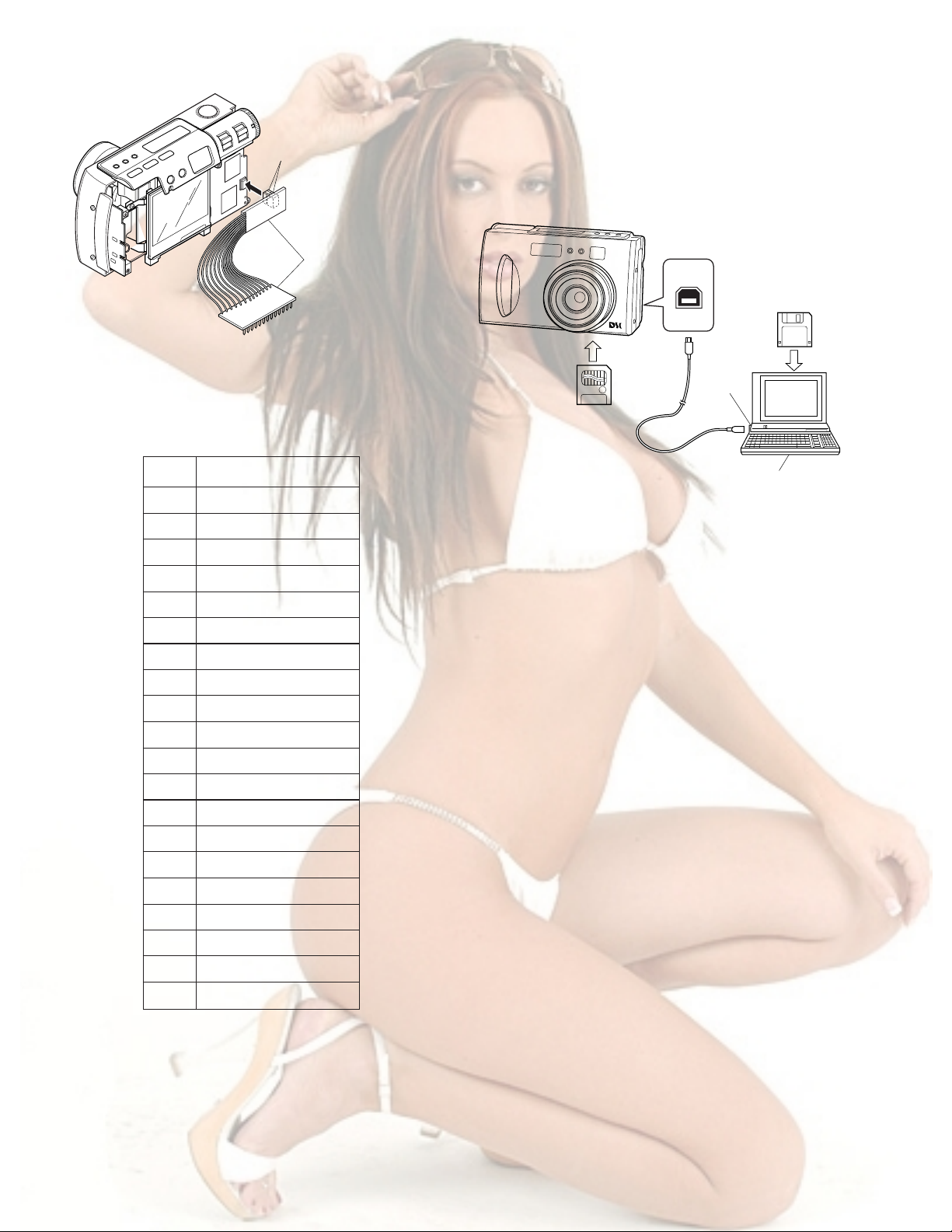

2.1.5 Setup (CCD ADJUSTMENT)

Setup for electrical adjustment with personal computer

Note 1:

As a general rule for adjustment with a personal

computer, connect a personal computer to its

DIGITAL terminal.

Note 2:

Use DC cord to supply the power.

USB

USB

port

16MB

Smart media

Card

Service support system

YTU94057-47

MENU

Pin No. FUNCTION

1 135TMS

2 135TDI

3 nTRST

4 AL_3.3V

5 32DBI

6 GND

7 M_COM

8 M_SIG_C

9 M_RED

10 M_SIG_GND

11 JTAGMODE

12 135TDO

13 135TCK

14 AL_3.3V

15 32RST

16 M_BLUE

17 RPD

18 M_PSIG

19 M_GREEN

20 NC

Personal computer

Fig. 2-1-3 Setup for electrical adjustment with

personal computer (I)

2-2

Table 2-1-1 Jig Connector Function

Page 20

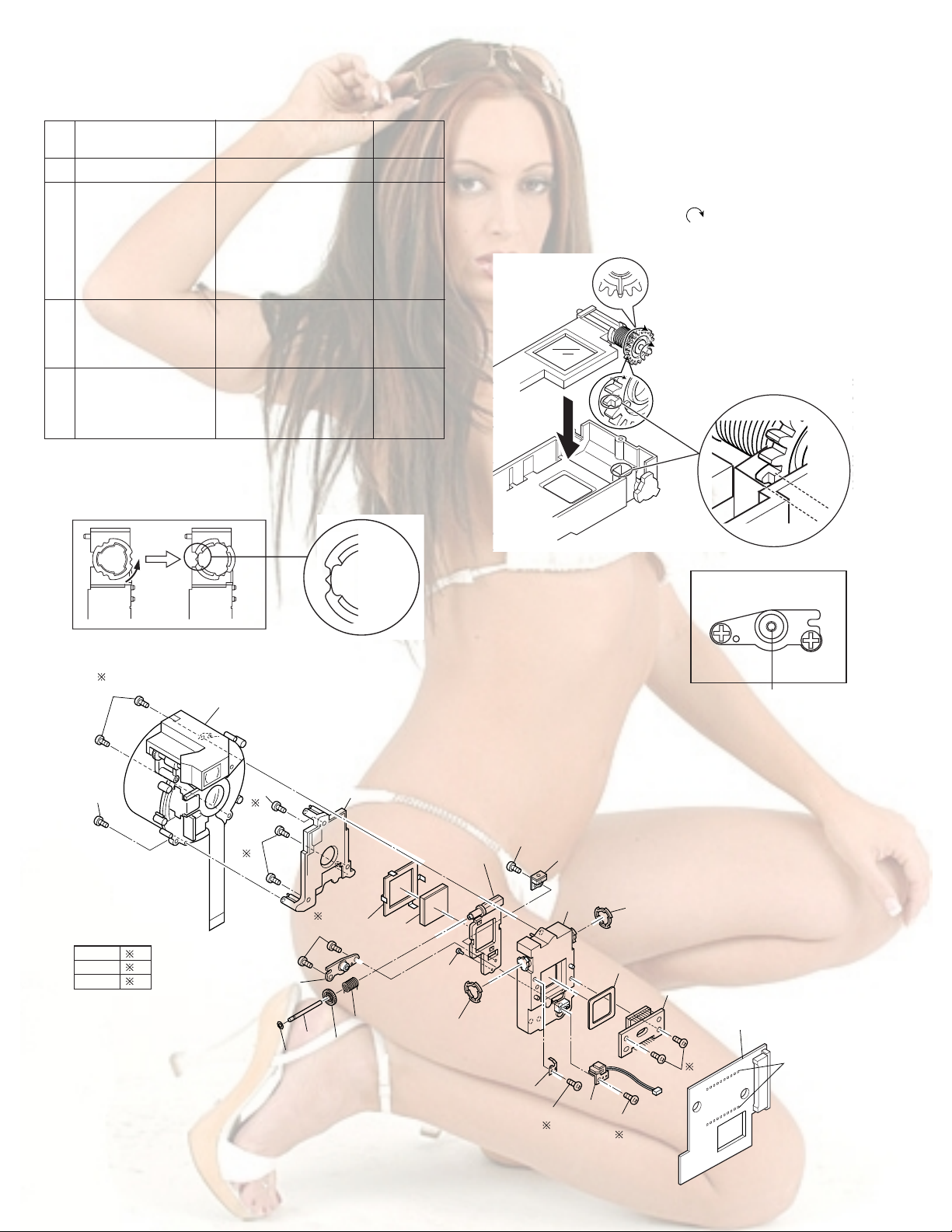

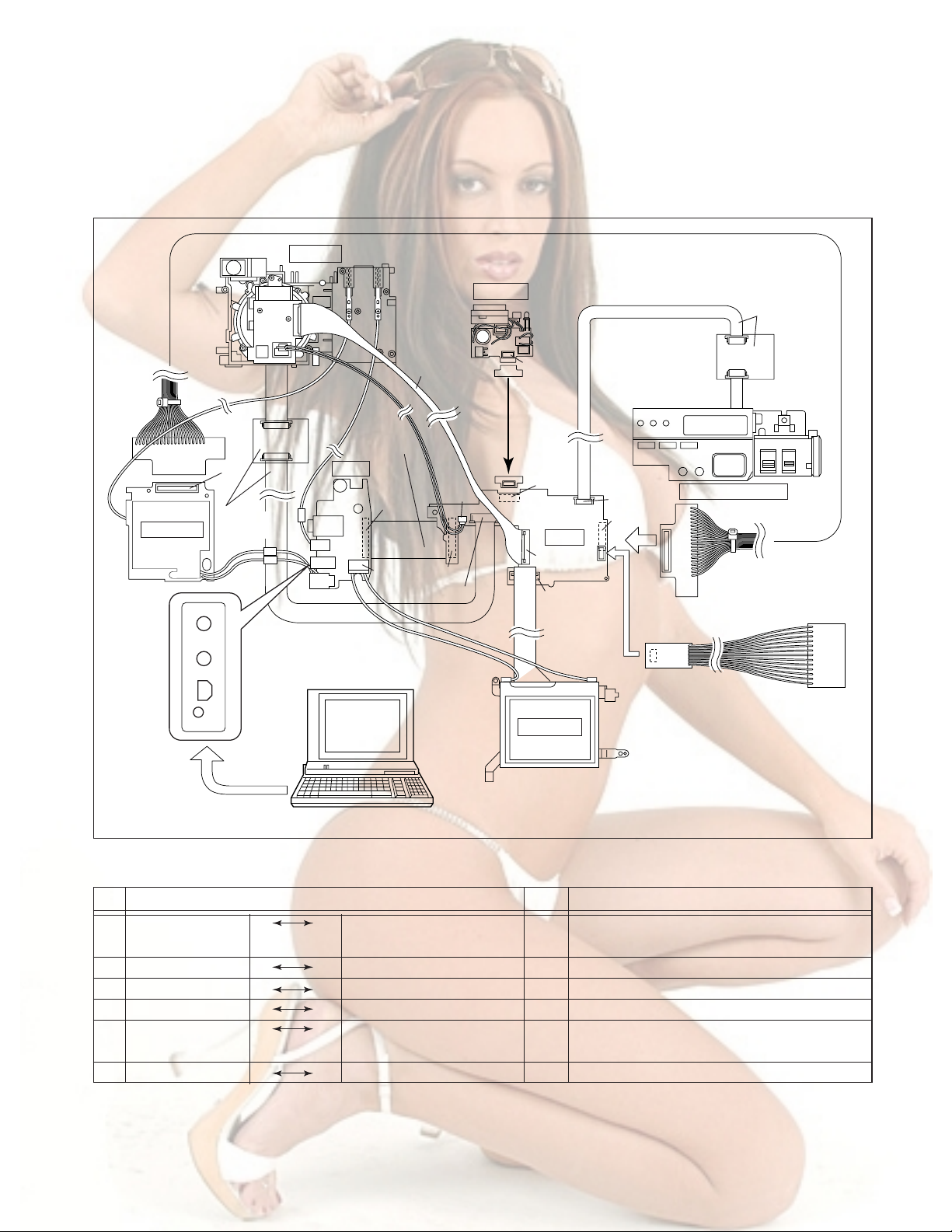

2.2 Setup with patch cords and jig connector cables

Note:

Fig. 2-2-1 shows an example of expansion setup that facilitates inspection of major boards because main components are

connected by means of patch cords and jir cables.For proceeding to electrical adjustment in such the setup, disassemble the

set at certain level required for the current adjustment objectives referring to the section 1 "DISASSEMBLY" and properly set

up the expanded set and test instruments.

OP/CCD

MON/REGMON/REG

PRINTER

DIGITAL

VIDEO

CN9001

DC

5V

5

YTU94077-22

YTU94071-22

4YTU94077-38

JACK

CN101

CN7101

MENU

3YTU94077-28

CN502

CN5501

CN501

STROBE

CN6501

CN6601

MAIN

CN2001

CN3002

MONITOR

CN4001

CN2002

YTU94077-12

1

YTU94074-12

OPERATION UNIT

2YTU94126B-80

6YTU63091B

Personal computer

Fig. 2-2-1

Connection

Pin No. Parts Number

1 MAIN CN4001 OPRATION UNIT 12 YTU94077-12 FPC wire

YTU94074-12 FPC CN.ASSY

2 MAIN MON/REG CN9001 80 YTU94126B-80 B TO B CN.ASSY

3 MAIN CN2001 CCD CN1001 28 YTU94077-28 FPC wire

4 MAIN CN5501 JACK CN101 38 YTU94077-38 FPC wire

5 MAIN CN501 OPUNIT 22 YTU94077-22 FPC wire

YTU94074-22 FPC CN.ASSY

6 MAIN CN2202 20 YTU93091B JIG CN.cable

2-3

Page 21

Page 22

JVC SERVICE & ENGINEERING COMPANY OF AMERICA

DIVISION OF JVC AMERICAS CORP.

Head office

East Coast

Midwest

West Coast

Atlanta

Hawaii

Head office

Montreal

Vancouver

1700 Valley Road Wayne, New Jersey 07470-9976

:

10 New Maple Avenue Pine Brook, New Jersey 07058-9641

:

705 Enterprise Street Aurora, Illinois 60504-8149

:

5665 Corporate Avenue Cypress, California 90630-0024

:

1500 Lakes Parkway Lawrenceville, Georgia 30043-5857

:

2969 Mapunapuna Place Honolulu, Hawaii 96819-2040

:

JVC CANADA INC.

:

21 Finchdene Square Scarborough, Ontario M1X 1A7

:

16800 Rte Trans-Canadienne, Kirkland, Quebec H9H 5G7

:

13040 Worster Court Richmond, B.C. V6V 2B3

(973)315-5000

(973)396-1000

(630)851-7855

(714)229-8011

(770)339-2582

(808)833-5828

(416)293-1311

(514)871-1311

(604)270-1311

S40895-03

Printed in Japan

Page 23

DIGITAL STILL CAMERA

GC-QX3

ENGLISH

STILL CAMERA

INSTRUCTIONS

For Customer Use:

Enter below the Model No. and Serial

No. which is located on the bottom of

cabinet. Retain this information for

future reference.

Model No.

Serial No.

LYT0543-001C

Page 24

2 EN

Dear Customer,

Thank you for purchasing the Digital Still

Camera. Before use, please read the safety

information and precautions contained in the

following pages to ensure safe use of your new

Digital Still Camera.

Using This Instruction Manual

• All major sections and subsections are listed in the

Table Of Contents (Z pg. 8, 9).

• Notes appear after most subsections. Be sure to read

these as well.

• Basic and advanced features/operation are separated

for easier reference.

It is recommended that you . . .

..... refer to “CONTROLS, CONNECTORS AND

INDICATORS” (Z pg. 10 – 17) and

familiarize yourself with button locations, etc.

before use.

..... read thoroughly the Safety Precautions and Safety

Instructions that follow. They contain extremely

important information regarding the safe use of

your new Digital Still Camera.

You are recommended to carefully read the

cautions on pages 89 – 91 before use.

SAFETY

PRECAUTIONS

The AA-V37 AC Power Adapter should be used

with:

AC 120 V`, 60 Hz in the USA and Canada,

AC 110 – 240 V`, 50/60 Hz in other countries.

CAUTION (applies to the AA-V37)

TO PREVENT ELECTRIC SHOCK MATCH WIDE

BLADE OF PLUG TO WIDE SLOT, FULLY

INSERT.

ATTENTION (s’applique à l’AA-V37)

POUR ÉVITER LES CHOCS ÉLECTRIQUES,

INTRODUIRE LA LAME LA PLUS LARGE DE LA

FICHE DANS LA BORNE CORRESPONDANTE

DE LA PRISE ET POUSSER JUSQU’AU FOND.

NOTES:

●

The rating plate (serial number plate) and

safety caution are on the bottom and/or the

back of the main unit.

●

The rating plate (serial number plate) of the

AC Power Adapter is on its bottom.

This camera is designed to be used with NTSCtype color television signals. It cannot be used

for playback with a television of a different

standard. However, shooting and LCD monitor

playback are possible anywhere.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK.

DO NOT REMOVE COVER (OR BACK).

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

NO USER-SERVICEABLE PARTS INSIDE.

The lightning flash with arrowhead symbol, within an

equilateral triangle, is intended to alert the user to the

presence of uninsulated "dangerous voltage" within the

product's enclosure that may be of sufficient magnitude

to constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in

the literature accompanying the appliance.

WARNING:

TO PREVENT FIRE OR SHOCK

HAZARD, DO NOT EXPOSE

THIS UNIT TO RAIN OR

MOISTURE.

Page 25

IMPORTANT PRODUCT

SAFETY INSTRUCTIONS

Electrical energy can perform many useful functions. But improper use can result in potential

electrical shock or fire hazards. This product has

been engineered and manufactured to assure your

personal safety. In order not to defeat the built-in

safeguards, observe the following basic rules for its

installation, use and servicing.

ATTENTION:

Follow and obey all warnings and instructions

marked on your product and its operating instructions. For your safety, please read all the safety and

operating instructions before you operate this

product and keep this manual for future reference.

INSTALLATION

1. Grounding or Polarization

(A) Your product may be equipped with a polarized

alternating-current line plug (a plug having one

blade wider than the other). This plug will fit into

the power outlet only one way. This is a safety

feature.

If you are unable to insert the plug fully into the

outlet, try reversing the plug. If the plug should still

fail to fit, contact your electrician to replace your

obsolete outlet. Do not defeat the safety purpose of

the polarized plug.

(B) Your product may be equipped with a 3-wire

grounding-type plug, a plug having a third

(grounding) pin. This plug will only fit into a

grounding-type power outlet. This is a safety

feature.

If you are unable to insert the plug into the outlet,

contact your electrician to replace your obsolete

outlet. Do not defeat the safety purpose of the

grounding-type plug.

2. Power Sources

Operate your product only from the type of power

source indicated on the marking label. If you are not

sure of the type of power supply to your home, consult

your product dealer or local power company. If your

product is intended to operate from battery power, or

other sources, refer to the operating instructions.

3. Overloading

Do not overload wall outlets, extension cords, or

integral convenience receptacles as this can result in a

risk of fire or electric shock.

4. Power Cord Protection

Power supply cords should be routed so that they are

not likely to be walked on or pinched by items placed

upon or against them, paying particular attention to

cords at plugs, convenience receptacles, and the point

where they exit from the product.

EN 3

5. Ventilation

Slots and openings in the cabinet are provided for

ventilation. To ensure reliable operation of the product

and to protect it from overheating, these openings must

not be blocked or covered.

•Do not block the openings by placing the product on

a bed, sofa, rug or other similar surface.

•Do not place the product in a built-in installation

such as a bookcase or rack unless proper ventilation

is provided or the manufacturer’s instructions have

been adhered to.

6. Wall or Ceiling Mounting

The product should be mounted to a wall or ceiling

only as recommended by the manufacturer.

ANTENNA INSTALLATION

INSTRUCTIONS

1. Outdoor Antenna Grounding

If an outside antenna or cable system is connected to

the product, be sure the antenna or cable system is

grounded so as to provide some protection against

voltage surges and built-up static charges. Article 810

of the National Electrical Code, ANSI/NFPA 70,

provides information with regard to proper grounding

of the mast and supporting structure, grounding of the

lead-in wire to an antenna discharge unit, size of

grounding conductors, location of antenna discharge

unit, connection to grounding electrodes, and

requirements for the grounding electrode.

2. Lightning

For added protection for this product during a lightning

storm, or when it is left unattended and unused for long

periods of time, unplug it from the wall outlet and

disconnect the antenna or cable system. This will

prevent damage to the product due to lightning and

power-line surges.

3. Power Lines

An outside antenna system should not be located in the

vicinity of overhead power lines or other electric light

or power circuits, or where it can fall into such power

lines or circuits. When installing an outside antenna

system, extreme care should be taken to keep from

touching such power lines or circuits as contact with

them might be fatal.

EXAMPLE OF ANTENNA GROUNDING AS PER

NATIONAL ELECTRICAL CODE, ANSI/NFPA 70

ANTENNA

LEAD IN WIRE

GROUND CLAMP

ANTENNA

DISCHARGE UNIT

(NEC SECTION

ELECTRIC SERVICE

EQUIPMENT

POWER SERVICE GROUNDING ELECTRODE SYSTEM

(NEC ART 250. PART H)

NEC – NATIONAL ELECTRICAL CODE

810-20)

GROUNDING CONDUCTORS

(NEC SECTION 810-21)

GROUND CLAMPS

Page 26

4 EN

USE

1. Accessories

To avoid personal injury:

•Do not place this product on an unstable cart,

stand, tripod, bracket or table. It may fall, causing

serious injury to a child or adult, and serious

damage to the product.

•Use only with a cart, stand, tripod, bracket, or

table recommended by the manufacturer or sold

with the product.

•Use a mounting accessory recommended by the

manufacturer and follow the manufacturer’s

instructions for any mounting of the product.

•Do not try to roll a cart with small casters across

thresholds or deep-pile carpets.

2. Product and Cart Combination

A product and cart combination should be moved

with care. Quick stops, excessive force, and uneven

surfaces may cause the product and cart combination to overturn.

3. Water and Moisture

Do not use this product

near water—for example,

near a bath tub, wash

bowl, kitchen sink or

laundry tub, in a wet

basement, or near a

swimming pool and the

like.

4. Object and Liquid Entry

Never push objects of any kind into this product

through openings as they may touch dangerous

voltage points or short-out parts that could result in

a fire or electric shock. Never spill liquid of any

kind on the product.

5. Attachments

Do not use attachments not recommended by the

manufacturer of this product as they may cause

hazards.

6. Cleaning

Unplug this product from the wall outlet before

cleaning. Do not use liquid cleaners or aerosol

cleaners. Use a damp cloth for cleaning.

7. Heat

The product should be situated away from heat

sources such as radiators, heat registers, stoves, or

other products (including amplifiers) that produce

heat.

PORTABLE CART WARNING

(Symbol provided by RETAC)

SERVICING

1. Servicing

If your product is not operating correctly or exhibits

a marked change in performance and you are

unable to restore normal operation by following the

detailed procedure in its operating instructions, do

not attempt to service it yourself as opening or

removing covers may expose you to dangerous

voltage or other hazards. Refer all servicing to

qualified service personnel.

2. Damage Requiring Service

Unplug this product from the wall outlet and refer

servicing to qualified service personnel under the

following conditions:

a. When the power supply cord or plug is damaged.

b. If liquid has been spilled, or objects have fallen

into the product.

c. If the product has been exposed to rain or water.

d. If the product does not operate normally by

following the operating instructions. Adjust only

those controls that are covered by the operating

instructions as an improper adjustment of other

controls may result in damage and will often

require extensive work by a qualified technician

to restore the product to its normal operation.

e. If the product has been dropped or damaged in

any way.

f. When the product exhibits a distinct change in

performance—this indicates a need for service.

3. Replacement Parts

When replacement parts are required, be sure the

service technician has used replacement parts

specified by the manufacturer or have the same

characteristics as the original part. Unauthorized

substitutions may result in fire, electric shock or

other hazards.

4. Safety Check

Upon completion of any service or repairs to this

product, ask the service technician to perform safety

checks to determine that the product is in safe

operating condition.

Page 27

QUICK START

EN 5

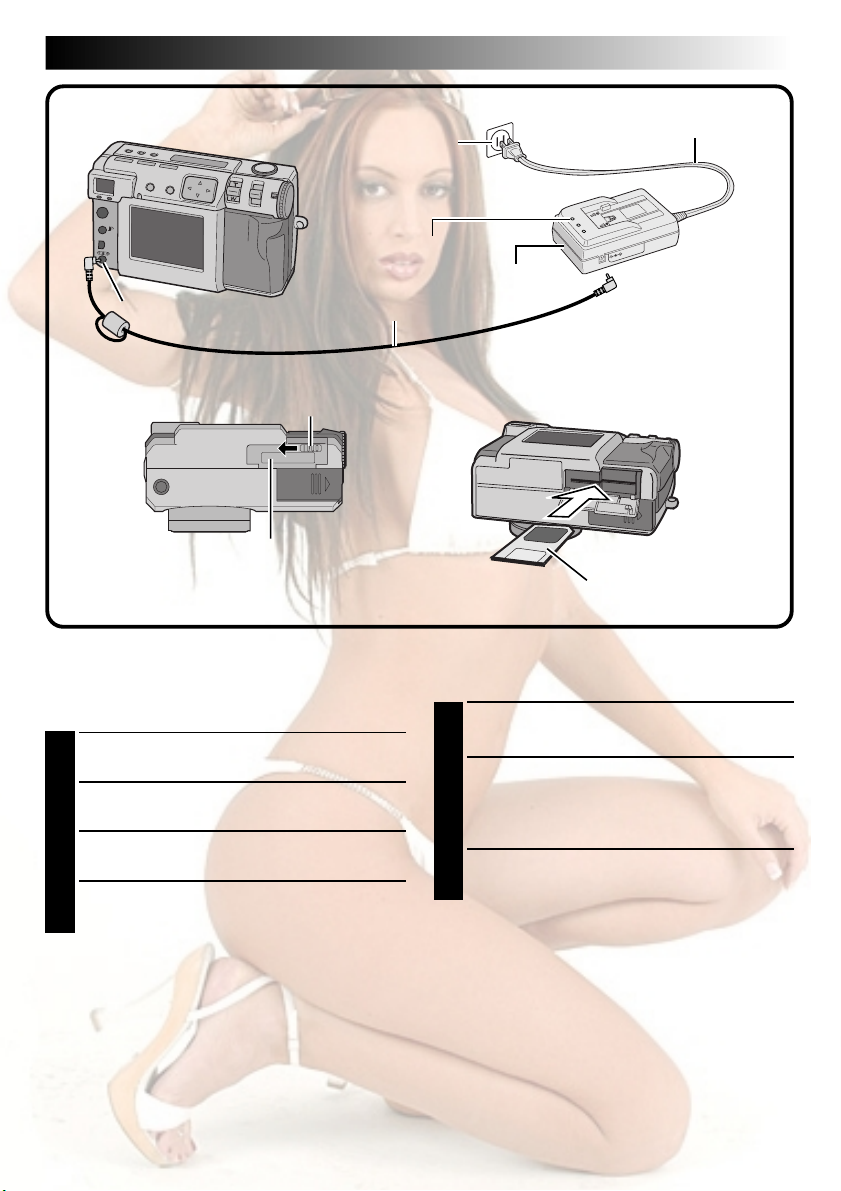

DC input connector

Knob

Memory card cover

Connect the Camera to a Power

Outlet. (Z pg. 20)

Open the connector cover on the rear of the

1

camera.

Connect the DC cord to the DC input

2

connector.

Connect the DC cord to the DC input

3

connector on the AC adapter.

Connect the power cord to a power outlet.

4

•The power lamp lights.

Power outlet

Power lamp

DC cord

Power cord

AC adapter

(AA-V37)

Memory card (3.3V type)

Insert the Memory card. (Z pg. 22)

Open the Memory card cover.

1

•Slide the knob to the open position.

Insert the Memory card.

2

•Insert the card so that the contact surface is

facing up and the notch on the card is on the

right.

Close the Memory card cover.

3

•Slide the knob to the close position.

Page 28

6 EN

OFF

M

4

SET

V

QUICK START (cont.)

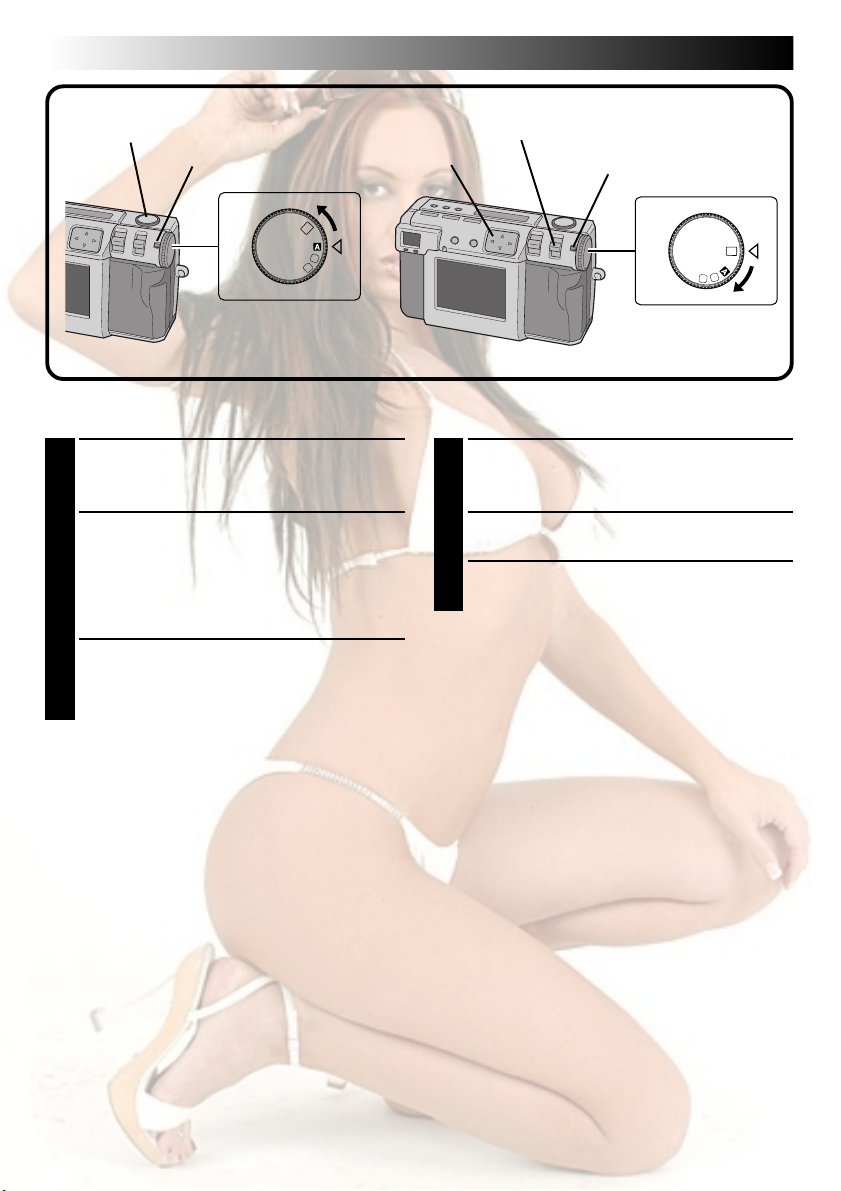

Shutter button

Lock button

Power dial

SET

4

OFF

M

V

Shoot a Picture. (Z pg. 30)

Turn the Power dial to “A” (full auto mode).

1

•Hold the Lock button down while turning the

Power dial.

Point the lens at the subject, position yourself,

2

and half-press the Shutter button.

•Look through the finder.

•The focus is attained when the shoot standby

lamp (green) changes from flashing to

steadily on.

Press the Shutter button all of the way to take

3

the picture.

•The picture image is stored in the Memory

card.

MODE switch

w e button

Lock button

Play back a Picture. (Z pg. 31)

Turn the Power dial to “B”.

1

•Hold the Lock button down while turning the

Power dial.

Select “STILL PB” with the MODE switch.

2

Press the w e button to select the picture that

3

you wish to view.

Power dial

Page 29

MAJOR FEATURES

EN 7

Three high-quality still image shooting modes

1. 6M Pro-Still (Pixel Shift Mode) (Z pg. 46)

This mode collects twice as much image data by

using two exposures (with the CCD shifted one

pixel for the second exposure), resulting in an

image consisting of 6 million pixels, or twice as

many in normal mode.

2. DR Pro-Still (Wide Range Mode) (Z pg. 47)

This mode uses two exposures, one with the

exposure adjusted for the dark portions of the

image, and one with the exposure adjusted for the

bright portions of the image. By using the image

data from both exposures, it is possible to achieve a

wide dynamic range that was previously impossible.

This mode avoids pictures where part of the image

is blacked out or whited out, which occurs easily

with conventional digital cameras.

3. NR Pro-Still (Noise Reduction Mode) (Z pg. 48)

This mode uses several exposures to collect a large

amount of image information, then extracts the

signal components and eliminates the noise

components. This mode eliminates electronic noise,

which occurs easily with conventional digital

cameras.

Video Shooting

This feature is useful, if you want to send a short

video by e-mail.

Collage shooting

This feature allows you to combine a subject with a

previously photographed background with a simple

operation.

Using the SmartMedia™ card* increases

photo capacity

This unit is compatible with SmartMedia™ cards*

(optional), which can be used to increase the

number of pictures that can be taken.

* “SmartMedia™ card” (which is described as

“Memory card” in this instruction manual) is a

trademark of Toshiba Corporation.

Before taking important photos

● When you need to take an important photo,

always take a test photo first and confirm that the

camera is operating normally.

● Memory card is not installed when this unit is

purchased. Be sure to install a Memory card

before taking photos.

● Before shooting, always confirm how much

memory is remaining from the memory card.

● We cannot bear any responsibility for an inability

to shoot, record, or playback material normally in

the event of a problem with a digital video

camera, Memory card, etc.

● Store backups of important photos on a personal

computer, etc. We cannot bear any responsibility

for pictures stored in memory that are lost or

altered.

Copyrights

You may only use material that you photograph or

record with this digital camera for your own

personal use, and not in any way that infringes on

the copyrights of a third party. (Note that some

performances and exhibits have restrictions against

photography, even if only for your personal use.)

Page 30

8 EN

CONTENTS

SAFETY PRECAUTIONS 2

QUICK START 5

MAJOR FEATURES 7

CONTENTS 8

CONTROLS, CONNECTORS AND INDICATORS 10

GETTING STARTED 18

Charging the Battery ..................................................................................................... 18

Installing a Charged Battery .......................................................................................... 19

Connecting the Camera to a Power Outlet .................................................................... 20

Attaching the Hand strap .............................................................................................. 21

Attaching the Lens Cover .............................................................................................. 21

Inserting the Memory Card ........................................................................................... 22

Formatting a Memory Card ........................................................................................... 23

BASIC OPERATION 24

Viewfinder .................................................................................................................... 24

Shutter Button ............................................................................................................... 24

Good Photography Posture ........................................................................................... 25

Mounting the Camera on a Tripod ................................................................................ 25

Selecting the Shooting Mode ........................................................................................ 26