Page 1

SERVICE MANUAL

Self timer

Photo quality

Number of storable photos

(with an 8MB Memory card,

STANDARD/FINE/NO COMP.)

Battery

Printer connector

VIDEO output connector

Digital output connector

: 1 second, 8 seconds

: 3 modes (STANDARD/FINE/NO COMP.)

: 2032 x 1536: approx. 10/8/0

1024 x 768: approx. 43/32/3

640 x 480: approx. 87/65/9

: Lithium ion battery

: Output for optional printer

: Two-pole plug, 3.5 mm diameter (NTSC)

: Mini-USB connector

AC Power Adapter/Charger AA-V37

E. & O. E. Design and specifications subject to change without notice.

: AC 120 V`, 60 Hz

: AC 110 V – 240 V`, 50 Hz/60 Hz

: 23 W

: DC 3.6 V

, 0.77 A

: DC 5.0 V

, 1.5 A

:0°C to 40°C (32°F to 104°C)

[when charging: 10°C to 35°C (50°F to 95°F)]

: 68 (W) mm x 38 (H) mm x 110 (D) mm

(2-11/16" x 1-1/2" x 4-3/8")

: Approx. 230 g (0.51 lbs) (without a DC cord)

Power requirement

U.S.A. and Canada

Other countries

Power consumption

Output

Charge

Camera

Operating temperature

Dimensions

Weight

DIGITAL STILL CAMERA

GC-QX3U

SPECIFICATIONS

Dimensions

Power consumption

Weight

Power source

Flash

Recommended distance for flash

LCD screen

Storage media

CCD

Recording pixels

Focal distance

Lens

Video

Recording format

Sensitivity

Iris value (F value)

Exposure control

Exposure compensation

Minimum subject distance

Light measurement system

Shutter type

Shutter speed

White balance

Focus

: 108 (W) mm x 64 (H) mm x 57 (D) mm

(4-5/16" x 2-9/16" x 2-1/4")

: 4.0 W (when the LCD screen is off)

5.6 W (when the LCD screen is on)

: Approx. 290 g (0.64 lbs)

(without a Memory card and battery)

: DC 5 V

: Built-in,

Auto/red-eye prevention/forced/disabled

: 2.3 m to 5.2 m

: 2.0 inch, cool polysilicon TFT, 200,000 pixels

: SmartMedia

: 3.34 million pixels (3.24 million valid pixels),

1/1.8" square pixels, primary color filter,

interlace scan CCD

: 2032 x 1536 (TIFF 9.5MB, FINE 1MB, STD 700KB)

1024 x 768 (TIFF 2.4MB, FINE 500KB, STD 300KB)

640 x 480 (TIFF 980KB, FINE 150KB, STD 80KB)

: 7.5 mm to 17.5 mm

(equivalent to 37mm to 86 mm on a 35 mm still camera)

: 2.3X optical zoom lens

: 160 x 120, 20 seconds (80KB – 200KB) JVC original

: Exif Ver. 2.1 (DCF compliant), TIFF (Uncompressed),

DPOF-compatible

: 80/160/320 (ISO compliant)

: F2.8/3.8, 5.6, 8, 11

: Program AE, iris priority AE

: +/–2EV (0.5EV steps)

: Approx. 2 cm to 50 cm (in Macro mode)

: Multi, spot

: Electronic shutter

: Auto (Program AE: 1/8 – 1/750, Iris priority AE: 1/4 – 1/750)

: Auto/Manual (

: Auto/Manual

TM

3.3V (up to 64MB)

, , , MWB)

This service manual is made from all recycled paper.

COPYRIGHT © 2000 VICTOR COMPANY OF JAPAN, LTD

No.XXXXX

XXXXX 2000

Page 2

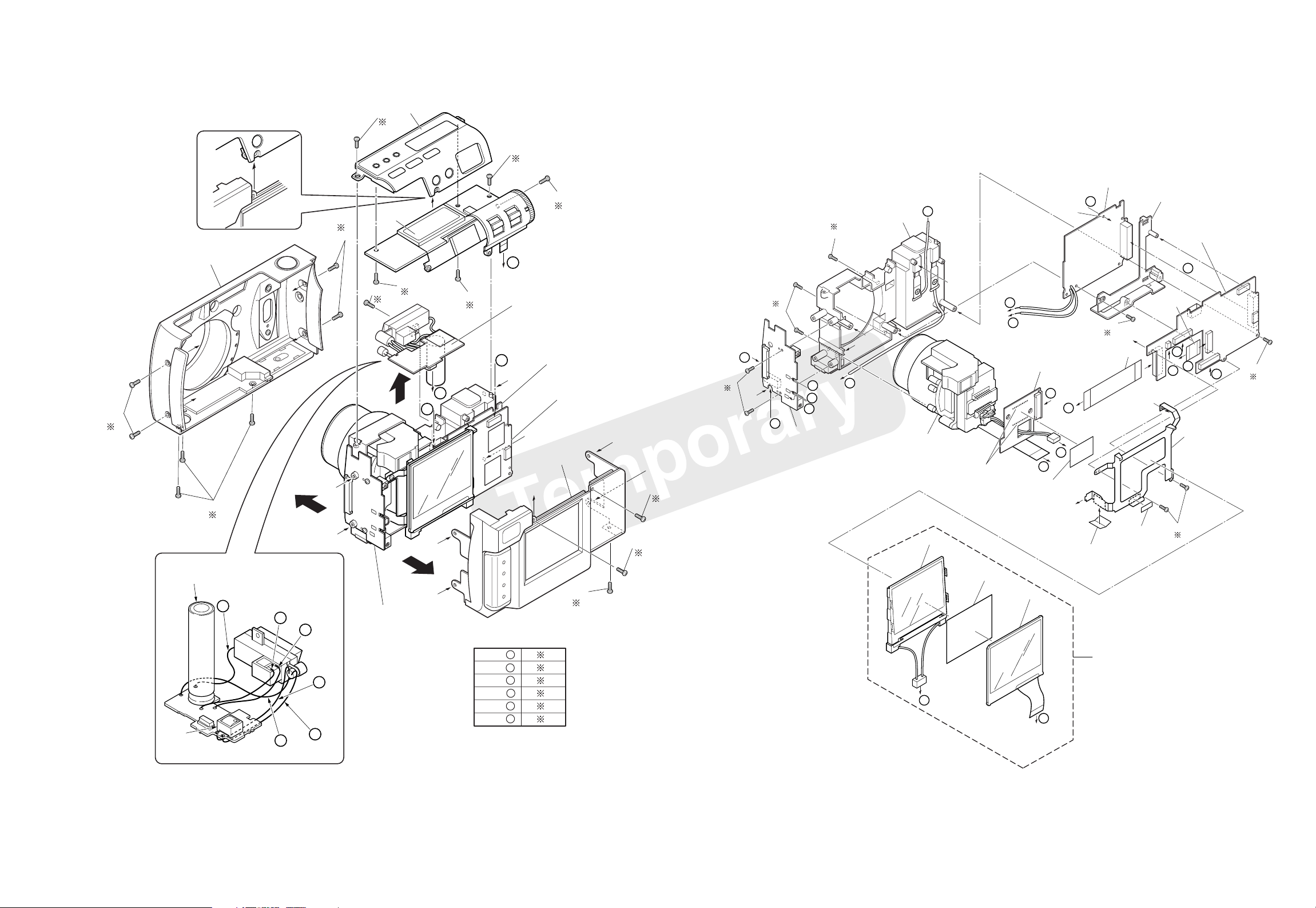

SECTION 1

DISASSEMBLY

1.1 BEFORE ASSEMBLY AND DISASSEMBLY

1.1.1 Precautions

1. Be sure to remove the power supply unit prior to mounting and soldering of parts.

2. When connecting and disconnecting the connectors, be

careful not to damage the wire.

3. When replacing chip parts (especially IC parts), desolder

completely first (to prevent peeling of the pattern).

4. Tighten screws properly during the procedures.

Unless specified otherwise, tighten screws at a torque

of 0.1N•m (1.0 kgf•cm).

CAUTION!!

RISK OF ELECTRIC SHOCK

When disassembling the unit, electric hazards may

occur in some cases if the capacitor for strobe

emission (STROBE board C6512) has been charged.

Therefore be also very careful when performing repairs

and inspections.

It is recommended that operations be carried out after

waiting for more than ten minutes with the power

supply removed or after discharging the capacitor

forcibly.

Discharge the capacitor according to <NOTE 2> on

Page 1-3.

C6512 is located behind the STROBE board.

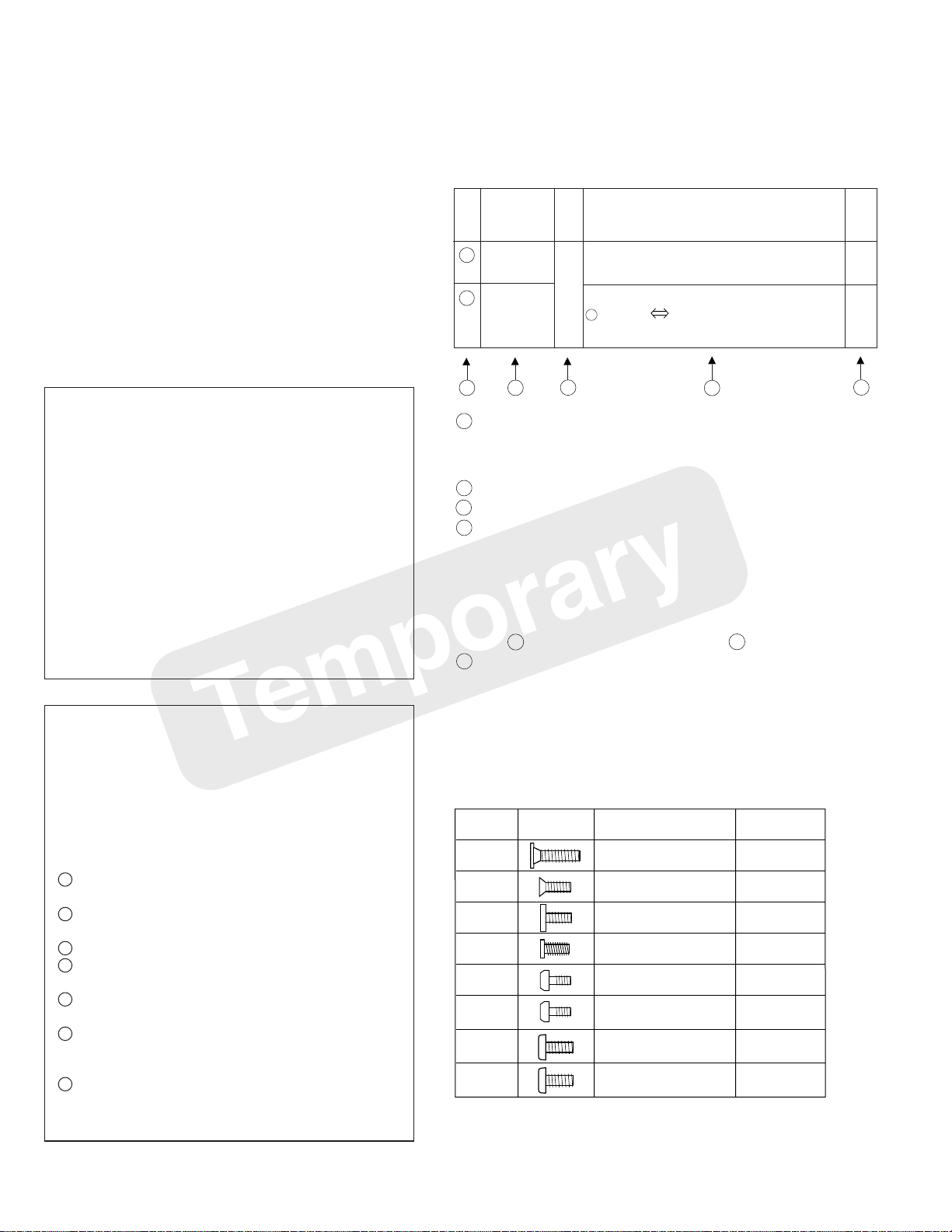

1.1.2 Assembly and disassembly

STEP

PART NAME

1 FRONT CASE Remove screws

REAR CASE

2 OPERATION UNIT Remove the Connector Remove screws NOTE 1

12 3 4 5

FIG.

NO.

Fig

1-2-1

r MAIN CN4001 OPERATION UNIT

Remove the TOP COVER 2 (115)

POINT

2(115), 3(156), 4(114), 1(116)

3 (116)

1 : Indicate the disassembly steps. When assembling,

perform in the reverse order of these steps. This

number corresponds to the number in the disassem-

bly diagram.

2 : Indicates the name of disassembly/assembly parts.

3 : Indicates the number in the disassembly diagram.

4 : Indicates parts and points such as screws, washers,

springs which must be removed during disassembly/

assembly.

Lock (L), soldering (SD), shield, connector, etc.

[Example]

• (115) = Remove the parts No 115 screw.

• (SD1) = Desoldering at the point SD1.

• a = Disconnect the connector/ML a .

5 : Precautions on disassembly/assembly.

PRECAUTIONS ON HANDLING

THE LITHIUM SECONDARY BATTERY

This unit is equipped with a coin type lithium secondary

battery.

Improper handling of this battery may cause heat to

be generated, damage, fires, or leakage. Always follow

the precautions below.

1 Do not short-circuit, disassemble, distort, nor heat

the battery.

2 Load the battery with its + and - poles connected

correctly.

3 Do not solder the battery itself.

4 When replacing parts, also refer to the numbers

listed in the Parts List of the manual.

5 Do not store the battery in direct sunlight and hot

and humid places.

6 When replacing the battery, handle it with care and

do not attempt to hold it with tweezers as it may

short-circuit.

7 When disposing the battery, wind tape around the

terminal to insulate the battery, and dispose the

battery according to the method prescribed.

1.1.3 Screws used in assembly of cabinet parts and

boards

The following Table 1-1-1 shows the symbols, shapes, and

parts numbers of the screws used in the disassembly and

assembly diagrams of cabinet parts and board assemblies.

Prior to assembly, check the following table and be sure to

use the correct screw.

SHAPE PARTS NO.SYMBOL COLOR

101E

114

115

116

117

153F

155

156

LY30018-019A Black

LY30018-060A Silver

LY30018-010A Black

LY30018-023A Black

LY30019-025A Gold

QYSPSGT1740Z Gold

LY30018-056A Silver

LY30018-059A Silver

Table 1-1-1

1-1

Page 3

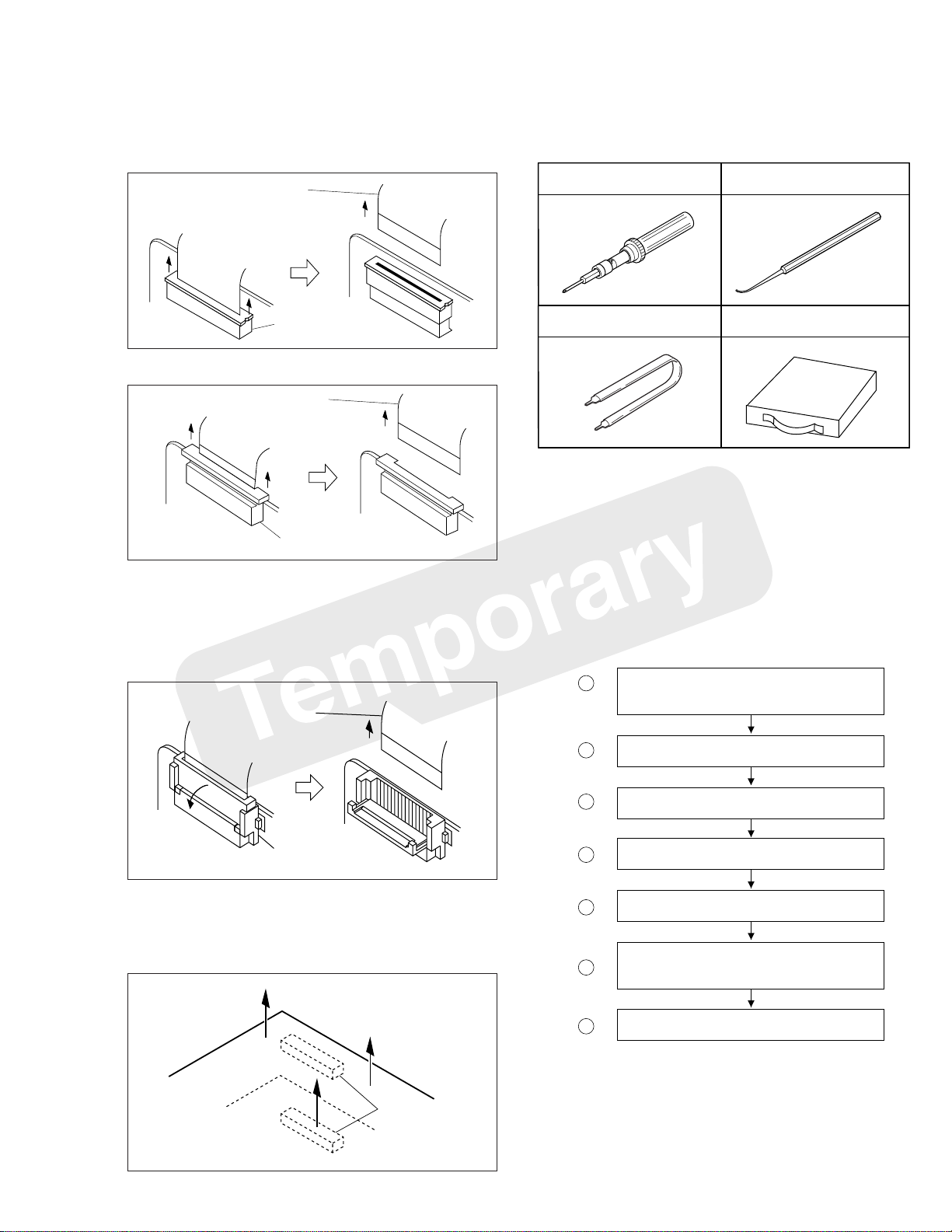

1.1.4 Disconnection of Connectors (Wires)

FRONT CASE

REAR CASE

OPERATION UNIT

STROBE BOARD ASSEMBLY

JACK BOARD ASSEMBLY

LCD MODULE

MAIN BOARD ASSEMBLY

MONI/REG BOARD ASSEMBLY

OP UNIT

1

2

3

4

5

6

7

Torque driver

YTU94088

12

Clip IC replacement jig

PTS40844-2

Connector catcher

YTU94036A

34

Soldering kit

YTU96016B

Connector

Pull both ends of the connector in the arrow direction, remove the lock and disconnect the flat wire.

Flat wire

Connector 1

Fig. 1-1-1 Connector 1

Flat wire

Connector 2

Fig. 1-1-2 Connector 2

Extend the locks in the direction of the arrow for unlocking

and then pull out the wire. After removing the wire,

immediately restore the locks to their original positions

because the locks are apt to come off the connector.

1.2 TOOLS AND EQUIPMENTS REQUIRED FOR

ADJUSTMENTS

1.2.1 Tools required for adjustments

1.3 DISASSEMBLY/ASSEMBLY OF CABINET PARTS

1.3.1 Disassembly flow chart

The following flow chart shows the steps for disassembling

the cabinet parts. To assemble, perform the steps of the flow

chart in the reverse order.

The encircled numbers indicate the order for disas-

Note:

sembling the cabinet parts.

The screw numbers indicate the disassembling order.

Flat wire

Connector 3

Fig. 1-1-3 Connector 3

B-B connector

Pull the board by both the sides in the direction of the arrow

for disconnecting the B-B connector.

Fig. 1-1-4 Connector 4

Connector 4

1-2

Page 4

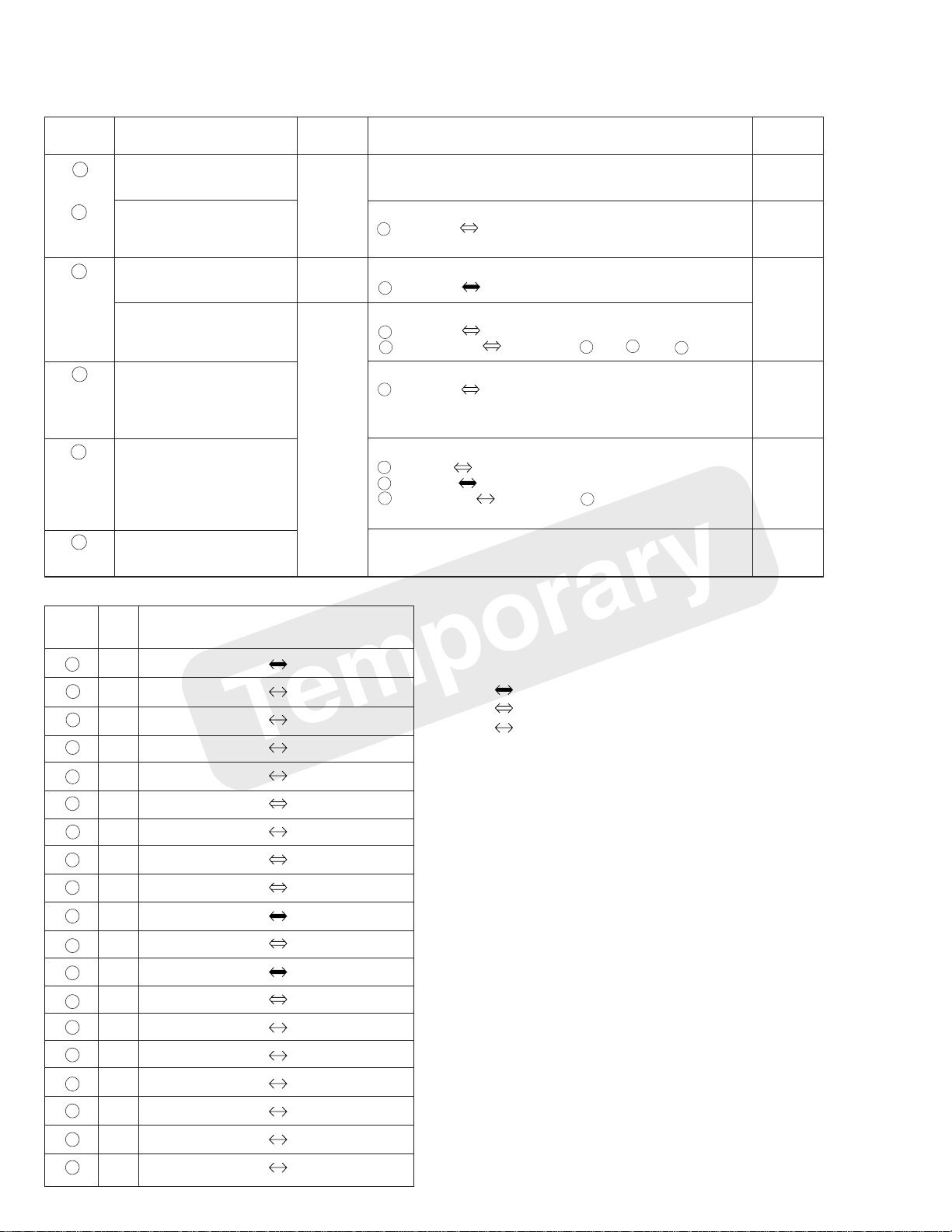

1.3.2 Disassembly method

STEP

1 FRONT CASE Remove screws

REAR CASE 2 (115), 3 (156), 4 (114), 1 (116)

2 OPERATION UNIT Remove the Connector Remove screws NOTE 1

3 STROBE BOARD ASSEMBLY Remove the Connector Remove screw NOTE 1

JACK BOARD ASSEMBLY Remove the Connector Remove screws

4 LCD MODULE Remove the Connector Remove screws NOTE 1

5 MAIN BOARD ASSEMBLY Remove the Connector NOTE 1

MONI/REG BOARD ASSEMBLY Remove the PWB HOLDER Remove screws 2 (114)

6 OP UNIT Remove from the Frame Assy Remove screws 3 (117)

PART NAME

Fig

1-2-1

Fig

1-2-1

Fig

1-2-2

r MAIN CN4001

Remove the TOP COVER 2 (115)

n MAIN CN6601

p MAIN CN5501

m LCD MODULE (BL)

k MAIN CN3002

Remove from the Frame Assy

Remove from the LCD Holder

h MAIN CN501

c MAIN CN3001

d MON/REG TL9001

Remove from the CCD BOARD CN1001 20Pin (SD2)

OPERATION UNIT 3 (116)

STROBE CN6501 1 (114) NOTE 2

JACK CN101 2 (114)

LCD MODULE (LCD) 2 (114)

OP UNIT

MON/REG CN9001

Frame Assy d (SD1)

POINTFIG. NO.

JACK CN701 e (SD3), f (SD4), g (SD5)

CONNEC- NO.OF

TOR/HL PINS

c

80 MAIN Board CN3001

d

1 MONI/REG Board TL9001

e

1 JACK Board TP3

f 1 JACK Board TP2

g

1 JACK Board TP1

h

22 MAIN Board CN501

j

2 MAIN Board CN502

k

24 MAIN Board CN3002

m 2 JACK Board CN701

n

14 MAIN Board CN6601

p 38 MAIN Board CN5501

q

28 MAIN Board CN2001

r 12 MAIN Board CN4001

s

t

STROBE UNIT WIRE (ORANGE)

1

STROBE UNIT WIRE (BROWN)

1

CONNECTION

MONI/REG Board CN9001

MAIN FRAME (RED)

MAIN FRAME (BROWN)

MONI/REG Board J9001 (BLACK)

MONI/REG Board J9002 (RED)

OP UNIT

OP UNIT

LCD MODULE (LCD)

LCD MODULE (BL)

STROBE Board CN6501

JACK Board CN101

CCD Board CN1001

OPERATION UNIT

STROBE Board J6501 (Through hole)

STROBE Board J6502 (Through hole)

<NOTE 1>

Destination of connectors

Three kinds of double-arrows in connection tables

Note:

respectively show kinds of connector/wires.

: Board to Board connector

: Flat wire

: Wire

<NOTE2>

Be careful from electric shock hazard because the capacitor

(C6512) for the strobe is exposed. Be sure to positively discharge the capacitor if it is energized by short-circuiting a

resistor (10 - 22 kΩ ) connected at both capacitor terminals.

Please be very careful when doing this job.

1-3

u

1 STROBE UNIT WIRE (RED)

v

w

x

STROBE UNIT WIRE (BLACK)

1

STROBE UNIT WIRE (Red, Thin wire) STROBE Board J6505 (Through hole)

1

STROBE UNIT WIRE (BLACK, Thin wire)

1

STROBE Board J6503 (Through hole)

STROBE Board J6504 (Through hole)

STROBE Board J6506 (Through hole)

Page 5

116

114

117

117

F

101

103

114

B

A

C

j

p

p

q

g

e

e

d

B

C

m

f

g

f

j

h

q

k

c

CCD BOARD ASSY

< 03 >

MAIN BOARD ASSY

< 01 >

MONI/REG BOARD ASSY

< 02 >

JACK BOARD ASSY

< 04 >

114

109

107B

105

107C

107A

107

104

106

113

(SD2)

(SD1)

(SD3)

(SD4)

(SD5)

102

A

108

114

k

m

h

d

5

5

6

6

3

4

110

2

116

2

D

116

2

111

1

155

153

G

114

H

E

F

156

1

C6512

L6501

114

E

u

t

v

F

x

JACK BOARD ASSY

< 04 >

w

1

s

115

2

3

n

n

E

F

115

2

Remove screw marks

r

STEP 1

STEP 2

STEP 3

STEP 4

STEP 5

STEP 6

r

STROBE

BOARD ASSY

< 05 >

MONI/REG BOARD ASSY

< 02 >

G

MAIN BOARD ASSY

< 01 >

H

152

D

114

1

1

2

3

4

5

6

G

H

116

1

156

1

Fig.1-3-1

1-4

1-5

Fig.1-3-2

Page 6

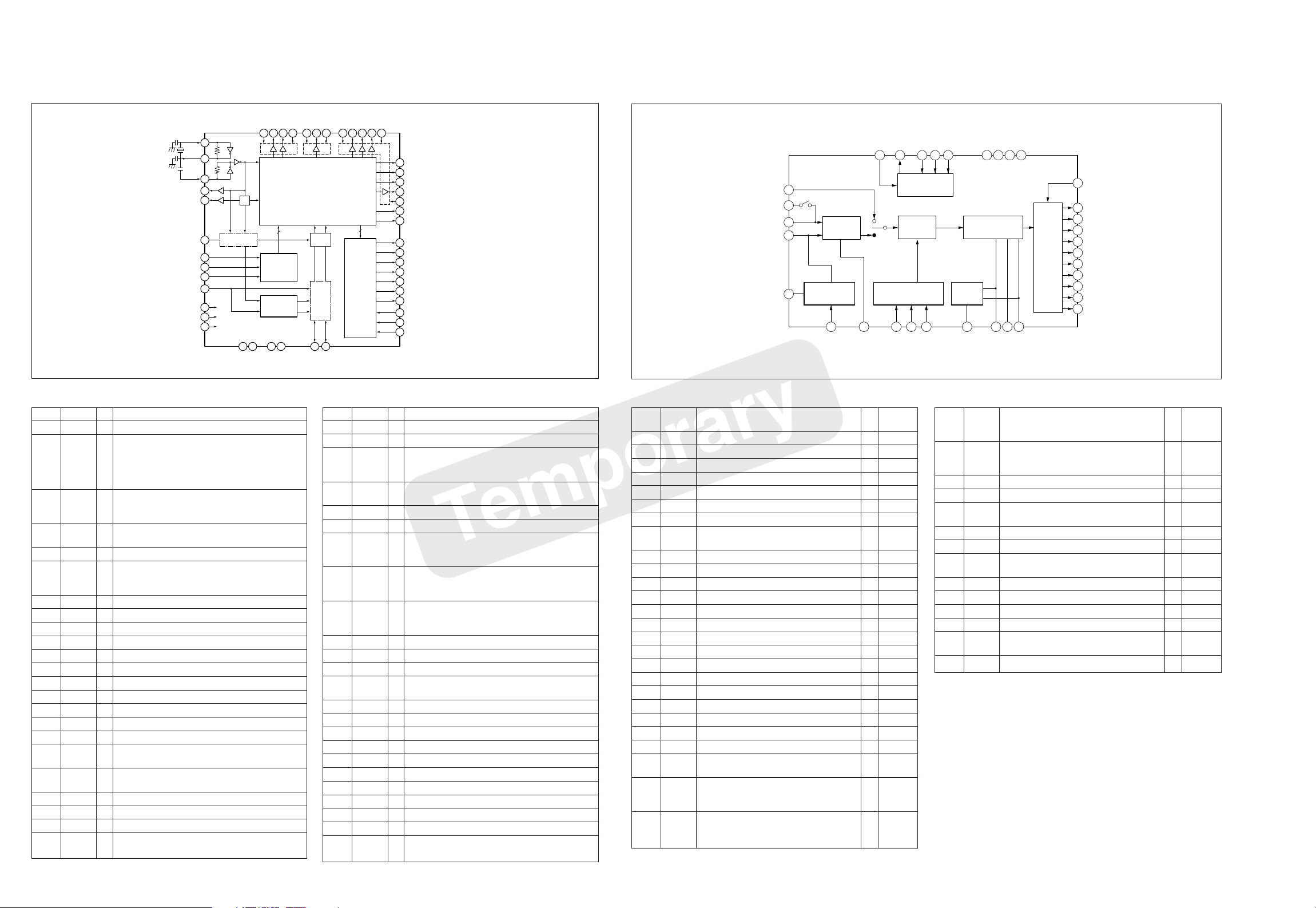

1.4 IC BLOCK DIAGRAM

1.4.1 IC 1002 (CXD2497R)

1.4.2 IC 2001 (CDS/AGL)

3

DD

V

OSCI

28

OSCO

27

CKI

26

25

CKO

MCKO

SNCSL

SSI

SCK

SEN

SSGSL

RST

TEST1

TEST2

30

3

31

32

33

6

2

37

48

Selctor

1/2

Register

1

5

DD

DD

V

V

Pin Descriptions

Pin No. Pin Name I/O Description

1VSS1 - GND

2 RST I System reset input terminal H: Reset released L: Reset

activated

(Should be activated at power ON, normally.)

(Schmitt trigger input/without protection diode on power

supply side)

3 SNCSL I Sync system switching control input terminal

(with pull-down resistor)

H: CKI sync L: MCKO sync

4 ID O Line identification pulse output terminal in the vertical

direction

5 WEN O Memory write timing pulse output terminal

6 SSGSL I Built-in SSG enable input terminal (with pull-down

resistor)

H: Built-in SSG is effective. L: External sync is effective.

7VDD1 - 3.3V power (for common logic section)

8VDD2 - 3.3V power (for RG terminal)

9 RG O Reset gate pulse output terminal for CCD

10 VSS2 - GND

11 VSS3 - GND

12 H1 O Clock output terminal for CCD horizontal register

13 H2 O Clock output terminal for CCD horizontal register

14 VDD3 - 3.3V to 5.0V power (for H1 and H2 terminals)

15 VDD4 - 3.3V power (for CDS system terminals)

16 XSHP O CCD pre-charge level sample/hold pulse output terminal

17 XSHD O CCD data level sample/hold pulse output terminal

18 XRS O Sample/hold pulse output terminal for phase matching in

analog-to-digital conversion

19 PBLK O Pulse output terminal for pulse cleaning during

horizontal and vertical blanking period

20 CLPDM O Pulse output terminal for CCD dummy signal clamping

21 VSS4 - GND

22 OBCLP O Pulse output terminal for CCD optical black signal

23 ADCLK O Clock output terminal for analog-to-digital conversion IC

Logical phase is adjustable with the serial interface data

H1H2V

SSG

1

5

SS

SS

V

V

2

3

DD

SS

V

11

Pulse Generator

35361297

Latch

HD

RG

Selector

34

VD

4

2

DD

SS

V

V

XSHP

V Driver

XSHD

181716151098 21131214

XRS

4

SS

V

19

PBLK

CLPDM

20

22

OBCLP

23

ADCLK

24

SS

5

V

4

ID

5

WEN

41

V1A

43

V1B

39

V2

44

V3A

46

V3B

40

V4

47

SUB

VH

42

VM

38

VL

45

24 VSS5 - GND

25 CKO O Inverter output terminal

26 CKI I Inverter input terminal

27 OSCO O Inverter output terminal for oscillation (If not used,

should be opened or connected to GND through a

capacitor.)

28 OSCI I Inverter input terminal for oscillation (If not used, should

be fixed to "Low".)

29 VDD5 - 3.3V power (for common logic section)

30 MCKO O System clock output terminal for signal processing IC

31 SSI I Serial interface data input terminal for setting each IC

mode (Schmitt trigger input/without protection diode on

power supply side)

32 SCK I Serial interface clock input terminal for setting each IC

mode (Schmitt trigger input/without protection diode on

power supply side)

33 SEN I Serial interface strobe input terminal for setting each IC

mode (Schmitt trigger input/without protection diode on

power supply side)

34 VD I/O Vertical sync signal input/output terminal

35 HD I/O Horizontal sync signal input/output terminal

36 VSS6 - GND

37 TEST1 I IC test terminal 1 with pull-down resistor (Should be

fixed to GND normally.)

38 VM - GND (for vertical drivers)

39 V2 O Clock output terminal for CCD vertical register

40 V4 O Clock output terminal for CCD vertical register

41 V1A O Clock output terminal for CCD vertical register

42 VH - 15.0V power (for vertical drivers)

43 V1B O Clock output terminal for CCD vertical register

44 V3A O Clock output terminal for CCD vertical register

45 VL - -7.5V power (for vertical drivers)

46 V3B O Clock output terminal for CCD vertical register

47 SUB O Pulse output terminal for CCD electronic shutter

48 TEST2 I IC test terminal 2 with pull-down resistor (Should be

fixed to GND normally.)

21

27

ADCIN

25

CDSSW

26

CDSIN

BLKSH

BLKFB

28

29

CDS PGA

DC offset

compensatory

17

20

OBP

PBLK

Pin Descriptions

Pin No. Pin Name Description I/O

Analog (A) or

1 NC No internal connection - 2 D0 Digital output terminal (LSB) O D

3-10 D1-D8 Digital output terminals O D

11 D9 Digital output terminal (MSB) O D

12 NC No internal connection - 13 OADCLK Latch clock output terminal for D0 to D9 O D

14 DVSS Digital GND (0V) - D

15 DV

DD Power for digital 3.0V system - D

(Should be connected to AVDD outside the IC.)

16 ADCLK Analog-to-digital conversion clock input terminal I D

17 OBP Optical black pulse input terminal I D

18 SPBLK Black level sampling clock input terminal I D

19 SPSIG Signal level sampling clock input terminal I D

20 PBLK Pre-blanking signal input terminal I D

21 OADSW OADCLK enable input terminal I D

22 AVSS Analog GND (0V) - A

23 AVDD Power for analog 3.0V system - A

24 NC No internal connection - 25 CDSSW Signal level sampling output terminal O A

26 CDSIN CDS input terminal I A

27 ADCIN ADC input terminal I A

28 BLKSH Black level sample/hold terminal - A

29 BLKFB Black level feedback terminal - A

30 AVSS Analog GND (0V) - A

31 AVDD Power for analog 3.0V system - A

(Should be connected to DVDD outside the IC.)

32 VRT Reference voltage terminal 3 - A

(Ceramic capacitor of 0.1µF or more should be

connected between this terminal and AVss.)

33 VRB Reference voltage terminal 2 - A

(Ceramic capacitor of 0.1µF or more should be

connected between this terminal and AVss.)

OADSW

OADCLK

13 16 18 19

Serial

Interface

44

SCK

Digital (D)

ADCLK

SPBLK

TIMING

gen

43CS45

SDATA

SPSIG

Occurrence

Bias

35

BIAS

41

AVDDDVDD

46

10bit

ADC

33

VRT

AVSS

DVSS

40

48

42 OEB

11 D9

10 D8

9D7

Output

Latch

circuit

32

34

VRB

VRM

8D6

7D5

6D4

5D3

4D2

3D1

D0

2

34 VRM Reference voltage terminal 1 - A

(Ceramic capacitor of 0.1µF or more should

be connected between this terminal and AVss.)

35 BIAS Internal bias terminal - A

(A 24-Kohm resistor should be connected

between this terminal and AVss.)

36 NC No internal connection - 37 AVSS Analog GND (0V) - A

38 AV

DD Power for analog 3.0V system - A

(Should be connected to DVDD outside the IC.)

39 NC No internal connection - 40 AVSS Analog GND (0V) - A

41 AVDD Power for analog 3.0V system - A

(Should be connected to DVDD outside the IC.)

42 OEB Digital output enable control input terminal I D

43 CS Serial interface control input terminal I D

44 SCK Serial clock input terminal I D

45 SDATA Serial data input terminal I D

46 DVDD Power for digital 3.0V system - D

(Should be connected to AVDD outside the IC.)

47,48 DVSS Digital GND - D

1-6

1-7

Page 7

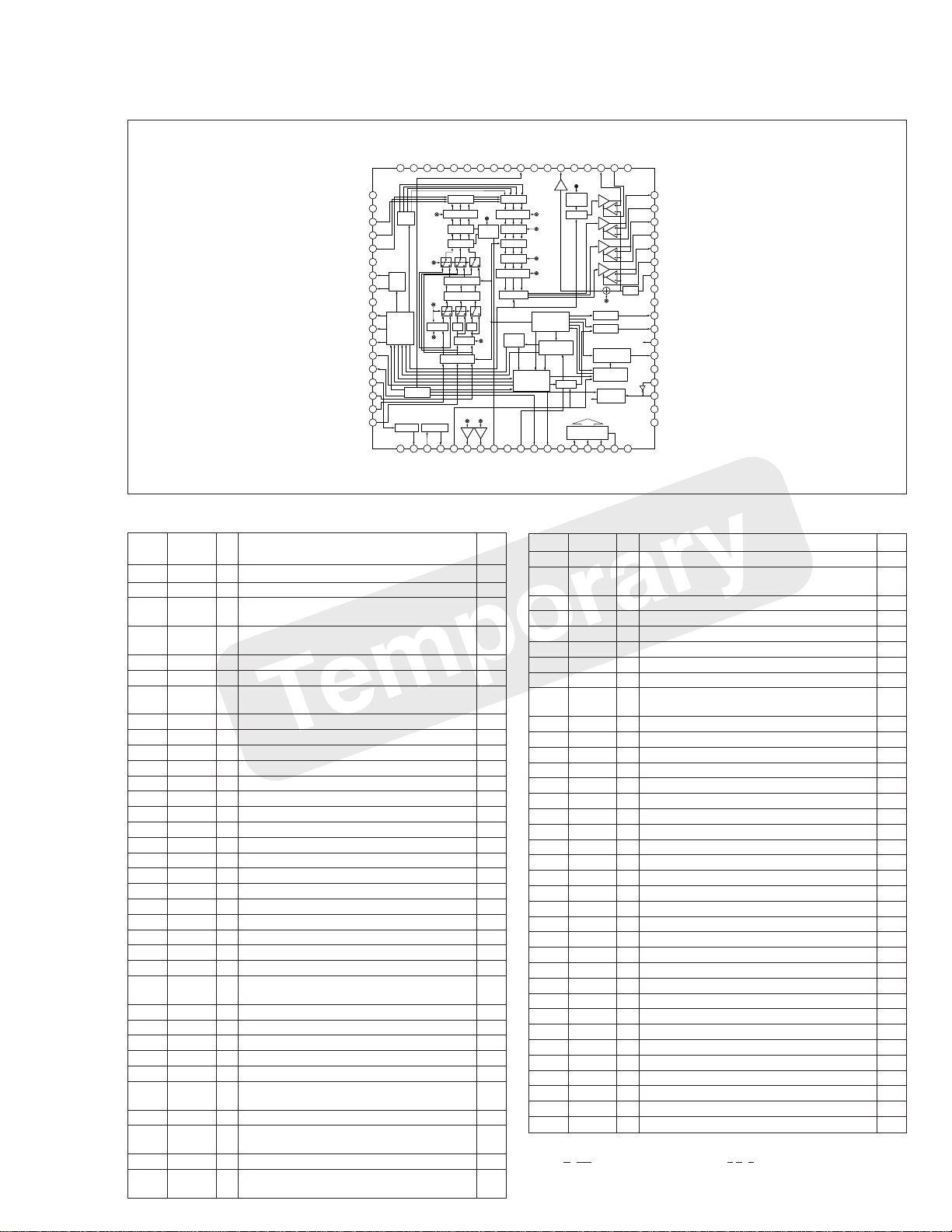

1.4.3 IC 7302 (CXA3268AR)

VSSVSSTST10

TST9

51 38 37

V

SSVSS

+3.0V

55

V

DD

56

TST11

OSD B

OSD R

OSD G

HCK1

HCK2

VCC1

FIL IN

B/B-Y

R/R-Y

57

58

59

60

NC

61

HCK

GEN

62

+3.0V

63

64

HST

HCOUNTER

HPULSE

65

EN

GEN

66

VCK

67

VST

67

RGT

69

70

71

G/Y

72

H.FILTER SYNC SEP

SS

V

CONTRAST

S/H

CONT

GEN

GR

MODE

PIC-G

PIC-F

MODE

SS

V

FIL OUT

SYNC IN

SYNC OUT

Pin Descriptions

Pin No. Pin Name I/O Description

1 Vss - GND terminal for digital 3.0V system

2 FIL OUT O H filter output terminal (for internal sync separator use)

3 SYNC IN I Sync input terminal for sync separator circuit

(for internal sync separator use)

4

SYNC OUT

O Sync output terminal for sync separator circuit

(for internal sync separator use)

5

CSYNC/HD

I CSYNC/horizontal sync signal input terminal

6 DA OUT O DAC output terminal

7 REF O Level shifter circuit reference voltage output terminal for

LCD panel

8 F ADJ O f0 adjust resistor connecting terminal for TRAP

9 GND1 - GND terminal for analog 3.0V system

10 VD I Vertical sync signal input terminal

11 DWN O Up/Down switching signal output terminal

12 WIDE O 16:9 wide display switching pulse output terminal

13 TST1 - Test terminal (Should be opened.)

14 SCK I Serial clock input terminal

15 SEN I Serial load input terminal

16 SDAT I Serial data input terminal

17 R INJECT O Resistor connecting terminal for serial block current control

18 VSS - GND terminal for digital 3.0V system

19 VDD - Power for digital 3.0V system

20 VDD - Power for digital 3.0V system

21 CKO O Oscillation cell output terminal

22 CKI I Oscillation cell input terminal

23 Vss - GND terminal for digital 3.0V system

24 RPD O Phase comparison output terminal

25 XCLR I Capacitor connecting terminal for power-on reset (for

timing generating system)

26 VDO O VDO pulse output terminal

27 HDO O HDO pulse output terminal

28 TST2 - Test terminal (Should be connected to GND.)

29 GND2 - GND terminal for analog 12.0V system

30 SIG.C I DC voltage adjust terminal for R, G, B and PSIG outputs

31 B DC DET O Capacitor connecting terminal for B signal's DC voltage

feedback circuit

32 B OUT O B signal output terminal

33 R DC DET O Capacitor connecting terminal for R signal's DC voltage

feedback circuit

34 R OUT O R signal output terminal

35 G DC DET O Capacitor connecting terminal for G signal's DC voltage

feedback circuit

TST8

OSD RGB

TRAP

LPF

CLAMP

MATRIX

DL1PICTURE

HUE

CLAM[P

SYNC/HD

TST7

DL1

COLOR

DA

Buf Buf

DA OUT

FILTER

FILTER

B

BGR

HUE

CLP

REF

Input

TST6

LPF

BIAS

REF

Res.

L

H

TST5NCPOF

S/H

USER-BRIGHT

GAMMAM

CLAMP

BLK-LIM

SUB-BRIGHT

POL SW

PULSE

ELM

V COUNTER

GND1

F ADJ

GND1

VD

U-GRT

γ1γ2

WHITLIM

SUB-CONT R

SUB-CONT B

BLKLIM

SUB-BRT R

SUB-BRT B

TST4

GND3

PLL

COUNTER

V CONTROL

V POSITION

DWN

GND3

WIDE

COM

Buf

V SEP

TST1

3

CC

V

+12.0V +12.0V

PSIGBRT

PSIGBRIGHT

POL SW

S/P CONV

REGISTER DAC

SCK

TST3

394041424344454647484950525354

Buf

Buf

Buf

Buf

COM-DC

HDO GEN

VDO GEN

COMPARATOR

HSYNC DET

H SKEW DET

CLK

1615141312111098765321 4 17 18

SEN

PSIG OUT

PHASE

CK

CONTROL

SDAT

2

CC

PSIG DC DET

V

SIG.C

MCK

V

SS

SS

V

R INJECT

+3.0V

+3.0V

GND2

V

36

G OUT

35

G DC OUT

34

R OUT

33

R DC DET

32

B OUT

31

B DC DET

30

SIG. C

29

GND2

28

TST2

27

HDO

26

VFO

25

XCLR

24

RPD

23

SS

SS

V

22

CKI

21

CKO

20

DD

V

19

V

DD

36 G OUT O G signal output terminal

37 VCC2 - Power for analog 12.0V system

38 PSIG DC O Capacitor connecting terminal for G signal's DC voltage

DET feedback circuit

39 PSIG OUT O PSIG output terminal

40 TST3 - Test terminal (Should be opened.)

41 VCC3 - Power for analog 12.0V system COM (CS)

42 COM O

Common electrode voltage output terminal (CS) for LCD panel

43 GND3 - GND terminal for analog 12.0V system COM (CS)

44 TST4 - Test terminal (Should be opened.)

45 POF O LCD panel power ON/OFF terminal

(Open, if this function is not used.)

46 NC - No internal connection

47 TST5 - Test terminal (Should be connected to GND.)

48 TST6 - Test terminal (Should be connected to GND.)

49 TST7 - Test terminal (Should be opened.)

50 TST8 - Test terminal (Should be opened.)

51 TST9 - Test terminal (Should be opened.)

52 TST10 - Test terminal (Should be opened.)

53 VSS - GND terminal for digital 3.0V system

54 VSS - GND terminal for digital 3.0V system

55 VDD - Power for digital 3.0V system

56 TST11 - Test terminal (Should be connected to GND.)

57 OSD B I OSD B input terminal

58 OSD R I OSD R input terminal

59 OSD G I OSD G input terminal

60 NC - No internal connection

61 HCK1 O H clock pulse 1 output terminal

62 HCK2 O H clock pulse 2 output terminal

63 VCC1 - Power for analog 3.0V system

64 HST O H start pulse output terminal

65 EN O EN pulse output terminal

66 VCK O V clock pulse output terminal

67 VST O V start pulse output terminal

68 RGT O Right/Left switching signal output terminal

69 FIL IN I H FILTER input terminal (for internal sync separator use)

70 B/B-Y I B/B-Y signal input terminal

71 G/Y I G/Y signal input terminal

72 R/R-Y I R/R-Y signal input terminal

* DWN:

DOWN SCAN and UP SCAN RGT: RIGHT SCAN and LEFT SCAN

H: Pull-up resistor incorporated L: Pull-down resistor incorporated

1-8

Page 8

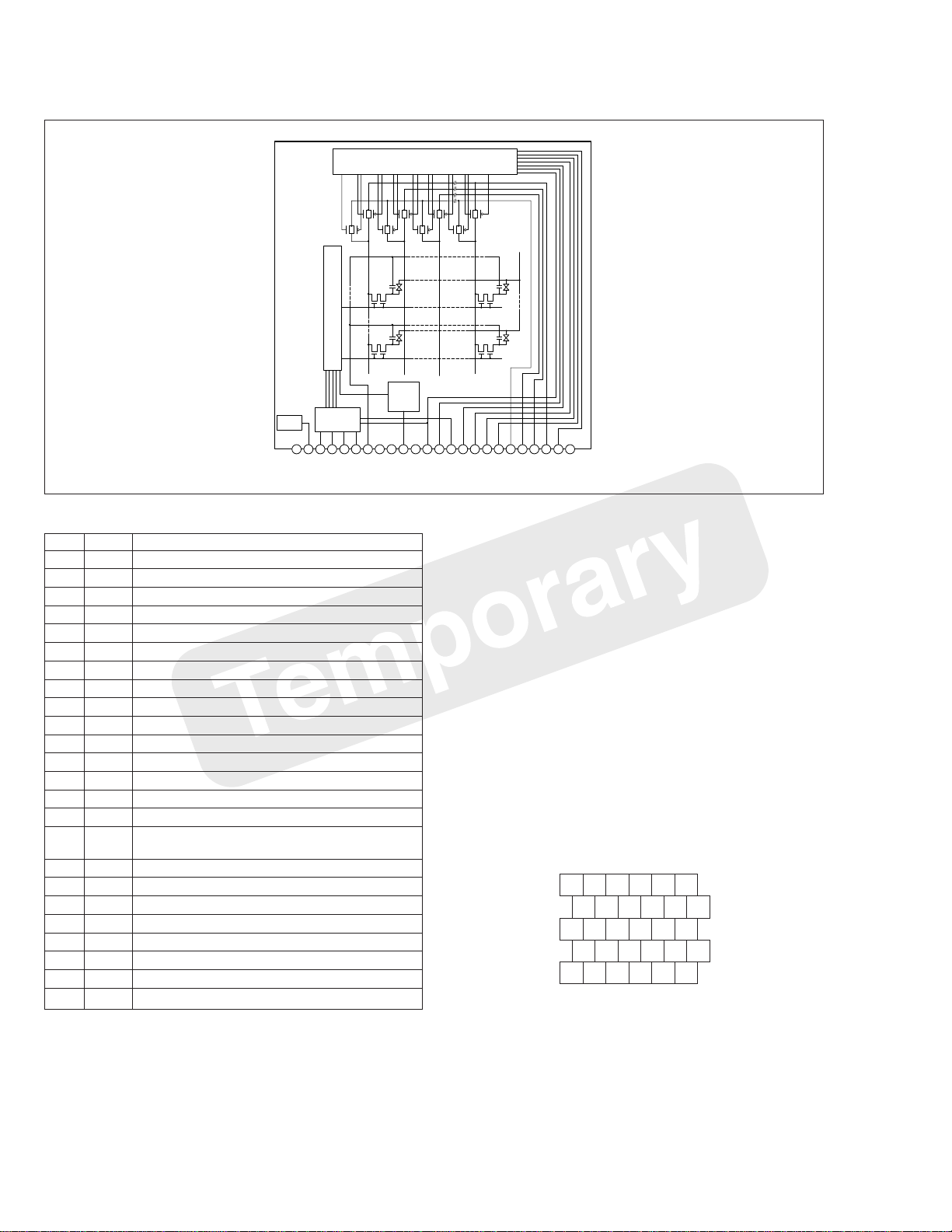

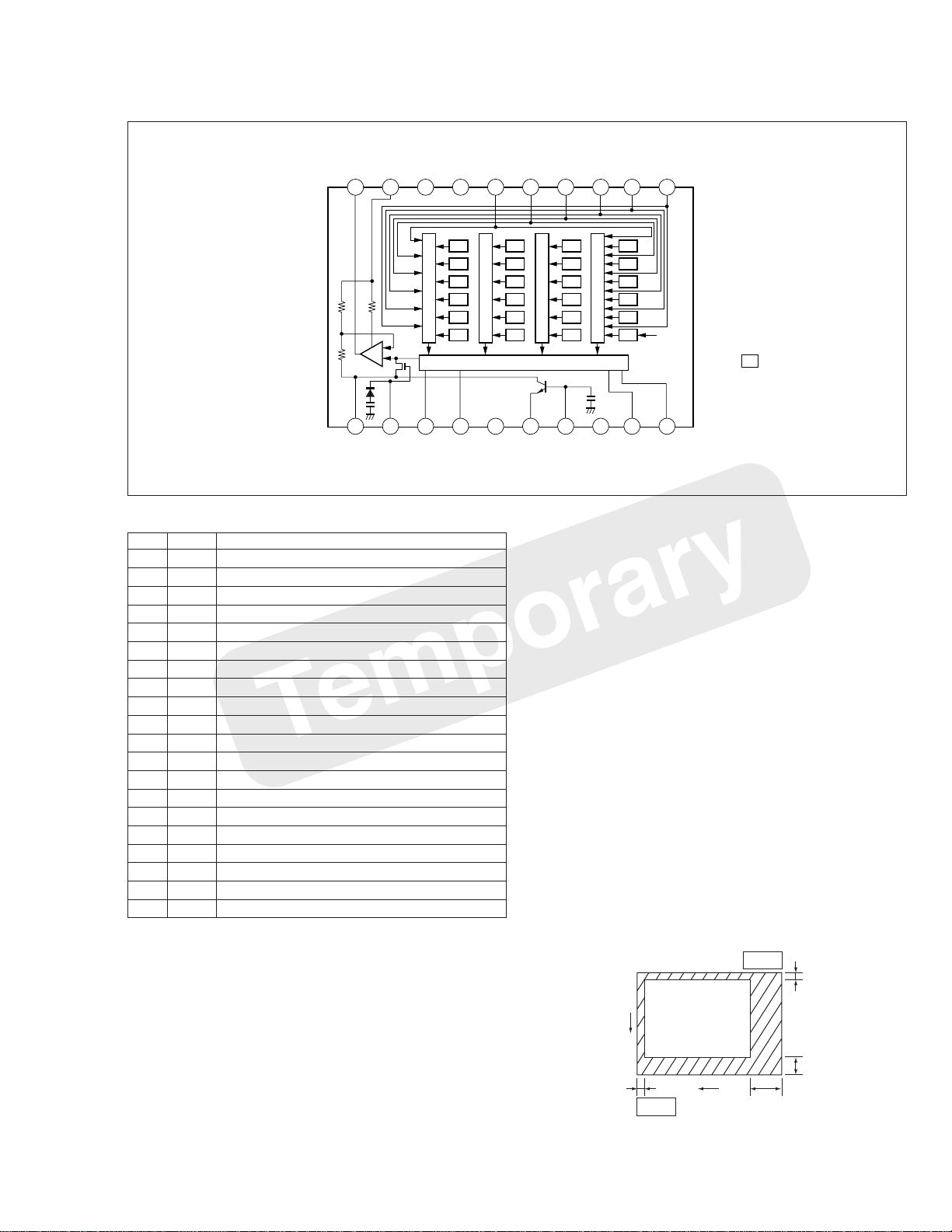

1.4.4 LCD (ACX301AK)

BGRBRG

RBGRGB

RBGRGB

BGRBRG

RBGRGB

V shift register

COM

V Level shifter

Electrode

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

TESTL

Pin Descriptions

Pin No. Pin Name Description

1 TESTL Panel testing terminal (Should be opened.)

2 COM Common electrode voltage input terminal for panel

3 VST Start pulse input terminal for V shift register drive

4 VCK Clock input terminal for V shift register drive

5 EN Enable signal input terminal for gate select pulse

6 DWN Drive direction signal input terminal for V shift register

7VVDD Power for V driver

8VSS GND for H and V drivers

9HVDD Power for H driver

10 VSSG Negative voltage setting terminal for V driver

11 TEST2 Connected to GND through a 1-Mohm resistor in the panel

12 WIDE Pulse input terminal for 16:9 mode

13 HST Start pulse input terminal for H shift register drive

14 REF Level shifter circuit reference voltage input terminal

15 TEST Panel testing terminal (Should be opened.)

16 Cext/Rext Power input terminal for setting H shift register drive time

constant

17 HCK2 Clock input terminal for H shift register drive

18 HCK1 Clock input terminal for H shift register drive

19 PSIG Uniformity improving signal input terminal

20 GREEN Video signal (G) input terminal for the panel

21 RED Video signal (R) input terminal for the panel

22 BLUE Video signal (B) input terminal for the panel

23 RGT Drive direction signal input terminal for H shift register

24 TESTR Panel testing terminal (Should be opened.)

COM

EN

VST

VCK

DWN

H Level shifter & Shift register

LCCs

Negative

Voltage

Occurence

Circuit

VSS

VVDD

VSSQ

HVDD

TEST2

COM

HST

WIDE

REF

TEST

HCK2

Cext/Rext

HCK1

PSIG

GREEN

RED

BLUE

RTG

TESTR

Features

• Device Structure

- Active matrix panel with internal driver using lowtemperature polysilicon transistors

- Pixels

Total dots: 896 (H) x 230 (V) =206,080

Display dots: 880 (H) x 228 (V) =200,640 (2.0 in.)

• Total dots: 200,000 dots 5.1cm diagonal (2.0 in.)

• Horizontal resolution: 440 TV scanning lines

• Light permeability: 5.6% (standard)

• Smooth screen image with RGB delta array

• NTSC/PAL compatible

• High image quality internal circuitry

• 16:9 screen display function

• Low-reflection screen display processing assures easy

viewing even outdoors

• Anti-grime display

Delta array

1-9

Page 9

1.4.5 CCD (ICX262AQ)

11

V

DD

10

V

OUT

12

ØRG

9

GND

13

H

Ø2

8

TEST

14

H

Ø1

7

TEST

15

GND

6

V

Ø1B

16

5

V

Ø1A

17

C

SUB

4

V

Ø2

18

V

L

3

V

Ø3B

19

H

Ø1

2

V

Ø3A

20

H

Ø2

1

V

Ø4

B

Gr

B

Gr

B

Gr

Gb

R

Gb

R

Gb

Gb

B

Gr

B

Gr

B

Gr

Gb

R

Gb

R

Gb

R

Vertical register

Horizontal register

(NOTE)

(NOTE)

: Photo Sensor

Pin Descriptions

Pin No. Pin Name Description

1Vø4 Vertical register transfer clock

2Vø3A Vertical register transfer clock

3Vø3B Vertical register transfer clock

4Vø2 Vertical register transfer clock

5Vø1A Vertical register transfer clock

6Vø3B Vertical register transfer clock

7 TEST Test terminal*

8 TEST Test terminal*

1

1

9 GND GND

10 VOUT Signal output

11 VDD Circuit power

12 øRG Reset gate clock

13 Hø2 Horizontal register transfer clock

14 Hø1 Horizontal register transfer clock

15 GND GND

16 øSUB PCB clock

17 CSUB PCB bias*

2

18 VL Protection transistor bias

19 Hø1 Horizontal register transfer clock

20 V

ø2 Horizontal register transfer clock

*1: Terminal should be opened.

*2: A 0.1µF capacitor should be connected between the pin and GND, since the

DC bias is generated inside the CCD.

Features

• Field period readout system

• Interline CCD image sensor

• Total number of pixels: 2140 (H) x 1560 (V) approx. 3340k

pixels

• Number of effective pixels: 2088 (H) x 1550 (V) approx.

3240k pixels

• Effective number of pixels: 2080 (H) x 1542 (V) approx.

3210k pixels (1.18in)

• Chip size: 8.10mm (H) x 6.64mm (V)

• Unit cell size: 3.45µ␣ m (H) x 3.45µ␣ m (V)

• Optical black:

Horizontal (H) direction : front 4 pixels, rear 48 pixels

Vertical (V) direction : front 8 pixels, rear 2 pixels

• Number of dummy bits: Horizontal 28 Vertical 1 (even fields

only)

• Square pixels

• Horizontal drive frequency: 18kHz

• RGB basic color mosaic on-chip color filter

• High sensitivity

• Cyclic, variable speed shutter

• Excellent anti-blooming characteristics

1pin

2

V

8

4

11pin

H

48

Optical black wiring diagram

(Top View)

1-10

Page 10

SECTION 2

ELECTRICAL ADJUSTMENT

2.1 ELECTRICAL ADJUSTMENT

2.1.1 Precautions

Both the camera section and deck section of this model

are designed and manufactured to be adjustment-free.

However, if both or either of the following parts is replaced,

it needs special adjustment with a personal computer at a

JVC service equipment after the part replacement

• OP block assembly

• EEPROM (on the MAIN board)

When there is some trouble in the electric circuit, it is required

to detect the faulty part with specified test instruments first

and then to proceed to repair, replacement and adjustment.

1. When cheking a signal at a chip test point, be sure to use

an IC clip or the like not to apply any stress to the test point.

When replacing a chip part (IC in particular), completely

remove solder chips from it and its periphery before

proceeding to part replacement (in order to avoid exfoliation

of the pattern).

2. Carefully disconnect/connect connectors because they

are apt to get damaged.

2.1.2 Test instruments 0required for electrical

adjustment

12

34

Patch cord

YTU93099A

Service support system

YTU94057-47

Jig connector cable

YTU93102A

PC cable

QAM0099-002

12

14

Gray scale chart

YTU94133A

Cleaning cloth

KSMM-01

Smart media card

16MB

Light box assembly

910

11

13

YTU93096A

Color bar chart

YTU94133C

USB

QAM0252-001

2.1.3 Required test equipment

1. Color TV monitor.

2. AC power adapter (AA-V37 or equivalent)

3. Oscilloscope (dual-trace type, for more than 20 MHz).

4. Digital voltmeter

5. Frequency counter (with threshold level adjuster)

6. Personal computer

2.1.4 Setup (LCD ADJUSTMENT)

Setup for electrical adjustment with personal computer

Note 1:

As a general rule for adjustment with a personal

computer, connect a personal computer to its

PRINTER terminal.

Note 2:

Use DC cord to supply the power.

Jig connector cable

5

78

YTU93091B

INF adjustment lens

YTU92001B

Extension connector

6

Camera stand

YTU94145A

YTU93079

2-1

PRINTER

PC cable

QAM0099-002

Service support system

YTU94057-47

RS-232C

port

MENU

Personal computer

Fig. 2-1-1 Setup for electrical adjustment with

personal computer (I)

Page 11

Extension connector

Personal computer

USB

port

Service support system

YTU94057-47

16MB

Smart media

Card

MENU

USB

Note) It is needs to connect

the extension

double for use the DC

cord(coupler)

Jig connector cable

(YTU93091B)

Fig. 2-1-2 Setup for electrical adjustment with

personal computer (II)

Pin No. FUNCTION

1 135TMS

2 135TDI

3 nTRST

4 AL_3.3V

5 32DBI

6 GND

7 M_COM

8 M_SIG_C

9 M_RED

10 M_SIG_GND

11 JTAGMODE

12 135TDO

13 135TCK

14 AL_3.3V

15 32RST

16 M_BLUE

17 RPD

18 M_PSIG

19 M_GREEN

20 NC

connector

2.1.5 Setup (CCD ADJUSTMENT)

Setup for electrical adjustment with personal computer

Note 1:

As a general rule for adjustment with a personal

computer, connect a personal computer to its

USB terminal.

Note 2:

Use DC cord to supply the power.

Fig. 2-1-3 Setup for electrical adjustment with

personal computer (I)

Table 2-1-1 Jig Connector Function

2-2

Page 12

3.2 BOARD INTERCONNECTION

NOTE : When ordering parts, be sure to order according

to the Part Number indicated in the Parts List.

3-3 3-4

Page 13

3.3 MAIN (SYSCON) SCHEMATIC DIAGRAM

NOTE : When ordering parts, be sure to order according

to the Part Number indicated in the Parts List.

3-5 3-6

❈ MARK IS NOT USED

Page 14

3.4 MAIN (DSP96) SCHEMATIC DIAGRAM

NOTE : When ordering parts, be sure to order according

to the Part Number indicated in the Parts List.

3-7 3-8

❈ MARK IS NOT USED

Page 15

3.5 MAIN (DSP97) SCHEMATIC DIAGRAM

NOTE : When ordering parts, be sure to order according

to the Part Number indicated in the Parts List.

3-9 3-10

❈ MARK IS NOT USED

Page 16

3.6 MAIN (G/A JCY0148) AND MAIN (SD SUB) SCHEMATIC DIAGRAM

3.7 MAIN (F/Z MDA) ANDMAIN (IRIS) SCHEMATIC DIAGRAMS

NOTE : When ordering parts, be sure to order according

to the Part Number indicated in the Parts List.

NOTE : When ordering parts, be sure to order according

to the Part Number indicated in the Parts List.

❈ MARK IS NOT USED

❈ MARK IS NOT USED

3-11 3-12

Page 17

3.8 MAIN (CCD AGC A/D AND ARM ROM) SCHEMATIC DIAGRAM

3.9 MAIN (STROBE CONTROL AND STROBE FLASH) SCHEMATIC DIAGRAM

NOTE : When ordering parts, be sure to order according

to the Part Number indicated in the Parts List.

NOTE : When ordering parts, be sure to order according

to the Part Number indicated in the Parts List.

❈ MARK IS NOT USED

3-13 3-14

❈ MARK IS NOT USED

Page 18

3.10 CCD SCHEMATIC DIAGRAM

3.11 MONI REG (MONITOR) SCHEMATIC DIAGRAMS

NOTE : When ordering parts, be sure to order according

to the Part Number indicated in the Parts List.

NOTE : When ordering parts, be sure to order according

to the Part Number indicated in the Parts List.

❈ MARK IS NOT USED

❈ MARK IS NOT USED

3-15 3-16

Page 19

3.12 MONITOR REG (DC/DC) SCHEMATIC DIAGRAMS

NOTE : When ordering parts, be sure to order according

to the Part Number indicated in the Parts List.

3-17 3-18

❈ MARK IS NOT USED

Page 20

3.13 JACK(VIDEO OUT/USB/PRINTER/DC JACK) AND MONITOR BACK LIGHT SCHEMATIC DIAGRAM

NOTE : When ordering parts, be sure to order according

to the Part Number indicated in the Parts List.

- WAVEFORM -

(Page 3-19)

❈ MARK IS NOT USED

3-19 3-20

Page 21

SECTION 4

5

PARTS LIST

SAFETY PRECAUTION

Parts identified by the symbol are critical for safety. Replace only with specified part numbers.

4.1 PACKING AND ACCESSORY ASSEMBLY <M1>

The instruction manual to be provided with this product will differ according to the destination.

17

AC POWER ADAPTER

AA-V37U

(Refer to Sec.5)

8

18

FINAL ASSY <M2>

(GC-QX3U)

6

16

BATTERY PACK

(BN-V37U)

5A

2

7

4

3

25

9

10

27

21

24

26

28

35

31

32

33

1

LABEL

(SERIAL)

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

--------------- ----------------------- ----------------------------------------------------- ---------------- ----------------------- ------------------------------------------------------

✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽

PACKING AND ACCESSORY ASSEMBLY <M1>

1 LY31465-002A PACKING CASE

2 LY30023-016A POLY BAG

3 LY31466-001A CUSHION

4 LY42548-001A SHEET

5 LY31822-001A HOOD(OP)

5A QPA01001505 POLY BAG

6 PEAC0449 DC PLUG CORD

7 PEAC0496 VIDEO CABLE

8 QAM0252-001 USB CABLE

9 LY31074-007A CD ROM ASSEMBLY

10 BT-51020-2 REGIST.CARD

16 QQR0491-002 CORE FILTER

17 QQR0491-001 CORE FILTER,x2

18 QQR0917-002 CORE FILTER

21 QPA02003006 POLY BAG

24 LY30663-001A HAND STRAP

25 LY31468-002A LENS CAP

26 LY42313-001A STRING

27 LY31737-001A MEDIA CARD ASSEMBLY

28 BT-51005-4 WARRANTY INF.

31 LYT0543-001A INST.BOOK(EN)

32 LYT0543-002A INST.BOOK(FR)

33 LYT0543-003A INST.BOOK(SP)

35 LYT0543-005A SHEET(HOOD)

4-1

4-2

Page 22

FINAL ASSEMBLY

153

<M2>

153C

116

110

111

BEWARE OF BOGUS PARTS

Parts that do not meet specifications may cause trouble

in regard to safety and performance. We recommend that

116

116

D

genuine JVC parts be used.

156

153B

E

153D

153A

112

115

G

H

F

114

114

116

E

p

F

m

155

116

153E

116

117

e

f

g

JACK BOARD ASSY

< 04 >

114

117

e

n

101A

A

C

115

101D

B

102

r

STROBE

BOARD ASSY

< 05 >

d

101C

G

H

CCD BOARD ASSY

< 03 >

101B

101E

101E

f

g

h

113

101

MONI/REG BOARD ASSY

< 02 >

d

114

A

108

q

p

j

103

c

n

109

h

q

j

B

104

k

r

107B

MAIN BOARD ASSY

< 01 >

114

E

F

107C

107A

G

152

D

152A

H

116

156

114

4-3

4-4

C

107

106

105

114

m

k

Page 23

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

--------------- ----------------------- ----------------------------------------------------- ---------------- ----------------------- ------------------------------------------------------

✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽

CABINET AND CHASSIS ASSEMBLY <M2>

101 LY31451-001B FRAME ASSY

101A LY20518-001A FRAME

101B LY41858-001A BRAKET(STOPPER)

101C LY41860-001A TERMINAL(BATTERY)

101D LY41861-001A SPRING(BATTERY)

101E LY30018-019A SPECIAL SCREW

102 LY31490-001B OP ASSEMBLY

103 LY31457-002A PWB HOLDER ASSEMBLY

104 LY31467-001A HOLDER(LCD)

105 LY30029-031A SPACER(A)

106 LY30016-085A SPACER-A

107A QLD0131-001 LCD MODULE

107B QLL0084-001 BACK LIGHT

107C LY42322-001A SHEET

108 QUQ105-3805AA FFC WIRE,MAIN-JACK

109 QAL0234-001 FPC,MAIN-CCD

110 LY31460-003A TOP COVER ASSY

111 LY20521-002B OPERATION UNIT

112 LY30016-078A SPACER-A

113 LY30029-016A SPACER(A)

114 LY30018-060A SPECIAL SCREW

115 LY30018-010A SPECIAL SCREW

116 LY30018-023A SPECIAL SCREW

117 LY30019-025A SPECIAL SCREW

152 LY20519-003B REAR COVER ASSEMBLY

152A LY31456-001A COVER(JACK)

153A LY20516-003A FRONT COVER

153B LY42320-001A GRIP ASSEMBLY

153C LY41854-001A KNOB(SHUTTER)

153D LY30002-042B COMPRES. SPRING

153E LY31446-001A HOOD

155 LY30018-056A SPECIAL SCREW

156 LY30018-059A SPECIAL SCREW

4-5

Page 24

SECTION 5

AC POWER ADAPTER (AA-V37U)

SAFETY PRECAUTION

Parts identified by the ! symbol are critical for safety. Replace only with specified part numbers.

6.1 CABINET ASSEMBLY <MA>

1

4

MAIN&TERMINAL <91>

6

RATING LABEL

#!REF No. PART No. PART NAME, DESCRIPTION

----------------------- ------------------------------ ----------------------------------------------------------------------------

✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽

3

2

5

5

CABINET ASSEMBLY <MA>

! 1 PTY20545-012 UPPER CASE ASSY

! 2 PTY20483-021 LOWER CASE

! 3 PTY20290-040 POWER CORD

4 PTY20545-054 SWITCH COVER

5 YQ10531-011 TAP SCREW, x2

6 PTY20545-055 TAP SCREW, x3

Page 25

6.2 SCHEMATIC DIAGRAM

NOTE:

91 MAIN & TERMINAL

5

!

AC110

240V

50/60Hz

When ordering parts, be sure to order according to

the Part Number indicated in the Parts List.

!

S1WBA60

!

0.068

!

Safety precautions

The components identified by the symbol ! are critical

for safety . For continued safety , replace safety critical components only with manufacturer’s recommended parts.

!

!

!

Q26

2SC2925

!!

4

!

FS2KM18A

Q2

25D2227

!

2SB1413

DTC114YU

Q22

SW21

3

!

2

121.0K

0.001µ

1

0.001µ

DTC114YU

DTC114YU

TERMINAL

ABCD E F G

Page 26

6.4 ELECTRICAL PARTS LIST

#!REF No. PART No. PART NAME, DESCRIPTION

----------------------- ------------------------------ ----------------------------------------------------------------------------

✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽

MAIN & TERMINAL BOARD ASSEMBLY <91>

PW1 PTY20545-502 MAIN&TERMINAL BOARD ASSY

IC1 AN8167K CHARGER IC

Q1 FS2KM18A MOS FET

Q2 2SD2227 TRANSISTER

Q3 2SD2227 TRANSISTER

Q21 DTC114YU-X TRANSISTER

Q22 2SB1434 TRANSISTOR

Q23 UN5114TX TRANSISTOR

Q24 DTC114YU-X TRANSISTOR

Q25 DTC114YU-X TRANSISTOR

Q26 2SC2925TTA TRANSISTOR

D1 S1WBA60 B DIODE 600V 1A

D2 1SS244T77 DIODE 200V 6A

D3 1SS244T77 DIODE 200V 6A

D21 MA7D56 DIODE 60V 10A

D22 ERB83004V1 DIODE 40V 1.7A

D23 1SS244T77 DIODE 200V 6A

D24 1SS244T77 DIODE 200V 6A

D25 1SS244T77 DIODE 200V 6A

D26 1SS244T77 DIODE 200V 6A

ZD1 MTZJ12C-T2 ZENER DIODE 12V 500mW

ZD2 MTZJ9.1B ZENER DIODE 9.1V500mW

ZD21 MTZJ7.5B-T2 ZENER DIODE 7.5V500mW

ZD22 MTZJ12C-T2 ZENER DIODE 12V 500mW

ZD23 MTZJ2.2A-T2 ZENER DIODE 2.2V 500mW

ZD24 MTZJ16T-77 ZENER DIODE 16V 500mW

ZD26 MTZJ11A-T2 ZENER DIODE 11V 500mW

ZD27 MA4047N/M/T2 ZENER DIODE 4.7V 0.37W

ZD28 MTZJ7.5B-T2 ZENER DIODE 7.5V 500mW

ZD29 MTZJ24C-T2 ZENER DIODE 24V 500mW

LED21

PTY20545-641 LED(RED)

LED22

PTY20545-642 LED(ORANGE)

LED23

PTY20545-643 LED(GREEN)

R1 QRN141J-105Y RESISTOR 1MΩ 1/4W

R2 NRSA02J-753X MG RESISTOR 75kΩ 1/10W

R3 PTY20545-601 MF RESISTOR 0.56Ω1W

R4 QRE141J-334Y RESISTOR 330kΩ 1/4W

R5 QRE141J-334Y RESISTOR 330kΩ 1/4W

R7 PTY20545-602 MG RESISTOR 910Ω1/2W

R8 NRSA02J-163X MG RESISTOR 16kΩ 1/10W

R9 NRSA02J-392X MG RESISTOR 3.9kΩ 1/10W

R10 NRSA02J-104X MG RESISTOR 100kΩ 1/10W

R11 NRSA02J-752X MG RESISTOR 7.5kΩ 1/10W

R12 QRE141J-470Y RESISTOR 47Ω 1/4W

R13 QRE141J-334Y RESISTOR 330kΩ 1/4W

R14 QRE141J-334Y RESISTOR 330kΩ 1/4W

R15 NRSA02J-182X MG RESISTOR 1.8kΩ 1/10W

R21 NRSA02J-470X MG RESISTOR 47Ω 1/10W

R22 PTY20545-603 MF RESISTOR 0.47Ω 2W

R23 NRSA02J-472X MG RESISTOR 4.7kΩ 1/10W

R24 NRSA02F-4752X MG RESISTOR 47.5kΩ 1/10W

R25 NRSA02J-472X MG RESISTOR 4.7kΩ 1/10W

R26 NRSA02F-1213X MG RESISTOR 121kΩ 1/10W

R27 NRSA02J-101X MG RESISTOR 100Ω 1/10W

R28 NRSA02J-362X MG RESISTOR 3.6kΩ 1/10W

R29 NRSA02J-103X MG RESISTOR 10kΩ 1/10W

R30 NRSA02J-181X MG RESISTOR 180Ω 1/10W

R31 NRSA02J-242X MG RESISTOR 2.4kΩ 1/10W

#!REF No. PART No. PART NAME, DESCRIPTION

----------------------- ------------------------------ ----------------------------------------------------------------------------

R32 NRSA02J-331X MG RESISTOR 330Ω 1/10W

R33 NRSA02J-273X MG RESISTOR 27kΩ 1/10W

R41 NRSA02F-5621X MG RESISTOR 5.62kΩ 1/10W

R42 NRSA02J-103X MG RESISTOR 10kΩ 1/10W

R43 NRSA02F-681X MG RESISTOR 680Ω 1/10W

R44 NRSA02F-1961X MG RESISTOR 1.96kΩ 1/10W

R45 NRSA02J-472X MG RESISTOR 4.7kΩ 1/10W

R46 NRSA02J-563X MG RESISTOR 56kΩ 1/10W

R47 NRSA02F-822X MG RESISTOR 8.2kΩ 1/10W

R48 NRSA02F-183X MG RESISTOR 18kΩ 1/10W

R49 NRSA02J-0R0X MG RESISTOR 0Ω 1/10W

R50 NRSA02F-2151X MG RESISTOR 2.15kΩ 1/10W

R51 NRSA02J-471X MG RESISTOR 470Ω 1/10W

R52 NRSA02J-471X MG RESISTOR 470Ω 1/10W

R53 NRSA02F-204X MG RESISTOR 200kΩ 1/10W

R54 NRSA02J-274X MG RESISTOR 270kΩ 1/10W

R55 NRSA02J-221X MG RESISTOR 220Ω 1/10W

R56 NRSA02J-181X MG RESISTOR 180Ω 1/10W

R57 NRSA02J-102X MG RESISTOR 1kΩ 1/10W

! C1 PTY20292-303 CAPACITOR 0.068µF 275V

C2 YQ10626-402 E CAPACITOR 47µF 400V

C4 NCB21CK-224X CAPACITOR 0.22µF 16V

C5 PTY10067-653 CAPACITOR 0.01µF 50V

C6 NCB21HK-102X CAPACITOR 0.001µF 50V

! C7 PTY20292-358 CAPACITOR 1000pF 250V

C10 NDC21HJ-151X CAPACITOR 150pF 50V

C11 NDC21HJ-151X CAPACITOR 150pF 50V

C21 PTY10067-657 CAPACITOR 0.01µF 250V

C22 PTY20545-621 E CAPACITOR 330µF 35V

C23 PTY20545-622 E CAPACITOR 220µF 10V

C24 NCF21EZ-104X CAPACITOR 0.1µF 25V

C25 PTY20545-623 E CAPACITOR 220µF 25V

C26 NCF21EZ-104X CAPACITOR 0.1µF 25V

C40 QCBB1HK-104Y CAPACITOR 0.1µF 50V

C43 QEHA1HM-475 E CAPACITOR 4.7µF 50V

C44 NCB21CK-224X CAPACITOR 0.22µF 16V

C45 NCB21CK-224X CAPACITOR 0.22µF 16V

C46 PTY20545-624 E CAPACITOR 47µF 16V

C47 NCB21HK-102X CAPACITOR 0.001µF 50V

C48 NCB21HK-102X CAPACITOR 0.001µF 50V

C49 NCB21EK-104X CAPACITOR 0.1µF 25V

C50 NCB21HK-103X CAPACITOR 0.01µF 50V

C51 NCB21EK-104X CAPACITOR 0.1µF 25V

C52 NCF21HZ-104X CAPACITOR 0.1µF 50V

C60 PTY20545-625 CAPACITOR 0.22µF 25V

C61 PTY20545-625 CAPACITOR 0.22µF 25V

C62 NCF21EZ-104X CAPACITOR 0.1µF 25V

C63 NCF21EZ-104X CAPACITOR 0.1µF 25V

C64 NCF21EZ-104X CAPACITOR 0.1µF 25V

C65 NCB21CK-224X CAPACITOR 0.22µF 16V

! L1 PTY20450-401 LINE FILTER

L21 PTY10067-703 COIL

L22 PTY20545-651 B INDUCTOR

L23 PTY10067-707 B INDUCTOR 120mH

! HS1 PTY20483-071 HEAT SINK A

! HS2 PTY20545-072 HEAT SINK B

OT1 PTY10067-551 TAP SCREW,X2(HEAT SINK)

! F1 PTY20450-40 FUSE 2A 250V

JK21 YQ21032-301 DC JACK

! T1 PTY20545-661 SW TRANS

SW21 PTY20545-662 SWITCH

WR1 PTY20545-052 FLAT CABLE(9PIN),CN21

LS1 PTY20545-053 LED SPACER,X3(LED21,LED22,LED23)

TB1 PTY20545-051 TERMINAL,X4 (CN21, + – )

VR41 PTY20483-101 VOLUME 2kΩ

! PHC1 PC817A PHOTO COUPLER

! orPC817X1 PHOTO COUPLER

Page 27

JVC SERVICE & ENGINEERING COMPANY OF AMERICA

DIVISION OF JVC AMERICAS CORP.

Head office

East Coast

Midwest

West Coast

Atlanta

Hawaii

Head office

Montreal

Vancouver

1700 Valley Road Wayne, New Jersey 07470-9976

:

10 New Maple Avenue Pine Brook, New Jersey 07058-9641

:

705 Enterprise Street Aurora, Illinois 60504-8149

:

5665 Corporate Avenue Cypress, California 90630-0024

:

:

1500 Lakes Parkway Lawrenceville, Georgia 30043-5857

:

2969 Mapunapuna Place Honolulu, Hawaii 96819-2040

JVC CANADA INC.

:

21 Finchdene Square Scarborough, Ontario M1X 1A7

:

16800 Rte Trans-Canadienne, Kirkland. Quebec H9H 5G7

:

13040 Worster Court Richmond B.C. V6V 2B3

(973)315-5000

(973)396-1000

(630)851-7855

(714)229-8011

(770)339-2582

(808)833-5828

(416)293-1311

(514)871-1311

(604)270-1311

S40895-03

Printed in Japan

Loading...

Loading...