Page 1

SERVICE MANUAL

DIGITAL STILL CAMERA

GC-QX3HDU/GC-QX5HDU

STILL CAMERA

Regarding service information other than these sections, refer to the GC-QX3U service manual (No.86564).

Also, be sure to note important safety precautions provided in the service manual.

SPECIFICATIONS

Power source

Power consumption

Dimensions

Weight

Operating temperature

Relative humidity

Storage temperature

LCD screen

Storage media

CCD

Focal distance

Lens

Video

Recording format

Sensitivity

Iris value (F value)

Exposure control

Exposure compensation

Minimum subject distance

Light measurement system

Flash

Recommended distance for flash

Shutter speed

White balance

Focus

: DC 5 V

: 3.6 W (when the LCD screen is off)

4.8 W (when the LCD screen is on)

: 111 (W) mm x 67 (H) mm x 59 (D) mm

(4-3/8" x 2-11/16" x 2-3/8") (except protruding parts)

: Approx. 290 g (0.64 lbs)

(without a Memory card and battery)

:0°C to 40°C (32°F to 104°F)

: 35% to 80%

: –20°C to 50°C (–4°F to 122°F)

: 2.0 inch, polysilicon TFT (200,000 pixels)

: SmartMedia

: 3.34 million pixels (3.24 million valid pixels),

1/1.8" square pixels, primary color filter,

interlace scan CCD

: 7.5 mm to 17.5 mm

(equivalent to 37mm to 86 mm on a 35 mm still camera)

: 2.3X optical zoom lens

: 160 pixels x 120 pixels, 20 seconds, JVC original format

: Exif Ver. 2.1 (DCF compliant), TIFF (Uncompressed),

DPOF-compatible

: 80/160/320 (ISO compliant)

: F2.8/3.8, 5.6, 8, 11

: Program AE, iris priority AE

: ±2EV (0.5EV steps)

: Approx. 2 cm to 50 cm (in Macro mode)

: Multi, spot

: Built-in,

Auto/red-eye prevention/forced/disabled

: Approx. 2.5 m

: Auto (Program AE: 1/8 seconds – 1/750 seconds,

Iris priority AE: 2 seconds – 1/750 seconds )

: Auto/Manual (

: Auto/Manual

TM

3.3V (up to 64MB)

, , , MWB, )

Self timer

Photo quality

Number of storable photos

(with an 8MB Memory card,

STANDARD/FINE/NO COMP.)

Battery

Printer connector

VIDEO output connector

Digital output connector

: 1 second, 8 seconds

: 3 modes (STANDARD/FINE/NO COMP.)

: 2032 x 1536: approx. 10/8/0

1024 x 768: approx. 43/32/3

640 x 480: approx. 87/65/8

: Lithium ion battery

: Output for optional printer

: Two-pole plug, 3.5 mm diameter (NTSC)

: Mini-USB connector

AC Power Adapter/Charger AA-V37

Power requirement

U.S.A. and Canada

Other countries

Power consumption

Output

Charge

Camera

Operating temperature

Dimensions

Weight

E. & O. E. Design and specifications subject to change without notice.

: AC 120 V`, 60 Hz

: AC 110 V – 240 V`, 50 Hz/60 Hz

: 14 W

: DC 3.6 V

: DC 5.0 V

:0°C to 40°C (32°F to 104°F)

[when charging: 10°C to 35°C (50°F to 95°F)]

: 68 (W) mm x 38 (H) mm x 110 (D) mm

(2-11/16" x 1-1/2" x 4-3/8")

: Approx. 230 g (0.51 lbs) (without a DC cord)

, 0.77 A

, 1.5 A

No.86588

October 2000

Page 2

TABLE OF CONTENTS

Section Title Page

Important Safety Precautions

DIFFERENT TABLE

1. DISASSEMBLY

1.3.2 Disassembly method ( I ) ............................................ 1-1

2. ELECTRICAL ADJUSTMENT

2.1 ELECTRICAL ADJUSTMENT .......................................... 2-1

2.1.1 Precautions ................................................................. 2-1

Test instruments required for electrical adjustment .............

2.1.2

2-1

2.1.3 Required test equipment ............................................ 2-1

2.1.4 Setup (LCD ADJUSTMENT) ........................................ 2-1

2.1.5 Setup (CCD ADJUSTMENT) ....................................... 2-2

2.2 Setup with patch cords and jig connector cables............ 2-3

3. CHARTS AND DIAGRAMS

NOTES OF SCHEMATIC DIAGRAM ........................................ 3-1

CIRCUIT BOARD NOTES ......................................................... 3-2

3.1 BOARD INTERCONNECTION ......................................... 3-3

3.2 MAIN (SYSCON) SCHEMATIC DIAGRAM ...................... 3-5

3.3 MAIN (DSP146) SCHEMATIC DIAGRAM........................ 3-7

3.4 MAIN (DSP97) SCHEMATIC DIAGRAM.......................... 3-9

3.5 MAIN (CDS AGC A/D AND ARM ROM)

SCHEMATIC DIAGRAM ................... 3-11

3.6 MAIN (STROBE CONTROL AND AUDIO ) AND

STROBE FLASH SCHEMATIC DIAGRAMS........ 3-12

3.7 MAIN (F/Z_MDA / IRIS) SCHEMATIC DIAGRAM......... 3-13

JACK (VIDEO OUT/USB/PRINTER/DC JACK/

3.8

MONITOR BACK LIGHT) SCHEMATIC DIAGRAM ....

3-14

3.9 CCD SCHEMATIC DIAGRAM........................................ 3-15

3.10 MONI REG (MONITOR) SCHEMATIC DIAGRAM ......... 3-16

3.11 MONITOR REG (DC/DC) SCHEMATIC DIAGRAM........ 3-17

3.12 MAIN CIRCUIT BOARD (YB10299-01-01) ..................... 3-19

3.13 MAIN CIRCUIT BOARD (YB10299-01-03) ..................... 3-25

3.14 MONITOR REG CIRCUIT BOARD (YB10300-01-01) ..... 3-31

3.15 MONITOR REG CIRCUIT BOARD (YB10300-01-02) ..... 3-31

3.16 JACK CIRCUIT BOARD (YB10300-01-01) .................... 3-35

3.17 JACK CIRCUIT BOARD (YB10300-01-02) .................... 3-37

3.18 CCD CIRCUIT BOARD (YB10300-01-01) ...................... 3-39

3.19 CCD CIRCUIT BOARD (YB10300-01-02) ...................... 3-40

STOROBE FLASH CIRCUIT BOARD

3.20

STOROBE FLASH CIRCUIT BOARD

3.21

(YB10300-01-01) ... 3-41

(YB10300-01-02) ... 3-42

3.22 OVER ALL BLOCK DIAGRAM....................................... 3-43

SOFTW ARE SECTION FOR Windows

Operating Environment

The host computer that runs the Windows

operating environment must satisfy the following

conditions.

USB Driver

®

1. Microsoft

2. Available USB port

3. CD-ROM drive

Video Player

1. CPU: Intel

2. Microsoft

3. Display capability of 65,536 colors or more

4. CD-ROM drive

5. Minimum RAM requirement: 32MB

6. Minimum hard disk space requirement: 1MB

* The system requirements information is not a

* Microsoft

* Intel

* Other trademarks are property of their respective

* If you use Windows

Windows® 98/Windows® 98 Second

Edition, Full version (Not Upgrade)/Windows

2000 Professional (Not Upgrade)

®

Pentium® 200MHz class or higher

®

Windows® 95/Windows® 98

guarantee that provided software applications will

work on all personal computers meeting those

requirements.

®

, Windows® are either registered

trademarks or trademarks of Microsoft corporation

in United States and/or other countries.

®

, Pentium® are registered trademarks of Intel

corporation.

owners.

which does not have a USB port, use an optional

flash path, conversion card adapter, etc. For

details on the operating environment of these

devices, contact the dealers or manufacturers.

®

95 or a personal computer

®

®

SOFTW ARE SECTION FOR Macintosh

Operating Environment

The host computer that runs the Macintosh

operating environment must satisfy the following

conditions.

USB Driver

1. USB-compatible computer (iMac™, iBook™,

®

Power Mac™ G3/G4, Power Book™ G3, etc.)

2. Mac OS 8.5.1/Mac OS 8.6/Mac OS 9.0

JVC Video Decoder

1. Power PC 603e/120MHz or faster

2. Mac OS 7.6.1 or later

3. QuickTime 3.0 or later

4. Minimum RAM requirement: 32MB

5. Minimum hard disk space requirement: 1MB

®

is a registered trademark of Apple

* Macintosh

Computer.

* Other trademarks are property of their respective

owners.

* If you use Macintosh

port, use an optional flash path, conversion card

adapter, etc. For details on the operating environment of these devices, contact the dealers or

manufacturers.

®

which does not have a USB

®

®

4. PARTS LIST

4.1 PACKING AND ACCESSORY ASSEMBLY <M1> ........... 4-1

4.3 FINAL ASSEMBLY <M2> .............................................. 4-3

4.4 ELECTRICAL PARTS LIST ............................................... 4-6

MAlN BOARD ASSEMBLY <01> .................................... 4-6

CCD BOARD ASSEMBLY <02> .................................... 4-11

MONI REG BOARD ASSEMBLY <03> ......................... 4-12

JACK BOARD ASSEMBLY <04> .................................. 4-14

STROBE FLASH BOARD ASSEMBLY <05> ................. 4-15

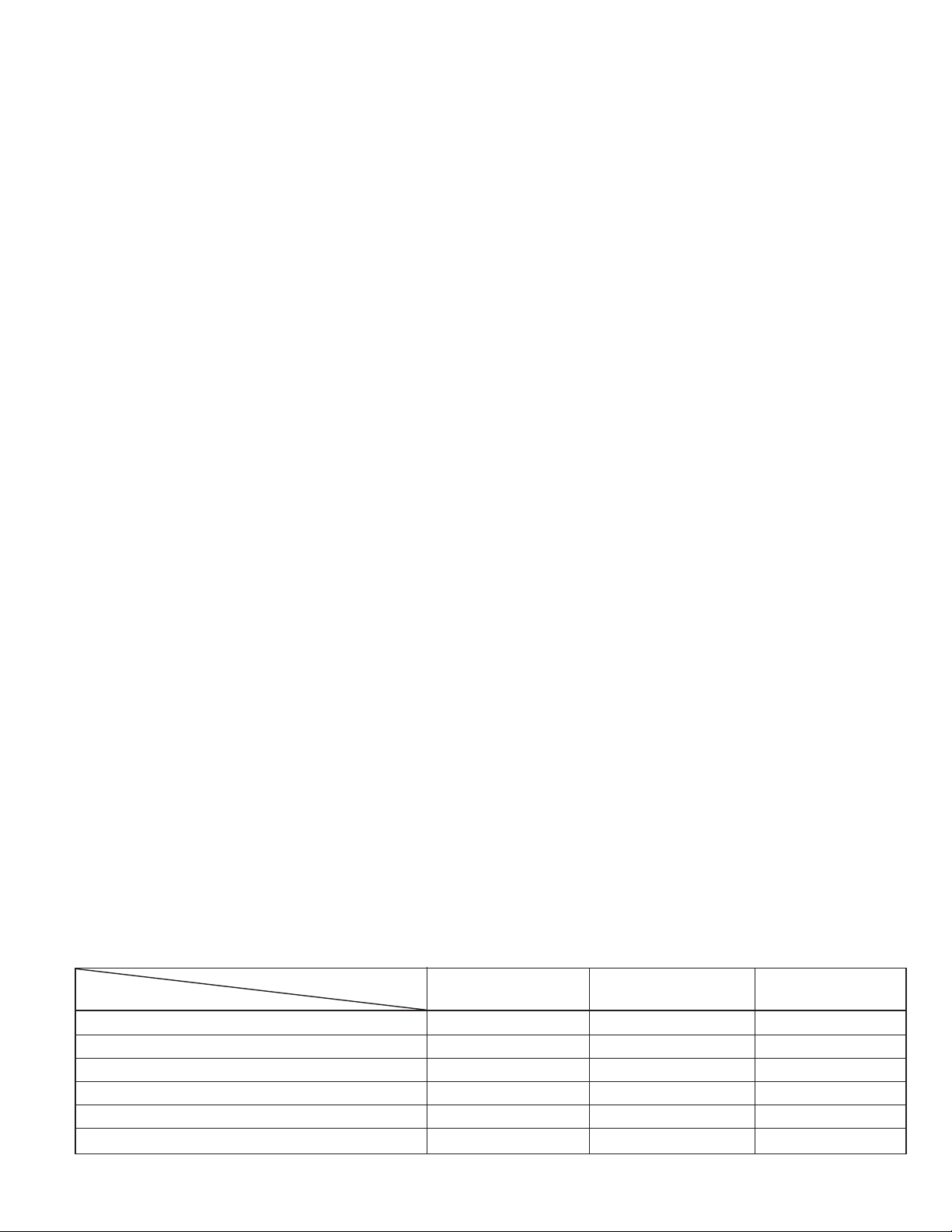

The following table indicate main different features between models GC-QX3U, GC-QX3HDU and GC-QX5HDU.

MODEL

ITEM

GC-QX3U GC-QX3HDU

Shooting Continuous Photos YES NO YES

Collage Mode YES NO YES

6M Pro-Still(Pixel Shift Mode) YES NO YES

DR Pro-Still(Wide Range Mode) YES NO YES

Installing the Film Copying Adapter NO NO YES

Shooting Film(Film Copy Mode) NO NO YES

GC-QX5HDU

Page 3

The following table indicate different parts number between models GC-QX3U, GC-QX3HDU and GC-QX5HDU.

P ACKING ASSEMBL Y <M1>

REF NO.

1 PACKING CASE LY31465-002A LY31465-013A LY32048-002A

2 POLY BAG LY30023-016A LY30023-016A +

3 CUSHION LY31466-001A LY31466-001A +

4 SHEET LY42548-001A –––– ––––

5 HOOD(OP) LY31822-001A –––– ––––

5A POLY BAG QPA01001505 –––– ––––

9 CD-ROM ASSEMBLY LY31074-007A LY31133-018A +

13 FILM COPY ADAP. –––– –––– LY20687-001A

14 FILM HOLDER AS –––– –––– LY32047-001A

15 CUSHION(ACC) –––– –––– LY32050-001A

19 CABLE ASSY(AUDIO/VIDEO) –––– QAM0297-001 +

20 POLY BAG –––– QPA01202505 +

27 MEDIA CARD ASSY LY31737-001A + LY31737-002A

! 31 INST.BOOK(EN) LYT0543-001C LYT0668-001C LYT0668-001A

! 32 INST.BOOK(FR) LYT0543-002A LYT0668-002C LYT0668-002A

! 33 INST.BOOK(SP) LYT0543-003A LYT0668-003C LYT0668-003A

ITEM

MODEL

GC-QX3U

GC-QX3HDU

GC-QX5HDU

Note : Mark –– is not used.

FINAL ASSEMBLY <M1>

REF NO.

103 BOARD HOLDER ASSEMBLY LY31457-002A + LY31457-007B

107C SHEET LY42322-001A –––– ––––

110 TOP COVER ASSEMBLY LY31460-003A LY31460-009A LY31460-008B

111 OPERATION UNIT LY20521-002C LY20521-002D LY20521-007B

113 SPACER(A) LY30029-016A –––– ––––

118 MICROPHONE –––– LY31454-001A +

125 S.SHEET(FFC) LY42506-001A –––– ––––

130 SHEET –––– LY42890-001A +

131 SPACER(A) –––– LY30029-0C2A +

152 REAR COVER ASSEMBLY LY20519-003B LY20519-009A LY20519-010A

153 FRONT COVER ASSEMBLY LYH20147-001A LYH20222-003A LYH20222-002A

153A FRONT COVER LY20516-003A LY20516-009A LY20516-008A

153B GRIP LY42320-001A LY31444-001A +

ITEM

MODEL

GC-QX3U

GC-QX3HDU

GC-QX5HDU

Note : Mark –– is not used.

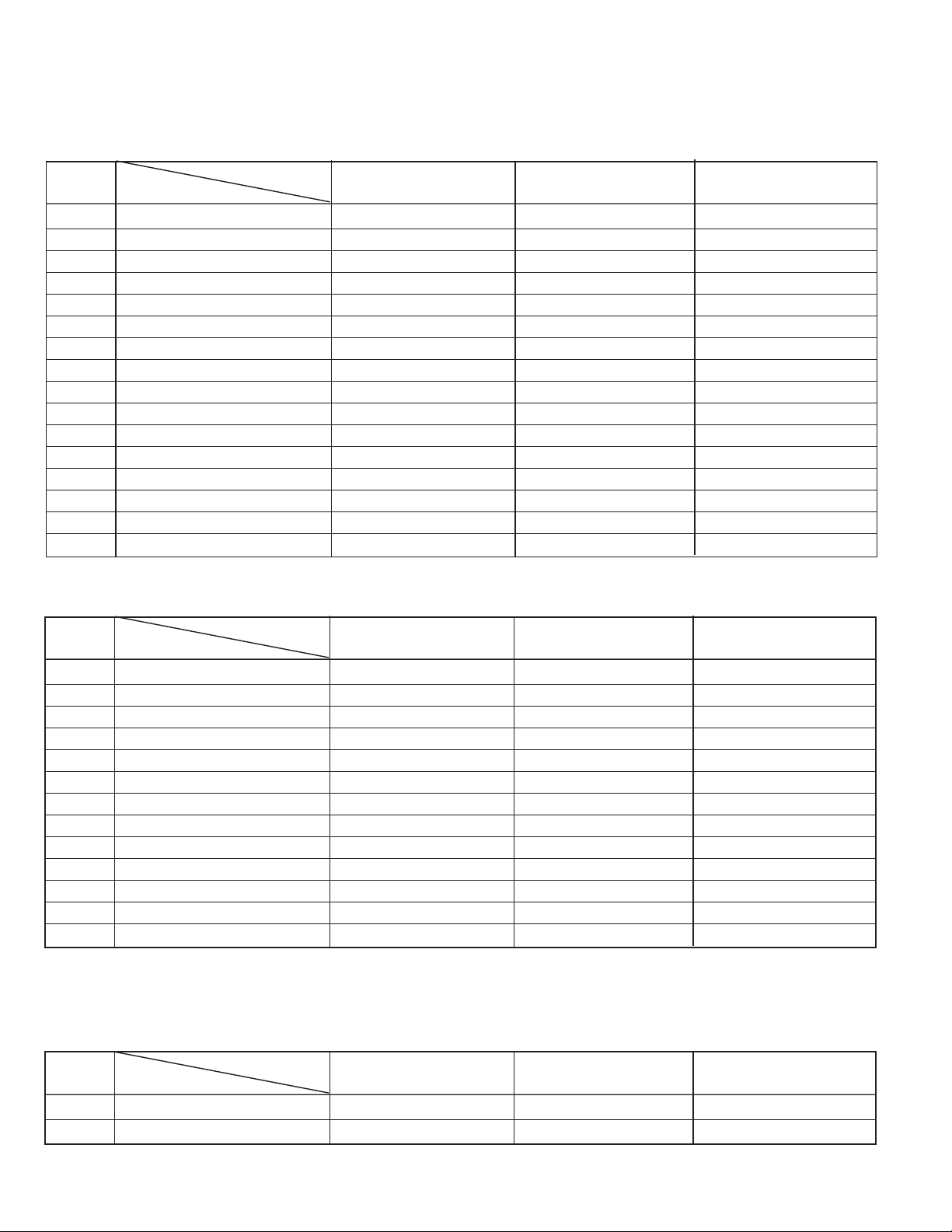

OP BLOCK ASSEMBLY <M3>

REF NO.

203 OPTICAL BLOCK ASSEMBLY

221 TILT FRAME *LY20716-001A ++

ITEM

MODEL

GC-QX3U

LY31490-001B LY31490-004A +

GC-QX3HDU

GC-QX5HDU

Note : Mark –– is not used.

Note : Mark * is GC-QX3U was also changed.

Page 4

MAIN BOARD ASSEMBLY <01>

REF NO.

PW1 MAIN BOARD ASSEMBLY

ITEM

MODEL

GC-QX3U

YB10282B-06 YB10299K-03 YB10299U-01

GC-QX3HDU

GC-QX5HDU

CCD BOARD ASSEMBLY <02>

REF NO.

PW1 CCD BOARD ASSEMBLY

ITEM

MODEL

GC-QX3U

YB10283A1-04 YB10300K1-02 YB10300U1-01

GC-QX3HDU

GC-QX5HDU

MONI REG BOARD ASSEMBLY <03>

REF NO.

PW4

ITEM

MONI REG BOARD ASSEMBLY

MODEL

GC-QX3U

YB10283A4-04 YB10300K4-02 YB10300U4-01

GC-QX3HDU

GC-QX5HDU

JACK BOARD ASSEMBLY <04>

REF NO.

PW2 JACK BOARD ASSEMBLY YB10283A2-04 YB10300K2-02 YB10300U2-01

ITEM

MODEL

GC-QX3U

GC-QX3HDU

GC-QX5HDU

STROBE BOARD ASSEMBLY <05>

REF NO.

PW3 STROBE BOARD ASSEMBLY YB10283A3-04 YB10300K3-02 YB10300U3-01

ITEM

MODEL

GC-QX3U

GC-QX3HDU

GC-QX5HDU

Page 5

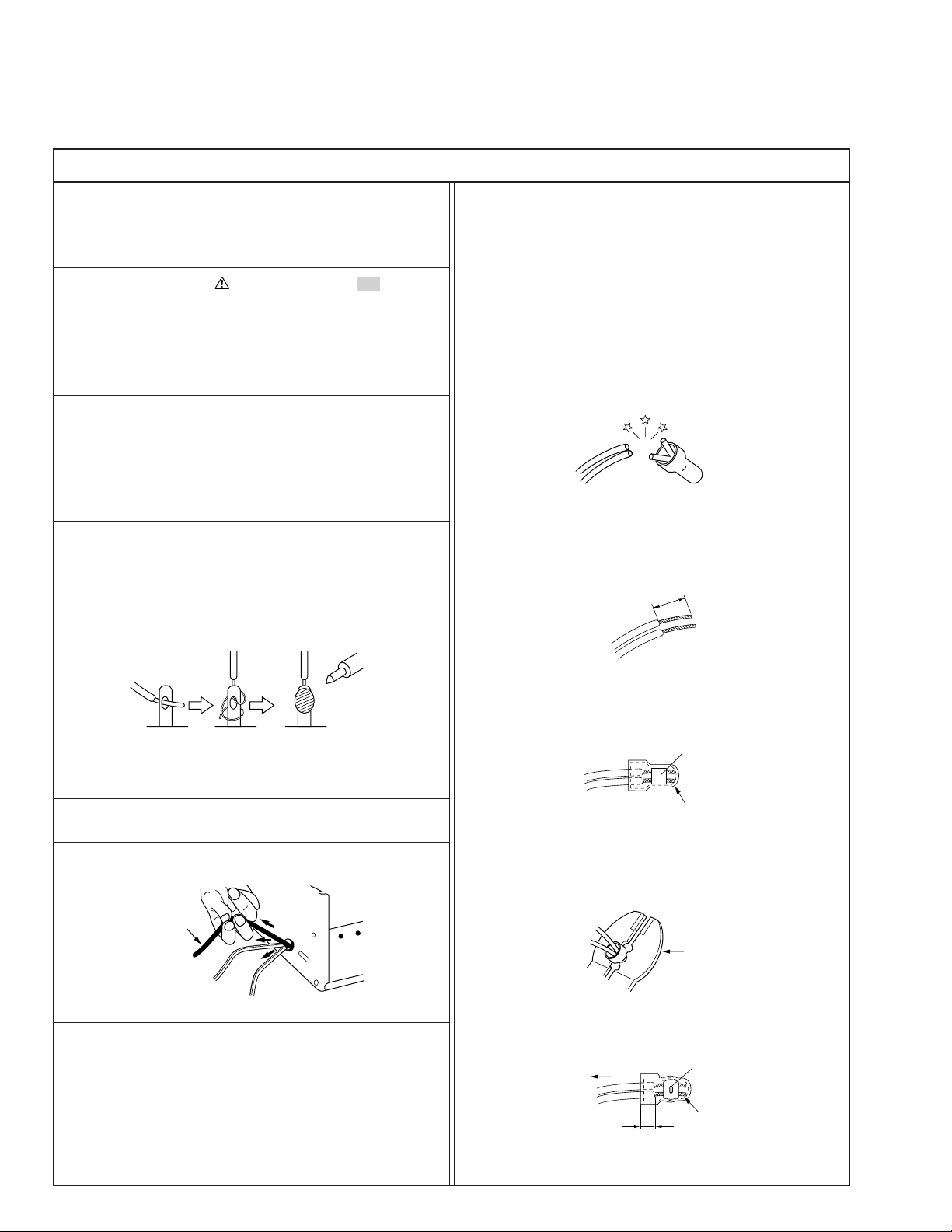

Important Safety Precautions

cut close to connector

15 mm

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes

of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the

following precautions when a set is being serviced.

v

Precautions during Servicing

1. Locations requiring special caution are denoted by labels and

inscriptions on the cabinet, chassis and certain parts of the

product. When performing service, be sure to read and comply with these and other cautionary notices appearing in the

operation and service manuals.

2. Parts identified by the

critical for safety.

Replace only with specified part numbers.

Note: Parts in this category also include those specified to com-

ply with X-ray emission standards for products using

cathode ray tubes and those specified for compliance

with various regulations regarding spurious radiation

emission.

3. Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

4. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

5. Use specified insulating materials for hazardous live parts.

Note especially:

1) Insulation Tape 3) Spacers 5) Barrier

2) PVC tubing 4) Insulation sheets for transistors

6. When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

symbol and shaded ( ) parts are

12. Crimp type wire connector

In such cases as when replacing the power transformer in sets

where the connections between the power cord and power

transformer primary lead wires are performed using crimp type

connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely

according to the following steps.

1) Connector part number : E03830-001

2) Required tool : Connector crimping tool of the proper type

which will not damage insulated parts.

3) Replacement procedure

(1) Remove the old connector by cutting the wires at a point

close to the connector.

Important : Do not reuse a connector (discard it).

Fig.3

(2) Strip about 15 mm of the insulation from the ends of

the wires. If the wires are stranded, twist the strands to

avoid frayed conductors.

Fig.1

7. Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

8. Check that replaced wires do not contact sharp edged or

pointed parts.

9. When a power cord has been replaced, check that 10-15 kg of

force in any direction will not loosen it.

Power cord

Fig.2

10. Also check areas surrounding repaired locations.

11. Products using cathode ray tubes (CRTs)

In regard to such products, the cathode ray tubes themselves,

the high voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the cathode ray tubes and other parts with only the specified parts.

Under no circumstances attempt to modify these circuits.

Unauthorized modification can increase the high voltage value

and cause X-ray emission from the cathode ray tube.

Fig.4

(3) Align the lengths of the wires to be connected. Insert

the wires fully into the connector.

Metal sleeve

Connector

Fig.5

(4) As shown in Fig.6, use the crimping tool to crimp the

metal sleeve at the center position. Be sure to crimp fully

to the complete closure of the tool.

1.25

2.0

5.5

Fig.6

(5) Check the four points noted in Fig.7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Fig.7

Crimping tool

Crimped at approx. center

of metal sleeve

Conductors extended

1

S40888-01

Page 6

v

d'

d

Chassis

Power cord,

primary wire

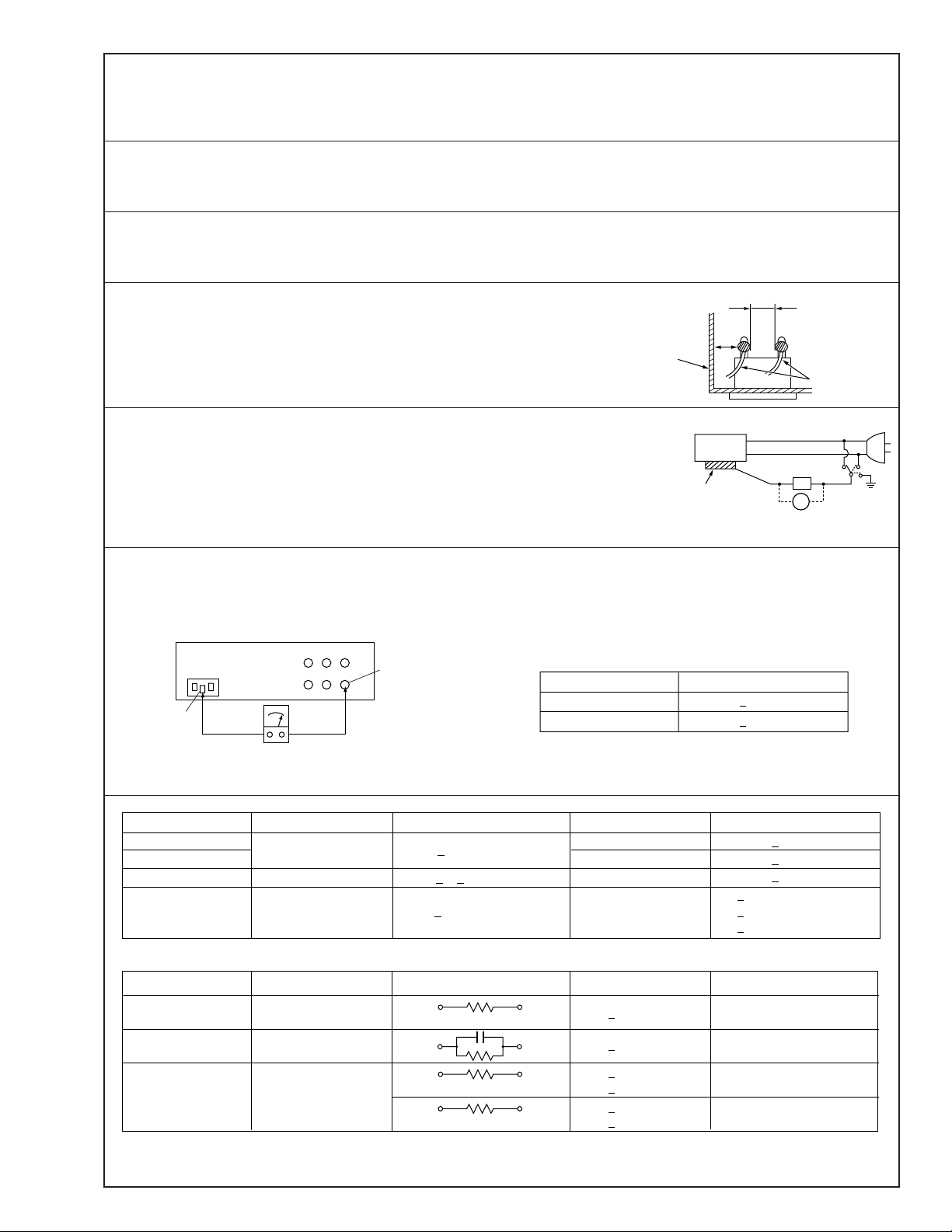

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety standards.

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and

externally exposed parts of the set (RF terminals, antenna terminals, video and audio input

and output terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed

accessible parts of the set (RF terminals, antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

3. Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d’) between soldered terminals, and between terminals and surrounding metallic parts. See table 1

below.

Fig. 8

4. Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure across both terminals of load Z. See figure 9 and

following table 2.

Externally

exposed

accessible part

Z

V

Fig. 9

ab

c

5. Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin in AC inlet and externally exposed accessible parts (Video in,

Video out, Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and exposed accessible parts. See figure 10 and grounding specifications.

AC inlet

Earth pin

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Exposed accessible part

Milli ohm meter

Fig. 10

Region

Japan

USA & Canada

Europe & Australia R 10 MΩ/500 V DC

Region Load Z

Insulation Resistance (R)

≤

R 1 MΩ/500 V DC

≥≥

1 MΩ R 12 MΩ/500 V DC

≤

Table 1 Specifications for each region

Grounding Specifications

Region

USA & Canada

Europe & Australia

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 miute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(Class 2)

(Class 1)

Grounding Impedance (Z)

≤

Z 0.1 ohm

≤

Z 0.5 ohm

Clearance Distance (d), (d')

≤

d, d' 3 mm

≤

d, d' 4 mm

≤

d, d' 3.2 mm

≤

d 4 mm

≤

d' 8 mm (Power cord)

≤

d' 6 mm (Primary wire)

a, b, cLeakage Current (i)AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Note: These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

Japan

USA & Canada

Europe & Australia

Table 2 Leakage current specifications for each region

1 kΩ

0.15 µF

1.5 kΩ

2 kΩ

50 kΩ

2

≤

i 1 mA rms Exposed accessible parts

≤

i 0.5 mA rms

≤

i 0.7 mA peak

≤

i 2 mA dc

≤

i 0.7 mA peak

≤

i 2 mA dc

Exposed accessible parts

Antenna earth terminals

Other terminals

S40888-01

Page 7

Page 8

161

NOTE :

This service manual has indicated only the item different from GC-QX3U No.86564.

1.3.2 Disassembly method ( I )

SECTION 1

DISASSEMBLY

STEP

1 FRONT CASE Remove screws

REAR CASE 2 (115), 3 (156), 4 (157), 1 (154)

2 OPERATION UNIT Remove the Connector Remove screws Note 1

3 STROBE BOARD ASSEMBLY Remove the Connector Remove screw Note 1

JACK BOARD ASSEMBLY Remove the Connector Remove screws

4 LCD MODULE Remove the Connector Remove screws Note 1

5 MAIN BOARD ASSEMBLY Remove the Connector Note 1

MONI/REG BOARD ASSEMBLY Remove the PWB HOLDER Remove screws 2 (114) Note 1

6 OP UNIT Remove from the Frame Assy Remove screws 3 (117)

PART NAME

Fig

1-3-1

Fig

1-3-1

Fig

1-3-2

Fig

1-3-3

r MAIN CN4001

Remove the TOP COVER 2 (115)

n MAIN CN6601

p MAIN CN5501

m LCD MODULE (BL)

k MAIN CN3002

Remove from the Frame Assy

Remove from the LCD Holder

h MAIN CN501

z MAIN CN2501

c MAIN CN3001

d MON/REG TL9001

OPERATION UNIT 3 (116)

STROBE CN6501 1 (114) Note 2

JACK CN101 2 (114)

LCD MODULE (LCD) 2 (114)

OP UNIT

MIC

MON/REG CN9001

Frame Assy d (SD1)

POINTFIG. NO.

JACK CN701 e (SD3), f (SD4), g (SD5)

Note 3

NOTE

CONNEC- NO.OF

TOR/HL PINS

c

d

e

f

g

h

j

k

m

n

p

q

r

s

t

u

v

w

x

z

80 MAIN Board CN3001

1 MONI/REG Board TL9001

1 JACK Board TP3

1 JACK Board TP2

1 JACK Board TP1

22 MAIN Board CN501

2 MAIN Board CN502

24 MAIN Board CN3002

2 JACK Board CN701

14 MAIN Board CN6601

38 MAIN Board CN5501

28 MAIN Board CN2001

12 MAIN Board CN4001

1

1

1 STROBE UNIT WIRE (RED)

1

1

1

2 MAIN CN2501

CONNECTION

MONI/REG Board CN9001

MAIN FRAME (RED)

MAIN FRAME (BROWN)

MONI/REG Board J9001 (BLACK)

MONI/REG Board J9002 (RED)

OP UNIT

OP UNIT

LCD MODULE (LCD)

LCD MODULE (BL)

STROBE Board CN6501

JACK Board CN101

CCD Board CN1001

OPERATION UNIT

STROBE UNIT WIRE (ORANGE)

STROBE UNIT WIRE (BROWN)

STROBE UNIT WIRE (BLACK)

STROBE UNIT WIRE (Red, Thin wire) STROBE Board J6505 (Through hole)

STROBE UNIT WIRE (BLACK, Thin wire)

STROBE Board J6501 (Through hole)

STROBE Board J6502 (Through hole)

STROBE Board J6503 (Through hole)

STROBE Board J6504 (Through hole)

STROBE Board J6506 (Through hole)

MIC

Note 1

Destination of connectors.

Note

: Three kinds of double-arrows in connection tables

respectively show kinds of connector/wires.

: Board to Board connector

: Flat wire

: Wire

Note 2

Be careful from electric shock hazard because the capacitor

(C6512) for the strobe is exposed. Be sure to positively discharge the capacitor if it is energized by short-circuiting a

resistor (10 - 22 k ) connected at both capacitor terminals.

Please be very careful when doing this job.

Note 3

LCD panel is fixed by four hooks of backlight.

Insert LCD panel in a hook firmly.

no

slippege

4 sprts locked

Note 5

Stick to let it pass between LEDs.Stick to

come out on the left of the sheet metal of

a video terminal.

1-1

Page 9

Note 5

114

Pass this through the inside of the boss.

118

6

117

6

117

A

p

3

F

m

e

(SD3)

f

(SD4)

g

(SD5)

JACK BOARD ASSY

< 04 >

C

e

d

101

OP BLOCK ASSY

<M3>

MONI/REG BOARD ASSY

< 02 >

(SD1)

B

f

g

CCD BOARD ASSY

< 03 >

q

(SD2)

h

d

114

5

108

p

125

j

130

103

c

109

A

h

q

j

B

104

161

MAIN BOARD ASSY

< 01 >

k

114

5

107B

m

129

Fig.1-3-2

107A

C

105

106

107

k

114

4

1-2

Page 10

SECTION 2

PC cable

QAM0099-002

Personal computer

RS-232C

port

Service support system

YTU94057-49

MENU

PRINTER

9

Gray scale chart

YTU94133A

Cleaning cloth

KSMM-01

10

Color bar chart

YTU94133C

11

Smart media card

16MB

12

USB

QAM0252-001

13

ELECTRICAL ADJUSTMENT

2.1 ELECTRICAL ADJUSTMENT

2.1.1 Precautions

Both the camera section and deck section of this model

are designed and manufactured to be adjustment-free.

However, if both or either of the following parts is replaced,

it needs special adjustment with a personal computer at a

JVC service equipment after the part replacement

• OP block assembly

• EEPROM (on the MAIN board)

When there is some trouble in the electric circuit, it is required

to detect the faulty part with specified test instruments first

and then to proceed to repair, replacement and adjustment.

1. When cheking a signal at a chip test point, be sure to use

an IC clip or the like not to apply any stress to the test point.

When replacing a chip part (IC in particular), completely

remove solder chips from it and its periphery before

proceeding to part replacement (in order to avoid exfoliation

of the pattern).

2. Carefully disconnect/connect connectors because they

are apt to get damaged.

2.1.2 Test instruments required for electrical

adjustment

Patch cord ASSY

12

34

5

YTU93105

Service support system

YTU94057-49

Jig connector cable

YTU93106A

Jig connector cable

YTU93104B

PC cable

QAM0099-002

INF adjustment lens

6

YTU92001B

2.1.3 Required test equipment

1. Color TV monitor.

2. AC power adapter (AA-V37 or equivalent)

3. Oscilloscope (dual-trace type, for more than 20 MHz).

4. Digital voltmeter

5. Frequency counter (with threshold level adjuster)

6. Personal computer

2.1.4 Setup (LCD ADJUSTMENT)

Setup for electrical adjustment with personal computer

Note 1:

As a general rule for adjustment with a personal

computer, connect a personal computer to its

PRINTER terminal.

Note 2:

Use DC cord to supply the power.

Camera stand

7

YTU93079

8

Light box assembly

YTU93096A

Fig. 2-1-1 Setup for electrical adjustment with

personal computer (I)

2-1

Page 11

2.1.5 Setup (CCD ADJUSTMENT)

Setup for electrical adjustment with personal computer

Note 1:

As a general rule for adjustment with a personal

computer, connect a personal computer to its

DIGITAL terminal.

Note 2:

Use DC cord to supply the power.

Fig. 2-1-2 Setup for electrical adjustment with

Pin No. FUNCTION

1 AL3.3V

2 AL3.3V

3 JTAGMODE

4 135TDI

5 135nTRST

6 32RST

7 32nTRST

8 32TDO

9 32TCK

10 M_BLUE

11 RPD

12 M_PSIG

13 M_GREEN

14 NC

15 GND

Jig connector cable

(YTU93106A)

personal computer (II)

Pin No FUNCTION

16 AL3.3V

17 NC

18 135TMS

19 135TDO

20 135TCK

21 32DBI

22 32TMS

23 32TDI

24 NC

25 M_COM

26 M_SIG_C

27 M_RED

28 M_SIG_GND

29 GND

30 GND

16MB

Smart media

Card

USB

Service support system

YTU94057-49

USB

port

MENU

Personal computer

Fig. 2-1-3 Setup for electrical adjustment with

personal computer (I)

2-2

Table 2-1-1 Jig Connector Function

Page 12

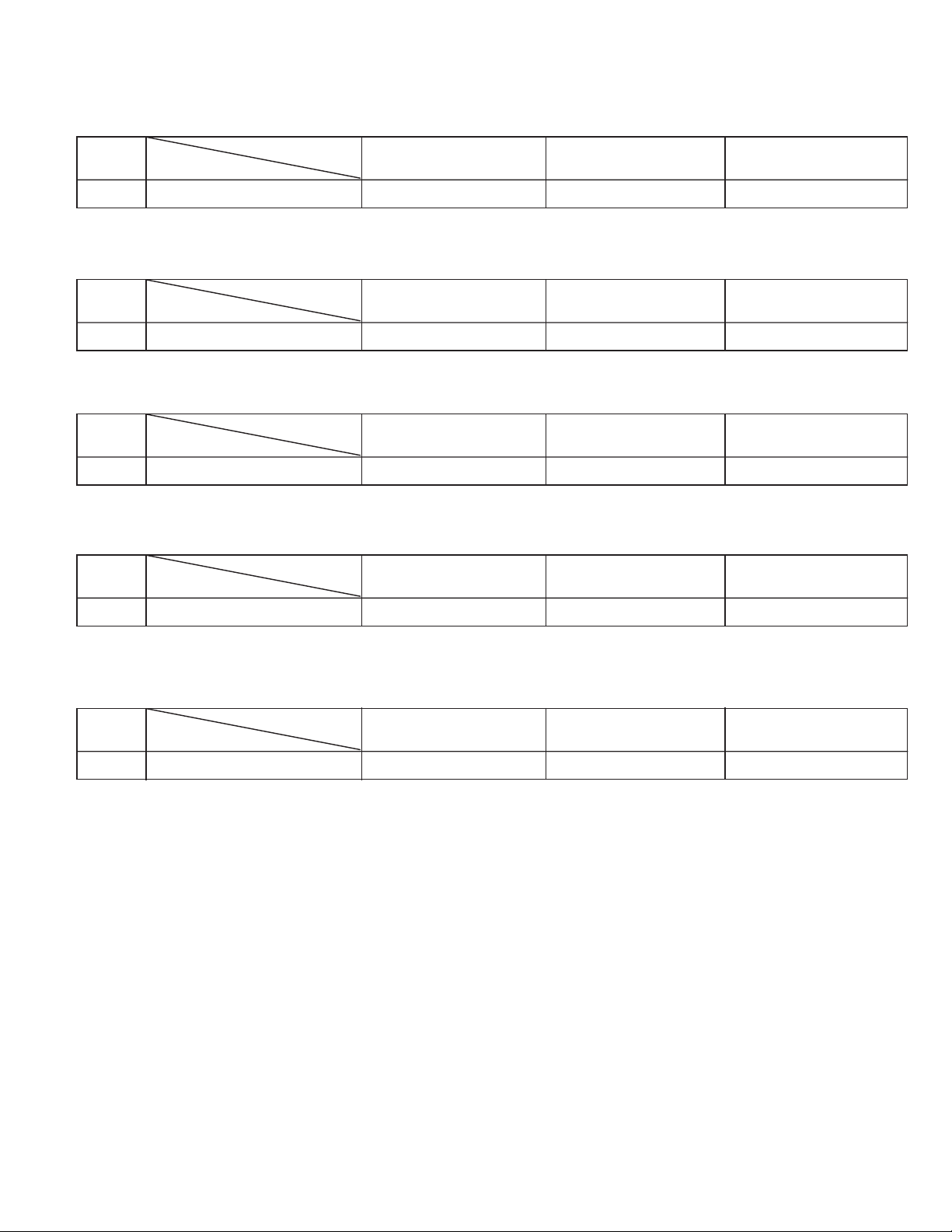

2.2 Setup with patch cords and jig connector cables Note:

Fig. 2-2-1 shows an example of expansion setup that facilitates inspection of major boards because main components are

connected by means of patch cords and jir cables.For proceeding to electrical adjustment in such the setup, disassemble the

set at certain level required for the current adjustment objectives referring to the section 1 "DISASSEMBLY" and properly set

up the expanded set and test instruments.

OP BLOCK/CCD

MON/REGMON/REG

PRINTER

DIGITAL

CN9001

VIDEO

DC

5V

5

YTU94077-22

YTU94071-22

4 YTU94077-38

JACK

CN101

CN7101

MENU

STROBE

3 YTU94077-28

MIC

CN502

CN5501

CN501

CN6501

CN6601

CN2501

MAIN

CN2001

CN3002

MONITOR

CN2002

CN4001

CN3001

YTU94077-12

1

YTU94074-12

OPERATION UNIT

2YTU94126B-80

6YTU93106A

Personal computer

Fig. 2-2-1

Connection

Pin No. Parts Number

1 MAIN CN4001 OPRATION UNIT 12 YTU94077-12 FPC wire

YTU94074-12 FPC CN.ASSY

2 MAIN CN3001 MON/REG CN9001 80 YTU94126B-80 B TO B CN.ASSY

3 MAIN CN2001 CCD CN1001 28 YTU94077-28 FPC wire

4 MAIN CN5501 JACK CN101 38 YTU94077-38 FPC wire

5 MAIN CN501 OPUNIT 22 YTU94077-22 FPC wire

YTU94074-22 FPC CN.ASSY

6 MAIN CN2202 30 YTU93106A JIG CN.cable

2-3

Page 13

Page 14

JVC SERVICE & ENGINEERING COMPANY OF AMERICA

DIVISION OF JVC AMERICAS CORP.

Head office

East Coast

Midwest

West Coast

Atlanta

Hawaii

Head office

Montreal

Vancouver

1700 Valley Road Wayne, New Jersey 07470-9976

:

10 New Maple Avenue Pine Brook, New Jersey 07058-9641

:

705 Enterprise Street Aurora, Illinois 60504-8149

:

5665 Corporate Avenue Cypress, California 90630-0024

:

1500 Lakes Parkway Lawrenceville, Georgia 30043-5857

:

2969 Mapunapuna Place Honolulu, Hawaii 96819-2040

:

JVC CANADA INC.

:

21 Finchdene Square Scarborough, Ontario M1X 1A7

:

16800 Rte Trans-Canadienne, Kirkland, Quebec H9H 5G7

:

13040 Worster Court Richmond, B.C. V6V 2B3

(973)315-5000

(973)396-1000

(630)851-7855

(714)229-8011

(770)339-2582

(808)833-5828

(416)293-1311

(514)871-1311

(604)270-1311

S40895-03

Printed in Japan

Loading...

Loading...