Page 1

FS-SD5 / FS-SD7 / FS-SD9

SCHEMATIC DIAGRAMS

COMPACT COMPONENT SYSTEM

FS-SD5

FS-SD7 / FS-SD9

CD-ROM No.SML200012

Contents

REMOTE CONTROL

DIMMER SLEEP

DISPLAY FM MODE

PROGRAM

AHB PRO

BASS TREBLE CANCEL

FADE MUTING

MD/AUX FM / AM

REMOTE CONTROL

DIMMER SLEEP

DISPLAY FM MODE

PROGRAM

AHB PRO

BASS TREBLE CANCEL

FADE MUTING

MD/AUX FM / AM

Area Suffix

AUTO

PRESET

REPEATRANDOM

DOOR

CD

SLIDE

UP

SET

DOWN

CD

VOLUME

UT

FS-SD5

AUTO

PRESET

REPEATRANDOM

DOOR

CD

SLIDE

UP

SET

DOWN

CD

VOLUME

FS-SD7, FS-SD9

These models are different only speaker systems.

FS-SD7 and FS-SD9 are different only speaker cabinet.

Taiwan

Block diagrams

Standard schematic diagrams

Printed circuit board

This schematic diagrams is printed on 100% recycled paper.

COPYRIGHT 2000 VICTOR COMPANY OF JAPAN, LTD.

2-1

2-3

2-7

No.20885SCH

Dec. 2000

Page 2

FS-SD5/FS-SD7/FS-SD9

1. This design of this product contains special hardware and many circuits and components specially

for safety purposes. For continued protection, no changes should be made to the original design

unless authorized in writing by the manufacturer. Replacement parts must be identical to those

used in the original circuits. Services should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of

the product should not be made. Any design alterations or additions will void the manufacturer`s

warranty and will further relieve the manufacture of responsibility for personal injury or property

damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics.

These characteristics are often not evident from visual inspection nor can the protection afforded

by them necessarily be obtained by using replacement components rated for higher voltage,

wattage, etc. Replacement parts which have these special safety characteristics are identified in

the Parts List of Service Manual. Electrical components having such features are identified by

shading on the schematics and by ( ) on the Parts List in the Service Manual. The use of a

substitute replacement which does not have the same safety characteristics as the recommended

replacement parts shown in the Parts List of Service Manual may create shock, fire, or other

hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the

like to be separated from live parts, high temperature parts, moving parts and/or sharp edges

for the prevention of electric shock and fire hazard. When service is required, the original lead

routing and dress should be observed, and it should be confirmed that they have been returned

to normal, after re-assembling.

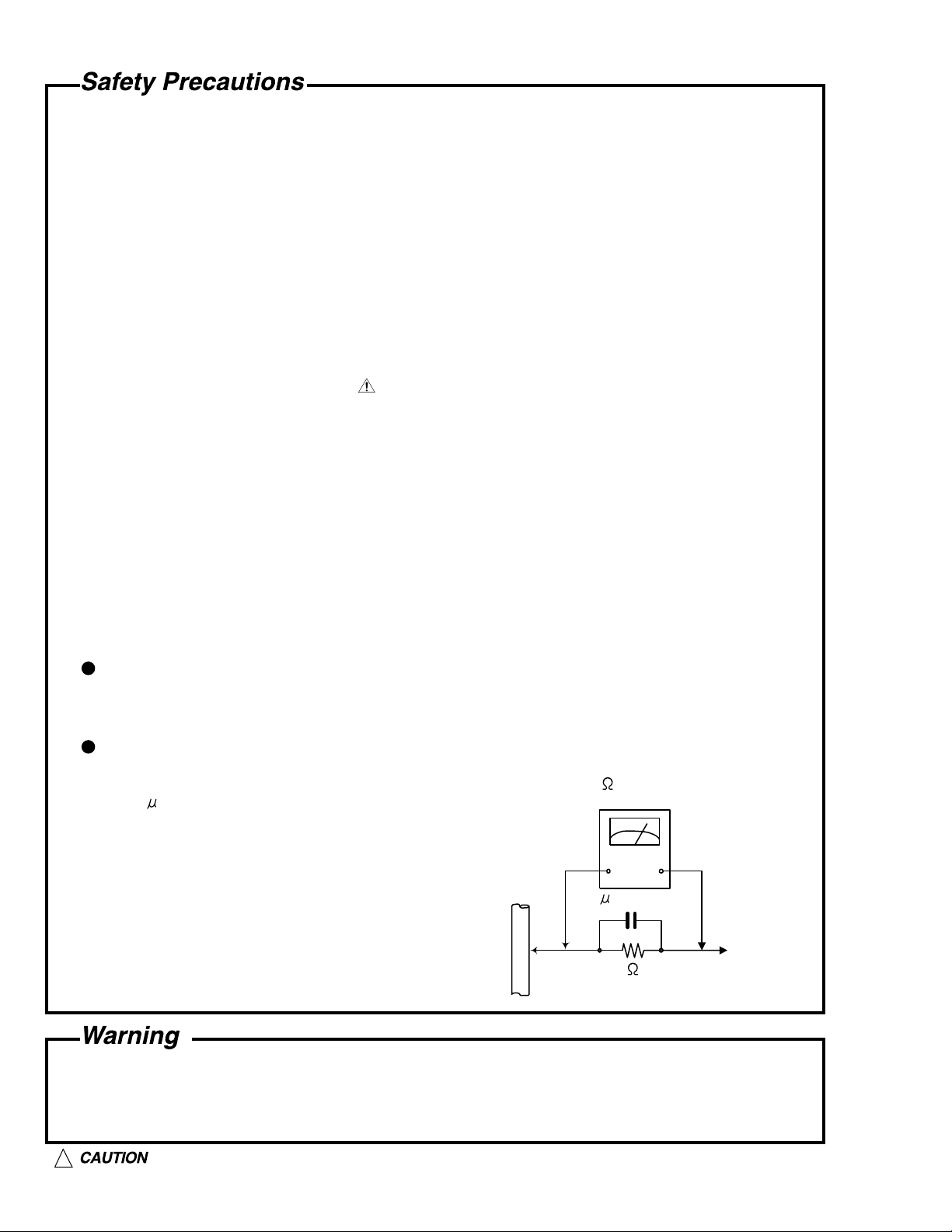

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts

of the product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control

shafts, etc.) to be sure the product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure

the leakage current from each exposed metal parts of the cabinet , particularly any exposed

metal part having a return path to the chassis, to a known good earth ground. Any leakage

current must not exceed 0.5mA AC (r.m.s.)

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms

per volt or more sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by

a 0.15 F AC-type capacitor between an exposed

metal part and a known good earth ground.

Measure the AC voltage across the resistor with the

AC voltmeter.

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Move the resistor connection to eachexposed metal

part, particularly any exposed metal part having a

return path to the chassis, and meausre the AC

voltage across the resistor. Now, reverse the plug in

the AC outlet and repeat each measurement. voltage

measured Any must not exceed 0.75 V AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Place this

probe on

each exposed

metal part.

This corresponds to 0.5 mA AC (r.m.s.).

Good earth ground

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-2

Page 3

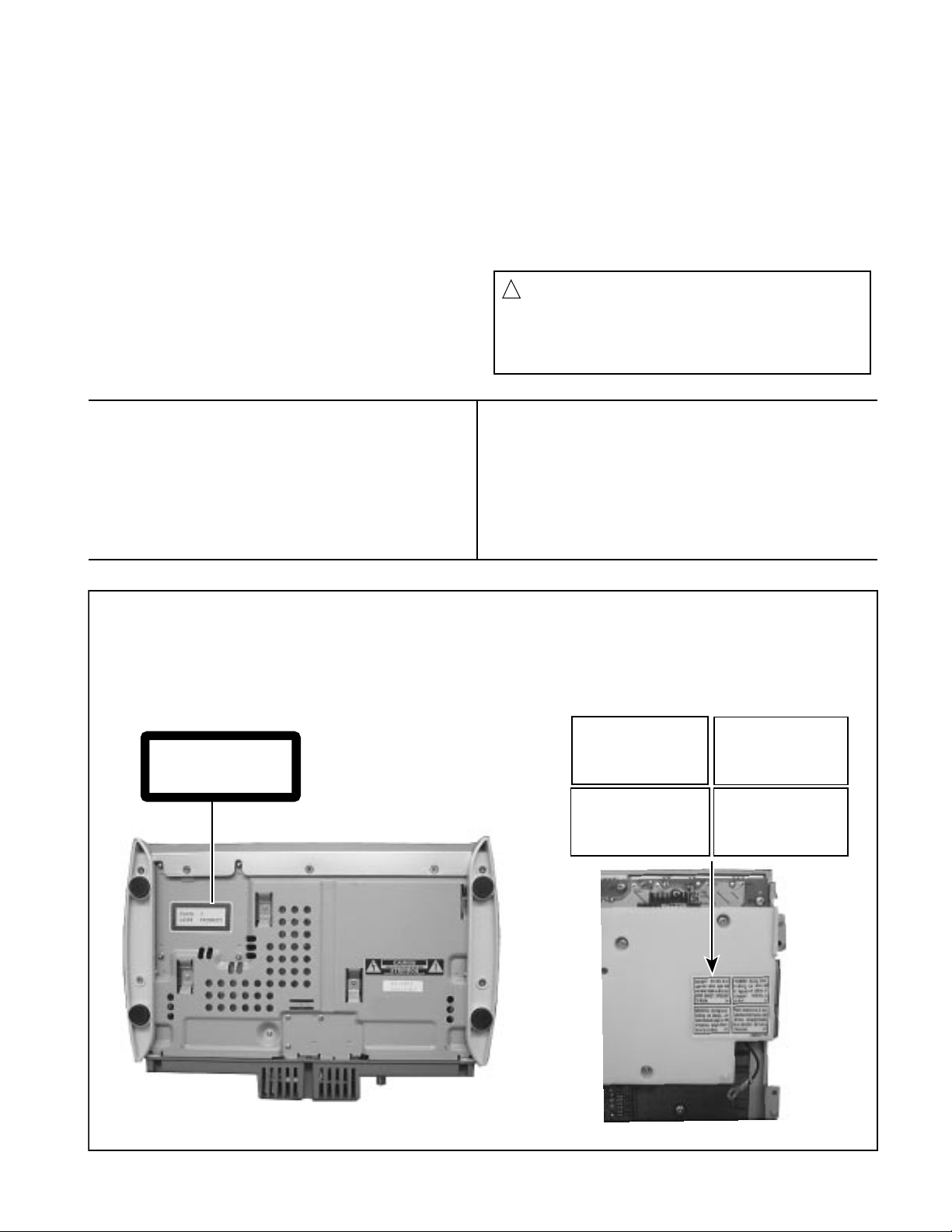

Important for Laser Products

FS-SD5/FS-SD7/FS-SD9

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The compact disc player uses invisible

laserradiation and is equipped with safety switches

whichprevent emission of radiation when the drawer is

open and the safety interlocks have failed or are de

feated. It is dangerous to defeat the safety switches.

VARNING : Osynlig laserstrålning är denna del är öppnad

och spårren är urkopplad. Betrakta ej strålen.

VARO : Avattaessa ja suojalukitus ohitettaessa olet

alttiina näkymättömälle lasersäteilylle.Älä katso

säteeseen.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

ADVARSEL : Usynlig laserstråling ved åbning , når

sikkerhedsafbrydere er ude af funktion. Undgå

udsættelse for stråling.

ADVARSEL : Usynlig laserstråling ved åpning,når

sikkerhetsbryteren er avslott. unngå utsettelse

for stråling.

REPRODUCTION AND POSITION OF LABELS

WARNING LABEL

CLASS 1

LASER PRODUCT

DANGER : Invisibie laser radiation

when open and interlock or

defeated.

AVOID DIRECT EXPOSURE TO

BEAM (e)

VARNING : Osynlig laserstrålning är

denna del är öppnad och spårren är

urkopplad. Betrakta ej strålen. (s)

VARO : Avattaessa ja suojalukitus

ohitettaessa olet alttiina

näkymättömälle lasersäteilylle.Älä

katso säteeseen. (d)

ADVARSEL :Usynlig laserstråling

ved åbning , når

sikkerhedsafbrydere er ude af

funktion. Undgå udsættelse for

stråling. (f)

1-3

Page 4

FS-SD5/FS-SD7/FS-SD9

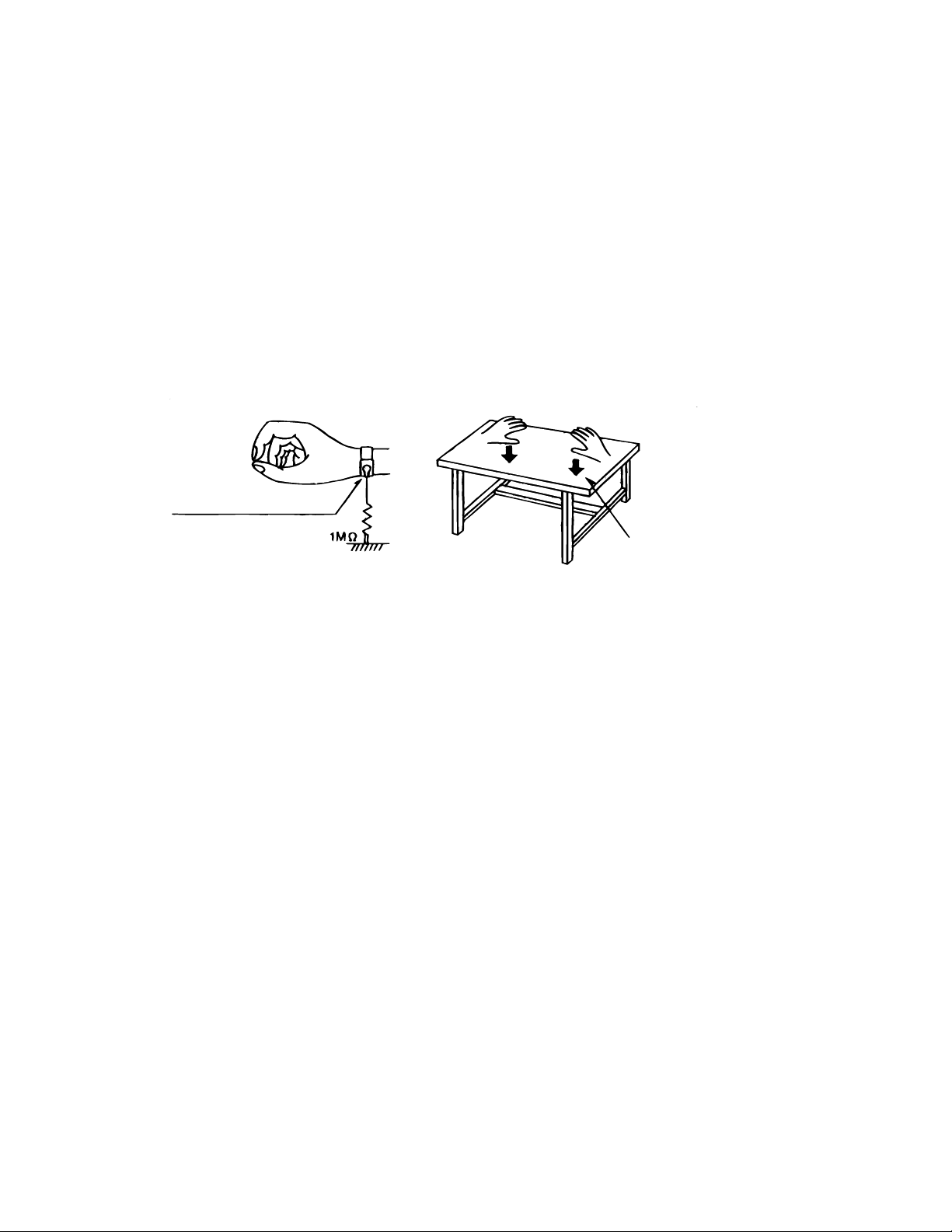

Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.1. Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as DVD players.

Be careful to use proper grounding in the area where repairs are being performed.

1.1.1. Ground the workbench

1. Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

1.1.2. Ground yourself

1. Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

1.1.3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

1.2. Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

1-4

Page 5

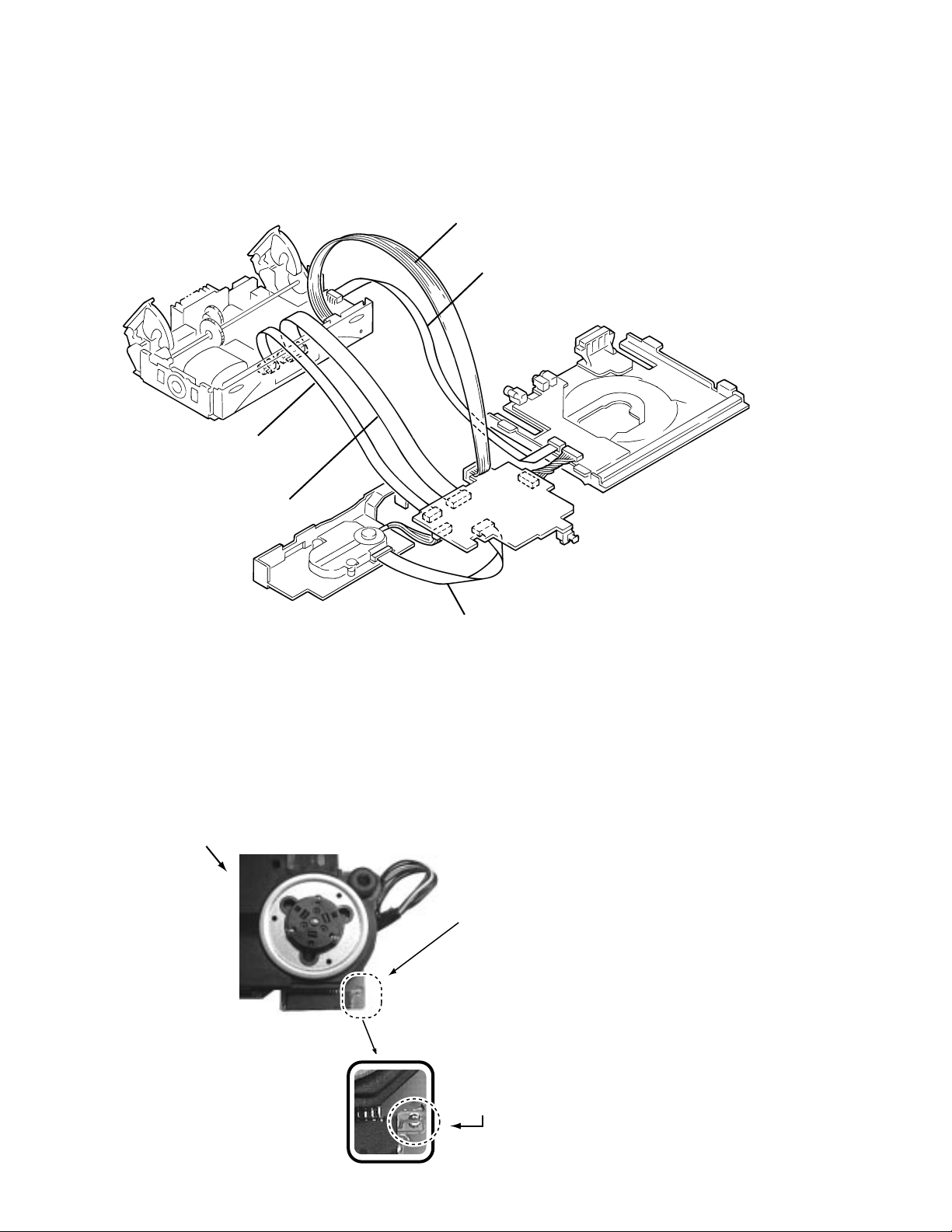

FS-SD5/FS-SD7/FS-SD9

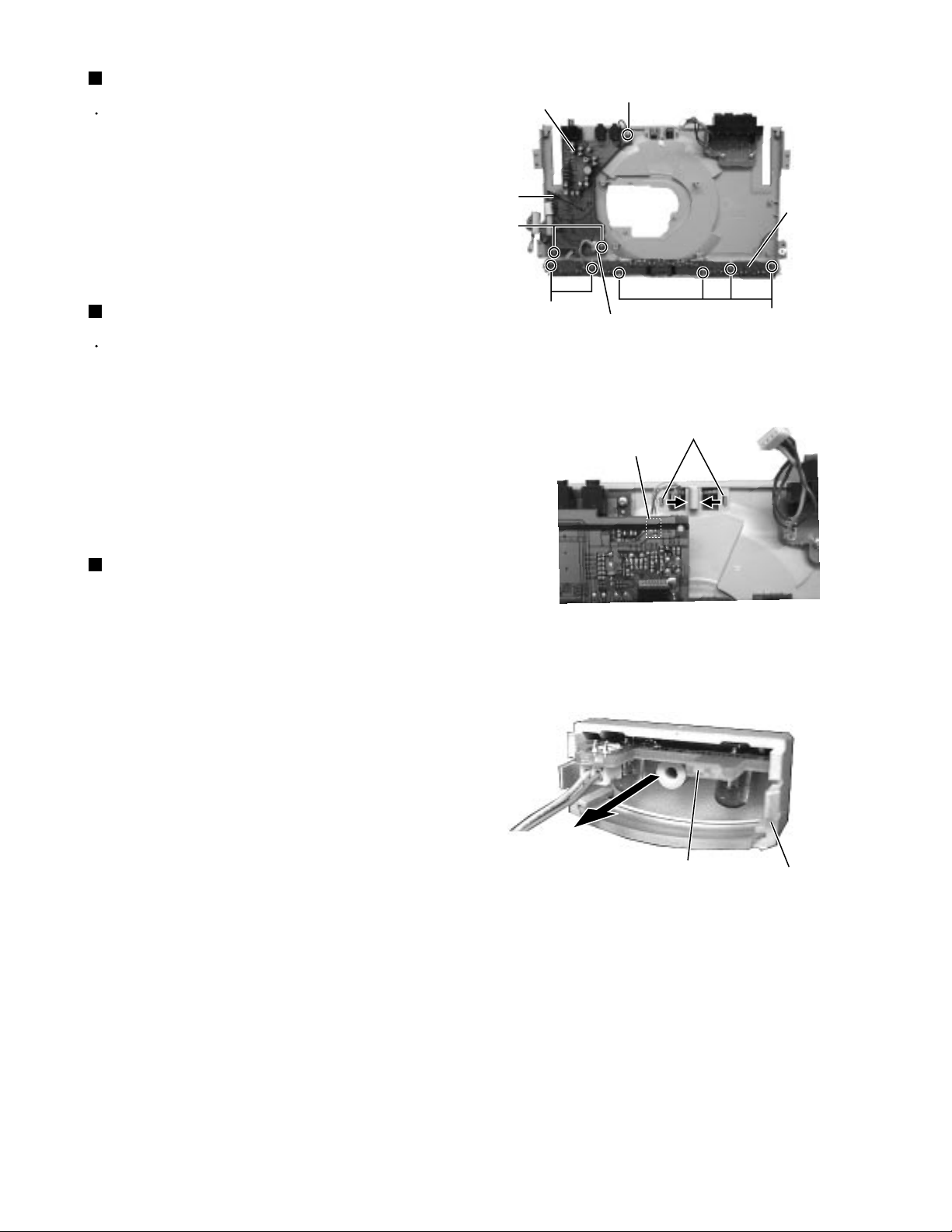

Dismantling and assembling the traverse unit

Notice regarding replacement of optical pickup

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing

repairs to the optical pickup or connected devices.

1. Do not touch the area around the laser diode and actuator.

2. Do not check the laser diode using a tester, as the diode may easily be destroyed.

3. It is recommended that you use a grounded soldering iron when shorting or removing the laser diode.

Recommended soldering iron: HAKKO ESD-compatible product

4. Solder the land on the optical pickup's flexible cable.

Note : Short the land after shorting the terminal on the flexible cable using a clip, etc., when using an

ungrounded soldering iron.

Note : After shorting the laser diode according to the procedure above, remove the solder according

to the text explanation.

Laser pick-up unit

KSM-770ABA

Shorting

Short circuit land

1-5

Page 6

FS-SD5/FS-SD7/FS-SD9

Disassembly method

<Main body>

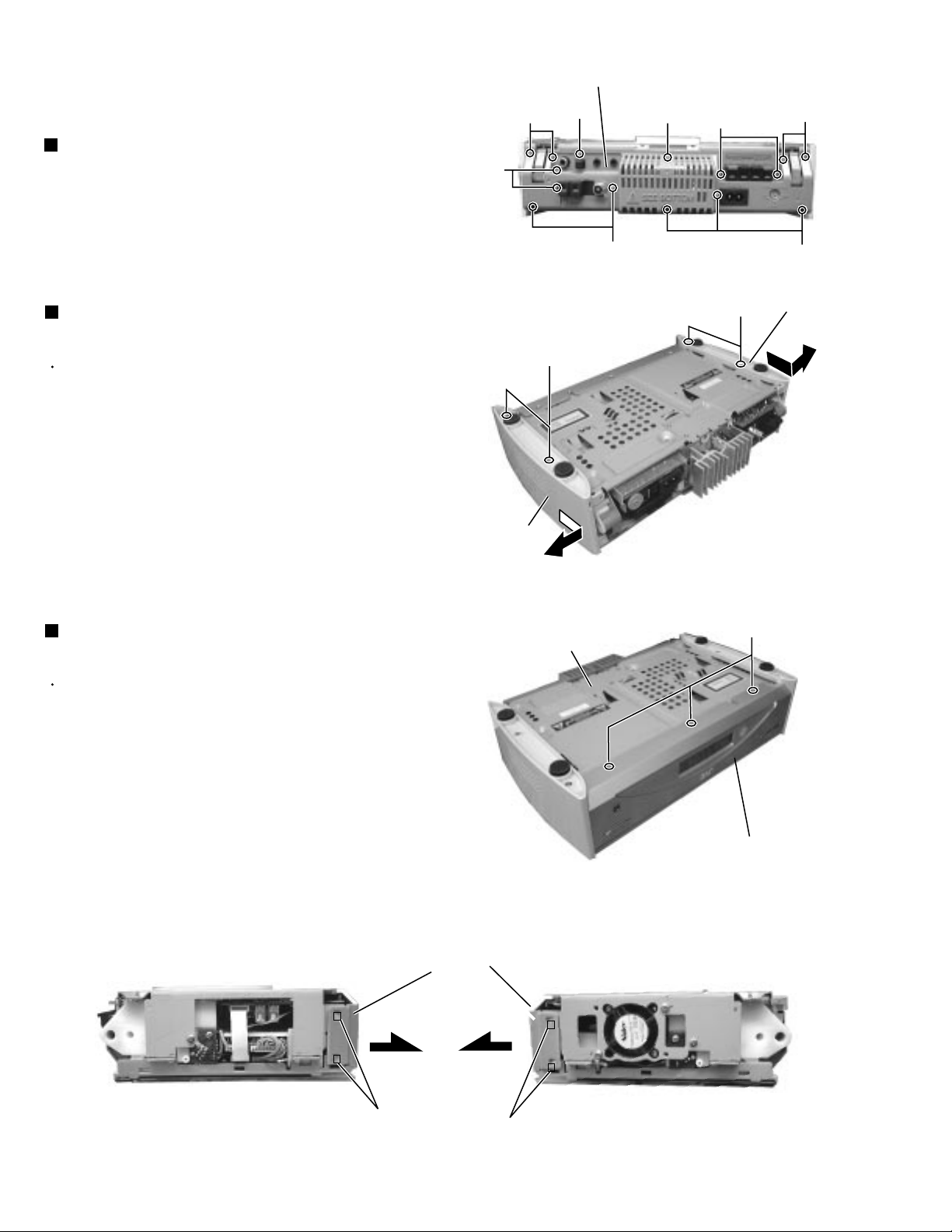

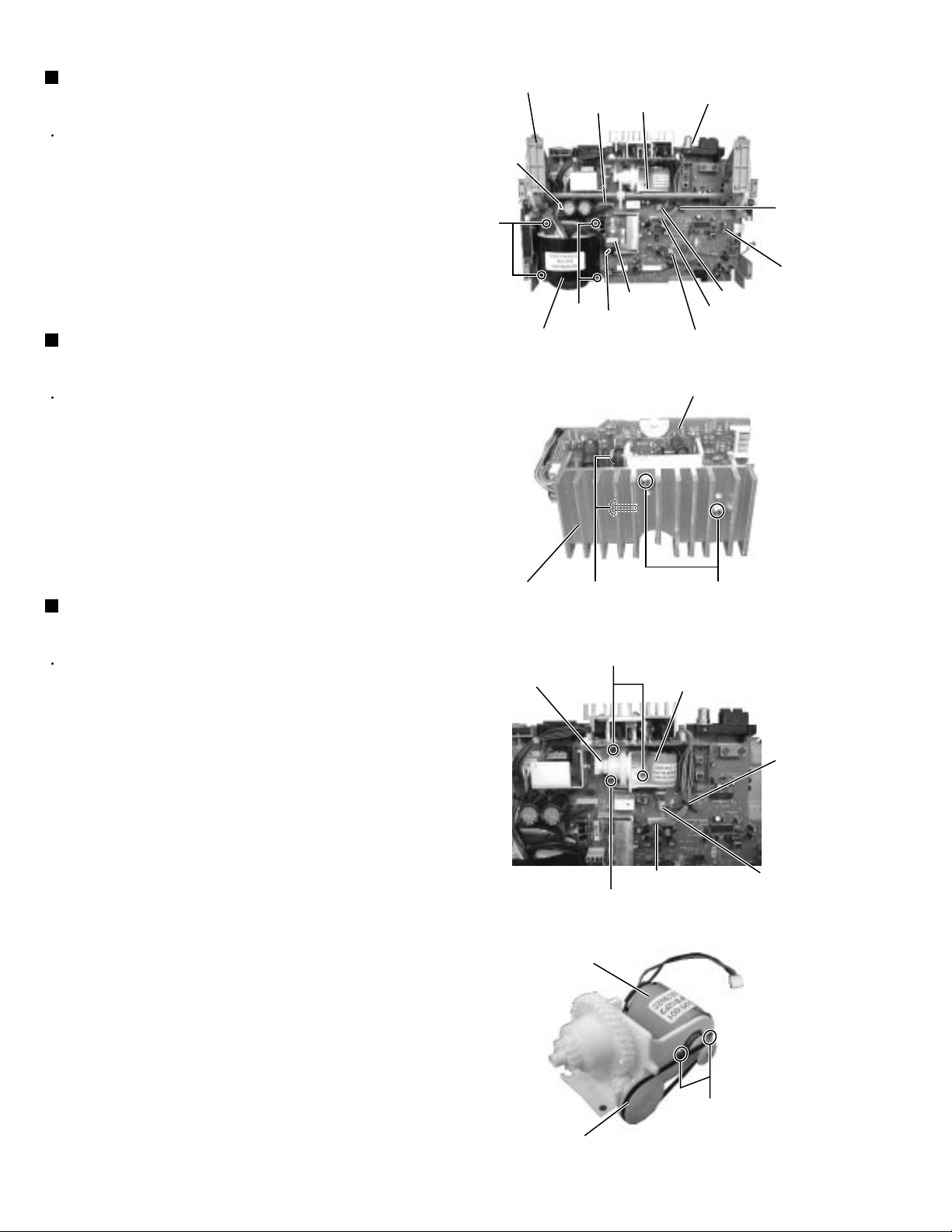

Removing the rear cover (See Fig.1)

1.

Remove the ten screws A and the five screws B

attaching the rear cover on the back of the body.

Removing the right and left covers

(See Fig.2)

Prior to performing the following procedure, remove

the rear cover.

1.

Remove the four screws C attaching the side covers

on the bottom of the body.

2.

Move the left cover backward and remove outward.

Also remove the right cover in the same way.

A

B

C

Rear cover

A

A

Fig.1

B

A

Right cover

C

B

A

Removing the front panel assembly

(See Fig.3 to 5)

Prior to performing the following procedure, remove

the rear cover and the side covers.

1.

Remove the three screws D on the bottom of the

body.

2.

Release two joints a and two joints b on both sides of

the body using a screwdriver and remove the front

panel assembly toward the front.

Left side

Left cover

Fig.2

D

Bottom

Front panel assembly

Fig.3

Front panel assembly

Right side

1-6

Joints a

Joints b

Fig.5Fig.4

Page 7

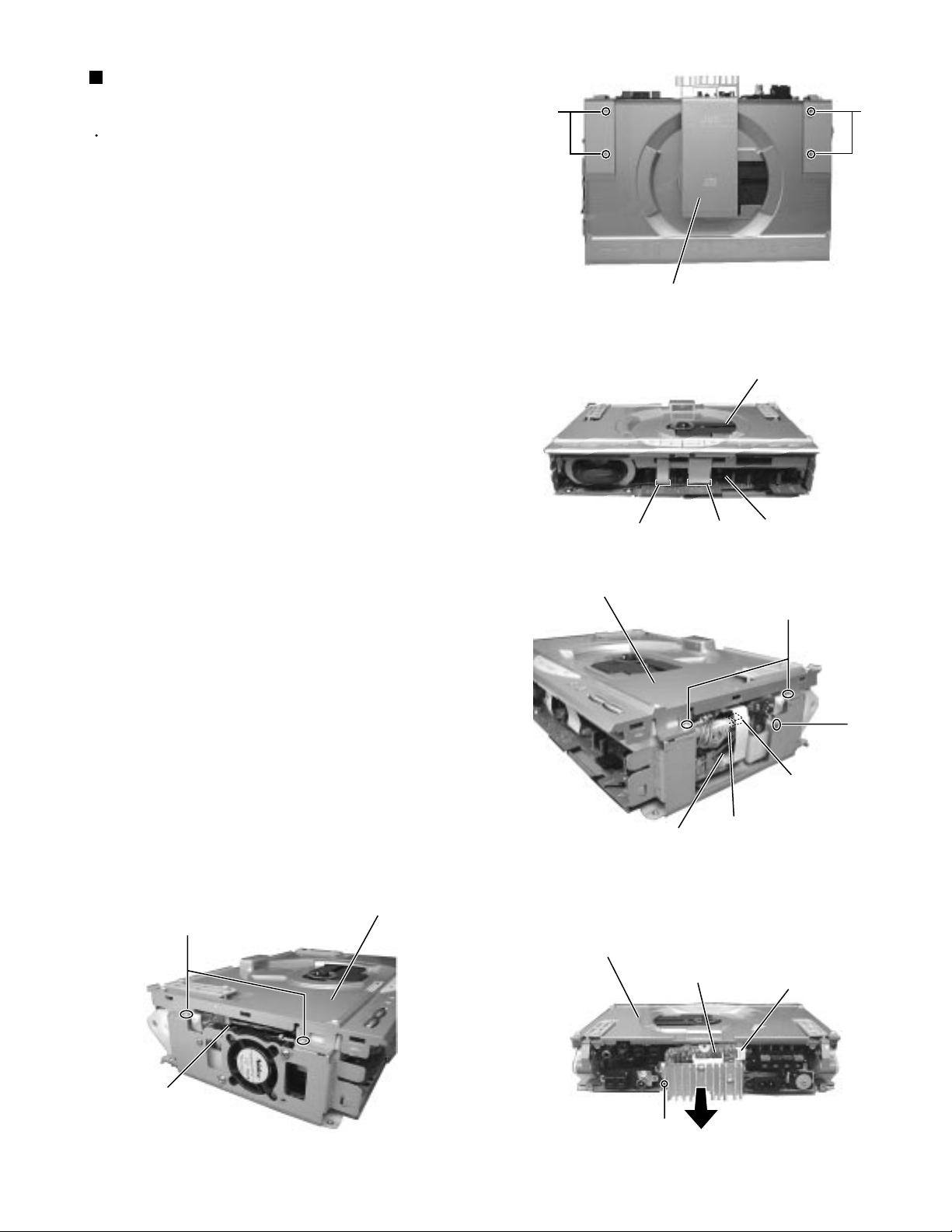

Removing the CD mechanism base

assembly (See Fig.6 to 13)

Prior to performing the following procedure, remove

the rear cover, the side covers and the front panel

assembly.

1.

Remove the four screws E attaching the CD door on

the upper side of the body.

2.

Disconnect the card wire from connector CN104 and

CN105 of the main board in the front part of the

body. Disconnect the card wire from CN101 of the

main board on the right side, and the harness from

CN705 and CN708 of the CD mechanism base

assembly respectively.

3.

Remove the four screws F attaching the CD

mechanism base assembly on the upper side of the

body. Remove the screw I attaching the earth

terminal on the right side.

E

FS-SD5/FS-SD7/FS-SD9

E

CD door

Fig.6

CD mechanism base assembly

4.

Remove the screw G attaching the heat sink board

on the back of the body. Disconnect the harness

from connector CN301 and pull the heat sink board

fully outward.

CD mechanism base assembly

F

CN104

Fig.7

CD mechanism base assembly

Main bard

CN101

Fig.8

CD mechanism base assembly

CN105

CN708

Main bard

F

I

CN705

CN804

Fig.9

Heat sink board

G

Fig.10

CN301

1-7

Page 8

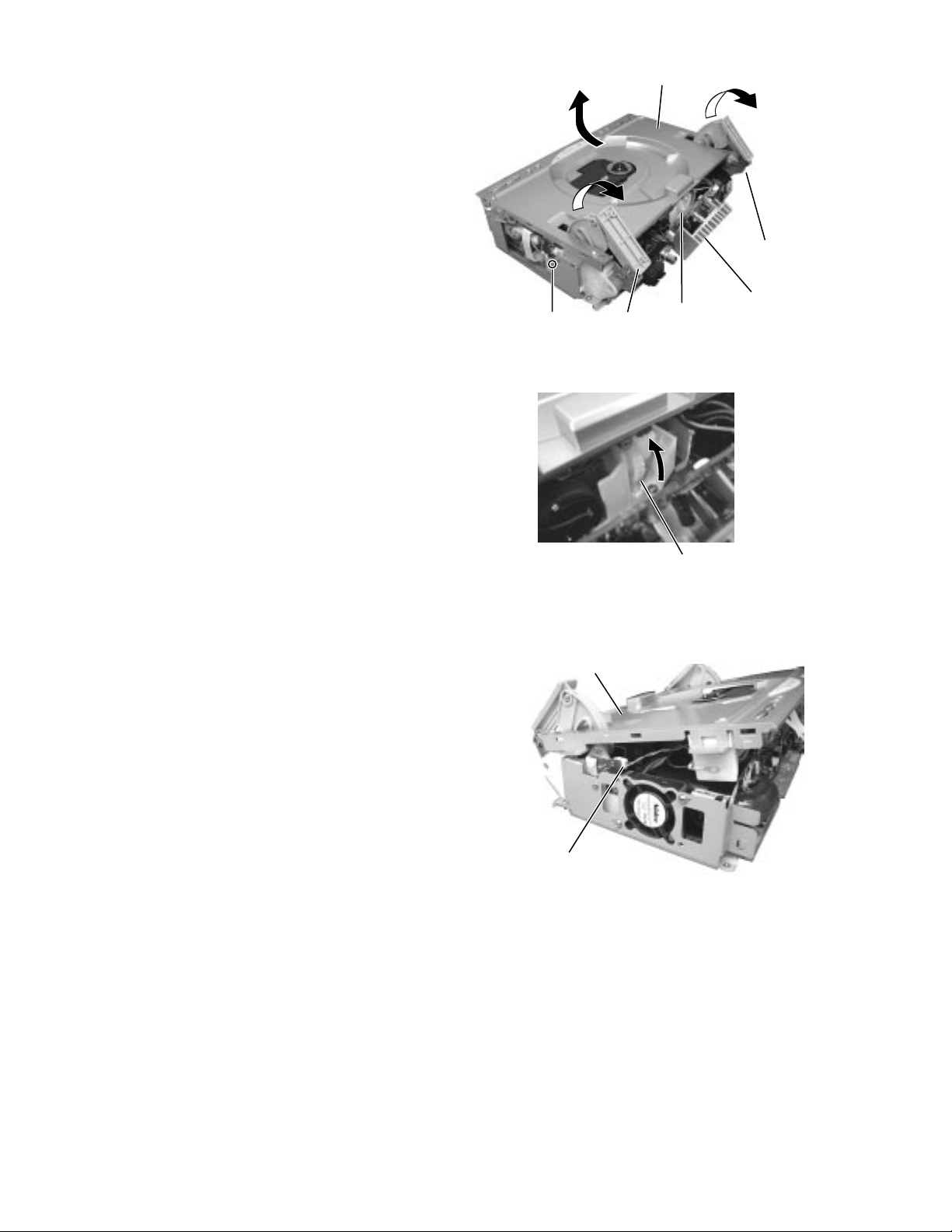

FS-SD5/FS-SD7/FS-SD9

5.

Raise the right and left door arms by turning the gear

a in the rear of the heat sink board.

6.

After the CD mechanism base assembly is detached

from the door arms, pull the CD mechanism base

assembly toward the front and disconnect the

harness from connector CN804 on the left side of the

door arm board.

7.

Pull out the CD mechanism base assembly toward

the front.

I

CD mechanism base assembly

Heat sink board

Door arm

Gear a

Fig.11

Door arm

Fig.12

CD mechanism base assembly

Door arm board (L)

CN804

Fig.13

Gear a

1-8

Page 9

FS-SD5/FS-SD7/FS-SD9

Removing the door arm assembly / the

door arm board (R) and (L)

(See Fig.14 to 19)

Prior to performing the following procedure, remove

the rear cover, the side covers, the front panel

assembly and the CD mechanism base assembly.

1.

In case that the upper parts of the door arms

attached to the CD door are not level, let down them

to the level position by turning the gear a in the

direction of the arrow.

ATTENTION:

2.

Remove the four screws H on the upper side and

the one screw I on the left side of the body.

3.

Remove the four screws J attaching the door arm

board (L) and (R) on both sides of the door arm

assembly.

When the door arms incline, the door

arm assembly and the door arm board

(R) and (L) may not be removed.

Door arm

Door arm board (R)

Door arm

Door arm board (L)

Fan motor

Fig.14

Door arms (Attached to the CD door)

H

Door arm board (L)

Door arm assembly

Fig.16

J

Fig.15

Door arm assembly

H

Fig.17

Door arm assembly

J

Door arm board (R)

J

I

Fig.18

J

Fig.19

1-9

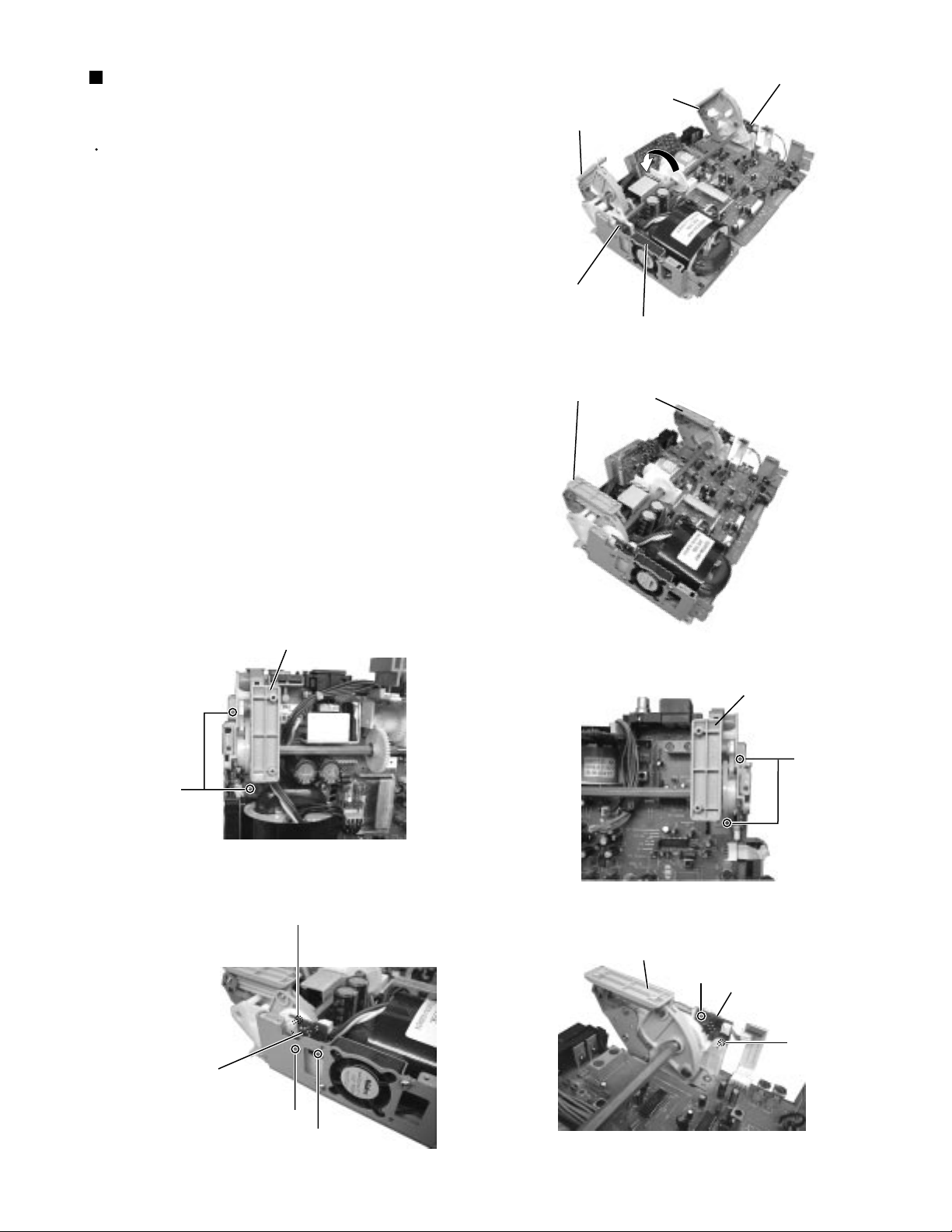

Page 10

FS-SD5/FS-SD7/FS-SD9

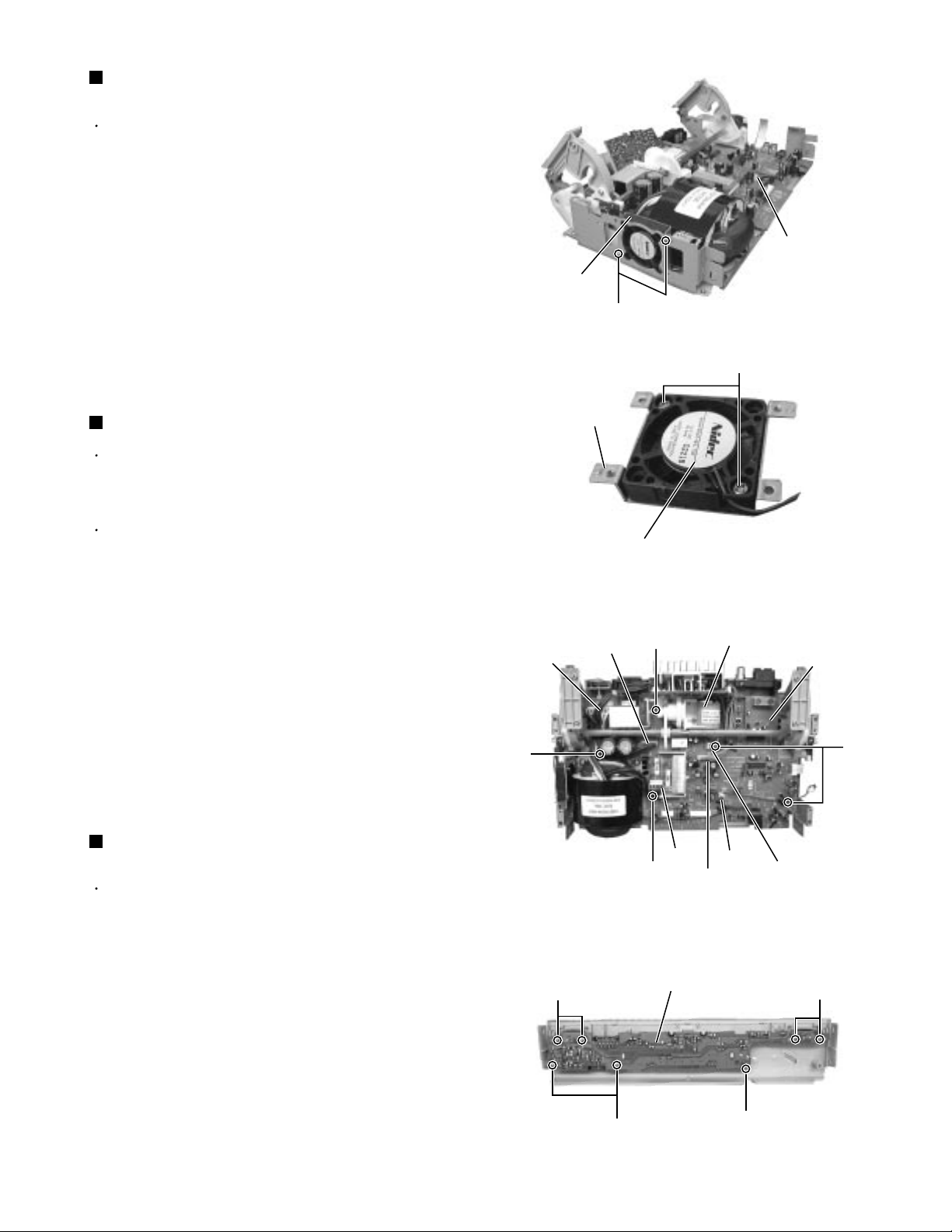

Removing the power amplifier board

(See Fig.20 and 21)

Prior to performing the following procedure, remove

the CD mechanism base assembly.

1.

Disconnect the harnesses from connector CN102

and CN193 on the main board and release them

from the cord stopper respectively.

2.

Remove the two screws K and the two screws L

attaching the heat sink and the power amplifier

board.

Removing the transformer assembly

(See Fig.20)

Prior to performing the following procedure, remove

the CD mechanism base assembly.

1.

Disconnect the harnesses from connector CN191

and CN192 on the main board and release them

from the cord stopper respectively.

2.

Remove the four screws M attaching the

transformer assembly.

Door arm assembly

Cord stopper

M

Transformer assembly

CN191

M

Cord stopper

CN193

CN192

Fig.20

Heat sink board

Cord

stopper

Main board

CN106

CN102

CN181

Heat sink board

Removing the gear motor assembly

(See Fig.22 to 24)

Prior to performing the following procedure, remove

the CD mechanism base assembly and the door arm

assembly.

1.

1.Disconnect the harness from connector CN106 on

the main board and release it from the cord stopper.

2.

2.Remove the three screws N attaching the gear

motor assembly. Remove the gear motor assembly

with the gear motor stopper.

3.

Remove the belt from the gear motor assembly.

4.

Remove the two screws O from the gear motor

assembly.

Heat sink

Gear motor stopper

Motor

L

Fig.21

K

N

Gear motor assembly

Cord

stopper

CN102

CN106

N

Fig.22

1-10

O

Belt

Fig.23

Page 11

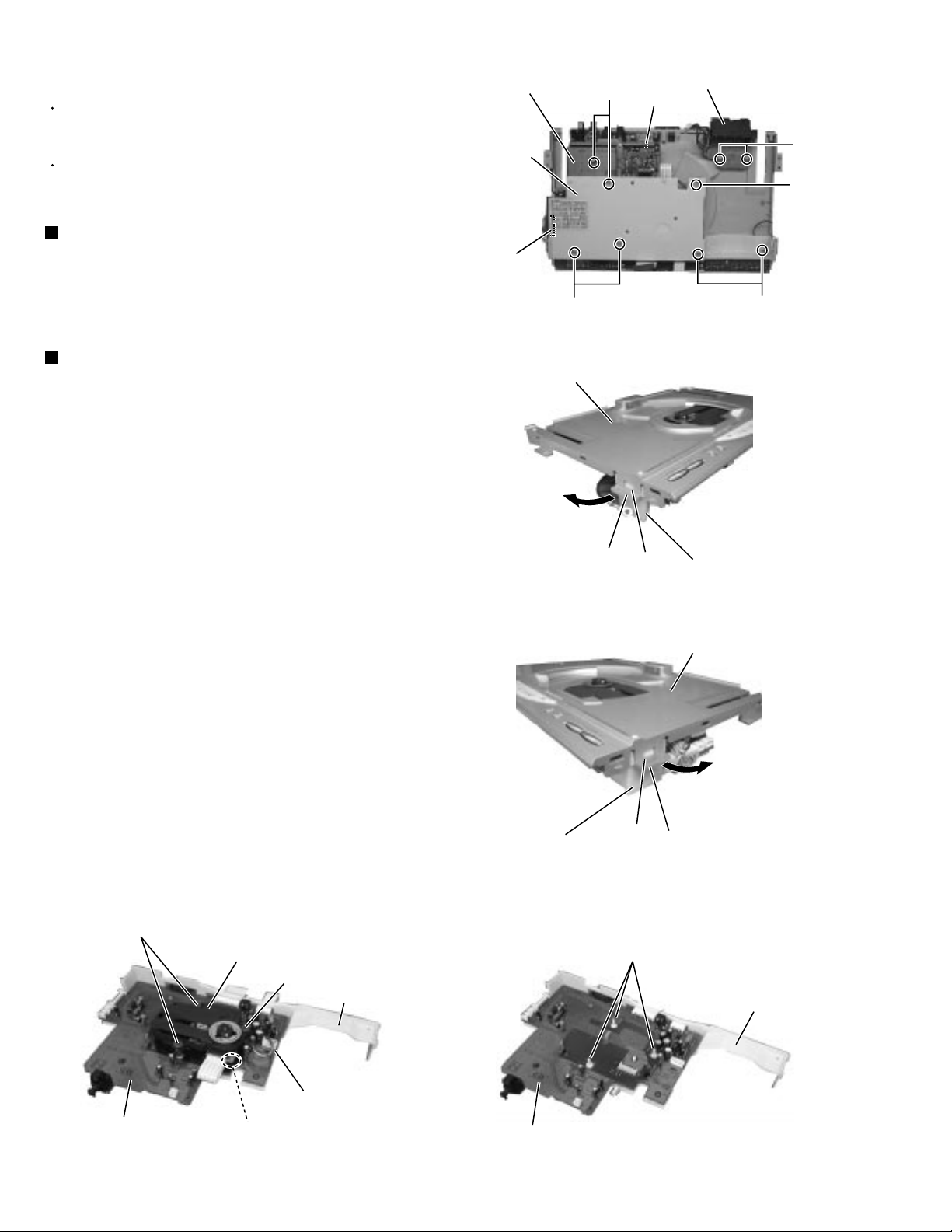

Removing the fan motor assembly

(See Fig.24 and 25)

Prior to performing the following procedure, remove

the CD mechanism base assembly.

1.

Disconnect the harness from connector CN181 on

the main board.

2.

Remove the two screws P on the left side of the

body. Move the fan motor assembly upward to

remove it from the base chassis.

3.

Remove the two screws Q and the fan motor from

the fan bracket.

Fan motor

P

FS-SD5/FS-SD7/FS-SD9

Main bard

CN181

Fig.24

Q

Removing the main board (See Fig.26)

Prior to performing the following procedure, remove

the CD mechanism base assembly and the door arm

assembly.

To facilitate operation process, remove the gear

motor assembly before performing the following

procedure.

1.

Disconnect the harnesses from connector CN102,

CN106, CN191, CN192, CN193 and CN181 on the

main board.

2.

Remove the five screws R attaching the main board

with the cord clamp.

<Front panel assembly>

Removing the front panel board

(See Fig.27)

Prior to performing the following procedure, remove

the front panel assembly.

1.

Remove the seven screws S attaching the front

panel board inside the front panel assembly.

Fan bracket

CN191

R

S

Fan motor

Fig.25

Gear motor assembly

CN193

R

CN192

R

CN102

Fig.26

Front panel assembly

CN181

Main board

R

CN106

S

S

S

Fig.27

1-11

Page 12

FS-SD5/FS-SD7/FS-SD9

<CD mechanism base assembly>

Prior to performing the following procedure, remove

the CD mechanism base assembly.

Refer to "Dismantling and assembling the CD

mechanism assembly" on page 1-5 for the treatment of

optical pickup.

Removing the speaker terminal board

(See Fig.28)

1.

Remove the two screws T attaching the speaker

terminal board on the underside of the CD

mechanism base assembly.

Removing the CD mechanism board / CD

mechanism assembly (See Fig.28 to 32)

1.

Turn over the CD mechanism base assembly and

disconnect the harness from connector CN703 and

CN706 on the CD mechanism board.

2.

Turn over the CD mechanism base assembly and

disconnect the harness from connector CN703 and

CN706 on the CD mechanism board.

CD mechanism board

CD mechanism

cover

CN703

U

CD mechanism assembly

U

Speaker terminal board

CN706

T

U

U

Fig.28

3.

Turn back the CD mechanism assembly and detach

the CD mechanism cover while pulling the CD

mechanism assembly outward to release the two

joint tabs marked c.

4.

Disconnect the card wire from the connector of the

CD mechanism assembly inside the CD mechanism

cover. Disconnect the harness from CN605 on the

CD mechanism board. Pull the CD mechanism

assembly out of the three shaft of the CD

mechanism cover.

ATTENTION:

5.

Remove the CD mechanism board from the CD

mechanism cover.

Cushion

When reassembling, confirm that the

cushion of the CD mechanism

assembly is reattached to the three

shafts.

CD mechanism assembly

Cushion

CD mechanism cover

Joint c

CD mechanism cover

Tab

Fig.29

Tab

Fig.30

Shafts

CD mechanism cover

CD mechanism assembly

Joint c

CD mechanism cover

CD mechanism board

1-12

Short circuit land

Fig.31

CN605

CD mechanism board

Fig.32

Page 13

FS-SD5/FS-SD7/FS-SD9

Removing the jack board (See Fig.33)

Prior to performing following procedure, remove the

CD mechanism board.

1.

Disconnect the harness from connector CN502 on

the jack board.

2.

Remove the four screws V attaching the jack board.

Removing the switch board (See Fig.33)

Prior to performing following procedure, remove the

CD mechanism board.

1.

Disconnect the harness from connector CN502 on

the jack board.

2.

Remove the six screws W attaching the switch

board.

Jack board

V

V

W

CD mechanism board

CN502

V

Fig.33

Tabs d

Switch board

W

Removing the LED board

(See Fig.34 and 35)

1.

Disconnect the harness from connector CN706 on

the CD mechanism board on the underside of the

CD mechanism base assembly.

2.

Push inward the two tabs d attaching the LED board

case and release them.

3.

Pull out the LED board from the LED board case.

Fig.34

LED board

Fig.35

LED board case

1-13

Page 14

FS-SD5/FS-SD7/FS-SD9

Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to

clean the lens with a alcohol soaked cotton

swab.

(2) Life of the laser diode

When the life of the laser diode has expired,

the following symptoms will appear.

1. The level of RF output (EFM output:amplitude

of eye pattern) will below.

Is the level of

RFOUT under

1.25V 0.22Vp-p?

YES

O.K

NO

Replace it.

Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord from the ac outlet.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Plug the power cord in,and turn the power on.

At this time,check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at TP1.

Finish.

(3) Semi-fixed resistor on the APC PC board The semi-fixed resistor on the APC printed circuit board which is

attached to the pickup is used to adjust the laser power.Since this adjustment should be performed to match the

characteristics of the whole optical block, do not touch the semi-fixed resistor.

If the laser power is lower than the specified value,the laser diode is almost worn out, and the laser pickup should

be replaced.

If the semi-fixed resistor is adjusted while the pickup is functioning normally,the laser pickup may be damaged

due to excessive current.

1-14

Page 15

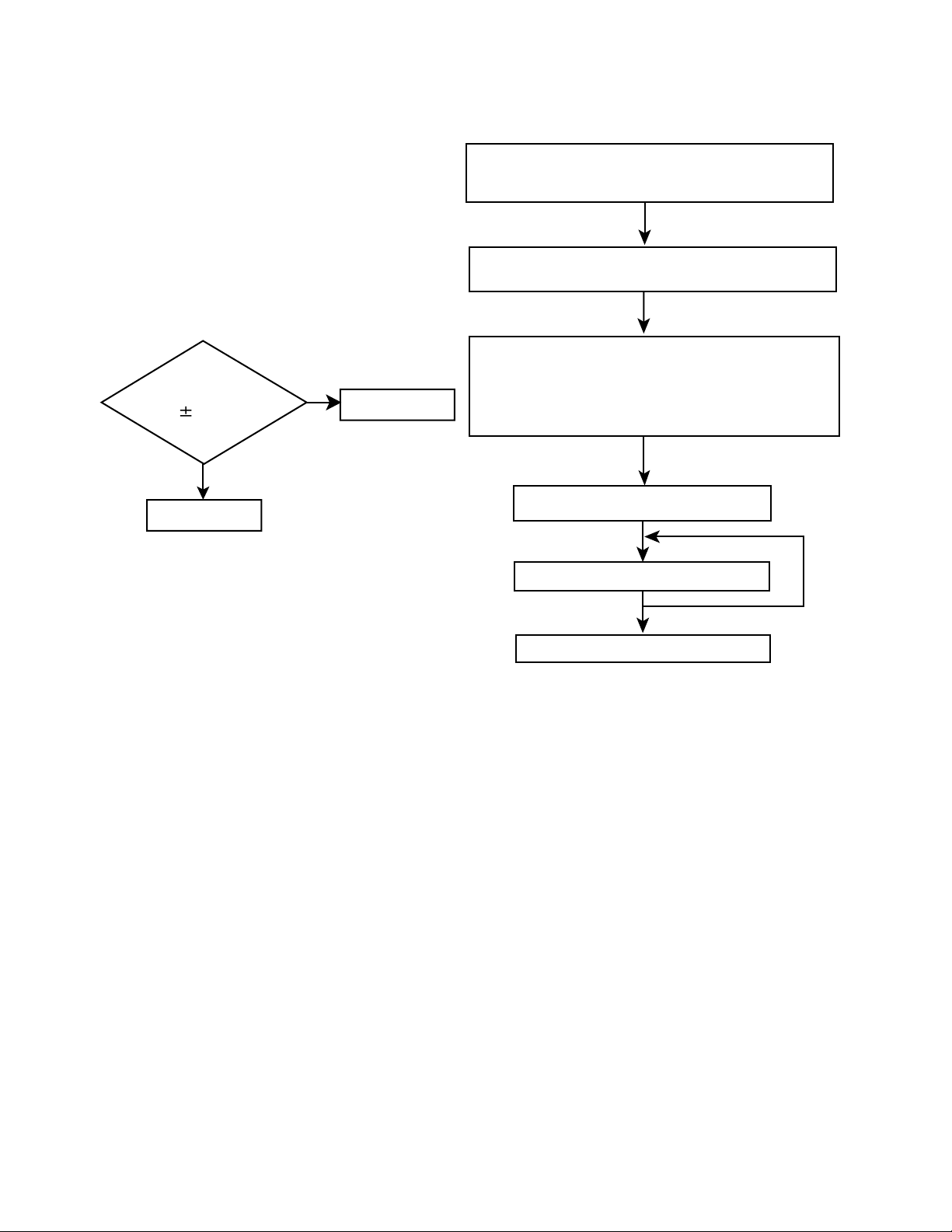

Flow of functional operation until TOC read

Power ON

Play Key

Slider turns REST

SW ON.

Automatic tuning

of TE offset

Confirm that the voltage at the pin4

of CN605 is "H"/"L"/"H".

FS-SD5/FS-SD7/FS-SD9

Check Point

Tracking error waveform at TOC reading

Approx.3sec

Tracking

servo

off states

Automatic measurement

of TE amplitude and

automatic tuning of

TE balance

VREF

pin 25 of

IC601(TE)

Approx

1.8V

Disc states

to rotate

Tracking

servo

on states

Disc to be

braked to stop

TOC reading

finishes

500mv/div

2ms/div

Fig.1

Laser ON

Detection of disc

Automatic tuning of

Focus offset

Automatic measurement of

Focus S-curve amplitude

Disc is rotated

Focus servo ON

(Tracking servo ON)

Automatic measurement of

Tracking error amplitude

Automatic tuning of

Tracking error balance

Check that the voltage at the

pin40 of IC603 is + 5V?

Confirm that the Focus error

S-cuve signal at the pin28 of

IC603 is approx.2Vp-p

Confirm that the signal from

pin24 IC603 is 0V as a

accelerated pulse during

approx.400ms.

Confirm the waveform of

the Tracking error signal.

at the pin 25 of IC601 (R6009)

(See fig-1)

Automatic tuning of

Focus error balance

Automatic tuning of

Focus error gain

Automatic tuning of

Tracking error gain

TOC reading

Play a disc

Confirm the eys-pattern

at the lead of TP602

1-15

Page 16

FS-SD5/FS-SD7/FS-SD9

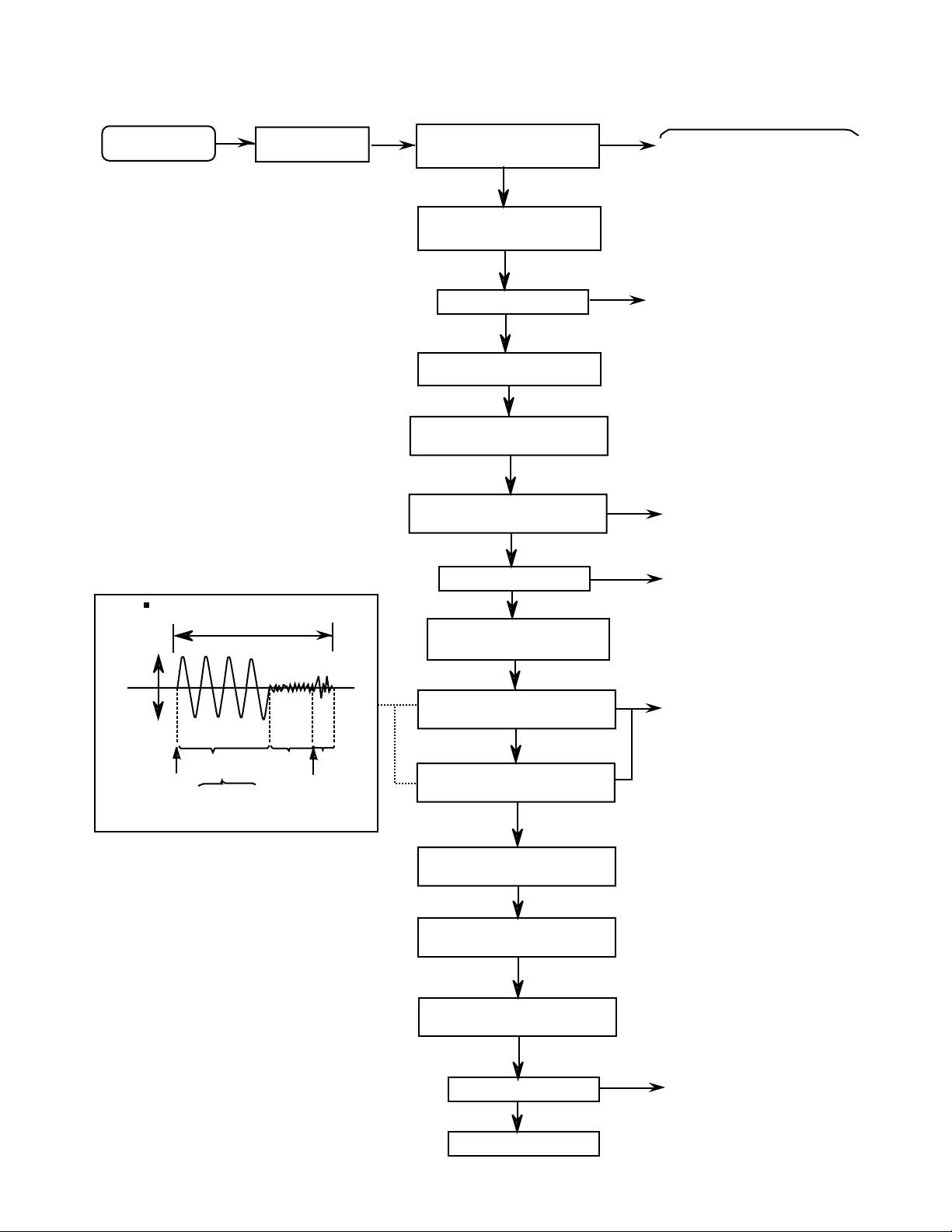

Method of connecting treatment device wire

When the KSM-770ABA mechanism is used, the expansion cable is used as follows.

EXTFSSD5-JIG

extension wire

QUQB12-0840CJ

8pin card wire

QUQB12-0940DJ

9pin card wire

QUQB12-1840DJ

18pin card wire

QUQB12-1640DJ

16pin card wire

First short-circuit the pickup circuit before removing the pickup.Then carry out the replacement.

Refer to "Dismantling and assembling the traverse unit" on page 1-5.

KSM-770ABA

Laser pick-up unit

Shorting

1-16

Short circuit land

Page 17

FS-SD5/FS-SD7/FS-SD9

Description of major ICs

BD3861FS-X (IC501) : Audio sound control

1. Pin layout

32 18

117

2. Block diagram

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17

0dB~

-70dB

Vcc/2 Vcc/2

Vcc/2

Vcc/2

25k

25k

12345678910111213141516

25k

25k

25k

25k

25k

25k

Treble1

f0=10kHz

25k

25k

Treble2

f0=10kHz

Vcc/2

Vcc/2

25k

25k

Middle2

f0=1kHz

25k

25k

25k

25k

Middle1

f0=1kHz

25k

25k

25k

25k

Bass1

f0=90Hz

12k

100k

0dB~

-59dB

24k

Vcc/2

Vcc/2

Bass2

f0=90Hz

0dB~

-59dB

Vcc/2

Vcc/2

Logic

3. Pin function

Pin

Symbol SymbolFunction Function

No.

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

A1

A2

B1

B2

C1

C2

D1

D2

E1

E2

MIC

FIL

GND

DATA

CLK

Vcc

CH1 input pin A

CH2 input pin A

CH1 input pin B

CH2 input pin B

CH1 input pin C

CH2 input pin C

CH1 input pin D

CH2 input pin D

CH1 input pin E

CH2 input pin E

Microphone input pin

Filter pin

Ground pin

Serial data latch receiving pin

Serial clock receiving pin

Power supply pin

17

18

BASS21

19

BASS22

20

21

BASS11

22

BASS12

23

24

25

26

27

28

29

30

31

32

OUT2

OUT1

MID11

MID12

MID21

MID22

TRE2

TRE1

VOL1

VOL2

GOUT2

GOUT1

CH2 output pin

CH2 bass filter setting pin

CH2 bass filter setting pin

CH1 output pin

CH1 bass filter setting pin

CH1 bass filter setting pin

CH1 middle filter setting pin

CH1 middle filter setting pin

CH2 middle filter setting pin

CH2 middle filter setting pin

CH2 treble filter setting pin

CH1 treble filter setting pin

CH1 input volume input pin

CH2 input volume input pin

CH2 input gain output pin

CH1 input gain output pin

1-17

Page 18

FS-SD5/FS-SD7/FS-SD9

UPD780024AGKA11 (IC701) : CPU for KSM-770ABA

1. Pin layout

64 ~ 49

1

48

2. Block diagram

~

16

17 ~ 32

16-bit TIMER/

EVENT COUNTER

8-bit TIMER/

EVENT COUNTER50

8-bit TIMER/

EVENT COUNTER51

WATCHDOG TIMER

WATCH TIMER

SERIAL

INTERFACE30

33

~

PORT0

PORT1

PORT2

PORT3

78K/0

CPU

CORE

ROM

(32K

BYTE)

PORT4

PORT5

SERIAL

INTERFACE31

UART0

A/D CONVERTER

INTERRUPT

CONTROL

BUZZER OUTPUT

CLOCK OUTPUT

CONTROL

RAM

(1024

BYTE)

VDD0 VDD1 Vss0 Vss1 IC

PORT6

PORT7

EXTERNAL

ACCESS

SYSTEM

CONTROL

1-18

Page 19

FS-SD5/FS-SD7/FS-SD9

3. Pin function

Pin

No.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

1

2

3

4

5

6

7

8

9

Symbol I/O Function

MT0

MT1

MTS

BLCTL

AHB

SMUTE

TUST

CDLED

VSS0

VDD0

MPX

RDSDI

DRMUTE

SCD

TUDATA(I)

TUDATA(O)

TUCK

SUBQ

XRST

SQCK

MLD

M DATA

MCLK

VDD1

AVSS

S TAT

REST

KEY1

KEY2

KEY3

SAFETY

LDCK

VERSION

AVREF

AVDD

RESET

XT2

XT1

IC

X2

X1

VSS1

REM

RDSCK

XKILL

BEAT

BUP

+BCTL

V DATA

VCLK

DOOR1

DOOR2

DOOR3

LOMUTE

RS

E

D84

D85

D86

D87

DIMMER

POUT

FTU

FCD

O

CD door motor control signal 0 output

O

CD door motor control signal 1 output

O

Motor speed control output (L:Normal, H:Slow)

O

Back light power supply control output

O

AHB ON/OFF control signal output (L:ON, H:OFF)

O

System mute control signal output

O

Tuner control strove output

O

CD LED control signal output (L:OFF, H:ON)

-

Ground at port section

-

Power supply at port section

I

Stereo indicator control signal input (L:Stereo)

I

RDS data input

O

Driver mute output

I

Voltage detection for safety of CD

I

Tuner control data input

O

Tuner control data output

O

Tuner control clock output

I

CD control Q code input

O

CD control reset signal output

O

CD control Q code clock signal output

O

CD control command load signal output

O

CD control command data signal output

O

CD control command clock signal output

-

Power supply without port section

-

Ground of A/D converter

I

CD control status signal input

I

CD rest switch detection signal input

I

Main body top section tact switch detection signal input

I

Main body top section tact switch detection signal input

I

Main body front section tact switch detection signal input

I

Voltage detection for safety

I

CD door motor lock detection signal input

I

Version detection

I

Reference voltage input for A/D converter

-

Analog power supply for A/D converter

I

System reset signal input

-

Sub clock

I

Sub clock signal input 32.768kHz

I

Connect to VSS0 or VSS1

-

Main clock

I

Main clock signal input 4.19MHz

-

Ground without port section

I

Remote controller signal input

I

RDS clock signal input

O

Sub clock OSC control signal output

O

Main clock shift control signal output

I

Back up detection signal input

O

Power supply control at back up operating

O

BD3861FS (VOL & FUNC IC) control data signal output

O

BD3861FS (VOL & FUNC IC) control clock signal output

I

Cd door position detection switch input

I

CD door position detection switch input

I

CD door position detection switch input

O

LINE OUT muting control signal output

O

LCD driver control resistor select signal output

O

LCD driver control enable signal output

O

LCD driver control data bus signal output

O

LCD driver control data bus signal output

O

LCD driver control data bus signal output

O

LCD driver control data bus signal output

O

Back light DIMMER control signal output

O

Power supply control signal output for amp section

O

Power supply control signal output for TUNER function

O

Power supply control signal output for CD function

UPD780024AGKA11

1-19

Page 20

FS-SD5/FS-SD7/FS-SD9

AN8806SB-W(IC601) :RF&SERVO AMP

1.Pin layout

PD 1

LD 2

LDON 3

LDP 4

VCC 5

RF- 6

RF OUT 7

RF IN 8

C.AGC 9

ARF 10

C.ENV 11

C.EA 12

CS BDO 13

BDO 14

CS BRT 15

OFTR 16

/NRFDET 17

GND 18

2.Block diagram

36 PDAC

35 PDBD

34 PDF

33 PDE

32 PDER

31 PDFR

30 TBAL

29 FBAL

28 EF27 EF OUT

26 TE25 TE OUT

24 CROSS

23 TE BPF

22 VDET

21 LD OFF

20 VREF

19 ENV

6

29

728

27

910 17

8

11

12 19

+

- +

+

EQ

AGC

RF

DET

ENV CURCUIT

36

+

35

+

31

34

-

+

VCBA

-

+

VCBA

-

-

VCBA

+

+

OFTR

BDO

+

13

14

15

16

20

+

- +

32

33

+

-

VCBA

+

+ -

+

- +

21

2

+

-

24 25

30

23

26

22

14

3

1-20

Page 21

FS-SD5/FS-SD7/FS-SD9

3. Pin function

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

symbol

/NRFDET

PD

LD

LD ON

LDP

VCC

RF-

RF OUT

RF IN

C.AGC

ARF

C.ENV

C.EA

CS BDO

BDO

CS BRT

OFTR

GND

ENV

VREF

LD OFF

VDET

TE BPF

CROSS

TE OUT

TE-

FE OUT

FEFBAL

TBAL

PDFR

PDER

PDF

PDE

PD BD

PD AC

I/O

I

APC amp . Input terminal

APC amp . Output terminal

O

LD ON/OFF control terminal

I

Connect to GND

-Power supply

-RF amp . Reversing input terminal

I

RFamp . Output terminal

O

AGC input terminal

I

AGC loop filter connection terminal

I/O

ARF output terminal

O

RF detection capacity connection terminal

I/O

HPF-amp capacity connection terminal

I/O

Capacity connection terminal for RF discernment side envelope detection

I/O

BDO output terminal

O

Capacity connection terminal for RF discernment side envelope detection

I/O

O

OFTR output terminal

RFDET output terminal

O

--

Connect to GND

O

3TENV output terminal

O

VREF output terminal

--

APC OFF control terminal

O

VDET output terminal

I

VDET input terminal

O

CROSS output terminal

O

TE amp . Output terminal

I

FE amp . Reversing input terminal

O

FE amp . output terminal

I

FE amp . Reversing input terminal

I

F.BAL control terminal

I

T.BAL control terminal

I/O

I-V amp conversion resistance adjustment terminal

I/O

I-V amp conversion resistance adjustment terminal

I

I-V amp input terminal

I-V amp input terminal

I

I

I-V amp input terminal

I

I-V amp input terminal

Function

AN8806SB-W

1-21

Page 22

FS-SD5/FS-SD7/FS-SD9

LA6541-X(IC602) : Servo Driver

1. Pin Layout & Block Diagram

Vcc Vref Vin4 Vg4 Vo8 Vo7

24 23

22

20

21

19

11k

Vcc

Gnd

Vo6 Vo5 Vg3 Vin3 Cd Res

18

17 16

ohm

- +

- +

Level

shift

Level

shift

B T L

driver

B T L

driver

B T L

driver

B T L

driver

Level

shift

Level

shift

11k

ohm

1

2

Vcc Mute Vin1 Vg1 Vo1 Vo2 Vo3 Vo4 Vg2 Vin2 Reg

3456

Gnd

7 8 9101112

2. Pin functions

Pin

Symbol Function

No.

1

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

2

3

4

5

6

7

8

9

Vcc

Mute

Vin1

Vg1

Vo1

Vo2

Vo3

Vo4

Vg2

Vin2

Reg Out

Reg In

Res

Cd

Vin3

Vg3

Vo5

Vo6

Vo7

Vo8

Vg4

Vin4

Vref

Vcc

Power supply (Shorted to pin 24)

All BTL amplifier outputs ON/OFF

BTL AMP 1 input pin

BTL AMP 1 input pin (For gain adjustment)

BTL AMP 1 input pin (Non inverting side)

BTL AMP 1 input pin (Inverting side)

BTL AMP 2 input pin (Inverting side)

BTL AMP 2 input pin (Non inverting side)

BTL AMP 2 input pin (For gain adjustment)

BTL AMP 2 input pin

External transistor collector (PNP) connection. 5V power supply output

External transistor (PNP) base connection

Reset output

Reset output delay time setting (Capacitor connected externally)

BTL AMP 3 input pin

BTL AMP 3 input pin (For gain adjustment)

BTL AMP 3 output pin (Non inverting side)

BTL AMP 3 output pin (Inverting side)

BTL AMP 4 output pin (Inverting side)

BTL AMP 4 output pin (Non inverting side)

BTL AMP 4 output pin (For gain adjustment)

BTL AMP 4 output pin

Level shift circuit's reference voltage application

Power supply (Shorted to pin 1)

15

14

13

11k

ohm

RESET

Regulator

11k

ohm

Reg

out

In

1-22

Page 23

LA4905 (IC301) : 2ch BTL power IC

1. Pinlayput

123

FS-SD5/FS-SD7/FS-SD9

2. Block diagram

STBY

D.C

PRE GND

IN 1

21

20

Vcc Vcc(SW)

Standby SW

10

Switching

regulator block

11

8

9

Ripple

filter

2

Input amplifier

H.L.S.

ABCD

H.L.S. :

Higher

Level signal

selector

Amplifier output stage

Nonlinear/output stage

SW

drive

SW B

15

SW E

14

SW OUT1

12

SW OUT2

13

SW GND

16

A

+OUT 1

7

3

CH 1

B

PWR GND 1

5

BEEP

IN 2

ON TIME

4

1

23

BEEP

amplifier

Input amplifier

ON MUTE

muting circuit

Power supply/ground shorting

protection circuit

Overvoltage/thermal protection

circuit

CH 2

Nonlinear amplifier/output stage

Pop noise

prevention circuit

-OUT 1

6

C

D

18

19

17

22

-OUT 2

PWR GND 2

+OUT 2

N.C.

1-23

Page 24

FS-SD5/FS-SD7/FS-SD9

MN35510(IC603):Digital servo & Digital signal processer

1. Terminal Layout

20 ~ 1

2.Block Diagram

LRCKIN(MSEL)

BCLK(SSEL)

SRDATAIN

(PSEL)

IOSEL

CLVS

CRC

BLKCK

CLDCK

SBCK

SUBC

DEMPH

RESY

FLAG6(RESY)

SSEL

SQCK

SUBQ

AVDD2

AVDD2

PCK

EFM

PLLF

DSLF

IREF

DRF

ARF

RSEL

PSEL

MLD

MCLK

MDATA

CK384(EFM)

VCOF

BYTCK

SMCK

FCLK

CSEL

MSEL

X2

X1

ÊSTAT

DIGITAL

DEEMPHSIS

SUB

CODE

BUFFER

DSL.

PLL

VCO

VCO

ITUNING

GENERATION

PITCH

CONTROL

21

~

40

41 ~ 60

8TIMES

OVER SAMPUNC

DIGITAL FILTER

EFM

DEMODULATION

SYNC

INTERPOLATION

SUBCODE

DEMODULATION

MICRO

COMPUTER

INTERFACE

CONVERTER

A/D

80

~

61

1BIT

DAC

LOGIC

S

CIRC

ERROR

CORRECTION

DEINTERLEVE

CLV

SERVO

16k

SRAM

INPUT

PEM

(R)

PEM

(L)

D/A

CONVERTER

OUTPUT

DIGITAL

AUDIO

INTERFASE

DIGITAL

AUDIO

INTERFASE

INTER POLATION

SOFT MUTING DIGITAL

ATTENUATION

PEAK DETECTIVE

AUTO CUE

PORT

SERVO

TIMING GENERATOR

AVSS1

AVDD1

OUTR

OUTL

FLAG

IPFLAG

TX

ECM

PC

LRCK

SRDATA

BCLK

DMUTE

TRKV

KICK

VREF

TRVSTR

ECS

TVD

TRD

FOD

TBAL

FBAL

TOFS

TES

/TLOCK

/FLOCK

PLAY

LDON

WVEL

SENSE

1-24

D

/

D

V

V

V

S

D

D

S

D

D

1

/

R

V

T

S

S

E

T

S

S

1

T

F

E

R

T

F

E

E

N

V

T

R

C

R

S

B

V

D

D

O

E

T

/

R

F

D

E

O

F

T

Page 25

FS-SD5/FS-SD7/FS-SD9

3. Description

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

symbol

BCLK

LRCK

SRDATA

DVDD1

DVSS1

TX

MCLK

MDATA

MLD

SENSE

FLOCK

TLOCK

BLKCK

SQCK

SUBQ

DMUTE

STATUS

RST

SMCK

PMCK

TRV

TVD

PC

ECM

ECS

KICK

TRD

FOD

VREF

FBAL

TBAL

FE

TE

RF ENV

VDET

OFT

TRCRS

RFDET

BDO

LDON

I/O

O

O

O

O

O

O

O

O

Description

Not used

Not used

Not used

I

Power supply (Digital)

I

Connected to GND

Digital audio interface output

Micom command clock signal input

I

(Data is latched at signal's rising point)

Micom command data input

I

I

Micom command load signal input

Sence signal output

Focus lock signal output Active :Low

Tracking lock signal output Active :Low

sub-code - block - clock signal output

I

Outside clock for sub-code Q resister input

Sub-code Q -code output

O

I

Connected to GND

Status signal

O

(CRC,CUE,CLVS,TTSTOP,ECLV,SQOK)

Reset signal input (L:Reset)

I

I

Not used

I

Not used

O

Traverse enforced output

O

Traverse drive output

I

Not used

Spindle motor drive signal (Enforced

O

mode output) 3-State

Spindle motor drive signal (Servo error

O

signal output)

Kick pulse output

O

Tracking drive output

O

O

Focus drive output

Reference voltage input pin for D/A

I

output block (TVD,FOD,FBA,TBAL)

Focus Balance adjust signal output

O

O

Tracking Balance adjust signal output

Focus error signal input(Analog input)

I

Tracking error signal input(Analog input)

I

I

RF envelope signal input(Analog input)

Vibration detect signal input(H:detect)

I

Off track signal input(H:off track)

I

Track cross signal input

I

RF detect signal input(L:detect)

I

BDO input pin(L:detect)

I

Laser ON signal output(H:on)

O

Pin

No.

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

symbol

TES

PLAY

WVEL

ARF

IREF

DRF

DSLF

PLLF

VCOF

AVDD2

AVSS2

EFM

PCK

PDO

SUBC

SBCK

VSS

XI

X2

VDD

BYTCK

CLDCK

FLAG

IPPLAG

FLAG

CLVS

CRC

DEMPH

RESY

IOSEL

TEST

AVDD1

OUT L

AVSS1

OUT R

RSEL

CSEL

PSEL

MSEL

SSEL

I/O

Tracking error shunt signal output(H:shunt)

O

I

Not used

I

Not used

I

RF signal input

Reference current input pin

I

Bias pin for DSL

I

I/O

Loop filter pin for DSL

Loop filter pin for PLL

I/O

I

Not used

I

Power supply(Analog)

Connected to GND(Analog)

Not used

II I

Not used

I

Not used

I

Not used

I

Not used

Connected to GND(for X'tal oscillation

I

circuit)

Input of 16.9344MHz X'tal oscillation circuit

I

Output of X'tal oscillation circuit

O

I

Power supply(for X'tal cscillation circuit)

I

Not used

I

Not used

I

Not used

I

Not used

I

Not used

I

Not used

I

Not used

Not used

I

Not used

III

pull up

pull up

Power supply(Digital)

Lch audio output

O

I

Connected to GND

Rch audio output

O

II

pull up

Connected to GND

I

Connected to GND

I

Connected to GND

I

Pull up

Description

MN35510

1-25

Page 26

FS-SD5/FS-SD7/FS-SD9

LC72136N (IC2) : PLL Frequency synthesizer

1. Pin layout

FM/AM

CLOCK

FM/ST/VCO

AM/FM

2. Block

XT

CE

DI

DO

SDIN

1

2

3

4

5

6

7

8

9

10

11

22

21

20

19

18

17

16

15

14

13

12

XT

GND

LPFOUT

LPFIN

PD

VCC

FMIN

AMIN

IFCONT

IFIN

3. Function

Pin

Symbol

No.

1

FM/AM

2

3

4

CLOCK

5

6

FM/ST/VCO

7

AM/FM

8

9

10

11

1

22

16

15

3

4

5

6

17

21

XT

CE

DI

DO

LW

MW

SDIN

Reference

Driver

Swallow Counter

1/2

C

2

B

I/F

Powe r

on

Reset

Function

I/O

X'tal oscillator connect (75kHz)

I

LOW:FM mode

O

When data output/input for 4pin(input) and

I

Swallow Counter

1/16,1/17 4bit

1/16,1/17 4bit

12bit

Programmable

Drivers

Data Shift Register & Latch

7821113

6pin(output): H

Input for receive the serial data from

I

controller

Sync signal input use

I

Data output for Controller

O

Output port

"Low": MW mode

O

Open state after the power on reset

O

Input/output port

I/O

Input/output port

I/O

Data input/output

I/O

Phase

Detector

Charge Pump

Unlock

Detector

Universal

Counter

Pin

No.

12

13

14

15

16

17

18

19

20

21

22

Symbol

IFIN

IFCONT

AMIN

FMIN

VCC

PD

LPFIN

LPFOUT

GND

XT

18

19

20

12

I/O

Function

IF counter signal input

I

IF signal output

O

Not use

-

AM Local OSC signal output

I

FM Local OSC signal input

I

Power suplly(VDD=4.5-5.5V)

When power ON:Reset circuit move

PLL charge pump output(H: Local OSC

O

frequency Height than Reference frequency.

L: Low Agreement: Height impedance)

Input for active lowpassfilter of PLL

I

Output for active lowpassfilter of PLL

O

Connected to GND

X'tal oscillator(75KHz)

I

1-26

Page 27

TA2057N (IC1) : FM/AM IF AMP & Detector

1.Block Diagrams

FM

IF IN

24 23 22 21 20 19 18 17 16 15 14 13

AM

MIX

OUT Vstb QUAD FM OUT AM OUT MPX IN LPF 1 LPF 2 VCO L OUT

AM

IF IN

FS-SD5/FS-SD7/FS-SD9

AM

MIX

123456789 1110 12

AM

RF IN

2.Pin Function

Pin

No.

I/O

1

I

2

3

4

5

6

7

8

9

10

11

12

AM S.SENS

FM S.SENS

-

AM OSC OUT

O

-

I

-

O

O

O

O

REG

FM

IF

S.SENSFMS.SENS

Symbol

AM RF

AM OSC

VCC

AGC

GND

IF OUT

TU IND

ST IND

Rch OUT

AMRF signal input

AM local oscillation circuit

AM local oscillation signal output

Power supply

AGC voltage input terminal

Connect to GND

IF REQ signal output to IC2

Indicator drive output when tuning

Stereo indicator output

"H"mono . "L"stereo

Output Rch

TUN

LED

TUN

LED

VCO

DIVIDE

DECODE

LEVEL

SW

IF

BUFF

IF REQ

SW

Symbol

Lch OUT

O

O

O

O

MPX IN

I

AM OUT

O

FM OUT

O

FM QUAD

I

AM IF IN

I

-

AM MIX OUT

O

FM IF IN

I

AM

VCO

LPF2

LPF1

Vst

/REQ

Output Lch

Voltage controlled terminal

When voltage of terminal is MONO

at "H" and ST at "L"

When voltage of terminal is AM at

"H" and FM at "L"

Multi plex signal input

AM detection signal output

FM detection signal output

Bypass to FMIF

Input of AMIF signal

Fixed voltage output terminal

Output terminal for AM mixer

Input of FMIF signal

FM

DET

AM

IF

AM

OSC

AM

OSCAMOSC

BUFF

OUT

Function Function

AM

DET

AGC

Vcc AGC GND IF OUT

Pin

No.

I/O

13

14

15

16

17

18

19

20

21

22

23

24

AM/FM

MONO

SW

ST

LED

ST

LED

MUTE

R OUTAM

1-27

Page 28

FS-SD5/FS-SD7/FS-SD9

KIA78S06P-T (IC702) : Regulator

1. Pin layout 2. Block diagram

3 INPUT

Q14

Q1

R9

1 2 3

Z1

Q16

R1

Q2 Q7

R11 R10

TA8409F-W (IC108) : Bridge driver

Q4

Q3

Q6

R2

R3

Q8

C1

R4

Q9

Q5

Q10

Q11

Q12

R8

Q13

R7R5R6

1 OUTPUT

2 COMMON

1. Pin layout 2. Pin function

Pin

No.

1

10

1

2

3

4

5

5

6

6

7

8

9

10

3. Block diagram

Vcc

2/2

STANDBY

CIRCUIT

9/10

IN1

1/1

IN2

SYMBOL

IN2

Vcc

OUT2

NC

GND

NC

Vs

OUT1

Vref

IN1

FUNCTION

INput terminal

Supply voltage terminal for logic

Output terminal

Non connection

GND terminal

Non connection

Supply voltage terminal for motor driver

Output terminal

Reference voltage terminal for control circuit

Input terminal

Vs

6/7

Vref

CIRCUIT

Vref

8/9

OUT1

7/8

M

3/3

OUT2

1-28

THERMAL

SHUTDOWN

CIRCUIT

5/5

GND

Page 29

FS-SD5/FS-SD7/FS-SD9

BA15218F-W (IC102) : Dual ope. amp.

1. Pin layout & Block diagram

OUT1 1

- IN1 2

-

8 Vcc

7 OUT2

1

+ IN1 3

+

-

6 - IN2

2

VEE 4

+

5 + IN2

GP1U271X (IC801) : Receiver for remote

NJM4580D-D (IC101) : Dual ope amp.

1. Pin layout & Block diagram

A OUT 1

A -IN 2

AB

A +IN 3

V- 4

8 V+

7 B OUT

6 B -IN

5 B +IN

+

–

Amp.

Limiter Integrator Comparator

UPD78L5J-T (IC191) : Regulator

1. Pin layout 2. Block diagram

R13

Q10

R14

R15

D1

OUTPUT INPUT

GND

R16

Q15

B.P.F

Q5

Q11

Q4

R1 R2

Q1

Demodulator

R17 R9

Q8 Q9

Q6

R5

R4

Q2

R3

C1

R6

Q3

Q13

GND

R13

Q7

VCC Vout

D2

Q12

R14

R12

R11

R4

R7

INPUT

Q14

R10

OUTPUT

GND

1-29

Page 30

FS-SD5 / FS-SD7 / FS-SD9

VICTOR COMPANY OF JAPAN, LIMITED

AUDIO & COMMUNICATION BUSINESS DIVISION

PERSONAL & MOBILE NETWORK BUINESS UNIT. 10-1,1Chome,Ohwatari-machi,maebashi-city,371-8543,Japan

No.20885SCH

Printed in Japan

200012(V)

Page 31

Block diagram

PICKUP

KSM-770ABA

A,B,C

D,E ,F

PD,LD

CN603

SM

FM

AM

FM

RF & SERVO

F ,T

BTL DRIVER

J1

IC601

AMP

IC602

HOT

L1

RFIN

CD DOOR

TU1

SWITCH

RFENV,TRCRS

TBAL,FBAL

VDET,TE,FE

OFT,BDO

RFDET,ARF

LDON

TRV,TVD,ECS,ECM

KICK,FDD,TRD

AMOSC

AMRF

FMIN

W8003

CN804

DOOR3

DIGITAL SERVO

DIGITAL SIGNAL

IC1

FM IF/DET/MPX

AM RF/IF/DET

AMIN IFOUT/CONT

IC2

TUST,TUDATA

PLL

TUCK,Vt/FM+B

AUX IN

AUX OUT

S.W. OUT

KEY

SWITCH

IC603

PROCESSOR

W8002

&

MLD,MDATA

MCLK,SUBQ

SQCK,XRST

S TAT,REST

SCD,DRMUTE

Lch

Rch

MPX

E1,E2

PRI1

PRI2

J5303J5302J5301

OUT1

CN502

KEY1

KEY2

DOOR3

CDL,CDR

CD+B

2-1

MPX

FILTER

TUNERL

TUNERR

IC601

FUNC

/ VOL

AMP

VCLK

V DATA

CD LED

CONTROL

FAN+B

TU5V

SIGL

SIGR

CN101

CN501

TUNERL

TUNERR

SIGL

SIGR

SW10V

CLOCK

DATA

CDL

CDR

KEY1

KEY2

LOMUTE

DOOR3

CD LED

US5V

SW10V

BUCKUP

IC702

US6VREG

RESET

SW5V

CONTROL

X1,X2

CLOCK

CN102

OUT1

IC101

OUT2

AHB

SW10V

SW10V

MT0

MOTOR

MT1

DRIVER

CD+B

+B

CN104W5001 CN106

CN701CN703

+B

CD LED

CONTROL

LED+B

CN105

CN702

POUT

FTU

FCD

MT0

MT1

MTS

TUCK

IC701

SYSTEM

CONTROL

SW10V

LED+B

CN706CN708 CN705

W8005 W8004

OUT1

OUT2

SAFETY

BLCTL

AHB

SMUTE

TUST

MPX

TUDATA

LOCK

DIMMER

D84~87

RESET

DOOR1

DOOR2

DOOR1

DOOR2

POUT

KEY3

TXDO

RXDO

CN301

IC108

DOOR

M

REM

E,RS

CD DOOR

SWITCH

SIGL

SIGR

POUT

AHBNF

CN802

CN704 CN707

IC301

POWER

AMP

W3901

CN193

IC102

HP AMP

HPMUTE

HPL

HPR

CN103

CN801

HPL

HPR

HP

MUTING

KEY3

REM,POUT

D84~87

DIMMER

BL6VCD7V

US7V

E,RS

OUT1

OUT2

T1

KEY

SWITCH

IC801

REMOCON

LCD

DIMMER

CONTROL

CN803

W8001

BACK

LIGHT

W3002

CN301

CN181

W1801

CN192 J8301

CN191

SPEAKER

J3001

J1901

HEADPHONE

OUT

Page 32

FS-SD5/FS-SD7/FS-SD9

< MEMO >

2-2

Page 33

Standard schematic diagrams

CD servo control section (for KSM-770ABA)

5

F

E

A+C

B+D

C6022

C6006

47/6.3

FS-SD5/FS-SD7/FS-SD9

J6001

C6159

0.1

150P

R6056

C6158

MLD

01K0

R6057

MCLK

MDATA

0

R6058

GP1FA550TZ

470

C6058

R6060

6P

C6055

0.047

C6080

220/10

D6063

22

R6068

1SS355-X

STAT

XRST

SQCK

SUBQ

R6005

270K

0.0022

0.022

C6015

C6016

0.022

NI

C6007

R6007

27K

C6019

270P

R6006

47K

R6009 R6012

56K 10K

C6020

180P

C6018

0.0022

R6010

100K

C6017

0.022

R6008

R6080

R6081

C6021

820P

NI

C6001

100/6.3

0

0

C6023

0.1

TBAL

FBAL

RFENV

TRCRS

VDET

FE

TE

XRST

SUBQ

SQCK

STAT

150P

150P

1K

1K

1K

C6156

C6053

C6154

0.022

100P

R6051

R6052

R6053

C6157

R6054

MCLK

MLD

MDATA

REST

SCD

DRMUTE

R6015

120

R6013

LA6541-X

IC602

D6031

AN8806SB-W

IC601

12

10

R6014

NI

C6034

MTZJ5.6C-T2

1K

R6003

LDON

2SA1037AK/R/-X

R6021

Q6001

R6022

R6023

R6121

10/16

R6122

R6123

C6002

T-

C6096

390P

SM+

SM-

C6097

390P

100/6.3

C6032

F+

C6003

R6001

F-

FM-

3.5P

150

150

150

150

150

150

C6098

390P

FM+

C6099

C6014

12K

C6089

0.0047

390P

0.1

C6008

ARF

1/50

C6010C6009

R6040

1K

0.027

100P

R6046

C6011

R6041

43K

C6094

0.1

0

BDO

0.0022

R6050

C6091

1/50

R6048

2.2k

C6012

3.3K

0.015

C6090

R6045

R6043

R6044

OFT

0.01

RFDET

R6002

R6042

4.7k

R6082

3.9k

2.2M

C6031

2.2/50

R6047

3.3k

43K

12K

68K

C6005

330P

C6028

220/10

R6049

1.5K

C6092

0.047

C6029

TRD

KICK

FOD

ECM

ECS

TVD

TRV

100/6.3

FBAL

TBAL

FE

TE

RFENV

VDET

OFT

TRCRS

RFDET

BDO

LDON

ARF

D6033

1SR35-100A-T5

D6032

TRV

TVD

ECM

ECS

KICK

TRD

FOD

R6067

22

D6062

1SS355-X

C6061

470P

R6061

220/10

C6063

C6081

R6069

1.5M

QQR0601-001Z

IC603

100K

0.022

K6051

R6063

C6064

C6076

0.001

120K

0.022

CDMG

R6064

MN35510

C6062

0.33 680

C6065

CDDGT+CDR

CD+B

0.022

AG

CDL

C6083

0.022

470

R6059

X6051

QAX0413-001Z

C6051

C6052

12P

15P

C6073

220/10

C6075

0.001

1K

R6071

R6072

1K

C6072

0.0022

C6071

0.0022

R6066

22

D6061

1SS355-X

CD signal

4

CN603

QGF1008F1-16

R6025

150K

R6024

150K

R6016

91

R6026

39K

R6029

39K

R6028

39K

R6027

39K

E

F

A+C

B+D

FTT+

F+

3

CN605

QGA2001C1-06

2

SMSM+

FMFM+

680

R6031

Q6031

2SC2060/QR/-T

680

R6032

1

C6033

10/16

FS-SD5/7/9LVS20028-001A

ABCD E F G

2-3

Page 34

Power supply & main circuit section

FS-SD5/FS-SD7/FS-SD9FS-SD5/FS-SD7/FS-SD9

Q1101

2SD2114K/VW/-X

D1301

C1202

R1205

C1102

R1105

LOCK

#

#

MT0

MT1

MTS

LOCK

SAFETY

#

#

POUT

SAFETY

RDSCK

R1111

10K

R1211

10K

Q1301

DTA123EKA-X

1K

R1311

D1305

MPX

RDSI

TUCK

TUDATA

C1103

C1203

C1308

TUST

D1304

SMUTE

#

#

R1207

Q1201

2SD2114K/VW/-X

10/50

MTS

BLCTL

AHB

R1805

MT1

R1103

0.001

0.001

C1110

R1203

10K

C1210

3.3K

R1104

10K

3.3K

R1204

LF111

QQR0590-001

1.2K

R1101

1.2K

R1201

5

TUCK

TUDATA

TUST

RDSCK

RDSI

LF121

QQR0590-001

MPX

C1101

C1201

0.0056

0.0056

R1102R1202

5.6K5.6K

Q1914

2SA1037AK/R/-X

D1915D1916

100/16

C1924

1K

R1930

R1931

39

D1914

MTZJ3.9B-T2

Q1915

2SC2412K/R/-X

4.7/50

C1923

27K

R1929

1.2K

R1928

51K

10/25

R1301

C1301

AHB

FTU

4

CN101

QGF1201F3-08

CN501

QGF1201F3-08

J5302

QNS0047-001

1K

C5212

C5112

0.001

0.001

0.01

C5308

CN502

QGA2001C1-04

3

K5302

0.001

C5304

C5309

C5310

0.001

R5304

1K

0.01

WR501

C5307

QQR0779-001Z

150P

C5111

0.01

47K

2SD2114K/VW/-X

R5303

Q5302

W5001

WR502

J5301

QNS0047-001

J5303

QNN0198-001

2

R5109

R5209

R5101

R5201

C5211

R5302

2.2K

22K

22K

150P

C5303

R5103

R5203

56K

56K

Q5301

DTA114EKA-X

1/50

22K

R5301

3K

3K

68K

R5202

R5102

R5107

1K

Q5101

2SD2114K/VW/-X

R5108

2.2K

R5208

2.2K

4.7/50

C5102

4.7/50

C5202

4.7/50

C5103

4.7/50

C5203

C5101

4.7/50

4.7/50

C5201

68K

47/35

C5302

C5301

100/16

1.5

R5305

BD3861FS-X

R5106

R5206R5207

2SD2114K/VW/-X

IC501

Q5201

3.9K

3.9K

47K

R5105

47K

R5205

C5205

C5105

10/16

10/16

C5104

10/35

C5204

10/35

R5204

1.8K

R5104

1.8K

0.0033

C5108

0.0033

C5208

R5110

0.15

C5110

C5109

C5107

C5210

C5209

C5207

0.15

22/16

0.15

0.15

22/16

3.3K

R5210

3.3K

CN105

QGF1201F3-18

FCD

BLCTL

SMUTE

1

470

470

15K

R1109

R1312

R1313

R1108R1107

#15K

#

R1106

47/25 470

C1302 R1302

#

R1206

C1802

100/35

10

10

R1804

Q1102

2SC2412K/R/-X

R1116

2.2K

R1112

3.3K

R1212

3.3K

R1216 R1214

2.2K 1K

Q1202

2SC2412K/R/-X

MT0

POUT

FTU

FCD

C1105

C1104

#

C1204

#

R1208

#15K

IC108

TA8409F-W

R1801

R1807

R1808

Q1801

2SC2412K/R/-X

C1107

4.7/50

C1207

4.7/50

K1801

QQR0779-001Z

47/16

C1205

47/16

15K

R1209

IC102

BA15218F-W

R1215

560

R1310

1K

C1803

1.5

CN106

QGA2501C1-02

470

470

470

R1806

18K

R1115

560

C1209

DTA123EKA-X

C1109

Q1302

R1110

#

R1210

#

R1802

0.0022

150P

C1307

10/50

IC101

15K

47K

R1803

C1208

0.0022

1KMTZJ5.1A-T2

R1303D1302

NJM4580D-D

D1801

L1801

C1801

C1108

150P

C1106

22/35

C1206

22/35

#

C1303

DSK10C-T1QQL25CK-221Z

10/50

R1114

1K

R1113

R1213

56K56K

R1304

#

C1304

1/50

R1306

#

2SD2144S/VW/-T

D1907

C1915

9.1K

R1307

10K

47/16

R1308

C1306

D1303

Q1907

100/16

C1305

CN102

120K

R1305

1K

47/50

C1914

R1920

D1906

R1309

10

100/35

CN104

QGF1201F3-09

QGA2501C1-06

D1905

MTZJ10A-T2

R1913

2.7K

560

MTZJ11A-T2

R1912

5.6K

R1937

W3001

0.01

C1913

R1914

470

C1912

220P

Q1903

2SC2412K/R/-X

D1909

47/25

#

C1925

C1918

R3101

#

R3201

#

Q3301

DTA143TKA-X

2SD2114K/VW/-X 2SD2114K/VW/-X

R1911

470

2SC2412K/R/-X

4.7K

R1910

0.01

MTZJ6.8B-T2

C1917

C1916

220P

R1935

2.7K

150

R1936

D1908

10K

R1924

CN103

QGB1216J1-08S

R3107

2.2K

R3207

2.2K

Q3101 Q3201

Q1901

2SA1359/OY/

Q1902

1K1K1K

1K

R1907

R1909

R1908

R1938

Q1909

2SC2412K/R/-X

R1933

680

Q1910

2SC2412K/R/-X

1.5K

R1934

MTZJ6.8B-T2

D1913

#

R3102

DTA144TKA-X

8.2K1K1.2K

R1915R1916R1917

DTC144TKA-X

Q1908

2SA1359/OY/

330

R1932

IC191

UPC78L05J-T

0.1

10/25

C1921

C1922

C3201

10/35

Q1905

Q1906

C3101

10/35

#

R3202

R1923

0.001

0.001

C3102

C3202

R1902

R1903

R1904

Q1904

2SA1037AK/R/-X

D1904

MTZJ5.6C-T2

4.7

4.7

R1922

0.1

10/16

C3204

C3301

2.2

R3204

1

1

1

15K

R1918

5.1K

R1919

22/25

MTZJ10A-T2

C1920

D1912

C3320

0.001

0.1

C3203

2.2

R3203

R1905R1906

D1903

1501K

R1926

10K

R1927

0.0015

C3302

12K10/16

C1919

#

C3303

D1911

IC301

LA4905

1/50

C3304

QSK0116-001

0.01

C1928

D1910

6A10E2

Q1912

2SA1175/FE/-T

MTZJ6.8A-T2

560

R1925

0.1

0.1

C3103

C3104

2.2

2.2

R3103

R3104

W3901

CN193

QGA2501C1-07

RY191

D1917

4.7

R1921

Q1913

2SC2412K/R/-X

C3306

R3303

0.01

C1929

33/16#10K

C3308

C1903

C1901

0.01

C1927

CN301

QGA2501F1-04

22K

22K

22K

22K

R3105

R3205

R3106

R3206

C3309

C3310

1/50

1/50

6.8K

6.8K

0.047

0.047

D3302

D3303

C3311

R3304

R3305

C3312

D1901 D1902

D5SBA20-S1 D3SBA20-S1

C1905

C1904

0.1 0.1 0.1

0.1

8200/25

C1910

C1907

0.1 0.1 0.1

C1902

0.01

C1911

C1926

Tuner signal

CD signal

6800/25

QGA7901C1-02

QGA7901C1-02

CN191

QGA7901C1-04

W3002

0.1

S1901

VMZ0126-003

C1906

C1908

LF311

QQR0797-002

LF321

QQR0797-002

QQR0799-001

QQR0799-001

LF191

R1901

3.3M

C3105

C3205

0.0033

0.0033

QNB0092-001

CN181

QGA2001C1-02

W1801

CN192

QGA3901C1-04

EP131

QNZ0136-001Z

J1901

QNC0030-001

J1901

QNC0052-001

EP191

QNZ0136-001Z

J1901

QNC0030-001

J3001

Main signal

FS-SD5/7/9 LVS10057-001A

2-4

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

HABC DE FG

Page 35

FS-SD5/FS-SD7/FS-SD9

System control section

2.2K

R8302

2.2K

R8301

L8101

QQL231K-470Y

L8201

QQL231K-470Y

R8101

22

5

CN801

QGB1216K1-08S

C8201

220/10

R8201

22

4

KEY2

KEY1

LOMUTE

DOOR3

VCLK

VDATA

CDL

AG

CDR

CN707

QGF1201F3-06

TXD0

RXD0

3

2

RESET

POUT

FTU

FCD

MT0

MT1

MTS

BLCTL

AHB

SMUTE

TUST

MPX

RDSDI

TUDATA

TUCK

RDSCK

SAFETY

LOCK

CN702CN701 CN703

QGF1201F3-18QGF1201F3-09 QGA2001F1-11

KIA78S06P-T

0.1

C7014

D7008

IC702

2.2K2.2K

R8102R8202

S8002

Q8101C8101

2SD2114K/VW/-X220/10

Q8201

2SD2114K/VW/-X

D7005

MTZJ8.2B-T2

100/16

C7013

D7009

R8103

2.7K

R8203

2.7K

S8001

D7004

D7007

R7052

R8001R8002

1K12K

QGB1216K1-14S

MTZJ5.1C-T2

R7051

47K

33K

2SC2412/R/-X

4.7/50

C7020

10K

R7044

CN802

Q7006

D7003

D7006

R7043

10K

100K

R7050

R7042

DIMMER

10K

REM

Q7004

2SC2412/R/-X

R7041

K8301

QQR0601-001Z

560

Q8002

DTC114EKA-X

C7023

10/16

Q7009

2SA1037AK/R/-X

TH701

10K

D7010

R7079

5.1K

R8005

R7076

10K

1SS355-X

Q7011

2SA1037AK/R/-X

DTA114EKA-X

Q7007

DTC114EKA-X

Q8003

DTA114EKA-X

Q7010

DTC144EKA-X

Q7008

330

Q8001

DTC114TKA-X

R8003

330

R8004

D8002

D8001

SPR-39MVWF

IC801

GP1U271X

100K

R8010

100P

C8004

DI801

QLD0120-001

DB7

DB6

DB5

DB4ERS

CN704

DB6

2.2/50

C7019

DB5

R7020

R7021

R7022

R7023

R7024

R7025

R7026

DB4ERS

10K

10K

R7029

R7031

330

R7005

C7012

QEZ0229-479Z

QGB1216J1-14S

2.2K

1K

1K

1K

1K

1K

1K

R7027

R7028

R7030

R7032

R7034

R7036

R7037

10K

10K

R7035

R7033

R7047

R7049

R7040

Q7003

DTA114TKA-X

QQL01BK-100Z

D7002

QQR0601-001Z

C7017

100P

1K

2.2K

2.2K

2.2K

2.2K

2.2K

2.2K

L7002

QQL01BK-100Z

1K

1K

L7001

K7001

R7075

100/10

C7010

10K

100P

C7016

0.01

C7009

R7074

0.01

C7022

10K

TUCK

SUBQ

XRST

SQCK

MLD

MDATA

MCLK

STAT

REST

KEY1

KEY2

SAFETY

LOCK

DB7

10K

C7021

RS

R7018

R7038R7039

0

RXD0

0.01

C7018

R7019

TXD0

DB4

E

1K

2.2K

R7017

TUDATA

SCD

0.1

C7011

18P

C7002

QAX0401-001

DB5

2.2K

R7016

X7001

DB6

R7015

DRMUTE

RESET

R7045

R8007