JVC DR-MH300BE, DR-MH300BEK, DR-MH300SE, DR-MH300SEF, DR-MH300SEK service manual

...

SERVICE MANUAL

HDD&DVD VIDEO RECORDER

YD089200512

DR-MH300BE, DR-MH300BEK,

DR-MH300SE,DR-MH300SEF,

DR-MH300SEK,DR-MH300SER,

DR-ED400SE

Area Suffix

Only ver.E,EF,EK

Only ver.EK

TM

Only ver.ER

E ------- Continental Europe

Northern Europe

EF --------------------- France

EK ------------------------ U.K.

ER ---- Russian Federation

Only ver.E,EF,ER

TM

HDD DVD

STANDBY/ON

DR-MH300BE, DR-MH300BEK, DR-MH300SE, DR-MH300SEF,

DR-MH300SEK, DR-MH300SER, DR-ED400SE [D5HR10]

Since the whole mechanism assembly unit is replaced, the DVD recorder

mechanism of this unit need not be adjusted.

RAM/RW

NAVIGATION

GUIDE

PR

ENTER

PUSH-OPEN

PR

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.YD089

2005/12

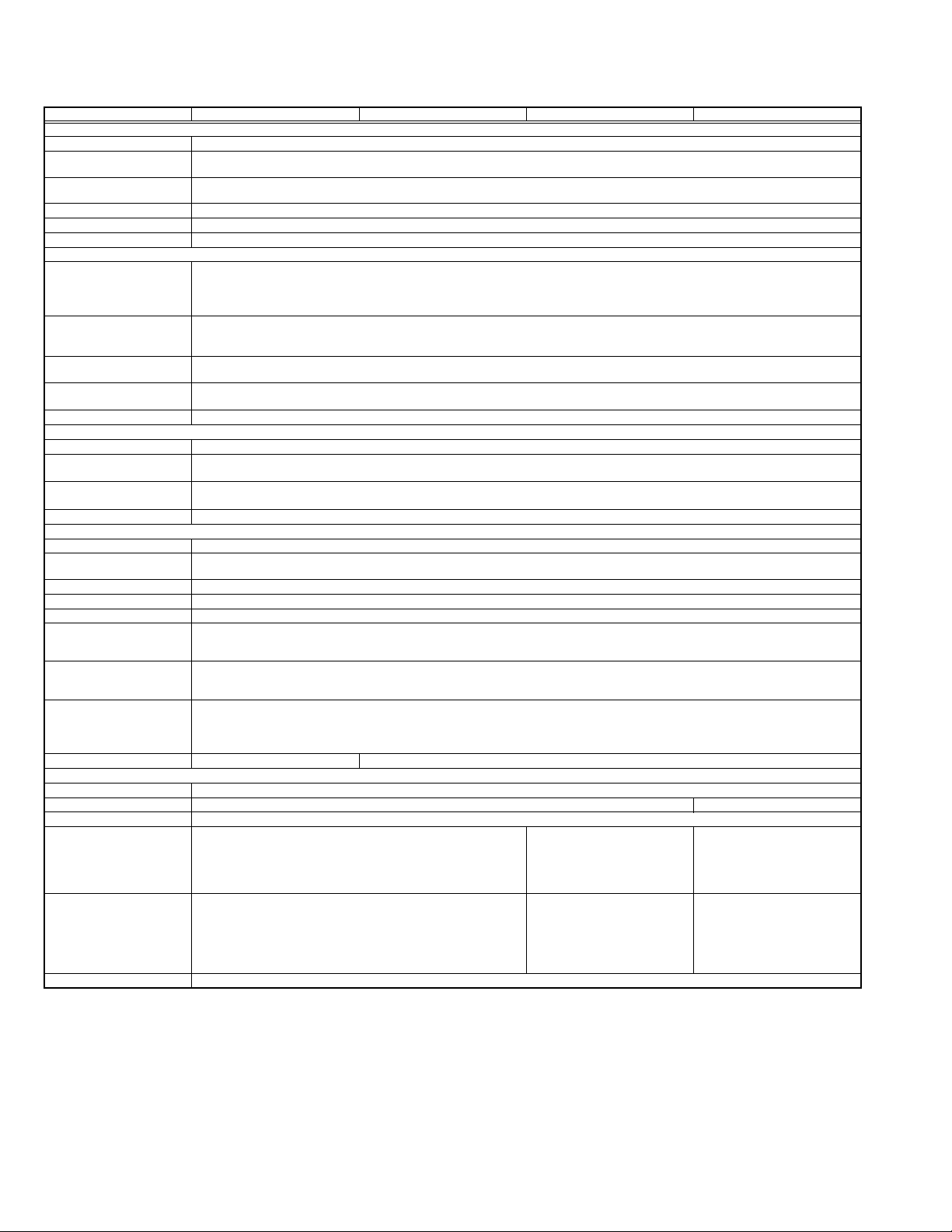

SPECIFICATION

GENERAL

Power requirement AC 220 V - 240 V~, 50 Hz/60 Hz

Power consumption Power on : 36 W

Temperature Operating : 5°C to 35°C

Operating position Horizontal only

Dimensions (W × H × D) 435 mm × 70 mm × 300 mm

VIDEO/AUDIO (DVD Deck)

Recordable disc DVD-RAM 12 cm (4.7 GB/9.4 GB*1),DVD-RAM 8 cm (1.4 GB/2.8 GB*2),DVD-R 12 cm (4.7 GB),DVD-R 8 cm (1.4 GB),DVD-RW 12

Recording format DVD-RAM : DVD Video Recording format

Audio recording system Dolby Digital (2 ch)

Video recording compression system

VIDEO/AUDIO (HDD Deck)

Audio recording system

Video recording compression system

Input/Output

21-pin SCART connectors

Component video output Y : 1.0 Vp-p, 75 ohms

Digital audio output Coaxial

G-LINK - 3.5 mm Jack

TUNER/TIMER

TV channel storage capacity

Channel coverage

Channel coverage(PAL) VHF : 47 MHz - 89 MHz/

Memory backup time Approx. 10 minutes.

E.& O.E. Design and specifications subject to change without notice.

• Manufactured under license from Dolby Laboratories. “Dolby” and the double-D symbol are trademarks of Dolby Laboratories.

• “DTS” and “DTS Digital Out” are trademarks of Digital Theater Systems, Inc.

• This product incorporates copyright protection technology that is protected by U.S. patents and other intellectual property rights. Use of this copyright protection

technology must be authorized by Macrovision. Reverse engineering or disassembly is prohibited.

• GUIDE Plus+, SHOWVIEW,VIDEO Plus+, G-LINK are (1) registered trademarks or trademarks of, (2) manufactured under license from and (3) subject of various

international patents and patent applications owned by, or licensed to, Gemstar-TV Guide International, Inc. and/or its related affiliates.

• GEMSTAR-TV GUIDE INTERNATIONAL, INC. AND/OR ITS RELATED AFFILIATES ARE NOT IN ANY WAY LIABLE FOR THE ACCURACY OF THE PROGRAM SCHEDULE INFORMATION PROVIDED BY THE GUIDE PLUS+ SYSTEM. IN NO EVENT SHALL GEMSTAR-TV GUIDE INTERNATIONAL, INC. AND

/OR ITS RELATED AFFILIATES BE LIABLE FOR ANY AMOUNTS REPRESENTING LOSS OF PROFITS, LOSS OF BUSINESS, OR INDIRECT, SPECIAL,

OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH THE PROVISION OR USE OF ANY INFORMATION, EQUIPMENT, OR SERVICES RELATING

TO THE GUIDE PLUS+ SYSTEM.

• i-LINK is a trademark of Sony Corp .

• HDMI is a trademark of HDMI Licensing, LLC .

Weight 4.6 kg

Recording time

Capacity 160 GB

Recording time (DV) : Approx. 11 hours,(XP) : Approx. 34 hours,(SP) : Approx. 69 hours,(LP) : Approx. 138 hours,

S-video input Y:1.0 Vp-p,75 ohms

Video input 1.0 Vp-p, 75 ohms (pin jack)

Audio input 2 Vrms (pin jack)

i.Link 4-pin for DV Input/Output

HDMI output 19-pin, Corresponding to HDCP

Tuning system Frequency synthesised tuner

Signal system PAL/SECAM colour signal, 625 lines/50 fields

(SECAM-L)

DR-MH300SER

Power off : 6.4 W

Storage : -20°C to 60°C

cm (4.7 GB),DVD-RW 8 cm (1.4 GB)

*1 9.4 GB double-sided discs

*2 2.8 GB double-sided discs

DVD-R : DVD Video format, DVD Video Recording format

DVD-RW : DVD Video format, DVD Video Recording format

Maximum 8 hours (with 4.7 GB disc)

(XP) : Approx. 1 hour, (SP) : Approx. 2 hours, (LP) : Approx. 4 hours, (EP) : Approx. 6 hours, (FR) : Approx. 1 hour - 8 hours

Linear PCM (XP mode only)

MPEG2 (CBR/VBR)

(EP) : Approx. 209 hours,(FR480) : Approx. 300 hours

Dolby Digital (2 ch)

Linear PCM (XP mode only)

MPEG2 (VBR)

IN/OUT X 1, IN/DECODER X 1

C : 0.3Vp-p, 75 ohms

PB/PR: 0.7 Vp-p, 75 ohms

Corresponding to copy protection

Video : 576i/576p/1080i/720p

Audio : 2 ch PCM/Bitstream

Corresponding to Dolby Digital and DTS Digital Surround,

Bit stream

Selectable in digital audio output setting menu

99 positions (+AUX position)

-

104 MHz - 300 MHz/

302 MHz - 470 MHz

UHF : 470MHz - 862MHz

DR-MH300BE,DR-MH300SE,DR-ED400SE

DR-MH300SEF

VHF(LOW):49 MHz-65 MHz(2-4)

VHF(HIGH):104 MHz-300 MHz(510CATV)

Hyper:300 MHz-470 MHz(CATV)

UHF:470 MHz-862 MHz(21-69)

VHF(LOW):47 MHz-89 MHz

(E2-E4,X,Y,Z)

VHF(HIGH):104 MHz-300 MHz

(E5-E12,S1-S20,M1-M10,U1-U10)

Hyper:302 MHz-470 MHz(S21-S41)

UHF:470 MHz-862 MHz(E21-E69)

DR-MH300BEK,DR-MH300SEK

PAL colour signal,625 lines/50 fields

-

VHF : 44.5MHz - 143MHz/

143MHz - 470MHz/

UHF : 470MHz - 862MHz

1-2 (No.YD089)

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

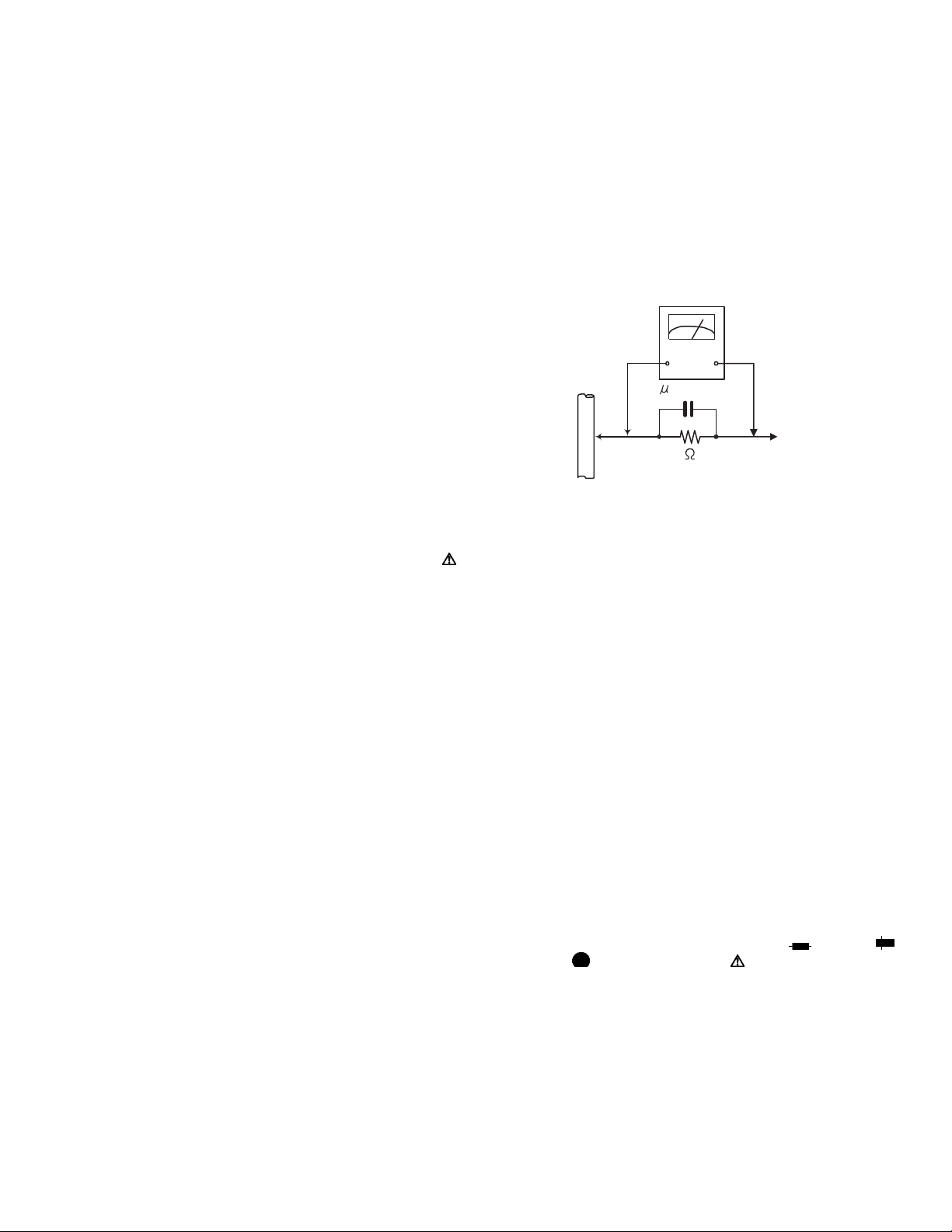

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.YD089)1-3

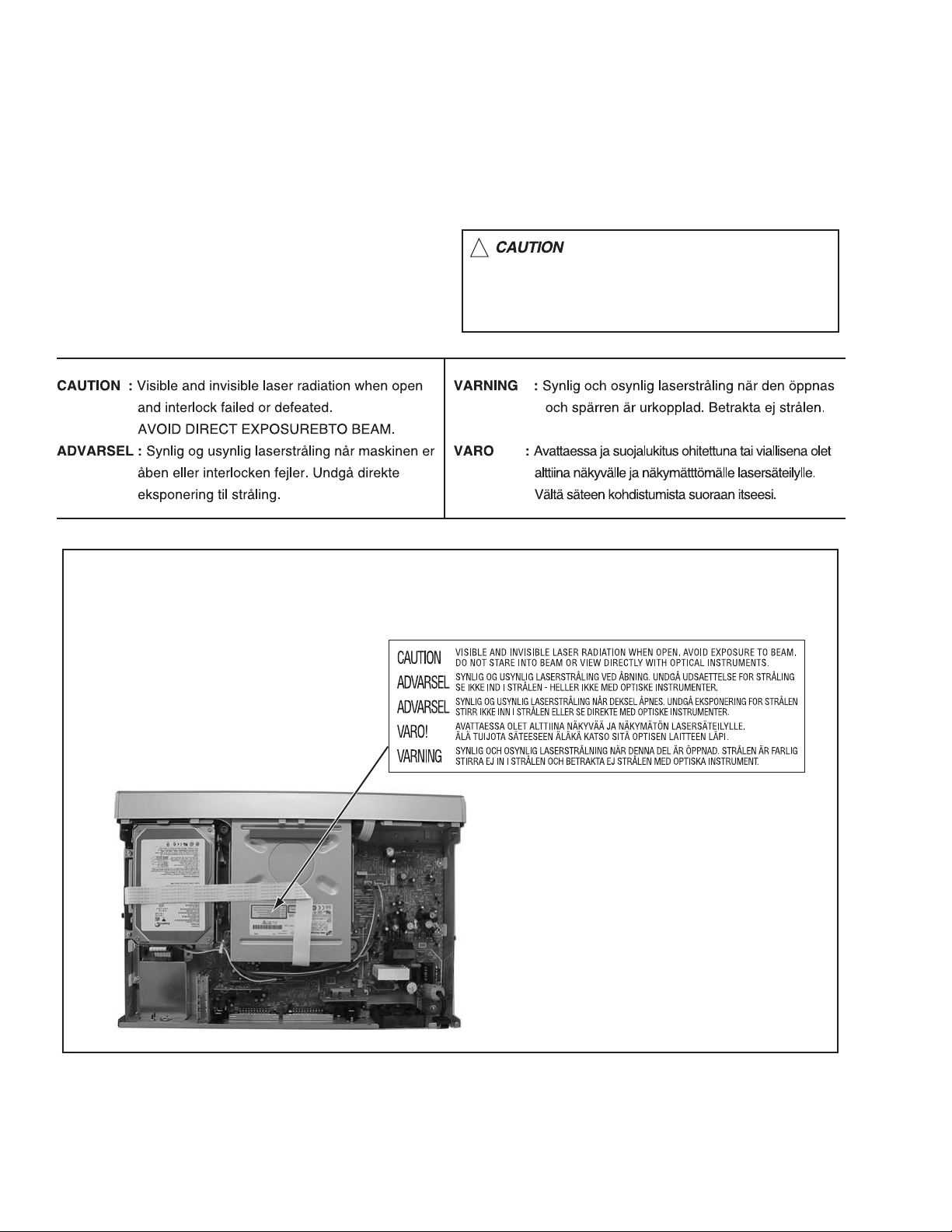

1.5 Important for laser products

!

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The CD,MD and DVD player uses invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABEL

On mechaism assembly

1-4 (No.YD089)

1.6 Hard Disk Drive (HDD) Handling Precautions

The HDD is a precision device for use in reading and writing a large amount of data on or from a disk rotating at a high speed. If it is

not handled carefully, either abnormal operation may result or it may not be possible to read data. The HDD is sensitive to the following

items and special care is required in safeguarding against them when handling an HDD. Also take care in handling a set incorporating

an HDD.

(1) Vibrations and impacts

(2) Static electricity

(3) Rough handling

1.6.1 Handling in transport, etc.

• Be sure to place the HDD in the manufacturer's specified package carton before transport.

• When receiving a package containing an HDD, check that the

package carton is not damaged (such as having holes in the

carton, crushed corners, etc.).

• Do not impact the packaging carton when loading or unloading

HDD

Do not throw or

drop packages.

it.

• It is not permitted to use the inner package carton only for

transporting an HDD.

• Do not stack package cartons one upon another.

Be sure to package and

transport the HDDs correctly.

1.6.2 Handling an HDD in the stand-alone status

• When handling an HDD on a hard workbench, place an antistatic mat (rubber sheet) or similar object on the hard surface

(to prevent any impacts occurring between the HDD and

bench).

• Do not stack the HDDs one upon another.

• Do not knock an HDD with a hard object (such as a screwdriver).

• Do not place an HDD on its side panel without using a support

(do not place an HDD in an unstable position).

1.6.3 Handling the installation of an HDD

• Place antistatic mats or similar sheets on all of the surfaces on which work is conducted or when the HDD is transported.

• Do not permit the HDD to knock against the set's brackets.

• When screwing the brackets, be careful not to knock the HDD. When using a power screwdriver, use a low-shock model and arrange

the tightening torque properly.

• When mounting an HDD in a main body, take care not to apply excessive force to the brackets.

(No.YD089)1-5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-6 (No.YD089)

Loading...

Loading...