Page 1

XA013200311

r

SERVICE MANUAL

DVD VIDEO RECORDER

DR-M1SL

Area Suffix

B -------------------------- U.K.

E ------ Continental Europe

EF -------------------- France

for ver.B

Since the whole mechanism assembly unit is replaced, the DVD recorde

mechanism of this unit need not be adjusted.

for ver.E,EF

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LIMITED

No.XA013

2003/11

Page 2

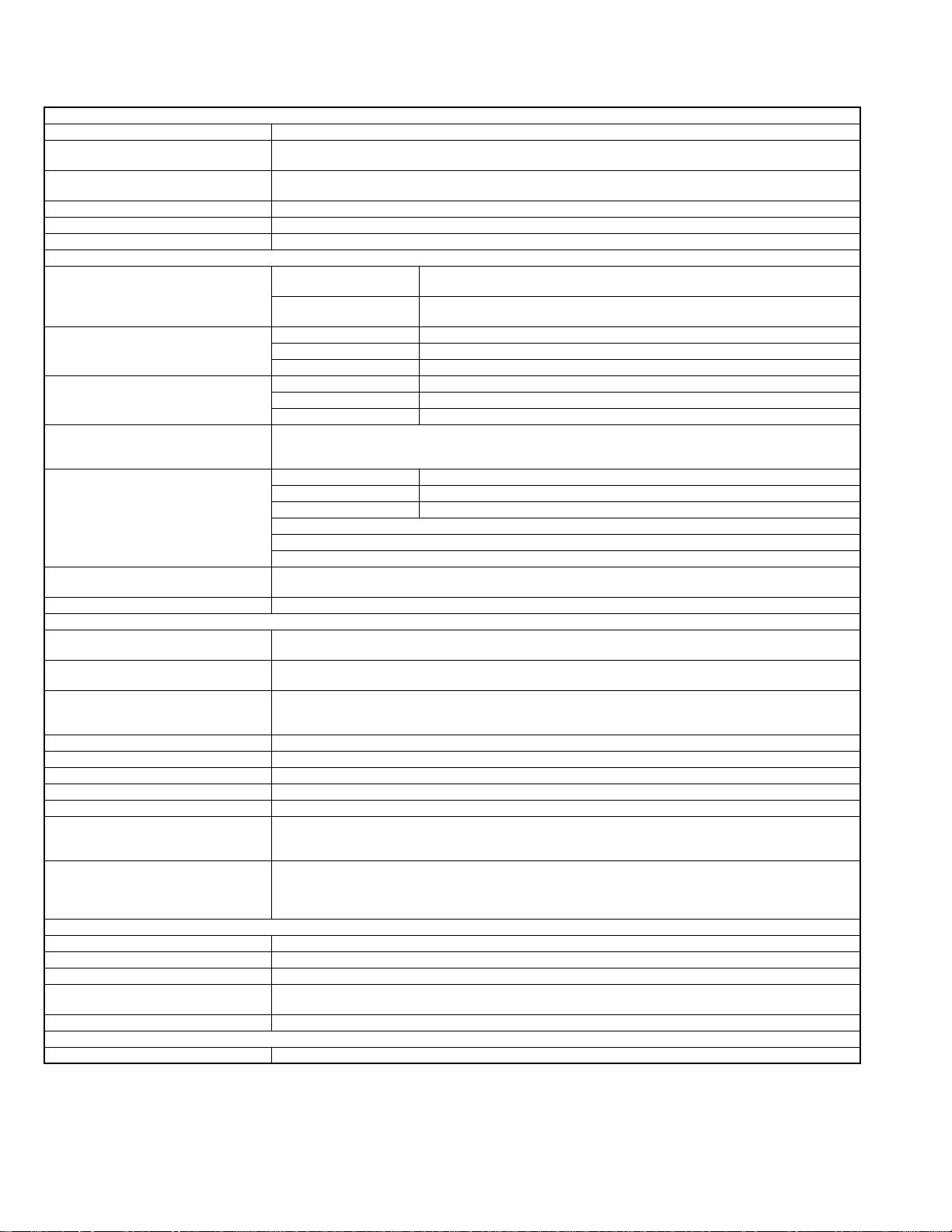

SPECIFICATION

GENERAL

Power requirement AC 220 V - 240 Vd, 50 Hz/60 Hz

Power consumption Power on : 34 W

Temperature Operating : 5°C to 40°C

Operating position Horizontal only

Dimensions (W × H × D) 435 mm × 70 mm × 346 mm

Weight 4.5 kg

VIDEO/AUDIO

Recordable disc DVD-RAM 12 cm : 4.7 GB/9.4 GB, 8 cm : 1.4 GB/2.8 GB

Recording format DVD-RAM DVD Video Recording format

Recording time Maximum 6 hours (with 4.7 GB disc)

Playable disc DVD-RAM 12 cm : 4.7 GB/9.4 GB, 8 cm : 1.4 GB/2.8 GB

Audio recording system Dolby Digital (2 ch)

Video recording compression system MPEG2 (CBR/VBR)

Input/Output

S-video input Y : 0.8 - 1.2 Vp-p, 75 Ω

S-video output Y : 1.0 Vp-p, 75 Ω

RGB output R : 0.7 Vp-p, 75 Ω

Video input 0.5 - 2.0 Vp-p, 75 Ω (pin jack)

Video output 1.0 Vp-p, 75 Ω (pin jack)

Audio input -8 dB, 50 kΩ (pin jack) Corresponding to mono (lef t)

Audio output -8 dB, 1 kΩ (pin jack)

Component video output Y : 1.0 Vp-p, 75 Ω

Optical digital audio output -18 dBm, 660 nm

TUNER/TIMER

Signal system PAL-type colour signal and CCIR monochrome signal, 625 lines 50 fields

TV channel storage capacity 99 positions (+AUX position)

Tuning system Frequency synthesized tuner

Channel coverage VHF 44.5 MHz - 143 MHz/143 MHz - 470 MHz

Memory backup time Approx. 60 min.

ACCESSORIES

Provided accessories RF cable, 21-pin SCART cable, Satellite Controller, Infrared remote control unit, "AA" battery × 2

Specifications shown are for SP mode unless otherwise specified.

E.& O.E. Design and specifications subject to change without notice.

Power off : 18.5 W

Storage : -20°C to 60°C

Pickup CD Wavelength : 780 nm

Maximum output power : 0.5 mW

DVD Wavelength : 650 nm

Maximum output power : 1.0 mW

DVD-R 12 cm: 4.7 GB, 8 cm: 1.4 GB for General Ver. 2.0

DVD-RW 4.7 GB for Ver. 1.0/1.1

DVD-R DVD-Video format

DVD-RW DVD-Video format, DVD Video Recording format

(XP) : Approx. 1 hour, (SP) : Approx. 2 hours, (LP) : Approx. 4 hours, (EP) : Approx. 6 hours, (FR) :

Approx. 1 hour - 6 hours

DVD-R 12 cm: 4.7 GB, 8 cm: 1.4 GB for General Ver. 2.0

DVD VIDEO, DVD-RW 4.7 GB

Music CD (CD-DA)

Video CD

CD-R/RW (CD-DA, Video CD formatted discs)

Linear PCM (XP mode only)

C : 0.2 - 0.4 Vp-p, 75 Ω

C : 0.3 Vp-p, 75 Ω

G : 0.7 Vp-p, 75 Ω

B : 0.7 Vp-p, 75 Ω

i.Link 4-pin for DV input

CB/CR, PB/PR : 0.7 Vp-p, 75 Ω

Corresponding to copy protection

Corresponding to Dolby Digital and DTS Digital Surround

Bit stream

Selectable in digital audio output setting men u

UHF 470 MHz - 862 MHz

1-2 (No.XA013)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of th is product contains special hardw are and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

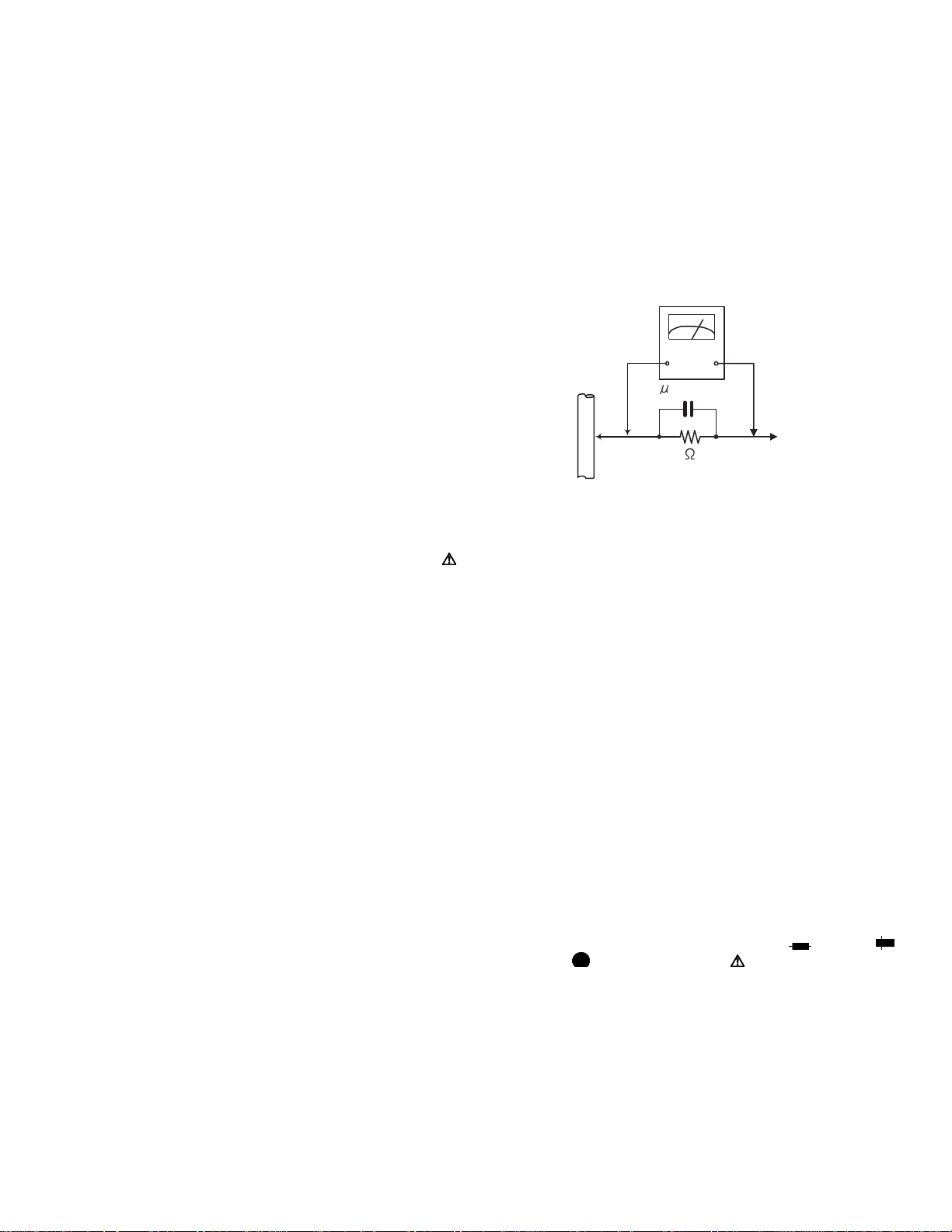

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal resp onsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical compone nts are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.XA013)1-3

Page 4

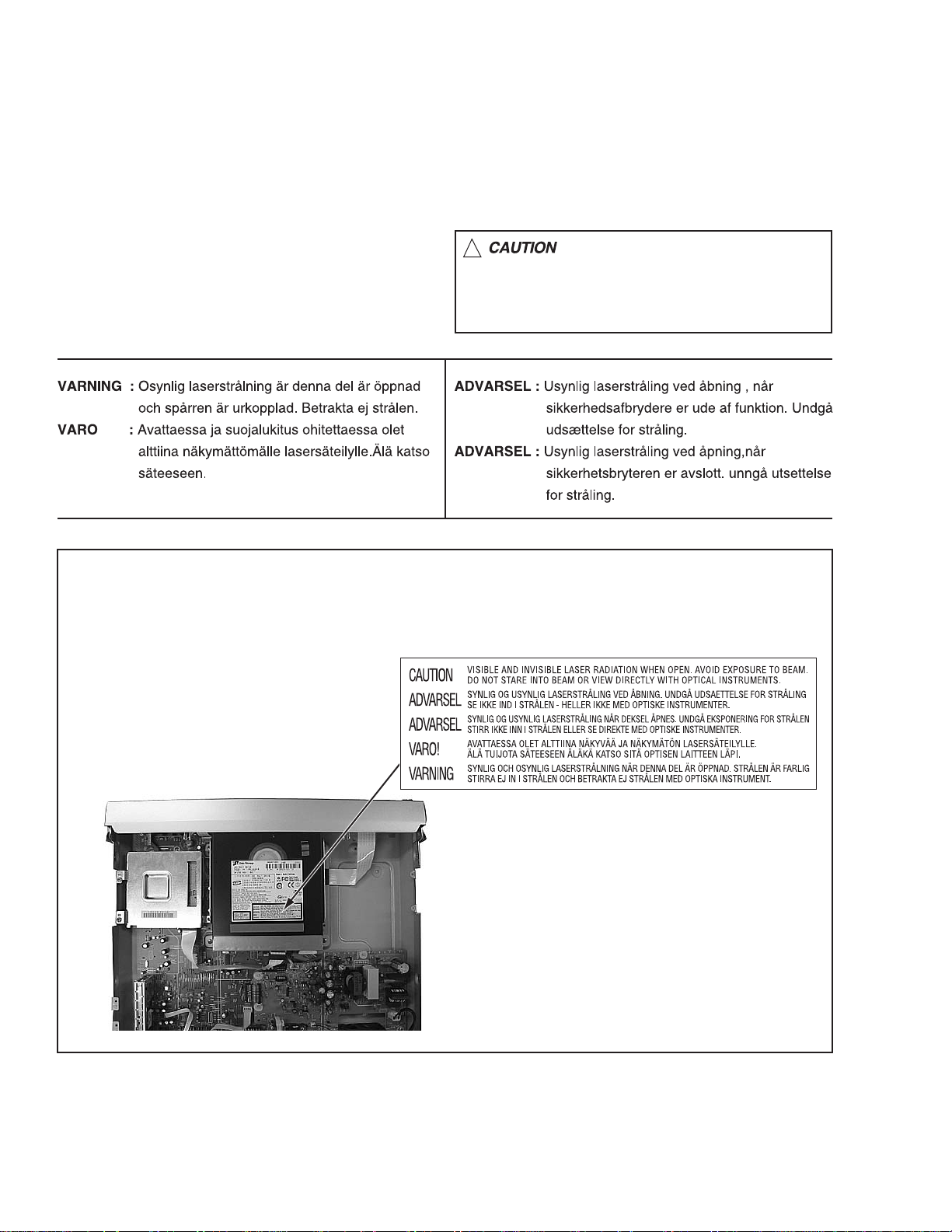

1.5 Important for laser products

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The compact disc player uses invisible laser

radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are de

feated. It is dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABEL and PRINT

WARNING LABEL and PRINT

On mechaism assembly

1-4 (No.XA013)

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

(No.XA013)1-5

Page 6

SECTION 3

Top cover

DISASSEMBLY

3.1 Main body section

3.1.1 Remove the top cover (See figure 1)

(1) Remove the four screws A attaching the top cover on both

sides of the main body.

(2) Remove the five screws B attaching the top cover on the

back of the main body.

(3) Raise the both sides and lower part of the rea r of the top

cover, with opening them slightly in an outward direction.

And the top cover will be removed.

3.1.2 Remove the front panel assembly (See figure 2, figure 3)

• Prior to performing the following procedure, remove the top

cover.

• There is no need to remove the mechanism assembly.

(1) Disconnect the card wire from connector CN3002

main board.

(2) Disconnect the card wire from connector CN7001

FL display board.

(3) Hook a and b are removed respectively, and the front panel

assembly is removed.

on the

on the

A x 2

CN3002

Top cover

A x 2

Fig.1

Front panel assembly

B

B

B

B

B

FL Display board

CN7001

Main board

Fig.2

Hook a

Hook b

Hook b

Front panel

assembly

Hook b

Hook a

Fig.3

1-6 (No.XA013)

Page 7

3.1.3 Remove the mechanism assembly (See figure 4)

• Prior to performing the following procedure, remove the top

cover.

• There is no need to remove the front panel assembly.

(1) Disconnect the socket wire from connector CN5303

power supply board.

(2) Disconnect the card wire from connector CN2201

module board.

(3) Remove the four screws C attaching the mechani sm as-

sembly.

on the

on the

Module board

Mechanism assembly

C C

3.1.4 Remove the module board (See figure 5, figure 6)

• Prior to performing the following procedure, remove the top

cover.

(1) Disconnect the card wire from connector CN2201

module board.

(2) Remove the four screws D attaching the module board.

(3) Lift the module board up, and remove it. Then, the module

board is removed from the connector CN4104

terminal board and the connector CN4101

board. In attaching the module board, insert the connector

on the module board in these connectors securely.

on the

on the DV

on the main

CN2201

Module board

D

C

D

CN2201

CN5303

Fig.4

D

Fig.5

Power supply

C

board

Module board DV Terminal board

CN4104

Main board

Fig.6

CN4101

(No.XA013)1-7

Page 8

3.1.5 Remove the power supply board (See figure 7)

Fastener

• Prior to performing the following procedure, remove the top

cover.

(1) Disconnect the wire from connector CN5301, CN5302,

CN5303, CN5305, CN5001 on the power supply board.

(2) Remove the two screws F attaching the power supply

board.

(3) Four fasteners are removed.

Fastener

CN5303

Power supply board

Fastener

3.1.6 Remove the main board (See figure 8, figure 9)

• Prior to performing the following procedure, remove the top

cover/front panel assembly/mechanism assembly/module

board/power supply board.

(1) Remove the three screws G attaching the main board.

(2) Disconnect the wire from connector CN7301

the main board.

(3) Remove the seven screws H attaching the rear panel with

main board.

, CN7302 on

CN5301

G

Fastener

CN5302

Main board

CN7301CN7302

CN5305

Fig.7

G

Fig.8

F

CN5001

G

1-8 (No.XA013)

H

Rear panel

H

Fig.9

Page 9

SECTION 4

ADJUSTMENT

4.1 Timer clock adjustment (for only ver.E)

If an error comes to arise for a clock, the following procedure will adjust.

Signal (A1) No signal

Mode (B) EE

Equipment (C) Frequency counter

Measuring point (D1)

Adjustment part (F) C3025 (TIMER CLOCK)

Specified value (G1) 1024.008 ±0.001 Hz

(1) Connect the frequency counter to the measuring point (D1).

(2) Connect the short wire between the short point (D2) and Vcc (5V).

(3) Short the leads of capacitor (D3) once in order to reset the microprocessor of the system controller.

(4) Disconnect the short wire between the short point (D2) and Vcc then connect it again.

(5) Adjust the Adjustment part (F) so that the output frequency becomes the specified value (G).

IC3001 pin 61

(D2)

IC3001 pin 17

(D3)

C3026 + and -

(976.5549 ±0.0010 usec)

(No.XA013)1-9

Page 10

SECTION 5

TROUBLESHOOTING

5.1 JIG Mode

The following remote control units are required to set and cancel JIG mode.

For setting : a remote control unit attached to DR-M1SL.

For cancellation : JIG remote control unit (part number : PTU94023A)

Remote control unit

attached to DR-M1SL

RM-SDR

VD RECORDER

D

JIG remote control unit

JIG remote control unit

[Data transmission]

Set the data code,

and then press the

" " button.

3

Custom code

43:A Code

53:B Code

6F:C Code

7F:D Code

Data code

Initial mode

When the main body is set to JIG mode and when the main body is under JIG mode, the remote control unit attached to DR -M1SL

operates only in "Remote Control Code 1". Since DR-M1SL is in "Remote Control Code 3" when it is shipped and just after its batteries

are changed, "Remote Control Code 3" needs to be changed to "Remote Control Code 1."

< Changing Remote Control Code >

(1) Switch TV/CABLE/SAT/DVD Switch to "DVD"

(2) Press the numeric button "1" of the remote control unit whil e pressing the "SET UP" button of the remote co ntrol unit. Then,

press the "ENTER" button, and then release the "SET UP" button.

(3) Press the "PLAY" button of the main body for five seconds or longer while the main body is in stand-by mode, and a curre nt

remote control code of the main body is displayed in FL indicator of the main body.

(4) While keeping the state of (3), press the "STOP" button of the remote control unit toward the main body.

(5) When FL indicator displays "DVD1," it means that the Remote Control Code has been changed to "1."

*DR-M1SL has remote control codes of 1, 2, 3, and 4.

*The remote control codes "DVD 1, 2, 3, and 4" of DR-M1SL are the same as the remote control codes

"A, B, C, and D" of video cassette recorders manufactured in JVC.

1-10 (No.XA013)

(1)

"(2) a-c" shows the order of pressing the buttons.

(2)b

(2)c

(2)a

(4)

(3),(5)

DVD 1

(3)

Page 11

5.1.1 Setting JIG mode

To display SYSTEM INFO or to upgrade firmware, the main body needs to be set to JIG mode.

(1) Turn the main body ON.

(2) Press the buttons of the remote control unit attached to DR-M1SL in the fol l owing order : "SET UP" → "2" → "8" → "ENTER"

(3) When a colon ":" between "ho ur" and "time" of a clock in FL indicator disappea rs, it means th at the main bod y has been set t o

JIG mode properly.

not in JIG mode 3:07 PM → in JIG mode 3 07 PM

(4) Turn the main body OFF, and then turn it ON again.

*Once the main body is set to JIG mode, the JIG mode cannot be cancelled even if the power co rd is pulled out from the wa ll

socket.

"(2) a-d" shows the order of pressing the buttons.

(2)b

(2)c

(3)

3 07 PM

(2)d

(2)a

(1),(4)

5.1.2 Ca nceling JIG mode

(1) Transmit "43-9D" to the main body by using JIG remote control unit.

(2) A colon ":" between "hour" and "time" of a clock in FL indicator appears.

(3) Turn the main body OFF, and then turn it ON again.

NOTE:

After repair work, be sure to cancel JIG mode. Before returning DR-M1SL to a user, confirm that a colon ":" between "hour" and

"time" of a clock in FL indicator appears.

(No.XA013)1-11

Page 12

5.1.3 Displaying SYSTEM INFO

SYSTEM INFO contains information on firmware version of the main body and the mechanism drive, and an initialize execution menu.

(1) Set the main body to JIG mode.

(2) Transmit "43-8B" to the main body by using JIG remote control unit.

(3) SYSTEM INFO menu is displayed in the television screen.

(4) To move cursor in SYSTEM INFO, use the "", "", "", and "" buttons of a remote control unit atta ch ed to D R- M 1SL.

< VERSION >

SYSTEM INFO

VERSION INITIALIZE INFORMATION

CPRM Key Download

C-Ware / A-Ware

JVRI / Host

1394 / OSD

Analog / Destination

EXIT

SET UP

ENTER

SELECT WITH [CURSORS]

THEN PRESS [ENTER]

SELECT

Done

PROD11 / JVC03_18

0049s / V0236

0034 / NEXT32

025 / 2

Version of firmware

This part is updated after the firmware of the

main body is upgraded.

System controller version/Region code

NOTE :

Items other than the ones described above are not used in service work.

(5) To quit the SYSTEM INFO menu, transmit "43-8B" to the main body by using JIG remote control unit.

(6) Cancel JIG mode.

5.1.4 Upgrading firmware of the main body

• Firmware upgrade disk supports only DVD-RAM media.

• When firmware needs to be upgraded, Optical disc CSG will distribute a firmware upgrade disk.

(1) Set the main body to JIG mode.

(2) Transmit "43-70" to the main body by using JIG remote control unit.

(3) "UPDATE" appears in FL indicator. Load DVD - RAM disk for upgrade on the tray, and close the tray.

(4) Wait for approx.30 seconds while FL indicator is displayed as "UPDATE."

(5) Then, "FW UPDATE" appears in FL indicator. It takes approx. 3 minutes at maximum to upgrade firmware.

(6) The tray is ejected. Then, take out the disk and close the tray.

(7) Turn the main body OFF, and pull out the power cord from the wall socket. The n, plug the power cord into the wall socket.

(8) "LOADING" of FL indicator disappears. Then, turn the main body ON.

(9) Display the SYSTEM INFO menu, and check the version of the firmware.

(10) Cancel JIG mode.

ATTENTION :

Firmware may sometimes not be upgraded successfully.

If firmware is not upgraded successfully, the tray opens, and "ERROR" appears in FL indicator.

If firmware is upgraded successfully, the tray opens, and "OPEN" appears in FL indicator.

If the power cord is pulled out from the wall socket while " ERROR" appears, data in the flash memory is destroyed and the main

body cannot start: the flash memory needs to be replaced.

After upgrading procedure, pay enough attention to FL indicator when the tray opens.

When "ERROR" appears, upgrade firmware again in the following way to restore the firmware.

(1) Transmit "43-70" to the main body by using JIG remote control unit while the tray opens.

(2) When "UPDATE" appears in FL indicator, close the tray and make the main body read the disk. Upgrading starts.

(3) After (2), perform upgrading procedure (4) - (10) of 5.1.4 Upgrading firmware of the main body above.

1-12 (No.XA013)

Page 13

5.1.5 T aking out a disc

A disc can be taken out manually even when the main body is turned off.

(1) Open the front door.

(2) Pass a thin wire through a hole in the DVD recorder mechanism unit.

(3) The disc tray comes out slightly. Take out the disc tray manually.

DVD recorder mechanism unit

Front door Hole Disc tray

(No.XA013)1-13

Page 14

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY OPTICAL DISC CATEGORY 1644, Shimotsuruma, Yamato, Kanagawa 242-8514, Japan

(No.XA013)

Printed in Japan

WPC

Loading...

Loading...