Page 1

SERVICE MANUAL

DVD VIDEO RECORDER

YD05820053

DR-M100SUS, DR-M100SUC,

DR-M100SUJ

Area Suffix

US ---------------- U.S.A.

UC -------------- Canada

UJ ------- U.S.A Militaly

R

+

STANDBY/ON

Since the whole mechanism assembly unit is replaced, the DVD recorder

mechanism of this unit need not be adjusted.

RAM/RW

DR-M100SUS, DR-M100SUC, DR-M100SUJ [D5R10]

CH

PUSH-OPEN

-

CH

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.YD058

2005/3

Page 2

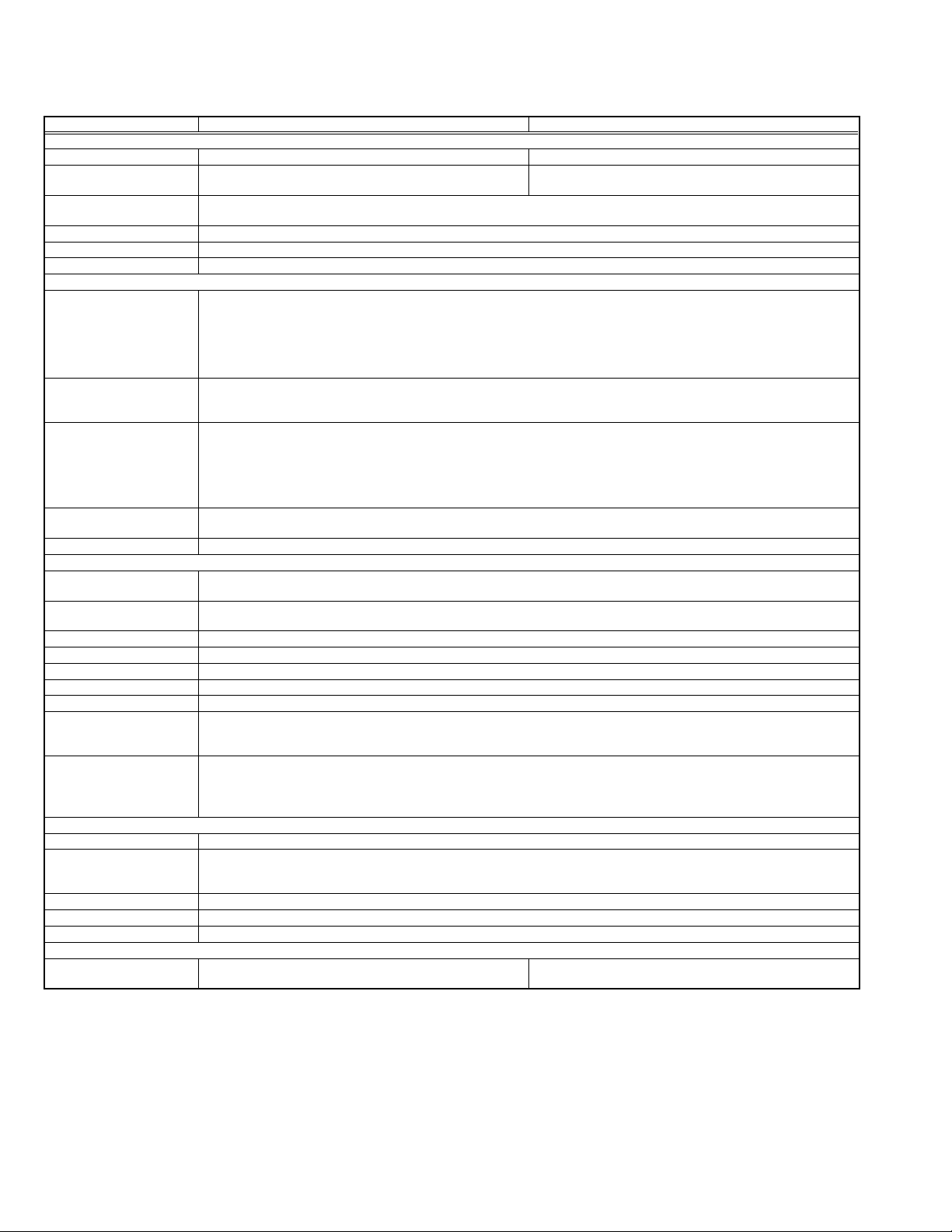

SPECIFICATION

DR-M100SUS,DR-M100SUC DR-M100SUJ

GENERAL

Power requirement AC 120 V~, 60 Hz AC 220 V-240 V~,50/60 Hz

Power consumption Power on : 30 W

Temperature Operating : 5°C to 35°C(41°F to 95°F)

Operating position Horizontal only

Dimensions (W × H × D) 435 mm × 70 mm × 300 mm (17-3/16" x 2-11/16" x 11-13/16")

VIDEO/AUDIO

Recordable disc

Recording format DVD-RAM : DVD Video Recording format

Recording time Maximum 8 hours (with 4.7 GB disc)

Audio recording system Dolby Digital (2 ch)

Video recording compression system

Input/Output

S-video input Y:1.0 Vp-p, 75 ohms

S-video output Y : 1.0 Vp-p, 75 ohms

Video input 1.0 Vp-p, 75 ohms (pin jack)

Video output 1.0 Vp-p, 75 ohms (pin jack)

Audio input 2Vrms (pin jack)

Audio output 2Vrms (pin jack)

Component video output Y : 1.0 Vp-p, 75 ohms

Digital audio output Coaxial

TUNER/TIMER

Tuning system Frequency synthesized tuner

Channel coverage VHF: Channels 2 - 13

Clock reference Quartz

Program capacity 30 days programmable timer/8 programs

Memory backup time Approx. 5 sec.

ACCESSORIES

Provided accessories RF cable, Audio/video cable, Infrared remote control unit,

Specifications shown are for SP mode unless otherwise specified. E. & O.E. Design and specifications subject to change without notice.

• Manufactured under licence from Dolby Laboratories. “Dolby” and double-D symbol are trademarks of Dolby Laboratories.

• “DTS” and “DTS DIGITAL OUT “ are trademarks of Digital Theater Systems, Inc.

• VCR Plus+ and PlusCode are registered trademarks of Gemstar Development Corporation.

The VCR Plus+ system is manufactured under license from Gemstar Development Corporation.

TM

• DSS

• This product incorporates copyright protection technology that is protected by method claims of certain U.S. patents and other intellectual property

is an official trademark of DIRECTV, Inc., a unit of GM Hughes Electronics. DISH NetworkTM is a trademark of Echostar Communications

Corporation.

rights owned by Macrovision Corporation and other rights owners. Use of this copyright protection technology must be authorized by Macrovision

Corporation, and is intended for home and other limited viewing users only unless otherwise authorized by Macrovision Corporation. Reverse engineering or disassembly is prohibited.

Power off : 2.7 W

Storage : -20°C to 60°C(-4°F to 140°F)

Weight 3.4 kg (7.5 lbs)

DVD-RAM 12 cm (4.7 GB/9.4 GB)

DVD-RAM 8 cm (1.4 GB/2.8 GB)

DVD-R 12 cm(4.7 GB)

DVD-R 8 cm(1.4 GB)

DVD-RW 12 cm(4.7 GB)

DVD-RW 8 cm(1.4 GB)

DVD-R : DVD-Video format

DVD-RW : DVD-Video format, DVD Video Recording format

(XP) : Approx. 1 hour

(SP) : Approx. 2 hours

(LP) : Approx. 4 hours

(EP) : Approx. 6 hours

(FR) : Approx. 1 hour - 8 hours

Linear PCM (XP mode only)

MPEG2 (CBR/VBR)

C : 0.286 Vp-p, 75 ohms

C : 0.3 Vp-p, 75 ohms

i.Link 4-pin for DV input

PB/PR: 0.7 Vp-p, 75 ohms

Corresponding to copy protection

Corresponding to Dolby Digital and DTS Digital Surround

Bit stream

Selectable in digital audio output setting menu

UHF: Channels 14 - 69

CATV: 113 Channels

”AA” battery x 2

Power on : 29 W

Power off : 5.2 W

RF cable, Audio/video cable, Infrared remote control unit,

”AA” battery x 2, Conversion pliug

1-2 (No.YD058)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

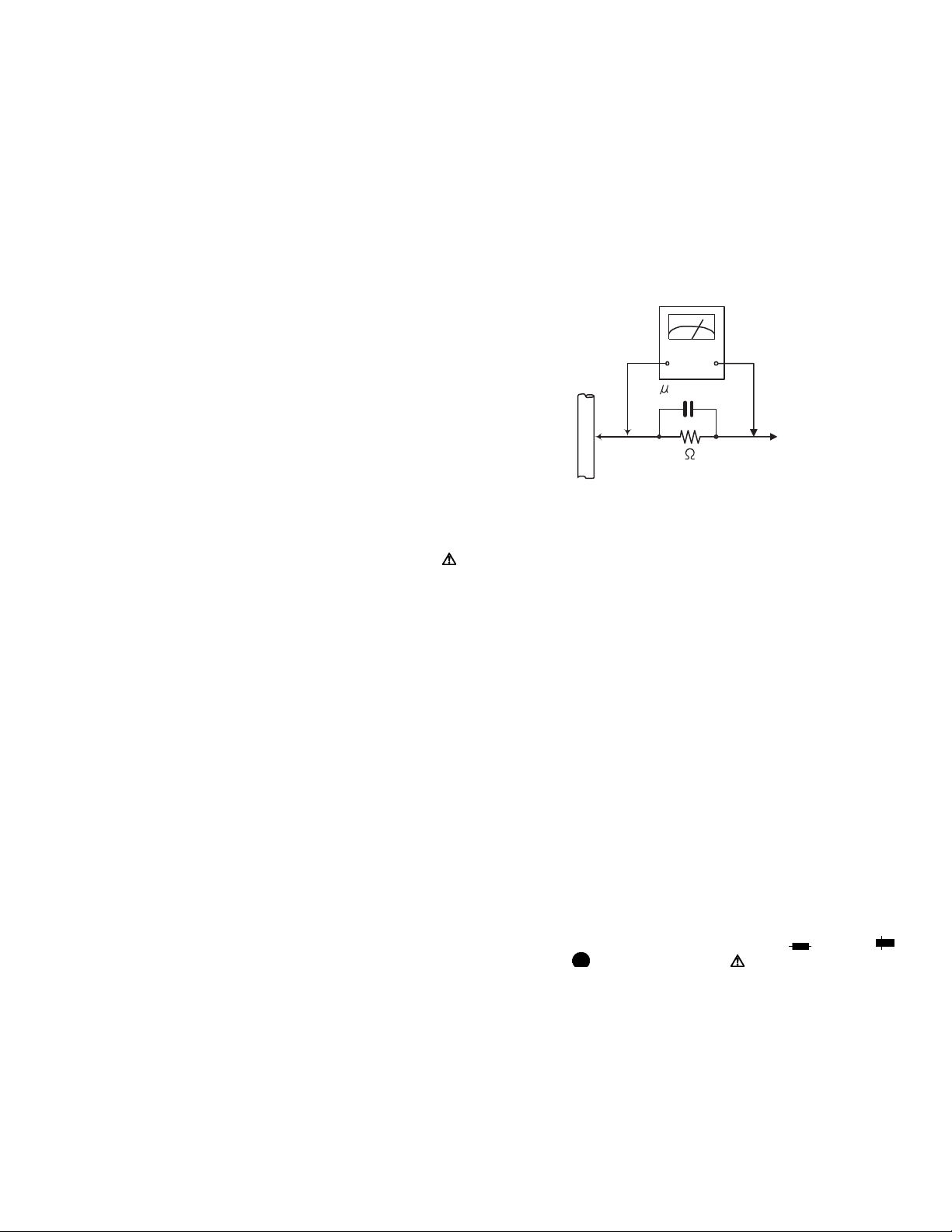

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.YD058)1-3

Page 4

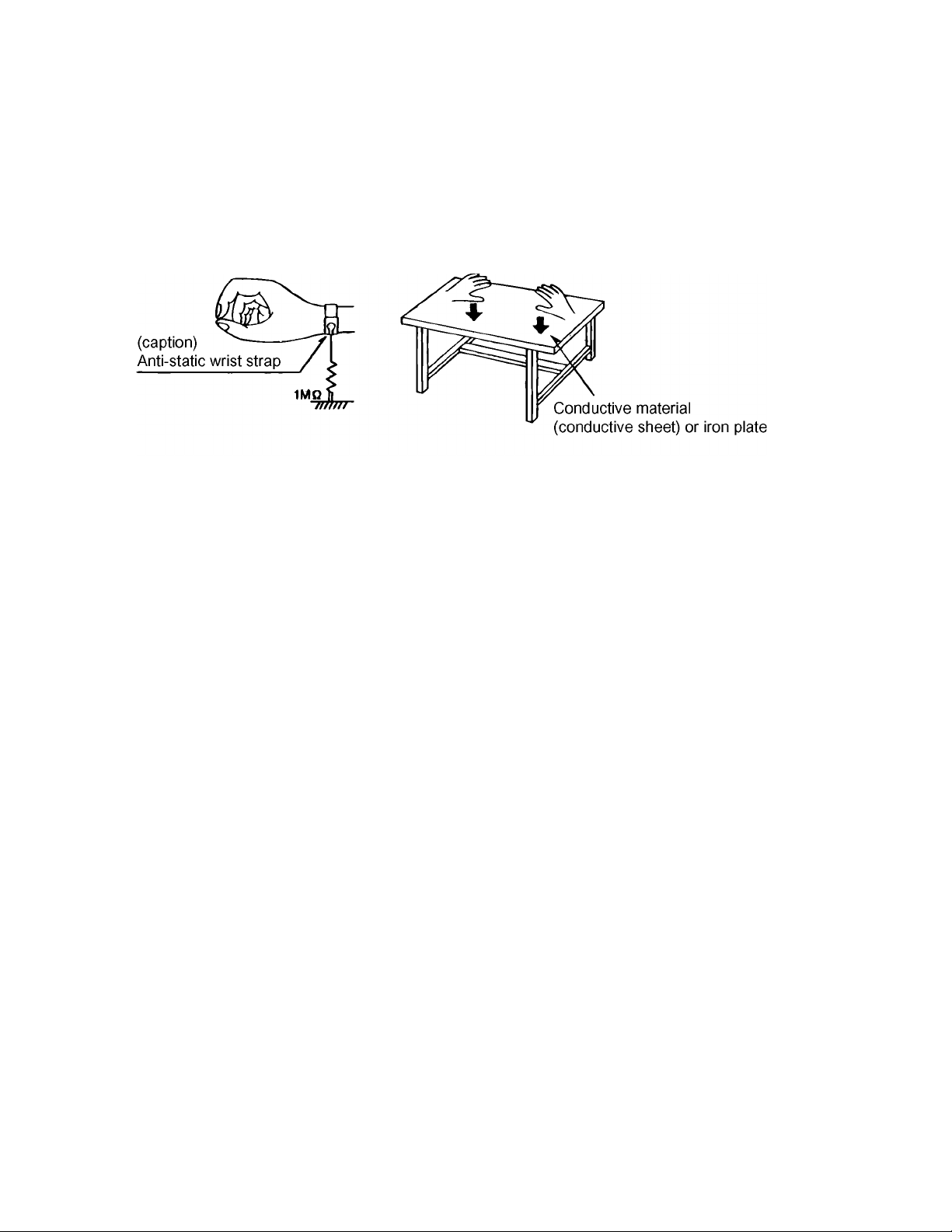

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as DVD players or recorder.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long

a time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1-4 (No.YD058)

Page 5

1.7 Important for laser products

Importance administering point on the safety

W1613

W253

CN3002

W1614

W1415

CN4001

W262

CN4101CN4102

W241

W1018

W1407

W222

W832

W1010

W604

W811

CN3003

W220

L6033

TU6001

W249

B5508

W2203

W2809

W829

C8202

C8212

W1811

W1808

C8210

W1017

W1807

CN4103

W223

W221

C6516

C6520

C6515

C6519

W219

C6510

L6501

L6032

CF6031

W217

W1401

W1002

L6004

C6005

D6002

W213

GN1

L6001

C6007

W601

J4106

W251

GN2

C8027

C8025

C8023

W821

W1020

C8021

C6523

W1210

C6522

C6502

C8022

C8014

W233

W1608

W2003

C6501

C6503

C5329

W214

C8217

J4103 J4104

W2807

C8012

C8010

C8011

W1805

W1604

W1603

W1601

W810

W1204

W805

C8215

W1019

W1016

W2404

C6521

C6505

C6509

C5331

CN5304

W204

J4105

W802

W2205

W1612

W1818

W1820

W1819

W2406

W823

W1809

C8005

C8009

C8008

C8007

W1206

W1207

W1015

W228

W2004

W3003

W3002

W2402

W1403

W2601

W1205

W3001

W1008

W1402

W258

B4111

C4105

C4102

W2201

L4101

C4113

C4111

C4114

C4117

W806

C4112

C8218

W212

W211

W1201

C8216

W209

W208

J4102

W1607

W2407

W1217

W1219

W1216

W1215

W609

W826

W825

W824

W242

W608

W239

W236

W234

W3004

W3006

W3005

W259

C4106

C4124

C4123

W1801

C4119

W803

J4002

W201

W1610

W606

W1013

W1605

W1606

W3012

W2803

W2403

W3010

W3007

W3008

W3009

W2401

W1006

W1804

W1005

W1803

W2001

C4118

C4008

C4125

W1202

W804

W210

W207

W1001

J4003

CN3001

W2207

W2206

W1816

W1817

W610

C3020

W240

X3001

X3002

C3040

W226

W224

W2005

W1014

W1806

W3011

W2805

W2804

W2602

W2802

W2202

W2002

W1223

W1203

W1802

W807

W602

W205

W203

W202

J4101

W801

J7301

W2405

W830

W243

W257

W238

C3030

C3033

W818

C3038

W815

W1609

W2007

W1406

W227

GN3

W252

W605

W812

W1012

W1011

W1009

W1007

W1602

W809

W260

W2801

L4001

W218

C4036

W603

B4002

W216

C4038

W215

Q7201

CN7301

R7204

ST1

D7303

D7304

D7301

J7201

D7302

#PC00029

W263

W255

W1416

W827

L4002

W2204

W250

W612

W831

W828

W1022

W1410

W1611

D3002

W256

W614

B5503

W1212

W1810

W3014

W1208

W1211

W1209

W2806

W1026

W229

W814

W3013

W2006

CP5301

W1404

C5337

CN5302

CN3004

W1004

CN5301

W1003

L7201

W206

C8501

C7202

CN5303

C8503

L8501

C8401

J8501

J8401

W816

C3010

CN3901

W247

W237

C3011

W1411

W2008

W1812

D5314

W819

D5310

B5501

W1408

D5308

D5307

D5311

D5313

C5307

W231

D5312

W230

L5205

W607

W1405

W225

Q5301

R5323

R5319

C5201

D5202

IC5301

C5302

D5208

D5201

C5301

W808

PC5101

R5105

D5103

D5105

D5106

D5104

C5104

C5004

IC5101

C5105

R5001

CN5305

C5319

W613

W254

W833

W813

W3016

C3042

D3003

W2810

W2808

W2605

W1023

D3005

D3004

W1813

D5317

B5505

W1409

D5319

Q5310

C5312

W2603

D5309

C5325

D5318

W817

W232

C5306

D5303

C5305

R5307

D5302

L5203

C5205

C5206

C5202

C5208

W1220

D5205

D5213

D5206

D5209

T5001

W1025

W1024

C5003

D5001

C5103

R5108

IC5309

C5316

C5321

W248

W1414

D5306

GN4

W1413

W1021

W1222

W1815

Q5316

C5209

C5101

W2604

C5318

CP5302

L5204

D5210

CN5001

D5315

W246

C5311

W1214

W1221

W1218

W245

C5310

Q5304

R5320

W244

W1814

D5305

W822

W1213

R5311

R5313

W820

C5303

D5304

Q5307

W834

C5304

Q5306

C5308

R5329

L5206

D5203

C5002

B5301

D5316

L5201

R5328

L5202

GN5

C5203

R5308

D5301

C5204

C5210

D5211

D5212

D5204

D5207

C5207

W261

D5101

R5109

R5103

C5102

LF5001

C5001

VA5001

FC5002

B5001

FC5001

F5001

C5005

VA5003

W611

L3001

B5507

C5315

D5214

R5101

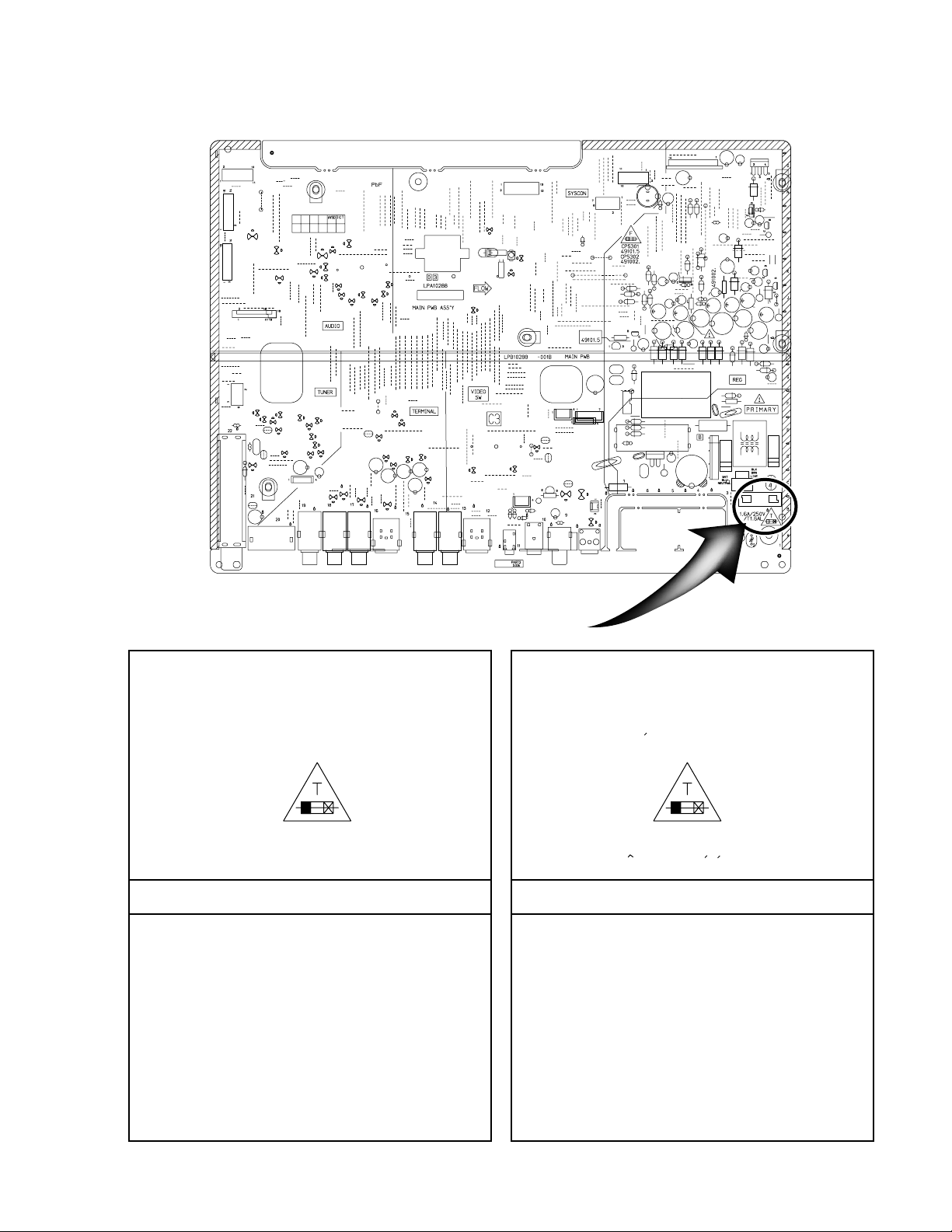

Full Fuse Replacement Marking

Graphic symbol mark

(This symbol means fast blow type fuse.)

should be read as follows ;

FUSE CAUTION

FOR CONTINUED PROTECTION AGAINST RISK

OF FIRE, REPLACE ONLY WITH SAME TYPE

AND RATING OF FUSES ;

F5001 : 1.6 A / 250 V F5001 : 1.6 A / 250 V

Marquage Pour Le Remplacement

Complet De Fusible

Le symbole graphique (Ce symbole signifie

fusible de type a fusion rapide.)

doit etre interprete comme suit ;

PRECAUTIONS SUR LES FUSIBLES

POUR UNE PROTECTION CONTINUE CONTRE

DES RISQUES D'INCENDIE, REMPLACER

SEULEMENT PAR UN FUSIBLE DU MEME TYPE ;

(No.YD058)1-5

Page 6

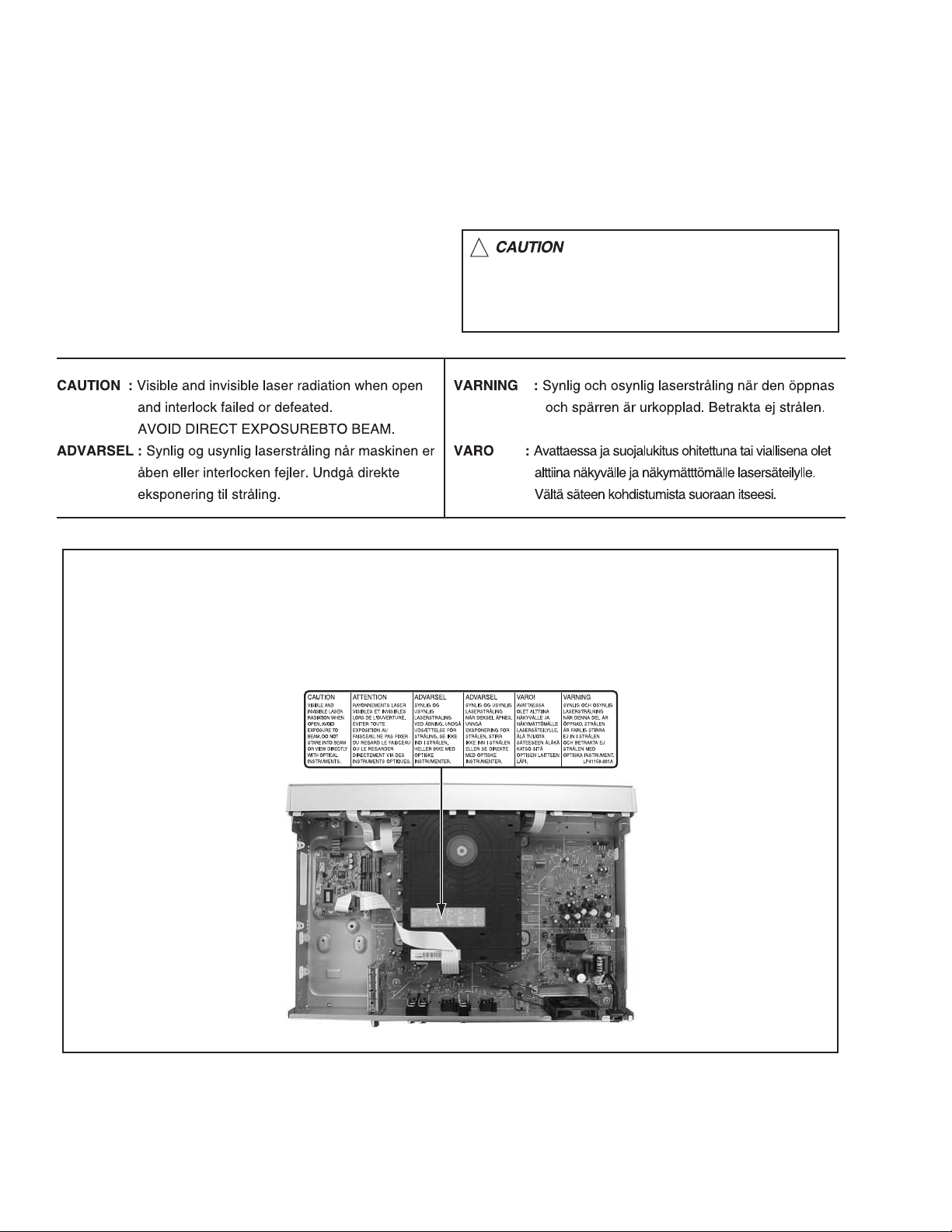

1.8 Important for laser products

!

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The CD,MD and DVD player uses invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABEL

On mechanism assembly

1-6 (No.YD058)

Page 7

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

(No.YD058)1-7

Page 8

SECTION 3

TOP COVER

Hook b

DISASSEMBLY

3.1 Main body section

3.1.1 Remove the top cover (See figure 1)

(1) Remove the four screws A attaching the top cover on both

sides of the main body.

(2) Remove the five screws B attaching the top cover on the

back of the main body.

(3) Raise the both sides and lower part of the rear of the top

cover, with opening them slightly in an outward direction.

And the top cover will be removed.

3.1.2 Remove the front panel assembly (See figure2, figure 3)

• Prior to performing the following procedure, remove the top

cover.

• There is no need to remove the mechanism assembly.

(1) Disconnect the card wires from connectors CN7002

CN7003, CN4001 on the main board and display board.

(2) Hooks a and b are removed respectively, and the front

panel assembly is removed.

,

A x 2

TOP COVER

TOP COVER

A x 2

B

Fig.1

Front panel assembly

CN7002CN4001 CN7003

B

B

B

B

Display board

Main board

Fig.2

Hook a

Front panel assembly

Hook b

Hook a

Fig.3

1-8 (No.YD058)

Page 9

3.1.3 Remove the drive unit (See figure 4)

• Prior to performing the following procedure, remove the top

cover.

• There is no need to remove the front panel assembly.

(1) Disconnect the socket wire from connector CN5302

main board.

(2) Disconnect the card wire from connector CN2201

digital board.

(3) Remove the four screws C attaching the drive unit.

on the

on the

Digital board

CN1801

D

D

CN1101

D

C

Drive unit

C

3.1.4 Remove the digital board (See figure 4)

• Prior to performing the following procedure, remove the top

cover.

(1) Disconnect the card wire from connectors CN2201

CN1103 on the digital board.

(2) Disconnect the socket wire from connectors CN1101,

CN1102

(3) Remove the four screws D attaching the digital board.

, CN1801 on the digital board.

CN2201

D

CN1103 Main board

,

C C CN5302

CN1102

Fig.4

(No.YD058)1-9

Page 10

3.1.5 Remove the main board (See figure 5, figure 6)

• Prior to performing the following procedure, remove the top

cover, drive unit.

(1) Disconnect the card wire from connectors CN4001,

CN4103 on the main board.

(2) Disconnect the socket wire from connectors CN1101

CN1102

(3) Disconnect the socket wire from connector CN5303, on the

main board.

(4) Disconnect the power cord from connector CN5001

main board.

(5) Remove the six screws E attaching the main board.

(6) Remove the six screws F and G attaching the rear panel

with main board.

, CN7001 on the digital board and display board.

, on the

CN1101

Digital board E

,

CN4001

Display board

CN7001

E

CN5001

E

E

3.1.6 Remove the dispiay board (See figure 7)

• Prior to performing the following procedure, remove the top

cover, drive unit, front panel assembly.

(1) Disconnect the socket wire from connector CN7001

display board.

(2) Remove the two screws H attaching the display board.

on the

CN1102

CN4103

E E

Main board

Fig.5

FG

Fig.6

CN5303

Rear panel

Display board HH CN7001

Fig.7

1-10 (No.YD058)

Page 11

3.2 Loading mechanism assembly

3.2.1 Remove the clamper base (See figure 1, figure 2)

(1) The part a on the reverse side of a mechanism assembly is

made to slide in the direction of an arrow with a driver etc.

(A tray ejects a few.)

(2) Remove the two screws A attaching the clamper base.

(3) After making a clamper base slide in the direction of an ar-

row, it raises upward and removes.

(4) A tray is removed.

Par t a

Fig.1

A

A

Clamper base

Fig.2

(No.YD058)1-11

Page 12

3.2.2 Remove the traverse mechanism assembly (See figure 3, figure 4, figure 5)

• Prior to performing the following procedure, remove the

clamper base and tray.

(1) It solder to part b section on the pick-up unit.

㧯

Pick-up unit

E

D

Leaf spring

CN1

Par t b

(2) Disconnect the card wire from connector CN1

up unit.

ATTENTION:

Please extract the wire after short-circuited on the pickup unit in part b with solder. Please remove the solder of

part b after connecting the wire with CN1

bling.

(3) Disconnect the flexible wire from connector CN301

servo control board.

(4) Remove the one screw B attaching the mechanism brack-

et.

(5) Remove the four screws C and D attaching the leaf spring.

(6) Remove the two screws E and F attaching the traverse

mechanism assembly.

(7) When a traverse mechanism assembly is in the lowest po-

sition, a gear 1 is turned clockwise, and since a traverse

mechanism assembly is moved to the upper position, it is

removed.

on the pick-

when reassem-

on the

Pick-up unit

F

Traverse mechanism

Mechanism

bracket

B

assembly

Fig.3

1-12 (No.YD058)

Servo control board

Fig.4

Traverse mechanism assembly

Gear 1

Fig.5

CN301

Page 13

3.2.3 Remove the flexible wire assembly (See figure 6)

• Prior to performing the following procedure, remove the

clamper base and tray.

(1) Remove the four screws G and H attaching the flexible wire

assembly.

(2) Remove the solder part c soldered to the feed motor.

(3) Remove the two screws I attaching the shaft guide.

(4) Disconnect the flexible wire from connector CN1

spindle motor board.

on the

Par t c

G

Flexible wire

assembly

Spindle motor assembly

I

CN1

3.2.4 Remove the servo control board and board bracket (See figure 7, figure 8)

• Prior to performing the following procedure, remove the

clamper base and tray.

(1) Remove the soler part d and e soldered on the servo con-

trol board.

(2) Disconnect the flexible wire from connector CN301

servo control board.

(3) Disconnect the card wire from connector CN101

servo control board.

(4) Remove the two screws J attaching the servo control

board.

(5) Remove the four screws K attaching the board bracket.

on the

on the

K

Servo control board

CN101

J

Par t e

Fig.6

Fig.8

H

G

G

KKLBelt

Par t d

3.2.5 Remove the loading motor (See figure 7, figure 8)

• Prior to performing the following procedure, remove the

clamper base and tray.

(1) Remove the soler part d soldered on the servo control

board.

(2) A belt is removed.

(3) Remove the two screws L attaching the loading motor.

J

Fig.7

CN301

(No.YD058)1-13

Page 14

SECTION 4

ADJUSTMENT

This service manual does not describe ADJUSTMENT.

1-14 (No.YD058)

Page 15

SECTION 5

TROUBLESHOOTING

5.1 JIG Mode

The following remote control units are required to set and cancel JIG mode.

For setting : a remote control unit attached to product.

For cancellation : JIG remote control unit (part number : PTU94023B)

Remote control unit

attached to product

JIG remote control unit

JIG remote control unit

[Data transmission]

Set the data code,

and then press the

" " button.

3

Custom code

43:A Code

53:B Code

6F:C Code

7F:D Code

Data code

Initial mode

When the main body is set to JIG mode and when the main body is under JIG mode, the remote control unit attached to product operates only in "Remote Control Code 1". Since main body is in "Remote Control Code 3" when it is shipped and just after its batteries

are changed, "Remote Control Code 3" needs to be changed to "Remote Control Code 1."

< Changing Remote Control Code >

(1) Press the numeric button "1" of the remote control unit while pressing the "SET UP" button of the remote control unit. Then,

press the "ENTER" button, and then release the "SET UP" button.

(2) Press the "PLAY" button of the main body for five seconds or longer while the main body is in stand-by mode, and a current

remote control code of the main body is displayed in FL indicator of the main body.

(3) While keeping the state of (2), press the "STOP" button of the remote control unit toward the main body.

(4) The code that was set by the remote control unit blinks for 5 seconds, before the code is set to the main body.

When the FL indicator changes to "DVD1," it shows that the remote control code has been changed to "1."

"(1) a-c" shows the order of pressing the buttons.

(1)b

(1)c

(3)

(1)a

STANDBY/ON

RAM/RW

(2),(4)

DVD 1

(2)

+

CH

PUSH-OPEN

-

CH

(No.YD058)1-15

Page 16

5.1.1 Setting JIG mode

To display SYSTEM INFO or to upgrade firmware, the main body needs to be set to JIG mode.

(1) Turn the main body ON.

(2) Press the buttons of the remote control unit attached to product in the following order : "SET UP" → "2" → "8" → "ENTER"

(3) When a colon ":" between "hour" and "minute" of a clock in FL indicator blink, it means that the main body has been set to JIG

mode properly.

[ Example ]

Not in JIG mode In JIG mode

15 : 07

15 07

A colon blinks.

(4) Turn the main body OFF, and then turn it ON again.

*Once the main body is set to JIG mode, the JIG mode cannot be cancelled even if the power cord is pulled out from the wall

socket.

"(2) a-d" shows the order of pressing the buttons.

(2)b

(2)c

(3)(1),(4)

(2)d

+

CH

PUSH-OPEN

-

CH

(2)a

STANDBY/ON

RAM/RW

15:07

5.1.2 Canceling JIG mode

(1) Transmit "43-9D" to the main body by using JIG remote control unit.

(Please end a setting menu pushing “SET UP” button of the remote control unit appended to the commodity beforehand when

a setting menu is displayed.)

(2) A colon ":" between "hour" and "minute" of a clock in FL indicator light.

(3) Turn the main body OFF, and then turn it ON again.

NOTE:

After repair work, be sure to cancel JIG mode. Before returning product to a user, confirm that a colon ":" between "hour" and

"minute" of a clock in FL indicator light.

1-16 (No.YD058)

Page 17

5.2 Displaying SYSTEM INFO

In the SYSTEM INFO there is information including firmware versions of the main body and the drive unit.

(1) Set the main body to JIG mode.

(2) Transmit "43-8B" to the main body by using JIG remote control unit.

(Please end a setting menu pushing “SET UP” button of the remote control unit appended to the commodity beforehand when

a setting menu is displayed.)

(3) SYSTEM INFO menu is displayed in the television screen.

(4) To move cursor in SYSTEM INFO, use the "", "", "", and "" buttons of a remote control unit attached to product.

< VERSION >

SYSTEM INFO

VERSION INITIALIZE INFORMATION

CPRM Key Download

C-Ware / A-Ware

JVRI / Host

1394 / OSD

Analog / BE-R / FE-R

SET UP

ENTER

SELECT

SELECT WITH [CURSORS]

THEN PRESS [ENTER]

Done

PROD116 / JVC03_47

0111 / V0069

0054 / 2005M01

100 / 1 / 1

< INFORMATION >

SYSTEM INFO

VERSION INITIALIZE INFORMATION

Silicon version of E5

BSP

Drive firmware version

Drive last error

SET UP

ENTER

SELECT WITH [CURSORS]

THEN PRESS [ENTER]

SELECT

NOTE :

Items other than the ones described above are not used in service work.

1B0

1.2/101

6601

00 00 00

Version of firmware

This part is updated after the firmware of the

main body is updated.

System controller version

/ Region code (Backend) / Region code (Frontend)

Version of firmware of mechanism drive

(5) To quit the SYSTEM INFO menu, transmit "43-8B" to the main body by using JIG remote control unit.

(6) Cancel JIG mode.

(No.YD058)1-17

Page 18

5.3 Updating the firmware of the main body

• Firmware update disk supports CD-R media.

• When firmware update is necessary. information is available from the homepage of DIGITAL VIDEO STORAGE CATEGORY, CS

group.

• Please check the details of the update disc creation method by JS-NET.

(1) Set the main body to JIG mode.

(2) Transmit "43-70" to the main body by using JIG remote control unit.

(3) "UPDATE" appears in FL indicator. Load disk for update on the tray, and close the tray.

(4) Update processing is started automatically.

(5) Then, "FW UPDATE" appears in FL indicator. It takes approx. 3 minutes at maximum to update firmware.

(6) The tray is ejected. Then, take out the disk and close the tray.

(7) Turn the main body OFF, and pull out the power cord from the wall socket. Then, plug the power cord into the wall socket.

(8) "LOADING" of FL indicator disappears. Then, turn the main body ON.

(9) Display the SYSTEM INFO menu, and check the version of the firmware.

(10) Cancel JIG mode.

ATTENTION :

Firmware may sometimes not be update successfully.

If firmware is not update successfully, the tray opens, and "ERROR" appears in FL indicator.

If firmware is update successfully, the tray opens, and "OPEN" appears in FL indicator.

If the power cord is pulled out from the wall socket while "ERROR" appears, data in the flash memory is destroyed and the main

body cannot start: the flash memory needs to be replaced.

After update procedure, pay enough attention to FL indicator when the tray opens.

When "ERROR" appears, update firmware again in the following way to restore the firmware.

(1) Transmit "43-70" to the main body by using JIG remote control unit while the tray opens.

(2) When "UPDATE" appears in FL indicator, close the tray and make the main body read the disk. Update starts.

(3) The following procedures are the same as a usual update.

5.4 Updating the firmware of the drive unit

• Firmware update disc supports only DVD-RAM media.

• When firmware update is necessary, written discs are distributed by DIGITAL VIDEO STORAGE CATEGORY, CS group.

(1) Turn the main body ON.

(2) Load the update DVD-RAM disc on the tray and close the tray.

(3) “READING” is displayed in the FL indicator and the update is started.

(4) In a short while “READING” in the FL indicator disappears, open the tray to remove the disc and close the tray.

(5) Turn the power OFF and pull out the power code from the wall socket, then plug the power cord into the wall socket again.

(6) Set to the JIG mode and check the firmware version of the drive.

5.5 Setting after the drive unit replacement

When the drive unit is replaced, it is necessary to set a region code. Service drive units for replacement are not set for any region

code, and they are in an indefinite condition.

Make sure to set region code after attaching the drive unit to the main body.

Without the setting of the region code, discs that have regions cannot be played back.

(1) Replace a drive unit.

(2) Turn POWER switch of the unit ON.

(3) Set the main body to JIG mode.

(4) Insert a DVD-RAM disc in the unit to make the unit read the DVD-RAM disc.(The DVD-RAM disk used in this procedure is not a

disk for upgrade. If it is a DVD-RAM disk, it is good anything.)

(5) Send "43-F2" to the unit by using JIG remote control unit.

(6) "REGION 1" is displayed on FL display.

(7) Set the unit to STANDBY.

(8) Turn the POWER switch ON.

(9) To cancel JIG MODE, send "43-9D" to the unit by using JIG remote control unit.

(10) Colon is displayed on a clock on FL display.

(11) Setting is completed in the procedure above.

1-18 (No.YD058)

Page 19

5.6 Taking out a disc

5.6.1 Method 1

There is compulsive tray ejection mode by electric operation.

(1) AC Plug is pulled out at once and inserted again.

(2) It is displayed on FL display as "LOADING", and while it blinks, pushing the EJECT button of a main body is continued.

(3) After a while, a tray opens (About 20 seconds).

(4) A disk is removed, the tray is pushed, and a tray is made to close.

(5) The "LOADING" blink display of FL display disappears and it will be in a standby state.

(6) If the POWER button is pushed, it will usually be operating.

5.6.2 Method 2

When a disk is not able to be taken out by operation of "Method 1"

A tray can be ejected mechanically, without switching on a power supply.

(1) A drive unit is removed from a main body.

(2) The part a on the reverse side of a drive unit is made to slide in the direction of an arrow with a screw driver etc.

(3) Since a tray ejects a few, a tray is pulled out manually.

Par t a

5.7 Initialization to the factory shipment state

When the initialization is operated, internal information changes as follows. It is essential to obtain the client’s permission before the

operation.

• All DVD library is all deleted.

• All the DVD initial settings go back to the initial status.

(1) Set to the JIG mode.

(2) Transmit “43-6F” with the JIG remote control unit.

(3) FL indicator displays “FACTORY”, and changes to “CHECK OK” after blinking for a short while.

(4) Pull out the power code from the wall socket.

(5) The JIG mode is forced to cancel at the same time with the initialization, check whether the JIG mode is canceled by plugging

the power code into the wall socket again. (The colon “:” in time display should be continuously ON, not blinking.)

If the JIG mode is not canceled, transmit “43-9D” with JIG remote control unit to cancel the JIG mode.

(No.YD058)1-19

Page 20

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY DIGITAL VIDEO STORAGE CATEGORY 12, 3-chome, Moriya-cho, kanagawa-ku, Yokohama, kanagawa-prefecture, 221-8528, Japan

(No.YD058)

Printed in Japan

VPT

Loading...

Loading...