Page 1

PARTS LIST

[DR-M100SUS, DR-M100SUC, DR-M100SUJ]

* SAFETY PRECAUTION

Parts identified by the symbol are critical for safety. Replace only with

specified part numbers.

* BEWARE OF BOGUS PARTS

Parts that do not meet specifications may cause trouble in regard to safety and

performance. We recommend that genuine JVC parts be used.

* (x_) in a description column shows the number of the used part.

Area Suffix

US ---------------------- U.S.A.

UC -------------------- Canada

UJ ------------- U.S.A Militaly

- Contents -

Exploded view of general assembly and parts list

DVD mechanism assembly and parts list

Electrical parts list

Packing materials and accessories parts list

3-2

3-4

3-6

3-14

(No.YD058)3-1

Page 2

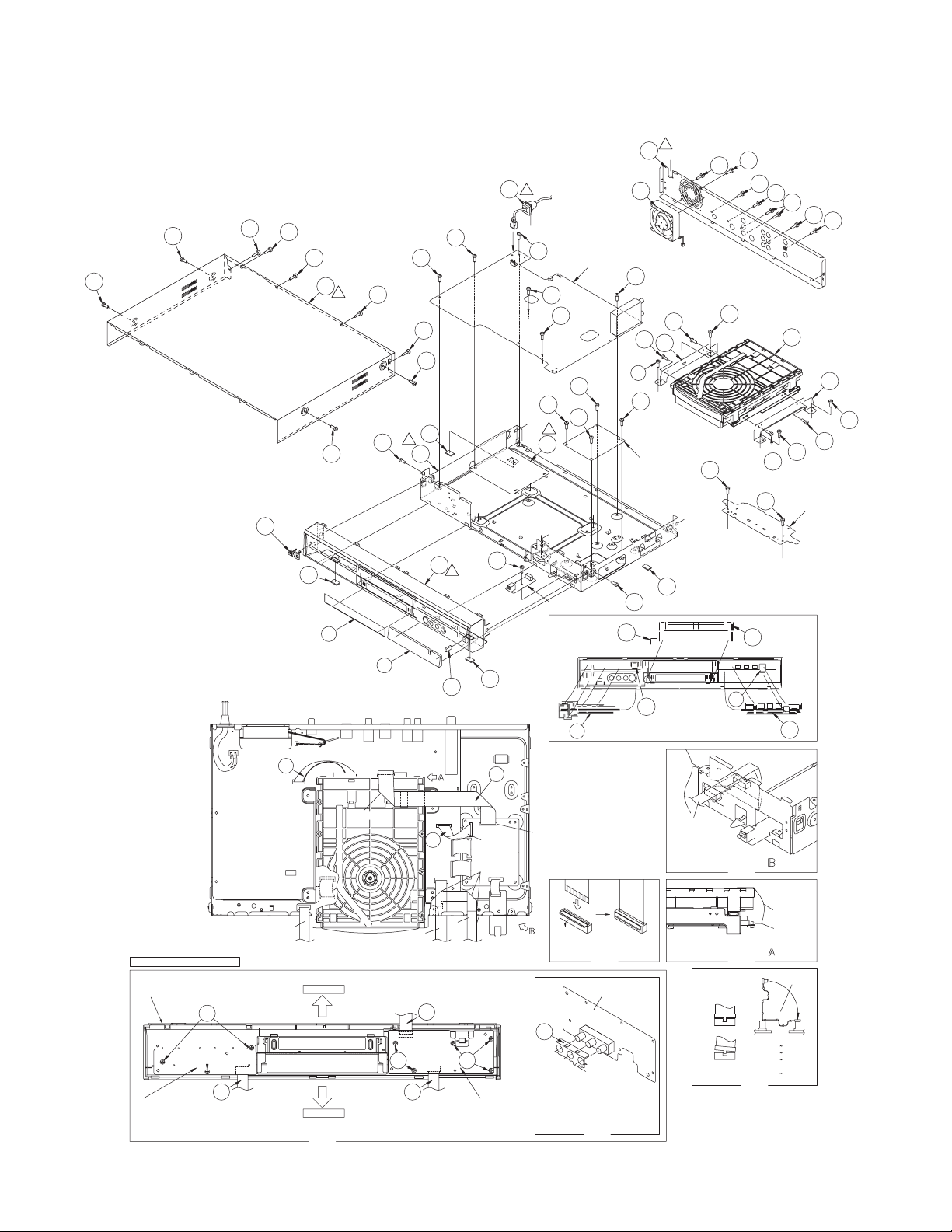

Exploded view of general assembly and parts list

26

!

5

4

4

5

5

3

!

5

20

20

5

4

4

15

9

b

c

13

!

37

1

38

!

39

d

20

C

N

5

0

0

1

C

N

5

3

0

3

MAIN BOARD ASSY

<03>

20

20

a

a

21

21

21

e

!

14

b

a

b

a

b

c

23

JACK BOARD

ASSY<36>

10

12

20

18

19

21

DIGITAL BOARD

ASSY<50>

15

35

Block No.M1MM

!

d

18

16

b

b

e

13

11

11

24

24

24

24

25

e

19

28

17

19

b

b

22

18

22

18

19

DISPLAY BOARD

ASSY<28>

c

c

33

CN5001

FRONT PANEL SUB ASS'Y

FRONT PANEL ASS'Y

(REFER TO LPH20769-****)

6

OPERATION BOARD

NOTE) WHEN YOU FIX ANY PWB WITH THE SCREW.

PUT IT ON THE JIGS.

WR3

ASSY<26>

FAN

MAIN PWB ASS'Y

right side

from OPERATIN P.AY

CN7103

to DISPLAY PWB AY

(CN7003)

WR6

CN5302

CN3901

CN7003

(CN7103)

CN5303

ST1

CN3001

CN7001

BOTTOM SIDE

TOP SIDE

FIG.1

34

38

36

CN1

CN451

make a crease

to MAIN PWB ASSY

(CN4001)

NOTE) INSERT FFC WIRE TO THE CONNECTOR BEFORE

ATTACHING TO FRONT PANEL.

CN4103

WR2

CN4001

back side

from SW/JACK PWB AY

(CN7102)

WR1

CN7102

6

CN7101

WR4

to DISPLAY PWB AY

(CN7002)

CN1102

CN2201

CN1102 CN1101

CN4102

right side

DIGITAL PWB

CN4101

make a crease

CN7002

right side

from SW/JACK PWB AY

(CN7101)

6

SW/JACK BOARD

WR5

ASS'Y

CN1801

CN4104

ASSY<27>

31

30

Be careful not to damage

REFER TO FIG.6

Lock

NOTE) CN2201 (DIGITAL PWB) should lock,

after inserting FCC WIRE.

FIG.6

SW/JACK PWB AY parts surface

7

NOTE) Insert the EARTH PLATE up to the root of J7002.

(Fix it touch to surface of mold of J7002.)

Is should be done on eve of PWB fix to FRONT PANEL.

J7002

FIG.2

FFC WIRE with BOTTOM CHASSIS.

32

CN4001

CN7002

DRAWING FROM DIRECTION

FIG.5

DRAWING FROM DIRECTION

FIG.4

NOTE) FJ CONN should be

insert as follows.

OK

CN

NG

CN

29

Slack is given.

make a crease

Don't swell.

DIGITAL PWB CN1101

MAIN PWB CN4101

DIGITAL PWB CN1102

MAIN PWB CN4102

DIGITAL PWB CN1801JACK PWB CN4104

DISPLAY PWB CN3001

DIGITAL PWB CN7001

FIG.3

3-2(No.YD058)

Page 3

General assembly

Symbol No. Part No. Part Name Description Local

1 LP10581-001B FRONT PANEL

3 LP21361-002A TOP COVER (SERVICE)

4 QYSDSGY3006RA TAP SCREW TOP SIDE(x4)

5 QYSDSGY3006RA TAP SCREW TOP REAR(x5)

6 QYSBSF2608ZA TAP SCREW FRONT PWB(x8) UC,US

6 QYSDSF2608ZA TAP SCREW FRONT PWB(x8) UJ

7 LP31514-001B EARTH PLATE FRONT JACK

9 LP10578-001A BOTTOM CHASSIS

10 LP21362-006A REAR PANEL UJ

10 LP21362-001A REAR PANEL UC,US

11 QYSDSF3008MA TAP SCREW FAN(x2)

12 QAR0349-001 COOLING FAN

13 LP30002-0K1A SPACER FOOT(x2)

14 LP31485-001A PROTECT SHEET UJ

14 LP31485-002A PROTECT SHEET UC,US

15 QYSDSG3008ZA TAP SCREW SIDE(x2)

16 LP31480-001A DVD BKT(L)

17 LP31481-001A DVD BKT(R)

18 QYSBSGG3006ZA TAP SCREW DRIVE(x4)

19 QYSBSGG3006ZA TAP SCREW DVD BKT(x4)

20 QYSBSGG3006ZA TAP SCREW MAIN PWB(x6)

21 QYSBSGG3006ZA TAP SCREW DIGI PWB(x4)

22 QYSBSGG3006ZA TAP SCREW FL PWB(x2)

23 QYSBSGG3006ZA TAP SCREW DV PWB

24 QYSBSGY3008MA TAP SCREW JACK(x5)

25 QYSBST3004MA TAP SCREW TUNER

26 QMPR700-170-K POWER CORD(US/CA) 1.7m BLACK UJ

26 QMPD190-170-K POWER CORD(US/CA) 1.7m BLACK UC,US

28 PMD0118A-CS DVD MECHANISM ASSY

29 LP21350-001B P.BUTTON(L)

30 LP21351-001B P.BUTTON(R)

31 LP21352-001A P.BUTTON(EJ)

32 LP31477-001A REMOTE LENS

33 LP21376-001B LID

34 LP21353-001A DOOR(R)

35 LP41219-001B SPRING

36 QZW0020-001 LATCH

37 GN40020-002A JVC MARK

38 LP30002-0K1A SPACER (x2)

39 LP31474-001A WINDOW SCREEN

WR1 QUQ112-1112CG-E FFC WIRE MAIN CN4001-F.SW CN7102

WR2 QUQ210-1510CJ-E FFC WIRE DIGI CN1102-MAIN CN4103

WR3 QUQ112-1009CG-E FFC WIRE F.OP CN7103-F.FDP CN7003

WR4 QUQ112-1016CG-E FFC WIRE F.SW CN7101-F.FDP CN7002

WR5 QUQ105-4030AH-E FFC WIRE DRIVE CN1-DIGI CN2201

WR6 QJJ015-071202-E SIN CR C-C WIRE DRIVE CN451-MAIN CN5302

Block No. [M][1][M][M]

(No.YD058)3-3

Page 4

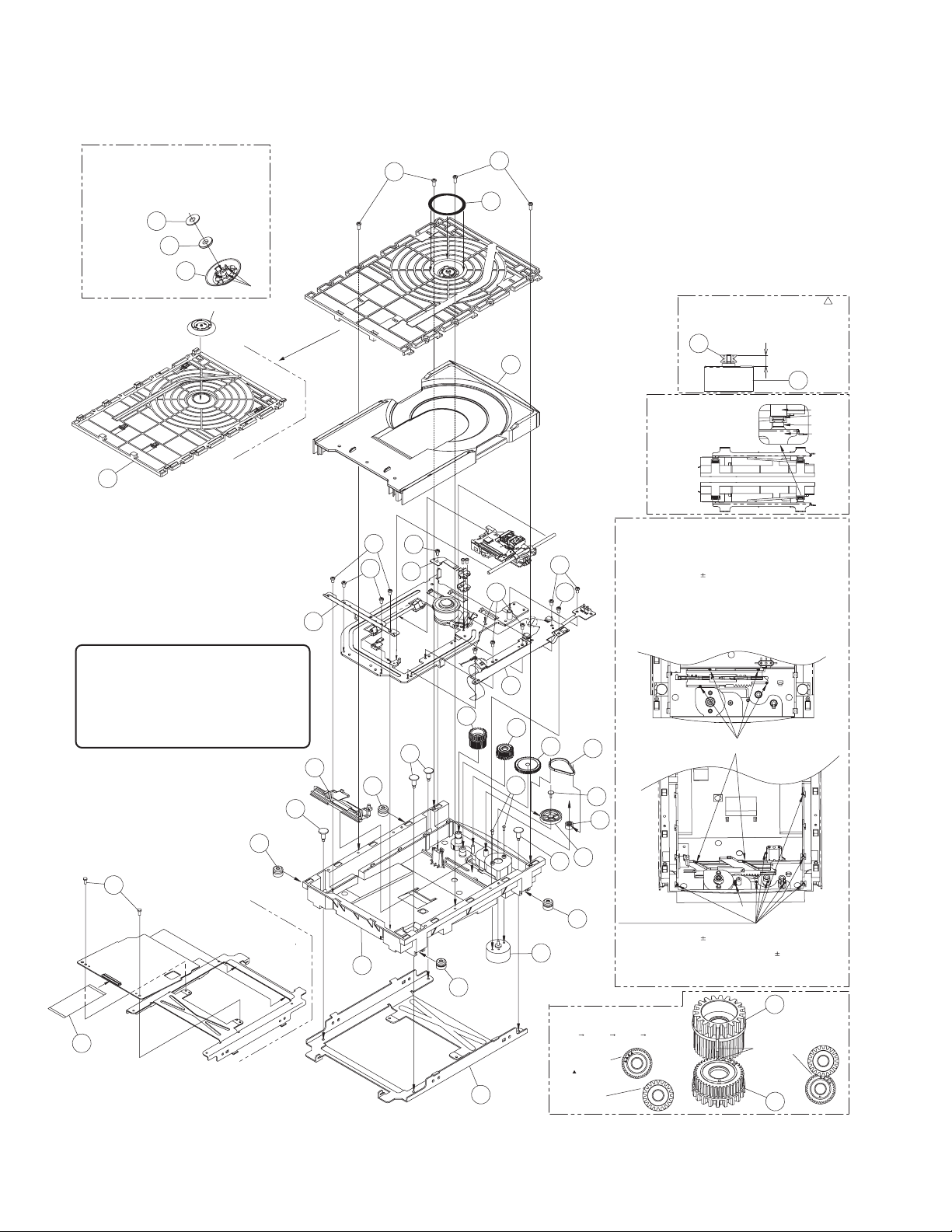

DVD mechanism assembly and parts list

CLAMPER SA

NOTES:

1.Attach the MAGNET to the CLAMPER.

2.Lock the MAGNET and BACK YORK to the CLAMPER firmly

with its 3 hooks.

3.Make sure that none of the 3 hooks of the CLAMPER is

broken/ bent/ changed in shape.

26

25

24

CLAMPER SA

TOP COVER Back

23

28

3 hooks

28

27

22

Block No.M2MM

[FIG-1] LOADING MOTOR - PULLEY Press Fitting.

MOTOR PULLEY Height should be

(Measurement between the top part of the PULLEY

and the top of the MOTOR Can)

6

[FIG-2] INSULATOR Attachment

NOTES:

1.Insert the INSULATOR firmly without mixing

up the top and bottom side.

2.After the attachment of the INSULATOR,

fasten the LOADER SCREW.

3.Be sure that the LOADER SCREW is not

fastened at an angle of improperly fastened.

DRAWING FROM

DIRECTION A

DRAWING FROM

DIRECTION B

1

-0.1

5.35

-0.4

-0.1

5.35

-0.4

5

LOWER CASE

LOADER SCREW

INSULATOR

LOADER BKT

We cannot supply parts that are not

in the Parts List, as they are not

exchangeable because of the

design feature. Please handle the

replacement with Mechanism

Assembly Units.

8

19

18

Back

17

15

21

21

3

20

3

3

21

2

[FIG-3] LOWER CASE/ SLIDER Grease Application Point

SLIDER: 6 Grease Application Points

Type of Grease: TAG- 200R

Amount of Grease: 8 1mg each

NOTES:

1.After the attachment of the SLIDER to the LOWER CASE, pull

the SLIDER towards the SNAPFIT (left side). Apply the grease

to the points shown in the figure below.

2.Grease should be applied before the attachment of

TRAVERSE BASE SA.

LOWER CASE

1

10

17

8

4

8

16

9

11

14

7

b

c

17

13

6

12

8

5

[FIG-3] GEAR Attachment

NOTES:

1.Attachment order of the GEARS is as follows,

[GEAR 2] [GEAR 3] [GEAR 1] [PULLEY GEAR].

Be sure to adjust the Phase of GEAR 2 and GEAR 3.

NOTES:

<GEAR 2 Phase Mark>

<GEAR 3 Phase Mark>

Make mark as a Phase

Adjustment Mark

Make the salient of the outer circumference

of GEAR 3 as a Phase Adjustment Mark.

LOWER CASE

LOWER CASE: 9 Grease Application Points

Type of Grease: TAG- 200R

Amount of Grease: 8 1mg each

NOTES:

3.Apply Grease in the center of GEAR Attaching SHAFT.

4.Apply Grease before attaching any kind of GEARS.

SLIDER Grease Application Points

"a"

Note: Application amount at area "a"

(left of PULLEY GEAR SHAFT) is 64 4mg.

10

Correct Phase Adjustment

Each Phase Adjustment Mark

is on the straight line.

9

3-4(No.YD058)

Page 5

DVD mechanism

Symbol No. Part No. Part Name Description Local

1 QAL0496-001 FPC

2 LP41195-001A BASE HOLDER

3 QYSDSP2604ZA SCREW M2.6 x 4mm(x7)

4 LP10566-001A LOWER CASE

5 QAR0352-001 LOADING MOTOR

6 LP41183-001A MOTOR PULLEY

7 LP41117-001A SCREW (x2)

8 LP31204-001A INSULATOR (x4)

9 LP41186-001A GEAR 2

10 LP41187-001A GEAR 3

11 LP41185-001A GEAR 1

12 LP41184-001A PULLEY GEAR

13 LP41042-001A SCREW

14 LP41015-001A BELT

15 LP21329-001A SLIDER

16 LP21349-001A LOADER BKT

17 LP41225-001A LOADER SCREW (x4)

18 LP41144-001A FFC WIRE PU/F.ENDP

19 QYSDST2606ZA TAP SCREW F.END PWB(x2)

20 LP41194-001A BASE SPRING

21 QYSDSF2606ZA TAP SCREW M2.6 x 6mm(x4)

22 LP10570-001B TRAY NON-CRTG

23 LP10565-001A TOP COVER

24 LP31447-001A CLAMPER

25 QQR1441-001 P.C.MAGNET

26 LP41188-001A BACK YOKE

27 LP41203-001A COVER SHEET

28 QYSDSF2606ZA TAP SCREW TOP COVER(x4)

Block No. [M][2][M][M]

(No.YD058)3-5

Page 6

Electrical parts list

Main board

Block No. [0][3]

Symbol No.

PW1 LPA10288-04C1 MAIN BOARD ASSY UJ

PW1 LPA10288-01C1 MAIN BOARD ASSY UC,US

IC3001 MN101D10GDD IC(MCU) MASK

IC3002 IC-PST3425U-X IC

IC3004 LPN0962-001D-27 IC(EEPROM) *(REFER TO BELOW)

IC4001 BH7623KS2 IC

IC4101 BH7868FS-X IC

IC5101 STR-G6653-F9 IC

IC5301 TL431/A/-T IC

IC5301 or MM1431AT-T IC

IC5301 or UTCTL431-T IC

IC5303 MM1689BH-X IC

IC5304 RT9167A-18PS-X IC

IC5307 MM1662GH-X IC

IC5308 MM1665AH-X IC

IC5309 PQ5EV3 IC

IC6501 AN5832SA-W IC

IC8001 AK5366VQ-W IC

IC8201 AK4385VT-X IC

IC8201 or AK4385ET-X IC

IC8202 RC4558D-X IC

IC8501 SN74LV08APW-X IC

Q3004 2SD601A/QRS/-X TRANSISTOR

Q3004 or

Q3004 or

Q3005 UN2211-X TRANSISTOR

Q3005 or DTC114EKA-X DIGI TRANSISTOR

Q3005 or RT1N141C-X DIGI TRANSISTOR

Q4001 2SA1037AK/QR/-X TRANSISTOR

Q4001 or 2SB709A/QR/-X TRANSISTOR

Q4001 or 2SA1530A/QR/-X TRANSISTOR

Q5301 2SC3576-JVC-T TRANSISTOR

Q5301 or 2SD2144S/UV/-T TRANSISTOR

Q5302 UN2111-X TRANSISTOR

Q5302 or RT1P141C-X DIGI TRANSISTOR

Q5302 or DTA114EKA-X DIGI TRANSISTOR

Q5303 UN2211-X TRANSISTOR

Q5303 or RT1N141C-X DIGI TRANSISTOR

Q5303 or DTC114EKA-X DIGI TRANSISTOR

Q5304 2SA1585S/QR/-T TRANSISTOR

Q5305 UN2211-X TRANSISTOR

Q5305 or RT1N141C-X DIGI TRANSISTOR

Q5305 or DTC114EKA-X DIGI TRANSISTOR

Q5306 2SA1585S/QR/-T TRANSISTOR

Q5308 UN2111-X TRANSISTOR

Q5308 or RT1P141C-X DIGI TRANSISTOR

Q5308 or DTA114EKA-X DIGI TRANSISTOR

Q5309 UN2211-X TRANSISTOR

Q5309 or RT1N141C-X DIGI TRANSISTOR

Q5309 or DTC114EKA-X DIGI TRANSISTOR

Q5310 2SD1858/QR/-T TRANSISTOR

Q5312 UN2211-X TRANSISTOR

Q5312 or RT1N141C-X DIGI TRANSISTOR

Q5312 or DTC114EKA-X DIGI TRANSISTOR

Q5313 2SD601A/QRS/-X TRANSISTOR

Q5313 or

Q5313 or

Q5314 UN2111-X TRANSISTOR

Q5314 or RT1P141C-X DIGI TRANSISTOR

Q5314 or DTA114EKA-X DIGI TRANSISTOR

Q5315 UN2211-X TRANSISTOR

Q5315 or RT1N141C-X DIGI TRANSISTOR

Q5315 or DTC114EKA-X DIGI TRANSISTOR

Q5316 2SC3576-JVC-T TRANSISTOR

Q5316 or 2SD2144S/UV/-T TRANSISTOR

Q6030 2SA1037AK/QR/-X TRANSISTOR

Q6030 or 2SB709A/QR/-X TRANSISTOR

Q6030 or 2SA1530A/QR/-X SI TRANSISTOR

Q8203

Q8203 or 2SD601A/QRS/-X TRANSISTOR

Part No. Part Name Description Local

2SC2412K/QRS/-X

2SC3928A/QRS/-X

2SC2412K/QRS/-X

2SC3928A/QRS/-X

2SC2412K/QRS/-X

TRANSISTOR

TRANSISTOR

TRANSISTOR

TRANSISTOR

TRANSISTOR

Symbol No.

Q8203 or

Q8205

Q8205 or 2SD601A/QRS/-X TRANSISTOR

Q8205 or

Q8207 UN221E-X TRANSTSTOR

Q8207 or DTC144WKA-X DIGI TRANSISTOR

Q8207 or RT1N44HC-X DIGI TRANSISTOR

Q8208 UN211E-X DIGI TRANSISTOR

Q8208 or DTA144WKA-X TRANSISTOR

Q8208 or RT1P44HC-X DIGI TRANSISTOR

D3002 1SS133-T2 DIODE

D3002 or 1SS270A-T2 SI DIODE

D3003 MTZJ39C-T2 Z DIODE

D3004 10EDB20-T2 SI DIODE

D3005 10EDB20-T2 SI DIODE

D4001 DA204U-X SI DIODE

D4002 DA204U-X SI DIODE

D5001 D3SBA60 DIODE

D5101 SARS01-T2 SI DIODE

D5103 AU01Z-T2 FR DIODE

D5103 or 10ERB20-T2 FR DIODE

D5104 1SS133-T2 SI DIODE

D5104 or 1SS270A-T2 SI DIODE

D5105 AU01Z-T2 FR DIODE

D5105 or 10ERB40-T2 FR DIODE

D5106 AU01Z-T2 FR DIODE

D5106 or 10ERB20-T2 FR DIODE

D5201 AU01Z-T2 FR DIODE

D5201 or 10ERB20-T2 FR DIODE

D5202 AU01Z-T2 FR DIODE

D5202 or 10ERB20-T2 FR DIODE

D5204 RL2Z-LFB2 FR DIODE

D5205 RK34-LFB2 FUSEIODE

D5206 RK34-LFB2 FUSEIODE

D5207 AU01Z-T2 FR DIODE

D5207 or 10ERB20-T2 FR DIODE

D5208 RK14-LFB2 SB DIODE

D5208 or 21DQ04-F SBD

D5210 RK34-LFB2 FUSEIODE

D5211 AU01Z-T2 FR DIODE

D5211 or 10ERB20-T2 FR DIODE

D5212 RL2Z-LFB2 FR DIODE

D5213 RK14-LFB2 SB DIODE

D5213 or 21DQ04-F SBD

D5214 RK34-LFB2 FUSEIODE

D5301 MTZJ15C-T2 Z DIODE

D5302 1SS133-T2 SI DIODE

D5302 or 1SS270A-T2 SI DIODE

D5303 MTZJ27C-T2 Z DIODE

D5304 RK34-LFB2 FUSEIODE

D5305 RK34-LFB2 FUSEIODE

D5306 RK34-LFB2 FUSEIODE

D5307 10EDB20-T2 SI DIODE

D5308 AW04-T2 SB DIODE

D5309 MTZJ5.6C-T2 Z DIODE

D5310 10EDB20-T2 SI DIODE

D5311 AW04-T2 SB DIODE

D5312 10EDB20-T2 SI DIODE

D5313 10EDB20-T2 SI DIODE

D5314 10EDB20-T2 SI DIODE

D5315 MTZJ11C-T2 Z DIODE

D5318 AW04-T2 SB DIODE

D5319 AW04-T2 SB DIODE

D6002 HZ30-2L-T2 Z DIODE

PC5101 PS2581AL1/QW/ PHOTO COUPLER

C3002 NCB31HK-272X C CAPACITOR 2700pF 50V K

C3003 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

C3004 NRSA63J-103X MG RESISTOR 10k

C3020 QEKJ1EM-106Z E CAPACITOR 10uF 25V M

C3022 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C3024 NCB31CK-104X C CAPACITOR 0.1uF 16V K

Part No. Part Name Description Local

2SC3928A/QRS/-X

2SC2412K/QRS/-X

2SC3928A/QRS/-X

TRANSISTOR

TRANSISTOR

TRANSISTOR

Ω

1/16W J

3-6(No.YD058)

After exchanging EEPROMs, a main part does not correspond to some remote control commands at Jig RCU mode.

Please cancel the Jig RCU mode of a main part after exchanging EEPROMs. Please refer to the "Canceling JIG mode"

about the release method.

Page 7

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

C3029 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C3030 QEKJ0JM-476Z E CAPACITOR 47uF 6.3V M

C3031 NDC31HJ-180X C CAPACITOR 18pF 50V J

C3032 NDC31HJ-270X C CAPACITOR 27pF 50V J

C3034 NDC31HJ-220X C CAPACITOR 22pF 50V J

C3035 NDC31HJ-180X C CAPACITOR 18pF 50V J

C3037 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C3039 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C3040 QEKJ0JM-476Z E CAPACITOR 47uF 6.3V M

C3041 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C3042 QETN0JM-477Z E CAPACITOR 470uF 6.3V M

C4001 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

C4002 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C4005 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C4006 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

C4007 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C4008 QEKJ1CM-106Z E CAPACITOR 10uF 16V M

C4009 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C4010 NCF31AZ-105X C CAPACITOR 1uF 10V Z

C4011 NCF31AZ-105X C CAPACITOR 1uF 10V Z

C4012 NCF31AZ-105X C CAPACITOR 1uF 10V Z

C4013 NCF31AZ-105X C CAPACITOR 1uF 10V Z

C4014 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C4015 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

C4016 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

C4017 NCB31CK-333X C CAPACITOR 0.033uF 16V K

C4018 NDC31HJ-101X C CAPACITOR 100pF 50V J

C4019 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C4020 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C4021 NDC31HJ-101X C CAPACITOR 100pF 50V J

C4022 NCB31CK-333X C CAPACITOR 0.033uF 16V K

C4026 NCF31AZ-105X C CAPACITOR 1uF 10V Z

C4027 NCF31AZ-105X C CAPACITOR 1uF 10V Z

C4029 NCF31AZ-105X C CAPACITOR 1uF 10V Z

C4031 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C4032 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C4033 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C4035 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

C4036 QEKJ0JM-476Z E CAPACITOR 47uF 6.3V M

C4037 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C4038 QEKJ0JM-476Z E CAPACITOR 47uF 6.3V M

C4039 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C4042 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

C4043 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

C4101 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C4102 QEKJ0JM-476Z E CAPACITOR 47uF 6.3V M

C4103 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C4104 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C4105 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C4106 QEKJ1CM-226Z E CAPACITOR 22uF 16V M

C4107 NCF31AZ-105X C CAPACITOR 1uF 10V Z

C4108 NCF31AZ-105X C CAPACITOR 1uF 10V Z

C4109 NCF31AZ-105X C CAPACITOR 1uF 10V Z

C4110 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C4111 QEKJ1CM-226Z E CAPACITOR 22uF 16V M

C4112 QETN0JM-107Z E CAPACITOR 100uF 6.3V M

C4113 QEKJ1CM-226Z E CAPACITOR 22uF 16V M

C4114 QETN0JM-107Z E CAPACITOR 100uF 6.3V M

C4115 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C4116 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C4117 QETN0JM-107Z E CAPACITOR 100uF 6.3V M

C4118 QETN0JM-107Z E CAPACITOR 100uF 6.3V M

C4119 QETN0JM-107Z E CAPACITOR 100uF 6.3V M

C4123 QEKJ1CM-226Z E CAPACITOR 22uF 16V M

C4124 QEKJ1CM-226Z E CAPACITOR 22uF 16V M

C4125 QEKJ1CM-226Z E CAPACITOR 22uF 16V M

C5001 QFZ9075-683

C5002 QFZ9075-223

C5003 QEZ0374-107 E CAPACITOR 100uF 400V M UJ

C5003 QETM2DM-157 E CAPACITOR 150uF 200V M UC,US

C5004 QCZ9071-222 C CAPACITOR 2200pF AC400V M UJ

C5004 QCZ9071-472 C CAPACITOR 4700pF AC400V M UC,US

C5005 QCZ9079-101 C CAPACITOR 100pF AC250V K UC,US

C5102 QCZ0349-472Z C CAPACITOR 4700pF 1kV K

C5103 QEZ0619-276Z E CAPACITOR 27uF

C5104 QCZ0136-101Z C CAPACITOR 100pF 1kV K

C5105 QFLC1HJ-471Z M CAPACITOR 470pF 50V J

C5106 NCB31HK-103X C CAPACITOR 0.01uF 50V K

MPP CAPACITOR

MPP CAPACITOR

0.068uF 275V M

0.022uF 275V M

C5107 NDC31HJ-121X C CAPACITOR 120pF 50V J

C5201 QEZ0562-227Z E CAPACITOR 220uF 6.3V M

C5202 QEZ0620-186Z E CAPACITOR 18uF

C5204 QEZ0701-128 E CAPACITOR 1200uF

C5205 QECS1AM-158 E CAPACITOR 1500uF 10V M

C5206 QEZ0564-128 E CAPACITOR 1200uF 10V M

C5207 QETN2AM-475Z E CAPACITOR 4.7uF 100V M

C5208 QEZ0564-128 E CAPACITOR 1200uF 10V M

C5209 QEZ0564-278 E CAPACITOR 2700uF 10V M

C5210 QEZ0620-186Z E CAPACITOR 18uF

C5301 QFVF1HJ-154Z MF CAPACITOR 0.15uF 50V J

C5302 QFLC1HJ-333Z M CAPACITOR 0.033uF 50V J

C5304 QETN1CM-107Z E CAPACITOR 100uF 16V M

C5305 QETN1AM-107Z E CAPACITOR 100uF 10V M

C5306 QETN1AM-107Z E CAPACITOR 100uF 10V M

C5307 QETN1AM-107Z E CAPACITOR 100uF 10V M

C5308 QETN1AM-107Z E CAPACITOR 100uF 10V M

C5309 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C5310 QETN1CM-107Z E CAPACITOR 100uF 16V M

C5311 QETN1HM-225Z E CAPACITOR 2.2uF 50V M

C5312 QETN1AM-107Z E CAPACITOR 100uF 10V M

C5313 NCB31AK-105X C CAPACITOR 1uF 10V K

C5314 NCB31HK-471X C CAPACITOR 470pF 50V K

C5315 QETN1HM-226Z E CAPACITOR 22uF 50V M

C5316 QETN1AM-107Z E CAPACITOR 100uF 10V M

C5326 NCB31AK-105X C CAPACITOR 1uF 10V K

C5327 NCB31HK-471X C CAPACITOR 470pF 50V K

C5332 NCB10JK-106X C CAPACITOR 10uF 6.3V K

C5333 NCB31AK-105X C CAPACITOR 1uF 10V K

C5334 NCB31AK-105X C CAPACITOR 1uF 10V K

C5335 NCB31AK-105X C CAPACITOR 1uF 10V K

C5336 NCB31AK-105X C CAPACITOR 1uF 10V K

C5342 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C5343 NCB31AK-105X C CAPACITOR 1uF 10V K

C5344 NCB31AK-105X C CAPACITOR 1uF 10V K

C6501 QEKJ1EM-106Z E CAPACITOR 10uF 25V M

C6502 QEKJ1HM-334Z E CAPACITOR 0.33uF 50V M

C6503 QEKJ1HM-335Z E CAPACITOR 3.3uF 50V M

C6504 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C6506 NCB31EK-223X C CAPACITOR 0.022uF 25V K

C6507 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C6508 NCB31CK-333X C CAPACITOR 0.033uF 16V K

C6509 QEKJ1HM-225Z E CAPACITOR 2.2uF 50V M

C6510 QEKJ1HM-334Z E CAPACITOR 0.33uF 50V M

C6511 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C6512 NCB31AK-224X C CAPACITOR 0.22uF 10V K

C6514 NCB31HK-102X C CAPACITOR 1000pF 50V K

C6515 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C6516 QEKJ1HM-225Z E CAPACITOR 2.2uF 50V M

C6520 QEKJ1HM-225Z E CAPACITOR 2.2uF 50V M

C6521 QEKJ1EM-106Z E CAPACITOR 10uF 25V M

C6522 QEKJ1EM-106Z E CAPACITOR 10uF 25V M

C6523 QEKJ1HM-225Z E CAPACITOR 2.2uF 50V M

C8005 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C8007 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C8008 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C8011 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C8012 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C8014 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C8021 QERF1HM-475Z E CAPACITOR 4.7uF 50V M

C8022 QERF1HM-475Z E CAPACITOR 4.7uF 50V M

C8023 QERF0JM-107Z E CAPACITOR 100uF 6.3V M

C8024 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C8025 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C8026 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C8027 QEKJ0JM-107Z E CAPACITOR 100uF 6.3V M

C8028 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C8029 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C8201 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C8202 QETJ0JM-477Z E CAPACITOR 470uF 6.3V M

C8203 NCB31HK-472X C CAPACITOR 4700pF 50V K

C8204 NDC31HJ-471X C CAPACITOR 470pF 50V J

C8205 NDC31HJ-471X C CAPACITOR 470pF 50V J

C8206 NCB31HK-472X C CAPACITOR 4700pF 50V K

C8207 NDC31HJ-471X C CAPACITOR 470pF 50V J

C8208 NDC31HJ-471X C CAPACITOR 470pF 50V J

C8209 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C8210 QETJ1CM-107Z E CAPACITOR 100uF 16V M

(No.YD058)3-7

Page 8

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

C8211 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C8212 QETJ1CM-107Z E CAPACITOR 100uF 16V M

C8215 QETJ1EM-476Z E CAPACITOR 47uF 25V M

C8217 QETJ1EM-476Z E CAPACITOR 47uF 25V M

C8501 QEKJ1CM-107Z E CAPACITOR 100uF 16V M

C8502 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C8503 QETN1HM-475Z E CAPACITOR 4.7uF 50V M

C8504 NDC31HJ-151X C CAPACITOR 150pF 50V J

C8505 NDC31HJ-331X C CAPACITOR 330pF 50V J

C8506 NCB31CK-104X C CAPACITOR 0.1uF 16V K

R3004 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R3005 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3006 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3007 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3008 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3009 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R3010 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3011 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3013 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3014 NRSA63J-0R0X MG RESISTOR 0

R3015 NRSA63J-0R0X MG RESISTOR 0

R3016 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3017 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R3018 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R3019 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3020 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3021 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R3022 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R3025 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3026 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R3027 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R3028 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3030 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3031 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R3032 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R3035 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R3042 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R3045 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R3049 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R3050 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R3052 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3055 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3057 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3058 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3060 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3061 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3065 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R3067 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R3068 NRSA63J-103X MG RESISTOR 10k

R3069 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R3070 NRSA63J-103X MG RESISTOR 10k

R3072 NRSA63J-103X MG RESISTOR 10k

R3074 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R3075 NRSA63J-103X MG RESISTOR 10k

R3076 NRSA63J-103X MG RESISTOR 10k

R3083 NRSA63J-104X MG RESISTOR 100kΩ 1/16W J

R3085 NRSA63J-0R0X MG RESISTOR 0

R3092 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3093 NRSA63J-0R0X MG RESISTOR 0

R3094 NRSA63J-0R0X MG RESISTOR 0

R3201 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R3202 NRSA63J-103X MG RESISTOR 10k

R3204 NRSA63J-103X MG RESISTOR 10k

R3205 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R3207 NRSA63J-682X MG RESISTOR 6.8k

R3209 NRSA63J-472X MG RESISTOR 4.7k

R3213 NRSA63J-474X MG RESISTOR 470k

R3214 NRSA63J-334X MG RESISTOR 330k

R3218 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R3219 NRSA63J-472X MG RESISTOR 4.7k

R3220 NRSA63J-104X MG RESISTOR 100k

R3221 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R3222 NRSA63J-103X MG RESISTOR 10k

R3223 NRSA63J-103X MG RESISTOR 10k

R3224 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R3225 NRSA63J-101X MG RESISTOR 100

R3226 NRSA63J-105X MG RESISTOR 1M

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

R3227 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R3229 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R3231 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R3234 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R4002 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R4003 NRSA63J-0R0X MG RESISTOR 0

R4005 NRSA63J-394X MG RESISTOR 390k

R4006 NRSA63J-394X MG RESISTOR 390kΩ 1/16W J

R4007 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R4008 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R4009 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R4010 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R4011 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R4012 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R4021 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R4022 NRSA63J-123X MG RESISTOR 12kΩ 1/16W J

R4023 NRSA63J-392X MG RESISTOR 3.9kΩ 1/16W J

R4024 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R4038 NRSA63J-750X MG RESISTOR 75Ω 1/16W J

R4039 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R4040 NRSA63J-101X MG RESISTOR 100

R4041 NRSA63J-0R0X MG RESISTOR 0

R4042 NRSA63J-750X MG RESISTOR 75Ω 1/16W J

R4043 NRSA63J-750X MG RESISTOR 75Ω 1/16W J

R4044 NRSA63J-750X MG RESISTOR 75Ω 1/16W J

R4045 NRSA63J-750X MG RESISTOR 75Ω 1/16W J

R4108 NRSA63J-750X MG RESISTOR 75Ω 1/16W J

R4109 NRSA63J-750X MG RESISTOR 75Ω 1/16W J

R4110 NRSA63J-750X MG RESISTOR 75Ω 1/16W J

R4111 NRSA63J-750X MG RESISTOR 75Ω 1/16W J

R4112 NRSA63J-750X MG RESISTOR 75Ω 1/16W J

R4114 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R4115 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R4126 NRSA63J-750X MG RESISTOR 75Ω 1/16W J

R4127 NRSA63J-750X MG RESISTOR 75Ω 1/16W J

R4128 NRSA63J-750X MG RESISTOR 75Ω 1/16W J

R5001 QRZ9046-475Z C RESISTOR 4.7MΩ 1/2W K UC,US

R5101 QRG02GJ-683 OMF RESISTOR 68kΩ 2W J

R5102 NRSA63J-122X MG RESISTOR 1.2kΩ 1/16W J

R5103 QRE141J-684Y C RESISTOR 680kΩ 1/4W J

R5104 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R5105 QRE141J-820Y C RESISTOR 82Ω 1/4W J

R5106 NRSA63J-392X MG RESISTOR 3.9kΩ 1/16W J

R5107 NRSA63J-681X MG RESISTOR 680Ω 1/16W J

R5108 QRT01DJ-R33X MF RESISTOR 0.33Ω 1W J

R5109 QRZ9005-470X FUSI RESISTOR 47Ω 1/4W G

R5301 NRSA63J-221X MG RESISTOR 220Ω 1/16W J

R5302 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R5303 NRSA63J-152X MG RESISTOR 1.5kΩ 1/16W J

R5304 NRSA63D-682X MG RESISTOR 6.8k

R5305 NRSA63D-203X MG RESISTOR 20kΩ 1/16W D

R5306 NRSA63D-392X MG RESISTOR 3.9k

R5307 QRZ9005-470X FUSI RESISTOR 47Ω 1/4W G

R5308 QRE141J-271Y C RESISTOR 270Ω 1/4W J

R5309 NRSA63J-562X MG RESISTOR 5.6k

R5310 NRSA63J-103X MG RESISTOR 10k

R5311 QRE141J-471Y C RESISTOR 470Ω 1/4W J

R5314 NRSA63J-302X MG RESISTOR 3k

R5315 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R5318 NRSA63J-471X MG RESISTOR 470

R5319 QRE141J-150Y C RESISTOR 15

R5320 QRE123J-151X C RESISTOR 150Ω 1/2W J

R5321 NRSA63J-103X MG RESISTOR 10k

R5322 NRSA63J-102X MG RESISTOR 1k

R5323 QRE121J-102Y C RESISTOR 1kΩ 1/2W J

R5324 NRSA63J-102X MG RESISTOR 1k

R5336 NRSA63J-122X MG RESISTOR 1.2k

R5337 NRSA63J-102X MG RESISTOR 1k

R5341 NRSA63J-103X MG RESISTOR 10k

R6020 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R6021 NRSA63J-102X MG RESISTOR 1k

R6022 NRSA63J-103X MG RESISTOR 10k

R6030 NRSA63J-332X MG RESISTOR 3.3kΩ 1/16W J

R6031 NRSA63J-101X MG RESISTOR 100

R6501 NRSA63J-103X MG RESISTOR 10k

R6503 NRSA63J-332X MG RESISTOR 3.3kΩ 1/16W J

R6504 NRSA63J-101X MG RESISTOR 100

R6505 NRSA63J-101X MG RESISTOR 100

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W D

Ω

1/16W D

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/4W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

3-8(No.YD058)

Page 9

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R6508 NRSA63J-184X MG RESISTOR 180kΩ 1/16W J

R6509 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R6510 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R6511 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R6512 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R8001 NRSA63J-513X MG RESISTOR 51k

R8002 NRSA63J-513X MG RESISTOR 51k

R8007 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R8008 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R8013 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R8014 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R8017 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R8019 NRSA63D-473X MG RESISTOR 47kΩ 1/16W D

R8020 NRSA63D-473X MG RESISTOR 47kΩ 1/16W D

R8023 NRSA63D-473X MG RESISTOR 47kΩ 1/16W D

R8024 NRSA63D-473X MG RESISTOR 47kΩ 1/16W D

R8026 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R8031 NRSA63D-203X MG RESISTOR 20kΩ 1/16W D

R8032 NRSA63D-203X MG RESISTOR 20kΩ 1/16W D

R8033 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R8034 NRSA63J-101X MG RESISTOR 100

R8035 NRSA63J-101X MG RESISTOR 100

R8040 NRSA63J-470X MG RESISTOR 47Ω 1/16W J

R8042 NRSA63J-470X MG RESISTOR 47Ω 1/16W J

R8044 NRSA63J-683X MG RESISTOR 68kΩ 1/16W J

R8045 NRSA63J-104X MG RESISTOR 100kΩ 1/16W J

R8048 NRSA63J-4R7X MG RESISTOR 4.7Ω 1/16W J

R8049 NRSA63J-4R7X MG RESISTOR 4.7Ω 1/16W J

R8201 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R8202 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R8203 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R8204 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R8206 NRSA63J-104X MG RESISTOR 100kΩ 1/16W J

R8207 NRSA63J-4R7X MG RESISTOR 4.7Ω 1/16W J

R8211 NRSA63D-432X MG RESISTOR 4.3kΩ 1/16W D

R8212 NRSA63D-432X MG RESISTOR 4.3kΩ 1/16W D

R8213 NRSA63D-512X MG RESISTOR 5.1kΩ 1/16W D

R8214 NRSA63D-512X MG RESISTOR 5.1kΩ 1/16W D

R8215 NRSA63D-121X MG RESISTOR 120Ω 1/16W D

R8216 NRSA63D-121X MG RESISTOR 120Ω 1/16W D

R8217 NRSA63D-432X MG RESISTOR 4.3kΩ 1/16W D

R8218 NRSA63D-432X MG RESISTOR 4.3kΩ 1/16W D

R8219 NRSA63D-512X MG RESISTOR 5.1kΩ 1/16W D

R8220 NRSA63D-512X MG RESISTOR 5.1kΩ 1/16W D

R8221 NRSA63D-121X MG RESISTOR 120Ω 1/16W D

R8222 NRSA63D-121X MG RESISTOR 120Ω 1/16W D

R8223 NRSA63J-221X MG RESISTOR 220Ω 1/16W J

R8224 NRSA63J-221X MG RESISTOR 220Ω 1/16W J

R8233 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R8234 NRSA63J-473X MG RESISTOR 47k

R8241 NRSA63J-273X MG RESISTOR 27kΩ 1/16W J

R8242 NRSA63J-471X MG RESISTOR 470

R8244 NRSA63J-103X MG RESISTOR 10k

R8249 NRSA63J-273X MG RESISTOR 27kΩ 1/16W J

R8250 NRSA63J-471X MG RESISTOR 470

R8252 NRSA63J-103X MG RESISTOR 10k

R8501 NRSA63J-4R7X MG RESISTOR 4.7Ω 1/16W J

R8502 NRSA63J-561X MG RESISTOR 560

R8503 NRSA63J-561X MG RESISTOR 560Ω 1/16W J

R8504 NRSA63J-820X MG RESISTOR 82

R8505 NRSA63J-100X MG RESISTOR 10

R8506 NRSA63J-100X MG RESISTOR 10Ω 1/16W J

R8507 NRSA63J-561X MG RESISTOR 560

L3001 QQL231J-R22Y COIL 0.22uH J

L4001 QQL29BJ-100Z P COIL 10uH J

L4002 QQL29BJ-100Z P COIL 10uH J

L4101 QQL29BJ-100Z P COIL 10uH J

L5202 QQL26AK-330Z COIL 33uH K

L5203 QQL26AK-330Z COIL 33uH K

L5204 QQL26AK-330Z COIL 33uH K

L5205 QQL26AK-330Z COIL 33uH K

L5206 QQL26AK-330Z COIL 33uH K

L6001 QQL071J-1R0Y COIL 1uH J

L6004 QQL071J-1R0Y COIL 1uH J

L8501 QQL071J-1R0Y COIL 1uH J

T5001 QQS0333-001 SW TRANSF

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

B4102 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

B4104 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

B4110 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

B4112 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

B5504 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

B8001 NRSA63J-0R0X MG RESISTOR 0

CN3001 QGB1231M1-13 CONNECTOR DISPLAY

CN4001 QGF1207C1-11 CONNECTOR FRONT IN

CN4101 QGB1231M1-15 CONNECTOR DIGITAL

CN4102 QGB1231M1-15 CONNECTOR DIGITAL

CN4103 QGF1016C3-15 CONNECTOR 1-15PIN

CN5001 QGA7901C3-02 CONNECTOR W-B (1-2)

CN5302 QGA2001C1-07 CONNECTOR DVD JVC

CN5303 QGA2001C1-02 CONNECTOR FAN

F5001 QMF51E2-1R6-J1 FUSE 1.6A AC250V UJ

F5001 QMF51N2-1R6-J1 FUSE 1.6A AC250V UC,US

FC5001 QNG0006-001Z FUSE CLIP

FC5002 QNG0006-001Z FUSE CLIP

GN1 QNZ0136-001Z EARTH PLATE

GN2 QNZ0136-001Z EARTH PLATE

GN4 QNZ0136-001Z EARTH PLATE

HS1 QZW0155-001 HEAT SINK FOR IC5101 UJ

J4002 QNN0685-001 PIN JACK REAR 1 IN

J4101 QND0131-001 S JACK S IN

J4102 QND0131-001 S JACK S OUT

J4105 QNN0686-001 PIN JACK SIKISA AV

J8501 QNN0573-001 PIN JACK

K6001 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

K6004 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

K8501 NQR0227-004X FERRITE BEADS

LF5001 QQR0908-001 LINE FILTER

ST1 QZW0007-001 POST PIN

TU6001 QAU0409-001 TUNER

VA5001 QAF0023-431Z VARISTOR 430V UC,US

W1 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

W2 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

W3 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

W4 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

W5 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

W6 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

W7 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

W8 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

W9 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

W10 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

W11 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

W12 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

W13 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

W14 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

W15 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

W16 NRSA63J-0R0X MG RESISTOR 0

W17 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

W18 NRSA63J-0R0X MG RESISTOR 0

W21 NRSA63J-0R0X MG RESISTOR 0

W22 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

W24 NRSA63J-0R0X MG RESISTOR 0

W25 NRSA63J-0R0X MG RESISTOR 0

W26 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

W27 NRSA63J-0R0X MG RESISTOR 0

W28 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

W29 NRSA63J-0R0X MG RESISTOR 0

W30 NRSA63J-0R0X MG RESISTOR 0

W31 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

X3001 QAX0728-001 CRYSTAL 14.318180MHz

X3002 QAX0444-001 CRYSTAL 32.768kHz

OT1 QYTDST3008ZA TAP SCREW FOR IC5101 UJ

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

(No.YD058)3-9

Page 10

Digital board

Symbol No.

PW1 LPA10289-01C DIGITAL BOARD ASSY

IC1201 LPN0963-001A IC(FLASH) (SERVICE)

IC1202

IC1202 or TC74LCX373FT-X IC

IC1203

IC1203 or TC74LCX373FT-X IC

IC1401 DMN8602-B0 IC(DIGITAL)

IC1404

IC1601

IC1602

IC1701 LP2996MR-X IC

IC1801 TSB41AB2PAP IC

IC1901

Q1901 2SA1530A/QR/-X TRANSISTOR

Q1901 or 2SB709A/QR/-X TRANSISTOR

Q1901 or 2SA1037AK/QR/-X TRANSISTOR

Q1903

Q1903 or 2SD601A/QRS/-X TRANSISTOR

Q1903 or

D1401 MA111-X SI DIODE

D1401 or 1SS355-X SI DIODE

D1402 MA111-X SI DIODE

D1402 or 1SS355-X SI DIODE

C1101 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1102 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1103 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1104 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1105 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1106 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1107 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1108 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1109 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1110 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1111 N EHM 0JM- 107X E CAPACITOR 100uF 6.3V M

C1112 NEX60GM-337X E CAPACITOR 330uF 4V M

C1113 NEHM0JM-107X E CAPACITOR 100uF 6.3V M

C1116 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1117 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1118 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1119 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1120 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1121 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1122 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1123 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1124 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1125 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1126 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1127 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1203 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1204 NBE20JM-106X

C1206 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1207 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1209 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1210 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1419 NBE20JM-106X

C1420 NBE20JM-106X

C1421 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1422 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1423 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1424 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1425 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1427 NBE20JM-106X

C1428 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1429 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1430 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1434 NBE20JM-106X

C1435 NBE20JM-106X

C1436 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1437 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1438 NCB31CK-104X C CAPACITOR 0.1uF 16V K

Part No. Part Name Description Local

SN74LVC373APW-X

SN74LVC373APW-X

SN74HCT08APW-X

NT5DS16M16CS-6K

NT5DS16M16CS-6K

TVP5150AM1PBS-W

2SC3928A/QRS/-X

2SC2412K/QRS/-X

IC(DIGITAL)

IC(DIGITAL)

IC

IC

IC

IC

TRANSISTOR

TRANSISTOR

TA E CAPACITOR

TA E CAPACITOR

TA E CAPACITOR

TA E CAPACITOR

TA E CAPACITOR

TA E CAPACITOR

10uF 6.3V M

10uF 6.3V M

10uF 6.3V M

10uF 6.3V M

10uF 6.3V M

10uF 6.3V M

Block No. [5][0]

Symbol No.

C1442 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1444 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1445 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1447 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1448 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C1452 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1453 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1455 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1457 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1459 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C1460 NDC31HJ-120X C CAPACITOR 12pF 50V J

C1461 NDC31HJ-120X C CAPACITOR 12pF 50V J

C1462 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1605 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1606 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1607 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1608 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1609 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1610 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1611 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1612 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1613 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1614 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1615 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1616 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1617 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1618 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1619 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1620 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1621 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1622 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1623 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1624 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1625 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1626 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1627 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1642 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1646 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1652 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1654 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1656 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1658 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1701 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1702 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C1704 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1705 NBE20JM-226X

C1706 NCB10JK-106X C CAPACITOR 10uF 6.3V K

C1801 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C1802 NDC31HJ-271X C CAPACITOR 270pF 50V J

C1803 NBE20JM-226X

C1804 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1805 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C1807 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1808 NDC31HJ-120X C CAPACITOR 12pF 50V J

C1809 NDC31HJ-120X C CAPACITOR 12pF 50V J

C1810 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1811 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1812 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1813 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1901 NBE20JM-226X

C1902 NBE20JM-226X

C1903 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1904 NBE20JM-226X

C1905 NRSA63J-0R0X MG RESISTOR 0

C1906 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1907 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1908 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1909 NDC31HJ-120X C CAPACITOR 12pF 50V J

C1910 NDC31HJ-120X C CAPACITOR 12pF 50V J

C1911 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1912 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1913 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C1914 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C1915 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C1916 NCB31CK-104X C CAPACITOR 0.1uF 16V K

R1216 NRSA63J-101X MG RESISTOR 100

R1222 NRSA63J-222X MG RESISTOR 2.2k

Part No. Part Name Description Local

TA E CAPACITOR

TA E CAPACITOR

TA E CAPACITOR

TA E CAPACITOR

TA E CAPACITOR

22uF 6.3V M

22uF 6.3V M

22uF 6.3V M

22uF 6.3V M

22uF 6.3V M

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

3-10(No.YD058)

Page 11

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R1223 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R1224 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R1225 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1226 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R1229 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R1230 NRSA63J-472X MG RESISTOR 4.7k

R1231 NRSA63J-472X MG RESISTOR 4.7k

R1401 NRSA63F-1181X MG RESISTOR 1.18kΩ 1/16W F

R1403 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1408 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R1409 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1410 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1412 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1413 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1415 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R1430 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1431 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1432 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1433 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1434 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1435 NRSA63J-101X MG RESISTOR 100

R1436 NRSA63J-101X MG RESISTOR 100

R1439 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1440 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1443 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R1445 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1446 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1447 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1448 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1449 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1456 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1462 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1465 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1467 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1469 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R1470 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R1472 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1473 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1474 NRSA63J-221X MG RESISTOR 220Ω 1/16W J

R1475 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1476 NRSA63J-221X MG RESISTOR 220Ω 1/16W J

R1478 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1480 NRSA63J-221X MG RESISTOR 220Ω 1/16W J

R1481 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1483 NRSA63J-821X MG RESISTOR 820Ω 1/16W J

R1485 NRSA63D-151X MG RESISTOR 150Ω 1/16W D

R1486 NRSA63D-151X MG RESISTOR 150Ω 1/16W D

R1487 NRSA63D-151X MG RESISTOR 150Ω 1/16W D

R1488 NRSA63D-151X MG RESISTOR 150Ω 1/16W D

R1489 NRSA63D-151X MG RESISTOR 150

R1490 NRSA63D-151X MG RESISTOR 150Ω 1/16W D

R1491 NRSA63J-102X MG RESISTOR 1k

R1494 NRSA63J-103X MG RESISTOR 10k

R1495 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1499 NRSA63J-105X MG RESISTOR 1M

R1601 NRSA63J-330X MG RESISTOR 33

R1602 NRSA63J-330X MG RESISTOR 33Ω 1/16W J

R1603 NRSA63J-330X MG RESISTOR 33

R1604 NRSA63J-330X MG RESISTOR 33Ω 1/16W J

R1605 NRSA63J-101X MG RESISTOR 100

R1606 NRSA63J-220X MG RESISTOR 22

R1607 NRSA63J-220X MG RESISTOR 22Ω 1/16W J

R1608 NRSA63J-220X MG RESISTOR 22

R1609 NRSA63J-220X MG RESISTOR 22

R1611 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1612 NRSA63J-101X MG RESISTOR 100

R1613 NRSA63J-101X MG RESISTOR 100

R1614 NRSA63J-101X MG RESISTOR 100

R1618 NRSA63J-101X MG RESISTOR 100

R1620 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1624 NRSA63J-101X MG RESISTOR 100

R1626 NRSA63J-101X MG RESISTOR 100

R1629 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1630 NRSA63J-101X MG RESISTOR 100

R1631 NRSA63J-101X MG RESISTOR 100

R1632 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1642 NRSA63J-330X MG RESISTOR 33

R1701 NRSA63J-0R0X MG RESISTOR 0

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W D

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

R1801 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1802 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1803 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1804 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1807 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1809 NRSA63J-103X MG RESISTOR 10k

R1810 NRSA63J-394X MG RESISTOR 390k

R1813 NRSA63J-560X MG RESISTOR 56Ω 1/16W J

R1814 NRSA63J-560X MG RESISTOR 56Ω 1/16W J

R1815 NRSA63J-560X MG RESISTOR 56Ω 1/16W J

R1816 NRSA63J-560X MG RESISTOR 56Ω 1/16W J

R1817 NRSA63J-512X MG RESISTOR 5.1kΩ 1/16W J

R1818 NRSA63D-562X MG RESISTOR 5.6kΩ 1/16W D

R1819 NRSA63D-751X MG RESISTOR 750Ω 1/16W D

R1820 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1821 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R1824 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1825 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1901 NRSA63J-391X MG RESISTOR 390Ω 1/16W J

R1902 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1905 NRSA63J-104X MG RESISTOR 100k

R1906 NRSA63J-222X MG RESISTOR 2.2k

R1907 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1908 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1909 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R1910 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R1913 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1914 NRSA63J-271X MG RESISTOR 270Ω 1/16W J

R1915 NRSA63J-471X MG RESISTOR 470Ω 1/16W J

R2201 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R2202 NRSA63J-562X MG RESISTOR 5.6kΩ 1/16W J

R2203 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R2204 NRSA63J-330X MG RESISTOR 33Ω 1/16W J

R2205 NRSA63J-820X MG RESISTOR 82Ω 1/16W J

R2206 NRSA63J-220X MG RESISTOR 22Ω 1/16W J

R2207 NRSA63J-220X MG RESISTOR 22Ω 1/16W J

R2208 NRSA63J-820X MG RESISTOR 82Ω 1/16W J

R2209 NRSA63J-220X MG RESISTOR 22Ω 1/16W J

R2210 NRSA63J-820X MG RESISTOR 82Ω 1/16W J

R2211 NRSA63J-330X MG RESISTOR 33Ω 1/16W J

RA1609 NRZ0087-330W NET RESISTOR 33

RA1610 NRZ0087-330W NET RESISTOR 33

RA1611 NRZ0087-330W NET RESISTOR 33

RA1612 NRZ0087-330W NET RESISTOR 33

RA1613 NRZ0087-330W NET RESISTOR 33

RA1614 NRZ0087-330W NET RESISTOR 33

RA1615 NRZ0087-330W NET RESISTOR 33

RA1616 NRZ0087-330W NET RESISTOR 33

RA1617 NRZ0087-101W NET RESISTOR 100

RA1618 NRZ0087-101W NET RESISTOR 100

RA1619 NRZ0087-101W NET RESISTOR 100

RA1620 NRZ0087-101W NET RESISTOR 100

RA1621 NRZ0087-101W NET RESISTOR 100

RA1622 NRZ0087-101W NET RESISTOR 100

RA1623 NRZ0087-101W NET RESISTOR 100

RA1624 NRZ0087-101W NET RESISTOR 100

RA1625 NRZ0087-330W NET RESISTOR 33

RA1626 NRZ0087-330W NET RESISTOR 33

RA1627 NRZ0087-330W NET RESISTOR 33

RA1628 NRZ0087-330W NET RESISTOR 33

RA1629 NRZ0087-101W NET RESISTOR 100

RA1630 NRZ0087-101W NET RESISTOR 100

RA1631 NRZ0087-101W NET RESISTOR 100

RA1632 NRZ0087-101W NET RESISTOR 100

RA1633 NRZ0087-101W NET RESISTOR 100

RA1634 NRZ0087-330W NET RESISTOR 33

RA1635 NRZ0087-330W NET RESISTOR 33

RA1801 NRZ0087-103W NET RESISTOR 10k

RA1802 NRZ0087-103W NET RESISTOR 10k

RA1803 NRZ0087-101W NET RESISTOR 100

RA1804 NRZ0087-101W NET RESISTOR 100

RA1901 NRZ0087-101W NET RESISTOR 100

RA1902 NRZ0087-101W NET RESISTOR 100

RA2208 NRZ0087-330W NET RESISTOR 33

RA2209 NRZ0087-330W NET RESISTOR 33

RA2210 NRZ0087-330W NET RESISTOR 33

RA2211 NRZ0087-330W NET RESISTOR 33

RA2212 NRZ0087-330W NET RESISTOR 33

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

(No.YD058)3-11

Page 12

Symbol No.

B1204 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

B1402 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

B1701 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

CN1101 QGB1231L2-15W CONNECTOR FJ 15PIN

CN1102 QGB1231L2-15W CONNECTOR FJ 15PIN

CN1103 QGF1016C2-15W CONNECTOR 1-15

CN1402 QGA2001C6-04X CONNECTOR CPRM

CN1403 QGF1016C2-04W CONNECTOR LOG

CN1801 QGB1231L2-09W CONNECTOR FJ 9PIN

CN2201 QGF0550C1-40W CONNECTOR F/T F_END

GN1101 QNZ0136-001Z EARTH PLATE

GN1102 QNZ0136-001Z EARTH PLATE

GN1103 QNZ0136-001Z EARTH PLATE

GN1104 QNZ0136-001Z EARTH PLATE

K1101 NQR0022-002X FERRITE BEADS

K1102 NQR0022-002X FERRITE BEADS

K1103 NQR0022-002X FERRITE BEADS

K1104 NQR0022-002X FERRITE BEADS

K1108 NQR0022-002X FERRITE BEADS

K1110 NQR0022-002X FERRITE BEADS

K1112 NQR0022-005X FERRITE BEADS

K1113 NQR0022-005X FERRITE BEADS

K1114 NQR0022-005X FERRITE BEADS

K1115 NQR0022-005X FERRITE BEADS

K1116 NQR0022-005X FERRITE BEADS

K1117 NQR0022-005X FERRITE BEADS

K1118 NQR0022-005X FERRITE BEADS

K1119 NQR0022-005X FERRITE BEADS

K1120 NQR0022-005X FERRITE BEADS

K1121 NQR0022-005X FERRITE BEADS

K1122 NQR0022-005X FERRITE BEADS

K1123 NQR0022-005X FERRITE BEADS

K1126 NQR0022-002X FERRITE BEADS

K1127 NQR0022-002X FERRITE BEADS

K1128 NQR0022-002X FERRITE BEADS

K1129 NQR0022-002X FERRITE BEADS

K1130 NQR0022-002X FERRITE BEADS

K1131 NQR0022-002X FERRITE BEADS

K1201 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

K1401 NQR0022-002X FERRITE BEADS

K1402 NQR0022-002X FERRITE BEADS

K1403 NQR0022-002X FERRITE BEADS

K1404 NQR0022-002X FERRITE BEADS

K1406 NQR0022-002X FERRITE BEADS

K1408 NQR0022-002X FERRITE BEADS

K1801 NQR0022-002X FERRITE BEADS

K1802 NQR0022-002X FERRITE BEADS

K1901 NQR0022-002X FERRITE BEADS

K1902 NQR0022-002X FERRITE BEADS

K2201 NQR0022-002X FERRITE BEADS

K2202 NQR0022-002X FERRITE BEADS

K2203 NQR0022-002X FERRITE BEADS

K2204 NQR0022-002X FERRITE BEADS

K2205 NQR0022-002X FERRITE BEADS

K2206 NQR0022-002X FERRITE BEADS

K2207 NQR0022-002X FERRITE BEADS

K2208 NQR0022-002X FERRITE BEADS

K2209 NQR0022-002X FERRITE BEADS

K2210 NQR0022-002X FERRITE BEADS

K2211 NQR0022-002X FERRITE BEADS

K2212 NQR0022-002X FERRITE BEADS

K2213 NQR0022-002X FERRITE BEADS

K2214 NQR0022-002X FERRITE BEADS

K2215 NQR0022-002X FERRITE BEADS

K2216 NQR0022-002X FERRITE BEADS

K2217 NQR0022-002X FERRITE BEADS

K2218 NQR0022-002X FERRITE BEADS

K2219 NQR0022-002X FERRITE BEADS

K2220 NQR0022-002X FERRITE BEADS

K2221 NQR0022-002X FERRITE BEADS

LC1101 NQR0512-008X EMI FILTER

LC1102 NQR0512-008X EMI FILTER

LC1103 NQR0512-008X EMI FILTER

LF1801 NQR0568-005X CHOKE COIL

X1401 NAX0768-001X CRYSTAL

X1801 NAX0666-001X CRYSTAL 24.576000MHz

X1901 NAX0733-001X CRYSTAL

Part No. Part Name Description Local

Operation board

Symbol No.

PW1 LPA10281-01C3 OPERATION P.AY

IC7101 GP1UM281XKVF IR DETECT UNIT

IC7101 or PNA4652M00XB IR DETECT UNIT 38kHz

Q7101 2SC1740S/QRS/-T TRANSISTOR

Q7101 or KTC3199/YG/-T TRANSISTOR

D7101 1SS133-T2 SI DIODE

D7101 or 1SS270A-T2 SI DIODE

D7105 1SS133-T2 SI DIODE

D7105 or 1SS270A-T2 SI DIODE

D7106 SDPB3DC0/Z1/ LED BLUE LIGHT

C7101 QEKJ0JM-476Z E CAPACITOR 47uF 6.3V M

R7104 QRE141J-392Y C RESISTOR 3.9kΩ 1/4W J

R7105 QRE141J-182Y C RESISTOR 1.8kΩ 1/4W J

R7106 QRE141J-270Y C RESISTOR 27Ω 1/4W J

CN7103 QGF1208F1-10 CONNECTOR FFC/FPC (1-10)

S7101 QSW0381-001Z TACT SWITCH OPERATION

OT1 LP31478-001A LED HOLDER FOR D7106

Part No. Part Name Description Local

Block No. [2][6]

3-12(No.YD058)

Page 13

Sw/Jack board

Symbol No.

Part No. Part Name Description Local

Block No. [2][7]

Jack board

Symbol No.

Part No. Part Name Description Local

Block No. [3][6]

PW1 LPA10281-01C2 SW/JACK BOARD ASSY

D7113 1SS133-T2 SI DIODE

D7113 or 1SS270A-T2 SI DIODE

D7114 1SS133-T2 SI DIODE

D7114 or 1SS270A-T2 SI DIODE

D7115 1SS133-T2 SI DIODE

D7115 or 1SS270A-T2 SI DIODE

D7116 1SS133-T2 SI DIODE

D7116 or 1SS270A-T2 SI DIODE

D7117 1SS133-T2 SI DIODE

D7117 or 1SS270A-T2 SI DIODE

R7151 QRE141J-750Y C RESISTOR 75Ω 1/4W J

R7152 QRE141J-750Y C RESISTOR 75Ω 1/4W J

R7153 QRE141J-750Y C RESISTOR 75Ω 1/4W J

R7154 QRE141J-101Y C RESISTOR 100

R7155 QRE141J-101Y C RESISTOR 100

CN7101 QGF1207C1-10 CONNECTOR FFC/FPC (1-10)

CN7102 QGF1207C1-11 CONNECTOR FFC/FPC (1-11)

J7001 QND0084-001 S JACK

J7002 QNN0364-002 PIN JACK

S7112 QSW0381-001Z TACT SWITCH CH+/UP

S7113 QSW0381-001Z TACT SWITCH CH-/DOWN

S7114 QSW0381-001Z TACT SWITCH RIGHT/PLAY

S7115 QSW0381-001Z TACT SWITCH LEFT/STOP

S7132 QSW0381-001Z TACT SWITCH OPEN/CLOSE

S7135 QSW0381-001Z TACT SWITCH OK/REC

Ω

1/4W J

Ω

1/4W J

Display board

Symbol No.

Part No. Part Name Description Local

PW1 LPA10288-04C2 JACK BOARD ASSY UJ

PW1 LPA10288-01C2 JACK BOARD ASSY UC,US

B4121 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

B4122 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

B4123 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

B4124 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

CN4104 QGB1231M1-09 CONNECTOR DIGITAL

GN4101 QNZ0136-001Z EARTH PLATE

J4112 QNZ0675-001 D CONNECTOR F-DV

Block No. [2][8]

PW1 LPA10281-01C1 DISPLAY BOARD ASSY

IC7001 PT6315 IC

D7021 MTZJ9.1B-T2 Z DIODE

C7001 QCFB1HZ-104Y C CAPACITOR 0.1uF 50V Z

C7002 QCFB1HZ-104Y C CAPACITOR 0.1uF 50V Z

C7003 QEKJ1HM-106Z E CAPACITOR 10uF 50V M

C7007 QCFB1HZ-104Y C CAPACITOR 0.1uF 50V Z

C7008 QEKJ0JM-227Z E CAPACITOR 220uF 6.3V M

C7010 QCFB1HZ-473Y C CAPACITOR 0.047uF 50V Z

C7011 QCFB1HZ-473Y C CAPACITOR 0.047uF 50V Z

Ω

R7001 QRE141J-103Y C RESISTOR 10k

R7002 QRE141J-103Y C RESISTOR 10k

R7003 QRE141J-823Y C RESISTOR 82kΩ 1/4W J

R7005 QRE141J-472Y C RESISTOR 4.7k

R7006 QRE141J-472Y C RESISTOR 4.7k

R7007 QRE141J-102Y C RESISTOR 1kΩ 1/4W J

R7009 QRE141J-103Y C RESISTOR 10k

R7010 QRE141J-103Y C RESISTOR 10k

R7013 QRE141J-333Y C RESISTOR 33kΩ 1/4W J

R7014 QRE141J-333Y C RESISTOR 33k

R7015 QRE141J-102Y C RESISTOR 1k

CN7001 QGB1231L1-13 CONNECTOR B-B (1-13)

CN7002 QGF1208F1-10 CONNECTOR FFC/FPC (1-10)

CN7003 QGF1207C1-10 CONNECTOR FFC/FPC (1-10)

DI7001 QLF0159-001 FL TUBE

HD1 LP21359-001A FL HOLDER(L)

HD2 LP21360-001A FL HOLDER(U)

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

(No.YD058)3-13

Page 14

Packing materials and accessories parts list

ADHESIVE TAPE

Block No.M3MM

13

6

5

4

12

11

2

FINAL ASSY<M1>

7

9

3

2

10

8

3-14(No.YD058)

1

SPEC OF BARCODE

Page 15

Packing and accessories

Symbol No. Part No. Part Name Description Local

1 LP31492-002A PACKING CASE

2 LP31494-001B CUSHION ASSY

3 QPC06005515P POLY BAG 60cm x 55cm

4 QAM0501-003 RF CABLE

5 QAM0522-001 A/V CABLE

6 ------------ BATTERY R6TYPE(x2)

7 QPC02202230P POLY BAG ACCESSORY

8 LPT1013-002B INST. BOOK FRENCH UC

8 LPT1022-001A INST. BOOK ENGLISH UJ

8 LPT1013-001B INST. BOOK ENGLISH UC,US

9 QPC02503530P POLY BAG INST

10 BT-51034-2 REGISTRATION CARD UJ,US

11 RM-SDR027U REMOCON UNIT

12 ------------ WARRANTY CARD BT-52006-2 UC

13 QAM0027-002 CONVERSION PLUG UJ

Block No. [M][3][M][M]

(No.YD058)3-15

Loading...

Loading...