Page 1

OPERATIONS MANUAL

for a

JVC

Pan/Tilt Head

.

Prepared for: JVC Professional Products Company

1700 Valley Road

Wayne, NJ 07470

Document No. D0153

Date: 10 June 2002

Rev: -

Due to design changes and device availability, the information and data presented in this

manual are subject to possible change without prior notice.

Page 2

Table of Contents

1. INTRODUCTION .............................................................................................................................................. 4

2. PAN & TILT HEAD SPECIFICATIONS:....................................................................................................... 5

3. OPERATION ..................................................................................................................................................... 7

3.1 CONTROLLER................................................................................................................................................... 7

3.1.1 RS-422........................................................................................................................................................ 7

3.1.2 RS-232........................................................................................................................................................ 7

3.2 COMPUTER ...................................................................................................................................................... 7

3.3 SYSTEM TEST .................................................................................................................................................. 7

3.3.1 Power “ON” Test ...................................................................................................................................... 7

3.3.2 Pan & Tilt Limit Adjustment ...................................................................................................................... 8

4. SWITCH PANEL, CONTROLS AND INDICATORS ................................................................................ 10

4.1 CONTROLS..................................................................................................................................................... 10

4.1.1 Power Switch ........................................................................................................................................... 10

4.1.2 Setup Switch Pack.................................................................................................................................... 10

4.2 INDICATORS................................................................................................................................................... 12

4.2.1 Power Indicator-Green LED ................................................................................................................... 12

4.2.2 Data Indicator-Red LED ......................................................................................................................... 12

5. CONNECTOR INFORMATION .................................................................................................................... 13

5.1 CONNECTOR PANEL....................................................................................................................................... 13

5.1.1 Lens I/F Connector: NOT USED JVC Configuration ............................................................................. 13

5.1.2 Communications Interface....................................................................................................................... 14

5.1.3 RS-422 Connector.................................................................................................................................... 14

5.1.4 RS-232 Connector.................................................................................................................................... 15

5.1.5 +15 VDC Power Jack .............................................................................................................................. 16

5.1.6 VIDEO ..................................................................................................................................................... 16

5.2 PAN & TILT TRUNNION CONNECTORS ........................................................................................................... 16

5.2.1 Video in .................................................................................................................................................... 16

5.2.2 DIN, 8 pin Circular.................................................................................................................................. 16

5.3 DPT JUMPER INSTALLATION. ........................................................................................................................ 18

6. INSTALLATION.............................................................................................................................................. 19

6.1 TOOLS AND EQUIPMENT NEEDED .................................................................................................................. 19

6.2 STANDARD INSTALLATION............................................................................................................................ 19

6.3 DPT 115 FOOTPRINT DRAWING .................................................................................................................... 21

6.4 MOUNTING TELECONFERENCING LENS ADAPTER.......................................................................................... 22

6.5 BALANCING CAMERA AND LENS ................................................................................................................... 23

2/12/05 Document D0153

2

Page 3

6.6 INVERTED INSTALLATION .............................................................................................................................. 25

6.7 WALL MOUNT INSTALLATION ....................................................................................................................... 26

6.8 TRIPOD INSTALLATION .................................................................................................................................. 27

6.9 CABLING ....................................................................................................................................................... 28

6.9.1 Attach Video Cable, User Equipment ...................................................................................................... 28

6.9.2 Attach 18 Inch Coax Video Cable............................................................................................................ 28

6.9.3 Attach Interface Cable to Pan and Tilt. ................................................................................................... 28

6.9.4 RS-422 Cable Installation........................................................................................................................ 28

6.9.5 RS-232 Cable Installation........................................................................................................................ 29

6.9.6 Power Cable Installation ......................................................................................................................... 29

6.9.7 Lens I/F Connector ................................................................................................................................. 29

Lens Control Cable Installation............................................................................................................................. 29

6.9.8.1 KY-F32 Configuration.....................................................................................................................................29

KY-F55 Configuration.......................................................................................................................................................... 30

DPT 115 LDCC Cable Installation (Used with LDCC Option Only).................................................................... 30

7. TROUBLE SHOOTING ...................................................................................................................................... 31

7.1 PAN & TILT ................................................................................................................................................... 31

7.2 LENS CONTROL ............................................................................................................................................. 31

7.3 LDCC ........................................................................................................................................................... 31

7.4 PRESETS ........................................................................................................................................................ 32

7.5 TECHNICAL SUPPORT..................................................................................................................................... 32

8. CABLE DRAWINGS...................................................................................................................................... 33

8.1 LENS CABLE DRAWING ................................................................................................................................. 33

8.2 PAN & TILT LDCC CABLE DRAWING ........................................................................................................... 34

8.3 RS-422 CABLE DRAWING ............................................................................................................................. 35

8.4 RS-232 CABLE DRAWING ............................................................................................................................. 35

9. SERIAL COMMAND LIST ................................................................................................................................. 36

10. GLOSSARY ....................................................................................................................................................... 37

2/12/05 Document D0153

3

Page 4

1. INTRODUCTION

This document describes the operations of the DPT 115 Digital Pan and Tilt head which is

designed for remote, long distance control requirements. This unit also provides presets for

applications needing camera and lens pre-programmed pan, tilt, zoom, and focus settings.

Applications such as teleconferencing, distance learning, tele-medicine and theater

instrumentation are all ideally suited for a DPT 115 installation. The DPT 115 is a lightweight

pan & tilt head designed to carry a variety of load configurations. The digital design of the

DPT 115 allows flexibility in lens selection and the adaptability necessary for special

requirements. Teleconferencing and CCTV lenses may all be easily interfaced to the versatile

DPT 115. Presets are available on the DPT 115 for pan, tilt, zoom and focus. The resolution of

the presets is 12 bits giving an angular resolution of 0.1 degree. Setup switches located at the

base of the unit make special functions and configuration changes easily implemented. A

family of digital controllers which may control from 1 to 5 DPT 115 Pan & Tilt Heads is

available. The Model 80, Model 88 and Model 180 family of digital controllers was

specifically designed to get the most from a DPT 115.

2/12/05 Document D0153

4

Page 5

2. PAN & TILT HEAD SPECIFICATIONS:

CHARACTERISTICS:

Operating Environment ................................................Indoor

Temperature.................................................................40 to 104 degrees F. (0 to 40 degrees C.)

Pan Rotation ................................................................260 degrees with adjustable limit switches

Tilt Angle ......................................................................+/- 45 degrees with adjustable limit switches

Pan Speed ...................................................................Continuously variable to 15 degrees/second

Tilt Speed .....................................................................Continuously variable to 7.5 degrees/second

Load Mounting..............................................................Side loading with alignment of image plane

and center of rotation

Capacity .......................................................................8 pounds

AN/TILT CONTROL:

P

Pan/Tilt .........................................................................0 to +12 VDC (DC coreless motor)

Presets .........................................................................Yes

Max. distance between controller & p/t head................2,000 feet (Contact ESI for longer distances)

Interface to Controller...................................................RS-422 differential over 4 wire cable

..................................................RS-232 Interface for Controller/computer

control and dual controllers

Special Functions .........................................................Externally accessible DIP switches

ENS CONTROL:

L

Focus ...........................................................................Teleconferencing and CCTV lenses

Zoom ............................................................................Teleconferencing and CCTV lenses

Iris (Optional)................................................................Teleconferencing and CCTV lenses

Multi-Lens Control ........................................................Different lens configurations selected from

Internal Jumper settings

Lens Interface Cable ....................................................Available (see Interface Cable Design Guide)

Presets .........................................................................Zoom & focus

PHYSICAL CHARACTERISTICS:

Size (surface mount) ...................................................4.5 (W) X 7.5 (H) X 3.5 (D) inches

Weight ..........................................................................5 Pounds

Mounting ......................................................................4 mounting holes (1 15/16 x 4 15/16)

P

OWER INPUT REQUIREMENTS:

Voltage .........................................................................+15 VDC unregulated

Current .........................................................................0.8 Amperes

Power ON Switch .........................................................Yes, located on Pan & Tilt base

Power ON Indicator......................................................Yes, located on Pan & Tilt base

Power Adapter..............................................................Supplied with Pan & Tilt head

Power Input ..................................................................From either supplied power adapter

or other appropriate DC power source

2/12/05 Document D0153

5

Page 6

ONNECTORS:

C

RS-422 Serial Interface ................................................4 conductor RJ-11 style

RS-232 Serial Interface ................................................9 pin D connector

Power ...........................................................................DC Jack

Pass through ................................................................8 pin mini- DIN lens pass through connector

Video ............................................................................BNC

2/12/05 Document D0153

6

Page 7

3. OPERATION

This section describes the operation of the DPT 115 and related system components. The DPT

115 receives serial data commands from one of two sources in all applications, a hardware

controller or a computer system. The pan and tilt unit will accept RS-232, RS-422 or both.

Functions of the pan and tilt include manual camera positioning, manual zoom and focus control,

and presets. Presets are stored pan, tilt, zoom, and focus positions that the DPT 115 will return to

automatically when recalled. The preset data is stored within the pan and tilt head. This data is

stored and recalled from the controller or computer system.

3.1 C

ONTROLLER

A controller is a device designed exclusively to provide ASCII serial commands to the pan and

tilt. These units generally have a joystick for up, down, left, and right direction commands. There

will also be some form of seesaw or switch controls for zoom and focus. Switches will also be

provided for preset control. The controller will transmit commands in RS-232 or RS-422

formats.

3.1.1 RS-422

RS-422 format is a balanced four wire interface. The signals are transmit plus, transmit minus,

receive plus, and receive minus. This interface is typically 26 AWG wire with a distance

limitation of 2000 feet.

3.1.2 RS-232

RS-232 format is a three wire single ended interface. The signals are transmit receive, and

ground. This interface is typically 20-24 AWG wire with a distance limitation of 100-200 feet.

3.2 C

OMPUTER

A computer can also be used to provide ASCII serial commands to the pan and tilt. Software

may be written to output the serial command over the serial port to remotely control the pan and

tilt. A computer program is available from the manufacturer that will allow a user to operate the

pan and tilt via the serial port of their personal computer. To obtain a copy of this program call

the manufacturer at the technical support center.

3.3 SYSTEM TEST

3.3.1 Power “ON” Test

Apply power to the pan and tilt electronics by activating the slide switch on the base of the pan

and tilt. The power green power LED should illuminate indicating the unit has DC power. The

red LED will flash once during power up.

2/12/05 Document D0153

7

Page 8

3.3.2 Pan & Tilt Limit Adjustment

The pan & tilt head has separate adjustments for limiting pan-left, pan-right, tilt-up and tiltdown. The adjustment of these limits are described below.

NOTE: These adjustments are to be made after the controller has been interfaced to the DPT

115. The controller will allow one to move the pan & tilt head and check the pan & tilt limits.

Pan Adjustment

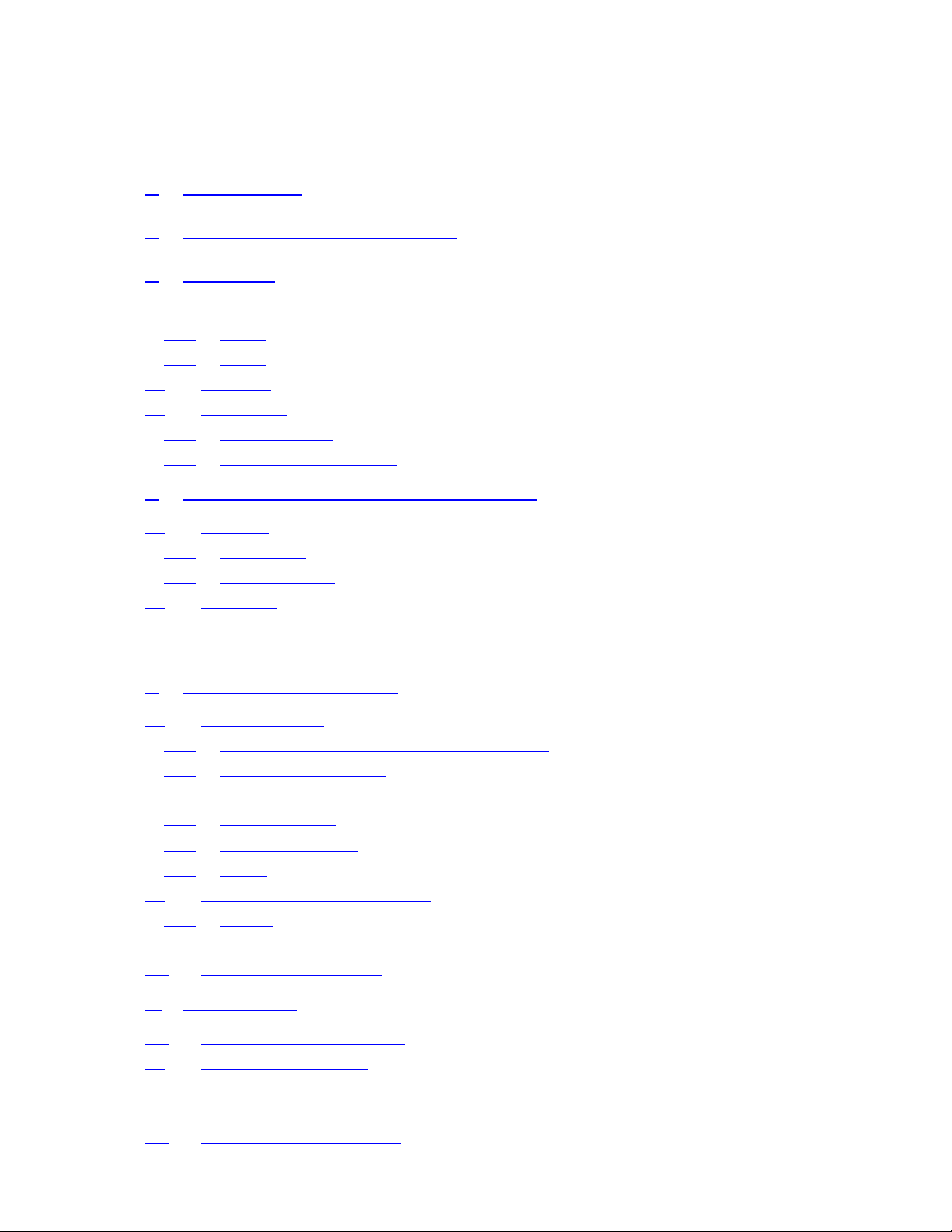

View A illustrates the location of the pan limit

Tilt Vertical

Position Keys

adjustments on the trunnion. To adjust the limit of pan

travel, loosen the “Right Pan Limit Adjustment” screw

and rotate the pan-right limit block to the desired

Video from

Camera

Camera

Mounting

Adjustment

position. Loosen the “Pan-Left Limit Adjustment screw

and rotate the pan-left limit block to the desired

position.

Pan Limit

Switch

Adjustment

With the controller power “ON”, move the joystick in the

pan position. Check the pan-right travel and the pan-left

Video Output

travel. If either limit is still not adjusted properly, repeat

the adjustments described above.

VIEW A

maximum travel by ESI.

NOTE: The pan limit switch adjustments are set at their

2/12/05 Document D0153

8

Page 9

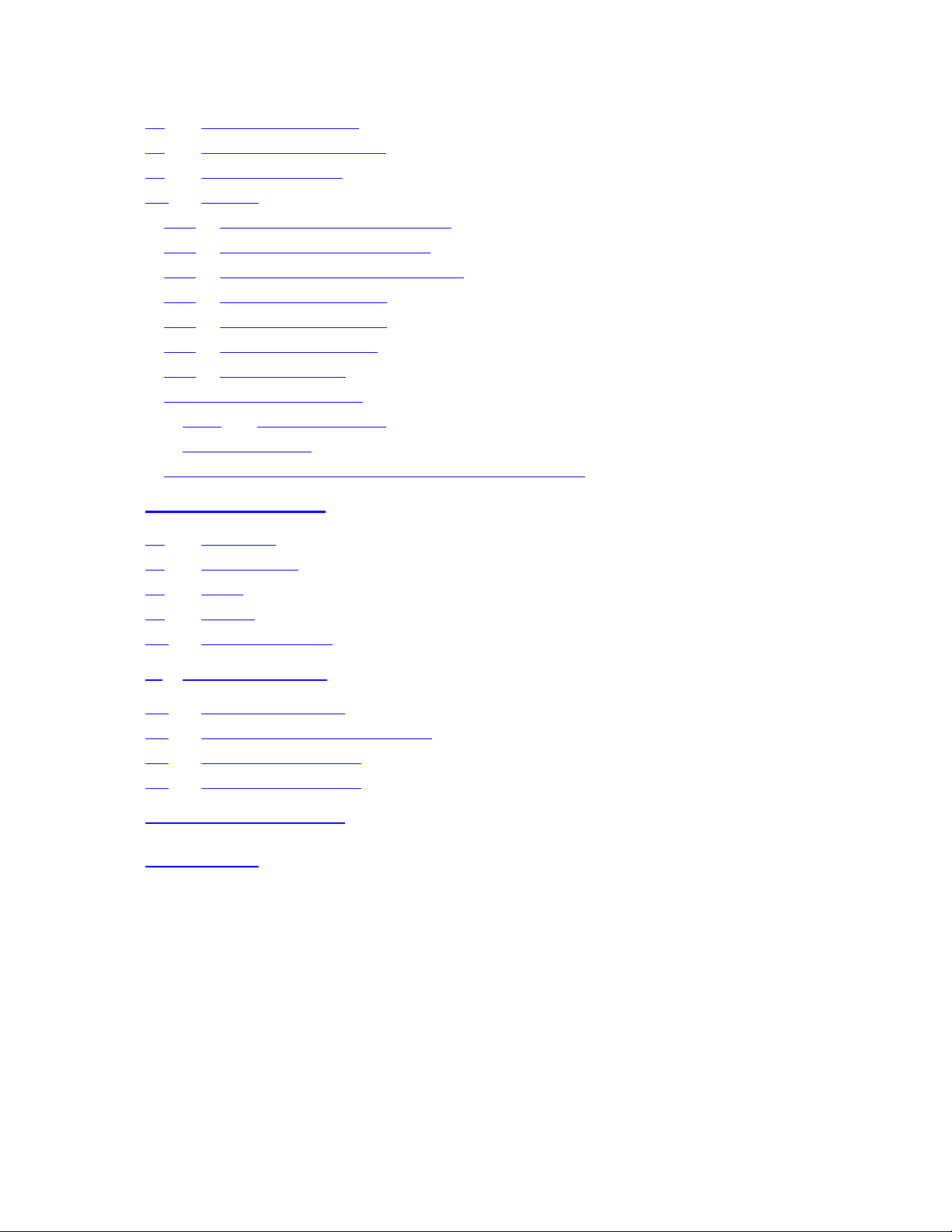

Tilt Adjustment

View B illustrates the location of the Tilt Up and Tilt Down Limit Adjustments. With the camera

mounted on the pan & tilt as shown in Figure 3, turn the system power “ON” and move the

JOYSTICK up until the rear of the camera nears the bottom of the pan & tilt. Make sure the

camera does not hit the pan & tilt when tilted fully up. If it does, DAMAGE COULD BE

Tilt Limit

+

+

Switch

Adjustment

CAUSED TO THE SERVO MOTORS IN THE PAN &

TILT HEAD OR TO THE CAMERA/LENS

-

-

ASSEMBLY. If the camera rear does hit the pan & tilt

head when fully positioned upward, readjust the “Tilt

Limit Switch Adjustment” until the camera rear does not

Video from

Camera

touch the pan & tilt head.

Move the JOYSTICK down until the front of the camera

nears the bottom of the pan & tilt. Make sure the camera

does not hit the pan & tilt when tilted fully down. IF IT

Video Output

DOES, DAMAGE COULD BE CAUSED TO THE

SERVO MOTORS IN THE PAN & TILT HEAD OR TO

VIEW B

THE CAMERA/LENS ASSEMBLY. If the camera front

does hit the pan & tilt head when fully positioned

downward, readjust the “Tilt Limit Switch Adjustment” until the camera front does not touch the

pan & tilt head.

2/12/05 Document D0153

9

Page 10

4. SWITCH PANEL, CONTROLS AND INDICATORS

4.1 CONTROLS

4.1.1 Power Switch

A main power switch is provided at the switch panel of the pan and tilt head. When closed this

small slide switch provides DC voltage from the pan and tilt power supply to the electronics

located within the base of the head. The “POWER” LED will illuminate indicating that power is

applied to the pan and tilt head control electronics. The power switch is “ON” when it is in the

down position.

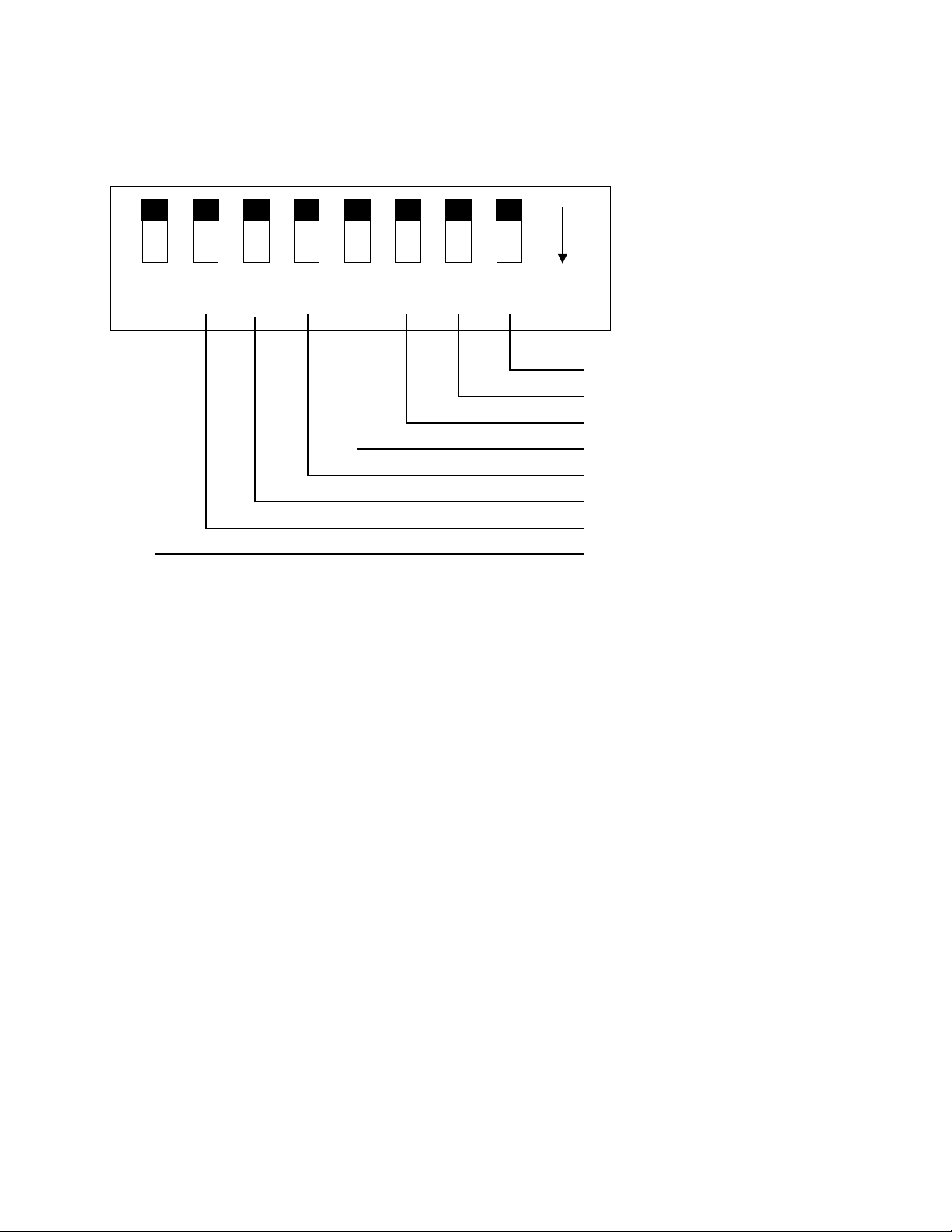

4.1.2 Setup Switch Pack

The eight “SETUP” switches are located adjacent to the power indicator on the pan and tilt

switch panel. These switches are labeled one through eight, the function of these switches are

defined in the diagram on the next page.

2/12/05 Document D0153

10

Page 11

Setup Switches located on the base of the DPT 115

12345678

The Function of each of these switches is as follows:

8, Pan & Tilt Only

• Up: Pan, Tilt, Zoom and Focus Presets are enabled

• Down: Only Pan & Tilt Presets are allowed

7, Teleconferencing Lens

• Up: CCTV Lens

• Down: Teleconferencing Lens

6, Common Return

• Up: Independent Return for Zoom & Focus (4 Wire Control)

• Down: Common Return for Zoom & Focus (3 Wire Control)

5, Reserved

• Up: TBD

• Down: TBD

4, RS-422

• Up: Polls between RS-232 & RS-422 if DIP Switch 3 is also “Up”

• Down: RS-422 Communications only ( If both RS-232 & RS-422 are “DOWN”, LDCC Mode)

3, RS-232

• Up: Polls between RS-232 & RS-422 if DIP Switch 4 is also “Up”

• Down: RS-232 Communications only ( If both RS-232 & RS-422 are “DOWN”, LDCC Mode)

2, 1/2 Manual Speed

• Up: Pan & Tilt has maximum speed capability when manually controlled

• Down: Pan & Tilt has 1/2 maximum speed capability when manually controlled

1, 1/2 Preset Speed

• Up: Pan & Tilt has maximum speed capability when in Preset Mode

• Down: Pan & Tilt has 1/2 maximum speed capability when in Preset Mode

ON

Pan & Tilt Only

Teleconferencing Lens

Common Return

Reserved

RS-422

RS-232

1/2 Manual Speed

1/2 Preset Speed

2/12/05 Document D0153

11

Page 12

4.2 INDICATORS

4.2.1 Power Indicator-Green LED

The Power LED is located adjacent to the power switch on the pan and tilt switch panel. When

the “POWER” LED is illuminated, the power switch is closed and power is applied to the pan

and tilt head control electronics.

4.2.2 Data Indicator-Red LED

The red Data LED is located adjacent to the power switch on top of the power LED on the pan

and tilt switch panel. When the “DATA” LED is illuminated, data is being sent to pan and tilt, or

pan/tilt is in the process of going to a preset.

2/12/05 Document D0153

12

Page 13

5. CONNECTOR INFORMATION

5.1 CONNECTOR PANEL

5.1.1 Lens I/F Connector: NOT USED JVC Configuration

The connector labeled “LENS I/F” on the connector plate is an eight mini DIN female (socket)

type. This connector provides signals to and from the camera lens in special applications.

Internal wiring for this connector can be found on the MPU Module schematic diagram and is

directly wired to the 8 pin DIN connector located on the body of the pan & tilt. This is a

convenient location to monitor control signals to the lens during troubleshooting

DIN Connector Signal Name Lens I/F Connector

Pin Number Pin Number

1 Focus + 1

2 Zoom + 2

3 N/A (Jumper 8 & 9) 3

4 N/A (Jumper 4 & 5) 4

5 N/A (Jumper 6) 5

6 N/A (Jumper 7) 6

7 Ground 7

8 N/A (Jumper 3) 8

Lens I/F Connector – View Looking at DPT Base

2/12/05 Document D0153

13

Page 14

5.1.2 Communications Interface

Control of the pan and tilt is accomplished by sending packets of ASCII characters to the head.

The standard communications protocol is 9600 baud, eight data bits, one stop bit , and no parity.

These commands tell the head and lens which direction and at what rate to move. Preset related

commands are also passed over the communication link between the head and the controller. In

most cases the communications link is either RS-422 or RS-232. The micro-processor in the pan

and tilt head will automatically detect the communication type being received, and select that

communication interface type to transmit data back to the controller. The pan and tilt also has the

provision to use both type interfaces concurrently for special purpose application

The RS-422 communications interface is also used to pass camera control commands to the

camera in the camera control mode (LDCC) for JVC cameras. In this mode the controller sends

the camera commands to the head in RS-422 format on the four wire cable. The commands are

received in RS-422 and converted to TTL levels by electronics in the head. These commands are

the sent out the RS-232 connector via the pan and tilt LDCC cable (P/N ACA96037900) to the

camera. These camera control commands enter the camera on the six pin mini-DIN “REMOTE”

connector on the rear panel of the camera

5.1.3 RS-422 Connector

The connector labeled “RS422” on the connector plate is a six position, four conductor modular

jack. This connector provides differential 0 to +5 VDC voltage signals to and from the digital

pan and tilt head, this is the most common interface from the controller to the heads. Shown

below is the pin-out for the RS-422 connector. The pin assignment for this connector follows:

Pin 1

Not

Used

Pin 2 Pin 5

Pin 6

Not

Used

The pin assignment for this connector follows:

Pin # Description

2 P/T Data Out -

3 P/T Data Out +

4 P/T Data In -

5 P/T Data In +

2/12/05 Document D0153

14

Page 15

5.1.4 RS-232 Connector

The connector labeled “RS232” on the connector plate is a nine pin sub-miniature female

(socket) “D” type. This connector provides data for either the LDCC option or a RS-232

computer interface to the digital pan and tilt head. The pin numbers for the RS-232 connector are

clearly labeled on the connector. Internal wiring for this connector can be found on the MPU

Module schematic diagram. The pin assignment for this connector when used as LDCC option

interface follows:

Pin # Description, LDCC Application

1. SID1 (TTL Data to Camera)

2. N/A

3. N/A

4. Operate

5. Ground

6. N/A

7. N/A

8. N/A

9. SID2 (TTL Data from Camera)

The pin assignment for this connector when used as RS-232 interface follows:

Pin # Description, RS-232 Application

1. N/A

2. RS-232 Transmit Data Out of Pan & Tilt

3. RS-232 Receive Data into Pan & Tilt

4. N/A

5. Ground

6. N/A

7. N/A

8. N/A

9. N/A

2/12/05 Document D0153

15

Page 16

5.1.5 +15 VDC Power Jack

This connector provides the DC power required to operate the pan and tilt head. The connector

type is a Switchcraft 722 series. The outer conductor is for 15 VDC, the center conductor is

ground from the power source. The pan and tilt head requires a power supply capable of a

minimum of .8 amps at 15 DC. The power connection to the pan and tilt head is made via a 5.5

mm X 2.10 mm female DC plug located on the power supply. Caution: the center pin of this jack

is ground. The DC voltage is applied via the outer ring of the DC plug.

5.1.6 VIDEO

The BNC type video connector provides a convenient means to connect the users equipment to

the pan and tilt head. The video source originates at the camera’s system video connector

(“VIDEO OUT”). This video is routed to the trunnion (rotating section of head) of the pan and

tilt via a 18 inch seventy five ohm video connector. The video is routed to the base of the head

using the pan and tilt’s cable wrap technique, which is internal to the rotating mechanism of the

pan and tilt.

5.2 PAN & TILT TRUNNION CONNECTORS

5.2.1 Video in

This BNC type video connector located on the trunnion provides a means to connect the users

camera to the pan and tilt head. Note that this connector is not labeled. The video source

originates at the camera’s video connector (“VIDEO OUT”). This video is routed to the trunnion

of the pan and tilt via a short 18 inch video cable and this connector. The video is routed to the

base of the head using the pan and tilt’s cable wrap technique which is internal to the rotating

mechanism of the pan and tilt.

5.2.2 DIN, 8 pin Circular

This connector which is located on the trunnion adjacent to the video BNC connector provides a

means to connect the camera lens control signals from the pan and tilt head to the camera/lens

assembly. The output pin assignments for this connector are jumper selectable from within the

pan and tilt base. The figure below illustrates the pin lay out for the eight pin circular DIN

connector. Note that this connector is not labeled

8 Pin DIN

Connector

7

6

8

3

1

5

4

2

Mating Connector

View

2/12/05 Document D0153

7

8

3

5

2

Wiring Side

View

6

1

4

16

Page 17

The pin assignments schemes for teleconferencing lenses with preset capabilities are shown in

the table below:

DIN Connector Teleconferencing *

1 Focus

2 Zoom

3 Auto/Manual Iris

4 Iris

5 Zoom Select

6 +5VDC (Lens Sense)

7 Ground

8 N/U

2/12/05 Document D0153

17

Page 18

5.3 DPT JUMPER INSTALLATION.

It will be necessary to disassemble pan and tilt mechanism from base of DPT unit to gain access

to the configuration jumpers on the MPU PWA. The MPU PWA is the top board and will be

accessible as soon as the pan and tilt mechanism is removed. The following steps describe

reconfiguring the jumpers. The equipment necessary for this procedure are a No. 2 Phillips screw

driver a small pair of needle nose pliers and a 2” x 8” x 8” block of some type. Verify the DC

jack providing power to the unit has been removed prior to proceeding.

5. Position the pan and tilt at the parked or normal position. This position is defined as the

camera mounting plate being horizontal to the work surface and the two video BNC

connectors on the pan and tilt being on the same side facing the individual working on

the unit.

6. Remove the four Phillips head screws fastening the pan and tilt mechanism to the base.

7. Position the block directly behind the pan and tilt unit.

8. Remove pan and tilt mechanism by lifting slightly and rotating away from you, this step

will leave the pan and tilt mechanism laying on the side away from the BNC connector

behind the base.

9. The three position jumper posts will now be accessible at the far left corner of the PWA.

10. Place the pan and tilt mechanism back on the base.

11. Replace the four Phillips head screws fastening the pan and tilt mechanism to the base.

2/12/05 Document D0153

18

Page 19

6. INSTALLATION

6.1 TOOLS AND EQUIPMENT NEEDED

• Screwdriver and Mounting Screws: The only tool needed to install the DPT 115 is a

screwdriver for securing the pan & tilt base to its mount.

• #2 Phillips Screwdriver: To be used if access into the Electronics module is required.

• Customer furnished video cable from pan & tilt head to the user monitor.

6.2 STANDARD INSTALLATION

To get optimum performance from any pan and tilt it is important to have the weight of the

camera and lens balanced. This balance assures the pan and tilt will go in the up and down

directions at the same speed. Returning to presets accurately is also achieved when the load on

the pan and tilt is balanced.

To balance the load, determine the balance point of the camera and lens assembly. Mark this

point on the camera/lens with a small piece of tape. Position the camera and lens on the pan and

tilt mounting plate as shown with the center point of the load positioned over the center point of

the mounting plate. Note that in most cases the camera is mounted as far to the rear of the pan

and tilt as possible. In some cases it may not be possible to get the balance and still have the

camera mounting screw on the mounting plate. For these situations see the following sections for

installing and balancing the camera using the teleconferencing lens adapter bracket.

2/12/05 Document D0153

19

Page 20

BALANCE POINT

OF CAMERA & LENS

OVER CENTER OF P/T

JVC 3-CCD

2/12/05 Document D0153

20

Page 21

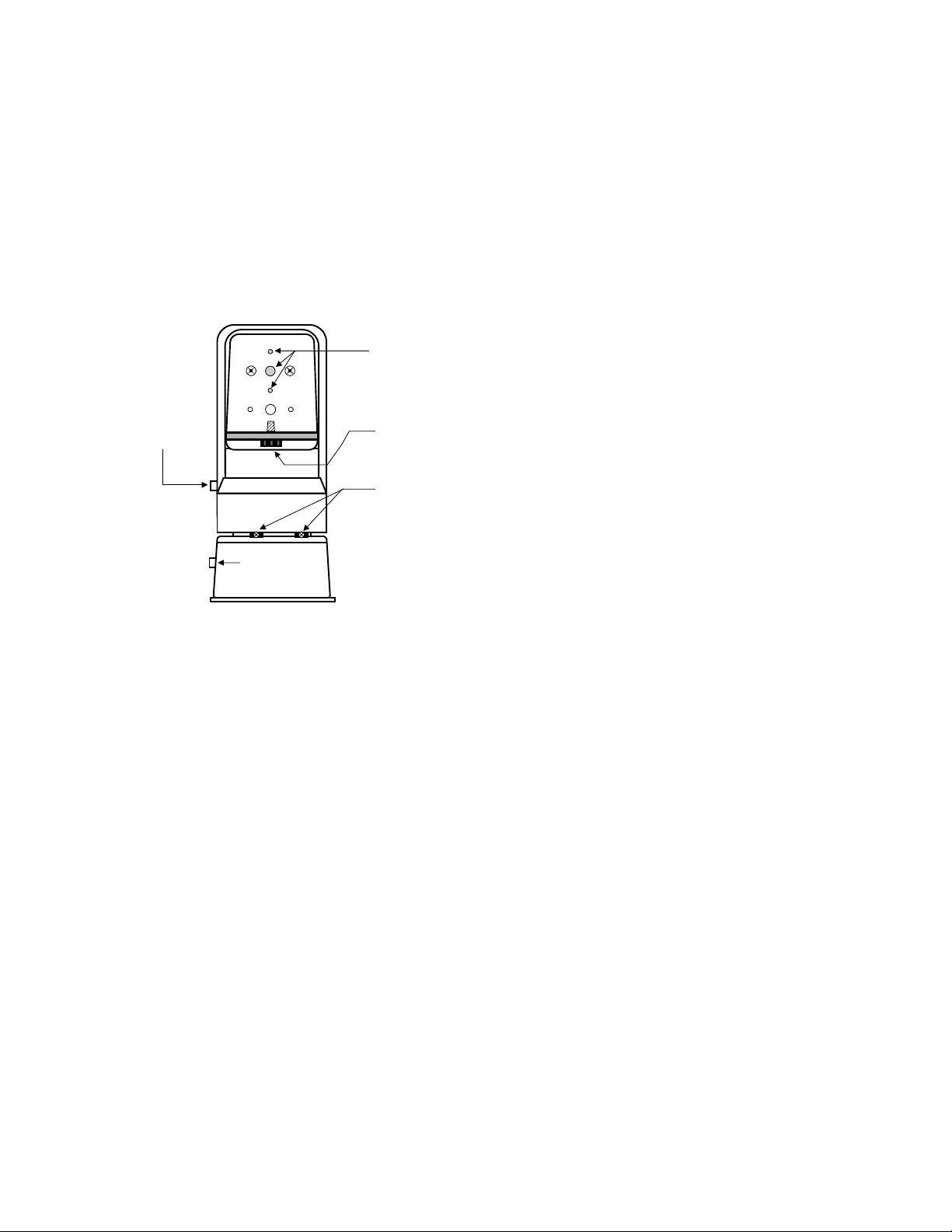

6.3 DPT 115 FOOTPRINT DRAWING

The required hole pattern for securing the pan & tilt head to a mounting surface is a symmetrical

two-inch by five-inch pattern. Four (4) mounting screws are needed to mount the pan & tilt head.

Care is to be taken to mount the pan & tilt in the proper orientation. Note the location of the

connector plate on the base of the pan & tilt head. This surface is the rear of the pan & tilt

assembly. The rear of the trunnion portion of the pan & tilt is the surface with the eight pin

circular DIN connector and the upper of the two BNC (Video) connectors. The pan & tilt head is

to be secured to it’s mounting location using No. 6 or No. 8 screws consistent with the mounting

material. The mounting screws and mounting surface are to be provided by the installer.

Shown below is the physical mounting dimensions for the pan and tilt head. The unit can be

fastened to any flat surface using #8 or #10 wood or machine screws.

5.50 in.

DPT 115

Digital

3.50 in.

Make mounting holes without threads and large enough for a #10 screw

2/12/05 Document D0153

Pan & Tilt

footprint

Front

4.95 in.

21

#10 Mounting

Holes 4 places

1.95 in.

Page 22

6.4 MOUNTING TELECONFERENCING LENS ADAPTER

Mount adapter bracket as shown to camera and lens assembly using ¼-20 screw and appropriate

flat and lock washers. Using this bracket allows the camera and lens assembly to be mounted on

the pan and tilt with the balance point of the weight centrally aligned to the tilt pivot point of the

pan and tilt head.

JVC KY-F32 Camera & Lens

JVC 3-CCD

Teleconferencing Lens Adapter

P/N: WCA97059400

2/12/05 Document D0153

22

Page 23

6.5 BALANCING CAMERA AND LENS

1. Place the camera/lens/adapter plate on a flat surface. Place a pencil or other small round

cylindrical item under the teleconferencing lens adapter plate as shown.

2. Move the camera/lens/adapter plate laterally, both left and right to determine the balance point

of the assembly. This the point at which the assembly would rock easily on the pencil resembling

a seesaw for children.

3. Using a small piece of masking tape or “post it note” mark the balance or pivot point on the

lens.

4. Remove the pencil or pivot item.

BALANCE POINT

JVC 3-CCD

PENCIL

2/12/05 Document D0153

23

Page 24

5. Place the camera/lens/adapter plate on the pan and tilt as shown below. Position

camera/lens/adapter plate assembly such that balance point is located directly over center

point of the tilt axis of the pan and tilt head. Install mounting screw and washers at this

time, Do not tighten.

6. Move the camera/lens/adapter plate assembly to the right (forward) approximately 1/8

inch. The mounting screw should be tightened at this point. Remove the tape marking the

pivot point at this time.

BALANCE POINT

OF CAMERA & LENS

JVC 3-CCD

2/12/05 Document D0153

24

Page 25

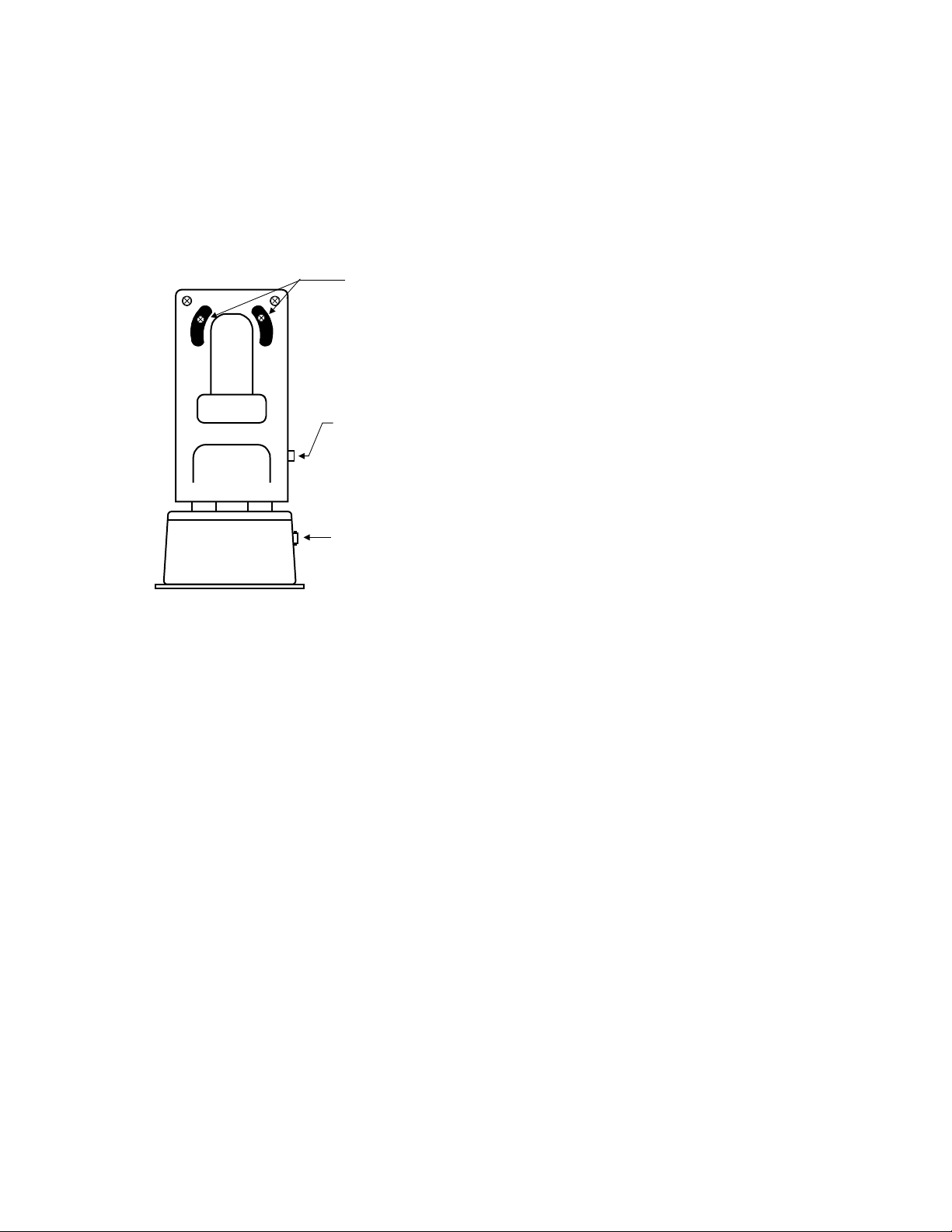

6.6 INVERTED INSTALLATION

The pan and tilt unit may be inverted or hung in certain applications. The teleconferencing lens

adapter bracket is required to provide the necessary clearance between the lens and the side of

the pan and tilt. If the unit is hung the pan left, pan right, tilt up, and tilt down functions will be

backwards for that particular camera station. This condition can be corrected by reversing the

manual controls to the pan and tilt for this particular camera. This operation is done at the

controller. For detailed instructions refer to the Pan/Tilt Controller Manual.

JVC 3-CCD

2/12/05 Document D0153

25

Page 26

6.7 WALL MOUNT INSTALLATION

JVC 3-CCD

4, # 10 FLAT HEADSCREWS

WITH SELF LOCKING NUTS

TRIPOD ADAPTER

PLATE

¼-20 SCREW

LARGE FLAT

LOCK

2/12/05 Document D0153

26

Page 27

6.8 TRIPOD INSTALLATION

2/12/05 Document D0153

27

Page 28

6.9 CABLING

6.9.1 Attach Video Cable, User Equipment

Attach the user’s video cable to BNC on the pan and tilt base. This cable provides the video

interface to the customer equipment from the pan and tilt/camera/lens assembly. This user

provided cable is to be connected between the “VIDEO IN” connector on the customers

equipment and the BNC “VIDEO” connector on the base of the pan and tilt head.

6.9.2 Attach 18 Inch Coax Video Cable

Attach the Video Cable (18 inch coax video cable) between the camera and the pan and tilt

trunnion connectors. The trunnion connector on the rotating section of the pan and tilt head.

Figure 3-1: 18 Inch Video Cable

The 18 inch video cable (P/N ACA95018700) illustrated above provides the video interface from

the camera to the pan and tilt trunnion assembly. This provided short video cable is to be

connected between the “VIDEO OUT” connector on the rear of the camera and the BNC

connector on the trunnion (upper portion) of the pan and tilt head.

6.9.3 Attach Interface Cable to Pan and Tilt.

The interface between the controller or computer and the pan and tilt head is accomplished using

a RS-422 interface cable. The pan and tilt head will automatically be configured for either

voltage interface based on which connector and cable that it is receiving data from.

6.9.4 RS-422 Cable Installation.

This interface is the normal connection to the digital controllers. Figure 3-2 illustrates a typical

RS-422 interface cable. Each camera station in the system must be connected to the controller

via a RS-422 cable. Connect one end of RS-422 to the connector on the rear of the controller or

computer interface. Connect the other end of the cable to the connector on the pan and tilt head

labeled “RS422”. Note: pins 1 and 6 are not used.

ACA96037900

1

2

3

4

5

6

P/T Out -

P/T Out +

P/T In -

P/T In +

Black

Red

Green

Yellow

1

2

3

4

5

6

2/12/05 Document D0153

28

Page 29

6.9.5 RS-232 Cable Installation.

The RS-232 cable provides the control interface between the DPT 115 pan and tilt head and the

controller if an RS-232 interface is desired. Figure 3-3 illustrates a typical RS-232 cable.

P2 P1

Red

3

Black

5

Black

2

White

Red

Black

Black

White

2

5

3

Figure 3-3: Typical RS-232 Cable

Connect the plug (male) end of RS-232 to the nine pin “D” connector on the pan and tilt head.

Connect the other end of the cable to the connector on the RS-232 controller.

6.9.6 Power Cable Installation

Attach the power cord plug on the power supply provided with the pan and tilt head to the DC

jack on the connector panel labeled “POWER”.

6.9.7 Lens I/F Connector

This connector is not used for most applications. No connections should be made to this

connector during normal setup. In the event this connector is to be used a full description will be

provided in the application note for that particular configuration.

Lens Control Cable Installation

6.9.8.1 KY-F32 Configuration

Attach the 8-pin circular DIN male connector of the lens control cable (ACL99088000) to the 8pin female DIN on the trunnion of the pan and tilt. Attach the other end, a male Hirose connector

to the female Hirose on the teleconferencing lens.

At this time there will be one cable on the teleconferencing lens not connected. Plug this male

Hirose connector into the female “LENS” connector on the rear of the KY-F32 camera.

2/12/05 Document D0153

29

Page 30

KY-F55 Configuration

Attach the 8-pin circular DIN male connector of the lens control cable (ACL99088000) to the 8pin female DIN on the trunnion of the pan and tilt. Attach the other end, a male Hirose connector

to the female Hirose on the teleconferencing lens.

At this time there will be one cable on the teleconferencing lens not connected. Plug this male

Hirose connector into the female “LENS” connector on the rear of the KY-F32 camera.

DPT 115 LDCC Cable Installation (Used with LDCC Option Only)

Attach the 9-pin Dsub male connector of the DPT 115 LDCC cable (ACA96052200) to the

“RS232” connector on the base of the pan and tilt. Connect other end, 6-pin male mini-DIN to

“REMOTE” connector on rear of camera.

2/12/05 Document D0153

30

Page 31

7. TROUBLE SHOOTING

7.1 PAN & TILT

Problem: No pan/tilt or lens functions.

Verify proper power is supplied to head.

Verify data is being sent to head.

7.2 LENS CONTROL

Problem: No zoom or focus.

Verify lens control cable is plugged in pan and tilt head.

Verify lens control cable is plugged into correct Hirose cable on lens. Verify the gender of the

connectors. It is possible to mix these up.

Problem: Zoom position returns to previous position when the zoom seesaw is released.

Check set-up switch settings, switch 7 should be down for teleconferencing lens.

7.3 LDCC

Problem: No RCU functions.

Verify the camera is in the “REMOTE” mode. See the camera’s operation manual.

Verify RCU adapter cable is attached to rear panel of controller and RM-LP55.

Verify LDCC cable (P/N: ACA96052200) is attached to “REMOTE” connector on the rear panel of the

camera. Inspect the rubber boot on the six-pin mini-DIN connector; insure that boot did not slide down

barrel of connector preventing a good connection. Verify cable end with 9 pin Dsub is connected to

RS232 connector on base of pan and tilt.

Verify “AUX2” switch is depressed.

Verify configuration of 4 conductor RS-422 interface cable to pan and tilt head. See cable drawing

section.

Verify set-up switches 3 and 4 are in the down (ON) position.

There are several set up items on the controller which will also provide these symptoms. These are listed

in the controller operation manual.

2/12/05 Document D0153

31

Page 32

7.4 PRESETS

Problem: Camera does not return to preset locations consistently.

Verify camera and lens are balanced properly.

Verify cable assemblies do not restrict camera and lens movement.

Problem: Red LED does not extinguish when going to a reset.

Verify camera and lens are balanced properly.

7.5 TECHNICAL SUPPORT

For technical assistance call (321) 956-0095 or go to web site at esi-inc.com. Have serial number of unit

and description of camera and lens on pan and tilt head.

2/12/05 Document D0153

32

Page 33

8. CABLE DRAWINGS

8.1 LENS CABLE DRAWING

FOCUS + (Near Command)

1

ZOOM + (Wide Command)

2

3

4

5

6

7

Auto Iris

IRIS

Zoom Select

+ 5 VDC(Lens Sense)

(POT-) GND

7

6

8

1

5

4

2

PAN

&

TILT

ACL99088000

Red

Yellow

Gray

Orange

Blue

Green

Black

3

CONNECTOR

JACK

7.5 VDC

Focus Select

1

2

10

11

3

4

5

8

9

4

5

2

1

1

1

3

9

1

8

712

6

LENS

REMOTE

CONTROL

2/12/05 Document D0153

33

Page 34

8.2 PAN & TILT LDCC CABLE DRAWING

P1

ACA96052200

P2

1

2

3

4

5

6

7

8

9

1 2 3 4 5

6 7 8 9

9 Pin Male

"D" (Plug)

BLU

RED

GRN

BLK

YEL

SID1 (Data to Camera)

*Operate(To Camera)

Ground

Ground

SID2 (Data from Camera)

5 6

3 4

1 2

5

2

1

3

6

4

View From

Mating Connector

6 Pin Male

Mini-DIN(Plug)

2/12/05 Document D0153

34

Page 35

8.3 RS-422 CABLE DRAWING

2

3

4

5

P/T Tx -

P/T Tx +

P/T Rx -

P/T Rx +

8.4 RS-232 CABLE DRAWING

Black

Red

Green

Yellow

ACA96037900

2

3

4

5

ACA96041600

1

2

3

4

5

6

7

8

9

J1

9 Pin Female

(Model 80)

RED DATA FROM DPT 115

GRN DATA TO DPT 115

BLK

TD

RD

SG

1

2

3

4

5

6

7

8

9

P1

9 Pin Male

(DPT 115)

2/12/05 Document D0153

35

Page 36

9. SERIAL COMMAND LIST

Commands or Actions used to control the DPT 115 Digital Pan & Tilt Head.

Command Letter Hex

Joystick

Up U 55

Down D 44

Left L 4C

Right R 52

Focus

Near N 4E

Far F 46

Zoom

Wide (Speed) W 57

Wide (Position) w 77

Telephoto (Speed) T 54

Telephoto (Position) t 74

Iris

Open O 4F

Close C 43

Auto A 41

Auxiliary

Rotate Right S 53

Rotate Left K 4B

Preset

Preset P 50

Communication

Carriage Return CR 0D

Inquiry ENQ3 B3

2/12/05 Document D0153

36

Page 37

10. GLOSSARY

Base: Bottom portion of the pan & tilt head which does not move.

BNC: A connector type used to interface video sources

CCTV Lens: A lens in which the zoom and focus motors are driven directly from the

DPT 115 lens control electronics.

Controller: The ESI Model 180 Pan & Tilt and Camera/Lens Controller.

DIN: Large circular connector on the trunnion of the pan & tilt head. Mates to the large

circular DIN connector on the ESI furnished W2 connector.

LED: Light Emitting Diode.

Limit Switch: Switches which disengage the electronic drive when the pan & tilt head

reaches a preset position.

MINI DIN: A small circular connector commonly used on cameras. Miniature version of

the DIN connector.

Position Keys: Locators on the Vertical face of the pan & tilt head which allows the “L”

bracket to be located in either of two positions.

Teleconferencing Lens: A lens in which the zoom and focus control electronics are

located within the lens. The DPT 115 supplies a single wire interface to each of the zoom

and focus electronic inputs.

Trunnion: Moveable top portion of the pan & tilt head.

2/12/05 Document D0153

37

Loading...

Loading...