Page 1

No.51831

Aug. 2001

C-N14210

1

COPYRIGHT © 2001 VICTOR COMPANY OF JAPAN, LTD.

Aug. 2001

C-N14210

/S

CONTENTS

!

SPECIFICATIONS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2

!

SAFETY PRECAUTIONS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

3

!

FEATURES

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・

・・・・・・

・・・

4

!

FUNCTIONS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・

・・・・

・・

5

!

SPECIFIC SERVICE INSTRUCTIONS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・

6

!

SERVICE ADJUSTMENTS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

10

!

PARTS LIST

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・

25

★

OPERATING INSTRUCTIONS

★

STANDARD CIRCUIT DIAGRAM

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

2-1

SER VICE MANUAL

COLOR TELEVISION

BASIC CHASSIS

FV4

Page 2

No. 51831

C-N14210

2

SPECIFICATIONS

Items Content

Dimensions (W

××××H××××

D)

14-3/8”×13-1/8”×14-3/4” / 36.4cm×33.4cm×37.4cm

Mass

19.8 Ibs / 9.0 kg

TV System and Color system

TV RF System

Sound System

CCIR(M)

NTSC BTSC System

TV Receiving Channels and Frequency

VL Band

VH Band

UHF Band

(02~06) 54MHz~88MHz

(07~13) 174MHz~216MHz

(14~69) 470MHz~806MHz

CATV Receiving Channels and Frequenc y

Low Band

High Band

Mid Band

Super Band

Hyper Ban d

Ultr a B a nd

Sub Mid Band

TV/CATV To tal Channel

(02~06, A-8 ) by (02~06&01)

(07~13) by (07~13)

(A~1) by (14~22)

(J~W) by (23~36)

(W+1~W+28) by (37~64)

(W+29~W+84) by (65~125)

(A8, A4~A1) by (0 1, 96~99)

180 Channels

Intermediate Frequency

Video IF Carrier

Sound IF Carrier

Color Sub Carrier

45.75MHz

41.25MHz (4.5MHz)

3.58MHz

Antenna Input Impedance

75Ω(VHF/UHF) Terminal, F-Type Connector

Power Input

120V AC, 60Hz

Power Consumpt ion

60W

Picture Tube

14” (34cm) M eas ur ed Diagon al l y

High Voltage

22.5kV±1kV (at zer o b eam current)

Speaker

3-1/16” (8cm) Round type

Audio Power Output

1W

Video Input

1Vp-p, 75

Ω

Audio Input

500mVrms ( -4dBs ), High Impedance

Earphone Jack

3.5mm mono mini jack

Remote Control Unit

RM-C205 (AA / R6 / UM-3 dry battery×2)

Design & specificat ions ar e s ubjec t to change without notice.

(54MHz~804MHz)

Page 3

No.51831

C-N14210

3

SAFETY PRECAUTIONS

1. The design of this product contains special hardware, many

circuits and components specially for safety purposes. For

continued protection, no changes should be made to the original

design unless authorized in writing by the manufacturer.

Replacement parts must be identical to those used in the original

circuits. Service should be performed by qualified personnel

only.

2. Alterations of the design or circuitry of the products should not be

made. Any design alterations or additions will void the

manuf act ur er 's w arranty and wil l fur t h er reli ev e the manufacturer

of responsi bility f or personal inj ury or pr operty dam age resul ting

therefrom.

3. Many electrical and mechanical parts in the products have

special safety-related charact eristics. Thes e characteristics are

often not evident f rom visual i nspection nor can t he protect ion

afforded by them n ecessar ily be obt ained by us ing rep lacem ent

componen ts rated f or higher voltag e, watt ag e, etc. R epl acem ent

parts that have t hese sp eci al safet y c h ar ac t er is tic s are ident if i ed

in the parts list of Service manual.

Electrical components

having such features are identified by shading on the

schemati cs a nd by (

!!!!

) on the parts list in Serv ice manu al.

The use of a s ubstitute repl ac ement which d oes not have the

same saf ety char acteristics as the rec ommended repl ac ement

part show n in the p arts list of S ervic e m anual m ay caus e s hoc k,

fire, or other hazards.

4.

Don't short b etween the LIVE side groun d a nd ISOLATED

(NEUTRAL) side ground or EARTH side ground when

repairing.

Some model's power circuit is partly different in the GND. The

difference of the GND is show n b y the LIVE : (") side GND, the

ISOLATED(NEUTRAL ) : (#) side GND and EARTH : ($) side

GND. Don't short between the LIVE side GND and

ISOLATED(NEUTRAL) side GND or EARTH side GND and

never meas ure with a measuri ng apparatus (osc illoscope etc .)

the LIVE side GND and ISOLATED(NEUTRAL) side GND or

EARTH side GND at the same time.

If above not e wi ll n ot b e kept, a fus e or any part s will be broken.

5. If any repair has been made to the chassis, it is recommended

that the B1 setting should be checked or adjusted (See

ADJUSTMENT OF B1 POWER SUPPLY).

6. The hig h voltage app lied to th e picture tu be must conf orm wit h

that specified in Service manual. Excessive high voltage can

cause an increase in X-Ray emission, arcing and possible

component damage, therefore operation under excessive high

voltag e conditions s hould be k ept to a mi nimum, or should be

prevented. If severe arcing occurs, remove the AC power

immediately and determine the cause by visual inspection

(incorrec t installati on, c racked or m elted high voltage harness,

poor solderi ng, etc.). To main tain the proper min imum level of

soft X-Ray emission, components in the high voltage circuitry

includin g the picture tu be must be the exact replacements or

alternatives approved by the manufacturer of the complete

product.

7. Do not check high voltage by drawing an arc. Use a high voltage

meter or a high voltage probe with a VTVM. Discharge the

picture tube bef ore attempting meter connection, by connect ing

a clip le ad to th e gr oun d fr am e and c on necti ng t h e oth er end of

the lead through a 10k! 2W resistor to the anod e butt on .

8. W hen servic e is required, obser ve the origin al lead dress . Extr a

precaut ion shou ld be gi ven to assure c orrect l ead dress in th e

high voltage circuit area. Where a short circuit has occurred,

those comp onents that in dicate evi denc e of overheating should

be replaced. Always use the manufacturer's replacement

components.

9.

Isolation Check

(Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an isolation

check on the exposed metal parts of the cabinet (antenna

termin als , video/audio input and output term in als , Control kn obs ,

metal cabinet, screw"heads, ear phone jac k, control shafts, etc.)

to be sure the product is safe to operate without danger of

electrical shock.

(1)

Dielectr i c St rength Test

The isol ation b etween th e AC pr imar y circuit and all metal parts

expos ed t o the user , p ar tic u larly any exp osed metal part ha vi ng a

return p ath to the chassis should withst and a voltage of 3 000V

AC (r.m.s .) for a period of one secon d.

(. . . . W ithstand a voltage of 1100 V AC (r .m.s.) to an applianc e

rated up t o 120V, and 3000V AC (r. m.s.) t o an appl iance rat ed

200V or more, f or a peri od of one secon d.)

This method of test requir es test equip ment not gen erally f ound

in the service trade.

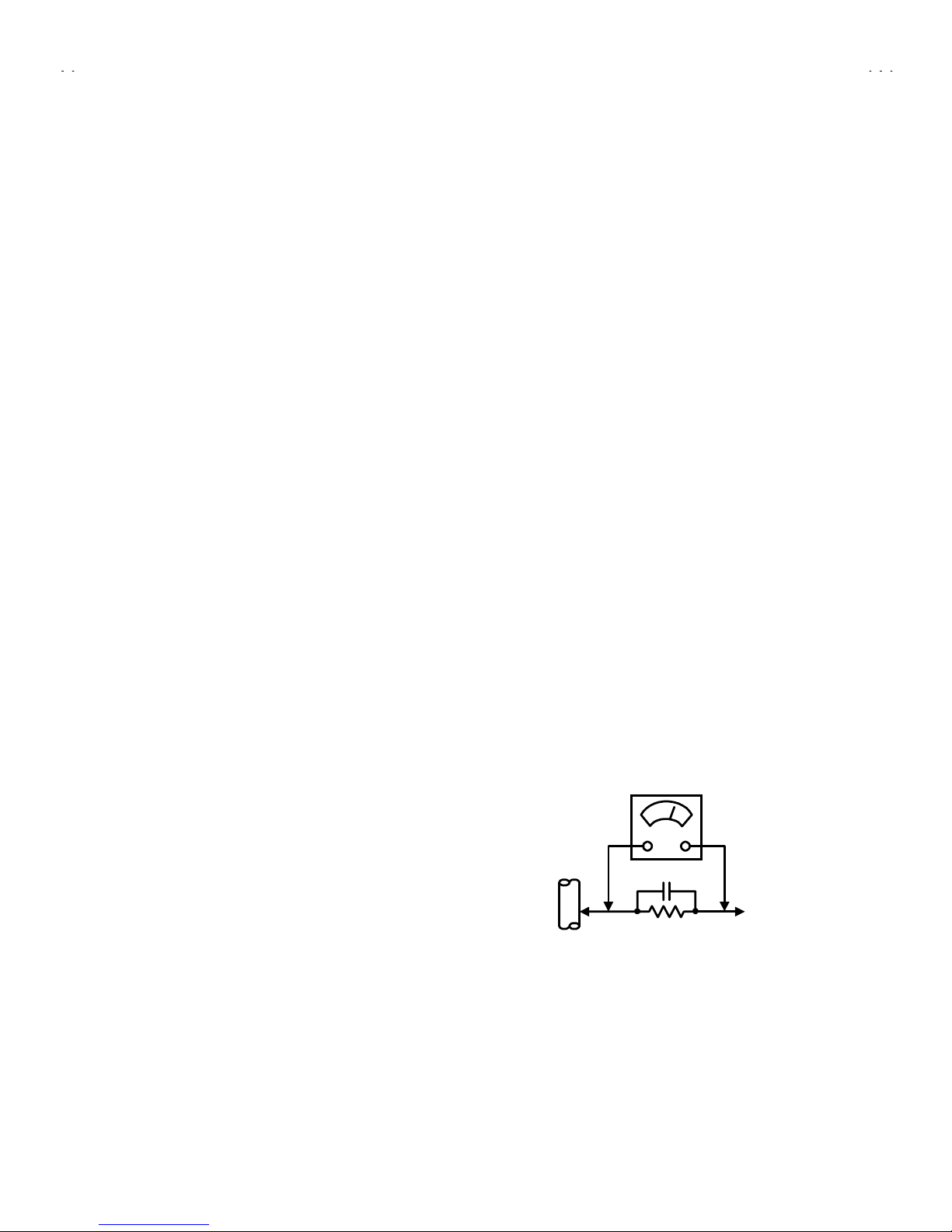

(2)

Leakage Current Check

Plug the AC lin e c or d dir ec tly into the AC outlet ( d o not use a line

isolation transformer during this check.). Using a "Leakage

Current Tester", measure the leakage current from each exposed

metal part of the cabinet, particularly any exposed metal part

having a return path to the chassis, to a known good earth

ground ( water pipe, etc.) . An y leak age c urr ent mus t not exceed

0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

""""

Alternate Check Method

Plug the AC lin e c or d dir ec tly into the AC outlet ( d o not use a line

isolati on transform er during t his check. ). Use an AC voltmet er

having 1000 ohms per volt or more sensiti vity in the following

manner. Connect a 1 500! 10W resistor paralleled by a 0.15#F

AC-typ e capacitor betw een an expos ed metal part and a known

good earth ground (water pipe, etc.). Measure the AC voltage

across the resistor with the AC voltmeter. Move the resistor

connect ion t o each exp os ed met al p art, part icul arl y any exp osed

metal part h avin g a return p ath to th e chassis, and measur e th e

AC voltag e across the resis tor. N ow, re verse th e plug in the AC

outlet and repeat each measurement. Any voltage measured

must not exceed 0.75V AC (r.m.s.). This corresponds to 0.5mA

AC (r.m.s.).

However , in tr opical ar ea, this m us t not exc eed 0.3V AC ( r . m.s . ).

This corresponds to 0.2mA AC (r.m.s.).

0.15μF AC-TYPE

1500

!

10W

GOOD EARTH GROUND

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

AC VOLTMETER

(HAVING 1000

!

/V,

OR MORE SENSITIVITY)

Page 4

No. 51831

C-N14210

4

FEATURES

"

New chassis design enables use of a single board with simplified

circuitry.

"

Provided wi th miniature tuner (T V/ CA T V ).

"

Multifunctional remote control permits picture adjustment.

"

Adoption of the CHANNEL GUARD function prevents the

specific ch annels from being selec t ed, un l ess t he “ID nu m ber” is

key in.

"

Adoption of the VIDEO ST ATUS function.

"

Adoption of the ON/OFF TIMER function.

"

With 75ΩV/U in common (F-Type) ANT Terminal.

"

SLEEP TIMER for setting in real time.

"

Closed-caption broadcasts can be viewed.

"

Audio Video input terminal.

"

Built-in V-CHIP system.

Page 5

No. 51831

C-N14210

5

FUNCTIONS

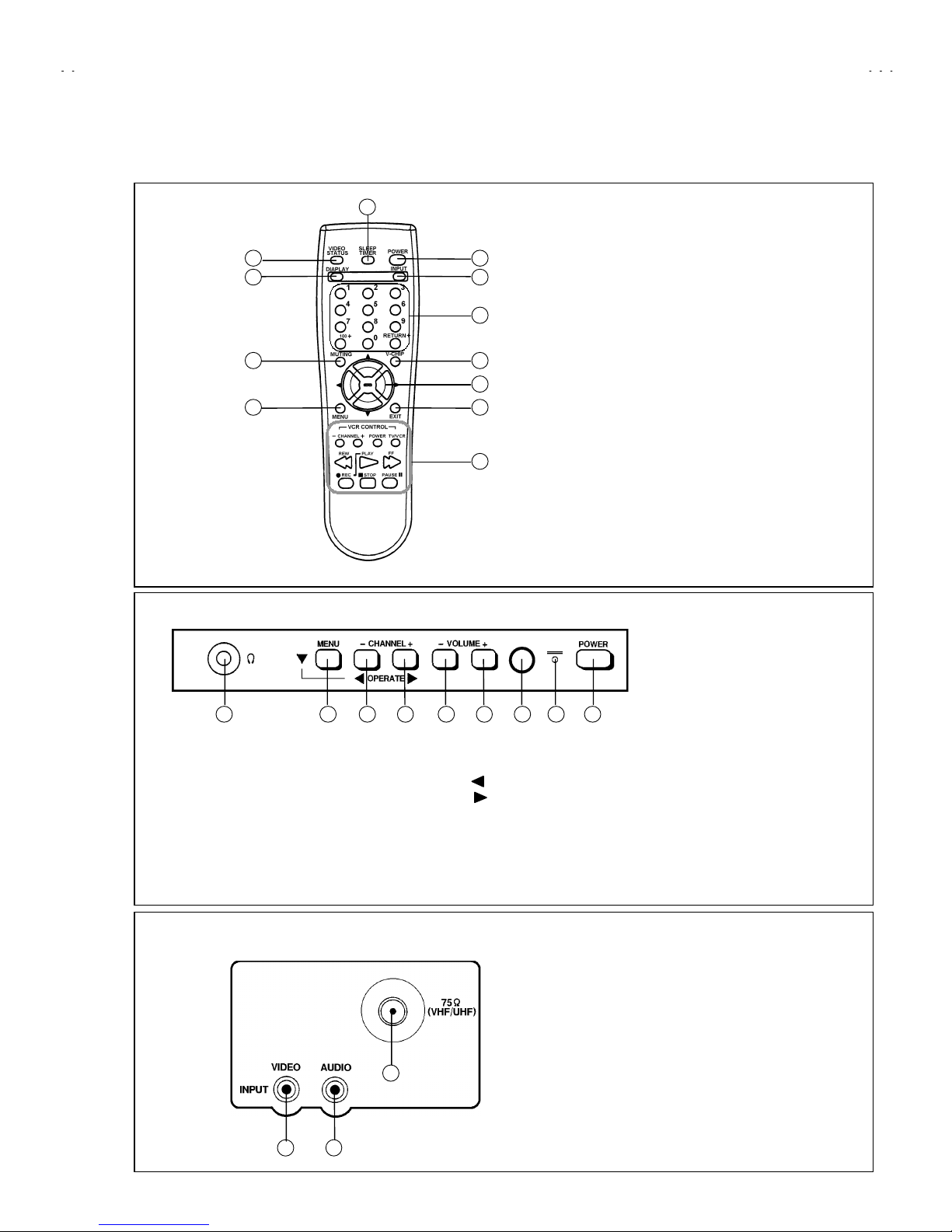

■■■■

REMOTE CONTROL UNIT

■■■■

FRONT PANEL

■■■■

REAR PANEL

①

Headphone terminals

②

MENU button

③

CHANNEL - (Operate ) button

④

CHANNEL + (Operate ) button

⑤

VOLUME - button

⑥

VOLUME + button

⑦

Remocon window

⑧

Indicator lamp (TIMER / POWER)

⑨

POWER

button

①

VIDEO(INPUT) terminal

②

AUDIO(INPUT) terminal

③

Antenna terminal

①

VIDEO STATUS key

②

DISPLAY keys

③

MUTING key

④

MENU key

⑤

POWER key

⑥

INPUT SELECT key

⑦

CHANNEL key

⑧

V-CHIP key

⑨

FUNCTION key

⑩

EXIT key

⑪

SLEEP TIMER key

⑫

VCR CONTROL keys

1 2 3 4 5 6 7 8 9

1 2

3

1

2

3

4

5

6

7

8

9

10

11

12

Page 6

No. 51831

C-N14210

6

SPECIFIC SERVICE INSTRUCTIONS

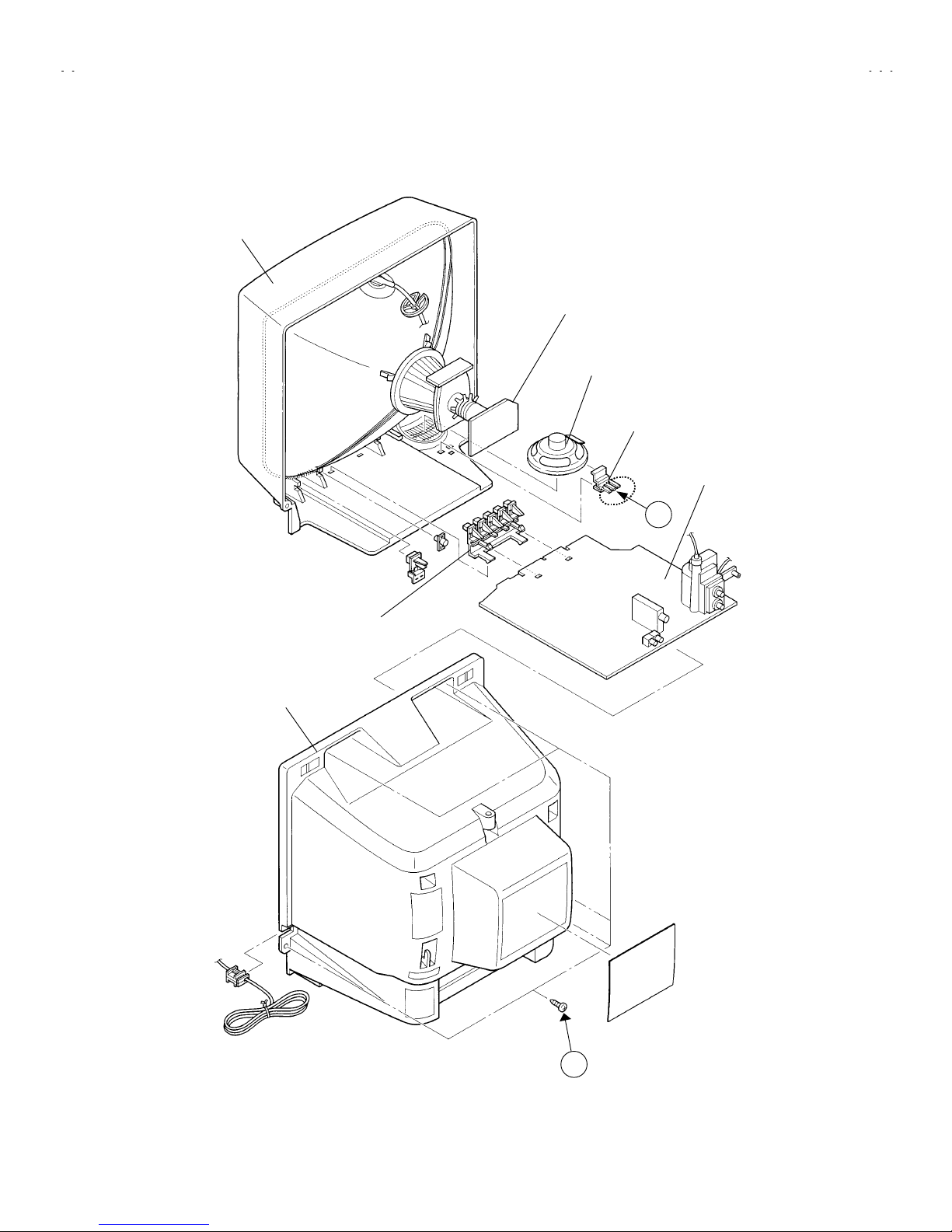

DISASSEMBLY PROCEDURE

REMOVING THE REAR COVER

1. Unplug the power supply cord.

2. Remove the 5 screws marked

!!!!

as shown in Fig.1.

3. Withdraw the REAR COVER toward you.

[CAUTION]

•

When reinstalling the rear cover, carefully push it inward after

inserting the MAIN PWB into the rear cover groove.

REMOVING THE MAIN PW BOARD

1. Slightly raise the both s i d es of t he MAIN PW Board b y han d and

withdraw the MAIN PW Board backward.

(If necessary, t ak e off th e wir e cl am p an d c onnectors , etc .)

REMOVING THE SPEAKER

• After removing the MAIN PW board.

1. B y holding up th e SPEAKER HOLDER mark ed

""""

slightl y and

unlocking the cl aw, the SPEAKER HOLDER c an be removed.

Then you can remove the SPEAKER.

CHECKING THE MAIN PW BOARD

1. To c h eck th e backs id e of the MAIN PW Board.

1) Pull out the MAIN PWB. (Refer to REMOVING THE MAIN

PWB).

2) Erect th e chassis ver tically so th at you can eas ily check t he

backside of the MAIN PW Board.

[CAUTION]

•

When erecting the MAIN PWB, be careful so that there will be no

contact i ng wit h ot her P W Board.

•

Before t ur ning on p ower, m ak e s ure th at t he CRT earth wire and

other connectors are properly connected.

WIRE CLAMPING AND CABLE TYING

1. Be sure clamp the wire.

2. Never remove the cable tie used for tying the wires together.

Should i t b e inad vertent l y removed, be sur e t o t ie the wires with

a new cable tie.

Page 7

No. 51831

C-N14210

7

FRONT CABINET

CRT SOCKET PWB

(Within MA IN PWB)

SPEAKER

REAR COVER

SPEAKER HOLDER

Fig.1

A

B

CONTROL KNOB

MAIN PWB

Page 8

No. 51831

C-N14210

8

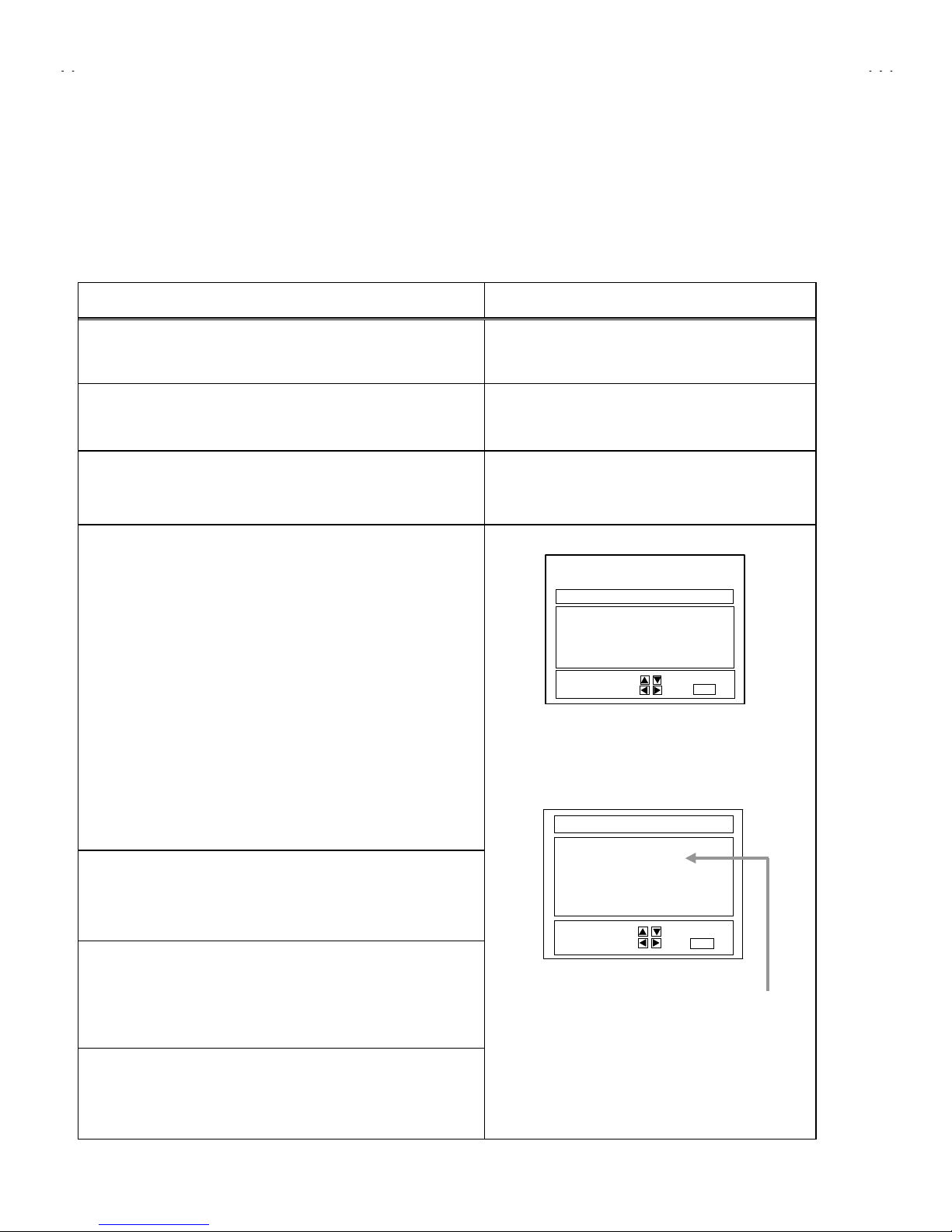

MEMORY IC REPLAC EMENT

1. Memory I C

This model uses a memory IC.

This memory IC stores data for proper operation of the video and deflection circuits.

When replacing, be sure to use an IC containing this (initial value) data.

2. Memory I C replacement procedure

Procedure Screen display

(1) Power off

Switch off th e pow er and disc onn ec t t h e pow er c ord f r om t h e out l et .

(2) Replace the memory IC

Initial val u e mus t b e ent ered into th e new IC .

(3) Power on

Connect the power cord to the outlet and switch on the power.

(4) System constant ch eck and setting

1) Press

SLEEP TIMER

key and, while the ind icati on of “

SLEEP 0 M IN.

”

is being displ ayed, press

DISPLAY

key and

VIDEO STAT US

key on

the remote control unit simultaneously.

2) The SERVICE MENU screen of Fig.1 is displayed.

3) While the S ERVICE MENU is dis played, again simul taneously press

the DISPLA Y and VIDEO S TAT US keys to disp lay the Fi g.2 SYST EM

CONSTANT screen.

4) Refer to t he S YSTEM C ONST ANT t able and ch eck th e settin g it ems.

Where thes e dif fer, s elect t he s etting item w ith th e MENU UP/DO W N

key and adjust the setting with t he MENU LEFT/RIGHT keys. (The

letters of the selected item are displayed in yellow.)

5) After adjusting, release the MENU LEFT/RIGHT key to store the setting

value.

6) Press the EXIT key twice to return the normal screen.

(5) Receive channel setting

Refer to the OPERATING INSTRUCTIONS (USER'S GUIDE) and s et

the receive channels (Channels Preset) as described.

(6) User settings

Check the user setting items according to Table 2.

Where these do not agree, refer to the OP ERATING INSTRUCTIONS

(USER'S GUIDE) and set the items as described.

(7) SERVICE MENU setting

Verify what to set in the SERVICE MENU, and set whatever is

necessary.(Fig.1) Refer to the SERVICE ADJUSTMENT for setting.

SYSTEM CONSTANT

MODEL :

*******

**************

*******

V-CHIP : YES

CAN V-CHIP : YES

********-*****

********-*************-*****

********-*****

SELECT BY EXIT BY

OPERATE BY EXIT

Fig.2

SERVICE MENU

PICTURE

GAME

LOW LIGHT HIGH LIGHT

RF AFC CHK

VCO

(CW)

SELECT BY EXIT BY

OPERATE BY EXIT

Fig.1

Indicate the model name

Page 9

No. 51831

C-N14210

9

TABLE 1 (System Constant setting)

Setting item Setting content Setting value

MODEL Display th e eac h applic ation model C onf or m abl e m od el n ame

V-CHIP YES

CAN V-CHIP YES

TABLE 2 (User setting value)

Setting item Setting value

1. Use remote controller keys

POWER

CHANNEL

CHANNEL PRESET

VOLUME

INPUT (TV/VIDEO)

OFF

CH 02

See OPERATING INSTRUCTIONS.

10

TV

DISPLAY

SLEEP TIMER

VIDEO STATUS

OFF

0

STANDARD

2. Settin g of MEN U

TINT

COLOR

PICTURE

BRIGHT

DETAIL

CENTER

CENTER

CENTER

CENTER

CENTER

NOISE MUTING

SET VIDEO STATUS

ON

ALL CENTER

SET CLOCK

ON/OFF TIMER

LANGUAGE

CLOSED CAPTION

BACK GROUND

Unnecessary to set

NO

SPANISH

OFF

BLACK

AUTO TUNER SETUP

CHANNEL SUMMARY

V-CHIP

SET LOCK CODE

TUNER MODE : AIR

Unnecessary to set

OFF

Unnecessary to set

YES NO

YES NO

Page 10

No. 51831

C-N14210

10

SERVICE ADJUSTMENTS

ADJUSTMENT PREPARATION

1. You can make the necessary adjust ments for this unit with

either the Remote Control Unit or With th e adjustme nt tools

and parts as given below.

2. Adjustment with the Remote Control Unit is made on the

basis of the initial setting values, however, the new setting

values wh ich set the scree n t o its optimu m condition may

differ from the initial settings.

3. Make sure that AC power is turned on correctly.

4. Turn on the power for set and test eq uipment before us e, and

start the adjustmen t procedur es after waitin g at leas t 30 mi nutes.

5. Unless otherwis e specif ied, prep are the m ost suit able rec eption

or input signal for adjustment.

6. N ever touc h any adj ustm ent par ts which are not s pecif ied in t he

list for this adjustment - variable resistors, transformers,

condens er s , etc .

7. Presetting b ef or e ad jus t m ent.

Unless oth erwis e specif ied in th e adjustm ent ins tructi ons, p reset

the following functions with the remote control unit:

VIDEO STATUS STANDARD

TINT/COLOR

PICTURE/BRIGHT

DETAIL

CENTER

ADJUSTMENT EQUIPMENT

1. DC voltmeter (or digital voltmeter)

2. Oscilloscope

3. Signal generator (Pattern generator)[NTSC

]

4. Remote control unit

5. TV audio multiplex s ignal generator.

6. Frequency counter

ADJUSTMENT ITEMS

Adjustment items Adjustment items

B1 POWER SUPPLY

WHITE BALANCE

(Low Light )

IF VCO

WHITE BALANCE

(High Light)

RF. AGC SUB BRIGHT

FOCUS SUB CONTRAST

V. SIZE SUB COLOR

H. POSITION SUB TINT

ADJUSTMENT LOCATIONS

MAIN PWB

S756

FRONT

POWER

INDICATOR LAMP

(TIMER / POWER)

REMOCON

RECEIVER

VOL

+

-

CH

+

-

MENU

IC702

IC701

PW

F901

IC201

T131

T161

DEG

CW

T

TUNER

X

U

C

HV

IC921

TP-E

( )

T522

UPPER : FOCUS

LOWER : SCREEN

TP-91

(B1)

R926

F902

VIDEO

IN

CW

TOP

CRT SOCKET PWB

(SOLDE R SIDE)

(W ithin MAIN PWB ASS'Y )

TP-E

U

T

TP-R

CRT EARTH

(BRAIDED ASS'Y)

E1

AUDIO

IN

TP-12B

S

MEMORY

Page 11

No. 51831

C-N14210

11

BASIC OPERATION SERVICE MENU

1.

TOOL OF SERVICE MENU OPER ATION

Operate the SERVICE MENU with the REMOTE CONTROL UNIT.

2.

SERVICE MENU ITEMS

In general, basic setting (adjustments) items or verifications are performed in the SERVICE MENU.

"

PICTURE

・・・・・・・・・・・・・・・・・・・・

This sets the setting values (adjustment values) of the VIDEO/CHROMA and DEFLECTION circuits.

"

GAME

・・・・・・・・・・・・・・・・・・・・・・・

This is used when the GAME MODE is adjusted.

"

LOW LIGHT

・・・・・・・・・・・・・・・・・・

This sets the setting values (adjustment values) of the WHITE BALANCE circuit.

"

HIGH LIGHT

・・・・・・・・・・・・・・・・・

This sets the setting values (adjustment values) of the WHITE BALANCE circuit.

"

RF AFC CHK

・・・・・・・・・・・・・・・・・

This is used when the IF VCO is adjusted.

[Do not adjust]

"

VCO (CW)

・・・・・・・・・・・・・・・・・・・

This is used when the IF VCO is adjusted.

3. Basic Opera tions of the SER VI C E M EN U

(1) How to enter the SERVICE MENU.

Press

SLEEP TIMER

key and, while the ind ication of “

SLEEP TIM ER 0 MIN.

” is being displayed, press

DISPLAY

key and

VIDEO

STATUS

key on the remote control unit simultaneously to enter the

SERVICE MENU

screen ① shown in the next figure page.

(2) SERVICE MENU screen selection

Press the UP / DOWN key of the MENU to select any of the following items.

(The lett ers of t h e sel ec t ed it ems are disp l ayed in y ell ow .)

●

PICTURE

●

GAME

●

LOW LIGHT

●

HIGH LIGHT

●

RF AFC CHK

●

VCO(CW)

(3) Enter the any setting ( adjustment ) mode

"

PICTURE mode

1) If select any of PIC TU RE item , and th e LE FT / RIG HT key is press ed f r om SER VICE ME NU ( MA IN MENU ) , th e sc reen ② will be

displayed as shown in figure page later.

2) Then the UP / DOWN key is pressed, the PICTURE mode screen ③ is displayed, and the PICTURE setting can be performed.

"

GAME, LOW LIGHT, HIGH LIGHT, RF AFC CHK and VCO (CW) mode

1) If selec t an y of GA ME / LOW LI GHT / HIG H L IGHT / RF AFC C H K / V CO (CW) items, and t h e LEFT / RIG HT ke y is press ed f rom

SERVICE MENU ( MAIN MENU ), the screens ④ ⑤ ⑥ ⑦ ⑧ will be displayed as shown in figure page later.

2) Then the settings or ver ifications c an be perform ed.

Page 12

No. 51831

C-N14210

12

SERVICE MENU

SELECT BY

OPERATE BY

EXIT BY

IT

PICTURE

GAME

LOW LIGHT HIGH LIGHT

RF AFC CHK

VCO

(CW)

EXIT

SELECT BY

EXIT BY

IT

EXIT

BRIGHT

EXIT BY

IT

BRIGHT

EXIT

***

******

***

*** *** ***

*** *** ****** *** ***

*** *** ***

SELECT BY

OPERATE BY

EXIT BY

IT

1. BRIGHT

EXIT

STATUS

***

******

***

********

****************

********

EXIT BY

IT

HIGH LIGHT

EXIT

***

******

***

EXIT BY

IT

TOO HIGH

ABOVE REFERENCE

BELOW REFERENCE

TOO LOW

SYNC : YES

EXIT

SELECT BY

OPERATE BY

EXIT BY

IT

RF AFC

FINE

STATUS

EXIT

①①①①

SERVICE MENU (MAIN MENU)

②②②②

SCREEN

⑥⑥⑥⑥

HIGH LIGHT MODE

***

******

***

⑧⑧⑧⑧

VCO (CW) MODE

④④④④

GAME MODE

SELECT BY

OPERATE BY

EXIT BY

IT

TINT

COLOR

PICTURE

BRIGHT

DETAIL

EXIT

***

******

***

***

******

***

***

******

***

***

******

***

***

******

***

⑦⑦⑦⑦

RF AFC CHK MODE [DO NOT ADJUST]

ON

********

****************

********

⑤⑤⑤⑤

LOW LIGHT MODE

③③③③

PICTURE MODE

***

******

***

Page 13

No. 51831

C-N14210

13

(4) Setting method

1) UP / DOWN key of the MENU

Select the SETTING ITEM.

2) LEFT / RIGHT key of the MENU

Setting(adjust) the SETTING VALUE of the SETTING ITEM.

When th e key is rel eased the SET TING VALUE will b e st ored

(memorized).

3) EXIT key

Return t o the previous sc reen.

(5) Releasing SERVICE MENU

1) After returni ng to the SERVICE M ENU upon completi on of the

setting (adjustment) work, press the EXIT key again.

★

The settin gs f or LOW LIGHT and HIGH LIGHT are d escrib ed in t he

WHITE BALANCE page of ADJUSTMENT .

★

The setting for VCO(CW) are described in the IF VCO page of

ADJUSTMENT.

SELECT BY

OPERATE BY

EXIT BY

IT

1. BRIGHT

EXIT

STATUS

***

******

***

********

****************

********

PICTURE MODE

INITIAL

SETTING VALUE

↓ (Adjust)

SETTING VALUE

SETTING

ITEM

SELECT BY

OPERATE BY

EXIT BY

IT

TINT

COLOR

PICTURE

BRIGHT

DETAIL

EXIT

***

******

***

***

******

***

***

******

***

***

******

***

***

******

***

GAME MOD E

The letter of the selected

Items are dis p layed in yell ow .

Page 14

No. 51831

C-N14210

14

INITIAL SETTING VALUE OF SERVICE MENU

1. Adjustment of the SERVICE MENU is made on the basis of the initial setting values; however, the new s etting values which set the screen

in its optimum condition may differ from the initial setting.

2. Do not change the initial setting values of the setting (Adjustment) items not listed in “ADJUSTMENT”.

""""

PICTURE MODE

#

The four settin g it ems in t he vid eo mode No.7 E XT BR I ., No.8 E XT P IC., No.11 E XT TINT and N o.12 EXT COL . ar e li nk ed to the items in

the TV MODE No.1 BRIG HT, No.2 PICTURE , No.5 TINT and No.6 COLO R, respectivel y. W hen the setting items in the TV mode are

adjust ed, the values i n the set t in g items in the vid eo mode are revis ed au t omaticall y to th e same valu es in the T V m od e. (The initial setting

values given in ( ) are off-set values.)

#

When the f our items ( No.7, 8, 11 and 12) are adjusted in the vid eo mode, the s etti ng values in eac h item are revis ed in d ependently.

No. Setting (Adjustment) items Variable range initial setting value

1. BRIGHT

0 ~ 127

64

2. PICTURE

0 ~ 127

60

3. TV DTL(TV DETAIL)

0 ~ 63

23

4. TV BPF(TV B.P.FILTER) 0 / 1 0

5. TINT

0 ~ 127

57

6. COLOR

0 ~ 127

55

7. EXT BRI.(EXT.BRIGHT)

±

25

(-2)

8. EXT PIC.(EXT.PICTURE)

±

25

(-2)

9. EXT DTL(EXT.DETAIL)

0 ~ 63

25

10. EXT BPF( EXT.B.P.FILTER) 0 / 1 0

11. EXT TINT

±

25

(+9)

12. EXT COL.(EXT.COLOR)

±

25

(+3)

13. V SIZE

0 ~ 63

20

14. V CENT.(V.CENTER)

0 ~ 7

0

15. H POS.(H.POSITION)

0 ~ 31

20

16. OSD HP (OSD H POSITION)

0 ~ 31

23

17. OSD VP (OSD V POSITION)

0 ~ 15

14

18. H AFC 0 / 1 0

19. RF AGC

0 ~ 63

40

20 OSC SEL 0 / 1 0

Page 15

No. 51831

C-N14210

15

"

GAME MODE

Setting (Adjustment) item Variable range initial setting value

TINT

±

20

±

0

COLOR

±

20

±

0

PICTURE

±

20

-10

BRIGHT

±

20 -2

DETAIL

±

15

+10

"

LOW LIGHT MODE

Setting (Adjustment) item Variable range initial setting value

R CUTOFF

G CUTOFF

B CUTOFF

0 ~ 255

0 ~ 255

0 ~ 255

20

20

20

"

HIGH LIGHT MODE

Setting (Adjustment) item Variable range initial setting value

G DRIVE

B DRIVE

0 ~ 255

0 ~ 255

128

128

"

RF AFC CHECK MODE

Setting (Adjustment) item Variable range initial setting value

RF AFC

FINE

ON / OFF

-77 ~ +77

ON

±××

DO NOT

ADJUST

Page 16

No. 51831

C-N14210

16

ADJUSTMENTS

B1 POWER SUPPLY

Item

Measuring

instrument

Test point Adjustment part Description

Check of

B1 POWER

SUPPLY

DC Voltmeter TP-91 (B1)

TP-E(

""""

)

1. Receive a black- and-white signal.

2. Connect the DC Volt m eter to TP- 91 (B1) and TP-E(

""""

) (See the

page of Adjustment Locations).

3. Confirm that the voltage is DC134V

ADJUSTMENT OF VIDEO / DEF. CIRCUIT

Item

Measuring

instrument

Test point Adjustment part Description

IF VCO

adjustment

Signal

generator

CW TRANSF. (T131)

[VCO(CW)] MODE

"

Und er n orm al c onditions, no adjustm ent is r equ ired.

1. Receive a NTSC broadcast. (use channels without offset

frequency).

2. Select the VCO(CW) mode from the SERVICE MENU.

3. Confirm the color change (yellow) from “TOO HIGH” to “TOO

LOW”by CW TRANSF. and “SYNC : YES” being shown on

the screen. Then, adjust CW TRANSF. until “BELOW

REFERENCE” mark turns yellow and confirm again “ SYNC :

YES” being s hown on the sc r een.

RF. AGC

adjustment

No.19 RF AGC

1. Rec eive a br oadcast.

2. Select “No.19 RF AGC” of the PICTURE MODE.

3. Press the MUTE key and turn off color.

4. With th e MENU LEFT key, g et noise in t he screen p icture. ( 0

side of sett in g value)

5. Press the MENU RIGHT key an d stop when no ise dis appears

from the screen.

6. Change to other channels and make sure that there Is no

irregularity.

7. Press the MUTE key and get color out.

FOCUS

adjustment

Signal

generator

FOCUS VR

[In HVT]

1. Receive a crosshatch signal.

2. While looking at the screen, adjust FOCUS VR so that the

vertic al and hor i z ont al lines will be clear and in f in e det ail.

3. Make sure that the picture is in focus even when the screen gets

darkened.

+2V

-2.5V.

EXIT BY

IT

TOO HIGH

ABOVE REFERENCE

BELOW REFERE NCE

TOO LOW

SYNC : YES

EXIT

YELLOW

Page 17

No. 51831

C-N14210

17

Item

Measuring

instruments

Test point Adjustment pa rt Description

V.SIZE

Adjustment

Signal

generator

No.13 V.SIZE

1. Receive a crosshatch signal.

2. Select No.13 V SIZE in the PICTURE MODE.

3. Set the initial setting value of No.13 V SIZE with the LEFT / RIGHT

key of the MENU.

4. Adjust No.13 V SIZE until the vertical screen size is 92%.

H.POSITION

Adjustment

Signal

generator

No.15 H PO S .

1. Receive a crosshatch signal.

2. Select the No.15 H POS. of the PICTURE MODE.

3. Set the i nitial s etti ng value of the No.1 5 H POS . with th e LEFT /

RIGHT key of the MENU.

4. Adjust the No.15 H POS. until the screen will be horizontally

centered.

Screen size

Picture size 100%

Screen

size

92%

Picture

size

100%

Page 18

No. 51831

C-N14210

18

Item

Measuring

instruments

Test point A djustment p art Descri ption

WHITE

BALANCE

(Low Light)

Adjustment

Signal

generator

BRIGHT

R. CU TOFF

G. CUTOFF

B. CU TOFF

SCREEN VR

[In HVT]

1. Receive a blac k-and- w hit e si gn al. ( Color off)

2. Select the【LOW LIGHT】MODE from the SERVICE MENU.

3. Set the initial setting value of BRIGHT with the LEFT / RIGHT

key of the remote control unit.

4. S et the init i al s etting val u e of R CU TO FF, G CUT OF F an d B

CUTOFF with the ④ to ⑨ key of the remote control unit.

5. Displ ay a si ngle h oriz ontal li ne b y pr essing t he ①key of the

remote control unit.

6. Turn the screen VR all the way to the left.

7. T urn the screen VR graduall y to the right f rom the left until

either one of the red, blue or green colors appears faintly.

8. Adjus t the two c ol ors which di d not appear until the sin gle

horizontal line that is displayed bec omes white using the

④

to ⑨ keys of the remot e c ontrol unit.

9. T urn the sc reen VR to wh ere th e sin gl e h orizon tal l in e gl ows

faintly.

10. Press the ② key to return to the regular screen.

*

The ③ EXIT key is the cancel key for the WHITE

BALANCE.

WHITE

BALANCE

(High Light)

Adjustment

Signal

generator

G. DRIVE

B. DRI V E

1. Receive a black-and-whit e si gnal. (Col or off)

2. Select the【HIGH LIGHT】MODE in the SERVICE MENU.

3. Set the initial s etting val u e of G DRIV E and B DRIVE w it h t h e

⑤, ⑥, ⑧

and ⑨ keys of the remote control unit.

4. Adjust the scr een until it bec om es white us i ng the ⑤, ⑥,

⑧

and ⑨ keys of the remote control unit.

*

The ③ (EXIT) key is the cancel key for the WHITE

BALANCE.

[LOW LIGHT] MODE

BRIGHT

EXIT BY

IT

BRIGHT

EXIT

***

******

***

***

******

***

***

******

***

***

******

***

1 2 3

6

987

54

REMOTE CONTROL UNIT

H.LINE ON E X ITH.LINE OFF

R CUTOFF B CUTOFFG CUTOFF

R CUTOFF B CUTOFFG CUTOFF

BRIGHT

G CUTOFF

B CUTOFF

R CUTOFF

[HIGH LIGHT] MODE

EXIT BY

IT

HIGH LIGHT

EXIT

***

******

*** ***

******

***

G DRIVE

B DRIVE

Remote Control Unit

①

key : H.LINE ON

②

key : H.LINE OFF

③

key : EXIT

⑤

key : G DRIVE

▲

⑥

key : B DRIVE

▲

⑧

key : G DRIVE

▼

⑨

key : B DRIVE

▼

Page 19

No. 51831

C-N14210

19

Item

Measuring

instruments

Test point A djustment p art Descri ption

SUB

BRIGHT

Adjustment

No.1 BRIGHT

1. Receive a br oadcast.

2. Select No.1 BRIGHT of the PICTURE MODE.

3. S et the initial setting valu e of the No.1 BRIGHT with th e LEFT

/ RIGHT key of the MENU.

4. I f the br i gh tn ess is not best with th e i nitial sett i ng val u e, m ak e

fine adjustment of the No.1 BRIGHT until you get the optimum

brightness.

SUB

CONTRAST

Adjustment

No.2 PICTURE

1. Receive a broadcas t.

2. Select No.2 PICTURE of the PICTURE MODE.

3. Set the initial setting value of the No.2 PICTURE with the

LEFT / RIGHT key of the MENU.

4. If the contr ast is not best with the in itial setting value, mak e

fine adjustment of the No.2 PICTURE until you get the

optimum contrast.

SUB

COLOR

Adjustment

No.6 COL OR

1. Receive a br oadcast.

2. Select No.6 COLOR of the PICTURE MODE.

3. Set the initial setting value of the No.6 COLOR with the

LEFT / RIGHT key of the MENU.

4. If the color is not best with the initi al settin g value, m ake fine

adjustment of the No.6 COLOR until you get the optimum

color.

SUB TINT

Adjustment

No.5 TINT

1. Receive a broadcas t.

2. Select No.5 TINT of the PICTURE MODE.

3. Set the initi al setting val ue of the No.5 TIN T with the LEFT /

RIGHT key of the MENU.

4. If the tint is n ot best with th e in itial setting value, mak e fine

adjust m ent of t h e No. 5 TIN T until you get th e optimum ti nt.

Page 20

No. 51831

C-N14210

20

PURITY, CONVERGENCE

PURITY ADJUSTMENT

1. Demagnetize CRT with the demagnetizer.

2. Loosen the retainer screw of the deflection yoke.

3. Remove the w ed g es.

4. I nput a green r aster signal fr om the sign al gener ator, and t urn

the screen to green raster.

5. Move the defl ec tion yoke bac k w ard.

6. Brin g the long l ug of the purit y magnets on the sh ort lug an d

position them horizontally. (Fig.2)

7. Adjust the g ap between t w o l ugs s o t h at the GREEN RAST ER

will come into the center of the screen. (Fig.3)

8. Move the defl ec tion yoke forw ar d, and fix the position of the

deflection yoke so that the whole screen will become green.

9. Insert the wedge to the top side of the deflection yoke so that it

will not move.

10. Input a crosshatch signal.

11. Verify that the screen is hori z ont al.

12. Inp ut red and blu e raster si gnals, and make su re that pur ity is

properl y adjusted.

CRT

WEDGE

DEFLECTION

YOKE

P / C

MAGNETS

P

46

PURITY MAGNETS

Long lug

Short lug

Bring the long lug over the short lug

and position them horizontally.

(

FRONT VIEW

)

GREEN RASTER

CENTER

P : PURITY MAGNET

4 : 4 POLES

(con vergence m agn ets )

6 : 6 POLES

(con vergence m agn ets )

$

P/C M AGNE TS

Fig.1

Fig.3

Fig.2

Page 21

No. 51831

C-N14210

21

STATIC CONVERGENCE ADJUSTMENT

1. Input a crosshatch signal.

2. Using 4- pole converg ence magnet s, overlap the r ed and blue

lines in the center of the screen (Fig.1) and turn them to

magenta (red/blue).

3. Using 6-pole convergence magnets, overlap the

magent a(red/bl ue) and green lines in th e center of th e screen

and turn them to white.

4. Repeat 2 and 3 abov e, and make b est c on vergenc e.

DYNAMIC CONVERGENCE ADJUSTMENT

1. Move the deflec tion yok e up an d d own an d over lap th e lines in

the periphery. (Fig. 2)

2. Move the deflection yoke left to right and overlap the lines in the

periphery. (Fig. 3)

3. Repeat 1 and 2 abov e, and make b est c on vergenc e.

●

After adjus tment, fi x the w ed g e at the or i gi nal positi on.

Fasten the retainer screw of the deflection yoke.

Fix the 6 m agnets with glue.

(FRONT VIEW)

GREEN

(FRONT VIEW)

BLUE

RED

BLUE

GREEN

RED

RED

GREEN

BLUE

GREEN RED

BLUE

GREEN

(FRONT VIEW)

BLUE

RED

BLUE

GREEN

RED

RED

GREEN

BLUE

GREEN

RED

BLUE

Fig.3

Fig.2

Fig.1

Page 22

No. 51831

C-N14210

22

HOW TO CHECK THE HIGH VOLTAGE HOLD DOWN CIRCUIT

1. HIGH VOLTAGE HOLD DOWN CIRCUIT

After rep airing the high v oltage hold d ow n circuit sh ow n in Fi g. 1.

This circuit shall be checked to operate correctly.

2. CHECKING OF THE HIGH VOLTAGE HOLD DOWN CIRC UIT

(1) Turn the POWER SW ON.

(2) As shown in Fig. 1, set the resistor (between X connector 1 & 3 ).

(3) Make sure that the screen picture disappears.

(4) Temp or ar il y un plug the pow er c ord.

(5) Remove the resistor (between X connector 1 & 3 ).

(6) Again plug the power cord, make sure that the normal picture is displayed on the screen.

Fig. 1

4

HVT

CONNECTOR

RESISTOR

14.46k

Ω±

Ω±Ω±

Ω±

1% 1/4W

HEATER

R562

D561

R561

X

C561

R563

D562

3 2 1

Q561

12V

D563

Q562

Q951

D958

R953

12V

RY901

POWER

ON OFF

C562

R564

Page 23

No. 51831

C-N14210

23

SELF CHECK FUNCTIONS

1. Outline

This model has self ch eck func t i ons gi ven below. When a malf unc ti on has been d etected, t h e POWER is turn ed off and t h e L ED flashes to

inform of the failure. The malfunction is detected by the signal input state of the control line connected to the microcomputer.

2. Self check items

Check item Details of detect ion Method of detection State of malfunct ion

CRT NECK protector

Also detected if the

power su pply lin e output

from the HVT (High

voltage Transformer) has

shorted with the ground.

W hen th e ve rt ic al ci rcu it Scorrection capacitor C427

is shorted, detect the

potenti al drop of the C427,

and prevent the burn

damage to the CRT NECK.

(Grounding of shorting of

the power supply output

from the HVT to the vertical

circuit, and the smal l sign al

power supply is also

detected.)

The microcomputer detects at 1second intervals.

If NG is detected for more than 1

ms, a malfu nc ti on is interpreted.

When a malfunction has been

detected, the POWER is turned

off. While the POWER is being

turned off, the power key of the

remote contr oller is not op er ation al

until the power code is taken out

and put in ag ain.

3. Self check indicating function

The self-c heck funct ion begins detecti on about 5 s econds after

power is supplied.

In the event a malfunction is detected, the power is cut off

immediately.

At this time, the ON-TIMER LED flashes to inform of the

malfunction.

[ON-TIMER LED indication]

The ON-TIMER LED flashes at 0.5 seconds intervals.

POWER

Supplied

After about

5 seconds

Malfunction

is detected

POWER OFF

Flashin

g

ON-TIMER LED

Start of

detection

Page 24

No. 51831

C-N14210

24

REPLACEMENT OF CHIP COMPONENT

!

CAUTIONS

1. Avoid heating for more than 3 seconds.

2. Do not rub the electrodes and the resist parts of the pattern.

3. When removing a chip part, melt the solder adequately.

4. Do not reus e a chip part after rem ovi ng it.

!

SOLDERING IRON

1. U s e a high ins ul at i on s old er in g iron with a thin p ointed end of it.

2. A 30w soldering iron is recommended for easily removing parts.

ADJUSTMENTS

!

REPLACEMENT STEPS

1.

How to remove Chip parts

%

Resistor s, ca pa ci t or s, et c.

(1) As shown in the figure, push the part with tweezers and

alternat ely melt th e s old er at eac h en d.

(2) Shift with tw eez er s an d rem o ve t h e ch ip p ar t.

%

Transistors, diodes, variable resistors, etc.

(1) Apply extra solder to each lead.

(2) As shown in the figure, push the part with tweezers and

alternat ely melt th e s old er at eac h l ead . Shift and remove th e

chip part.

Note : After rem oving the par t, rem ov e r em a in ing solder from the

pattern.

2. How t o i nst al l Chip p arts

%

Resistor s, ca pa ci t or s, et c.

(1) Apply solder to the pattern as indicated in the figure.

(2) G r asp the chip p art wit h t w e ez ers and plac e it on the sol d er.

Then heat an d m elt the solder at b oth en ds of t h e chip part.

%

Transistors, diodes, variable resistors, etc.

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the solder.

(3) First solder lead

A

as indicated in the figure.

(4) Then solder leads

B

and C.

SOLDER

SOLDER

A

B

C

A

B

C

Page 25

N14210S-MEM #3

4

VP 0108

DP3051

V

ICTOR COMPANY OF JAPAN, LIMITED

HOME AV NETWORK BUSINESS UNIT 12, 3-chome, Moriya-cho, Kanagawa-ku, Yokohama, Kanagawa-prefecture, 221-8528, Japan

Loading...

Loading...