Page 1

SERVICE MANUAL

COLOR TELEVISION

AV-N29320

BAS IC CHAS SIS

AV-N29320

AV-N29320

/S

/R

FE

CONTENTS

!

SPECIFICATIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

! SAFETY PRECAUT IONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

! FEATU RES・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

★

OPERATING INSTRUCTIONS (APPENDIX)

!

MAIN DIFFERENCE LIST ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

! HOW TO IDENTIFY MODELS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

FUN CTIONS

!

SPECIFIC S ERVIC E INSTRUCTIONS

! SERVICE ADJUSTMENTS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

★ ST AND AR D CIRCUIT DIAGRAM (APPEN DIX) ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

PARTS LIST

1

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

COPYRIGHT © 2002 VICTOR COMPANY OF JAPAN, LTD.

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 2

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・ 3

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・ 5

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・ 5

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・ 8

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・ 12

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・ 4

・・・・・・

1-1

・・

・・・・

・・・・・2- 1

・・・・・・・・・・

31

6

No.520 09

May. 2002

May 2002

Page 2

A

V-N29320

(

)

)

)

SPECIFICATIONS

Items

AV-N29320/S AV-N29320/R

Dimensions (W×××× H×××× D) 65 4m m× 5 93mm×4 94mm

Mass 31 .1 kg

TV System and Color System

TV RF System

Color System

Sound System

TV Recei ving Channels and Frequency

VL B a nd

VH B and

UHF Band

CATV Receiving Channel s and Frequency

Low Band

High Band

Mid Band

Super Band

Hy p er Band

Ul tr a B and

Sub Mid Band

TV/CATV Total Channe l

Intermediate Frequency

Vide o IF Car rier

Sound IF Carrier

Color Sub Carrier

Power Input

Power Consumpti on

CCIR(M)

NTSC,

BTS C S ystem (Multi-Ch annel S ound )

(02~06) 54 MHz ~88MHz

(07~13) 17 4M H z~21 6M Hz

(14~69) 47 0M H z~80 6M Hz

(02~06, A-8) by (02~06 &01)

(07~13) by (07~13)

(A~1) b y ( 14~22)

(J~W) by (23~36)

(W +1~W+ 28) b y (3 7~ 64 )

(W +29 ~W + 84) b y (65 ~1 25)

(A8, A4~ A1) by (01, 96~99 )

18 1 Cha nn els

45 .75 MHz

41.25 MHz ( 4 .5MHz)

3.58MHz

12 0V AC , 60H z

11 3W

Contents

(54MHz~80 4MH z)

Picture Tube

Hi gh Vo l t ag e

Speake r

Audio Powe r Out put

Input terminal

Input 1 S-Video

Comp onent(V/Y , P

Input 2

Fr on t

Output ter minal

Variabl e Audio Output (R/L) More than 0~1550mVrms (+6dBs)

Antenna termina l 75Ω(VHF/UHF) Terminal, F-T ype Connector

Remote Control Unit RM-C 20 5 (AA /R6/U M- 3 b att ery× 2)

B, PR

Au dio (L , R )

Vide o(V

Au di o(L, R

29 ” (6 8cm) Mea sured Diag on al l y

28 .0 kV±1.3kV (at zero beam current)

5×12cm Oval type×2

1.2 W + 1.2 W

Y: 1Vp-p P ositive ( neg ative s ync p r ovided , wh en ter minat ed with 7 5Ω)

C: 0. 286V

)

1V p- p 7 5Ω(positive sync)

50 0m Vr ms ( -4 dBs ), High I mp ed ance ( RCA pin j ack)

1V p- p 7 5Ω(RCA pi n ja ck)

50 mV rm s (-4dB s), H i gh Imped an ce ( RCA pin j ack)

Low impedance (400Hz when modulated 100%) (RCA pin jack)

p-p

(bu rst si gnal, when t erm inate d with 75Ω)

De sign & speci f icatio ns ar e su bje ct to cha ng e wi thou t notice.

2

No.52009

Page 3

A

0

SAFETY PRECAUTIONS

V-N2932

1. The d es ign of t hi s p ro du ct c ont ains s pec ial h ardware, m an y

ci rcu its and c o mp on ent s s peci ally for saf ety purp oses. For

continued protection, no changes should be made to the

origina l des ign u nless a uth or i zed in wr iti ng by t he man uf actu re r.

Replacem en t par ts m ust be id ent ic al t o thos e u sed in th e

origina l circui t s. S er vic e sho ul d be perf or me d b y qu al i fied

p ers onnel o nly.

2. Alte r ation s of th e des i g n o r circu itr y of th e p r odu cts s hou l d n ot

b e m ad e. A ny de sign al te ra ti ons o r ad di tio ns will vo id th e

manufacturer's warranty and will furth er relieve t he

manu fac t urer of resp ons ibi lit y f or pe rs ona l in ju r y or p rope rt y

d am age r es u lt in g t heref rom .

3. M an y e lectrical an d mec h an ic al pa rt s in th e produ cts h ave

sp ecial s af ety-relat ed c haract eris tic s. Th ese char acter i sti cs ar e

oft en not e viden t from visu al inspe cti on nor can t he pr ote cti on

aff orde d by th em n ecess ar ily be obta in ed by usi ng

replac ement compon ent s rated for h ig her vo ltag e, wa ttag e, etc.

Replacem en t pa rt s wh ic h h ave t hes e sp ec ial s afet y

ch aracter istics a re i d entifi e d in th e par ts l ist of S ervi c e m an ual.

Electrical components ha ving such fe atur es are identified

by shading on the schematics and by (!!!!) on the parts list

in S erv ice manual. Th e us e of a su bst itu te re pl ac emen t whi ch

does not have the same saf et y characterist ics as the

reco mmen ded replac emen t pa rt sho wn i n the pa rts li s t of

Se rvi c e ma nu al m ay c ause sh ock, f ire, or o ther hazards.

4. Use iso lat io n tr an sf orme r when hot chass is .

The chassis and any sub-chassis contained in s ome products

are c onnect ed to on e side of th e AC p ow er l i ne . An i sola ti on

tr ansf or m er of ad equ ate cap acity s h ou ld be inser t ed bet ween

th e p rodu ct and t he AC p ow er s u pp ly p oi nt whil e p erfor m ing

an y ser vice on so me pr oducts when th e H OT ch assis is

exp ose d.

5. Don't short between the LIVE side ground and I SOLATED

(NEUTRAL) side ground or EARTH side ground when

repairing.

So m e mod el 's p ower c ircuit is par t ly di f fer en t in the GN D. T h e

diff er enc e of t he GND i s sh own by th e LI VE : (") side GND,

th e ISO LAT ED(NEU TRAL) : (#) sid e GND and EAR TH : ( $)

si de GND. Don 't sho rt be tw ee n t he LIVE sid e GN D a nd

ISO LATE D(N EUTR AL) si de GN D or EART H si de GND and

never measure with a measuring apparatus (oscilloscope etc.)

th e LI VE s ide GND a nd ISO LATED ( N EUTRA L) si d e G ND or

EARTH sid e GND at the s ame time.

If above note will not be kept, a fuse or any parts will be broken.

6. If any re pa ir h as b ee n mad e to th e ch assi s, i t i s re commend ed

th at t he B1 se tti n g s h ou ld b e chec k ed or ad juste d (S ee

ADJUSTM ENT OF B 1 POW E R SUPPL Y).

7. The hig h volt age a pplied t o the pictu re tu be mu s t c o nform with

that specified in Service manual. Excessive high voltage can

cau se an incr ease i n X-R a y emis sion , arcin g and p ossi bl e

com po nent d am ag e, th eref or e op er ation un der exces s ive hi gh

vol ta ge c ond it i ons sh ould be ke pt to a m in i mu m, or sh ou l d be

preve nt ed. I f seve re arc in g occu rs, r em ove th e AC p ower

immediately and determine the cause by visual inspection

(incor r ec t i nsta lla ti on , cr ac ked o r melte d hi gh vol tag e harness ,

p oor s olde ring, etc . ). T o mainta in the prop er minimum level of

soft X-Ray emission, components in the high voltage circuitry

incl ud i ng the pi ctu r e tu be mu s t be the ex a c t r ep lac em en ts or

alte rn at ives a ppr o v ed b y th e ma nuf actu r er of the co mplete

prod uct.

8. Do n ot c hec k high vol ta ge by dr awing a n ar c. U s e a hi gh

vol ta ge m ete r or a hi gh volt age pro be w i th a VTVM. Dis char ge

th e p ictu r e tu be bef ore a tte mp ti ng meter co nne ction , b y

con nec ting a cl i p lead to th e gr ou nd fram e a nd con n ecti ng the

oth er e nd of t he lead th roug h a 10 kΩ 2W resist or to t he ano de

bu tto n.

9. W hen s e rvice is r equ i r ed, ob serve th e o rig in al l ea d dress.

Extra p r ecau ti on sh ou ld be giv en to assu r e correct lea d dr es s

in the hi gh volta ge c ircu it area . W her e a sh ort cir cuit ha s

occu rr e d, th ose c ompon en ts that i nd ic ate ev iden ce of

overheating should be replaced. Always use the

manu fac t urer 's r epl acem ent com p on ents.

10 . Isolation Check

(Safety for Electrical Shock Hazard)

Af ter re-a ssem bl i ng th e prod uct , alw ay s pe rf or m an iso lati on

ch eck on th e expo sed m eta l p ar ts of th e c abi n et ( ant en na

ter m i na ls, vi de o/a ud i o in pu t and out put ter mi n al s , C on trol

knobs, metal cabinet, screwheads, earphone jack, control

sh afts, etc.) to be s ur e th e pr o duc t is saf e t o op er at e with out

d ang er of elect rica l shoc k.

(1) Dielectric Strength Test

The is olat io n b etwe en the AC primary c ircu it and all meta l parts

exp osed t o the us er, par t icu lar l y an y expo sed metal p ar t h aving

a re tur n pat h to the ch assis sh ou ld w i ths t and a volta ge of

11 00V AC (r .m .s.) for a per i od of on e sec ond.

(. . . . Withstand a volta ge of 1100 V A C (r.m.s.) to an appliance

rate d up to 1 20V , and 3 000V AC ( r .m. s.) t o an appl i anc e ra ted

200V or more, for a period of one second.)

Thi s m eth od of test r equ ires a t est eq uip me nt n ot g enerally

fou nd in t he servi c e t ra de.

(2) Leakage Current Check

Plug t he A C line c or d di r ect ly int o th e AC ou tl et (do not u se a

line is olati on tra nsf orm er dur i ng this che ck.). Usi ng a " L eakage

Current Test er", m ea sure t he lea kag e c ur r en t fr om each

exp ose d m eta l par t of th e c a bi ne t, p ar tic ul ar l y an y expo s ed

metal part having a retu r n path to t he ch assis , to a known good

ea rt h gr o und ( water p i pe, etc.) . A ny l ea kag e c ur r en t must not

exce ed 0.5m A AC ( r .m. s.) .

Howev e r, in t ro pical a rea, thi s m ust no t e xc eed 0.2m A AC

(r.m.s.).

"""" Alte rn at e Che ck M ethod

Plug t he A C line c or d di r ect ly int o th e AC ou tl et (do not u se a

line isolation transformer during this check.). Use an AC

vol tm et er h aving 100 0 o hms per v olt or m or e sen siti vit y in the

follo wing ma nne r. C on nec t a 1 50 0Ω 1 0W resi s tor pa ralle l ed

by a 0.15μ F AC-typ e cap acitor b etwe en an exp ose d meta l

p art and a k no wn go od ear th gr ou nd ( w ate r pip e, et c.).

Measu re th e A C vo ltag e acr os s th e r esist or wit h t he AC

voltmeter. Move the res istor connection to each exposed metal

part, particularly any exposed metal part having a return path to

th e ch assis , an d m ea sur e t he A C volta ge acr oss the r esis to r.

Now, reve rs e th e plu g in t he A C out l et a nd rep e at e ach

measu rem ent. An y volta ge measu re d mus t not exce ed 0.7 5V

AC (r.m. s.) . This corresponds t o 0 .5 mA AC (r.m. s.).

Howev e r, i n trop ic al ar ea, thi s must n ot excee d 0 .3V AC

(r.m.s.). This corr esp onds t o 0 .2mA A C (r.m .s.).

AC VOLTMETER

(HAVING 1000 Ω/V,

GOOD

EARTH

GR OUND

11 . High voltage hold down circuit check.

Af ter rep ai r of th e high vol t age h ol d d own c ir cui t, th is c i rcu it

sh all be c hec ked to op er ate correctly.

See item "Ho w to check the high voltage hold down

cir cuit".

This mark shows a fas t

operating fuse, the

letters indi cated below

show the rating.

0.15μF AC-T YPE

1500Ω 10W

OR MOR E SENSIT IVITY)

PLACE THIS PROBE

ON E A C H EX PO SE D

ME T AL PA RT

A V

No. 52009

3

Page 4

A

V-N29320

FEATURES

New chas sis design en abl es use of a si ngl e boar d with simp lif ied

"

circuit ry.

User s can m ak e fun t o c onnect th e Digi tal Video Disk pl ayer wit h

"

the comp onent vi deo signal i npu t termi nal .

Provid ed w ith miniatu re tuner (TV/CATV ).

"

Multif unct ion al rem ote con tro l p ermits pic tu re a dj ustm ent.

"

Ad opti on of t he CHANNEL GU ARD fu nction pr events th e speci fi c

"

chan nels from being selected, unl ess th e “ID numbe r” is k ey in.

2

"

I

C bus control utilizes single chip ICs.

"

Adoption of the VIDEO STATUS f unction .

"

Adoption of the ON/OFF TIM ER fun cti on.

With 75ΩV/U in c ommon ( F-Type) ANT Ter m in al.

"

SLEEP TIMER for s etting in re al t ime.

"

Clos ed- capti on b roa dcasts can be view ed.

"

"

Bu ilt - in MT S sys tem.

"

Built-in H YPER-SURROUND system.

"

S-VIDEO in put termi nal for tak i ng bes t advantag e of S uper VH S .

Variable Au di o outp ut te rminal.

"

3 L IN E D i gi tal Comb f ilter Im pr oved pictu re q ual ity.

"

4

No.52009

Page 5

A

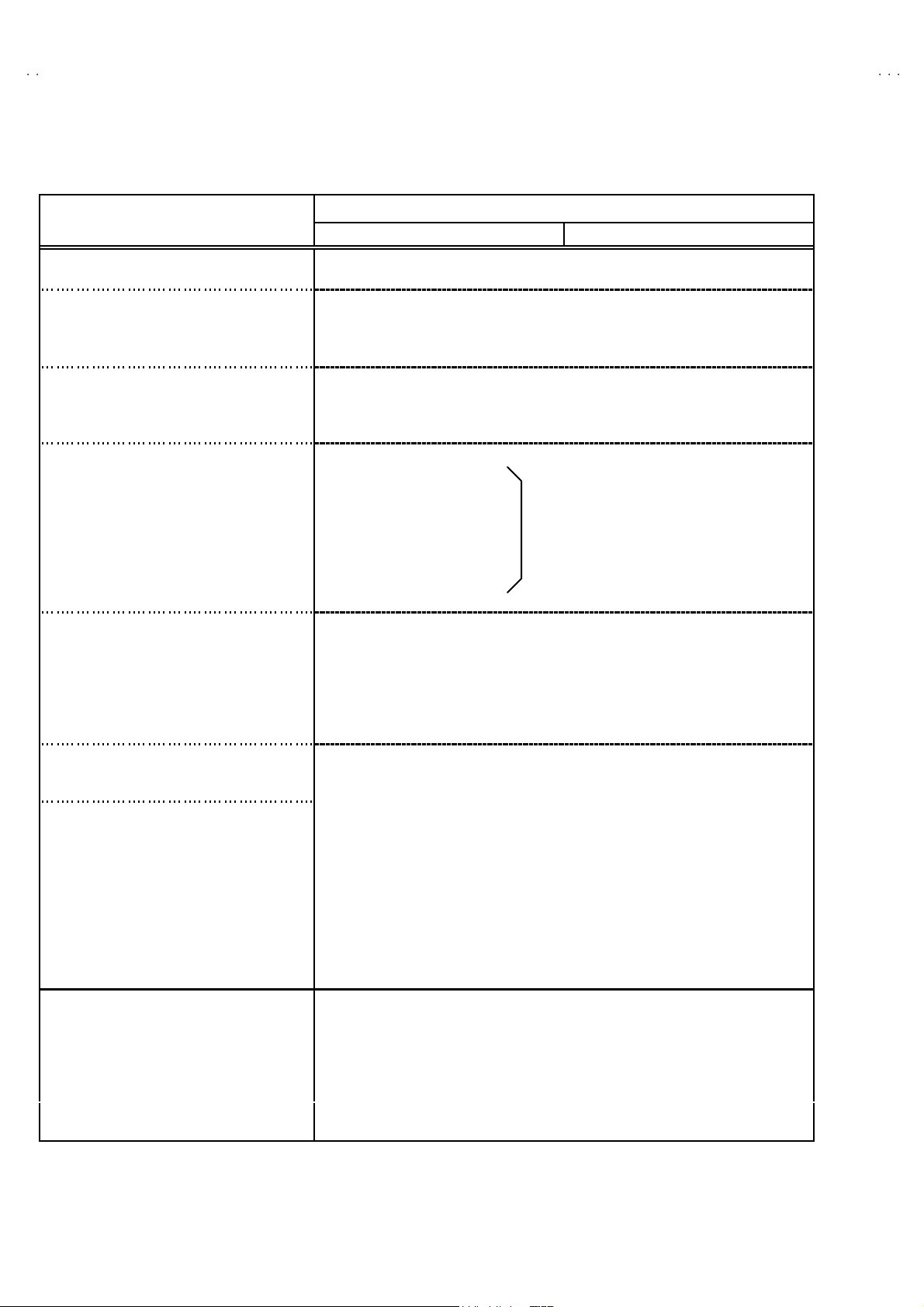

MAIN DIFFERENCE LIST

V-N29320

!!!!

Parts Name

MAIN PW B SFE-10 10A -M 2 SF E- 1011A -M 2

!!!!

ITC TU BE A6 8QD N 891 X001 A6 8AD T 25 X881

Model name

AV-N29320/S AV-N29320/R

HOW TO IDENTIFY MODELS

The differenc e between AV -N29 320 /S and AV -N29 320 /R is i n th e PICT U RE TUBE.

As t he res ul t of the diffe ren ce in pictu re t ube, the MAIN PW B al so dif fer s.

!

Model

Parts na me

AV-N29320/S AV-N29320/R

Ind ic ated A V- N2 932 0

Ind ic ated A V- N2 932 0

!

RAT ING L ABEL

Indic ated “S”

Indic ated “R”

No.52009

5

Page 6

A

V-N29320

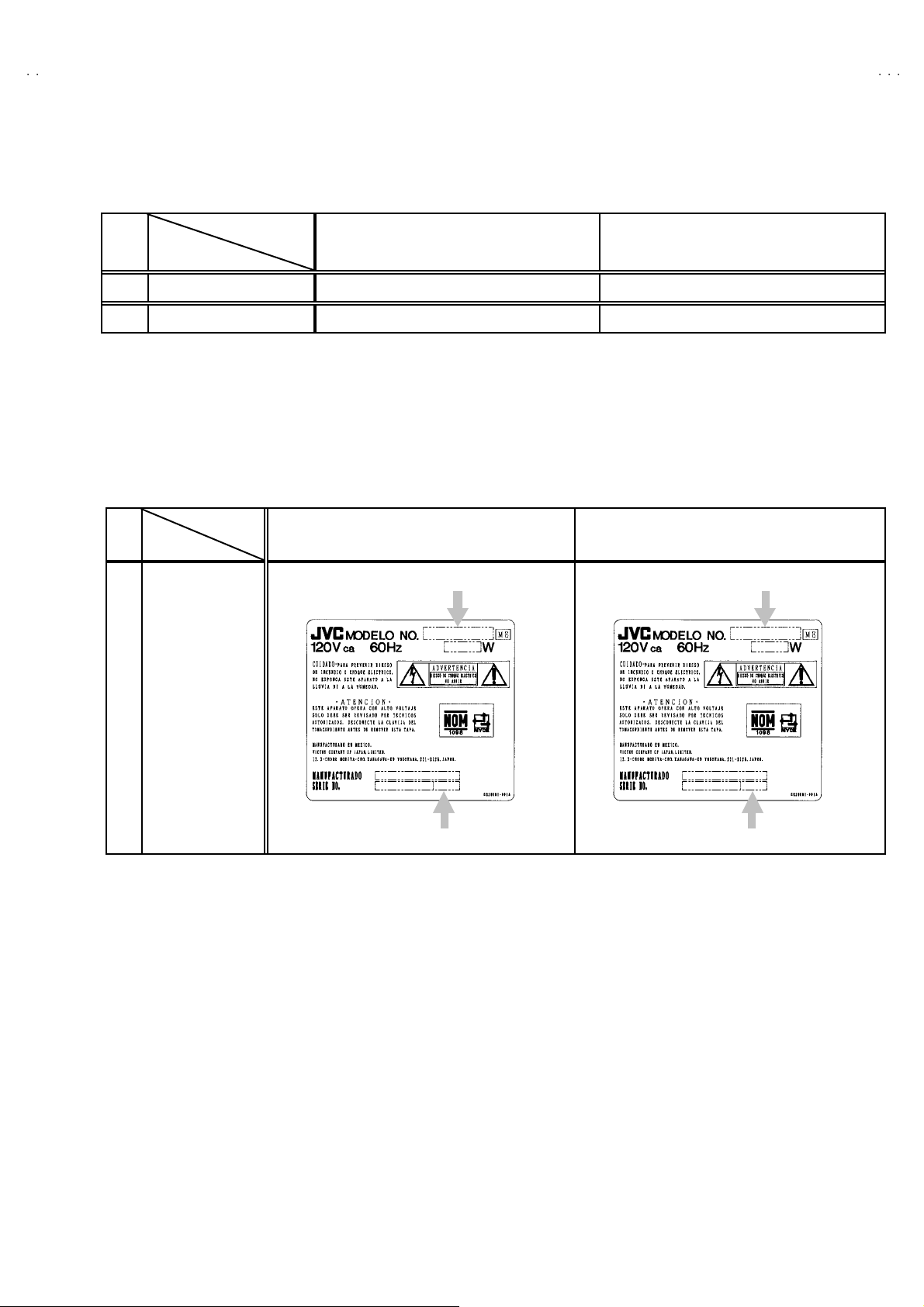

FUNCTIONS

■■■■

FRONT PANEL CONTROL

2

1

3 6

5 8

4

7

1

INPUT2 VIDEO terminal

2

I NPUT2 AUDIO L MONO terminal VOLU ME -/+ buttons

3

INPUT2 AUDIO R terminal ON TIMER LED

4

MENU but ton POW ER button

■■■■

REAR TERMINAL

CHANNEL -/+ buttons

5

OPERATE / buttons

6

7

8

1

AUD I O O UTPUT (L, R) t erm inals

INPUT1 (S, V/Y, PR, PB, L, R) terminals

2

VHF / UHF terminal

3

1

6

2

3

No.52009

Page 7

A

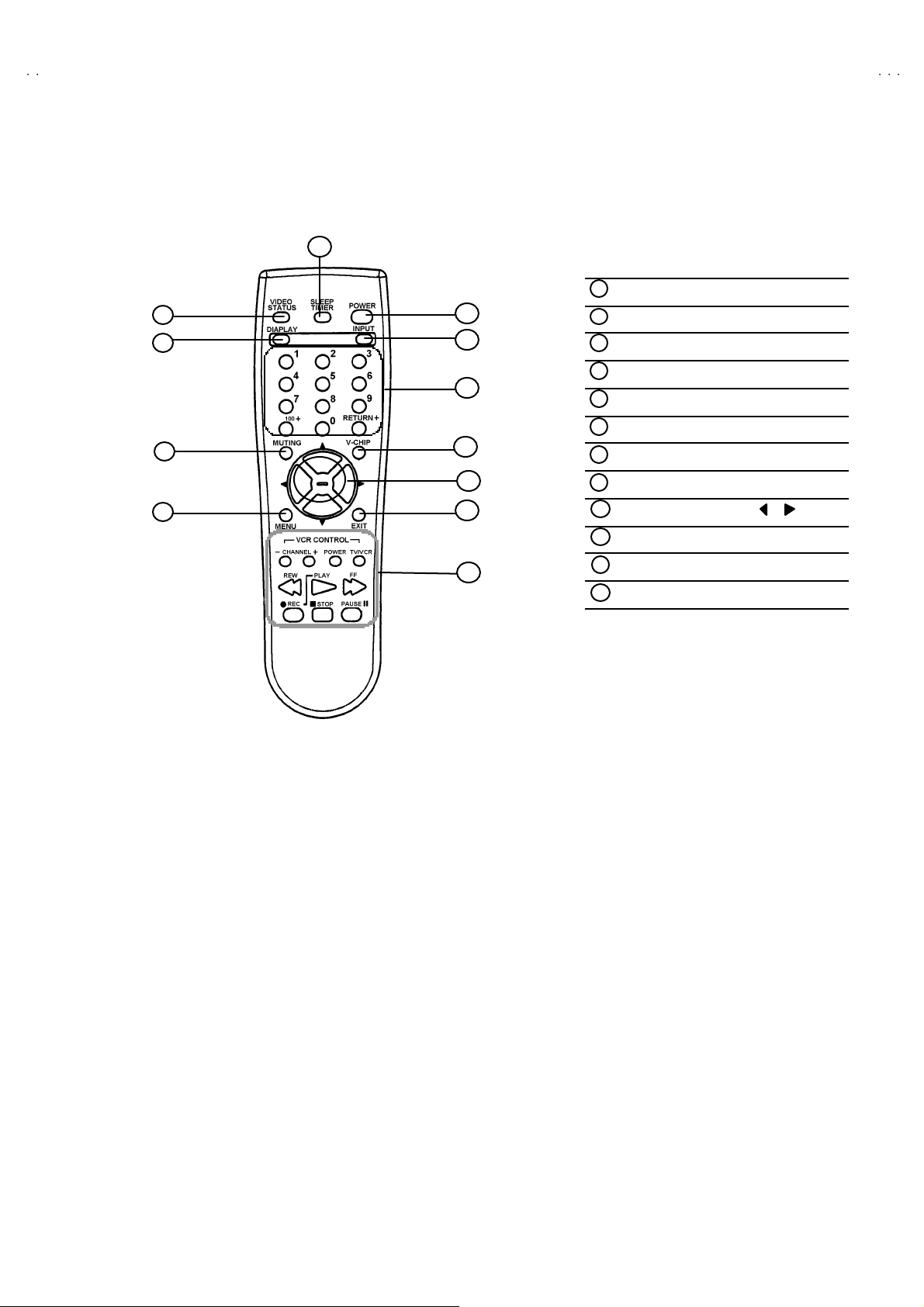

■

REMOTE CONTROL UNIT [RM-C205]

11

1

2

3

4

V-N29320

1

VI DEO STATUS key

5

6

7

8

9

10

12

DISPLAY k ey

2

MUTING key

3

MENU key

4

5

POWER key

INPUT key

6

CHANNEL keys

7

V-CHIP key

8

FU NCTI ON ( ▼/ ▲, / ) Key s

9

EXIT key

10

SLEEP TIMER k ey

11

VCR CONTROL keys

12

No.52009

7

Page 8

A

V-N29320

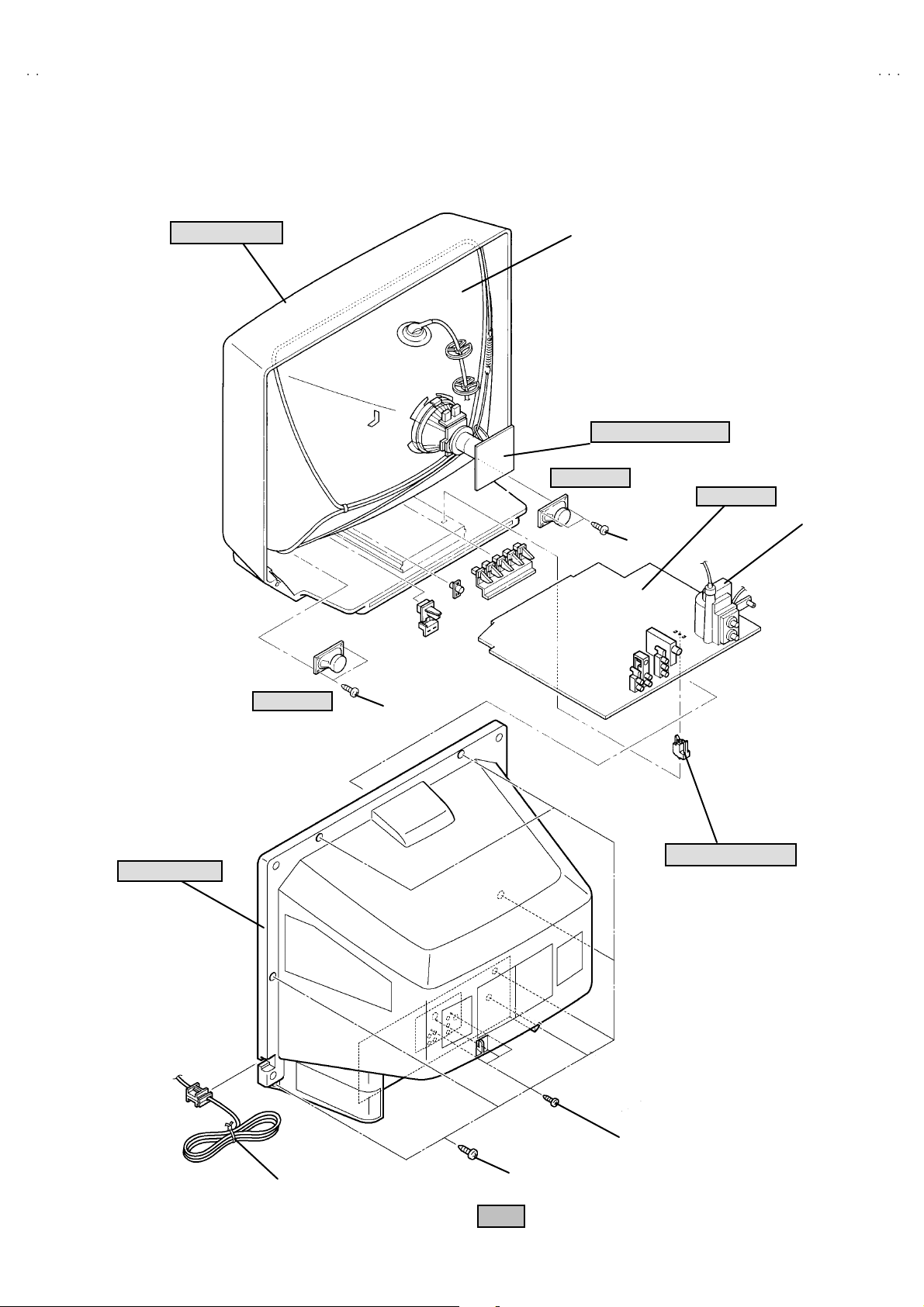

SPECIFIC SERVICE INSTRUCTIONS

DISASSEMBLY PROCEDURE

REMOVING THE REAR COVER

1. Disc onnec t t he po w er pl u g f rom wa ll out le t.

2. As s hown i n th e Fig .1, r em o ve th e 7 screws marked

3. As s hown i n Fig.1 , re mo ve t he 3 screws marked

4. Then remo ve th e REAR COVER toward you.

""""

!!!!

.

.

CHECKIN G THE PW BOARD

To check the PW Boar d from back side.

1. Pull out the ch assis ( refer t o REMOVI NG TH E MAIN PWB ).

2. Erect th e chas sis ver tic a lly s o th at you c an ea sily ch eck th e bac k

si de of the PW Boar d.

REMOVING THE MAIN PWB

" After r emovi ng the REAR C OV ER.

1. Pic k th is s i de of th e MA IN PWB an d r aise on e slig htl y, tak e off the

PW B stopp er mar ked

2. W i thdr a w t he chass is backw a rd .

(If n ecess ary , r emove t he wire clam p, c onn ec t ors etc.)

####

f rom th e c abin et b ott om .

REMOVING THE SPEAKER

"

After removing the rear cover.

1. As shown in Fig. 1, removing the screws marked

remove the speaker.

2. Foll ow th e s ame st eps when r em oving th e oth er ha nd sp eak er.

NOTE : When removing the screws marked

remove th e lower si de s crew first, an d th en r em ove t he

up per one .

$$$$

of th e sp eak er ,

$$$$

then

,

CAUTION

"

When e recti ng th e ch assi s, b e c ar ef ul s o tha t th er e w ill b e no

contacting with other PW Board.

"

Befor e tu rni ng o n power, m ake s ure th at t he w i r e con nec tor i s

prop er l y con nected .

"

When conducting a che ck with power supplied, be sure to

confirm that the CRT EART H WIRE (BRAIDED ASS’’’’ Y) is

connec ted to the CRT SOCKET PW boar d.

WIRE CLAMPIN G AND CABLE T YING

1. Be sure t o cl a mp th e wire.

2. Never rem o ve th e c able ti e use d f or tying th e wi res togethe r.

Should it be inadverte ntly removed, be sure to tie the w ires with a

new cable tie.

8

No.52009

Page 9

A

V-N2932

0

FRONT CABINET

CRT

CRT SOCKET PWB

SP EAKER

MAIN PWB

HV T

$$$$

REAR COVER

SP EAKER

$$$$

####

PWB STOP PER

""""

POWER CORD

!!!!

Fig .1

No.52009

9

Page 10

A

V-N29320

C BUS

S)

)

SYS0

MEMORY IC REPLACEMENT

1. Memory IC

This TV uses memory IC.

Thi s m em or y IC st ores d at a f or pr op er o per a tion of the video a nd defl ection ci r cuits.

When r ep la cing t he mem or y IC, be sure to use an IC co ntai ni ng this (initia l value ) dat a.

2. Memory IC replacement procedure

(1) Power off

Switch off th e pow er an d di scon nec t th e p ow er c o rd fro m t he outlet.

(2) Replace the memory IC

Be sure t o use a memory I C writte n with th e initia l s ettin g data.

(3) Power on

Con nect th e power cord to th e o utlet a nd s witch on th e power.

(4)Confirm t he sy st em con st an t v alue

"

12 .S YSTEM (SYS ) do not a dj ust norm ally.

"

The adjustment should not be done without signal.

! Ho w t o ent er t he SY STEM (SYS ).

1) Pr ess the SL EEP TIMER ke y and se t SL EEP TIM ER f or 「0 min」.

2) Be for e disap pear the dis pl a y of S LEEP TIM ER set ti ngs , simu ltan eo usly

press the DISP LAY key an d VIDEO STA TUS ke y of the remot e c ont rol

un it.

3) The SERV ICE M EN U s cr een of Fig.1 is d isp layed.

4) While the S ERVICE MENU is displayed, select t he 12.SYSTEM(SYS)

item with FUNCTION ▼/▲ keys, and the FUNCTION / keys is

pressed, the screen will be displayed as shown in Fig.2.

5) R efe r to the SY STEM ( SY STEM C ON STA NT) TAB LE 1 a nd check t he

setting items. If the value is different, select the setting item with the

FUNCTION ▼/▲ keys and ad just t he sett ing wi th th e FU NCTION

/ keys . (The let ter s of th e s el ec te d i t em are displ a yed in yellow.)

6) W hen adjustment has co mp lete d, t he v al ues sto re in to memory IC

automat ically

7) Press the EX IT key t wice to r eturn th e norm al screen.

SETTING N o

SE RVICE MEN U

SERVICE MEN U

1.V/C(S) 2.DEF(D)

3. SOUND(A) 4 .OTHERS( F)

5.PIP(PIP) 6.3L Y/C(LYC)

7.LOW LIGHT 8.HIGH LIGHT

9.RF AFC 10.VCO

12.SYSTEM(SY

11.I2

SELECT BY

OPERATE BY EXIT BY

Fig.1

12 .SY STEM(SY S

SETTING ITEM

1 VI DEO IN

Fig.2

Verif ied

EXIT

***

SETTING VAL UE

KEY ASSIGNMENT OF REMOTE CONTROL UNIT

(5) Rec eive channel setting

Refe r to the OPERA TING IN S TRUCTIO NS (USER'S GU IDE) and set

th e r ec e i ve ch annel s ( Cha nn els Pr eset) as des crib ed.

VIDEO

STA TUS

SLEEP

TIMER

DISP LAY

(6) User settin gs

Check th e us er s ett ing it em s acc ording to TABL E 2 .

Where thes e d o not agree, r ef er to th e OP ERATIN G I NSTRU CTION S

(USER'S GU IDE) an d s et t he it ems as de scrib ed.

FUNCTION

FUNCTION

▼/▲

/

(7) SERVICE MENU setting

Ve rif y what to s et i n th e SER VI CE MENU, a nd s et wh at ever is

necessary. (Fig. 1) Ref er to the SERVICE A DJUSTM ENT f or setting.

10

No. 52009

EXI T

Page 11

A

0

TABLE 1 (System Constant setting)

No Setting item Variabl e range

SY S01 VIDEO IN 0~4 2

SY S02 PIP 0~1 0

SY S03 3D Y/ C 0~1 0

SY S04 Y CV 0~1 0 SY S16 EZ SU RF 0~1 0

SY S05 CCD PCH K 0~1 1 SY S17 ID DISP 0~1 0

SY S06 PUR ITY 0~1 0 SY S18 COMPU LIN K 0~1 0

SY S07 VM 0 ~1 0 SY S19 C CD 0~1 1

SY S08 NOISE CR 0~1 0

SY S09 CLR TEMP 0~1 0

SY S10 TH EATE R 0~1 0

SY S11 TH EATE R PRO 0~1 0

SY S12 BB E 0~1 0 SY S24 CXA1 875 0~1 0

Initial setting

value

No Settin g item Variabl e ra nge

SYS 13 HYP SURR

SY S14 16:9 MD

SY S15 HYP S CA N

SY S20 VCH IP

SY S21 VCH IP C A

SY S22 JVC L OGO

SY S23 CMP IN

0~1

0~1

0~1

0~1

0~1

0~1

0~1

TABLE 2 (User setting)

Setting item Setting value Setting item Setting value

Use remo t e co ntrol ler ke ys

V-N2932

Initial setting

value

0

0

1

1

1

1

0

POWE R OFF DISPLA Y OFF

CHA NNEL CH-02 VIDEO STATUS DYNAMIC

VOL UME 10 HYPE R S URROUND OFF

TV/V IDEO TV

Settings of ME NU

PICTURE MENU INITIAL SETUP MENU

TINT CENTER

COLO R CENTER FRONT PANELLOCK OFF

PICTURE CENTER+8 V2 COMPONENT-I N NO

BRIGHT CENTER AUTO SHUT O FF OFF

DETAIL CENTER+10

COLO R TEMPERATURE HIGH

NOISE MUTING ON CHANNE L SU MM AR Y U nn ecess ary to set

SOUND ADJUST MENU

BASS CEN TER

TR EBL E CEN TER XD S I D

BALANCE CENTER

LA NG U AGE

CLOS ED CAPTIO N OFF

AUTO TUNER SET UP AIR

V-CHI P OFF

SE T LOC K C ODE ( 000 0) Unn eces sary to set

ENG

ON

MTS ST E RE O

CLOCK / TIMERS MENU

SE T CLOC K

ON / O FF TIMER OFF

MA NUA L

TIME ZONE : PACIFIC

D.S.T. : OFF

No. 52009

11

Page 12

A

V-N29320

SERVICE ADJUSTMENTS

ADJUSTMENT PREPARATION

1. You c an ma ke the nec es sary adjustme nts for t his unit wi th

eit her t h e R emo t e Co ntrol Unit o r With th e adjustme nt

tools and parts as given below.

2. Ad justment with t he Remote Control Unit is ma de on t he

bas is of t h e initial sett in g v al ues, howev er, t he ne w s etti ng

values which set the screen to its optimum condition may

differ f rom the init ia l s ett ings.

3. Make sure t hat AC p ower i s tu r ned on c orrec tly.

4. T ur n on t he pow e r f or set an d test e qu i pm ent bef ore us e, an d

start th e adjus tme nt p r oced ur es aft er wai ti n g at least 3 0

min ute s.

5. Unless oth erw is e spec if ied, prep ar e the m ost s uitab l e r ece pti o n

or inp ut sign al for adjust ment.

6. Never t ouc h an y adjustmen t p arts which a re n ot sp ecified i n th e

list for this adjustment - variable resistors, transformers,

condensers, etc.

7. Pr es etti n g b efore a djust ment.

Unl es s oth er w is e spec if i ed in th e ad jus tm en t instruct ions,

pres et t he f ollowing function s w i th the rem ote co ntr ol u nit:

User menu preset value

MENU ITEM PRES ET V ALUE

PICTURE MODE (VSM) DYNAMIC 0

BA SS, TREB LE, BA LANCE

TINT, COLOR,

PICTURE, BRIGHT , DETAIL

MTS

CENTER

CENTER

STEREO

ADJUSTMENT EQUIPMENT

1. DC voltmeter (or digital voltmeter)

2. Oscilloscop e

3. Sign al g en erat or (P att er n g ener at or)[NTSC

4. Remote control unit

5. TV a ud i o m ul ti pl e x sign al ge ne rator .

6. Frequ enc y cou nte r

]

ADJUSTMENT ITEMS

Ad just ment it em s Adju st men t it ems

B1 POW ER SU PPL Y SUB B RI GH T

MAIN VCO SUB CONTRAST

RF. AGC SUB COLOR

FOC US SUB TI NT

V. HEIGH T V. CENT ER MTS IN PUT L EVEL check

H. CENTER

WHITE BA LANCE ( Low L igh t)

MTS SEP ARATIO N

KEY ASSIGNMENT OF REMOTE CONTROL UNIT

VIDEO

STA TUS

DISP LAY

FUNCTION

/

SLEEP

TIMER

FUNCTION

▼/▲

EXI T

WHITE BA LANCE ( Hig h L ight )

12

No.52009

Page 13

A

0

ADJUSTMENT LOCATIONS

(

)

V-N2932

FRONT

POWER

MAIN PWB

POWER

CRT SOCKET PWB

Within MAIN PWB ASS'Y

TP-B

T

TP-E

(SOLDER SIDE)

VOL+ VOL- CH+ CH- MENU

E1

TOP

CR T EAR TH

(BRAIDED ASS' Y)

S

IC70 2

F901

IC20 1

T111

HV

IC42 1

IC10 1

S401

TUNER

HV T

IC90 1

U

B1

X

UPPE R : FOCU S

AV IN / OUT

No.52009

LOWER : SCREEN

13

Page 14

A

V-N29320

BASIC OPERATION OF SERVICE MENU

1. TOOL OF SERVICE MENU OPE RATION

Operat e the SERVICE MEN U with th e REM OTE CO NT ROL UNIT.

2. In gene ral, basic setting (adjustments) items or verifications are perfor med in the SERVICE MENU.

(1) V/C (S) ・・・・・・・ ・・・・・・・・・・・・・ ・ This se t th e s ettin g valu es ( a djustm e nt values) of th e VIDEO/CHRO MA circu its.

(2) DEF (D)

(3) SOUND (A) ・・・・・・・・・・・・・・・・・ This se t th e s etting valu es (adjustment values) of the AUD IO circuit.

(4) OTHERS (F)

(5) PIP (PIP) ・・・・・・・・・・・・・・・・・・・ This se t the s ettin g valu es( adjustm ent va lues) of th e P ICTURE-IN- PICT UR E circ uit.

(6) 3L Y/C (LYC) ・・・・・・・ ・・・・・・・・・ This i s us ed when the 3 L Y/C MODE is verified . [Do not adjust]

(7) LOW LIGHT

(8) HIGH LIGHT ・・・・・・・・・・・・・・・・ Thi s se ts th e setti ng values ( adj ust me nt val ues) of t he W HITE BALAN CE cir cuit

(9) RF AFC ・・・・・・・・・・・・・・・・・・・・ This is used when the RF AFC MODE is verified. [Do not adjust]

(10) VCO ・・・・・・・・・・・・・・・・・・・・ ・・・ This i s us ed w hen the I F VC O is adj us ted .

(11) I2C BU S ・・・・・・・・・・・・・・・・・・・・ This i s us ed w hen ON/O FF of t he I2C BUS CTRL is set. [Fixed ON]

(12) SY STEM ( SYS) ・・・・・・・ ・・・・・・・ This i s us ed w hen the S YST E M is ve rif ied. [Do not adjust]

3. Basi c Op era tio ns of the SERVI CE M ENU

(1) Ho w to enter the SERVICE MENU.

(2) SERVICE MENU screen selection

・・・・・・・ ・・・・・・・・・・・・・

・・・・・・・ ・・・・・・・・・

・・・・・・・ ・・・・・・・・・・

Press the SLEEP TIM ER key and set the SLE EP TIM ER for

「0 MIN」 .

Then press the DISPLA Y key and VIDEO STA TUS key of

the remote contr ol u nit at the same time to ent er th e

SERVICE MENU screen.

In SERVICE MENU, press th e FUNCTION ▼/▲ key to

sel ect an y of th e SU B MEN U it em s.

(The l e tte rs of the s elect ed it em s are disp layed in ye llo w. )

This se t th e s etting valu es (adjustment values) of th e DEFLECTIO N circuit.

Thi s is us ed w hen the O THERS MO D E i s ver i fi ed . [Do not adjust]

(PIP i s me ans as P icture I n P ictur e) [Do not have Function]

Thi s se ts th e s ettin g va l ues (a djust ment val u es ) of the WHITE BA LANCE cir cuit.

SERVIC E MENU

1.V/C(S) 2.DEF(D)

3.SOUND(A) 4.OTHERS(F)

5.PIP(PIP) 6.3L Y/C(LYC)

7.LOW LIGHT 8.HIGH LIGHT

9.RF AFC 10.VCO

11.I2C BUS 12.SYSTEM(SYS)

SELECT BY

OPERATE BY EXIT BY

EXIT

(3) Enter the any setting ( adjustment ) mode

"

1.V/C (S), 2.DEF (D), 3.SOUND (A), 4.OTHERS (F),

5. PIP ( PI P), 6. 3L Y/ C (LY C), 7. LO W L IG HT, 8 .HI GH

LIGHT, 9.RF AFC 10.VCO 1 1.I2C BUS an d 12.SYSTEM

(SYS) mode

1) If s elect an y of 1.V/ C (S) / 2.DEF (D) / 3.SOUND (A)

/ 4.OT HERS (F) / 5.PIP ( PIP ) / 6.3L Y/C ( LYC) /

7.LOW LIG HT / 8.HIGH LIGHT / 9.RF AFC /

10 .VC O / 11.I2C BUS /12.SY STEM (SYS) it ems ,

an d t he FU NCTION / key is pr es s ed fr om

SERVICE MENU ( MAIN MENU ), the each scree ns

will b e dis played as shown in figure page later.

2) The n the sett in gs or verification s ca n be p erfor m ed

KEY ASSIGNMENT OF REMOTE CONTROL UNIT

VIDEO

STA TUS

DISP LAY

FUNCTION

/

SLEEP

TIMER

FUNCTION

▼/▲

EXI T

14

No. 52009

Page 15

A

0

SERV ICE M ENU (MAIN MENU)

SE RV IC E M EN U

1.V/C (S) 2.DE F(D)

3.SOUND(A) 4. OTH ER S(F)

5.PIP (P IP) 6. 3L Y/C( LYC)

7.LOW LIGHT 8 .HIGH LIG HT

9.RF AFC 10 .VCO

11.12 C BUS 12.SYST EM(SYS)

SELECT BY

OPE RAT E BY EXIT BY

EXIT

V-N2932

1.V/C ( S)

R F 4 : 3 S T D L O W

S0 1 BR IG H T

2.DEF (D)

R F 4 : 3 S T D L O W

D 01 V F REQ

3.SOU ND(A)

A 01 IN L EVE L

***

***

***

7.LOW LIGH T

BRIGHT

***

***

***

8.HIGH LIG HT

***

9.RF AFC

TOO HIGH GOOD T OO LOW

T U NE R M AI N

AF G O N

FIN E

DO not ad ju st

**

4.OTHERS( F)

F0 1 OS D POSI

5.PIP(PIP)

PI P01 B RIG HT

6.3L Y/C(LY C)

LYC01 MODE

***

***

***

10.VCO

T U NE R MA IN

HI GH LE V EL

RE FERENCE LEVEL

LO W LEVEL

SY N C NO

11.I2C BUS

I2 C BU S ON

12.SY ST EM ( SY S)

SY S01 VIDE O IN

DO not ad ju st

***

No. 52009

15

Page 16

A

V-N29320

G

(4) Setting method

1) FUNCTION ▼/▲ key.

Select t he SETTIN G IT EM .

2) FUNCTION / key

Setti ng (adjust) the SETTIN G VA LUE of t he SETTIN G ITEM.

When the key is r el ea sed th e SET TI NG VAL UE w ill b e st ored

(memorized).

3) EX IT key

Retu rn s to the p revious scr een .

(5) Rel easing SERVICE MENU

1) Af ter retu rn i ng to t he SE RV ICE MENU up on c o mp l eti on of th e s etti n g

(adjus tment) wo rk, pr ess t he EXI T key ag ain.

★ The s etting s f or L OW LIGH T and HI GH L IGH T are des cribe d i n th e

WHITE BA LANCE p age of AD JU STMENT .

★ The s ettin g for MA IN VCO ar e d escribed in th e VC O p age of

ADJUSTM ENT.

SETTING N o

RF 4 : 3 STD LOW

SETTING

ITEM

1.V/C (S)

BRI GHT

***

***

***

7.LOW LIGHT

***S01 B RIG HT

SETTING VAL UE

***

8.HIGH LIGHT

TUNER MAIN

HI

H LEVEL

REF ERE NCE L EVEL

LOW LEVEL

SYNC NO

10.VCO

16

No. 52009

Page 17

A

V-N2932

0

INITIAL SETTING VALUE OF SERVICE MENU

1. Adjustment of the SERVICE MENU is made on the basis of the ini tial setti ng va lu es ; ho wev er, the new setting values whic h

set the scree n in its optimum condition may differ from the initial setting.

2. Do no t change the initial Setting Values of the Setting (Adjustment) items not listed In “ADJUSTMENT”.

"

V / C M O DE

Initial setting value

RF EXTERNAL (S,CV ) COMPONENTNo. Setting item

STANDARD THEATER STANDARD THEATER STANDARD THEATER

S01 BRIGHT

S02 PICTURE

S03 COLOR

S04 TIN T

S05 DET AIL

S06 BRIGHT +-

S07 PICT+ -

S08 COLOR +-

S09 TIN T+-

S10 DETAIL +-

No. Setting item

S11 R CUT OFF 50 --- --- --- --- --- --- ---

S12 G CUT OFF 50 --- --- --- --- --- --- ---

S13 B CUT OFF 50 --- --- --- --- --- --- ---

S14 R DRIVE 64 --- --- --- --- --- --- ---

S15 B DRIVE 64 --- --- --- --- --- ---

S16 R CUT+-

S17 G CUT+- --- 0 0 0 0 --- --- ---

S18 B CUT+- --- 0 0 0 -10 --- --- ---

S19 R DRV+- --- +5 +7 +7 0 --- --- ---

S20 B DRV+- ---+6-9-9 0 ---------

S21 NT SC MAT 33112211

S22 BLACK S T 2 - -- 1 - -- - -- - -- - -- - --

S23 DCREST 1 - -- 1 - -- - -- - -- - -- - --

S24 DCRSW 1 - -- 1 - -- - -- - -- - -- - --

64 --- --- --- --- ---

65 --- --- --- --- ---

45 --- --- --- 47 ---

60 --- --- --- 64 ---

30 - -- 35 --- 40 ---

--- 0 0 --- +3 ---

- -- - 15 0 --- 0 - --

----3-2---------

--- -6+2------ ---

--- +3 --- --- --- ---

Initial setting value

RF/EXT (S,CV)

STANDARD THEATER STANDARD

LOW HIGH LOW HI GH LOW HIGH LOW HI GH

--- 0 0 0 -10 --- --- ---

COMPONENT

--- c a n n ot be ad ju stm ent

THEATER

No. Setting item

S25 AS Y SHRP 444

S26 BP F FO 00---

S27 KIL R OFF 00---

S28 KIL R SEN 11---

RF EXTERNAL (S,CV ) COMPONENT

No. 52009

Initial setting value

17

Page 18

A

V-N29320

No. Setting item Initial setting value No. Setting it e m Initial setting v alue

S29 RGB MU TE 0 S3 9 Y MUTE 0

S30 BLUE B 0 S40 SVM G AIN 0

S31 VIDEO SW 3 S4 1 SV M PH 0

S32 CMP ABCL 0

S33 RGB ABCL 0 S43

S34 OSD CON T 9 S44 V1 GAI N 4

S35 SUB CONT 8 S45 AGC ADJ 80

S36 AB L GA IN 0 S46 VMOFF DE 0

S37 ABL PNT 3 S4 7 AP C CL K 1

S38 Y G AM MA 1

S42 WPL

COL G MM

0

0

"

DE F M O D E

Initial setting value Initial setting value

No. Setting item

D01 V FREQ 0303D18

D02 AFC GAI N 0202D19 EWCR TOP 16 16 16 16

D03 H POSI 12 12 12 12 D20

D04 H POSI+- --- --- --- --- D21 EWCR BTM 16 16 16 16

D05

V PHASE

D06 V PH+- --- --- --- --- D23 EW PARA 26 26 26 26

D07

V S IZE

D08 V SIZE +- --- --- --- --- D25 V EHT 0000

D09

V CENTER

D10

V CENT+- --- --- --- ---

D11

V S CORR

D12

V S CO+- --- --- --- ---

D13 V LIN 11 11 11 11 D30 TRAPEZ+- --- --- --- ---

D14 V LIN+- --- --- --- --- D31 V AGC 0000

D15 H SIZE 32 32 32 32 D32 BLANK SW 0000

D16

H SIZE +-

D17 WVMT TOP 0000

AV-N293 20/ S AV - N2 9320/ R AV- N2 9320/ S AV-N293 20/ R

RF EXT

0000D22

55 55 55 55 D24

32 32 32 32 D26

4433D28

--- --- --- --- D33

RF EXT

No. Setting item

RF EX T RF EX T

WVMT BTM

EWCR T+-

EWCR B+ -

EW PA RA+-

V EHT +-

D27

H EHT 0000

H EHT+-

D29

TR APE Z 34 34 34 34

VRMP BI

0000

--- --- --- ---

--- --- --- ---

--- --- --- ---

--- --- --- ---

--- --- --- ---

0000

--- c a n n ot be ad ju stm ent

" SOUND MODE

No. Setting ite m Init ial setting v al ue

A01 IN LEVEL 012

A02 LOW SEP 03 9

A03 HI SEP 01 6

A04 SA PC 00 0

A05 BB E BA SS 000

A06 BB E TRE 00 0

18

No. 52009

Page 19

A

V-N2932

0

"

OTHERS MODE (Do not adjust)

No. Setting item Init ial setting v al ue No . Setting it e m Initial setting value

F01 OSD POS I 27 F15 VCSN 1 0

F02 OSD PR EQ 83 F16 VCSN 2 10

F03 CCD POSI 45 F17 VCSN 3 20

F04 CCD FREQ 93 F18 VCSN STP 02

F05 OSD CONT 11 F19 VM D AT A +8

F06 PUR WBCK 0 F20 VM DAT B -4

F07 PUR CONT 62 F21 VM D AT C -10

F08 SN TYP E 0 F22 VM DAT D -16

F09 YC SN TM 5 F23 VM DAT E 0

F10 YC SN E 5 F24 VMOFF TY 0

F11 YC SN F 16 F25 YC VM OFF 255

F12 YC SN G 32 F26 EZSF T M 40

F13 VNR CHK 3 F27 XDSID T M 15

F14 VC SN TM 5 F28 FM TRAP 1

" 3L Y / C MODE (Do not adjust)

No. Setting item Init ial setting v al ue

LYC01 MO DE 4

LYC02 VE NH 1

LYC03 PDSO FF 0

LYC04 CB 0

LYC05 VNLR 2

LYC06 GSE L0 0

LYC07 GSE L1 1

LYC08 COR 0

LYC09 TRAP 1

LYC10 CHT RAP 0

LYC11 CBPF 0

LYC12 ENHOFF 0

Se tting item ca n n ot di s pla y

"

SY STEM MODE ( Do no t a djust )

No. Setting item

SY S01 VIDEO IN 2

SY S02 PIP 0

SY S03 3D Y/ C 0

SY S04 Y CV 0

SY S05 CCD PC HK 1

SY S06 PURITY 0 SYS18 C OMP ULINK 0

SY S07 VM 0

SY S08 NOISE CR 0

SY S09 CLR TEM P 0

SY S10 THEATE R 0

SY S11 THEATE R PRO 0

SY S12 BBE 0

Initial setting value

No. Se tting item Initial set ting v al ue

SY S13 HYP SU R R

SY S14 16:9 MD 0

SY S15 HYP S CA N 1

SY S16 EZ SU RF 0

SY S17 ID DISP 0

SY S19 CCD 1

SY S20 VCH IP 1

SY S21 VCH IP C A 1

SY S22 JVC L OGO 1

SY S23 CMP IN 0

SY S24 CXA1 875 0

No. 52009

0

19

Page 20

A

V-N29320

" PIP MODE (Do not adjust)

No. Se ttin g it e m Init ial se tting v al ue No . Setting it e m Initial setting value

PIP01 BRIGHT 0 PIP 27 U VPO LAR 0

PIP 02 PICTURE 30 PIP28 MAT 1

PIP 03 TINT 42 PIP29 YCOR 1

PIP 04 COLO R 6 PIP 30 XFREQF 1

PIP 05 R CUTO FF 0 PIP 31 WTCHDG 1

PIP 06 G CUTOFF 0 PIP 32 C OLO N 0

PIP 07 B CUTOFF 0 PIP33 ACQNEW 0

PIP 08 R DRI VE 63 PIP34 DSTD ET 1

PIP 09 G DRIVE 65 PIP 35 CRI BEOK 0

PIP 10 B DRIVE 65 PIP36 FCBEOK 0

PIP11 L POSI 22 PIP37 NOCRID 0

PIP 12 R POS I 15 PIP38 NONSED 0

PIP 13 UPR POS I 12 PIP 39 PIP AD J 4

PIP 14 LWR PO SI 11 PIP40 BRI EXT 0

PIP 15 PICT L CK 1 PIP 41 PCT EX T 0

PIP16 SELDEL 0 PIP 42 TN T EXT 0

PIP 17 AGCFIX 1 PIP 43 COR EXT 0

PIP18 AGCADST 0 PIP44 R-D EXT 0

PIP 19 AGC 7 PIP 45 G-D EXT 0

PIP 20 BL KINVB 0 PIP 46 B- D EXT 0

PIP 21 BL KINVR 0 PIP47 BRT COMP 0

PIP22 VSPDEL 0 PIP48 PCT COMP 0

PIP23 VSPISQ 1 PIP49 TNT COMP 40

PIP24 R GBIN 0 PIP50 C OR COMP 5

PIP 25 FR SEL 1 PIP 51 R-D COMP 0

PIP26 OUTFOR 0 PIP 52 G-D C OMP 0

PIP53 B-D COMP 0

NOTE

"

LOW LIGHT MODE

No. Setting ite m Initial setting value

1RED 50

2GREEN 50

3BLUE 50

"

HIGH L IGHT MODE

No. Setting ite m Initial setting value

1RED 64

2BLUE 64

The AV- N29 320 /S, R mo del d o not h av e PIP f unction, Bu t, i f m em or y da ta is o ut of v ar iab l e r an ge , occ as i ona lly s o me pr o blem s

h app en. Th en we ne ed to in pu t t hes e data .

20

No. 52009

Page 21

A

0

■

)

ADJUSTMENTS

B1 POWER SUPPLY

Item

Check of

B1 POWER

SUPP LY

Measuring

instrume nt

DC Volt met er 【【【【B1 】】】】

ADJUS TMENT OF VCO

Test point Ad justment part Description

1. R eceive the blac k-a nd -whit e sign al . ( c olo r off )

Connector

TP-91

TP-E(#)

2. C on nect th e DC vol tmet er to 【B1 】co nne ctor 【1】pin (TP-91)

an d TP -E (#) (B1 c on nect or【3】pin ).

3. Confirm that the voltage is DC134V±2V.

V-N2932

Item

MAI N VCO

adjus tme nt

TUNER MAIN

HIGH LEVEL

REF ERE NCE L EVEL

LOW LEVEL

SYNC NO

Measuring

instrume nt

Signal

gener ator

Test point Ad justment part Description

10.VCO MAIN

CW TRANSF.(T111

[MAIN PWB]

GREE N

"

It must n ot adjust w ithout sig nal

1. Se le ct a rece ivable br oa dcast .

2. Pu s h th e FU N CTI ON ▼ / ▲ key, and selec t th e 10.VC O

mod e from th e S ERVICE MENU.

3. Push the FUNCTION / key, and select MAIN.

4. C onf irm that the c o lo r ch an ge from 「HIGH LEV EL」 to 「LOW

LEVEL」 b y CW TRAN SF T11 1 at M AIN PW B, and ch eck th e

「SYNC : YES」.

5. Adjust until 「REFFERENCE LEVEL」 mark tu rn s gre en.

And th en con firm t hat the 「SY NC : YES」 ag ain.

ADJUS TMENT OF RF AGC

Item

RF. AGC

adjus tme nt

No. Setting item

S45 AGC ADJ 0~127 80

Measuring

instrume nt

Test point Ad justment part Description

S45 AGC ADJ 1. R eceive a bl ack and w hi t e signal (col or of f).

2. Select S45 AGC ADJ of th e V /C MODE.

3. Pr ess the MUTING ke y an d t urn of f c ol or .

4. Wi th th e FUNCTION k ey t o ge t th e n ois e in t he s cre en

pictu re ( zero s id e of s etting va lue) .

5. Press the FUNCTION key several times and st ep when

Variabl e

range

Initial setting

value

n ois e dis appear s f rom th e scr ee n ( a t th at ti me , n ot to in cr eas e

th e va lu e too mu ch).

6. Cha nge to oth er ch anne ls a nd make sur e t hat th er e I s n o

irregularity.

7. Press the MUTING key and get color out.

No. 52009

21

Page 22

A

V-N29320

(

)

)

ADJUS TMENT OF FOCUS

Item

FOCUS

adjus tme nt

Measuring

instrume nt

Signal

gener ator

Test point Ad justment part Description

FOCUS VR

[In HV T]

ADJUS TMENT OF DEFLECTION C IRCUIT

1. R eceive the cr oss -hatc h s i gn al .

2. Whi l e loo king at t he scr ee n, adj u s t th e F OC U S VR to the

vertical and horizontal lines will be clear and in fine detail.

3. M ake sure t hat th e pict ure is i n f ocus even whe n t he scr ee n

g ets d ar ken ed.

Item

V. HE IGHT

V. CENTER

adjus tme nt

Scr een

size

( 90.0 %)

Measuring

instrume nt

Signal

gener ator

Scr een s ize

Picture size (100 %

Test point Ad justment part Description

D05 V P HAS E

D07 V SI Z E

V. CENTER SW

(S40 1)

[MAIN PWB]

Picture

size

100 %

1. Recei v e th e cross -hatch sign al.

2. Se le c t t he D05 V PHASE of th e DE F (D) mod e, a nd it che cks

th at t he valu e of D05 V PHASE is 0.

3. Ad ju st the v e rt ic al sc r ee n s i ze of th e screen t op to 90. 0% wit h

the D07 V SIZ E an d V CENTER SW S401

No. Setting item

D05 V PHASE 0~7 0

D07 V SIZE 0~127 55

Variabl e

range

Initial setting

value

H. CENTER

adjus tme nt

22

Signal

gener ator

D03. H POSI 1. Rec ei ve th e cros s -hatch sign al.

2. Select D03. H PO S I from DEF ( D) mode .

3. Adjust by H POSITION to b e sa me size at both side .

Variabl e

No. Setting item

D03 H POSI 0~31 12

No. 52009

range

Initial setting

value

Page 23

A

0

ADJUS TMENT OF WHITE BALANC E

Item

WHITE

BALANCE

(Low Light)

adjus tme nt

Measuring

instrume nt

Signal

gener ator

BRI GHT

***

Test point Ad justment part Description

[LOW LIGHT]

***

***

R CUTOFF (S11)

G CUTOFF (S12)

B CUTOFF (S13)

BR IG HT (S 01)

SCREEN VR

[ in HVT]

V-N2932

1. R eceive the blac k an d w h it e s ign al ( colo r off ).

2. Select t he [LOW LIGHT] MODE f r om th e SERVICE MEN U.

3. Set the initial setting value of “R CUTOFF”, “G CUTOFF”

“B CUTOFF” and BRIGHT.

4. D isp lay a si ng le ho rizo nta l line by p ressing t he ①①①① key of t he

remote control unit.

5. T ur n t he s creen VR a l l the way t o t he left.

6. Turn th e s creen V R g ra du all y t o the righ t from th e l eft u nti l

eith er o ne of the red, blu e o r g r een colors ap pears f aintl y.

7. Adju s t the tw o c ol or s whi c h d id no t a ppe ar u ntil th e s ing l e

h orizo ntal l in e t hat is di spla yed bec omes whit e us ing th e ④④④④ to

⑨⑨⑨⑨

keys o f th e re mo te c ont r ol un it .

8. T ur n the s cree n VR u ntil the s i ng l e hor i zon tal lin e i s displa yed

fain tly.

9. Pr es s the

10 . Ad ju st th e BRIG HT lev el to b ecom e th e blac k compon en t

shines whit e slightly.

11 . C onf irm that whet her the color ing redie nt of R,G, or B is visible

to th e b l ack c o mp one nt, which shines w hi te sl ig htly

12 . When the c ol o r in gr ed ient can be seen , t wo colors o ther tha n a

visible color are adjusted, and it is made to look white.

13. Return the value of BRIGHT to initial s etting value.

②②②②

key to cancel the single horizontal line mode.

REMOTE CONTROL UNIT

H. LI NE ON EXI TH. LI NE OFF

1 2 3

R CU TOFF B CUT OFFG C UTO FF

54

R CU TOFF B CUT OFFG C UTO FF

●

③③③③

The

EXIT key is the cancel key for the WHIT E BALANCE.

No. Setting item

Variabl e

range

Initial setting

value

S11 R CUT OFF 0~255 50

S12 G CUT OFF

6

S13 B CUT OFF

S01 BRIG HT

987

0~255

0~255

0~127

50

50

64

No.52009

23

Page 24

A

V-N29320

Item

WHITE

BALANCE

(Hi gh Light)

adjus tme nt

Measuring

instrume nt

Signal

gener ator

[HIGH LIGHT]

***

Test point Ad justment part Description

R DRI VE ( S1 4)

B DR I VE ( S 1 5)

1. R eceive the blac k-a nd -w hit e si gn al ( co lo r off ) .

2. Select t he [HIGH LI GHT] MODE in the SERVICE MENU.

3. Set the initial setting value of “R DRI VE” and “B DRIVE” with

the ④④④④, ⑥⑥⑥⑥ , ⑦⑦⑦⑦and ⑨⑨⑨⑨ k eys of the rem ot e contr o l unit.

4. Ad jus t th e scr een u ntil i t b ecomes w h it e usi ng th e ④④④④ , ⑥⑥⑥⑥, ⑦⑦⑦⑦

an d ⑨⑨⑨⑨ keys of the rem ot e contr o l unit.

●The ③③③③ EXIT key is the cancel key for the WHIT E BALANCE.

Remote Control Unit

①key : H.LINE ON

②key : H.LINE OFF

③key : E XIT

④key : R DRIVE ▲

⑥

key : B DRIVE

⑦key : R DRIVE ▼

⑨key : B DRIVE ▼

No .

S14 R DRI VE

Settin g item Va riabl e

range

0~127

▲

Initial setting

value

64

SUB BRIGHT

adjus tme nt

No. Setting item Variable

S01 BRIG HT

SUB

CONT RAST

adjus tme nt

No. Setting item Variable

range

0~127

range

S15 B DRIVE

S0 1. BR I G HT 1. R ec eive the b r oad cast.

2. Select S0 1. BRI G HT of th e V /C MODE.

3. Set the in iti al s ettin g value of the S01. BR IGHT wi t h t he

FUNCTION / key.

4. If the brigh tness is not the best wit h the initial sett ing value,

make fine a djustm en t of th e S01. BRI GHT unt il you ge t the

Initial setting

value

64

S02. PICTURE 1. Rec eive the b r oad cast.

Initial setting

value

op ti mu m br i ght ness .

2. Select S0 2 . PI CT URE of the V/C M ODE.

3. Set th e i n itial s e tting valu e of th e S0 2. PICT URE with the

FUNCTION / key.

4. If the contrast is not t he best with t he initial setting value, make

fin e adj ust me nt of th e S02. PICTURE until you get the

optimum contrast.

0~127

64

S02 PICTURE

24

0~127

65

No.52009

Page 25

A

V-N2932

0

y

G

g

Item

adjus tme nt

Measuring

instrume nt

Signal

gener ator

Remote

control unit

gener ator

Oscilloscope

Remote

control unit

Test point Ad justment part Description

[ Method of adj ustment without measuring i nstrument ]SUB COLOR

1. R eceive the b r oad c ast.

2. Select S03. COLOR of th e V/C M ODE.

3. Set the initial setting value of the S0 3. C OLOR with the

FUNCTION / key.

4. If t he c ol or i s n ot t he best with th e I nitial se tting valu e, m ak e

fin e a djust ment of the S0 3. COLOR unt il you g et t he o ptimum

color.

Setting item

No .

S03 COLOR

[ Method of adj ustment using measuring instrument ]Signal

1. Inp ut the fu l l fi el d c olor bar sign al ( 7 5% whit e) .

2. Select S03. COLOR of th e V /C MODE.

3. Se t th e i ni ti al sett ing v alu e of the S0 3. C OLOR with the

FUNCTION / ke y.

4. C on nect th e osc ill osc ope be twee n TP-B and TP-E.

5. Ad just COL OR and b rin g t he v al u e of (A) in the illustration to

th e vo lt age sh ow n in th e table be llo w.

Variabl e

range

0~127

TP-B

TP-E(#### )

[CRT

SOCKET

PWB]

S03. COLOR

S03. COLOR

Initial setting

value

45

W-B

Models

AV-N293 20/ S +10V

AV-N293 20/ R + 17V

W

C

M

RY

(A)

(-)

0V

(+)

B

No. 52009

Volt age

25

Page 26

A

V-N29320

(B)

g

(-)

Item

SUB TINT

adjus tme nt

Measuring

instrume nt

Signal

gener ator

Remote

control unit

gener ator

Oscilloscope

Remote

control unit

Test point Ad justment part Description

[ Method of adj ustment without measuring i nstrument ]

1. R eceive the b r oad c ast.

2. Select S04. TINT of the V/C M ODE.

3. Se t the initial s etti ng v alu e of t he S0 4. T I NT with the

FUNCTION / ke y.

4. If the ti n t is not th e bes t with the i ni ti a l set ting v al u e, make fine

ad justmen t of th e S04. TINT u ntil yo u g et t he opti mum ti nt.

No. Setting item

S04 TIN T

[ Method of adj ustment using measuring instrument ]Signal

1. Inp ut th e fu l l fi el d c olor b ar si gn al ( 7 5% whit e) .

2. Select S04. TINT of th e V/C M ODE.

3. Se t the initi a l s ettin g value of th e S0 4. T I NT with the

FUNCTION / key.

4. C on nect th e osc illosc ope be tw ee n TP-B and TP-E.

5. Ad jus t TI NT an d br i ng th e val u e of (B ) in the il lustration to the

voltage shown in the table bellow.

Variabl e

range

0~127

TP-B

TP-E(#### )

[CRT

SOCKET

PWB]

S04. TI NT

S04. TI NT

Initial setting

value

60

W

CyG

BRY

0V

(+)

W-Mg

Models

AV-N293 20/ S +18V

AV-N293 20/ R + 25V

Volt age

M

26

No. 52009

Page 27

A

0

ADJUS TMENT OF MTS CIRCUIT

V-N2932

Item

MTS IN PUT

LEVE L

che ck

MTS

SE PARATIO N

adjus tme nt

Measuring

instrume nt

TV audi o

mult iplex

signal

gener ator

Oscilloscope

Test point Ad justment part Description

A01 IN LEV EL 1. Se le ct t he A01 IN LEV EL of the SOUND MODE.

2. Verif y that the A01 IN LEVEL is set at its initial sett ing value.

No. Setting item Variable

range

A01 IN LEVEL 0~15 01 2

R OUT

L OUT

[AUDIO OUT]

A02 LOW SEP.

A03 HI SE P.

1. Inp ut th e ste r eo L s ig na l (30 0H z) f r om t he TV au dio multi ple x

si gn al g ene r ator t o the ant enna term in al .

2. Connect an oscilloscope to R OUT pin of the AUDIO OUT, and

disp lay on e c ycle p ort ion of t he 300H z si g nal.

3. Se lec t t he A02 LOW SE P. of the SOUND MODE.

4. Set the initial setting value of the A02 LOW SEP. with the

FUNCTION / key.

5. Ad jus t t he A02 LOW SE P. so that the stroke element of the

300Hz signal will bec ome minimum.

6. C ha nge th e con nect i on of th e osci l lo scop e t o L O UT pin of th e

AUDIO O UT , and en lar ge th e volt age axi s.

7. C ha nge t he si g nal to 3 k H z, an d si milarly a djus t t he A0 3 H I

SE P.

Initial setting

value

1 cycle

L- Chann el

signal wave form

R-C hannel

crosstalk por ti on

Mi n i m u m

Setting item

No .

A02 LOW SEP.

A03 HI SE P.

Variabl e

range

0~63

0~63 01 6

Initial setting

value

03 9

No. 52009

27

Page 28

A

V-N29320

9XC529R53 3D526

3

Q9

Q923R9

HOW TO CHECK THE HIGH VOLTAGE HOLD DOWN C IRCUIT

1. HIGH VOLTAGE HOLD DOWN CIRCUIT

After repairing the high voltage hold down c ircuit shown in Fig. 1.

Thi s ci r cuit sh all b e ch eck ed to op erat e co rrect ly.

2. CHECKING OF THE HIGH VOLTAG E HOLD DOWN CIRCUIT

(1) Turn the power swit ch to on.

(2) As shown in Fig. 1, set the resistor between X c on nec tor 1 a nd 3 .

(3) Make sure t hat th e scr ee n pic ture disappe ar s.

(4) Temporarily unplug the power plug.

(5) Remove the resistor replaced X con nect or 1 an d 3 .

(6) Ag ai n plug th e pow er pl u g, ma ke su re that t he norm al pi ctur e is displ a yed on th e scr ee n.

RESISTOR

Ω±

Ω±

Ω±Ω±

D931

22

HEATER

2 1

22

4

R52

Fig. 1

28

No. 52009

Page 29

A

0

REPLACEMENT OF CHIP COMPONENT

!

CAUT IONS

1. Avoid heating for more than 3 seconds.

2. D o n ot ru b the elect ro des an d the r esis t p arts of the p att ern.

3. W hen r em oving a c hip part, mel t th e s older adequ ately.

4. D o n ot r euse a ch ip p ar t afte r re mo ving it .

! SOLDERING IRON

1. U se a hi g h i ns ulatio n s older i ng iron with a t hin po in ted end of it .

2. A 3 0w s older i ng iron is r ec ommend ed for easil y rem oving par ts.

! REPLACEMENT STEPS

1. How to remove Chip parts

#### Resi st o rs, capacit ors , etc

(1) As s h own in the f igure, pu s h th e pa rt with tw ee zer s and

alte rn at ely melt the s ol de r at each end.

(2) Sh if t with tweeze rs and r em o ve the ch ip p ar t.

#### Tr ans ist o rs, d io des , va ria bl e r esist or s, etc

(1) Ap pl y e xt ra so lder to each le ad .

SOLDE R SO LD ER

V-N2932

2. How to install Chip parts

####

Resi st o rs, capacitor s , et c

(1) Ap ply sold er to the pattern as indic ate d in the figure.

(2) Gr asp the c h i p p art with tw ee z er s and pl ac e it on th e s old er.

The n hea t and me lt th e solder a t b oth en ds of t he chi p part.

#### Tran s istors, diodes , varia bl e r esist or s, etc

(1) Ap ply sold er to the pattern as indic ate d in the figure.

(2) Grasp the ch ip p art wit h t we eze rs and p lace it on the s o l der .

(3) First solder lead A as indicated in t he figure.

A

(2) As s h own in the f igure, pu s h th e pa rt with tw ee zer s and

alte rn at ely melt th e sol d er at each l e ad. S hi ft an d r em ov e the

chip part.

(4) T he n s o ld er l e ads B and C.

Note : A fte r re moving t he part , r emove remain ing solder fr o m the

pattern.

C

A

C

No.52009

B

B

29

Page 30

A

V-N29320

30

No.52009

Loading...

Loading...