Page 1

SERVICE MANUAL

COLOR TELEVISION

AV-36P903

AV-32P903

BASIC CHASSIS

AV-36P903

AV-32P903

/Y

/Y

SBⅡⅡⅡⅡ

CONTENTS

SPECIFICATIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

SAFETY PRECAUTIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

FEATURES・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

FUNCTIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

SPECIFIC SERVICE INSTRUCTIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

SERVICE ADJUSTMENTS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

PARTS LIST ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

★ OPERATING INSTRUCTIONS

★ STANDARD CIRCUIT DIAGRAM ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

COPYRIGHT © 2002 VICTOR COMPANY OF JAPAN, LTD.

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 2

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・ 3

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・ 17

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 51

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・ 4

・・・・・・

・・ 8

・・・・

・・・・・・・・・・・・ 10

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・ 2-1

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

No.52008

Jul. 2002

July 2002

Page 2

A

V-36P903

A

V-32P903

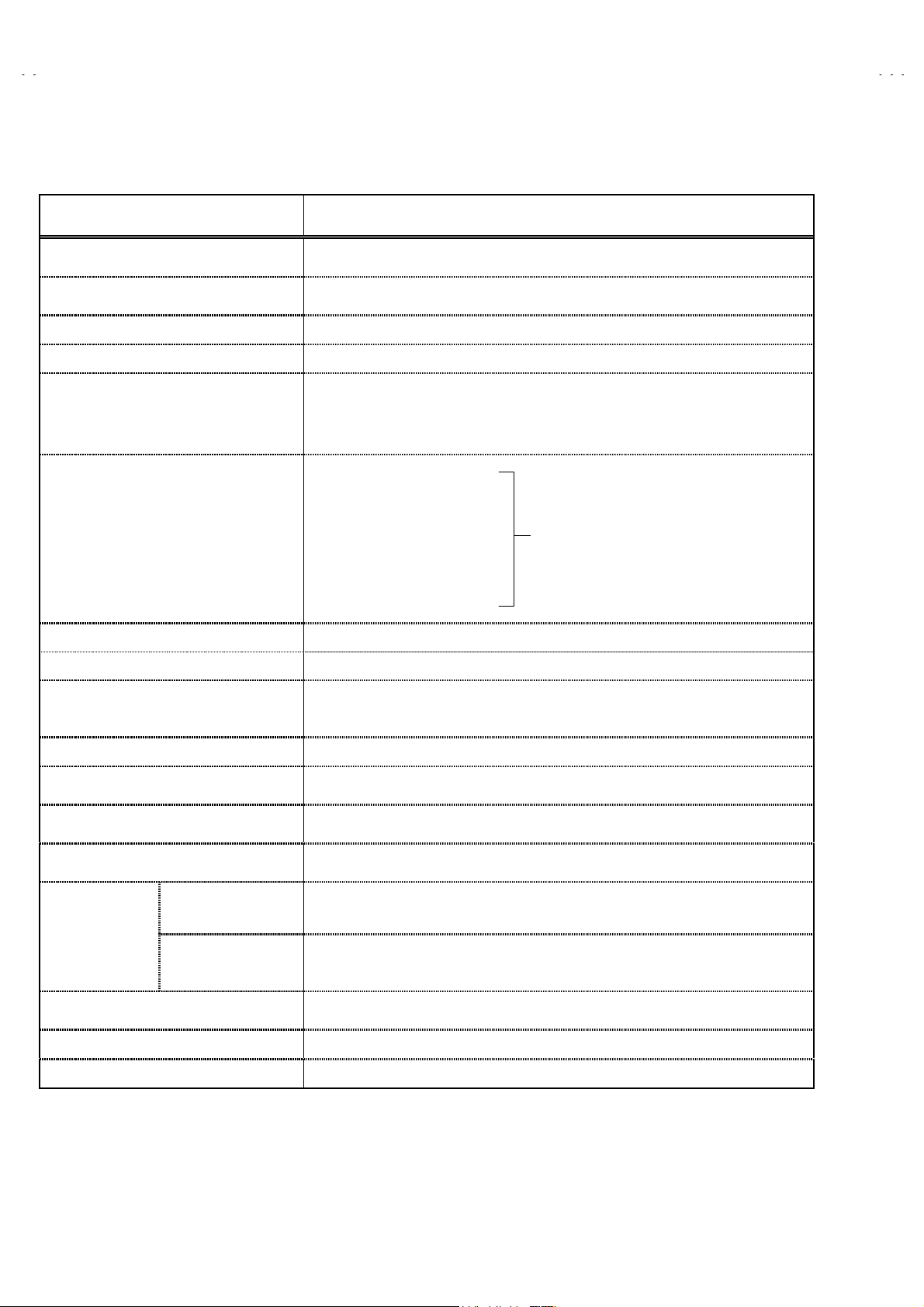

SPECIFICATIONS

Items Contents

Dimensions (W××××H××××D)

Mass

TV RF System CCIR(M)

Color Sound System NTSC / BTSC System (Multi Channel Sound)

TV Receiving Channels and Frequency

VL Band

VH Band

UHF Band

CATV Receiving Channels and Frequency

Low Band

High Band

Mid Band

Super Band

Hyper Band

Ultra Band

Sub Mid Band

TV/CATV Total Channel 181 Channels

Antenna terminal 75Ω(VHF/UHF) Terminal, F-Type Connector

Intermediate Frequency

Video IF Carrier

Sound IF Carrier

Color Sub Carrier 3.58MHz

Power Input

Power Consumption

Picture Tube

High Voltage

Speaker

Audio Power Output

External Input

Video

Audio (R/L)

S-Video

component

Audio Output Variable

Fixed

Digital- In DVI 25pin connector Digital-In terminal is not compatible with computer signal.

38-1/8”×30-3/8”×24-1/8” inch (967mm×770mm×610mm) [AV-36P903

34-5/8”×27-5/8”×22-1/4” inch (877mm×699mm×565mm) [AV-32P903

187.0 Ibs (85.0 kg) [AV-36P903

145.2 Ibs (66.0 kg) [AV-32P903

(02~06) 54MHz~88MHz

(07~13) 174MHz~216MHz

(14~69) 470MHz~806MHz

(02~06, A-8) by (02~06&01)

(07~13) by (07~13)

(A~1) by (14~22)

(J~W) by (23~36)

(W+1~W +28) by (37~64)

(W+29~W +84) by (65~125)

(A8, A4~A1) by (01, 96~99)

45.75MHz

41.25MH z (4.5MHz)

120V AC, 60Hz

215W

36” (90cm)/32”(80cm) Measured Diagonally

32kV±1.0kV (at zero beam current)

2”×4-3/4” (5cm×12cm) Oval type×2

5W +5W

1Vp-p, 75Ω

500mVrms ( -4dBs ), High Impedance

Y: 1Vp-p Positive (negative sync provided, when terminated with 75Ω)

p-p

C: 0.286V

/ PR : 0.7Vp-p, 75Ω

P

B

More then 0~1000mVrms (+2.2dBs), LOW Impedance(400Hz when modulated 100%)

500mVrms(-4dBs) Low Impedance (400Hz when modulated 100%)

(burst signal, when terminat ed with 75Ω)

/Y]

/Y]

(54MHz~804MH z)

/Y

/Y

]

]

Remote Control Unit RM-C324G (AA/R6/UM-3 battery×2)

Design & specifications are subject to change without notice.

2

No.52008

Page 3

A

A

SAFETY PRECAUTIONS

V-36P903

V-32P903

1. The design of this product contains special hardware, many

circuits and components specially for s afety purposes. For

continued protection, no changes should be made to the

original design unless authorized in writing by the manufacturer.

Replacement parts must be identical to those used in the

original circuits. Servic e should be performed by qualified

personnel only.

2. Alterations of the design or circuitry of the products should not

be made. Any design alterations or additions will void the

manufacturer's warranty and will further relieve the

manufacturer of r esponsibility for personal injury or property

damage resulting therefrom.

3. Many electr ical and mechanical parts in the products have

special safety-related characteristics. These characteristics are

often not evident from visual inspection nor can the protection

afforded by them necess arily be obtained by using

replacement c omponents rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in the parts list of Service manual.

Electrical components having such featur es are ident ified

by shading on the schematics and by (!!!!) on the parts list

in Service manual. The use of a substitute replacement which

does not have the same safety characteristics as the

recommended replacement part shown in the parts list of

Ser vice man ual may c aus e s hoc k, fire, or oth er haz ar ds.

4. Use isolation transformer when hot chassis.

The chassis and any sub-chassis c ontained in some products

are connect ed to one sid e of the AC power lin e. An isolati on

transformer of adequate capacity should be inserted between

the product and the AC power supply point while performing

any service on s ome products when the HOT chassis is

exposed.

5. Don't short between the LIVE side ground and ISOLATED

(NEUTRAL) side ground or EARTH side ground when

repairing.

Some model's power circuit is partly different in the GND. The

differenc e of the GND is shown by the LIVE : (") side GND,

the ISOLATED(NEUTRAL) : (#) side GND and EARTH : ($)

side GND. Don't short between the LIVE side GND and

ISOLATED(NEUTRAL) side GND or EARTH side GND and

never measure with a measuring appar atus (osc illosc ope etc.)

the LIVE side GND and ISOLATED(NEUTRAL) side GND or

EARTH side GND at the same time.

If above note will not be kept, a fuse or any parts will be br oken.

6. If any repair has been made to the chassis, it is recommended

that the B1 setting should be checked or adjusted (See

ADJUSTMENT OF B1 POWER SUPPLY).

7. The high voltage applied to the picture tube must conform with

that specified in Service manual. Excessive high voltage can

cause an increase in X-Ray emission, arcing and possible

component damage, therefore operation under excessive high

voltage conditions should be kept to a minimum, or should be

prevented. If severe arcing occurs, remove the AC power

immediately and det ermine the cause by visual inspection

(incorrect installation, cr acked or melted high voltage harness,

poor soldering, etc.). To maintain the proper minimum level of

soft X-Ray emission, components in the high voltage circuitry

including the picture tube must be the exact replacements or

alternatives approved by the manufacturer of the c omplet e

product.

8. Do not check high voltage by drawing an arc. Use a high

voltage meter or a high voltage probe with a VTVM. Discharge

the picture tube before attempting meter connection, by

connecting a clip lead to the ground frame and connecting the

other end of the lead through a 10kΩ 2W resistor to the anode

button.

9. When service is r equired, obser ve the original lead dr ess.

Extra precaution should be given to assure correct lead dress

in the high voltage circuit area. Where a short circuit has

occurred, those c omponents that indicate evidence of

overheating should be replaced. Always use the

manufacturer's replacement c omponents.

10. Isolation Check

(Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an isolation

check on the expos ed metal parts of the c abinet (antenna

terminals, video/audio input and output terminals, Control

knobs, metal cabinet, scr ewheads, earphone jack, control

shafts, etc.) to be sure the product is s afe to operate without

danger of electrical shock.

(1) Dielectr ic Strength Test

The isolation between the AC primary circuit and all metal parts

exposed to the user, particularly any exposed metal part having

a return path to the chassis should withstand a voltage of

1100V AC (r.m.s.) for a period of one second.

(. . . . W ithstand a voltage of 1100V AC (r.m.s.) to an appliance

rated up to 120V, and 3000V AC (r.m.s.) to an appliance rated

200V or more, for a period of one second.)

This method of test requires a test equipment not generally

fou nd in th e s er vic e trade.

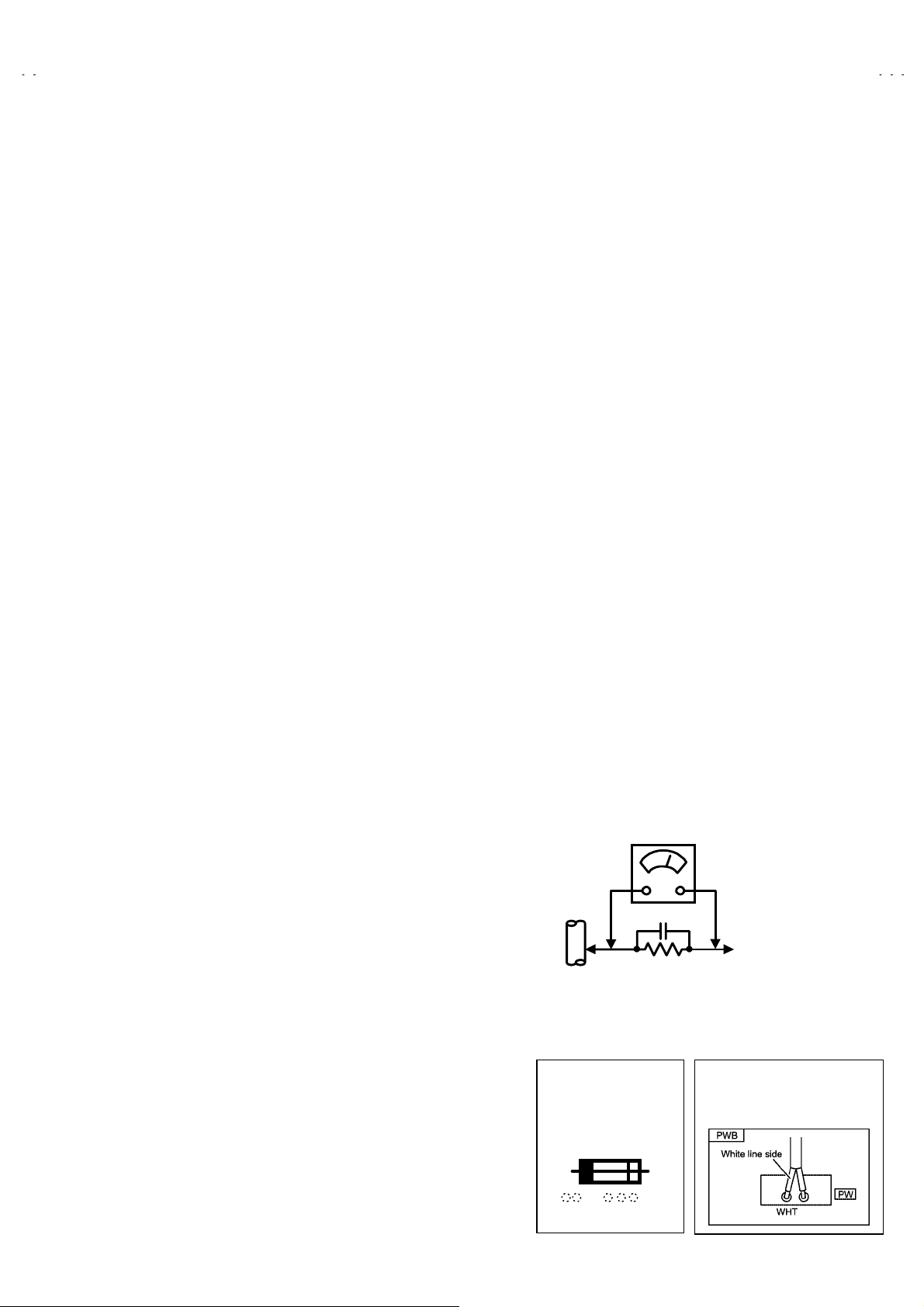

(2) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use a

line isolation transformer during this check.). Using a "Leakage

Current Tester", measure the leakage current from each

exposed metal part of the cabinet, particularly any exposed

metal part having a return path to the chassis, to a known good

earth gr ound (water pipe, etc.). Any leakage current must not

exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

"""" Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not use a

line isolation transformer during this check.). Use an AC

voltmeter having 1000 ohms per volt or more sensitivity in the

following manner. Connect a 1500Ω 10W resistor paralleled

by a 0.15μ F AC-type capacitor between an exposed metal

part and a known good earth ground (water pipe, etc.).

Measure the AC voltage across the resistor with the AC

voltmeter. Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return path to

the chassis, and measure the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Any voltage measur ed must not exceed 0.75V

AC (r.m.s.). This corresponds to 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000

GOOD

EARTH

GROUND

11. High voltage hold down circuit check.

After repair of the high voltage hold down circuit, this circuit

shall be checked to operate c orrectly.

See item "How to check the high voltage hold down

circuit".

This mark shows a fast

operating fuse, the

letters indicated below

show the rating.

0.15μF AC-TYPE

1500

10W

Ω

OR MORE SENSITIVITY)

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

POWER CORD

REPLACEMENT W ARNING.

Connecting the white line side of power

cord to “WHT” character side.

/V,

Ω

A V

No. 52008

3

Page 4

A

V-36P903

A

V-32P903

FEATURES

■ Multi screen function

• Dual screen (P&P)

Two programs can be seen at once.

• Contents index.

A favorable program can be selected from the nine

preview PIPs on the screen.

■ Provided with twin tuner / twin mode (16:9&4:3mode).

■ Multifunctional remote control permits picture

adjustment.

■ The CH.GUARD function prevents the specific

channels from being selected, unless the “ID

number” is entered.

2

C bus control utilizes single chip ICs.

■ I

■ Adoption of the VIDEO STATUS function.

• The VIDEO STATUS key gives you a choice of 3

picture display settings, including a display of your

own preferences.

STANDARD DYNAMIC THEATER

■ Digital-In

To receive digital broadcasts.

Digital-In will display when the 480p (or 1080i)

picture signal in Digital-In is displayed.

■ Natural Cinema

When you watch the movie or animation, press the

Natural Cinema to adjust the out line of the images

to make thin more sharp.

■ Built-in V-CHIP system.

• This TV is equipped with V-CHIP technology which

enables TV parental guidelines and movie

guideline controls.

■ Closed-caption broadcasts can be viewed.

■ Built-in MTS (

In addition to mono or stereo sound, an MTS

broadcast may also include a Second Audio

Program (SAP).

■ Built-in HYPER-SURROUND system & BBE sound

system.

■ S-VIDEO input terminal for taking best advantage

of Super VHS.

■ Digital Comb filter Improves picture quality.

■ Plug-In menu

The plug-In menu comes up automatically when

you first turn on the TV after plugging it in.

Multi-channel Television Sound

) system.

4

No.52008

Page 5

A

A

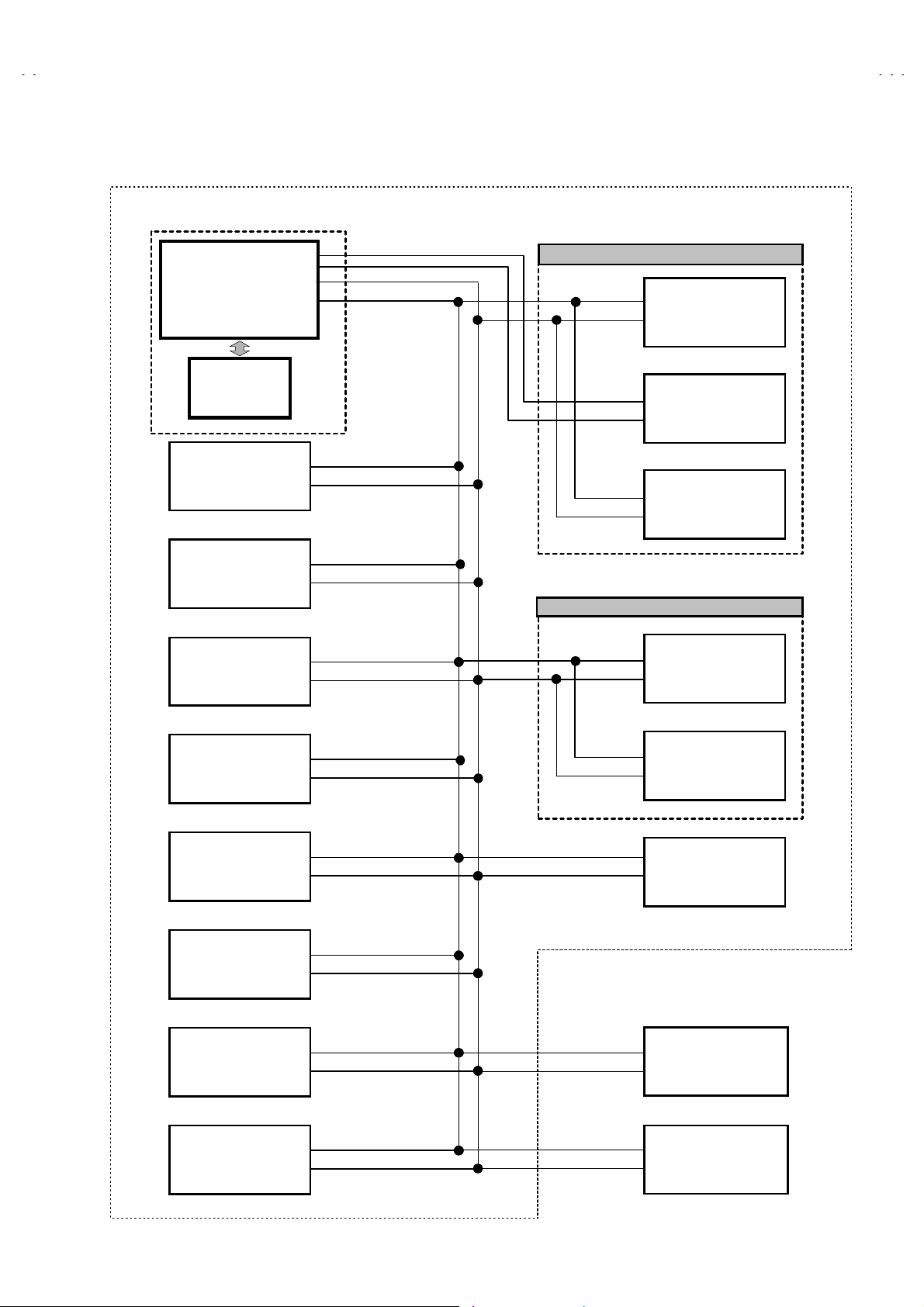

SYSTEM BLOCK DIAGRAM

MAIN PWB

SDA2

SCL2

V-36P903

V-32P903

SUB TUNER (RECEIVER) PWB

MAIN MICROCOMPUTER

IC701

IC703

MEMORY IC

TU101

U / V TUNER

IC501

AV SELECTOR

IC211

HD SYNC

SDA0

SCL0

TU101

U / V TUNER

IC201

MTS & TONE / VOL

CONTROL

IC651

MICOM LATCH

DEF OSC PWB

IC161

DEF CONTROL

IC241

CHROMA

DECODER

IC301

RGB PROCESSOR

IC302

DAC

IC502

MICOM LATCH

IC560

MICOM LATCH

IC212

DEF CONTROL SW

IC151

COMPONENT SW

DIGITAL INPUT

MODULE

I/P MODULE

No. 52008

5

Page 6

A

V-36P903

A

V-32P903

■■■■ MAIN MICON (CPU) FUNCTION

(MIN102H57K)

PIN

№№№№

PIN NAME

1 NC

2 /VSYNC

3 LB_PRO

4 NC

5 /RST

6 NC

7 /TEST

8 YS

9 NC

10 NC

11 A_MUTE

12 /HSYNC

13 M_MUTE

14 OSDXI

15 OSDXO

16 NC

17 AC_IN

18 NC

19 /TU_POW

20 VCOI

21 PDO

22 /IP_RESET

23 YM

24 B

25 LED_POW ER

26 G

27 R

28 VREF

29 IP_ERR

30 IREF

31 COMP

32 AVDD

33 CLL

34 VREFLS

35 SUB_CCD

36 NC

37 VSS

38 MAIN_CCD

39 VREFHS

40 CLH

41 VDD

42 LED_DATA

I/O

I/O

I/OI/O

OOOO

NC

IIII

V.SYNC IN for OSD

IIII

LOW B Protection

-

NC

IIII

Micon Reset input

OOOO

NC

IIII

+3.3V

OOOO

OSD YS OUT

OOOO

Micon test pin

OOOO

NC

OOOO

TV Sound Muting

IIII

H.sync input for OSD

OOOO

Monitor Out Muting

-

-

OOOO

NC

IIII

AC 50/60Hz in

OOOO

NC

OOOO

Tuner Power Control

IIII

LPF input

OOOO

LPF output

OOOO

OOOO

OSD YM out

OOOO

OSD Blue out

OOOO

LED for Power

OOOO

OSD Green Out

OOOO

OSD Red Out

IIII

IIII

AMDP pr ogram load det.

IIII

IIII

IIII

+3.3V

IIII

For Sub CCD

IIII

STD VOL in for Sub CCD

IIII

For Sub CCD

-

NC

IIII

GND

IIII

For main CCD

IIII

STD VOL in for CCD

IIII

For main CCD

OOOO

+3.3V

OOOO

Front control Data

FUNCTION

PIN

№№№№

PIN NAME

43 LED_CLOCK

44 LED_ON_TIMER

45 SB01

46 SBD1

47 SBT1

48 INC

49 ECO.RST

50 ROT COIL L

51 ROT COIL R

52 H_BLK

53 SN_ COIL_R

54 SN_ COIL_L

55 NC

56 I2C.STOP

57 TU2_A/D(AFC2)

58 /LOB_POW

59 NC

60 /POWERGOOD

61 /MECA_ON

62 /MAIN_POW

63 NC

64 /B1 POW

65 AFC1

66 X-RAY

67

68 KEY2

69 KEY1

70 SCL1

71 SDA1

72 REMO

73 NC

74 VSS

75 OSC2

76 OSC1

77 VDD

78 SCL0

79 NC

80 SDA0

81 SCL2

82 SDA2

83 NC

84 P MUTE

I/O

I/O

I/OI/O

OOOO

OOOO

OOOO

IIII

IIII

IIII

OOOO

OOOO

OOOO

OOOO

OOOO

Terrestrial Magnetism Sensor

OOOO ↑

OOOO

OOOO

IIII

OOOO

IIII AV CompulinkⅢInput

IIII

IIII

OOOO

-

OOOO

IIII

IIII

OOOO

IIII

IIII

OOOO

I/O

I/O

I/OI/O

IIII

OOOO

IIII

OOOO

IIII

IIII

OOOO

OOOO

I/O

I/O

I/OI/O

OOOO

IIII

-

OOOO

FUNCTION

F. LED CLK

LED on timer

Use for

Use for ON board W riting

NC

Eco Rest

Picture rotation

Picture rotation

H.BLK

NC

I2C BUS STOP

Tuner2 gain input

LOB power control

Power Condition Check

Machine SW Interrupt

MAIN POWER CONTROL

NC

B1 POWER CONTROL

AFC main in

X-ray detection

Front Key input 2

Front Key input 1

I2C BUS (CLK) for E2PROM

I2C BUS (SDA) for E2PROM

Remocon IN

NC

GND

4MHz OSC

4MHz OSC

+3.3V

I2C BUS (CLK) for General

NC

I2C BUS (SDA) for General

I2C BUS (CLK) for MTS

I2C BUS (SDA) for MTS

NC

Picture muting

6

No.52008

Page 7

A

A

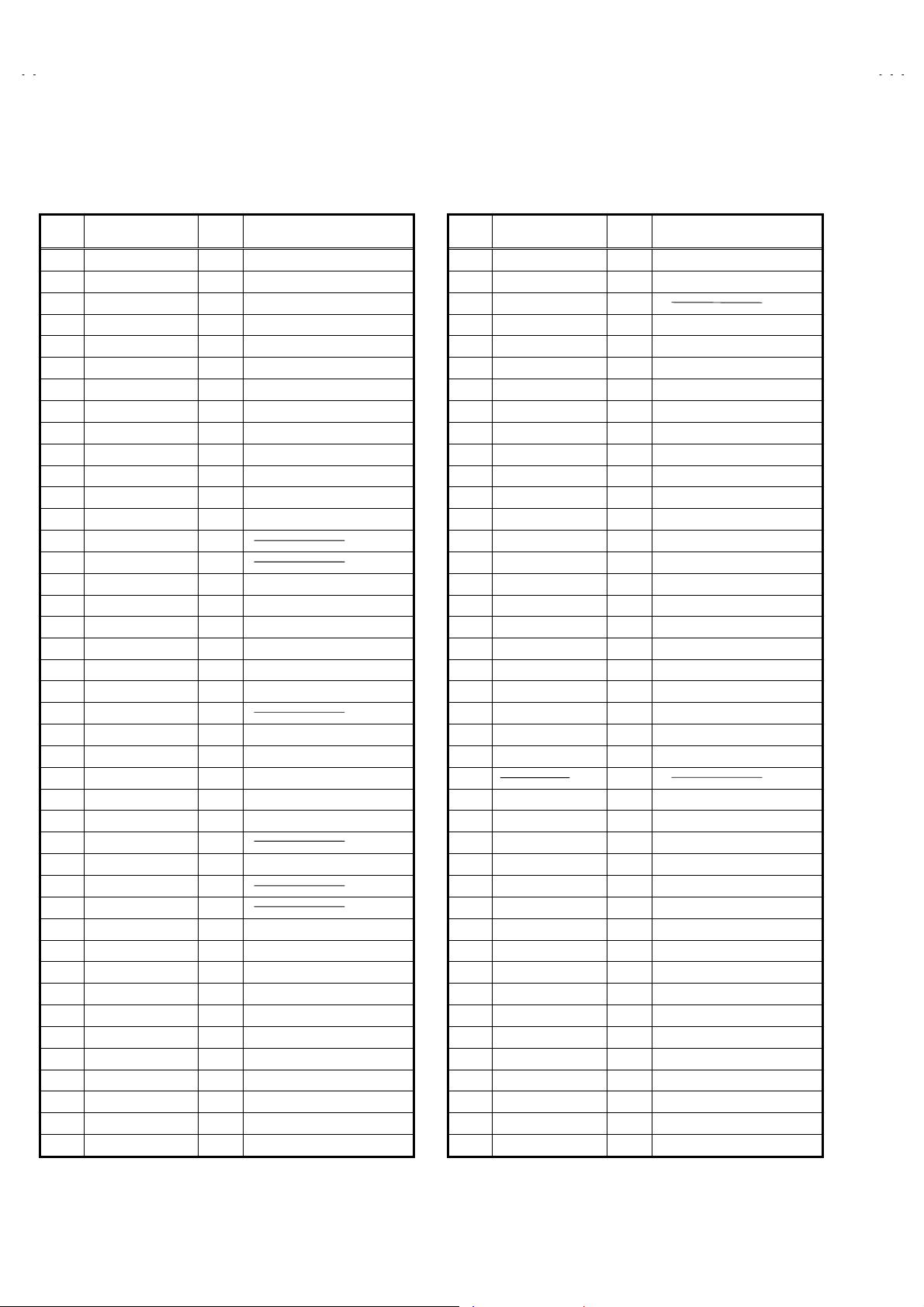

■■■■ DIGITAL-IN TERMINAL FUNCTIONS

V-36P903

V-32P903

PIN

No.

1 RX2- 13 RX3+

2RX2+14 5V

3 GND2/ 4 15 GND

4RX4-16HTPLG

5 RX4+ 17 RX0-

6 SCL 18 RX0+

7 SDA 19 GND0/5

8NC20RX5-

9 RX1- 21 RX5+

10 RX1+ 22 GNDC

11 GND1/3 23 TXC+

12 RX3- 24 TXC-

PIN NAME

PIN

No.

25 GND

PIN NAME

PIN ASSIGNMENT

17

18

19

20

21

22

23

24

25

9

10

1

2

11

3

12

4

13

5

6

14

7

8

15

16

No.52008

7

Page 8

A

V-36P903

A

V-32P903

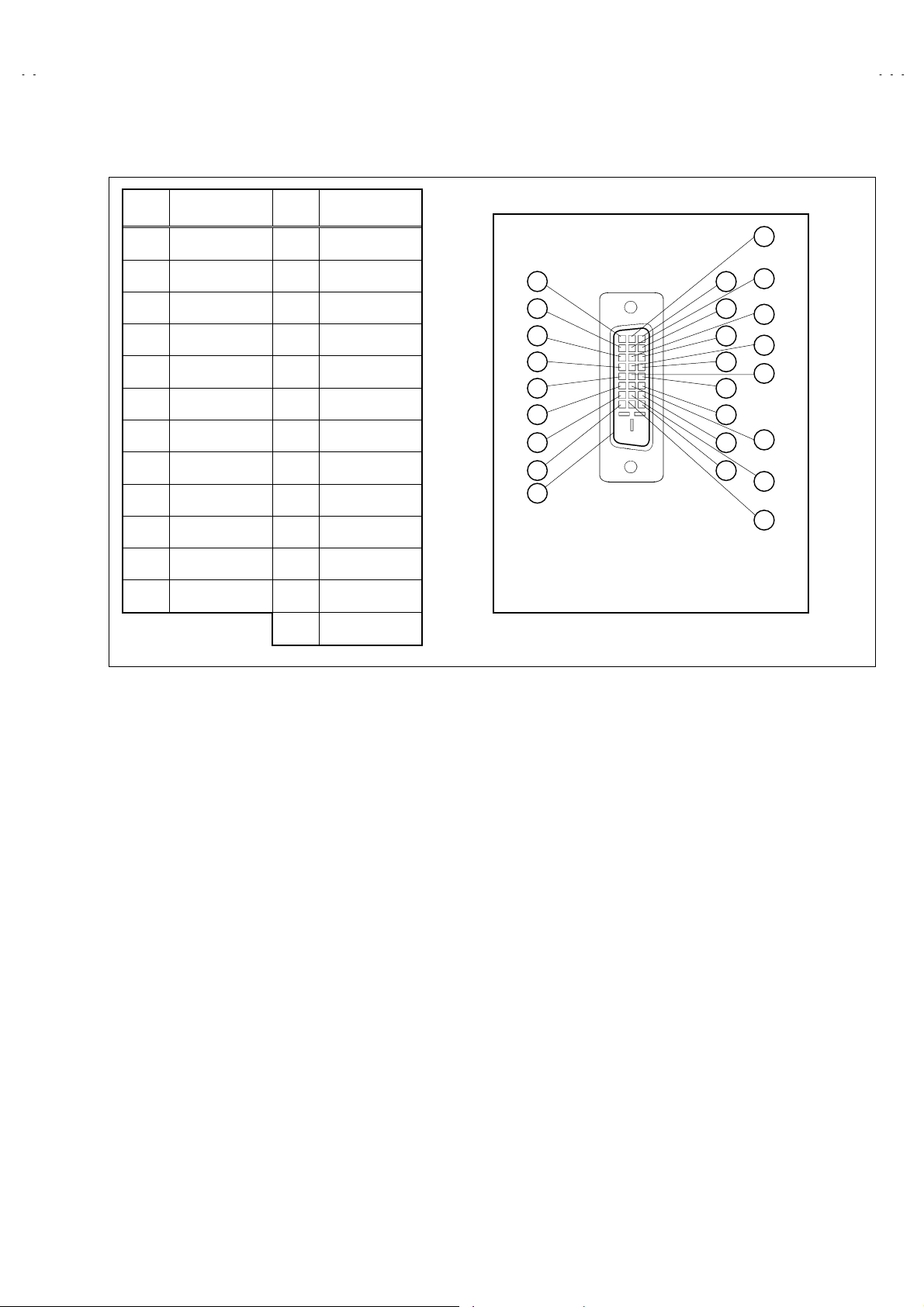

FUNCTIONS

" FRONT PANEL

① INPUT -4 terminals (S -Video, Video, Audio L/MONO / R)

② MENU button

③ CHANNEL ----/++++ button or OPERATE button

④ VOLUME ----/++++ button

⑤ SENSOR Remote control

⑥ POWER & ON TIMER lamp

⑦ POWER(Main) button

1 2 3 4 5 6 7

" AV TERMINAL (REAR)

1

2

3

5

6 7

① ANT 75Ω(VHF/UHF) Terminal

② AUDIO OUTPUT (L/R) terminal

③ AUDIO INPUT (L/R) Terminal

④ AV COMPULINKⅢ Jack

⑤ DIGITAL-IN Terminal

⑥ INPUT-2 (Y/P

⑦ INPUT-3 (Y/PB/PR) Terminal (Component Video )

⑧ INPUT-1 Terminal (S-Video / Video /Audio L/R)

⑨ INPUT-2 Terminal (Video/Audio L/R)

⑩ INPUT-3 Terminal (S-Video / Video /Audio L/R)

B/PR)Terminal (Component Video )

4 8 9 10

8

No.52008

Page 9

A

A

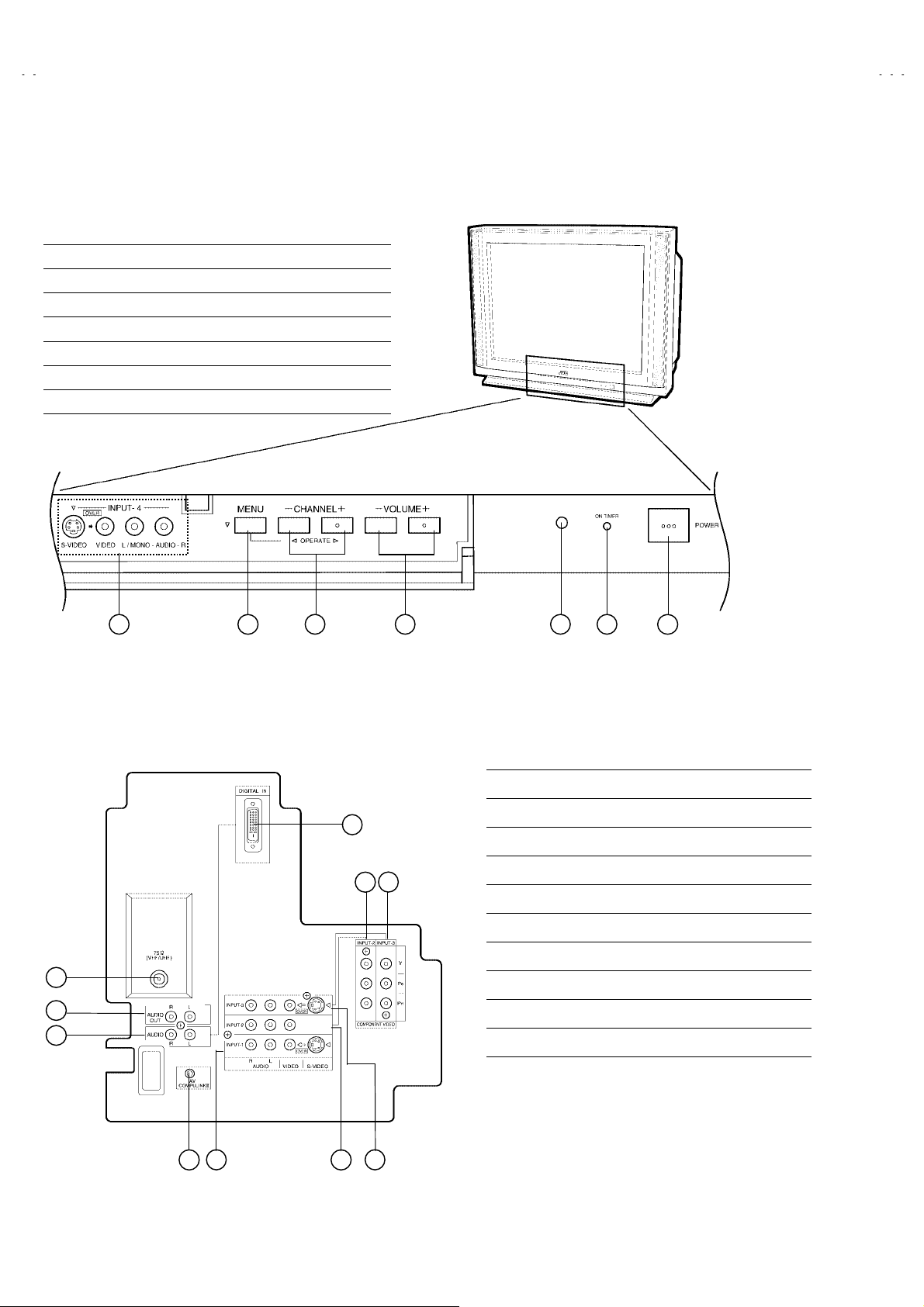

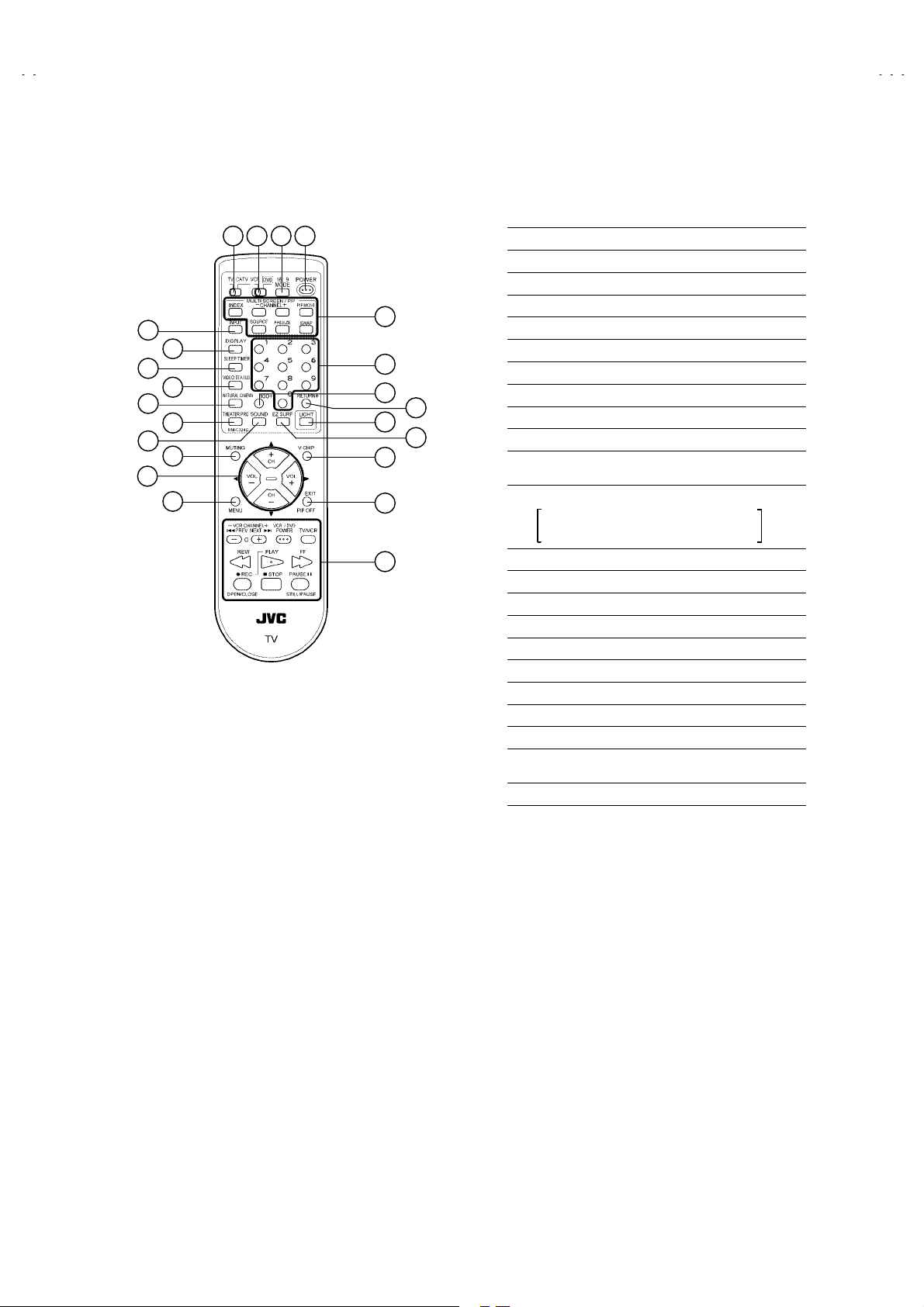

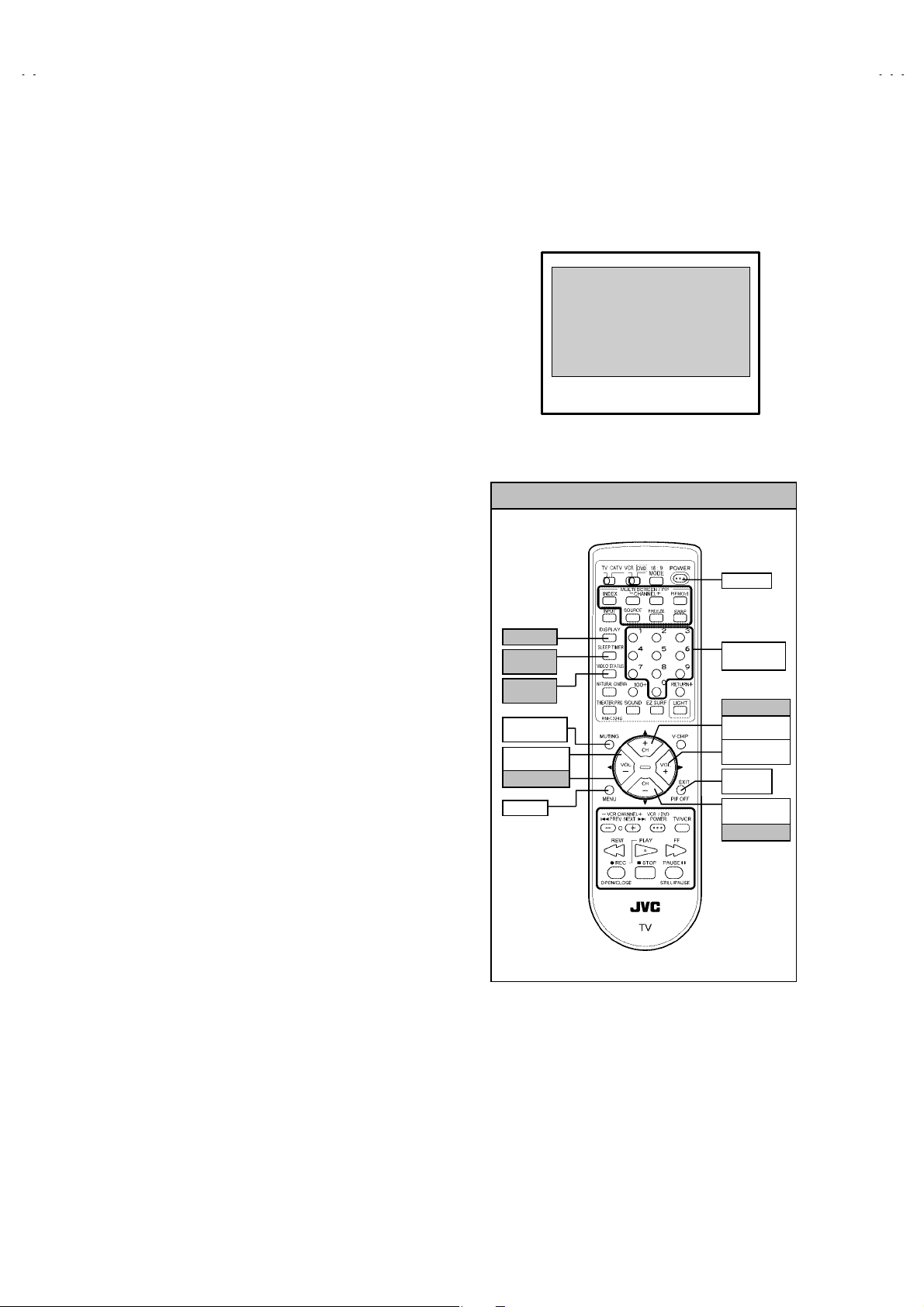

" REMOTE CONTROL (RM-C324G)

V-36P903

V-32P903

13

10

11

1 2 3 4

12

5

6

7

8

9

18

21

14

15

16

17

23

19

20

22

1TV / CATV switch

2VCR / DVD switch

316 : 9 MODE Key

4POWER Key

5DISPLAY key

6SLEEP TIMER Key

7VIDEO STATUS Key

8NATURAL CINEMA Key

9THEATER key

ASOUND key

BFUNCTIONS Key

(CH +/-, VOL +/- & SERVICE MODE)

CMULTI SCREEN / PIP Key

INDEX / -CHANNEL+ / PIP/MOVE

SOURCE / FREEZ / SWAP

DINPUT Key

ENUMBERS Key

F100+ Key

GRETURN+ Key

HLIGHT Key

IMUTING Key (memory Key)

JV-CHIP Key

KEXIT / PIP OFF Key

LMENU Key

MVCR / DVD Key

For VCR/DVD operation Keys

NEZ SURF Key

Keys

No.52008

9

Page 10

A

V-36P903

A

CO

CHASSIS

C

V-32P903

SPECIFIC SERVICE INSTRUCTIONS

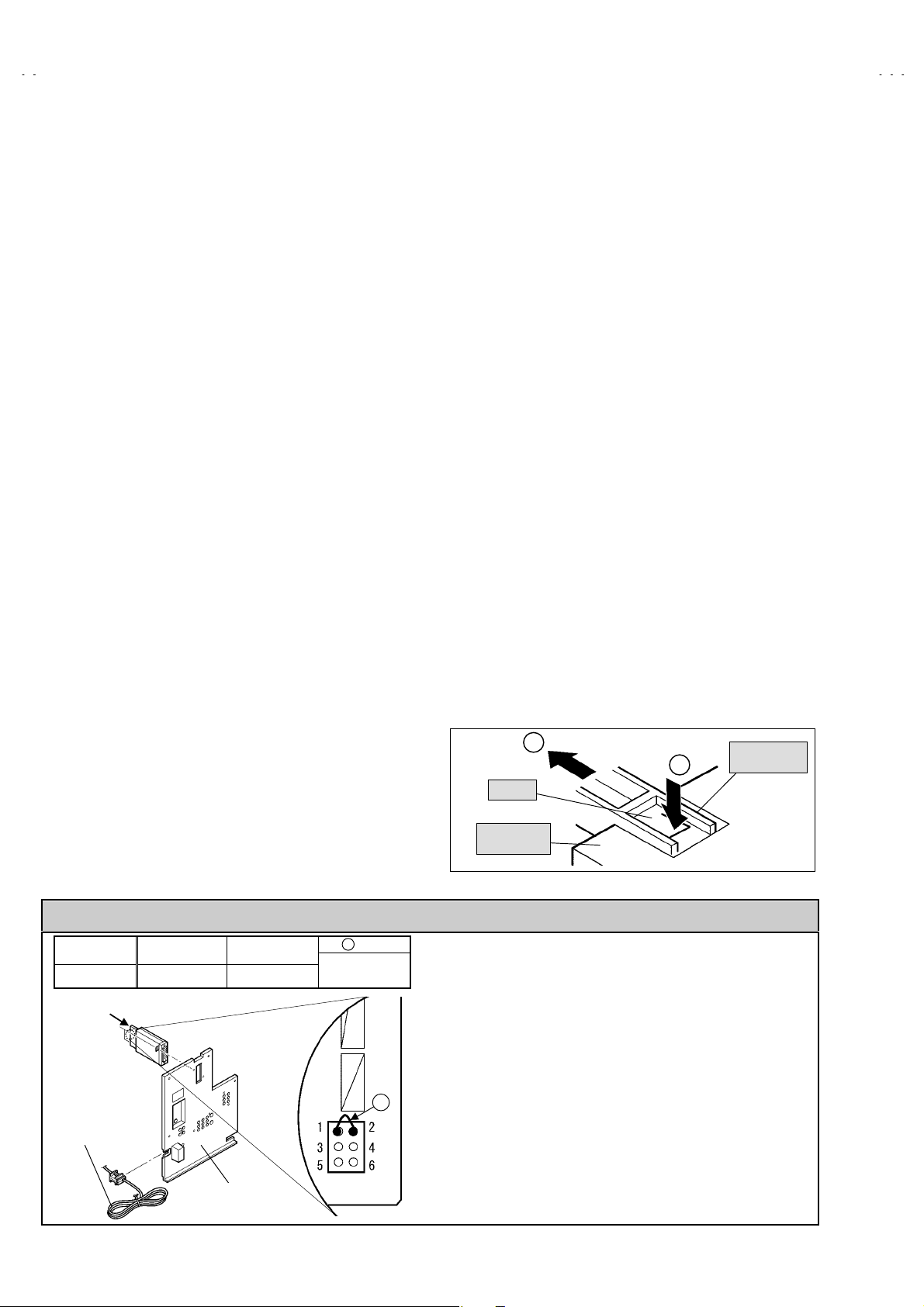

DISASSEMBLY PROCEDURE

REMOVING THE REAR COVER

" Unplug the power supply cord.

1. Remove the 15screws marked !!!! as s hown in Fig.2.

2. Remove the r ear cover toward you.

* When reinstalling the rear cover, carefully push it inward after

inserting the chassis into the rear cover gr oove.

REMOVING THE TERMINAL BOARD

" After removing the rear cover.

1. Remove the 5 screws marked """" as shown in Fig.2.

2. When you pull out the TERMINAL BOARD in the direction of

arrow marked #### as shown in Fig.2, it can be removed.

REMOVING THE CHASSIS

" After removing the rear cover.

1. Slightly raise the both sides of the chassis by hand and remove

the 2 claws under the both sides of the chassis from the front

cabinet.

2. Draw the chassis backward along the rail in the arrow direction

marked #### as shown in the Fig.2.

(If necessary, take off the wire clamps, connectors etc.)

* W hen conducting a check with power supplied, be sure to

confirm that the CRT earth wire is connected to the CRT

SOCKET PWB and MAIN PWB or DEF.POWER PWB.

REMOVING THE CONTROL BASE

" Af ter removing the rear cover and the chassis.

1. While pushing down the claws marked $$$$ as shown in Fig.1.

2. Remove the CONTROL BASE in the arrow direction

marked%&

%&.

%&%&

( If necessary, take off the wire clamps, c onnect ors etc. )

REMOVING THE SPEAKER / SPEAKER HOLDER

" After removing the rear cover and the chassis.

1. Remove the 2 screws marked ''''as shown in Fig.2, then remove

the speaker holder toward you.

2. Remove the 2 screws marked ((((as shown in Fig.2.

3. Draw the speaker toward you.

4. Follow the same steps when removing the other hand speaker.

REMOVING THE DIGITAL INPUT MODULE PWB

" After removing the rear cover and terminal board.

1. Remove the 2 screws marked ))))as shown in Fig.2.

2. Remove the DIGITAL INPUT MODULE PW B in the arrow

direction marked ****.

* If necessary, take off the wire clamps, connectors etc.

CHECKING THE PW BOARD

1. To check the backside of the circuit board.

(1) Pull out the chassis. (Refer to REMOVING THE CHASSIS).

(2) Erect the chassis vertically so that you can easily check the

backside of the PW Board.

[CAUTION]

• When erecting the chassis, be careful so that there will be no

contact with other PWB.

• Before turning the power on, make sure that the CRT earth wire

and other connectors are properly connected.

WIRE CLAMPING AND CABLE TYING

1. Be sure to clamp the wire.

2. Never remove the cable tie used f or tying the wires together.

Should it be inadvertently removed, be sure to tie the wires with

a new cable tie.

E

D

LAW

BASE

NTROL

BASE

10

AV-36P903/Y

AV-32P903/Y

DIGITAL INPUT MODULE

POWER CORD

36P903CP-S

32P903CP-S

CAUTION AT DISASSEMBLY

SSB-7836A- M2

SSB-7837A- M2

TERMINAL BOARD

*

wire

WJJ0247-001A

*

SB

connect or

Fig. 1

" Prior to disassembly, unplug the power cord from the wall

outlet without fail. (Turn the power “off”.)

" Short the SB connector (1) pin and (2) pin of the digital input

unit. (At the time of assembling)

" Before the rear cover is inserted into the cabinet, release the

short-circuit bet ween the SB connector (1) pin and (2) pin of

the digital input unit.

" After releasing the short-circuit between the SB connectors, do

not turn the pow er on until the rear cover is inserted into the

cabinet.

* Negligenc e in carrying out the above steps may cause the

inactivation of the TV.

No. 52008

Page 11

A

A

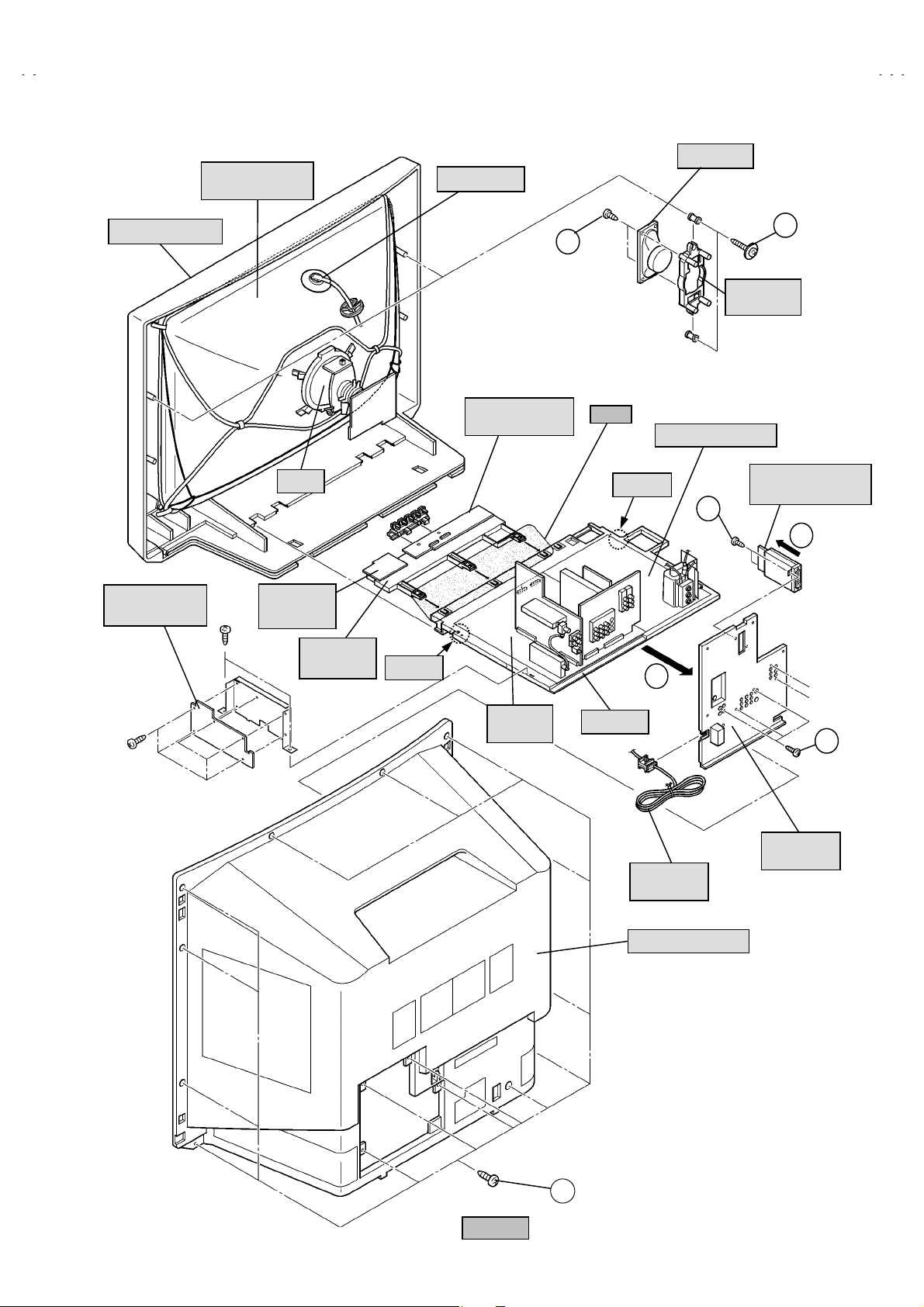

HOLDER

CRT

(

)

PICT URE TUBE

V-36P903

V-32P903

SPEAKER

ANODE CAP

FRONT CABINET

LINE

FILTER PWB

DY

POWER

SW PWB

CONTROL

BASE

CLAW

FRONT

CONTROL PWB

G

(×2)

Fig.1

DEF. POWER PWB

CLAW

C

H

(×2)

F

(×2)

SPEAKER

DIGITAL INPUT

MODULE PWB

I

MAIN

PWB

CHASSIS

B

(×5)

TERM INAL

BOARD

POWER

CORD

REAR COVER

A

Fig.2

(×15)

No. 52008

11

Page 12

A

V-36P903

A

V-32P903

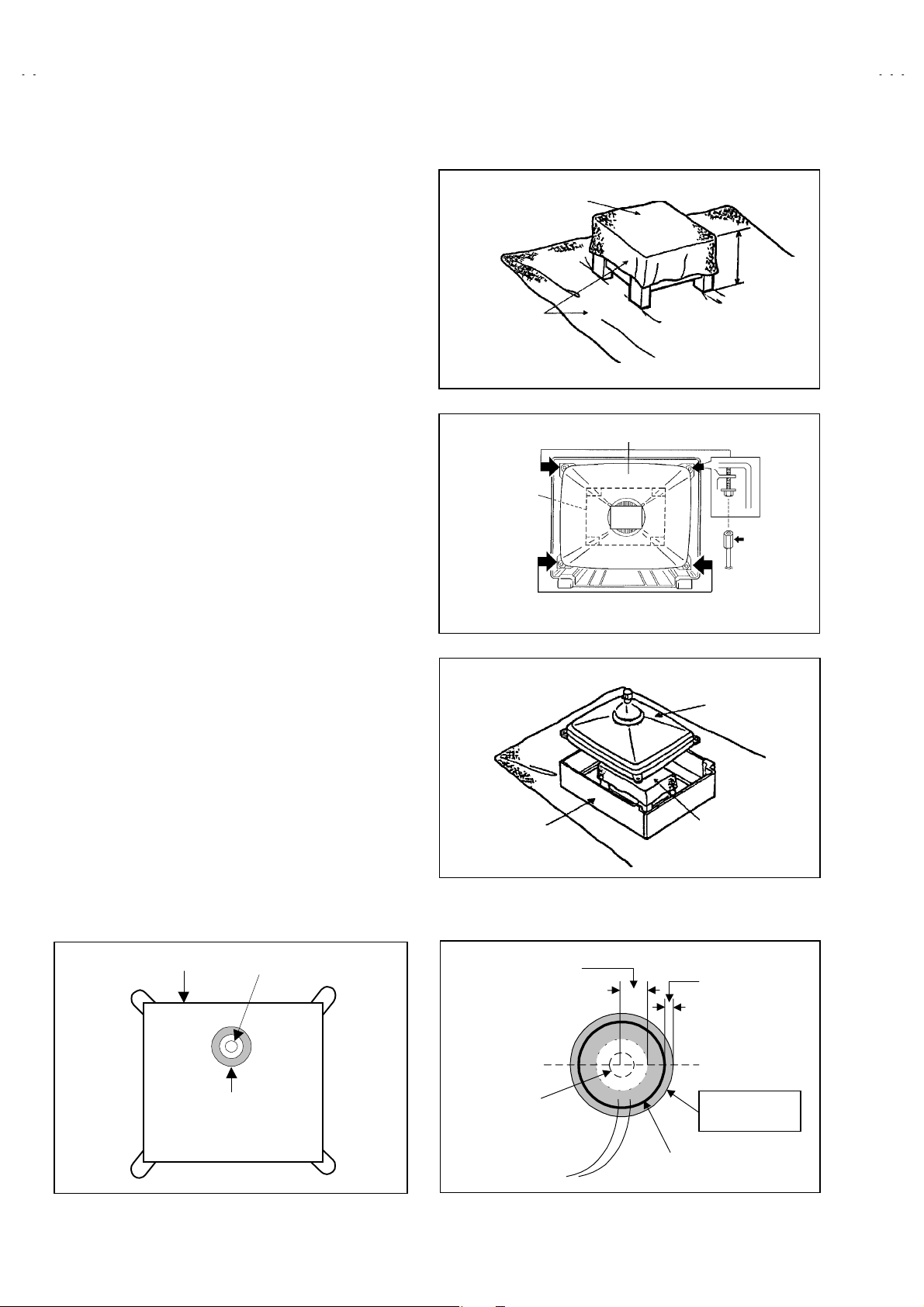

REMOVING THE CRT ( Picture Tube )

∗ Replacement of the CRT should be perf ormed by 2 or more

persons.

• After removing the rear cover, chassis etc.,

1. Putting the CRT change table on s oft cloth, the CRT change

table should also be covered with such soft cloth (shown in

Fig.3).

2. While keeping the surface of CRT down, mount the TV s et on

the CRT change table balanced will as shown in Fig.4.

3. Remove 4 screws marked by arrows with a box type

screwdriver as shown in Fig.4.

• Since the cabinet will drop when screws have been removed,

be sure to support the cabinet with hands.

4. After 4 scr ews have been r emoved, put the cabinet slowly on

cloth (At this time, be carefully so as not to damage the front

surface of the c abinet) shown in Fig.5.

• The CRT should be assembled acc ording to the opposite

sequence of its dismounting steps.

∗ The CRT change table should preferably be smaller that the

CRT surface, and its height be about 35cm.

CRT CHANGE TABLE

APPROX.

35cm

CLOTH

Fig. 3

CRT

CRT

CHANGE

TABLE

BOX

TYPE

SCREW

DRIVER

COATING OF SILICON GREASE FOR ELECTRICAL

INSULATION ON THE CRT ANODE CAP SECTION.

• Subsequent to replacement of the CRT and HV transf ormer or

repair of the anode c ap, etc. by dismounting them, be sur e to

coat silicon grease for electric al insulation as shown in Fig.6.

Wipe around the anode button with clean and dry cloth. (Fig.6)

Coat silicon grease on the section around the anode button. At

this time, take care so that any silicon greases dose not sticks

to the anode button. (Fig.7)

★★★★ Silicon grease product No. KS - 650N

CRT

Anode button

Silicon grease

coating

CABINET

Approx.

20mm (Do not

coat greas e on

this section

Anode button

(N o stic king of

silicon gr ease)

Fig. 4

CRT

CRT

CHANGE TABLE

Fig. 5

Silicon grease

should be coated

by 5mm or more

from the outside

diameter of anode

cap.

Coating position

of silicon grease

Anode c ap

Fig. 6 Fig. 7

12

No. 52008

Page 13

A

A

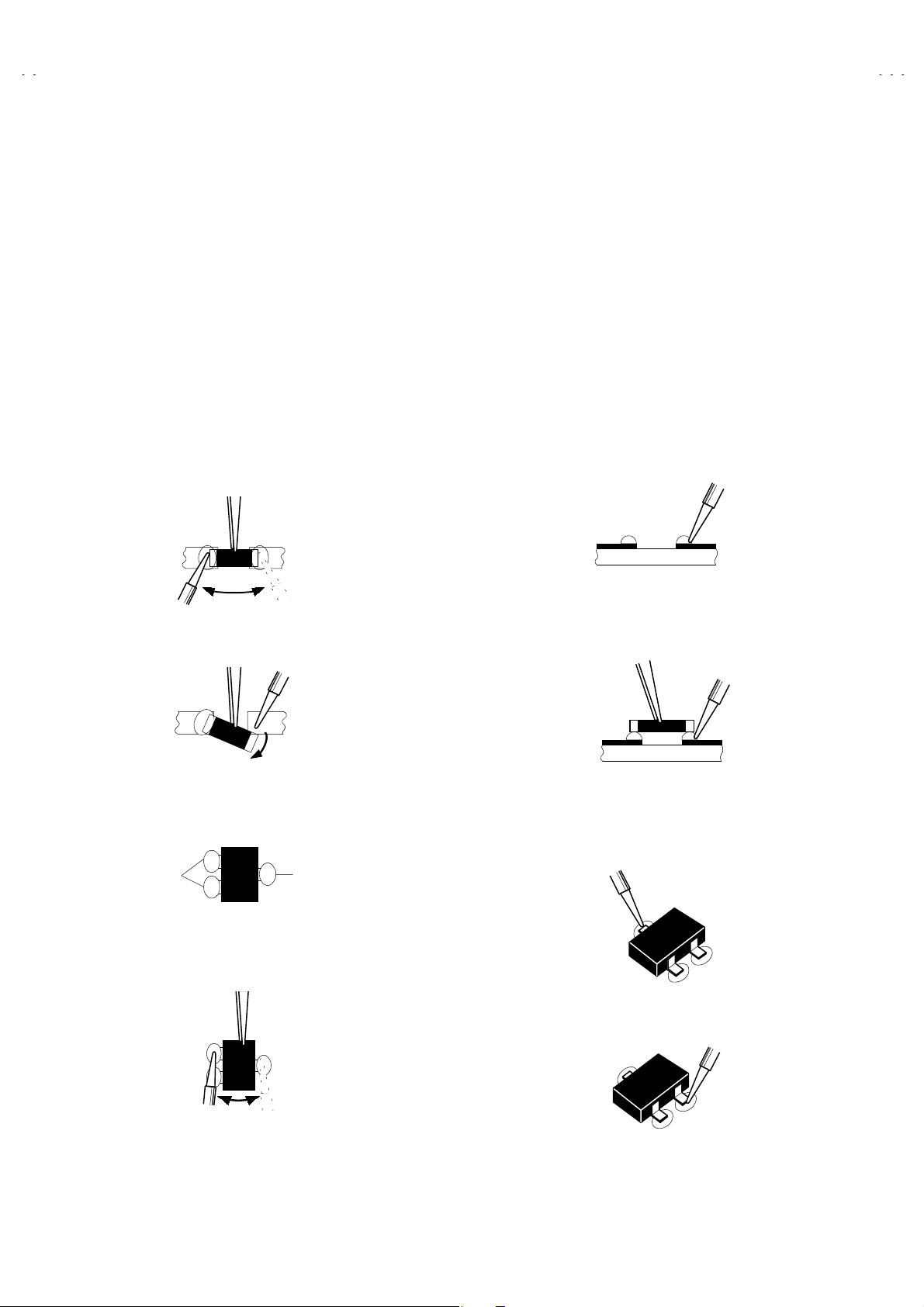

REPLACEMENT OF CHIP COMPONENT

! CAUTIONS

1. Avoid heating f or more than 3 s econds.

2. Do not rub the electrodes and the resist parts of the pattern.

3. When removing a chip part, melt the solder adequately.

4. Do not reuse a chip part after removing it.

! SOLDERING IRON

1. Use a high insulation soldering iron with a thin pointed end of it.

2. A 30w s oldering iron is recommended for easily removing parts.

! REPLACEMENT STEPS

1.

How to remove Chip parts

#### Resistors, capacitors, etc

(1) As shown in the figure, push the part with tweezers and

alternately melt the solder at each end.

(2) Shift with tweezers and remove the chip part.

#### Transistor s, diodes, variable r esistors, etc

(1) Apply extra s older to each lead.

V-36P903

V-32P903

2. How to install Chip parts

#### Resistors, capacitors, etc

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on t he solder.

Then heat and melt the solder at both ends of the chip part.

#### Transistor s, diodes, variable r esistors, etc

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on t he solder.

(3) First solder lead

as indicated in the figure.

A

SOLDER

(2) As shown in the figure, push the part with tweezers and

alternately melt the solder at each lead. Shift and remove the

chip part.

Note : After removing the part, remove remaining solder from the

pattern.

SOLDER

No. 52008

A

(4) Then solder leads

A

C

and C.

B

C

B

B

13

Page 14

A

V-36P903

A

V-32P903

MEMORY IC REPLACEMENT

1. Memory IC

This model uses a memory IC.

This memory IC stores data for proper operation of the video

and deflection circuits.

When replacin g t he m em or y IC , b e sur e to use an IC

containing this (initial value) data.

2. Memory IC replacement procedure

(1) Power off

Switch the power off and disconnect the power cord from

the wall outlet.

(2) Replace the memory IC

Initial value must be entered into the new IC.

(3) Power on

Connect the power cord to the wall outlet and switch the

power on.

(4) SERVICE MENU setting

1) Press SLEEP TIMER key and, while the indic ation of

SLEEP TIMER 0 MIN is being displayed, press

DISPLAY key and VIDEO STAT US key on the remote

control unit (Fig.2) simultaneously.

2) The SERVICE MENU screen as shown in Fig.1 is

displayed.

3) Verif y what to set in the SERVICE MENU, and s et

whatever is necessary (Fig.1).

Refer to the SERVICE ADJUSTMENT for setting.

4) Press the EXIT key twice to r eturn normal screen.

(5) Receive channel setting

Refer to the OPERATING INSTRUCTIONS (USER’S

GUIDE) and set the receive channels (Channels Preset) as

described.

SERVICE MENU

SERVICE MENU

SERVICE MENU

SERVICE MENU SERVICE MENU

1.PICTURE/SOUND

1.PICTURE/SOUND 7.I2C BUS

1.PICTURE/SOUND1.PICTURE/SOUND

2.YC SEP

2.YC SEP 8.PP

2.YC SEP2.YC SEP

3.LOW LIGHT

3.LOW LIGHT 9.IP

3.LOW LIGHT3.LOW LIGHT

4.HIGH LIGHT

4.HIGH LIGHT 0.SELF-CHK

4.HIGH LIGHT4.HIGH LIGHT

5.RF AFC

5.RF AFC

5.RF AFC5.RF AFC

6.PIP

6.PIP

6.PIP6.PIP

Fig.1

SERVICE MENU SELECT KEY

DISPLAY

SLEEP

TIMER

VIDEO

STATUS

MEMORY

(MUTING)

VALUE

SELECT(-)

FUNCTION

MENU

7.I2C BUS

7.I2C BUS7.I2C BUS

8.PP

8.PP8.PP

9.IP

9.IP9.IP

0.SELF-CHK

0.SELF-CHK0.SELF-CHK

POWER

NUMBERS

key

FUNCTION

ITE M

SELECT(▲)

VALUE

SELECT(+)

EXIT /

PIP OFF

ITE M

SELECT(▼)

FUNCTION

(6) User settings

Check the user s etting items according to the steps

described in the after page.

Where these do not agree, refer to the OPERATING

INSTRUCTIONS (USER’S GUIDE) and set the items as

described.

Fig.2

14

No. 52008

Page 15

A

V-36P903

A

V-32P903

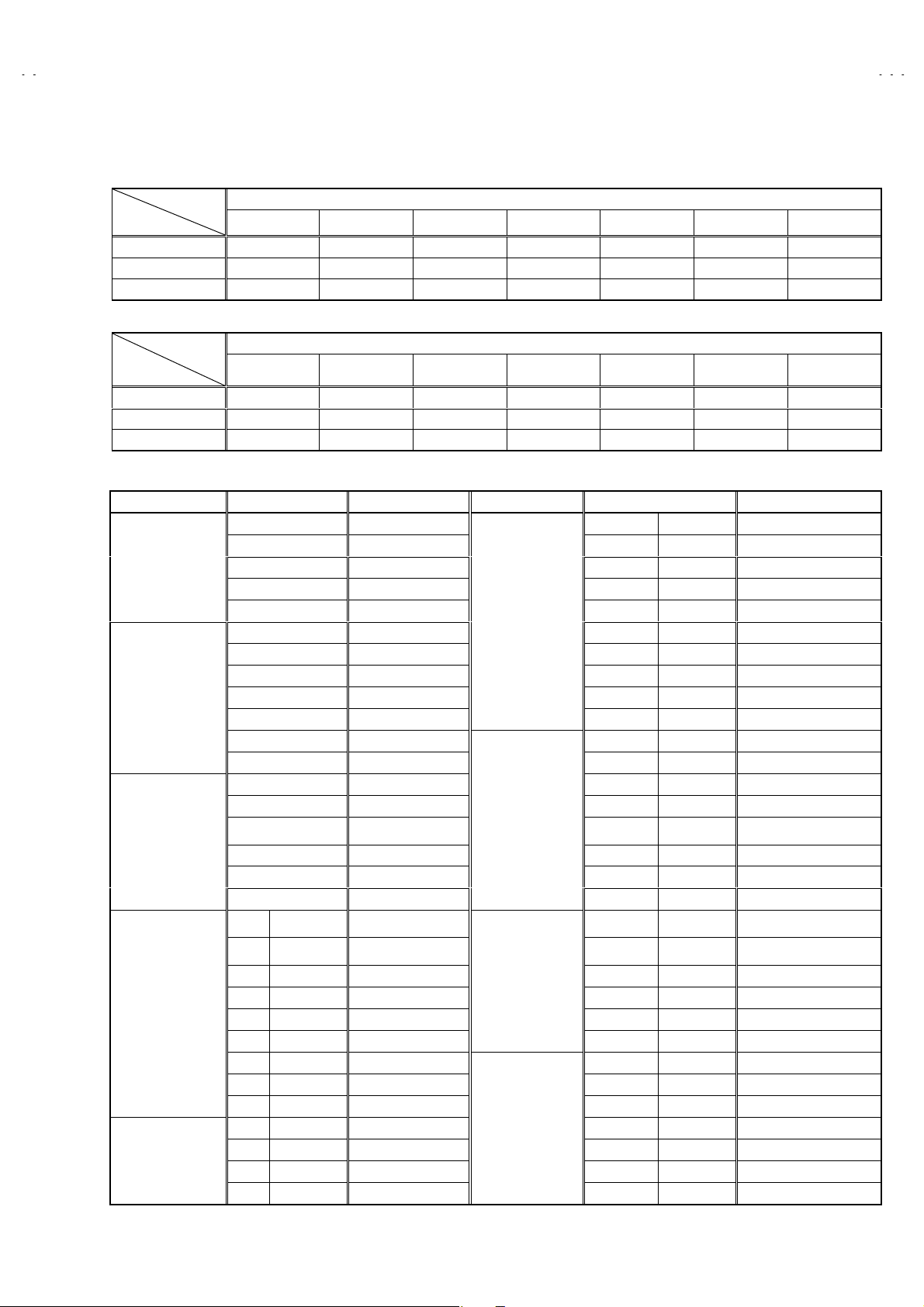

LAST MEMORY OF FACTORY

NTSC / 525p(ED) system

Item

TINT COLOR PICTURE BRIGHT DET AIL

STANDARD 00 00 00 00 00 LOW 00

THATER 00 00 00 00 00 HIGH 00

DYNAMIC 00 00 +30 00 +03 HIGH 00

HD(1080i) system

Item

TINT COLOR PICTURE BRIGHT DET AIL

STANDARD 00 00 00 00

THATER 00 00 00 00

DYNAMIC0000+20000HIGH00

SETTING VALUE

SETTING VALUE

DIGI. NOISE

(CLEAR)

DIGI. NOISE

(CLEAR)

00

00

COLOR

(TEMPERATURE)

COLOR

(TEMPERATURE)

LOW

00 LOW 00

CH. SETTING ( CHANNEL SUMMARY) [ ○○○○:Add. CH / ――

―― :Erase CH]

――――

BAND Ch Display Setting BAND Ch Display Setting

02 ○ N27 ――

――

――

――――

○

○

○

○

――

――

――――

SUPER

○

――

――

――――

○

――

――

――――

○

○

○

――

――

――――

――

――

――――

SUBMID

○

○

○

○

○

HYPER

○ ――

○

――

――

○ ――

――

―― ――

ULTRA

○

―― ――

――

O28

P29――――――

Q30――――――

R31

S32

T33――――――

U34――――――

V35――――――

W36

A-7 93

A-6 94

A-5 95

A-4 96

A-3 97

A-2 98

A-1 99

A-8 01

W+11 47

W+12 48

W+17 53

―― ――

――――

W+23 59

――

―― ――

――――

W+29 65

―― ――

――――

W+51

―― ――

――――

W+78

―― ――

――――

W+84

―― ――

――――

―― ――

――――

―― ――

――――

――

―― ――

――――

―― ――

――――

――

―― ――

――――

―― ――

――――

――

―― ――

――――

VHF

VHF

UHF

MID

SUPER

03

L

04

05

06

07

08

09

H

10

11

12

13

14

36

41

46

63

69

A14

B15

C16

D17

E18

F19――――――

G20――――――

H21

I22――――――

J23――――――

K24

L25――――――

M26――――――

――

――――

○

――

――

○

○

――

――

――

○

――

――

――――

――

――

――――

――

――

――――

○

○

(EXCEPT 32”TV)

○

――

――

――――

――

――

――――

○

(EXCEPT 32”TV)

○

(EXCEPT 32”TV)

○

――

――――

○

――

――――

――

――

――――

――

――――

――

――――

――

――――

――

――――

――

――――

――

――――

No. 52008

15

Page 16

A

V-36P903

A

V-32P903

LAST MEMORY OF FACTORY

(USER SETTING)

Setting item Setting value Setting item Setting value

POWER

CHANNEL

BBE

VOLUME

INPUT

OFF

AIR-02

ON

10

TV

NOISE MUTING

AUDIO OUT

BASS

TREBLE

BALANCE

ON

FIX

CENTER

CENTER

CENTER

DISPLAY

NATURAL CINEMA

16 : 9 MODE

VIDEO STATUS

HYPER SURROUND OFF

PIP SOURCE

PIP POSITION

TINT / COLOR / PICTURE

/BRIGHT / DETAIL

VSM

COLOR TEMPERTURE

DIG. NOISE CLEAR

OFF

OFF

4 : 3

DYNAMIC

CH-04

BOTTOM ( LEFT SIDE )

Refer to setting of Video

status memory at packing

ON

HIGH

CENTER

MTS

TV SPEAKER

SET CLOCK

ON / OFF TIMER

LANGUAGE

CLOSED CAPTION

FRONT PANEL LOCK

AUTO SHUT OFF

AUTO TUNER SET UP

DIGITAL-IN( at 480p signal input)

CHANNEL SUMMARY

V-CHIP

SET LOCK CODE

AUTO DEMO

STEREO

ON

Unnecessary to set

NO

ENG

OFF ( CC1 / T1 )

OFF

OFF

Unnecessary to set

SIZE 1

Refer to Last memory

(CH. summary)

OFF

Unnecessary to set

OFF

16

No. 52008

Page 17

A

A

SERVICE ADJUSTMENTS

V-36P903

V-32P903

ADJUSTMENT PREPARATION

1. You can make the necessary adjust ments for this unit with

either the Remote Control Unit or with the adjustment tools

and parts as given belo w.

2. Adjustment with the Remote Control Unit is made on the

basis of the initial setting values, however, the new setting

values which set the screen to its optimum condition may

differ from the initial settings.

3. Make sure that AC power is turned on correctly.

4. Turn on the power for set and test equipment before use, and

start the adjustment procedur es after waiting at least 30 minutes.

5. Unless otherwise specified, prepare the most suitable reception

or input signal for adjustment.

6. Never touch any adjustment setting value which are not

specified in the list for this adjustment.

7. Presetting before adjustment.

Unless otherwise specified in the adjustment instructions, preset

the following functions with the remote contr ol unit:

" Setting position

VIDEO STATUS STANDARD

BASS, TREBLE, BALANCE CENTER

HYPER SURROUND OFF

TINT, COLOR, PICTURE,

BRIGHT, DETAIL

CENTER

ADJUSTMENT EQUIPMENT

1. DC voltmeter (or digital voltmeter)

2. Oscilloscope

3. Signal generator (Pattern generator) [NTSC / HD / ED / HDCP]

****【【【【HD:1080i / ED:525p=4 80p / DVD:525i=480i 】】】】

4. Remote control unit

5. TV audio multiplex signal generator.

6. Frequency c ounter

ADJUSTMENT ITEMS

Adjustment items

% B1 POWER SUPPLY Check

% X-RAY protec tor chec k

% FOCUS adjustment

% DEF. adjustment

V. CENTER & TRAPE / V. HEIGHT & V. LIN. adjustment

H. WIDTH / H.POSI. / EW. CORNER, UPPER /

LOWER & TRAPEZUM adjustment

HDCP DISPLAY POSITION adjustment

CH. PROGRAM LIST & AREA, DISPLAY POSITION

adjustment

% V/C adjustment

WHITE BALANCE (Low Light & High Light) adjustment

PIP WHITE BALANCE (High Light) adjustment

BRIGHT / CONT. in sub screen adjustment

SUB BRIGHT / SUB CONT. / COLOR /

TINT in sub screen / COLOR / TINT B-Y AXIS GAIN

% MTS adjustment

CAUTION

Never change the initial setting value any adjustments except for those that are

designated in the adjustment procedures.

In case where you have made undesignated adjustments by mistake, never press the

MUTING key on the remote control unit.

Whenever you had not pressed the MUTING key, you would be able to recover the initial

value by switching the POWER SW (on/off) key.

No. 52008

17

Page 18

A

V-36P903

A

V-32P903

MAIN PARTS (PWB) LOCATION

A : CRT SOCKET PWB

B : DY PWB (Within DY )

C:MAIN PWB

D : DEF. POWER PWB

E : LINE FILTER PWB

F : JACK PWB

G:DEF OSC PWB

H : FRONT CONTROL PWB

I : POWER SW PWB

J : DIGITAL INPUT MODULE PWB

B

K : I/P M OD ULE PWB

L : SUB TUNER (RECEIVER) PWB

A

J

TERMINAL

BOARD

H

D

G

KL

C

POWER

CORD

FBT

I

TUNER1

E

18

TUNER2

No. 52008

F

Page 19

A

A

ADJUSTMENT LOCATION (1/2)

POWER SW PWB FRONT CONTROL PWB

V-36P903

V-32P903

FRONT

FRONT

FRONT

F

POWER

SW

B

LED IND.

SP

MAIN PWB

SENSOR

Y

F

CN010

R

VIDEO

Y

(+)(-)

VOL. CH.

G

(+)(-)

MENU

H

L/MONO

S-V

DEG. COIL

FRONT

G

M

H

SUB TUNER

IC701

CPU

MEMORY I C

IC703

(RECEIVER)

PWB

B

CN001

DEF. POW ER

PWB

CN002

J

CRT SOCKET PWB

TOP

FUSE

PW

LINE FILTER

PWB

TUNER 1

E1

TUNER2

(TU101)

CN005

CN005

No. 52008

CN007

AF

I/P MODULE

PWB

JACK PWB

CN006

E

CN010

CN003

DEF OSC PW B

S1

19

Page 20

A

V-36P903

A

V-32P903

ADJUSTMENT LOCATION (2/2)

TOP

DIGITAL INPUT MODULE PWB

REAR

IC

LINE FILTER

PWB

FRONT

CONTROL

PWB

MAIN PW B

IC701

CPU

H

MEMORY IC

IC703

DC

SY

CRT SOCKET PWB

TOP

TP-R

Q

E

SB

CONNECT

TP-G

A J

TP-B

CRT SOC KET

E2

(parts side)

VM

DY

TP-E1

DEF. POWER PWB

B

DEG COIL

CN001

CN002

J

DEG

FRONT

JACK PWB

CN006

E

CN003

CN010

HV

DY

DEF OSC PWB

FBT

A

H.(FOCUS) VR

H.(FOCUS) VR

H.(FOCUS) VRH.(FOCUS) VR

V.FOCUS VR

V.FOCUS VR

V.FOCUS VRV.FOCUS VR

SCREEN VR

SCREEN VR

SCREEN VRSCREEN VR

S1

1Pin : TP-E ( )

2Pin : X-ray2

3Pin : X-ray1

4Pin : NC

5Pin : TP-91(B1)

S1

5555

1111

20

No. 52008

Page 21

A

A

BASIC OPERATION OF SERVICE MENU

1. TOOL OF SERVICE MENU OPERATION

Operate the SERVICE MENU with the REMOTE CONTROL UNIT.

2. SERVICE MENU ITEMS

In general, basic setting (adjustments) items or verific ations are perf ormed in the SERVICE MENU.

1. PICTURE / SOUND・・・・・・・・・ This sets the setting values of the VIDEO/CHROMA /AUDIO and DEFLECTION circuits.

2. YC SEP ・・・・・・・・・・・・・・・・・・・ This is used when the YC mode is adjusted. [Do not adjust]

3. LOW LIGHT ・・・・・・・・・・・・・・・ This sets the setting values of the WHITE BALANCE circuit.

4. HIGH LIGHT ・・・・・・・・・・・・・・・ This sets the setting values of the WHITE BALANCE circuit.

5. RF AFC CHK ・・・・・・・・・・・・・・ This is used when the IF VCO is adjusted. [ Do not adjust]

6. PIP ・・・・・・・・・・・・・・・・・・・・・・・ This is used when the OUTPUT of PIP data is adjusted. [Do not adjust]

2

C BUS・・・・・・・・・・・・・・・・・・・ This is used when ON/OFF if the I2C BUS c ontrol is stop. [Do not adjust]

7. I

8. PP ・・・・・・・・・・・・・・・・・・・・・・・ This sets the setting value of the output of P&P data. [Do not adjust]

9. IP ・・・・・・・・・・・・・・・・・・・・・・・・ This sets the setting value of the IP circuit. [Do not adjust]

0. SELF-CHK・・・・・・・・・・・・・・・・・ This sets the self checking of the TV circuit.

3. Basic Operations of the SERVIC E MENU

(1) How to enter the SERVICE MENU.

Press SLEEP TIMER key and, while the indication of “SLEEP

TIMER 0 MIN.” is being displayed, press DISPLAY key and

VIDEO STATUS key on the remote control unit simultaneous ly

to enter the SERVICE MENU screen as shown in the Fig.1.

(2) SERVICE MENU screen selection

Press the ten key to s elect any of the following items.

SERVICE MENU

1.PICTURE/SOUND 7.I2C BUS

2.YC SEP 8.PP

3.LOW LIGHT 9.IP

4.HIGH LIGHT 0.SELF-CHK

5.RF AFC

6.PIP

V-36P903

V-32P903

1.PICTURE/SOUND 7.I2C BUS

2.YC SEP 8.PP

3.LOW LIGHT 9.IP

4.HIGH LIGHT 0.SELF-CHK

5.RF AFC

6.PIP

(3) Enter any setting mode

" 1. PICTURE / SOUND mode

1) Select 1. PICTURE / SOUND items with the number key

and press the function (

) key to select the

▲/▼

1. PICTURE/SOUND mode. Then the screen will be

displayed as shown in figure in the sub sequent page.

2) Then the settings or verifications can be perf ormed.

" 2.YC SEP, 3.LOW LIGHT, 4.HIGH LIGHT, 5.RF AFC,

6.PIP, 7.I

2

C BUS, 8.PP, 9.IP and 0.SELF-CHK mode

1) If you select any of 2.YC SEP 3.LOW LIGHT 4.HIGH

LIGHT 5.R F AFC 6.PIP, 7.I

2

C BUS, 8.PP, 9.IP and

0.SELF-CHK mode items, and the numbers key is press ed

from SERVICE MENU, the each screen will be displayed

as shown in the figure in the sub sequent page.

2) Then the settings or verifications can be perf ormed.

DISPLAY key

SLEEP TIMER

key

VIDEO STATUS

key

MEMORY key

(MUTING)

MENU key

Fig. 1

KEY FUNCTION of SERVICE MENU

NUMBERS key

EXIT key

(PIP OFF)

FUNCTION key

(▲/▼) & ( / )

Select the setting value

Select the setting Item

No. 52008

21

Page 22

A

V-36P903

A

V-32P903

FUNCTION

VOL. -/+ key

FUNCTION

CH -/+ key

SERVICE MENU

SERVICE MENU

1.PICTUR E/SOUND 7.I2C BUS

2.YC SEP 8.PP

3.LOW LIGHT 9.IP

4.HIGH LIGHT 0.SELF-CHK

5.RF AFC

6.PIP

1.PICTURE/SOUND

***** *****

NTSC

A01 001

A01

*********

*** *** ******* ******

A16

~~~~

DO NOT ADJUST

LOW

HW-BAL

PIP

***

4.HIGH LIGHT

5.RF AFC

T

UNER

**

AFC

**

F

INE

***

6.PIP

DO NOT ADJUST

PIP001

028

~~~~

YC001

~~~~1

S01

D01

F01

F

07

~~~~

S60

S01

*** **********

*** *** **********

20

D

~~~~

I2C

***

D01

*** *********

*** *** **** **** *

F65

~~~~

01

*** *********

*** *** ******* **** *

PPA001

DO NOT ADJUST

2.YC SEP

***

YC001

*** *** *** ***

IP001

3.LOW LIGHT 0.SELF-CHK

7.I2C BUS

8.PP

***

9.IP

*** ********** *

PPA001

PPT001

PPD001

PPB001

PPM001

PPS001

IP001

017

~~~~

014

~~~~

054

~~~~

048

~~~~

038

~~~~

041

~~~~

107

~~~~

LW-BAL

22

No. 52008

Page 23

A

A

(4) Setting method

1) UP / DOW N (

Select the SETTING ITEM.

▲/▼) function key on remote control unit.

2) LEFT / RIGHT ( / ) function key on remote control unit

Setting (adjust) the setting value of the SETTING.

When the MUTING key is pressed the setting value

will be stored ( memorized).

3) EXIT key

Returns to the previous scr een.

(5) Releasing SERVICE MENU

1) After returning to the SERVICE MENU upon completion

of the s etting work, press the EXIT key again.

SIGNAL

SYSTEM

SIGNAL

SYSTEM

SETTING

ITEM

1. PICTURE/SOUND

NTSC FULL DYNAMIC LOW

A01 001 OFF F RAME

**** *** *******

~~~~

A16 / S0 1

D20 / F01

~~~~

~~~~

S52

F65

~~~~

A01

D01

2. YC SEP

YC001

***

*** *** *** *** ** *

WHITE BALANCE

VIDEO STATU S

SETTING VALUE

DO NOT ADJUST

SETTING IT EM

~~~~

YC001

YC107

SETTING VALUE

V-36P903

V-32P903

" WHITE BALANCE setting

The setting for 3.LOW LIGHT and 4.HIGH LIGHT are described in the

WHITE BALANCE page of ADJUSTMENT.

KEY FUNCTION of SERVICE MENU

H.LINE OFF

H.LINE ON

G.CUT OFF (▲)

R.CUT OFF

R.DRIVE

R.CUT OFF

R.DRIVE

MEMORY key

(MUTING)

MENU key

FUNCTION key

(▲/▼) & ( / )

(▲)

(▼)

Select the setting value

Select the setting Item

G.CUT OFF (▼)

B.CUT OFF

B.DRIVE

B.CUT OFF

B.DRIVE

RETURN key

(PIP OFF)

(▲)

(▼)

WHITE BALANCE

■■■■

3. LOW LIGHT

LW-BAL

4. HIGH LIGHT

HW-BAL

5. RF AFC

TUNER 2

AFC ON

FINE

***

SETTING IT EM

SETTING IT EM

DO NOT ADJUST

(NOTE)

TUNER 1 (main)/2(SUB: PIP)

AFC Select ON/OFF

FINE FineTuning(-77

AFC ON:Auto Setti ng

~~~~

+77)

No. 52008

23

Page 24

A

V-36P903

A

V-32P903

6.PIP

(Do not adjust)

SETTING ITEM

~~~~

(PIP001

PIP028)

SETTING VALUE

PIP

PIP001

***

PIP

PIP008

6.PIP setting

1) FUNCTION (

2) FUNCTION ( /

) key ・・・・・・・・・・・・・・・・・・・・・ Select the setting Item.

▲/▼

) key ・・・・・・・・・・・・・・・・・・・・・ Select the setting value.

3) MUTING Key ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ Setting value will be stored.

4) EXIT key・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ Returns to the service menu.

5) MENU key ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ Releasing the servic e menu.

8.PP

(Do not adjust)

PPA001

PPA017/PPT001

~~~~

~~~~

PPD001

PPD054/PPB001

~~~~

PPM038/PPS001

PPM001

SETTING ITEM

SETTING VALUE

~~~~

~~~~

~~~~

PPT014

PPB048

PPS041

***

VALUE

ITEM

9.IP

(Do not adjust)

SETTING ITEM

~~~~

(IP001

IP107)

SETTING VALUE

PPA001

***

***

*** ***

NTSC OFF FRAM

**

**

** **

8.PP / 9.IP setting

1) FUNCTION(

2) FUNCTION ( /

) key・・・・・・・・・・・・・・・・・・・・・ Select the setting Item

▲/▼

) key ・・・・・・・・・・・・・・・・・・・・ Select the setting value.

3) SLEEP TIMER key ・・・・・・・・・・・・・・・・・・・・・・・ Skip the each setting Item.

4) MUTING Key ・・・・・・・・・・・・・・・・・・・・・・・・・・・・ Setting value will be stored.

5) EXIT key ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ Returns to the service menu.

6) MENU key ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ Releasing the service menu.

0.SELF-CHK DISPLAY

Press 0 key of remot e control that checks the circuit

operating status and in event of malfunction displays

stores the data in memory. (as shown in figure)

24

No. 52008

IP001

***

***

*** ***

NTSC OFF FRAM

0.SELF-CHK

XRAY NG2 OCP NG2

XRAY NG2 OCP NG2

XRAY NG2 OCP NG2XRAY NG2 OCP NG2

LOB OK TIM OK

LOB OK TIM OK

LOB OK TIM OKLOB OK TIM OK

SYNC M:OK S:OK HD:NG

SYNC M:OK S:OK HD:NG

SYNC M:OK S:OK HD:NGSYNC M:OK S:OK HD:NG

MEM OK AVSW OK

MEM OK AVSW OK

MEM OK AVSW OKMEM OK AVSW OK

VCD NG2 BS OK

VCD NG2 BS OK

VCD NG2 BS OKVCD NG2 BS OK

AIO OK YC OK

AIO OK YC OK

AIO OK YC OKAIO OK YC OK

TUN OK GCR OK

TUN OK GCR OK

TUN OK GCR OKTUN OK GCR OK

PP NG4 IP OK

PP NG4 IP OK

PP NG4 IP OKPP NG4 IP OK

***

***

*** ***

Page 25

A

A

INITIAL SETTING VALUE OF SERVICE MENU

1. Adjustment of the SERVICE MENU is made on the basis of the initial setting values; however, the new setting values which set the

screen in its optimum condition may differ from the initial setting.

2. Do not change the initial setting values of the setting items NOT LISTED IN ADJUSTMENT.

3. The (*1 or *2)marked items in f ollowing table, it is NO REQUIREMENT for adjustment. If values had change by the missing, set the

initial values in the following table.

■■■■SOUND MODE

Item

No.

Item name

Variable

range

initial setting

value

Item

No.

Item name

Variable

range

A01 NOISE DET. 0 / 1 001 A09 5FH MON 0 / 1 000

A02 INPUT LEVEL 0 ~ 63 032 A10 SAP VCO 0 ~ 63 034

A03 FH MONITOR 0 / 1 000 A11 INPUT GAIN 0 / 1 000

A04 STEREO VCO 0 ~ 63 035 A12 FIL OFFSET -128 ~ +127 000

A05 PILOT CAN 0 / 1 000 A13 BBE BASS -128 ~ +127 000

A06 FILTER 0 ~ 63 029 A14 BBE TREBLE -128 ~ +127 000

A07 LOW SEP 0 ~ 63 027 A15 BASS -128 ~ +127 -005

A08 HI SEP 0 ~ 63 028 A16 TREBLE -128 ~ +127 -008

initial setting

value

V-36P903

V-32P903

■■■■DEFLECTION MODE

Item

No.

D01

D02

D03

D04 *1

D05

D06

D07

D08

D09

D10 *1

D11 *1

D12 *1

D13 *1

D14

D15 *2

D16

D17 *1

D18 *1

D19 *1

D20 *1

Item name Variable range

V-HEIGHT 0~127 STANDARD -1 +2 -42

EW PARABORA 0~63 STANDARD +2 +1 1

H-WIDTH

V S-CORRECTION 0~63 STANDARD 35 +35 +35 +35

V-LINEARITY 0~63 STANDARD +2 0 -3

V CENTER

TRAPEZIUM 0~63 STANDARD +3 +1 -1

EW CORNER LOWER

EW CORNER UPPER 0~15 STANDARD 0 +1 +1

V EHT

H EHT 0~7 STANDARD 1 ( 1 ) ( 1 ) ( 1 )

EHT GAIN 0~7 STANDARD 5 ( 5 ) ( 5 ) ( 5 )

TEXT CO NTR OL

H CENTER 0~255 STANDARD +2 +30 0

HORIZONTAL

FREQUENCY

H.BLK 0~63 STANDARD 0 0 0

OSD OFFSET

COMPULSION

TWIN SCREEN

COMPULSION

DEF RST OUTPUT

COMPULSION 1080i 0 / 1 STANDARD 0 0 0 0

****

(

1:Fixed value /

****

2:Offset (-107) v alue for HD D15 value)

NTSC

INDEX

( 9 screen )

0~63

4 : 3 PIP

STANDARD 0 +1 1

*1 *1 *1

0~63

0~15

0~7

STANDARD +3 -3 -2

STANDARD 0 0 0

STANDARD 3 ( 3 ) ( 3 ) ( 3 )

*1 *1 *1

*1 *1 *1

*1 *1 *1

0~15

0~255

-127~28

0~6 STANDARD 0 0 0 0

0 / 1 STANDARD 0 0 0 0

STANDARD 0 ( 0 ) ( 0 ) ( 0 )

STANDARD

STANDARD 0 0 0

*1 *1 *1

*2 *2 *2

---

*1 *1 *1

*1 *1 *1

*1 *1 *1

*1 *1 *1

(1/3)

16:9

No. 52008

25

Page 26

A

V-36P903

A

V-32P903

■■■■DEFLECTION MODE (2/3)

Item

No.

D01

D02

D03

D04 *1

D05

D06

D07

D08

D09

D10 *1

D11 *1

D12 *1

D13 *1

D14

D15 *2

D16

D17 *1

D18 *1

D19 *1

D20 *1

Item name Variable range

V-HEIGHT 0~127 STANDARD 0 -42 -42

EW PARABORA 0~63 STANDARD +1 -1 -1

H-WIDTH 0~63 STANDARD 0 +1 +1

V S-CORRECTION

V-LINEARITY 0~63 STANDARD -1 -3 -3

V CENTER

TRAPEZIUM 0~63 STANDARD 0 -2 -1

EW CORNER LOWER

EW CORNER UPPER 0~15 STANDARD 0 +1 +1

V EHT 0~7 STANDARD 3 ( 3 ) ( 3 ) ( 3 )

H EHT

EHT GAIN 0~7 STANDARD 5 ( 5 ) ( 5 ) ( 5 )

ADJUSTMENT

H CENTER 0~255 STANDARD -30 -30 +1

HORI FREQ

ADJUSTMENT

H. BLK

OSD OFFSET -127~128 STANDARD 0 0 0

COMPULSION

TWIN SCREEN

COMPULSION

DEF RST OUTPUT

COMPULSION 1080i 0 / 1 STANDARD 0 0 0 0

0~63

0~63

0~15

0~7

0~15

0~255 STANDARD -- 0

0~63

0~6 STANDARD 0 0 0 0

0 / 1 STANDARD 0 0 0 0

NTSC

4 : 3

STANDARD 35 +35 +35 +35

STANDARD -3 -4 -3

STANDARD 0 0 0

STANDARD 1 ( 1 ) ( 1 ) ( 1 )

STANDARD 0 ( 0 ) ( 0 ) ( 0 )

STANDARD 0 0 0

ED

4 : 3

ED

16 : 9

*1 *1 *1

*1 *1 *1

*1 *1 *1

*1 *1 *1

*1 *1 *1

*2 *2 *2

*1 *1 *1

*1 *1 *1

*1 *1 *1

*1 *1 *1

720p

16 : 9

■■■■DEFLECTION MODE (3/3)

Item

No.

D01

D02

D03

D04 *1

D05

D06

D07

D08

D09

D10 *1

D11 *1

D12 *1

D13 *1

D14

D15 *2

D16

D17 *1

D18 *1

D19 *1

D20 *1

Item name Variable range

V-HEIGHT 0~127 STANDARD 0 -42 0 -42 -42

EW PARABORA

H-WIDTH 0~63 STANDARD 0 +1 0 +1 +1

V S-CORRECTION 0~63 STANDARD 35 ( 35 ) ( 35 ) ( 35 ) ( 35 ) ( 35 )

V-LINEARITY 0~63 STANDARD -1 -2 -2 -3 -2

V CENTER 0~63 STANDARD -3 -4 -4 -4 -5

TRAPEZIUM

EW CORNER LOWER 0~15 STANDARD 0 0 0 0 0

EW CORNER UPPER

V EHT 0~7 STANDARD 3 ( 3 ) ( 3 ) ( 3 ) ( 3 ) ( 3 )

H EHT 0~7 STANDARD 1 ( 1 ) ( 1 ) ( 1 ) ( 1 ) ( 1 )

EHT GAIN

ADJUSTMENT 0~15 STANDARD 0 ( 0 ) ( 0 ) ( 0 ) ( 0 ) ( 0 )

H CENTER

HORI FREQ

ADJUSTMENT

H. BLK 0~63 STANDARD ( 0 ) ( 0 ) ( 0 ) ( 0 ) ( 0 )

OSD OFFSET

COMPULSION

TWIN SCREEN

COMPULSION

DEF RST OUTPUT

COMPULSION 1080i 0 / 1 STANDARD 0 ( 0 ) ( 0 ) ( 0 ) ( 0 ) ( 0 )

0~63

0~63

0~15

0~7

0~255

0~255 ST ANDARD -----

-127~128

0~6 STANDARD 0 ( 0 ) ( 0 ) ( 0 ) ( 0 ) ( 0 )

0 / 1 ST ANDARD 0 ( 0 ) ( 0 ) ( 0 ) ( 0 ) ( 0 )

NTSC

4 : 3

STANDARD +1 -1 +1 -1 -1

4 : 3

( SIZE1 )

16 : 9

( SIZE1 )

*1 *1 *1 *1

STANDARD 0 -2 0 -2 -2

STANDARD 0 +1 0 +1 +1

*1 *1 *1 *1

*1 *1 *1 *1

STANDARD 5 ( 5 ) ( 5 ) ( 5 ) ( 5 ) ( 5 )

*1 *1 *1 *1

*1 *1 *1 *1

STANDARD 0 -1 +62 +62 -35

*2 *2 *2 *2

STANDARD ( 0 ) ( 0 ) ( 0 ) ( 0 ) ( 0 )

*1 *1 *1 *1

*1 *1 *1 *1

*1 *1 *1 *1

*1 *1 *1 *1

HDCP

4 : 3

( SIZE2 )

16 : 9

( SIZE2 )

720p

*1

*1

*1

*1

*1

*2

*1

*1

*1

*1

26

No. 52008

Page 27

A

V-36P903

A

V-32P903

■■■■PICTURE MODE

Item

No.

S01

S02

( HD / 720p / HDCP )

Item

No.

S01

S02

( NTSC / DVD )

Item

No.

S03

Item name

SUB COLOR 0~127 73 75 71 73 74 79 75 69 71 76 69 74

SUB TINT 0~127 69 65 65 60 71 67 78 71 72 71 80 78

Item name

SUB BRIGHT

SUB CONT RAST 0~127 75 72 67 66 +3 +3 -1 -1 -7 -7 -15 -15

Item name

SUB BRIGHT 0~255 128 128 126 130 ----124 125 128 128 ----

( NTSC / DVD / ED )

Variable

range

Variable

range

0~255

Variable

range

(1/2)

NTSC DVD (525i / 480i) ED (480p / 525p)

Standard Theater Standard Theater Standard Theater

32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36”

(2/2)

HD (1080i) / 720p HDCP

Standard Theater

32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36”

63 68 59 63 -20 -20 -20 -20 -15 -15 -14 -14

480p (525p) 1080i / 720p

Standard Theater Standard Theater

(1/3)

NTSC DVD (525i / 480i)

4 : 3 16 : 9 4 : 3 16 : 9

Standard Theater Standard Theater Standard Theater Standard Theater

32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36”

SUB CONT RAST 0~127 89 96 62 62 ----91 95 61 59 ----

S04

SUB BRIGHT OFFSET

S05

CUB CONTRAST

S06

OFFSET

( ED / HD / 720p )

-128~127 ----

-128~127 ----

0000

-15 -15 -7 -7

----

----

0000

-15 -15 -7 -15

ED (480p / 525p) HD (1080i) / ED (480p / 525p) 720p

Item

No.

S03

S04

S05

S06

( MULTI / HDPC )

Item name

SUB BRIGHT 0~255 ----121 121 124 125 ----

SUB CONT RAST 0~127 ----81 83 57 58 ----

SUB BRIGHT OFFSET -128~127 +1 -1 +2 -2 ---- -2 -3 -2 -6

CUB CONTRAST

OFFSET

Variable

range

-128~127

Standard Theater Standard Theater Standard Theater

32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36”

+8 +9 +3 +3

4 : 3 16 : 9 16 : 9

----

-10 -5 0 +5

MULTI HDCP

Item

No.

S03

Item name

SUB BRIGHT 0~255 ----------------

Variable

range

9 PICTURES 480p (4:3) 480p / 1080i (16:9) 720p (16:9)

Standard Theater Standard Theater Standard Theater Standard Theater

32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36”

(2/3)

(3/3)

SUB CONT RAST 0~127 ----------------

S04

SUB BRIGHT OFFSET -128~1270000+5+5+5+5+30+30+31+31+3+3+2+2

S05

CUB CONTRAST

S06

OFFSET

-128~12700000000-4-4-2-2-9-900

No. 52008

27

Page 28

A

V-36P903

A

V-32P903

( NTSC / DVD / ED, HDCP480p / HD / 720p / HDCP1080i / HDCP720p )

Item

No.

B-Y AXIS GA IN

S07

R-Y ANGLE GAIN

S08

G-Y MATRIX SW

S09

( NTSC / DVD)

Item

No.

R Drive 0~255 --128 135 ------125 134 ----

S10

R Drive OFFSET -128~127 +6 +6 --+10 +10 +20 +20 +7 +7 --+13 +13 +18 +18

S11

B Drive 0~255 --170 165 ------169 162 ----

S12

B Drive OFFSET -128~127 +7 +7 ---11 -11 -34 -34 +10 +10 ---12 -12 -32 -32

S13

Item name

Item name

Variable

range

0~63

0~7

0~3

Variable

range

NTSC DVD ED / HDCP4 80p

Standard Theater Standard Theater Standard Theater Standard Theater

32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36”

16 15 21 18 18 18 17 16 13 11 20 16 6 3 15 13

7700772277223333

1133113311332222

Standard Theater Standard Theater

High Low High Low High Low High Low

32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36”

NTSC DVD

HD / 720p / HDCP1080i

HDCP720p

(1/3)

( ED / HD / 720p ) (2/3)

ED HD 720p

Item

No.

S10

S11

S12

S13

( HDCP ) (3/3)

Item name

R Drive 0~255 ----------134 149 ------------

R Drive OFFSET -128~127 +2 +2 +9 +9 +12 +12 +10 +10 +2 +2 --+12 +12 +14 +14 +17 +17 +15 +15 +27 +27 +29 +29

B Drive 0~255 ----------171 174 ------------

B Drive OFFSET -128~127 +11 +11 +5 +5 -9 -9 -25 -25 +11 +11 ---9 -9 -26 -26 +22 +22 +11 +11 +2 +2 -15 -15

Variable

range

Standard Theater Standard Theater Standard Theater

High Low High Low High Low High Low High Low High Low

32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36”

HDCP

Item

No.

S10

S11

S12

S13

Item name

R Drive 0~255 ----------------

R Drive OFFSET -128~127 +2 +2 +9 +9 +12 +12 +10 +10 +2 +2 0 0 +12 +12 +14 014

B Drive 0~255 ----------------

B Drive OFFSET -128~127 +11 +11 +5 +5 -9 -9 -25 -25 +11 +11 0 0 -9 -9 -26 -26

Variable

range

Standard Theater Standard Theater

High Low High Low High Low High Low

32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36”

480p / 1080p 720p

28

No. 52008

Page 29

A

V-36P903

A

V-32P903

( NTSC / DVD / ED / HD / 720p )

Item

No.

S14

S15

S16

S17

S18

S19

S20

S21

( HDCP )

Item

No.

S14

Item name

R CUT OFF

R CUT OFF OFFSET -128~127 -- 00-- 00-- 000000

G CUT OFF 0~255 71 71 --73 73 --92 92 ------

G CUT OFF

OFFSET

B CUT OFF 0~255 139 139 --153 153 --153 153 ------

B CUT OFF

OFFSET

R CUT OFF SW

B CUT OFF SW

Item name

R CUT OFF 0~255 --------

(1/2)

Variable

range

0~255

-128~127 --+6 +5 --+2 0 ---6 -5 +1 0 +1 -5

-128~127 --+13 0 --+4 0 ---60-40-40

0~3

0~3

NTSC DVD ED / HD 720p

Standard Theater Standard Theater Standard Theater Standard Theater

32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36” 32” 36”

70 70

11

11

--

--

--

70 70

11

11

--

--

--

70 70

11

11

------

------

------

(2/2)

HDCP

Variable

range

480p / 1080i 720p

Standard Theater Standard Theater

32” 36” 32” 36” 32” 36” 32” 36”

R CUT OFF OFFSET -128~12700000000

S15

G CUT OFF 0~255 --------

S16

G CUT OFF

S17

OFFSET

B CUT OFF 0~255 -------1 -

S18

B CUT OFF

S19

OFFSET

R CUT OFF SW

S20

B CUT OFF SW

S21

( NTSC / DVD / ED / HD / 720p / HDCP480p / HDCP1080i / HDCP 720p )

Item

No.

S22

S23

S24

S25

S26

S27

Item name

BLACK GRAD CORR

START LEVEL

BLACK GRAD CORR

GAIN

WHITE GRAD CORR

START LEVEL

WHITE GRAD CORR

GAIN

WHITE CHARA CORR

START LEVEL

WHITE CHARA CORR

GAIN

-128~127 0 0 -3 -3 -6 -6 -6 -6

-128~127

0~3 --------

0~3 --------

Variable

range

0~15 15 15 15

0~15666

0~15000

0~15 15 15 15

0~15211

0~15

0 0 +4 +4 -1 -1 -1 -1

NTSC DVD

( 32” / 36” ) ( 32” / 36” ) ( 32” / 36” )

321

ED / HD / 720p / HDCP480p

HDCP1080i / HDCP720p

No. 52008

29

Page 30

A

V-36P903

A

V-32P903

( ALL SIGNAL )

Item

No.

S28

S29

S30

S31

S32

S33

S34

( NTSC / DVD/ HD / 720p / HDCP1080i / HDCP720p / ED / HDCP480p)

Item

No.

S35

( ALL SIGNAL )

Item name

ABL GAIN 0~15 15 15

ABL START

ACL GAIN

ACL START

CONTRAST LINK 0 / 1 0 0

BLACK GRADATION

CORRECTION OFF

WHITE GRADATION

CORRECTION OFF

Item name

TINT HD / NTSC 0 / 1

Variable

range

0~15

0~15

0~15

0 / 1 0 1

0 / 1 0 0

Variable

range

Standard Theater

( 32” / 36” ) ( 32” / 36” )

15 15

15 15

00

NTSC / DVD

( 32” / 36” ) ( 32” / 36” ) ( 32” / 36” )

101

HD / 720p / HDCP1080i

HDCP720p

ED / HDCP480p

Item

No.

S36

S37

S38

S39

S40

( NTSC / DVD / ED / HD / 720p / HDCP480p / HDCP1080i / HDCP 720p )

Item

No.

S41

( 16 : 9 / THEATER / PIP / OTHER )

Item

No.

S42

Item name

ABL OFF 0 / 1 0 0

ABL OFF 0 / 1 0 0

DC TRANSMIT

POLARITY

DC TRANSMIT

CORR

BLANKING ON / OFF 0 / 1 0 0

Item name

DC REBIRTH

Item name

ACL CONTROL

Variable

range

0 / 1 1 1

0 / 1 0 0

Variable

range

0~255

Variable

range

0~255

Standard Theater

( 32” / 36” ) ( 32” / 36” )

NTSC DVD

Standard Theater Standard Theater Standard Theater

( 32” / 36” ) ( 32” / 36” ) ( 32” / 36” ) ( 32” / 36” ) ( 32” / 36” ) ( 32” / 36” )

160 120 160 120 150 120

( Inc. 720p / HD / HDCP720p / HDCP1080i )

16 : 9 Theater PIP OTHER

( 32” / 36” ) ( 32” / 36” ) ( 32” / 36” ) ( 32” / 36” )

160 50 0 0

ED / HD / 720p / HDCP480p

HDCP1080i / HDCP720p

30

No. 52008

Page 31

A

A

( ALL SIGNAL )

Item

No.

S43

S44

S45

( NTSC / DVD / OTHER )

Item name

CONT. LOW ER LIMIT -128~127

CONT. UPPER LIMIT -128~127

BRIGHT LOW ER LIMIT -128~127

Variable

range

V-36P903

V-32P903

Standard Theater

32” 36” 32” 36”

-45 -45 -15 -15

+17 +17 +17 +17

-20 -20 -20 -20

Item

No.

EE THEAT ER BRT

S46

EE THEAT ER CONT . -128~127

S47

( ALL SIGNAL )

Item

No.

BRIGHT EE CONT. CORRECTION

S48

REFRAIN EE CONT. CORRECTION 0~31

S49

REFRAIN EE BRIGHT OFFSET

S50

CORR (max)

BRIGHT EE ACL CORR. COEFF. 0~255

S51

REFRAIN EE ACL CORR. COEFF. 0~255

S52

( ALL SIGNAL )

Item

No.

Item name

Variable

range

-128~127

NTSC ( 4 : 3 / 16 : 9 ) DVD ( 4 : 3 / 16 : 9 ) OTHER

( 32” / 36” ) ( 32” / 36” ) ( 32” / 36” )

000

+20 +20 +20

Item name Variable range Common Value

0~31

0~127

Item name Variable range Common Value

7

27

4

85

140

VSM OFF OFFSET

S53

VSM ON LOW -128~127

S54

VSM ON MID

S55

VSM ON HIGH -128~127

S56

VSM ON OFFSET -128~127

S57

VSM ON OFFSET

S58

VSM ON OFFSET -128~127

S59

VSM ON OFFSET

S60

0~225

-128~127

-128~127

-128~127

No. 52008

+5

-20

-10

+10

-2

-1

0

+1

31

Page 32

A

V-36P903

A

V-32P903

■■■■OTHERS MODE

Item

No.

Item name

Variable

Range

Setting

Value

Item

No.

Item name

Variable

Range

F01 E2PROM Ver 1 0~255 026 F32 DIRECT SELECT 2 PIC. 0 / 1 000

F02 E2PROM Ver 2 0~255 002 F33

F03 H.LINE ON (BRIGHT) 0~255 133 F34

CAPTION OSD

OSCSELECT

CH.PROGRAM SEARCH

WA IT T IME

0~7002

0~255 040

F04 H.LINE OFF (BRIGHT) 0~255 125 F35 VSM SHIPPING MODE 0 / 1 000

F05 H.LINE CONTRAST 0~127 095 F36 DNR SET 0~3000

F06 C38 / C41 SW 0 / 1 001 F37 2PICTURE 16:9MODE 0 / 1 000

F07 MODEL SELECT 0~255 040 F38

V/C DECODE

H.MASK SETTING

0 / 3 000

F08 F39 LOUDNESS SW 0 / 1 000

F09 Auto Scroll Adjust 1 0~15 002 F40 POW ER OFF WHITE 0 / 1 000

F10 Auto Scroll Adjust 2 0~15 004 F41 WHITE BACK ON/OFF 0 / 1 000

F11 Auto Scroll Adjust 3 0~15 004 F42

F12 Auto Scroll Adjust 4 0~15 005 F43

Setting

Value

F13 Auto Scroll Adjust 5 0~15 006 F44

F14 Auto Scroll Adjust 6 0~15 007 F45

F15 Auto Scroll Adjust 7 0~15 007 F46

F16 V Scroll MAX (VARI) -128~127 -001 F50

F17 V Scroll MIN (VARI) -128~127 +001 F51

F18 V Scroll MAX (CORR.) -128~127 000 F52

F19 V Scroll MIN (CORR.) -128~127 000 F53 S / N (RF) CORR.WIDTH 0~255 004

F20 V LIN . MAX (CORR.) -128~127 000 F54 S / N (RF) CORR.START 0~255 006

F21 V LIN. MIN (CORR.) -128~127 000 F55 S / N (BS) CORR.WIDTH 0~255 005

F22 V Scroll MAX (VARI) 0~255 000 F56 S / N (BS) CORR.START 0~255 006

F23 V Scroll MIN (VARI) 0~255 000 F57

V-CHIP ON/OFF (CANADA)

F24

EARTH MAGNETIC

F25

CORR. PICTURE

OSD OFFSET

F26

(480p / 720p) (HDCP / 480p)

OSD OFFSET

F27

(1080i / HDCP1080i)

CH.PROGRAM

F28

SEARCH CYCLE

PIP FUNCTION

F29

ON / OFF

0 / 1 001 F58

0~127 127 F59 S / N (S) CORR.WIDTH 0~255 005

0~63 033 F60 S / N (S) START 0~255 006

0~63 018 F61 OCD OFFSET (HORI.) 0~63 045

0~255 010 F62 ATT GAIN 0 / 1 000

0 / 1 001 F63 V.HEIGHT OFFSET -128~127 -006

F30 PIP 2 PICTURE 0 / 1 000 F64

S / N (Comp.)

CORR.WIDTH

S / N (Comp.)

CORR.START

TEXT MODE

CONT.CORR.

0~255 005

0~255 006

-128~127 000

F31 V.CHIP ON OFF 0 / 1 001 F65 -128~127

Item

No.

Item name

Variable

Range

NTSC DVD ED HD 720p

Setting Value

HDCP480p HDCP1080i

F47 SEP.LEVEL 0~3 000 002 002 002 002 --

F48 CLAMP PLUS 0 / 1 000 000 000 001 001 --

F49 HD PHASE 0~63 063 027 030 030 028 --

32

No. 52008

Page 33

A

A

■■■■ADJUSTMENT

B1 POWER SUPPLY check

Item

Check of B1

Power supply

X-RAY protector check

Item

Check of

X-Ray

protector circuit

Measurin g

Instrument

Signal generator

DC Voltmeter

Measurin g

Instrument

Resistor

12kΩΩΩΩ1/6W

±±±±5%

Test point

S1 connector

pin 5 (TP-91)

S1 connector

pin 1 (TP-E)

( #### )

Test point

S1 connector

pin

(X-Ray2)

2222

pin

(X-Ray1)

3333

V-36P903

V-32P903

Adjustment Item Description

1. Input a black and white signal (color off).

2. Connect the DC voltmeter to the S1 connector pin 5

(TP-91) and TP-E( #### ) (S1 connector pin 1).

3. Confirm that the voltage is DC140V±2V .

Adjustment Item Description

1. Connect the following resistors between pin ②②②② & pin

③③③③ of the connector S1.

2. Confirm that the X-RAY protector functions are

activated.

FOCUS adjustment

Item

FOCUS

adjustment

Signal

generator

Horizontal line

Measurin g

Instrument

MODEL No. CRT Resistor

AV-36P903/Y 36V 12.0kΩ±60Ω

AV-32P903/Y 32V 22.0kΩ±60Ω

Test point Adjustment Item Description

H (FOCUS)

(UPPER in FBT)

FOCUS

(CENTER in FBT)

1. Input a crosshatch signal.

2. Select the FULL mode.

3. While watching at the scr een, adjust the H (FOCUS)

VR (Fig.2) to make the horizontal lines as fine and

sharp as possible. (Fig.1)

4. Then adjust the FOCU S VR (Fig.2) to make the

vertical lines as fine and sharp as position. (Fig.1)

5. Make sure that when the screen is darkened, the lines

remain in good focus.

Vertical line

Fig. 1 Fig. 2

No. 52008

H

H(FOCUS) VR

FOCUS

FOCUS V R

SCREEN

SCREEN

33

Page 34

A

V-36P903

A

V-32P903

HORIZONTAL FREQUENCY adjustment

Item

Hor. FRE Q.

adjustment

Measurin g

Instrument

signal

generator

Remote Control

unit

DEFLECTION CIRCUIT adjustment

Item

V. POSITION &

TRAPEZ

V. HEIGHT &V.

LIN.

Adju stment

Screen

Vertical

Center

Measurin g

Instrument

Signal

generator

Pallalel

Test point Adjustment Item Description

D15 : H. FREQ.

D19 : DEF. RST

Test point Adjustment Item Description

D06 : V. CENTER

D07 : TRAPEZ

D01 : V. HEIG HT

D05 : V. LIN.

1. Receive the monoscope signal.

2. Enter the SERVICE MENU.

3. Pr eset the value from 0 to 1 for the D19:DEF. RST in

the SERVICE MODE, then adjust the D15:H. FREQ.

and memorize the data with the MUTING key.

4. For the 720p data, input offset data ( 0 ) or NTSC data.

5. Then receive the HD monoscope and memorize the

data same as Item 3.

6. After adjustment, preset the value from 1 to 0 for the

D19:DEF. RST (Compulsion DEF. RST output) and the

memorize the data same as Item 3.

1. Receive the Full mode cross-hatch signal.

2. Enter the SERVICE MENU.

3. Select the D07:TRAPEZ of the 1.PICTURE/SOUND

mode in the SERVICE MENU with the FUNCTION

(

key and adjust the DO7:TRAPEZ to make the

▼/▲)

vertical lines straight with the FUNCTION ( / ) key.

4. Select t he D06:V. CENTER with the FUNCTION (

key.

5. Adjust the D06:V. CENTER so that the horizontal line

of the vert ical center on the cross-hatch screen is

agreement with the screen center marker. The screen

center markers (Fig.1) are positioned at both side of the

screen vertical center.

6. Readjust the D07:TRAPEZ and adjust each vertical

lines to be positioned equally (pallalel) of the screen

(Fig.1).

* Reconfirm the V. CENTER after adjustment of the

TRAPEZ distortion.

7. Select t he D01:V. HEIGHT of the 1. PICTURE/SOUND

mode in the SERVICE MENU.

8. Adjust the V. Height to squeeze the raster.

▲/▼)

Fig.1

34

No. 52008

Page 35

A

V-36P903

A

V-32P903

Item

Screen

size

(A)

Measurin g

Instrument

Screen size

Picture size 100%

Fig.2

16 : 9 SCREEN

Test point Adjustment Item Description

9. Adjust the vertical screen size to (A) by the D01: V.

HEIG HT with the FUNCTION ( / ) key (Fig.2).

10. Then select the D05:V. LIN. with the FUNCTION

(▲/▼) key, and adjust the linearity of the top (B) and