Page 1

52104200304

AV-32430

AV-32432

SERVICE MANUAL

COLOR TELEVISION

BASIC CHASSIS

AV-32430/M, AV-32432/M,

GE2

AV-32430

AV-32430

/R, AV-32432/R,

/Y, AV-32432/Y

TABLE OF CONTENTS

1 PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD.

No.52104

2003/04

Page 2

AV-32430

AV-32432

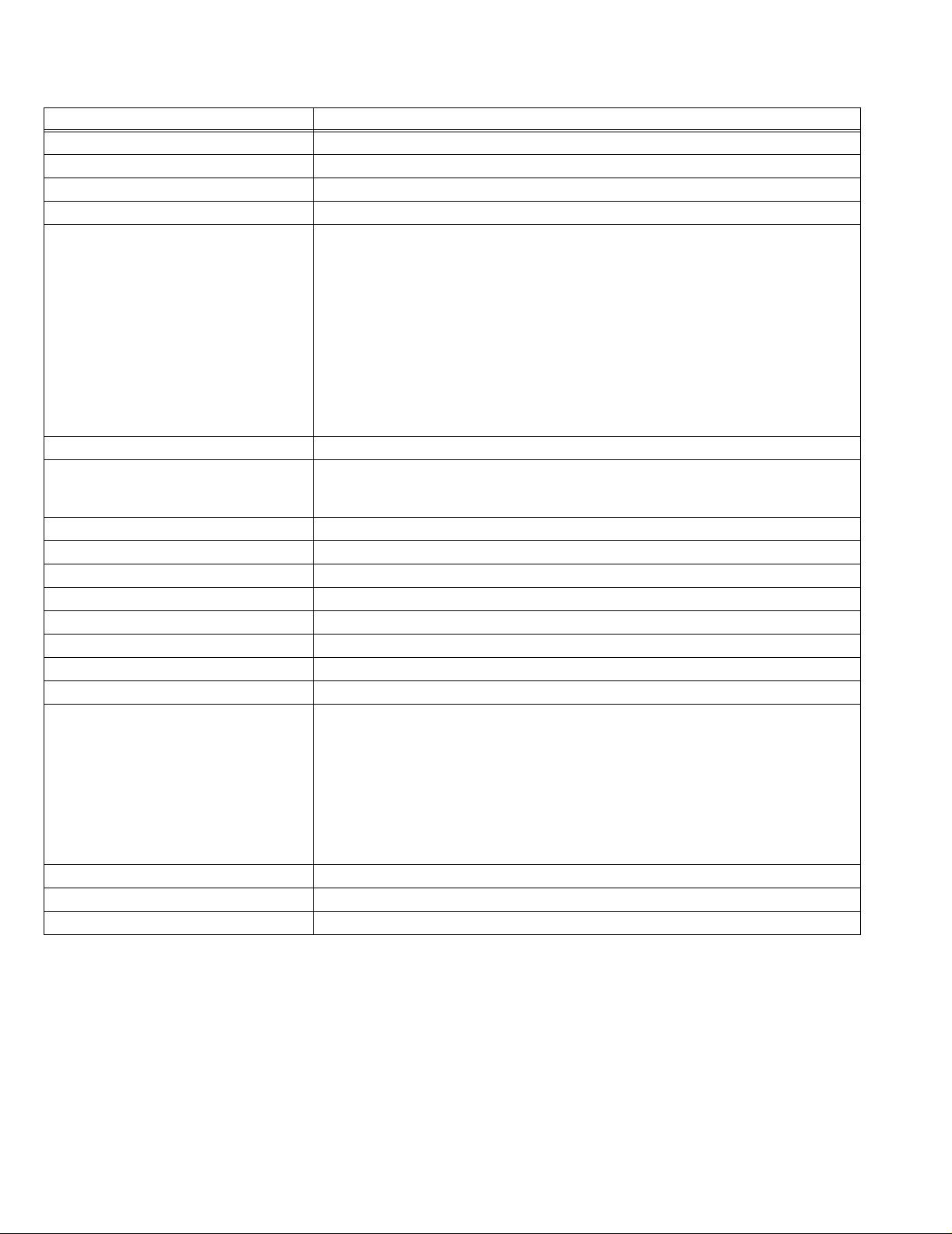

SPECIFICATION

Items Contents

Dimensions (W x H x D) 76.8cm x 66.7cm x 54.7cm (30-1/4” x 26-1/4” x 21-1/2”)

Mass 51.0kg (112.2 Ibs)

TV RF System CCIR (M)

Color Sound System NTSC, BTSC System (Multi Channel Sound)

TV Receiving Channels and Frequency

VHF LOW

VHF HIGH

TV/CATV Total Channel 180 Channels

Intermediate Frequency

Video IF Carrier

Sound IF Carrier

Color Sub Carrier 3.58MHz

Power Input AC 120V, 60Hz

Power Consumption 128W

Picture Tube 32” (80cm) Measured diagonally H:65.6cm x V:49.6cm

High Voltage 31kV±1.3kV (at zero beam current)

Speaker 8 x 12cm (3-1/4” x 4-3/4”) Oval type x 2

Audio Power Output 3W + 3W

Antenna Terminal (VHF/UHF) F-type connector, 75ohm

Video / Audio Input (1 / 2 / 3)

Video (1 / 3)

Audio (1 / 2 / 3)

S-Video (1)

Component video (2)

Audio Output (Fix) 500mV(rms), low impedance, (1kHz when modulated 100%) (RCA pin jack x 2)

AV Compulink lll 3.5mm mini jack x 1

Remote Control Unit RM-C203 (Lithium cell battery x 1)

02ch~06ch : 54MHz~88MHz

07ch~13ch : 174MHz~216MHz

UHF

14ch~69ch : 470MHz~806MHz

CATV

54MHz~804MHz

Low Band : 02~06, A-8 by 02~06&01

High Band : 07~13 by 07~13

Mid Band : A~1 by 14~22

Super Band : J~W by 23~36

Hyper Band : W+1~W+28 by 37~64

Ultra Band : W+29~W+84 by 65~125

Sub Mid Band : A8, A4~A1 by 01, 96~99

45.75MHz

41.25MHz (4.5MHz)

1V(p-p), 75ohm (RCA pin jack x 2)

500mV(rms) (-4dBs), high impedance (RCA pin jack x 8)

Mini DIN 4pin x 1

Y : 1V(p-p) positive (negative sync provided, when terminated with 75ohm)

C : 0.286V(p-p) (burst signal when terminated with 75ohm)

RCA pin jack x 3

Y : 1V(p-p) positive (negative sync provided, when terminated with 75ohm)

Pb/Pr : 0.7V(p-p) 75ohm

Design & specifications are subject to change without notice.

1-2 (No.52104)

Page 3

SECTION 1

PRECAUTIONS

AV-32430

AV-32432

1.1 SAFETY PRECAUTIONS

(1) The design of this product contains special hardware , many circuits

and components specially for safety purposes. For continued

protection, no changes should be made to the original design unless

authorized in writing by the manufacturer. Replacem ent parts must

be identical to those used in the original circuits. Service should be

performed by qualified personnel only.

(2) Alterations of the design or circuitry of the pr oducts should not be

made. Any design alterations or additions will void the manufacturer's

warranty and will further relieve the manufacturer of responsibility for

personal injury or property damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have special

safety-related characteristics. These characteristics are often not

evident from visual inspection nor can the protection afforded by them

necessarily be obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts that have these

special safety characteristics are identified in the parts list of Service

manual. Electrical components having such features are

identified by shading on the schematic s and by ( ) on the parts

list in Service manual. The use of a substitute replacement which

does not have the same safety characteristics as the recommended

replacement part shown in the pa rts list of Service manual ma y cause

shock, fire, or other hazards.

(4) Use isolation transformer when hot chassis.

The chassis and any sub-chassis contained in some products ar e

connected to one side of the AC power line. An isolation transformer

of adequate capacity should be inserted between the product and the

AC power supply point while performing any service on some

products when the HOT chassis is exposed.

(5) Don't short between the LIVE side ground and ISOLATED

(NEUTRAL) side ground or EARTH side ground when repairing.

Some model's power circuit is partly different in the GND. The

difference of the GND is shown by the LIVE : ( ) side GND, the

ISOLATED(NEUTRAL) : ( ) side GND and EARTH : ( ) side GND.

Don't short between the LIVE side GND and I SOLATED (NEUTRAL )

side GND or EARTH side GND and never measure with a measuring

apparatus (oscilloscope etc.) the LIVE side GND and

ISOLATED(NEUTRAL) side GND or EARTH side GND at the same

time.

If above note will not be kept, a fuse or any parts will be broken.

(6) The high voltage applied to the picture tube m ust conform with that

specified in Service manual. Excessive high voltage can cause an

increase in X-Ray emission, arcing and possible component damage,

therefore operation under excessive high voltage con ditions should

be kept to a minimum, or should be prevented. If severe arcing

occurs, remove the AC power immediately and determine the cause

by visual inspection (incorrect installation, cracked or melted high

voltage harness, poor soldering, etc.). To maintain the proper

minimum level of soft X-Ray emission, components in the high

voltage circuitry including the picture tube must be the exact

replacements or alternatives approved by the manufact urer of the

complete product.

(7) If any repair has been made to the ch assis, it is recomme nded that

the B1 setting should be checked or adjusted (See ADJUSTMENT

OF B1 POWER SUPPLY).

(8) Do not check high voltage by drawing an arc. Use a high voltage

meter or a high voltage probe with a VTVM. Discharge the picture

tube before attempting meter connection, by connecting a clip lead to

the ground frame and connecting the other end of the lead through a

10kΩ 2W resistor to the anode button.

(9) When service is required, observe the original lead dress. Extra

precaution should be given to assure correct lead dress in the hig h

voltage circuit area. Where a short circuit has occurred, those

components that indicate evidence of overheating should be

replaced. Always use the manufacturer's replacement components.

(10) Isolation Check

(Safety for Electrical Shock Hazard)After re-assembling the

product, always perform an isolation check on the exposed metal

parts of the cabinet (antenna terminals, video/audio input and output

terminals, Control knobs, metal cabinet, screwheads, earphone jack,

control shafts, etc.) to be sure the pro duct is saf e to operat e with out

danger of electrical shock.

a) Dielectric Strength Test

The isolation between the AC primary circuit and all metal

parts exposed to the user, particularly any exposed metal part

having a return path to the chassis should withstand a voltage

of 1100V AC (r.m.s.) for a period of one second.

(. . . . Withstand a voltage of 1100V AC (r.m.s.) to an appliance

rated up to 120V, and 3000V AC (r.m.s.) to an appliance rated

200V or more, for a period of one second.)

This method of test requires test equipment not generally

found in the service trade.

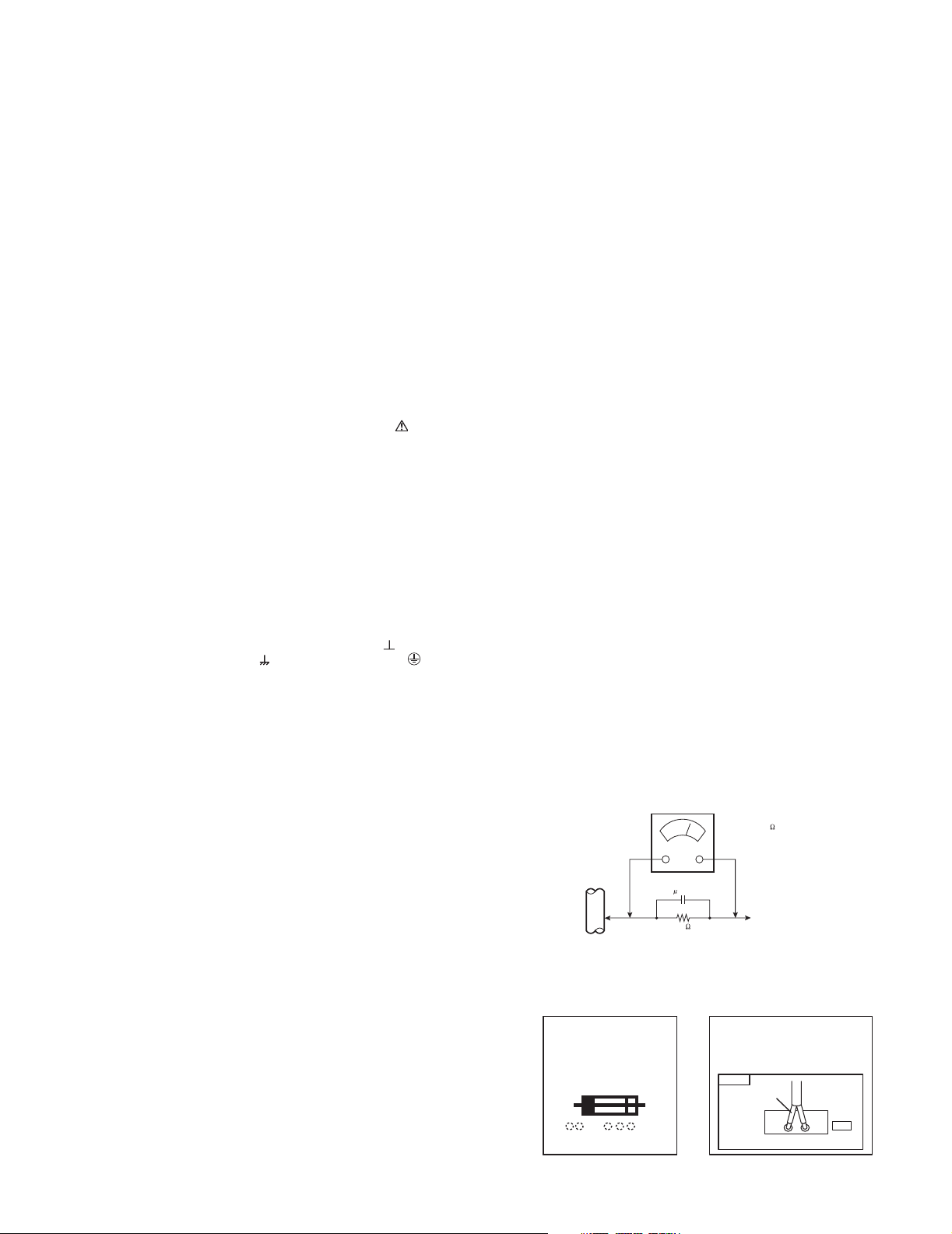

b) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use a

line isolation transformer during this check.). Using a "Leakage

Current Tester", measure the leakage current from each

exposed metal part of the cabinet, particularly any exposed

metal part having a return path to the chassis, to a known good

earth ground (water pipe, etc.). Any leakage current must not

exceed 0.5mA AC (r.m.s.). However, in tropical area, this must

not exceed 0.2mA AC (r.m.s).

• Alternate Check Method

Plug the AC line cord directly into the A C ou tle t ( do not use

a line isolation transformer during this check.). Use an AC

voltmeter having 1000 ohms per volt or more sensitivity in

the following manner. Connect a 1500ohm 10W resistor

paralleled by a 0.15µF AC-type capacitor between an

exposed metal part and a known good earth ground (water

pipe, etc.). Measure the AC voltage across the resistor with

the AC voltmeter. Move the resistor connection to each

exposed metal part, particularly any exposed metal part

having a return path to the chassis, and measure the AC

voltage across the resistor. Now, reverse the plug in the AC

outlet and repeat each measurement. Any voltage

measured must not exceed 0.75V AC (r.m.s.). This

corresponds to 0.5mA AC (r.m.s.).

However, in tropical area, this must not exce ed 0.3V AC

(r.m.s.). This corresponds to 0 .2mA AC (r .m.s .).

AC VOLTMETER

(HAVING 1000 /V,

OR MORE SENSITIVITY)

0.15 F AC-TYPE

PLACE THIS PROBE

(11) High voltage hold down circuit ch eck.

GOOD EARTH GROUND

1500 10W

ON EACH EXPOSED

METAL PART

After repair of the high voltage hold down circui t, this circuit shall b e

checked to operate correctly.

See item "How to check the high voltage hold down circuit".

This mark shows a fast

operating fuse, the

letters indicated below

show the rating.

A V

POWER CORD

REPLACEMENT WARNING.

Connecting the white line side of power

cord to "WHT" character side.

PWB

White line side

WHT

PW

(No.52104)1-3

Page 4

AV-32430

AV-32432

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 FEATURES

TELETEXT (CLOSED CAPTION) Title TELETEXT broadcast of C1~C4 and T1~T4 formula is receivable.

DIGITAL COMB FILTER By the three-line digital comb filter, the refreshed image can be seen.

VIDEO STATUS Expression of a favorite screen can be chosen by the VIDEO STATUS function

(STANDARD / DYNAMIC / SPORTS / GAME).

V-CHIP Since the V chip is built in, it can choose, view and listen to a healthy program.

COMPONENT VIDEO INPUT TERMINAL Since the component signal input terminal is equipped, it reappears direct without

deteriorating the signal from DVD.

MTS STEREO SYSTEM The voice multiplex function of the MTS system is built in. (MTS = Multi channel TV

Sound system)

EZ SURF By the EZ SURF function, channel ID and a program name are displayed in the screen

automatically.

RETURN PLUS you program a specific channel to return to while scanning through the channels using

the CH+ and CH- buttons.

AV COMPULINK lll By the AV COMPULINK lll function, operation interlocked with the DVD deck can be

performed from remote control.

ON / OFF & SLEEP TIMER The on/off timer lets you progr am your television to turn itself on or off. You can use it as

an alarm to wake up, to help you remember important programs, or as a decoy when

you're not home.

HYPER SCAN A quick favorite program can be looked for by the HYPER SCAN function.

FRONT PANEL LOCK This allows you to lock the keys on the front of the TV, so that a child may not accidentally

change your viewing preferences.

NOISE MUTING This feature inserts a blank blue screen over channels which are not broadcasting or are

too weak to be received clearly.

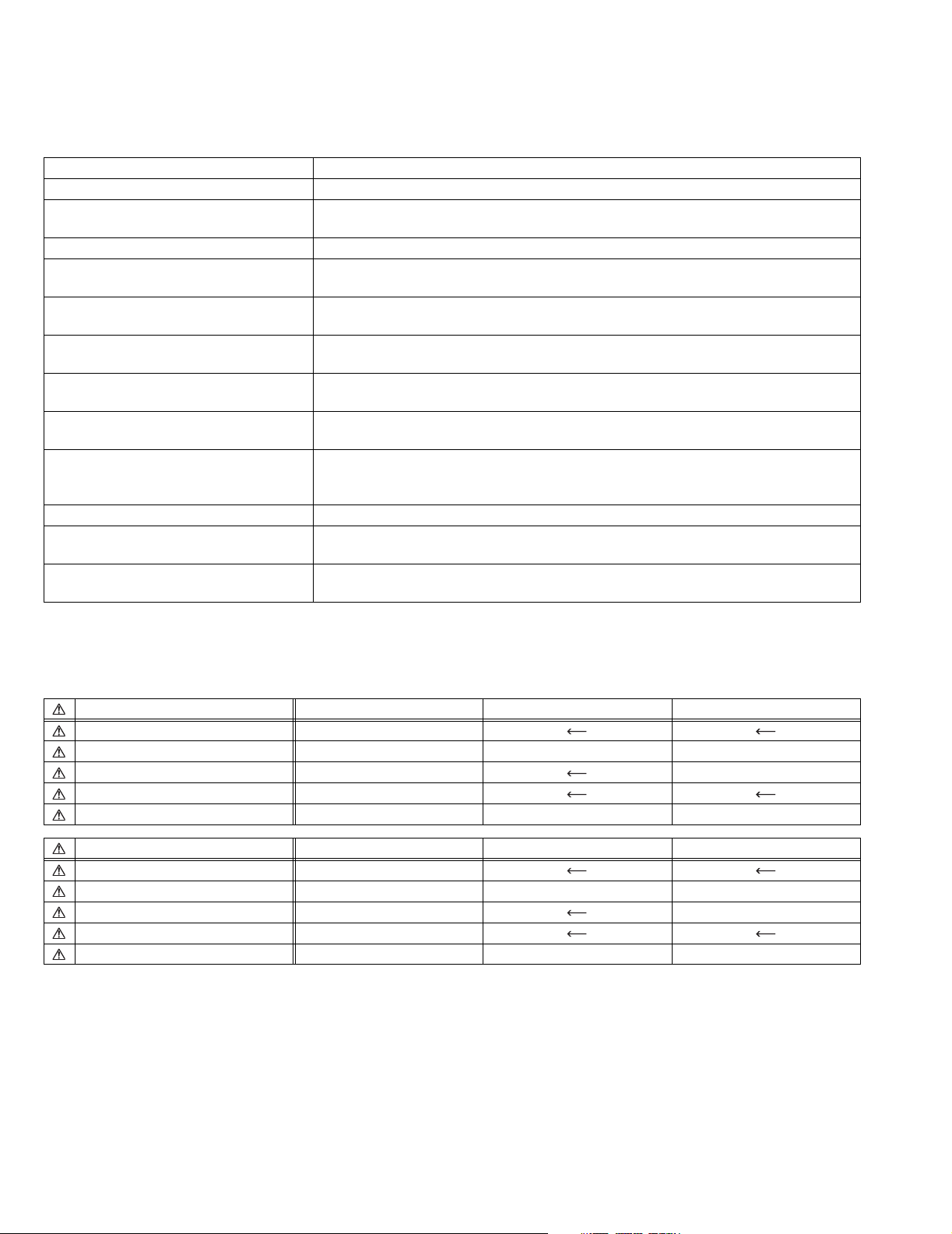

2.2 MAIN DIFFERENCE LIST

• The difference between MA models, RA model, and YA models is in the PICTURE TUBE. As the result of the difference in PICTURE

TUBE, the MAIN PWB also differ.

• The difference between AV-32430 series models and AV-32432 series models are in the FRONT CABINET color.

PART NAME AV-32430/MA AV-32430/RA AV-32430/YA

FRONT CABINET (BLACK) CM12914-010-MA

MAIN P.W.B. ASSY SGE-1064A-M2 SGE-1066A-M2 SGE-1065A-M2

CRT SOCKET P.W.B. ASSY SGE-3061A-M2 SGE-3062A-M2

AV SELECT P.W.B. ASSY SGE-5062A-M2

PICTURE TUBE (ITC) M80JUA061X06 A80AEJ15X01 A80AKB50X04

PART NAME AV-32432/MA AV-32432/RA AV-32432/YA

FRONT CABINET (SILVER) CM12914-012-MA

MAIN P.W.B. ASSY SGE-1061A-M2 SGE-1063A-M2 SGE-1062A-M2

CRT SOCKET P.W.B. ASSY SGE-3061A-M2 SGE-3062A-M2

AV SELECT P.W.B. ASSY SGE-5061A-M2

PICTURE TUBE (ITC) M80JUA061X06 A80AEJ15X01 A80AKB50X04

1-4 (No.52104)

Page 5

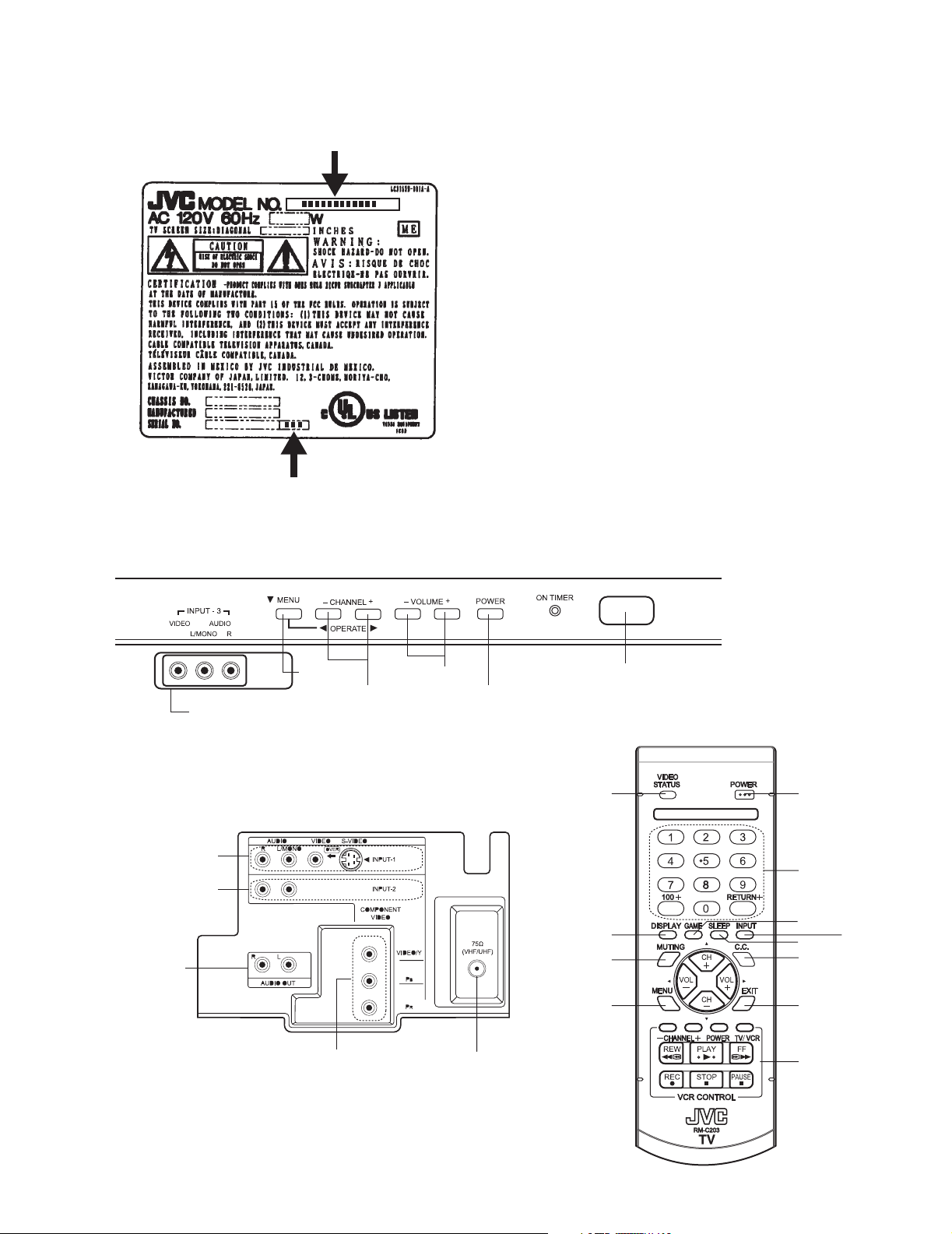

2.3 HOW TO IDENTIFY MODELS

How to recognize from the appearance of the model concerned is written below.

Please distinguish from several contents printed on the rating label.

Indicated model name

AV-32430

AV-32432

2.4 FUNCTIONS

FRONT CONTROL PANEL

INPUT-3 (V, L, R)

REAR TERMINAL

INPUT-1

(S, V, L, R)

INPUT-2

(L, R)

AUDIO OUT

(L, R)

Indicated /M, /R or /Y model

MENU

CHANNEL -/+

VOLUME -/+

POWER SW

REMOCON

WINDOW

REMOTE CONTROL UNIT

VIDEO

STATUS

DISPLAY

MUTING

MENU

POWER

BUTTON

NUMBER

KEYS

GAME

SLEEP

C.C

EXIT

INPUT

INPUT-2

(Y, Pb, Pr)

ANTENNA

TERMINAL

VCR

CONTROL

KEYS

(No.52104)1-5

Page 6

AV-32430

AV-32432

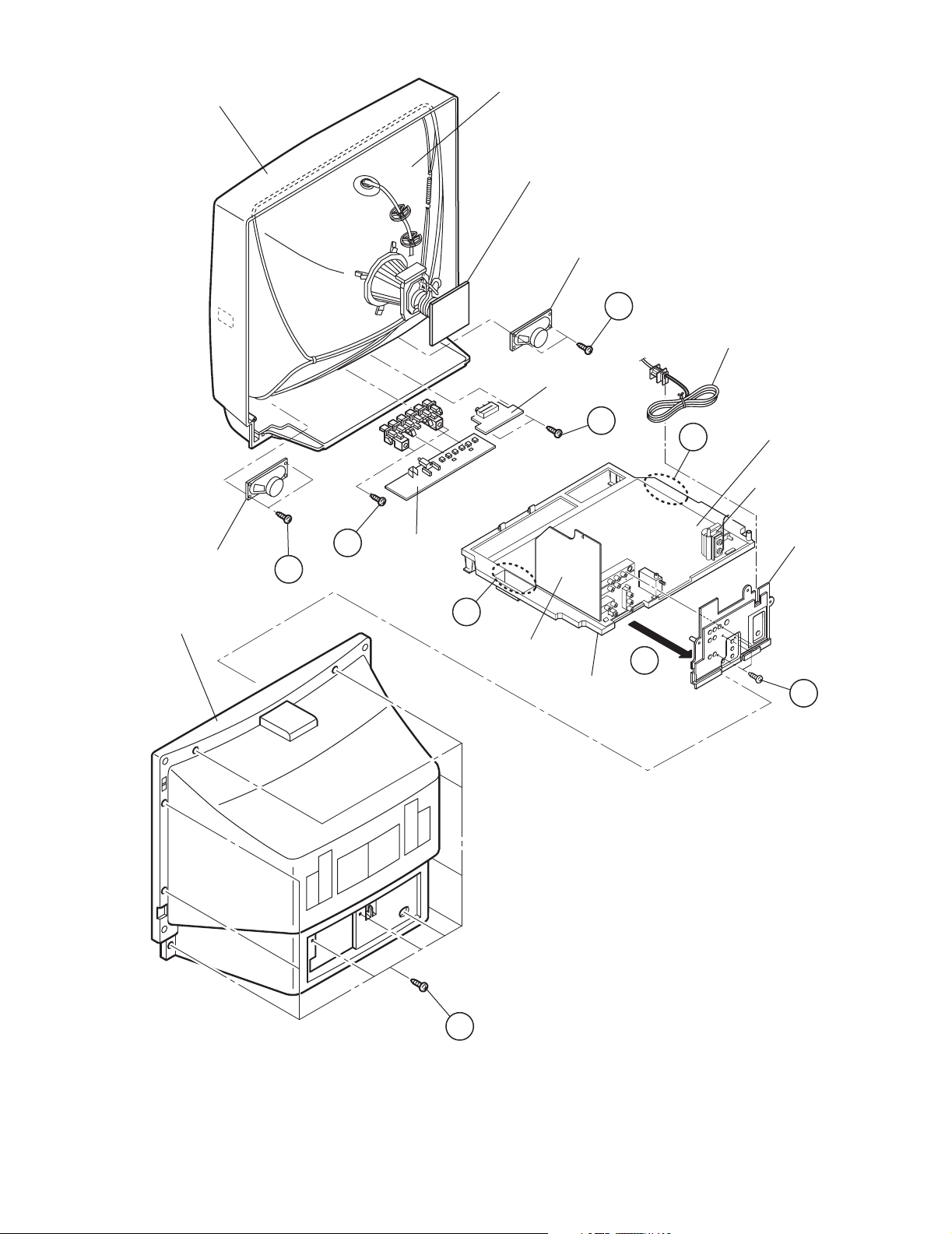

2.5 DISASSEMBLY PROCEDURE

2.5.1 REMOVING THE REAR COVER

• Unplug the power plug.

(1) Remove the 11 screws [A], as shown in Fig.1.

(2) Remove the rear cover toward you.

NOTE:

When reinstalling the REAR COVER, carefully push it inward

after inserting the chassis into the rear cover groo ve .

2.5.2 REMOVING THE TERMINAL BOARD

• Remove the REAR COVER.

(1) Remove the 4 screws [E] as shown in Fig.2.

(2) When you pull out the TERMINAL BOARD, it can be

removed.

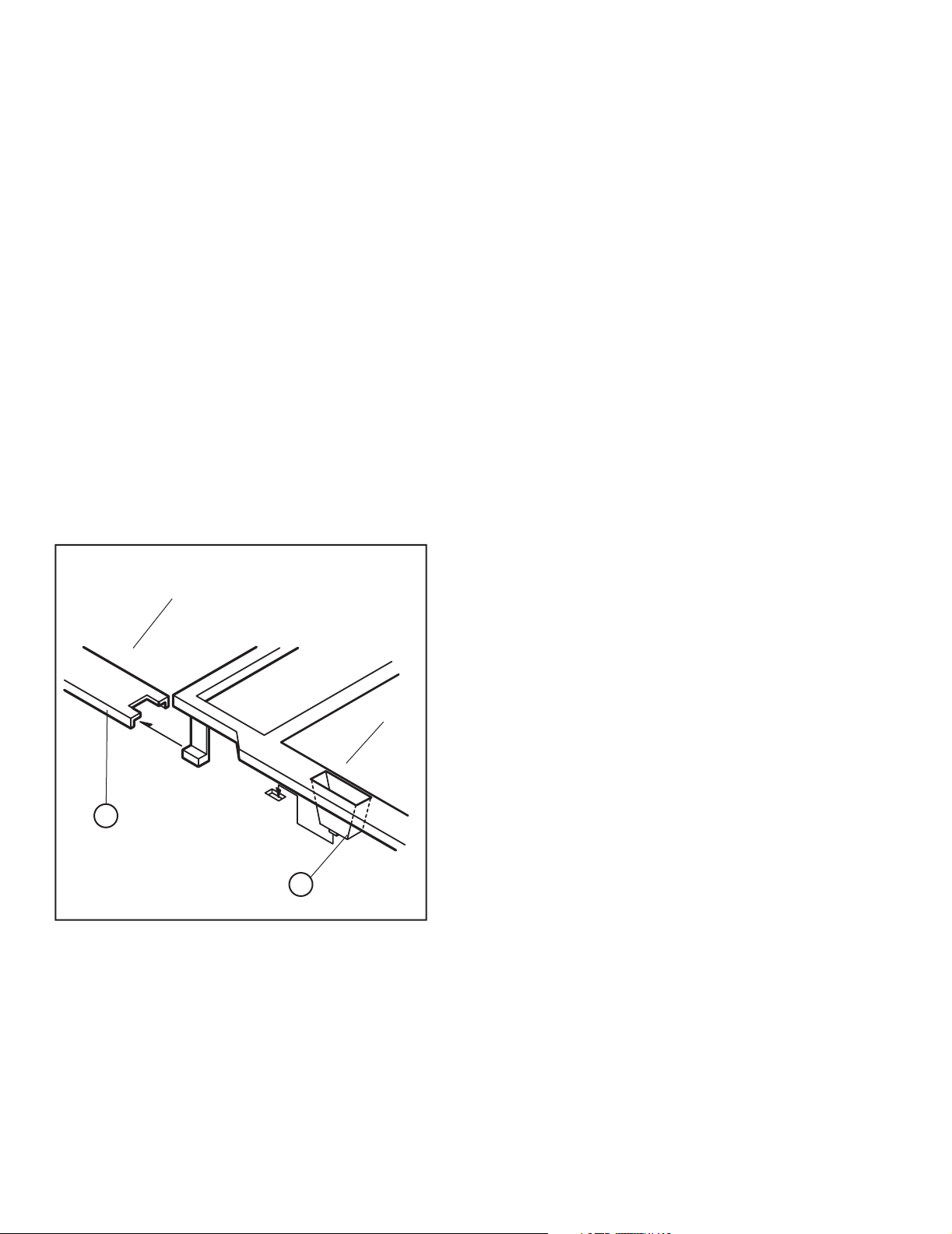

2.5.3 REMOVING THE MAIN PWB

• Remove the REAR COVER.

(1) Slightly raise the both sides of the CHASSIS BASE by

hand, and remove the 2 claws [B] (Fig.1 and Fig.2) under

the both sides of the chassis from the chassis rail.

(2) Draw the CHASSIS BASE backward along the chassis rail

[C] in the arrow direction [D] as shown in Fig.1 and Fig.2.

(If necessary, detach the wire clamp, connector's etc.)

NOTE:

When conducting a check with power supplied, be sure to

confirm that the CRT earth wire is connected to the CRT

SOCKET PWB and the MAIN PWB.

FRONT CABINET

2.5.4 REMOVING THE FRONT CONTROL PWB

• Remove the REAR COVER.

• Remove the MAIN PWB.

(1) Remove the 2 screws [F] attached the FRONT CONTROL

PWB with the front cabinet as shown in Fig.2.

(2) Then remove the FRONT CONTROL PWB.

2.5.5 REMOVING THE FRONT TERMINAL PWB

• Remove the REAR COVER.

• Remove the CHASSIS BASE.

(1) Remove the 2 screws [G], as shown in Fig.2.

(2) Then remove the FRONT AV IN PWB.

2.5.6 REMOVING THE SPEAKER

• Remove the REAR COVER.

• Remove the CHASSIS BASE.

(1) Remove the 2 screws [H], as shown in Fig.2.

(2) Follow the same steps when removing the other hand

speaker.

2.5.7 CHECKING THE MAIN PWB

(1) Pull out the CHASSIS BASE. (Refer to REMOVING THE

CHASSIS BASE).

(2) Erect the chassis vertically so that you can easily check

from the backside of the MAIN PWB.

2.5.8 CAUTION

(1) When erecting the chassis, be careful so that there will be

no contacting with other PWB.

(2) Before turning on power, make sure that the CRT earth

wire and other connectors are properly connected.

2.5.9 WIRE CLAMPING AND CABLE TYING

(1) Be sure to clamp the wire.

(2) Never remove the cable tie used for tying the wires

together. Should it be inadvertently removed, be sure to tie

MAIN PWB

the wires with a new cable tie.

C

B

Fig.1

1-6 (No.52104)

Page 7

AV-32430

AV-32432

FRONT CABINET

SPEAKER

CRT

CRT SOCKET PWB

SPEAKER

H

POWER CORD

FRONT TERMINAL

PWB

G

B

CLAW

F

FRONT

H

CONTROL

PWB

MAIN PWB

HVT

TERMINAL

BOARD

REAR COVER

CLAW

B

AV SELECTOR

PWB

A

CHASSIS BASE

D

E

Fig.2

(No.52104)1-7

Page 8

AV-32430

AV-32432

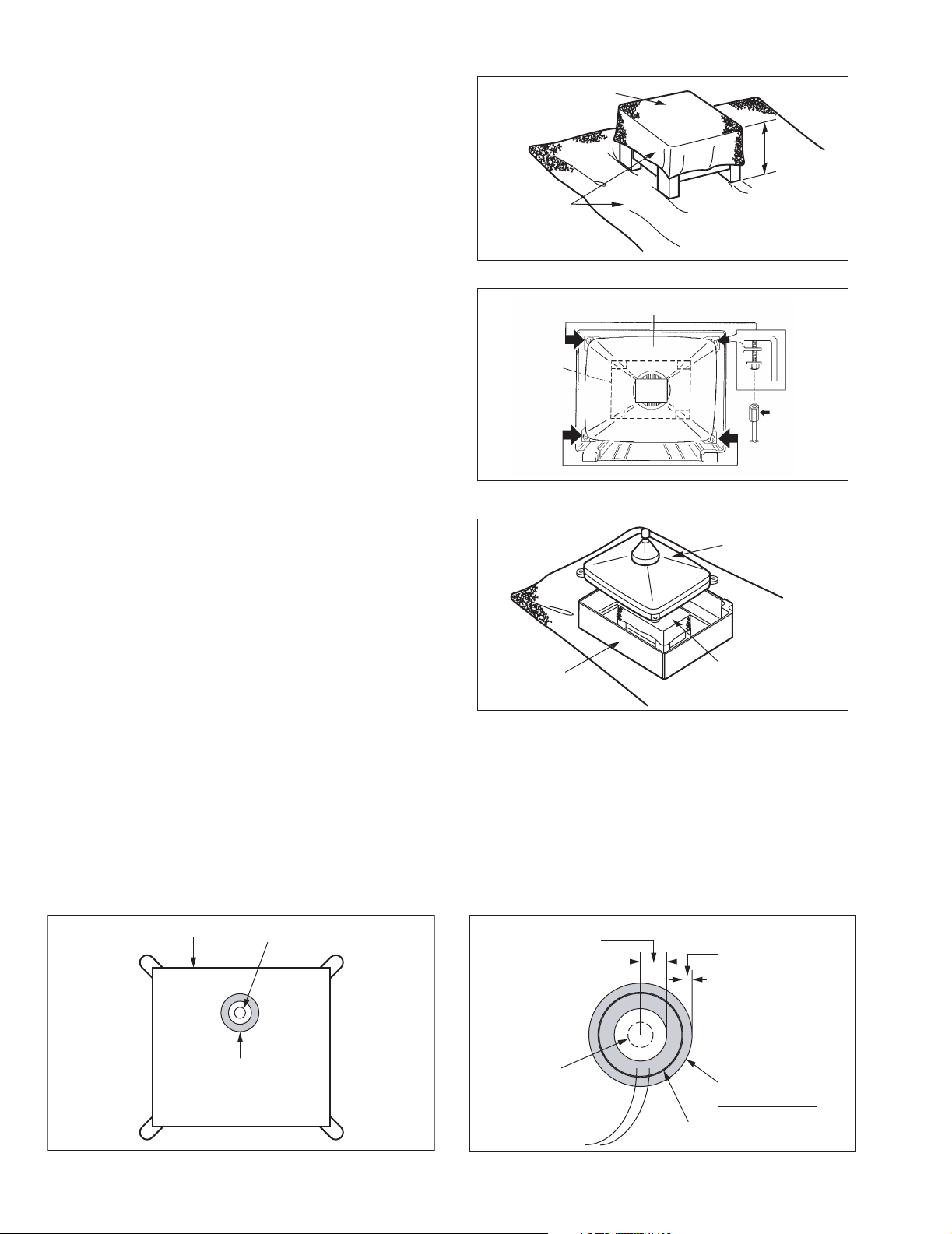

2.6 REMOVING THE CRT NOTE:

• Replacement of the CRT should be performed by 2 or more

persons.

• After removing the REAR COVER, CHASSIS etc.,

(1) Putting the CRT change table on soft cloth, the CRT

change table should also be covered with such soft clo th

(shown in Fig. 3).

(2) While keeping the surface of CRT down, mount the TV set

on the CRT change table balanced will as shown in Fig. 3.

(3) Remove 4 screws marked by arrows with a box type screw-

driver as shown in Fig. 4.

NOTE:

Since the cabinet will drop when screws have been removed, be sure to support the cabinet with hands.

(4) After 4 screws have been removed, put the cabinet slowly

on cloth (At this time, be carefully so as not to damage the

front

surface of the cabinet) shown in Fig. 5.

NOTE:

• The CRT should be assembled according to the opposite sequence of its dismounting steps.

• The CRT change table should preferably be smaller

that the CRT surface, and its height be about 35cm.

CRT CHANGE TABLE

CLOTH

CRT

CHANGE

TABLE

Fig.3

CRT

Fig.4

APPROX.

35cm

BOX

TYPE

SCREW

DRIVER

CABINET

Fig.5

COATING OF SILICON GREASE FOR ELECTRICAL INSULATION ON THE CRT ANODE CAP SECTION.

Subsequent to replacement of the CRT and HV transformer or

repair of the anode cap, etc. by dismounting them, be sure to

coat silicon grease for electrical insulation as shown in Fig.6.

Wipe around the anode button with clean and dry cloth. (Fig.6)

Coat silicon grease on the section around the anode button. At

this time, take care so that any silicon greases dose not sticks

to the anode button. (Fig.7)

Silicon grease product No. KS - 650N

CRT

Anode button

Approx.

20mm (Do not

coat grease on

this section

CRT

CRT

CHANGE T ABLE

Silicon grease

should be coated

by 5mm or more

from the outside

diameter of anode

cap.

1-8 (No.52104)

Silicon grease

coating

Fig.6

Anode button

(No sticking of

silicon grease)

Fig.7

Coating position

of silicon grease

Anode cap

Page 9

2.7 MEMORY IC REPLACEMENT

2.7.1 MEMORY IC

This TV use memory IC.

In the memory IC, there are memorized data for correctly operating the video and deflection circuits.

When replacing the memory IC, be sure to use IC written with the initial values of data.

2.7.2 PROCEDURE FOR REPLACING MEMORY IC

(1) Power off

Switch the power off and unplug the power plug.

(2) Replace IC

Be sure to use a memory IC written with the initial setting data.

(3) Power on

Connect the power plug and switch the power on.

(4) Setting of receive channels

Set the receive channels. For setting, refer to the OPERATING INSTRUCTIONS.

(6) User settings

Check the user setting items according to TABLE 2, and if these are different, set the correct value.

(7) SERVICE MENU setting

Verify what to set in the SERVICE MENU, and set whatever is necessary. Refer to the SERVICE ADJUSTMENT for setting.

AV-32430

AV-32432

SERVICE MENU

SERVICE MENU

1.V/C(S)

3.SOUND(A)

7.LOW LIGHT

9.VCO

11.I2C BUS

SELECT BY

OPERATE BY

2.DEF(D)

4.OTHERS(F)

8.HIGH LIGHT

EXIT BY

EXIT

(No.52104)1-9

Page 10

AV-32430

AV-32432

2.7.3 USER SETTING VALUES

Setting item Setting value Setting item Setting value

REMOTE CONTROL UNIT KEY

POWER OFF DISPLAY OFF

CHANNEL CH-02 VIDEO STATUS DYNAMIC

VOLUME 15 SLEEP TIMER 0

TV/VIDEO TV

SETTING OF MENU

PICTURE MODE INITIAL SETUP MODE

TINT Center LANGUAGE ENG

COLOR Center FRONT PANEL LOCK OFF

PICTURE +8 V2 COMPONENT-IN NO

BRIGHT Center AUTO SHUT OFF OFF

DETAIL +10 CLOSED CAPTION OFF

NOISE MUTING ON AUTO TUNER SETUP AIR

SOUND MODE CHANNEL SUMMARY Unnecessary to set

BASS Center V-CHIP OFF

TREBLE Center SET LOCK CODE (0000) Unnecessary to set

BALANCE Center XDS ID ON

MTS STEREO

CLOCK / TIMERS MODE

SET CLOCK MANUAL

TIME ZONE : PACIFIC

D.S.T. : OFF

ON / OFF TIMER OFF

TABLE 2

1-10 (No.52104)

Page 11

2.8 REPLACEMENT OF CHIP COMPONENT

2.8.1 CAUTIONS

(1) Avoid heating for more than 3 seconds.

(2) Do not rub the electrodes and the resist parts of the pattern.

(3) When removing a chip part, melt the solder adequately.

(4) Do not reuse a chip part after removing it.

2.8.2 SOLDERING IRON

(1) Use a high insulation soldering iron with a thin pointed end of it.

(2) A 30w soldering iron is recommended for easily removing parts.

2.8.3 REPLACEMENT STEPS

1. How to remove Chip parts

[Resistors, capacitors, etc.]

(1) As shown in the figure, push the part with twe ezers and

alternately melt the solder at each end.

AV-32430

AV-32432

2. How to install Chip parts

[Resistors, capacitors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Shift with the tweezers and remove the chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply extra solder to each lead.

SOLDER

SOLDER

(2) As shown in the figure, push the part with twe ezers and

alternately melt the solder at each lead. Shift and remove

the chip part.

(2) Grasp the chip part with tweezers and place it on the

solder. Then heat and melt the solder at both ends of the

chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder.

(3) First solder lead A as indicated in the figure.

A

B

C

(4) Then solder leads B and C.

Note :

After removing the part, remove remaining solder from the

pattern.

A

B

C

(No.52104)1-11

Page 12

AV-32430

AV-32432

SECTION 3

ADJUSTMENT

3.1 ADJUSTMENT PREPARATION

(1) There are 2 ways of adjusting this TV : One is with the REMOTE CONTROL UNIT and the other i s the conventional method

using adjustment parts and components.

(2) The adjustment using the REMOTE CONTROL UNIT is made on the basis of the initial setting values. The setting values which

adjust the screen to the optimum condition can be different from the initial setting values.

(3) Make sure that connection is correctly made AC to AC power source.

(4) Turn on the power of the TV and measuring instruments for warming up for at least 30 minutes before starting adjustments.

(5) If the receive or input signal is not specified, use the most appropriate signal for adjustment.

(6) Never touch the parts (such as variable resistors, transformers and condensers) not shown in the adjustment items of this service

adjustment.

(7) Preparation for adjustment. Unless otherwise specified in the adjustment items, preset the following functions with the REMOTE

CONTROL UNIT.

Item Preset value

VIDEO STATUS DYNAMIC

TINT, COLOR, PICTURE, BRIGHT, DETAIL Center

NOISE MUTING OFF

BASS, TREBLE, BALANCE Center

MTS STEREO

3.2 MEASURING INSTRUMENT AND FIXTURES

(1) DC voltmeter (or digital voltmeter)

(2) Oscilloscope

(3) Frequency counter

(4) Signal generator (Pattern generator) [NTSC]

(5) TV audio multiplex signal generator

(6) Remote control unit

1-12 (No.52104)

Page 13

3.3 ADJUSTMENT LOCATIONS

HVT

3.1 5A

V C ENTE R S W

VCO

CRT SOCKET PWB

(SOLDER SIDE)

AV-32430

AV-32432

TOP

TP-R

CN3004

TP-G

TP-E( )

FRONT CONTROL PWB

IC7701

CN7007

TP-B

CN30E2

POWER MENUVOL CH

CN3005

CRT EARTH

(BRAIDED ASS'Y)

FRONT

FRONT

FRONT AV IN PWB

F

FRONT

MAIN PWB

SS

AV SELECTOR PWB

CN001

CN003

T

T111

CN007

MEMORY IC

IC101

VCO

IC702

IC201

CN004

TUNER

PW

V CENTER SW

U

F901

3.15A

S421

DEG.

1:TP-91(B1)

2:NC

3:TP-E( )

HV

E1

CRT EARTH

(BRAIDED ASS'Y)

1

3

B1

HVT

UPPER : FOCUS

LOWER : SCREEN

(No.52104)1-13

Page 14

AV-32430

AV-32432

3.4 BASIC OPERATION OF SERVICE MENU

3.4.1 TOOL OF SERVICE MENU OPERATION

Operate the SERVICE MENU with the REMOTE CONTROL UNIT.

3.4.2 SERVICE MENU ITEMS

With the SERVICE MENU, various adjustments can be made, and they are broadly classified in the following items of settings.

(1) V/C (S) This mode adjusts the VIDEO and CHROMA control circuit.

(2) DEF (D) This mode adjusts the DEFLECTION control circuit.

(3) SOUND (A) This mode adjusts the SOUND control circuit.

(4) OTHERS (F) This mode adjusts the display setting and the other settings (Do not change the values).

(7) LOW LIGHT This mode adjusts the WHITE BALANCE (LOW LIGHT) control circuit.

(8) HIGH LIGHT This mode adjusts the WHITE BALANCE (HIGH LIGHT) control circuit.

(9) VCO This mode adjusts the VCO control circuit.

2

(11) I2C BUS This mode adjusts the I

C BUS control circuit (They are fixed).

3.4.3 BASIC OPERATION IN SERVICE MENU

3.4.3.1 HOW TO ENTER THE SERVICE MENU

Press the [SLEEP TIMER] key and set the SLEEP TIMER for "0

MIN".

SERVICE MENU

Then press the [DISPLAY] key and [VIDEO STATUS] key of the

remote control unit at the same time to enter the SERVICE

MENU screen.

SERVICE MENU

1.V/C(S)

3.SOUND(A)

2.DEF(D)

4.OTHERS(F)

7.LOW LIGHT

8.HIGH LIGHT

9.VCO

11.I2C BUS

3.4.3.2 SUB MENU SCREEN SELECTION

Press [VOLUME (-/+)] keys of the REMOTE CONTROL UNIT,

and select the SUB MENU SCREEN from SERVICE MENU.

In SERVICE MENU, press the [CHANNEL (-/+)] key to select any

of the SUB MENU items. The letters of the selected items are

displayed in yellow.

1.V/C(S) 2.DEF(D)

3.SOUND(A) 4.OTHERS(F)

7.LOW LIGHT 8.HIGH LIGHT

9.VCO

11.I2C BUS

SELECT BY

OPERATE BY

VIDEO

STATUS

DISPLAY

VOLUME

- / +

EXIT BY

EXIT

SLEEP

TIMER

CHANNEL

+ / -

EXIT

1-14 (No.52104)

Page 15

3.4.3.3 SETTING METHOD

[1.V/C(S), 2.DEF(D) AND 3.SOUND(A) ADJUSTMENT MODE]

1) Press the [CHANNEL (-/+)] keys to select the one of setting item from S01 BRIGHT to S21 AGC ADJ.

2) Press the [VOLUME (-/+)] keys to change the setting value. The setting value will be stored automatically when release

the REMOTE CONTROL UNIT keys.

It can adjust the items 2.DEF(D) and 3.SOUND(A) in the same procedure.

[7.LOW LIGHT, 8.HIGH LIGHT AND 9.VCO ADJUSTMENT MODE]

Since the key operation in this mode is peculiar, please refer to the clause of the "ADJUSTMENT PROCEDURE".

[4.OTHERS AND 11.I2C BUS ADJUSTMENT MODE]

These are no requirement for adjustment. Don't change these values.

3.4.3.4 Release of SERVICE MENU

When adjustment is completed, press the [EXIT] key twice. Then return to the normal screen.

AV-32430

AV-32432

(No.52104)1-15

Page 16

AV-32430

AV-32432

3.4.4 SERVICE MENU FLOW CHART

SERVICE MENU (MAIN MENU)

SERVICE MENU

1.V/C(S) 2.DEF(D)

3.SOUND(A) 4.OTHERS

7.LOW LIGHT 8.HIGH LIGHT

9.VCO

2

11.I

C BUS

1.V/C(S)

RF 4 : 3 STD LOW

SELECT BY

OPERATE BY EXIT BY

EXIT

S01 BRIGHT

2.DEF(D)

RF 4 : 3 STD LOW

D01 V FREQ

3.SOUND(A)

A01 IN LEVEL

4.OTHERS(F)

1-16 (No.52104)

[Do not adjust]

9. VCO MAIN

TUNER MAIN

HIGH LEVE L

REFERENCE LEVEL

LOW LEVEL

SYNC NO

11.I2C BUS

I2

C BUS ON

F01 OSD POSI

7.LOW LIGHT

BRIGHT

8.HIGH LIGHT

Page 17

3.5 INITIAL SETTING VALUE OF SERVICE MENU

(1) Adjustment of the SERVICE MENU is made on the basis of the initial setting values. However, the new setting values which

displays on the screen in its optimum condition may differ from the initial setting value.

(2) Do not change the initial setting values of the items not listed in "ADJUSTMENT PROCEDURE".

(3) "---" is impossible to adjust.

3.5.1 [1.V / C]

Initial setting value

No. Setting item Variable range

STANDARD THEATER STANDARD THEATER STANDARD THEATER

S01 BRIGHT 0~127 64 --- --- --- --- --S02 PICTURE 0~127 55 --- --- --- --- --S03 COLOR 0~127 50 --- --- --- 55 --S04 TINT 0~127 60 --- --- --- 78 --S05 DETAIL 0~63 37 --- 35 --- 40 --S06 BRIGHT +- -128~+127 --- 1 -2 --- 0 --S07 PICT+- -128~+127 --- -10 0 --- 0 --S08 COLOR +- -128~+127 --- -3 -2 --- --- --S09 TINT+- -128~+127 --- -3 2 --- --- --S10 DETAIL+- -128~+127 --- 0 --- --- --- ---

RF EXTERNAL (SV,CV) COMPONENT

AV-32430

AV-32432

Initial setting value

No. Setting item Variable range

S11 R CUT OFF 0~255 30 --- --- --- --- --- --- --S12 G CUT OFF 0~255 30 --- --- --- --- --- --- --S13 B CUT OFF 0~255 30 --- --- --- --- --- --- --S14 R DRIVE 0~127 64 --- --- --- --- --- --- --S15 B DRIVE 0~127 64 --- --- --- --- --- --- --S16 R CUT+- -128~+127 --- 0 0 0 -10 --- --- --S17 G CUT+- -128~+127 --- 0 0 0 0 --- --- --S18 B CUT+- -128~+127 --- 0 0 0 -10 --- --- --S19 R DRV+- -128~+127 --- 0 7 7 0 --- --- --S20 B DRV+- -128~+127 --- 0 -9 -9 0 --- --- ---

No. Setting item Variable range Initial setting value

S21 AGC ADJUST 0~127 80

STANDARD THEATER STANDARD THEATER

LOW HIGH LOW HIGH LOW HIGH LOW HIGH

RF/EXT (SV,CV) COMPONENT

(No.52104)1-17

Page 18

AV-32430

AV-32432

3.5.2 [2.DEF]

Initial setting value

AV-32430 /M

No. Setting item Variable range

D01AFC GAIN0~3020202

D02 H POSI 0~31 20 20 20 20 20 20

D03 V SIZE 0~125 63 63 70 70 70 70

D04V S CORR0~15555555

D05V LIN 0~15121212121212

D06 H SIZE 0~63 17 17 26 26 27 27

D07WVMT TOP0~3000000

D08WVMT BTM0~3000000

D09EWCR TOP0~31121212121212

D10EWCR BTM0~3115151515 1515

D11EW PARA0~63303036363636

D12BLANK SW0~1000000

3.5.3 [3.SOUND]

No. Setting item Variable range Initial setting value

A01 IN LEVEL 0~63 36

A02 FH MON 0~1 0

A03 ST VCO 0~63 43

A04 PIL CAN 0~1 0

A05 FILTER 0~63 35

A06 LOW SEP 0~63 8

A07 HI SEP 0~63 26

A08 5FH MON 0~1 0

A09 SAP VCO 0~63 44

AV-32432 /M

RF

EXTERNAL

(SV, CV)

AV-32430 /Y

AV-32432 /Y

RF

EXTERNAL

(SV, CV)

AV-32430 /R

AV-32432 /R

RF

EXTERNAL

(SV, CV)

3.5.4 [4.OTHERS]

No. Setting item Variable range Initial setting value

F01 OSD POSI 0~255 40

F02 OSD PREQ 0~255 90

F03 CCD POSI 0~63 47

F04 CCD FREQ 0~255 93

F05 CCD CONT 0~63 7

F06 PUR CONT 0~255 2

F07 VNR CHK 0~255 3

F08 VCSN TM 0~255 5

F09 CCD PCHK 0~1 1

3.5.5 [7.LOW LIGHT]

No. Setting item Variable range Initial setting value

1 RED 0~255 30

2 GREEN 0~255 30

3 BLUE 0~255 30

3.5.6 [8.HIGH LIGHT]

No. Setting item Variable range Initial setting value

1 RED 0~255 64

2 BLUE 0~255 64

1-18 (No.52104)

Page 19

3.6 ADJUSTMENT PROCEDURE

3.6.1 CHECK ITEM

Item

B1 POWER

Measuring

instrument

DC voltmeter

SUPPLY

check

Signal

generator

3.6.2 IF VCO

Test point Adjustment part Description

B1 Connector

TP-91, TP-E

[MAIN PWB]

(1) Receive the black-and-white signal. (color off)

(2) Connect the DC voltmeter to TP-91 (B1 connector 1

pin) and TP-E (B1 connector 3 pin).

(3) Confirm that the voltage is DC134V

AV-32430

AV-32432

±2V.

Item

Measuring

instrument

IF VCO Remote

control unit

3.6.3 RF AGC

Item

Measuring

instrument

RF AGC Signal

generator

Remote

control unit

No.

S21

Setting item

AGC ADJ 0~127

Test point Adjustment part Description

[9.VCO]

CW transf. (T111)

[MAIN PWB]

TOO HIGH GOOD TOO LOW

SYNC: YES

AFC ON

FINE 0

Test point Adjustment part Description

[1.V/C(S)]

S21 : AGC ADJ

Variable

range

Initial setting

value

80

• It must not adjust without inputting the RF signal.

(1) Receive a broadcast.

(2) Select 9.VCO.

(3) Change the [AFC] to OFF and [FINE] to 0.

(4) Confirm that the color change from "TOO HIGH" to

"TOO LOW" by CW transf. on MAIN PWB, and

check the [SYNC] is YES.

(5) Adjust CW transf. until "GOOD" letters turns green.

And then confirm that the [SYNC] is YES again.

Adjustment can be done in this statement.

(6) It return the [AFC] to ON.

(7) Push the [EXIT] key to exit the [9.VCO] mode.

(1) Receive a black-and-white signal (colour off).

(2) Select 1.V/C.

(3) Select <S21>(AGC ADJ).

(4) Press the [MUTING] key and turn the picture color

off.

(5) With the [VOLUME (-)] key to get the noise in the

screen picture (zero side of setting value).

(6) Press the [VOLUME (+)] key several times and step

when noise disappears from the screen (at that time,

not to increase the value too much).

(7) Change to other channels and make sure that there

is no irregularity.

(8) Press the [MUTING] key and get color out.

3.6.4 FOCUS

Item

Measuring

instrument

FOCUS Signal

generator

Test point Adjustment part Description

FOCUS VR

[In HVT]

(1) Receive the crosshatch signal.

(2) While looking at the screen, adjust the FOCUS VR

to the vertical and horizontal lines will be clear and in

fine detail.

(3) Make sure that the picture is in focus even when the

screen gets darkened.

(No.52104)1-19

Page 20

AV-32430

AV-32432

3.6.5 DEFLECTION CIRCUIT

Item

V. SIZE &

V. CENTER

Signal

generator

Remote

control unit

Measuring

instrument

Test point Adjustment part Description

[2.DEF(D)]

D03 : V SIZE

(1) Receive the crosshatch signal.

(2) Select 2.DEF(D).

(3) Select the <D03>(V SIZE).

V. CENTER SW(S421)

[MAIN PWB]

(4) Adjust the <D03> so that the vertical screen size

becomes 92.0%.

(5) Adjust the V. CENTER SW to agree the vertical

center with display center.

H. SIZE /

H. CENTER /

SIDEPIN

Screen

size

Model Name D03 V SIZE Initial setting value

AV-32430 /M

AV-32432 /M

AV-32430 /Y

AV-32432 /Y

AV-32430 /R

AV-32432 /R

Signal

generator

Picture

size

(100%)

63

70

70

[2.DEF(D)]

D02 : H POSI

D06 : H SIZE

Remote

control unit

D16 : EW PARA

D09 : EWCR TOP

D10 : EWCR BTM

Straight Straight

(1) Receive the crosshatch signal.

(2) Select 2.DEF(D).

(3) Select <D02>(H POSI).

(4) Adjust <D02> so that left width and right width of the

crosshatch screen becomes equal.

(5) Adjust <D06>(H SIZE) so that screen horizontal

width becomes 92.0%.

(6) Adjust <D16>(EW PARA) so that vertical line

becomes straight at both top and bottom edge.

(7) When vertical lines of four corner does not turn into

straight, adjust with <D09>(EWCR TOP) and

<D10>(EWCR BTM) to correctly.

1-20 (No.52104)

SIDE PINCUSHION ADJUSTMENT

Screen size

Picture size 100%

HORIZONTAL SIZE ADJUSTMENT

Page 21

3.6.6 VIDEO CIRCUIT

Item

WHITE

BALANCE

Measuring

instrument

Signal

generator

(LOW LIGHT)

Remote

control unit

No.

S11

S12 G CUT OFF 0~255 30

S13 B CUT OFF 0~255 30

S01 BRIGHT 0~127 64

Setting item

R CUT OFF 0~255

H LINE ON

Test point Adjustment part Description

[7.LOW LIGHT]

(1) Receive the black-and-white signal (color off).

(2) Select 7.LOW LIGHT.

[1.V/C(S)]

S11 : R CUTOFF

S12 : G CUTOFF

S13 : B CUTOFF

S01 : BRIGHT

(3) Set the initial setting value of <S11>(R CUTOFF),

<S12>(G CUTOFF), <S13>(B CUTOFF) and

<S01>(BRIGHT).

(4) Display a single horizontal line by pressing the [1]

key.

(5) Turn the SCREEN VR all the way to the left.

SCREEN VR

[in HVT]

(6) Turn the SCREEN VR gradually to the right from the

left until either one of the red, blue or green color

appears faintly.

R CUTOFF

H LINE OFF

G CUTOFF

(7) Adjust the two colors which did not appear until the

single horizontal line that is displayed becomes

white using the [4] to [9] keys.

(8) Turn the SCREEN VR until the single horizontal line

is displayed faintly.

EXIT

B CUTOFF

B CUTOFF

(9) Press the [2] key to cancel the single horizontal line

mode.

(10) Adjust the <S01> level to become the black

component shines white slightly by [VOLUME (-/+)]

key.

(11) Confirm that whether the color ingredient of R,G,or B

G CUTOFF

R CUTOFF

is visible to the black component, which shines white

slightly.

(12) When the color ingredient can be seen, two colors

other than a visible color is adjusted, and it is made

Variable

range

Initial setting

value

30

to look white.

(13) Return the value of <S01> to initial setting value.

If [3] key is pressed, it can escape from WHITE BALANCE

adjustment mode.

AV-32430

AV-32432

WHITE

BALANCE

(HIGH LIGHT)

No.

S14

S15 G DRIVE 0~127 64

Signal

generator

Remote

control unit

R DRIVE

R DRIVE

Setting item

R DRIVE 0~127

Variable

range

[8.HIGH LIGHT]

S14 : R DRIVE

S15 : B DRIVE

EXIT

B DRIVE

B DRIVE

Initial setting

value

64

(1) Receive the black-and-white signal (color off).

(2) Select the 8.HIGH LIGHT.

(3) Set the initial setting value of <S14>(R DRIVE) and

<S15>(B DRIVE) with the [4], [6], [7] and [9] keys of

the remote control unit.

(4) Adjust the screen until it becomes white using the

[4], [6], [7] and [9] keys of the remote control unit.

If [3] key is pressed, it can escape from WHITE BALANCE

adjustment mode.

(No.52104)1-21

Page 22

AV-32430

AV-32432

Item

Measuring

instrument

SUB BRIGHT Remote

control unit

No.

S01

SUB

CONTRAST

No.

S02

Setting item

BRIGHT 0~127

Remote

control unit

Setting item

PICTURE 0~127

SUB COLOR Signal

generator

Remote

control unit

No.

Setting item

Test point Adjustment part Description

[1.V/C(S)]

S01 : BRIGHT

(1) Receive the broadcast.

(2) Select 1.V/C(S).

(3) Select <S01>(BRIGHT).

(4) Set the initial setting value of the <S01> with the

Variable

range

Initial setting

value

[VOLUME (-/+)] key.

(5) If the brightness is not the best with the initial setting

value, make fine adjustment of the <S01> until you

64

[1.V/C(S)]

S02 : PICTURE

get the optimum brightness.

(1) Receive the broadcast.

(2) Select 1.V/C(S).

(3) Select <S02>(PICTURE).

(4) Set the initial setting value of the <S02> with the

Variable

range

Initial setting

value

[VOLUME (-/+)] key.

(5) If the contrast is not the best with the initial setting

value, make fine adjustment of the <S02> until you

65

[1.V/C(S)]

S03 : COLOR

get the optimum contrast.

(1) Receive the broadcast.

(2) Select 1.V/C(S).

(3) Select <S03>(COLOR).

(4) Set the initial setting value of the <S03> with the

[VOLUME (-/+)] key.

If the color is not the best with the Initial setting value,

make fine adjustment of the <S03> until you get the

optimum color.

Variable

range

Initial setting

value

S03

COLOR 0~127

SUB TINT Signal

generator

Remote

control unit

No.

S04

Setting item

TINT 0~127

Variable

range

50

[1.V/C(S)]

S04 : TINT

Initial setting

value

60

(1) Receive the broadcast.

(2) Select 1.V/C(S).

(3) Select <S04>(TINT).

(4) Set the initial setting value of the <S04> with the

[VOLUME (-/+)] key.

If the tint is not the best with the Initial setting value, make

fine adjustment of the <S04> until you get the optimum

tint.

1-22 (No.52104)

Page 23

3.6.7 MTS CIRCUIT

Item

MTS INPUT

LEVEL

instrument

Remote

control unit

check

Measuring

Test point Adjustment part Description

[3.SOUND(A)]

A01 : IN LEVEL

(1) Select the <A01>(IN LEVEL).

(2) Verify that the <A01> is set at its initial setting value.

AV-32430

AV-32432

No.

A01

MTS

STEREO VCO

No.

A02

A03 ST VCO 0㨪63 043

MTS SAP

VCO

No.

Setting item

IN LEVEL 0~63

Frequency

counter

Variable

R OUT

[AUDIO OUT]

Signal

generator

Remote

control unit

Setting item

FH MON 0

Frequency

counter

Variable

R OUT

[AUDIO OUT]

Signal

generator

Remote

control unit

Setting item

Variable

range

range

㨪63

range

Initial setting

value

036

[3. SOUND(A)]

A02 : FH MON

A03 : ST VCO

Initial setting

value

0

[3. SOUND(A)]

A08 : 5FH MON

A09 : SAP VCO

Initial setting

value

(1) Receive the RF signal (no modulated sound signal)

from the antenna terminal.

(2) Select 3.SOUND(A).

(3) Select the <A02>(FH MON) and change the setting

value from 0 to 1.

(4) Connect the frequency counter to R OUT of the

AUDIO OUT.

(5) Select the <A03>(ST VCO).

(6) Set the initial setting value of the <A03>.

(7) Adjust the <A03> so that the frequency counter will

display 15.73kHz

±0.1kHz.

(8) Select the <A02> of the SOUND mode, and reset the

setting value from 1 to 0.

(1) Receive the RF signal (non modulated sound signal)

from the antenna terminal.

(2) Select 3.SOUND(A).

(3) Select the <A08> (SFH MON) and reset the setting

value from 0 to 1.

(4) Connect the frequency counter to R out of the

AUDIO OUT.

(5) Select the <A09> (SAP VCO).

(6) Set the initial setting value of <A09>.

(7) Adjust the <A09> so that the frequency counter will

display 78.67kHz

±0.5kHz.

(8) Select the <A08>, and reset the setting value from 1

to 0.

A08

A09 SAP VCO 0㨪63 044

5FH MON 0㨪1

MTS FILTER Remote

control unit

No.

A04

A05 FILTER 0㨪63 035

Setting item

PIL CAN 0㨪1

Variable

range

0

[3. SOUND(A)]

A04 : PILOT CAN

A05 : FILTER

Initial setting

value

0

(1) Select 3.SOUND(A).

(2) Select the <A05> (FILTER).

(3) Select the <A04> (PILOT CAN) and reset the setting

value from 0 to 1.

(4) Verify that the <A05> is set at its initial setting value.

(No.52104)1-23

Page 24

AV-32430

AV-32432

Item

MTS

SEPARATION

1 cycle

No.

Measuring

instrument

TV audio

multiplex

signal

generator

Oscilloscope

Remote

control unit

L-Channel

signal waveform

Setting item

Test point Adjustment part Description

R OUT

L OUT

[AUDIO OUT]

[3.SOUND(A)]

A06 : LOW SEP

A07 : HI SEP

(1) Input the stereo L signal (300Hz) from the TV audio

multiplex signal generator to the antenna terminal.

(2) Connect an oscilloscope to R OUT pin of the AUDIO

OUT, and display one cycle portion of the 300Hz

signal.

(3) Select 3.SOUND(A).

(4) Select the <A06> (LOW SEP).

(5) Set the initial setting value of the <A06> with the

[VOLUME (-/+)] key.

(6) Adjust the <A06> so that the stroke element of the

300Hz signal will become minimum.

(7) Change the connection of the oscilloscope to L OUT

pin of the AUDIO OUT, and enlarge the voltage axis.

R-Channel

crosstalk portion

Minimum

Variable

range

Initial setting

value

(8) Change the signal to 3kHz, and similarly adjust the

<A07> (HI SEP).

A06

A07 HI SEP 0~63 026

LOW SEP 0~63

008

1-24 (No.52104)

Page 25

3.6.8 HOW TO CHECK THE HIGH VOLTAGE HOLD DOWN CIRCUIT

3.6.8.1 HIGH VOLTAGE HOLD DOWN CIRCUIT

After repairing the high voltage hold down circuit.

This circuit shall be checked to operate correctly.

3.6.8.2 CHECKING OF THE HIGH VOLTAGE HOLD DOWN CIRCUIT

(1) Turn the power switch to on.

(2) Refer to the following figure, set the resistor between X connector 1 and 3 .

(3) Make sure that the screen picture disappears.

(4) Temporarily unplug the power plug.

(5) Remove the resistor replaced X connector 1 and 3 .

(6) Again plug the power plug, make sure that the normal picture is displayed on the screen.

RESISTOR

22.8 k 0.5% 1/4W

AV-32430

AV-32432

Fig.3-5-9

CONNECTOR

S13 2 1

(No.52104)1-25

Page 26

AV-32430

AV-32432

JVC SERVICE & ENGINEERING COMPANY OF AMERICA

DIVISION OF JVC AMERICAS CORP.

www.jvcservice.com(US Only)

JVC CANADA INC.

Head office : 21 Finchdene Square Scarborough, Ontario M1X 1A7 (416)293-1311

(No.52104)

Printed in Japan

200304WPC

Loading...

Loading...