Page 1

SERVICE MANUAL

COLOUR TELEVISION

AV-29BF11ENS

AV-29BF11EPS

AV-29BF11ENS AV-29BF11EPS AV-29BF11EES

CONTENTS

AV-29BF11EES

SPECIFICATIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

SAFETY PRECAUTIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

FEATURES・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

MAIN DIFFERENCE LIST ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

SPECIFIC SERVICE INSTRUCTIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

SERVICE ADJUSTMENTS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

PARTS LIST ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

★ OPERATING INSTRUCTIONS

★ STANDARD CIRCUIT DIAGRAM ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

COPYRIGHT © 2002 VICTOR COMPANY OF JAPAN, LTD.

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 2

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・ 4

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・ 5

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・ 11

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 23

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・ 5

・・・・・・

・・・・・・・・・・・・・ 6

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・ 2-1

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

No.52084

Sep. 2002

Page 2

A

V-29BF11ENS

A

A

V-29BF11EPS

V-29BF11EES

SPECIFICATIONS

ITEM

Dimensions (WxHxD) 78.4 × 58.2 × 49.3 cm

Mass 46.2 kg

TV RF System B/G B/G, L B/G, D/K, K1

Colour System

Teletext System Fastext / Toptext

Stereo System German + NICAM

Tuning System Frequenc y Synthesizer Tuning System

Number of CH memory position 100 ch

Receiving Frequency

Intermediate Frequency

Colour Sub Carrier Frequency PAL (4.43MHz), SECAM (4.43MHz), NTSC (3.58MHz/4.43MHz)

Aerial Input Terminal 75 Ohm Unbalanced

Power Input AC 220 ~ 240V, 50Hz

Power Consumption 135W(Max.) / 120W (Avg.) , <4W(Standby)

Picture Tube Visible size : 68cm Measured diagonally

High Voltage 29.6kV

Speaker ( 77 ×128 mm oval type + Tweeter ) ×2

Audio Output 10W + 10W

Input

Output

Input Terminal

Output Terminal

Remote Control Unit VE-30017763 (RM-C1100) , Battery size:AA/R06 x 2

TV Mode PAL PAL / SECAM

Video Mode

VHF (VL) 46.25MHZ ~ 168.25MH z

VHF (VH) 175.25MHz ~ 463.25MHz

UHF 471.25MHz ~ 863.25MHz

CATV B/G :S01-S41, S75-S79

VIF Carrier 38.9MHz

SIF Carrier

Video 1V(p-p), 75 Ohm

Audio (L/R) 500 mV(rms), H igh Impedance

Video 1 V(p-p), 75 O hm

Audio (L/R) 500 mV(rms), Low Impedanc e

Rear Side

Front Side AV 3 (Video/Audio)

Front Side Headphone jack (Stereo mini jack 3.5φ)

Rear Side

AV-29BF11ENS AV-29BF11EPS AV-29BF11EE S

PAL / NTSC 3.58 /

NTSC 4.43

32.4MHz (6.5MHz : L)

32.9MHz (6.0MHz : D/K)

33.4MHz (5.5MHz : B/G)

AV 1 (Video/Audio/RGB)

AV 2 (Video/Audio/S-VHS)

AV 1 (Video/Audio)

AV 2 (Video/Audio) (Selected TV, AV1 or AV3)

PAL / SECAM / NTSC 3.58 /

NTSC 4.43

B/G :S01-S41, S75-S79

L : S01-S41, S75-S77

Content

B/G :S01-S41, S75-S79

D/K : S01-S41

Design & specifications are subject to change without notice.

2

No.52084

Page 3

A

A

A

■■■■21-pin Euro connector (SCART socket) : AV 1 / AV 2

(P-P= Peak to Peak, S-W= Sync tip to white peak, B-W= Blanking to white peak)

Pin

No.

Signal Designation Matching Value AV 1 AV 2

1 AUDIO R output 500mV(r ms) (N ominal),Low impedanc e

2 AUDIO R input 500mV(r ms) (Nominal),High impedanc e

3 AUDIO L output 500mV(rms) (Nominal),Low impedance

4 AUDIO GND

V-29BF11ENS

V-29BF11EPS

V-29BF11EES

○

(TV OUT)

○○

○

(TV OUT)

○○

○

(TV/LINE OUT)

○

(TV/LINE OUT)

5 GND (B)

6 AUDIO L input 500mV(rms) (Nominal), High impedance

B-W

7B input

FUNCTON SW

8

(SLOW SW)

9 GND (G)

10 - NC -

11 G input

12 - NC -

13 GND (R)

14 GND (YS)

15 R / C input

16 Ys input

17 GND(VIDEO output)

18 GND(VIDEO input)

19 VIDEO output

20 VIDEO / Y input

700mV

Low : 0-3V, High : 8-12V, High impedance

700mV

R : 700mV

C : 300mV

Low : 0 – 0.4, High : 1 - 3V, 75Ω○

1V

1V

, 75Ω○

B-W, 75Ω○

B-W

, 75Ω

(P-P)

, 75Ω

S-W

(Negative going sync), 75Ω

S-W(Negative going sync), 75Ω○○

○○

○○

○

○○

○○

○

○

(R/C)

○○

○○

○

(TV)

(only C)

(TV/LINE OUT)

NC

NC

NC

NC

○

NC

○

21 COMMON GND

[

Pin assignment

]

No.52084

○○

3

Page 4

A

V-29BF11ENS

A

A

V-29BF11EPS

V-29BF11EES

SAFETY PRECAUTIONS

1. The design of this product cont ains special hardware, many

circuits and components specially for safety purposes. For

continued protection, no changes should be made to the original

design unless authorized in writing by the manufacturer.

Replacement parts must be identic al to those used in the original

circuits. Service should be performed by qualified personnel

only.

2. Alterations of the design or circuitry of the products should not be

made. Any design alterations or additions will void the

manufacturer's warranty and will further relieve the manufacturer

of responsibility for personal injur y or property damage resulting

theref rom.

3. Many electric al and mechanical parts in the products have

special safety-related characteristics. These characteristics are

often not evident from visual inspection nor c an the protection

afforded by them necessarily be obtained by using replacement

components rated for higher voltage, wattage, etc. Replacement

parts which have these special safety characteristics are

identified in the parts list of Service manual. Electrical

components having such features are identified by shading

on the schematics and by (!!!!) on the parts list in Service

manual. The use of a substitute replacement which does not

have the s ame safety characteristics as the recommended

replacement part shown in the parts list of Service manual may

cause shock, fire, or other hazards.

4. Don't short between the LIVE side ground and ISOLATED

(NEUTRAL) side ground or EARTH side ground when

repairing.

Some model's power circuit is partly different in the GND. The

differenc e of the GND is shown by the LIVE side GND , the

ISOLATED(NEUTRAL) side GND and EARTH side GND. Don't

short between the LIVE side GND and ISOLATED(NEUT RAL)

side GND or EARTH side GND and never measure with a

measuring apparatus (oscillosc ope etc.) the LIVE side GND and

ISOLATED(NEUTRAL) side GND or EARTH side GND at the

same time.

If above note will not be kept, a fuse or any parts will be broken.

5. If any repair has been made to the chassis, it is recommended

that the B1 setting should be checked or adjusted (See

ADJUSTMENT OF B1 POWER SUPPLY).

6. The high voltage applied to the picture tube must conform with

that specified in Service manual. Excessive high voltage can

cause an incr ease in X-Ray emission, arcing and possible

component damage, therefore operation under excessive high

voltage conditions should be kept to a minimum, or should be

prevented. If severe arcing occurs, remove the AC power

immediately and det ermine the caus e by visual inspection

(incorrect installation, cr acked or melted high voltage harness,

poor soldering, etc.). To maintain the proper minimum level of

soft X-Ray emission, components in the high voltage circuitry

including the picture tube must be the exact replacements or

alternatives approved by the manuf acturer of the complete

product.

7. Do not check high voltage by drawing an arc. Use a high voltage

meter or a high voltage probe with a VTVM. Discharge the

picture tube before attempting meter connection, by connecting

a clip lead to the ground frame and connecting the other end of

the lead through a 10kΩ 2W resistor to the anode button.

8. When service is required, obser ve the original lead dress. Extra

precaution should be given to assure correct lead dress in the

high voltage circuit area. W here a short circuit has occurr ed,

those components that indicate evidenc e of overheating should

be replaced. Always us e the manufactur er's replacement

components.

9. Isolation Check

(Safety for Electrical Shock Hazard)

After re-assembling the product, always perf orm an isolation

check on the exposed metal parts of the cabinet (antenna

terminals, video/audio input and output terminals, Control knobs,

metal c abinet, screwheads, earphone jack, c ontrol shafts, etc.)

to be sure the product is safe to operate without danger of

electr ic al sh oc k.

(1) Dielectr ic Strength Test

The isolation between the AC primary circuit and all metal parts

exposed to the user, particularly any expos ed metal part having a

return path to the chassis should withstand a voltage of 3000V

AC (r.m.s.) for a period of one second.

(. . . . Withstand a voltage of 1100V AC (r.m.s.) to an applianc e

rated up to 120V, and 3000V AC (r.m.s.) to an appliance rated

200V or more, for a period of one second.)

This method of test requires a test equipment not gener ally found

in the s ervice trade.

(2) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use a line

isolation transformer dur ing this check.). Using a " Leakage

Current T ester", measure the leakage current from each exposed

metal part of the cabinet, particularly any exposed metal part

having a return path to the chassis, to a known good earth

ground (water pipe, etc.). Any leakage c urrent must not exceed

0.5mA AC (r.m.s.).

However, in tr opical area, this must not exceed 0.2mA AC

(r.m.s.).

"""" Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not use a line

isolation transformer during this check.). Use an AC voltmeter

having 1000 ohms per volt or more sensitivity in the following

manner. Connect a 1500Ω 10W resistor paralleled by a 0.15µF

AC-type capacitor between an expos ed metal part and a known

good earth ground (water pipe, etc.). Measure the AC voltage

across the resistor with the AC voltmeter. Move the resistor

connection to each exposed metal part, particularly any exposed

metal part having a return path to the chassis, and measure the

AC voltage across the resistor. Now, reverse the plug in the AC

outlet and repeat each measurement. Any voltage meas ured

must not exceed 0.75V AC (r.m.s.). This corresponds to 0.5mA

AC (r.m.s.).

However, in tr opical area, this must not exc eed 0.3V AC (r.m.s.).

This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000 Ω/V,

OR MORE SENSITIVITY)

0.15μF AC-TYPE

PLACE THIS PROBE

1500 Ω 10W

GOOD EARTH GROUND

ON EACH EXPOSED

METAL PART

4

No.52084

Page 5

A

A

A

FEATURES

V-29BF11ENS

V-29BF11EPS

V-29BF11EES

1. It is a remote c ontrolled colour television.

2. 100 programs from VHF, UHF bands or cable channels can be

preset.

3. It can tune cable channels.

4. Controlling the TV is very easy by its menu driven s ystem.

5. It has two Euroconnector s ockets f or external device (such as

video recorder, video games, audio set, etc.)

6. Front AV Input available.

7. Stereo s ound systems (German + Nic am) are available.

8. Full function T eletext (Fastext, Toptext).

9. It is possible to connect headphone.

10. Direct channel access.

11. APS (Automatic Programming System).

12. All programs can be named.

13. Forward or backward automatic tuning.

14. Sleep timer

15. Child LOCK

16. Automatic sound mute when no transmission.

17. 5 minutes after the broadcasting (closedown), the T V switches

itself automatically to stand-by mode.

MAIN DIFFERENCE LIST

MODEL No.

Parts Name

MAIN PWB VE-20103272 VE-20103267 VE-20103265

AV-29BF11ENS AV-29BF11EPS AV- 29BF11EES

LABEL

CARTON BOX

INST BOOK VE-50028493 VE-50028296 VE-50028326

VE-20103656

VE-20103677(GER)

VE-20103679 (ITA)

VE-50028949

VE-50028950 (GER)

VE-20103654

VE-50028947 VE-50028945

VE-20103640

VE-20103638 (POL)

No.52084

5

Page 6

A

V-29BF11ENS

A

A

V-29BF11EPS

V-29BF11EES

SPECIFIC SERVICE INSTRUCTIONS

DISASSEMBLY PROCEDURE

REMOVING THE REAR COVER

1. Remove the 8 screws marked A.

2. Remove the 4 screws marked B.

3. W ithdraw the rear c over toward you.

REMOVING THE MAIN PWB

" Removing the rear cover.

1. Slightly raise the both sides of the chassis by hand and withdraw

MAIN PWB back ward.

[CAUTIONS]

If necessary, take off the wire clamp, connectors etc.

Be careful enough when developing a main chassis.

REMOVING THE FRONT AV & HEADPHONE

BOARD ASS’Y

" Removing the rear cover.

" Removing the MAIN PWB.

1. Remove the 2 screws marked C, and remove the FRONT AV &

HEADPHONE BOARD ASS’Y.

REMOVING THE FRONT CONTROL PWB

"

Removing the rear cover.

" Removing the MAIN PWB.

1. Remove the 3 screws marked D, and remove the FRONT

CONTROL PWB.

CHECKING THE PW BOARD

To check the back side of the PW Board.

1) Pull out the PW Board. (Refer to REMOVING THE MAIN

PWB).

2) Erect the PW Board vertically so that you can easily check

the back side of the PW Board.

[CAUTION]

" When er ecting the PW Board, be careful so that there will be no

contac ting with other PW Boar d.

" Before turning on power, make sure that the wire connector is

properly connected.

" When conducting a check with power supplied, be sure to confirm

that the CRT EARTH WIRE (BRAIDED ASS’Y) is connected to

the CRT SOCKET PW board.

WIRE CLAMPING AND CABLE TYING

1. Be sure t o clamp the wire.

2. Never remove the cable tie us ed for tying the wires together.

Should it be inadvertently removed, be sure to tie the wires with

a new cable tie.

REMOVING THE WOOFER and TWEETER

" Removing the rear cover.

1. Remove the 4 screws marked E, and remove the WOOFER.

2. Remove the 2 screws marked F, and remove the TW EETER.

3. Remove an opposite side similarly.

REMOVING THE MAIN SWITCH

" Removing the rear cover.

" Removeing MAIN PWB.

1. Remove the 2 screws marked G, and remove the MAIN

SWITCH.

6

No.52084

Page 7

A

A

A

A

(×8)

V-29BF11ENS

V-29BF11EPS

V-29BF11EES

B

(×4)

REAR COVER

FRONT CABINET

MAIN PWB

E

(×4)

F

(×2)

E

(×4)

SPEAKER

(WOOFER)

F

(×2)

SPEAKER

(TWEETER)

D

(×3)

FRONT CONTROL

PWB

No.52084

G

(×2)

MAIN

SWITCH

C

(×2)

FRONT AV &

HEADPHONE

PWB

7

Page 8

A

V-29BF11ENS

A

A

V-29BF11EPS

V-29BF11EES

REPLACEMENT OF CHIP COMPONENT

! CAUTIONS

1. Avoid heating f or more than 3 s econds.

2. Do not rub the electrodes and the resist parts of the patter n.

3. When removing a chip part, melt the solder adequately.

4. Do not reuse a chip part after removing it.

! SOLDERING IRON

1. Use a high insulation soldering iron with a thin pointed end of it.

2. A 30w s oldering iron is recommended for easily removing parts.

! REPLACEMENT STEPS

1.

How to remove Chip parts

#### Resistors, capacitors, etc

(1) As shown in the figure, push the part with tweezers and

alternately melt the solder at each end.

(2) Shift with tweezers and remove the chip part.

#### Transistors, diodes, variable resistors, etc

(1) Apply extra s older to each lead.

SOLDER

SOLDER

2. How to install Chip parts

#### Resistors, capacitors, etc

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the solder.

Then heat and melt the solder at both ends of the chip part.

#### Transistors, diodes, variable resistors, etc

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the solder.

(3) First solder lead

as indicated in the figure.

A

A

(2) As shown in the figure, push the part with tweezers and

alternately melt the solder at each lead. Shift and remove the

chip part.

(4) Then solder leads

Note : After removing the part, remove remaining solder from the

pattern.

8

No.52084

B

C

and C.

A

C

B

B

Page 9

A

A

A

MEMORY IC REPLACEMENT

1. Memory IC

This model use a memory IC.

This memory IC stores data for proper operation of the video

and deflection circuits.

When replacing, be sur e to use an IC containing this (initial

value) data.

2. Memory IC replacement procedure

(1) Power off

Switch off the power and disconnect the power cord from

the wall outlet.

(2) Replace the memory IC

Initial value must be entered into the new IC.

(3) Power on

Connect the power cord to the wall outlet and s witch on the

power.

V-29BF11ENS

V-29BF11EPS

V-29BF11EES

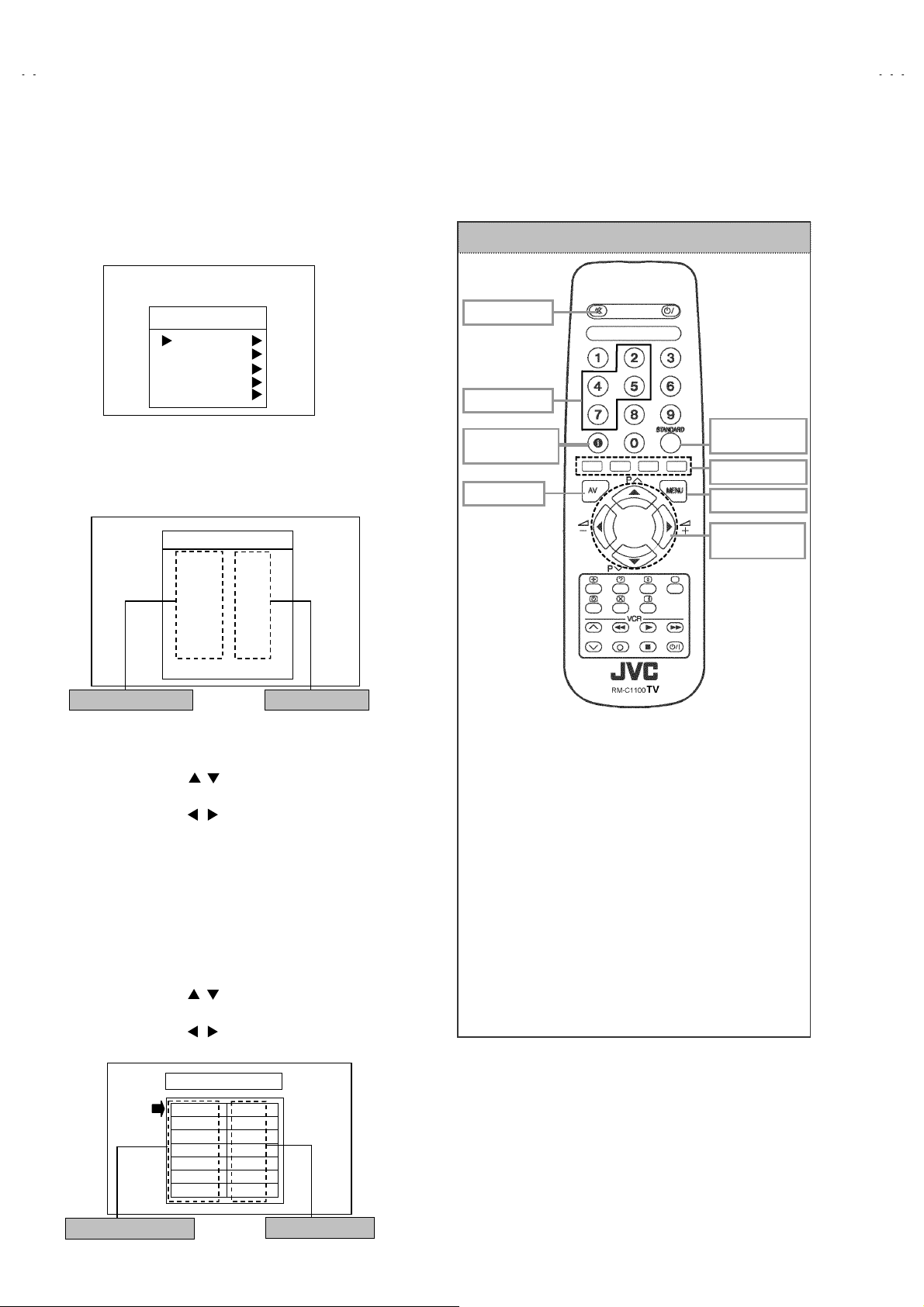

SERVICE MENU

Fig.1

SERVICE MENU SELECT KEY

(4) SERVICE MENU setting

1) Press MENU key and, while the displayed MENU

screen, press 4, 7, 2, 5 key on the remote control unit or

press MUTING key and INFORMATION key at the

simultaneously.

2) The SERVICE MENU screen of Fig.1 is displayed.

3) Verif y what to set in the SERVICE MENU, and set

whatever is necessary (Fig.1). Refer to the SERVICE

ADJUSTMENT for setting.

4) Press the STANDARD key to exit SERVICE MENU.

(5) Receive channel setting

Refer to the OPERATING INSTRUCTIONS (USER’S

GUIDE) and set the receive channels (Channels Preset) as

described.

(6) User settings

Check the user setting items acc ording to after page.

Where these do not agree, refer to the OPERATING

INSTRUCTIONS (USER’S GUIDE) and set the items as

described.

MUT ING

INFO RMATIO N

ITE M

SELECT(▲)

VALUE

SELECT(-)

FUNCTION

Fig.2

POWER

NUMBER

STANDARD

COLOUR key

MENU

VALUE

SELECT(+)

ITE M

SELECT(▼)

TELETEXT

No. 52084

9

Page 10

A

V-29BF11ENS

A

A

V-29BF11EPS

V-29BF11EES

SETTING OF THE LAST MEMORY FOR SHIPMENT

■■■■ USER SETTING VALUES

Setting Item Setting Value Setting Item Setting Value

SOUND MENU FEATURE MENU

BALANCE CENTER SLEEP TIMER OFF

BASS

TREBLE

EFFECT OFF AV-2 OUTPUT TV

PICTURE MENU INSTALL

BRIGHTNESS PROGRAMME

CONTRAST BAND

COLOUR CHANNEL

SHARPNESS SEARCH

HUE (only NTSC)

PICTURE MODE AUTO STORE

SETTING APS BIT IN SERVICE MENU

■

1) Enter service menu in TV mode by pressing “INFORMATION” and “MUTING” keys simultaneously. S ervice Menu will appear.

2) Select TX1(TELETEXT OPTION) by pressing Up/Down keys on remote c ontrol unit.

3) Press the 7 key on remote control unit to set APS bit. (After this, bit 7 of TX1 will be “1”). (Do not change any other bit.)

4) Press STANDARD key on remote control unit to exit s ervice mode.

NOTE : DO NOT TURN OFF THE TV BY USING POWER BUTTON ON THE FRONT PANEL.

These adjust are automatically

restored when APS bit in Service

menu is s et.

The proc edure f or setting APS

bit is described bellow.

↑

↑

CHILD LOCK OFF

LANGUAGE ENGLISH

Refer to the INSTRUCTION

BOOK.

FINE TUNING

10

No. 52084

Page 11

A

A

A

SERVICE ADJUSTMENTS

ADJUSTMENT PREPARATION

1. You can make the necessary adjustments for this unit with

either the Remote Control Unit or with the adjustment tools

and parts as given belo w.

2. Adjustment with the Remote Control Unit is made on the

basis of the initial setting values, however, the new setting

values which set the screen to its optimum condition may

differ from the initial settings.

3. Make sure that AC power is turned on correctly.

4. Turn on the power for set and test equipment before use, and

start the adjustment procedures after waiting at least 30 minutes.

5. Unless otherwise specified, prepare the most suitable reception

or input signal for adjustment.

6. Never touch any adjustment parts which are not specified in the

list for this adjustment - variable resistors, transformers,

condensers, etc.

7. Presetting before adjustment.

Unless otherwise specified in the adjustment instructions, pr eset

the following functions with the remote control unit.

BRIGHTNESS

CONTRAST

COLOUR

SHARPNESS

V-29BF11ENS

V-29BF11EPS

V-29BF11EES

CENTER

ADJUSTMENT EQUIPMENT

1. DC voltmeter (or digital voltmeter)

2. Signal generator (Pattern generator)[PAL/SECAM/NTSC]

3. Remote c ontrol unit

MAIN PARTS LOCATIONS

HEADPHONE JACK

FRONT

VIDEO

RL

AUDIO.

LED

REMOCON

RECEIVER

ADJUSTMENT ITEM

! SCREEN ADJUSTMENT

! OSD HORIZONTAL POSITION ADJUSTMENT

! IF ADJUSTMENT

! AGC AUTOMATICALLY ADJUSTMENT

! DEFLECTION CIRCUIT ADJUSTMENT

! GEOMETRY MENU ADJUSTMENT

! WHITE BALANCE ADJUSTMENT

! TXT BRIGHTNESS ADJUSTMENT

MENU

FRONT AV & HEADPHONE PWB FRONT CONTROL PWB

IC500

IC501

MEMOR Y IC

MICOM

(+)

(+) (-)

(-)

(+)(+)

(-)(-)

PROG

/Ch.

(+)

(+) (-)

(-)

(+)(+)

(-)(-)

VOL

TOP

FRONT

FBT

SCART

jack

TUNER

AV-1 AV-2

SCART

jack

MAIN PWB

No. 52084

UPPER : FOCUS VR

LOWER : SCREEN VR

11

Page 12

A

V-29BF11ENS

A

A

V-29BF11EPS

V-29BF11EES

BASIC OPERATION SERVICE MENU

■■■■ HOW TO ENTER THE SERVICE MENU

1) Press the MENU key.

2) MENU screen of fig.1 will be displayed

MENU SCREEN

REMOTE CONTROL UNIT key NAME

MENU

SOUND

PICTURE

FEAT URE

INSTALL

PROGRAM

Fig.1

3) W hile the MENU screen is displayed , press the 4,7,2,5 key or

INFORMATION key and MUTING key simultaneously.

4) The SERVICE MENU screen (Fig.2) will be displayed.

SERVICE MENU

JVCAK30/37 B04

OSD

IF1

IF2

IF3

IF4

AGC

VLIN

RGBH

VSOF

VPOF

: 0 1

059

004

065

004

065

033

044

005

+05

-01

ADJUSTMENT ITEM SETTING VALUE

Fig.2

■ SELECTION OF ADJUSTMENT ITEMS

1) Enter the SERVICE MENU

2) Press the FUNCTION / key and select the ADJUSTMENT

ITEM.

3) Press the FUNCTION / key and set the SETT ING VALUE.

■ HOW TO EXIT SERVICE MODE

1) Press the ST ANDARD Key on REMOTE CONTROL UNIT.

■ HOW TO ENTER THE GEOMETRY MENU

" This model is built-in GEOMETRY MENU f or geometry

adjustment. For details, refer to the adjustment.

1) Enter the SERVICE MENU

2) Press the GREEN key, geometry menu appears (Fig. 3).

3) Press the FUNCTION / key and select the ADJUSTMENT

ITEM.

4) Press the FUNCTION / key and set the SETT ING VALUE.

GEOMETRY MENU

MUTING key

NUMBER key

INFORMATION

key

AV key

" FUNCTION OF COLOUR key

RED key :

It switches the AVL(Automatic volume control) to

ON or OFF mode on service menu. AVL word is

visible on service menu when AVL is on.

GREEN key :

It switches to GEOMETRY adjust menu. Geometry

of the picture is adjust ed in this menu.

YELLOW key :

It switches to VERTICAL SCAN DISABLE mode.

It is useful to adjust screen voltage.

BLUE key :

It is used to adjust AGC and IF automatically on

service menu.

STANDARD

key

COLOUR key

MENU key

FUNCTION

key

GEOMETRY

VSIZ 038

VPOS 022

VSCO 005

VCCO 007

HSIZ 009

HPOS 030

HPIN 014

ADJUSTMENT ITEM

Fig.3

12

SETTING VALUE

No. 52084

Page 13

A

A

A

■ ADJUSTMENT ITEM & INITIAL SETTING VALUE in the SERVICE MENU

ADJUSTMENT

ITEM

OSD HORIZONTAL POSITION OF OSD 059

IF1 IF COARSE ADJUSTMENT 004

IF2 IF FINE ADJUSTMENT 065

IF3 IF COARSE ADJUSTMENT FOR L-PRIME 004

IF4 IF FINE ADJUSTMENT FOR L-PRIME 065

AGC AUTOMATIC GAIN CONTROL Automatically

VLIN VERTICAL LINEARITY Not used

RGBH RGB MODE HORIZONTAL SHIFT OFFSET 005

VSOF VERTICAL SIZE OFFSET for 60Hz +05

VPOF VERTICAL POSITION OFFSET for 60Hz -01

HSOF HORIZONTAL SIZE OFFSET for 60Hz -02

HPOF HORIZONTAL POSITION OFFSET for 60Hz -06

HTOF HORIZONTAL TRAPEZOID OFFSET for 60Hz -03

WR WHITE POINT ADJUSTMENT FOR RED 030

WG WHITE POINT ADJUSTMENT FOR GREEN 030

WB W HITE POINT ADJUSTMENT FOR BLUE 030

BR BIAS FOR RED 028

BG BIAS FOR GREEN 029

APR AUTOMATIC RGB PEAK REGULATION THRESHOLD 004

BRI BRIGHTNESS 032

CON CONTRAST 033

COL COLOUR 030

SHR SHARP 006

HUE HUE 031

VOL VOLUME 009

WR-R WHITE POINT ADJUSTMENT for RED (RGBmode) 022

WG-R WHITE POINT ADJUSTMENT for GREEN (RGBmode) 032

WB-R WHITE POINT ADJUSTMENT for BLUE (RGBmode) 022

FMP1 FM PRESCALER WHEN AVL IS OFF Not used

NIP1 NICAM PRESCALER W HEN AVL IS OFF Not used

SCP1 SCART PRESCALER WHEN AVL IS OFF Not used

SEC1 SECAM PRESCALER WHEN AVL IS OFF Not used

FMP2 FM PRESCALER WHEN AVL IS ON 015

NIP2 NICAM PRESCALER W HEN AVL IS ON 045

SCP2 SCART PRESCALER WHEN AVL IS ON 017

SEC2 SECAM PRESCALER WHEN AVL IS ON Not used

F1H HIGH BYTE OF VHF1-VHF3 CROSS-OVER FREQUENCY 00001001

F1L LOW BYTE OF VHF1-VHF3 CROSS-OVER FREQUENCY 10010010

F2H HIGH BYTE OF VHF3-UHF CROSS-OVER FREQUENCY 00011011

F2L LOW BYTE OF VHF3-UHF CROSS-OVER FREQUENCY 10000010

BS1 BAND SWITCHING BYTE FOR VHF1 00000011

BS2 BAND SWITCHING BYTE FOR VHF3 00000110

BS3 BAND SWITCHING BYTE FOR UHF 10000101

CB CONTROL BYTE 10001110

DESCRIPTION INITIAL VALUE

V-29BF11ENS

V-29BF11EPS

V-29BF11EES

1/2

No. 52084

13

Page 14

A

V-29BF11ENS

A

A

V-29BF11EPS

V-29BF11EES

ADJUSTMENT

ITEM

OP1 PERIPHERAL OPTIONS 11110111

OP2 RECEPTION STANDARD OPTIONS

OP3 VIDEO OPTIONS

OP4 TV FEATURES 10001000

OP5 CHANNEL TABLES 0000000D

TX1 TELETEXT OPTIONS

GEOM GEOMETRY OPTIONS 00100000

OP8 PIP PR ESET CHANGE 00000100

DESCRIPTION INITIAL VALUE

00001001 (EN)

01011001 (EP)

00011001 (EE)

01101100(EN)

11101100(EP/EE)

11010101 (EN)

11000101 (EP)

11001101 (EE)

[GEOMETRY MENU]

ADJUSTMENT

ITEM

VSIZ VERTICAL SIZE for 50Hz 038 009

VPOS VERTICAL POSITION f or 50Hz 022 025

VSCO VERTICAL S-CORRECTION for 50Hz 005 005

VCCO VERTICAL CORNER CORRECTION for 50Hz 007 007

HSIZ HORIZONTAL SIZE for 50Hz 009 013

HPOS HORIZONTAL POSITION for 50Hz 030 030

HPIN HORIZONTAL PINCUSHION for 50Hz 014 012

HCCO HORIZONTAL CORNER CORRECTION for 50Hz 010 010

HTRP HORIZONTAL TRAPEZOID for 50Hz 013 018

VZSZ VERTICAL ZOOM SIZE for 50Hz Not used Not used

DESCRIPTION

4:3 MODE 16:9 MODE

INITIAL VALUE

2/2

14

No. 52084

Page 15

A

A

A

ADJUSTMENTS

■■■■ SCREEN ADJUSTMENT

V-29BF11ENS

V-29BF11EPS

V-29BF11EES

Item

SCREEN

adjustment

Measurin g

instrument

Remote

control unit

Test point Adjustment part Description

SCREEN VR

[On the FBT]

■■■■ OSD HORIZONTAL POSITION ADJUSTMENT

Item

HORIZONTAL

POSITION OF

OSD

adjustment

Measurin g

instrument

Test point Adjustment part Description

Remote

control unit

SERVICE MENU SCREEN

JVCAK30/37 B04

OSD

059

IF1

004

IF2

065

IF3

004

IF4

065

AGC

033

VLIN

044

RGBH

005

VSOF

+05

VPOF

: 1 1

-01

OSD 1. Enter SERVICE MENU.

Referenc e bar

1. Enter SERVICE MENU.

2. Press YELLOW key to disable vertical scan.

3. Adjust SCREEN VR. on the FBT as thin as possible.

4. Press YELLOW key again to enable vertical scan.

5. Press STANDARD key to leave service menu.

FOCUS VR

SCREEN VR

FBT

2. Select OSD (On screen display) with FUNCTION ( / ) key

3. Adjust the OSD horizontal position with the FUNCTION ( / )

key, which shifts the reference bar on the bottom of the

SERVICE MENU horizontally, so that the OSD is positioned on

the screen cent er. (X=X’)

XX’

Screen size

■■■■ IF ADJUST MENT

Item

IF adjustment Remote

Measurin g

instrument

control unit

Test point Adjustment part Description

IF 1

IF 2

IF 3

IF 4

1. Receive a PAL colour bar pattern.

2. Enter SERVICE MENU.

3. Select IF 1 with FUNCTION ( / ) key

4. Press BLUE key during IF 1 is highlighted, IF 1 and IF 2 values

are adjusted automatically by software.

5. If the standard is L-prime, IF 3 and IF 4 values are adjustment

automatically when BLUE key is press ed during IF 1 is

highlighted.

No. 52084

15

Page 16

A

V-29BF11ENS

A

A

V-29BF11EPS

V-29BF11EES

■■■■ AGC AUTOMATICALLY ADJUSTMENT

Item

AGC

AUTOMATIC-

Measurin g

instrument

Remote

control unit

Test point Adjustment part Description

AGC 1. Enter SERVICE MENU.

ALLY

adjustment

& check

SERVICE MENU SCREEN

JVCAK30/37 B04

059

OSD

004

IF1

065

IF2

004

IF3

065

IF4

033

AGC

044

VLIN

005

RGBH

+05

VSOF

-01

VPOF

: 1 1

■■■■ DEFLECTION CIRCUIT ADJUSTMENT

Item

RGB M ODE

HORIZONTAL

SHIFT

OFFSET

adjustment

Measurin g

instrument

Signal

generator

Remote

control unit

A

Test point Adjustment part Description

RGBH 1. Input R/G/B circle pattern signal via video input terminal.

B

2. Receive a 60dBμV RF signal level.

3. Select AGC with the FUNCTION ( / ) key.

4. Press BLUE key on the remote control unit.

5. Then the adjustment will be done automatically by software.

6. See the AGC indicator on SERVICE MENU, it must be “1”.

7. Check that picture is normal at 90dBμV signal level.

:11

IF INDICATOR AGC INDICATOR NONE

2. Press AV key on the remote control unit, f orce the TV to RGB

mode.

3. Enter SERVICE MENU.

4. Select RGBH (RGB mode horizontal shift) with the

FUNCTION ( / ) key.

5. Adjust RGBH with the FUNCTION ( / ) key until the circle

pattern is horizontally center ed.(A=B)

6. Check and readjust RGBH item if the adjustment becomes

improper after some other geometric adjustments are done.

VERTICAL

SIZE OFFSET

adjustment

(60Hz)

Signal

generator

Remote

control unit

VSOF 1. Receive a NTSC-M cross-hatch pattern of vertical frequency

60Hz.

2. Enter SERVICE MENU.

3. Select VSOF (Vertical size) with the FUNCTION ( / ) key.

4. Adjust VSOF with the FUNCTION ( / ) key until the

horizontal black lines on both the upper and lower part of the

Very close

pattern become very close to the upper and lower horizontal

sides of picture size and nearly about to disappear.

5. Check and readjust VSOF item if the adjustment becomes

improper after some other geometric adjustments are done.

Screen

size

Picture

size

100%

Very close

16

No. 52084

Page 17

A

V-29BF11ENS

A

A

V-29BF11EPS

V-29BF11EES

Item

VERTICAL

POSITION

OFFSET

adjustment

(60Hz)

HORIZONTAL

SIZE

OFFSET

adjustment

(60Hz)

Measurin g

instruments

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Picture size 100%

Test point Adjustment part Description

VPOF 1. Receive a NTSC-M circle pattern of vertical fr equency 60Hz.

2. Enter SERVICE MENU.

3. Select VPOF (Vertical position) with the FUNCTION ( / )

key.

4. Adjust VPOF with the FUNCTION ( / ) key until the

picture is vertically centered.(C=D)

5. Check and readjust vertical position item if the adjustment

becomes improper after some other geometric adjustments

C

D

HSOF 1. Receive a NTSC-M cross-hatch patt ern of vertical frequency

are done.

60Hz.

2. Enter SERVICE MENU.

3. Select HSOF (Horizontal size) with the FUNCTION ( / )

key.

4. Adjust HSOF with the FUNCTION ( / ) key until the

vertical black lines on both the left and right part of the

pattern become very close to the left and right vertical sides

of picture size and nearly about to disappear.

5. Check and readjust a HSOF item if the adjustment becomes

improper after some other geometric adjustments are done.

Very close

HORIZONTAL

POSITION

OFFSET

adjustment

(60Hz)

Signal

generator

Remote

control unit

E

Screen size

Very close

HPOF 1. Receive a NTSC-M circle pattern signal of vertical frequency

60Hz.

2. Enter SERVICE MENU.

3. Select HPOF (Horizontal position) with the FUNCTION ( / )

key.

4. Adjust HPOF with the FUNCTION ( / ) key until the circle

F

pattern is horizontally centered.(E=F)

6. Check and readjust a horizontal position item if the adjustment

becomes improper after s ome other geometric adjustments

are done.

No. 52084

17

Page 18

A

V-29BF11ENS

A

A

V-29BF11EPS

V-29BF11EES

Item

HORIZONTAL

TRAPEZOID

OFFSET

adjustment

(60Hz)

Measurin g

instruments

Signal

generator

Remote

control unit

Test point Adjustment part Description

HTOF 1. Receive a NTSC-M cross-hatch patter n signal of vertical

frequency 60Hz.

2. Enter SERVICE MENU.

3. Select HTOF with the FUNCTION ( / ) key.

4. Adjust HTOF with the FUN CTION ( / ) key until both

lengths of the upper side and lower side of the closs-hatch

pattern become equal.

Pallalel

18

No. 52084

Page 19

A

A

A

■■■■ GEOMETRY MENU ADJUSTMENT (Adjust 4:3MODE / 16:9MODE respectively)

V-29BF11ENS

V-29BF11EPS

V-29BF11EES

Item

VERTICAL

SIZE

adjustment

(50Hz)

Very close

Screen

size

Very close

VERTICAL

POSITION

adjustment

(50Hz)

Measurin g

instruments

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

VSIZ 1. Receive a PAL B/G cross-hatch pattern of vertical frequency

50Hz.

2. Enter SERVICE MENU.

3. Press the GREEN key on the remove control unit then enter

the GEOMETRY MENU.

4. Select VSIZ (Vertical size) with the FUNCTION ( / ) key.

5. Adjust VSIZ with the FUNCTION ( / ) key until the

horizontal black lines on both the upper and lower part of the

pattern become very close to the upper and lower horizontal

sides of picture size and nearly about to disappear.

6. Check and readjust VSIZ item if the adjustment becomes

Picture

size

100%

VPOS 1. Receive a PAL B/G circle pattern signal of vertical frequenc y

A

improper after some other geometric adjustments are done.

50Hz.

2. Enter GEOMETRY MENU.

3. Select VPOS (Vertical position) with the FUNCTION ( / )

key.

4. Adjust VPOS with the FUNCTION ( / ) key until the circle

pattern is vertic ally centered.(A=B)

5. Check and readjust VPOS item if the adjustment becomes

improper after some other geometric adjustments are done.

VERTICAL

S-CORRECTION

adjustment

(50Hz)

Signal

generator

Remote

control unit

B

VSCO 1. Receive a PAL B/G cross-hatch pattern signal of vertical

frequency 50Hz.

2. Enter GEOMETRY MENU.

3. Select VSCO (Vertical s-correction) with the FUNCTION

( / ) key.

4. Adjust VSCO with the FUNCTION ( / ) key until the vertical

length of the center squarer of the cross-hatch pattern

becomes equal to upper and lower part squares of the crosshatch pattern.

5. Check and readjust VSCO item if the adjust ment becomes

improper after some other geometric adjustments are done.

No. 52084

19

Page 20

A

V-29BF11ENS

A

A

V-29BF11EPS

V-29BF11EES

Item

VERTICAL

CORNER

CORRECTION

adjustment

(50Hz)

HORIZONTAL

SIZE

adjustment

(50Hz)

Measurin g

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Picture size 100%

Test point Adjustment part Description

VCCO 1. Receive a PAL B/G cr oss-hatch pattern signal of vertical

frequency 50Hz.

2. Enter GEOMETRY MENU.

3. Select VCCO (Vertical corner correction) with the FUNCTION

( / ) key.

4. Adjust VCCO with the FUNCTION ( / ) key until the vertical

length of the upper and lower part squares of the cross-hatch

pattern become equal to each other.

5. Check and readjust VCCO it em if the adjustment becomes

improper after some other geometric adjustments are done.

HSIZ 1. Receive a PAL B/G cross- hatch pattern signal of vertical

frequency 50Hz.

2. Enter GEOMETRY MENU.

3. Select HSIZ (Horizontal size) with the FUNCTION ( / ) key.

4. Adjust HSIZ with the FUNCTION ( / ) key until the vertical

black lines on both the left and right part of the cross-hatch

pattern become very close to the left and right horizontal sides

of picture tube and nearly about to dis appear.

HORIZONTAL

POSITION

adjustment

(50Hz)

Very close

Signal

generator

Remote

control unit

C

Screen size

Very close

HPOS 1. Receive a PAL B/G circle pattern signal of vertic al frequency

50Hz.

2. Enter GEOMETRY MENU.

3. Select HPOS (Horizontal position) with the FUNCTION ( / )

key.

4. Adjust HPOS with the FUNCTION ( / ) key until the circle

D

pattern is horizontally centered.(C=D)

5. Check and readjust HPOS item if the adjustment becomes

improper after some other geometric adjustments are done.

20

No. 52084

Page 21

A

V-29BF11ENS

A

A

V-29BF11EPS

V-29BF11EES

Item

HORIZONTAL

PINC USHION

adjustment

(50Hz)

HORIZONTAL

CORNER

CORRECTION

adjustment

(50Hz)

Measurin g

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

HPIN 1. Receive a PAL B/G cr oss-hatch pattern signal of vertical

frequency 50Hz.

2. Enter GEOMETRY MENU.

3. Select HPIN (Horizontal pincushion) with the FUNCTION

( / ) key.

4. Adjust HPIN with the FUNCTION ( / ) key until the bending

of the vertical line of the cross-hatch pattern are c orrected.

5. Check and readjust HPIN item if the adjustment becomes

improper after some other geometric adjustments are done.

HCCO 1. Receive a PAL B/G cross-hatch pattern signal of vertical

frequency 50Hz.

2. Enter GEOMETRY MENU.

3. Select HCCO (Horizontal corner correction) with the

FUNCTION ( / ) key.

4. Adjust HCCO with the FUNCTION ( / ) key until the bending

of the vertical line of the cross-hatch pattern are c orrected.

5. Check and readjust HCCO item if the adjustment becomes

improper after some other geometric adjustments are done.

HORIZONTAL

TRAPEZOID

adjustment

(50Hz)

Signal

generator

Remote

control unit

HTRP 1. Receive a PAL B/G cross-hatch pattern signal of vertical

frequency 50Hz.

2. Enter GEOMETRY MENU.

3. Select HTRP (Horizontal trapezoid) with the FUNCTION

( / ) key.

4. Adjust HTRP with the FUNCTION ( / ) key until both lengths

of the upper side and lower side of t he cross-hatch pattern

A

B

become equal.(A=B)

No. 52084

21

Page 22

AV-29BF11ENS

AV-29BF11EPS

AV-29BF11EES

■■■■ WHITE BALANCE ADJUSTMENT

Item

WHITE

BALANCE

adjustment

(Low light)

Measuring

instrument

Signal

generator

Remote

control unit

Test point Adjustment part Description

WR

WG

WB

Item WR WG WB

1. Receive a black & white signal (colour off).

2. Enter SERVICE MENU.

3. Select WR / WG / WB with the ( / ) key, respectively.

4. Adjust WR / WG / WB with the FUNCTION ( / ) key,

respectively, until the white part turns to pure white without any

other colour.

Initial setting value

WHITE

BALANCE

adjustment

(High light)

Signal

generator

Remote

control unit

Initial setting value

■■■■ TXT BRIGHTNESS ADJUSTMENT

Item

TELETEXT

BRIGHTNESS

adjustment

Measuring

instrument

Remote

control unit

Test point Adjustment part Description

030 030 030

BR

BG

Item BR BG

1. Receive a black & white signal (colour off)

2. Enter SERVICE MENU.

3. Select BR / BG with the FUNCTION ( / ) key respectively.

4. Adjust BR / BG with the FUNCTION ( / ) key respectively,

until the white part of screen make white colour.

028 029

1. Receive a teletext broadcast.

2. Enter the SERVICE MENU.

3. Press the TELETEXT key on the remote control unit, then

change TXT brightness.

4. Adjust the TXT brightness with FUNCTION ( / ) key.

5. Press the TELETEXT key again. You can return to the

SERVICE MENU.

22

No. 52084

Recommended value

TXT BRIGHTNESS

025

Page 23

A

A

A

PARTS LIST

CONTENTS

V-29BF11ENS

V-29BF11EPS

V-29BF11EES

! USING P.W. BOARD & REMOTE CONTROL UNIT

! EXPLODED VIEW PARTS LIST

! EXPLODED VIEW

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

! PRINTED WIRING BOARD PARTS LIST

[ AV-29BF11ENS]

" MAIN P.W. BOARD ASS'Y ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

" CRT SOCKET P.W . BOARD ASS'Y ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

" FRONT AV & HEADPHONE P.W . BOARD ASS’Y ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

" FRONT CONTROL P.W. BOARD ASS’Y・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

[ AV-29BF11EPS]

" MAIN P.W. BOARD ASS'Y ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

" CRT SOCKET P.W . BOARD ASS'Y ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

" FRONT AV & HEADPHONE P.W . BOARD ASS’Y ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

" FRONT CONTROL P.W. BOARD ASS’Y・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

[ AV-29BF11EES]

" MAIN P.W. BOARD ASS'Y ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

" CRT SOCKET P.W . BOARD ASS'Y ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

" FRONT AV & HEADPHONE P.W . BOARD ASS’Y ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

" FRONT CONTROL P.W. BOARD ASS’Y・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

23

24

25

26

30

30

30

31

30

30

30

35

30

30

30

! PACKING / PACKING PARTS LIST

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

USING P.W. BOARD & REMOTE CONTROL UNIT

Model

PWB AS S'Y

MAIN PWB

CRT SOCKET PWB

FRONT AV & HEADPHONE

PWB

FRONT CONTROL PWB VE-20100168

REMOTE CONTROL UNIT

AV-29BF11ENS AV-29BF11EPS AV-29BF11EES

VE-20103272 VE-20103267 VE-20103265

VE-20094670

VE-20083646

VE-30017763

(RM-C1100)

39

No. 52084

23

Page 24

A

V-29BF11ENS

A

A

V-29BF11EPS

V-29BF11EES

EXPLODED VIEW PARTS LIST

[ AV-29BF11ENS, AV-29BF11EPS, AV-29BF11EES ]

! Ref.No. Part No. Part Name Description

! V01 VE-20098924 CRT KIT Inc. DEG COIL(VE-30012971),

! TR601 VE-30017522 FBT

! 1 VE-300 12971 DEG COIL&EARTH CB.

3 VE-35000013 SPRING(ON/OFF SWITCH)

! 4 VE-20059930 BUTTON(ON/OFF)

! 5 VE-20003605 PIN(CONTROL PANEL DOOR)(×2)

! 6 VE-40000026 EJECTOR CLIP-CLAP

! 7 VE-20102640 CONTROL PANEL DOOR

! 8 VE-20103272 FRONT PANEL

! 9 VE-20081212 LENS LED

! 10 VE-20082371 BUTTON FUNCTION

11 VE-40009351 SPONGE (×2)

12 VE-30001950 SPEAKER(8R 15W) (×2)

13 VE-30001947 TWEETER(8R 15W) (×2)

! 14 VE-20097423 BACK COVER(REAR COVER)

15 VE-35004572 SCREW (×8)

! 16 VE-20067720 BACK DOOR(TERMINAL BOARD)

17 VE-35000211 SCREW (×4)

18 VE-40009154 JVC LOGO

! 19 VE-20103656 LABEL [AV-29BF11ENS]

! 19 VE-20103677 LABEL [AV-29BF11ENS(for GER models)]

! 19 VE-20103679 LABEL [AV-29BF11ENS(for ITA models)]

! 19 VE-20103654 LABEL [AV-29BF11EPS]

! 19 VE-20103640 LABEL [AV-29BF11EES]

! 19 VE-20103638 LABEL [AV-29BF11EES(for POL models)]

! 20 VE-30002174 MAIN SWITCH (ON/OFF)

! -- VE-30016513 POWER CORD 2.2MT(W/FILTER)

! -- VE-50025747 WARNING LABEL(HUN) [AV-29BF11EES]

CONN.ASSY,SPRING

24

No. 52084

Page 25

A

A

A

EXPLODED VIEW

!

19

17

!

16

V-29BF11ENS

V-29BF11EPS

V-29BF11EES

15

!

14

MAIN PWB

!

TR601

!

!

V01

FRONT

CONTROL

PWB

11

!

8

12

13

!

6

!

1

11

12

5

!

9

13

!

!

10

20

FRONT AV &

18

!

3

!

4

7

HEADPHONE

PWB

No. 52084

25

Page 26

A

V-29BF11ENS

PRINTED WIRING BOARD PARTS LIST

[ AV-29BF11ENS ]

MAIN P.W. BOARD ASS’Y (VE-20103272)

! Symbol No. Part No. Part Name Description

VARIABLE RESISTOR

VR800 VE-30001064 RES ADJ 1/10W 470R VER (MAN)

RESISTOR

R102 VE-30012657 SMD RES. 1/16W 1K J

R103 VE-30012657 SMD RES. 1/16W 1K J

R106 VE-30012713 SMD RES. 1/16W 75R J

R107 VE-30012649 SMD RES. 1/16W 150R J

R109 VE-30012713 SMD RES. 1/16W 75R J

R110 VE-30012713 SMD RES. 1/16W 75R J

R111 VE-30012649 SMD RES. 1/16W 150R J

R113 VE-30012713 SMD RES. 1/16W 75R J

R114 VE-30012713 SMD RES. 1/16W 75R J

R115 VE-30012713 SMD RES. 1/16W 75R J

R117 VE-30000792 CF RES. 1/4W 75R J

R118 VE-30012713 SMD RES. 1/16W 75R J

R121 VE-30012649 SMD RES. 1/16W 150R J

R122 VE-30000792 CF RES. 1/4W 75R J

R123 VE-30000792 CF RES. 1/4W 75R J

R124 VE-30012649 SMD RES. 1/16W 150R J

R126 VE-30012657 SMD RES. 1/16W 1K J

R129 VE-30012713 SMD RES. 1/16W 75R J

R135 VE-30012657 SMD RES. 1/16W 1K J

R137 VE-30000466 CF RES. 1/4W 1K J

R138 VE-30012657 SMD RES. 1/16W 1K J

R139 VE-30012713 SMD RES. 1/16W 75R J

R141 VE-30012657 SMD RES. 1/16W 1K J

R145 VE-30012713 SMD RES. 1/16W 75R J

R149 VE-30012703 SMD RES. 1/16W 56K J

R151 VE-30012696 SMD RES. 1/16W 47K J

R152 VE-30000752 CF RES. 1/4W 56K J

R153 VE-30012657 SMD RES. 1/16W 1K J

R154 VE-30000723 CF RES. 1/4W 47K J

R155 VE-30012649 SMD RES. 1/16W 150R J

R169 VE-30012703 SMD RES. 1/16W 56K J

R171 VE-30012713 SMD RES. 1/16W 75R J

R172 VE-30012692 SMD RES. 1/16W 4.7K J

R174 VE-30012713 SMD RES. 1/16W 75R J

R175 VE-30012713 SMD RES. 1/16W 75R J

R176 VE-30012703 SMD RES. 1/16W 56K J

R201 VE-30012674 SMD RES. 1/16W 27K J

R202 VE-30012692 SMD RES. 1/16W 4.7K J

R204 VE-30000459 CF RES. 1/4W 100R J

R206 VE-30000459 CF RES. 1/4W 100R J

R319 VE-30014076 SMD RES. 1/16W 4.7R J

R320 VE-30014076 SMD RES. 1/16W 4.7R J

R324 VE-30012667 SMD RES. 1/16W 220K J

R328 VE-30012649 SMD RES. 1/16W 150R J

R329 VE-30012692 SMD RES. 1/16W 4.7K J

R332 VE-30012641 SMD RES. 1/16W 10K J

R333 VE-30012702 SMD RES. 1/16W 560R J

R338 VE-30012641 SMD RES. 1/16W 10K J

R340 VE-30012644 SMD RES. 1/16W 12K J

R341 VE-30012702 SMD RES. 1/16W 560R J

R343 VE-30012659 SMD RES. 1/16W 2.2K J

R370 VE-30012669 SMD RES. 1/16W 22K J

R371 VE-30012669 SMD RES. 1/16W 22K J

R391 VE-30012696 SMD RES. 1/16W 47K J

R417 VE-30012510 SMD RES. 1/16W 100R J

R418 VE-30012510 SMD RES. 1/16W 100R J

R419 VE-30012649 SMD RES. 1/16W 150R J

R420 VE-30000466 CF RES. 1/4W 1K J

R421 VE-30012650 SMD RES. 1/16W 15K J

R422 VE-30012659 SMD RES. 1/16W 2.2K J

R423 VE-30012712 SMD RES. 1/16W 8.2K J

R425 VE-30012510 SMD RES. 1/16W 100R J

R426 VE-30012659 SMD RES. 1/16W 2.2K J

R427 VE-30012674 SMD RES. 1/16W 27K J

R428 VE-30012510 SMD RES. 1/16W 100R J

R430 VE-30012702 SMD RES. 1/16W 560R J

R431 VE-30012674 SMD RES. 1/16W 27K J

R432 VE-30012707 SMD RES. 1/16W 680R J

R433 VE-30012683 SMD RES. 1/16W 330K J

R437 VE-30000466 CF RES. 1/4W 1K J

R438 VE-30000466 CF RES. 1/4W 1K J

R439 VE-30012657 SMD RES. 1/16W 1K J

R440 VE-30012714 SMD RES. 1/16W 820R J

R441 VE-30012674 SMD RES. 1/16W 27K J

R442 VE-30000466 CF RES. 1/4W 1K J

R446 VE-30012714 SMD RES. 1/16W 820R J

! Symbol No. Part No. Part Name Description

RESISTOR

R447 VE-30012714 SMD RES. 1/16W 820R J

R448 VE-30012683 SMD RES. 1/16W 330K J

R450 VE-30012702 SMD RES. 1/16W 560R J

R458 VE-30012510 SMD RES. 1/16W 100R J

R459 VE-30012668 SMD RES. 1/16W 220R J

R460 VE-30012668 SMD RES. 1/16W 220R J

R461 VE-30012668 SMD RES. 1/16W 220R J

R449 VE-30012659 SMD RES. 1/16W 2.2K J

R462 VE-30012510 SMD RES. 1/16W 100R J

R467 VE-30000670 CF RES. 1/4W 330K J

R468 VE-30000670 CF RES. 1/4W 330K J

R469 VE-30000628 CF RES. 1/4W 2.7K J

R471 VE-30014022 SMD RES. 1/16W 47R J

R472 VE-30012662 SMD RES. 1/16W 2.7K J

R474 VE-30012662 SMD RES. 1/16W 2.7K J

R481 VE-30000466 CF RES. 1/4W 1K J

R482 VE-30012657 SMD RES. 1/16W 1K J

R483 VE-30012657 SMD RES. 1/16W 1K J

R485 VE-30012657 SMD RES. 1/16W 1K J

R486 VE-30012657 SMD RES. 1/16W 1K J

R487 VE-30012657 SMD RES. 1/16W 1K J

R507 VE-30000466 CF RES. 1/4W 1K J

R508 VE-30012510 SMD RES. 1/16W 100R J

R509 VE-30012641 SMD RES. 1/16W 10K J

R510 VE-30012702 SMD RES. 1/16W 560R J

R511 VE-30012657 SMD RES. 1/16W 1K J

R512 VE-30000495 CF RES. 1/4W 1.2K J

R513 VE-30000459 CF RES. 1/4W 100R J

R514 VE-30000459 CF RES. 1/4W 100R J

R515 VE-30012659 SMD RES. 1/16W 2.2K J

R516 VE-30012659 SMD RES. 1/16W 2.2K J

R517 VE-30012692 SMD RES. 1/16W 4.7K J

R518 VE-30000471 CF RES. 1/4W 10K J

R519 VE-30012698 SMD RES. 1/16W 5.6K J

R525 VE-30012649 SMD RES. 1/16W 150R J

R526 VE-30012641 SMD RES. 1/16W 10K J

R527 VE-30012692 SMD RES. 1/16W 4.7K J

R528 VE-30012698 SMD RES. 1/16W 5.6K J

R529 VE-30012698 SMD RES. 1/16W 5.6K J

R530 VE-30012698 SMD RES. 1/16W 5.6K J

R532 VE-30012659 SMD RES. 1/16W 2.2K J

R533 VE-30012644 SMD RES. 1/16W 12K J

R534 VE-30000628 CF RES. 1/4W 2.7K J

R537 VE-30012641 SMD RES. 1/16W 10K J

R538 VE-30012698 SMD RES. 1/16W 5.6K J

R539 VE-30012659 SMD RES. 1/16W 2.2K J

R540 VE-30012644 SMD RES. 1/16W 12K J

R545 VE-30012644 SMD RES. 1/16W 12K J

R548 VE-30012641 SMD RES. 1/16W 10K J

R554 VE-30012641 SMD RES. 1/16W 10K J

R555 VE-30012659 SMD RES. 1/16W 2.2K J

R556 VE-30012657 SMD RES. 1/16W 1K J

R560 VE-30012674 SMD RES. 1/16W 27K J

R561 VE-30012692 SMD RES. 1/16W 4.7K J

R568 VE-30000594 CF RES. 1/4W 22K J

R572 VE-30012659 SMD RES. 1/16W 2.2K J

R573 VE-30012641 SMD RES. 1/16W 10K J

R574 VE-30012657 SMD RES. 1/16W 1K J

R603 VE-30000459 CF RES. 1/4W 100R J

R604 VE-30012510 SMD RES. 1/16W 100R J

R606 VE-30000471 CF RES. 1/4W 10K J

R607 VE-30000554 CF RES. 1/4W 180R J

R608 VE-30000859 MF RES. 1/2W 1R F

R609 VE-30000711 CF RES. 1/2W 470R J

R610 VE-30000599 CF RES. 1/4W 220K J

R611 VE-30012708 SMD RES. 1/16W 68K J

R616 VE-30012685 SMD RES. 1/16W 33K J

R617 VE-30000572 CF RES. 1/4W 2K J

R630 VE-30012702 SMD RES. 1/16W 560R J

R634 VE-30000633 CF RES. 1/4W 27K J

R639 VE-30000471 CF RES. 1/4W 10K J

R640 VE-30000628 CF RES. 1/4W 2.7K J

R646 VE-30000775 CF RES. 1/4W 6.8K J

R647 VE-30000466 CF RES. 1/4W 1K J

! R648 VE-30001246 FUSE RES. 1W 0.47R J

R650 VE-30012702 SMD RES. 1/16W 560R J

R651 VE-30012668 SMD RES. 1/16W 220R J

! R656 VE-30001247 FUSE RES. 1/2W 4.7R J

! R657 VE-30001228 FUSE RES. 1/2W 2.2R J

R662 VE-30012674 SMD RES. 1/16W 27K J

R666 VE-30000531 CF RES. 1/4W 15K J

26

No. 52084

Page 27

A

[ AV-29BF11ENS ]

V-29BF11ENS

! Symbol No. Part No. Part Name Description

RESISTOR

R668 VE-30000607 CF RES. 1/4W 2.2R J

R669 VE-30012510 SMD RES. 1/16W 100R J

R670 VE-30012510 SMD RES. 1/16W 100R J

R677 VE-30001124 MO RES. 3W 220R J

R678 VE-30014022 SMD RES. 1/16W 47R J

R680 VE-30000477 CF RES. 1/4W 100K J

R681 VE-30012509 SMD RES. 1/16W 100K J

R674 VE-30012662 SMD RES. 1/16W 2.7K J

! R675 VE-30001208 FUSE RES. 1W 10R J

R682 VE-30017082 WW RES. 5W 75R J RAD.

R683 VE-30017083 WW RES. 5W 2.2K J RAD.

R689 VE-30000718 CF RES. 1/4W 4.7K J

R690 VE-30000466 CF RES. 1/4W 1K J

R691 VE-30012696 SMD RES. 1/16W 47K J

R692 VE-30012509 SMD RES. 1/16W 100K J

R693 VE-30012708 SMD RES. 1/16W 68K J

R694 VE-30000689 CF RES. 1/4W 3.9K J

R695 VE-30000775 CF RES. 1/4W 6.8K J

R696-Y VE-30001350 ZENER DIODE 12V

R697 VE-30000712 CF RES. 1/4W 470R J

R698 VE-30012657 SMD RES. 1/16W 1K J

R700 VE-30012649 SMD RES. 1/16W 150R J

R701 VE-30000459 CF RES. 1/4W 100R J

R703 VE-30000459 CF RES. 1/4W 100R J

R705 VE-30000459 CF RES. 1/4W 100R J

R715 VE-30012702 SMD RES. 1/16W 560R J

R717 VE-30012702 SMD RES. 1/16W 560R J

R719 VE-30012657 SMD RES. 1/16W 1K J

R721 VE-30012510 SMD RES. 1/16W 100R J

R722 VE-30012510 SMD RES. 1/16W 100R J

R723 VE-30012510 SMD RES. 1/16W 100R J

R724 VE-30012510 SMD RES. 1/16W 100R J

R801 VE-30000718 CF RES. 1/4W 4.7K J

R803 VE-30012659 SMD RES. 1/16W 2.2K J

R805 VE-30000650 CF RES. 1/4W 33R J

R806 VE-30000982 MF RES. 1/4W 4.7K J

R807 VE-30001173 MO RES. 1W 0.47R J

R809 VE-30007784 MO RES. 5W 33K J(RADIAL)

! R810 VE-30001257 MG RES. 1/2W 4.7M J

R811 VE-30000718 CF RES. 1/4W 4.7K J

R812 VE-30012641 SMD RES. 1/16W 10K J

R813 VE-30000466 CF RES. 1/4W 1K J

R814 VE-30000466 CF RES. 1/4W 1K J

R817 VE-30000880 MF RES. 1/4W 130K F

R818 VE-30012675 SMD RES. 1/16W 2K J

R819 VE-30000526 CF RES. 1/4W 1.5K J

R828 VE-30000530 CF RES. 1/2W 15K J

R829 VE-30000530 CF RES. 1/2W 15K J

R834 VE-30001159 MO RES. 1W 0.33R J

R836 VE-30012662 SMD RES. 1/16W 2.7K J

R839 VE-30000526 CF RES. 1/4W 1.5K J

R842 VE-30014128 SMD RES. 1/16W 33R J

R844 VE-30012641 SMD RES. 1/16W 10K J

R845 VE-30012509 SMD RES. 1/16W 100K J

R846 VE-30012692 SMD RES. 1/16W 4.7K J

R847 VE-30014128 SMD RES. 1/16W 33R J

R848 VE-30012641 SMD RES. 1/16W 10K J

R849 VE-30012510 SMD RES. 1/16W 100R J

R851 VE-30000718 CF RES. 1/4W 4.7K J

R852 VE-30000650 CF RES. 1/4W 33R J

R853 VE-30012642 SMD RES. 1/16W 120K J

R855 VE-30000459 CF RES. 1/4W 100R J

R856 VE-30012694 SMD RES. 1/16W 470K J

R857 VE-30001263 WW RES. 5W 3.9R J (RAD)

CAPACITOR

C141 VE-30007081 EL CAP. 4.7UF 50V M (NPL)

C142 VE-30007081 EL CAP. 4.7UF 50V M (NPL)

C143 VE-30012589 SMD CAP. 4.7NF 50V K

C144 VE-30012589 SMD CAP. 4.7NF 50V K

C145 VE-30012589 SMD CAP. 4.7NF 50V K

C146 VE-30012589 SMD CAP. 4.7NF 50V K

C147 VE-30012589 SMD CAP. 4.7NF 50V K

C148 VE-30012589 SMD CAP. 4.7NF 50V K

C149 VE-30012589 SMD CAP. 4.7NF 50V K

C150 VE-30012589 SMD CAP. 4.7NF 50V K

C155 VE-30012560 SMD CAP. 100PF 50V J

C157 VE-30012560 SMD CAP. 100PF 50V J

C159 VE-30000352 EL CAP. 100UF 16V M

C160 VE-30000345 EL CAP. 10UF 50V M

C161 VE-30000345 EL CAP. 10UF 50V M

! Symbol No. Part No. Part Name Description

CAPACITOR

C162 VE-30012573 SMD CAP. 47PF 50V J

C164 VE-30012692 SMD RES. 1/16W 4.7K J

C165 VE-30000413 EL CAP. 4.7UF 50V M

C201 VE-30000400 EL CAP. 47UF 50V M

C205 VE-30000345 EL CAP. 10UF 50V M

C206 VE-30012610 SMD CAP. 10NF 50V J

C207 VE-30012610 SMD CAP. 10NF 50V J

C230 VE-30016654 SMD CAP. 100NF 16V K R

C246 VE-30000295 CER CAP. 100NF 50V Z F

C303 VE-30000100 MKT CAP. 330NF 63V J

C305 VE-30012590 SMD CAP. 47NF 50V K

C310 VE-30000345 EL CAP. 10UF 50V M

C333 VE-30000083 MKT CAP. 150NF 63V J

C363 VE-30000083 MKT CAP. 150NF 63V J

C364 VE-30012590 SMD CAP. 47NF 50V K

C366 VE-30000407 EL CAP. 470UF 16V M

C368 VE-30012590 SMD CAP. 47NF 50V K

C404 VE-30000190 CER CAP. 100PF 50V J CH

C408 VE-30012586 SMD CAP. 22NF 50V K

C409 VE-30000345 EL CAP. 10UF 50V M

C410 VE-30000384 EL CAP. 2.2UF 50V M

C411 VE-30000345 EL CAP. 10UF 50V M

C412 VE-30016654 SMD CAP. 100NF 16V K R

C413 VE-30000362 EL CAP. 1UF 50V M

C414 VE-30012585 SMD CAP. 2.2NF 50V K R

C415 VE-30012581 SMD CAP. 1NF 50V K R

C416 VE-30000362 EL CAP. 1UF 50V M

C417 VE-30000362 EL CAP. 1UF 50V M

C418 VE-30016654 SMD CAP. 100NF 16V K R

C419 VE-30000384 EL CAP. 2.2UF 50V M

C420 VE-30000100 MKT CAP. 330NF 63V J

C422 VE-30000352 EL CAP. 100UF 16V M

C423 VE-30000352 EL CAP. 100UF 16V M

C424 VE-30000352 EL CAP. 100UF 16V M

C425 VE-30016654 SMD CAP. 100NF 16V K R

C427 VE-30016654 SMD CAP. 100NF 16V K R

C429 VE-30012589 SMD CAP. 4.7NF 50V K

C430 VE-30016654 SMD CAP. 100NF 16V K R

C431 VE-30000362 EL CAP. 1UF 50V M

C432 VE-30016654 SMD CAP. 100NF 16V K R

C433 VE-30000345 EL CAP. 10UF 50V M

C434 VE-30016654 SMD CAP. 100NF 16V K R

C435 VE-30016654 SMD CAP. 100NF 16V K R

C436 VE-30000109 MKT CAP. 470NF 63V J

C437 VE-30016654 SMD CAP. 100NF 16V K R

C438 VE-30016654 SMD CAP. 100NF 16V K R

C439 VE-30016654 SMD CAP. 100NF 16V K R

C440 VE-30000295 CER CAP. 100NF 50V Z F

C441 VE-30012582 SMD CAP. 10NF 50V K R

C442 VE-30000109 MKT CAP. 470NF 63V J

C443 VE-30000362 EL CAP. 1UF 50V M

C444 VE-30000384 EL CAP. 2.2UF 50V M

C448 VE-30012586 SMD CAP. 22NF 50V K

C449 VE-30012560 SMD CAP. 100PF 50V J

C453 VE-30000352 EL CAP. 100UF 16V M

C455 VE-30000345 EL CAP. 10UF 50V M

C459 VE-30012560 SMD CAP. 100PF 50V J

C501 VE-30016654 SMD CAP. 100NF 16V K R

C502 VE-30000400 EL CAP. 47UF 50V M

C504 VE-30016654 SMD CAP. 100NF 16V K R

C505 VE-30012589 SMD CAP. 4.7NF 50V K

C507 VE-30000345 EL CAP. 10UF 50V M

C510 VE-30016654 SMD CAP. 100NF 16V K R

C511 VE-30012566 SMD CAP. 22PF 50V J

C513 VE-30000345 EL CAP. 10UF 50V M

C514 VE-30016654 SMD CAP. 100NF 16V K R

C515 VE-30012560 SMD CAP. 100PF 50V J

C517 VE-30016654 SMD CAP. 100NF 16V K R

C518 VE-30016654 SMD CAP. 100NF 16V K R

C519 VE-30012560 SMD CAP. 100PF 50V J

C520 VE-30012560 SMD CAP. 100PF 50V J

C521 VE-30012562 SMD CAP. 15PF 50V J

C522 VE-30012562 SMD CAP. 15PF 50V J

C523 VE-30012585 SMD CAP. 2.2NF 50V K R

C524 VE-30012566 SMD CAP. 22PF 50V J

C525 VE-30012566 SMD CAP. 22PF 50V J

C526 VE-30016654 SMD CAP. 100NF 16V K R

C527 VE-30000345 EL CAP. 10UF 50V M

C529 VE-30012589 SMD CAP. 4.7NF 50V K

C530 VE-30012589 SMD CAP. 4.7NF 50V K

C532 VE-30016654 SMD CAP. 100NF 16V K R

C536 VE-30000295 CER CAP. 100NF 50V Z F

C541 VE-30000362 EL CAP. 1UF 50V M

No. 52084

27

Page 28

A

V-29BF11ENS

[ AV-29BF11ENS ]

! Symbol No. Part No. Part Name Description

CAPACITOR

C542 VE-30000107 MKT CAP. 47NF 250V J

C543 VE-30000431 CER CAP. 100PF 1KV M

C544 VE-30000345 EL CAP. 10UF 50V M

C547 VE-30000345 EL CAP. 10UF 50V M

C565 VE-30016654 SMD CAP. 100NF 16V K R

C566 VE-30016654 SMD CAP. 100NF 16V K R

C567 VE-30000431 CER CAP. 100PF 1KV M

C602 VE-30017319 MKT CAP. 120NF 63V J

C604 VE-30000356 EL CAP. 100UF 63V M

C605 VE-30000360 EL CAP. 1000UF 25V M

C607 VE-30012581 SMD CAP. 1NF 50V K R

! C618 VE-30000168 MKP CAP. 6.2NF 1.6KV 3.5%

! C621 VE-30000136 MKP CAP. 12NF 2000V %3.5

C622 VE-30012003 MKP CAP. 18NF 630V J

C623 VE-30000406 EL CAP. 47UF 250V M (HR)

! C625 VE-30000177 MKP CAP. 820NF 250V J

C627 VE-30000162 MKP CAP. 470NF 250V J

C629 VE-30013003 MKP CAP. 1UF 250V J P=15

C632 VE-30000100 MKT CAP. 330NF 63V J

C635 VE-30000385 EL CAP. 2.2UF 250V M

C636 VE-30000387 EL CAP. 33UF 50V M

C640 VE-30000100 MKT CAP. 330NF 63V J

C641 VE-30000090 MKT CAP. 22NF 100V J

C642 VE-30000407 EL CAP. 470UF 16V M

C644 VE-30000409 EL CAP. 470UF 25V M

C645 VE-30000090 MKT CAP. 22NF 100V J

C646 VE-30000100 MKT CAP. 330NF 63V J

C647 VE-30007748 EL CAP. 1000UF 35V M

C648 VE-30000394 EL CAP. 3.3UF 160V M

C649 VE-30000295 CER CAP. 100NF 50V Z F

C652 VE-30000330 CER CAP. 4.7NF 50V K B

C653 VE-30000107 MKT CAP. 47NF 250V J

C700 VE-30012565 SMD CAP. 1.8PF 50V J CH

C701 VE-30012565 SMD CAP. 1.8PF 50V J CH

C702 VE-30012576 SMD CAP. 56PF 50V J CH

C703 VE-30012576 SMD CAP. 56PF 50V J CH

C704 VE-30012576 SMD CAP. 56PF 50V J CH

C705 VE-30000345 EL CAP. 10UF 50V M

C706 VE-30000345 EL CAP. 10UF 50V M

C708 VE-30016654 SMD CAP. 100NF 16V K R

C712 VE-30000345 EL CAP. 10UF 50V M

C713 VE-30016654 SMD CAP. 100NF 16V K R

C714 VE-30000100 MKT CAP. 330NF 63V J

C716 VE-30000100 MKT CAP. 330NF 63V J

C717 VE-30000100 MKT CAP. 330NF 63V J

C718 VE-30000100 MKT CAP. 330NF 63V J

C719 VE-30016654 SMD CAP. 100NF 16V K R

C720 VE-30000345 EL CAP. 10UF 50V M

C721 VE-30000100 MKT CAP. 330NF 63V J

C723 VE-30000100 MKT CAP. 330NF 63V J

C724 VE-30000345 EL CAP. 10UF 50V M

C729 VE-30016654 SMD CAP. 100NF 16V K R

C730 VE-30000393 EL CAP. 3.3UF 50V M

C733 VE-30000345 EL CAP. 10UF 50V M

C734 VE-30000345 EL CAP. 10UF 50V M

C735 VE-30016654 SMD CAP. 100NF 16V K R

C736 VE-30000345 EL CAP. 10UF 50V M

C737 VE-30000384 EL CAP. 2.2UF 50V M

C738 VE-30000384 EL CAP. 2.2UF 50V M

C739 VE-30000384 EL CAP. 2.2UF 50V M

C740 VE-30000384 EL CAP. 2.2UF 50V M

C741 VE-30012589 SMD CAP. 4.7NF 50V K

C742 VE-30012589 SMD CAP. 4.7NF 50V K

C745 VE-30016654 SMD CAP. 100NF 16V K R

! C801 VE-30000094 MKT CAP. 220NF AC275V M

! C802 VE-30000094 MKT CAP. 220NF AC275V M

! C803 VE-30000433 CER CAP. 1NF 1KV M B

! C804 VE-30000433 CER CAP. 1NF 1KV M B

C808 VE-30012590 SMD CAP. 47NF 50V K

C809 VE-30000421 EL CAP. 220UF 400V M (FOR 28'')

C810 VE-30000387 EL CAP. 33UF 50V M

C811 VE-30000161 MKP CAP. 47NF 630V J

C812 VE-30007708 CER CAP. 1NF 1KV K (PULSE)

! C816 VE-30000440 CER CAP. 2.2NF 4KV M

C817 VE-30000198 CER CAP. 120PF 500V J SL

C818 VE-30012590 SMD CAP. 47NF 50V K

C819 VE-30012590 SMD CAP. 47NF 50V K

C822 VE-30007308 CER CAP. 220PF 1KV K (PULSE)

C826 VE-30000406 EL CAP. 47UF 250V M (HR)

C827 VE-30000411 EL CAP. 4700UF 16V M

C828 VE-30012590 SMD CAP. 47NF 50V K

C829 VE-30000407 EL CAP. 470UF 16V M

C830 VE-30000383 EL CAP. 2200UF 25V M

! Symbol No. Part No. Part Name Description

CAPACITOR

C832 VE-30012590 SMD CAP. 47NF 50V K

C833 VE-30000407 EL CAP. 470UF 16V M

C834 VE-30012590 SMD CAP. 47NF 50V K

C835 VE-30012590 SMD CAP. 47NF 50V K

C838 VE-30000407 EL CAP. 470UF 16V M

C839 VE-30000407 EL CAP. 470UF 16V M

C840 VE-30000407 EL CAP. 470UF 16V M

C848 VE-30000407 EL CAP. 470UF 16V M

C850 VE-30000383 EL CAP. 2200UF 25V M

C851 VE-30012590 SMD CAP. 47NF 50V K

! C852 VE-30000440 CER CAP. 2.2NF 4KV M

C857 VE-30000106 MKT CAP. 47NF 100V J

C858 VE-30007708 CER CAP. 1NF 1KV K (PULSE)

C859 VE-30009208 CER CAP. 470PF 1KV K (PULSE)

C860 VE-30000296 CER CAP. 100NF 100V Z F

C872 VE-30007708 CER CAP. 1NF 1KV K (PULSE)

TRANSF

TR600 VE-30002090 LINE DRIVER

! TR601 VE-30017522 FBT TRF

! TR802 VE-30018785 SMPS TRF

COIL

L101 VE-30001971 FERRITE BEAT

L102 VE-30001971 FERRITE BEAT

L106 VE-30001971 FERRITE BEAT

L108 VE-30001971 FERRITE BEAT

L109 VE-30001971 FERRITE BEAT

L110 VE-30001971 FERRITE BEAT

L111 VE-30001971 FERRITE BEAT

L112 VE-30001971 FERRITE BEAT

L113 VE-30001971 FERRITE BEAT

L114 VE-30001971 FERRITE BEAT

L115 VE-30001971 FERRITE BEAT

L116 VE-30001971 FERRITE BEAT

L117 VE-30001971 FERRITE BEAT

L201 VE-30001979 FIXED COIL 1UH Q45 M-A

L210 VE-30001971 FERRITE BEAT

L215 VE-30001971 FERRITE BEAT

L401 VE-30001971 FERRITE BEAT

L402 VE-30001992 FIXED COIL 10UH Q65 K-A

L403 VE-30001971 FERRITE BEAT

L405 VE-30014048 ADJ. COIL 44MHZ Q=64 C=39pF

L406 VE-30001971 FERRITE BEAT

L408 VE-30001992 FIXED COIL 10UH Q65 K-A

L501 VE-30001971 FERRITE BEAT

L502 VE-30001971 FERRITE BEAT

L503 VE-30001971 FERRITE BEAT

L504 VE-30001971 FERRITE BEAT

L600 VE-30002031 FIXED COIL INJECTION 15MH

L602 VE-30017085 LINEARITY COIL 20UH

L603 VE-30016083 FIXED COIL 1MH AK33 HIGH CURREN

L700 VE-30001971 FERRITE BEAT

L701 VE-30001971 FERRITE BEAT

L702 VE-30001992 FIXED COIL 10UH Q65 K-A

L703 VE-30001971 FERRITE BEAT

L704 VE-30001971 FERRITE BEAT

L801 VE-30002011 COIL CHOKE 150UH 0.82A RAD

L803 VE-30001992 FIXED COIL 10UH Q65 K-A

DIODE

D101 VE-30007760 ZENER DIODE

D104 VE-30007760 ZENER DIODE

D105 VE-30007760 ZENER DIODE

D106 VE-30007760 ZENER DIODE

D107 VE-30007760 ZENER DIODE

D303 VE-30001329 DIODE

D405 VE-30007763 ZENER DIODE

D407 VE-30001284 DIODE

D408 VE-30001285 DIODE

D409 VE-30001284 DIODE

D413 VE-30018526 ZENER DIODE

D501 VE-30001285 DIODE

D505 VE-30001285 DIODE

D506 VE-30001284 DIODE

D512 VE-30001285 DIODE

D513 VE-30001369 ZENER DIODE

28

No. 52084

Page 29

A

[ AV-29BF11ENS ]

V-29BF11ENS

! Symbol No. Part No. Part Name Description

DIODE

D533 VE-30001377 ZENER DIODE

D601 VE-30001329 DIODE

D603 VE-30001285 DIODE

D605 VE-30001320 DIODE

D606 VE-30007681 DIODE

D609 VE-30001318 DIODE

D610 VE-30001318 DIODE

D613 VE-30001318 DIODE

D614 VE-30001285 DIODE

D616 VE-30003696 DIODE

D617 VE-30001318 DIODE

D651 VE-30001285 DIODE

D653 VE-30001285 DIODE

D657 VE-30007763 ZENER DIODE

D658 VE-30007763 ZENER DIODE

D659 VE-30001350 ZENER DIODE

D661 VE-30001350 ZENER DIODE

D700 VE-30001285 DIODE

D701 VE-30001369 ZENER DIODE

D800 VE-30001318 DIODE

D801 VE-30001372 ZENER DIODE

D802 VE-30001318 DIODE

D803 VE-30001315 DIODE

D804 VE-30001318 DIODE

D805 VE-30001315 DIODE

D806 VE-30001315 DIODE

D808 VE-20092405 CN.ASY. UF5407+FERRITE

D809 VE-30001329 DIODE

D810 VE-30009366 DIODE

D811 VE-30009366 DIODE

D812 VE-30001285 DIODE

D889 VE-30001384 TR

! D891 VE-30007758 DIODE

D892 VE-30001318 DIODE

D893 VE-30001318 DIODE

D894 VE-30001285 DIODE

D897 VE-30001329 DIODE

TRANSISTOR

Q104 VE-30001457 TR

Q106 VE-30001457 TR

Q141 VE-30001457 TR

Q142 VE-30001457 TR

Q307 VE-30001457 TR

Q316 VE-30001458 TR

Q403 VE-30001457 TR

Q404 VE-30001457 TR

Q503 VE-30001457 TR

Q504 VE-30001458 TR

Q600 VE-30001435 TR

! Q601 VE-30001441 TR

Q602 VE-30001429 TR

Q603 VE-30001458 TR

Q604 VE-30001457 TR

Q605 VE-30001458 TR

Q700 VE-30001458 TR

Q801 VE-30001386 TR

Q802 VE-30001457 TR

Q804 VE-30001454 TR

IC

IC301 VE-30016113 IC

IC403 VE-30014521 IC

IC500 VE-20103251 IC (SERVICE)

IC501 VE-20093395 PR.IC. (MICOM)

IC601 VE-30013985 IC

IC700 VE-30013658 IC

IC800 VE-30011968 IC

! IC801 VE-30015087 IC

IC802 VE-30001622 IC

IC803 VE-30001500 IC

IC804 VE-30001622 IC

IC818 VE-30001506 IC

! Symbol No. Part No. Part Name Description

OTHERS

! F801 VE-30001731 FUSE 2.5A 250V 5*20MM

! TH800 VE-30001270 PTC 9 OHM

! TR801 VE-30002104 LINE FILTER

TU201 VE-30009637 TUNER WSP (PLL) 38.9 MK2 - BATC

X401 VE-30001749 XTAL

X402 VE-30015592 XTAL

X501 VE-30002851 XTAL

X700 VE-30001756 XTAL

Z401 VE-30001705 SAW FILTER

Z402 VE-30015591 SAW FILTER

VE-30001964 FERRITE BAR

No. 52084

29

Page 30

A

V-29BF11ENS

[ AV-29BF11ENS ]

CRT SOCKET P.W. BOARD ASS’Y

(VE-20094670 : Common to all models)

! Symbol No. Part No. Part Name Description

RESISTOR

R900 VE-30000788 CF RES. 1/4W 6.8M J

R902 VE-30000459 CF RES. 1/4W 100R J

R903 VE-30000459 CF RES. 1/4W 100R J

R904 VE-30000459 CF RES. 1/4W 100R J

R906 VE-30000535 CF RES. 1/2W 150K J

R907 VE-30000477 CF RES. 1/4W 100K J

R908 VE-30000477 CF RES. 1/4W 100K J

R909 VE-30000525 CF RES. 1/2W 1.5K J

R910 VE-30000525 CF RES. 1/2W 1.5K J

R911 VE-30000525 CF RES. 1/2W 1.5K J

R912 VE-30000477 CF RES. 1/4W 100K J

R913 VE-30000525 CF RES. 1/2W 1.5K J

R914 VE-30001084 MO RES. 1W 1K J

R916 VE-30001170 MO RES. 1W 4.7K J

! R917 VE-30001208 FUSE RES. 1W 10R J

R918 VE-30000471 CF RES. 1/4W 10K J

R921 VE-30000599 CF RES. 1/4W 220K J

R922 VE-30000590 CF RES. 1/4W 2.2K J

CAPACITOR

C900 VE-30000075 MKT CAP. 100NF 250V K (DC)

C902 VE-30000415 EL CAP. 4.7UF 250V M

C903 VE-30000438 CER CAP. 2.2NF 2KV

C904 VE-30000295 CER CAP. 100NF 50V Z F

C905 VE-30000234 CER CAP. 270PF 50V J SL

C906 VE-30000350 EL CAP. 10UF 250V M

C907 VE-30000075 MKT CAP. 100NF 250V K (DC)

C909 VE-30000385 EL CAP. 2.2UF 250V M

C910 VE-30000438 CER CAP. 2.2NF 2KV

C911 VE-30000433 CER CAP. 1NF 1KV M B

COIL

L900 VE-30002170 FTZ/RAD COIL

DIODE

D901 VE-30001329 DIODE

D902 VE-30001318 DIODE

D903 VE-30001329 DIODE

D904 VE-30001329 DIODE

D905 VE-30001284 DIODE

D906 VE-30001284 DIODE

D907 VE-30001284 DIODE

D908 VE-30001284 DIODE

D909 VE-30001344 ZENER DIODE

NOT1 VE-30001329 DIODE

TRANSISTOR

Q900 VE-30001427 TR

Q901 VE-30001454 TR

IC

IC900 VE-30008721 IC

OTHERS

! PL900 VE-30001855 CRT SOCKET

SG901 VE-30000428 SPARK GAP 300V

SG902 VE-30000428 SPARK GAP 300V

SG903 VE-30000428 SPARK GAP 300V

SG904 VE-30000428 SPARK GAP 300V

VE-20000954 HE.ASY. CONTAINS HEATSINK+IC900

FRONT AV & HEADPHONE P.W. BOARD ASS’Y

(VE-20083646 : Common to all models)

! Symbol No. Part No. Part Name Description

RESISTOR

R107 VE-30000594 CF RES. 1/4W 22K J

R108 VE-30000712 CF RES. 1/4W 470R J

R109 VE-30000594 CF RES. 1/4W 22K J

R110 VE-30000712 CF RES. 1/4W 470R J

R113 VE-30000744 CF RES. 1/4W 560R J

R114 VE-30000744 CF RES. 1/4W 560R J

R115 VE-30000712 CF RES. 1/4W 470R J

R116 VE-30000712 CF RES. 1/4W 470R J

CAPACITOR

C103 VE-30000213 CER CAP. 180PF 50V J CH

C104 VE-30000213 CER CAP. 180PF 50V J CH

C106 VE-30000190 CER CAP. 100PF 50V J CH

TRANSF

T103 VE-30001962 FERRITE

T104 VE-30001963 FERRITE

T107 VE-30001963 FERRITE

COIL

L103 VE-30001996 FIXED COIL 22UH Q40 K

L104 VE-30001996 FIXED COIL 22UH Q40 K

OTHERS

CON102 VE-30001893 RCA JACK

CON103 VE-30001891 RCA JACK

CON104 VE-30001892 RCA JACK

CON106 VE-30001900 HEADPHONE JACK HP01/2/3/4/5/6

FRONT CONTROL P.W. BOARD ASS’Y

(VE-20100168 : Common to all models)

! Symbol No. Part No. Part Name Description

RESISTOR

R1 VE-30000689 CF RES. 1/4W 3.9K J

R2 VE-30000526 CF RES. 1/4W 1.5K J

R3 VE-30000770 CF RES. 1/4W 680R J

R4 VE-30000712 CF RES. 1/4W 470R J

R5 VE-30000623 CF RES. 1/4W 270R G

CAPACITOR

C1 VE-30000295 CER CAP. 100NF 50V Z F

OTHERS