JVC AV-28H50SU, AV-28H5BL, AV-28H5BU, AV-28H5SK, AV-28H5SL Service Manual

...

SERVICE MANUAL

COLOUR TELEVISION

YA26320054

AV-28H5BU, AV-28H5BL, AV-28H5SK,

AV-28H5SL, AV28H5SR, AV-28H5SU,

AV-28H50SU, AV-32H5BU, AV-32H5SK,

AV-32H5SR, AV-32H5SU, AV-32H50SU,

AV-32H57SU

BASIC CHASSIS

ML3

1

2

3

4

5

6

7

8

9

0

AV

MENU

P

TV OK

P

L

/

F.T

TV

AV-28H5BU, AV-28H5BL

AV-28H50SU, AV-32H50SU AV-32H57SU

AV-28H5SK, AV-28H5SL

AV-28H5SR, AV-28H5SU

AV-32H5BU, AV-32H5SK

AV-32H5SR, AV-32H5SU

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

5 TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.YA263

2005/4

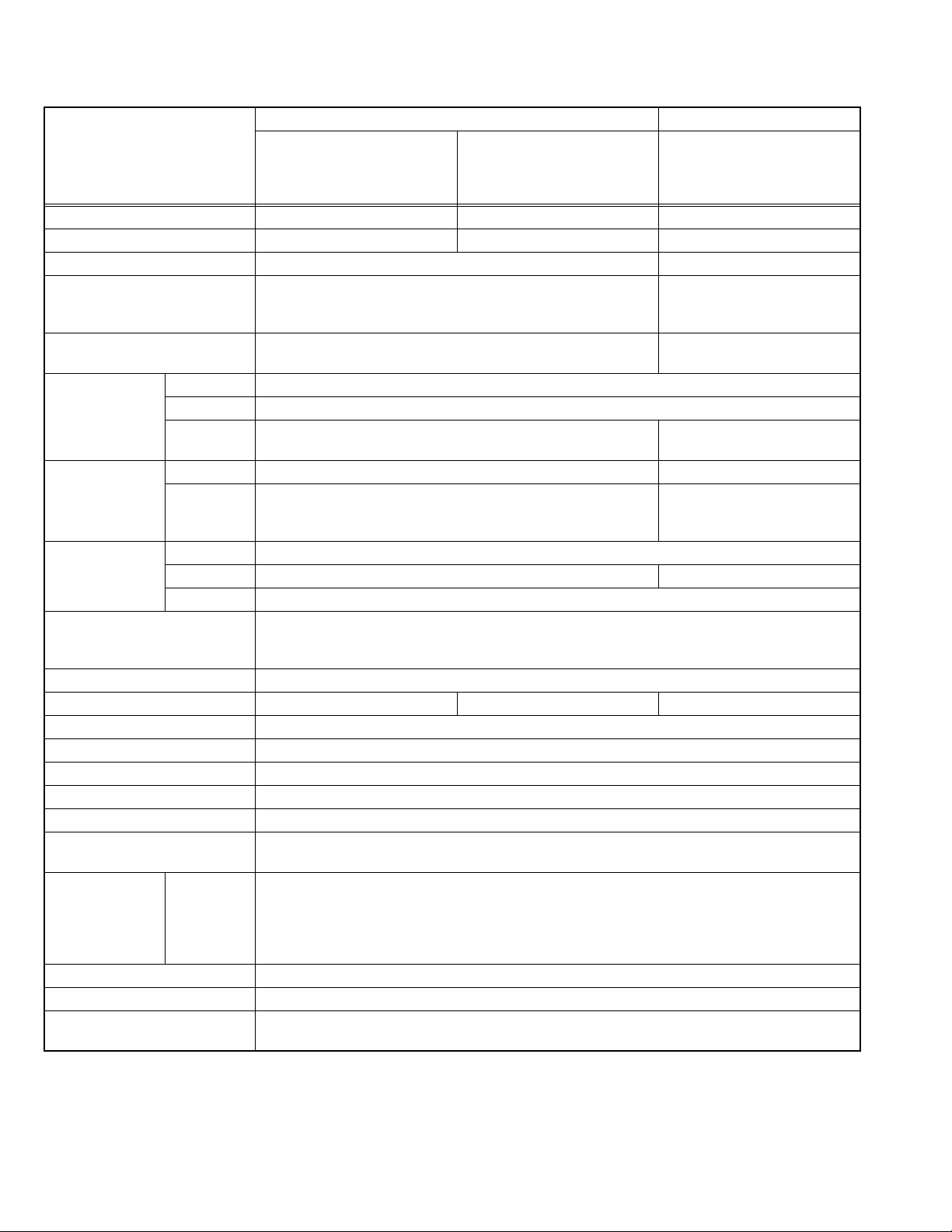

SPECIFICATION

Contents

Items

Dimensions ( W × H × D ) 76.2 cm × 52.8 cm × 49.2 cm 85.4 cm × 50.8 cm × 49.0 cm 76.2 cm × 52.8 cm × 49.2 cm

Mass 38.0 kg 39.0 kg 38.0 kg

TV RF System CCIR (B/G, I, D/K, L) CCIR (I)

Colour System PAL

SECAM

NTSC3.58 / NTSC4.43 (Only EXT mode)

Stereo System A2 (B/G, D/K)

NICAM (B/G, I, D/K, L)

Receiving

Frequency

French CATV 116 MHz - 172 MHz

Intermediate

Frequency

Colour Sub

Carrier Frequency

Teletext System TOP (German system)

Power Input AC220 V - AC240 V, 50 Hz

Power Consumption 120 W, Standby : 0.6 W 120 W, Standby : 2.5 W 120 W, Standby : 0.6 W

Picture Tube Visible size : 66 cm [measured diagonally (H : 58.3 cm × V : 33.0 cm)

High Voltage 31.0 kV (+1 kV / -1.5 kV) (at zero beam current)

Speaker 13 cm × 6.5 cm oval type × 2

Audio Power Output 10 W + 10 W

Aerial Input Terminal 75 Ω unbalanced, coaxial

EXT-1 / EXT-2 / EXT-3

(Input / Output)

EXT-4 (Input) S-Video

Audio output 0-1000 mV (rms), Low impedance, RCA pin jack × 2

Headphone Jack 3.5 mm stereo mini jack × 1

Remote Control Unit

VHF 47 MHz - 470 MHz [Except AV-28H5SK]

UHF 470 MHz - 862 MHz

220 MHz - 469 MHz

VIF 38.9 MHz (B/G, I, D/K, L) 38.9 MHz (I)

SIF 33.4 MHz (5.5 MHz :B/G)

32.9 MHz ( 6.0 MHz:I )

32.4 MHz (6.5 MHz :L, D/K)

PAL 4.43 MHz

SECAM 4.40625 MHz / 4.25 MHz ---

NTSC 3.58 MHz / 4.43 MHz

FLOF (Fastext)

WST (Standard system)

21-pin Euro connector (SCART socket × 3)

Mini-Din 4 pin × 1

Y : 1 V(p-p) positive (negative sync, 75Ω)

C : 0.3 V(p-p) (Burst signal, 75Ω)

Video

1 V(p-p) 75 Ω, RCA pin jack × 1

Audio (L/R)

500 mV(rms) (-4 dBs), High impedance, RCA pin jack × 2

RM-C1502 (AA/R6 dry cell battery × 2) [AV-28H5SU/AV-28H5SL/AV-28H5SK/AV-28H5SR/AV-28H50SU]

RM-C1502B (AA/R6 dry cell battery

AV-28H5BU

AV-28H5BL

AV-28H5SU

AV-28H5SL

AV-28H50SU

×

2) [AV-28H5BU/AV-28H5BL]

AV-28H5SK

AV-28H5SR

PAL

NTSC3.58 / NTSC4.43 (Only EXT mode)

NICAM (I)

---

32.9 MHz ( 6.0 MHz:I )

Design & specifications are subject to change without notice.

1-2 (No.YA263)

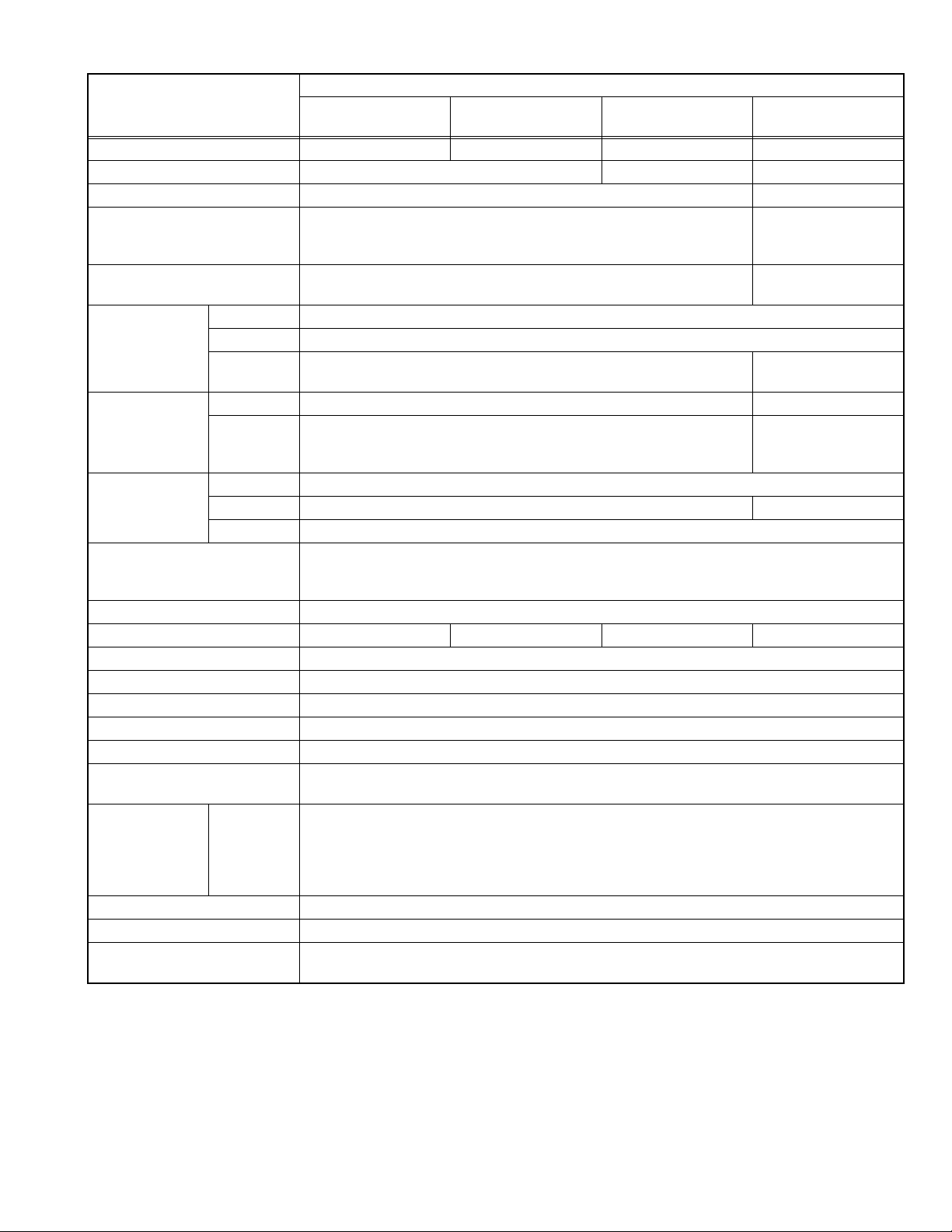

Contents

Items

Dimensions ( W × H × D )

Mass 53.0 kg 52.5 kg 53.0 kg

TV RF System CCIR (B/G, I, D/K, L) CCIR (I)

Colour System PAL

Stereo System A2 (B/G, D/K)

Receiving

Frequency

French CATV 116 MHz - 172 MHz

Intermediate

Frequency

Colour Sub

Carrier Frequency

Teletext System TOP (German system)

Power Input AC220 V - AC240 V, 50 Hz

Power Consumption 130 W, Standby : 0.6 W 130 W, Standby : 2.5 W 130 W, Standby : 2.5 W 130 W, Standby : 0.6 W

Picture Tube Visible size : 76 cm [measured diagonally] (H : 67.4 cm × V : 38.4 cm)

High Voltage 31.0 kV (+1 kV / -1.5 kV) (at zero beam current)

Speaker 13 cm × 6.5 cm oval type × 2

Audio Power Output 10 W + 10 W

Aerial Input Terminal 75 Ω unbalanced, coaxial

EXT-1 / EXT-2 / EXT-3

(Input / Output)

EXT-4 (Input) S-Video

Audio output 0-1000 mV (rms), Low impedance, RCA pin jack × 2

Headphone Jack 3.5 mm stereo mini jack × 1

Remote Control Unit

VHF 47 MHz - 470 MHz [Except AV-32H5SK]

UHF 470 MHz - 862 MHz

VIF 38.9 MHz (B/G, I, D/K, L) 38.9 MHz (I)

SIF

PAL 4.43 MHz

SECAM 4.40625 MHz / 4.25 MHz ---

NTSC 3.58 MHz / 4.43 MHz

Video

Audio (L/R)

AV-32H5BU

AV-32H5SU

86.4 cm × 58.7 cm × 55.0 cm 94.6 cm × 56.1 cm × 54.7 cm 94.8 cm × 56.2 cm × 55.0 cm 86.4 cm × 58.7 cm × 55.0 cm

SECAM

NTSC3.58 / NTSC4.43 (Only EXT mode)

NICAM (B/G, I, D/K, L)

220 MHz - 469 MHz

33.4 MHz (5.5 MHz :B/G)

32.9 MHz ( 6.0 MHz:I )

32.4 MHz (6.5 MHz :L, D/K)

FLOF (Fastext)

WST (Standard system)

21-pin Euro connector (SCART socket × 3)

Mini-Din 4 pin × 1

Y : 1 V(p-p) positive (negative sync, 75Ω)

C : 0.3 V(p-p) (Burst signal, 75Ω)

1 V(p-p) 75 Ω, RCA pin jack × 1

500 mV(rms) (-4 dBs), High impedance, RCA pin jack × 2

RM-C1502 (AA/R6 dry cell battery × 2) [AV-32H5SU/AV-32H5SK/AV-32H5SR/AV-32H50SU/AV-32H57SU]

RM-C1502B (AA/R6 dry cell battery

AV-32H50SU AV-32H57SU

×

2) [AV-32H5BU]

AV-32H5SK

AV-32H5SR

PAL

NTSC3.58 / NTSC4.43

(Only EXT mode)

NICAM (I)

---

32.9 MHz ( 6.0 MHz:I )

Design & specifications are subject to change without notice.

(No.YA263)1-3

SECTION 1

PRECAUTION

1.1 SAFETY PRECAUTIONS [EXCEPT FOR UK]

(1) The design of this product contains special hardware,

many circuits and components specially for safety

purposes. For continued protection, no changes should be

made to the original design unless authorized in writing by

the manufacturer. Replacement parts must be identical to

those used in the original circuits. Service should be

performed by qualified personnel only.

(2) Alterations of the design or circuitry of the products should

not be made. Any design alterations or additions will void

the manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or

property damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These

characteristics are often not evident from visual inspection

nor can the protection afforded by them necessarily be

obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in

the parts list of Service manual. Electrical components

having such features are identified by shading on the

schematics and by ( ) on the parts list in Service

manual. The use of a substitute replacement which does

not have the same safety characteristics as the

recommended replacement part shown in the parts list of

Service manual may cause shock, fire, or other hazards.

(4) Don't short between the LIVE side ground and

ISOLATED (NEUTRAL) side ground or EARTH side

ground when repairing.

Some model's power circuit is partly different in the GND.

The difference of the GND is shown by the LIVE : ( ) side

GND, the ISOLATED (NEUTRAL) : ( ) side GND and

EARTH : ( ) side GND.

Don't short between the LIVE side GND and ISOLATED

(NEUTRAL) side GND or EARTH side GND and never

measure the LIVE side GND and ISOLATED (NEUTRAL)

side GND or EARTH side GND at the same time with a

measuring apparatus (oscilloscope etc.). If above note will

not be kept, a fuse or any parts will be broken.

(5) If any repair has been made to the chassis, it is

recommended that the B1 setting should be checked or

adjusted (See B1 POWER SUPPLY check).

(6) The high voltage applied to the picture tube must conform

with that specified in Service manual. Excessive high

voltage can cause an increase in X-Ray emission, arcing

and possible component damage, therefore operation

under excessive high voltage conditions should be kept to

a minimum, or should be prevented. If severe arcing

occurs, remove the AC power immediately and determine

the cause by visual inspection (incorrect installation,

cracked or melted high voltage harness, poor soldering,

etc.). To maintain the proper minimum level of soft X-Ray

emission, components in the high voltage circuitry

including the picture tube must be the exact replacements

or alternatives approved by the manufacturer of the

complete product.

(7) Do not check high voltage by drawing an arc. Use a high

voltage meter or a high voltage probe with a VTVM.

Discharge the picture tube before attempting meter

connection, by connecting a clip lead to the ground frame

and connecting the other end of the lead through a 10kΩ

2W resistor to the anode button.

(8) When service is required, observe the original lead dress.

Extra precaution should be given to assure correct lead

dress in the high voltage circuit area. Where a short circuit

has occurred, those components that indicate evidence of

overheating should be replaced. Always use the

manufacturer's replacement components.

(9) Isolation Check (Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an

isolation check on the exposed metal parts of the cabinet

(antenna terminals, video/audio input and output terminals,

Control knobs, metal cabinet, screw heads, earphone jack,

control shafts, etc.) to be sure the product is safe to operate

without danger of electrical shock.

a) Dielectric Strength Test

The isolation between the AC primary circuit and all metal

parts exposed to the user, particularly any exposed metal

part having a return path to the chassis should withstand a

voltage of 3000V AC (r.m.s.) for a period of one second. (.

. . . Withstand a voltage of 1100V AC (r.m.s.) to an

appliance rated up to 120V, and 3000V AC (r.m.s.) to an

appliance rated 200V or more, for a period of one second.)

This method of test requires a test equipment not generally

found in the service trade.

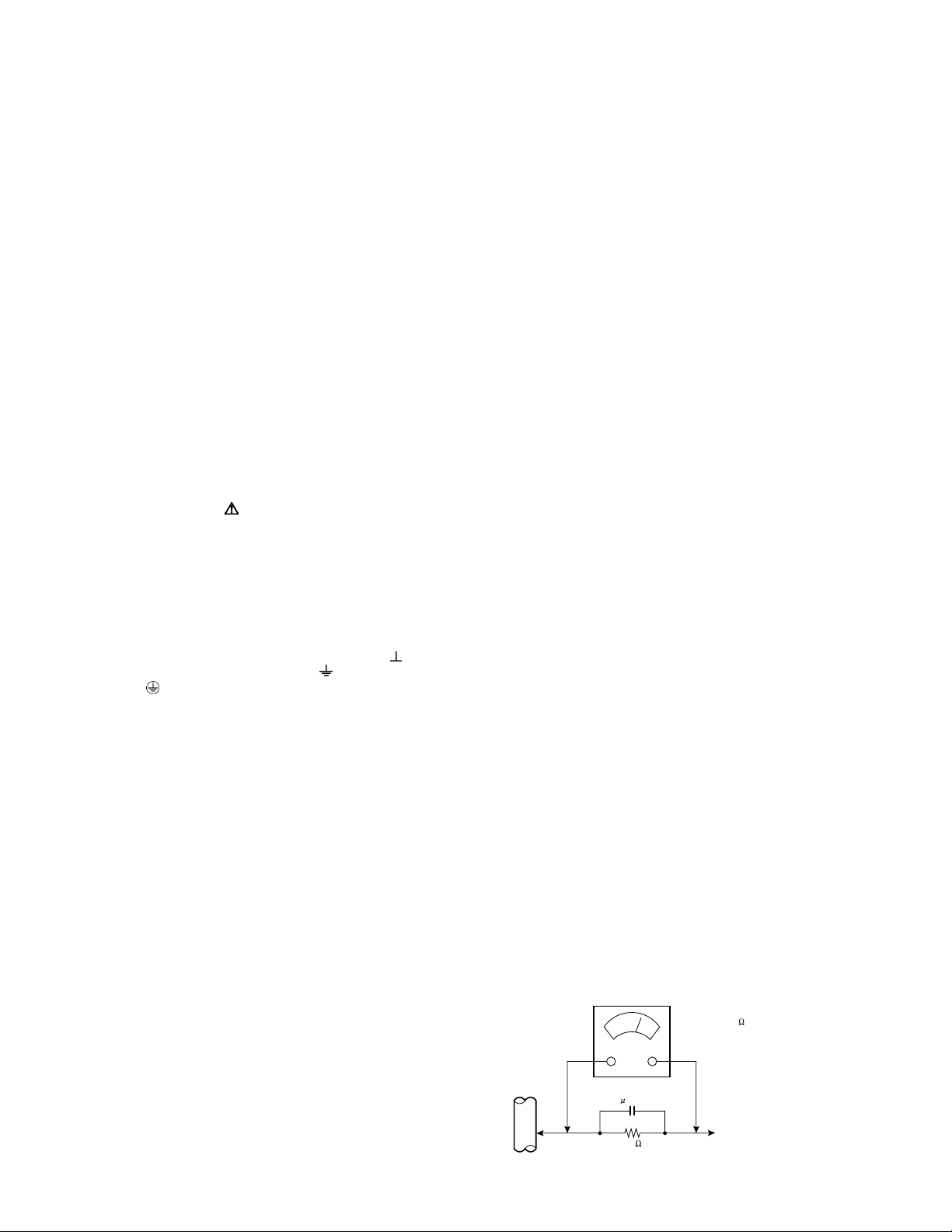

b) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use

a line isolation transformer during this check.). Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal part of the cabinet, particularly

any exposed metal part having a return path to the chassis,

to a known good earth ground (water pipe, etc.). Any

leakage current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not

use a line isolation transformer during this check.). Use

an AC voltmeter having 1000Ω per volt or more

sensitivity in the following manner. Connect a 1500Ω

10W resistor paralleled by a 0.15µF AC-type capacitor

between an exposed metal part and a known good earth

ground (water pipe, etc.). Measure the AC voltage

across the resistor with the AC voltmeter. Move the

resistor connection to each exposed metal part,

particularly any exposed metal part having a return path

to the chassis, and measure the AC voltage across the

resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Any voltage measured must

not exceed 0.75V AC (r.m.s.). This corresponds to

0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000 /V,

OR MORE SENSITIVITY)

0.15 F AC-TYPE

PLACE THIS PROBE

1500 10W

GOOD EARTH GROUND

ON EACH EXPOSED

ME TAL PAR T

1-4 (No.YA263)

1.2 SAFETY PRECAUTIONS [FOR UK]

(1) The design of this product contains special hardware and many circuits and components specially for safety purposes. For

continued protection, no changes should be made to the original design unless authorized in writing by the manufacturer.

Replacement parts must be identical to those used in the original circuits. Service should be performed by qualified personnel

only.

(2) Alterations of the design or circuitry of the product should not be made. Any design alterations or additions will void the

manufacturer's warranty and will further relieve the manufacturer of responsibility for personal injury or property damage

resulting therefrom.

(3) Many electrical and mechanical parts in the product have special safety-related characteristics. These characteristics are often

not evident from visual inspection nor can the protection afforded by them necessary be obtained by using replacement

components rated for higher voltage, wattage, etc. Replacement parts which have these special safety characteristics are

identified in the Parts List of Service Manual. Electrical components having such features are identified by shading on the

schematics and by ( ) on the Parts List in the Service Manual. The use of a substitute replacement which does not have the

same safety characteristics as the recommended replacement part shown in the Parts List of Service Manual may cause shock,

fire, or other hazards.

(4) The leads in the products are routed and dressed with ties, clamps, tubing’s, barriers and the like to be separated from live parts,

high temperature parts, moving parts and / or sharp edges for the prevention of electric shock and fire hazard. When service is

required, the original lead routing and dress should be observed, and it should be confirmed that they have been returned to

normal, after re-assembling.

WARNING

(1) The equipment has been designed and manufactured to meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant safety standards.

(4) It is essential that safety critical components are replaced by approved parts.

(5) If mains voltage selector is provided, check setting for local voltage.

(No.YA263)1-5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 FEATURES

ZOOM

This function can change the screen size according to the

picture aspect ratio.

PICTURE MODE

This function can adjust the picture settings automatically.

T-V LINK

When you have a T-V LINK compatible VCR connected to the

EXT-2 Terminal on the TV,it is easier to set up the VCR and to

view videos.

2.2 MAIN DIFFERENCE LIST

Item AV-28H5BU AV-28H5BL AV-28H5SK AV-28H5SL AV28H5SR AV-28H5SU AV-28H50SU

CABINET COLOUR BLACK ← SILVER ←←←←

RF SYSTEM PAL,SECAM ← PAL PAL,SECAM PAL PAL,SECAM ←

BROADCASTING SYSTEM

REMOTE CONTROL UNIT

MAIN PWB

POWER & DEF PWB

CRT SOCKET PWB

SIDE CONTROL PWB

FRONT CONTORL PWB

AV JACK PWB

100HZ PWB

B/G, D/K, I, L ← I B/G, D/K, I, L I B/G, D/K, I, L ←

RM-C1502B ← RM-C1502 ←←←←

SML-1302A-U2

SML-2302A-S2

SML-3302A-U2

SML-8131A-U2

SML-8301A-U2

SML0J301A-U2

SML0Z301A-U2

←

←←←

←←←←←←

←←←←←

←←←←←

←←←←←←

←←←←←←

SML-1932A-U2 SML-1302A-U2

DIGITAL VNR

This function cuts down the amount of noise in the original

picture.

HYPER SOUND

You can enjoy sounds with a wider ambience.

←←←

SML-2302A-U2 SML-2302A-S2

←

SML-8133A-U2

SML-8302A-U2

Item AV-32H5BU AV-32H5SK AV-32H5SR AV-32H5SU AV-32H50SU AV-32H57SU

CABINET COLOUR BLACK SILVER ←←←←

RF SYSTEM PAL,SECAM PAL ← PAL,SECAM ←←

BROADCASTING SYSTEM

REMOTE CONTROL UNIT

MAIN PWB

POWER & DEF PWB

CRT SOCKET PWB

SIDE CONTROL PWB

FRONT CONTORL PWB

AV JACK PWB

100HZ PWB

B/G, D/K, I, L I ← B/G, D/K, I, L ←←

RM-C1502B RM-C1502 ←←←←

SML-1301A-U2 SML-1931A-U2 SML-1301A-U2

SML-2301A-S2

SML-3301A-U2

SML-8131A-U2

SML-8301A-U2

SML0J301A-U2

SML0Z301A-U2

←

←←←←←

←←←

←←←

←←←←←

←←←←←

SML-2301A-U2 SML-2301A-S2

←←←

←

SML-8133A-U2

SML-8302A-U2

SML-2301A-U2

←

←

1-6 (No.YA263)

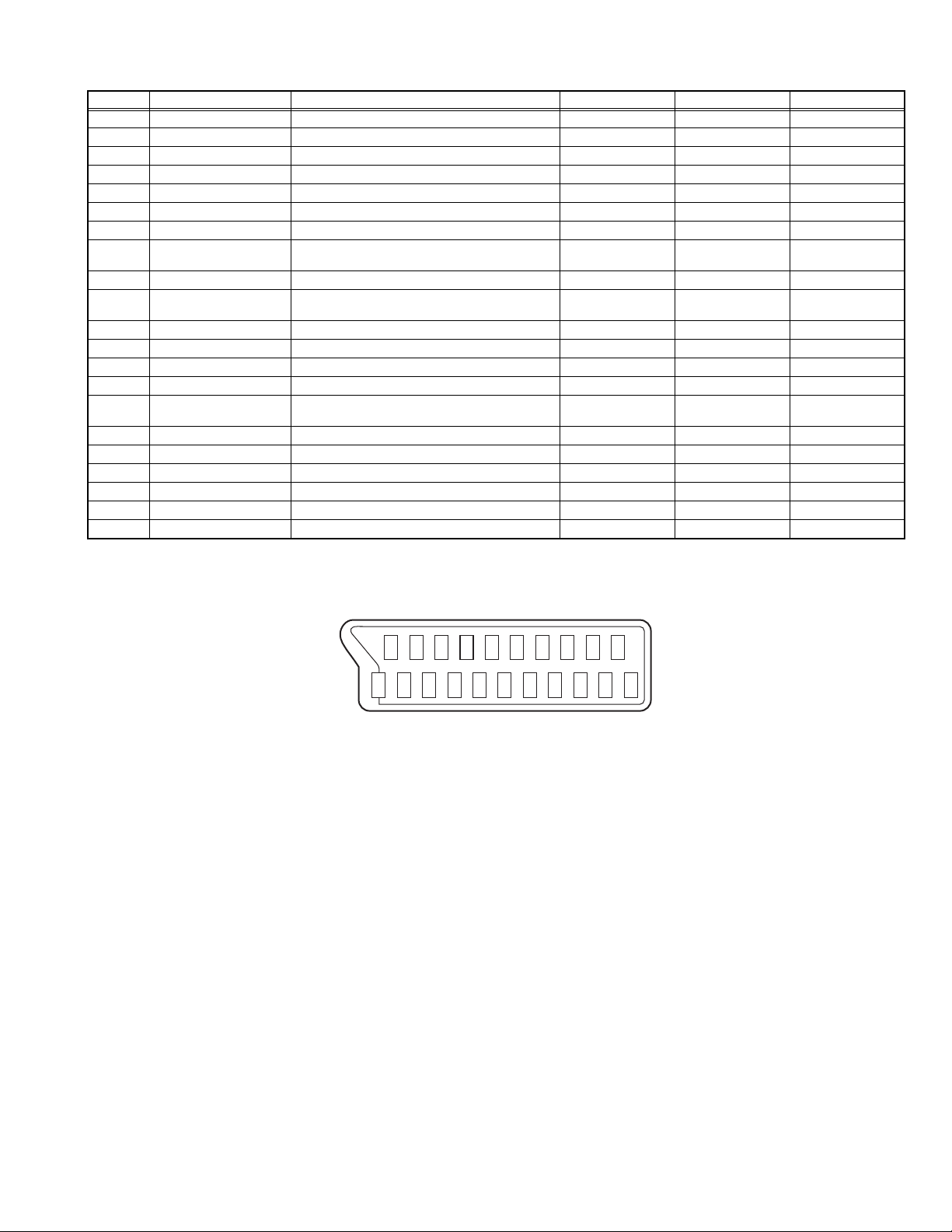

2.3 21-PIN EURO CONNECTOR (SCART) : EXT-1/EXT-2/EXT-3

Pin No. Signal designation Matching value EXT-1 EXT-2 EXT-3

1 AUDIO R output 500mV(rms) (Nominal), Low impedance Used (TV OUT) Used (LINE OUT) Not used

2 AUDIO R input 500mV(rms) (Nominal), High impedance Used (R1) Used (R2) Used (R3)

3 AUDIO L output 500mV(rms) (Nominal), Low impedance Used (TV OUT) Used (LINE OUT) Not used

4AUDIO GND UsedUsedUsed

5 GND (B) Used Used Used

6 AUDIO L input 500mV(rms) (Nominal), High impedance Used (L1) Used (L2) Used (L3)

7 B input 700mV

FUNCTION SW

8

(SLOW SW)

Low : 0V-3V

High : 8V-12V, High impedance

9 GND (G) Used Used Used

10 SCL / T-V LINK Not used

11 G input 700mV

12 SDA Not used Used (SDA2) Not used

13 GND (R) Used Used Used

14 GND (YS) Used Not used Not used

15 R / C input

R : 700mV

C : 300mV

16 Ys input (FAST SW) Low : 0V-0.4V, High : 1V-3V, 75

17 GND (VIDEO output) Used Used Used

18 GND (VIDEO input) Used Used Used

19 VIDEO output 1V

20 VIDEO / Y input 1V

(P-P)

(P-P)

21 COMMON GND Used Used Used

, 75Ω Used Used Not used

(B-W)

Used Used Used

Used

(SCL2 / TV-LINK)

, 75Ω Used Used Not used

(B-W)

, 75Ω

(B-W)

(P-P)

, 75Ω

Used (R) Used (C2/R) Used (C3)

Not used

Ω Used Used Not used

(Negative sync), 75Ω Used (TV OUT) Used (LINE OUT) Not used

(Negative sync), 75Ω Used Used Used

(P-P= Peak to Peak, B-W= Blanking to white peak)

[Pin assignment]

20 18 16 14 12 10 8 6 4 2

21 19 17 15 13 11 9 7 5 3 1

(No.YA263)1-7

2.4 TECHNINAL INFORMATION

2.4.1 MAIN MI-COM (CPU) PIN FUNCTION

Pin No. Pin name I/O Function Pin No. Pin name I/O Function

1 D1 I/O Data bit for SRAM 51 NC -- Not used

2 D4 I/O Data bit for SRAM 52 XTAL2 I System clock (6MHz)

3 D2 I/O Data bit for SRAM 53 XTAL1 O System clock (6MHz)

4 D3 I/O Data bit for SRAM 54 NC -- Not used

5 XROM I External ROM access (Enable: L) 55 VSSA -- GND

6 VDD25 I 2.5V 56 VDDA25 I 2.5V

7 VSS25 -- GND 57 R O Red for OSD / Teletext

8 VDD33 I 3.3V 58 G O Green for OSD / Teletext

9 P0.0 O I2C bus clock for E2PROM 59 B O Blue for OSD / Teletext

10 P0.1 I/O I2C bus data for E2PROM 60 BLANK/COR O Output for blanking and contrast reduction

11 P0.2 O I2C bus clock for generally 61 NC -- Not used

12 P0.3 I/O I2C bus data for generally 62 P1.7 O Not used

13 P0.4 O Not used 63 NC -- Not used

14 P0.5 O Not used 64 WR O External memory write strobe for SRAM

15 P0.6 O Audio muting (Muting: H) 65 RD O External memory read strobe for SRAM

16 P0.7 O Power on/off control (ON: L) 66 NC -- Not used

17 ENE I Not used 67 A19 O Address bit for SRAM

18 STOP I Not used 68 A18 O Address bit for SRAM

19 OCF I Not used 69 A17 O Address bit for SRAM

20 EXTIF I Extended memory interface (Enable: L) 70 A16 O Address bit for SRAM

21 CVBS I Composite video signal input 71 A15 O Address bit for SRAM

22 VDDA25 I 2.5V 72 FL_RGM I Not used

23 VSSA -- GND 73 VDD25 I 2.5V

24 P2.0 I AFC voltage from tuner 74 VSS -- GND

25 P2.1 I Key scan from front control CH+ CH- MENU 75 VDD33 I 3.3V

26 P2.2 I AGC voltage from tuner 76 A14 O Address bit for SRAM

27 P2.3 O Not used 77 A12 O Address bit for SRAM

28 NC -- Not used 78 A13 O Address bit for SRAM

29 HS/SSC I Horizontal sync 79 A7 O Address bit for SRAM

30 VS I Vertical sync 80 FL_RST I Not used

31 P3.0 O Not used 81 A8 O Address bit for SRAM

32 P3.1 O Not used 82 A6 O Address bit for SRAM

33 P3.2 I Remote control 83 A9 O Address bit for SRAM

34 P3.3 I Receive data from TV_LINK 84 A5 O Address bit for SRAM

35 P3.4 O DDP reset (Reset: H) 85 A11 O Address bit for SRAM

36 P3.5 I

37 P3.6 I/O Not used 87 ALE O Enable for address latch

38 P3.7 I Not used 88 PSEN O Enable for program store

39 VSS -- GND 89 A3 O Address bit for SRAM

40 VDD33 I 3.3V 90 A10 O Address bit for SRAM

41 P1.0 O Not used 91 VSS -- GND

42 P1.1 O Not used 92 VDD33 I 3.3V

43 P1.2 O Not used 93 A2 O Address bit for SRAM

44 P1.3 O Output data for TV_LINK 94 A1 O Address bit for SRAM

45 P1.4 O MSP reset (Reset: H) 95 FL_CE I Not used

46 P1.5 O Not used 96 D7 I/O Data bit for SRAM

47 P1.6 O Power indication control (ON: L) 97 A0 O Address bit for SRAM

48 P4.2 O Not used 98 D6 I/O Data bit for SRAM

49 P4.3 O Not used 99 D0 I/O Data bit for SRAM

50 RST I Reset for main CPU 100 D5 I/O Data bit for SRAM

X-ray HB LB EW correction Protection detection (Normal: H)

86 A4 O Address bit for SRAM

1-8 (No.YA263)

SECTION 3

DISASSEMBLY

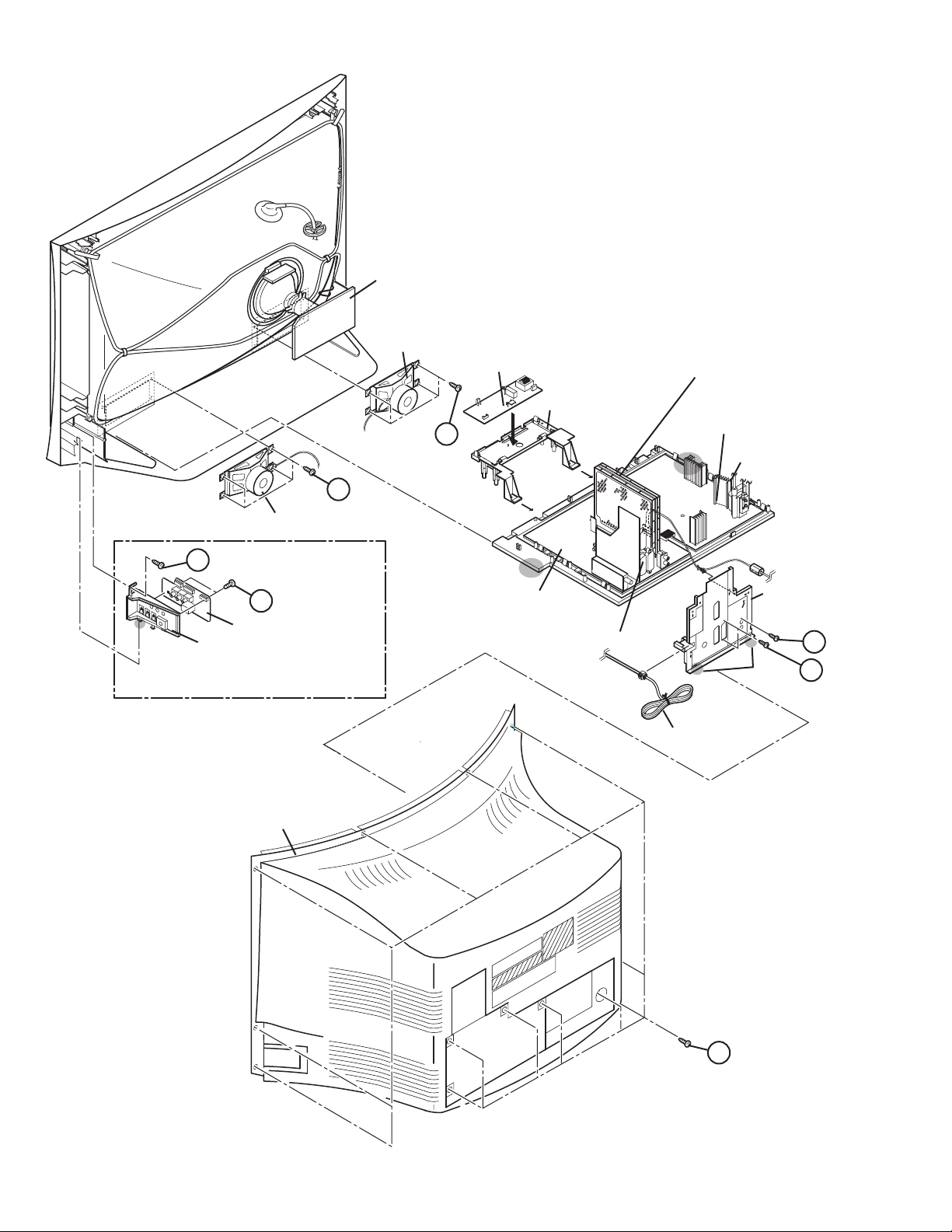

3.1 DISASSEMBLY PROCEDURE [H5 series]

3.1.1 REMOVING THE REAR COVER

(1) Remove the 13 screws [A], then withdraw the REAR

COVER toward you.

3.1.2 REMOVING THE SIDE CONTROL JACK ASS'Y

• Remove the REAR COVER.

(1) Remove the 1 screw [B] and 1 claw, then remove the SIDE

CONTROL JACK ASS’Y.

3.1.3 REMOVING THE SIDE CONTROL PWB

• Remove the REAR COVER.

• Remove the SIDE CONTROL JACK ASS'Y.

(1) Remove the 2 screws [C], then remove the SIDE

CONTROL PWB.

3.1.4 REMOVING THE CHASSIS BASE

• Remove the REAR COVER.

(1) Slightly raise the both sides of the chassis by hand and

remove the 2 claws under the both sides of the CHASSIS

BASE from the front cabinet.

(2) Withdraw the CHASSIS backward.

(If necessary, take off the wire clamp, connectors etc.)

3.1.5 REMOVING THE AV TERMINAL BOARD

• Remove the REAR COVER.

(1) Remove the 3 screws [D].

(2) Remove the 2 claws under the CHASSIS, then remove the

AV TERMINAL BOARD.

3.1.6 REMOVING THE SPEAKER

• Remove the REAR COVER.

• Remove the SIDE CONTROL JACK ASS'Y.

• Remove the CHASSIS BASE.

(1) Remove the 4 screws [E], then remove the SPEAKER.

(2) Follow the same steps when removing the other hand

SPEAKER.

3.1.7 CHECKING THE PW BOARD

• To check the back side of the PW Board.

(1) Pull out the CHASSIS BASE. (Refer to REMOVING THE

CHASSIS BASE).

(2) Erect the CHASSIS BASE vertically with the HVT side

facing up so that you can easily check the back side of the

PW board.

CAUTION:

• When erecting the CHASSIS BASE, be careful so that there

will be no contacting with other PW Board.

• Before turning on power, make sure that the wire connector

is properly connected.

• When conducting a check with power supplied, be sure to

confirm that the CRT EARTH WIRE (BRAIDED ASS'Y) is

connected to the CRT SOCKET PWB.

3.1.8 WIRE CLAMPING AND CABLE TYING

(1) Be sure to clamp the wire.

(2) Never remove the cable tie used for tying the wires

together. Should it be inadvertently removed, be sure to tie

the wires with a new cable tie.

(No.YA263)1-9

SPEAKER

CRT SOCKET PWB

SPEAKER

E

FRONT CONTROL PWB

CONTROL BASE

E

100Hz PWB

POWER & DEF PWB

Claw

CHASSIS BASE

B

C

SIDE CONTROL PWB

Claw

SIDE CONTROL BASE

SIDE CONTROL JACK ASS'Y

REAR COVER

Claw

MAIN PWB

AV JACK PWB

POWER CORD

AV TERMINAL

BOARD

D

Claw

D

1-10 (No.YA263)

A

Fig.1

3.2 DISASSEMBLY PROCEDURE [H50/H57 series]

3.2.1 REMOVING THE REAR COVER

(1) Remove the 13 screws [A], then withdraw the REAR

COVER toward you.

3.2.2 REMOVING THE SIDE CONTROL JACK ASS'Y

• Remove the REAR COVER.

(1) Remove the 1 screw [B], then remove the SIDE

CONTROL JACK ASS’Y.

3.2.3 REMOVING THE SIDE CONTROL PWB

• Remove the REAR COVER.

• Remove the SIDE CONTROL JACK ASS'Y.

(1) Remove the 2 claws, then remove the SIDE CONTROL

PWB.

3.2.4 REMOVING THE CHASSIS BASE

• Remove the REAR COVER.

(1) Slightly raise the both sides of the chassis by hand and

remove the 2 claws under the both sides of the CHASSIS

BASE from the front cabinet.

(2) Withdraw the CHASSIS backward.

(If necessary, take off the wire clamp, connectors etc.)

3.2.5 REMOVING THE AV TERMINAL BOARD

• Remove the REAR COVER.

(1) Remove the 3 screws [C].

(2) Remove the 2 claws under the CHASSIS, then remove the

AV TERMINAL BOARD.

3.2.6 REMOVING THE SPEAKER

• Remove the REAR COVER.

• Remove the SIDE CONTROL JACK ASS'Y.

• Remove the CHASSIS BASE.

(1) Remove the 2 screws [D], then remove the SPEAKER with

SPEAKER ADAPTER.

(2) Remove the 4 screws [E], then remove the SPEAKER from

SPEAKER ADAPTER.

(3) Follow the same steps when removing the other hand

SPEAKER.

3.2.7 CHECKING THE PW BOARD

• To check the back side of the PW Board.

(1) Pull out the CHASSIS BASE. (Refer to REMOVING THE

CHASSIS BASE).

(2) Erect the CHASSIS BASE vertically with the HVT side

facing up so that you can easily check the back side of the

PW board.

CAUTION:

• When erecting the CHASSIS BASE, be careful so that there

will be no contacting with other PW Board.

• Before turning on power, make sure that the wire connector

is properly connected.

• When conducting a check with power supplied, be sure to

confirm that the CRT EARTH WIRE (BRAIDED ASS'Y) is

connected to the CRT SOCKET PWB.

3.2.8 WIRE CLAMPING AND CABLE TYING

(1) Be sure to clamp the wire.

(2) Never remove the cable tie used for tying the wires

together. Should it be inadvertently removed, be sure to tie

the wires with a new cable tie.

(No.YA263)1-11

Loading...

Loading...