JVC AV-28GT10UF, AV-28GT1BJF, AV-28GT1BUF/A /B /C, AV-28GT1SJF, AV-28GT1SUF/A /B /C Service Manual

Page 1

52136200310

SERVICE MANUAL

COLOUR TELEVISION

AV-28GT1BJF,

AV-28GT1BUF

AV-28GT1SJF,

AV-28GT1SUF

AV-28GT10UF

/A, /B, /C,

/A, /B, /C,

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LIMITED

No.52136

2003/10

Page 2

SPECIFICATION

Items Contents

Dimensions ( W × H × D ) 81cm × 51cm × 48.5cm

Mass 36kg

TV RF System B/G, D/K, L/L'

Colour System TV Mode PAL / SECAM

Video Mode PAL / SECAM / NTSC 3.58 / NTSC 4.43

Sound System NICAM / A2 (Germany system)

Teletext System FLOF (Fastext) / TOP (German system)

Tuning System Frequency synthesizer tuning system

Number of CH memory position 100 ch

Receiving

Frequency

Intermediate

Frequency

Colour Sub Carrier Frequency PAL (4.43MHz), SECAM (4.43MHz), NTSC (3.58MHz/4.43MHz)

Power Input AC220V ~ AC240V, 50Hz

Power Consumption 148W(Max), 3W(Standby)

Aerial Input Terminal 75Ω unbalanced, coaxial

Picture Tube Visible size : 66cm (Measured diagonally)

High Voltage 29kV

Speaker Main:5.7cm × 16cm oval type × 2 / Tweeter: 8W,15W × 2

Audio Output 10W + 10W

Input Video 1V(p-p) 75Ω

Output Video 1V(p-p) 75Ω

Input Terminal Rear Side EXT-1 (Video / Audio / RGB)

Output Terminal Rear Side EXT-1 (Video / Audio)

Remote Control Unit VE-30021286 (RM-C1512B), (AA/R06 dry battery × 2)

VHF Low 46.25MHz ~ 168.25MHz

VHF High 175.25MHz ~ 463.25MHz

UHF 471.25MHz ~ 863.25MHz

CATV S01-S41 & S75-S79

VIF 38.9MHz (B/G, D/K, L) / 33.9MHz (L')

SIF 33.4MHz (5.5MHz:B/G) / 32.9MHz (6.0MHz:D/K) / 32.4MHz (6.5MHz:L) / 40.4MHz (6.5MHz:L')

S-Video Y : 1V(p-p) positive

C : 0.286V(p-p)

Audio (L/R) 500mV(rms) (-4dBs), High impedance (RCA pin jack × 2)

Audio (L/R) 500mV(rms), Low Impedance

EXT-2 (Video / Audio / RGB / S-VHS)

EXT-3 (Video / Audio)

Right Side EXT-4 (Video / Audio)

EXT-2 (Video / Audio)

EXT-3 (Video / Audio)

Right Side Headphone Jack (Stereo mini jack O3.5mm × 1)

: AV-28GT1BJF, AV-28GT1BUF

VE-30021287 (RM-C1512S), (AA/R06 dry battery × 2)

: AV-28GH1SJF, AV-28GH1SJF, AV-28GH10UF

Design & specifications are subject to change without notice.

1-2 (No.52136)

Page 3

SECTION 1

PRECAUTION

1.1 SAFETY PRECAUTIONS

(1) The design of this product contains special hardware,

many circuits and components specially for safety

purposes. For continued protection, no changes should be

made to the original design unless authorized in writing by

the manufacturer. Replacement parts must be identical to

those used in the original circuits. Service should be

performed by qualified personnel only.

(2) Alterations of the design or circuitry of the products should

not be made. Any design alterations or additions will void

the manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or

property damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These

characteristics are often not evident from visual inspection

nor can the protection afforded by them necessarily be

obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in

the parts list of Service manual. Electrical components

having such features are identified by shading on the

schematics and by ( ) on the parts list in Service

manual. The use of a substitute replacement which does

not have the same safety characteristics as the

recommended replacement part shown in the parts list of

Service manual may cause shock, fire, or other hazards.

(4) Don't short between the LIVE side ground and

ISOLATED (NEUTRAL) side ground or EARTH side

ground when repairing.

Some model's power circuit is partly different in the GND.

The difference of the GND is shown by the LIVE : ( ) side

GND, the ISOLATED (NEUTRAL) : ( ) side GND and

EARTH : ( ) side GND.

Don't short between the LIVE side GND and ISOLATED

(NEUTRAL) side GND or EARTH side GND and never

measure the LIVE side GND and ISOLATED (NEUTRAL)

side GND or EARTH side GND at the same time with a

measuring apparatus (oscilloscope etc.). If above note will

not be kept, a fuse or any parts will be broken.

(5) If any repair has been made to the chassis, it is

recommended that the B1 setting should be checked or

adjusted (See B1 POWER SUPPLY check).

(6) The high voltage appli ed to the picture tube must confo rm

with that specified in Service manual. Excessive high

voltage can cause an increase in X-Ray emission, arcing

and possible component damage, therefore operation

under excessive high voltage conditions should be kept to

a minimum, or should be prevented. If severe arcing

occurs, remove the AC power immediately and determine

the cause by visual inspection (incorrect installation,

cracked or melted high voltage harness, poor soldering,

etc.). To maintain the proper minimum level of soft X-Ray

emission, components in the high voltage circuitry

including the picture tube must be the exact replacements

or alternatives approved by the manufacturer of the

complete product.

(7) Do not check high voltage by d rawing an arc. Use a high

voltage meter or a high voltage probe with a VTVM.

Discharge the picture tube before attempting meter

connection, by connecting a clip lead to the gr ound frame

and connecting the other end of the lead through a 10kΩ

2W resistor to the anode button.

(8) When service is required, obse rve the original lead dress.

Extra precaution should be given to assure correct lead

dress in the high voltage circuit area. Where a short circuit

has occurred, those components that indicate evidence of

overheating should be replaced. Always use the

manufacturer's replacement components.

(9) Isolation Check (Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an

isolation check on the exposed metal parts of the cabinet

(antenna terminals, video/audio input and output terminals,

Control knobs, metal cabinet, screw heads, earphone jack,

control shafts, etc.) to be sure the product is safe to operate

without danger of electrical shock.

a) Dielectric Strength Test

The isolation between the AC primary circuit and all metal

parts exposed to the user, particularly any exposed metal

part having a return path to the chassis should withstand a

voltage of 3000V AC (r.m.s.) for a period of one second. (. .

. . Withstand a voltage of 1100V AC (r.m.s.) to an appliance

rated up to 120V, and 3000V AC (r.m.s.) to an appliance

rated 200V or more, for a period of one second.)

This method of test requires a test equipment not generally

found in the service trade.

b) Leakage Current Chec k

Plug the AC line cord directly into the AC outlet (do not use

a line isolation transformer during this check.). Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal part of the cabinet, particularly

any exposed metal part having a return path to the chassis,

to a known good earth ground (water pipe, etc.). Any

leakage current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not

use a line isolation transformer during this check.). Use

an AC voltmeter having 1000Ω per volt or more

sensitivity in the following manner. Connect a 1500Ω

10W resistor paralleled by a 0.15µF AC-type capacitor

between an exposed metal part and a known good earth

ground (water pipe, etc.). Measure the AC voltage

across the resistor with the AC voltmeter. Move the

resistor connection to each exposed metal part,

particularly any exposed metal part having a return path

to the chassis, and measure the AC voltage ac ross the

resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Any voltage measured must

not exceed 0.75V AC (r.m.s.). This corresponds to

0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000 /V,

OR MORE SENSITIVITY)

0.15 F AC-TYPE

PLACE THIS PROBE

1500 10W

GOOD EARTH GROUND

ON EACH EXPOSED

METAL PART

(No.52136)1-3

Page 4

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

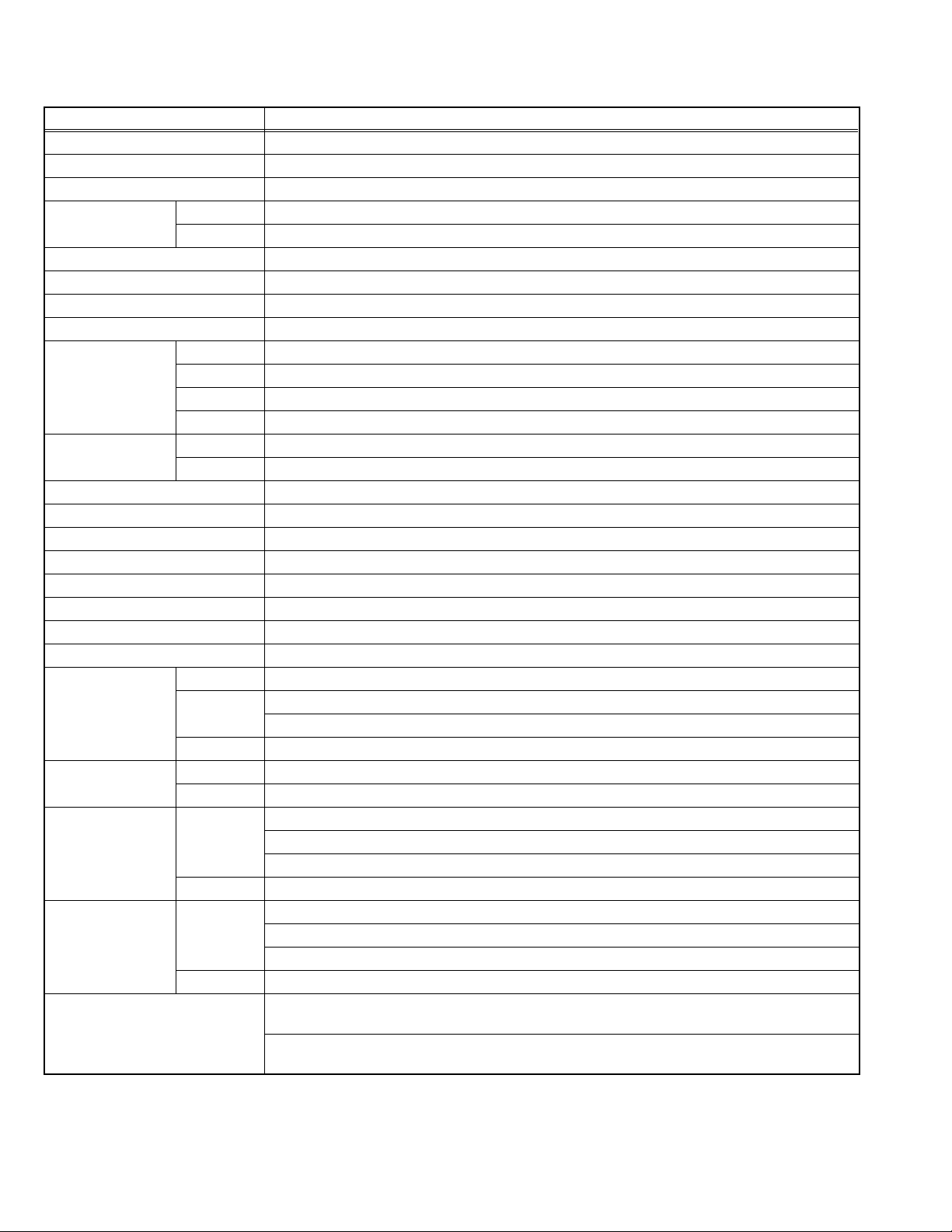

2.1 21-pin Euro connector (SCART) : EXT-1 / EXT-2 / EXT-3 Pin No. Signal Designation Matching Value EXT-1 EXT-2 EXT-3

1 AUDIO R output 500mV(rms) (Nominal),

Low impedance

2 AUDIO R input 500mV(rms) (Nominal),

High impedance

3 AUDIO L output 500mV(rms) (Nominal),

Low impedance

4 AUDIO GND --- Used Used Used

5 GND (B) --- Used Used Used

6 AUDIO L input 500mV(rms) (Nominal),

High impedance

7 B input 700mV(B-W), 75 Ω Used Used Not used

8 FUNCTION SW

(SLOW SW)

9 GND (G) --- Used Used Used

10 SCL / T-V LINK --- Not used Used

11 G input 700mV(B-W), 75 Ω Used Used Not used

12 SDA3 --- Not used Not used Not used

13 GND (R) --- Used Used Used

14 GND (YS) --- Used Used Used

15 R / C input R : 700mV(B-W), 75 Ω

16 Ys input

(FAST SW)

17 GND (VIDEO output) --- Used Used Used

18 GND (VIDEO input) --- Used Used Used

19 VIDEO output 1V

20 VIDEO / Y input 1V

21 COMMON GND --- Used Used Used

Low : 0V-3V, High : 8V-12V,

High impedance

C : 300mV

Low : 0V-0.4V, 75 Ω

High : 1V-3V, 75 Ω

(Negative sync),

(P-P)

75 Ω

(Negative sync),

(P-P)

75 Ω

(P-P)

, 75 Ω

Used Used Used

Used (R1) Used (R2) Used (R3)

Used Used Used

Used (L1) Used (L 2) Used (L3)

Used Used Used

Not used

(SCL / TV-LINK)

Used (R) Used (C2/R) Not used

Used Used Not used

Used Used Used

Used Used Used

(P-P= Peak to Peak, B-W= Blanking to white peak)

[Pin assignment]

21 19 17 15 13 11 9 7 5 3 1

1-4 (No.52136)

20 18 16 14 12 10 8 6 4 2

Page 5

2.2 FEATURES

• It is a remote controlled color television.

• 100 programs from VHF, UHF bands or cable channels can be

preset.

• It can tune cable channels.

• Controlling the TV is very easy by its menu driven system.

• It has two Euroconnector sockets for external device (such as

video recorder, video games, audio set, etc.)

• Side AV Input (EXT-4) available.

• Stereo sound systems (German + Nicam) are available.

• Full function Teletext (Fastext, Toptext).

• It is possible to connect headphone.

• Direct channel access.

• APS (Automatic Programming System).

• All programs can be named.

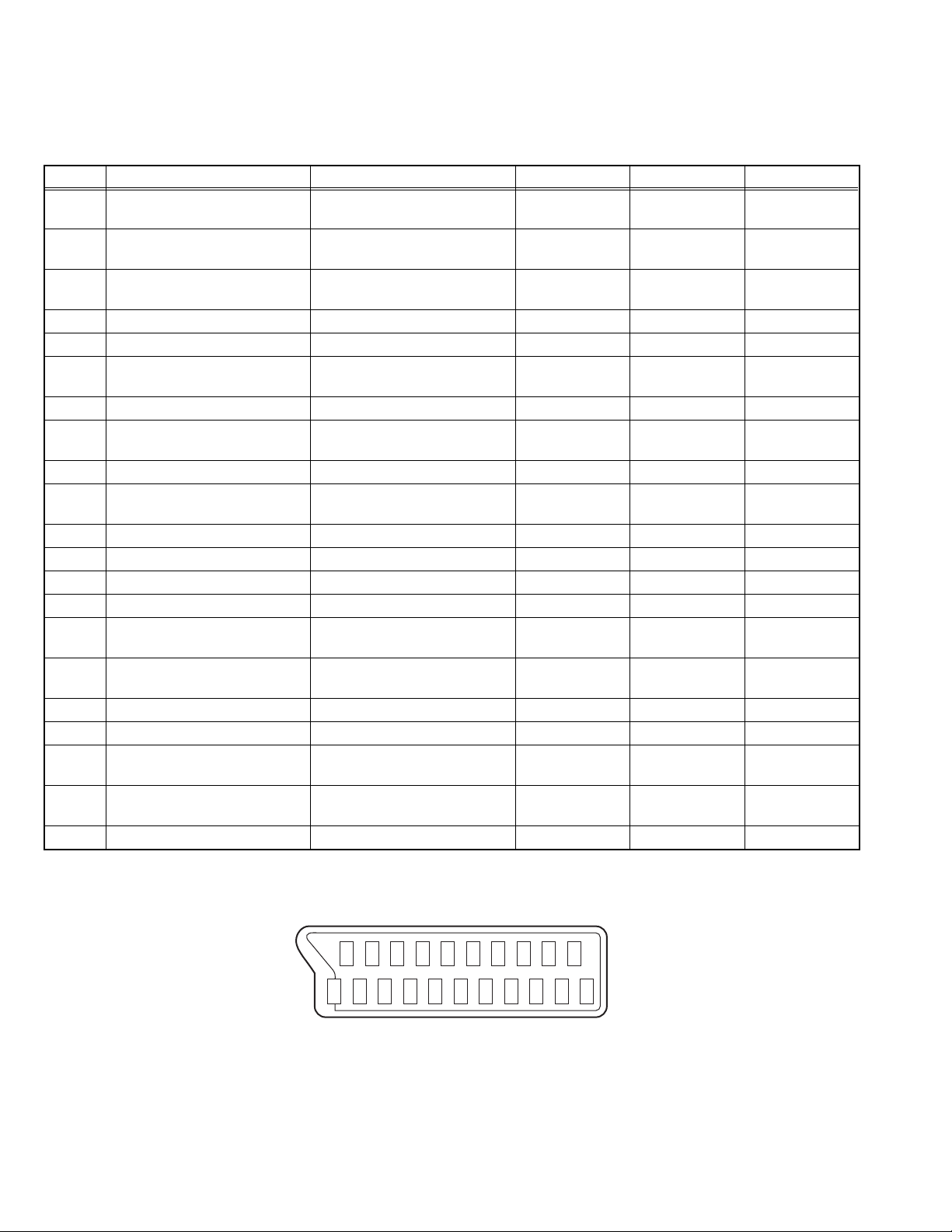

2.3 MAIN DIFFERENCE LIST

• Forward or backward automatic tuning.

• Sleep timer.

• Child Lock.

• Blue Background

• Panoramic mode.

• Comb FIlter

• CTI (Colour Transient Improvement)

•T-V Link

• Automatic sound mute when no transmission.

• 5 minutes after the broadcasting (close down), the TV switches

itself automatically to stand-by mode.

• WSS (Wide Screen Signaling)

• NTSC Playback.

AV-28GT1BJF

Part Name

MODEL COLOUR BLACK MODEL SILVER MODEL

FRONT CABINET VE-20121496 VE-20120047

BACK COVER VE-20121498 VE-20111866

BACK DOOR VE-20108124 VE-20120043

FUNCTION BUTTON VE-20091798 VE-20096498

POWER BUTTON VE-20111864 VE-20120046

JVC LOGO VE-40013592 VE-40013593

REMOTE CONTROL UNIT VE-30021286 (RM-C1512B) VE-30021287 (RM-C1512S)

2.4 DIFFERENCE LIST BY ELECTRONICS

Part Name

MAIN PWB VE-20120603 VE-20120602 VE-20127797 VE-20127793

IC500 (MI-COM) VE-20139901 VE-20139901 VE-20137151 VE-20139902

IC502 (MEMORY) VE-20120620 VE-20120611 VE-20134093 VE-20126316

AV-28GT1BUF

AV-28GT1BJF

AV-28KT1SJF

AV-28GT1BUF/A

AV-28GT1SUF/A

AV-28GT1SJF

AV-28GT1SUF

AV-28GT10UF

AV-28GT1BUF/B

AV-28GT1SUF/B

AV-28GT10UF

AV-28GT1BUF/C

AV-28GT1SUF/C

2.5 DIFFERENCE LIST BY OSD LANGUAGE

Part Name

OSD LANGUAGES ENG, GER, FRE, ITA

AV-28GT1BUF/A

AV-28GT1SUF/A

SPA, DUT, POR, TUR

AV-28GT1BUF/B

AV-28GT1SUF/B

ENG, GER, FRE, SWE

NOR, DAN, FIN, GRE

AV-28GT1BUF/C

AV-28GT1SUF/C

ENG, GER, CZE, POL

HUN, BUL, ROM, CRO

(No.52136)1-5

Page 6

SECTION 3

DISASSEMBLY

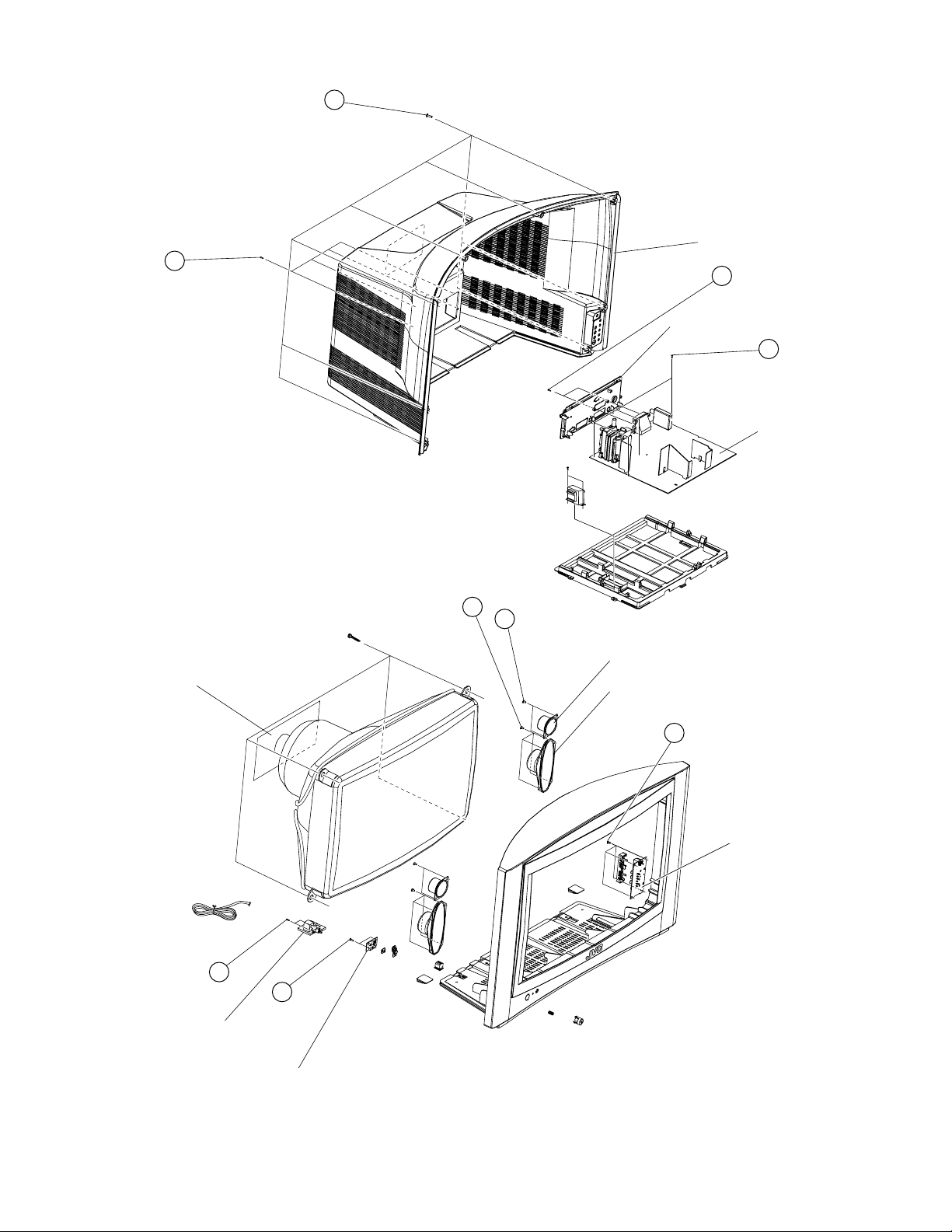

3.1 DISASSEMBLY PROCEDULE

3.1.1 REMOVING THE REAR COVER

(1) Unplug the power cord.

(2) Remove the 8 screws [A] as shown in the Fig. 1.

(3) Remove the 4 screws [B].

(4) Withdraw the REAR COVER toward you.

3.1.2 REMOVING THE BACK DOOR

• Remove the REAR COVER

(1) Remove the 2 screws [C].

(2) Withdraw the BACK DOOR toward you.

3.1.3 REMOVING THE SPEAKER and TWEETER

• Remove the REAR COVER.

(1) Remove the 4 screws [H], and remove the SPEAKER.

(2) Remove the other hand SPEAKER in the same steps.

(3) Remove the 2 screws [I], and remove the TWEETER.

(4) Remove the other hand TWEETER in the same steps.

3.1.4 REMOVING THE MAIN PWB

• Remove the REAR COVER.

• Remove the BACK DOOR.

(1) Remove the 4 screws [D].

(2) Slightly raise the both sides of the MAIN PWB by hand and

withdraw the MAIN PWB backward.

CAUTION :

If necessary, take off the wire clamp, connectors etc.

Be careful enough when developing a MAIN PWB.

3.1.8 CHECKING THE PW BOARD

• To check the back side of the PW Board.

(1) Pull out the PW Board . (Refer to REMOVING THE MAIN

PWB).

(2) Erect the PW Board vertically so that you can easily check

the back side of the PW Board.

3.1.9 CAUTION

• When erecting the PW Board, be careful so that there will be

no contacting with other PW Board.

• Before turning on power, make sure that the wire connector is

properly connected.

• When conducting a check with power supplied, be sure to

confirm that the CRT EARTH WIRE (BRAIDED ASS'Y) is

connected to the CRT SOCKET PW board.

3.1.10 WIRE CLAMPING AND CABLE TYING

(1) Be sure to clamp the wire.

(2) Never remove the cable tie used for tying the wires

together.

Should it be inadvertently removed, be sure to tie the wires

with a new cable tie.

3.1.5 REMOVING THE SIDE CONTROL PWB

• Remove the REAR COVER.

(1) Remove the 4 screws [E].

(2) Remove the SIDE PWB.

3.1.6 REMOVING THE POWER SWITCH PWB

• Remove the REAR COVER.

(1) Remove the 2 screws [F], and remove the POWER

SWITCH PWB.

3.1.7 REMOVING THE LED PWB

• Remove the REAR COVER.

• Remove the POWER SWITCH PWB.

(1) Remove the 2 screws [G], and remove the LED PWB.

1-6 (No.52136)

Page 7

x8

A

x4

B

CRT PWB

H

x4

REAR COVER

x2

C

BACK DOOR

D

x4

MAIN PWB

I

x2

TWEETER

SPEAKER

F

x2

G

x2

POWER SWITCH PWB

LED PWB

Fig.1

E

x4

SIDE CONTROL

PWB

(No.52136)1-7

Page 8

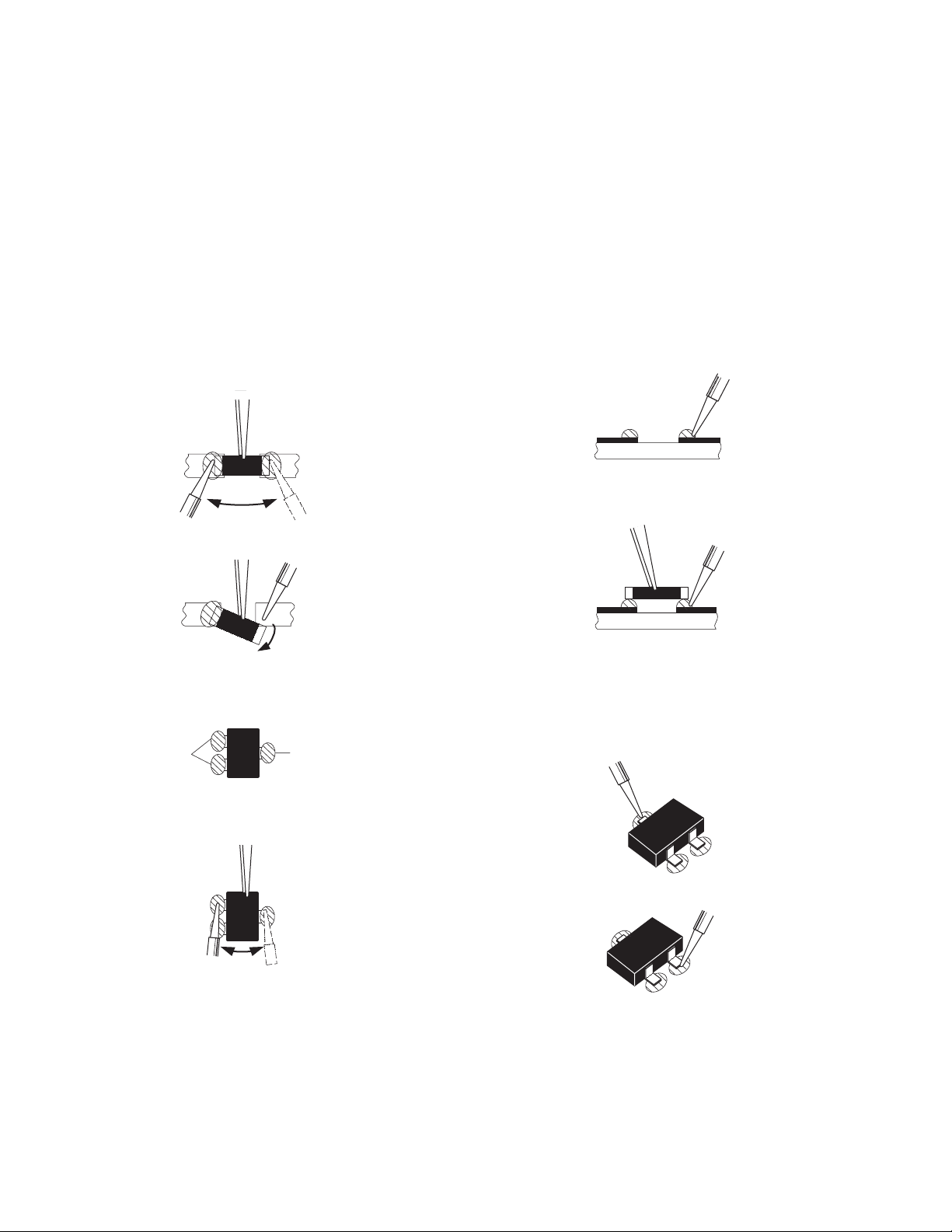

3.2 REPLACEMENT OF CHIP COMPONENT

3.2.1 CAUTIONS

(1) Avoid heating for more than 3 seconds.

(2) Do not rub the electrodes and the resist parts of the pattern.

(3) When removing a chip part, melt the solder adequately.

(4) Do not reuse a chip part after removing it.

3.2.2 SOLDERING IRON

(1) Use a high insulation soldering iron with a thin pointed end of it.

(2) A 30w soldering iron is recommended for ea sily removing parts.

3.2.3 REPLACEMENT STEPS

1. How to remove Chip parts

2. How to install Chip parts

[Resistors, capacitors, etc.]

(1) As shown in the figure, push the part with tweezers and

alternately melt the solder at each end.

(2) Shift with the tweezers and remove the chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply extra solder to each lead.

SOLDER

SOLDER

[Resistors, capacitors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder. Then heat and melt the solder at both ends of the

chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder.

(3) First solder lead A as indicated in the figure.

(2) As shown in the figure, push the part with tweezers and

alternately melt the solder at each lead. Shift and remove

the chip part.

NOTE :

After removing the part, remove remaining solder from the

pattern.

1-8 (No.52136)

A

B

C

(4) Then solder leads B and C.

A

B

C

Page 9

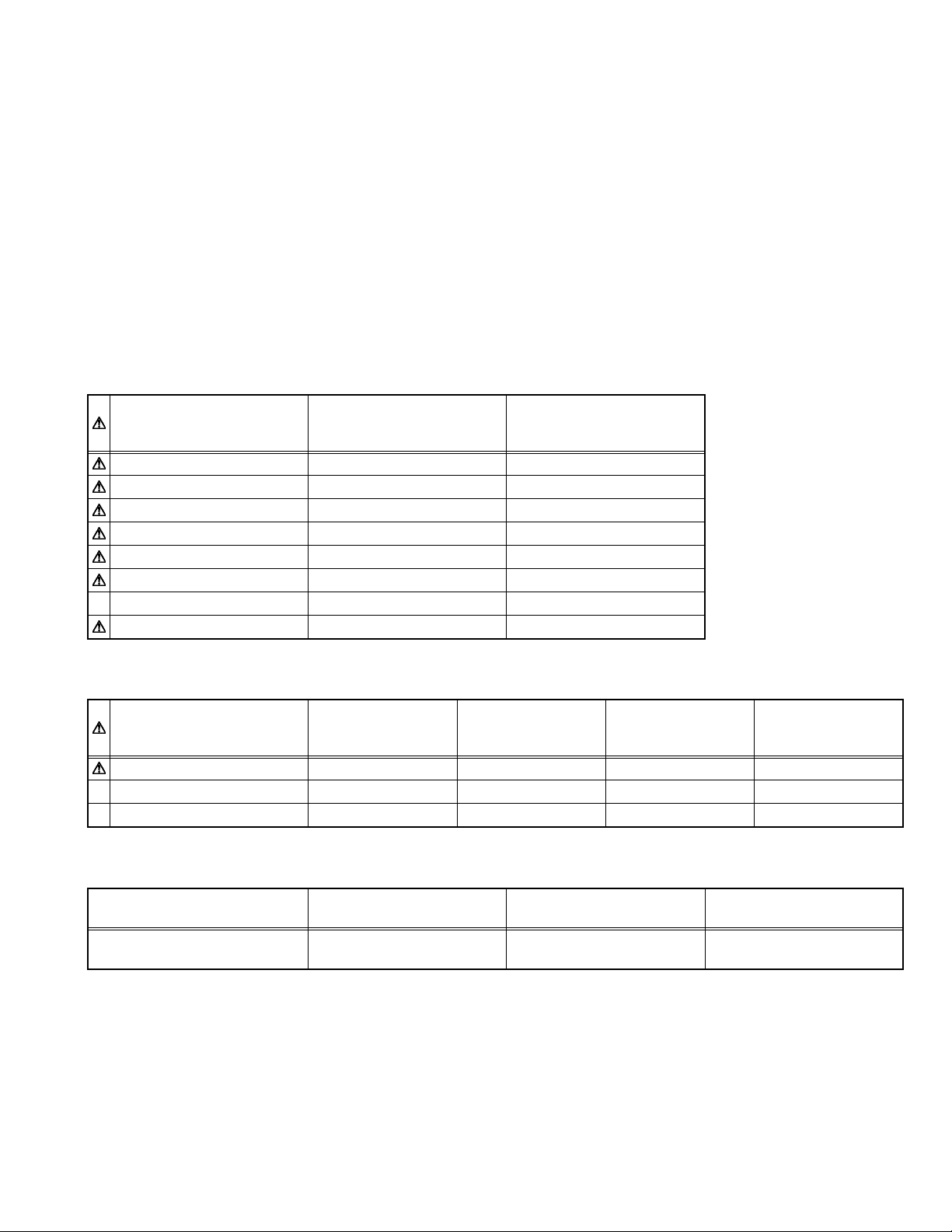

3.3 SETTING OF THE LAST MEMORY FOR SHIPMENT

3.3.1 USER SETTING VALUES

Setting Item Setting Value Setting Item Setting Value

SOUND MENU FEATURE MENU

BALANCE CENTER SLEEP TIMER OFF

BASS CENTER CHILD LOCK OFF

TREBLE CENTER LANGUAGE ENGLISH

HYPER SOUND OFF EXT-2 OUTPUT TV

PICTURE MENU BLUE BACKGROUND ON

BRIGHTNESS These adjust are automatically

CONTRAST PROGRAMME Refer to instruction book

COLOUR BAND

SHARPNESS CHANNEL

HUE (only NTSC) STANDARD

PICTURE MODE USER COLOUR SYSTEM

COLOUR TEMP NORMAL DECODER (EXT-2)

ZOOM AUTO FINE TUNING

restored when A.P.S. bit in Service

menu is set.

The procedure for setting APS

bit is described bellow.

INSTALL. MENU

SEARCH

STORE

3.3.2 SETTING A.P.S. (AUTO STORE)

(1) Press [MENU] key on the remote control unit to display the main menu.

(2) Press [/] keys to select PROGRAM item, them [/] keys to display the PROGRAM menu.

(3) Press the [BLUE] key to enter the AUTOSTORE mode.

(4) Press [/] keys to choose the COUNTRY, then press [/] keys the choose country you are nou located.

(5) Press [/] keys to choose the CONTINUE, then press [] key to start A.P.S. The following message appears.

NOTE:

To cancel the A.P.S., press the [STANDARD] key.

(6) After A.P.S. is finalized, the PROGRAM menu appears again.

(7) Press [STANDARD] key to exit main menu.

(No.52136)1-9

Page 10

SECTION 4

ADJUSTMENT

4.1 ADJUSTMENT PREPARATION

(1) You can make the necessary adjustments for this unit with

either the Remote Control Unit or with the adjustment tools

and parts as given below.

(2) Adjustment with the Remo te Control Unit is made on the

basis of the initial setting values, however, the new setting

values which set the screen to its optimum condition may

differ from the initial settings.

(3) Make sure that AC power is turned on correctly.

(4) Turn on the power for set and test equipment before use,

and start the adjustment procedures after waiting at least

30 minutes.

(5) Unless otherwise specified, prepare the most suitable

reception or input signal for adjustment.

(6) Never touch any adjustment parts which a re not specified

in the list for this adjustment - variable resistors,

transformers, condensers, etc.

(7) Presetting before adjustment.

Unless otherwise specified in the adjustment instructions,

preset the following functions wi t h th e re mote control unit:

4.4 ADJUSTMENT LOCATIONS

Setting Item Setting value

BRIGHTNESS CENTER

CONTRAST

COLOUR

SHARPNESS

COLOUR TEMP

ZOOM AUTO

4.2 MEASURING EQUIPMENT

(1) DC voltmeter (or digital voltmeter)

(2) Signal generator (Pattern generator)

[PAL / SECAM / NTSC]

(3) Remote control unit

4.3 ADJUSTMENT ITEM

• SCREEN ADJUSTMENT

• DEFLECTION CIRCUIT ADJUSTMENT

• WHITE BALANCE ADJUSTMENT

TOP

HEADPHONE

MENU

P/Ch

VIDEO

SIDE CONTROL PWB

TUNER

TU200

IC500 (MI-COM)

IC502 (MEMORY)

FRONT

MAIN PWB

FBT

UPPER : FOCUS

LOWER : SCREEN

1-10 (No.52136)

Page 11

4.5 BASIC OPERATION OF SERVICE MENU

4.5.1 HOW TO ENTER THE SERVICE MENU

(1) Press the [INFORMATION] key and [MUTING] key

simultaneously in the main menu, and the SERVICE

MENU screen (Fig.1) will be displayed.

SERVICE MENU

SERVICE

ADJUST...

OPTIONS...

AK45JA***

AK45JA***

REMOTE CONTROL UNIT key NAME

MUTING key

Select for adjustment Do not adjust

Fig.1

(2) While the SERVICE MENU screen is displayed, pr ess the

[/] and [/] key and select the "ADJUST...", then

ADJUST MENU sucreen (Fig.2) will be displayed.

ADJUST MENU

ADJUST...

000

***

001

***

002

***

003

***

004

***

005

***

006

***

007

***

008

***

009

***

SETTING ITEM No. SETTING VALUE

Fig.2

4.5.2 SELECTION OF ADJUSTMENT ITEMS

(1) Enter the SERVICE MENU and select ADJUST.

(2) Press the [/] key and select the ADJUSTMENT ITEM.

(3) Press the [/] key and set the SETTING VALUE.

(4) Changed values are stored automatically.

MENU key

UP / DOWN

[ ] key

LEFT / RIGHT

[ ] key

INFORMATION key

4.5.3 HOW TO EXIT SERVICE MODE

(1) Press the [MENU] key.

(No.52136)1-11

Page 12

4.5.4 SERVICE MENU SCREEN

SERVICE MENU

SERVICE

ADJUST...

OPTIONS...

AK45JA***

AK45JA***

ADJUST MENU

ADJUST...

000

***

001

***

002

***

003

***

004

***

005

***

006

***

007

***

008

***

009

***

SETTING ITEM No.

000~143

SETTING VALUE

Do Not Adjust

OPTIONS MENU

OPTIONS..

000

********

**

001

********

**

002

********

**

003

********

**

004

********

**

005

********

**

006

********

**

007

********

**

008

********

**

009

********

**

SETTING ITEM No.

000~063

NOTE:

Do not adjust the OPTIONS MENU. If you change the setting value, the set will not function correctly.

SETTING VALUE

1-12 (No.52136)

Page 13

ADJUSTMENT ITEM

adjustment No. adjustment part description

0 White Point RED Not used

1 White Point GREEN Not used

2 Whit Point BLUE Not used

3 AGC (Automatic Gain Control)

4 IF-PLL Negative Not used

5 IF-PLL Positive Not used

6 Y-Delay

7 Y-Delay SECAM

8 Y-Delay NTSC

9 Y-Delay OTHER Not used

10 Vertical Position Offset Fixed

11 Vertical Amplitude Offset Fixed

12 Horizontal Position Offset Fixed

13 Horizontal Amplitude Offset Fixed

14 Vertical Blank Start (It will be used only at 4:3 tube for 16:9 mode adjustment)

15 Vertical Blank Stop (It will be used only at 4:3 tube for 16:9 mode adjustment)

16 Angle

17 Bow

18 4:3 Horz. Blank Start Do not adjust

19 4:3 Horz. Blank Stop Do not adjust

20 EHTV compensation

21 EHTTM compensation

22 EHTEW compensation

23 WDR Video processor

24 WDG

25 WDB

26 CR

27 CG

28 CB

29 COR coring level

30 REGULAR VERT_POS (Vertical Position)

31 REGULAR VERT_AMPL (Vertical Amplitude)

32 REGULAR VERT_SCOR (Vertical S Correction)

33 REGULAR VERT_SSYM (Vertical S Symmetry)

34 REGULAR TRAPEZE

35 REGULAR CUSHION

36 REGULAR HOR_COR_SYM(Horizontal Corner Symmetry)

37 REGULAR HOR_CORNER (Horizontal Corner)

38 REGULAR HORZ_POS (Horizontal Position)

39 REGULAR HORZ_AMPL (Horizontal Amplitude)

40 PANORAMIC VERT_POS

41 PANORAMIC VERT_AMPL

42 PANORAMIC VERT_SCOR

43 PANORAMIC VERT_SSYM

44 PANORAMIC TRAPEZE

45 PANORAMIC CUSHION

46 PANORAMIC HOR_COR_SYM

47 PANORAMIC HOR_CORNER

48 PANORAMIC HORZ_POS

adjust itself.

(No.52136)1-13

Page 14

adjustment No. adjustment part description

49 PANORAMIC HORZ_AMPL

50 14:9 ZOOM VERT_POS

51 14:9 ZOOM VERT_AMPL

52 14:9 ZOOM VERT_SCOR

53 14:9 ZOOM VERT_SSYM

54 14:9 ZOOM TRAPEZE

55 14:9 ZOOM CUSHION

56 14:9 ZOOM HOR_COR_SYM

57 14:9 ZOOM HOR_CORNER

58 14:9 ZOOM HORZ_POS

59 14:9 ZOOM HORZ_AMPL

60 16:9 ZOOM VERT_POS

61 16:9 ZOOM VERT_AMPL

62 16:9 ZOOM VERT_SCOR

63 16:9 ZOOM VERT_SSYM

64 16:9 ZOOM TRAPEZE

65 16:9 ZOOM CUSHION

66 16:9 ZOOM HOR_COR_SYM

67 16:9 ZOOM HOR_CORNER

68 16:9 ZOOM HORZ_POS

69 16:9 ZOOM HORZ_AMPL

70 16:9 ZOOM SUBTITLE VERT_POS

71 16:9 ZOOM SUBTITLE VERT_AMPL

72 16:9 ZOOM SUBTITLE VERT_SCOR

73 16:9 ZOOM SUBTITLE VERT_SSYM

74 16:9 ZOOM SUBTITLE TRAPEZE

75 16:9 ZOOM SUBTITLE CUSHION

76 16:9 ZOOM SUBTITLE HOR_COR_SYM

77 16:9 ZOOM SUBTITLE HOR_CORNER

78 16:9 ZOOM SUBTITLE HORZ_POS

79 16:9 ZOOM SUBTITLE HORZ_AMPL

80 OSD Position

81 BCLTHR Beam current threshold

82 BCLG Beam current loop gain

83 ROTATION (TILT)

84 LSLSA Luma soft limiter Fixed

85 LSLSB Luma soft limiter Fixed

86 LSL2 Luma soft limiter Fixed

87 LSLTA Luma soft limiter Fixed

88 LSLTB Luma soft limiter Fixed

89 REFERENCE WDR RED (NORMAL)

90 REFERENCE WDR GREEN (NORMAL)

91 REFERENCE WDR BLUE (NORMAL)

92 REFERENCE CUTOFF RED Fixed

93 REFERENCE CUTOFF GREEN Fixed

94 REFERENCE CUTOFF BLUE Fixed

95 IBRM

96 WDRV

97 ACC_SAT (COLOUR OFFSET)

98 G2_CUTOFF_REFERENCE Fixed

1-14 (No.52136)

Page 15

adjustment No. adjustment part description

99 G2_WDR_REFERENCE Fixed

100 POFS2 (RGB HORIZANTAL SHIFT)

101 REFERENCE WDR RED COOL

102 REFERENCE WDR GREEN COOL

103 REFERENCE WDR BLUE COOL

104 REFERENCE WDR RED WARM

105 REFERENCE WDR GREEN WARM

106 REFERENCE WDR BLUE WARM

107 STANDARD MODE BRIGHTNESS

108 STANDARD MODE COLOUR

109 STANDARD MODE CONTRAST

110 FULL VERT_POS (16:9 MODE)

111 FULL VERT_AMPL

112 FULL VERT_SCOR

113 FULL VERT_SSYM

114 FULL TRAPEZE

115 FULL CUSHION

116 FULL HOR_COR_SYM

117 FULL HOR_CORNER

118 FULL HORZ_POS

119 FULL HORZ_AMPL

120 BRIGHT MODE BRIGHTNESS

121 BRIGHT MODE COLOUR

122 BRIGHT MODE CONTRAST

123 SOFT MODE BRIGHTNESS

124 SOFT MODE COLOUR

125 SOFT MODE CONTRAST

126 PERSONAL MODE FACTORY SETTING BRIGHTNESS Fixed

127 PERSONAL MODE FACTORY SETTING COLOUR Fixed

128 PERSONAL MODE FACTORY SETTING CONTRAST Fixed

129 SCINC FOR PANORAMIC MODE

130 SCINC1 FOR PANORAMIC MODE

131 VOLUME AFTER APS

132 VERTICAL SCROLL

133 14:9 HORIZONTAL START

134 14:9 HORIZONTAL STOP

135 4:3 RGB HORIZONTAL AMPLITUDE

136 4:3 RGB CUSHION

137 14:9 RGB HORIZONTAL AMPLITUDE

138 14:9 RGB CUSHION

139 PANAROMIC RGB HORIZONTAL AMPLITUDE

140 16:9 RGB HORIZONTAL AMPLITUDE

141 16:9 SUBTITLE RGB HORIZONTAL AMPLITUDE

142 FULL RGB HORIZONTAL AMPLITUDE

143 TELETEXT HORIZONTAL POSITION

(No.52136)1-15

Page 16

4.6 ADJUSTMENT PROCEDURE

4.6.1 FOCUS / SCREEN ADJUSTMENT

Item

FOCUS

adjustment

Measuring

instrument

Signal

generator

Remote

control unit

Test point Adjustment part Description

FOCUS VR

[On the FBT]

(1) Receive a PAL cross-hatch signal.

(2) Adjust FOCUS VR on the FBT as thin as possible.

FOCUS VR

SCREEN VR

FBT

SCREEN

adjustment

4.6.2 AGC ADJUSTMENT

Item

AGC

adjustment

Remote

control unit

Measuring

instrument

Signal

generator

Remote

control unit

Volt meter

002

SCREEN VR

[On the FBT]

Test point Adjustment part Description

003 (1) Receive a PAL BG signal at 60dBµV RF signal level.

(1) Enter the OPTIONS MENU.

(2) Select option No.002 and change bit 6 from 0 to 1

disabling vertical scan. Then horizontal line appears.

(3) Adjust horizontal line as thin as possible via screen

adjust pot.

(4) Press number 0 key to leave servi ce menu.

(2) Enter the SERVICE MENU.

(3) Select ADJUST MENU.

(4) Select 003.

(5) Adjust 003 by pressing till voltage at pin 1 of TUNER

is equal to 3.0V.

1-16 (No.52136)

Page 17

4.6.3 DEFLECTION CIRCUIT ADJUSTMENT

Item

VERTICAL

POSITION

Measuring

instrument

Signal

generator

Test point Adjustment part Description

adjustment

Remote

control unit

030 (REGULAR)

040 (PANORAMIC)

050 (14:9 ZOOM)

060 (16:9 ZOOM)

070 (16:9 ZOOM

SUBTITLE)

110 (FULL)

A

B

(1) Receive a PAL circle pattern signal.

(2) Enter the SERVICE MENU.

(3) Select ADJUST MENU.

(4) Select 030.

(5) Adjust 030 to make A=B.

(6) Check and readjust 030 item if the adjustment

becomes improper after some other geometric

adjustments are done.

(7) Select 040 (PANORAMIC).

(8) Adjust 040 in the same procedure.

(9) Select 050 (14:9 ZOOM).

(10) Adjust 050 in the sa me pr ocedure.

(11) Select 060 (16:9 ZOOM).

(12) Adjust 060in the same procedure.

(13) Select 070 (16:9 ZOOM SUBTITLE).

(14) Adjust 070 in the sa me pr ocedure.

(15) Select 110 (FULL ).

(16) Adjust 110 in the sa me pr ocedure.

VERTICAL SIZE

adjustment

Very close

Screen

size

Very close

Signal

generator

Remote

control unit

031 (REGULAR)

041 (PANORAMIC)

051 (14:9 ZOOM)

061 (16:9 ZOOM)

071 (16:9 ZOOM

SUBTITLE)

111 (FULL)

Picture

size

100%

(1) Receive a PAL cross-hatch signal.

(2) Enter the SERVICE MENU.

(3) Select ADJUST MENU.

(4) Select 031 (REGULAR).

(5) Adjust 031 until horizontal black lines on both the

upper and lower part of the cross-hatch pattern

become very closeted the upper and lower

horizontal sides of picture size and nearly about to

disappear.

(6) Check and readjust 031 item if the adjustment

becomes improper after some other geometric

adjustments are done.

(7) Select 041 (PANORAMIC).

(8) Adjust 041 in the same procedure.

(9) Select 051 (14:9 ZOOM).

(10) Adjust 051 in the sa me pr ocedure.

(11) Select 061 (16:9 ZOOM).

(12) Adjust 061 in the sa me pr ocedure.

(13) Select 071 (16:9 ZOOM SUBTITLE).

(14) Adjust 071 in the sa me pr ocedure.

(15) Select 111 (FULL ).

(16) Adjust 111 in the sa me pr ocedure.

(No.52136)1-17

Page 18

Item

VERTICAL

S-CORRECTION

& LINEARITY

adjustment

HORIZONTAL

POSITION

adjustment

Measuring

instrument

Signal

generator

Test point Adjustment part Description

032 (REGULAR)

033 (REGULAR)

042 (PANORAMIC)

Remote

control unit

043 (PANORAMIC)

052 (14:9 ZOOM)

053 (14:9 ZOOM)

062 (16:9 ZOOM)

063 (16:9 ZOOM)

072(16:9 ZOOM

SUBTITLE)

073(16:9 ZOOM

SUBTITLE)

112 (FULL)

113 (FULL)

UPPER

CENTER

(10) Select 042 (PANORAMIC).

(11) Adjust 042in the same procedure as 5.

(12) Select 043 (PANORAMIC).

(13) Adjust 043 in the same procedure as 8.

LOWER

(14) Select 052 (14:9 ZOOM).

(15) Adjust 052 in the same procedure as 5.

(16) Select 053 (14:9 ZOOM).

(17) Adjust 053 in the same procedure as 8.

(18) Select 062 (16:9 ZOOM).

(19) Adjust 062 in the same procedure as 5.

(20) Select 063 (16:9 ZOOM).

(21) Adjust 063 in the same procedure as 8.

(22) Select 072 (16:9 ZOOM SUBTITLE).

(23) Adjust 072 in the same procedure as 5.

(24) Select 073 (16:9 ZOOM SUBTITLE).

(25) Adjust 073 in the same procedure as 8.

(26) Select 112 (FULL).

(27) Adjust 112 in the same procedure as 5.

(28) Select 113 (FULL).

(29) Adjust 113 in the same procedure as 8.

Signal

generator

038 (REGULAR)

048 (PANORAMIC)

058 (14:9 ZOOM)

Remote

control unit

068 (16:9 ZOOM)

078 (16:9 ZOOM

SUBTITLE)

118 (FULL)

CD

(10) Adjust 058 in the same procedure.

(11) Select 068 (16:9 ZOOM).

(12) Adjust 068 in the same procedure.

(13) Select 078 (16:9 ZOOM SUBTITLE).

(14) Adjust 078 in the same procedure.

(15) Select 118 (FULL).

(16) Adjust 118 in the same procedure.

(1) Receive a PAL cross-hatch signal.

(2) Enter the SERVICE MENU.

(3) Select ADJUST MENU.

(4) Select 032 (REGULAR).

(5) Adjust 032 till the size of squares on both the upp er

and lower part of cross-hatch pattern become equal

to the squares laying on the vertical center of the

cross-hatch pattern.

(6) Check and readjust 032 item if the adjustment

becomes improper after some other geometric

adjustments are done.

(7) Select 033 (REGULAR).

(8) Adjust 033 till all the size of squares of the cross-

hatch pattern become in equal size from the top of

the screen to its bottom of the whole screen.

(9) Check and readjust 033 item if the adjustment

becomes improper after some other geometric

adjustments (especially after than S-COR

adjustment) are done.

(1) Receive a PAL circle pattern signal.

(2) Enter the SERVICE MENU.

(3) Select ADJUST MENU.

(4) Select 038 (REGULAR).

(5) Adjust 038 to make C=D.

(6) Check and readjust 038 item if the adjustment

becomes improper after some other geometric

adjustments are done.

(7) Select 048 (PANORAMIC).

(8) Adjust 048 in the same procedure.

(9) Select 058 (14:9 ZOOM).

1-18 (No.52136)

Page 19

Item

HORIZONTAL

SIZE

adjustment

Very

close

Measuring

instrument

Signal

generator

Remote

control unit

Test point Adjustment part Description

039 (REGULAR)

049 (PANORAMIC)

059 (14:9 ZOOM)

069 (16:9 ZOOM)

079 (16:9 ZOOM

SUBTITLE)

119 (FULL)

(1) Receive a PAL cross-hatch signal.

(2) Enter the SERVICE MENU.

(3) Select ADJUST MENU.

(4) Select 039 (REGULAR).

(5) Adjust 039 until vertical lines on both the left and

right part of the cross-hatch will be visible nor screen

will be so wide.

(6) Check and readjust 039 item if the adjustment

Screen size

Very

close

becomes improper after some other geometric

adjustments are done.

(7) Select 049 (PANORAMIC).

(8) Adjust 049 in the same procedure.

(9) Select 059 (14:9 ZOOM).

(10) Adjust 059 in the sa me pr ocedure.

(11) Select 069 (16:9 ZOOM).

(12) Adjust 069 in the sa me pr ocedure.

(13) Select 079 (16:9 ZOOM SUBTITLE).

(14) Adjust 079 in the sa me pr ocedure.

(15) Select 119 (FULL ).

Picture size 100%

(16) Adjust 119 in the sa me pr ocedure.

ANGLE

adjustment

BOW

adjustment

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

016 (1) Receive a PAL cross-hatch signal.

(2) Enter the SERVICE MENU.

(3) Select ADJUST MENU.

(4) Select 016.

(5) Adjust 016 till the vertical lines of the cross-hatch

pattern become straight.

(6) Check and readjust 016 item if the adjustment

becomes improper after some other geometric

adjustments are done.

017 (1) Receive a PAL cross-hatch signal.

(2) Enter the SERVICE MENU.

(3) Select ADJUST MENU.

(4) Select 017.

(5) Adjust 017 till the vertical line s become straight.

(6) Check and readjust 017 item if the adjustment

becomes improper after some other geometric

adjustments are done.

NOTE:

In case where there is a bow-shaped distortion of

images on the screen. (Figure)

(No.52136)1-19

Page 20

Item

TRAPEZIUM

adjustment

SIDE PIN

adjustment

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

034 (REGULAR)

044 (PANORAMIC)

054 (14:9 ZOOM)

064 (16:9 ZOOM)

074 (16:9 ZOOM

SUBTITLE)

114 (FULL)

Parallel

035 (REGULAR)

045 (PANORAMIC)

055 (14:9 ZOOM)

065 (16:9 ZOOM)

075 (16:9 ZOOM

SUBTITLE)

115 (FULL)

Parallel

(1) Receive a PAL cross-hatch signal.

(2) Enter the SERVICE MENU.

(3) Select ADJUST MENU.

(4) Select 034 (REGULAR).

(5) Adjust 034 till vertical li nes, especially lines at the

sides of the picture frame become parallel to the

both sides of picture tubes as close as possible.

(6) Check and readjust 034 item if the adjustment

becomes improper after some other geometric

adjustments are done.

(7) Select 044 (PANORAMIC).

(8) Adjust 044 in the same procedure.

(9) Select 054 (14:9 ZOOM).

(10) Adjust 054 in the same procedure.

(11) Select 064 (16:9 ZOOM).

(12) Adjust 064 in the same procedure.

(13) Select 074 (16:9 ZOOM SUBTITLE).

(14) Adjust 074 in the same procedure.

(15) Select 114 (FULL).

(16) Adjust 114 in the same procedure.

(1) Receive a PAL cross-hatch signal.

(2) Enter the SERVICE MENU.

(3) Select ADJUST MENU.

(4) Select 035 (REGULAR).

(5) Adjust 035 till vertical lines close to the both sides of

the picture frame become parallel to vertical sides of

picture tube without any bending to left or to right

side of the screen.

(6) Check and readjust 035 item if the adjustment

becomes improper after some other geometric

adjustments are done.

(7) Select 045 (PANORAMIC).

(8) Adjust 045 in the same procedure.

(9) Select 055 (14:9 ZOOM).

(10) Adjust 055 in the same procedure.

(11) Select 065 (16:9 ZOOM).

(12) Adjust 065 in the same procedure.

(13) Select 075 (16:9 ZOOM SUBTITLE).

(14) Adjust 075 in the same procedure.

(15) Select 115 (FULL).

(16) Adjust 115 in the same procedure.

1-20 (No.52136)

Page 21

Item

CORNER

adjustment

Measuring

instrument

Signal

generator

Remote

control unit

Test point Adjustment part Description

036 (REGULAR)

037 (REGULAR)

046 (PANORAMIC)

047 (PANORAMIC)

056 (14:9 ZOOM)

057 (14:9 ZOOM)

066 (16:9 ZOOM)

067 (16:9 ZOOM)

076(16:9 ZOOM

SUBTITLE)

077(16:9 ZOOM

SUBTITLE)

116 (FULL)

117 (FULL)

Straight Straight

(1) Receive a PAL cross-hatch signal.

(2) Enter the SERVICE MENU.

(3) Select ADJUST MENU.

(4) Select 036 (REGULAR).

(5) Adjust 036 till vertical line s at the upper corners of

the picture frame become vertical and parallel to

vertical corner sides of picture tube.

(6) Check and readjust 036 item if the adjustment

becomes improper after some other geometric

adjustments are done.

(7) Select 037 (REGULAR).

(8) Adjust 037 till vertical lines at the lower corners of the

picture frame become vertical and parallel to vertical

corner sides of picture tube.

(9) Check and readjust 037 item if the adjustment

becomes improper after some other geometric

adjustments are done.

(10) Select 116 (FULL ).

(11) Adjust 116 in the same pr ocedure as 5.

(12) Select 117 (FULL ).

(13) Adjust 117 in the same pr ocedure as 8.

ROTATION

adjustment

Signal

generator

Remote

control unit

083 (1) Receive a PAL cross-hatch signal.

(2) Enter the SERVICE MENU.

(3) Select ADJUST MENU.

(4) Select 083.

(5) Adjust 083 to rotate the complete master clock-wise

and counter clock-wise depending on the CRT.

(6) Check and readjust 083 item if the adjustment

becomes improper after some other geometric

adjustments are done.

(No.52136)1-21

Page 22

Item

NTSC

HORIZONAL

SIZE

adjustment

Very

close

Measuring

instrument

Signal

generator

Remote

control unit

Test point Adjustment part Description

135 (REGULAR)

(1) Receive a NTSC cross-hatch signal.

(2) Enter the SERVICE MENU.

142 (FULL)

(3) Select ADJUST MENU.

(4) Select 135 (REGULAR).

(5) Adjust 135 till vertical lines on b oth the l eft a nd right

part of the cross-hatch will be visible nor screen will

Screen size

Very

close

be so wide.

(6) Check and readjust TRAPEZ item if the adjustment

becomes improper after some other geometric

adjustments are done.

(7) Select 142 (FULL).

(8) Adjust 142 in the same procedure.

Picture size 100%

NTSC

SIDE PIN

adjustment

TELETEXT

SCREEN SIZE

adjustment

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Parallel

136 (REGULAR) (1) Receive a NTSC cross-hatch signal.

(2) Enter the SERVICE MENU.

(3) Select ADJUST MENU.

(4) Select 136 (REGULAR).

(5) Adjust 136 till vertical lines close to the both sides of

the picture frame become parallel to vertical sides of

picture tube without any bending to left or to right

side of the screen.

(6) Check and readjust 136 item if the adjustment

becomes improper after some other geometric

adjustments are done.

143 (1) Receive a PAL cross-hatch signal.

(2) Enter the SERVICE MENU.

(3) Select ADJUST MENU.

(4) Select 143.

(5) Adjust 143 to adjust the proper vertical size of

Teletext screen.

(6) Check and readjust 143 item if the adjustment

becomes improper after some other geometric

adjustments are done.

1-22 (No.52136)

Page 23

4.6.4 VIDEO CIRCUIT

Item

WHITE

BALANCE

adjustment

COLOUR

CUTOFF LEVEL

adjustment

PAL

Y DELAY

adjustment

SECAM

Y DELAY

adjustment

NTSC

Y DELAY

adjustment

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

023

024

025

026

027

028

006 (1) Receive a PAL colour bar signal.

007 (1) Receive a SECAM colour bar signal.

008 (1) Receive a NTSC colour bar signal from an external

(1) Receive a PAL black & white signal.

(2) Enter the SERVICE MENU.

(3) Select ADJUST MENU.

(4) Select 023, 024 and 025 respectively.

(5) Adjust 023, 024 and 025 respectively, until the white

part turns to pure white without any other colour.

(1) Receive a PAL cross-hatch signal.

(2) Enter the SERVICE MENU.

(3) Select ADJUST MENU.

(4) Select 026, 027 and 028 respectively.

(5) Adjust 026, 027 and 028 respectively, until the black

part turns to pure black without any other colour.

(2) Enter the SERVICE MENU.

(3) Select ADJUST MENU.

(4) Select 006.

(5) Adjust 006 till the colour transients on the colour bar

pattern becomes as sharper and possible as colours

between transients do not mix with each other.

(2) Enter the SERVICE MENU.

(3) Select ADJUST MENU.

(4) Select 007.

(5) Adjust 007 by pressing till th e colour transients on

the colour bar pattern becomes as sharper and

possible as colouers between transients do not mix

with each other.

source (e.g. FRONT AV : EXT-3).

(2) Enter the SERVICE MENU.

(3) Select ADJUST MENU.

(4) Select 008.

(5) Adjust 008 by pressing till th e colour transients on

the colour bar pattern becomes as sharper and

possible as colouers between transients do not mix

with each other.

(No.52136)1-23

Page 24

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

1-24 (No.52136)

Page 25

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY VIDEO DISPLAY CATEGORY 12, 3-chome, Moriya-cho, kanagawa-ku, Yokohama, kanagawa-prefecture, 221-8528, Japan

(No.52136)

Printed in Japan

WPC

Loading...

Loading...