Page 1

SERVICE MANUAL

COLOR TELEVISION

AV-27F802

BASIC CHASSIS

AC

AV-27F802

TV

/SME

CONTENTS

a SPECIFICATIONS....................................................................................................................................2

a SAFETY PRECAUTIONS ........................................................................................................................3

a FEATURES ..............................................................................................................................................4

a FUNCTIONS.............................................................................................................................................5

a SPECIFIC SERVICE INSTRUCTIONS ....................................................................................................6

a SERVICE ADJUSTMENTS ....................................................................................................................11

¤ ST ANDARD CIRCUIT DIAGRAM (APPENDIX) .................................................................................. 2-1

a P ARTS LIST ...........................................................................................................................................33

COPYRIGHT © 2000 VICTOR COMPANY OF JAPAN, LTD.

No. 51785

Dec. 2000

Page 2

AV-27F802

SPECIFICATIONS

Items Contents

Dimensions (W × H × D)

················································································································································································································

Mass

················································································································································································································

TV RF System

················································································································································································································

Color Sound System

················································································································································································································

TV Receiving Channels and Frequency

VL Band

VH Band

UHF Band

················································································································································································································

CATV Receiving Channels and Frequency

Low Band

High Band

Mid Band

Super Band

Hyper Band

Ultra Band

Sub Mid Band

TV/CATV Total Channel

················································································································································································································

Intermediate Frequency

Video IF Carrier

Sound IF Carrier

Color Sub Carrier

················································································································································································································

Power Input

Power Consumption

················································································································································································································

Picture Tube

High Voltage

················································································································································································································

Speaker

Audio Power Output

················································································································································································································

Video / Audio Input (1 / 2 / 3 / 4)

29-7/8” × 23-3/8” × 19-3/4” / 75.8cm × 59.3cm × 50.0cm

101.2 lbs / 46 kg

CCIR(M)

NTSC, BTSC System (Multi Channel Sound)

(02

~06) 54MHz~88MHz

(07

~13) 174MHz~216MHz

(14

~69) 470MHz~806MHz

~06, A-8) by (02~06&01)

(02

(07

~13) by (07~13)

(A

~1) by (14~22)

(J

~W) by (23~36) (54MHz~804MHz)

(W+1

~W+28) by (37~64)

(W+29

~W+84) by (65~125)

(A8, A4

~A1) by (01, 96~99)

180 Channels

45.75MHz

41.25MHz (4.5MHz)

3.58MHz

120V AC, 60Hz

140W / 2.0A

27” (68cm) Measured Diagonally

30kV±1kV (at zero beam current)

2” × 4-3/4” / 5 × 12cm Oval type × 2

5W × 2

Video(1,3,4) : 1Vp-p, 75Ø (RCA pin jack)

Audio(1,2,3,4) : 500mVrms ( -4dBs ), High Impedance (RCA pin jack)

S-Video ( Input 1 / 3 / 4 Over )

Y : 1Vp-p Positive (negative sync provided, when terminated with 75Ø)

C : 0.286Vp-p (burst signal, when terminated with 75Ø)

Component Input ( Input 2 / 4 )

Y : 1Vp-p positive (negative sync provided, when terminated with 75Ø)

P

B/PR : 0.7Vp-p 75 Ø

—

—

················································································································································································································

Audio Output

(Variable / Fix : Selectable)

················································································································································································································

AV Compu link EX Input

················································································································································································································

Antenna terminal

················································································································································································································

Remote Control Unit

Variable : More then 0

Low impedance (400Hz when modulated 100%)

Fix : 500mVrms(-4dBs)

Low impedance (400Hz when modulated 100%)

3.5mm mini jack

75Ø(VHF/UHF) Terminal, F-Type Connector

RM-C301G-2A

(AA/R6/UM-3 battery × 2)

~1550mVrms (+6dBs)

(RCA pin jack)

(RCA pin jack)

Design & specifications are subject to change without notice.

2 No. 51785

Page 3

GOOD

EARTH

GROUND

0.15 µF AC-TYPE

AC VOLTMETER

(HAVING 1000Ø/V,

OR MORE SENSITIVITY)

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

1500Ø 10W

A V

This mark shows a fast

POWER CORD

REPLACEMENT WARNING

Connecting thr white line side of

power cord to “WHT” character side.

operating fuse, the

letters indicated below

show the rating.

PWB

WHT

PW

White line side

SAFETY PRECAUTIONS

1. The design of this product contains special hardware, many circuits

and components specially for safety purposes. For continued protection, no changes should be made to the original design unless

authorized in writing by the manufacturer. Replacement parts must

be identical to those used in the original circuits. Service should be

performed by qualified personnel only.

2. Alterations of the design or circuitry of the products should not be

made. Any design alterations or additions will void the manufacturer's warranty and will further relieve the manufacturer of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special

safety-related characteristics. These characteristics are often not

evident from visual inspection nor can the protection afforded by

them necessarily be obtained by using replacement components

rated for higher voltage, wattage, etc. Replacement parts which have

these special safety characteristics are identified in the parts list of

Service manual. Electrical components having such features are

identified by shading on the schematics and by (

parts list in Service manual. The use of a substitute replacement

which does not have the same safety characteristics as the recommended replacement part shown in the parts list of Service manual

may cause shock, fire, or other hazards.

4. Use isolation transformer when hot chassis.

The chassis and any sub-chassis contained in some products are

connected to one side of the AC power line. An isolation transformer

of adequate capacity should be inserted between the product and

the AC power supply point while performing any service on some

products when the HOT chassis is exposed.

5. Don't short between the LIVE side ground and ISOLATED (NEU-

TRAL) side ground or EARTH side ground when repairing.

Some model's power circuit is partly different in the GND. The difference of the GND is shown by the LIVE : (

ISOLATED(NEUTRAL) : (

GND. Don't short between the LIVE side GND and

ISOLATED(NEUTRAL) side GND or EARTH side GND and never

measure with a measuring apparatus (oscilloscope etc.) the LIVE

side GND and ISOLATED(NEUTRAL) side GND or EARTH side

GND at the same time.

If above note will not be kept, a fuse or any parts will be broken.

6. If any repair has been made to the chassis, it is recommended that

the B1 setting should be checked or adjusted (See ADJUSTMENT

OF B1 POWER SUPPLY).

7. The high voltage applied to the picture tube must conform with that

specified in Service manual. Excessive high voltage can cause an

increase in X-Ray emission, arcing and possible component damage, therefore operation under excessive high voltage conditions

should be kept to a minimum, or should be prevented. If severe

arcing occurs, remove the AC power immediately and determine

the cause by visual inspection (incorrect installation, cracked or

melted high voltage harness, poor soldering, etc.). To maintain the

proper minimum level of soft X-Ray emission, components in the

high voltage circuitry including the picture tube must be the exact

replacements or alternatives approved by the manufacturer of the

complete product.

8. Do not check high voltage by drawing an arc. Use a high voltage

meter or a high voltage probe with a VTVM. Discharge the picture

tube before attempting meter connection, by connecting a clip lead

to the ground frame and connecting the other end of the lead through

a 10kØ 2W resistor to the anode button.

9. When service is required, observe the original lead dress. Extra

precaution should be given to assure correct lead dress in the high

voltage circuit area. Where a short circuit has occurred, those components that indicate evidence of overheating should be replaced.

Always use the manufacturer's replacement components.

) side GND and EARTH : ( ) side

) on the

) side GND, the

No. 51785 3

AV-27F802

10. Isolation Check

(Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an isolation check

on the exposed metal parts of the cabinet (antenna terminals, video/

audio input and output terminals, Control knobs, metal cabinet,

screwheads, earphone jack, control shafts, etc.) to be sure the product is safe to operate without danger of electrical shock.

(1)Dielectric Strength Test

The isolation between the AC primary circuit and all metal parts

exposed to the user, particularly any exposed metal part having a

return path to the chassis should withstand a voltage of 1100V AC

(r.m.s.) for a period of one second.

(. . . . Withstand a voltage of 1100V AC (r .m.s.) to an appliance rated

up to 120V, and 3000V AC (r.m.s.) to an appliance rated 200V or

more, for a period of one second.)

This method of test requires a test equipment not generally found in

the service trade.

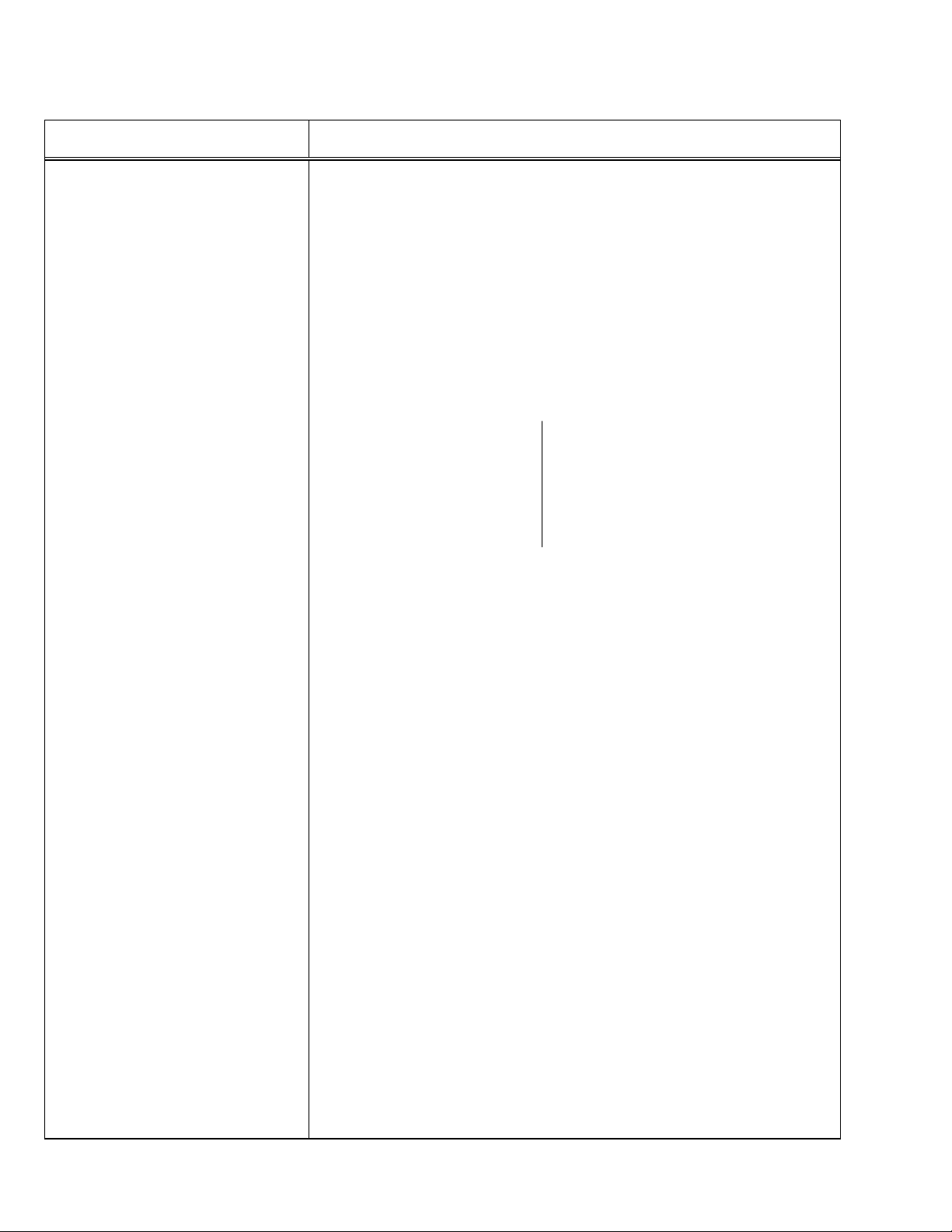

(2)Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use a line

isolation transformer during this check.). Using a “Leakage Current

Tester”, measure the leakage current from each exposed metal part

of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground (water pipe, etc.).

Any leakage current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC (r.m.s.).

Alternate Check Method

•

Plug the AC line cord directly into the AC outlet (do not use a line

isolation transformer during this check.). Use an AC voltmeter having 1000 ohms per volt or more sensitivity in the following manner.

Connect a 1500Ø 10W resistor paralleled by a 0.15µF AC-type capacitor between an exposed metal part and a known good earth

ground (water pipe, etc.). Measure the AC voltage across the resistor with the AC voltmeter. Move the resistor connection to each exposed metal part, particularly any exposed metal part having a return path to the chassis, and measure the AC voltage across the

resistor. Now, reverse the plug in the AC outlet and repeat each

measurement. Any voltage measured must not exceed 0.75V AC

(r.m.s.). This corresponds to 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC (r.m.s.).

This corresponds to 0.2mA AC (r.m.s.).

11. High voltage hold down circuit check.

After repair of the high voltage hold down circuit, this circuit shall be

checked to operate correctly.

See item “How to check the high voltage hold down circuit”.

Page 4

AV-27F802

FEATURES

Full-flat CRT (cathode ray tube) reproduces fine textured picture in

•

every detail.

I2C bus control utilizes single chip ICs.

•

Built in Twin Tuner system.

•

Built-in HYPER-SURROUND system.

•

Built-in BBE.

•

Adoption of the Picture-In-Picture (PIP) function.

•

3 LINE Digital Y/C Separation circuit improved picture quality.

•

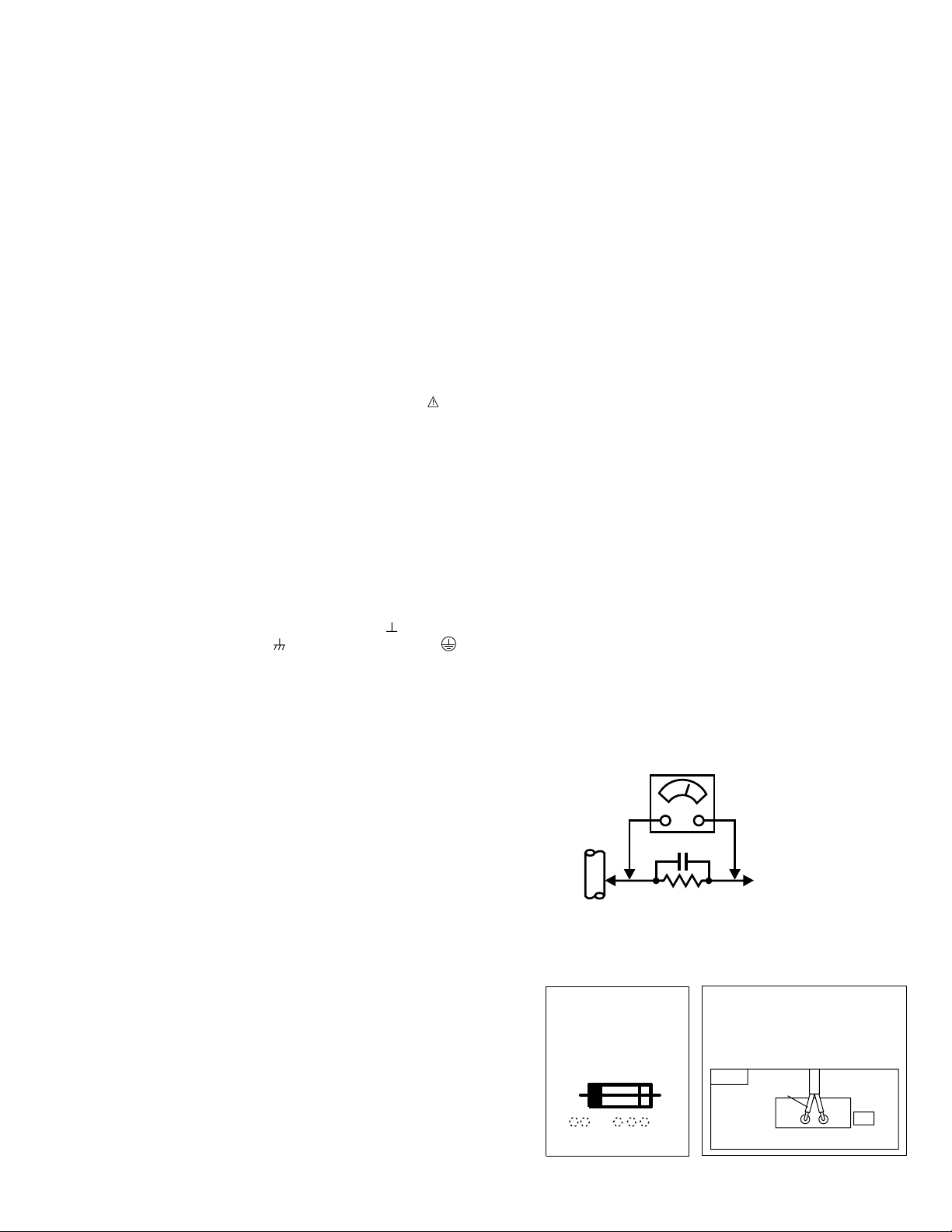

a SYSTEM BLOCK DIAGRAM

IC702

E2PROM 4k bit

SCL 1 SDA 1

Component input terminal for talking best advantage of Component

•

Video Signal.

Audio Video input terminal. (S-input ×2, V-input ×2)

•

Variable/Fix audio output terminal.

•

Closed-caption broadcasts can be viewed.

•

With AV COMPU LINK EX terminal.

•

IF2

AFC 2

Remote

control

unit

IC301

PIP

CONTROL

SCL 0 SDA 0

IC701

MAIN MICON

IC101

1 CHIP

CONTROL

IC501

AVSW

CONTROL

AFC 1

TU001

TUNER 1

TU001

TUNER 2

IC001

MTS, TONE

SURROUND CONTROL

4 No. 51785

3-D Y/C

Page 5

FUNCTIONS

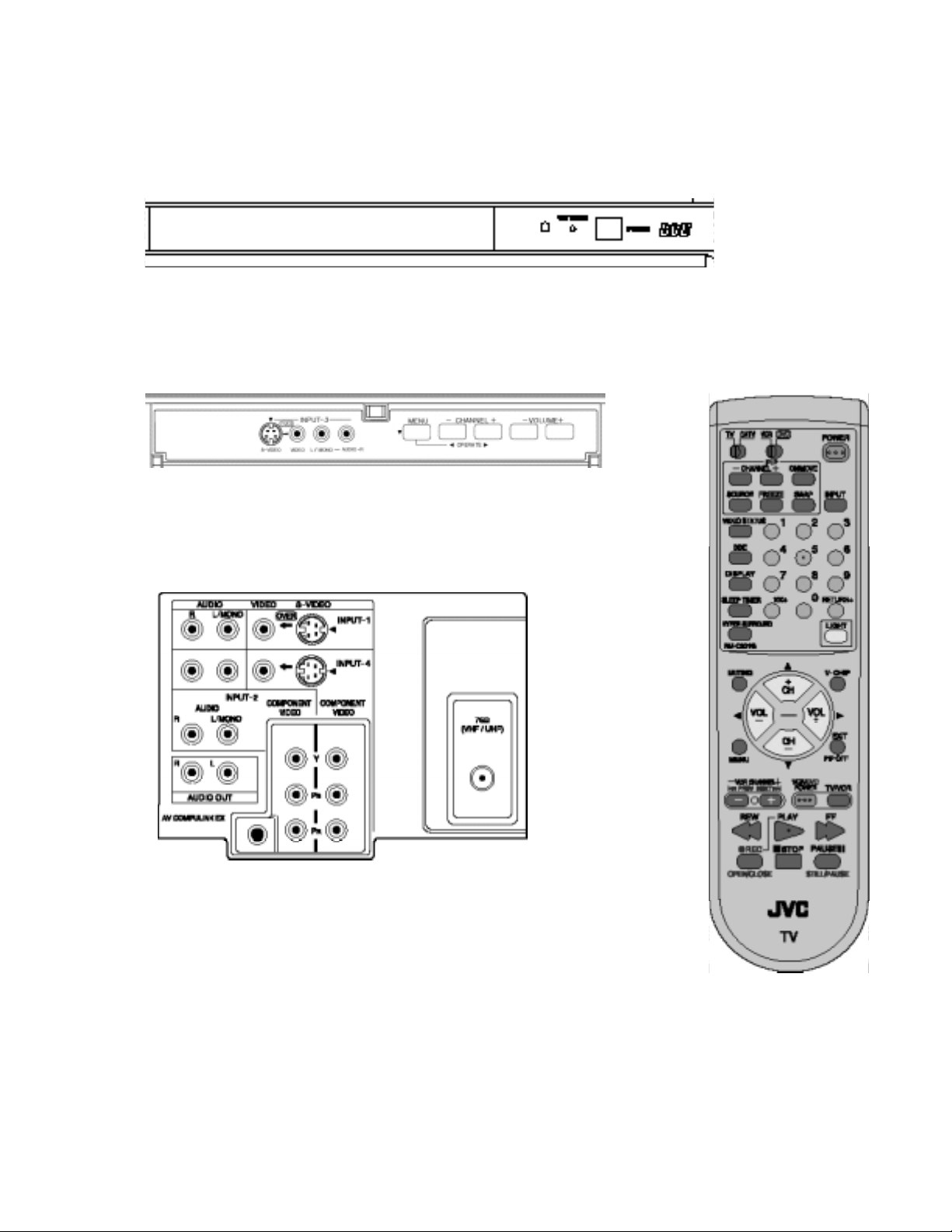

a FRONT P ANEL

AV-27F802

a FRONT PANEL DOOR OPENED

a REAR P ANEL

a REMOTE CONTROL UNIT

(RM-C301G-2A)

No. 51785 5

Page 6

AV-27F802

SPECIFIC SERVICE INSTRUCTIONS

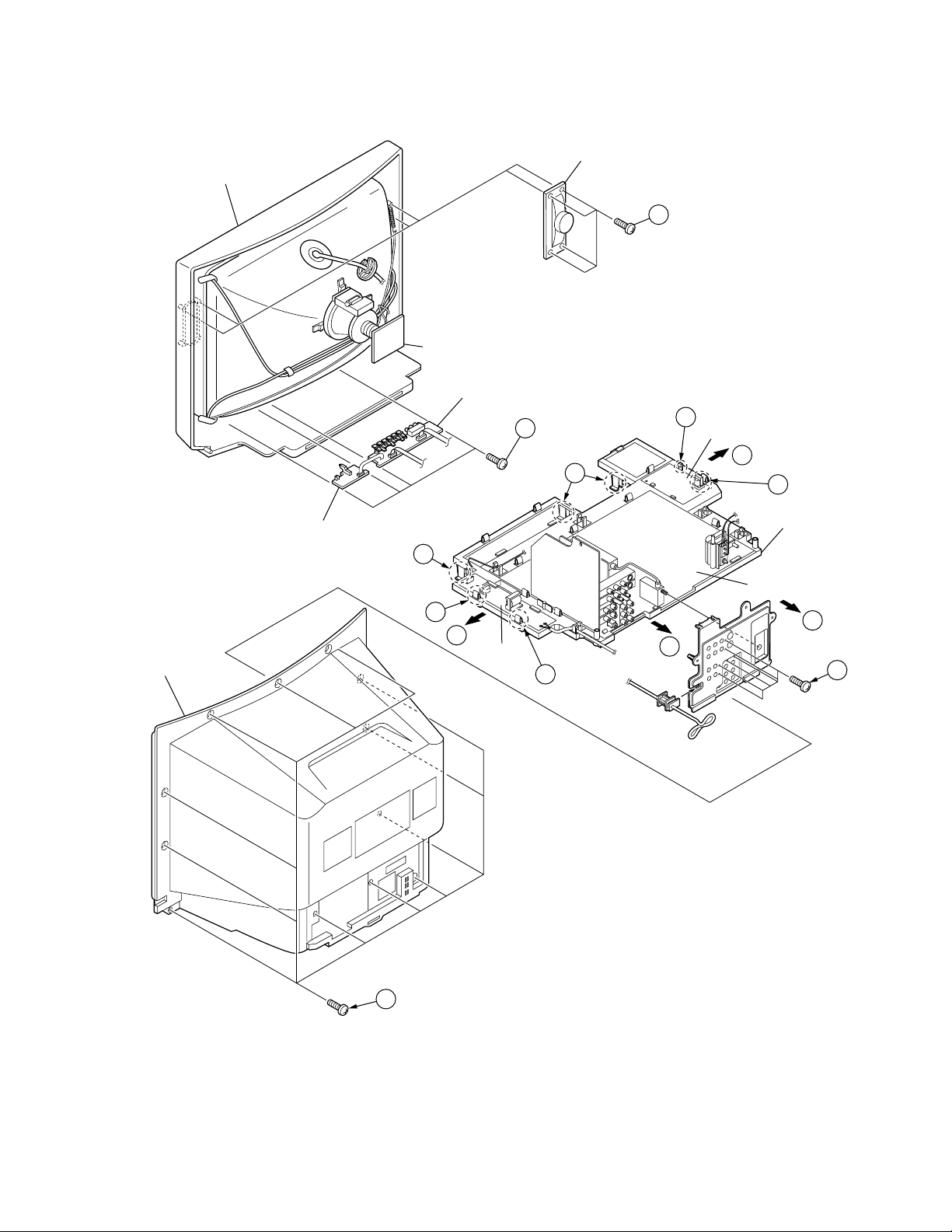

DISASSEMBLY PROCEDURE

REMOVING THE REAR COVER

1. Unplug the power supply cord.

2. Remove the 12 screws marked A as shown in Fig.1.

3. Withdraw the REAR COVER toward you.

[CAUTION]

When reinstalling the rear cover, carefully push it inward after in-

•

serting the MAIN PWB into the rear cover groove.

REMOVING THE CHASSIS

After removing the rear cover.

•

1. Slightly raise the both sides of the chassis by hand and remove the

3 claws marked B under the chassis from the front cabinet as

shown in Fig.1.

2. Withdraw the chassis backward along the rail in the arrow direction

marked C as shown in Fig.1.

(If necessary, take off the wire clamp, connector’s etc.)

When conducting a check with power supplied, be sure to confirm

*

that the CRT earth wire is connected to the CRT SOCKET PWB

and the MAIN PWB.

REMOVING THE TERMINAL BOARD

After removing the rear cover.

•

1. Remove the 6 screws marked D as shown in Fig.1.

2. When you pull out the TERMINAL BOARD in the direction of arrow

marked E as shown in Fig.1, it can be removed.

REMOVING THE DAF PW BOARD

After removing the rear cover and chassis.

•

1. Lift the right side of the DAF PWB while pressing the PWB stopper

marked J and claw marked K in the arrow direction marked L as

shown in Fig.1.

2. Then remove the DAF PWB.

(If necessary, take off the wire, connector’s etc.)

REMOVING THE SPEAKER

After removing the rear cover.

•

1. Remove the 4 screws marked M as shown in Fig.1.

2. Withdraw the speaker backward.

3. Follow the same steps when removing the other hand speaker.

CHECKING THE MAIN PW BOARD

1. To check the back side of the MAIN PW Board.

1) Pull out the chassis. (Refer to REMOVING THE CHASSIS).

2) Erect the chassis vertically so that you can easily check the back

side of the MAIN PW Board.

[CAUTION]

When erecting the chassis, be careful so that there will be no con-

•

tacting with other PW Board.

Before turning on power, make sure that the CRT earth wire and

•

other connectors are properly connected.

REMOVING THE FRONT AND POWER SW PW BOARDS

After removing the rear cover and chassis.

•

1. Remove the 4 screws marked F as shown in Fig.1.

2. Then remove the FRONT PWB and POWER SW PWB.

(If necessary, take off the wire, connector’s etc.)

REMOVING THE LF PW BOARD

After removing the rear cover and chassis.

•

1. Lift the left side of the LF PWB while pressing the 2 PWB stoppers

marked G in the arrow direction marked H as shown in Fig.1.

2. Then remove the LF PWB.

(If necessary, take off the wire, connector’s etc.)

WIRE CLAMPING AND CABLE TYING

1. Be sure clamp the wire.

2. Never remove the cable tie used for tying the wires together.

Should it be inadvertently removed, be sure to tie the wires with a

new cable tie.

6 No. 51785

Page 7

D

F

M

A

DAF PWB

PWB STOPPER

PWB

STOPPER

PWB

STOPPER

CLAW

SPEAKER

CHASSIS

MAIN PWB

LF PWB

POWER SW PWB

REAR COVER

FRONT PWB

CRT SOCKET PWB

FRONT CABINET

(x12)

(x6)

(x4)

(x4)

E

L

H

C

K

CLAW

CLAW

B

B

G

G

J

AV-27F802

Fig.1

No. 51785 7

Page 8

AV-27F802

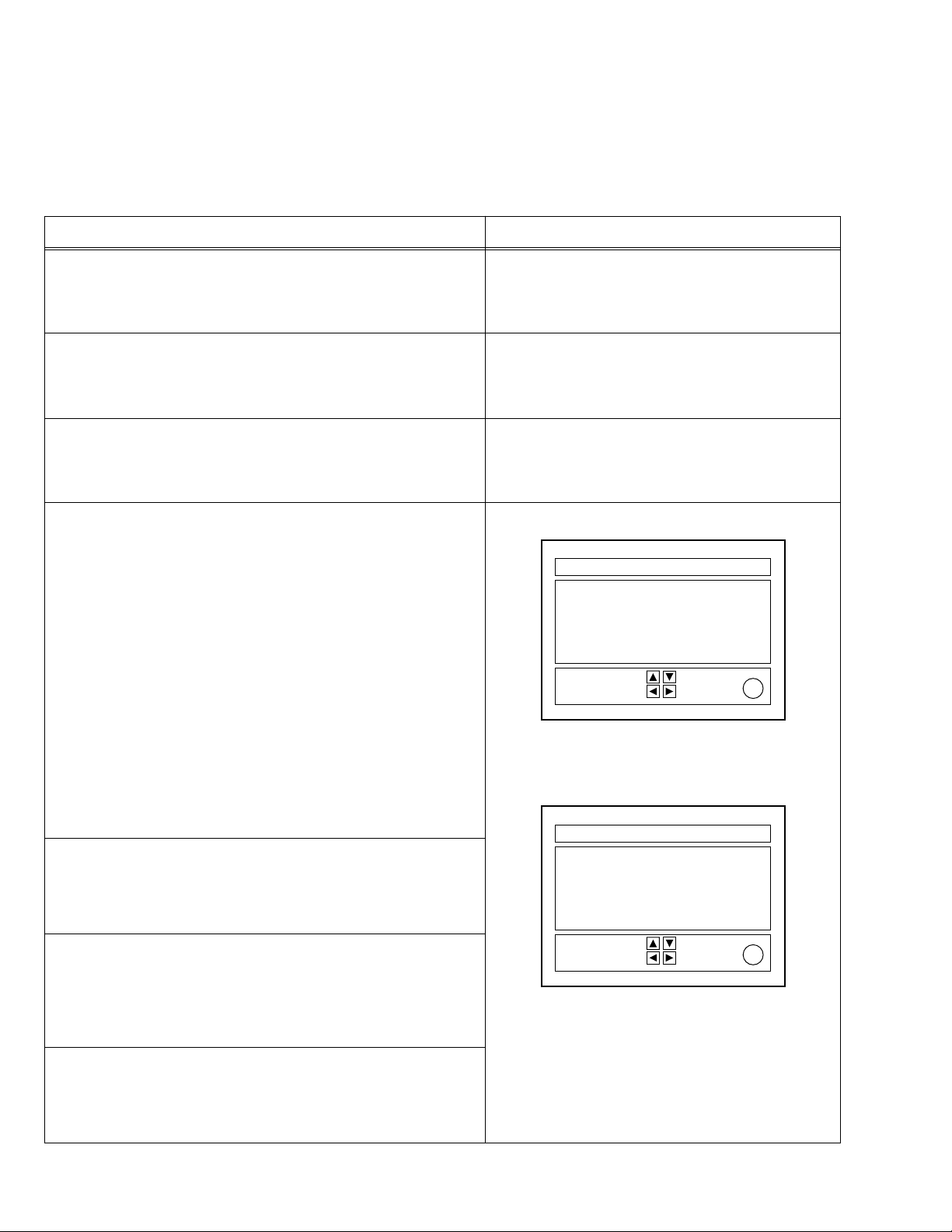

MEMORY IC REPLACEMENT

1. Memory IC

This model use a memory IC.

This memory IC stores data for proper operation of the video and deflection circuits.

When replacing, be sure to use an IC containing this (initial value) data.

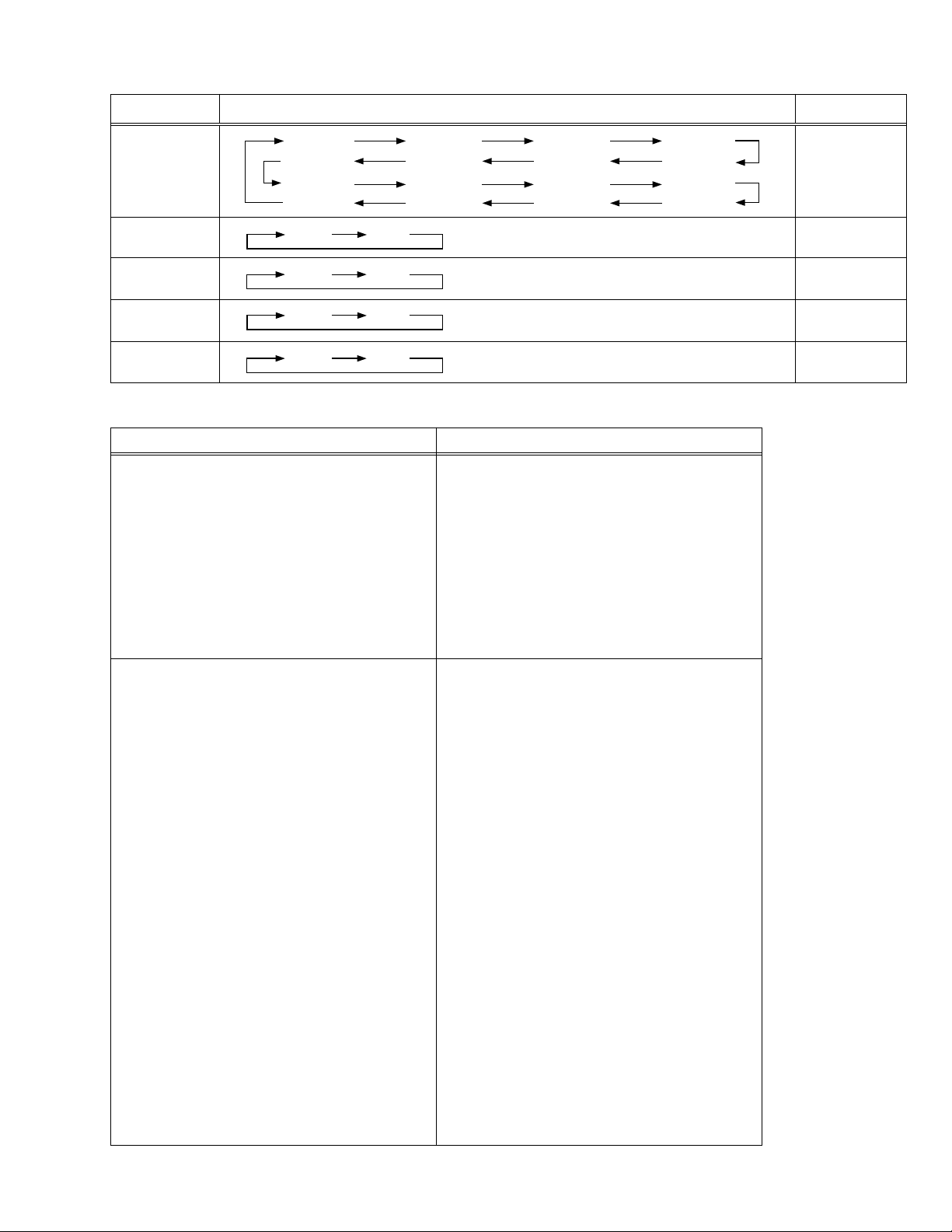

2. Memory IC replacement procedure

Procedure Screen display

(1) Power off

Switch off the power and disconnect the power cord from the outlet.

(2) Replace the memory IC

Initial value must be entered into the new IC.

(3) Power on

Connect the power cord to the outlet and switch on the power.

(4) System constant check and setting

1) Press SLEEP TIMER key and, while the indication of “SLEEP TIMER

0 MIN.” is being displayed, press DISPLAY key and VIDEO STATUS

key on the remote control unit simultaneously.

2) The SERVICE MENU screen of Fig.1 is displayed.

3) While the SERVICE MENU is displayed, again simultaneously press

the DISPLAY and VIDEO STATUS keys to display the Fig.2 SYSTEM

CONSTANT screen.

4) Refer to the SYSTEM CONSTANT table and check the setting items.

Where these differ, select the setting item with the MENU UP/DOWN

key and adjust the setting with the MENU LEFT/RIGHT keys. (The

letters of the selected item are displayed in yellow.)

5) After adjusting, release the MENU LEFT/RIGHT key to store the

setting value.

6) Press the EXIT key twice to return the normal screen.

(5) Receive channel setting

Refer to the OPERATING INSTRUCTIONS(USER'S GUIDE) and set the

receive channels (Channels Preset) as described.

(6) User settings

Check the user setting items according to Table 2.

Where these do not agree, refer to the OPERATING INSTRUCTIONS (USER'S GUIDE) and set the items as described.

SERVICE MENU

PICTURE SOUND

THEATER OTHERS

PIP 3-D Y/C

LOW LIGHT HIGH LIGHT

RF AFC1 RF AFC2

VCO(CW) I2C BUS CTRL

SELECT BY

OPERATE BY

Fig.1

SYSTEM CONSTANT

MODEL :99–

TM CORR. : NO

CCD : YES

V-CHIP : YES

CAN V-CHIP : NO

EXIT BY

99999

999999999 999

SELECT BY

OPERATE BY

Fig.2

EXIT BY

EX

IT

EX

IT

(7) SERVICE MENU setting

Verify what to set in the SERVICE MENU, and set whatever is

necessary.(Fig.1) Refer to the SERVICE ADJUSTMENT for setting.

8 No. 51785

Page 9

AV-27F802

TABLE 1 (System Constant setting)

Setting item Setting content Setting value

AV-27F802 AV-32F802 AV-36F802 AV-27F702

MODEL

AV-32D602 AV-27D602 AV-36F702 AV-32F702

AV-36D602 AV-27D502 AV-32D502 AV-36D502

AV-36D202 AV-32D202 AV-36D302 AV-32D302

AV-27F802

TM CORR.

CCD

V-CHIP

CAN V-CHIP

YES NO

YES NO

YES NO

YES NO

TABLE 2 (User setting value)

Setting item Setting value

1. Use remote controller keys

POWER NO

CHANNEL CH-02

VOLUMEN 05

INPUT TV

HYPER SURROUND NO

BBE SI

DISPLAY NO

SLEEP TIMER 0

VIDEO STATUS MEMORIA

PIP SOURCE CH-04

PIP ON (PIP POSITION) LEFT LOWR SIDE

2. Setting of MENU

NO

YES

YES

NO

AJUSTAR IMAGEN

TINTE CENTER

COLOR CENTER

CONTRASTE CENTER

BRILLO CENTER

DETALLE CENTER

PANTALLA AZUL SI

FIJAR VIDEO STATUS ALL CENTER

AJUSTAR SONIDO

GRAVES CENTER

AGUDOS CENTER

BALANCE CENTER

MTS ESTEREO

RELOJ/REGULADOR

AJUSTE DEL RELOJ Unnecessary to set

TEMPORIZADOR SI

SISTEMA INICIAL

ALTAVOCES SI

SALIDA AUDIO FIJO

V4 COMPONENT-IN SI

IDIOMA ESP

SUBTITULOS OCULTOS NO

AUTOPROGRAMACION Unnecessary to set

LISTA DE CANALES Unnecessary to set

V-CHIP NO

BLOQUEO DE CANAL Unnecessary to set

No. 51785 9

Page 10

AV-27F802

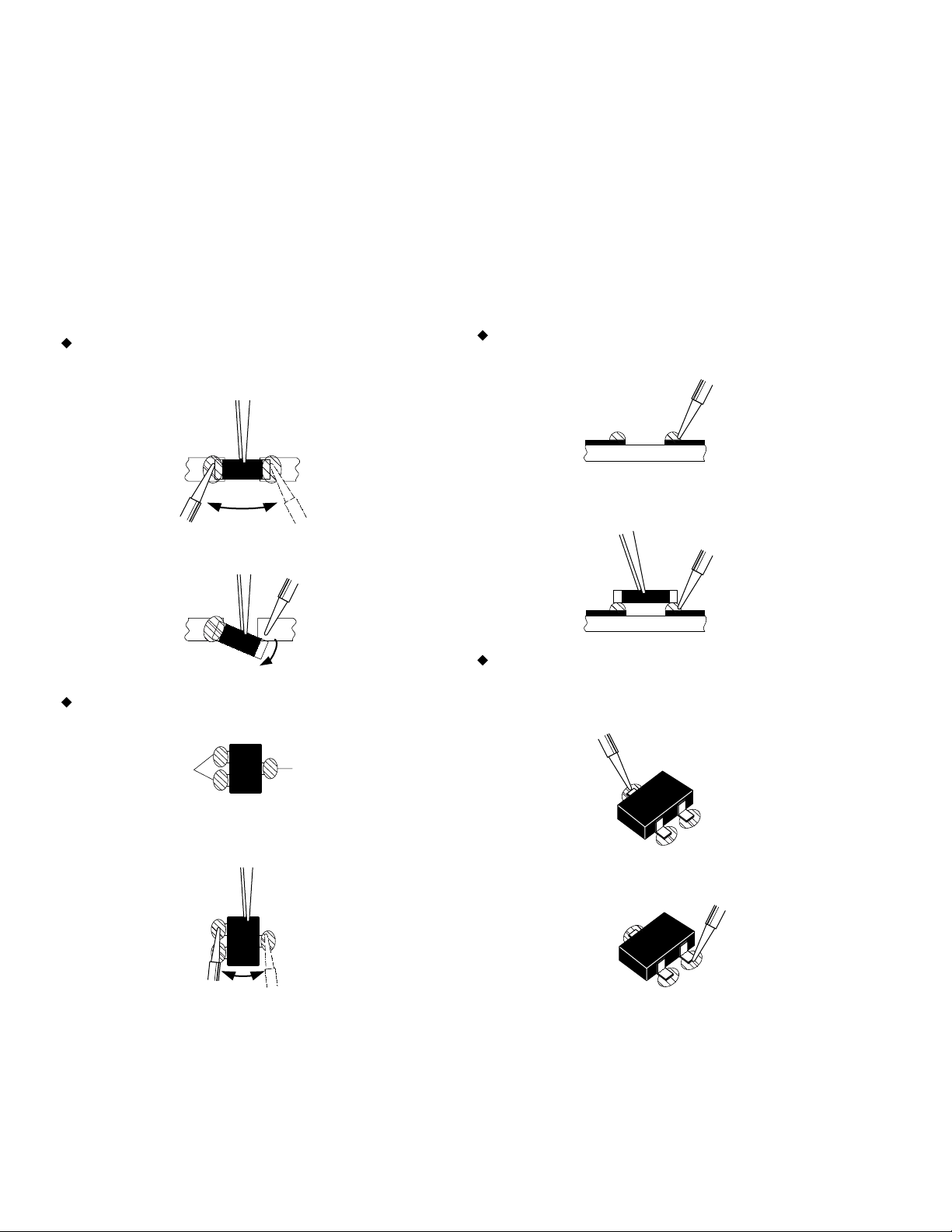

REPLACEMENT OF CHIP COMPONENT

CAUTIONS

a

1. Avoid heating for more than 3 seconds.

2. Do not rub the electrodes and the resist parts of the pattern.

3. When removing a chip part, melt the solder adequately.

4. Do not reuse a chip part after removing it.

SOLDERING IRON

a

1. Use a high insulation soldering iron with a thin pointed end of it.

2. A 30w soldering iron is recommended for easily removing parts.

REPLACEMENT STEPS

a

1. How to remove Chip parts

Resistors, capacitors, etc.

(1) As shown in the figure, push the part with tweezers and alter-

nately melt the solder at each end.

2. How to install Chip parts

Resistors, capacitors, etc.

(1) Apply solder to the pattern as indicated in the figure.

(2) Shift with tweezers and remove the chip part.

Transistors, diodes, variable resistors, etc.

(1) Apply extra solder to each lead.

SOLDER

(2) As shown in the figure, push the part with tweezers and alter-

nately melt the solder at each lead. Shift and remove the chip

part.

SOLDER

(2) Grasp the chip part with tweezers and place it on the solder.

Then heat and melt the solder at both ends of the chip part.

T ransistors, diodes, variable resistors, etc.

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the solder.

(3) First solder lead

(4) Then solder leads

A as indicated in the figure.

A

B

C

B and C.

A

Note : After removing the part, remove remaining solder from the

pattern.

10 No. 51785

B

C

Page 11

AV-27F802

SERVICE ADJUSTMENTS

ADJUSTMENT PREP ARATION:

1. You can make the necessary adjustments for this unit with either the remote control unit or with the adjustment equipment and parts

as given below.

2. Adjustment with the remote control unit is made on the basis of the initial setting values, however, the new setting values which set the

screen to its optimum condition may differ from the initial settings.

3. Make sure that AC power is turned on correctly.

4. Turn on the power for the set and test equipment before use, and start the adjustment procedures after waiting at least 30 minutes.

5. Unless otherwise specified, prepare the most suitable reception or input signal for adjustment.

6. Never touch any adjustment parts, which are not specified in the list for this adjustment-variable resistors, transformers, capacitors, etc.

7. Presetting before adjustment.

Unless otherwise specified in the adjustment instructions, preset the following functions with the remote control unit.

User mode setting position

•

VIDEO STATUS STANDARD

HYPER SURROUND OFF

BASS, TREBLE, BALANCE CENTER

TINT, COLOR, PICTURE,

BRIGHT, DETAIL

CENTER

MEASURING INSTRUMENT

1. DC voltmeter(or digital voltmeter)

2. Oscilloscope

3. Signal generator ( Pattern generator ) [NTSC]

4. Remote control unit

5. TV audio multiplex signal generator

6. Frequency counter

7. Resistor (1MØ)

ADJUSTMENT ITEMS

Check of B1 POWER SUPPLY

•

RF AGC adjustment

•

FOCUS adjustment

•

WHITE BALANCE adjustment

•

WHITE BALANCE (Low Light) adjustment

WHITE BALANCE (High Light) adjustment

PIP HIGH LIGHT WHITE BALANCE Adjustment

BRIGHT adjustment

•

SUB BRIGHT adjustment

CONTRAST adjustment

•

SUB CONTRAST adjustment

DEFLECTION adjustment

•

V.CENTER and TRAPEZIUM adjustment

V-SIZE and V-LINEARITY adjustment

H SIZE and H POSITION adjustment

SIDE PIN and CORNER PIN adjustment

PIP DISPLAY POSITION adjustment

CHROMA adjustment

•

SUB COLOR adjustment

SUB TINT adjustment

MTS circuit adjustment

•

INPUT LEVEL check

STEREO VCO adjustment

SAP VCO adjustment

FILTER check

SEPARATION adjustment

No. 51785 11

Page 12

AV-27F802

ADJUSTMENT LOCATIONS

FRONT

LINE FILTER

PWB

P

E3

F901

125V 5A

E1

PW

MAIN PWB

CN006

SS

CN002 CN001

POWER SW PWB FRONT PWB

MPX

S706

B CN007

E1

C

D101

S701

CN007

IC701 CPU

3D Y/C MODULE PWB

CN004

CN003

J601

J602

IC101

IC702

R027

S705 S703

P

K

S1

S702S704

CN005

FRONT

S702 : MENU

S703 : CHANNEL–

CN006B

DEG

S704 : CHANNEL+

S705 : VOLUME–

S706 : VOLUME+

FRONT

DAF PWB

Q

K

Q511

Heatsink

HV

CP

Q

R507

DAF

FRONT

DAFCP

AV SW PWB

J501

J502

FRONT

TOP

CN001

CN002

J504 J503

TU001

TU001

PIP PWB

TU001

FRONT

TOP

CN003

UPPER : H

MIDDLE : FOCUS

LOWER : SCREEN

CRT SOCKET PWB

TP-G

CN004

(SOLDER SIDE)

TP-E1

CN005

TOP

E2

12 No. 51785

Page 13

BASIC OPERATION OF SERVICE MENU

1. TOOL OF SERVICE MENU OPERATION

Operate the SERVICE MENU with the REMOTE CONTROL UNIT.

2. SERVICE MENU ITEMS

In general, basic setting (adjustments) items or verifications are performed in the SERVICE MENU.

PICTURE ............................... This sets the setting values (adjustment values) of the VIDEO/CHROMA and DEFLECTION circuits.

•

SOUND.................................. This sets the setting values (adjustment values) of the AUDIO circuit.

•

THEATER .............................. This is used when the THEATER MODE is adjusted.

•

OTHERS................................ This is used when the OTHERS MODE is adjustment.

•

PIP ......................................... This sets the setting values (adjustment values) of the PIP circuit.

•

3-D Y/C .................................. This sets the setting values (adjustment values) of the 3-D Y/C circuit.

•

LOW LIGHT ........................... This sets the setting values (adjustment values) of the WHITE BALANCE circuit.

•

HIGH LIGHT .......................... This sets the setting values (adjustment values) of the WHITE BALANCE circuit.

•

RF AFC1................................ This is used when the RF AFC1 MODE is verified. [Do not adjust]

•

RF AFC2................................ This is used when the RF AFC2 MODE is verified. [Do not adjust]

•

VCO (CW).............................. This is not used for service.

•

I2C BUS CTRL ...................... This is used when ON/OFF of the I2C BUS CTRL is set. [Fixed ON]

•

3. Basic Operations of the SERVICE MENU

(1) How to enter the SERVICE MENU.

Press SLEEP TIMER key and, while the indication of “SLEEP TIMER 0 MIN.” is being displayed, press DISPLAY key and VIDEO STATUS

key on the remote control unit simultaneously to enter the SERVICE MENU screen

shown in the next figure page.

1

AV-27F802

(2) SERVICE MENU screen selection

Press the UP / DOWN key of the MENU to select any of the following items.

(The letters of the selected items are displayed in yellow.)

PICTURE

•

THEATER

•

PIP

•

LOW LIGHT

•

RF AFC1

•

VCO(CW)

•

(3) Enter the any setting ( adjustment ) mode

PICTURE, SOUND, OTHERS and 3-D Y/C mode

•

1) If select any of PICTURE, SOUND, OTHERS or 3-D Y/C items, and the LEFT / RIGHT key is pressed from SERVICE MENU ( MAIN

MENU ), the screen 2 will be displayed as shown in figure page later.

2) Then the UP / DOWN key is pressed, the PICTURE mode screen 3 or the SOUND mode screen 4 or the OTHER mode screen 5 or

the 3-D Y/C mode screen 6 is displayed, and the PICTURE, SOUND, OTHERS or 3-D Y/C setting can be performed.

PIP mode

•

1) If select the PIP item, and the LEFT/RIGHT key is pressed from SERVICE MENU (MAIN MENU), the screen 7 will be displayed as shown

in figure page later.

2) Then the UP/DOWN key is pressed, the PIP mode screen 8 is displayed, and the PIP setting can be performed.

THEA TER, LOW LIGHT, HIGH LIGHT, RF AFC1, RF AFC2, VCO(CW) and I2C BUS CTRL mode

•

1) If select any of THEA TER / LOW LIGHT / HIGH LIGHT / RF AFC1 / RF AFC2 / VCO (CW) / I2C BUS CTRL items, and the LEFT / RIGHT

key is pressed from SERVICE MENU ( MAIN MENU ), the screens 9 10 1 1 12 13 14 15 will be displayed as shown in figure page later .

2) Then the settings or verifications can be performed.

SOUND

•

OTHERS

•

3-D Y/C

•

HIGH LIGHT

•

RF AFC2

•

I2C BUS CTRL

•

No. 51785 13

Page 14

AV-27F802

1

SERVICE MENU (MAIN MENU) SCREEN PICTURE MODE

SERVICE MENU

PICTURE SOUND

THEATER OTHERS

PIP 3-D Y/C

LOW LIGHT HIGH LIGHT

RF AFC1 RF AFC2

VCO(CW) I2C BUS CTRL

SELECT BY

OPERATE BY

11

HIGH LIGHT MODE

HIGH LIGHT

999 999

12

RF AFC1 MODE

EXIT BY

EX

IT

[DO NOT ADJUST]

TOO HIGH GOOD TOO LOW

RF AFC1 ON

FINE

SELECT BY

OPERATE BY

EXIT BY

999

EX

IT

2

SELECT BY

4

SOUND MODE OTHERS MODE 3-D Y/C MODE

1. NOISE DET.

STATUS

7

SCREEN PIP MODE

SELECT BY

EXIT BY

999

99999999

EXIT BY

EX

IT

EX

IT

3

1. BRIGHT

STATUS

5

1. OSD POS. 999

8

1. PIP BR

STATUS

999

99999999

999

99999999

1. YC 001

STATUS

6

999

99999999

13

RF AFC2 MODE

[DO NOT ADJUST]

TOO HIGH GOOD TOO LOW

RF AFC2 ON

FINE

SELECT BY

OPERATE BY

14

VCO (CW) MODE

999

EXIT BY

[DO NOT USE]

HIGH LEVEL

REFERENCE LEVEL

LOW LEVEL

SYNC : YES

15

I2C BUS CTRL MODE

[FIXED ON]

I2C BUS ON

SELECT BY

OPERATE BY

EXIT BY

EX

IT

9

THEA TER MODE (1/2) THEA TER MODE (2/2)

TINT 999 B CUT. 999

COLOR 999 R DRIVE 999

PICTURE 999 B DRIVE 999

BRIGHT 999 DC REST. 999

DETAIL 999 BLK ST. 999

R CUT. 999 GMM PNT 999

G CUT. 999

SELECT BY

OPERATE BY

10

LOW LIGHT MODE

EX

IT

BRIGHT

999 999

999

EXIT BY

PAGE 1/2

999

EX

IT

CD MAT. 99 CMP CD M 99

RY GAIN 99 CMP RY G 99

GY PHASE 99 CMP GY P 99

CORING 99 CMP COR 99

SELECT BY

OPERATE BY

PAGE 2/2

EXIT BY

EX

IT

14 No. 51785

Page 15

(4) Setting method

1. BRIGHT

STATUS

999

99999999

SETTING ITEM

INITIAL

SETTING VALUE

(Adjust)

SETTING VALUE

PICTURE MODE

1) UP / DOWN key of the MENU

Select the SETTING ITEM.

2) LEFT / RIGHT key of the MENU

Setting (adjust) the SETTING VALUE of the SETTING ITEM.

When the key is released the SETTING VALUE will be stored (memorized).

3) EXIT key

Returns to the previous screen.

(5) Releasing SERVICE MENU

1) After returning to the SERVICE MENU upon completion of the setting (adjustment) work, press the EXIT key again.

AV-27F802

¤ The settings for LOW LIGHT and HIGH LIGHT are described in the WHITE BAL-

ANCE page of ADJUSTMENT.

No. 51785 15

Page 16

AV-27F802

INITIAL SETTING VALUE OF SERVICE MENU

1. Adjustment of the SERVICE MENU is made on the basis of the initial setting values; however, the new setting values which set the

screen in its optimum condition may differ from the initial setting.

2. Do not change the initial setting values of the setting (Adjustment) items not listed in “ADJUSTMENT”.

PICTURE MODE

•

The four setting items in the video mode No.6 EXT BRI., No.7 EXT PIC., No.8 EXT COL. and No.9 EXT TINT are linked to the items in the TV

MODE No.1 BRIGHT, No.2 PICTURE, No.3 COLOR and No.4 TINT, respectively. When the setting items in the TV mode are adjusted, the

values in the setting items in the video mode are revised automatically to the same values in the TV mode.(The initial setting values given in ( )

are off-set values.)

When the four items (No.6, 7, 8 and 9) are adjusted in the video mode, the setting values in each item are revised independently.

No. Setting (Adjustment) item Variable range Initial setting value

1 BRIGHT 000 — 127 063

2 PICTURE 000 — 127 070

3 COLOR 000 — 127 072

4 TINT 000 — 127 056

5 TV DETAIL 000 — 063 045

6 EXT BRIGHT ±025 ±000

7 EXT PICT. ±025 ±002

8 EXT COLOR ±025 ±004

9 EXT TINT ±025 ±000

10 EXT DETAIL 000 — 063 045

11 CMP BRIGHT ±025 +001

12 CMP PICT. ±025 +014

13 CMP COLOR 000 — 127 082

14 CMP TINT 000 — 127 078

15 CMP DETAIL 000 — 063 050

16 CMP R CUT ±025 –011

17 CMP G CUT ±025 ±000

18 CMP B CUT ±025 –001

19 CMP R DRV ±025 ±000

20 CMP B DRV ±025 ±000

21 WPL 000 / 001 001

22 B. B. SW 000 / 001 000

23 C TRAP 000 / 001 000

24 CORING 000 / 001 001

25 CMP CORING 000 / 001 001

26 TV SHARPF 000 / 001 001

27 EXT SHARPF 000 / 001 001

28 CMP SHARPF 000 / 001 001

29 RGB CONT 000 — 063 031

30 TV ID SEN S 000 / 001 000

31 EXT ID SEN 000 / 001 000

32 F ID 000 / 001 000

33 Y MUTE 000 / 001 000

34 AUDIO A TT 000 — 127 127

35 SUB CONT 000 — 015 008

16 No. 51785

Page 17

AV-27F802

No. Setting (Adjustment) item Variable range Initial setting value

36 R Y GAIN 000 / 001 001

37 CMP R Y GA 000 / 001 001

38 G Y PHASE 000 / 001 001

39 CMP G Y PH 000 / 001 000

40 CD MATRIX 000 — 003 003

41 CMP CD MAT 000 — 003 002

42 BLACK ST 000 — 003 001

43 DC REST 000 — 003 001

44 COLOR GMM 000 / 001 000

45 UV/CBCR 000 / 001 000

46 AT FLESH 000 / 001 000

47 ABL GAIN 000 — 003 000

48 ABL ST PNT 000 — 003 003

49 RGB ABCL 000 / 001 001

50 TV BPF TOF 000 / 001 000

51 EXT BPF TOF 000 / 001 000

52 GMM PNT 000 — 003 003

53 SVM GAIN 000 — 003 002

54 CMP SVM GA 000 — 003 002

55 SVM PHASE 000 / 001 000

56 AUDIO SW 000 / 001 000

57 BUZZ 000 / 001 000

58 IF FREQ 000 / 001 000

59 RF AGC 000 — 063 045

60 AFT MUTE 000 / 001 000

61 AFT SENS 000 / 001 001

62 R/G DRV SW 000 / 001 001

63 BLK SW 000 / 001 000

64 V S COR 000 — 015 012

65 V LIN 000 — 015 008

66 V SIZE 000 — 127 065

67 V AGC 000 / 001 000

68 V CENTER 000 — 063 043

69 TV AFC 000 — 003 002

70 EXT AFC 000 — 003 002

71 V POSI 000 — 007 000

72 H POSI 000 — 031 011

73 H SIZE 000 — 063 023

74 TV V FREQ 000 — 003 000

75 EXT V FREQ 000 — 003 000

76 SIDE PIN 000 — 063 027

77 STAND BY 000 / 001 000

78 TRAPEZ 000 — 063 035

79 V RAMP REF 000 / 001 001

80 V 48HZ 000 / 001 000

81 V EHT 000 — 007 000

82 TOP PIN 000 — 031 010

No. 51785 17

Page 18

AV-27F802

No. Setting (Adjustment) item Variable range Initial setting value

83 H EHT 000 — 007 000

84 BTM PIN 000 — 031 012

85 V BLK LOW 000 — 003 000

86 V BLK UP 000 — 003 000

87 CAPTION IN 000 / 001 000

88 H BLK 000 / 001 000

89 SCREEN 000 / 001 000

90 ACB SW 000 / 001 000

91 ACB PULSE 000 — 015 007

92 OVER MODU 000 / 001 001

93 CB/CR FIL 000 / 001 001

94 TEST 000 — 255 128

95 RF S/N TY 000 — 002 001

96 EXT S/N TY 000 — 002 001

97 RF SN YC E 000 — 255 005

98 RF SN YC F 000 — 255 016

99 RF SN YC G 000 — 063 032

100 RF SN YC H 000 — 255 025

101 EX SN YC E 000 — 255 005

102 EX SN YC F 000 — 255 016

103 EX SN YC G 000 — 063 032

104 EX SN YC H 000 — 255 025

105 RF SN VC 1 000 — 063 000

106 RF SN VC 2 000 — 063 007

107 RF SN VC 3 000 — 063 014

108 RF SN VC 4 000 — 063 021

109 EX SN VC 1 000 — 063 000

110 EX SN VC 2 000 — 063 007

111 EX SN VC 3 000 — 063 014

112 EX SN VC 4 000 — 063 021

113 COR LEVEL 000 — 003 003

114 VNR CHK 000 — 255 003

115 YC SN TIME 000 — 255 005

116 VC SN TIME 000 — 255 005

117 VM DATA A ±127 +008

118 VM DATA B ±127 –004

119 VM DATA C ±127 –016

120 VM DATA D 000 / 001 001

121 VC SN STOP 000 — 255 010

18 No. 51785

Page 19

SOUND MODE

•

No. Setting (Adjustment) item Variable range Initial setting value

1 NOISE DET. 000 / 001 001

2 IN LEVEL 000 — 063 025

3 FH MONITOR 000 / 001 000

4 STEREO VCO 000 — 063 030

5 PILOT CAN. 000 / 001 000

6 FILTER 000 — 063 030

7 LOW SEP. 000 — 063 028

8 HI SEP . 000 — 063 025

9 5FH MON. 000 / 001 000

10 SAP VCO 000 — 063 003

11 IN GAIN 000 / 001 000

12 FIL. OFFSET ±010 ±000

13 BBE BASS ±010 +001

14 BBE TRE ±010 –001

THEA TER MODE

•

Setting (Adjustment) item Variable range Initial setting value

AV-27F802

TINT ±20 –06

COLOR ±20 –03

PICTURE ±50 –15

BRIGHT ±20 ±00

DETAIL ±20 +03

R CUT. ±20 ±00

G CUT. ±20 ±00

B CUT. ±20 ±00

R DRIVE ±99 +07

B DRIVE ±99 –25

DC REST. 00 — 03 01

BLK ST. 00 — 03 00

GMM PNT 00 — 03 01

CD MATRIX 00 — 03 01

RY GAIN 00 / 01 01

GY PHASE 00 / 01 00

CORING 00 / 01 01

CMP CD M 00 — 03 01

CMP RY G 00 / 01 01

CMP GY P 00 / 01 00

CMP COR 00 / 01 01

No. 51785 19

Page 20

AV-27F802

OTHERS MODE

•

No. Setting (Adjustment) item Variable range Initial setting value

1 OSD POS. 000 — 007 002

2 CCD POS. 000 — 015 003

3 EOSEL 000 / 001 000

4 MENU COLOR 000 — –030 –010

5 MENU PICT. 000 — –030 –010

6 MENU BRI. 000 — –030 –010

PIP MODE

•

No. Setting (Adjustment) item Variable range Initial setting value

1 PIP BR 000 — 015 005

2 PIP PICT 000 — 075 045

3 PIP TINT 000 — 063 036

4 PIP COL 000 — 015 006

5 P R CUT 000 — 015 003

6 P G CUT 000 — 015 000

7 P B CUT 000 — 015 002

8 P R DR 000 — 255 052

9 P G DR 000 — 255 055

10 P B DR 000 — 255 060

11 LEFT POS. 000 — 255 012

12 RIGHT POS. 000 — 255 026

13 UPPER POS. 000 — 127 012

14 LOWER POS. 000 — 127 011

15 PICT LOCK 000 / 001 001

16 SELDEL 000 — 015 000

17 AGCFIX 000 / 001 001

18 AGCADST 000 / 001 000

19 AGC 000 — 015 007

20 VSPDEL 000 — 031 000

21 VSPISQ 000 / 001 001

22 YCOR 000 / 001 001

23 XFREQF 000 / 001 001

24 WTCHDG 000 / 001 001

25 COLON 000 / 001 000

26 ACQNEW 000 / 001 000

27 DSTDET 000 / 001 001

28 CRIBEOK 000 / 001 000

29 FCBEOK 000 / 001 000

30 NOCRID 000 / 001 000

31 NONSED 000 / 001 000

20 No. 51785

Page 21

3-D Y/C MODE

•

No. Setting (Adjustment) item Variable range Initial setting value

1 YC 001 000 — 003 001

2 YC 002 000 — 003 001

3 YC 003 000 — 003 001

4 YC 004 000 — 003 000

5 YC 005 000 — 003 000

6 YC 006 000 — 003 000

7 YC 007 000 — 003 003

8 YC 008 000 — 003 000

9 YC 009 000 — 003 001

10 YC 010 000 — 003 000

11 YC 011 000 — 007 004

12 YC 012 000 — 007 002

13 YC 013 000 — 015 002

14 YC 014 000 — 015 010

15 YC 015 000 — 015 002

16 YC 016 000 — 015 004

17 YC 017 000 / 001 000

18 YC 018 000 / 001 000

19 YC 019 000 — 003 002

20 YC 020 000 / 001 000

21 YC 021 000 / 001 000

22 YC 022 000 — 003 002

23 YC 023 000 / 001 000

24 YC 024 000 / 001 000

25 YC 025 000 / 001 000

26 YC 026 000 — 003 000

27 YC 027 000 — 003 001

28 YC 028 N/A 000 — 003 001

29 YC 029 000 — 003 001

30 YC 030 000 — 003 001

31 YC 031 000 — 003 002

32 YC 032 000 / 001 000

33 YC 033 000 — 007 000

34 YC 034 000 — 015 000

35 YC 035 000 — 007 002

36 YC 036 000 — 031 015

37 YC 037 000 — 003 000

38 YC 038 000 — 015 009

39 YC 039 000 — 003 001

40 YC 040 000 — 003 001

41 YC 041 000 / 001 000

42 YC 042 000 / 001 000

43 YC 043 000 / 001 000

44 YC 044 000 / 001 001

45 YC 045 000 — 015 003

46 YC 046 000 — 015 012

47 YC 047 000 — 015 008

AV-27F802

No. 51785 21

Page 22

AV-27F802

No. Setting (Adjustment) item Variable range Initial setting value

48 YC 048 000 — 015 004

49 YC 049 000 — 015 010

50 YC 050 000 / 001 001

51 YC 051 000 / 001 001

52 YC 052 000 — 003 000

53 YC 053 000 / 001 000

54 YC 054 000 / 001 001

55 YC 055 000 / 001 001

56 YC 056 000 / 001 001

57 YC 057 000 — 015 000

58 YC 058 000 / 001 000

59 YC 059 000 / 001 001

60 YC 060 000 — 003 000

61 YC 061 000 — 015 000

62 YC 062 DBL 000 — 007 002

63 YC 063 N/A 000 — 015 002

64 YC 064 N/A 000 — 015 004

65 YC 065 N/A 000 — 015 002

66 YC 066 N/A 000 — 015 004

67 YC 067 000 / 001 000

68 YC 068 000 / 001 000

69 YC 069 000 / 001 000

70 YC 070 FIX 000 — 003 000

71 YC 071 000 / 001 000

72 YC 072 000 / 001 000

73 YC 073 000 / 001 001

74 YC 074 FIX 000 / 001 000

75 YC 075 FIX 000 / 001 000

76 YC 076 000 / 001 001

77 YC 077 FIX 000 / 001 000

78 YC 078 FIX 000 / 001 000

79 YC 079 FIX 000 — 007 005

80 YC 080 FIX 000 — 015 000

81 YC 081 FIX 000 — 015 008

82 YC 082 FIX 000 — 015 004

83 YC 083 FIX 000 — 015 004

84 YC 084 DBL 000 — 255 112

85 YC 085 DBL 000 — 255 008

86 YC 086 000 / 001 001

87 YC 087 000 — 003 003

88 YC 088 000 / 001 001

89 YC 089 000 / 001 000

90 YC 090 000 / 001 000

91 YC 091 000 / 001 000

92 YC 092 N/A 000 / 001 000

93 YC 093 N/A 000 / 001 000

94 YC 094 DBL 000 — 003 001

22 No. 51785

Page 23

No. Setting (Adjustment) item Variable range Initial setting value

95 YC 095 DBL 000 / 001 001

96 YC 096 DBL 000 / 001 001

97 YC 097 DBL 000 / 001 000

98 YC 098 DBL 000 / 001 000

99 YC 099 DBL 000 — 003 000

100 YC 100 DBL 000 — 003 000

101 YC 101 DBL 000 / 001 000

102 YC 102 DBL 000 / 001 000

103 YC 103 DBL 000 / 001 001

104 YC 104 DBL 000 / 001 000

105 YC 105 DBL 000 / 001 000

106 YC 106 DBL 000 / 001 000

107 YC 107 DBL 000 — 007 002

108 3-D Y/C 000 / 001 001

LOW LIGHT MODE

•

Setting (Adjustment) item Variable range Initial setting value

AV-27F802

R CUTOFF 0 — 255 85

G CUTOFF 0 — 255 85

B CUTOFF 0 — 255 85

HIGH LIGHT MODE

•

Setting (Adjustment) item Variable range Initial setting value

R DRIVE 0 — 127 60

B DRIVE 0 — 127 60

RF AFC1 MODE

•

Setting (Adjustment) item Variable range Initial setting value

RF AFC1 ON / OFF ON

FINE -77 — +77 ± × ×

RF AFC2 MODE

•

Setting (Adjustment) item Variable range Initial setting value

RF AFC2 ON / OFF ON

FINE -77 — +77 ± × ×

DO NOT

ADJUST

DO NOT

ADJUST

I2C BUS CTRL MODE

•

Setting (Adjustment) item Variable range Initial setting value

I2C BUS ON/OFF [FIXED ON]

No. 51785 23

DO NOT

ADJUST

Page 24

AV-27F802

ADJUSTMENTS

B1 POWER SUPPL Y

Item

Measuring

instrument

Test point Adjustment part Description

Check of

B1 POWER

SUPPLY

DC Voltmeter R507 C504

ADJUSTMENT OF RF AGC

Item

RF AGC

adjustment

Measuring

instrument

1. Receive a black-and-white signal.

side (B1)

Q511

heatsink (

Test point Adjustment part Description

)

No.59 RF AGC

2. Connect the DC V oltmeter to R507 C504 side (B1) and Q511 heatsink

).

(

3. Confirm that the voltage is DC134V .

1. Receive a broadcast.

2. Select the No.59 RF AGC of the PICTURE MODE.

3. Press the MUTE key of the remote control unit and turn off color.

4. With the LEFT key of the remote control unit, get noise in the screen

picture. (0 side of setting value)

5. Press the RIGHT key of the remote control unit and stop when noise

disappears from the screen.

6. Change to other channels and make sure that there Is no irregular-

ity.

7. Press the MUTE key and get color out.

+2V

-2V

ADJUSTMENT OF FOCUS

Item

FOCUS

adjustment

Measuring

instrument

Signal

generator

24 No. 51785

Test point Adjustment part Description

FOCUS VR

[In HVT]

H VR

[In HVT]

Notes:

•Proceed to the following this adjustment after having completed the

•Set VIDEO STATUS to “STANDARD”.

1. Receive a crosshatch signal.

2. While looking at the screen center, adjust the FOCUS VR so that

3. Adjust the H VR so that the vertical lines will be clear and in fine

4. Make sure that the picture is in focus even when the screen gets

Note:

The final adjustment of convergence must be done after the FOCUS

adjustment. (Convergence is changed by FOCUS adjustment.)

adjustments of B1 POWER SUPPLY, SUB BRIGHT and PICTURE.

the horizontal lines will be clear and in fine detail.

detail.

darkened.

Page 25

ADJUSTMENT OF WHITE BALANCE

Item

Measuring

instrument

Test point Adjustment part

AV-27F802

Description

WHITE

BALANCE

(Low Light)

Adjustment

Signal

generator

[LOW LIGHT] MODE

BRIGHT

999

R CUTOFF

REMOTE CONTROL UNIT

H.LINE ON

999

999 999

G CUTOFF

H.LINE OFF EXIT

123

R CUTOFF G CUTOFF B CUTOFF

456

R CUTOFF G CUTOFF B CUTOFF

789

No.1 BRIGHT

R CUTOFF

G CUTOFF

B CUTOFF

SCREEN VR

[In HVT]

BRIGHT

B CUTOFF

Note :

Set VIDEO STATUS to “STANDARD”.

1. Receive a black-and-white signal.(Color off)

2. Select the [LOW LIGHT] MODE from the SERVICE MENU.

3. Set the initial setting value of BRIGHT is 063 with the LEFT / RIGHT

key of the remote control unit.

4. Set the initial setting value of R CUTOFF, G CUTOFF and B CUTOFF is 085 with the 4 to 9 key of the remote control unit.

5. Display a single horizontal line by pressing the 1 key of the remote

control unit.

6. Turn the screen VR all the way to the left.

7. Turn the screen VR gradually to the right from the left until either

one of the red, blue or green colors appears faintly.

8. Adjust the two colors which did not appear until the single horizontal

line that is displayed becomes white using the 4 to 9 keys of the

remote control unit.

9. Turn the screen VR to where the single horizontal line glows faintly.

10.Press the 2 key to return to the regular screen.

9 The 3 EXIT key is the cancel key for the WHITE BALANCE.

WHITE

BALANCE

(High Light)

Adjustment

Signal

generator

[HIGH LIGHT] MODE

999

R DRIVE

H.LINE ON

HIGHT LIGHT

REMOTE CONTROL UNIT

H.LINE OFF EXIT

999

123

R DRIVE B DRIVE

456

R DRIVE B DRIVE

789

R DRIVE

B DRIVE

B DRIVE

Notes:

•Proceed to the following this adjustment after having completed the

adjustment of LOW LIGHT WHITE BALANCE.

•Set VIDEO STATUS to “STANDARD”.

1. Receive a black-and-white signal. (Color off)

2. Select the [HIGH LIGHT] MODE from the SERVICE MENU.

3. Set the initial setting value of R DRIVE and B DRIVE is 060 with the

4 , 6 , 7 and 9 keys of the remote control unit.

4. Adjust the screen until it becomes white using the 4 , 6 , 7 and 9

keys of the remote control unit.

9 The 3 (EXIT) key is the cancel key for the WHITE BALANCE.

No. 51785 25

Page 26

AV-27F802

Item

PIP

HIGH LIGHT

WHITE

BALANCE

Measuring

instrument

Signal

generator

ADJUSTMENT OF BRIGHT

Item

SUB BRIGHT

Adjustment

Measuring

instrument

Test point Adjustment part Description

No.8 P R DR

No.10 P B DR

PIP screen

Main screen

Test point Adjustment part Description

No.1 BRIGHT Notes:

Notes:

•Proceed to the following this adjustment after having completed the

adjustments of LOW LIGHT WHITE BALANCE and HIGH LIGHT

WHITE BALANCE for the main picture.

•Set VIDEO STATUS to “STANDARD”.

1. Receive a black-and-white signal. (Color off)

2. Select the PIP MODE from the SERVICE MENU.

3. Then adjust the white color of the PIP screen using the No. 8 P R

DR and the No. 10 P B DR of the PIP MODE so that it is the same

brightness as the main screen.

•Proceed to the following this adjustment after having completed the

adjustments of LOW LIGHT WHITE BALANCE and HIGH LIGHT

WHITE BALANCE.

•Set VIDEO STATUS to “STANDARD”.

ADJUSTMENT OF CONTRAST

Item

SUB

CONTRAST

Adjustment

Measuring

instrument

Test point Adjustment part Description

No.2 PICTURE

1. Receive a broadcast.

2. Select the No.1 BRIGHT of the PICTURE MODE.

3. Set the initial setting value of the No.1 BRIGHT with the LEFT /

RIGHT key of the remote control unit.

4. If the brightness is not best with the initial setting value, make fine

adjustment of the No.1 BRIGHT until you get the optimum brightness.

Notes:

•Proceed to the following this adjustment after having completed the

adjustment of SUB BRIGHT.

•Set VIDEO STATUS to “STANDARD”.

1. Receive a broadcast.

2. Select the No.2 PICTURE of the PICTURE MODE.

3. Set the initial setting value of the No.2 PICTURE with the LEFT /

RIGHT key of the remote control unit.

4. If the contrast is not best with the initial setting value, make fine

adjustment of the No.2 PICTURE until you get the optimum contrast.

26 No. 51785

Page 27

ADJUSTMENT OF DEFLECTION

Item

Measuring

instrument

Test point Adjustment part Description

AV-27F802

V CENTER and

TRAPEZIUM

Adjustment

V-SIZE and

V-LINEARITY

Adjustment

Signal

generator

Signal

generator

Screen size

No.68 V CENTER

No.78 TRAPEZ

No.66 V SIZE

No.65 V LIN

Note:

Proceed to the following this adjustment after having completed the

adjustments of SUB BRIGHT and SUB CONTRAST.

1. Receive a crosshatch signal.

2. Adjust the No.68 V CENTER of the PICTURE MODE to be the same

between the CRT vertical center and crosshatch vertical center.

3. Adjust the No.78 TRAPEZ of the PICTUER MODE to be the vertical

lines straight.

4. Confirm the vertical lines to be straight. If it is not straight, adjust to

be straight at the No.78 TRAPEZ.

Note:

Proceed to the following this adjustment after having completed the

adjustments of SUB BRIGHT and SUB CONTRAST.

1. Receive a crosshatch signal.

2. Select the No.66 V SIZE of the PICTURE MODE to squeeze the

laster.

3. Adjust the No.65 V LIN of the PICTURE MODE to be symmetrical.

4. Adjust the No.66 V SIZE until the vertical screen size is 92%.

Screen

size 92%

H SIZE and

H POSITION

Adjustment

Screen

size

Signal

generator

Picture size 100%

Screen size 90%

Picture

size 100%

No.73 H SIZE

No.72 H POSI

Picture

size 100%

Note:

Proceed to the following this adjustment after having completed the

adjustments of FOCUS, SUB BRIGHT , SUB CONTRAST, V CENTER,

TRAPEZIUM, V-SIZE and V-LINEARITY.

1. Receive a crosshatch signal.

2. Select the No.73 H SIZE of the PICTURE MODE.

3. Set the initial setting value of the No.73 H SIZE with the LEFT /

RIGHT key of the remote control unit.

4. Adjust the No.73 H SIZE until the horizontal screen size is 90%.

5. Adjust the No.72 H POSI until the screen will be horizontally centered.

Picture size 100%

No. 51785 27

Page 28

AV-27F802

Item

SIDE PIN and

CORNER PIN

Adjsutment

PIP DISPLAY

POSITION

Adjustment

Measuring

instrument

Signal

generator

Straight Straight

Test point Adjustment part Description

No.76 SIDE PIN

No.82 TOP PIN

No.84 BTM PIN

No.11 LEFT POS.

No.12 RIGHT POS.

No.13 UPPER POS.

No.14 LOWER POS.

Note:

Proceed to the following this adjustment after having completed the

adjustments of FOCUS, SUB BRIGHT , SUB CONTRAST, V CENTER,

TRAPEZIUM, V-SIZE and V-LINEARITY.

1. Receive a crosshatch signal.

2. Adjust such that vertical 2nd lines from left and right to be straight at

the No.76 SIDE PIN of the PICTURE MODE.

3. Adjust the end of vertical 2nd lines from left and right to be straight

at the No.82 TOP PIN and the No.84 BTM PIN of the PICTURE

MODE.

Notes:

•Proceed to the following this adjustment after having completed the

adjustments of V CENTER, TRAPEZIUM, V-SIZE, V-LINEARITY, H

SIZE, H POSITION, SIDE PIN and CORNER PIN for the main picture.

•Set VIDEO STATUS to “STANDARD”.

UPPER POS.

LOWER POS.

LEFT POS. RIGHT POS.

80%

±2%

80% ±2%

Main screen size

1. Receive a broadcast.

2. Select the PIP MODE from the SERVICE MENU.

3. Then adjust the PIP screen size so that it occupies 80% ± 2% of the

main screen area.

Main

screen

size

28 No. 51785

Page 29

ADJUSTMENT OF CHROMA

Item

Measuring

instrument

AV-27F802

Test point Adjustment part Description

SUB COLOR

adjustment

Signal

generator

Oscilloscope

Remote

control unit

Y

Cy

W

TP-B

TP-E1(

[CRT SOCKET

PWB]

G

R

Mg

No.3 COLOR

)

Notes:

•Proceed to the following this adjustment after having completed the

adjustment of CONTRAST.

•Set VIDEO STATUS to “STANDARD”.

[ Method of adjustment without measuring instrument ]

1. Receive a broadcast.

2. Select the No.3 COLOR of the PICTURE MODE.

3. Set the initial setting value of the No.3 COLOR with the LEFT/RIGHT

key of the remote control unit.

4. If the color is not the best with the Initial setting value, make fine

adjustment of the No.3 COLOR until you get the optimum color.

(A)

(–)

0V

B

(+)

Notes:

•Proceed to the following this adjustment after having completed the

adjustment of CONTRAST.

•Set VIDEO STATUS to “STANDARD”.

[ Method of adjustment using measuring instrument ]

1. Input the full field color bar signal (75% white).

2. Select the No.3 COLOR of the PICTURE MODE.

3. Set the initial setting value of the No.3. COLOR with the LEFT/RIGHT

key of the remote control unit.

4. Connect the oscilloscope between TP-B and TP-E1.

5. Adjust COLOR and bring the value of (A) in the illustration to the

voltage +6V (V

W-B).

SUB TINT

adjustment

Signal

generator

Oscilloscope

Remote

control unit

Y

Cy

W

TP-B

TP-E1(

[CRT SOCKET

PWB]

G

R

Mg

No.4 TINT

)

Notes:

•Proceed to the following this adjustment after having completed the

adjustment of CONTRAST.

•Set VIDEO STATUS to “STANDARD”.

[ Method of adjustment without measuring instrument ]

1. Receive a broadcast.

2. Select the No.4 TINT of the PICTURE MODE.

3. Set the initial setting value of the No.4 TINT with the LEFT/RIGHT

key of the remote control unit.

4. If the tint is not the best with the initial setting value, make fine ad-

justment of the No.4 TINT until you get the optimum tint.

(–)

0V

(+)

B

(B)

Notes:

•Proceed to the following this adjustment after having completed the

adjustment of CONTRAST.

•Set VIDEO STATUS to “STANDARD”.

[ Method of adjustment using measuring instrument ]

1. Input the full field color bar signal (75% white).

2. Select the No.4 TINT of the PICTURE MODE.

3. Set the initial setting value of the No.4 TINT with the LEFT/RIGHT

key to the remote control unit.

4. Connect the oscilloscope between TP-B and TP-E1.

5. Adjust TINT and bring the value of (B) in the illustration to the volt-

age +2V (V

W-Mg).

No. 51785 29

Page 30

AV-27F802

ADJUSTMENT OF MTS CIRCUIT

Item

Measuring

instrument

Test point Adjustment part Description

MTS INPUT

LEVEL

check

MTS STEREO

VCO

adjustment

MTS SAP

VCO

adjustment

Signal

generator

Frequency

counter

Signal

generator

Frequency

counter

[MPX]

Connector

2

pin AUDIO R

3 pin GND

[MPX]

Connector

4 pin TP_952.5

3 pin GND

2 pin AUDIO_R

No.2 IN LEVEL

No.3 FH MONITOR

No.4 STEREO VCO

No.9 5FH MON.

No.10 SAP VCO

1. Select the No.2 IN LEVEL of the SOUND MODE.

2. Verify that the No.2 IN LEVEL is set at its initial setting value.

Note: Menu “MTS” is set to “STEREO”

1. Receive a RF signal (nonmodulated sound signal) from the antenna

terminal.

2. Select the No.3 FH MONITOR of SOUND MODE, and change the

setting value from 0 to 1.

3. Connect the Frequency Counter to pin 2 of [MPX] connector and

GND (Pin 3 of [MPX] connector).

4. Select the No.4 STEREO VCO.

5. Set the initial setting value of the No.4 STEREO VCO with the LEFT/

RIGHT key of the remote control unit.

6. Adjust the No.4 STEREO VCO so that the frequency counter will

display 15.73kHz±0.1kHz.

7. Select the No.3 FH MONITOR of the SOUND MODE, and reset the

setting value from 1 to 0.

1. Receive a RF signal (non modulated sound signal) from the antenna terminal.

2. Connect between pin 4 of [MPX] connector and GND (Pin 3 of [MPX]

connector) through 1MØ Resistor.

3. Select the No.9 5FH MON. of the SOUND MODE, and reset the

setting value from 0 to 1.

4. Connect the Frequency Counter to pin 2 of [MPX] connector and

GND (Pin 3 of [MPX] connector) .

5. Select the No.10 SAP VCO.

6. Set the initial setting value of the No.10 SAP VCO with the LEFT/

RIGHT key of the remote control unit.

7. Adjust the No.10 SAP VCO so that the frequency counter will display 78.67kHz±0.5kHz.

8. Select the No.9 5FH MON. of the SOUND MODE, and reset the

setting value from 1 to 0.

MTS FILTER

check

MTS

SEPARATION

adjustment

L-Channel

signal waveform

1 cycle

TV audio

multiplex

signal

generator

Oscilloscope

[MPX]

Connector

1 pin AUDIO_L

2 pin AUDIO_R

3 pin GND

R-Channel

crosstalk portion

Minimum

No.6 FILTER

No.7 LOW SEP.

No.8 HI SEP.

1. Select the No.6 FILTER of the SOUND MODE.

2. Verify that the No.6 FILTER is set at its initial setting value.

Note: Menu “MTS” is set to “STEREO”

1. Input a stereo L signal (300Hz) from the TV audio multiplex signal

2. Connect an oscilloscope to pin 1 of [MPX] connector, and display

3. Change the connection of the oscilloscope to pin 2 of [MPX] con-

4. Select the No.7 LOW SEP. of the SOUND MODE.

5. Set the initial setting value of the No.7 LOW SEP. with the LEFT/

6. Adjust the No.7 LOW SEP. so that the 300Hz signal level will be-

7. Change the signal to 3kHz, and connect an oscilloscope to pin 1 of

8. Adjust the No.8 HI SEP. so that the 3kHz signal level will become

30 No. 51785

generator to the antenna terminal.

one cycle portion of the 300Hz signal.

nector, and enlarge the voltage axis.

RIGHT key of the remote control unit.

come minimum.

[MPX] connector.

minimum.

Page 31

HOW TO CHECK THE HIGH VOL T AGE HOLD DOWN CIRCUIT

1. HIGH VOLT AGE HOLD DOWN CIRCUIT

After repairing the high voltage hold down circuit shown in Fig. 1.

This circuit shall be checked to operate correctly.

2. CHECKING OF THE HIGH VOLT AGE HOLD DOWN CIRCUIT

(1) Turn the POWER SW ON.

RY951

S1

connector 2 & 3 ).

RESISTOR

20.3 kΩ ± 101 Ω 1/4 W

(2) As shown in Fig. 1, set the resistor (between

(3) Make sure that the screen picture disappears.

(4) Temporarily unplug the power cord.

S1

(5) Remove the resistor (between

(6) Again plug the power cord, make sure that the normal picture is displayed on the screen.

connector 2 & 3 ).

AV-27F802

POWER

ON OFF

R952

R532

D535

R951

R533

Q531

Q951

Q532

R534

+

C533

D534

D532

BW

D531

Fig. 1

23

R537 FR525

R535R538

S1 CONNECTOR

+

HEATER

T502

4

D525

C525

No. 51785 31

Page 32

AV-27F802

SELF CHECK FUNCTIONS

1. Outline

This model has self check functions given below. When a malfunction has been detected, the POWER is turned off and the LED flashes to inform

of the failure . The malfunction is detected by the signal input state of the control line connected to the microcomputer.

2. Self check items

Check item Details of detection Method of detection State of malfunction

Over-current protector

3. Self check indicating function

The self-check function begins detection about 5 seconds after power

is supplied.

In the event a malfunction is detected, the power is cut off immediately.

At this time, the ON-TIMER LED flashes to inform of the malfunction.

[ON-TIMER LED indication]

The ON-TIMER LED flashes at 0.5 seconds intervals.

Operation of B1 protector circuit. The microcomputer detects at 1

second intervals.

If NG is detected for more than

200 ms, a malfunction is interpreted.

POWER

Supplied

After about

5 seconds

Start of

detection

When a malfunction has been

detected, the POWER is turned

off. While the POWER is being

turned off , the power key of the

remote controller is not operational until the power code is

taken out and put in again.

Malfunction

is detected

POWER OFF

Flashing

ON-TIMER LED

32 No. 51785

Page 33

VICTOR COMPANY OF JAPAN, LIMITED

HOME AV NETWORK BUSINESS UNIT 1106 Heta, Iwai-city, Ibaraki-prefecture, 306-0698, Japan

27F802S-MEM #3

Printed in Japan

VP0012

SW

Loading...

Loading...