Page 1

SERVICE MANUAL

COLOUR TELEVISION

YA41520067

AV-21B16

BASIC CHASSIS

CG4

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

COPYRIGHT © 2006 Victor Company of Japan, Limited

No.YA415

2006/7

Page 2

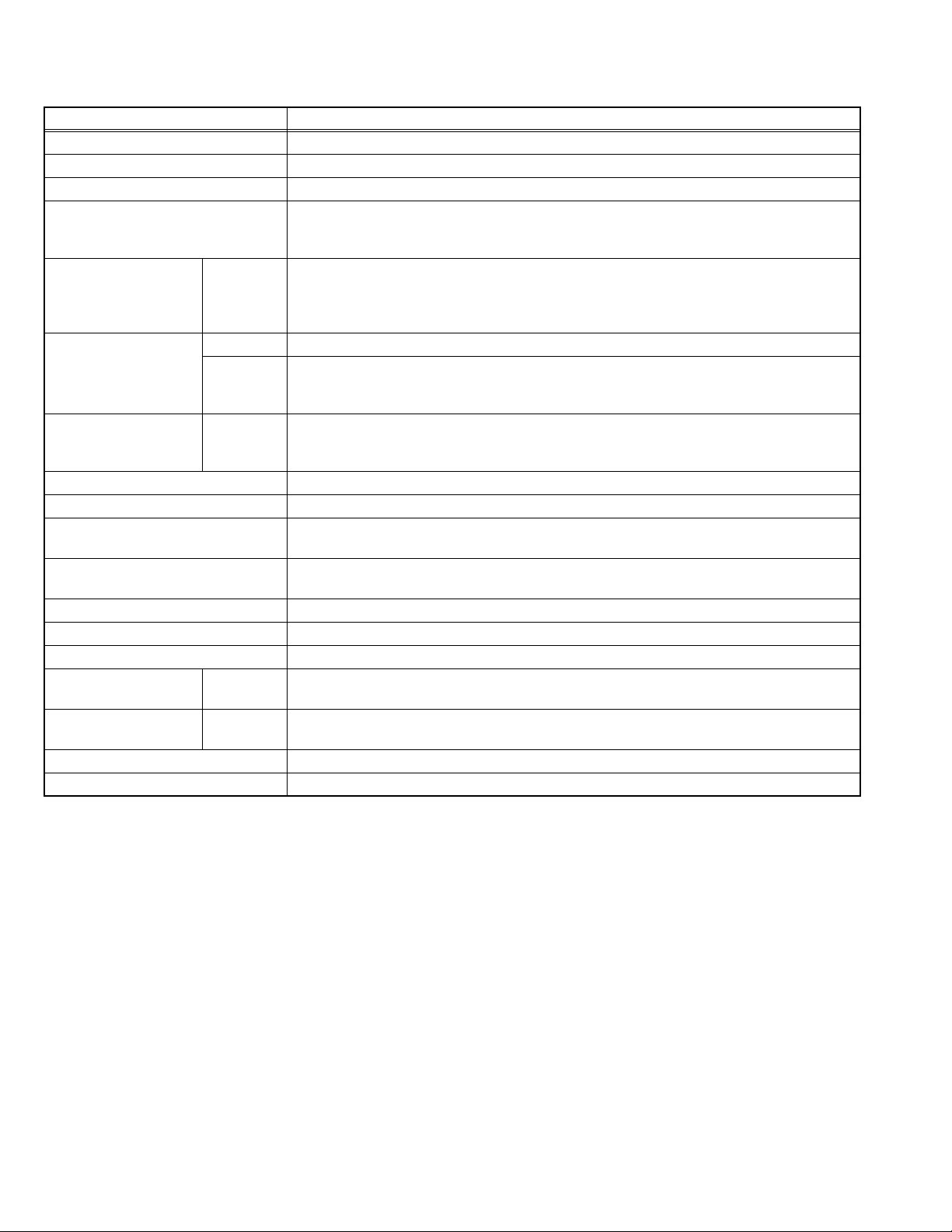

SPECIFICATION

Items Contents

Dimensions (W × H × D) 59.8 cm × 47.6 cm × 47.7 cm

Mass 22 kg

TV RF System B/G, I, D/K

Colour System PAL

SECAM

NTSC 3.58 / NTSC 4.43

Receiving

Frequency

Intermediate Frequency VIF 38.0 MHz (B/G, I, D/K)

Colour Sub Carrier PAL

Power Input AC110 V to AC240 V, 50 Hz / 60 Hz

Power Consumption 100 W (Max) / 65 W(Avg)

Picture Tube Visible size: 52.3 cm measured diagonally

High Voltage 26.5 kV±1.5kV (at zero beam current)

VHF Low

VHF High

SECAM

46.25 MHz to 140.25 MHz

147.25 MHz to 423.25 MHz

UHF

431.25 MHz to 863.25 MHz

CATV

Mid (X to Z+2, S1 to S10) / Super (S11 to S20) / Hyper (S21 to S41) bands

SIF 32.5 MHz (5.5 MHz: B/G)

32MHz (6.0 MHz: I)

31.5MHz (6.5 MHz: D/K)

4.43 MHz

4.40625 MHz / 4.25 MHz

NTSC

3.58 MHz / 4.43 MHz

( H : 41.6 cm × V : 31.5 cm)

Speaker 5 cm × 9 cm, Oval type × 1

Audio Power Output 3 W (monaural)

Aerial Input Terminal 75 Ω unbalanced, coaxial

Input Terminal

[Front / Rear]

Output Terminal

[Rear]

Headphone Jack 3.5 mm mini jack × 1

Remote Control Unit RM-C360GY (Battery size : AA / R6 / UM-3 × 2)

Design and specifications are subject to change without notice.

Video

1 V(p-p), 75 Ω, RCA pin jack × 2

Audio

500 mV(rms) (-4 dBs), High impedance, RCA pin jack × 2

Video

1 V(p-p), 75Ω, RCA pin jack × 1

Audio

500 mV(rms) (-4 dBs), Low impedance, RCA pin jack × 1

1-2 (No.YA415)

Page 3

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 FEATURES

PICTURE MODE

This function can adjust the picture settings automatically.

There are BRIGHT, STANDARD and SOFT in the PICTURE

MODE.

RETURN +

This function can set a channel you frequently view to the

Return Channel and you can view that channel at any time with

one-touch.

2.2 TECHNINAL INFORMATION

2.2.1 MAIN MI-COM (CPU) PIN FUNCTION

Pin

No.

Pin name I/O Function

1 REMOCON I Remote control 22 PROTECT I Low B protect detection [Detect: H]

2 SDA2 I/O Data for Inter IC control (For main memory) 23 P_ON/OFF I Main power control [ON : H]

3 SCL2 O Clock for Inter IC contorl (For main memory) 24 LOCK - Not used

4 BUS_FREE - Not used 25 3.58/OTH - Not used

5 NC - Not used 26 4.5/OTH - Not used

6 KEY1 I Key scan for front key (Menu CH -/+) 27 H_SYNC I Horizontal sync

7 KEY2 I Key scan for front key (Vol -/+) 28 I/II - Not used

8 ECO IN - Not used 29 OSD_Ys O Ys (blanking) for OSD

9 AFT I AFT voltage for tuner 30 OSD_B O Blue for OSD

10 LED[POW] - Not used 31 OSD_G O Green for OSD

11 LED[TIM] O Liting for timer [Liting : H] 32 OSD_R O Red for OSD

12 GND - GND 33 NC - Not used

13 NC - Not used 34 RST I CPU reset [Reset:L]

14 NC - Not used 35 V_SYNC I Vertical sync

15 TV/V - Not used 36 TCLOCK - Not used

16 TEXT RESET - Not used 37 SDA1 I/O Data for Inter IC control (For generally)

17 ACL ON/OFF - Not used 38 SCL1 O Clock for Inter IC contorl (For generally)

18 VOL O Volume control 39 VDD I 3.3V

19 A_MUTE O Aodio muting [Muting : H] 40 OSC1 I System clock oscillation (4MHz)

20 NC - Not used 41 OSC2 O System clock oscillation (4MHz)

21 TEXT/OTH - Not used 42 VSS - GND

CHILD LOCK

Use this function to prevent children from operating the TV

without parental consent.

VNR

This function can reduce the picture noise.

Pin

No.

Pin name I/O Function

1-4 (No.YA415)

Page 4

SECTION 3

DISASSEMBLY

3.1 DISASSEMBLY PROCEDURE

3.1.1 REMOVING THE REAR COVER

• Unplug the power cord.

(1) Remove the 6 screws [A], 1 screw [B] and 1 screw [C] as

shown in Fig.1.

(2) Withdraw the REAR COVER toward you.

CAUTION:

When reinstalling the rear cover, carefully push it inward after

inserting the MAIN PWB into the REAR COVER groove.

3.1.2 REMOVING THE MAIN PW BOARD

• Remove the REAR COVER.

(1) Slightly raise the both sides of the MAIN PWB by hand.

(2) Withdraw the MAIN PWB backward.

(If necessary, take off the wire clamp and connectors, etc.)

3.1.3 REMOVING THE SPEAKER

• Remove the REAR COVER.

(1) Remove the 2 screws [D] as shown in Fig.1.

(2) Follow the same steps when removing the other hand

SPEAKER.

3.1.4 CHECKING THE MAIN PW BOARD

• To check the back side of the MAIN PWB.

(1) Pull out the MAIN PWB. (Refer to REMOVING THE MAIN

PW BOARD).

(2) Erect the MAIN PWB vertically so that you can easily check

its back side.

CAUTIONS:

• Before turning on power, make sure that the CRT earth wire

and other connectors are properly connected.

• When repairing, connect the DEG. COIL to the DEG.

connector on the MAIN PWB.

3.1.5 WIRE CLAMPING AND CABLE TYING

(1) Be sure to clamp the wire.

(2) Never remove the cable tie used for tying the wires

together.

Should it be inadvertently removed, be sure to tie the wires

with a new cable tie.

(No.YA415)1-5

Page 5

FRONT CABINET

D

SPEAKER

D

CRT SOCKET PWB

(Within MAIN PWB)

FRONT LED PWB

(Within MAIN PWB)

POWER CORD

SPEAKER

MAIN PWB

REAR COVER

A

C

B

Fig.1

1-6 (No.YA415)

Page 6

3.2 MEMORY IC REPLACEMENT

• This model uses the memory IC.

• This memory IC stores data for proper operation of the video and drive circuits.

• When replacing, be sure to use an IC containing this (initial value) data.

3.2.1 MEMORY IC REPLACEMENT PROCEDURE

1. Power off

Switch off the power and disconnect the power plug from the

AC outlet.

2. Replace the memory IC

Be sure to use the memory IC written with the initial setting

values.

3. Power on

Connect the power plug to the AC outlet and switch on the

power.

4. System constant check and setting

• It must not adjust without adjustment signals.

(1) Press the [DISPLAY] key and the [PICTURE MODE]

key of the REMOTE CONTROL UNIT simultaneously.

(2) The SERVICE MENU screen of Fig. 1 will be displayed.

(3) While the SERVICE MENU is displayed, again press the

[DISPLAY] key and [PICTURE MODE] key

simultaneously, and the SYSTEM CONSTANT SET

screen of Fig. 2 will be displayed.

(4) Check the setting values of the SYSTEM CONSTANT

SETTING. If the value is different, select the setting item

with the [MENU /] key, and set the correct value with

the [MENU - / +] key.

(5) Press the [DISPLAY] key twice, and return to the normal

screen.

5. Receiving channel setting

Refer to the OPERATING INSTRUCTIONS and set the

receive channels (Channels Preset) as described.

6. User settings

Check the user setting items according to the given in page

later.

Where these do not agree, refer to the OPERATING

INSTRUCTIONS and set the items as described.

7. SERVICE MENU setting

Verify what to set in the SERVICE MENU, and set whatever is

necessary (Fig.1).

Refer to the SERVICE ADJUSTMENT for setting.

SERVICE MENU

1.IF 2.V/C

3.DEF 4.VSM PRESET

5.PRESET

6.SETUP TOUR OFF

1-6 : SELECT DISP : EXIT

************ **.***

*** ** **** ***

Fig.1

SYSTEM CONSTANT- I

SYSTEM CONSTANT SET 1

COLOUR : TRIPLE

BILINGUAL : NO

TUNER : MU

ECO SENSOR

LANGUAGE : E/C/M/I

: SELECT

/

- / + : OPERATE DISP : EXIT

SYSTEM CONSTANT- II

SYSTEM CONSTANT SET 2

B/B SOUND : OFF

LOCK : 180

COLOUR AUTO

QSS

ALC : NO

TEXT RATE

: SEL - / + : OPE DISP : EXIT

/

SYSTEM CONSTANT- III

: NO

: NO

: MINT

: 20

KEY ASSIGNMENT OF REMOTE CONTROL UNIT

POWER

SOUND

123

456

789

RETURN+

0

MENU

MENU

VOLUME

PICTURE

MODE

MUTING

PICTURE

MODE key

NUMBERS

key

-/--

MENU

/ key

DISPLAY key

MENU

- / + key

COLOUR

TV/VIDEO

OFF

TIMER

CHANNEL

SCAN

DISPLAY

CHANNEL

SYSTEM

SYSTEM CONSTANT SET 3

AMP TUNER : NO

VNR

TEXT TABLE : CYL

VOLUME PWM : POS

/

: SEL - / + : OPE DISP : EXIT

: YES

Fig.2

(No.YA415)1-7

Page 7

3.2.2 SETTINGS OF FACTORY SHIPMENT

3.2.2.1 BUTTON OPERATION

Setting item Setting position

POWER Off

CHANNEL PR1

VOLUME 10

3.2.2.2 REMOTE CONTROL DIRECT OPERATION

Setting item Setting position

CHANNEL PR1

VOLUME 10

TV/VIDEO TV

PICTURE MODE BRIGHT

COLOUR SYSTEM PAL

SOUND SYSTEM B/G

3.2.2.3 REMOTE CONTROL MENU OPERATION

(1) MENU-1

Setting item Setting position

INPUT TV

ON TIMER PR1 0:00

VNR OFF

3.2.3 SYSTEM CONSTANT SETTING

Setting item Setting value

COLOUR TRIPLE

BILINGUAL NO

TUNER MU

ECO SENSOR NO

LANGUAGE E / C / M / I

B/B SOUND OFF

LOCK 180

COLOUR AUTO NO

QSS MINT

ALC NO

TEXT RATE 20

AMP TUNER NO

VNR YES

TEXT TABLE CYL

VOLUM PWM POS

(2) MENU-2

Setting item Setting position

AUTO SHUTOFF OFF

CHILD LOCK OFF

BLUE BACK OFF

(3) MENU-3

Setting item Setting position

SETUP TOUR ON

LANGUAGE ENGLISH

(4) MENU-4

Setting item

TINT 15 15 15

COLOUR

BRIGHT 15 15 15

CONT. 30 15 11

SHARP 151512

BRIGHT STANDARD SOFT

15 15 15

Setting position

1-8 (No.YA415)

Page 8

3.2.4 SERVICE MENU SETTING ITEMS

Setting item Setting value Setting item Setting value

2. V/C 1.CUT OFF

2.DRIVE

3.BRIGHT

4.CONT.

5.COLOUR

6.TINT

7.SECAM BL ADJUST

8.SHARP [Do not adjust]

9.AMP T. SHARP [Do not adjust]

3. DEFLECTION 1. VER. POSITION

2. HOR. POSITION

3. VER. HEIGHT

4. VER. LINEARITY

5. VER. SCURVE

6. HOR. VCO ADJUST [Do not adjust]

4.VSM PRESET TINT

COLOUR

BRIGHT

CONT.

SHARP

5. PRESET

[Do not adjust]

Colour System 1. C-TRAP FIX

2. SHARP PEAK

3. ABL

4. GAMMA

5. Y. DELAY TIME

6. BLACK EXP START

7. C-BPF

8. CW / SCP

9. VIF DET LEVEL

11. IF AGC MIN

12. VIF AGC

13. VIF PMOD

19. VNR

20. RGB LIM

21. RGB LIMIT LEVEL

23. TEXT H. POSITION

24. READ DATA

Sound System 10. SIF DET LEVEL

14. SIF BPF BW ADJUST

15. SIF TRAP F0 ADJUST

16. SIF TRAP F0 ADJUST 2

17. SIF -TRAP

18. SIF -BPF

22. SIF SW

3.2.5 REPLACEMENT OF IC301 (IF V/C DECODER)

• For the IC301(IF V/C DECODER) of this model, all data are written in the micro-computer. So, write the data in the micro-

computer in accordance with the following procedures before starting adjustment.

PROCEDURES

(1) Turn the POWER OFF.

(2) Replace the IC301 with a new one.

(3) While pressing [MENU] button and [VOL+] button ON the FRONT CABINET simultaneously, turn the POWER ON. When the

POWER is turned ON, the data is written in the micro-computer immediately.

LOCATIONS OF FRONT PANEL BUTTONS

(No.YA415)1-9

Page 9

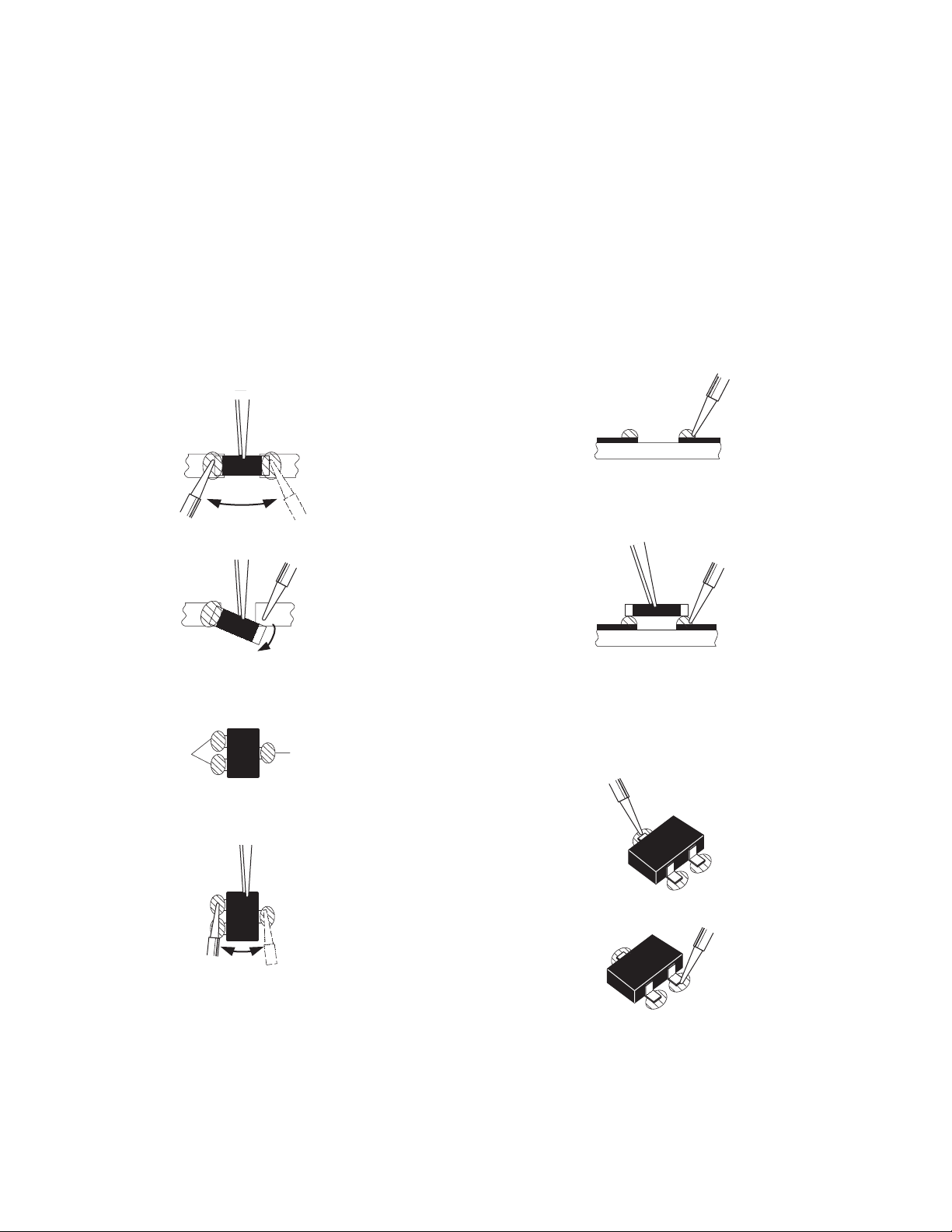

3.3 REPLACEMENT OF CHIP COMPONENT

3.3.1 CAUTIONS

(1) Avoid heating for more than 3 seconds.

(2) Do not rub the electrodes and the resist parts of the pattern.

(3) When removing a chip part, melt the solder adequately.

(4) Do not reuse a chip part after removing it.

3.3.2 SOLDERING IRON

(1) Use a high insulation soldering iron with a thin pointed end of it.

(2) A 30w soldering iron is recommended for easily removing parts.

3.3.3 REPLACEMENT STEPS

1. How to remove Chip parts

2. How to install Chip parts

[Resistors, capacitors, etc.]

(1) As shown in the figure, push the part with tweezers and

alternately melt the solder at each end.

(2) Shift with the tweezers and remove the chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply extra solder to each lead.

SOLDER

SOLDER

[Resistors, capacitors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder. Then heat and melt the solder at both ends of the

chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder.

(3) First solder lead A as indicated in the figure.

(2) As shown in the figure, push the part with tweezers and

alternately melt the solder at each lead. Shift and remove

the chip part.

NOTE :

After removing the part, remove remaining solder from the

pattern.

1-10 (No.YA415)

A

B

C

(4) Then solder leads B and C.

A

B

C

Page 10

SECTION 4

ADJUSTMENT

4.1 ADJUSTMENT PREPARATION

(1) There are 2 ways of adjusting this TV : One is with the

REMOTE CONTROL UNIT and the other is the

conventional method using adjustment parts and

components.

(2) The adjustment using the REMOTE CONTROL UNIT is

made on the basis of the initial setting values. The

setting values which adjust the screen to the optimum

condition can be different from the initial setting

values.

(3) Make sure that connection is correctly made AC to AC

power source.

(4) Turn on the power of the TV and measuring instruments for

warming up for at least 30 minutes before starting

adjustments.

(5) If the receive or input signal is not specified, use the most

appropriate signal for adjustment.

(6) Never touch the parts (such as variable resistors,

transformers and condensers) not shown in the adjustment

items of this service adjustment.

4.2 PRESET SETTING BEFORE ADJUSTMENT

Unless otherwise specified in the adjustment items, preset the

following functions with the REMOTE CONTROL UNIT.

Item Preset value

PICTURE MODE BRIGHT

TINT / COLOUR / BRIGHT / CONT. / SHARP Centre

VNR OFF

BLUE BACK OFF

OFF TIMER OFF

AUTO SHUT OFF OFF

4.3 MEASURING INSTRUMENT AND FIXTURES

(1) DC voltmeter (or digital voltmeter)

(2) Oscilloscope

(3) Signal generator

(Pattern generator : PAL / SECAM / NTSC)

(4) Remote control unit

4.4 ADJUSTMENT ITEMS

CHECK ITEM

• B1 VOLTAGE check

TUNER / IF CIRCUIT

• IF VCO adjustment

• DELAY POINT adjustment

FOCUS

• FOCUS adjustment

DEFLECTION CIRCUIT

• V.HEIGHT / V.POSITION adjustment

• H. POSITION adjustment

• V.LINEARITY / V.S-CURVE adjustment

VIDEO CIRCUIT

• WHITE BALANCE adjustment

• SUB BRIGHT adjustment

• SUB CONTRAST adjustment

• SUB COLOUR adjustment

• SUB TINT adjustment

• SECAM BALACK OFFSET adjustment

VSM PRESET SETTING

• VSM PRESET setting

(No.YA415)1-11

Page 11

4.5 ADJUSTMENT LOCATIONS

F901

TOP

CRT SOCKET PWB

TP-47G/R

T

IC701

(SOLDER SIDE)

U

TP-47B

TP-E

E1

CRT EARTH WIRE

(BRAIDED ASS'Y)

FRONT

IC702

MEMORY IC

PW

DEG

MAIN PWB

TU001

IC301

T

1Pin TP-91(B1)

2Pin NC

3Pin X-ray1

4Pin X-ray2

5Pin TP-E( )

S1

51

U

HV

HVT

UPPER:FOCUS

LOWER:SCREEN

1-12 (No.YA415)

Page 12

4.6 BASIC OPERATION OF SERVICE MENU

4.6.1 TOOL OF SERVICE MENU OPERATION

Operate the SERVICE MENU with the REMOTE CONTROL UNIT.

4.6.2 SERVICE MENU ITEMS

With the SERVICE MENU, various adjustments can be made, and they are broadly classified in the following items of settings.

1.IF Adjustment of the IF circuits.

2.V/C Adjustment of the VIDEO circuit.

3.DEF Adjustment of the DEFLECTION circuit.

4.VSM PRESET Adjustment of the initial setting values of VSM condition as STANDARD, SOFT and BRIGHT.

5.PRESET Adjustment of the RF circuit [Do not adjust].

6.SETUP TOUR It should be able to select mode (LANGUAGE and AUTO CH PRESET) [Should be OFF].

4.6.3 HOW TO ENTER THE SERVICE MENU

Press the [DISPLAY] key and the [PICTURE MODE] key of

the REMOTE CONTROL UNIT simultaneously. Then enter the

SERVICE MODE SELECT KEY

SERVICE MENU mode as shown in Fig.1.

POWER

SERVICE MENU

1.IF 2.V/C

3.DEF 4.VSM PRESET

5.PRESET

6.SETUP TOUR OFF

1-6 : SELECT DISP : EXIT

************ **.***

*** ** **** ***

Fig.1

4.6.4 HOW TO STORE OF SETTING VALUE

The setting value will be stored automatically when release the

REMOTE CONTROL UNIT keys

DISPLAY key

MENU

- / + key

SYSTEM

COLOUR

TV/VIDEO

OFF

TIMER

CHANNEL

SCAN

DISPLAY

CHANNEL

SOUND

RETURN+

MENU

MENU

PICTURE

123

456

789

0-/

MUTING

VOLUME

MODE

PICTURE

MODE key

NUMBERS

key

--

MENU

/ key

4.6.5 HOW TO EXIT THE SERVICE MENU

When complete the adjustment work, press the [DISPLAY]

key to return to the SERVICE MENU. And then press the

[DISPLAY] key again, return to the normal screen.

4.6.6 SELECTION OF SUB MENU SCREEN

Press one of [1] to [5] keys of the REMOTE CONTROL UNIT

and select the SUB MENU SCREEN form the SERVICE

MENU.

(No.YA415)1-13

Page 13

4.6.7 METHOD OF SETTING

1. IF

[1. VCO]

(1) [1] key Select 1. IF.

(2) [1] key Select 1. VCO.

(3) [MENU /] keys Select setting items.

(4) [MENU - / +] keys Adjust the values of the items.

(5) [DISPLAY] key As you press this key twice, you will return to the SERVICE MENU.

[2. DELAY POINT]

(1) [1] key Select 1. IF.

(2) [2] key Select 2. DELAY POINT.

(3) [MENU - / +] keys Set (adjust) the setting values of the setting items.

(4) [DISPLAY] key When this is pressed twice, you will return to the SERVICE MENU.

NOTE:

When the setting value has been changed, the new value will be stored in memory immediately.

2. V/C, 3. DEF and 4. VSM PRESET

(1) [2] to [4] keys Select one from 2. V/C, 3. DEF and 4. VSM PRESET.

(2) [MENU /] keys Select setting items.

(3) [MENU - / +] keys Adjust the values of the items.

(4) [DISPLAY] key When this is pressed, return to the SERVICE MENU.

NOTE:

When the setting value has been changed, the new value will be stored in memory immediately.

5. PRESET (Do not adjust)

6. SETUP TOUR

(1) By pressing the [6] key, you can change the ON or OFF [should be OFF].

Should be OFF:

If it is ON, when you turn off the power and turn on a power again, the JVC’s logo will be shown

about 15 seconds automatically, and the SETUP TOUR starts.

(2) [MENU - / +] keys Select Language.

(3) [MENU ] key Auto Search.

1-14 (No.YA415)

Page 14

4.6.8 SERVICE MENU FLOW CHART

************ **.***

SERVICE MENU

1. IF

SERVICE MENU

1.IF 2.V/C

3.DEF 4.VSM PRESET

5.PRESET

6.SETUP TOUR OFF

1-6 : SELECT DISP : EXIT

************ **.***

6. SETUP TOUR OFF

*** ** **** ***

ON / OFF

(By pressing [6] key)

IF

1. VCO

2. DELAY POINT

1-2 : SELECT DISP : EXIT

2. V/C

V/C PAL

1. CUTOFF

(G)

(B)

50Hz

/ : SELECT

- / + : OPERATE DISP : EXIT

(R)

* **

* **

* **

3. DEF

VCO (CW)

TOO HIGH

ABOVE REFERENCE

JUST REFERENCE

BELOW REFERENCE

TOO LOW

AFT ADJUST

VCO ADJUST

FINE

DISP : EXIT

DELAY POINT UHF

AGC TAKE-OVER

- / + : OPERATE DISP : EXIT

***.**

MHz

*** (**

*** (**

**

)

)

DEF PAL

1. VER. POSITION

50Hz

/ : SELECT

- / + : OPERATE DISP : EXIT

**

4. VSM PRESET

BRIGHT

TINT

COLOUR

BRIGHT

CONT.

SHARP

/ : SELECT

- / + : OPERATE DISP : EXIT

**

**

**

**

**

5. PRESET

PRESET PAL

1. C-TRAP FIX

*

50Hz B/G

/ : SELECT

- / + : OPERATE DISP : EXIT

(No.YA415)1-15

Page 15

4.7 INITIAL SETTING VALUE OF SERVICE MENU

• Adjustment of the SERVICE MENU is made on the basis of the initial setting values ; however, the new setting values which

set the screen in its optimum condition may differ from the initial setting.

• Do not change the initial Setting Values of the Setting (Adjustment) items not listed in "ADJUSTMENT PROCEDURE".

[2. V/C]

Setting item Variable range

1.CUT OFF RED -128 - +127 -50 -50 -50 -50

GREEN -128 - +127 -50 -50 -50 -50

BLUE -128 - +127 -50 -50 -50 -50

2.DRIVE RED -128 - +127 +0 +0 +0 +0

BLUE -128 - +127 +0 +0 +0 +0

3.BRIGHT -128 - +127 +0 +0 +0 +0

4.CONT. -63 - +63+0+0+0+0

5.COLOUR -63 - +63 +0 +0 +0 -5

6.TINT TV -63 - +63 --- --- --- ---

VIDEO -63 - +63 --- --- +0 -2

7.SECAM BL ADJUST -31 - +31 +0 +0 +0 +0

8.SHARP

(Do not adjust)

[3. DEFLECTION]

1. VER. POSITION -4 - +3 -1 -3

2. HOR. POSITION -16 - +15 +3 +3

3. VER. HEIGHT -64 - +63 -35 +1

4. VER. LINEARITY -32 - +31 +15 -1

5. VER. SCURVE -32 - +31 -32 +0

6. HOR. VCO ADJUST

TV -31 - +31 +2 (Fixed) +2 (Fixed) +2 (Fixed) +2 (Fixed)

VIDEO -31 - +31 +15 (Fixed) +15 (Fixed) +15 (Fixed) +15 (Fixed)

Setting item Variable range

[Do not adjust]

-63 - +63 +0 +0

PAL SECAM NTSC 3.58 NTSC 4.43

Initial setting value

fv : 50Hz fv : 60Hz

Initial setting value

[4.VSM PRESET]

Setting item Variable range

TINT 0 - 30 15 15 15

COLOUR 0 - 30 15 15 15

BRIGHT 0 - 30 15 15 15

CONT. 0 - 30 30 15 11

SHARP 0 - 30 15 15 12

1-16 (No.YA415)

BRIGHT STANDARD SOFT

Initial setting value

Page 16

[5. PRESET]

The items in the following table, it is no requirement for adjustment.If values had changed by the miss operation, set the

initial setting values in the following table.

z COLOUR SYSTEM (Do not adjust)

Setting item Variable range

1. C TRAP FIX 0 - 1 1 1 1 1

2. SHARP PEAK 0 - 1 0 0 0 0

3. ABL 0 - 11111

4. GAMMA 0 - 1 0 0 0 0

5. Y. DELAY TIME TV 0 - 3 0 2 2 3

VIDEO 0 - 30202

6. BLACK EXP START 0 - 3 3 3 3 3

7. C-BPFTV 0 - 11100

VIDEO 0 - 11111

8. CW / SCP 0 - 1 0 0 0 0

9. VIF DET LEVEL -63 - +63 +0 +0 +0 +0

11. IF AGC MIN 0 - 1 0 0 0 0

12. VIF AGC 0 - 1 0 0 0 0

13. VIF PMOD 0 - 1 0 0 0 0

19. VNR 0 - 63 15 15 15 15

20. RGB LIM 0 - 1 1 1 1 1

21. RGB LIMIT LEVEL 0 - 7 2 2 2 2

23. TEXT H. POSITION -16 - +15 -3 -3 -3 -3

24. READ DATA --- --- --- --- ---

PAL SECAM NTSC 3.58 NTSC 4.43

Initial setting value (Fixed value)

z SOUND SYSTEM (Do not adjust)

Setting item Variable range

10. SIF DET LEVEL -7 - +7 +0 +0 +0 +0

14. SIF BPF BW ADJUST -7 - +7 +0 +0 +0 +0

15. SIF TRAP FO ADJUST -7 - +7 +0 +0 +0 +0

16. SIF TRAP FO ADJUST 2 -7 - +7 +0 +0 +0 +0

17. SIF -TRAP 0 - 10000

18. SIF -BPF 0 - 10001

22. SIF SW 0 - 11110

B/G I D/K M

Initial setting value (Fixed value)

(No.YA415)1-17

Page 17

4.8 ADJUSTMENT PROCEDURE

4.8.1 CHECK ITEM

Item

B1 VOLTAGE Signal

Measuring

instrument

generator

DC voltmeter

TP-B1 : 1-pin

TP-E : 5-pin

(S1 connector)

[MAIN PWB]

4.8.2 TUNER / IF CIRCUIT

Test point Adjustment part Description

(1) Receive a whole black signal.

(2) Connect a DC voltmeter to 1-pin and 5-pin of S1

connector.

(3) Make sure that the voltage is DC116.2V±2.0V.

Item

Measuring

instrument

IF VCO Signal

generator

Remote

control unit

VCO (CW)

TOO HIGH

ABOVE REFERENCE

JUST REFERENCE

BELOW REFERENCE

TOO LOW

AFT ADJUST

VCO ADJUST

FINE

DISP : EXIT

ADJUSTMENT AT THIS POINT

IS USELESS

***.**

Test point Adjustment part Description

[1. IF]

1. VCO

• Please use a signal generator which frequency output is

correctly calibrated.

(1) Receive any broadcast.

(2) Select 1.IF from the SERVICE MENU.

(3) Select < 1.VCO >.

(4) Select VCO ADJUST with [MENU /] key.

MHz

(5) Press [MENU - / +] keys until the colour of the

characters TOO HIGH changes blue to yellow. Then

gradually press the [MENU - / +] keys until the TOO

YELLOW

LOW changes yellow. At this time, confirm that the

value of VCO ADJUST is near +00.

***(**

***(**

)

)

(6) Select AFT ADJUST with [MENU /] key.

(7) Press [MENU - / +] keys until the characters JUST

REFERENCE changes blue to yellow.

(8) Press the [DISPLAY] key three times to return to

normal screen.

TOO HIGH

ABOVE REFERENCE

JUST REFERENCE

BELOW REFERENCE

TOO LOW

ADJUSTMENT POINT

1-18 (No.YA415)

Page 18

Item

DELAY POINT

(AGC)

Measuring

instrument

Test point Adjustment part Description

Signal

generator

Remote

control unit

DELAY POINT UHF

AGC TAKE-OVER **

- / + : OPERATE DISP : EXIT

[1. IF]

2. DELAY POINT

(AGC TAKE-OVER)

(1) Receive a black and white signal (colour off).

(2) Select 1. IF.

(3) Select < 2. DELAY POINT >.

(4) Set the setting values of the setting items as shown

bellow table.

(5) Then adjust the [MENU - / +] keys until video noise

disappears.

(6) Turn to other channels and make sure that there are

no irregularities.

Setting Item

DELAY POINT

(AGC TAKE-OVER)

NTSC3.58

OTHER

4.8.3 FOCUS

Item

Measuring

instrument

FOCUS Signal

generator

Variable range

0 - 127

Initial setting value

45

35

Test point Adjustment part Description

FOCUS VR

[In HVT]

(1) Receive a crosshatch signal.

(2) While watching the screen, adjust the FOCUS VR to

make the vertical and horizontal lines as fine and

sharp as possible.

(3) Make sure that when the screen is darkened, the

lines remain in good focus.

(No.YA415)1-19

Page 19

4.8.4 DEFLECTION CIRCUIT

• There are 2 modes of adjustment (setting value) 50Hz mode and 60Hz mode, depending upon the kind of signals (vertical frequency

50Hz / 60Hz).

• When adjusted in 50Hz mode and 60Hz mode will be automatically set.

The setting (adjustment) using the REMOTE CONTROL UNIT is made on the basis of the initial setting values.The setting

values which adjust the screen to the optimum condition can be different from the initial setting values.

• Make sure that the adjustment is properly done on the screen of 60Hz mode.

NOTE:

• Adjust to make both 50Hz & 60Hz are the same v. size and fine straight line.

• When adjust again, adjust 50Hz mode first.

• When adjust in 60Hz mode, only 60Hz mode is adjust.

Item

V. HEIGHT /

V. POSITION

Measuring

instrument

Signal

generator

Remote

control unit

Test point Adjustment part Description

[3. DEF]

1. VER. POSITION

3. VER. HEIGHT

(1) Receive a crosshatch signal.

(2) Select 3. DEF from the SERVICE MENU.

(3) Select < 1. VER. POSITION >.

(4) Set the initial setting value of < 1. VER. POSITION >.

(5) Adjust < 1. VER. POSITION > to make the vertical

centre fall on the display centre.

(6) Select <3. VER. HEIGHT >.

(7) Set the initial setting value of <3. VER. HEIGHT >.

Screen

size

Picture

size

100%

(8) Adjust <3. VER. HEIGHT > to make the vertical

screen size be 92% of the picture size.

H. POSITION Signal

generator

Remote

control unit

V.LINEARITY /

V.S-CURVE

Signal

generator

Remote

control unit

(A)

Fig.1

Fig.2

[3. DEF]

2. HOR. POSITION

(B)

[3. DEF]

4. VER. LIN.

5. VER. SCURVE

Top

Centre

(1) Receive a circle pattern signal.

(2) Select 3. DEF from the SERVICE MENU.

(3) Select < 2. HOR. POSITION >.

(4) Set the initial setting value of < 2. HOR. POSITION >.

(5) Adjust <2.HOR. POSITION> to be equal the width of

(A) and (B) as shown in Fig.2.

• If the vertical linearity is noticeably deteriorated, perform

the following steps.

(1) Receive a crosshatch signal.

(2) Select 3. DEF from the SERVICE MENU.

(3) Select < 4. VER. LIN. >.

(4) Set the initial setting value of < 4. VER. LIN. >.

(5) Select < 5. VER. SCURVE >.

(6) Set the initial setting value of < 5. VER. SCURVE >.

(7) Adjust < 4. VER. LIN. > and < 5. VER. SCURVE >

so that the space of upper and lower lines as shown

in Fig.3 on TOP, CENTRE and BOTTOM become

uniform.

1-20 (No.YA415)

Bottom

Fig.3

Page 20

4.8.5 VIDEO CIRCUIT

The setting (adjustment) using the REMOTE CONTROL UNIT is made on the basis of the initial setting values. The setting

values which adjust the screen to the optimum condition can be different from the initial setting values. Do not change the

initial setting values of the setting items not listed in "ADJUSTMENT PROCEDURE".

Item

WHITE

BALANCE

(LOW LIGHT)

Measuring

instrument

Signal

generator

Remote

control unit

Test point Adjustment part Description

[2.V/C]

1. CUT OFF (R)

1. CUT OFF (G)

1. CUT OFF (B)

SCREEN VR

[IN HVT]

(1) Receive a black and white signal (colour off).

(2) Select 2. V/C from the SERVICE MENU.

(3) Select < 1. CUT OFF >.

(4) Set the initial setting value of < 1. CUT OFF >.

(5) Press the [1] key to show the single horizontal line

on screen.

(6) Turn the SCREEN VR fully counter-clockwise, then

slowly turn it clockwise to where one of a red, blue or

KEY ASSIGNMENT OF REMOTE CONTROL UNIT

green colour is faintly visible.

(7) Adjust the two colors which did not appear until the

CUTOFF OFF

(H.LINE OFF)

CUTOFF ON

(H.LINE ON)

R. CUTOFF( )

R. CUTOFF( )

123

456

789

G.CUTOFF( )

B. CUTOFF( )

B. CUTOFF( )

G.CUTOFF( )

single horizontal line that is displayed becomes

white using the [4] to [9] keys.

(8) Turn the SCREEN VR to where the single horizontal

line glows faintly.

(9) Press the [2] key to turn off the single horizontal line.

(10) Press the [DISPLAY] key twice to return to the nor-

mal screen.

R G B

WHITE

BALANCE

(HIGH LIGHT)

Signal

generator

Remote

control unit

KEY ASSIGNMENT OF REMOTE CONTROL UNIT

R. DRIVE( )

SUB BRIGHT Remote

control unit

SUB

CONTRAST

Remote

control unit

123

456

789

R B

[2.V/C]

2. DRIVE (R)

2. DRIVE (B)

B. DRIVE( )

B. DRIVE( )R. DRIVE( )

[2. V/C]

3. BRIGHT

[2. V/C]

4. CONT.

(1) Receive a black and white signal (colour off).

(2) Select 2. V/C from the SERVICE MENU.

(3) Select < 2. DRIVE >.

(4) Set the initial setting value of < 2. DRIVE >.

(5) Adjust the screen until it becomes white using the

[4], [6], [7] and [9] keys.

(6) Press the [DISPLAY] key twice to return to the nom-

al screen.

(1) Receive any broadcast.

(2) Select 2. V/C from the SERVICE MENU.

(3) Select < 3. BRIGHT >.

(4) Set the initial setting value of < 3. BRIGHT >.

(5) If the brightness is not the best with the initial setting

value, make fine adjustment until you get the best

brightness.

(1) Receive any broadcast.

(2) Select 2. V/C from the SERVICE MENU.

(3) Select < 4. CONT >.

(4) Set the initial setting value of < 4. CONT >.

(5) If the contrast is not the best with the initial setting

value, make fine adjustment until you get the best

contrast.

(No.YA415)1-21

Page 21

Item

Measuring

instrument

SUB COLOUR Remote

control unit

Signal

generator

Oscilloscope

Remote

control unit

W

Y

MODEL

AV-21B16

Test point Adjustment part Description

[2. V/C]

5. COLOUR

(PAL / SECAM / NTSC)

TP-47G/R

TP-E

[CRT SOCKET

[2. V/C]

5. COLOUR

(PAL / SECAM / NTSC)

PWB]

B

R

M

0V

(A)

C

G

PAL SECAM NTSC3.58 NTSC4.43

+12V +6V +8V (VDO) ---

(+)

Voltage setting (A)

[Method of adjustment without measuring instrument]

PAL COLOUR

(1) Receive a PAL broadcast.

(2) Select 2. V/C from the SERVICE MENU.

(3) Select < 5. COLOUR >.

(4) Set the initial setting value of < 5. COLOUR >.

(5) If the colour is not the best with the initial setting

value, make fine adjustment until you get the best

colour.

SECAM COLOUR

(1) Receive a SECAM broadcast.

(2) Make fine adjustment of SECAM COLOUR as

previously.

NTSC 3.58 COLOUR

(1) Receive a NTSC 3.58MHz broadcast.

(2) Make similar fine adjustment of NTSC 3.58

COLOUR as previously.

NTSC 4.43 COLOUR

(1) When NTSC 3.58 adjustment completed, NTSC

4.43 will be automatically set at the respective

values.

[Method of adjustment using measuring instrument]

PAL COLOUR

(1) Receive a PAL full field colour bar signal (75%

white).

(2) Select 2. V/C from the SERVICE MENU.

(3) Select < 5. COLOUR >.

(4) Set the initial setting value of < 5. COLOUR >.

(5) Connect the oscilloscope between TP-47G/R and

TP-E.

(6) Adjust PAL COLOUR to bring the value of (A) in

the voltage table.

SECAM COLOUR

(1) Receive a SECAM full field colour bar signal (75%

white).

(2) Set the initial setting value of SECAM COLOUR .

(3) Adjust SECAM COLOUR to bring the value of (A)

in the voltage table.

NTSC 3.58 COLOUR

(1) Receive a NTSC 3.58 full field colour bar signal

(75% white).

(2) Set the initial setting value of NTSC 3.58

COLOUR.

(3) Adjust NTSC 3.58 COLOUR to bring the value of

(A) in the voltage table.

NTSC 4.43 COLOUR

(1) When NTSC 3.58 is set, NTSC 4.43 will be

automatically set at the respective values.

1-22 (No.YA415)

Page 22

Item

Measuring

instrument

SUB TINT Signal

generator

Remote

control unit

Signal

generator

Oscilloscope

Remote

control unit

Test point Adjustment part Description

[2. V/C]

6. TINT

[Method of adjustment without measuring instrument]

NTSC 3.58 TINT

(1) Receive a NTSC 3.58 full field colour bar signal

(75% white).

(2) Select 2. V/C from the SERVICE MENU.

(3) Select < 6. TINT >.

(4) Set the initial setting value of < 6. TINT >.

(5) If you cannot get the best tint with the initial setting

value, make fine adjustment until you get the best

tint.

NTSC 4.43 TINT

(1) When NTSC 3.58 is set, NTSC 4.43 will be

automatically set at the respective values.

TP-47G/R

TP-E

[CRT SOCKET

PWB]

[2. V/C]

6. TINT

[Method of adjustment using measuring instrument]

NTSC 3.58 TINT

(1) Receive a NTSC 3.58 full field colour bar signal

(75% white).

(2) Select 2. V/C from the SERVICE MENU.

(3) Select < 6. TINT >.

(4) Set the initial setting value of < 6. TINT >.

(5) Connect the oscilloscope between TP-47G/R and

TP-E.

B

R

M

(6) Adjust NTSC 3.58 TINT to bring the value of (B)

in the voltage table in the left.

NTSC 4.43 TINT

(1) When NTSC 3.58 is set, NTSC 4.43 will be

(-)

automatically set at the respective values.

AV-21B16

SECAM BLACK

OFFSET

W

MODEL

Signal

generator

Remote

control unit

Y

C

G

Voltage setting (B)

NTSC3.58 NTSC4.43

+6V (VDO) ---

0V

(B)

(+)

[2. V/C]

7. SECAM BL ADJUST

(1) Input a SECAM full field colour bar signal.

(2) Select 2. V/C from the SERVICE MENU.

(3) Select < 7. SECAM BL ADJUST >.

(4) Set the initial setting value of < 7. SECAM BL

ADJUST >.

(5) Switch the [1] key (colour OFF) and [2] key (colour

ON) and make sure that there is no colour on the

black and white screen.

(6) If the black and white screen is not best with the

initial setting value, make fine adjustment until you

get the best black and white screen.

(7) While watching the screen, adjust the value to be the

same colour between ON & OFF by [1] or [2] key.

(8) Press the [DISPLAY] key twice to return to the

normal screen.

(No.YA415)1-23

Page 23

4.8.6 VSM PRESET SETTING

Item

Measuring

instrument

VSM PRESET Remote

control unit

TINT **

COLOUR **

BRIGHT **

CONT.

SHARP **

/ : SELECT

- / + : OPREATE DISP : EXIT

[4.VSM PRESET]

Test point Adjustment part Description

[4. VSM PRESET]

TINT

COLOUR

BRIGHT

CONT.

SHARP

(1) Select 4. VSM PRESET from the SERVICE MENU.

(2) Set the PICTURE MODE to BRIGHT.

(3) Select < TINT >.

(4) Set the initial setting value of < TINT > as shown in

the below table.

(5) Select < COLOUR > to < SHARP > in turn, and set

the values.

(6) Respectively select the "SOFT" and "STANDARD".

BRIGHT

**

Make similar adjustment as same step as above.

Setting

item

Variable

range

Initial setting value

BRIGHT

STANDARD

SOFT

TINT 0 - 30 15 15 15

COLOUR 0 - 30 15 15 15

BRIGHT 0 - 30 15 15 15

CONT. 0 - 30 30 15 11

SHARP 0 - 30 15 15 12

1-24 (No.YA415)

Page 24

4.8.7 PURITY AND CONVERGENCE

PURITY ADJUSTMENT

Note:

The final adjustment of CONVERGENCE must be done after

the FOCUS adjustment. (CONVERGENCE is changed by

FOCUS adjustment.)

When makes difference by FOCUS adjustment, should be

reconfirming PURITY adjustment.

(1) Demagnetize CRT with the demagnetizer.

(2) Loosen the retainer screw of the deflection yoke.

CRT

WEDGE

DEFLECTION

YOKE

P

4 6

P / C

MAGNETS

(3) Remove the wedges.

(4) Input a green raster signal from the signal generator, and

turn the screen to green raster.

(5) Move the deflection yoke backward.

(6) Bring the long lug of the purity magnets on the short lug and

position them horizontally. (Fig.2)

(7) Adjust the gap between two lugs so that the GREEN

RASTER will come into the centre of the screen. (Fig.3)

(8) Move the deflection yoke forward, and fix the position of the

deflection yoke so that the whole screen will become green.

(9) Insert the wedge to the top side of the deflection yoke so that

it will not move.

(10) Input a crosshatch signal.

• P/C MAGNETS

P : PURITY MAGNET

4 : 4 POLES (convergence magnets)

6 : 6 POLES (convergence magnets)

Fig.1

PURITY MAGNETS

Long lug

Short lug

Bring the long lug over the short lug

and position them horizontally.

Fig.2

(FRONT VIEW)

GREEN RASTER

(11) Verify that the screen is horizontal.

(12) Input red and blue raster signals, and make sure that purity

is properly adjusted.

CENTRE

Fig.3

(No.YA415)1-25

Page 25

STATIC CONVERGENCE ADJUSTMENT

(1) Input a crosshatch signal.

(2) Using 4-pole convergence magnets, overlap the red and

blue lines in the centre of the screen (Fig.1) and turn them

to magenta (red/blue).

(3) Using 6-pole convergence magnets, overlap the magenta

(red/blue) and green lines in the centre of the screen and

turn them to white.

(4) Repeat 2 and 3 above, and make best convergence.

DYNAMIC CONVERGENCE ADJUSTMENT

(1) Move the deflection yoke up and down and overlap the lines

in the periphery. (Fig. 2)

(2) Move the deflection yoke left to right and overlap the lines in

the periphery. (Fig. 3)

(3) Repeat 1 and 2 above, and make best convergence.

(4) Adjust XV by XV coil. (Fig.4)

(FRONT VIEW)

Fig.1

(FRONT VIEW)

GREEN

RED

RED

BLUE

BLUE

GREEN

Fig.2

(FRONT VIEW)

GREEN GREEN

RED

BLUE

BLUE

BLUE

RED

GREENGREEN

BLUE

RED

RED

RED

GREEN

BLUE

• After adjustment, fix the wedge at the original position. Fasten

the retainer screw of the deflection yoke. Fix the P/C magnets

with glue.

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

(FRONT VIEW)

Xv

BLUE

GREEN

RED

Fig.3

GREEN

Fig.4

1-26 (No.YA415)

Page 26

BLOCK DIAGRAM

MAIN PWB(1/3, 2/3)

STB_PW

IC703

5V REG.& RESET

POWER LED

FRONT IN

REAR IN

VIDEO

AUDIO

VIDEO

AUDIO

TU001

TUNER

SCL/SDA

IF

IC702

MEMORY

Q102

IF AMP

MICRO COMPUTER

SCL/SDA

IC701

SF102

SAW FILTER

SAW

SCL/SDA

EXT

RGB/YS

IC301

1CHIP DECODER

VIDEO IN

AUDIO IN

LED(TIM)

REMOCON

AUDIO OUT

R OUT

G OUT

B OUT

IC651

AUDIO AMP

TIMER LED

REMOCON

RECEIVER

HEADPHONE

SPEAKER L

SPEAKER R

MAIN PWB(3/3)

Q351

R OUT

Q352

G OUT

Q353

B OUT

CRT

REAR OUT

VIDEO

AUDIO

AC IN

POWER SW

LF901

D901

IC921

POWER

REG.

T921

SW

TRANSF.

IC971

9V REG.

IC972

5V REG.

VIDEO OUT

AUDIO OUT

9V OUT

5V OUT

V OUT

H OUT

IC421

V OUT

Q521

H DRIVE

Q522

H OUT

DEF YOKE

(V)

(H)

T522

FBT

B1

EHV

SCREEN

FOCUS

2-4(No.YA415)(No.YA415)2-3

Page 27

CIRCUIT DIAGRAMS

MAIN PWB CIRCUIT DIAGRAM (1/3) SHEET1

POWER LED(GREEN)

ON TIMER LED(RED)

R749

4.7k

R796

X

10k

R750

X

C732

C712

.01

R746

10k

*4

D707

A.PROT

IC704

C727

R771

.1/16

0

1/50

3.9k

R741

560

C744

.01

IC701

*

X

X

X

C733

C735

C734

1k

R708

R709

R710

4.7k

X

R734

R706

560

4.7k

X

OSD_YS

OSD_G

OSD_B

A_MUTE

X

C726

VOL

X

D706

R748

1k

R719

C725

X

P_ON/OFF

C719

C738

X

100

R740

X

C731

.01

C718

C720

.01

C723

3.58/OTH

MAIN PWB ASS'Y(1/3)

SCG-1546A-H2

R711

R773

4.7k

OSD_R

560

CN10A

CN00A

C736

R718

D704

R772

390

Q708

Q710

*3

1k

R725

X

560

R707

560

*3

C730

.01

1k

R729

C717

.01

C713

180p

C716

180p

Y705

K701

R715

R716

680

680

SCL1

SDA1

S702

S701

R726

4.7k

10k

R721

C728

180p

C729

180p

5.6

L701

X701

C711

C710

100/16

.01

S704

S703

R727

15k 4.7k

C721

.033

R737

R728

100k

1k

K703

K704

C709

.01

R738

10k

C722

100p

Q702

*1

R714

4.7k

R720

4.7k

R713

4.7k

R712

4.7k

PIC_MUTE

R730

R731

10K

R736

82k

IC702

R739

10k

Q703

*1

R742

56k

C724

R797

15k

150p

SDA1

AFT

V_SYNC

R723

STB_PW

CP701

S705

J005

IC703

R662 R661

270 270

PIC_MUTE

D731

*4

FBP

100/16

R306

C708

1000/10

C707

.01

LB

R655

47k

Y976

D305

D501

C504

*6

X

V_OUT

C309

C308

R401

.01

0

C402

10K

X

C437

C401

.47

.1

C706

.01

C705

470/16

27

R307

1.2k

R308

1.8k

X

R667

100

Q653

*2

D657

*4

C503 C502

10/50 .01

C316

10/50

SPEAKER

CN0S5

Y658

R327

4.7M

R666

100

D653

R654

22k

Q652

R323

10k

C313

3.3/50

*4

Y656

4.7/50

*1

C659

.027/25

Y657

Q651

R321

1.5k

Q301

*2

C322

R322

2.7k

X

R660 C654

15k 470/16

R653

330

C653

10/50

R651

4.7k

C651

*1

C314

.01

Y301

x

Y302

0

C317

.047/25

220/25

R659

4.7

C658

100/16

C162

1500p

R668

5.6

D652 D651

*7 *4

R664

6.8k

R652

1k

C652

.047

A_MUTE

AUDIO

LINE_A

C315

R324

1k

C324

33/50

D301

*5

C323

0.47/50

A.PROT

A_GND

A_VCC

VIDEO

R163

C164

*

R325

C161

X

*

R161

*

CF161

*

Y160

X

Q161

R165

**

R162 R164

R166

*

CF162

*

*

*

*

C166

*

*

C165

IC701

CF161

CF162

Q161

R161

R162

R163

R164

R165

R166

C114

C161

C164

C165

C166

TU001

*

X

X

X

X

X

X

X

X

X

.01

X

X

X

X

X

X

X

X

X

X

1K

X

1.2K

X

2.2K

X

X

220

22

X

X

820

0.1

X

X

.01

X

.01

.01

X

.1

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

0.1

0.1

X

X

X

X

X

X

X

X

Y655

X

Y654

X

Y653

X

IC651

D655

*4

C664

100/16

D654

*7

D656

*4

C657

100/25

C321

R503

6.8k

D303

R658

2.2k

12p

X302

D306

H_OUT

C663

.001

C655

10/50

C656

1/50

R665

10k

R656

8.2k

C665

.01

R657

2.2k

VOL

LINE_V

Q302

*1

1k

R314

.47/50

1k

H_VCC

BW

0

R501

R502

IC301

C312

R313

0

C501

47/25

.01

C310

220p

R312

C311

FRONT

REAR

REAR

OUT

AFT

C119

J006

X

IN

IN

J004

J003

R802

75

470/16

C841

1500p

C842

X

C805

220/16

C806

R807

68

R815

180

Q804

*1

VIDEO

1

AUDIO

R810

56

Q803

R811

220

LINE_V

R806

270

C811

1

10/50

R816

R817

LINE_A

680

4.7k

A_MUTE

C812

X

J002

NOTE) 1.Refer to the parts list for the part number of IC702.

OSD_YS

Y161

Y975

Y001

Y002

R374

6.8K

STB_PW

STB_PW

A_GND

A_GND

A_VCC

X_RAY5VA_VCC

X_RAY

P_ON/OFF

A.PROT

P_ON/OFF

A.PROT

FBP

FBP

H_VCC

H_VCC

H_OUT

H_OUT

V_OUT

V_OUT

2

2

V_SYNC

SCL1

V_SYNC

R301

0

C301

C341

680P

10/50

D341

C302

*4

4.7/50

R302

4.7k

SCL1

SDA1

9V

OSD_R

C365

1/50

R341

3.3K

C306

.01

ABL

OSD_G

OSD_B

C366

C367

1/50

1/50

C307

470/16

CN00T

MAIN PWB ASS'Y(3/3)

(CRT SOCKET)

R303

100

100

R304

CN10T

C303

C304

10p

100

R305

8.2

L103

47/25

SF102

C109

C305

.47/50

.47/50

X301

C113

.0047

C112

C114

*

C111

X

R118

R116

X

X

Q103

X

X

.01

C326

C115

220p

L104

X

C110

0

.01

220

C116

C122

.01

R121

SF101

X

C121

.01

R114 R109

X 6 .8k

D102

R117

X

C108

X

32V

.47/50

C120

120p

C117

R120

390

.22

C325

R326D302

100*5

10/50

SF122

L101

C106

C107

.0047

.0047

Q102

*10

R115

X

C105

.0047

R159

180k

R160

X

R158

X

R111

180

R112

10

R110

2.7k

R113

100

C104

.0047

CF103

C103

47/25

R103

10

X

3.58/OTH

CF102

L001

8.2

C003

x

C004

470/16

IC001

L002

X

C005

.1

X

R001

X

C009

X

X

R102

K001

10/50

D001

C002

.01

C006

X

R002

220

R003

220

C007

R004

X

56k

c21251001a.001_1/2

TU001

*

75

C001

C008

4.7/50

MAIN PWB(2/3) SHEET2

(No.YA415)2-5 2-6(No.YA415)

Page 28

MAIN PWB CIRCUIT DIAGRAM (2/3)(3/3) SHEET 2

AC110V-AC240V

50Hz/60Hz

!

CN0PW

!

VA901

!

S901

!

220

D931

F901

T3.15AL

RY971

X

!

C991

!

C992

.001

R901

!

C904

.001

D901

C929

!

C905

.001

C909

*

R903

R934

68k

*4

D921

R935

.01

R928

68k

C930

X

K901

*8

D933

*5

D925

D930

K902

*8

R933

4.7

*5

!

C993

!

R991

8.2M

DEG COIL

!

CNDEG

R904

IC921

Y904

Y905

!

C901

!

LF901

!

TH901

*

D928

Y903

!

C910

!

C907

.001

R923

R921

1.8

100k

R922

1M

R925

D927

R924

150K

*7

C925

33/50

3.9k

C926

3300p

*

Y902

R906

100k

C931

C927

C924

.1/50

4.7/50

X

R929

D929

C922

X

.1

C932

220p

D920

Q973

MAIN PWB(1/3) SHEET 1

STB_PW

A_GND

LB

A_VCC

Y973

0

Y961

R985

X

D973

X

R986

C972

X

K941

T921

X

R987

D974 R988

X

XX

560p

D942

D941

C941

D943

C944

C947

CP981

L943

4.7

!

*5

CP982

C945

1000/25

C948

1000/25

C949

470p

L942

C942

100/160

1000/25

L941

4.7

C946

82

CN0S2

!

!

K943

*8

K942

*8

*8

X

Q961

X

R961

R962

X

X

IC971

IC972

Q974

H004

R963

X

R964

X

C977

220/16

C979

X

220/10

R974

2.2k

C971

X

D986

X

Q982

Q962

X

R976

12

C976

220/25

R979

47

C978

220/25

R978

47k

R977

1.2k

Q975

*3

X

5V

H_VCC

Y972

X

R965

X

C961

X

D982

*4

D983

*4

R984

X

R983

Q981

X

R982

X

X

R981

X

32V

X_RAY

A.PROT

9V

P_ON/OFF

X

D985

X

C981

X

H_OUT

R980

15K

Q572

*1

ABL

V_OUT

V_SYNC

FBP

R422

R421

4.7k

X

R423

0

D424

X

R424

0

R425

C422

3.3k

X

V_OUT

Q402

R436

82k

*1

D427

Q401

R524

X

R525

C523

33

47/25

Q521

R531

R532

330

100/160

D571

C572

R578

10k

47/25

D562

XX

C561

R565

X

IC421

C427

100/35

C423

18p

R426

0

C424

R443

1

C436

.33

D425

*4

C429

10/50

.0033

1k

C531

R566

X

XX

C529

R573

C426

.001

R441

.01

R453

3.3K

R576

R577

8.2k

R432

3.9

T501

R526

270

R530

X

C526

.0082

R529

C530

R528

R574

R575

X

22k

Q571

D561

C562

K421

!

470

D421

*8

R521

Q522

56

C421

R431

10k

Y502

R571

2.2K

C571

100/10

R433

!

D584

R582

TP-47G/R

TP-47R/G

R349

4.7K

R369

X

X

R583

39k

R552

TP-47B

R581

1.8k

4.7/250

C554

D581

SK351

!

SK351

K351

Y303

Y304

!

X

C909

FOCUS

SCREEN

C351

.001

*

C352

TP-E

X

R365

12k

R368

R364

R367

1.8k

1.8k

R363

R366

T522

L353

R362

C356

390p

R359

R356

470

330

R348

X

12k

L352

R361

C355

270p

R358

R355

330

470

12k

L351

R360

R347

3.9K

C354

330p

R357

R354

1.8k

470

330

L354

CN10U

CN00U

!

R584

C581

.1

R585

D582

X

*5

C553

X

D552

*5

Q353

R353

150

Q352

R352

150

R345

X

CN10T

C357

470/10

X

R346

R351

150

D352

D353

Q351

MAIN PWB ASS'Y(3/3)

(CRT SOCKET)

X

R442

C433

4.7/50

C435

2200/25

10k

.0047

100/35

D423

C430

C428

*6

R430

82k

10k

R429

C425

X

CN00T

XXX

MAIN PWB ASS'Y(1/3)

R444

X

D351

SCG-1546A-H2

R440

*

C525

C528

X

C582

X

D555

X

X

Y501

C527

X

L522

26V

!

D554

*4

R554

680

R551

C552

1000/35

D553

C555

.1/100

C551

D551

L551

FR556

X

*5

X

MAIN PWB ASS'Y(2/3)

Y503

X

CN0S1

CN0HV

SCG-1546A-H2

c21251001a.001_2/2

ADJUSTMENT

CONNECTOR

2-8(No.YA415)(No.YA415)2-7

!

DEF YOKE

Page 29

PATTERN DIAGRAMS

MAIN PWB PATTERN

()

C927

W229

R906

W028

IC921

D927

D929

CNDEG

R904

C925

R921

R903

S901

C931

H003

R923

C554

CN00U

W548

C552

C421

C423

R4 30

D423

R429

D553

W106

W175

W634

CN0S5

R661

R573

R574

R571

C553

R552

D552

R585

W657

W016

D582

W017

FRONT

R582

IC421

D427

R551

R431

R441

W337

R347

R367

D581

W129

R424

C422

W105

D352

D421

H001

R425

D425

D354

K351

CN00T

D355

R583

W071

T522

C551

B1

D551

R433

R432

R444

D356

R358

Y304

C424

R453

C429

W576

C433

D353

R3

55

C355

K421

W495

R352

Y303

C357

R345

C430

C435

Y503

Q352

R529

R361

R440

L522

W476

C582

TP-E

CN0HV

H002

Y502

Y501

R528

C525

Q522

C530

R442

C527

D555

R530

R524

R532

W596

W032

C528

R521

T501

C529

C526

C523

R526

Q521

R525

()

R363

R354

R364

TP-47G/R

R357

C354

W611

R346

R351

L351

R360

52

L3

SCREEN

W336

C351

R366

Q351

TP-47R/G

R368

R356

R3

SK351

C352

R362

R359

C356

Q353

53

L353

R365

()

TOP

L354

CN00U

TP-47B

R369

C581

W605

R581

FR556

C562

D561

C555

C436

R443

W003

W087

W080

C427

90

W5

W635

C42

C426

5

R4

23

D424

Q402

W169

W176

R426

R422

R421

W011

R531

R436

Q401

R349

R348

W338

D351

Y001

R002

W041

R003

W012

C001

C659

C653

W422

W631

D707

W097

W654

W136

TU001

Y002

C007

W099

C003

C664

C663

C658

R652

R659

Y655

Y654

W632

W510

C008

W641

R004

C010

C011

R102

C002

W110

W030

R303

W214

R302

W069

C341

W159

W555

W655

W505

R741

R301

W150

W072

C365

W054

W066

W620

W623

W481

W217

C654

C366

W114

W113

W112

W101

R719

W473

W459

W517

91

R746

R726

C726

12C7

W646

W4

45

W5

R796

R748

C732

R750

C731

S702 S703 S704

R308

W656

W005

W618

C725

D706

CF102

W544

C304

01

20

C744

R802

CN00T

C3

C302

R708

C7

R707

J002

C842

R806

C806

CF103

R103

C109

Q103

C307

R304

R306

W090

Y976

C309

R401

C308

W479

R711

R710

R7

18

R7

09

R734

C7

33

C7

18

R749

R740

R807

R810

C103

C106

R110

C104

R109

Q102

C303

R503

W628

C721

R728

R721

R730

X301

Q703

C111

X302

C501

C723

R114

W117

D731

C722

R111

D306

D303

16

K701

C717

C112

IC301

C504

R738

R739

W120

C730

R729

C114

C312

C311

C716

C113

C321

R715R7

Y705

C713

W523

W602

X7 01

28

C107

C326

R3

22

C402

R714

R720

R725

C7

R731

L1 01

R118

C108

R116

L103

C305

W092

R305

C306

C437

C316

C5

02

C503

C401

R501

D501

R797

W155

Q702

R7 06

C7 36

C734

R737

C7

35

W423

W524

R727

SF101

Q803

C105

R112

D102

K704

R117

L104

C314

R327

R312

C313

R742

C729

Q302

R113

W432

C805

Q804

R817

R816

R815

R811

C811

R115

Y161

C121

C110

SF122

C122

SF102

C117

R121

C115

C116

R160

64

C162

R313

R314

W626

R321

Y972

Y975

C315

C310

R307

C166

C164

Y301

W617

R1

W168

W231

Q301

W604

W174

Y973

W616

C317

D305

C322

C724

W436

C812

W580

W424

R158

C119

C120

R120

R159

R3

D302

C165

R163

R1

65

R166

Q161

C161

R1

61

CF161

D301

W130

C323

R323

W502

W220

Y3

02

W206

D584

D341

W615

R341

W579

26

W095

W124

C325

Y160

R162

CF162

C324

R325

W494

W588

W482

W472

W451

R324

W504

R736

W247

W645

R584

W137

W613

W612

C708

L701

W431

C711

C710

W474

K703

IC701

S705

W496

C709

C705

IC703

C706

C707

IC702

R712

R713

J006

W429

CP701

J004

W413

B

C841

C991

L941

C993

W543

C942

K941

C949

D942

K942

CL003

C944

R978

Q974

R976

R977

W652

R986

D974

R988

Q973

C976 R502

A

R987

73

D9

RY971

K943

C941

C945

W563

IC971

CP982

W103

H004

R984

R983

R981

Q982

D986

C981

D985

D941

C948

CP981

C947

D943

W164

L943

R974

C971

W466

L942

W648

Y961

R9

C946

61

R962

Q975

R963

C961

R965

W014

C972

C977

W188

R979

IC972

C979

R985

D982

W148

W566

R964

D657

Q981

R982

CN0S2

W578

D983

Q961

R668

Q962

W187

W519

R657

W190

R374

W111

W053

R980

C005

C006

C004

D001

L002

L001

W098

K001

C009

IC001

R001

H006

R658

C656

R667

D654

R666

R660

W649

C978

W184

C657

C367

D656

B

IC651

Q653

W204

CN0S3

R655

Y653

R653

C652

D655

C655

W647

W173

CN00A

Q708

R771

CL005

C719

C727

R723

CN00A

R654

W653

C738

R656

C665

C651

Q652

R665

D653

Q651

D652

R664

R651

D651

S701

Q710

D921

D925

35

R9

R925

C926

R929

W023

D931

C922

W329

C924

R924

C932

R934

W049

D933

R933

T921

D928

D920

W227

W228

K901

K902

R922

C905

C909

TH901

Y905

Y904

LF901

C930

D930

W062

C929

C904

D901

C907

W603

R991

Y902

R901

C910

C992

Y903

R928

W061

CN0PW

VA

901

C901

F901

FC902

D704

R772

R773

FC901

IC704

R578

Q572

W009

W162

W195

W196

W198

W199

J003

W077

W094

W412

W201

CN0S1

R565

W411

CN0S4

W154

C531

Y656

C572

D571

J005

W004

R566

L551

D554

W638

W643

W644

C561

Y658

R575

C571

Q571

R577

R576

W073

W640

C428

D562

R554

W636

Y657

R662

(No.YA415)2-9 2-10(No.YA415)

Page 30

VOLTAGE CHARTS

<MAIN PWB>

MODE

PIN NO.

IC301

1 0

2 4.4

3 6.3

4 3.4

5 0

6 5.0

7 5.0

8 5.5

9 9.0

10 3.0

11 3.0

12 3.0

13 0

14 2.8

15 4.2

16 9.0

17 3.8

18 2.8

19 2.8

20 0

21 0

22 0

23 4.4

24 3.2

25 3.0

26 3.5

27 4.2

28 3.7

29 4.1

30 3.9

31 4.2

32 4.2

33 9.0

34 4.0

35 4.7

36 4.0

37 6.1

38 4.2

39 4.3

40 2.7

41 6.2

42 1.0

43 3.7

44 3.9

45 1.2

46 3.1

47 5.4

48 5.0

49 0.7

50 0

51 4.4

52 0.7

IC421

1 3.7

2 26.0

3 2.0

4 0

5 13.8

6 26.3

7 3.7

IC651

1 12.5

2 5.6

3 0

4 2.4

5 9.4

6 9.6

7 0

8 9.7

9 19.9

IC701

1 4.5

2 4.9

3 0

4 0

5 0

6 4.9

7 4.9

8 2.3

9 3.0

10 4.9

11 0

12 0

13 2.4

14 0.1

15 1.8

16 1.8

17 0

18 0.8

19 0

20 4.9

21 4.9

22 4.9

23 4.9

24 2.3

25 4.9

DC (V

MODE

)

PIN NO.

26 0

27 4.1

28 4.9

29 0

30 0

31 0

32 0

33 0

34 4.9

35 4.7

36 4.9

37 4.4

38 4.4

39 4.9

40 0

41 2.1

42 0

IC702

1 0

2 0

3 0

4 0

5 4.9

6 4.9

7 0

8 4.9

IC703

1 14.4

2 5.8

3 0

4 4.9

5 4.9

IC704

1 4.5

2 4.9

3 0

IC921

1 314.0

2 NC

3 0

4 0

5 31.8

6 0

7 0.7

IC971

1 12.8

2 9.0

3 0

IC972

1 9.2

2 4.9

3 0

Q102

E 0

C 9.0

B 2.3

Q103

E 0

C 0

B 4.0

Q161

E 2.5

C 8.3

B 3.2

Q301

E 4.6

C 0

B 4.0

Q302

E 4.0

C 9.0

B 4.6

Q401

E 0

C 0

B 5.4

Q402

E 0

C 4.9

B 0

Q521

E 0

C 9.7

B 0.3

Q522

E 0

C 115.3

B 0

Q571

E 115.5

C 0

B 115.1

Q572

E 0

C 4.9

B 0

DC (V

MODE

)

PIN NO.

Q651

E 0

C 0.3

B 0

Q652

E 0

C 1.0

B 0.6

Q653

E 15.1

C 0

B 15.2

Q702

E 0

C 4.2

B 0

Q703

E 0

C 4.8

B 0.1

Q708

E 0

C 2.0

B 0

Q710

E 0

C 0.1

B 0

Q803

E 0

C 8.1

B 4.7

Q804

E 0

C 0

B 0.1

Q974

E 15.3

C 15.1

B 0

Q975

E 0

C 0.1

B 4.3

TU001

1 4.6

2 NC

3 0

4 4.4

5 0

6 4.5

7 4.9

8 0

9 31.3

10 NC

11 0

DC (V

<CRT SOCKET PWB>

MODE

)

PIN NO.

Q351

E 2.5

C 125.8

B 3.2

Q352

E 2.6

C 123.3

B 3.3

Q353

E 2.5

C 128.5

B 3.2

DC (V

)

(No.YA415)2-11

Page 31

WAVEFORMS

-MAIN PWB-

(SHEET1)

IC301-10

IC301-11

(H)

(H)

IC301-12

(H)

IC301-14

(1µs)

IC301-36

(H)

IC301-40

(1µs)

IC301-42

(H)

3.5 Vp-p

IC301-46

2.5 Vp-p

(SHEET2)

IC421-1

0.6 Vp-p

Q522-B

2.0 Vp-p

(V)

(V)

(H)

IC701-27

5.0 Vp-p

IC421-3

T522-1

1000 Vp-p

3.5 Vp-p

30 Vp-p

(H)

(V)

(H)

IC701-35

5.0 Vp-p

IC421-5

60 Vp-p

T522-3

4.0 Vp-p

55Vp-p

(V)

(V)

(H)

IC421-6

T522-5

0.35 Vp-p

30 Vp-p

220 Vp-p

(V)

(H)

Q521-C

T522-7

3.0 Vp-p

38 Vp-p

25 Vp-p

(H)

(H)

Q521-B

T522-9

0.5 Vp-p

1.5 Vp-p

220Vp-p

(H)

(H)

Q522-C

2.5 Vp-p

(H)

1000Vp-p

-CRT SOCKET PWB-

(SHEET2)

Q351-C Q352-C Q353-C

110 Vp-p

(H)

120 Vp-p

2-12(No.YA415)

(H) (H)

120 Vp-p

Page 32

CONTENTS

USING P.W. BOARD & REMOTE CONTROL UNIT ................................................................................................... 3-3

EXPLODED VIEW PARTS LIST -1 ............................................................................................................................. 3-3

EXPLODED VIEW -1 ................................................................................................................................................... 3-4

PRINTED WIRING BOARD PARTS LIST ................................................................................................................... 3-5

MAIN P.W. BOARD ASS'Y (SCG-1546A-H2) .................................................................................................... 3-5

REMOTE CONTROL UNIT PARTS LIST (RM-C360GY-1H) ..................................................................................... 3-8

PACKING ..................................................................................................................................................................... 3-8

PACKING PARTS LIST ............................................................................................................................................... 3-8

3-2(No.YA415)

Page 33

USING P.W. BOARD & REMOTE CONTROL UNIT

P.W.B ASS'Y AV-21B16

MAIN P.W.B SCG-1546A-H2

REMOTE CONTROL UNIT RM-C360GY-1H

EXPLODED VIEW PARTS LIST -1

Ref.No. Part No. Part Name Description Local

V01 A51MBA11X05AN05 PICTURE TUBE(ITC) Inc.DEF YOKE, PC MAGNET

L01 QQW0125-001 DEG COIL

T522 QQH0170-001 FB TRANSF

1 GG30152-001A-H JVC MARK

2 GG30150-002A-H OPERATION SHEET

3 GG30149-001A-H LED LENS

11 QYSBSFG4016ZA TAP SCREW M4 x 16mm(x6)

12 QYSBSF3010ZA TAP SCREW M3 x 10mm

13 QYSBSFG4016ZA TAP SCREW M4 x 16mm

14 GG10421-002B-H REAR COVER

15 CM47005-A01-H POWER CORD CLAMP

16 QMPR340-165-K2 POWER CORD 1.65m BLACK

17 GG30119-001B-H SUB PCB HOLDER

18 A48457-3-H SPRING

19 WJY0008-006A-E BRAIDED ASS'Y

20 GG30151-001A-H CHASSIS RAIL (x2)

21 QYSBSF4012ZA TAP SCREW M4 x 12mm(x4)

22 QAS0347-001 SPEAKER (x2) SP01,SP02

30 SCG-1546A-H2 MAIN PWB

100 GG10419-002B-H FRONT CABINET ASS'Y Inc.101,102,103

101 GG20131-001B-H DOOR

102 GG30148-001B-H POWER KNOB

103 CM35235-003-H SPRING

(No.YA415)3-3

Page 34

EXPLODED VIEW -1

3

101

18

L01

22

21

V01

15

19

17

16

20

22

CRT SOCKET PWB

30

(Within MAIN PWB)

FRONT LED PWB

30

(Within MAIN PWB)

21

1

2

102

T522

103

30

MAIN PWB

100

3-4(No.YA415)

14

11

RATING LABEL

13

12

Page 35

PRINTED WIRING BOARD PARTS LIST

MAIN P.W. BOARD ASS'Y (SCG-1546A-H2)

Ref No. Part No. Part Name Description Local

IC301 NN5198K IC

IC421 LA78040N IC

IC651 AN5265 IC

IC701 MN1873287JL1 IC

IC702 ATE08-21YMG6 IC (SERVICE)

IC703 L78LR05E-MA IC

IC704 GP1UM281QK IR DETECT UNIT 38kHz

IC921 STR-W5753A/F5 IC

IC971 L7809CP IC

IC972 L7805CP IC

Q102 2SC5397/CD/-T TRANSISTOR