Page 1

SERVICE MANUAL

AC POWER ADAPTER/CHARGER

AA-V100U

SPECIFICATIONS

Power

Power

consumption

Output power

Operating

temperature

Dimensions

Weight

This service manual is printed on 100% recycled paper.

COPYRIGHT © 2001 VICTOR COMPANY OF JAPAN, LTD

USA and Canada

AC 120 V`, 60 Hz

Other countries

AC 110 V – 240 V`, 50 Hz/60 Hz

23 W

DC 7.2 V , 1.2 A (charge)

DC 6.3 V , 1.8 A (VTR)

0°C to 40°C (32°F to 104°F) [when

charging, 10°C to 35°C (50°F to

95°F)]

68 mm (W) x 44 mm (H) x

110 mm (D)

(2–11/16" x 1–3/4" x 4–3/8")

Approx. 255 g (0.57 lbs)

No.86648

June 2001

Page 2

Important Safety Precautions

cut close to connector

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes

of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the

following precautions when a set is being serviced.

v

Precautions during Servicing

1. Locations requiring special caution are denoted by labels and

inscriptions on the cabinet, chassis and certain parts of the

product. When performing service, be sure to read and comply with these and other cautionary notices appearing in the

operation and service manuals.

2. Parts identified by the

critical for safety.

Replace only with specified part numbers.

Note: Parts in this category also include those specified to com-

ply with X-ray emission standards for products using

cathode ray tubes and those specified for compliance

with various regulations regarding spurious radiation

emission.

3. Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

4. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

5. Use specified insulating materials for hazardous live parts.

Note especially:

1) Insulation Tape 3) Spacers 5) Barrier

2) PVC tubing 4) Insulation sheets for transistors

6. When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

symbol and shaded ( ) parts are

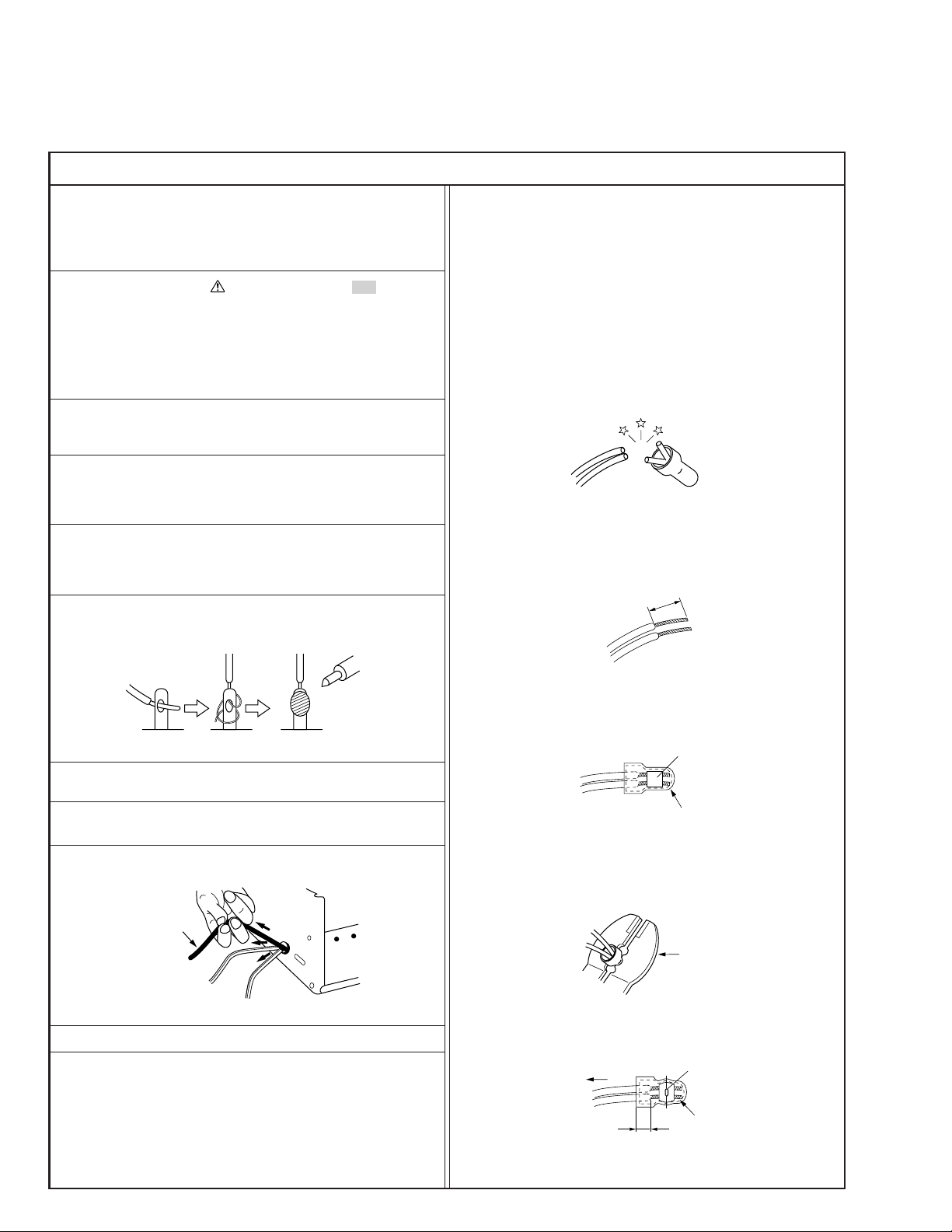

12. Crimp type wire connector

In such cases as when replacing the power transformer in sets

where the connections between the power cord and power

transformer primary lead wires are performed using crimp type

connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely

according to the following steps.

1) Connector part number : E03830-001

2) Required tool : Connector crimping tool of the proper type

which will not damage insulated parts.

3) Replacement procedure

(1) Remove the old connector by cutting the wires at a point

close to the connector.

Important : Do not reuse a connector (discard it).

Fig.3

(2) Strip about 15 mm of the insulation from the ends of

the wires. If the wires are stranded, twist the strands to

avoid frayed conductors.

15 mm

Fig.1

7. Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

8. Check that replaced wires do not contact sharp edged or

pointed parts.

9. When a power cord has been replaced, check that 10-15 kg of

force in any direction will not loosen it.

Power cord

Fig.2

10. Also check areas surrounding repaired locations.

11. Products using cathode ray tubes (CRTs)

In regard to such products, the cathode ray tubes themselves,

the high voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the cathode ray tubes and other parts with only the specified parts.

Under no circumstances attempt to modify these circuits.

Unauthorized modification can increase the high voltage value

and cause X-ray emission from the cathode ray tube.

Fig.4

(3) Align the lengths of the wires to be connected. Insert

the wires fully into the connector.

Metal sleeve

Connector

Fig.5

(4) As shown in Fig.6, use the crimping tool to crimp the

metal sleeve at the center position. Be sure to crimp fully

to the complete closure of the tool.

1.25

2.0

5.5

Fig.6

(5) Check the four points noted in Fig.7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Fig.7

Crimping tool

Crimped at approx. center

of metal sleeve

Conductors extended

1

S40888-01

Page 3

v

d'

d

Chassis

Power cord,

primary wire

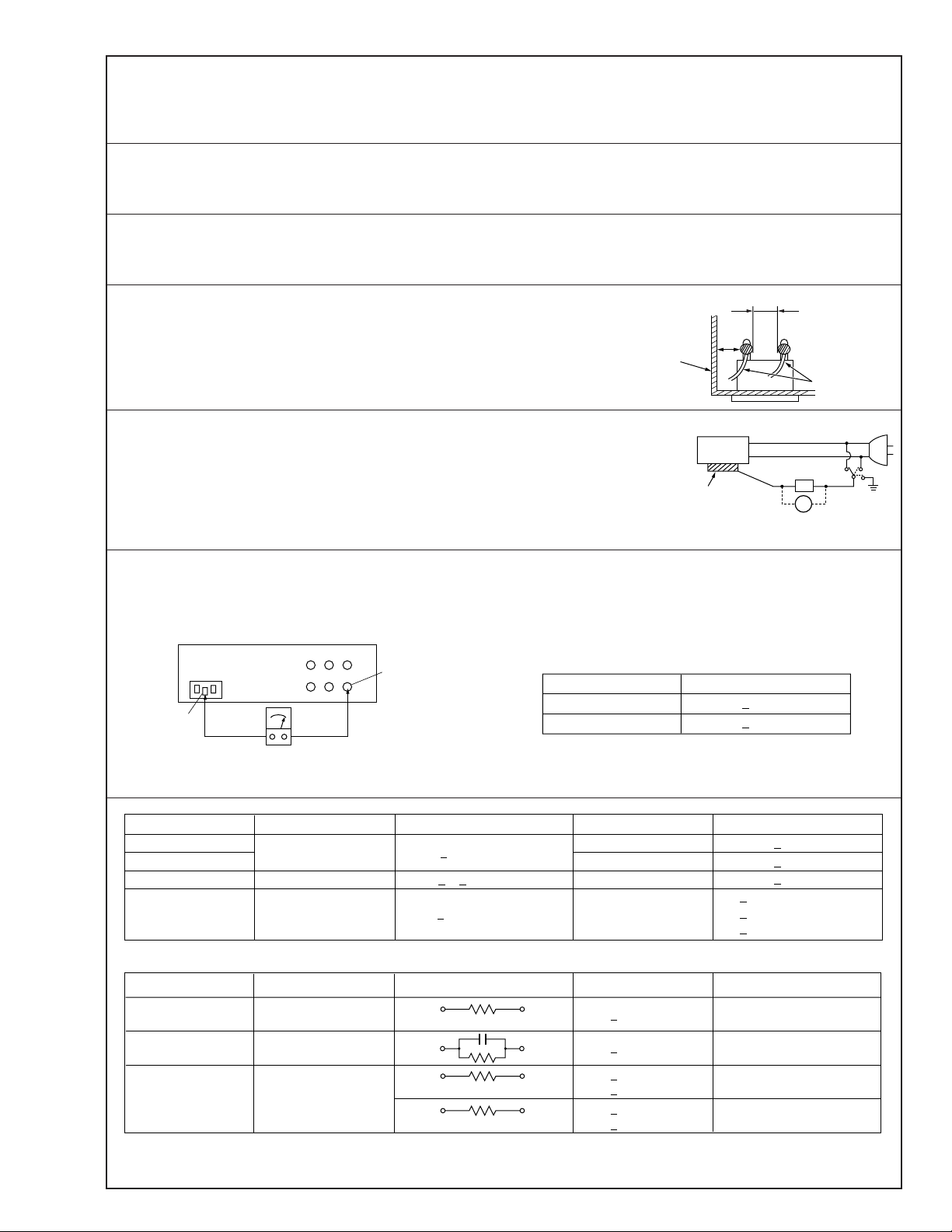

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety standards.

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and

externally exposed parts of the set (RF terminals, antenna terminals, video and audio input

and output terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed

accessible parts of the set (RF terminals, antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

3. Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d’) between soldered terminals, and between terminals and surrounding metallic parts. See table 1

below.

Fig. 8

4. Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure across both terminals of load Z. See figure 9 and

following table 2.

Externally

exposed

accessible part

Z

V

Fig. 9

ab

c

5. Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin in AC inlet and externally exposed accessible parts (Video in,

Video out, Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and exposed accessible parts. See figure 10 and grounding specifications.

AC inlet

Earth pin

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Exposed accessible part

Milli ohm meter

Fig. 10

Region

Japan

USA & Canada

Europe & Australia R 10 MΩ/500 V DC

Region Load Z

Insulation Resistance (R)

≤

R 1 MΩ/500 V DC

≥≥

1 MΩ R 12 MΩ/500 V DC

≤

Table 1 Specifications for each region

Grounding Specifications

Region

USA & Canada

Europe & Australia

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 miute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(Class 2)

(Class 1)

Grounding Impedance (Z)

≤

Z 0.1 ohm

≤

Z 0.5 ohm

Clearance Distance (d), (d')

≤

d, d' 3 mm

≤

d, d' 4 mm

≤

d, d' 3.2 mm

≤

d 4 mm

≤

d' 8 mm (Power cord)

≤

d' 6 mm (Primary wire)

a, b, cLeakage Current (i)AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Note: These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

Japan

USA & Canada

Europe & Australia

Table 2 Leakage current specifications for each region

1 kΩ

0.15 µF

1.5 kΩ

2 kΩ

50 kΩ

2

≤

i 1 mA rms Exposed accessible parts

≤

i 0.5 mA rms

≤

i 0.7 mA peak

≤

i 2 mA dc

≤

i 0.7 mA peak

≤

i 2 mA dc

Exposed accessible parts

Antenna earth terminals

Other terminals

S40888-01

Page 4

SAFETY PRECAUTION

Parts identified by the symbol are critical for safety. Replace only with specified part numbers.

1. PACKING AND ACCESSORY ASSEMBLY <M1>

The instruction manual to be provided with this product will differ according to the destination.

7

8

CARTON LABEL

6

2

FINAL

ASSEMBLY <M2>

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

--------------- ----------------------- ----------------------------------------------------- ---------------- ----------------------- ------------------------------------------------------

1

******************************

PACKING ASSEMBLY <M1>

1 LY31381-001A PACKING CASE

2 LY32337-001A CUHION SHEET

6 QPA01702505P POLY BAG

1

7 BT-51005-5 WARRANTY INF.

!

8 LYT0841-001A INST. BOOK(EN,FR,SP)

Page 5

2 FINAL ASSEMBLY <M2>

1

6

8

MAIN &

TERMINAL BOARD

<91>

5

2

4

7

5

3

4

RATING LABEL

#!REF No. PAR T No. PAR T NAME, DESCRIPTION

----------------------- ------------------------------ ----------------------------------------------------------------------------

******************************

FINAL ASSEMBLY <M2>

! 1 LY32286-001A UPPER CASE

! 2 PTY20483-021 LOWER CASE

! 3 PTY20290-040 AC POWER CORD

4 YQ10531-011 TAP SCREW, X2 LOWER

5 PTY20545-055 TAP SCREW, X2

6 PTY20754-052 SWITCH COVER

7 PTY20754-054 LOCK LEVER

8 PTY20754-055 LENS

2

Page 6

K

%

3. SCHEMATIC DIAGRAM

NOTE :

When ordering parts, be sure to order according to the Part Number

indicated in the Parts List.

5

1

9

TP1

L

N

AC110 240V

4

50/60Hz

MAIN&TERMINAL

F1

C1

L1

/250

R10

OPEN

0.068

Q1

FS2KM18A

D

ZD1

16V

TF1

0Ω

S

HEAT_SINK_A

1SS244

G

D2

1A

TP2

C8

1000p

D1

D21

MA7D56

T1

3.4

7

HEAT_SINK_B

C2

47

/400

C21

0.01u

5

R3

R4

C3

4700p

C5

68p

PHC1

R9

150K

Q2

D4

1SS244

R2

240K

R1

240K240K100K

R5

560

C4

1000p

R6

470

34.6K

ZD2

9.1V

R8

115K

1%

D3

1SS244

R7

1%

Q3

1.2

8

9

680u

C22

/16

ZD21

16V

TP4

L21

LED1

RED

R22

680

3

1000p

C7

R81

150 1/4W

C51

ZD26

4.7V

R27

1K

2

ZD25

4444444

8.2V

Q23

PHC1

C35

4444444

0.1u

R28

47

C36

0.1u

R56

0.047u

10K

TP14

Q22

R54

OPEN

R51

22K

R53

33K

C34

0.01u

C28

0.022u

TP9

C29

R46

R55

C27

0.0022u

4.7K

4.7K

0.047u

C45

0.1u

R29

220K

1%

TP10

R52

470

R30

220K

R32

10K

1%

1%

TP11

0.1u

C30

C37

0.1u

VCC

FBAD

GND

ADPT

PHC

FBCC

SW

VCHK

TH

DCJK

IC21

M61031FP

I IN

VREF

ADJ3

ADJ2

ADJ1

LED1

LED2

VDD

LED2

GREEN

TP18

C31

2200p

R3

115

1

R47

220

1/4W

CC

RC

TP17

R33

100K

1

3

ABC D

Page 7

Safety precautions

The components identified by the symbol ! are

critical for safety . For continued safety, replace

safety critical components only with manufacturer’s

recommended parts.

LED2

GREEN

TP4

L21

LED1

RED

R22

680

R23

0.1

C38

1000p

TP3

1%

R24

24.9K

1%

C23

470u

/16

R26

34.8K

1%

TF2

0Ω

JP21

C24

0.22u

JP22

ZD27

6.2V

TP15

JK1

TP16

R25

100

1/4W

Q21

TP8

16V

ZD23

C25

0.22u

TP6

C43

0.1u

CN2

T

S

_

TP7

TERMINAL PWB

+

T

S

++

T

SW1

__

TP13

R41

1%

28.7K

C31

2200p

115K

R34

R36

56.2K

1%

1%

R37

1.00K

1%

R72 R74

Q25

R70

56.2K

R35

10.0K

1%

10K 10K

R76

10K

R73

R75

10K

10K

1%

44.2K

Q27

Q26

R71

1%

TP19

TP17

R33

100K

R47

220

1/4W

TP18

DE FG

R38

47K

R60

10K

1.15K

VR1

2K

C44

C32

R42

11.5K

1%

R39

1%

4.7u

0.1u

/50

4

Page 8

4. CIRCUIT BOARD

1A 250V

CAUTION:

FOR CONTINUED PROTECTION AGAINST

FIRE HAZARD, REPLACE ONLY WITH SAME

TYPE AND RATED FUSE.

ATTENTION:

POUR UNE PROTECTION PERMANENTE

CONTRE LES RISQUE D'INCENDE,

REMPLACER LES FUSIBLE PAR UN AUTRE

DE MEME TYPE ET DE MEME TENSION.

5

Page 9

5. ELECTRICAL PARTS LIST

#!REF No. PAR T No. PAR T NAME, DESCRIPTION

----------------------- ------------------------------ ----------------------------------------------------------------------------

******************************

MAIN & TERMINAL BOARD ASSEMBLY <91>

! PW1 PTY20754-502 MAIN & TERMINAL BOARD ASSY

IC21 M61031FP Charge control IC 20pin SOP

Q1 FS2KM18A MOS FET

Q2 2SD2226KT146 TRANSISTER

Q3 2SD2226KT146 TRANSISTER

Q22 DTC114YUA-X DIG.TRANSISTOR

Q23 DTA114YUA-X DIG.TRANSISTOR

Q25 2SA1576A/QR/-X TRANSISTOR

Q26 2SA1577A/QR/-X TRANSISTOR

Q27 UN2211TX DIG.TRANSISTOR

D1 S1WBA60 B. DIODE 600V 1A

D2 1SS244T77 DIODE 200V 0.2A

D3 1SS244T77 DIODE 200V 0.2A

D4 1SS244T77 DIODE 200V 0.2A

D21 MA7D56 DIODE 60V 10A

ZD1 MTZJ16T-77 ZENER DIODE 16V 500mW

ZD2 MTZJ9.1B ZENER DIODE 9.1V 500mW

ZD21 MTZJ16T-77 ZENER DIODE 16V 500mW

ZD23 MTZJ16T-77 ZENER DIODE 16V 500mW

ZD25 MA4082N/M/-T2 ZENER DIODE 8.2V 500mW

ZD26 MA4047NM ZENER DIODE 4.7V 500mW

ZD27 MTZJ6.2B-T2 ZENER DIODE 6.2V 500mW

LED1 YQ10531-540 LED RED POWER

LED2 YQ10531-542 LED GREEN CHARGE

R1 QRE141J-244Y RESISTOR 240KØ 1/4W

R2 QRE141J-244Y RESISTOR 240KØ1/4W

R3 QRE141J-244Y RESISTOR 240KØ 1/4W

R4 QRE141J-104Y RESISTOR 100kØ 1/4W

R5 QRE141J-561Y RESISTOR 560Ø 1/4W

R6 QRE141J-471Y RESISTOR 470Ø 1/4W

R7 NRSA63F-3482X MG RESISTOR 34.8kØ 1/16W 1%

R8 NRSA63F-1153X MG RESISTOR 115kØ 1/16W 1%

R9 NRSA63J-154X MG RESISTOR 150kØ 1/16W

R22 QRE141J-681Y RESISTOR 680Ø 1/4W

R23 QRZ0192-R10X MF RESISTOR 0.1Ø 1W 2%

R24 NRSA63F-2492X MG RESISTOR 24.9kØ 1/16W 1%

R25 QRE141J-101Y RESISTOR 100Ø 1/4W

R26 NRSA63F-3482X MG RESISTOR 34.8kØ 1/16W 1%

R27 NRSA63J-102X MG RESIST OR 1kØ 1/16W

R28 NRSA63J-470X MG RESIST OR 47Ø 1/16W

R29 PTY20754-511 MG RESISTOR 220kØ 1/16W 1%

R30 PTY20754-511 MG RESISTOR 220kØ 1/16W 1%

R32 PTY20754-512 MG RESISTOR 10kØ 1/16W 1%

R33 NRSA63J-104X MG RESIST OR 100kØ 1/16W

R34 NRSA63F-5622X MG RESISTOR 56.2kØ 1/16W 1%

R35 PTY20754-512 MG RESISTOR 10kØ 1/16W 1%

R36 NRSA63F-1153X MG RESISTOR 115kØ 1/16W 1%

R37 PTY20754-513 MG RESISTOR 1.00kØ 1/16W 1%

R38 PTY20754-514 MG RESISTOR 47kØ 1/16W 1%

R39 NRSA63F-1151X MG RESISTOR 1.15kØ 1/16W 1%

R41 NRSA63F-2872X MG RESISTOR 28.7kØ 1/16W 1%

R42 NRSA63F-1152X MG RESISTOR 11.5kØ 1/16W 1%

R46 NRSA63J-472X MG RESIST OR 4.7kØ 1/16W

#!REF No. PAR T No. PAR T NAME, DESCRIPTION

----------------------- ------------------------------ ----------------------------------------------------------------------------

R47 QRE141J-221Y RESISTOR 220Ø 1/4W

R51 NRSA63J-223X MG RESISTOR 22kØ 1/16W

R52 NRSA63J-471X MG RESISTOR 470Ø 1/16W

R53 NRSA63J-333X MG RESISTOR 33kØ1/16W

R55 NRSA63J-473X MG RESISTOR 47kØ 1/16W

R56 NRSA63J-103X MG RESISTOR 10kØ 1/16W

R60 NRSA63J-103X MG RESISTOR 10kØ 1/16W

R70 NRSA63F-5622X MG RESISTOR 56.2kØ 1/16W 1%

R71 NRSA63F-4422X MG RESISTOR 44.2kØ 1/16W 1%

R72 NRSA63J-103X MG RESISTOR 10kØ 1/16W

R73 NRSA63J-103X MG RESISTOR 10kØ 1/16W

R74 NRSA63J-103X MG RESISTOR 10kØ 1/16W

R75 NRSA63J-103X MG RESISTOR 10kØ 1/16W

R76 NRSA63J-103X MG RESISTOR 10kØ 1/16W

R81 QRE141J-150Y RESISTOR 150Ø 1/4W

! C1 PTY20292-303 F CAPACITOR 0.068µF275V

C2 YQ10626-402 E CAPACITOR 47µF400V

C3 NCB31HK-472X CAPACITOR 4700pF 50V

C4 PTY20754-521 F CAPACITOR 1000pF 50V

C5 NDC31HJ-680X CAPACITOR 68pF 50V

! C7 PTY20292-368 CAPACITOR 1000pF 250V

! C8 PTY20292-368 CAPACITOR 1000pF 250V

C21 PTY10067-657 CAPACITOR 0.01µF250V

C22 PTY20292-321 E CAPACITOR 680µF16V

C23 QETL1CM-477 E CAPACITOR 470µF16V

C24 PTY20754-522 CAPACITOR 0.22µF16V

C25 QFLA1HJ-224 F CAPACITOR 0.22µF50V

C27 NCB31HK-222X CAPACITOR 0.0022µF50V

C28 NCB31EK-223X CAPACITOR 0.022µF25V

C29 PTY20754-523 CAPACITOR 0.047µF25V

C30 PTY20754-524 CAPACITOR 0.1µF50V

C31 NCB31HK-222X CAPACITOR 0.0022µF50V

C32 QEHA1HM-475 E CAPACITOR 4.7µF50V

C34 PTY20754-525 CAPACITOR 0.01µF50V

C35 PTY20754-526 CAPACITOR 0.1µF16V

C36 PTY20754-526 CAPACITOR 0.1µF16V

C37 PTY20754-524 CAPACITOR 0.1µF50V

C38 NCB31HK-102X CAPACITOR 0.001µF50V

C43 PTY20754-524 CAPACITOR 0.1µF50V

C44 PTY20754-524 CAPACITOR 0.1µF50V

C45 PTY20754-526 CAPACITOR 0.1µF16V

C51 NCB31CK-473X CAPACITOR 0.047µF16V

! L1 PTY20450-401 LINE FILTER

L21 PTY10067-703 COIL

! PHC1 PC817X1 PHOTO COUPLER

! orPC817A PHOTO COUPLER

! T1 PTY20754-531 SW TRANS

VR1 PTY20483-101 VOLUME 2kØ

JK1 YQ21032-301 DC JACK

! F1 PTY20450-041 FUSE 1A 250V

! HS1 PTY20483-071 HEAT SINK A

! HS2 PTY20591-072 HEAT SINK B

OT1 PTY10067-551 TAP SCREW,X2(HEAT SINK)

SW1 PTY20545-662 SWITCH

WR1 PTY20591-052 FLAT CABLE(4P)

TB1 PTY20754-053 BATTERY TERMINAL,X3

(VP)-M1ACC

6

Page 10

JVC SERVICE & ENGINEERING COMPANY OF AMERICA

DIVISION OF JVC AMERICAS CORP.

Head office

East Coast

Midwest

West Coast

Atlanta

Hawaii

Head office

Montreal

Vancouver

1700 Valley Road Wayne, New Jersey 07470-9976

:

10 New Maple Avenue Pine Brook, New Jersey 07058-9641

:

705 Enterprise Street Aurora, Illinois 60504-8149

:

5665 Corporate Avenue Cypress, California 90630-0024

:

1500 Lakes Parkway Lawrenceville, Georgia 30043-5857

:

2969 Mapunapuna Place Honolulu, Hawaii 96819-2040

:

JVC CANADA INC.

:

21 Finchdene Square Scarborough, Ontario M1X 1A7

:

16800 Rte Trans-Canadienne, Kirkland, Quebec H9H 5G7

:

13040 Worster Court Richmond, B.C. V6V 2B3

(973)315-5000

(973)396-1000

(630)851-7855

(714)229-8011

(770)339-2582

(808)833-5828

(416)293-1311

(514)871-1311

(604)270-1311

S40895-03

Printed in Japan

Loading...

Loading...