Page 1

SERVICE

MANUAL

Model 330

Model 340 SC

Model 370 SC

Hughes-JVC Technology Corporation

2310 Camino Vida Roble, Carlsbad, CA 92009-1504

☎

760-929-5300

DECLARATION OF CONFORMITY

760-929-5410

AX

F

service@hjt.com

e

✉

-

PER ISO/IEC GUIDE 22 AND EN 45014

Page 2

Manufacturer: Hughes-JVC Technology Corporation

2310 Camino Vida Roble

Carlsbad, CA 92009-1504

USA

Hughes-JVC declares that this product conforms to the following

Product Specifications (Directive/Standard):

Safety: EN 60950

IEC 950 (1992)

EMC: EN 55022 (1988) / CISPR-22 (1986) Class "A"

EN 50082-1 (1992) / IEC 801-2 (1991)

EN 50082-1 (1992) / IEC 801-3 (1984)

EN 50082-1 (1992) / IEC 801-4 (1988)

ANSI C63.4-1992, FCC, Part 15, Class A

In addition, the above product complies with the requirements of the

Low Voltage Directive 73/23 EEC and the EMC Directive 89/336/EEC.

105662 First Edition January 1998

Rev A September 1998

Hughes-JVC Technology Corporation

is ISO 9001 Registered and Certified.

Confidential and proprietary information.

© Copyright 1998 by Hughes-JVC Technology Corporation.

All worldwide rights reserved.

This manual was produced by Hughes-JVC Technology Corporation

and may be revised without prior notice.

No part of this manual may be reproduced in any form without

the express written permission of Hughes-JVC Technology Corporation.

®

is a registered trademark of Hughes-JVC Technology Corporation.

ILA

iii

Model 330, 340SC and 370SC Service Manual

Page 3

Safety Information

Introduction

Before operating or working on a Model 330, 340SC and 370SC Projector, especially

with the cover off, please read this safety information section thoroughly. Procedures

requiring the opening of the projector covers and/or contact with electrical components

should be performed by qualified service personnel. Strictly adhere to all notes and

warnings.

Safety Equipment

Safety equipment specified in the Hughes-JVC Series 300 Projector Service and

Operator’s Training Course and certification program or equivalent should be used for

maintenance of the equipment.

Safety

Warnings and Cautions

Warnings and Cautions

Warnings and Cautions in this manual should be read thoroughly and strictly adhered to.

Warning and Caution symbols and definitions are as follows:

WARNING!!!

and/or specific procedure or situation that could result in personal injury if

improperly performed.

CAUTION!

hazards that could cause severe eye injury or a specific procedure or situation

that could result in damage to the equipment if improperly used.

The following important safety instructions are designed to insure your safety and the

long life of your projector. Be sure to read these safety instructions thoroughly and adhere

to all warnings given below.

Warns user of a potential safety hazard or potential light

Warns user of a potential electric shock hazard

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) this device may not cause harmful interference and (2) this device

Model 330, 340SC, and 370SC Service Manual v

Page 4

Safety

must accept any interference received including interference that may cause undesired

operation.

Operation of this equipment in a residential area is likely to cause harmful interference, in

which case the user will be required to correct the interference at their own expense.

Shielded interconnect cables must be used with this equipment to insure compliance with

the pertinent RF emission limits governing this device.

Installation Safeguards

WARNING!!!

power on the projector until the damaged cable is replaced.

not

CAUTION!

If there is any visible damage to any of the cables

Place the projector on a smooth, stable and level surface

do

in an area free from dust and moisture. Do not place the equipment in direct

sunlight or near heat-radiating appliances. Smoke, steam and exposure to direct

sunlight could adversely affect the internal components. Avoid rough handling

when moving your equipment, as a strong shock could damage its internal

components.

CAUTION!

If installing a ceiling mount, use only parts supplied or

recommended by the manufacturer. Observe all instructions and warnings as

listed in this manual.

Projector Weight

The HJT projector and shipping container have a combined weight of either 512 (Model

330 and 340SC) or 550 (Model 370SC) pounds. The HJT shipping container weighs 170

pounds and the projector itself weighs either 342 (Model 330 and 340SC) or 380 (Model

370SC) pounds.

Do Not Tilt the Projector More Than 85 Degrees

Do not mount the projector on an excessively tilted base. The projector can be tilted a

maximum of 85 degrees. Mount it only on a stable, vibration-resistant base capable of

supporting at least three times its weight. If in doubt, contact the factory.

vi

Model 330, 340SC, and 370SC Service Manual

Page 5

Safety

Avoid Projector Angles of 15° to 23°

Due to voids in the prism fluid there is a dead zone of 19° ± 4°. For this reason, avoid

projector angles of 15° to 23°.

Maximum Projector to Screen Angle is 15°

The maximum vertical tilt angle from projector to screen is 15°. This is the maximum

amount of keystone correction that is possible.

Heat Safeguards

Fans

The projector has multiple fans (exact number varies with projector model number) to

cool the projector system. Do not block the intake or outflow of any of the fans.

Intense heat is emitted within the system and must be properly dissipated in order to keep

the system running properly.

CAUTION!

ports can lead to projector overheating. Do not enclose the unit in a restricted

space. Refer to the appropriate

thermal clearance and for specific clearances needed for heat dissipation. Allow

at least ten (10) minutes for projector cool down before removing power.

has stopped running. This fan protects the arc lamp from overheating.

CAUTION!

Light Safeguards

Ultra Violet and Infrared Li ght

Eye/face protection is required from ultra violet light and infrared light in accordance

with the following conditions:

1. X3 (up to 375 nanometers) shade goggles must be worn by anyone near the

projector when the lamp is lit and the cover is off.

2. X5 (375 to 700 nanometers) shade goggles when actually working on the

projector near the arc lamp source.

Do Not Block Ventilation. Blocking air intake or exhaust

Operator’s Manual

Do not unplug the power cord until after the arc lamp fan

for physical access and

vii

Model 330, 340SC, and 370SC Service Manual

Page 6

Safety

WARNING!!!

High temperature, ultraviolet and infrared light. Refer

all service to factory authorized personnel.

Ultraviolet radiation, dangerous glare, and high internal gas pressure

is present at the Xenon Arc Lamp. It is contained in a protective reflector housing

module.

DO NOT operate the Xenon Arc Lamp outside its intended standard housing or outside

of the projector.

When replacement is required, the arc lamp must be replaced as an entire module as

outlined in the Hughes-JVC Model 330, 340SC and 370SC Projector Service Manual.

No attempt should ever be made to replace the arc lamp inside its module!

The arc lamp produces dangerous intense light with hazardous levels of ultraviolet and

infrared radiation. It operates at high temperatures (180ºC, maximum 300º C or over 500º

F).

Do not touch the xenon arc lamp or any connections when the lamp is ignited or is arcing.

WARNING!!! BRIGHT LIGHT!

Never look directly at the Arc

Lamp, the lighted Projection Lens, or into the lamp housing, from any distance,

when the projector is ON and light is projected. Direct exposure to light of this

brightness can cause severe eye injury.

viii

WARNING!!!

High voltage access and safety interlock. Defeat

restricted to factory authorized service personnel!

WARNING!!!

Allow at least one minute to bleed off high voltage even after the unit has been turned off.

High voltage points up to 40,000 volts are exposed inside the covers.

Due to high voltage danger, DO NOT TOUCH:

!

White cables to CRTs—these cables can cause severe shock from a tiny, invisible

crack or hole and should never be touched while projector power is on.

!

CRT anodes—underneath the CRTs.

!

Main power +/- supply posts—if shorted with metal objects,

!

80 amps can flow across the terminals.

Model 330, 340SC, and 370SC Service Manual

Page 7

Safety

!

CRT yoke assemblies and other proximity electrical assemblies, components and

wiring—if performing the yoke rotation or width adjustment (outlined in Section

3.2), always use an

!

ANSI/ASTM 10,000 volt rated safety glove.

!

Periodically check the condition of safety gloves for cracks.

!

Arc Lamp main power ± posts.

Power Supply

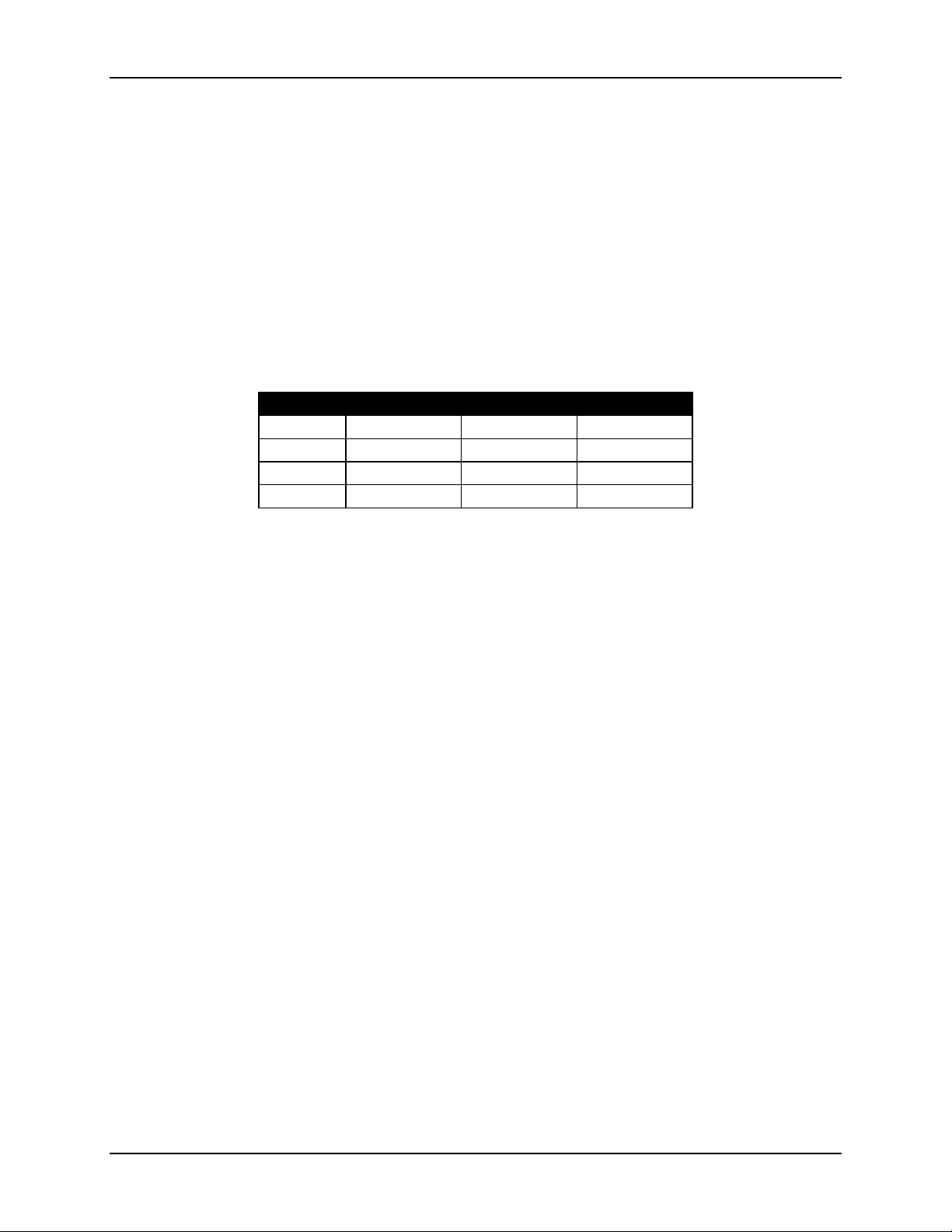

The projectors operate from power sources indicated in the table below. Verify that local

power source matches these requirements before operation!

Projector Power Supplies

Power

AC

Current

Hz

Watts

330

200-240V

20

50-60

2,700

340SC

200-240V

20

50-60

3,325

370SC

200-240V

30

50-60

4,550

Handle the power cord carefully and avoid excessive bending.

A damaged cord may cause electric shock or fire. For continued safe and reliable

operation, only use cables supplied by the manufacturer for power and signal connections.

Installation should be performed by an electrician with current knowledge of electrical

codes in the country of use.

Fluid Safeguards

Certain components of the projector contain fluid. If any fluid from the projector contacts

the skin, wash off with soap and water. If any fluid from the projector splashes into the

eyes, rinse with cool running water.

Ventilation and Foreign Object Retrieval

Ensure the projector’s multiple fans are free from obstructions and operating properly.

Air filters are located at vent ports on the cover. Air filters require periodic cleaning to

ensure adequate cooling of the projector (see Section 4.3). Verify that vent ports are clear

of all obstructions.

Keep the projector free from foreign objects, such as hairpins, nails, paper, etc. Do not

attempt to retrieve such objects yourself or insert metal objects such as wire and

screwdrivers inside the unit. If an object falls inside the projector, unplug the projector

immediately and call a Hughes-JVC certified technician for removal.

ix

Model 330, 340SC, and 370SC Service Manual

Page 8

Safety

WARNING!!!

Various procedures in this manual involve the removal

and replacement of system subassemblies. Ensure that the projector AC power

plug is removed from the AC outlet

to attempting any of these procedures.

prior

x

Model 330, 340SC, and 370SC Service Manual

Page 9

Safety

xi

Model 330, 340SC, and 370SC Service Manual

Page 10

1.0 Introduction

This Model 330, 340SC and 370SC Service Manual combines three (3) similar

projector models into one (1) reference book, and should be used in conjunction

with the appropriate projector Operator’s Manual. This manual provides more

detailed information on troubleshooting and maintaining the projectors and a more

in-depth functional description of the system subassemblies than the specific

Operator’s Manual, which cover the specific projector system description,

installation, adjustments, operation, maintenance, specifications, troubleshooting

guide, and parts list.

The areas covered in this Service Manual include any similarities and differences

of functional descriptions of Model 330, 340SC and 370SC projector electronics,

service adjustments, maintenance (removal and replacement of subassemblies),

and troubleshooting.

Chapter 1---Introduction

1.1 Acronyms Used In Manual

ALPS Arc Lamp Power Supply

CH Channel

CPU Central Processing Unit

CRT Cathode Ray Tube

DSP Digital Signal Processor

EPROM Erasable Programmable Read-Only Memory

F to V Frequency to Voltage

G2 CRT Grid 2

HDB Horizontal Deflection Board

HDTV High Definition Television

HSYNC Horizontal Sync

HVPS High Voltage Power Supply

ILA® Image Light Amplifier

I/O Input/Output

I/R Infrared

kHz Kilohertz

LED Light Emitting Diode

LVPS Low Voltage Power Supply

NTSC National Television Standards Committee

PCB Printed Circuit Board

PLL Phase Lock Loop

PLUGE Picture Line-Up Generating Equipment

RAM Random Access Memory

RGB Red, Green and Blue

ROM Read Only Memory

Model 330, 340SC and 370SC Service Manual 1-1

Page 11

Chapter 1---Introduction

RTG Raster Timing Generator

SCB System Control Board

SPS System Power Supply

TTL Transistor-Transistor Logic

VAB Video Amplifier Board

VCO Voltage Controlled Oscillator

VDB Vertical Deflection Board

VIN Video Input

VPB Video Processor PCB

VSYNC Vertical Sync

VTR Video Tape Recorder

1.2 Safety

High voltages and high intensity light sources exist in the Model 330, 340SC and

370SC Projector Systems and power supplies. Prior to performing any procedures,

adjustments or maintenance review the chapter on Safety Information at the front

of this manual.

1.3 Updates

This manual will be updated with information provided by Service Bulletins and

manual supplements whenever necessary.

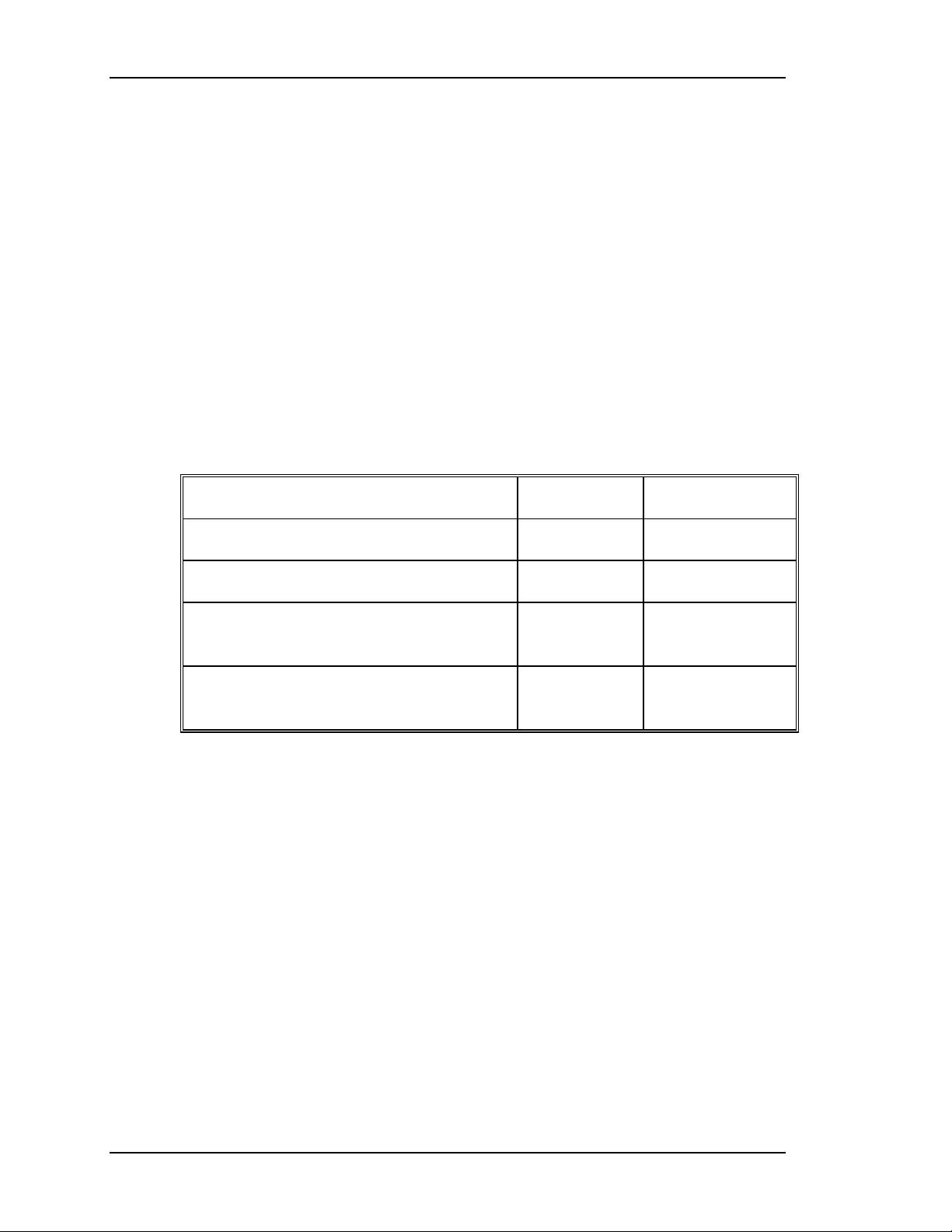

1.4 Hardware Compatibility

The table below lists part numbers currently compatible between the Model 330,

340SC and 370SC projectors, and those parts that are different in each.

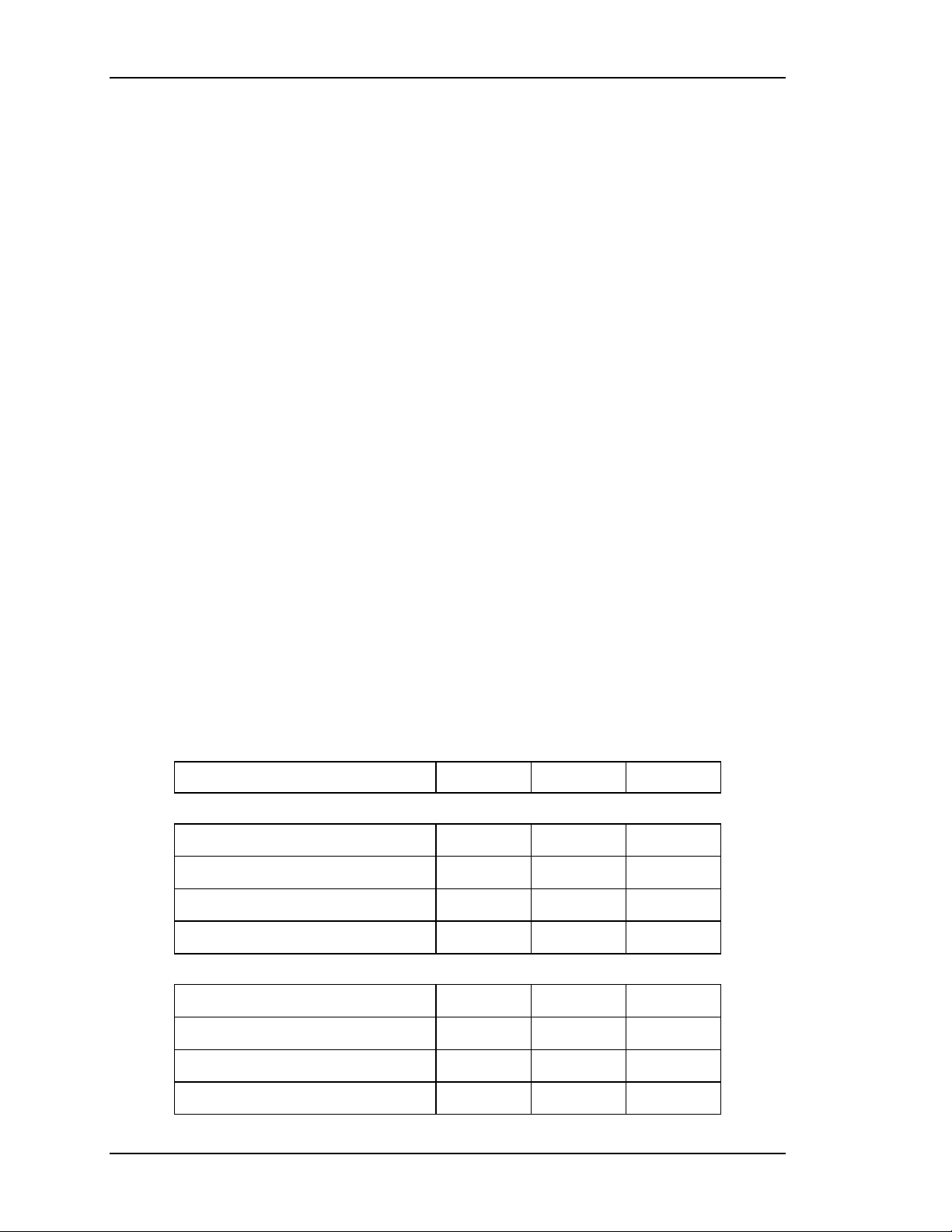

Table 1-1

Printed Circuit Boards

DIFFERENT

Lamp Assembly

Ignitor

System Power Supply

High Voltage Power Supply

SAME

Hardware Compatibility

330

900611S

102083

104070

100562

340SC

PART NUMBERS

104651

102207

104071

100562

370SC

104120

104475

104038

103769

1-2

Raster Timing Generator

Horizontal Deflection Board

Vertical Deflection Board

Video Processing Board

100568

102523

102521

104672

Model 330, 340SC and 370SC Service Manual

100568

102523

102521

104672

100568

102523

102521

104672

Page 12

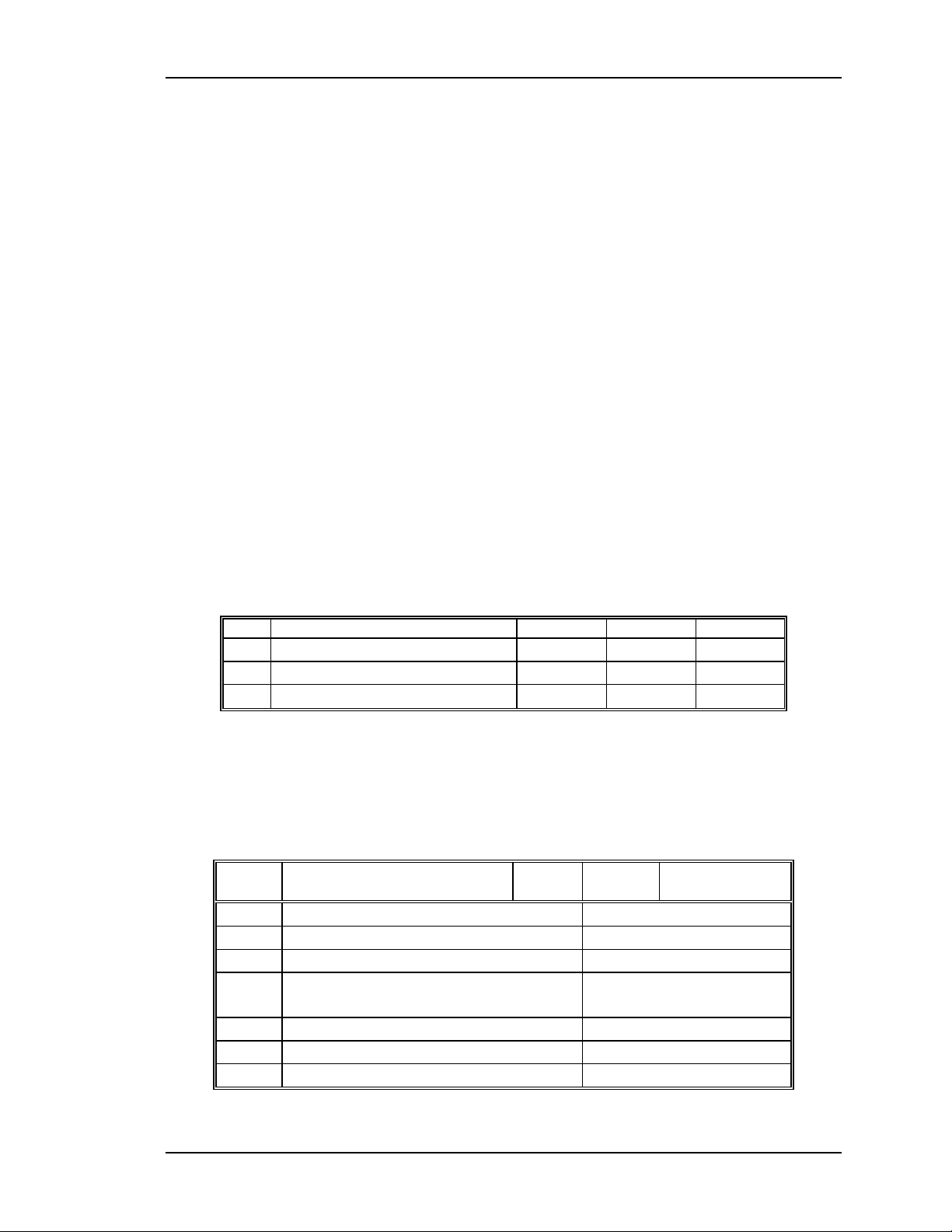

Chapter 1---Introduction

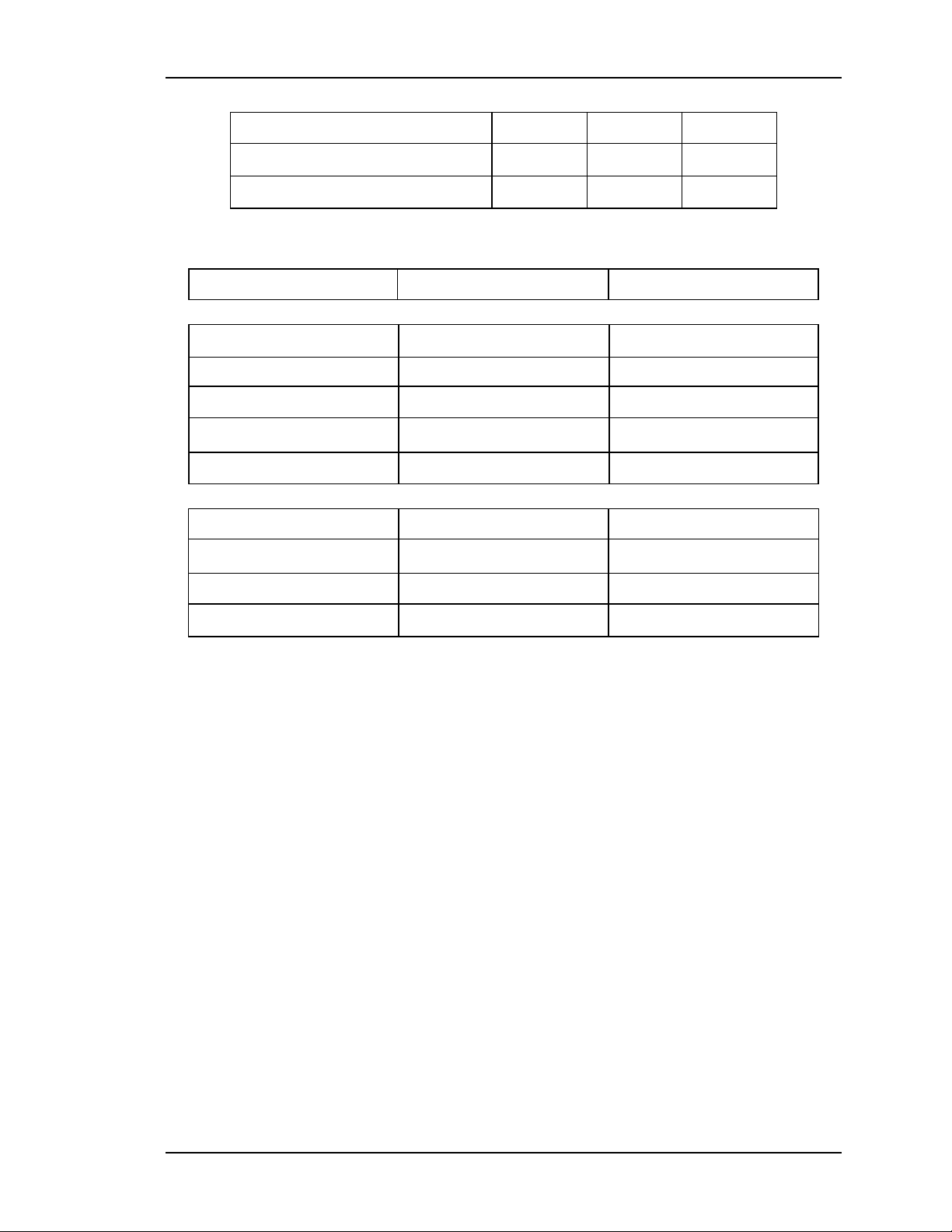

Printed Circuit Boards

Video Amplifier Board

System Controller Board

Table 1-2

Different

3,000 lumens

2,500 ANSI lumens

220V AC, 20A, 60Hz

2,700 Watts power

1,500 W Xenon arc lamp 2,000 W Xenon arc lamp 3,000 W Xenon arc lamp

Same

5.2.1 software

graphics enhancement

Projector Model Comparisons

330 Model

4,200 lumens

3,700 ANSI lumens

220V AC, 20A, 60Hz

3,325 Watts power

5.2.1 software

graphics enhancement

340SC Model

330

103774

104668

340SC

103774

104668

6,800 lumens

6,000 ANSI lumens

220V AC, 30A, 60Hz

4,550 Watts power

5.2.1 software

graphics enhancement

370SC

103774

104668

370SC Model

30 memories

decoder board option

30 memories

decoder board option

30 memories

decoder board option

Model 330, 340SC and 370SC Service Manual 1-3

Page 13

Chapter 2—Functional Descriptions

2.0 Functional Descriptions

Contents

2.1 Cover and Base............................................................................................2–2

2.2 External Power Requirements.....................................................................2–3

2.3 Electronics Systems Overview....................................................................2–3

2.4 System Power..............................................................................................2–5

System Power Supply................................................................................2–5

Arc Lamp Ignitor.......................................................................................2–9

High Voltage Power Supply......................................................................2-11

2.5 Card Cage....................................................................................................2-14

2.6 Circuit Boards .............................................................................................2-15

Raster Timing Generator Board (RTG) p/n 100568 ................................2-18

Horizontal Deflection Board P/N 102523 (HDB).....................................2-25

Vertical Deflection Board P/N 102521(VDB)..........................................2-32

Video Processor Board P/N 104672 (VPB)..............................................2-43

Video Amplifier Board P/N 103567 or 103774 (VAB)............................2-54

System Controller Board P/N 104668 (SCB)............................................2-59

Backplane Board p/n 100571...................................................................2-71

2.7 Optical Section............................................................................................2-72

CRT Assembly..........................................................................................2-72

Arc Lamp Assembly..................................................................................2-75

Optical Subassemblies...............................................................................2-76

2.8 Image Light Amplifier.................................................................................2-76

This chapter provides functional descriptions of the major assemblies in the

Model 330, 340SC and 370SC projectors.

Emphasis is placed on a description of system components to the functional block

level. A number of block diagrams are provided for user reference.

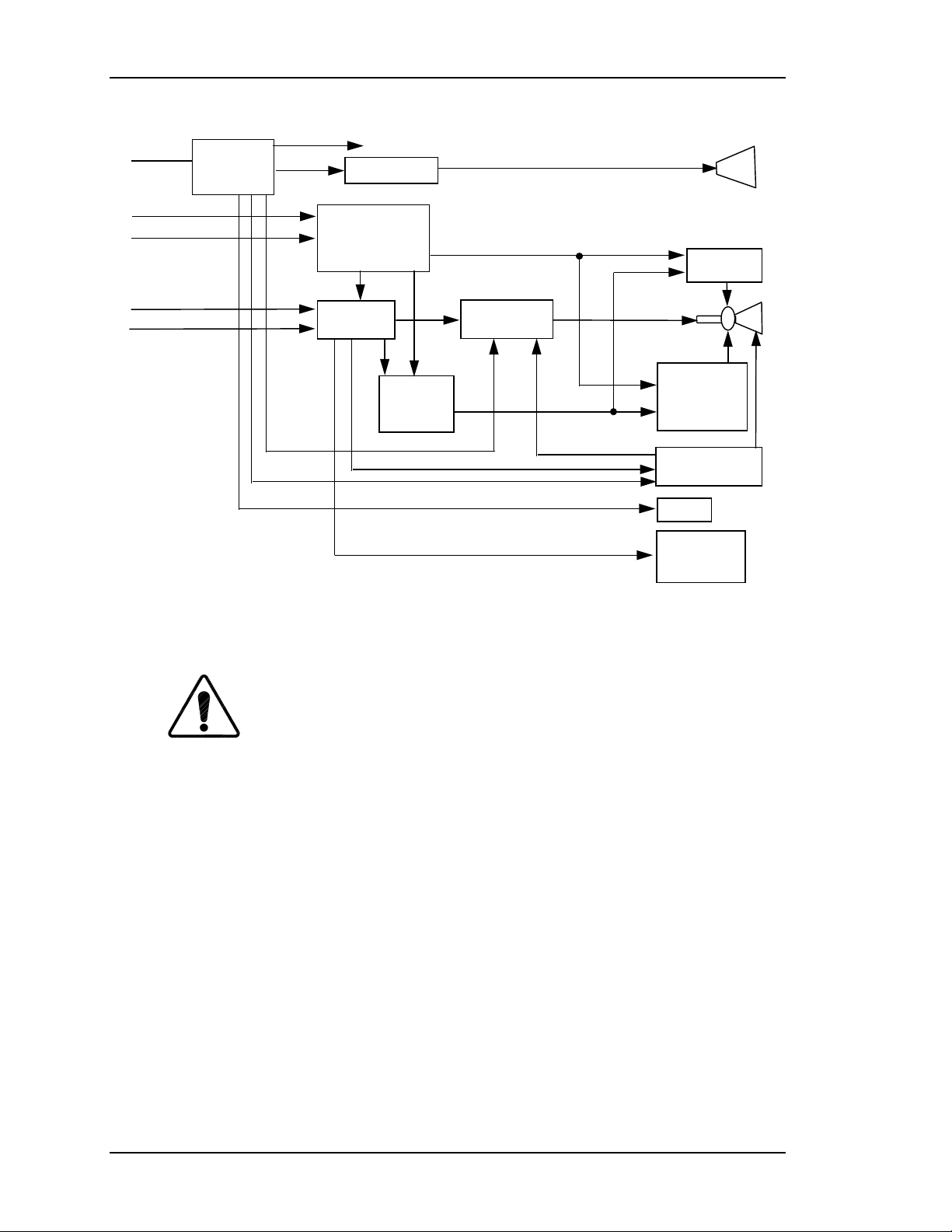

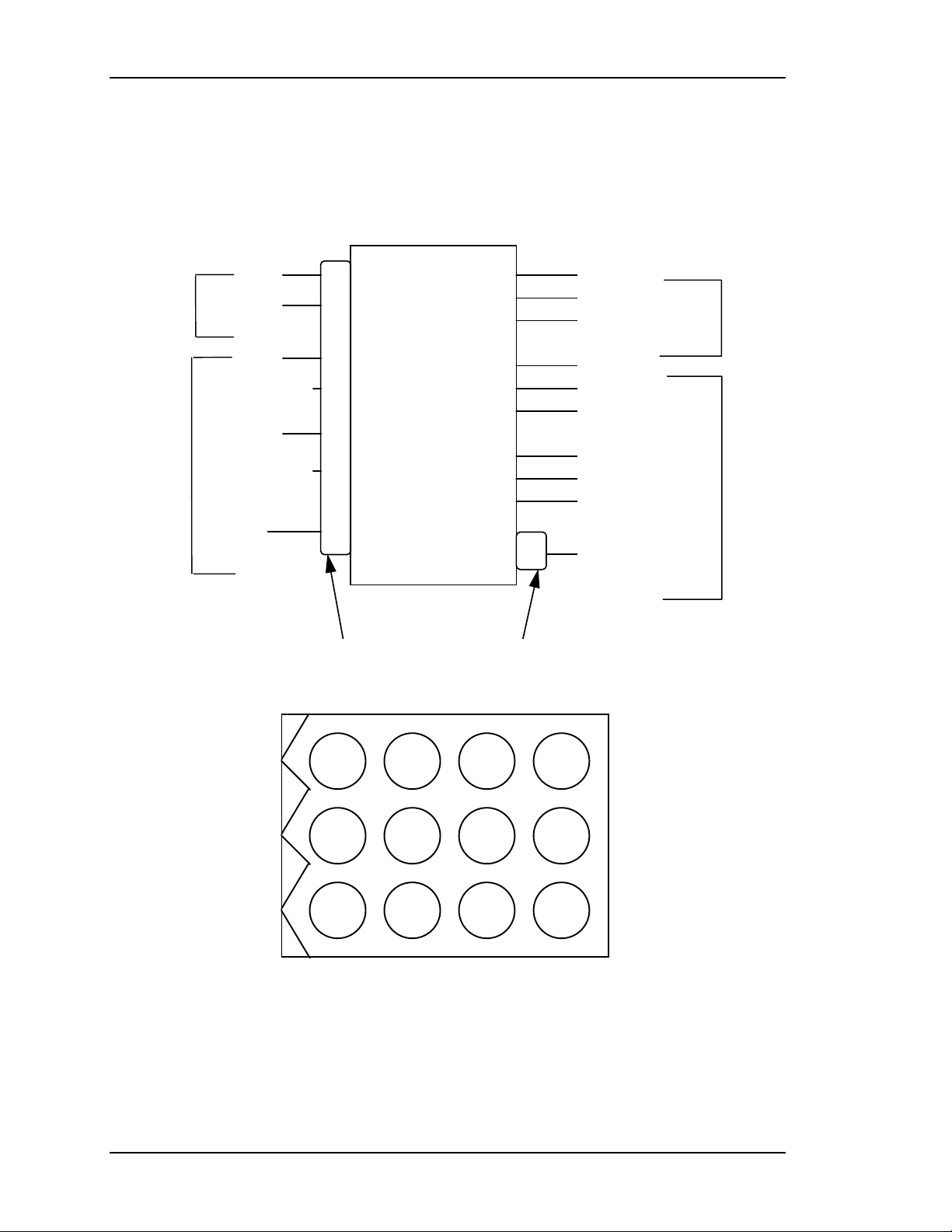

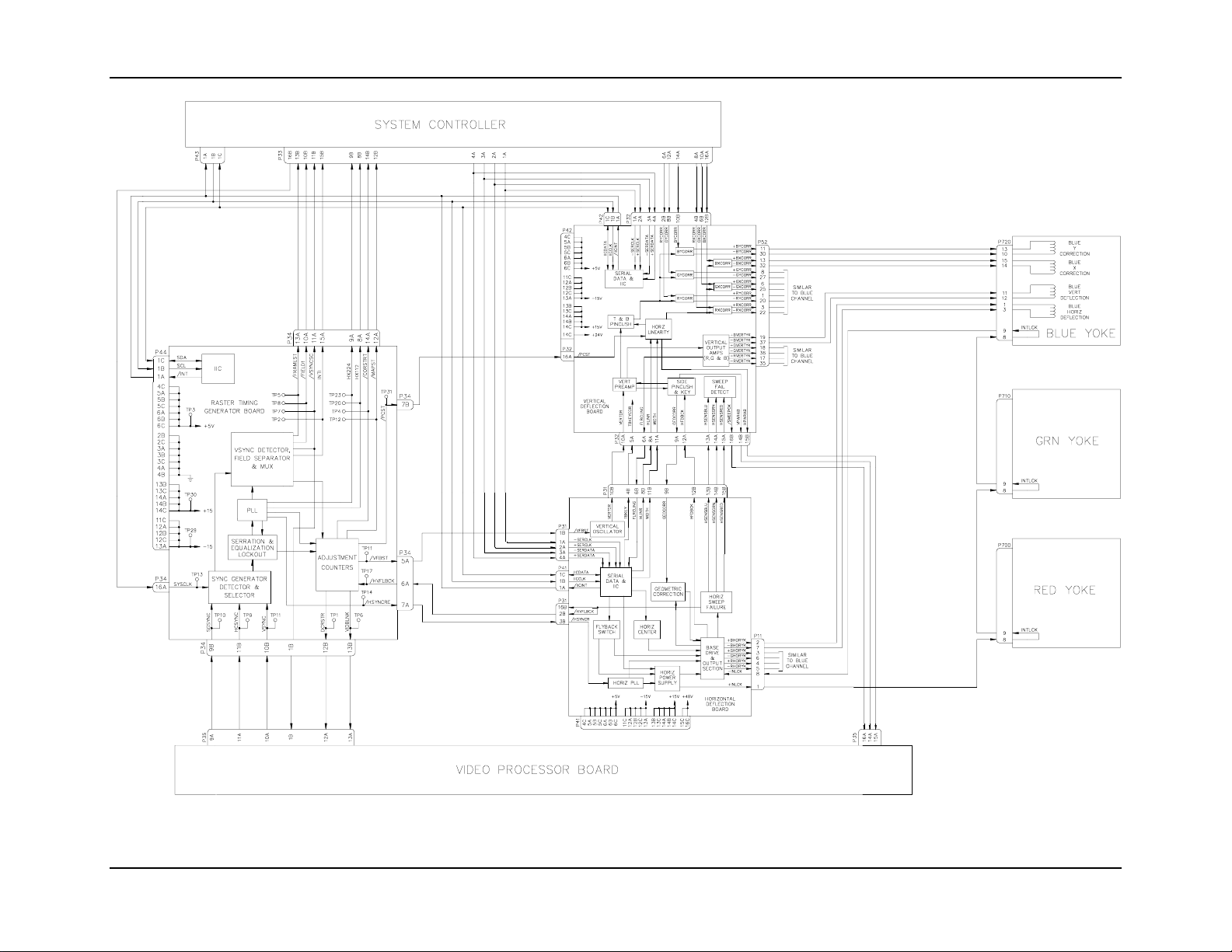

Figure 2-1 provides a block diagram overview of the HJT Model 330, 340SC and

370SC projectors. For simplicity, each major electronics assembly is shown with

signal paths between appropriate functional units. Major physical and electronics

assemblies will be described in more detail in the following sections of this

chapter.

Model 330, 340SC and 370SC Service Manual 2–1

Page 14

Chapter 2—Functional Descriptions

Low Voltage

Power Supply

Lamp Ignitor

System

Controller

Line Voltag e

RS 232

Infrared Remote

System

Power

Supply

Arc Lamp

Horizontal

Deflection

Channel 1

Channel 2

(R,G,B, H/V Sync)

Video

Processor

Figure 2-1

Model 330, 340SC and 370SC System Block Diagrams

2.1 Cover and Base

and 370SC projectors must be installed for proper operation.

Operation of the projector, other than for maintenance, with the

covers removed is not recommended and will void the projector

warranty.

CAUTION!

Video Output

Amplifier

Raster

Timing

Generator

The covers for the HJT Model 330, 340SC

Vertical

Deflection

and

Convergence

High Voltage

Power Supply

Fans

Image Light

Amplifiers

(3 each

CRTs

(3 each)

In addition to aesthetics, the covers on the Model 330, 340SC and 370SC

projectors serve several functions. The covers are an integral part of the cooling

system of the projector. Air intake filters are contained in the covers as are cooling

fans. The covers provide the operator and audience with protection from the

extremely bright light produced in the projector. The covers also serve to reduce

the noise generated by operation of the projector. The UL approval is only valid

with the covers installed since they provide the primary protection to prevent

personnel from coming into contact with the high voltages and currents contained

within the projector.

2–2 Model 330, 340SC, and 370SC Service Manual

Page 15

The HJT Model 330, 340SC and 370SC

WARNING!!!

projectors use high voltages and high currents. Operation with

covers removed exposes personnel to these dangerous conditions

and may result in serious injury or death. No user-serviceable parts

are contained within the projector. Refer all maintenance to only

factory authorized and trained technicians.

The projector cover is a two-piece molded assembly. It is fastened to the projector

frame by six (6) screws: two (2) on the rear cover; and four (4) on the front cover.

The fan intake side of the cover (right side) has filters on the intake vents.

Periodic cleaning of the filters is required and should be performed in accordance

with the procedure in this manual (Section 4.3). To avoid overheating the

projector, ensure that the cover vent ports are free of obstructions at all times and

that an adequate supply of fresh air is provided to the projector during operation.

2.2 External Power Requirements

Chapter 2—Functional Descriptions

The projectors require 208V to 240V, 50 Hz to 60 Hz, single-phase AC power.

The units are equipped with an attached AC power cord and 3-prong twist lock

plug (Model 330 and 340SC use Hubble Model 2323; Model 370SC uses Hubble

Model 2623 or equivalent).

CAUTION!

Operation at voltages and frequencies outside of these

listed parameters may cause damage to the projector and will void the warranty.

2.3 Electronics Systems Overview

The objective of this portion is to provide a good general understanding of the

projector electronics. The understanding gained will enable service personnel to

more effectively maintain the projector to produce the desired result—a great

picture on the screen —and quality you can see.

The Electronics Systems portion of this manual is based on block diagrams. The

diagrams used have been drawn with two purposes in mind. First, they are general

enough to be able to gain an understanding of the overall function of the various

components of the system. Second, the block diagrams contain enough detail to

make them valuable as a troubleshooting tool should the need arise. Schematics

are not used but, where necessary, simplified circuitry is shown to aid in

understanding the capabilities and/or limitations of the system. Discussion of

troubleshooting is included but is largely confined to symptoms and identification

of failed assemblies.

The Hughes-JVC Model 330, 340SC and 370SC projectors are multi-sync

projectors capable of data, graphics, and display from 15KHz to 90KHz

Model 330, 340SC and 370SC Service Manual 2–3

Page 16

Chapter 2—Functional Descriptions

horizontal and 45Hz to 120Hz vertical. The projected image is continuously

variable from 6 ft to 60 ft over throw distances (varies by projector model) from

10 ft to over 360 ft. All HJT Series 300 projectors are capable of keystone,

pincushion, and linearity correction. The projectors feature digital control of

functions, including convergence, picture adjustments, switching and diagnostics.

In addition, the projector provides the ability to control the relative brightness

anywhere on the screen.

The capabilities of the Model 330, 340SC and 370SC projectors are provided by a

sophisticated electronics system, which consists of power supplies, input/output

devices, and various circuit boards, and using both analog and digital components

to provide functionality with a simple user interface. The electronics systems are

assembled in modular fashion for ease of removal or maintenance.

The Model 330, 340SC and 370SC Electronics System consists of:

System Controller Board;

Video Processor Board;

Video Amplifier Boards (3);

Raster Timing Generator Board;

Horizontal Deflection Board;

Vertical Deflection Board;

Lamp Ignitor;

System Power Supply;

High Voltage Power Supply.

There are also image and sync signal inputs, an LED display, two (2) RS-232

communication ports, and two (2) IR receivers for projector control.

The digital and analog circuits of the System Controller Board direct the operation

of image and raster generation circuits as well as controlling the input/output and

power supply operation of the HJT Model 330, 340SC and 370SC projector

electronics systems.

The System Controller sets operating parameters of the system such as brightness

and contrast, produces internal test patterns and generates on-screen overlays, and

sets the timing for the raster generation to adjust phase, geometric corrections,

uniformity corrections and convergence. The System Controller houses the

program memory as well as the memory for all convergence and uniformity maps,

and has the responsibility of controlling communication with the user, power to

the other areas of the projector, and other necessary functions.

The Video Processor and Video Amplifiers select the desired input signal and

process it to produce the CRT beam modulation necessary to produce an image on

the raster.

2–4 Model 330, 340SC, and 370SC Service Manual

Page 17

Chapter 2—Functional Descriptions

The Raster Timing Generator provides timing signals to the System Controller

Board, selects the appropriate incoming sync signal and produces the timing

signals for controlling the geometry of the raster.

The Vertical and Horizontal Deflection Boards produce their respective sweep

currents to drive the deflection yokes. The Vertical Deflection Board also houses

the convergence amplifiers that drive correction coils.

The System Power Supply provides all DC power below 200V to the projector.

This includes the supply to the arc lamp/ignitor and the supply to the High

Voltage Power Supply.

The High Voltage Power Supply provides all voltages of 200V and higher. This

includes all CRT bias voltages except the cathode.

Image and sync inputs arrive in the projector at the Video Processor Board.

Inclusion of the Decoder Board is optional. User communication is accomplished

by on-screen displays, LED display output, IR remote input, or RS232

Input/Output. All of these devices are separate from, but communicate directly

with the System Controller Board.

The detailed functional description of the subassemblies are covered below in the

following order:

1. System Power.

2. Card Cage and Circuit Boards.

3. CRT Assembly.

4. Arc Lamp.

2.4 System Power

System Power Supply

The System Power Supply provides the connection between the external power

source and the projector. The System Power Supply provides all internal DC

power to the projector with the exception of that provided by the High Voltage

Power Supply (Section 2.4.3). This includes the low voltage power to the

electronics, the supply power to the HVPS, and the Arc Lamp power.

The System Power Supply is a AC-DC power supply with an input rectifier and

protection circuit and several separate switchers; one (1) for Arc Lamp power, one

(1) for +5V Standby power, one (1) for +24V Standby power, and others for the

other low voltages.

All of the power supply outputs are protected against overvoltage and overcurrent.

Overcurrent protection is a foldback circuit that limits the output current by

reducing the output voltage when an overcurrent condition is detected. An

overvoltage condition at the output of the supply will cause the affected voltage to

be shut down until input power is removed and reapplied.

Model 330, 340SC and 370SC Service Manual 2–5

Page 18

Chapter 2—Functional Descriptions

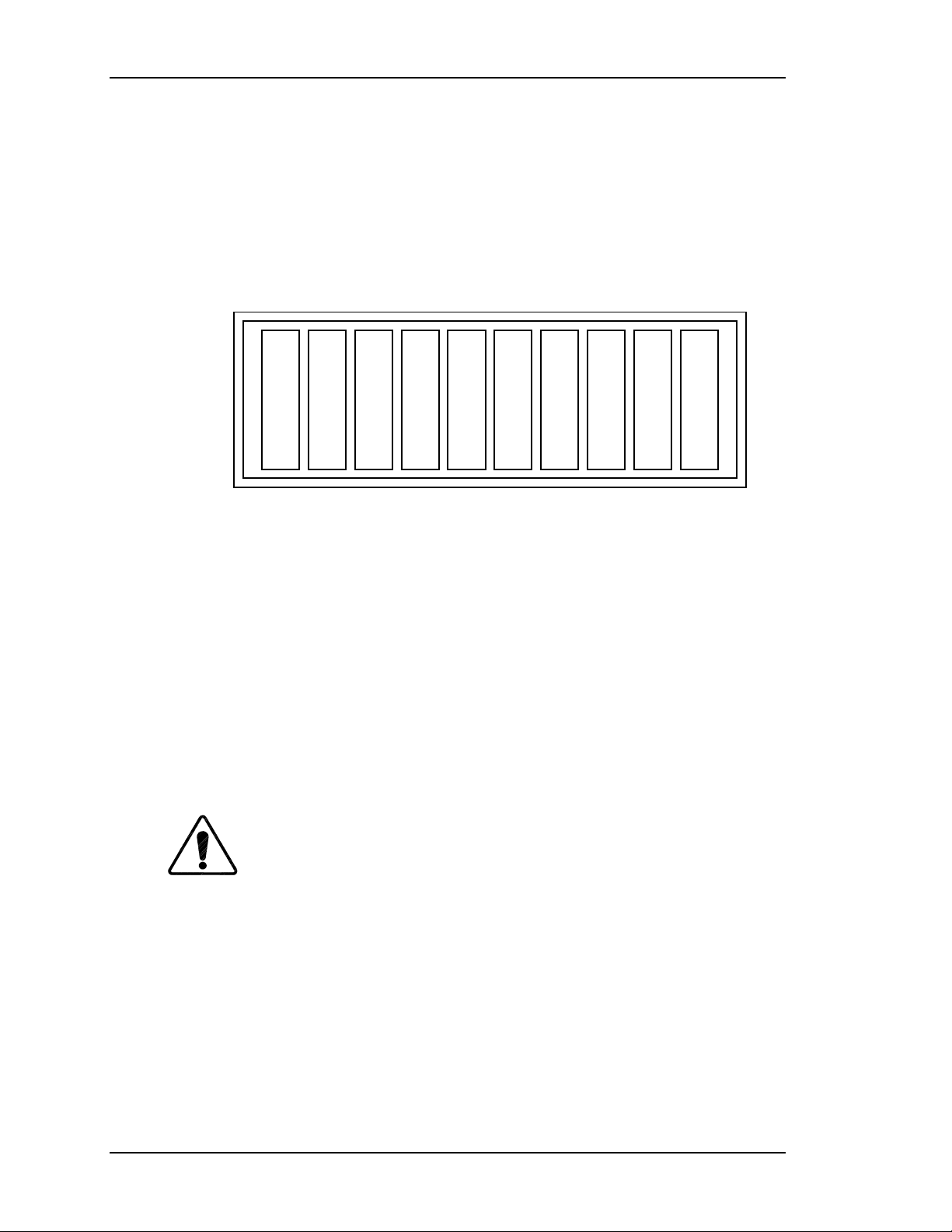

All of the SPS output voltages except Arc Lamp power are indicated by a LED

display (see ). The LEDs are located on a bar-type display on the backplane at the

left side of the card cage. The individual LEDs will be lit when the corresponding

voltage is energized. The LEDs are wired to the SPS output power using only a

current limiting resistor so when the LED is lit, it is an indication that there is a

voltage present, not necessarily the correct voltage. To verify whether or not the

voltage at the output is correct, a voltmeter must be used to probe the output

connectors J500, J501, or J502.

+5V +5V

STB

Figure 2-2

A safety interlock switch is located on top of the power supply. The interlock

+24V

STB

+6.3V +15V -15V +24V +48V+107V -200V

Backplane Status Indicators.

switch shuts off the System Power Supply whenever the cover is removed. During

normal operation with the cover installed, the switch is in the 'armed' position.

When the rear cover is removed, the switch will be released and cause power to

the projector to be interrupted. To run the unit without the cover installed,

override the interlock switch by pulling it up into the 'service' position. When the

cover is replaced, the switch will automatically be reset into the 'armed' position.

A circuit breaker is located on the right side of the System Power Supply. The

circuit breaker serves to remove all power from the projector (except for the

power at the input terminals) by switching it to the OFF position.

CAUTION!

The circuit breaker must be switched off, and the

projector must be disconnected from AC power prior to performance of any

maintenance, to ensure that all power is removed from the internal components of

the projector.

Normal operation of the System Power Supply is as follows:

When external power is applied, +5V Standby will always be energized as will the

internal SPS fans. +24V Standby power for operating the fans will be energized

whenever the lamp or electronics are turned-on and five (5) minutes after the

projector is shut down.

All other voltages are controlled by the power-up or power-down commands

issued by the operator.

2–6 Model 330, 340SC, and 370SC Service Manual

Page 19

Chapter 2—Functional Descriptions

The Arc Lamp power supply is a current-controlled supply with an open circuit

voltage of about 170V. When the Arc Lamp is operating at steady state, the power

supply provides the current set by the technician. The output of the supply has a

large capacitor that will, on initial ignition of the Arc Lamp, provide the very high

initial current necessary to ionize the xenon gas in the lamp and sustain the arc.

The current setpoint is initially set at the factory and must be reset by the

technician whenever an Arc Lamp is replaced.

AC INPUT

220-240vac

50Hz

From

System

Controller

POWER

FACTOR

CORRECTION

/FANENBL

J502

Model 330. Model 340SC = +25V/80a; Model 370SC = +30V/100a.

∇

/LVPSNBL

/ALENBL

Figure 2-3

System Power Supply Block Diagram.

STANDBY/

I/O CONTROL

+5v, +24v

LOW VOLTAGE

Power Supply

+5v,+6.3v,+-15v,

+24v,+48v,+107v

ARC LAMP

Power Supply

and Boost

+22v/68a

+170v/1.0a

∇

J502

J500

J503 (-)

J504 (+)

To

Backplane

To

Arc Lamp

Via

Ignitor

Normal system power-up (Electronics and Lamp):

1. Upon receipt of Power-On command, SCB pulls /FANENBL and

/ALENBL lines low.

2. +24V Standby and Arc Lamp power supplies turn on.

3. When Arc Lamp lights (run voltage sensed by a window comparator in the

SPS), SPS pulls /LAMPLIT line low.

4. When SCB senses /LAMPLIT low, SCB pulls /LVPSNBL line low.

5. Low voltage supplies turn on.

6. SCB senses +5V supply at correct level and enters normal program

sequence.

Lamp only power-up:

1. Upon receipt of Lamp-On command, SCB pulls /FANENBL and

/ALENBL lines low.

Model 330, 340SC and 370SC Service Manual 2–7

Page 20

Chapter 2—Functional Descriptions

2. +24V Standby and Arc Lamp power supplies turn on.

3. When Arc Lamp lights (run voltage sensed by a window comparator in the

SPS), SPS pulls /LAMPLIT line low.

4. SCB senses /LAMPLIT low and awaits further instructions.

Electronics only power-up:

1. Upon receipt of Electronics-On command, SCB pulls /FANENBL and

/LVPSNBL lines low.

2. +24V Standby and Low voltage supplies turn on.

3. SCB senses +5V supply at correct level and enters normal program

sequence, lamp can be turned on at any time.

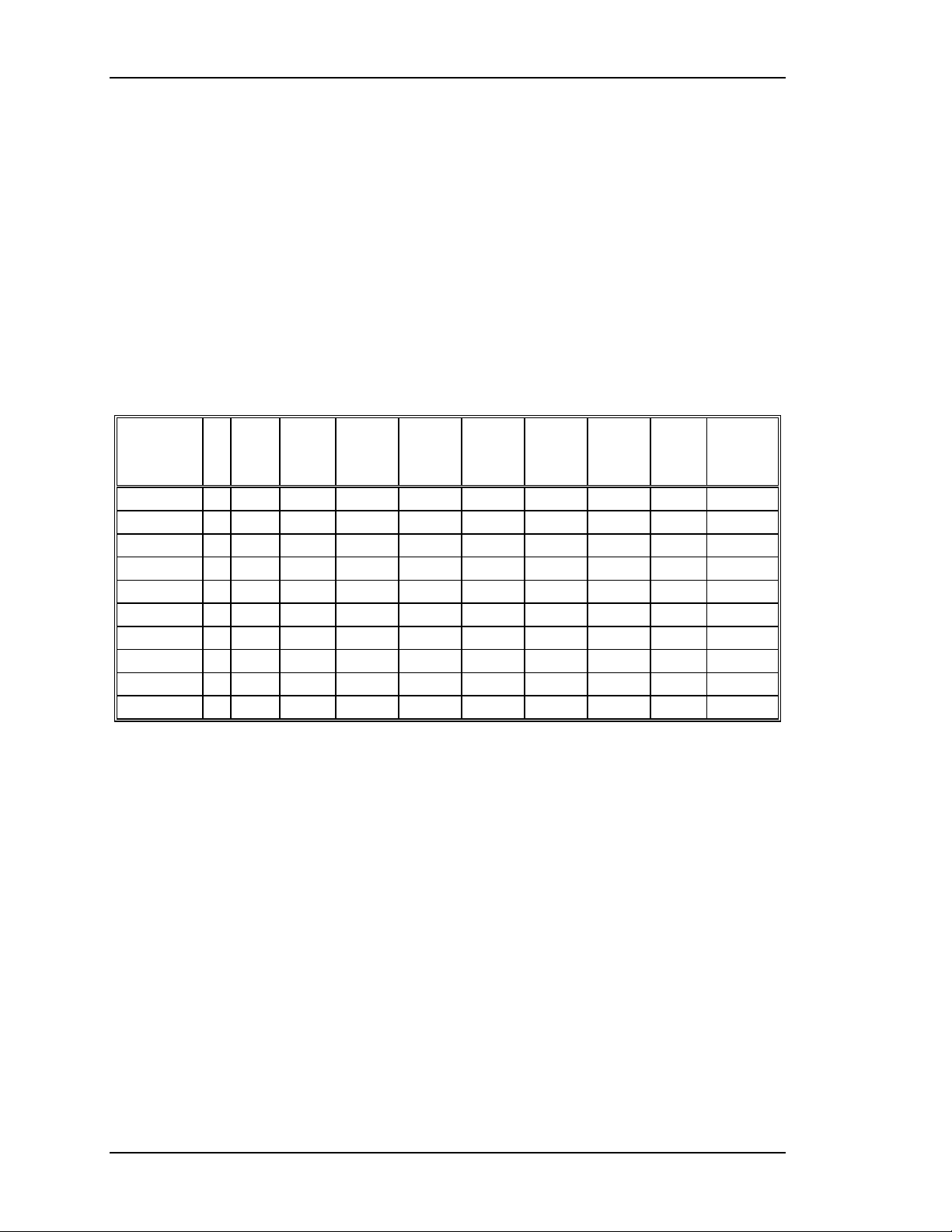

Table 2-1

VoltageFa

+5v

+5v Stb

+6.3v

+15v

-15v

+24v

+24v Stb

+48v

+107v

+170v

System Power Supply Voltage Distribution

HV

PS

n

CRT SCB HDB VDB VPB RTG VAB

Arc

Lamp/

Ignitor

2–8 Model 330, 340SC, and 370SC Service Manual

Page 21

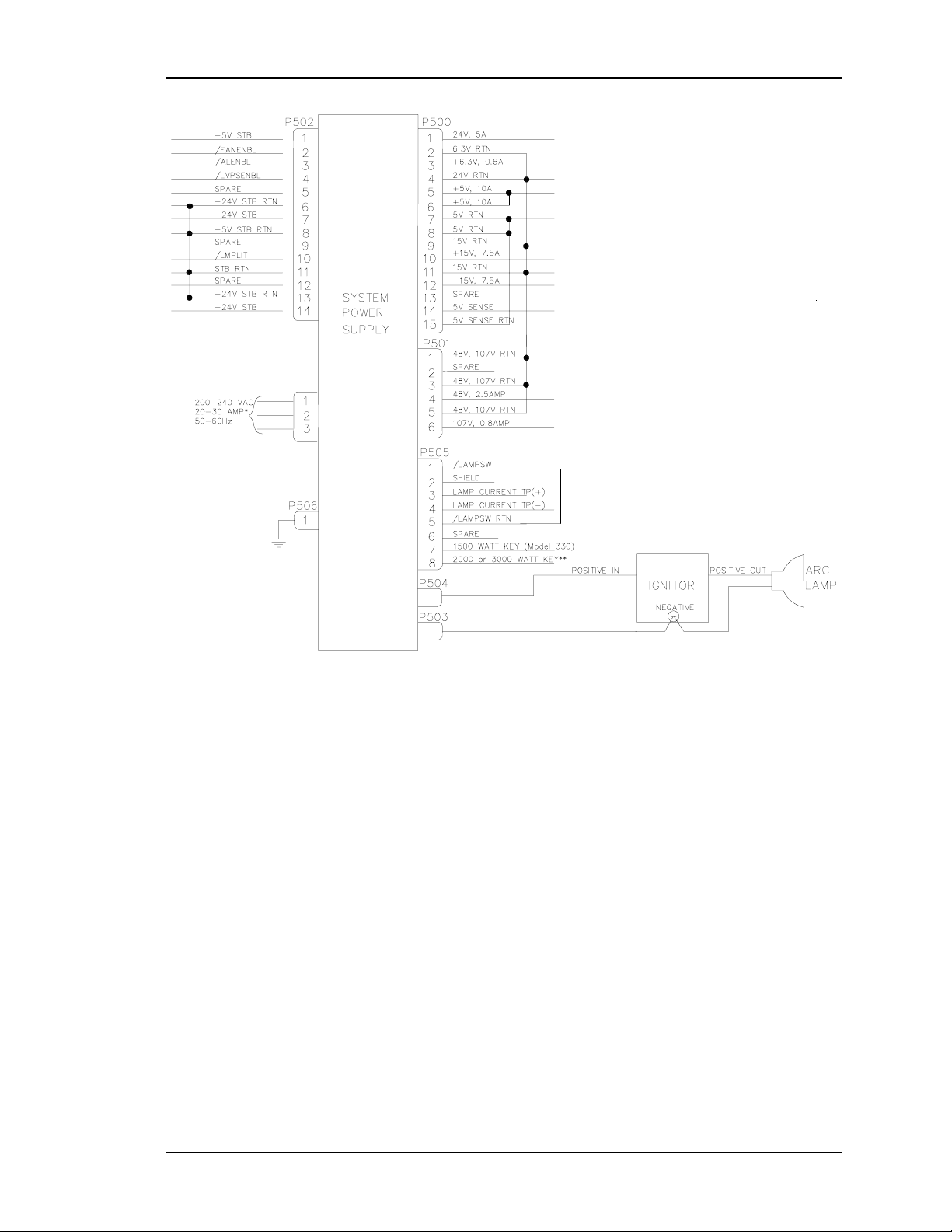

Chapter 2—Functional Descriptions

*Current depends on projector model (see Table 0-1 in Safety Chapter).

** Model 340SC = 2000 Watts; Model 370SC = 3000 Watts.

Figure 2-4

System Power Supply Input/Output Diagram

Arc Lamp Ignitor

The ignitor consists of a step-up power supply, a spark gap, and a transformer.

The Arc Lamp Ignitor is mounted under or next to the Arc Lamp. It provides the

high voltage pulse necessary to ignite the Xenon Arc Lamp that is the illumination

supply for the HJT Model 330, 340SC and 370SC projectors.

The System Power Supply’s Arc Lamp Supply section provides the necessary

voltage to activate the ignitor and to sustain the arc in the Arc Lamp once it has

been ignited. The SPS provides the power necessary to operate the ignitor.

The Ignitor is only active during the time between the Arc Lamp Power Supply

energizing and the Arc Lamp igniting. During steady state operation and when the

projector power is off, the ignitor is inactive.

Model 330, 340SC and 370SC Service Manual 2–9

Page 22

Chapter 2—Functional Descriptions

When the Arc Lamp supply first turns on, it supplies 170V to the ignitor. The

ignitor then senses this voltage, activates it’s on-board supply, and produces a

1µS, 38KV pulse to the Arc Lamp. This pulse strikes an arc in the lamp. The Arc

Lamp supply then provides the high current necessary to sustain the arc in the

lamp. Refer to Figure 2-5 and the summary below for a description on the Arc

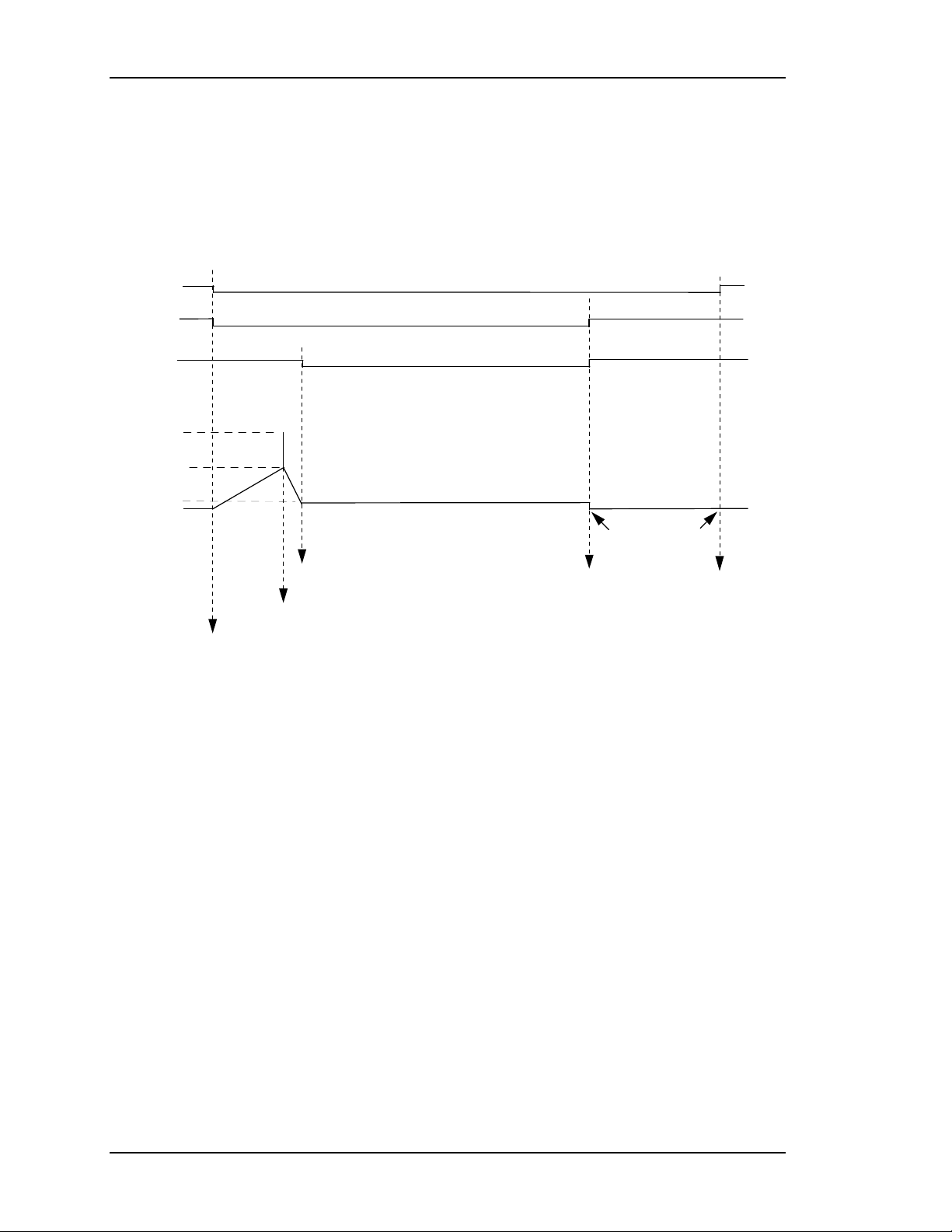

Lamp and Ignitor timing.

/FANENBL

/ALENBL

/LAMPLIT

38 KV

170V

22-30V

*

0V

1

2

3

4

5

6

ARC LAMP ON

IGNITOR FIRES

CPU TIME-OUT

5-10 MINUTES

LAMP-OFF

COMMAND

FAN DISABLE

LAMP-ON COMM A ND

*

22-30V depending on projector model.

Figure 2-5

Arc Lamp/Ignitor Timing Diagram Summary:

Arc Lamp Ignitor Timing Diagram

1. The operator powers Arc Lamp on. /ALENBL and /FANENBL from

System Controller Board are pulled low. SPS receives /ALENBL from

SCB and turns on the Arc Lamp PS.

2. Ignitor receives +170V boost voltage from the Arc Lamp PS.

3. Ignitor steps up the +170V boost voltage to a 1 µsec pulse, approximately

38KV.

4. Arc Lamp ignites from the 38kV pulse.

5. High current (about 68-100A depending on projector model) begins

through Arc Lamp and voltage drops to +22-30V (depending on projector

model).

6. /LAMPLIT signal goes to SCB to inform board that Arc Lamp is lit.

2-10 Model 330, 340SC, and 370SC Service Manual

Page 23

Chapter 2—Functional Descriptions

High Voltage Powe r Supply

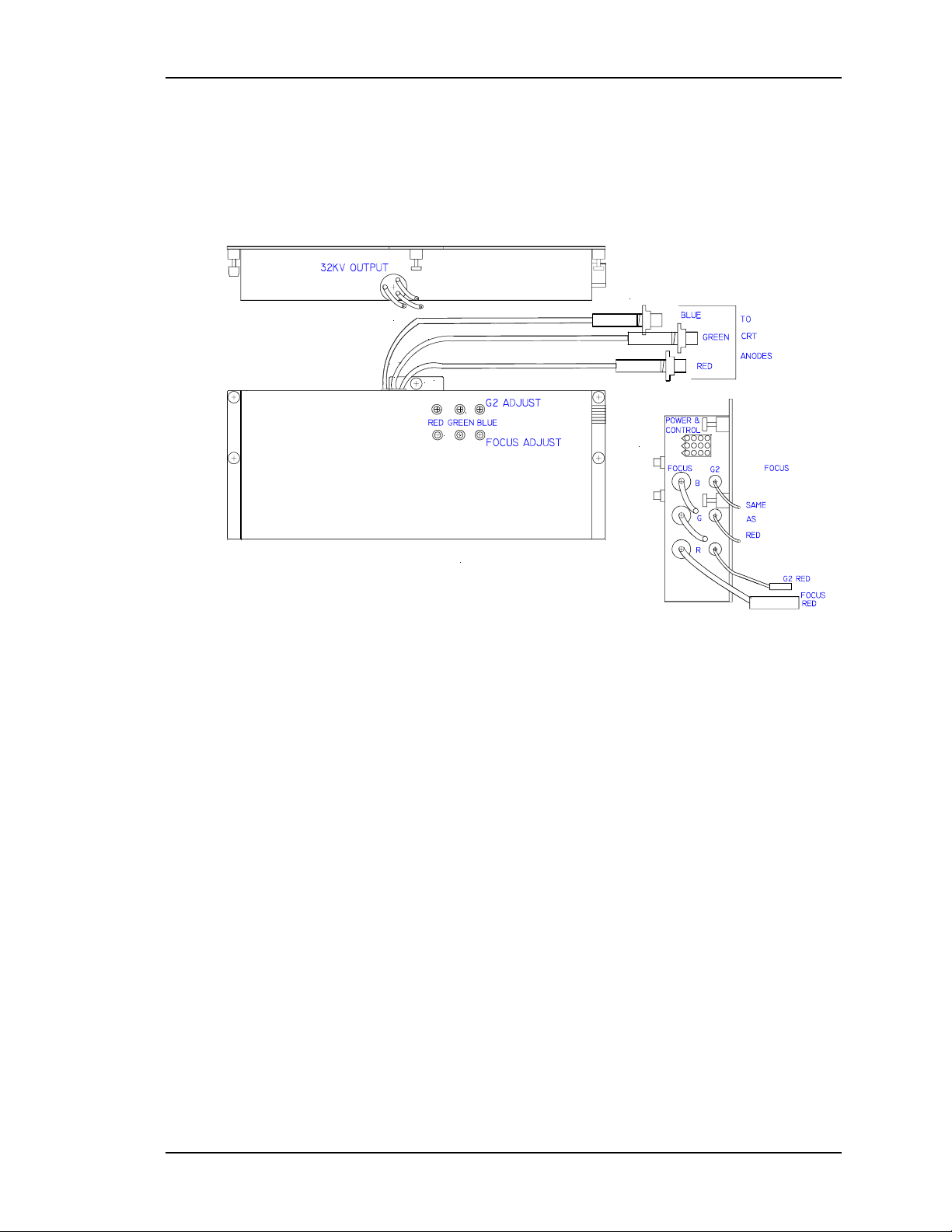

The High Voltage Power Supply is a DC-DC converter (see Figures 2-6 and 2-7)

and is located on the left side of the CRT housing. It provides all necessary

voltages for the CRTs except the cathode drive, which comes from +107V from

the SPS.

Figure 2-6

Input power is +24V at 5A from the SPS. The input power is converted into the

High Voltage Power Supply

high voltage necessary to bias the CRTs.

The HVPS is controlled by an enable line (/HVEN) originating at the Video

Processor Board. This enable line is controlled by logic that turns the HVPS off

when there is a fault that could damage the CRTs. There are two (2) different

conditions that could damage the HVPS:

1. If the +5V supply to the VPB is interrupted, the control and protection is

compromised and the HVPS must be turned off.

2. If the cathode drive power is lost on one of the Video Amplifiers, the

cathode current cannot be controlled and the HVPS is turned off.

3. Further details regarding this logic can be found in the functional

description on the Video Processor Board in Section 2.6.4.

Model 330, 340SC and 370SC Service Model 2-11

Page 24

Chapter 2—Functional Descriptions

The HVPS provides several voltages to the CRTs:

Anode

Grid 1

Grid 2

Focus

+24v

GROUND

HDFOCUS

HDFOCUS RTN 8

VDFOCUS

/HVEN

Figure 2-7

2

3

11

High

Voltage

12

9VDFOCUS RTN

7

Power and Control Connector

Power

Supply

6

(Pins 1,4,5,10 not used)

RED ANODE

GREEN ANODE

BLUE ANODE

RED FOCUS

GREEN FOCUS

BLUE FOCUS

RED G2

GREEN G2

BLUE G2

-200v

High Voltage Power Supply Input/Output Diagram

12369

11258

10147

Figure 2-8

2-12 Model 330, 340SC, and 370SC Service Manual

HVPS Power and Control Connector Jack, J603

Page 25

Chapter 2—Functional Descriptions

CRT anode voltages are not user controllable. They are fixed at 32KV with a

maximum output of 2.1mA total or 0.7mA per CRT. The anode voltage is the

primary acceleration voltage for the CRT. Other bias voltages (screen grid, G2,

and control grid, G1) are used to control the level of beam current. The anode

voltage is routed out of the top of the HVPS, into the CRT housing to three (3)

bulkhead connectors. From there, the anode wires on the CRTs route the anode

voltage directly to the CRT. The anode voltages are overvoltage and overcurrent

protected in the event of short circuits or CRT arcing.

Focus voltage (called Electronic Focus) is a modulated DC voltage. The DC level

is set by the user during initial setup to focus the CRT electron beam. The

Electronic Focus controls are located on the left side of the HVPS (see appropriate

model Operator’s Manual). There are three (one for each color) ¾ turn pots for

adjusting the Electronic Focus. Of the six (6) pots found on the HVPS, the bottom

three (3) are for focus while the top three (3) are for G2 adjustment (Section 3.10).

The DC voltage is modulated within the HVPS using the HDFOCUS and

VDFOCUS input signals. VDFOCUS is the vertical dynamic focus signal, which

is a waveform with parabolic shape at the vertical sweep frequency. HDFOCUS is

the horizontal dynamic focus signal. It is a combination of the vertical dynamic

focus signal and a parabolic waveform at the horizontal sweep rate. These two (2)

signals are combined in the HVPS to form a composite dynamic focus signal.

Dynamic focus is necessary to ensure that the CRT electron beam is converged to

a point as the beam sweeps across the CRT face. Since the CRT faceplate is flat,

the raster sweep causes a varying path length for the electron beam. This means

the focus voltage must be varied as the raster is traced. Focus voltage cannot be

conveniently measured during normal operation.

G2 screen grid voltage is a DC voltage that is set by the user. The three (3)

adjustment controls, one for each color, consist of ¾ turn pots and are located on

the left side of the HVPS immediately above the focus controls. This voltage is set

during initial projector setup to adjust the black level on the screen (see

appropriate model Operator’s Manual). The G2 voltage sets the bias on the screen

grid of the CRT and is normally used to set the cutoff level. However, since the

HJT light valve requires a non-zero input to produce a just-cut-off image on the

screen, G2 is set to produce a slightly greater-than-black raster on the CRT. The

G2 is adjustable from 100V to 1400V individually by color. The actual operating

level will be near 1200V. G2 voltage cannot be conveniently measured during

normal operation.

-200V is the supply to the control grid (G1) of the CRTs through the Video

Amplifier Board. This voltage is not user controllable. The -200V is the only

output voltage from the HVPS that goes to the backplane of the projector to be

routed to the Video Amplifier, and uses the rear-most LED of the backplane LED

bar for indication.

-200V is the only convenient means of directly observing whether or not the

HVPS is turned on, either by observing the indicator LED on the backplane, or by

probing the control connector with a voltmeter.

Model 330, 340SC and 370SC Service Model 2-13

Page 26

Chapter 2—Functional Descriptions

As with the other indicators on that LED bar, the LED is in series with current

limiting resistor, so a lit LED indicates only the presence of a voltage, not

necessarily the correct voltage.

The control grid, G1, voltage is regulated to -81V during normal operation.

During blanking, G1 is pulled to -111V. When the CRTs are disabled for

protection, G1 is pulled to its maximum negative level of -200V, which can be

measured, at the control connector, pin 6.

2.5 Card Cage

The Card Cage provides support and protection for five (5) circuit boards, the

Phase Locked Loop and the optional Decoder Board in the HJT Model 330,

340SC and 370SC projectors. The five-(5) circuit boards are, from rear to front,

the VPB, RTG, SCB, VDB, and HDB. Each circuit board has it's own keyed slot.

A circuit board cannot easily be plugged into the wrong slot since the connectors

will not match up.

Horizontal Deflection Board (HDB) P/N 102523

Vertical Deflection Board (VDB) P/N 102521

System Controller Board (SCB) P/N 104668

Raster Timing Generator

and Phase Locked Loop

Video Processor Board

(RTG)

P/N 100568

(PLL)

(VPB) P/N 104672

and optional Decoder Board

Figure 2-9

Four (4) fans on the right side of the card cage cool the circuit cards in the card

Electronics Card Cage

cage. These fans are energized by the +24V standby power from the SPS. They

start when either the Arc Lamp or the electronics are powered up and run for

approximately five (5) minutes after the projector is shut down.

The five-(5) cards in the card cage are held into position by both the friction of the

connectors and by a circuit board retaining bar. The circuit board retaining bar

should always be installed during projector operation.

A lightweight top cover is included with the card cage. Eight (8) screws secure the

cover. The cover provides for direction of air flow and for physical protection of

the circuit cards contained in the card cage. The cover should always be installed

when the projector is in operation to ensure adequate cooling of the circuit cards

and to prevent foreign materials from falling into the electronics.

2-14 Model 330, 340SC, and 370SC Service Manual

Page 27

The card cage is hinged in the rear to allow it to be folded backward for access to

the CRT housing (when folding the card cage backward be sure that nothing is

plugged into the rear electronic jacks or the plugs could be severely damaged).

During normal operation, the card cage should be in its upright position to ensure

proper cooling of the CRT enclosure.

A holddown screw is provided to secure the card cage and prevent it from rotating

backward during shipping or when the projector is mounted in an upwardpointing position. The holddown screw is located on the lower, front, right corner

of the card cage.

The rear panel of the card cage provides mounting for the projector controls. The

VPB, which receives all image and sync inputs, is secured to the rear panel by

four screws. The RS-232 control connectors and the IR receiver and repeater

inputs as well as the LED dot matrix status display are located on the lower left of

the rear panel. The projector model and serial numbers are also found on the rear

panel.

2.6 Circuit Boards

Chapter 2—Functional Descriptions

The Model 330, 340SC and 370SC projectors have a total of twelve (12)

accessible circuit boards. Seven (7) boards are located within the card cage

(Figure 2-9) and five (5) are located outside the card cage (Table 2-2).

Table 2-2

No. Description

Ignitor

1

Video Amp Boards (VABS)

3

Backplane

1

Each circuit board can be replaced individually except the Backplane board and

Circuit Boards Outside Card Cage

330

102083

103567

100571

340SC

102207

103567

100571

370SC

104475

103567

100571

the PLL. The PLL is replaced with the RTG as a unit. The Ignitor was previously

described in Section 2.4.2. The circuit boards covered in this Section are listed in

Table 2-3.

Table 2-3

Page

2-18 Raster Timing Generator

2-26 Horizontal Deflection Board (HDB)

2-34 Vertical Deflection Board (VDB)

2-44 Video Processor Board

Circuit Board

Circuit Boards

(RTG)

(VPB)

P/N

100568 and PLL

102523

102521

104672

and optional Decoder Board

2-55 Video Amplifier Board

2-58 System Controller Board

2-70 Backplane Board

(VAB)

(SCB)

103567

104668

100571

Model 330, 340SC and 370SC Service Model 2-15

Page 28

Chapter 2—Functional Descriptions

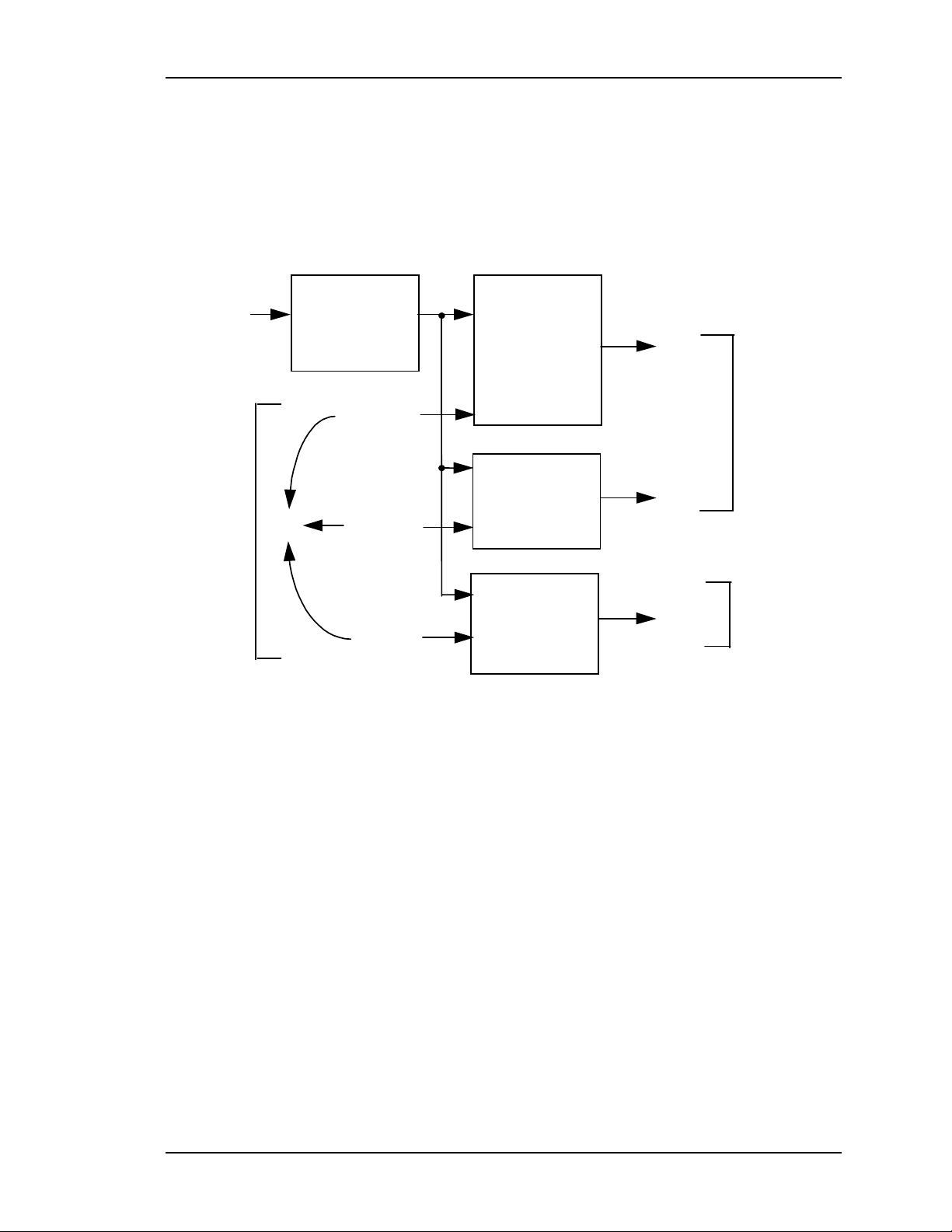

Figure 2-10 on the following page provides an overall view of how the raster is

produced. Details on the individual PCBs are provided in separate sections in this

chapter.

2-16 Model 330, 340SC, and 370SC Service Manual

Page 29

Chapter 2—Functional Description

Figure 2-10

Model 330, 340SC and 370SC Service Manual 2-17

Raster Generation Block Diagram

Page 30

Chapter 2—Functional Descriptions

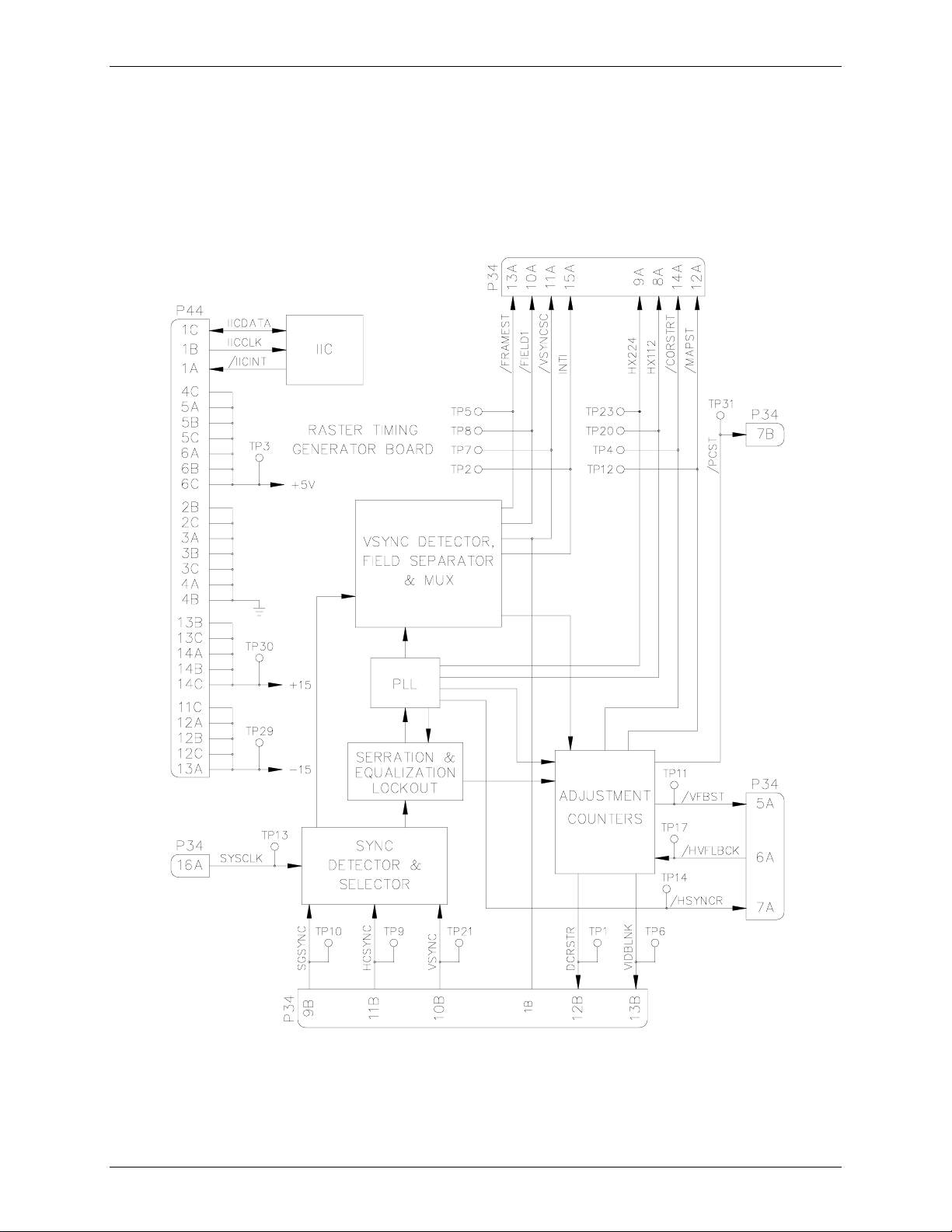

Raster Timing Generator Board (RTG) p/n 100568

The Raster Timing Generator board is located in the electronics card cage and plugs into

the backplane. It is the second board from the rear of the card cage and consists of a main

board and the PLL daughter board (see Figure 2-11). The PLL board must be installed for

the projector to operate.

Figure 2-11

2-18 Model 330. 340SC, and 370SC Service Manual

Raster Timing Generator Block Diagram

Page 31

The following functions are provided by the RTG:

Internal sync generation.

Sync detection and selection.

Serration and equalization pulse removal.

Timing clock pulse generation.

VSYNC separation and field detection.

Timing for several geometry and correction functions.

Serial communication with the SCB.

The block diagram ( see Figure 2-11) description, along with the I/O description in the

Chapter 2—Functional Description

Section following, provide information for module-level troubleshooting.

Sync Generator

The sync generator takes its input from the System Controller Board. The SCB provides a

4MHz clock signal, SYSCLK, which is used to generate a HDTV-like sync signal. The

internal sync signal generated is a 33.33KHz horizontal, 59.3Hz vertical, interlaced

signal. Because simply counting down from the 4MHz clock generates it, the actual

signal that is produced is a square wave signal. The square wave does not affect normal

operation of the projector but will cause a vertical bar to be generated on the screen when

the projector is operating on the internal sync with the DC restore timing set to BP or TL.

Sync Detector and Selector

The Sync Detector and Selector take inputs from the Video Processor Board. The VPB

sends the three (3) sync signals, SGSYNC (sync on green), HCSYNC (horizontal or

composite sync), and VSYNC (vertical sync only) of any polarity to the RTG. These are

the sync signals that come from the external source and are what the projector will genlock to when they are available. The sync selector uses a pre-determined priority to

determine which of these sync signals will be used, based on which signals are present at

the input.

The pre-determined priority to determine which sync signals used is:

1. Separate H and V sync will be used if both are available on their respective sync

inputs,

2. Composite sync on the HSYNC input will be used if available and no sync signal

is present on the VSYNC input,

3. Composite sync on the green image input will be used if no coherent sync signal

is available on the HSYNC input.

If no external sync signal is detected on the three (3) sync input lines, the RTG will send

out a signal to the SCB via the IIC interface indicating that there is no sync present

(/External Sync Detect). The SCB will then make a determination whether or not to

command the RTG, via the IIC interface, to select internal sync (Internal Sync Forced).

The selected sync signal(s) is inverted, if necessary, to provide the negative-going sync

signal needed by the downstream circuits.

Model 330, 340SC and 370SC Service Manual 2-19

Page 32

Chapter 2—Functional Descriptions

Serration and Equalizati on Lockout

The Serration and Equalization Lockout takes a composite sync signal and removes any

equalization and serration pulses from it. The Model 330, 340SC and 370SC projectors

do not require these pulses to operate. Removal of the serration and equalization pulses

provides a faster, more reliable response to the vertical sync and subsequent relock to

horizontal sync. This circuit uses the 4xHsync clock that is generated in the PLL to delete

any sync information present in the center portion of the incoming horizontal waveform.

Phase Locked Loop

The PLL receives horizontal sync stripped of the serration and equalization pulses from

the Serration and Equalization Lockout circuit.

The Horizontal Sync signal is fed to horizontal frequency decoder which uses a

frequency/voltage circuit to pre-tune the VCO of the PLL to ensure proper locking. The

Horizontal Frequency Decoder also provides a count of the number of horizontal lines per

frame. The H count is then sent via the IIC interface, to the SCB (HCOUNT). The SCB

uses this information to set up the correction and overlay maps and to calculate the H

frequency.

The PLL takes in the horizontal sync signal and generates a clock signal that is a square

wave of 224 times the horizontal frequency. The PLL will perform this function over the

entire range of horizontal frequencies, 15KHz to 90Khz. It will maintain that signal over

the full period of the raster including the vertical sync pulse. Counters in the PLL circuit

also provide clock signals with frequencies of Hx112, Hx4, Hx2, and Hx1. These clock

signals are square wave signals and are phase-coherent with respect to the H sync signal.

The Hx224, Hx112, and Hx1 signals are used on both the RTG and the SCB for timing of

corrections and raster adjustment. The signals that go to the SCB are Hx224, Hx112

(clock signals), and /HSYNCR (regenerated HSync, a negative-going pulse signal that is

timed to be on the leading edge of the Hx1 clock). The Hx4 and Hx2 clocks are used

exclusively on board the RTG for sync detection and timing.

Control of phase noise is critical—jitter will translate into a "smearing" of the projected

image. Therefore, if the PLL loses lock, the /Phase Lock signal is sent to the SCB via the

IIC interface. The SCB then makes a decision based on that information.

VSYNC Detector, Field Separator, and Mux

The VSync detector uses the Hx2 clock signal to detect the vertical sync signal from the

composite external sync signal that arrives on either the HSYNC input or the sync-ongreen input.

The field separator determines whether or not the signal is interlaced and, if so, which

field is currently being displayed. This information is sent to the SCB as the signals INTI

(interlace indication, high if interlaced), /FIELD1 (low when the field number 1 is

current), and /FRAMEST (indicates the beginning of a new frame).

The mux takes the external Vsync and field signals and multiplexes them with the

internal sync signal to select which will be used. The multiplexed Vsync signal is pulse-

2-20 Model 330. 340SC, and 370SC Service Manual

Page 33

Chapter 2—Functional Description

shaped to be three (3) horizontal periods in length. This signal, /VSYNCSC (pulseshaped vertical sync) is then sent to the SCB and the VPB.

Adjustment Counters

The adjustment counters implement the following timing functions:

Left side, right side, top side, and bottom side blanking.

Vertical and horizontal timing for convergence correction and overlay.

Pincushion and linearity correction timing.

Vertical phase.

DC restore timing.

The four-(4) sides' blanking adjustments are accomplished by counting from the

regenerated H and VSYNC signals respectively. Each adjustment is independent of the

others. Vertical blanking is accomplished by counting a specified number of horizontal

lines after the vertical sync signal out of the VSYNC Mux. The top blanking counts the

commanded number of lines then unblanks the picture. The bottom blanking counts the

commanded number of lines then blanks the image.

Horizontal blanking is accomplished by counting a specified number of Hx224 clock

pulses after the regenerated HSYNC pulse, /HSYNCR). The left side blanking counts the

commanded number of clock pulses then unblanks the image. The right blanking counts

the commanded number of clock pulses then blanks the image. The outputs from these

counters are combined with a signal indicating PLL lock, into a composite blanking

signal VIDBLANK (high when the image is to be blanked) that is sent to the VPB. The

user selects the actual position of the four sides' blanking by adjusting from the remote

control.

The SCB calculates the number of clock pulses to count for each of the four sides based

on the input from the user, and sends those numbers to the appropriate counters via the

IIC serial communication bus signals LBlank, RBlank, TBlank, and BBlank.

Adjustment counters also generate the convergence correction and overlay address

generators’ timing signals. The correction bit-map address counter's MAPST (timing

pulse to tell the correction and overlay address generators to start a new frame) timing

pulse is generated by counting the commanded number of /HSYNCR pulses since the

vertical deflection flyback start pulse. The /CORSTRT (signal that indicates to the SCB

when to start the correction and overlay address generators counting) timing signal is a

pulse signal sent to the SCB. Its timing is determined by counting the commanded

number of Hx224 pulses after the /HSYNCR signal.

The position of the overlays (including menus and test patterns) and correction maps is

controlled automatically in the vertical direction. In the horizontal direction, the user

controls the position via the MENU POSITION selection under the TIMING SETUP

MENU. This circuit also determines the phase between the regenerated HSYNC and the

HV Flyback from Deflection. This value is read by the SCB over the IIC bus.

The pincushion and linearity correction timing signal is a pulse signal called /PCST that

is sent to the Vertical Deflection Board. The signal is generated using the same timing

Model 330, 340SC and 370SC Service Manual 2-21

Page 34

Chapter 2—Functional Descriptions

method as the /CORSTRT signal but has a separate command from the SCB. It controls

the timing of the top and bottom pincushion correction, top and bottom keystone

correction, and horizontal linearity correction. The signal timing is selected by the user

and controlled by the SCB. Adjusting P

controls it.

Vertical phase adjustment is accomplished by timing the /VFBST (vertical start) signal

with respect to the regenerated vertical sync signal. This signal is generated by counting a

commanded number of horizontal lines after the vertical sync signal /VSYNCSC. The

signal timing is selected by the user and controlled by the SCB. It is controlled by

adjusting PHASE using the up/down arrows.

DC restore timing determines the point in time that the signal is clamped and the DC

restore (Section 2.6.4, Video Processor Board) function is accomplished. The user has

three (3) choices from which the DC restore timing can be selected. These are Backporch

(BP), Tri-level (TL), and Sync-tip (ST). The choices are selected in the SL column of the

C

HANNEL LIST

The DC restore timing counts a preset number of Hx224 clock pulses after the HSYNC

under the C

HANNEL MENU

signal leading edge. ST will clamp and DC restore during the time that the HSYNC pulse

is active. ST clamping is timed with respect to the leading edge of the HSYNC pulse. It is

seldom used but is necessary when there is no back porch to clamp on (image starts

immediately after the sync pulse). BP will clamp and DC restore shortly after the HSYNC

pulse. BP clamping is timed with respect to the trailing edge of the HSYNC pulse. The

timing is calculated to be on the back porch of the signal (after the sync pulse but before

the image begins). This is the most frequently used clamp timing.

INCUSHION POSN

under the T

(Figure 5-1, Menu Structure).

IMING SETUP MENU

The default setting for the DC restore timing is BP when a new channel is set up. TL

clamping occurs significantly after the HSYNC pulse. The purpose of TL timing is to

provide DC restore timing that is compatible with the Tri-level type sync used with

HDTV signals. Like BP, TL clamping is timed with respect to the trailing edge of the

HSYNC pulse. The output of the Synctip/Backporch circuit is a pulse signal (DCRSTR)

going to the VPB.

Serial Communication

The RTG uses only the IIC bus for serial communication with the SCB (Section 2.6.6).

The information transferred over the IIC bus is indicated below (I = input to RTG, O =

output from RTG). A change in output data generates an interrupt pulse.

Table 2-4

I/O

I

I

I

I

I

IIC BUS Information

Information

Priority Select

Description

Commanded sync selection priority

(always fixed as described above).

Vertical Flyback Start Delay Commanded V phase.

Map Start Delay

Commanded timing for vertical positioning

of correction map.

L Blank

R Blank

Commanded position of left blanking.

Commanded position of right blanking.

2-22 Model 330. 340SC, and 370SC Service Manual

Page 35

Chapter 2—Functional Description

O

O

O

O

T Blank

I

I

I

B Blank

/STBP

Commanded position of top blanking.

Commanded position of bottom blanking.

Command for DC restore timing on either

leading or trailing edge of sync pulse.

DC Restore Delay

I

Commanded timing of DC restore after

reference edge of sync pulse.

Internal Sync Forced

I

I

I

Correction Start Delay

Pincushion Start Delay

Command to force internal sync select.

Commanded H phase of correction map.

Commanded H phase of pincushion, keystone,

and linearity correction.

2H Sync Enable

I

I

Shifted Sync Enable

/External Sync Detect

HCount

/Phase Lock

Phase Count

Command determines path of H sync signal.

Command determines path of H sync signal.

Is an external sync available.

Count of H lines per frame.

Indication of PLL lock.

Indication of phase difference between

HSYNC and HFlyback.

Raster Timing Generator I/O

This section provides a description of the inputs to and outputs from the RTG. The I/O

description are arranged by the source/destination of the signal and so the assemblies

communicated with are used as the primary heading of each group of signals and then are

further subdivided into inputs and outputs. In each case, the signal's direction is noted,

with input referring to an input to the RTG, and output to an output from the RTG. (e.g.:

under System Controller Board “Input”; SYSCLK refers to the signal SYSCLK that is an

input to the RTG from the System Controller Board). When test points are provided for

the I/O they are noted.

Table 2-5

Inputs

SYSCLK 4 MHz clock signal for derivation of internal HDTV sync signal.

IICCLK

Outputs

/IICINT

/Hx224

Raster Timing Generator I/O Signals

System Controller Board

Description

(TP 13)

IIC clock line. Unidirectional clock line for control of

synchronous data transfer over IIC data bus.

Description

IIC interrupt line. Signal line for slave boards to inform the SCB

(master) that there is data to be transferred. Master then polls

slaves to determine the source of the interrupt.

Square wave signal 224 X the horizontal frequency for overlay

address generator clocking. (TP 23)

Model 330, 340SC and 370SC Service Manual 2-23

Page 36

Chapter 2—Functional Descriptions

/Hx112

112 times the horizontal frequency for convergence and Z axis

correction address generator clocking. (TP 20)

/CORSTRT Signal used to start the convergence and overlay address

generators during each horizontal sweep. (TP 4)

/FRAMEST Indicates the beginning of a frame. Used in the SCB for

counting vertical frequency. (TP 5)

INTI

/VSYNCSC Regenerated vertical sync signal, pulse shaped to 3 horizontal

Indicates when input source signal is interlaced. (TP 2)

lines in width. (TP 7)

/FIELD1

/MAPST

Low during field #1 of an interlaced input source. (TP 8)

Pulse signal to signal the overlay and correction address

generators to reset for a new frame. (TP 12)

I/O

IICDATA

IIC data line. Bi-directional serial line for synchronous data

Description

transfer between SCB and other circuit boards. See detailed

description for list of signals transferred and data direction.

Inputs

SGSYNC

Description

Stripped Green Sync is Sync-on-Green composite sync signal.

Video Processor Board

(TP 10)

HCSYNC

VSYNC

Outputs

DCRSTR

Horizontal/Composite Sync. (TP 9)

Vertical Sync used only for separate H and V sync. (TP 21)

Description

Pulse for DC restore timed to correspond to ST, BP, or TL.

(TP 1)

VIDBLNK Signal for image blanking from adjustment counters. (TP 6)

/VSYNCSC Vertical sync signal pulse for ILA bias sync. (TP 7)

Inputs

/HVFLBCK Signal representing horizontal flyback from the HDB. Used for

Description

Horizontal Deflection Board

determining H phase. (TP 17)

Outputs

/VFBST

/HSYNCRE Selected HSYNC signal. (TP 14)

Outputs

/PCST

Description

Signal to start the vertical retrace. (TP 11)

Vertical Deflection Board

Description

Signal to time the start of T/B pincushion and linearity

correction. (TP 31)

2-24 Model 330. 340SC, and 370SC Service Manual

Page 37

Inputs

+15V

Description

Power for the analog section of the RTG including the PLL.

System Power Supply

Chapter 2—Functional Description

(TP 30)

-15V

Power for the analog section of the RTG including the PLL.

(TP 29)

+5V

AGND

DGND

Power for the digital portions of the RTG. (TP 3)

Return for +/-15V, separated from DGND by an inductor.

Return for +5V, separated from AGND by an inductor.

Interlocks and Protection

This section describes the interactions between boards where one (1) board may cause

others to perform protection functions.

Input

None

Output

If the PLL falls out of sync, a signal indicating an out-of-lock condition (/PLOCK) will be

sent to the SCB.

Internal

When no external sync signal is present, the RTG will select it's internal sync signal, thus

preventing the need to provide another source for overlay generation.

Horizontal Deflection Board P/N 102523 (HDB)

The horizontal deflection board plugs into the electronics card cage and is the forwardmost card in the card cage.

The following functions are provided by the HDB:

Drive main horizontal deflection coils to provide horizontal raster

scan.

Horizontal raster centering.

Horizontal width adjustment.

Side pincushion correction.

L/R keystone correction.

Horizontal sweep reversal.

Horizontal phase adjustment.

Oscillator for vertical deflection.

The block diagram (see Figure 2-12) description and the I/O description, in the section

following, provide information to perform module level troubleshooting.

Model 330, 340SC and 370SC Service Manual 2-25

Page 38

Chapter 2—Functional Descriptions

Figure 2-12

Horizontal Deflection Board Block Diagram

Vertical Oscillator

The function of the vertical oscillator is to lock to the vertical signal, /VFBST, sent by the

RTG, and produce a pulsed output, VERTDR, of the same frequency. The /VFBST signal

initially is sent to a Frequency to Voltage converter to provide a program voltage to the

oscillator. This presets the oscillator frequency so the oscillator then is able to lock to the

incoming vertical sync signal.

2-26 Model 330. 340SC, and 370SC Service Manual

Page 39

The purpose for having an oscillator for the vertical sweep circuit is to maintain a sweep

Chapter 2—Functional Description

even in the event of loss of vertical sync signal to prevent damage to the CRT. The

vertical oscillator has a free-run frequency of approximately 35Hz when there is no input.

Horizontal Phase Locked Loop

The incoming signal, /HSYNCR initially is sent through a Frequency to Voltage

converter. The output from the F to V is used to provide a program voltage to the PLL, set

the horizontal phase adjustment range, and to set the frequency of the horizontal power

supply. The Horizontal PLL, like the vertical oscillator, takes the input pulsed signal,

/HSYNCR, from the RTG, locks to it, and produces a pulsed output of the same

frequency. The Horizontal PLL has the additional function of controlling the phase of the

output signal relative to the input signal. To do this, the horizontal PLL receives an input

from the SCB via the serial bus that indicates the desired phase relationship. The

incoming signal /HSYNCR is then compared with the flyback pulse (derived separately

from the /HVFLBCK signal listed in the I/O section) to measure the phase relationship.

To control horizontal phase, the operator presses the PHASE button on the remote

control, then adjusts phase with the left and right arrow keys. As with the vertical

oscillator, the Horizontal PLL provides for a minimum free-run frequency in the event of

loss of horizontal sync signal. That frequency is approximately 12.5kHz.

Horizontal Centering

Horizontal centering of each raster (R, G, and B) is accomplished by applying a direct

current bias to each horizontal deflection coil. The DC comes from a programmable

current source that is in series with the main deflection coil. The current source is capable

of providing either positive or negative polarity. Control input to the current sources

comes from the SCB via the serial interface. Pressing the POS (Position) button on the

remote control, then selecting the desired color can independently control the centering of

each individual color. The left and right arrow keys are then pressed to adjust horizontal

position. When controlling the position, Green is a master, i.e.: when Green is selected,

all three-(3) colors move. Red and Blue are independent.

Horizontal Power Supply

The horizontal power supply is a switching power supply that provides an output voltage

proportional to the horizontal frequency and width. The variable output of the power

supply is a negative voltage providing a sink for the horizontal deflection current. The

trace speed of the CRT spot will be determined by the voltage applied across the

deflection coil. The voltage at the power supply output directly determines this in turn. So

when the output from the power supply increases, a given width of raster can be obtained

in a shorter period of time, thus supporting a higher horizontal frequency. In addition to

providing for the maintenance of a constant raster size for varying frequency, a variable

power supply is also necessary for control of the raster width. The output voltage of the

horizontal power supply is controlled primarily by two (2) inputs.

Model 330, 340SC and 370SC Service Manual 2-27

Page 40

Chapter 2—Functional Descriptions

The first is an input derived from the F to V in the horizontal PLL circuit. This presets the

output of the supply to a voltage that will provide a nominal raster size for the horizontal

frequency applied.

The second input is provided by the SCB via the serial interface. This input allows

control of the raster width by the operator. To control the raster width, the operator

presses the SIZE button on the remote control. Pressing the left and right arrow keys then

controls the width. The three (3) rasters are not remotely controllable on an individual

basis. They can however, be set individually with respect to each other by adjusting the

cores of the variable inductors mounted on the yoke terminal boards (see appropriate

model Operator’s Manual).

Flyback Switching

Flyback switching, necessary to avoid overscan and excessive power consumption over

the wide range of horizontal frequencies covered, is accomplished using relays. When the

input source is changed, the relays are switched to change the response of the resonant

flyback circuit. Since horizontal flyback necessarily causes very high voltages, the relays

must not be switched while under load. When the SCB commands flyback switching to

occur, the switching circuit sends a signal to the GRN Horizontal sweep failure circuit to

turn off the CRT beams. It also sends a signal to the Horizontal Power Supply to turn it

off and shut down the horizontal sweep. The relays are then switched and the sweep and

CRT beams are allowed to return to normal. This sequence of events will occur each time

the input source to the projector changes, regardless of any line rate changes. There are

four frequency bands and flyback times that can be set. The frequency ranges and flyback

times are: 6.6uS @ 15-25.1kHz, 4.1uS @ 25-33.1kHz, 2.9uS @ 33-60.1kHz, and 2.4uS

@ 60-90kHz. Flyback switching is not manually controllable by the operator.

Geometric Correction

The HJT Model 330, 340SC and 370SC projectors provide the ability to obtain a

rectangular raster when shooting off-axis in the vertical direction from the screen. This

ability is provided by left/right keystone correction. A geometric correction signal,

GEOCORR, for controlling both the L/R keystone correction and the L/R pincushion

correction is obtained from the Vertical Deflection Board. The GEOCORR signal is a

periodic signal composed of a parabolic summed with a ramp signal, both at the vertical

frequency. This signal is used to vary the width of the horizontal sweep as the vertical

sweep progresses. It does this by modulating the negative voltage applied to the power

transistor, thereby modulating the horizontal width of the raster. The components of

GEOCORR, pincushion correction and keystone correction, are individually controllable

by the operator (see appropriate model Operator’s Manuals).

Output Section

The horizontal sync pulse signal produced by the Horizontal PLL is applied to the output

section to control the timing of the horizontal sweep. The output section includes the

power output transistor, base drive circuit, reversing connectors, and interlock circuit.

2-28 Model 330. 340SC, and 370SC Service Manual

Page 41

The three (3) horizontal deflection coils (B, G, and R) are driven in parallel by a single

Chapter 2—Functional Description

drive circuit and transistor. This is the reason for the inability to remotely control the

three (3) raster widths independently. Since the deflection coils are in parallel, it is

imperative that they all be connected prior to applying sweep voltage—the interlock

circuit ensures this. An output from the Horizontal Power Supply is sent, in series,

through all three (3) yoke connectors. This is part of the bias voltage used to operate the

base drive circuit for the output section. Thus, if any of the yoke connectors is not

connected, the output transistor will not turn on, and no horizontal sweep will be present.

There are two (2) output jumpers on the board, J500 and J501. Their function is to

reverse the direction of the current through the horizontal deflection coils for front and

rear projection. The output cable shall be connected to J501 for rear projection and J500

for front projection (Jumper Settings, Section 3.9).

Horizontal Sweep Failure Detection

Protection of the CRT from spot burns is accomplished by never allowing the CRT to

continue to have beam current when there is no deflection. To this end, the HDB has a

sensing circuit that detects when there is a loss of sweep that may cause CRT damage.

This circuit senses the horizontal flyback voltage and frequency. By sensing both

amplitude and frequency, the projector is able to maintain sweep over the widely varying

input conditions allowed and still protect the CRTs from damage. The flyback signal is

AC coupled and peak detected, then compared with a reference. As long as the flyback

amplitude and frequency are above the minimum allowed, the sweep detection outputs

(HSENSBLU, HSENSGRN, and HSENSRED) are pulled high. These signals are sent to

the VDB for processing.

Serial Communication

The HDB uses two (2) separate, interrelated serial data communication systems to

communicate with the SCB; the IIC bus, and a differential, synchronous data bus. The

information transferred over the serial busses is indicated below (I = input to HDB, O =

output from HDB). Also noted is whether the information is transferred over the IIC or

the serial bus. A change in output data generates an interrupt pulse.

Table 2-6

Bus

IIC

IIC

IIC

IIC

I

I

O

O

I/O

HDB Serial BUS Information

Information

Flyback switch select

Flyback switch pulse

Front/Rear indication

Floor/Ceiling