Page 1

MX480 3D Universal Edge Router

Hardware Guide

Published: 2013-02-04

Copyright © 2013, Juniper Networks, Inc.

Page 2

Juniper Networks, Inc.

1194 North Mathilda Avenue

Sunnyvale, California 94089

USA

408-745-2000

www.juniper.net

This productincludes the Envoy SNMP Engine, developed by Epilogue Technology, anIntegrated Systems Company. Copyright © 1986-1997,

Epilogue Technology Corporation. All rights reserved. This program and its documentation were developed at private expense, and no part

of them is in the public domain.

This product includes memory allocation software developed by Mark Moraes, copyright © 1988, 1989, 1993, University of Toronto.

This product includes FreeBSD software developed by the University of California, Berkeley, and its contributors. All of the documentation

and software included in the 4.4BSD and 4.4BSD-Lite Releases is copyrighted by the Regents of the University of California. Copyright ©

1979, 1980, 1983, 1986, 1988, 1989, 1991, 1992, 1993, 1994. The Regents of the University of California. All rights reserved.

GateD software copyright © 1995, the Regents of the University. All rights reserved. Gate Daemon was originated and developed through

release 3.0 by Cornell University and its collaborators. Gated is based on Kirton’s EGP, UC Berkeley’s routing daemon (routed), and DCN’s

HELLO routing protocol. Development of Gated has been supported in part by the National Science Foundation. Portions of the GateD

software copyright © 1988, Regents of the University of California. All rights reserved. Portions of the GateD software copyright © 1991, D.

L. S. Associates.

This product includes software developed by Maker Communications, Inc., copyright © 1996, 1997, Maker Communications, Inc.

Juniper Networks, Junos, Steel-Belted Radius, NetScreen, and ScreenOS are registered trademarks of Juniper Networks, Inc. in the United

States and other countries. The Juniper Networks Logo, the Junos logo, and JunosE are trademarks of Juniper Networks, Inc. All other

trademarks, service marks, registered trademarks, or registered service marks are the property of their respective owners.

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right to change, modify,

transfer, or otherwise revise this publication without notice.

Products made or sold by Juniper Networks or components thereof might be covered by one or more of the following patents that are

owned by or licensed to Juniper Networks: U.S. Patent Nos. 5,473,599, 5,905,725, 5,909,440, 6,192,051, 6,333,650, 6,359,479, 6,406,312,

6,429,706, 6,459,579, 6,493,347, 6,538,518, 6,538,899, 6,552,918, 6,567,902, 6,578,186, and 6,590,785.

MX480 3D Universal Edge Router Hardware Guide

Copyright © 2013, Juniper Networks, Inc.

All rights reserved.

Revision History

January 2013—Added support for Application Services ModularLine Card (AS MLC), and components ApplicationServices ModularStorage

Card (AS MSC) and Application Services Modular Processing Card (AS MXC).

September 2011—Added the upgrade procedure for the Enhanced MX SCB and information for the new SCB

July 2011—Updated AC and DC power specification topics.

April 2011—Added high-capacity power supply installation information.

March 2011—Updated Routing Engine content.

December 2010—Added RE-S-1800 content.

August 2010—Updated site electrical guidelines.

April 2010—Added installation and removal instructions for dual-wide MICs.

January 2010—Added information about Modular Port Concentrators (MPCs) and Modular Interface Cards (MICs).

July 2009—Updated product names. Updated information about securing power lugs.

10 April 2009—530-020794-01. Revision 6. Added information about the MX Series FPC2. Added warning about removing transceivers.

6 February 2009—530-020794-01. Revision 5. Added information about MX Series FPCs and PICs. Revised sections into modular topics

for easier customer access.

30 August 2008—530-020794-01. Revision 4. Corrected the specifications of the shipping crate, AUX/CONSOLE ports, and AC power

cords. Updated the number of Packet Forwarding Engines. Added a physical specifications appendix. Updated the location of the SCBs

and how to operate the SCB ejector handles. Removed DPC faceplate LED information.

15 May 2008—530-020794-01. Revision 3. Corrected the procedures to replace AC power cords and DC power cables, and to install the

router without a lift. Updatedthe AC andpower requirements andspecifications, host subsystem OFFLINE LED description, chassisgrounding

points description, and clearance requirements. Added recommendation to replace the air filter every 6 months.

19 October 2007—530-020794-01. Revision 2.Added cablemanagement brackets installation procedure. Fixed unresolvedcross-references.

Copyright © 2013, Juniper Networks, Inc.ii

Page 3

19 September 2007—530-020794-01. Revision 1. Initial release.

The information in this document is current as of the date on the title page.

YEAR 2000 NOTICE

Juniper Networks hardware and software products are Year 2000 compliant. Junos OS has no known time-related limitations through the

year 2038. However, the NTP application is known to have some difficulty in the year 2036.

END USER LICENSE AGREEMENT

The Juniper Networks product that is the subject of this technical documentation consists of (or is intended for use with) Juniper Networks

software. Use of such software is subject to the terms and conditions of the End User License Agreement (“EULA”) posted at

http://www.juniper.net/support/eula.html. By downloading, installing or using such software, you agree to the terms and conditions

of that EULA.

iiiCopyright © 2013, Juniper Networks, Inc.

Page 4

Copyright © 2013, Juniper Networks, Inc.iv

Page 5

Table of Contents

About the Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

Junos Documentation and Release Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

Documentation Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

Documentation Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Requesting Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Self-Help Online Tools and Resources . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Opening a Case with JTAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

Part 1 MX480 3D Universal Edge Router Overview

Chapter 1 MX480 Router Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

MX480 Router Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

MX480 Component Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2 MX480 Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

MX480 Chassis Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

MX480 Midplane Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

MX480 Dense Port Concentrator (DPC) Overview . . . . . . . . . . . . . . . . . . . . . . . . . 10

MX480 Dense Port Concentrator (DPC) Description . . . . . . . . . . . . . . . . . . . 10

DPC Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

MX480 Dense Port Concentrator (DPC) LEDs . . . . . . . . . . . . . . . . . . . . . . . . . 12

MX480 Modular Port Concentrator (MPC) Overview . . . . . . . . . . . . . . . . . . . . . . . 13

MX480 Modular Port Concentrator (MPC) Description . . . . . . . . . . . . . . . . . . 13

MPC Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

MX480 Modular Port Concentrator (MPC) LEDs . . . . . . . . . . . . . . . . . . . . . . . 15

MX480 Modular Interface Card (MIC) Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

MX480 Modular Interface Card (MIC) Description . . . . . . . . . . . . . . . . . . . . . 15

MX480 Modular Interface Card (MIC) LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MX480 Flexible PIC Concentrator (FPC) Overview . . . . . . . . . . . . . . . . . . . . . . . . 16

MX480 Flexible PIC Concentrator (FPC) Description . . . . . . . . . . . . . . . . . . . 16

FPC Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

MX480 Flexible PIC Concentrator (FPC) LEDs . . . . . . . . . . . . . . . . . . . . . . . . 18

FPCs Supported by the MX480 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

MX480 PIC Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

MX480 PIC Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

MX480 PIC LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

MX480 Application Services Modular Line Card (AS MLC) Overview . . . . . . . . . . 20

MX480 Application Services Modular Line Card Description . . . . . . . . . . . . . 20

MX480 AS MLC Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

AS MLC Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

vCopyright © 2013, Juniper Networks, Inc.

Page 6

MX480 3D Universal Edge Router Hardware Guide

MX480 SCB, Power Supply, and Cooling System Requirements for AS

MX480 Application Services Modular Storage Card Overview . . . . . . . . . . . . . . . 23

MX480 Application Services Modular Storage Card Description . . . . . . . . . . 23

MX480 AS MSC LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

MX480 Application Services Modular Processing Card Overview . . . . . . . . . . . . . 24

MX480 Application Services Modular Processing Card Description . . . . . . . 24

MX480 AS MXC LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

MX480 Host Subsystem Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

MX480 Host Subsystem Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

MX480 Host Subsystem LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

MX480 Switch Control Board (SCB) Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

MX480 Switch Control Board (SCB) Description . . . . . . . . . . . . . . . . . . . . . . 26

SCB Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

SCB Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

SCB Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

MX480 Switch Control Board (SCB) LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

MX480 Enhanced Switch Control Board Description . . . . . . . . . . . . . . . . . . . 29

MX SCBE Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

MX SCBE Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

MX SCBE Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

MX480 Enhanced Switch Control Board LEDs . . . . . . . . . . . . . . . . . . . . . . . . 30

MX480 Routing Engine Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

MX480 Routing Engine Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Routing Engine Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Routing Engine Interface Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Routing Engine Boot Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

RE-S-1800 Routing Engine Description for MX Series . . . . . . . . . . . . . . . . . . 34

RE-S-1800 Routing Engine Components . . . . . . . . . . . . . . . . . . . . . . . . . 34

RE-S-1800 Routing Engine Boot Sequence . . . . . . . . . . . . . . . . . . . . . . . 35

RE-S-1800 Routing Engine LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

MX480 Routing Engine LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

MX480 Craft Interface Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

MX480 Craft Interface Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Alarm LEDs and Alarm Cutoff/Lamp Test Button on the MX480 Craft

Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

MX480 Component LEDs on the Craft Interface . . . . . . . . . . . . . . . . . . . . . . 38

Host Subsystem LEDs on the MX480 Craft Interface . . . . . . . . . . . . . . . 38

Power Supply LEDs on the MX480 Craft Interface . . . . . . . . . . . . . . . . . 39

DPC and MPC LEDs on the MX480 Craft Interface . . . . . . . . . . . . . . . . . 39

FPC LEDs on the MX480 Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . 39

SCB LEDs on the MX480 Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . 40

Fan LEDs on the MX480 Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Alarm Relay Contacts on the MX480 Craft Interface . . . . . . . . . . . . . . . . . . . 40

MX480 Power Supply Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

MX480 Power System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

MX480 AC Power Supply Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

AC Power Supply Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

MX480 AC Power Supply LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

MLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Copyright © 2013, Juniper Networks, Inc.vi

Page 7

Table of Contents

MX480 DC Power Supply Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

DC Power Supply Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

MX480 DC Power Supply LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

MX480 Cooling System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

MX480 Cooling System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

MX480 Fan LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

MX480 Cable Management Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Part 2 Setting Up the MX480 Router

Chapter 3 Preparing the Site for MX480 Router Installation . . . . . . . . . . . . . . . . . . . . . 53

MX480 Site Preparation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

MX480 Router Rack Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Rack Size and Strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Spacing of Mounting Bracket Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Connection to Building Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

MX480 Router Clearance Requirements for Airflow and Hardware

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

MX480 Router Cabinet Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

MX480 Router Cabinet Size and Clearance Requirements . . . . . . . . . . . . . . . 57

MX480 Router Cabinet Airflow Requirements . . . . . . . . . . . . . . . . . . . . . . . . 58

Chapter 4 MX480 Router Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Installing an MX480 Router Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Chapter 5 Unpacking the MX480 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Tools and Parts Required to Unpack the MX480 Router . . . . . . . . . . . . . . . . . . . . 61

Unpacking the MX480 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Verifying the MX480 Router Parts Received . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Chapter 6 Installing the MX480 Router Mounting Hardware . . . . . . . . . . . . . . . . . . . . . 65

Installing the MX480 Router Mounting Hardware for a Rack or Cabinet . . . . . . . 65

Moving the Mounting Brackets for Center-Mounting the MX480 Router . . . . . . . 67

Chapter 7 Installing the MX480 Router with a Mechanical Lift . . . . . . . . . . . . . . . . . . . 69

Tools Required to Install the MX480 Router with a Mechanical Lift . . . . . . . . . . . 69

Removing Components from the MX480 Router Before Installing It with a

Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Removing the Power Supplies Before Installing the MX480 Router with a

Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Removing the Fan Tray Before Installing the MX480 Router with a Lift . . . . . 71

Removing the SCBs Before Installing the MX480 Router with a Lift . . . . . . . . 71

Removing the DPCs Before Installing the MX480 Router with a Lift . . . . . . . 72

Removing the FPCs Before Installing the MX480 Router with a Lift . . . . . . . . 73

Installing the MX480 Router Using a Mechanical Lift . . . . . . . . . . . . . . . . . . . . . . 74

Reinstalling Components in the MX480 Router After Installing It with a Lift . . . . 76

Reinstalling the Power Supplies After Installing the MX480 Router with a

Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Reinstalling the Fan Tray After Installing the MX480 Router with a Lift . . . . . 77

Reinstalling the SCBs After Installing the MX480 Router with a Lift . . . . . . . 78

Reinstalling the DPCs After Installing the MX480 Router with a Lift . . . . . . . 79

viiCopyright © 2013, Juniper Networks, Inc.

Page 8

MX480 3D Universal Edge Router Hardware Guide

Reinstalling the FPCs After Installing the MX480 Router with a Lift . . . . . . . 80

Installing the MX480 Router Cable Management Bracket . . . . . . . . . . . . . . . . . . . 81

Chapter 8 Installing the MX480 Router Without a Mechanical Lift . . . . . . . . . . . . . . . . 83

Tools Required to Install the MX480 Router Without a Mechanical Lift . . . . . . . . 83

Removing Components from the MX480 Router Before Installing It Without a

Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Removing the Power Supplies Before Installing the MX480 Router Without

a Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Removing the Fan Tray Before Installing the MX480 Router Without a

Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Removing the SCBs Before Installing the MX480 Router Without a Lift . . . . 85

Removing the DPCs Before Installing the MX480 Router Without a Lift . . . . 86

Removing the FPCs Before Installing the MX480 Router Without a Lift . . . . 87

Installing the MX480 Chassis in the Rack Manually . . . . . . . . . . . . . . . . . . . . . . . 89

Reinstalling Components in the MX480 Router After Installing It Without a

Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Reinstalling the Power Supplies After Installing the MX480 Router Without

a Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Reinstalling the Fan Tray After Installing the MX480 Router Without a

Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Reinstalling the SCBs After Installing the MX480 Router Without a Lift . . . . 93

Reinstalling the DPCs After Installing the MX480 Router Without a Lift . . . . 94

Reinstalling the FPCs After Installing the MX480 Router Without a Lift . . . . 95

Chapter 9 Connecting the MX480 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Tools and Parts Required for MX480 Router Connections . . . . . . . . . . . . . . . . . . . 97

Connecting the MX480 Router to Management and Alarm Devices . . . . . . . . . . . 97

Connecting the MX480 Router to a Network for Out-of-Band

Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Connecting the MX480 Router to a Management Console or Auxiliary

Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Connecting the MX480 Router to an External Alarm-Reporting Device . . . . 99

Connecting DPC, MPC, MIC, or PIC Cables to the MX480 Router . . . . . . . . . . . . 100

Chapter 10 Grounding and Providing Power to the MX480 Router . . . . . . . . . . . . . . . . 103

Tools and Parts Required for MX480 Router Grounding and Power

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Grounding the MX480 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Connecting Power to an AC-Powered MX480 Router with Normal-Capacity

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Installing the MX480 AC High-Capacity Power Supplies . . . . . . . . . . . . . . . . . . . 106

Powering On an AC-Powered MX480 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Connecting Power to a DC-PoweredMX480 Router withNormal Capacity Power

Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Installing an MX480 DC High-Capacity Power Supply . . . . . . . . . . . . . . . . . . . . . . 111

Powering On a DC-Powered MX480 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Powering Off the MX480 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Copyright © 2013, Juniper Networks, Inc.viii

Page 9

Table of Contents

Chapter 11 Configuring Junos OS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Initially Configuring the MX480 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Part 3 Hardware Maintenance, Troubleshooting, and Replacement

Procedures

Chapter 12 Maintaining MX480 Router Hardware Components . . . . . . . . . . . . . . . . . . 123

Tools and Parts Required to Maintain the MX480 Router . . . . . . . . . . . . . . . . . . . 123

Routine Maintenance Procedures for the MX480 Router . . . . . . . . . . . . . . . . . . . 123

Maintaining the MX480 Cooling System Components . . . . . . . . . . . . . . . . . . . . . 124

Maintaining the MX480 Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Maintaining the MX480 Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Maintaining the MX480 Host Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Maintaining MX480 Packet Forwarding Engine Components . . . . . . . . . . . . . . . 130

Maintaining MX480 DPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Maintaining MX480 FPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Maintaining MX480 PICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Maintaining MX480 MPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Maintaining MX480 MICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Maintaining Cables That Connect to MX480 DPCs, MPCs, MICs, or PICs . . . 138

Holding and Storing MX Series DPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

MX480 DPC Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Holding an MX480 DPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Storing an MX480 DPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Holding and Storing MX Series FPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

MX480 FPC Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Holding an MX480 FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Storing an MX480 FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Maintaining the MX480 Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Chapter 13 Troubleshooting MX480 Hardware Components . . . . . . . . . . . . . . . . . . . . . 149

Troubleshooting Resources for MX480 Routers . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Command-Line Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Chassis and Interface Alarm Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Alarm Relay Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Craft Interface LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Component LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Juniper Networks Technical Assistance Center . . . . . . . . . . . . . . . . . . . . . . . . 151

Troubleshooting the MX480 Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Troubleshooting the MX480 DPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Troubleshooting the MX480 FPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Troubleshooting the MX480 PICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Troubleshooting the MX480 MPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Troubleshooting the MX480 MICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Troubleshooting the MX480 Power System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

ixCopyright © 2013, Juniper Networks, Inc.

Page 10

MX480 3D Universal Edge Router Hardware Guide

Chapter 14 Replacing MX480 Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

MX480 Field-Replaceable Units (FRUs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Tools and Parts Required to Replace MX480 Hardware Components . . . . . . . . 162

Replacing the MX480 Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Removing the MX480 Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Installing the MX480 Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Replacing the MX480 Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Disconnecting the Alarm Relay Wires from the MX480 Craft Interface . . . . 165

Removing the MX480 Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Installing the MX480 Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Connecting the Alarm Relay Wires to the MX480 Craft Interface . . . . . . . . . 167

Replacing the MX480 Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Removing the MX480 Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Installing the MX480 Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Replacing MX480 Host Subsystem Components . . . . . . . . . . . . . . . . . . . . . . . . . 170

Effect of Taking the MX480 Host Subsystem Offline . . . . . . . . . . . . . . . . . . 170

Taking an MX480 Host Subsystem Offline . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Operating and Positioning the MX480 SCB Ejectors . . . . . . . . . . . . . . . . . . . 173

Replacing an MX480 SCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Removing an MX480 SCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Installing an MX480 SCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Upgrading an MX480 SCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Replacing an MX480 Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Removing an MX480 Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Installing an MX480 Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Replacing an SSD Drive on an RE-A-1800 or RE-S-1800 . . . . . . . . . . . . . . . 186

Replacing Connections to MX480 Routing Engine Interface Ports . . . . . . . . 188

Replacing the Management Ethernet Cable on an MX Series Router . . 188

Replacing the Console or Auxiliary Cable on an MX480 Router . . . . . . 189

Replacing an MX480 DPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Removing an MX480 DPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Installing an MX480 DPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Replacing an MX480 FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Removing an MX480 FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Installing an MX480 FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Replacing an MX480 PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Removing an MX480 PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Installing an MX480 PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Replacing an MX480 MPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Removing an MX480 MPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Installing an MX480 MPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Replacing an MX480 MIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Removing an MX480 MIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Installing an MX480 MIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Installing an MX480 Dual-Wide MIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Replacing an MX480 AS MLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Removing an MX480 AS MLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Installing an MX480 AS MLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Copyright © 2013, Juniper Networks, Inc.x

Page 11

Table of Contents

Replacing an MX480 AS MSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Removing an MX480 AS MSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Installing an MX480 AS MSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Replacing an MX480 AS MXC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Removing an MX480 AS MXC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Installing an MX480 AS MXC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Replacing a Cable on an MX480 DPC, MPC, MIC, or PIC . . . . . . . . . . . . . . . . . . . 222

Removing a Cable on an MX480 DPC, MPC, MIC, or PIC . . . . . . . . . . . . . . . . 222

Installing a Cable on an MX480 DPC, MPC, MIC, or PIC . . . . . . . . . . . . . . . . 224

Replacing an SFP or XFP Transceiver on an MX480 DPC, MPC, MIC, or PIC . . . . 225

Removing an SFP or XFP Transceiver from an MX480 DPC, MPC, MIC, or

PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Installing an SFP or XFP Transceiver into an MX480 DPC, MPC, MIC, or

PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Replacing MX480 Power System Components . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Replacing an MX480 AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Removing an MX480 AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . 228

Installing an MX480 AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Replacing an MX480 DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Removing an MX480 DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . 230

Installing an MX480 DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Replacing an MX480 AC Power Supply Cord . . . . . . . . . . . . . . . . . . . . . . . . 235

Disconnecting an MX480 AC Power Supply Cord . . . . . . . . . . . . . . . . . 235

Connecting an MX480 AC Power Supply Cord . . . . . . . . . . . . . . . . . . . 236

Replacing an MX480 DC Power Supply Cable . . . . . . . . . . . . . . . . . . . . . . . 236

Disconnecting an MX480 DC Power Supply Cable . . . . . . . . . . . . . . . . 236

Connecting an MX480 DC Power Supply Cable . . . . . . . . . . . . . . . . . . . 237

Replacing the MX480 Cable Management Brackets . . . . . . . . . . . . . . . . . . . . . . 239

Part 4 Appendixes

Appendix A Safety and Regulatory Compliance Information for the MX480 Router . . 243

Definition of Safety Warning Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

General Safety Guidelines for Juniper Networks Devices . . . . . . . . . . . . . . . . . . . 245

General Safety Warnings for Juniper Networks Devices . . . . . . . . . . . . . . . . . . . . 246

Qualified Personnel Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Restricted Access Area Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Preventing Electrostatic Discharge Damage to an MX480 Router . . . . . . . . . . . 248

Fire Safety Requirements for Juniper Networks Devices . . . . . . . . . . . . . . . . . . . 249

General Fire Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Fire Suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Fire Suppression Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Installation Safety Warnings for Juniper Networks Devices . . . . . . . . . . . . . . . . . 250

Installation Instructions Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Rack-Mounting Requirements and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . 251

Ramp Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

MX480 Chassis Lifting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

General Laser Safety Guidelines for Juniper Networks Devices . . . . . . . . . . . . . . 256

xiCopyright © 2013, Juniper Networks, Inc.

Page 12

MX480 3D Universal Edge Router Hardware Guide

Laser Safety Warnings for Juniper Networks Devices . . . . . . . . . . . . . . . . . . . . . . 257

Class 1 Laser Product Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Class 1 LED Product Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Laser Beam Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Radiation from Open Port Apertures Warning . . . . . . . . . . . . . . . . . . . . . . . . 258

Maintenance and Operational Safety Warnings for Juniper Networks Devices . . 259

Battery Handling Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Jewelry Removal Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Lightning Activity Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Operating Temperature Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Product Disposal Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Electrical Safety Guidelines and Warnings for the MX480 Router . . . . . . . . . . . 264

General Electrical Safety Warnings for Juniper Networks Devices . . . . . . . . 264

Grounded Equipment Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Grounding Requirements and Warning . . . . . . . . . . . . . . . . . . . . . . . . . 265

Midplane Energy Hazard Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Multiple Power Supplies Disconnection Warning . . . . . . . . . . . . . . . . . 266

Power Disconnection Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

In Case of an Electrical Accident . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

General Electrical Safety Guidelines and Warnings Electrical Codes for M

Series, MX Series, and T Series Routers . . . . . . . . . . . . . . . . . . . . . . . . . 268

TN Power Warning for M Series, MX Series, and T Series Routers . . . . . . . . 269

MX480 AC Power Electrical Safety Guidelines and Warnings . . . . . . . . . . . 270

MX480 AC Power Electrical Safety Guidelines and Warnings . . . . . . . . 270

MX480 DC Power Electrical Safety Guidelines and Warnings . . . . . . . . . . . . 271

MX480 DC Power Electrical Safety Guidelines . . . . . . . . . . . . . . . . . . . . 271

DC Power Electrical Safety Warnings for Juniper Networks Devices . . . 272

Agency Approvals and Compliance Statements for the MX480 Router . . . . . . . 275

Agency Approvals for MX480 Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Compliance Statements for NEBS for MX480 Routers . . . . . . . . . . . . . . . . 276

Compliance Statements for EMC Requirements for the MX480 Router . . . 277

Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

European Community . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Japan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

United States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Compliance Statements for Environmental Requirements for Juniper

Networks Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Compliance Statements for Acoustic Noise for the MX480 Router . . . . . . . 279

Appendix B MX480 Router Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

MX480 Router Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Appendix C MX480 Router Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . 283

MX480 Router Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Appendix D Power Guidelines, Requirements, and Specifications for the MX480

Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Calculating Power Requirements for MX480 Routers . . . . . . . . . . . . . . . . . . . . . 285

Power Requirements for an MX480 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Copyright © 2013, Juniper Networks, Inc.xii

Page 13

Table of Contents

MX480 Chassis Grounding Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

MX480 Chassis Grounding Points Specifications . . . . . . . . . . . . . . . . . . . . . 294

MX480 Router Grounding Cable Lug Specifications . . . . . . . . . . . . . . . . . . 296

MX480 Router Grounding Cable Specifications . . . . . . . . . . . . . . . . . . . . . . 296

MX480 AC Power Specifications and Requirements . . . . . . . . . . . . . . . . . . . . . . 297

AC Electrical Specifications for the MX480 Router . . . . . . . . . . . . . . . . . . . . 297

AC Power Circuit Breaker Requirements for the MX480 Router . . . . . . . . . . 298

AC Power Cord Specifications for the MX480 Router . . . . . . . . . . . . . . . . . 298

MX480 DC Power Specifications and Requirements . . . . . . . . . . . . . . . . . . . . . . 301

DC Power Supply Electrical Specifications for the MX480 Router . . . . . . . . 301

DC Power Circuit Breaker Requirements for the MX480 Router . . . . . . . . . . 302

DC Power Source Cabling and Cable Specifications for the MX480

Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

DC Power Source Cabling for the MX480 Router . . . . . . . . . . . . . . . . . 303

DC Power Cable Specifications for the MX480 Router . . . . . . . . . . . . . 304

Site Electrical Wiring Guidelines for MX Series Routers . . . . . . . . . . . . . . . . . . . . 305

Distance Limitations for Signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Radio Frequency Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Electromagnetic Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Appendix E Cable and Wire Guidelines and Specifications for the MX480 Router . . . 307

Understanding Fiber-Optic Cable Signal Loss, Attenuation, and Dispersion . . . 307

Signal Loss in Multimode and Single-Mode Fiber-Optic Cable . . . . . . . . . . 307

Attenuation and Dispersion in Fiber-Optic Cable . . . . . . . . . . . . . . . . . . . . . 307

Calculating Power Budget and Power Margin for Fiber-Optic Cables . . . . . . . . . 308

Calculating Power Budget for Fiber-Optic Cable . . . . . . . . . . . . . . . . . . . . . 308

Calculating Power Margin for Fiber-Optic Cable . . . . . . . . . . . . . . . . . . . . . . 309

Routing Engine Interface Cable and Wire Specifications for MX Series

Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Appendix F MX480 Cable Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

RJ-45 Connector Pinouts for an MX Series Routing Engine ETHERNET Port . . . . 313

RJ-45 Connector Pinouts for MX Series Routing Engine AUX and CONSOLE

Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

Appendix G Contacting Customer Support and Returning MX480 Hardware . . . . . . . 315

Locating MX480 Component Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Displaying MX480 Router Components and Serial Numbers . . . . . . . . . . . . 315

MX480 Chassis Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

MX480 SCB Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

MX480 DPC Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

MX480 FPC Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

MX480 PIC Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

MX480 MPC Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

MX480 MIC Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

MX480 Power Supply Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . 325

xiiiCopyright © 2013, Juniper Networks, Inc.

Page 14

MX480 3D Universal Edge Router Hardware Guide

MX480 Routing Engine Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . 326

Contacting Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

Returning a Hardware Component to Juniper Networks, Inc. . . . . . . . . . . . . . . . . 327

Tools and Parts Required to Replace Components from an M Series, MX Series,

or T Series Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

Packing the MX480 Router for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

Guidelines for Packing Router Components for Shipment . . . . . . . . . . . . . . . . . 330

Part 5 Index

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

Copyright © 2013, Juniper Networks, Inc.xiv

Page 15

List of Figures

Part 1 MX480 3D Universal Edge Router Overview

Chapter 2 MX480 Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 1: Front View of a Fully Configured Router Chassis . . . . . . . . . . . . . . . . . . . . 8

Figure 2: Rear View of a Fully Configured AC-Powered Router Chassis . . . . . . . . . . 8

Figure 3: Rear View of a Fully Configured DC-Powered Router Chassis . . . . . . . . . . 9

Figure 4: Midplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5: Typical DPCs Supported on the Router . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6: DPC Installed Horizontally in the Router . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 7: Typical MPC Supported on the MX Series Router . . . . . . . . . . . . . . . . . . . 14

Figure 8: MPC Installed Horizontally in the MX480 Router . . . . . . . . . . . . . . . . . . . 14

Figure 9: FPC Installed in the MX480 Router Chassis . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 10: Typical FPCs Supported on the MX480 Router . . . . . . . . . . . . . . . . . . . . 17

Figure 11: Application Services Modular Line Card (AS MLC) . . . . . . . . . . . . . . . . . . 21

Figure 12: Application Services Modular Storage Card . . . . . . . . . . . . . . . . . . . . . . 23

Figure 13: Application Services Modular Processing Card (AS MXC) . . . . . . . . . . . 25

Figure 14: SCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 15: MX SCBE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 16: Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 17: RE-S-1800 Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 18: Routing Engine–RE-S-1800 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 19: Front Panel of the Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 20: Alarm Relay Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 21: AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 22: High-Capacity AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 23: DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 24: High-Capacity DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 25: Airflow Through the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 26: Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 27: Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 28: Cable Management Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 29: Cable Management Brackets Installed on the Router . . . . . . . . . . . . . . 50

Part 2 Setting Up the MX480 Router

Chapter 3 Preparing the Site for MX480 Router Installation . . . . . . . . . . . . . . . . . . . . . 53

Figure 30: Typical Open-Frame Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 31: Clearance Requirements for Airflow and Hardware Maintenance for

an MX480 Router Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 32: Airflow Through the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Chapter 5 Unpacking the MX480 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

xvCopyright © 2013, Juniper Networks, Inc.

Page 16

MX480 3D Universal Edge Router Hardware Guide

Figure 33: Contents of the Shipping Crate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Chapter 6 Installing the MX480 Router Mounting Hardware . . . . . . . . . . . . . . . . . . . . . 65

Figure 34: Installing the Front Mounting Hardware for a Four-Post Rack or

Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 35: Installing the Mounting Hardware for an Open-Frame Rack . . . . . . . . . 67

Chapter 7 Installing the MX480 Router with a Mechanical Lift . . . . . . . . . . . . . . . . . . . 69

Figure 36: Removing a Power Supply Before Installing the Router . . . . . . . . . . . . 70

Figure 37: Removing the Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 38: Removing an SCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Figure 39: Removing a DPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Figure 40: Removing an FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Figure 41: Installing the Router in the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 42: Reinstalling a Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 43: Reinstalling a Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 44: Reinstalling an SCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 45: Reinstalling a DPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 46: Reinstalling an FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Figure 47: Installing the Cable Management Brackets . . . . . . . . . . . . . . . . . . . . . . 82

Chapter 8 Installing the MX480 Router Without a Mechanical Lift . . . . . . . . . . . . . . . . 83

Figure 48: Removing a Power Supply Before Installing the Router . . . . . . . . . . . . 84

Figure 49: Removing the Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Figure 50: Removing an SCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 51: Removing a DPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Figure 52: Removing an FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Figure 53: Installing the Router in the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 54: Reinstalling a Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Figure 55: Reinstalling a Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Figure 56: Reinstalling an SCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 57: Reinstalling a DPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Figure 58: Reinstalling an FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Chapter 9 Connecting the MX480 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Figure 59: Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Figure 60: Routing Engine Ethernet Cable Connector . . . . . . . . . . . . . . . . . . . . . . 98

Figure 61: Auxiliary and Console Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Figure 62: Routing Engine Console and Auxiliary Cable Connector . . . . . . . . . . . . 99

Figure 63: Alarm Relay Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Figure 64: Attaching a Cable to a DPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Figure 65: Attaching a Cable to a MIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Chapter 10 Grounding and Providing Power to the MX480 Router . . . . . . . . . . . . . . . . 103

Figure 66: Connecting AC Power to the Router (110V) . . . . . . . . . . . . . . . . . . . . . 106

Figure 67: Installing an AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Figure 68: Connecting DC Power to the Router . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Figure 69: DC High-Capacity Power Supply Input Mode Switch . . . . . . . . . . . . . . 111

Figure 70: Connecting DC Power to the Router . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Copyright © 2013, Juniper Networks, Inc.xvi

Page 17

List of Figures

Part 3 Hardware Maintenance, Troubleshooting, and Replacement

Procedures

Chapter 12 Maintaining MX480 Router Hardware Components . . . . . . . . . . . . . . . . . . 123

Figure 71: DPC Edges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Figure 72: Do Not Grasp the Connector Edge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Figure 73: Do Not Rest the DPC on an Edge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Figure 74: FPC Edges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Figure 75: Do Not Grasp the Connector Edge . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Figure 76: Do Not Carry an FPC with Only One Hand . . . . . . . . . . . . . . . . . . . . . . 145

Figure 77: Do Not Rest the FPC on an Edge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Figure 78: Do Not Stack FPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Chapter 14 Replacing MX480 Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Figure 79: Removing the Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Figure 80: Installing the Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Figure 81: Alarm Relay Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Figure 82: Removing the Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Figure 83: Installing the Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Figure 84: Alarm Relay Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Figure 85: Removing the Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Figure 86: Installing the Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Figure 87: Removing an SCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Figure 88: Installing an SCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Figure 89: Removing a Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Figure 90: Installing a Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Figure 91: RE-A-1800 Storage Drive Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Figure 92: RE-S-1800 Storage Drive Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Figure 93: Cable Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Figure 94: Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Figure 95: Auxiliary and Console Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Figure 96: Removing a DPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Figure 97: Installing a DPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Figure 98: Attaching a Cable to a DPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Figure 99: Removing an FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Figure 100: Installing an FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Figure 101: Removing a PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Figure 102: Installing a PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Figure 103: Removing an MPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Figure 104: Installing an MPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Figure 105: Removing a MIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Figure 106: Removing a Dual-Wide MIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Figure 107: Installing the Septum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Figure 108: Installing a MIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Figure 109: Removing the Septum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Figure 110: Installing a Dual-Wide MIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Figure 111: Removing an AS MLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Figure 112: Installing an AS MLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Figure 113: Removing an AS MSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Figure 114: Installing an AS MSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

xviiCopyright © 2013, Juniper Networks, Inc.

Page 18

MX480 3D Universal Edge Router Hardware Guide

Figure 115: Removing an AS MXC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Figure 116: Installing an AS MXC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Figure 117: Removing SFPs or XFPs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Figure 118: Removing an AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Figure 119: Installing an AC Power Supply in an MX480 Router . . . . . . . . . . . . . . 230

Figure 120: Removing a DC Power Supply from the Router . . . . . . . . . . . . . . . . . 232

Figure 121: Installing a DC Power Supply in the Router . . . . . . . . . . . . . . . . . . . . . 234

Figure 122: Connecting DC Power to the Router . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Figure 123: Connecting Power Cables to the DC Power Supply . . . . . . . . . . . . . . 238

Figure 124: Removing the Cable Management Brackets . . . . . . . . . . . . . . . . . . . 239

Part 4 Appendixes

Appendix A Safety and Regulatory Compliance Information for the MX480 Router . . 243

Figure 125: Placing a Component into an Electrostatic Bag . . . . . . . . . . . . . . . . . 249

Figure 126: MX480 Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Appendix D Power Guidelines, Requirements, and Specifications for the MX480

Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Figure 127: Connecting AC Power to the Router . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Figure 128: Connecting DC Power to the Router . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Figure 129: Grounding Cable Lug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Figure 130: AC Plug Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Figure 131: Typical DC Source Cabling to the Router . . . . . . . . . . . . . . . . . . . . . . . 303

Figure 132: DC Power Cable Lug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Appendix G Contacting Customer Support and Returning MX480 Hardware . . . . . . . 315

Figure 133: Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

Figure 134: MX480 Chassis Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . 318

Figure 135: SCB Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

Figure 136: DPC Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

Figure 137: FPC Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Figure 138: PIC Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

Figure 139: MPC Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

Figure 140: 2-Port MIC Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Figure 141: 4-Port MIC Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Figure 142: 20-Port MIC Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Figure 143: 40-Port MIC Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Figure 144: AC Power Supply Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . 325

Figure 145: DC Power Supply Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . 326

Figure 146: Routing Engine Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . 326

Copyright © 2013, Juniper Networks, Inc.xviii

Page 19

List of Tables

About the Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

Table 1: Notice Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

Table 2: Text and Syntax Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

Part 1 MX480 3D Universal Edge Router Overview

Chapter 2 MX480 Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 3: FPCs Supported by MX480 Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 4: AS MSC LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 5: AS MXC LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 6: SCB LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 7: Enhanced MX SCB LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 8: Routing Engine LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 9: Routing Engine LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 10: Alarm LEDs and Alarm Cutoff/Lamp Test Button . . . . . . . . . . . . . . . . . . 38

Table 11: Host Subsystem LEDs on the Craft Interface . . . . . . . . . . . . . . . . . . . . . . 38

Table 12: Power Supply LEDs on the Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 13: DPC and MPC LEDs on the Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 14: FPC LEDs on the Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 15: SCB LEDs on the Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 16: Fan LEDs on the Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 17: AC Power Supply LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 18: Power Supply Redundancy and Power Distribution . . . . . . . . . . . . . . . . 45

Table 19: DC Power Supply LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Part 2 Setting Up the MX480 Router

Chapter 3 Preparing the Site for MX480 Router Installation . . . . . . . . . . . . . . . . . . . . . 53

Table 20: Site Preparation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Chapter 5 Unpacking the MX480 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 21: Parts List for a Fully Configured Router . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Table 22: Accessory Box Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Chapter 6 Installing the MX480 Router Mounting Hardware . . . . . . . . . . . . . . . . . . . . . 65

Table 23: Four-Post Rack or Cabinet Mounting Hole Locations . . . . . . . . . . . . . . . 65

Part 3 Hardware Maintenance, Troubleshooting, and Replacement

Procedures

Chapter 14 Replacing MX480 Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Table 24: Field-Replaceable Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

xixCopyright © 2013, Juniper Networks, Inc.

Page 20

MX480 3D Universal Edge Router Hardware Guide

Table 25: Tools and Parts Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Table 26: Effect of Taking the Host Subsystem Offline . . . . . . . . . . . . . . . . . . . . . 171

Part 4 Appendixes

Appendix B MX480 Router Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Table 27: Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Appendix C MX480 Router Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . 283

Table 28: Router Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Appendix D Power Guidelines, Requirements, and Specifications for the MX480

Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Table 29: MX480 DC Zoning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Table 30: Sample Power Requirements for an MX480 Router . . . . . . . . . . . . . . 287

Table 31: Calculating Power Budget for a MX480 AC Chassis . . . . . . . . . . . . . . . 288

Table 32: Calculating Power Budget for a MX480 DC Chassis . . . . . . . . . . . . . . 288

Table 33: Calculating Input Power Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Table 34: Calculating Thermal Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Table 35: MX480 Router Common Component Power Requirements . . . . . . . . 289

Table 36: FRU Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Table 37: Grounding Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Table 38: AC Power Supply Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . 297

Table 39: AC Power System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

Table 40: AC Power Cord Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Table 41: Power Supply Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 301

Table 42: Power System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Table 43: DC Power Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Appendix E Cable and Wire Guidelines and Specifications for the MX480 Router . . . 307

Table 44: Estimated Values for Factors Causing Link Loss . . . . . . . . . . . . . . . . . 309

Table 45: Cable and Wire Specifications for Routing Engine Management and

Alarm Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Appendix F MX480 Cable Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Table 46: RJ-45 Connector Pinout for the Routing Engine ETHERNET Port . . . . 313

Table 47: RJ-45 Connector Pinout for the AUX and CONSOLE Ports . . . . . . . . . . 314

Copyright © 2013, Juniper Networks, Inc.xx

Page 21

About the Documentation

•

Junos Documentation and Release Notes on page xxi

•

Documentation Conventions on page xxi

•

Documentation Feedback on page xxiii

•

Requesting Technical Support on page xxiii

Junos Documentation and Release Notes

For a list of related Junos documentation, see

http://www.juniper.net/techpubs/software/junos/.

If the information in the latest release notes differs from the information in the

documentation, follow the Junos Release Notes.

To obtain the most current version of all Juniper Networks®technical documentation,

see the product documentation page on the Juniper Networks website at

http://www.juniper.net/techpubs/.

Documentation Conventions

Table 1: Notice Icons

Table 1 on page xxi defines the notice icons used in this guide.

DescriptionMeaningIcon

Indicates important features or instructions.Informational note

Indicates a situation that might result in loss of data or hardware damage.Caution

Alerts you to the risk of personal injury or death.Warning

Alerts you to the risk of personal injury from a laser.Laser warning

xxiCopyright © 2013, Juniper Networks, Inc.

Page 22

MX480 3D Universal Edge Router Hardware Guide

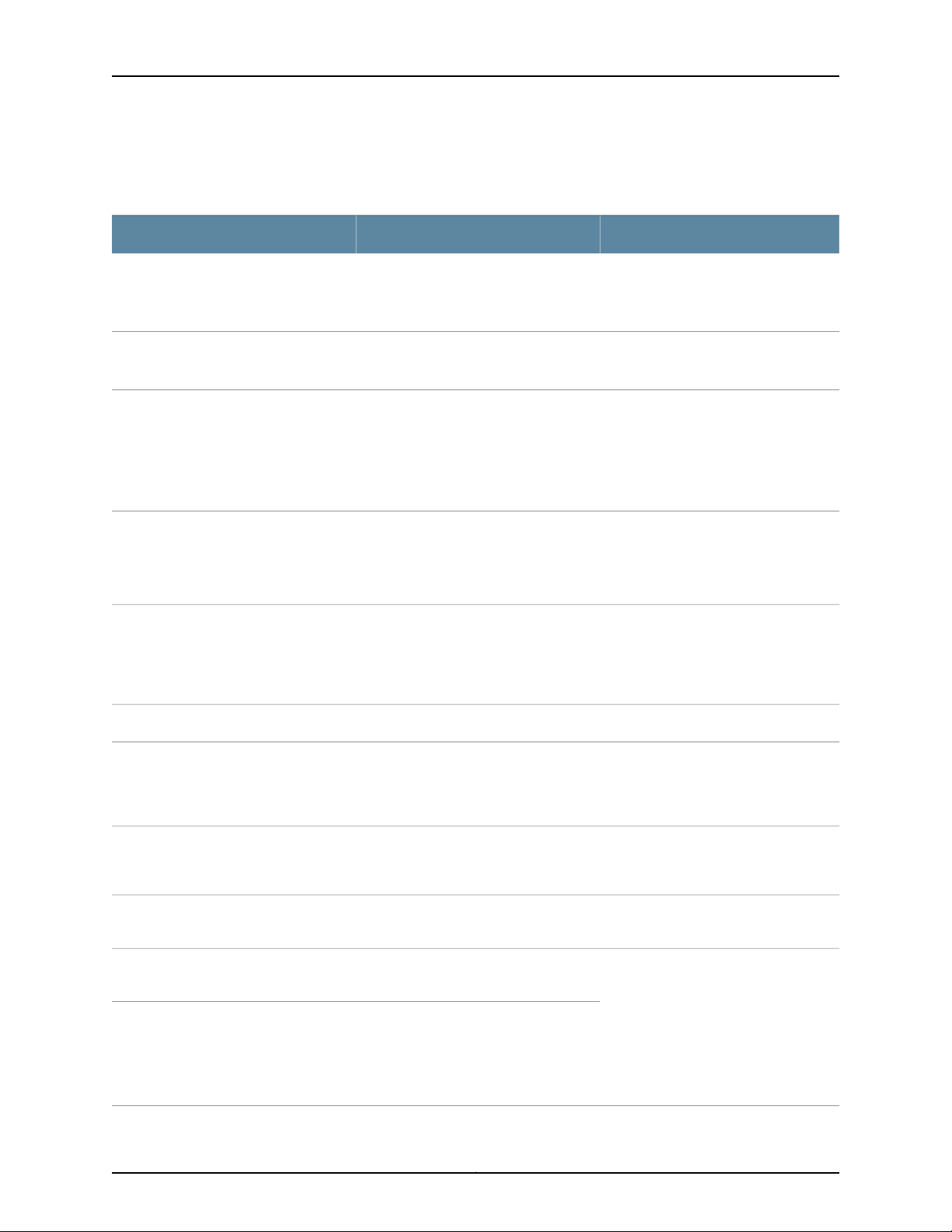

Table 2 on page xxii defines the text and syntax conventions used in this guide.

Table 2: Text and Syntax Conventions

ExamplesDescriptionConvention

Fixed-width text like this

Italic text like this

Italic text like this

Text like this

Represents text that you type.Bold text like this

Represents output that appears on the

terminal screen.

•

Introduces or emphasizes important

new terms.

•

Identifies book names.

•

Identifies RFC and Internet draft titles.

Represents variables (options for which

you substitute a value) in commands or

configuration statements.

Represents names of configuration

statements, commands, files, and

directories;configurationhierarchy levels;

or labels on routing platform

components.

To enter configuration mode, type

theconfigure command:

user@host> configure

user@host> show chassis alarms

No alarms currently active

•

A policy term is a named structure

that defines match conditions and

actions.

•

Junos OS SystemBasics Configuration

Guide

•

RFC 1997, BGP Communities Attribute

Configure the machine’s domain name:

[edit]

root@# set system domain-name

domain-name

•

To configure a stub area, include the

stub statement at the[edit protocols

ospf area area-id] hierarchy level.

•

The console port is labeled CONSOLE.

stub <default-metric metric>;Enclose optional keywords or variables.< > (angle brackets)

| (pipe symbol)

# (pound sign)

[ ] (square brackets)

Indention and braces ( { } )

; (semicolon)

Indicates a choice betweenthe mutually

exclusivekeywords or variables on either

side of the symbol. The set of choices is

often enclosed in parenthesesfor clarity.

same lineas theconfiguration statement

to which it applies.

Enclose a variable for which you can

substitute one or more values.

Identify a level in the configuration

hierarchy.

Identifies a leaf statement at a

configuration hierarchy level.

broadcast | multicast

(string1 | string2 | string3)

rsvp { # Required for dynamic MPLS onlyIndicates a comment specified on the

community name members [

community-ids ]

[edit]

routing-options {

static {

route default{

nexthop address;

retain;

}

}

}

Copyright © 2013, Juniper Networks, Inc.xxii

Page 23

Table 2: Text and Syntax Conventions (continued)

J-Web GUI Conventions

Bold text like this

Represents J-Web graphical user

interface (GUI) items you click or select.

About the Documentation

ExamplesDescriptionConvention

•

In the Logical Interfaces box, select

All Interfaces.

•

To cancel the configuration, click

Cancel.

> (bold right angle bracket)

Documentation Feedback

We encourage you to provide feedback, comments, and suggestions so that we can

improve the documentation. You can send your comments to

techpubs-comments@juniper.net, or fill out the documentation feedback form at

https://www.juniper.net/cgi-bin/docbugreport/ . If you are using e-mail, be sure to include