Page 1

Juniper Networks

Intrusion Detection and Prevention

IDP 75, 250, 800, and 8200

Installation Guide

Releases 4.1r2a and 4.2

April 2008

Juniper Networks, Inc.

1194 North Mathilda Avenue

Sunnyvale, CA 94089

USA

408-745-2000

www.juniper.net

Part Number: 530-023834-01

Page 2

Copyright Notice

Copyright © 2008 Juniper Networks, Inc. All rights reserved.

Juniper Networks, the Juniper Networks logo, NetScreen, and ScreenOS are registered trademarks of Juniper Networks, Inc. in the United States and

other countries. All other trademarks, service marks, registered trademarks, or registered service marks in this document are the property of Juniper

Networks or their respective owners. All specifications are subject to change without notice. Juniper Networks assumes no responsibility for any

inaccuracies in this document or for any obligation to update information in this document. Juniper Networks reserves the right to change, modify,

transfer, or otherwise revise this publication without notice.

FCC Statement

The following information is for FCC compliance of Class A devices: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. The equipment generates, uses, and can radiate radio-frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case users will be required to correct the interference at their own expense.

The following information is for FCC compliance of Class B devices: The equipment described in this manual generates and may radiate radio-frequency

energy. If it is not installed in accordance with Juniper Networks’ installation instructions, it may cause interference with radio and television reception.

This equipment has been tested and found to comply with the limits for a Class B digital device in accordance with the specifications in part 15 of the FCC

rules. These specifications are designed to provide reasonable protection against such interference in a residential installation. However, there is no

guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Consult the dealer or an experienced radio/TV technician for help.

Connect the equipment to an outlet on a circuit different from that to which the receiver is connected.

Caution: Changes or modifications to this product could void the user's warranty and authority to operate this device.

Disclaimer

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT SHIPPED

WITH THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE OR LIMITED

WARRANTY, CONTACT YOUR JUNIPER NETWORKS REPRESENTATIVE FOR A COPY.

Page 3

Table of Contents

About This Guide xi

Audience......................................................................................................... xi

Conventions.................................................................................................... xi

Documentation .............................................................................................. xii

Web Access for Documentation............................................................... xii

Requesting Technical Support ........................................................................ xii

Self-Help Online Tools and Resources..................................................... xiii

Chapter 1 Planning an Installation 1

IDP Configuration Basics ..................................................................................2

IDP Sensor Placement ............................................................................... 2

IDP Sensor Deployment Mode ................................................................... 2

NetScreen-Security Manager ...................................................................... 5

Chapter 2 Hardware Overview 7

IDP Sensors......................................................................................................7

IDP 75 Sensor............................................................................................ 8

IDP 250 Sensor.......................................................................................... 8

IDP 800 Sensor.......................................................................................... 8

IDP 8200 Sensor........................................................................................ 9

Traffic Ports (Forwarding Interfaces) ..............................................................10

Configurable NIC States ...........................................................................10

Normal State .....................................................................................11

NIC Bypass State ...............................................................................11

NIC Bypass and Cable Choices ..........................................................12

External Bypass Unit State ................................................................ 12

NICs Off State ................................................................................... 12

Peer Port Modulation............................................................................... 13

Management Ports......................................................................................... 13

Hard Drives and USB Ports ............................................................................ 13

Power Supplies .............................................................................................. 13

IDP Sensor LEDs ............................................................................................14

System Status LEDs ................................................................................. 14

Management and High Availability Port LEDs.......................................... 14

Traffic Port LEDs ..................................................................................... 15

Hard Drive LEDs on Front Panel .............................................................. 15

Power Supply LEDs on Back Panel .......................................................... 16

Chapter 3 Installing the Sensor 17

General Installation Guidelines ....................................................................... 17

Rack Mounting the IDP Sensor ....................................................................... 18

Required Tools ........................................................................................ 18

Table of Contents iii

Page 4

IDP 75, 250, 800, and 8200 Installation Guide

Connecting Power.......................................................................................... 20

Chapter 4 Configuring the IDP Sensor 21

Initial Configuration Options .......................................................................... 21

Connecting to the Sensor ............................................................................... 22

Connecting Forwarding Interfaces .................................................................28

Verifying Traffic Flow..................................................................................... 28

Connecting the High Availability Port.............................................................28

Mounting Using Device Rack Rails........................................................... 18

Mounting Using Midmount Brackets ........................................................ 19

Simple Configuration ...............................................................................21

Simple Configuration Settings ...........................................................21

Simple Configuration Values ............................................................. 22

Advanced Configuration ..........................................................................22

Using the Console Serial Port to Configure the Sensor ............................. 22

Using the Management Port to Configure the Sensor............................... 24

Connecting Directly Using the Management Port .............................. 24

Connecting Remotely Using the Management Port ........................... 25

Simple or Advanced Configuration Using the Management Port.............. 25

QuickStart Simple Configuration ....................................................... 26

ACM Advanced Configuration ...........................................................26

Chapter 5 Adding the Sensor to NSM 29

Adding Your Sensor to NSM ...........................................................................29

Checking the Status of Your Sensor................................................................ 33

Chapter 6 Updating Software on the Sensor 35

Updating IDP Sensor Software Using NSM Firmware Manager....................... 35

Loading a Sensor Image into NSM ........................................................... 35

Upgrading Sensor Software .....................................................................36

Updating IDP Sensor Software Without NSM ................................................. 36

Reimaging the IDP Sensor.............................................................................. 37

Chapter 7 Servicing the Device 39

Replacing a Power Supply (IDP 800, and 8200 Only).....................................39

Remove a Power Supply .......................................................................... 39

Install a Power Supply ............................................................................. 40

Replacing a Hard Drive (IDP 800 and 8200 Only) .......................................... 40

Remove a Hard Drive .............................................................................. 40

Install a Hard Drive.................................................................................. 41

Chapter 8 Advanced Configuration 43

Advanced Deployment Modes ....................................................................... 43

Bridge Mode ............................................................................................43

Router Mode............................................................................................ 45

Proxy-ARP Mode .....................................................................................46

IDP High Availability Deployment Modes....................................................... 46

iv Table of Contents

Appendix A Specifications 47

IDP 75 Technical Specifications ..................................................................... 48

IDP 250 Technical Specifications ................................................................... 49

Page 5

Table of Contents

IDP 800 Technical Specifications ................................................................... 50

IDP 8200 Technical Specifications .................................................................51

Safety Compliance .........................................................................................52

EMI Compliance............................................................................................. 52

Immunity....................................................................................................... 52

Index 53

Table of Contents

v

Page 6

IDP 75, 250, 800, and 8200 Installation Guide

vi Table of Contents

Page 7

List of Figures

Figure 1: Sniffer Mode (Passive) ..................................................................... 3

Figure 2: Transparent Mode (Inline Active) ....................................................4

Figure 3: IDP 75 Front Panel ..........................................................................8

Figure 4: IDP 250 Front Panel ........................................................................8

Figure 5: IDP 800 Front Panel ........................................................................9

Figure 6: IDP 8200 Front Panel ....................................................................10

Figure 7: Traffic Ports ................................................................................... 10

Figure 8: LEDs for Management and HA Ports.............................................. 15

Figure 9: Rail with Hinged Rear Bracket ....................................................... 19

Figure 10: 2 RU Device Midmount Bracket ..................................................... 19

Figure 11: 1 RU Device (IDP 75) Midmount Bracket ....................................... 20

Figure 12: Begin Add Device Procedure..........................................................30

Figure 13: Add Device Wizard - Device Name ................................................ 30

Figure 14: Add Device Wizard - Connection Settings ...................................... 31

Figure 15: Add Device Wizard - Verification Settings ......................................31

Figure 16: Add Device Wizard - Retrieved Settings ......................................... 32

Figure 17: Add Device Wizard - Adding the Device......................................... 32

Figure 18: Add Device Wizard - Importing the Device .................................... 33

Figure 19: Viewing Device Status.................................................................... 33

Figure 20: Hard Drive Latch in Closed Position .............................................. 41

Figure 21: Bridge Mode .................................................................................44

Figure 22: Router Mode ................................................................................. 45

Figure 23: Proxy-ARP Mode............................................................................46

List of Figures vii

Page 8

IDP 75, 250, 800, and 8200 Installation Guide

viii List of Figures

Page 9

List of Tables

Table 1: Notice Icons .................................................................................... xi

Table 2: Advantages and Disadvantages of Sniffer Mode (Passive) ................4

Table 3: Advantages and Disadvantages of Transparent Mode (Inline Active) 5

Table 4: NIC State Options .......................................................................... 11

Table 5: IDP Sensor Drives .......................................................................... 13

Table 6: IDP Sensor Power Supplies ............................................................ 14

Table 7: Front Panel System Status LEDs .................................................... 14

Table 8: IDP Sensor Management and High Availability Port LED ...............15

Table 9: IDP Sensor Traffic Port LEDs .........................................................15

Table 10: Hard Drive LED Definitions............................................................ 16

Table 11: Power Supply LED Definitions .......................................................16

Table 12: Information Needed for QuickStart Configuration.......................... 26

Table 13: Information Needed for ACM Configuration................................... 26

Table 14: Advantages and Disadvantages of Bridge Mode ............................. 44

Table 15: Advantages and Disadvantages of Router Mode............................. 45

Table 16: Advantages and Disadvantages of Proxy-ARP Mode ......................46

Table 17: Physical Specifications................................................................... 48

Table 18: AC Power Specifications ................................................................ 48

Table 19: Power Cord Specifications ............................................................. 48

Table 20: Environmental Specifications......................................................... 48

Table 21: Physical Specifications................................................................... 49

Table 22: AC Power Specifications ................................................................ 49

Table 23: Power Cord Specifications ............................................................. 49

Table 24: Environmental Specifications......................................................... 49

Table 25: Physical Specifications................................................................... 50

Table 26: AC Power Specifications ................................................................ 50

Table 27: Power Cord Specifications ............................................................. 50

Table 28: Environmental Specifications......................................................... 50

Table 29: Physical Specifications................................................................... 51

Table 30: AC Power Specifications ................................................................ 51

Table 31: Power Cord Specifications ............................................................. 51

Table 32: Environmental Specifications......................................................... 51

List of Tables ix

Page 10

IDP 75, 250, 800, and 8200 Installation Guide

x List of Tables

Page 11

About This Guide

This guide describes the physical features of Juniper Networks Intrusion Detection

and Prevention (IDP) solution: the IDP 75, IDP 250, IDP 800, and IDP 8200

sensors. It also explains how to install, configure, update/reimage, and service the

IDP system.

This preface has the following sections:

Audience on page xi

Conventions on page xi

Documentation on page xii

Requesting Technical Support on page xii

Audience

This guide is intended for experienced system and network specialists.

Conventions

The term sensor is used to denote an IDP 75, 250, 800, or 8200 appliance.

Table 1 defines notice icons used in this guide.

Table 1: Notice Icons

Icon Meaning Description

Informational note Indicates important features or instructions.

Caution Indicates that you may risk losing data or damaging your

hardware.

Warning Alerts you to the risk of personal injury.

Audience xi

Page 12

IDP 75, 250, 800, and 8200 Installation Guide

Documentation

This guide is shipped in the box with all new IDP sensors. It provides the basic

procedures for getting your IDP system running.

With each major software release, Juniper Networks provides the IDP

Documentation CD. The CD contains the documentation set in PDF format.

The IDP documentation set includes the following books:

Release Notes—Contain the latest information about features, changes, known

problems and resolved problems. If the information in the Release Notes differs

from the information found in the documentation set, follow the Release Notes.

Intrusion Detection and Prevention Concepts & Examples Guide—Explains

basic concepts of the IDP system and provides examples of how to use the

system.

IDP 75, 250, 800, and 8200 Installation Guide (this manual)—Describes the

hardware components of the IDP 75, 250, 800, and 8200 sensors. Provides

instructions for rack-mounting, cabling, basic configuration, management

server installation, and user interface installation.

Online Help—Available through the IDP Appliance Configuration Manager

(ACM). The online help provides explanations for sensor configuration options

as well as step-by-step directions for performing common tasks.

Web Access for Documentation

To view the documentation on the Web, go to:

http://www.juniper.net/techpubs/software/management/idp/

Requesting Technical Support

Technical product support is available through the Juniper Networks Technical

Assistance Center (JTAC). If you are a customer with an active J-Care or JNASC

support contract, or are covered under warranty, and need post sales technical

support, you can access our tools and resources online or open a case with JTAC.

JTAC policies—For a complete understanding of our JTAC procedures and

policies, review the JTAC User Guide located at

http://www.juniper.net/customers/support/downloads/710059.pdf.

xii Documentation

Product warranties—For product warranty information, visit

http://www.juniper.net/support/warranty/.

JTAC hours of operation—The JTAC centers have resources available 24 hours a

day, 7 days a week, 365 days a year.

Page 13

Self-Help Online Tools and Resources

For quick and easy problem resolution, Juniper Networks has designed an online

self-service portal called the Customer Support Center (CSC) that provides you with

the following features:

Find CSC offerings: http://www.juniper.net/customers/support/

Search for known bugs: http://www2.juniper.net/kb/

Find product documentation: http://www.juniper.net/techpubs/

Find solutions and answer questions using our Knowledge Base:

http://kb.juniper.net/

Download the latest versions of software and review your release notes:

http://www.juniper.net/customers/csc/software/

Search technical bulletins for relevant hardware and software notifications:

http://www.juniper.net/alerts/

About This Guide

Join and participate in the Juniper Networks Community Forum:

http://www.juniper.net/company/communities/

Open a case online in the CSC Case Manager:

http://www.juniper.net/customers/cm/

To verify service entitlement by product serial number, use our Serial Number

Entitlement (SNE) Tool:

https://tools.juniper.net/SerialNumberEntitlementSearch/

Opening a Case with JTAC

You can open a case with JTAC on the Web or by telephone.

Use the Case Manager tool in the CSC at

http://www.juniper.net/customers/cm/.

Call 1-888-314-JTAC (1-888-314-5822—toll free in USA, Canada, and Mexico).

For international or direct-dial options in countries without toll-free numbers, visit

us at

http://www.juniper.net/customers/support/requesting-support/.

Requesting Technical Support xiii

Page 14

IDP 75, 250, 800, and 8200 Installation Guide

xiv Requesting Technical Support

Page 15

Chapter 1

Planning an Installation

This chapter provides an overview of IDP configuration options. This chapter has

the following sections:

Installation Roadmap on page 1

IDP Configuration Basics on page 2

Installation Roadmap

This section provides a high-level roadmap of an IDP sensor installation. With each

step is a reference to more information.

1. Install the NetScreen-Security Manager (NSM) server onto a dedicated host or

hosts. See the NetScreen-Security Manager Installation Guide for installation

instructions.

2. Install the NSM GUI on a Windows or Linux client machine. See the

NetScreen-Security Manager Installation Guide for installation instructions.

3. Decide on a place in your network for the sensor. Choose which mode you will

run. See Chapter 4, “Installing the Sensor,” on page 17.

4. Install the sensor on a rack. See Chapter 4, “Installing the Sensor,” on page 17.

5. Log into the sensor using the console port to run the EasyConfig script. This

script lets you specify a sensor mode, IP address, netmask, default gateway,

and date or time. See “Using the Console Serial Port to Configure the Sensor”

on page 22. You can use the default login name (root) and password (abc123)

for the sensor.

6. (Optional) If you want to change your default login and password, change port

speeds, or do more advanced configuration of the sensor, use a Web browser

to log into the sensor’s Appliance Configuration Manager (ACM). You can reach

it by typing

browser.

7. Start the NSM GUI. The default login ID is super. Use the password you

specified when you installed the NSM server.

https://SensorIPAddress in the Address or Location box of your

Installation Roadmap 1

Page 16

IDP 75, 250, 800, and 8200 Installation Guide

8. Add the sensor as an object in NSM using the Add Device wizard. Select Device

Manager > Security Devices from the left navigational pane, and then click

the + button. See “Adding Your Sensor to NSM” on page 29. The Add Device

Wizard creates a database entry in NSM for the sensor, imports the sensor’s

configuration, and loads the Juniper Networks Recommended policy onto the

sensor. At that point, your sensor is actively protecting your network.

To improve the performance and accuracy of your protection, use the IDP Concepts

& Examples Guide and the NetScreen-Security Manager Administrator’s Guide to tailor

your security policy to your network.

NOTE: You must update your attack objects to get the latest protection.

IDP Configuration Basics

This section provides an introduction to IDP configuration basics. An IDP

configuration consists of the following components:

IDP sensor placement—Decide where to position the sensor in the network.

IDP sensor placement mode—Decide to use passive or active mode when

deploying your IDP sensor.

NetScreen-Security Manager—Use NetScreen-Security Manager (NSM) to

administer the sensor.

IDP Sensor Placement

Juniper Networks IDP sensor is an ideal solution to be implemented inline between

gateway firewalls and DMZ or internal networks. IDP sensor placement is an

important part of the installation.

You should choose a location for your IDP sensor based on your existing network

hardware and the networks you want to protect. The examples provided in this

guide place the IDP sensor behind the firewall or router.

IDP Sensor Deployment Mode

IDP sensors can be installed individually or in high availability (HA) clusters of two

or more.

2 IDP Configuration Basics

For configurations without high availability, you can deploy the IDP sensor as a

passive sniffer or as an active gateway.

Passive Mode—The sniffer mode is passive. In sniffer mode, the IDP is not

directly involved with packet flow. While it can send resets, protection is not

guaranteed as attacks may have already happened before the reset can be

acted upon. In addition, attacker machines may ignore resets.

Page 17

Chapter 1: Planning an Installation

To use an IDP sensor as a passive intrusion detection system without

prevention capabilities, deploy the sensor in passive sniffer mode to monitor

and log network traffic. If the sensor is attached to a network switch, you must

configure the switch to mirror all traffic to that port. The IDP sensor defaults to

sniffer mode.

Active mode—The gateway (inline) mode is active. This mode takes full

advantage of IDP attack prevention capabilities and multimethod detection

mechanisms.

With inline modes, the sensor is directly involved in the packet flow. The

sensor can stop attacks by dropping malicious packets before they reach their

target.

Inline sensors are typically configured in transparent mode. For other inline

modes, see “Advanced Configuration” on page 43.

NOTE: For IDP 8200 Release 4.2, only transparent mode is available.

One step in setting up IDP on your network is to decide on a deployment mode.

Figure 1 and Figure 2 illustrate the possible deployment modes and their primary

advantages and disadvantages.

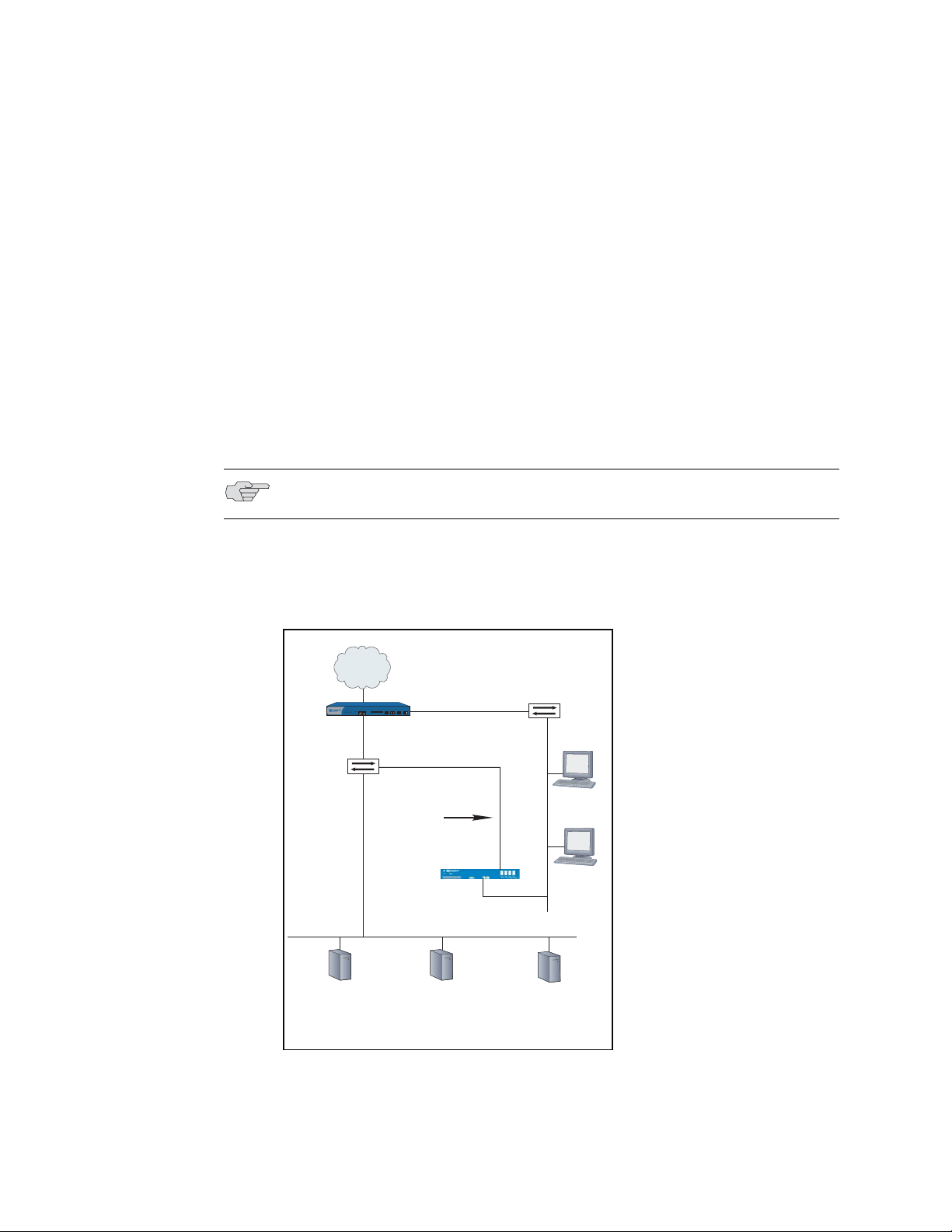

Figure 1: Sniffer Mode (Passive)

Internet

Hub or

eth2

Switch

Management

Server

IP 2.2.2.4

User Interface

IP 2.2.2.5

Firewall

Hub or

Switch

IP 1.1.1.1

IP 2.2.2.1

Mirror or SPAN port, if a switch

straight-through cable

IDP Sensor

MGT

port

eth0 IP 2.2.2.7

Server1

IP 1.1.1.2

GW 1.1.1.1

Server2

IP 1.1.1.3

GW 1.1.1.1

Protected Machines

Server3

IP 1.1.1.4

GW 1.1.1.1

Table 2 lists the advantages and the disadvantages of using the sensor in passive

sniffer mode.

IDP Configuration Basics 3

Page 18

IDP 75, 250, 800, and 8200 Installation Guide

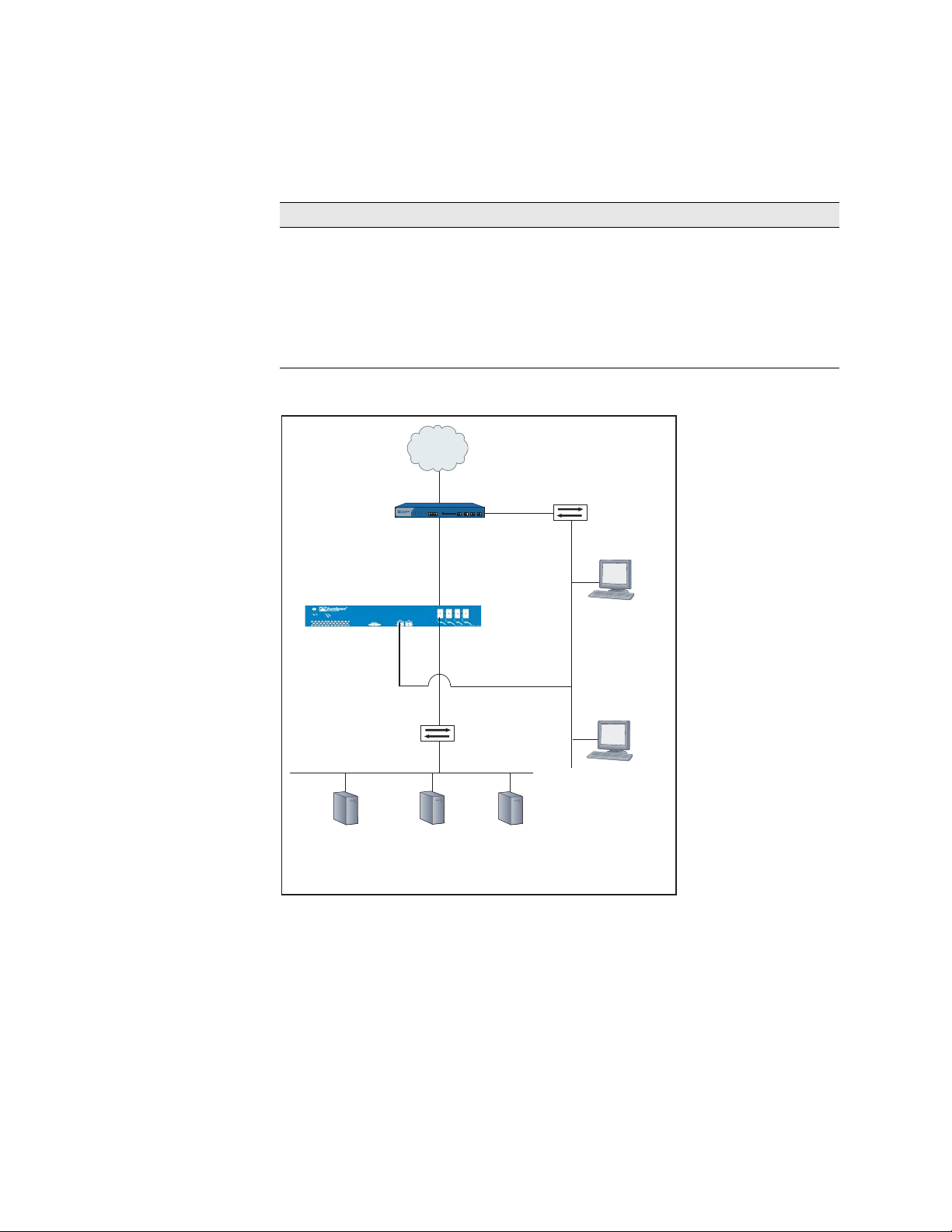

Management Server

IP 2.2.2.4

User Interface

IP 2.2.2.5

Protected Machines

Hub or

Switch

Firewall

eth2

No ip address

Forwarding Interface

Server1

IP 1.1.1.2

GW 1.1.1.1

Server2

IP 1.1.1.3

GW 1.1.1.1

Server3

IP 1.1.1.4

GW 1.1.1.1

IP 2.2.2.1

IP 1.1.1.1

IDP Sensor

Hub or

Switch

eth3

No IP address

Forwarding Interface

eth0 IP 2.2.2.7 MGT

Interface

Internet

Table 2: Advantages and Disadvantages of Sniffer Mode (Passive)

Advantages Disadvantages

Seamlessly replaces the current intrusion

detection

Causes minimal network changes

Does not create an additional

point-of-failure gateway

Monitors and logs suspicious network

activity

Figure 2: Transparent Mode (Inline Active)

Passively monitors with limited prevention

only

Requires a hub or the Switched Port Analyser

(SPAN) port of a switch

4 IDP Configuration Basics

Table 3 lists the advantages and the disadvantages of using the sensor in active

transparent (inline) mode.

Page 19

Table 3: Advantages and Disadvantages of Transparent Mode (Inline Active)

Advantages Disadvantages

Reliably responds to and prevents attacks

Simple, transparent deployment

Allows Layer 2 broadcasts

No changes to routing tables or network

equipment

Forwards non-IP traffic

NetScreen-Security Manager

Use NetScreen-Security Manager to administer the sensor. See the

NetScreen-Security Manager Administrator’s Guide to tailor your security policy to

your network. See the IDP Concepts & Examples Guide to improve the performance

and accuracy of your protection.

Chapter 1: Planning an Installation

Cannot connect IP networks with different

address spaces

IDP Configuration Basics 5

Page 20

IDP 75, 250, 800, and 8200 Installation Guide

6 IDP Configuration Basics

Page 21

Chapter 2

Hardware Overview

This chapter provides detailed descriptions of the Juniper Networks IDP sensors

and their components.

This chapter has the following sections:

IDP Sensors on page 7

Traffic Ports (Forwarding Interfaces) on page 10

Management Ports on page 13

Hard Drives and USB Ports on page 13

Power Supplies on page 13

IDP Sensor LEDs on page 14

IDP Sensors

This section provides an overview of the following IDP sensors:

IDP 75 Sensor on page 8

IDP 250 Sensor on page 8

IDP 800 Sensor on page 8

IDP 8200 Sensor on page 9

Each sensor contains a USB port you can use for reimaging the sensors.

CAUTION: Both the console serial port and the management network interface

port use the same RJ-45 connector. Do not plug a network cable into the console

serial port.

IDP Sensors 7

Page 22

IDP 75, 250, 800, and 8200 Installation Guide

IDP 75 Sensor

The IDP 75 sensor is optimal for small networks or low-speed network segments.

Figure 3 shows the following features:

One console serial port

One management network interface port

One USB port

Two copper Ethernet ports (10/100/1000 Mbps)

Figure 3: IDP 75 Front Panel

IDP 250 Sensor

IDP 800 Sensor

The IDP 250 sensor is optimal for medium central sites or large branch offices.

Figure 4 shows the following features:

One console serial port

One management network interface port

One dedicated high availability port

One USB port

Two IOC slots (each IOC containing four gigabit ports)

Figure 4: IDP 250 Front Panel

The IDP 800 sensor is optimal for medium-to-large central sites or high-traffic

areas. Figure 5 shows the following features:

8 IDP Sensors

One console serial port

One management network interface port

One dedicated high availability port

Page 23

One USB port

Two IOC slots (each IOC containing four gigabit ports)

Two built-in copper Ethernet ports (10/100/1000 Mbps)

Figure 5: IDP 800 Front Panel

Chapter 2: Hardware Overview

IDP 8200 Sensor

The IDP 8200 sensor is optimal for large central sites or high-traffic areas. Figure 6

shows the following features:

One console serial port

One management network interface port

One dedicated high availability port

One USB port

Four IOC slots (each IOC supports 16 copper/fiber 1-Gbit ports, one 10Gbit card

with copper/fiber 1Gbit ports, or two 10Gbit cards with copper\fiber 1Gbit

ports)

IDP Sensors 9

Page 24

IDP 75, 250, 800, and 8200 Installation Guide

Figure 6: IDP 8200 Front Panel

Traffic Ports (Forwarding Interfaces)

The IDP 75, 250, 800, and 8200 sensors have traffic ports (forwarding interfaces),

which are located on the front of each device. Sensors can have a combination of

copper and fiber ports.

Figure 7: Traffic Ports

Configurable NIC States

Copper port pairs on the IDP 75, 250, 800, and 8200 can be configured to take

specified actions when the sensor becomes unavailable. Using the Appliance

Configuration Manager (ACM), you can configure how the sensor responds when it

is shut down gracefully and how it responds when there is a failure.

10 Traffic Ports (Forwarding Interfaces)

Page 25

Table 4: NIC State Options

ACM

Settings

NIC bypass Transparent

External

bypass unit

NICS off All inline

Modes Availability Description

mode only

Transparent

mode only

modes

Chapter 2: Hardware Overview

Sensor failure

Graceful

shutdown

Sensor failure only While sensor is active, it passes NSRP

Sensor failure

Graceful

shutdown

While sensor is active, it does not pass

NSRP packets unless Layer 2 bypass is

enabled.

When sensor becomes unavailable, ports

mechanically join in a crossover. Traffic

continues to flow, but sensor does not

examine traffic.

packets even if Layer 2 bypass is disabled.

On failure, external bypass unit passes

traffic around the sensor.

Note: This is a global setting. If set for any

NIC, NSRP packets are allowed for all NICs.

While sensor is active, it does not pass

NSRP packets unless Layer 2 bypass is

enabled for transparent mode.

When sensor fails or when the sensor

software is shut down, NICs turn off even if

sensor still has power.

Normal State

When the IDP is active and NICs are in the normal state, NICs only pass Layer 2

traffic if in transparent mode and if Layer 2 bypass is enabled. NSRP packets are

not passed, so external bypass units do not behave correctly.

NIC Bypass State

Ethernet copper ports on the IDP 75, 250, 800, and 8200 sensors all have built-in

port bypass with crossover. Port bypass only works if the sensor is configured for

transparent mode. If a sensor fails or is shut down while in transparent mode, the

pair of copper ports will automatically fail into a crossover “connected” state, and

traffic will flow through them to and from the rest of the network without being

analyzed.

NIC bypass works using a watchdog timer. Each port pair has a timer. The sensor

sends each timer a reset signal every second. If a timer does not receive a reset

signal for three seconds (or the configured time period), the bypass is activated.

After the bypass is activated, the timer continues listening for a reset signal. When

IDP becomes active again, it sends a reset signal. When the timer receives the reset

signal, the bypass deactivates automatically and the sensor goes back to normal

operation.

When NICs are in NIC bypass state prior to shutdown or failure, they only pass

Layer 2 traffic if in transparent mode and if Layer 2 bypass is enabled. NSRP

packets are not passed.

Traffic Ports (Forwarding Interfaces) 11

Page 26

IDP 75, 250, 800, and 8200 Installation Guide

The fiber Ethernet ports are standard interfaces and do not incorporate the

integrated bypass feature. Automatic bypass is available for fiber ports through

third-party devices.

NIC Bypass and Cable Choices

When NIC bypass becomes active, it physically connects the pair of forwarding

interfaces to each other with a crossover cable.

If you are connecting devices that support auto-MDIX (medium dependent interface

crossover) to automatically switch to the proper configuration after a cable is

connected, and then you can use whatever cables you want, because auto-MDIX

negotiates the correct connection. However, if neither of the devices supports

auto-MDIX, and then you need to take special care to choose the right cables.

Suppose two devices, one connected to one sensor port and the other connected to

the other sensor port, are instead connected directly together.

If the two devices are connected with a straight-through cable, use one

straight-through cable and one crossover cable to connect the sensor to these

devices. When NIC bypass starts, the resulting effect is to create one, long

straight-through cable connecting the devices.

If the two devices are connected with a cross-over cable, use two

straight-through cables to connect the sensor to these two devices. When NIC

bypass starts, the resulting effect is to create one, long straight-through cable

connecting the devices.

External Bypass Unit State

This state is only available when the sensor is in transparent mode. It behaves the

same as normal state, except that NSRP packets are passed even if Layer 2 bypass

is not enabled.

NOTE: The External Bypass Unit setting is global. Selecting it for any interface

pair enables it for all interface pairs on the sensor. If enabled for one interface

pair, all interface pairs pass NSRP packets regardless of their individual settings.

The external bypass unit state appears only in the after system unavailability list

of the ACM. However, selecting it there enables it globally for all states.

NICs Off State

During sensor operation, this state behaves the same as normal state. NSRP

heartbeats are not passed unless the sensor is in transparent mode and Layer 2

bypass is enabled. The difference is this: when the sensor software becomes

unavailable because of graceful shutdown or unexpected failure, the NICs turn off

and no longer appear live to other devices on the network.

This setting is not global. It must be selected for each interface pair and in each

mode (after system unavailability and after graceful shutdown).

12 Traffic Ports (Forwarding Interfaces)

Page 27

Peer Port Modulation

Management Ports

Chapter 2: Hardware Overview

After peer port modulation (PPM) is enabled, the sensor deactivates all the

interfaces in that virtual router if the link goes down for any of the interfaces in a

virtual router. All devices connected to the virtual router will detect a port failure

and must be configured to take appropriate action.

You cannot enable NIC bypass and PPM on the same sensor. On the IDP 75, 250,

800, and 8200 sensors:

PPM works on both copper and fiber interfaces.

PPM works by turning off appropriate interfaces. Because of this, interface

speeds can be set to auto on the sensor and on attached switches.

These ports are provided on all IDP sensors.

Console Serial Port

The console serial port provides access, using an RJ-45 connector, to the sensor’s

command-line interface (CLI).

Management Port

The management port provides access to the ACM to the sensor through

10/100/1000 Mbps Ethernet. The ACM is accessed from the management port and

entering the correct URL in a browser window (

NOTE: Although both the console serial port and the management port use RJ-45

connectors, do not plug the network cable into the console serial port.

Hard Drives and USB Ports

Table 5 describes the hard drives and USB ports available on each sensor.

Table 5: IDP Sensor Drives

IDP Sensor Drives

75, 250 One USB port

800, 8200 One USB port

https://SensorIPAddress).

One internal hard drive

Two externally accessible, hot-swappable, RAID-1

mirrored hard drives

Power Supplies

Table 6 describes the types of power supplies available on each sensor.

Management Ports 13

Page 28

IDP 75, 250, 800, and 8200 Installation Guide

Table 6: IDP Sensor Power Supplies

IDP Sensor Power Supplies

75 One fixed power supply.

250 One removable power supply.

800, 8200 Two removable hot-swappable power supplies.

IDP Sensor LEDs

This section describes the LEDs for the following IDP sensor components:

System status

Management and high availability ports

Both sensors are shipped with the AC power supply.

The DC power supplies are optional as FRUs.

System Status LEDs

Traffic ports

Hard drives

Power supply (back panel)

The IDP 75, 250, 800, and 8200 sensors each have three system status lights on

the front panel to indicate power, hard drive activity, and overheating. See Table 7.

Table 7: Front Panel System Status LEDs

Color Function LED Action Status Description

Green Power Stays on when powered on.

Stays off when powered off.

Yellow Hard drive activity Flickers with activity.

Red Fault

Blinks slowly when a fan fails.

Blinks quickly when system is overheated.

Stays on when the power supply fails.

Stays off when the system is functioning at a normal

temperature.

Management and High Availability Port LEDs

14 IDP Sensor LEDs

Management and high availability (HA) ports each have two LEDs—LINK and

TX/RX (Figure 8). Management ports are on all sensors. HA ports are available on

the IDP 250, 800, and 8200 sensors only. Table 8 describes the LEDs for

management and HA ports

Page 29

Figure 8: LEDs for Management and HA Ports

Table 8: IDP Sensor Management and High Availability Port LED

Port LED Description Status

LINK Port connection/

activity indicator.

TX/RX Speed indicator.

Blinks amber to indicate activity on the port.

Stays off for 10 Mbps.

Glows green for 100 Mbps.

Glows amber for 1000 Mbps.

Chapter 2: Hardware Overview

Traffic Port LEDs

The IDP 75, 250, 800, and 8200 sensors each have two traffic status LEDs on each

traffic port.

Table 9: IDP Sensor Traffic Port LEDs

Indicator Location Color/Status Speed/Description

Link Activity Left LED Green Stays on when there is a link.

Link Speed Right LED None 10 Mbps

Hard Drive LEDs on Front Panel

The front panel of the sensors provide access to hard disk drives for 800 and 8200

sensors only. Table 10 shows the hard drive LED definitions for the 800 and the

8200 sensors.

Stays off when there is no link.

Blinks when there is activity.

Green 100 Mbps

Yellow 1 Gbps

Orange 10 Gbps

IDP Sensor LEDs 15

Page 30

IDP 75, 250, 800, and 8200 Installation Guide

Table 10: Hard Drive LED Definitions

Front Panel LED Description

Hard drive failure (800 and

8200 only)

Hard drive activity

(800 and 8200 only)

Power Supply LEDs on Back Panel

The back panel of the sensors provide access to power supplies on the 800 and

8200 sensors only. Table 11 shows the power supply LED definitions for the 800

and the 8200 sensors.

The left LED on the hard drive. The LED is off if the hard drive is

functioning normally. The LED is red if the hard drive has failed. In

addition, the system emits a high-pitch noise if a hard drive has

failed.

The LED flashes red if the drive is being rebuilt. Do not turn the

power off, unplug the unit, or remove either drive while the drive is

being rebuilt.

The right LED on the hard drive. The LED flashes green to indicate

hard drive activity.

Table 11: Power Supply LED Definitions

Back Panel LED Description

Power Supply Status (800

and 8200 only)

The LED is located on the power supply above the plug socket. It

glows amber to indicate that the power supply is receiving power. It

glows green to indicate that the power supply is powering the unit.

If a power supply has failed, or is not receiving power, the system

emits a high-pitched whine.

16 IDP Sensor LEDs

Page 31

Chapter 3

Installing the Sensor

This chapter describes how to install the IDP sensor in an equipment rack. This

chapter has the following sections:

General Installation Guidelines on page 17

Rack Mounting the IDP Sensor on page 18

Connecting Power on page 20

General Installation Guidelines

Observing the following precautions can prevent injuries, equipment failures, and

shutdowns.

WARNING: Never assume that the power supply is disconnected from a power

source. Always check first.

CAUTION: Room temperature might not be sufficient to keep equipment at

acceptable temperatures without an additional circulation system. Ensure that the

room in which you operate the IDP sensor has adequate air circulation.

Do not work alone if potentially hazardous conditions exist.

Look carefully for possible hazards in your work area, such as moist floors,

ungrounded power extension cables, frayed power cords, and missing safety

grounds.

NOTE: Although you can place the IDP sensor on a desktop for operation, we do

not recommend deploying it in this manner.

CAUTION: To prevent abuse and intrusion by unauthorized personnel, it is

extremely important to install the IDP sensor in a locked-room environment.

General Installation Guidelines 17

Page 32

IDP 75, 250, 800, and 8200 Installation Guide

Rack Mounting the IDP Sensor

The location of the sensor and the layout of your equipment rack or wiring room

are crucial for proper system operation.

Use the following guidelines while configuring your equipment rack.

Enclosed racks must have adequate ventilation. An enclosed rack should have

louvered sides and a fan to provide cooling air.

When mounting a chassis in an open rack, ensure that the rack frame does not

block the intake or exhaust ports. If you install a chassis on slides, check the

position of the chassis when it is seated all the way into the rack.

In an enclosed rack with a ventilation fan in the top, equipment higher in the

rack can draw heat from the lower devices. Always provide adequate

ventilation for equipment at the bottom of the rack.

Required Tools

Baffles can isolate exhaust air from intake air. The best placement of the baffles

depends on the airflow patterns in the rack.

The IDP 75 sensor occupies one rack unit (RU) in an equipment rack. One RU is

1.75 inches (44.45 mm) high. The IDP 250, IDP 800 (copper ports), and IDP 8200

sensors occupy two rack units in an equipment rack.

Rack mounting requires the following tools:

Flathead screwdriver

Number 2 Phillips-head screwdriver

Rack-compatible screws

Rack-mounting brackets (included). Each device comes with the following

brackets:

Two side-mounted rails for mounting to the front and back of the rack

Four midmount brackets for midmounting 2 RU devices

Two midmount brackets for midmounting 1 RU devices

Mounting Using Device Rack Rails

18 Rack Mounting the IDP Sensor

To mount the sensor using the rails in a device rack:

1. Use a flathead screwdriver to attach the rails to each side of the chassis with

the bracket screws. Make sure the hinged brackets are at the back of the

device. Make sure the rails are positioned so they reach the back of the rack

when the device is mounted. See Figure 9.

Page 33

Chapter 3: Installing the Sensor

Figure 9: Rail with Hinged Rear Bracket

2. Rotate the hinges on both rails so that they allow the device to slide into the

rack.

3. Slide the chassis into a set of rails.

CAUTION: Be sure to leave at least two inches of clearance on the sides of each

chassis for the cooling air inlet and exhaust ports.

4. Secure the front brackets to the rack.

5. Rotate the rear brackets so they prevent the device from sliding forward.

6. Secure the rear brackets to the rack.

Mounting Using Midmount Brackets

To mount the sensor using the midmount brackets in a device rack:

1. Use a flathead screwdriver to attach one rack-mounting bracket to each side of

the chassis with the bracket screws. See Figure 10 and Figure 11.

Figure 10: 2 RU Device Midmount Bracket

Rack Mounting the IDP Sensor 19

Page 34

IDP 75, 250, 800, and 8200 Installation Guide

Figure 11: 1 RU Device (IDP 75) Midmount Bracket

2. Place the chassis into position between rack posts in the equipment rack and

align the rack mounting bracket holes with the rack post holes.

Connecting Power

CAUTION: Be sure to leave at least two inches of clearance on the sides of each

chassis for the cooling air inlet and exhaust ports.

3. Attach the rack-mounting brackets on each chassis to the rack with the

appropriate rack screws.

4. (For 2 RU devices only) Attach the other two midmount brackets to the chassis

and the back of the rack to hold the device securely in place.

NOTE: Power is provided to the IDP sensor using 90/264 VAC from your facility.

To connect power to your sensor:

1. Connect the provided power cable to the receptacle on the power supply at the

rear of each chassis.

2. Connect the other end of the power cable to the electrical outlet.

3. (For IDP 800 and 8200 sensors only) Connect the second power cable to the

receptacle on the second power supply. This step is optional for the IDP 8200

sensor.

20 Connecting Power

4. (For IDP 800 and 8200 sensors only) Connect the other end of the second

power cable to the electrical outlet. This step is optional for the IDP 8200

sensor.

NOTE: If you have two power supplies and do not connect both of them, the PS

FAIL warning light illuminates and the sensor emits a warning tone when it is

turned on.

Page 35

Chapter 4

Configuring the IDP Sensor

This chapter describes how to connect to the IDP sensor and configure the device

for your network. After you have configured the sensor, you need to connect the

device in your network.

This chapter has the following sections:

Initial Configuration Options on page 21

Connecting to the Sensor on page 22

Connecting Forwarding Interfaces on page 28

Verifying Traffic Flow on page 28

Connecting the High Availability Port on page 28

Initial Configuration Options

When you first configure your sensor, you can choose a simple configuration that

sets options to the most commonly used settings, or you can do an advanced

configuration that allows you to choose each option individually.

Simple Configuration

A simple configuration can be done using the console serial port and the

EasyConfig utility, or through the management port and the QuickStart utility.

Simple Configuration Settings

A simple configuration lets you specify the following settings:

Sensor mode (inline transparent or passive sniffer)

IP address

Netmask

Default gateway

Time and time zone

Initial Configuration Options 21

Page 36

IDP 75, 250, 800, and 8200 Installation Guide

Simple Configuration Values

A simple configuration has the following settings and values:

Root password—abc123

Fully qualified domain name—Blank

High availability mode—Disabled

RADIUS support—Disabled

Network interfaces—Auto

Virtual routers—

Sniffer mode: One virtual router created (vr0)

Transparent mode: One virtual router created for each pair of interfaces

DNS—Disabled

NTP—Disabled

SSH on management port—Enabled

Run ACM process on sensor startup—Enabled

Advanced Configuration

If you wish to use a sensor mode other than inline transparent or passive sniffer, or

if you do not want to use the default options for the other settings, you will have to

use the Appliance Configuration Manager. See “ACM Advanced Configuration” on

page 26.

Connecting to the Sensor

Your sensor has two management interfaces: a console serial port and a

management Ethernet port. You can use either one to set the sensor IP address and

other basic configuration parameters.

The console serial port is used only for configuring and troubleshooting. After the

sensor is configured, you can disconnect the console port. The management port,

however, must be able to reach the NSM device server over the network. For this

reason, you must give the sensor an IP address that the NSM device server can

reach.

Using the Console Serial Port to Configure the Sensor

22 Connecting to the Sensor

Use this procedure if you want to set up your sensor in simple configuration, or if

you just want to set an IP address so the sensor is reachable over the network. After

the sensor’s management interface settings are in place, you can reconfigure the

sensor over the network.

Page 37

Chapter 4: Configuring the IDP Sensor

To configure your sensor using the console serial port, do the following:

1. Connect one end of the provided RJ-45 null modem serial cable to the

CONSOLE port located on the front of the sensor chassis.

2. Connect the other end of the cable to the serial port of your workstation.

3. Open a terminal emulation package such as Microsoft Windows HyperTerminal

or XModem. The settings for the software should be as follows:

9600 bps

8 data bits

No parity generation or checking

1 stop bit

No flow control

The serial port number where you connected the cable

4. Turn on the IDP sensor.

If nothing appears in the terminal window, press Enter to display the boot

messages.

5. Log into the IDP sensor as name (root) and password (abc123).

The EasyConfig script runs automatically. The following text appears:

Configuring the deployment mode...

The currently supported deployment modes in EasyConfig are the following,

1. Sniffer <default>

2. Inline transparent

Choose the deployment mode? [1]

6. Press 1 or 2, depending on which mode you want to use, and then press Enter.

The following text appears:

Configuring Management interface...

The management interface is currently configured as:

IP: 192.168.1.1

Mask: 255.255.255.0

What IP address do you want to configure for the management interface?

[192.168.1.1]

7. Type an IP address and press Enter.

The following text appears:

What netmask do you want to configure for the management interface?

[255.255.255.0]

8. Type your netmask and press Enter.

Connecting to the Sensor 23

Page 38

IDP 75, 250, 800, and 8200 Installation Guide

The system configures your interfaces. The following text appears:

Configuring default route...

The current default route is: X.X.X.X

Do you want to change the default route? (y/n) [n]

9. Type Y, and then press Enter.

The following text appears:

What IP address do you want to configure as default route? [X.X.X.X]

10. Type your default route (gateway address) and press Enter.

The system asks if you want to change the system time.

Configuring system time...

Currently configured time is Wed Jan 18 16:32:32 PST 2006

Do you want to change the system time? (y/n) [n]

11 . T y p e N if the time is correct. If the time is not correct, type Y and follow the

prompts to change the system time.

Configuration of the management port is now complete. EasyConfig does not run

the next time you log into the sensor.

Using the Management Port to Configure the Sensor

You can choose a simple or advanced configuration for the sensor using the

management port.

To connect the dedicated management port:

1. Attach your Ethernet cable to the dedicated management RJ-45 port (MGT)

located at the front of the chassis.

2. Connect the other end of your Ethernet cable to a switch or hub

(recommended) or to a standalone computer.

Verify that the link LED on the management port is green, indicating a proper

connection. (See Table 8 on page 15.)

Connecting Directly Using the Management Port

You can configure your sensor by directly connecting to the management port with

a crossover Ethernet cable. The default IP address of the sensor is 192.168.1.1 in

the Address or Location box.

24 Connecting to the Sensor

To connect directly to the management port:

1. Connect your computer directly to the sensor using an Ethernet cable.

Page 39

Chapter 4: Configuring the IDP Sensor

2. On a connected computer, open a Web browser. Type https://192.168.1.1.

NOTE: Because the ACM uses an SSL connection, you must type https:// before the

IP address.

3. Type the default user name (root) and password (abc123).

4. Skip to “Simple or Advanced Configuration Using the Management Port” on

page 25.

Connecting Remotely Using the Management Port

To connect to the management port remotely over the network, you must first have

configured an IP address for the sensor. See “Using the Console Serial Port to

Configure the Sensor” on page 22.

To connect remotely to the management port:

1. On a connected computer, open a Web browser.

2. Type the URL of the ACM wizard using the IP address you configured. For

example, if you configured the IP address 10.100.200.1 on the IDP sensor,

type https://10.100.200.1 in the browser’s Address or Location box.

NOTE: Because the ACM uses an SSL connection, you must type https:// before the

IP address.

3. Type the default user name (root) and password (abc123).

4. Go to “Simple or Advanced Configuration Using the Management Port” on

page 25.

Simple or Advanced Configuration Using the Management Port

The IDP sensor management port provides two different, but compatible,

configuration paths. The QuickStart option lets you configure the default IDP

settings quickly, while the Appliance Configuration Manager (ACM) option lets you

make more advanced changes to the sensor configuration.

After you log into the Web-based tools using the management port, you are

presented with two options: QuickStart and ACM. If you want to do a simple

configuration, click QuickStart and fill out the fields based on the information in

Table 12 on page 26.

If you want to do an advance configuration, click ACM, and then click Start

Configuration Wizard. Fill out the fields in the wizard based on the information in

Table 13 on page 26.

Connecting to the Sensor 25

Page 40

IDP 75, 250, 800, and 8200 Installation Guide

QuickStart Simple Configuration

Table 12 provides the information you need for a simple configuration.

Table 12: Information Needed for QuickStart Configuration

Field Configuration Information

Device

Deployment

mode

Management

Interface IP

Address

Management

Interface

Netmask

Default Route Your network’s default route.

Timezone/ Date/

Time

Other settings All other settings are the same as for “Simple Configuration” on page 21.

QuickStart offers the two most popular deployment modes. If you want to

use one of the other deployment modes, use the ACM instead.

Sniffer—You want the sensor to report on security events, but not take

action to prevent them.

Inline transparent—You want traffic to flow through the sensor. In this

mode, the sensor can block or drop traffic that violates security

parameters.

The IP address of the sensor management interface.

The netmask for the management interface IP address.

The time zone, date, and time where the sensor resides.

ACM Advanced Configuration

The ACM controls advanced configuration options, such as RADIUS, DNS, and SSH

configurations.

The sections listed in Table 13 correspond to sections in the ACM wizard. To start

the wizard, open ACM, then select ACM from the initial page.

For detailed information about ACM, see the ACM online help.

Table 13: Information Needed for ACM Configuration

Section Configuration Information

Setup IDP sensor root and admin passwords (default is abc123).

The new passwords you want to assign to the root and admin accounts.

The fully qualified domain name that you want to assign to the sensor.

(Example: Sensor1.example.com)

Mode

Deployment mode you have chosen: sniffer, router, bridge, transparent, or

proxy-ARP. If the mode you wish to use is already selected, select it again to

progress to the next screen. (The following modes are not available on the

IDP 8200 sensor: router, bridge, and proxy.)

For transparent mode, specify whether to enable Layer 2 bypass.

Your need for HA. See “Planning an Installation” on page 1. More

information on HA modes can be found in the NetScreen-Security Manager

Adm inistrato r’s Gu ide.

26 Connecting to the Sensor

Page 41

Chapter 4: Configuring the IDP Sensor

Table 13: Information Needed for ACM Configuration (continued)

Section Configuration Information

Networking Speed and duplex settings for IDP sensor interfaces. (Normally, these can be

set to auto-detect. With some switches, the speed and duplex settings have

to be set manually.)

The VLAN interfaces you want to configure.

Virtual LANs are not available for transparent or sniffer mode, though

security policies can apply rules based on VLAN tagging in these modes.

The virtual router information you want to configure.

More information on virtual routers can be found in the NetScreen-Security

Manager Administrator’s Guide.

The IP address and netmask for the management interface.

Forwarding interface information, such as, which ports will be connected to

which external devices.

Routing table.

System

Enable/configure DNS.

This is optional. Set if you want the sensor to be able to do DNS lookups.

Time and time zone.

Enable/configure NTP.

This is optional. Set if you want the IDP device to get its time information

from an NTP server.

Enable/configure RADIUS support.

This is optional. Set if you want certain users to be authenticated using

RADIUS. You can enable RADIUS authentication for CLI access, ACM access,

or both.

Enable/configure SSH access.

This is optional. Set if you want to access the sensor using a terminal

window, or if you want to be able to upload upgrade files to the sensor.

See the ACM online help for more information on system settings.

Management

IP address of the primary and secondary NSM GUI servers for this sensor and

a one-time password.

These values need to be set only if you are using the IP unreachable method

of adding devices to NSM. See the NetScreen-Security Manager

Adm inistrato r’s Gu ide.

Enable/configure ACM access.

Set if you want ACM to start automatically when the sensor boots.

Otherwise, you have to start ACM from the command line before you access

it.

Instant Virtual Extranet (IVE) communications.

Select Reset IVE OTP if you want to generate a one-time password for

IVE-IDP communications.

Complete information for configuring IVE-IDP communications is in the IVE

documentation.

Done View the current configuration and then save and apply the configuration to the

IDP sensor. (The Save Only option button tells the sensor to save the

configuration into a working file, but not to apply the configuration to the

sensor. The Save & Apply option button tell the sensor to apply the changes.)

You need to click Confirm Configuration, and then reboot the IDP sensor for

the changes to take effect.

Connecting to the Sensor 27

Page 42

IDP 75, 250, 800, and 8200 Installation Guide

In proxy-ARP or router mode, if you are using multiple subnets in your protected

network, you must configure static routes on the IDP sensor to these subnets.

Without static routes, incoming traffic to those subnets can be lost. Alternatively,

you can create a static route from the IDP sensor to an internal gateway that

contains inbound routes to the protected subnets. (This does not apply to the IDP

8200 sensor.)

Connecting Forwarding Interfaces

Connect the ports on the sensor to either the protected network or the external

network. See “Planning an Installation” on page 1 for the configuration you chose

to implement. See “NIC Bypass and Cable Choices” on page 12 for information on

using NIC bypass with transparent mode.

Inline transparent mode makes use of pairs of interfaces. On most sensors, the

pairs are horizontal port pairs 0-1and 2-3 on each NIC. Traffic in inline transparent

mode only flows between paired interfaces. You cannot have traffic flow from port

0 to port 2, for example, in inline transparent mode.

Other modes, such as router and proxy-ARP mode, do support non-paired

interfaces.

Verifying Traffic Flow

To verify that traffic is flowing through your sensor:

1. Make sure your sensor is connected to a live traffic feed.

2. Log onto the sensor as root using the console serial port, or open an SSH

3. Type sctop and press Enter.

4. Type s to see status information.

5. Examine the following information on the screen:

6. Make sure the UDP or TCP values are changing.

connection to the management port.

Protocol Packets Flows Sessions Peak Peak Time

Other 2 0 0 1 08/09/2006 03:08:07

ICMP 3 0 0 0 08/08/2006 18:03:51

UDP 3386 3 1 7 08/08/2006 19:31:01

TCP 151164 12 6 9 08/09/2006 07:01:36

Connecting the High Availability Port

28 Connecting Forwarding Interfaces

After you have set up both machines in the HA cluster, connect their HA ports to

each other using a crossover cable.

Page 43

Chapter 5

Adding the Sensor to NSM

This chapter describes how to add the IDP sensor to NetScreen-Security Manager

(NSM) and push the Recommended policy. When you have completed the steps in

this chapter, your IDP sensor will be protecting your network.

You must have NSM installed to complete the steps in this chapter. See the

NetScreen-Security Manager Installation Guide.

This chapter has the following sections:

Adding Your Sensor to NSM on page 29

Checking the Status of Your Sensor on page 33

Adding Your Sensor to NSM

This procedure assumes your sensor is installed, has a static IP address, and is

reachable using SSH. If your sensor is not yet available, has a dynamic IP address,

or is not reachable using SSH, see the IDP Concepts and Examples Guide for other

procedures.

To import an IDP 75, 250, 800, or 8200 sensor with a known IP address:

1. In NSM, select Tools > View / Update NSM Attack Database to run the attack

database wizard. This makes sure your attack database is up to date.

2. From the domain menu, select the domain in which to import the device.

3. Select Device Manager > Security Devices from the left navigation pane

(Figure 12).

Adding Your Sensor to NSM 29

Page 44

IDP 75, 250, 800, and 8200 Installation Guide

Figure 12: Begin Add Device Procedure

4. On the Security Devices age, click the +button and select Device to open the

Add Device wizard (Figure 13).

a. Type a name and select a color to represent the device in the UI.

b. Select Device is Reachable (default).

Figure 13: Add Device Wizard - Device Name

5. Click Next to display the Specify Connection Settings dialog box (Figure 14).

30 Adding Your Sensor to NSM

Page 45

Figure 14: Add Device Wizard - Connection Settings

Chapter 5: Adding the Sensor to NSM

6. Enter the following connection information:

NOTE: All passwords handled by NetScreen-Security Manager are case-sensitive.

a. Enter the IP address of the sensor.

b. Enter admin in the Admin User Name box.

c. Enter the password for the admin user name. The default password is

abc123.

d. Enter the password for the device root user. The default password is

abc123.

e. Select SSH Version 2 as the connection method. Leave the port number as

22.

f. Click Next to open the Verify Device Authenticity dialog box (Figure 15).

After a moment, the wizard displays the SSH key fingerprint information.

Figure 15: Add Device Wizard - Verification Settings

Adding Your Sensor to NSM 31

Page 46

IDP 75, 250, 800, and 8200 Installation Guide

7. Verify the SSH key fingerprint to prevent man-in-the-middle attacks:

a. Connect a PC or terminal to the IDP sensor using the console serial port.

b. Log in as root.

c. Type

cd /etc/ssh

and press Enter.

d. Type ssh-keygen -l -f ssh_host_dsa_key and press Enter.

You see something similar to this:

1024 f4:91:d0:04:b7:61:00:77:45:c3:cc:bd:af:b3:5b:a2 ssh_host_dsa_key.pub

8. After you have verified the key, click Next to display device information

retrievable by NSM (Figure 16). This takes a moment.

Figure 16: Add Device Wizard - Retrieved Settings

32 Adding Your Sensor to NSM

9. Verify that the device type, OS version, device serial number, and device mode

are correct.

10. Click Next to add the sensor to NSM as a managed device. (See Figure 17.)

Figure 17: Add Device Wizard - Adding the Device

11. Click Next to have NSM import settings already present on the sensor. (See

Figure 18.)

Page 47

Figure 18: Add Device Wizard - Importing the Device

12. Click Finish to update the sensor with the Juniper Networks Recommended

policy.

The Job Information dialog shows box the status of the Update Device job.

Checking the Status of Your Sensor

When the update device job finishes, move the mouse pointer over the device in

Device Manager to check the device status. The configuration state

indicates that the device is connected and that the management system has

successfully imported the device configuration (Figure 19).

Chapter 5: Adding the Sensor to NSM

Managed

Figure 19: Viewing Device Status

NSM is now managing your sensor. See the IDP Concepts & Examples Guide for

more information on managing your sensor.

Checking the Status of Your Sensor 33

Page 48

IDP 75, 250, 800, and 8200 Installation Guide

34 Checking the Status of Your Sensor

Page 49

Chapter 6

Updating Software on the Sensor

This chapter describes how to update the software on an IDP sensor. It has the

following sections:

Updating IDP Sensor Software Using NSM Firmware Manager on page 35

Updating IDP Sensor Software Without NSM on page 36

Reimaging the IDP Sensor on page 37

Updating IDP Sensor Software Using NSM Firmware Manager

You can use NSM to upgrade your IDP sensors. First, you must load a new sensor

image to NSM. Then, use NSM to load the new image onto your sensors.

Loading a Sensor Image into NSM

To make the sensor software available to NSM:

1. Download firmware image files from Juniper Networks onto the computer

running the NSM GUI.

2. In NSM, select Device Manager > Security Devices from the left navigation

pane.

3. From the menu bar, select Tools > Firmware Manager. The Firmware

Manager dialog box appears.

4. Click the + button to open the Open dialog box.

5. Select the image file on the computer running NSM and click Open. The image

file appears in the Firmware Manager dialog box, displaying the image name,

version, and applicable devices.

6. Click OK.

Updating IDP Sensor Software Using NSM Firmware Manager 35

Page 50

IDP 75, 250, 800, and 8200 Installation Guide

Upgrading Sensor Software

After you have made the software available to NSM, you can use NSM to upgrade

the sensor.

To upgrade the sensor using NSM:

1. From the menu bar, select Devices > Firmware > Change Device Firmware

to open the Change Device Firmware dialog box.

2. Select the devices whose firmware you want to upgrade.

3. Select the firmware you want installed on the device in the Select Target

Firmware Version box.

4. Click Next to display the device(s) and firmware that NetScreen-Security

Manager is to install in the Firmware Update Availability dialog box.

5. Select Automate ADM Transformation to automatically update the Abstract

Data Model (ADM) for the device after NSM installs the firmware. If you clear

the Automate ADM Transformation checkbox, the firmware is installed onto

the device, but you cannot manage the device from NSM until the device ADM

is updated.

6. Click Finish to display upgrade status in the Job Information dialog box.

7. When the upgrade finishes, click Close to exit the Job Information dialog box.

Updating IDP Sensor Software Without NSM

New versions of the IDP sensor software may be made available online or on a

CD-ROM.

To install the new software:

1. Verify that you have SSH enabled for the Management Port (eth0).

To enable SSH, access ACM by typing

Location box of the Web browser. Then select Modify SSH Access from the

ACM home page and follow the prompts.

access ACM by typing

the Web browser.

2. Download the sensor software from Juniper Networks and copy the file to the

/tmp directory of the sensor.

3. Unplug the HA port cable, if one is attached.

4. Log into the IDP sensor as root using the console serial port.

https://sensorIPaddress in the Address or Location box of

https://sensorIPaddress in the Address or

5. Change to the

6. Type

The sensor update script runs.

36 Updating IDP Sensor Software Without NSM

/tmp directory.

sh sensor_<version>.sh

and press Enter.

Page 51

7. Reboot the device when the script is finished.

Chapter 6: Updating Software on the Sensor

8. Type

9. Reconnect the HA cable after upgrading all of the sensors in the cluster.

10. In NSM, right-click the sensor in Device Manager, and then select Adjust OS

Vers i o n .

Reimaging the IDP Sensor

Each IDP sensor comes with software preinstalled. However, if you need to reload

the software onto your sensor, you can use the USB stick that was shipped with the

sensor. This process is known as imaging.

NOTE: You will need to reinstall the license when reimaging the IDP sensor.

Contact JTAC for information on how to obtain your license information. Go to

Requesting Technical Support on page xii for information on how to contact JTAC.