Page 1

G10 CMTS

Hardware Guide

Release 3.0

Juniper Networks, Inc.

1194 North Mathilda Avenue

Sunnyvale, CA 94089

USA

408-745-2000

www.juniper.net

Part Number: 530-009111-01, Revision 1

Page 2

This product includes the Envoy SNMP Engine, developed by Epilogue Technology, an Integrated Systems Company. Copyright © 1986–1997, Epilogue

•

Technology Corporation. All rights reserved. This program and its documentation were developed at private expense, and no part of them is in the public

•

domain.

•

•

This product includes memory allocation software developed by Mark Moraes, copyright © 1988, 1989, 1993, University of Toronto.

•

This product includes FreeBSD software developed by the University of California, Berkeley, and its contributors. All of the documentation and software

•

included in the 4.4BSD and 4.4BSD-Lite Releases is copyrighted by The Regents of the University of California. Copyright © 1979, 1980, 1983, 1986, 1988,

•

1989, 1991, 1992, 1993, 1994. The Regents of the University of California. All rights reserved.

•

GateD software copyright © 1995, The Regents of the University. All rights reserved. Gate Daemon was originated and developed through release 3.0 by

•

Cornell University and its collaborators. Gated is based on Kirton’s EGP, UC Berkeley’s routing daemon (routed), and DCN’s HELLO routing protocol.

•

Development of Gated has been supported in part by the National Science Foundation. Portions of the GateD software copyright © 1988, Regents of the

•

University of California. All rights reserved. Portions of the GateD software copyright © 1991, D. L. S. Associates.

•

This product includes software developed by Maker Communications, Inc., Copyright © 1996, 1997, Maker Communications, Inc.

•

•

Juniper Networks is registered in the U.S. Patent and Trademark Office and in other countries as a trademark of Juniper Networks, Inc. Broadband Cable

•

Processor, ERX, ESP, G10, Internet Processor, JUNOS, JUNOScript, M5, M10, M20, M40, M40e, M160, MRX, M-series, NMC-RX, SDX, ServiceGuard, T320,

T640, T-series, UMC, and Unison are trademarks of Juniper Networks, Inc. All other trademarks, service marks, registered trademarks, or registered service

•

marks are the property of their respective owners. All specifications are subject to change without notice.

•

•

G10 CMTS Hardware Guide

Copyright © 2003, Juniper Networks, Inc.

•

All rights reserved. Printed in USA.

•

•

Writer: Jerry Isaac

•

Editor: Stella Hackell

Illustrations: Paul Gilman

•

Covers and template design: Edmonds Design

•

•

Revision History

14 May 2003—First Edition.

•

•

The information in this document is current as of the date listed in the revision history.

•

•

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right to change, modify, transfer or

otherwise revise this publication without notice.

•

•

Products made or sold by Juniper Networks (including the M5, M10, M20, M40, M40e, and M160 routers, T320 router, T640 routing node, and the JUNOS

•

software) or components thereof might be covered by one or more of the following patents that are owned by or licensed to Juniper Networks: U.S. Patent

•

Nos. 5,473,599, 5,905,725, 5,909,440, 6,333,650, 6,359,479, and 6,406,312.

•

YEAR 2000 NOTICE

•

•

Juniper Networks hardware and software products are Year 2000 compliant. The JUNOS software has no known time-related limitations through the year

•

2038. However, the NTP application is known to have some difficulty in the year 2036.

•

SOFTWARE LICENSE

•

•

The terms and conditions for using this software are described in the software license contained in the acknowledgment to your purchase order or, to the

extent applicable, to any reseller agreement or end-user purchase agreement executed between you and Juniper Networks. By using this software, you

•

indicate that you understand and agree to be bound by those terms and conditions.

•

•

Generally speaking, the software license restricts the manner in which you are permitted to use the software and may contain prohibitions against certain

•

uses. The software license may state conditions under which the license is automatically terminated. You should consult the license for further details.

•

For complete product documentation, please see the Juniper Networks Web site at www.juniper.net/techpubs.

•

•

The Chassis Control Module and its corresponding JUNOSg software perform encryption that is subject to U.S. Customs and Export regulations and shall not

•

be exported, sold or transferred to a country outside the USA and Canada without an appropriate export license from the U.S. Government. The specific

Regulations governing exports of encryption products are set forth in the Export Administration Regulations, 15 C.F.R. (Code of Federal Regulations), Parts

•

730-774.

•

•

•

•

•

•

•

•

•

ii

Page 3

Table of Contents

About This Manual

Objectives............................................................................................................xiii

Audience.............................................................................................................. xiv

Document Organization....................................................................................... xiv

Related Documents.............................................................................................. xiv

Documentation Conventions ................................................................................ xv

Notes, Cautions, and Warnings...................................................................... xv

Contact Juniper Networks .................................................................................... xvi

Documentation Feedback....................................................................................xvi

Part 1

Product Overview

Chapter 1

Chapter 2

System Overview .....................................................................................................3

System Description.................................................................................................3

Field-Replaceable Units (FRUs)................................................................................6

G10 CMTS Features and Functions .........................................................................7

Functional Overview........................................................................................7

Broadband Cable Processor ASIC.....................................................................7

G10 CMTS Components..........................................................................................8

G10 CMTS Management .......................................................................................10

G10 CMTS Hardware Overview.............................................................................10

Hardware Component Overview ...................................................................19

Chassis..................................................................................................................19

Physical Characteristics .................................................................................20

Card Cage and Midplane................................................................................21

Chassis Versions............................................................................................25

Power Supplies ..............................................................................................26

Power Transition Modules .............................................................................28

Cooling and Fans...........................................................................................29

DOCSIS Module ....................................................................................................29

Functional Characteristics..............................................................................31

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Ta b l e o f C o n te nt s

iii

Page 4

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Chapter 3

System Architecture Overview ..................................................................... 57

Chassis Control Module ........................................................................................37

NIC Module...........................................................................................................42

Chassis Rear Modules...........................................................................................48

JUNOSg Internet Software Overview.....................................................................57

Data Path Processing............................................................................................62

Data Packet Processing ..........................................................................32

Higher Layer Functions...................................................................33

MAC Layer Functions......................................................................34

Physical Layer Functions.................................................................34

Modem Management .............................................................................35

MAC Layer Scheduling ....................................................................35

Cable Modem Management ............................................................35

Enhanced Routing and Bridging Features............................................... 35

Physical and Electrical Characteristics ...........................................................36

Functional Characteristics..............................................................................38

Configuration, State, and Alarm Data..................................................... 40

Physical and Electrical Characteristics ...........................................................40

Functional Characteristics..............................................................................44

Physical and Electrical Characteristics ...........................................................44

NIC Access Module........................................................................................ 48

HFC Connector Module .................................................................................50

Switched I/O Module .....................................................................................53

Hard Disk Module..........................................................................................55

Routing Engine Software Components .......................................................... 58

Routing Protocol Process........................................................................58

Routing Protocols............................................................................58

Routing and Forwarding Tables ...................................................... 59

Routing Policy ................................................................................59

Interface Process.................................................................................... 60

SNMP and MIB II Processes.................................................................... 60

Management Process .............................................................................60

Routing Engine Kernel ...........................................................................60

Tools for Accessing and Controlling the Software..........................................61

Software Monitoring Tools............................................................................. 61

Software Installation and Upgrade Procedures .............................................. 61

Downstream Data Path ................................................................................. 62

Upstream Data Path ......................................................................................63

JUNOSg 3.0 G10 CMTS Hardware Guide

iv

Page 5

Part 2

Initial Installation

Chapter 4

Chapter 5

Prepare the Site .....................................................................................................67

Safety Precautions ................................................................................................68

Notices..................................................................................................................70

Power ...................................................................................................................71

AC Power.......................................................................................................71

DC Power ......................................................................................................72

Environment.........................................................................................................72

Mounting ..............................................................................................................73

Tools and Equipment Required for Installation .....................................................74

Coaxial Cable Requirements .................................................................................75

Characterization of Installation Site.......................................................................75

Summary Checklist...............................................................................................82

Noise Measurement Methodology.........................................................................83

Average Upstream Noise Measurement .........................................................83

Peak Upstream Noise Measurement ..............................................................84

Additional Characterization Tables........................................................................85

Verification of Shipping Cartons............................................................................89

G10 CMTS Installation Checklist............................................................................90

Install the CMTS......................................................................................................93

Ground the Chassis...............................................................................................94

Rack Mounting......................................................................................................94

Install Power Supplies.........................................................................................101

Install a DOCSIS Module .....................................................................................103

Install an HFC Connector Module or SIM ............................................................105

Install a Chassis Control Module .........................................................................108

Install a Hard Disk Module..................................................................................108

Install a NIC Module............................................................................................108

Install a NIC Access Module ................................................................................108

Cable an HFC Connector Module or SIM .............................................................109

Cable the F-connector Ports.........................................................................109

Cable a Chassis Control Module ..........................................................................113

Cable a NIC Module ............................................................................................113

Cable a NIC Access Module.................................................................................115

Attach a PC to the Chassis Control Module..........................................................119

Connect to Power Sources ..................................................................................119

AC Power.....................................................................................................119

DC Power ....................................................................................................121

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Ta b l e o f C o n te nt s

v

Page 6

•

•

•

•

•

•

•

•

•

•

•

Part 3

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Troubleshooting and Maintenance

Chapter 6

Chapter 7

Chapter 8

Connect the Power and Perform Initial Configuration................123

Power On the G10 CMTS....................................................................................123

Power On and Configure the PC .........................................................................127

Perform Initial Software Configuration ..............................................................128

RF Measurements................................................................................................133

Downstream RF Measurement in CATV Mode.................................................... 134

Downstream RF Measurement in Spectrum Analyzer Mode ...............................135

Upstream RF Measurement ................................................................................ 137

Troubleshooting .................................................................................................... 141

Features for Troubleshooting ..............................................................................141

CMTS Power and Booting Issues.........................................................................148

Ideal HFC Plant Configuration Issues ..................................................................150

HFC Plant Related Issues ....................................................................................156

Flap List.......................................................................................................142

Use the Flap List for Troubleshooting ...................................................142

Local Event Log ...........................................................................................145

Operational Commands .............................................................................. 146

ServiceGuard Management System .............................................................147

CMTS Is Not Powering Up ...........................................................................148

CMTS Does Not Boot Successfully................................................................148

CMTS Powers Down....................................................................................149

Cable Modem Cannot Successfully Range....................................................150

Cable Modem Cannot Establish IP Connectivity ..........................................151

Cable Modem Cannot Successfully Register.................................................151

Cable Modem Throughput is Slow............................................................... 152

Cable Modem is Dropped............................................................................156

Cable Modem Cannot Successfully Range....................................................157

Cable Modem Throughput is Slow ...............................................................158

JUNOSg 3.0 G10 CMTS Hardware Guide

vi

Page 7

Part 4

Appendixes

Part 5

Index

Chapter 9

Appendix A

Appendix B

Appendix C

Index

Replacement Procedures ...............................................................................159

Power Supplies ...................................................................................................159

Fan Trays............................................................................................................162

Module Removal.................................................................................................166

Agency Certifications........................................................................................173

Safety .................................................................................................................173

EMC....................................................................................................................174

Immunity............................................................................................................174

Radio Frequency (RF) Specifications .....................................................175

EIA Channel Plans................................................................................................181

Index.............................................................................................................................189

Remove Power Supplies ..............................................................................160

Replace a Fan Tray......................................................................................162

Front Fan Trays....................................................................................163

Rear Fan Tray.......................................................................................163

Remove a DOCSIS Module...........................................................................166

Remove an HFC Connector Module or SIM..................................................168

Remove a Chassis Control Module...............................................................169

Remove a Hard Disk Module .......................................................................170

Remove a NIC Module.................................................................................170

Remove a NIC Access Module......................................................................170

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Ta b l e o f C o n te nt s

vii

Page 8

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

JUNOSg 3.0 G10 CMTS Hardware Guide

viii

Page 9

List of Figures

List of Figures

Figure 1: Typical CMTS Location..........................................................................4

Figure 2: Headend Architecture ..........................................................................5

Figure 3: G10 CMTS Components and Interfaces.................................................9

Figure 4: Front View of Fully Configured Chassis...............................................11

Figure 5: Front View of Partially Configured Chassis..........................................12

Figure 6: Rear View of Fully Configured Chassis ................................................13

Figure 7: Rear View of Partially Configured Chassis...........................................14

Figure 8: Chassis Top View Showing Midplane Slot Numbering ........................15

Figure 9: Midplane—Front and Rear Views........................................................23

Figure 10: Midplane Domains..............................................................................25

Figure 11: AC Power Supply Front Panel .............................................................27

Figure 12: DOCSIS Module Front Panel ...............................................................30

Figure 13: DOCSIS Module Block Diagram ..........................................................32

Figure 14: Packet Processing Layers....................................................................33

Figure 15: Chassis Control Module Front Panel....................................................39

Figure 16: NIC Module Front Panel......................................................................43

Figure 17: NIC Access Module Front Panel ..........................................................49

Figure 18: HFC Connector Module Rear Panel.....................................................51

Figure 19: G10 CMTS Data Flow .........................................................................52

Figure 20: SIM Rear Panel ...................................................................................54

Figure 21: Hard Disk Module Rear Panel .............................................................56

Figure 22: G10 CMTS Data Flow .........................................................................64

Figure 23: Average Upstream Noise Measurement Example................................84

Figure 24: Peak Upstream Noise Measurement Example.....................................85

Figure 25: Air Flow Through Chassis....................................................................96

Figure 26: Bottom of Chassis...............................................................................97

Figure 27: Lifting the Chassis...............................................................................98

Figure 28: Rack-Mounted Chassis........................................................................99

Figure 29: Rack Fully Populated with Three G10 CMTS Chassis.........................100

Figure 30: Power Supply Installation ................................................................102

Figure 31: Air Management Module Removal ....................................................104

Figure 32: DOCSIS Module Installation ..............................................................105

Figure 33: HFC Connector Module Installation ..................................................107

Figure 34: Example of Allocation of Multiple Interfaces Per Port .....................109

Figure 35: Rear Coaxial Cable Connections ......................................................112

Figure 36: NIC Module Cabling – Front View .....................................................114

Figure 37: NIC Access Module Cable Connections ............................................117

Figure 38: AC Power Cord and Retainer Clip .....................................................120

Figure 39: DC Power Transition Module ............................................................122

Figure 40: Downstream RF Signal (CATV Mode) ................................................135

Figure 41: Downstream RF Signal (Spectrum Analyzer Mode) ...........................136

Figure 42: Single Upstream Burst ......................................................................138

Figure 43: Multiple Upstream Bursts ..................................................................139

Figure 44: Power Supply Removal ....................................................................161

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

List of Figures

ix

Page 10

List of Figures

•

•

•

•

Figure 45: Front Fan Tray Replacement ...........................................................164

Figure 46: Rear Fan Tray Replacement ............................................................165

Figure 47: DOCSIS Module Removal .................................................................167

Figure 48: HFC Connector Module Removal .....................................................169

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

JUNOSg 3.0 G10 CMTS Hardware Guide

x

Page 11

List of Tables

List of Tables

Table 1: Chassis Physical Specifications ...........................................................20

Table 2: Chassis Environmental Specifications .................................................21

Table 3: Card Cage and Midplane Specifications ..............................................21

Table 4: Midplane P1 – P5 Connectors.............................................................22

Table 5: Midplane Configuration ......................................................................24

Table 6: Power Supply LEDs.............................................................................26

Table 7: Power Supply Specifications ..............................................................28

Table 8: DOCSIS Module Physical Dimensions .................................................36

Table 9: DOCSIS Module Operational Characteristics .......................................36

Table 10: DOCSIS Module LEDs .........................................................................36

Table 11: Chassis Control Module Physical Dimensions .....................................41

Table 12: Chassis Control Module Connectors....................................................41

Table 13: Chassis Control Module Switches........................................................41

Table 14: Chassis Control Module LEDs..............................................................41

Table 15: NIC Module Physical Dimensions........................................................44

Table 16: NIC Module Connectors ......................................................................44

Table 17: Single-Mode, Long-Range GBIC Specifications.....................................45

Table 18: Single-Mode, Midrange GBIC Specifications ........................................45

Table 19: Multimode GBIC Specifications ...........................................................46

Table 20: 1000BT GBIC Specifications................................................................46

Table 21: NIC Module LEDs................................................................................47

Table 22: NIC Access Module LEDs ....................................................................48

Table 23: HFC Connector Module Fast Ethernet LEDs ........................................50

Table 24: SIM Fast Ethernet Port LEDs ...............................................................54

Table 25: G10 CMTS Environmental Specifications ............................................72

Table 26: Coaxial Cable Requirements ...............................................................75

Table 27: RF Plant/HFC Environment Characterization ......................................76

Table 28: Existing DOCSIS Service Characterization...........................................77

Table 29: Upstream CMTS Parameter Characterization......................................78

Table 30: Downstream CMTS Parameter Characterization .................................80

Table 31: Upstream Frequency Spectrum Utilization..........................................81

Table 32: Pre-Installation Requirement Summary Checklist ...............................82

Table 33: Average Noise Spectrum Analyzer Settings.........................................83

Table 34: Peak Noise Spectrum Analyzer Setup..................................................84

Table 35: Existing DOCSIS Service Characterization...........................................86

Table 36: Upstream CMTS Parameter Characterization......................................87

Table 37: Downstream CMTS Parameter Characterization ................................89

Table 38: G10 CMTS Installation Checklist..........................................................90

Table 39: NIC Access Module Wiring Plan........................................................118

Table 40: Power Supply LEDs...........................................................................124

Table 41: DOCSIS Module LED Status...............................................................125

Table 42: Chassis Control Module LED Status...................................................126

Table 43: NIC Module LED Status.....................................................................126

Table 44: NIC Access Module LED Status..........................................................127

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

List of Tables

xi

Page 12

List of Tables

•

•

•

•

•

•

•

•

Table 45: Flap List Association to Potential Issues ............................................143

Table 46: Local Event Log Headings Displayed.................................................145

Table 47: Downstream RF Channel Transmission Characteristics ....................176

Table 48: Upstream RF Channel Transmission Characteristics .........................177

Table 49: Downstream RF Signal Output Characteristics..................................178

Table 50: DOCSIS Downstream Channel Rates and Spacing ............................178

Table 51: DOCSIS Maximum Upstream Channel Rates and Widths..................179

Table 52: EIA Channel Plan..............................................................................181

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

JUNOSg 3.0 G10 CMTS Hardware Guide

xii

Page 13

About This Manual

This chapter provides a high-level overview of the G10 CMTS Hardware Guide:

! Objectives on page xiii

! Audience on page xiv

! Document Organization on page xiv

! Related Documents on page xiv

! Documentation Conventions on page xv

! Contact Juniper Networks on page xvi

! Documentation Feedback on page xvi

Objectives

This manual explains the hardware installation and basic troubleshooting for the G10 CMTS

and your HFC plant. It contains procedures for preparing your site for CMTS installation,

installing the hardware, starting up the CMTS, performing initial software configuration, and

replacing field-replaceable units (FRUs). After completing the installation and basic

configuration procedures covered in this manual, refer to the JUNOSg software configuration

guides for information about further configuring the JUNOSg software.

To obtain additional information about Juniper Networks CMTSs—either corrections to

information in this manual or information that might have been omitted from this

manual—refer to the G10 CMTS hardware release notes.

To obtain the most current version of this manual, the most current version of the hardware

release notes, and other Juniper Networks technical documentation, refer to the product

documentation page on the Juniper Networks Web site, which is located at

http://www.juniper.net.

To order printed copies of this manual or to order a documentation CD-ROM, which contains

this manual, please contact your sales representative.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

About This Manual

xiii

Page 14

Audience

•

Audience

•

•

•

•

•

•

•

•

Document Organization

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Related Documents

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

This manual is designed for network administrators who are installing and maintaining a

G10 CMTS, or preparing a site for CMTS installation. It assumes that you have a broad

understanding of HFC networks, networking principles, and network configuration. Any

detailed discussion of these concepts is beyond the scope of this manual.

This manual is divided into several parts, each containing a category of information about

the CMTS:

! Part 1, “Product Overview,” provides an overview of the CMTS, describing its hardware

components, the JUNOSg software, and the system architecture.

! Part 2, “Initial Installation,” describes how to prepare and characterize your site for

installing the CMTS, providing environmental and power supply specifications, rack and

clearance requirements, and wiring and cabling guidelines. It also provides an overview

of the installation process and lists safety precautions. Finally, it explains how to install

the CMTS chassis and components and how to initially start the CMTS and configure the

software.

! Part 3, “Troubleshooting and Maintenance,” describes general troubleshooting

procedures for the CMTS, cable modem operation, and the HFC plant, and explains how

to track the source of problems. It also provides replacement procedures for some of the

field-replaceable units.

! Part 4, “Appendixes,” provides an appendix listing agency certifications, an appendix of

DOCSIS radio frequency (RF) specifications, and an appendix listing various channel

plans.

! Part 5, “Index,” provides an index of the manual.

For information about configuring the software, including examples, see the following

documents:

! JUNOSg Software Configuration Guide: Getting Started and System Management

! JUNOSg Software Configuration Guide: Interfaces, Cable, Policy, and Routing and Routing

Protocols

! JUNOSg Software Operational Mode Command Reference

JUNOSg 3.0 G10 CMTS Hardware Guide

xiv

Page 15

Documentation Conventions

Documentation Conventions

This manual uses the following text conventions:

! CMTS and CMTS component labels are shown in a sans serif font. In the following

example, ETHERNET is the label for the Ethernet management port on the CMTS:

The 10/100-Mbps Ethernet RJ-45 connector is used for out-of-band management of

the CMTS and is labeled ETHERNET.

! Statements, commands, filenames, directory names, IP addresses, and configuration

hierarchy levels are shown in a sans serif font. In the following example, stub is a

statement name and [edit protocols ospf area area-id] is a configuration hierarchy level:

To configure a stub area, include the stub statement at the [edit protocols ospf area

area-id] hierarchy level.

! In examples, text that you type literally is shown in bold. In the following example, you

type the words show chassis hardware:

For example, you can use the following command to get information about the

source of an alarm condition:

user@host> show chassis hardware

Notes, Cautions, and Warnings

Notes, cautions, and warnings are denoted by the following symbols:

A note indicates information that might be helpful in a

particular situation or that might otherwise be overlooked.

A caution indicates a situation that requires careful

attention. Failure to observe a cautionary note could result

in minor injury or discomfort to yourself, or serious

damage to the CMTS.

A warning indicates a potentially dangerous situation.

Failure to follow the guidelines in a warning could result in

severe injury or death.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

About This Manual

xv

Page 16

Contact Juniper Networks

•

Contact Juniper Networks

•

•

•

•

•

•

Documentation Feedback

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

For technical support, contact Juniper Networks at support@juniper.net, or at 1-888-314-JTAC

(within the United States) or (+1) 408-745-9500 (from outside the United States).

We are always interested in hearing from our customers. Please let us know what you like

and do not like about the product documentation, and let us know of any suggestions you

have for improving the documentation. Also, let us know if you find any mistakes in the

documentation. Send your feedback and comments to techpubs-comments@juniper.net.

JUNOSg 3.0 G10 CMTS Hardware Guide

xvi

Page 17

Part 1

Product Overview

! System Overview on page 3

! Hardware Component Overview on page 19

! System Architecture Overview on page 57

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

1

Page 18

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

JUNOSg 3.0 G10 CMTS Hardware Guide

2

Page 19

Chapter 1

System Overview

This chapter provides an overview of the G10 CMTS.

System Description

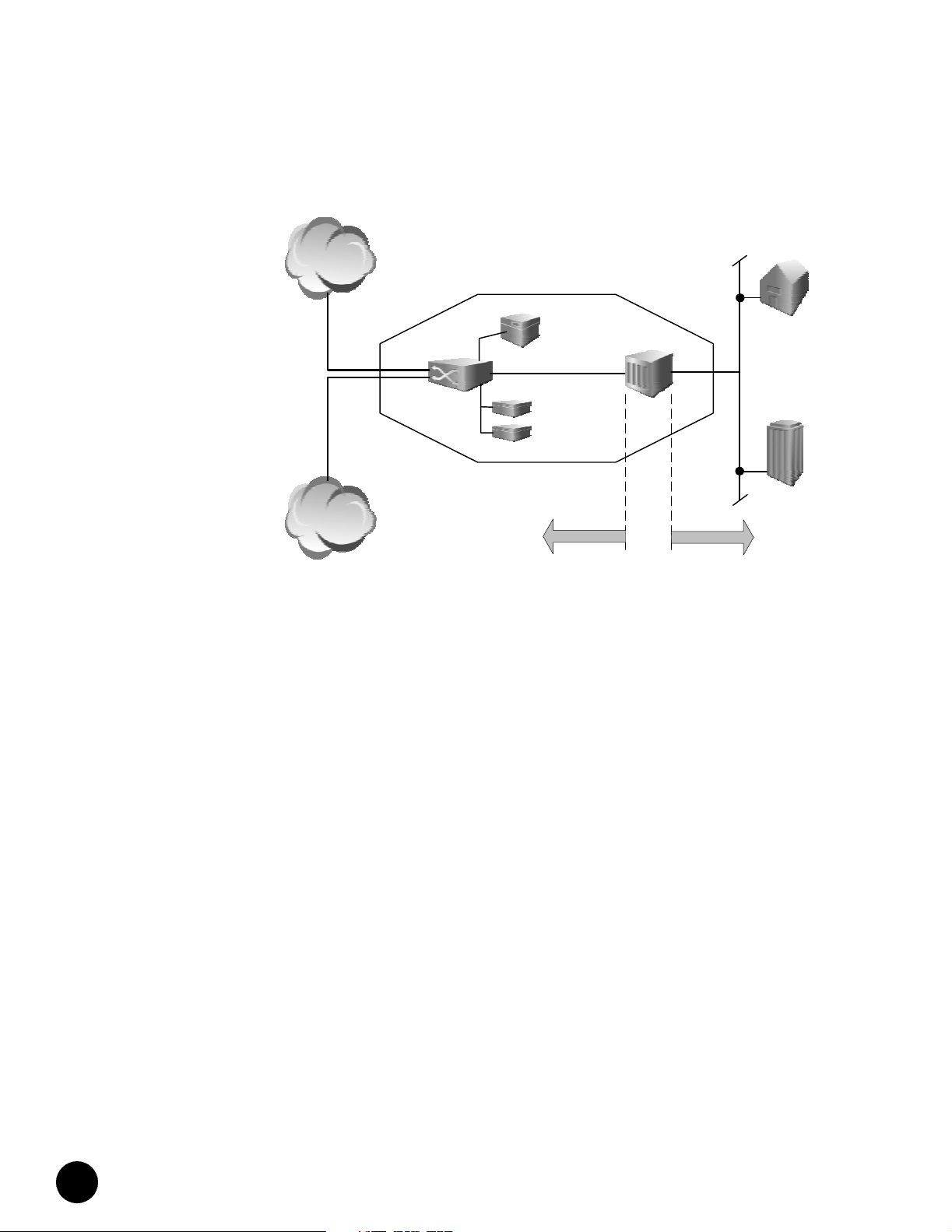

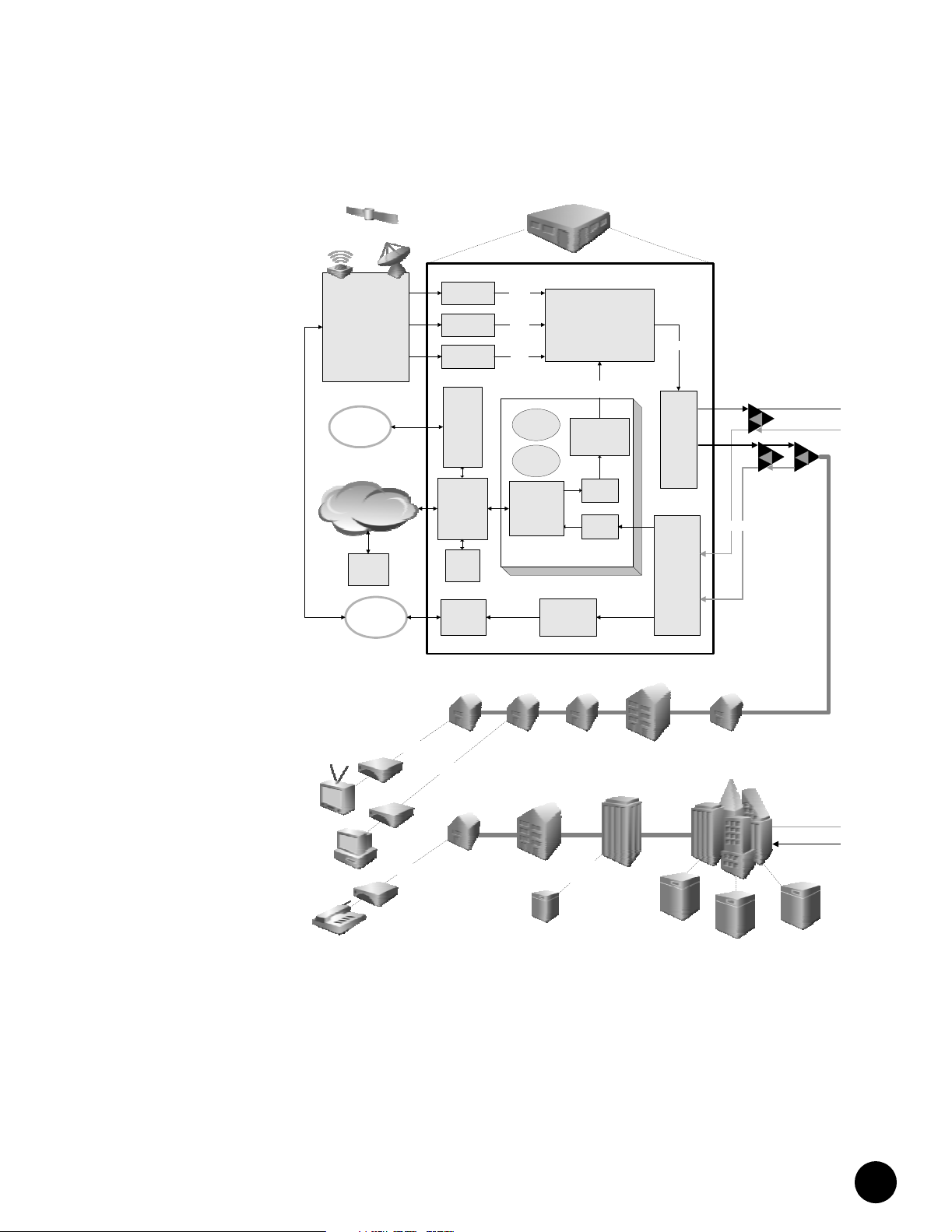

The JUNOSg software runs on the G10 cable modem termination system (CMTS) and

provides both IP routing (Layer 3) and IEEE 802.1 bridging (Layer 2), as well as software for

interface, network, cable services, and chassis management. The G10 CMTS manages

Internet voice and data. It functions as the interface between the service networks—Internet,

Public Switched Telephone Network (PSTN)—and the hybrid fiber/coax (HFC) network of

subscribers, as shown in Figure 1 on page 4. This is the “last mile” of broadband service, with

the CMTS typically located in the cable headend or distribution hub. It is targeted at the

following data and voice aggregation applications:

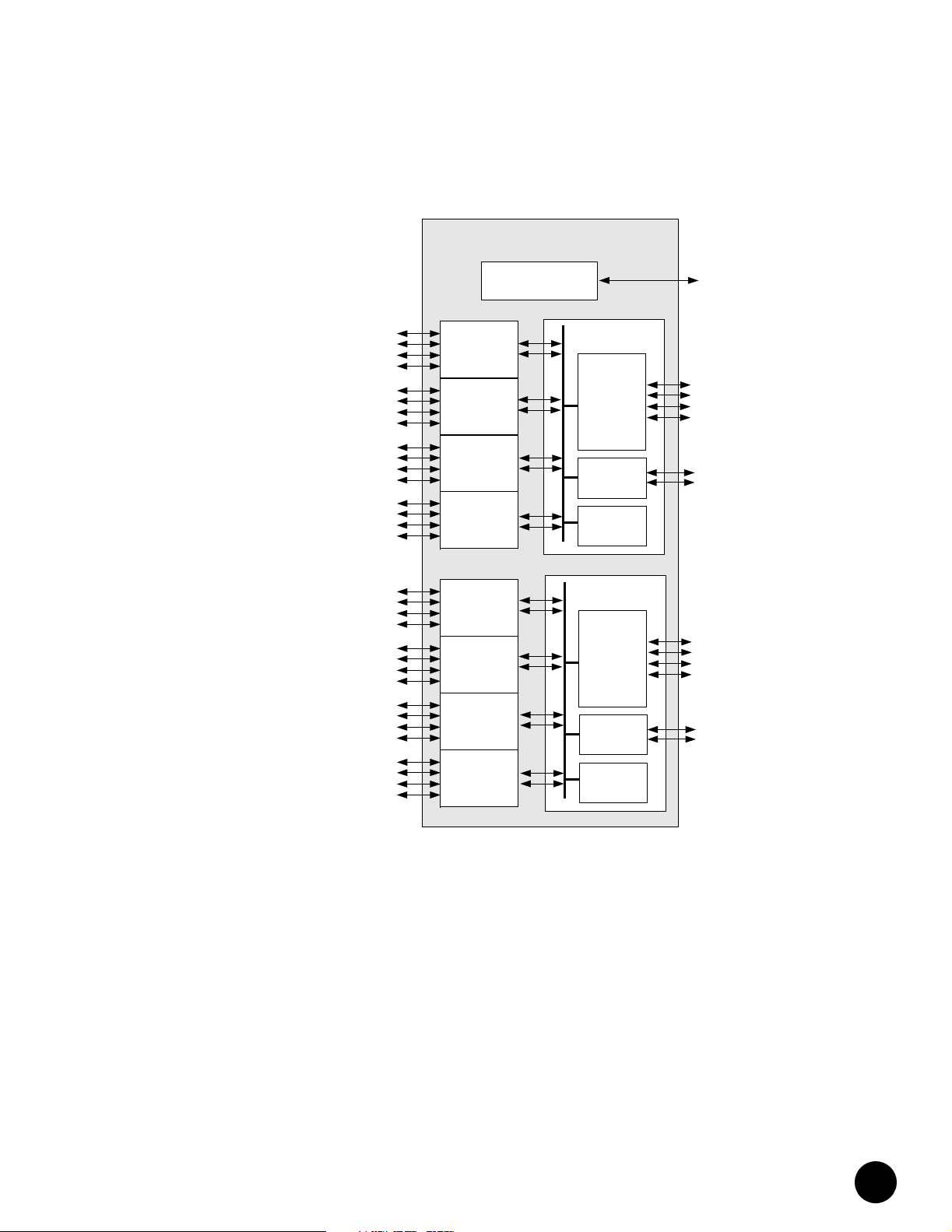

Figure 2 on page 5 illustrates a typical cable headend architecture.

! System Description on page 3

! Field-Replaceable Units (FRUs) on page 6

! G10 CMTS Features and Functions on page 7

! G10 CMTS Components on page 8

! G10 CMTS Management on page 10

! G10 CMTS Hardware Overview on page 10

! Large CATV hub sites—DOCSIS multiservice, residential, and commercial IP network

access over HFC networks maintained by cable television (CATV) multiple service

operators (MSOs) needing enhanced integrated data, voice, and video in large

metropolitan areas.

! Small CATV hub sites—Smaller hub sites aggregated over metropolitan fiber rings

supporting Gigabit Ethernet.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

System Overview

3

Page 20

System Description

•

Figure 1: Typical CMTS Location

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Internet

Backbone

PSTN

Switch/

Router

Cable Headend

or

Distribution Hub

Network

Management

Video

Servers

Network Side

Interface

Subscribers

CMTS

Hybrid Fiber/Coax

Network

JUNOSg 3.0 G10 CMTS Hardware Guide

4

Page 21

System Description

b

U

Figure 2: Headend Architecture

Broadcast Channels:

Satellite, Fiber,

Cable,

Others

PSTN

Backbone

Network

Remote

Server

Facility

ATM

Telephony

Video

Upconverter

Upconverter

Upconverter

Remote

Dial-Up

Access

Server

Backbone

Transport

Adapter,

Switch,

LAN, or

Hub

Local

Server

Facility

Interactive

Cable

Gateway

Data

Analog

Video

Digital

Video

Other

Operations

System

Support

Security &

Access

Control

Network

Termination

Upconverters

CMTS

Audio / Video

Demod

High-speed

Data

Combiner

QAM

Data

Mod

Demod

Head End

54-750 MHz

Splitter

Combiner

and

Signal

Router

5-42 MHz

E/O O/E

Coax Cable

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Fi

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

System Overview

5

Page 22

Field-Replaceable Units (FRUs)

•

Field-Replaceable Units (FRUs)

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Field-replaceable units (FRUs) are CMTS components that can be replaced at the customer

site. Replacing FRUs requires minimal CMTS downtime. A FRU can be ordered as a separate

unit for replacement into the CMTS or for stocking spare parts.

Following is an alphabetical list of G10 CMTS FRUs. See “G10 CMTS Hardware Overview” on

page 10 for a description of each FRU.

! AC power supply

! AC power tra nsi tio n mo dule

! Air management module

! Air management panel

! CCM Access Module

! Chassis

! Chassis Control Module

! DOCSIS Module

! DC power supply

! DC power transition module

! Front fan tray

! GBIC module

! Hard Disk Module

! HFC Connector Module

! NIC Module

! NIC Access Module

! NIC Access Module cable

! Power supply filler panel

! Rear fan tray

! Switched I/O Module (SIM)

JUNOSg 3.0 G10 CMTS Hardware Guide

6

Page 23

G10 CMTS Features and Functions

G10 CMTS Features and Functions

The G10 CMTS provides true multiservice support, including the ability to simultaneously

support DOCSIS IP services and VoIP services.

Functional Overview

The G10 CMTS is usually connected directly to a Gigabit-class core router that is part of a

multiple system operator’s (MSO) metropolitan core network. It receives network-side packet

streams originating from the Internet, Media Gateways or video servers, then processes them

into DOCSIS-compatible digital signals (MPEG) that are modulated onto an RF carrier for

transmission downstream over the HFC network to the subscribers’ cable modems.

Upstream signals consist of protocol data units (PDUs) in data bursts from the cable modems.

The G10 CMTS uses advanced scheduling algorithms to optimize the timing of these

transmissions. The packets are processed to recover the payload data, then routed, as IP

packets, to the appropriate destinations through the network-side interface.

The G10 CMTS’s high capacity of up to 32 downstream and 128 upstream interfaces and

other innovative features are provided by the Broadband Cable Processor ASIC

(application-specific integrated circuit).

Broadband Cable Processor ASIC

The Broadband Cable Processor ASIC provides all-digital processing of the return path. This,

plus advanced noise cancellation and equalization algorithms, enables modulation rates

beyond QPSK and allows traditionally problematic frequency ranges of the upstream

spectrum to be utilized. All-digital processing also accommodates full spectrum analysis by

capturing statistics of the upstream band in real time.

The Broadband Cable Processor ASIC incorporates key DOCSIS MAC (media access control)

functions such as concatenation, fragmentation, encryption, and decryption. Accelerating

these functions in hardware provides a high-performance, scalable CMTS solution that can

process thousands of simultaneous DOCSIS service flows.

Advanced timing and digital signal processing algorithms allow more efficient use of the

RF spectrum, resulting in increased channel capacity.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

System Overview

7

Page 24

G10 CMTS Components

•

G10 CMTS Components

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

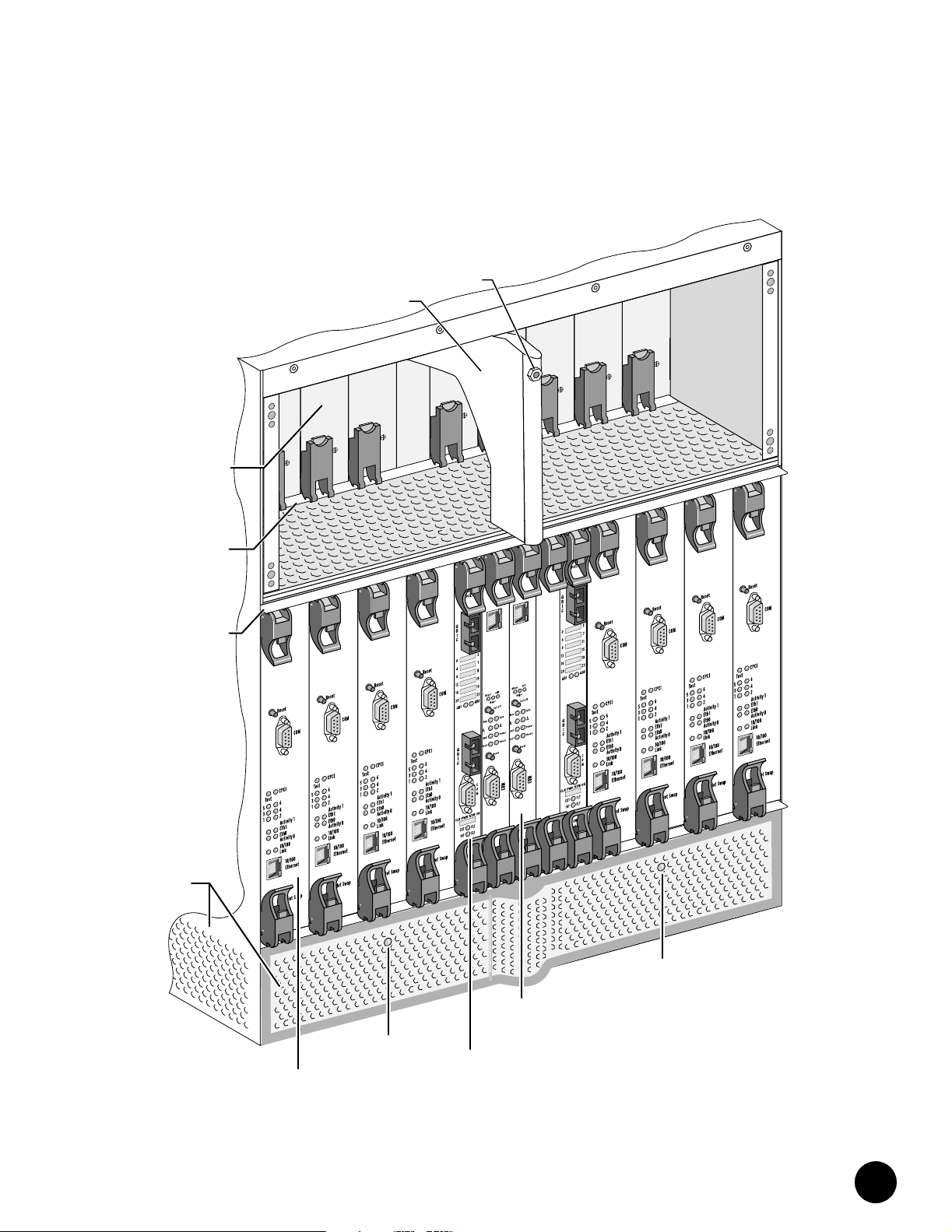

The G10 CMTS chassis employs front and rear modules that connect through a midplane.

Most of the cable connections are available in the rear of the unit. Following is a list of the

primary modules of the G10 CMTS:

! NIC Module—Provides Ethernet switching functionality for upstream and downstream

traffic and for the Fast Ethernet interfaces. Houses two Gigabit Ethernet ports with

Gigabit Interface Converters (GBICs).

! NIC Access Module—Fans out the Ethernet signals to individual 10/100Base-T lines,

which route to the HFC Connector Modules or Switched I/O Modules. A version of the

chassis provides internal Ethernet wiring between the NIC Modules and the DOCSIS

Modules.

! DOCSIS Module—Performs all data path processing functions, including Layer 2 bridging

and Layer 3 forwarding. Processes IP data into DOCSIS packets. Converts and modulates

data for RF transmission. Reverses these processes for upstream data.

! HFC Connector Module—Provides cable interfaces for a DOCSIS Module. Contains the

Fast Ethernet connectors for network-side data and the F-connectors for the HFC

cabling.

! Switched I/O Module—Provides the same functions as an HFC Connector Module, but

provides four additional upstream F-connectors for the HFC cabling.

! Chassis Control Module—Provides the management interface and runs the Routing

Engine software. Controls redundant protection functions and supplies software images

to all DOCSIS Modules. Runs the Simple Network Management Protocol (SNMP) agent

and environmental monitoring.

! Hard Disk Module—Contains the system nonvolatile memory implemented as a hard

disk. This module is installed opposite the Chassis Control Module.

The G10 CMTS relays traffic between DOCSIS RF interfaces, on which the cable modems

reside, and the network-side interfaces (Fast Ethernet and Gigabit Ethernet). Figure 3 on

page 9 illustrates the relationship between the primary modules in the chassis.

Each DOCSIS Module can support up to four cable interfaces, where a cable interface (MAC

domain) contains at least one downstream interface and one upstream interface. Each NIC

Module supports two Gigabit Ethernet interfaces and four Fast Ethernet interfaces. The

Chassis Control Module provides an out-of-band Fast Ethernet management interface.

See the JUNOSg Software Configuration Guide: Interfaces, Cable, Policy, and Routing and Routing

Protocols for more information on interfaces.

JUNOSg 3.0 G10 CMTS Hardware Guide

8

Page 25

G10 CMTS Components

t

Figure 3: G10 CMTS Components and Interfaces

32 Cable

Interfaces

ca-0/1/0

ca-0/1/1

ca-0/1/2

ca-0/1/3

ca-0/2/0

ca-0/2/1

ca-0/2/2

Domain A

Domain B

ca-0/2/3

ca-0/3/0

ca-0/3/1

ca-0/3/2

ca-0/3/3

ca-0/4/0

ca-0/4/1

ca-0/4/2

ca-0/4/3

ca-0/10/0

ca-0/10/1

ca-0/10/2

ca-0/10/3

ca-0/11/0

ca-0/11/1

ca-0/11/2

ca-0/11/3

ca-0/12/0

ca-0/12/1

ca-0/12/2

ca-0/12/3

ca-0/13/0

ca-0/13/1

ca-0/13/2

ca-0/13/3

DOCSIS

Module

DOCSIS

Module

DOCSIS

Module

DOCSIS

Module

DOCSIS

Module

DOCSIS

Module

DOCSIS

Module

DOCSIS

Module

G10 CMTS

Chassis Control

Module (Slot 6)

NIC Module &

NIC Access Module

3x Octal

Fast Ethernet

Switch Ports

2x Gigabit

Ethernet

Switch Ports

Switch

Element

NIC Module &

NIC Access Module

3x Octal

Fast Ethernet

Switch Ports

2x Gigabit

Ethernet

Switch Ports

Switch

Element

Management Por

fxp0

fx-0/5/0

fx-0/5/1

fx-0/5/2

fx-0/5/3

gx-0/5/0

gx-0/5/1

fx-0/9/0

fx-0/9/1

fx-0/9/2

fx-0/9/3

gx-0/9/0

gx-0/9/1

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

System Overview

9

Page 26

G10 CMTS Management

•

G10 CMTS Management

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

G10 CMTS Hardware Overview

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

The G10 CMTS supports the following system management applications and tools:

! Command-Line Interface (CLI)—The CLI provides the most comprehensive controls and

! SNMP—The CMTS can interact with SNMPv2c and SNMPv3-based Network

! ServiceGuard Management System – This optional advanced diagnostics application

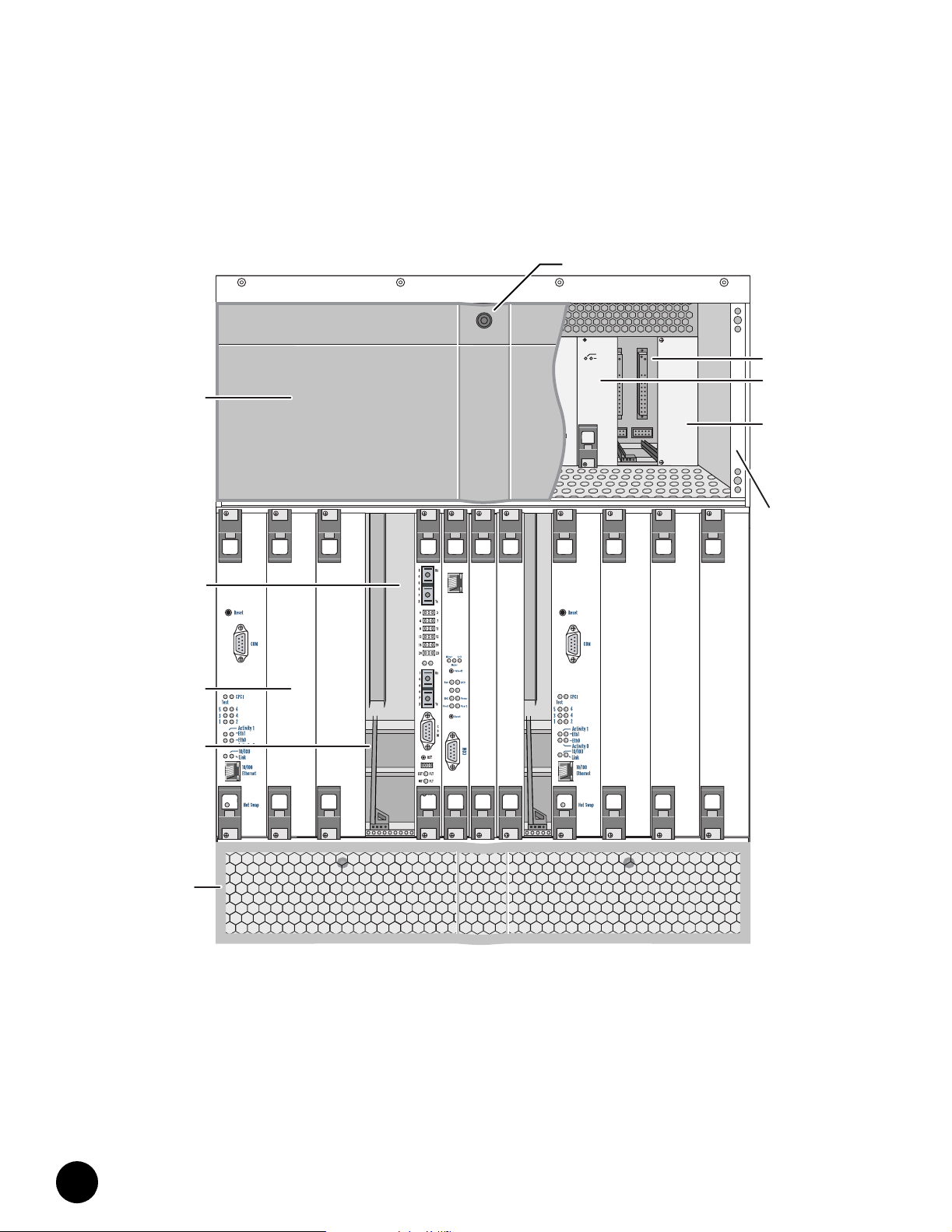

This section provides an overview of the modules and various hardware components of the

G10 CMTS and where they reside within the chassis. This overview presents material that is

specific to the installation and configuration of the G10 CMTS.

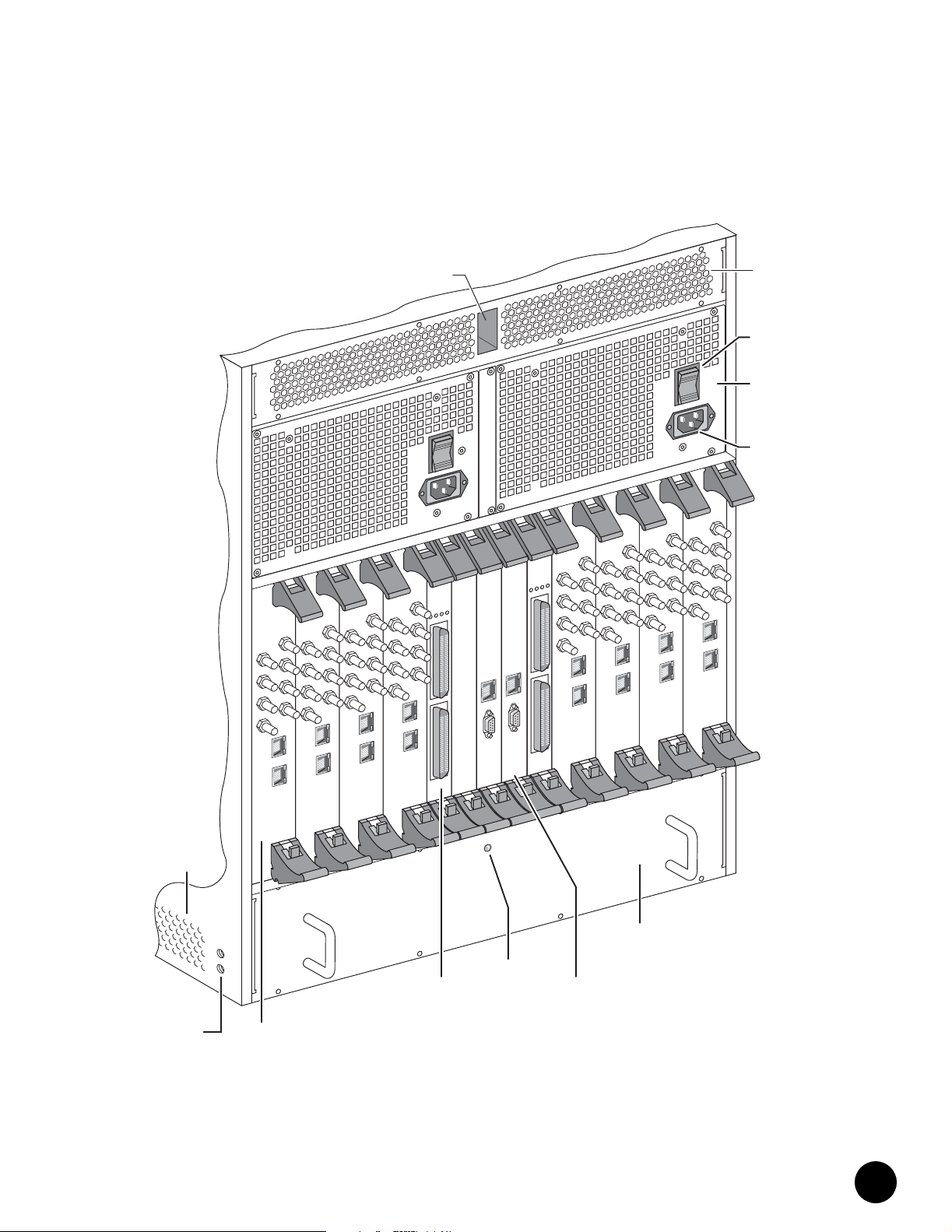

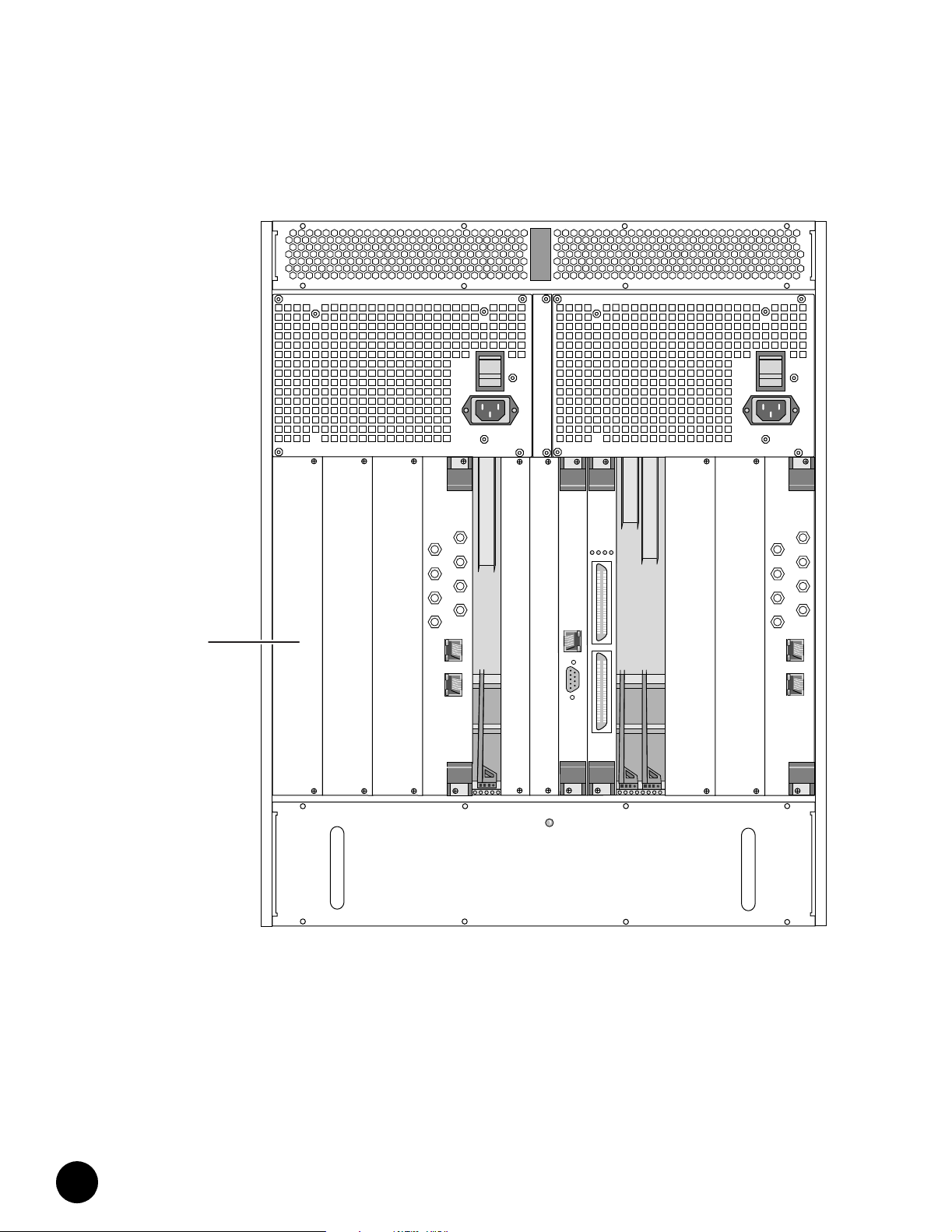

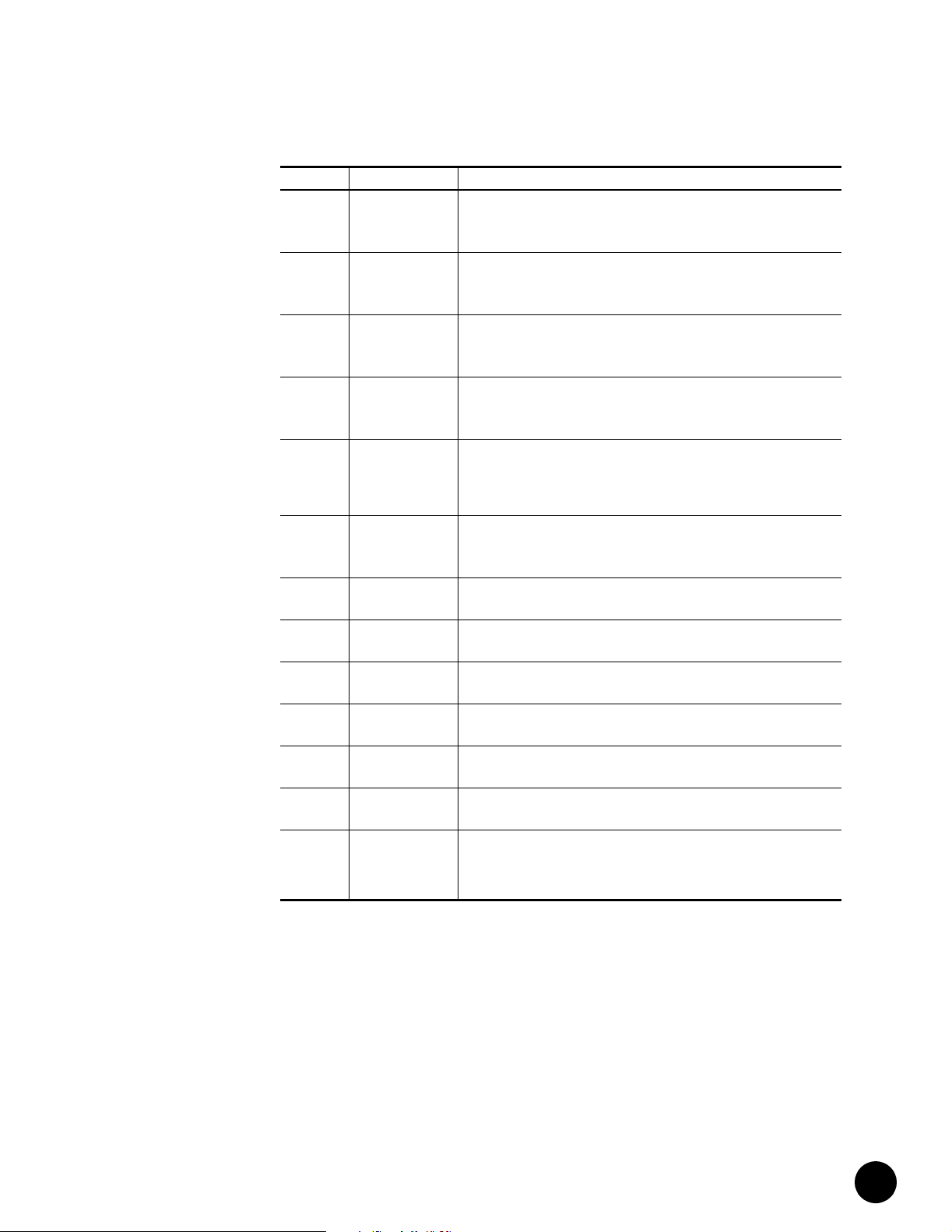

Figure 4 on page 11 illustrates a front view of a fully configured chassis. Figure 5 on page 12

illustrates a front view of a partially configured chassis in which DOCSIS Modules, a Chassis

Control Module (CCM), a Network Interface Card (NIC) Module, power supplies, air

management modules, and power supply filler panels have been removed. Figure 6 on

page 13 illustrates a rear view of a fully configured chassis that uses the AC power transition

module and HFC Connector Modules (see Figure 39 on page 122 for an illustration of the DC

power transition module). Figure 7 on page 14 illustrates the rear view of the partially

configured chassis in which HFC Connector Modules, a Hard Disk Module, a NIC Access

Module, and air management panels have been removed. Figure 8 on page 15 provides a top

view of the chassis midplane showing the slot numbering and the location of each module.

is instrumental for installation, configuration, troubleshooting, and upgrade tasks.

Management Systems using DOCSIS 1.0 and DOCSIS 1.1 MIBs and enterprise MIBs.

Events can conditionally be reported as system log messages or SNMP traps.

with a Java GUI provides a rendition of a spectrum analyzer for acquiring data on

upstream transmission cable performance. It incorporates an integrated Impairment

Identification tool that allows for unattended monitoring of statistics to characterize

compromised performance to a potential cause (such as impulse or burst noise, narrow

band ingress, or microreflections).

JUNOSg 3.0 G10 CMTS Hardware Guide

10

Page 27

G10 CMTS Hardware Overview

Figure 4: Front View of Fully Configured Chassis

Cable

Guide

Power

Power

Power

Fa

Fa

ult

Fault

ult

Power

Supply

Power

Supply

Ejector

Rail

Module

Ejector

Rail

Air

Intake

Front Fan

Tray LED

DOCSIS

Module

ESD

Strap

Jack

er

w

Po

Fault

Module

NIC

er

Pow

lt

u

Fa

Eth0

2

1

Chassis

Control

Module

•

•

•

•

•

er

Pow

lt

er

Pow

er

Pow

Fa

Fa

lt

u

Fau

lt

u

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

0

h

t

E

•

•

•

•

•

2

1

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Front Fan

Tray L E D

•

•

•

•

•

•

•

•

•

•

•

•

System Overview

11

Page 28

G10 CMTS Hardware Overview

•

Figure 5: Front View of Partially Configured Chassis

•

•

•

•

•

•

•

•

•

•

•

•

•

Power

Supply

Faceplate

Power

Power

Fault

Power

Fault

•

•

•

•

•

•

•

•

•

•

•

Midplane

•

•

•

•

•

•

Management

Air

Module

•

•

•

•

Card

Guide

•

•

•

•

•

•

•

•

Air

Intake

Faceplate

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

ESD

Strap

Jack

Power

Power

Fault

Power

Fault

Fault

Power

Power

Fault

Fault

Power

Fault

Supply

Bay

Power

Supply

Power

Supply

Filler

Panel

Power

Supply

Faceplate

Clip

JUNOSg 3.0 G10 CMTS Hardware Guide

12

Page 29

G10 CMTS Hardware Overview

Figure 6: Rear View of Fully Configured Chassis

Channel

S 0

D

0

0

S

D

S 0

D

US 0

S 1

0

US

1

US 1

2

2

US

US 3

Eth0

Eth1

D

DS 1

1

US

S 2

D

S 2

D

2

US

S 3

D

DS 3

US 3

Eth0

Eth1

US

US 0

DS 1

US 1

US 1

S 2

D

US 2

2

US

DS 3

US 3

US 3

Eth0

Eth0

Eth1

Eth1

Air

Intake

Chassis

Ground

Nuts

HFC

Connector

Module

Cable

OPERATIONAL

POWER

DS 0

1

S 1

D

S 2

D

S 3

D

NIC

Access

Module

INT FAULT

2

EXT FAULT

Eth

Eth

C

O

C

M

O

M

Rear Fan

Tray LED

OPERATIONAL

INT FAULT

POWER

1

2

EXT FAULT

0

US

1

US

US 2

US 3

Eth0

Eth1

CCM

Access

Module

S 0

D

S 1

D

S 2

D

DS 3

S 0

D

US 0

DS 1

1

US

S 2

D

2

US

DS 3

US 3

Eth0

Eth1

Rear Fan

Tray

•

•

•

•

•

•

Air

Exhaust

•

•

•

•

AC Power

Switch

AC Power

Transition

Module

AC Power

Receptacle

•

•

•

•

•

•

•

•

•

•

DS 0

S 0

D

0

US

S 1

US 0

US 1

2

US

US 3

Eth0

Eth1

D

1

S

D

US 1

2

S

D

DS 2

US 2

S 3

D

S 3

D

US 3

Eth0

Eth1

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

System Overview

13

Page 30

G10 CMTS Hardware Overview

•

Figure 7: Rear View of Partially Configured Chassis

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Management

Air

Panel

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

OPERATIONAL

EXT FAULT

DS 0

US 0

DS 1

US 1

DS 2

US 2

DS 3

US 3

Eth0

Eth1

INT FAULT

POWER

1

Eth

C

O

M

2

DS 0

US 0

DS 1

US 1

DS 2

US 2

DS 3

US 3

Eth0

Eth1

JUNOSg 3.0 G10 CMTS Hardware Guide

14

Page 31

G10 CMTS Hardware Overview

Figure 8: Chassis Top View Showing Midplane Slot Numbering

Rear

HFC Connector Module or

SIM

HFC Connector Module or

SIM

HFC Connector Module or

SIM

HFC Connector Module or

SIM

NIC Access Module

Hard Disk Module

Hard Disk Module

NIC Access Module

HFC Connector Module or

SIM

HFC Connector Module or

SIM

HFC Connector Module or

SIM

HFC Connector Module or

SIM

13

12

11

10

9

8

7

6

5

4

3

2

1

Midplane

with logical slot numbers

Slots 1 through 6 reside in domain A. Slots 7 and 9 through

13 reside in domain B.

DOCSIS Module

DOCSIS Module

DOCSIS Module

DOCSIS Module

NIC Module

Chassis Control Module

Chassis Control Module

NIC Module

DOCSIS Module

DOCSIS Module

DOCSIS Module

DOCSIS Module

Front

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

System Overview

15

Page 32

G10 CMTS Hardware Overview

•

Following is a brief explanation of each feature shown in Figure 4 through Figure 7:

•

•

•

Front Features ! DOCSIS Module—Module that contains the Broadband Cable Processor ASIC and resides

between the network-side interface (NSI) and the hybrid fiber/coax (HFC) interface.

•

•

•

! NIC Module—Module that provides the Gigabit Ethernet interface and the Fast Ethernet

switching functions for the network-side interface.

•

•

! Chassis Control Module—Module that performs management and monitoring functions.

•

•

•

! Module ejector rail—Rail into which a module’s ejector tabs fit when a module is

installed in a slot.

•

•

! ESD strap connector—Location where you can insert an ESD ground strap.

•

•

•

! Air intake—Slotted openings along the front (removable) and sides of the chassis where

air is drawn into the chassis for cooling the installed modules and power supplies.

•

•

! Air intake faceplate—Slotted removable panel that covers the two front fan trays.

•

•

! Air intake faceplate clip—Retainer clip used to mount the air intake faceplate.

•

•

! Front fan tray—Fan assembly that forces air upward through the front of the chassis.

•

•

! Front fan tray LED—LED that shows the status of the front fan tray.

•

•

•

! Power supply ejector rail—Rail into which the power supply ejector tabs fit when a

power supply is installed in a bay.

•

•

! Midplane—Passive electrical interconnecting device for all modules in the chassis.

•

•

•

! Air management module—Module installed in an unused module slot to redirect the air

flow through the chassis and to reduce EMI emissions.

•

•

•

! Card guide—Used to align a module or power supply while it is being inserted into its

slot or bay.

•

•

•

! Power supply—Converts AC or DC power supplied through the power transition modules

into the DC voltages required by the modules.

•

•

•

! Power supply faceplate—Panel along the top of the chassis that covers the power

supplies.

•

•

! Power supply faceplate clip—Retainer clip used to mount the power supply faceplate.

•

•

•

! Power supply bay—Chassis bay in which a single hot-swappable power supply is

inserted.

•

•

! Power supply filler panel—Panel covering an empty power supply bay.

•

•

•

! Cable channel—Channel through the top of the chassis that is used to route the network

cables from the rear of the chassis to the front.

•

•

•

! Cable guide—Guide used to route the network cables between the cable channel and the

lower opening in the power supply faceplate.

•

•

•

JUNOSg 3.0 G10 CMTS Hardware Guide

16

Page 33

G10 CMTS Hardware Overview

Rear Features ! HFC Connector Module—Module that functions as the DOCSIS Module’s physical access

to both the NSI and the HFC interfaces on the rear of the chassis.

! Switched I/O Module—Provides the same functions as an HFC Connector Module, but

provides four additional upstream F-connectors for the HFC cabling.

! NIC Access Module—Module that provides the network connections between the NIC

Modules and the HFC Connector Modules.

! Hard Disk Module—Contains the system nonvolatile memory implemented as a hard

disk. This module is installed opposite the Chassis Control Module.

! Rear fan tray—Fan assembly that forces air upward through the rear of the chassis.

! Rear fan tray LED—LED that shows the status of the rear fan tray.

! Air management panel—Panel installed over an unused module slot to redirect the air

flow through the chassis and to reduce EMI emissions.

! Air exhaust—Panel along the top and rear of the chassis where air is expelled from the

chassis for cooling.

! AC power transition module—Rear module that distributes the externally supplied AC

power to the midplane.

! AC power receptacle—AC power cord receptacle on AC power transition module.

! AC power switch—AC power On/Off switch that resides on the AC power transition

module.

! DC power transition module—Rear module that distributes the externally supplied DC

power to the midplane.

! DC power receptacle—DC power cord terminal block on DC power transition module.

! Chassis ground nuts—Location where the earth ground connection to the chassis is

made.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

System Overview

17

Page 34

G10 CMTS Hardware Overview

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

JUNOSg 3.0 G10 CMTS Hardware Guide

18

Page 35

Chapter 2

Hardware Component Overview