Page 1

Complete Hardware Guide for EX2200 Ethernet

Switches

Published: 2010-12-07

Revision 4

Copyright © 2010, Juniper Networks, Inc.

Page 2

Juniper Networks, Inc.

1194 North Mathilda Avenue

Sunnyvale, California 94089

USA

408-745-2000

www.juniper.net

This productincludes the EnvoySNMPEngine, developed byEpilogue Technology, an IntegratedSystemsCompany.Copyright © 1986-1997,

Epilogue Technology Corporation. All rights reserved. This program and its documentation were developed at private expense, and no part

of them is in the public domain.

This product includes memory allocation software developed by Mark Moraes, copyright © 1988, 1989, 1993, University of Toronto.

This product includes FreeBSD software developed by the University of California, Berkeley, and its contributors. All of the documentation

and software included in the 4.4BSD and 4.4BSD-Lite Releases is copyrighted by the Regents of the University of California. Copyright ©

1979, 1980, 1983, 1986, 1988, 1989, 1991, 1992, 1993, 1994. The Regents of the University of California. All rights reserved.

GateD software copyright © 1995, the Regents of the University. All rights reserved. Gate Daemon was originated and developed through

release 3.0 by Cornell University and its collaborators. Gated is based on Kirton’s EGP, UC Berkeley’s routing daemon (routed), and DCN’s

HELLO routing protocol. Development of Gated has been supported in part by the National Science Foundation. Portions of the GateD

software copyright © 1988, Regents of the University of California. All rights reserved. Portions of the GateD software copyright © 1991, D.

L. S. Associates.

This product includes software developed by Maker Communications, Inc., copyright © 1996, 1997, Maker Communications, Inc.

Juniper Networks, Junos, Steel-Belted Radius, NetScreen, and ScreenOS are registered trademarks of Juniper Networks, Inc. in the United

States and other countries. The Juniper Networks Logo, the Junos logo, and JunosE are trademarks of Juniper Networks, Inc. All other

trademarks, service marks, registered trademarks, or registered service marks are the property of their respective owners.

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right to change, modify,

transfer, or otherwise revise this publication without notice.

Products made or sold by Juniper Networks or components thereof might be covered by one or more of the following patents that are

owned by or licensed to Juniper Networks: U.S. Patent Nos. 5,473,599, 5,905,725, 5,909,440, 6,192,051, 6,333,650, 6,359,479, 6,406,312,

6,429,706, 6,459,579, 6,493,347, 6,538,518, 6,538,899, 6,552,918, 6,567,902, 6,578,186, and 6,590,785.

Complete Hardware Guide for EX2200 Ethernet Switches

Copyright © 2010, Juniper Networks, Inc.

All rights reserved. Printed in USA.

Writing: Appumon Joseph, Aviva Garrett, Greg Houde, Hemraj Rao S, Hareesh Kumar K N, Keldyn West, Shikha Kalra, Steve Levine

Editing: Cindy Martin, Rajan V K

Illustration: Faith Bradford Brown

Cover Design:

Revision History

17 February 2010—Revision 1

May 2010—Revision 2

August 2010—Revision 3

December 2010—Revision 4

The information in this document is current as of the date listed in the revision history.

YEAR 2000 NOTICE

Juniper Networks hardware and software products are Year 2000 compliant. The Junos OS has no known time-related limitations through

the year 2038. However, the NTP application is known to have some difficulty in the year 2036.

SOFTWARE LICENSE

Copyright © 2010, Juniper Networks, Inc.ii

Page 3

The terms and conditions for using this software are described in the software license contained in the acknowledgment to your purchase

order or, to the extent applicable, to any reseller agreement or end-user purchase agreement executed between you and Juniper Networks.

By using this software, you indicate that you understand and agree to be bound by those terms and conditions.

Generally speaking, the software license restricts the manner in which you are permitted to use the software and may contain prohibitions

against certain uses. The software license may state conditions under which the license is automatically terminated. You should consult

the license for further details.

For complete product documentation, please see the Juniper Networks Web site at www.juniper.net/techpubs.

iiiCopyright © 2010, Juniper Networks, Inc.

Page 4

END USER LICENSE AGREEMENT

READ THIS END USER LICENSE AGREEMENT (“AGREEMENT”) BEFORE DOWNLOADING, INSTALLING, OR USING THE SOFTWARE.

BY DOWNLOADING, INSTALLING, OR USING THE SOFTWARE OR OTHERWISE EXPRESSING YOUR AGREEMENT TO THE TERMS

CONTAINED HEREIN, YOU (AS CUSTOMER OR IF YOU ARE NOT THE CUSTOMER, AS A REPRESENTATIVE/AGENT AUTHORIZED TO

BIND THE CUSTOMER) CONSENT TO BE BOUND BY THIS AGREEMENT. IF YOU DO NOT OR CANNOT AGREE TO THE TERMS CONTAINED

HEREIN, THEN (A) DO NOT DOWNLOAD, INSTALL, OR USE THE SOFTWARE, AND (B) YOU MAY CONTACT JUNIPER NETWORKS

REGARDING LICENSE TERMS.

1. The Parties. The parties to this Agreement are (i) Juniper Networks, Inc. (if the Customer’s principal office is located in the Americas) or

Juniper Networks (Cayman) Limited (if the Customer’s principal office is located outside the Americas) (such applicable entity being referred

to herein as “Juniper”), and (ii) the person or organizationthat originally purchased from Juniper or an authorized Juniper reseller the applicable

license(s) for use of the Software (“Customer”) (collectively, the “Parties”).

2. The Software. In this Agreement, “Software” means the program modules and features of the Juniper or Juniper-supplied software, for

which Customer has paid the applicable license or support fees to Juniper or an authorized Juniper reseller, or which was embedded by

Juniper in equipment which Customer purchased from Juniper or an authorized Juniper reseller. “Software” also includes updates, upgrades

and new releases of such software. “Embedded Software” means Software which Juniper has embedded in or loaded onto the Juniper

equipment and any updates, upgrades, additions or replacements which are subsequently embedded in or loaded onto the equipment.

3. License Grant. Subject to payment of the applicable fees and the limitations and restrictions set forth herein, Juniper grants to Customer

a non-exclusive and non-transferable license, without right to sublicense, to use the Software, in executable form only, subject to the

following use restrictions:

a. Customer shall use Embedded Software solely as embedded in, and for execution on, Juniper equipment originally purchased by

Customer from Juniper or an authorized Juniper reseller.

b. Customer shall use the Software on a single hardware chassis having a single processing unit, or as many chassis or processing units

for which Customer has paid the applicable license fees; provided, however, with respect to the Steel-Belted Radius or Odyssey Access

Client software only, Customer shall use such Software on a single computer containing a single physical random access memory space

and containing any number of processors. Use of the Steel-Belted Radius or IMS AAA software on multiple computers or virtual machines

(e.g., Solaris zones) requires multiple licenses, regardless of whether such computers or virtualizations are physically contained on a single

chassis.

c. Product purchase documents, paper or electronic user documentation, and/or the particular licenses purchased by Customer may

specify limits to Customer’s use of the Software.Such limits may restrict use to a maximum number of seats, registeredendpoints, concurrent

users, sessions, calls, connections, subscribers, clusters, nodes, realms, devices, links, ports or transactions, or require the purchase of

separate licenses to use particular features, functionalities, services, applications, operations, or capabilities, or provide throughput,

performance, configuration, bandwidth, interface, processing, temporal, or geographical limits. In addition, such limits may restrict the use

of the Software to managing certain kinds of networks or require the Software to be used only in conjunction with other specific Software.

Customer’s use of the Software shall be subject to all such limitations and purchase of all applicable licenses.

d. For any trial copy of the Software, Customer’s right to use the Software expires 30 days after download, installation or use of the

Software. Customer may operate the Software after the 30-day trial period only if Customer pays for a license to do so. Customer may not

extend or create an additional trial period by re-installing the Software after the 30-day trial period.

e. The Global Enterprise Edition of the Steel-Belted Radius software may be used by Customer only to manage access to Customer’s

enterprise network. Specifically, service provider customers are expressly prohibited from using the Global Enterprise Edition of the

Steel-Belted Radius software to support any commercial network access services.

The foregoing license is not transferable or assignable by Customer. No license is granted herein to any user who did not originally purchase

the applicable license(s) for the Software from Juniper or an authorized Juniper reseller.

4. Use Prohibitions. Notwithstanding the foregoing, the license provided herein does not permit the Customer to, and Customer agrees

not to and shall not: (a) modify, unbundle, reverse engineer, or create derivative works based on the Software; (b) make unauthorized

copies of the Software (except as necessary for backup purposes); (c) rent, sell, transfer, or grant any rights in and to any copy of the

Software,in any form, to any third party; (d) removeany proprietary notices, labels, or marks on or in any copy of the Software or any product

in which the Software is embedded; (e) distribute any copy of the Software to any third party, including as may be embedded in Juniper

equipment sold in the secondhand market; (f) use any ‘locked’ or key-restrictedfeature,function, service, application, operation,or capability

without first purchasing the applicable license(s) and obtaining a valid key from Juniper, even if such feature, function, service, application,

operation, or capability is enabled without a key; (g) distribute any key for the Software provided by Juniper to any third party; (h) use the

Copyright © 2010, Juniper Networks, Inc.iv

Page 5

Software in any manner that extends or is broader than the uses purchased by Customer from Juniper or an authorized Juniper reseller; (i)

use Embedded Software on non-Juniper equipment; (j) use Embedded Software (or make it available for use) on Juniper equipment that

the Customer did not originally purchase from Juniper or an authorized Juniper reseller; (k) disclose the results of testing or benchmarking

of the Software to any third party without the prior written consent of Juniper; or (l) use the Software in any manner other than as expressly

provided herein.

5. Audit. Customer shall maintain accurate records as necessary to verify compliance with this Agreement. Upon request by Juniper,

Customer shall furnish such records to Juniper and certify its compliance with this Agreement.

6. Confidentiality. The Parties agree that aspects of the Software and associated documentation are the confidential property of Juniper.

As such, Customer shall exercise all reasonablecommercial efforts to maintain the Software and associated documentation in confidence,

which at a minimum includes restricting access to the Software to Customer employees and contractors having a need to use the Software

for Customer’s internal business purposes.

7. Ownership. Juniper and Juniper’s licensors, respectively, retain ownership of all right, title, and interest (including copyright) in and to

the Software, associated documentation, and all copies of the Software. Nothing in this Agreement constitutes a transfer or conveyance

of any right, title, or interest in the Software or associated documentation, or a sale of the Software, associated documentation, or copies

of the Software.

8. Warranty, Limitation of Liability, Disclaimer of Warranty. The warranty applicable to the Software shall be as set forth in the warranty

statementthataccompaniesthe Software (the “WarrantyStatement”).Nothing in this Agreement shall give rise to any obligationto support

the Software. Support services may be purchased separately.Any such support shall be governed by a separate, written support services

agreement. TO THE MAXIMUM EXTENT PERMITTED BY LAW, JUNIPER SHALL NOT BE LIABLE FOR ANY LOST PROFITS, LOSS OF DATA,

OR COSTSOR PROCUREMENTOF SUBSTITUTEGOODS OR SERVICES, OR FOR ANY SPECIAL, INDIRECT,OR CONSEQUENTIALDAMAGES

ARISING OUT OF THIS AGREEMENT,THE SOFTWARE, OR ANY JUNIPER OR JUNIPER-SUPPLIED SOFTWARE. IN NO EVENT SHALL JUNIPER

BE LIABLE FOR DAMAGES ARISING FROM UNAUTHORIZED OR IMPROPER USE OF ANY JUNIPER OR JUNIPER-SUPPLIED SOFTWARE.

EXCEPT AS EXPRESSLY PROVIDED IN THE WARRANTY STATEMENT TO THE EXTENT PERMITTED BY LAW, JUNIPER DISCLAIMS ANY

AND ALL WARRANTIES IN AND TO THE SOFTWARE (WHETHER EXPRESS, IMPLIED, STATUTORY, OR OTHERWISE), INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR NONINFRINGEMENT. IN NO EVENT DOES

JUNIPER WARRANT THAT THE SOFTWARE, OR ANY EQUIPMENT OR NETWORK RUNNING THE SOFTWARE, WILL OPERATE WITHOUT

ERROR OR INTERRUPTION, OR WILL BE FREE OF VULNERABILITY TO INTRUSION OR ATTACK. In no event shall Juniper’s or its suppliers’

or licensors’ liability to Customer, whether in contract, tort (including negligence), breach of warranty, or otherwise, exceed the price paid

by Customer for the Software that gave rise to the claim, or if the Software is embedded in another Juniper product, the price paid by

Customer for such other product. Customer acknowledges and agrees that Juniper has set its prices and entered into this Agreement in

reliance upon the disclaimers of warranty and the limitations of liability set forth herein, that the same reflect an allocation of risk between

the Parties (including the risk that a contract remedy may fail of its essential purpose and cause consequential loss), and that the same

form an essential basis of the bargain between the Parties.

9. Termination. Any breach of this Agreement or failure by Customer to pay any applicable fees due shall result in automatic termination

of the license granted herein. Upon such termination, Customer shall destroy or return to Juniper all copies of the Software and related

documentation in Customer’s possession or control.

10. Taxes. All license fees payable under this agreement are exclusive of tax. Customer shall be responsible for paying Taxes arising from

the purchase of the license, or importation or use of the Software. If applicable, valid exemption documentation for each taxing jurisdiction

shall be provided to Juniper prior to invoicing, and Customer shall promptly notify Juniper if their exemption is revoked or modified. All

payments made by Customer shall be net of any applicable withholding tax. Customer will provide reasonable assistance to Juniper in

connection with such withholding taxes by promptly: providing Juniper with valid tax receipts and other required documentation showing

Customer’s payment of any withholding taxes; completing appropriate applications that would reduce the amount of withholding tax to

be paid; and notifying and assisting Juniper in any audit or tax proceeding related to transactions hereunder. Customer shall comply with

all applicable tax laws and regulations, and Customer will promptly pay or reimburse Juniper for all costs and damages related to any

liability incurred by Juniper as a result of Customer’s non-compliance or delay with its responsibilities herein. Customer’s obligations under

this Section shall survive termination or expiration of this Agreement.

11. Export. Customer agrees to comply with all applicable export laws and restrictions and regulations of any United States and any

applicable foreign agency or authority, and not to export or re-export the Software or any direct product thereof in violation of any such

restrictions, laws or regulations, or without all necessary approvals. Customer shall be liable for any such violations. The version of the

Software supplied to Customer may contain encryption or other capabilities restricting Customer’s ability to export the Software without

an export license.

vCopyright © 2010, Juniper Networks, Inc.

Page 6

12. Commercial Computer Software. The Software is “commercial computer software” and is provided with restricted rights. Use,

duplication, or disclosure by the United States government is subject to restrictions set forth in this Agreement and as provided in DFARS

227.7201 through 227.7202-4, FAR 12.212, FAR 27.405(b)(2), FAR 52.227-19, or FAR 52.227-14(ALT III) as applicable.

13. Interface Information. To the extent required by applicable law, and at Customer's written request, Juniper shall provide Customer

with the interface information needed to achieve interoperability between the Software and another independently created program, on

payment of applicable fee, if any. Customer shall observe strict obligations of confidentiality with respect to such information and shall use

such information in compliance with any applicable terms and conditions upon which Juniper makes such information available.

14. Third Party Software. Any licensor of Juniper whose software is embedded in the Software and any supplier of Juniper whose products

or technology are embedded in (or services are accessed by) the Software shall be a third party beneficiary with respect to this Agreement,

and such licensor or vendor shall have the right to enforce this Agreement in its own name as if it were Juniper. In addition, certain third party

software may be provided with the Software and is subject to the accompanying license(s), if any, of its respective owner(s). To the extent

portions of the Software are distributed under and subject to open source licenses obligating Juniper to make the source code for such

portions publicly available (such as the GNU General Public License (“GPL”) or the GNU Library General Public License (“LGPL”)), Juniper

will make such source code portions (including Juniper modifications, as appropriate) available upon request for a period of up to three

years from the date of distribution. Such request can be made in writing to Juniper Networks, Inc., 1194 N. Mathilda Ave., Sunnyvale, CA

94089, ATTN: General Counsel. You may obtain a copy of the GPL at http://www.gnu.org/licenses/gpl.html, and a copy of the LGPL

at http://www.gnu.org/licenses/lgpl.html .

15. Miscellaneous. This Agreement shall be governed by the laws of the State of California without reference to its conflicts of laws

principles. The provisions of the U.N. Convention for the International Sale of Goods shall not apply to this Agreement. For any disputes

arising under this Agreement, the Parties hereby consent to the personal and exclusive jurisdiction of, and venue in, the state and federal

courts within Santa Clara County, California. This Agreement constitutes the entire and sole agreement between Juniper and the Customer

with respect to the Software, and supersedes all prior and contemporaneous agreements relating to the Software, whether oral or written

(including any inconsistent terms contained in a purchase order), except that the terms of a separate written agreement executed by an

authorized Juniper representative and Customer shall govern to the extent such terms are inconsistent or conflict with terms contained

herein. No modification to this Agreement nor any waiver of any rights hereunder shall be effective unless expressly assented to in writing

by the party to be charged. If any portion of this Agreement is held invalid, the Parties agree that such invalidity shall not affect the validity

of the remainder of this Agreement. This Agreement and associated documentation has been written in the English language, and the

Parties agree that the English version will govern. (For Canada: Les parties aux présentés confirment leur volonté que cette convention de

même que tous les documents y compris tout avis qui s'y rattaché, soient redigés en langue anglaise. (Translation: The parties confirm that

this Agreement and all related documentation is and will be in the English language)).

Copyright © 2010, Juniper Networks, Inc.vi

Page 7

Table of Contents

About This Topic Collection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

How to Use This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

List of EX Series Guides for Junos OS Release 10.4 . . . . . . . . . . . . . . . . . . . . . . . . . xv

Downloading Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Documentation Symbols Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Documentation Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

Requesting Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

Self-Help Online Tools and Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

Opening a Case with JTAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

Part 1 Switch and Components Overview and Specifications

Chapter 1 EX2200 Switch Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

EX2200 Switches Hardware Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

EX2200 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Uplink Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Power over Ethernet (PoE) Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

EX2200 Switch Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chassis Physical Specifications for EX2200 Switches . . . . . . . . . . . . . . . . . . . . . . . 5

Front Panel of an EX2200 Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Rear Panel of an EX2200 Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

EX2200 Switch Hardware and CLI Terminology Mapping . . . . . . . . . . . . . . . . . . . . 7

Chapter 2 Component Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chassis Status LEDs in EX2200 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Network Port and Uplink Port LEDs in EX2200 Switches . . . . . . . . . . . . . . . . . . . . 12

Management Port LEDs in EX2200 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Power Supply in EX2200 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cooling System and Airflow in an EX2200 Switch . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 3 Component Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

USB Port Specifications for an EX Series Switch . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Network Port Connector Pinout Information for an EX2200 Switch . . . . . . . . . . . 20

Console Port Connector Pinout Information for an EX Series Switch . . . . . . . . . . . 21

Management Port Connector Pinout Information for an EX2200 Switch . . . . . . . 22

Optical Interface Support in EX2200 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

viiCopyright © 2010, Juniper Networks, Inc.

Page 8

Complete Hardware Guide for EX2200 Ethernet Switches

Part 2 Planning for Switch Installation

Chapter 4 Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Site Preparation Checklist for EX2200 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . 33

General Site Guidelines for EX Series Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Site Electrical Wiring Guidelines for EX Series Switches . . . . . . . . . . . . . . . . . . . . 35

Environmental Requirements and Specifications for EX Series Switches . . . . . . . 36

Chapter 5 Mounting and Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Rack Requirements for EX2200 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cabinet Requirements for EX2200 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Requirements for Mounting an EX2200 Switch on a Desktop or Wall . . . . . . . . . 42

Clearance Requirements for Airflow and Hardware Maintenance for EX2200

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Chapter 6 Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Network Cable Specifications for EX2200 Switches . . . . . . . . . . . . . . . . . . . . . . . 45

Chapter 7 Planning Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Power Specifications for EX2200 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

AC Power Cord Specifications for EX2200 Switches . . . . . . . . . . . . . . . . . . . . . . . 47

Part 3 Installing and Connecting the Switch and Switch Components

Chapter 8 Installing the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Installing and Connecting an EX2200 Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Unpacking an EX2200 Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Mounting an EX2200 Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Mounting an EX2200 Switch on a Desk or Other Level Surface . . . . . . . . . . . . . . 54

Mounting an EX2200 Switch on Two Posts in a Rack or Cabinet . . . . . . . . . . . . . 55

Mounting an EX2200 Switch on Four Posts in a Rack or Cabinet . . . . . . . . . . . . . 57

Mounting an EX2200 Switch in a Recessed Position in a Rack or Cabinet . . . . . . 61

Mounting an EX2200 Switch on a Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Chapter 9 Installing Switch Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Installing a Transceiver in an EX Series Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Chapter 10 Connecting the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Connecting Earth Ground to an EX Series Switch . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Connecting Earth Ground to an EX2200 or EX3200 Switch . . . . . . . . . . . . . 68

Connecting Earth Ground to an EX4200 Switch . . . . . . . . . . . . . . . . . . . . . . . 69

Connecting Earth Ground to an EX4500 Switch . . . . . . . . . . . . . . . . . . . . . . . 70

Connecting Earth Ground to an EX8208 Switch . . . . . . . . . . . . . . . . . . . . . . . 71

Connecting Earth Ground to an EX8216 Switch . . . . . . . . . . . . . . . . . . . . . . . . 72

Connecting AC Power to an EX2200 Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Connecting an EX Series Switch to a Network for Out-of-Band Management . . . 74

Connecting an EX Series Switch to a Management Console . . . . . . . . . . . . . . . . . 76

Connecting an EX Series Switch to a Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Setting the Serial Console Speed for the Switch . . . . . . . . . . . . . . . . . . . . . . . 78

Configuring the Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Connecting the Modem to the Console Port . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Copyright © 2010, Juniper Networks, Inc.viii

Page 9

Table of Contents

Connecting a Fiber-Optic Cable to an EX Series Switch . . . . . . . . . . . . . . . . . . . . . 81

Chapter 11 Performing Initial Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

EX2200 Switch Default Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Connecting and Configuring an EX Series Switch (CLI Procedure) . . . . . . . . . . . . 87

Connecting and Configuring an EX Series Switch (J-Web Procedure) . . . . . . . . . 89

Part 4 Removing Switch Components

Chapter 12 Removing Switch Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Removing a Transceiver from an EX Series Switch . . . . . . . . . . . . . . . . . . . . . . . . . 95

Disconnecting a Fiber-Optic Cable from an EX Series Switch . . . . . . . . . . . . . . . . 97

Part 5 Switch and Component Maintenance

Chapter 13 Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Maintaining Fiber-Optic Cables in EX Series Switches . . . . . . . . . . . . . . . . . . . . . 101

Part 6 Returning Hardware

Chapter 14 Returning the Switch or Switch Components . . . . . . . . . . . . . . . . . . . . . . . . 105

Returning an EX2200 Switch or Component for Repair or Replacement . . . . . . 105

Locating the Serial Number on an EX2200 Switch or Component . . . . . . . . . . . 106

Listing the Switch and Components Details with the CLI . . . . . . . . . . . . . . . 106

Locating the Chassis Serial Number ID Label on an EX2200 Switch . . . . . . 106

Contacting Customer Support to Obtain Return Materials Authorization for EX

Series Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Packing an EX2200 Switch or Component for Shipping . . . . . . . . . . . . . . . . . . . 108

Packing a Switch for Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Packing Switch Components for Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Part 7 Safety Information

Chapter 15 General Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

General Safety Guidelines and Warnings for EX Series Switches . . . . . . . . . . . . . 113

Definitions of Safety Warning Levels for EX Series Switches . . . . . . . . . . . . . . . . . 114

Fire Safety Requirements for EX Series Switches . . . . . . . . . . . . . . . . . . . . . . . . . 116

Qualified Personnel Warning for EX Series Switches . . . . . . . . . . . . . . . . . . . . . . . 117

Warning Statement for Norway and Sweden for EX Series Switches . . . . . . . . . . 118

Chapter 16 Radiation and Laser Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Laser and LED Safety Guidelines and Warnings for EX Series Switches . . . . . . . . 121

General Laser Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Class 1 Laser Product Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Class 1 LED Product Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Laser Beam Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Radiation from Open Port Apertures Warning for EX Series Switches . . . . . . . . . 124

Chapter 17 Installation and Maintenance Safety Information . . . . . . . . . . . . . . . . . . . . . 127

Installation Instructions Warning for EX Series Switches . . . . . . . . . . . . . . . . . . . 127

Chassis Lifting Guidelines for EX2200 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . 128

ixCopyright © 2010, Juniper Networks, Inc.

Page 10

Complete Hardware Guide for EX2200 Ethernet Switches

Ramp Warning for EX Series Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Rack-Mounting and Cabinet-Mounting Warnings for EX Series Switches . . . . . . 129

Wall-Mounting Warnings for EX2200 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Grounded Equipment Warning for EX Series Switches . . . . . . . . . . . . . . . . . . . . . 134

Maintenance and Operational Safety Guidelines and Warnings for EX Series

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Jewelry Removal Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Lightning Activity Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Operating Temperature Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Product Disposal Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Chapter 18 Power and Electrical Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

General Electrical Safety Guidelines and Warnings for EX Series Switches . . . . . 141

Prevention of Electrostatic Discharge Damage on EX Series Switches . . . . . . . . 142

AC Power Electrical Safety Guidelines for EX Series Switches . . . . . . . . . . . . . . . 144

AC Power Disconnection Warning for EX Series Switches . . . . . . . . . . . . . . . . . . 145

TN Power Warning for EX Series Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

In Case of Electrical Accident: Action to Take on an EX Series Switch . . . . . . . . . 147

Part 8 Compliance Information

Chapter 19 Compliance Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Agency Approvals for EX Series Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Compliance Statements for EMC Requirements for EX Series Switches . . . . . . . 152

Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

European Community . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Japan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

United States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

FCC Part 15 Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Non-Regulatory Environmental Standards . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Compliance Statements for Acoustic Noise for EX Series Switches . . . . . . . . . . 154

Declaration of Conformity for EX2200 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Copyright © 2010, Juniper Networks, Inc.x

Page 11

List of Figures

Part 1 Switch and Components Overview and Specifications

Chapter 1 EX2200 Switch Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Figure 1: Front Panel of an EX2200 Switch with 48 Gigabit Ethernet Ports . . . . . . 6

Figure 2: Front Panel of an EX2200 Switch with 24 Gigabit Ethernet Ports . . . . . . 6

Figure 3: Rear Panel of an EX2200 Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 2 Component Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 4: Chassis Status LEDs in an EX2200 Switch . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 5: LEDs on the Network Ports on the Front Panel . . . . . . . . . . . . . . . . . . . . . 12

Figure 6: LEDs on the Uplink Ports and Port Status Mode LEDs . . . . . . . . . . . . . . . 12

Figure 7: LEDs on the Management Port on an EX2200 Switch . . . . . . . . . . . . . . . 14

Figure 8: Airflow Through Non-PoE Models of EX2200 Switches . . . . . . . . . . . . . 16

Figure 9: Airflow Through PoE Models of EX2200 Switches . . . . . . . . . . . . . . . . . . 16

Part 2 Planning for Switch Installation

Chapter 5 Mounting and Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 10: Clearance Requirements for Airflow and Hardware Maintenance for

EX2200 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 11: Airflow Through PoE Models of EX2200 Switches . . . . . . . . . . . . . . . . . 43

Figure 12: Airflow Through Non-PoE Models of EX2200 Switches . . . . . . . . . . . . 43

Chapter 7 Planning Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 13: AC Plug Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Part 3 Installing and Connecting the Switch and Switch Components

Chapter 8 Installing the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 14: Attaching Rubber Feet to a Switch Chassis . . . . . . . . . . . . . . . . . . . . . . 55

Figure 15: Attaching the Mounting Bracket Along the Front of the Switch . . . . . . 56

Figure 16: Mounting the Switch on Two Posts in a Rack . . . . . . . . . . . . . . . . . . . . . 57

Figure 17: Attaching the Front Bracket to the Side-Rail Bracket . . . . . . . . . . . . . . . 59

Figure 18: Attaching the Side-Rail Bracket to the Switch Chassis . . . . . . . . . . . . . 59

Figure 19: Mounting the Switch to the Front Posts in a Rack . . . . . . . . . . . . . . . . . 60

Figure 20: Sliding the Rear Brackets to the Rear of a Four-Post Rack . . . . . . . . . . 60

Figure 21: Attaching Wall-Mount Brackets to a Switch Chassis . . . . . . . . . . . . . . . 62

Figure 22: Measuring for Mounting Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 23: Mounting a Switch on a Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Chapter 9 Installing Switch Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 24: Installing a Transceiver in an EX Series Switch . . . . . . . . . . . . . . . . . . . 66

xiCopyright © 2010, Juniper Networks, Inc.

Page 12

Complete Hardware Guide for EX2200 Ethernet Switches

Chapter 10 Connecting the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 25: Connecting a Grounding Cable to an EX Series Switch . . . . . . . . . . . . . 67

Figure 26: Connecting the Grounding Lug to an EX4200 Switch on a Four-Post

Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 27: Connecting an AC Power Cord Retainer Clip to the AC Power Cord

Inlet on an EX2200 Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Figure 28: Connecting an AC Power Cord to the AC Power Cord Inlet on an

EX2200 Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Figure 29: Ethernet Cable Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 30: Connecting an EX Series Switch to a Network for Out-of-Band

Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 31: Ethernet Cable Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 32: Connecting an EX Series Switch to a Management Console Through

a Console Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 33: Connecting an EX Series Switch Directly to a Management

Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 34: Ethernet Cable Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 35: Connecting a Fiber-Optic Cable to an Optical Transceiver Installed in

an EX Series Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Chapter 11 Performing Initial Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Figure 36: LCD Panel in an EX3200, EX4200, EX4500, or EX8200 Switch . . . . . 90

Part 4 Removing Switch Components

Chapter 12 Removing Switch Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Figure 37: Removing a Transceiver from an EX Series Switch . . . . . . . . . . . . . . . . 96

Part 6 Returning Hardware

Chapter 14 Returning the Switch or Switch Components . . . . . . . . . . . . . . . . . . . . . . . . 105

Figure 38: Location of the Serial Number ID Label on EX2200 Switches . . . . . . . 107

Part 7 Safety Information

Chapter 18 Power and Electrical Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Figure 39: Place a Component into an Antistatic Bag . . . . . . . . . . . . . . . . . . . . . . 143

Copyright © 2010, Juniper Networks, Inc.xii

Page 13

List of Tables

Part 1 Switch and Components Overview and Specifications

Chapter 1 EX2200 Switch Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Table 1: EX2200 Switch Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 2: Physical Specifications of the EX2200 Switch Chassis . . . . . . . . . . . . . . . 5

Table 3: CLI Equivalents of Terms Used in Documentation for EX2200

Chapter 2 Component Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 4: Chassis Status LEDs in an EX2200 Switch . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 5: Link/Activity LED on the Network Ports and Uplink Ports in EX2200

Table 6: Status LED on the Network Ports and Uplink Ports in EX2200

Table 7: Link/Activity LED on the Management Port on an EX2200 Switch . . . . . . 14

Table 8: Status LED on the Management Port on an EX2200 Switch . . . . . . . . . . 14

Table 9: Power Consumed by EX2200 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 3 Component Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 10: Network Port Connector Pinout Information for EX2200 Switches . . . . 20

Table 11: EX Series Switches Console Port Connector Pinout Information . . . . . . . 21

Table 12: Management Port Connector Pinout Information for EX2200

Table 13: Optical Interface Support and Copper Interface Support for Gigabit

Table14: Optical InterfaceSupport for Fast Ethernet SFP Transceivers in EX2200

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Ethernet SFP Transceivers in EX2200 Switches . . . . . . . . . . . . . . . . . . . . . . . 23

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Part 2 Planning for Switch Installation

Chapter 4 Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 15: Site Preparation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 16: Site Electrical Wiring Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 17: EX Series Switch Environmental Tolerances . . . . . . . . . . . . . . . . . . . . . . 37

Chapter 5 Mounting and Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 18: Rack Requirements and Specifications for the Switch . . . . . . . . . . . . . . 39

Table 19: Cabinet Requirements and Specifications for the Switch . . . . . . . . . . . . 41

Chapter 7 Planning Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 20: AC Power Supply Electrical Specifications for EX2200 Switches . . . . . 47

Table 21: AC Power Cord Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

xiiiCopyright © 2010, Juniper Networks, Inc.

Page 14

Complete Hardware Guide for EX2200 Ethernet Switches

Part 3 Installing and Connecting the Switch and Switch Components

Chapter 8 Installing the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 22: Inventory of Components Provided with an EX2200 Switch . . . . . . . . . 52

Chapter 10 Connecting the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 23: Port Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Copyright © 2010, Juniper Networks, Inc.xiv

Page 15

About This Topic Collection

•

How to Use This Guide on page xv

•

List of EX Series Guides for Junos OS Release 10.4 on page xv

•

Downloading Software on page xvii

•

Documentation Symbols Key on page xviii

•

Documentation Feedback on page xix

•

Requesting Technical Support on page xx

How to Use This Guide

Complete documentation for the EX Series product family is provided on webpages at

http://www.juniper.net/techpubs/en_US/release-independent/information-products/

pathway-pages/ex-series/product/index.html. We have selected content from these

webpages and created a number of EX Series guides that collect related topics into a

book-like format so that the information is easy to print and easy to download to your

local computer.

This guide, Complete Hardware Guide for EX2200 Switches, collectstogether information

about the EX2200 fixed-configuration switches. The release notes are at

http://www.juniper.net/techpubs/en_US/junos10.4/information-products/topic-collections/

release-notes/10.4/junos-release-notes-10.4.pdf.

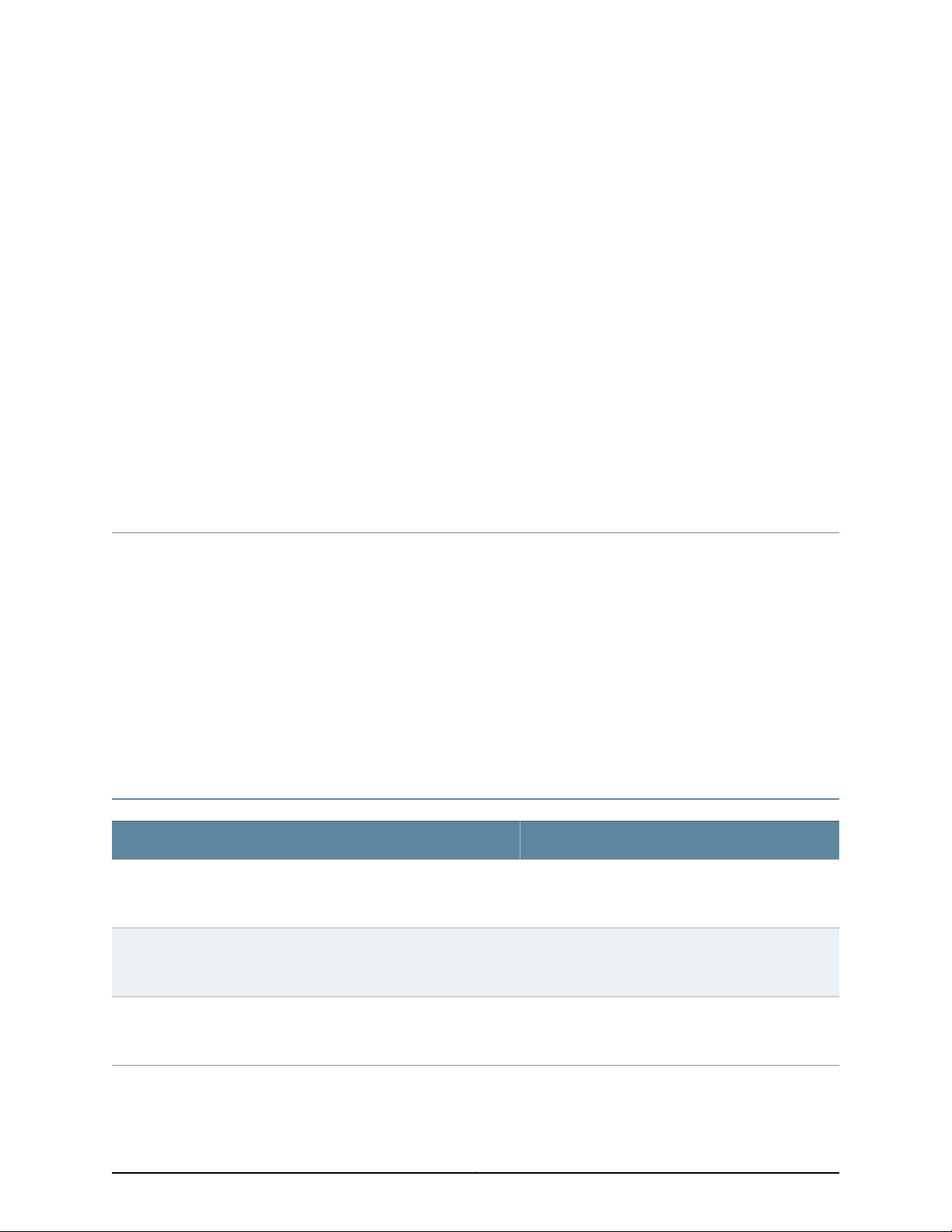

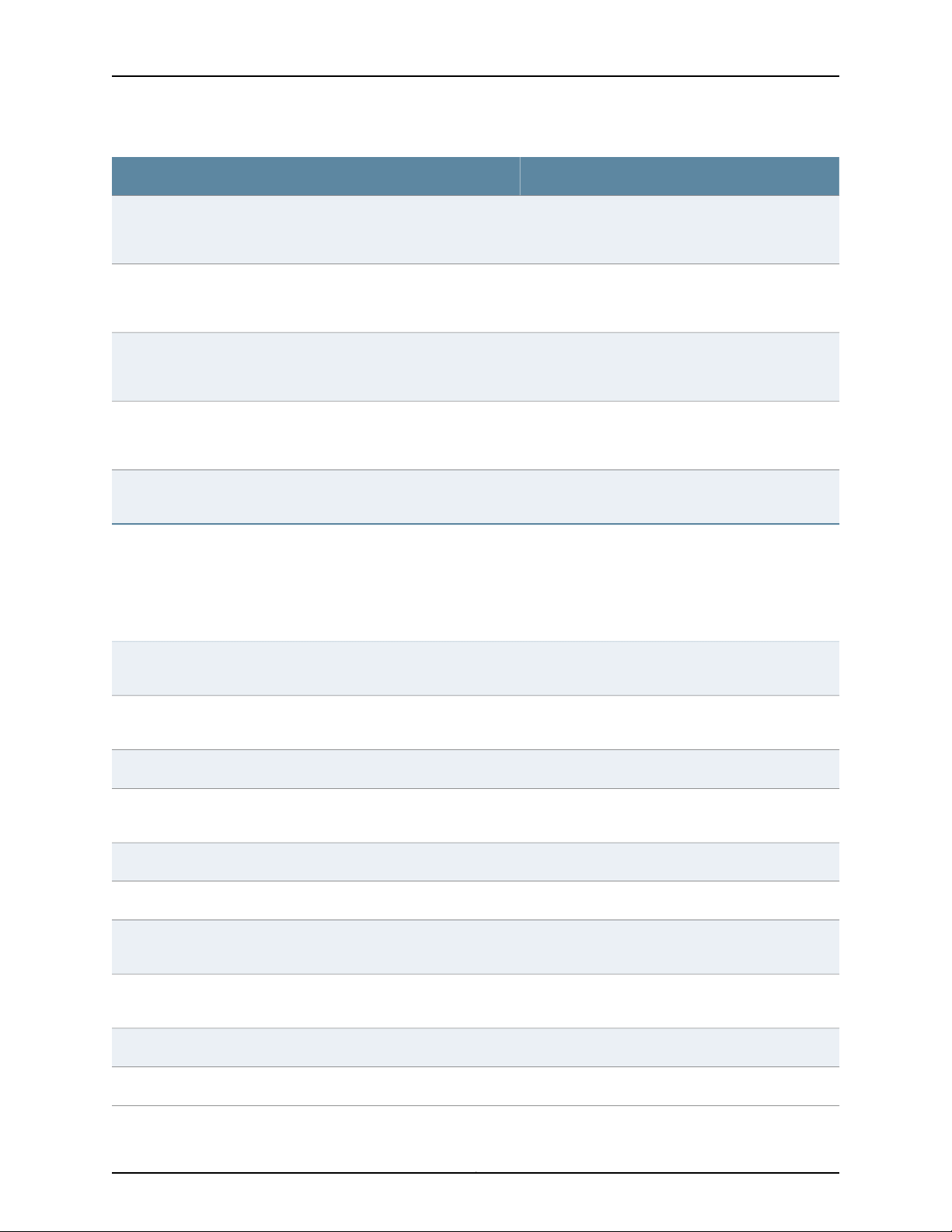

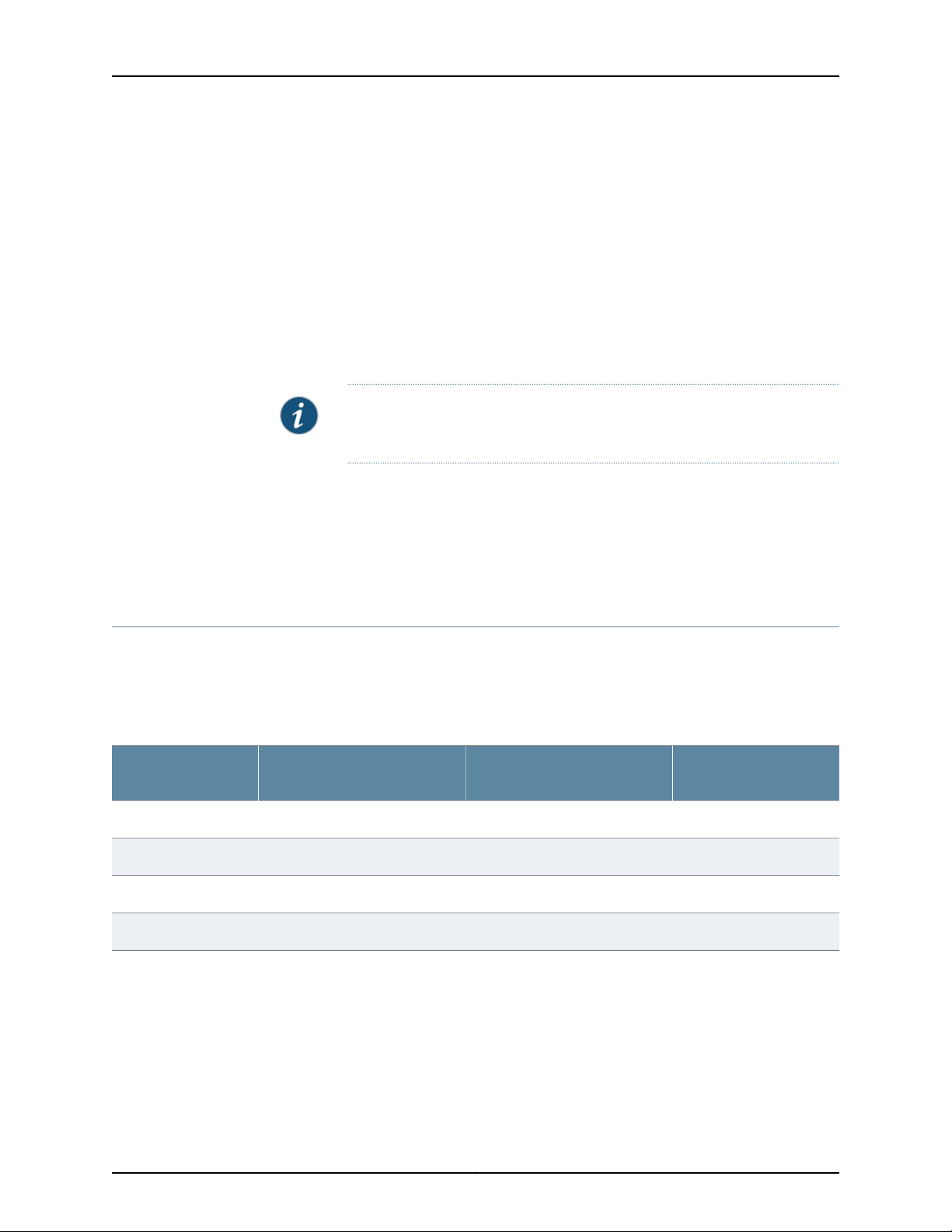

List of EX Series Guides for Junos OS Release 10.4

Complete Hardware Guide for EX2200 Ethernet Switches

Complete Hardware Guide for EX3200 Ethernet Switches

Complete Hardware Guide for EX4200 Ethernet Switches

DescriptionTitle

Component descriptions, site preparation, installation,

replacement, and safety and compliance information

for EX2200 Ethernet switches

Component descriptions, site preparation, installation,

replacement, and safety and compliance information

for EX3200 Ethernet switches

Component descriptions, site preparation, installation,

replacement, and safety and compliance information

for EX4200 Ethernet switches

xvCopyright © 2010, Juniper Networks, Inc.

Page 16

Complete Hardware Guide for EX2200 Ethernet Switches

DescriptionTitle

Complete Hardware Guide for EX4500 Ethernet Switches

Complete Hardware Guide for EX8208 Ethernet Switches

Complete Hardware Guide for EX8216 Ethernet Switches

Complete Hardware Guide for the XRE200 External Routing Engine

CompleteSoftware Guide for Junos®OS for EX Series Ethernet Switches,

Release 10.4

Software Topic Collections

Junos®OS for EX Series Ethernet Switches, Release 10.4: EX4200 Virtual

Chassis

Component descriptions, site preparation, installation,

replacement, and safety and compliance information

for EX4500 Ethernet switches

Component descriptions, site preparation, installation,

replacement, and safety and compliance information

for EX8208 Ethernet switches

Component descriptions, site preparation, installation,

replacement, and safety and compliance information

for EX8216 Ethernet switches

Component descriptions, site preparation, installation,

replacement, and safety and compliance information

for the XRE200 External Routing Engine

Softwarefeaturedescriptions, configurationexamples,

and tasks for Junos OS for EX Series switches

Softwarefeaturedescriptions, configuration examples

and tasks, and reference pages for configuration

statements and operational commands (This

information also appears in the Complete Software

Guide for Junos®OS for EX Series Ethernet Switches,

Release 10.4.)

Junos®OS for EX Series Ethernet Switches, Release 10.4: EX8200 Virtual

Chassis

Junos®OS for EX Series Ethernet Switches, Release 10.4: AccessControl

Junos®OS for EX Series Ethernet Switches, Release 10.4: Configuration

Management

Junos®OS for EX Series Ethernet Switches, Release10.4:Class of Service

Junos®OS for EX Series Ethernet Switches, Release 10.4: Device Security

Junos®OS for EX Series Ethernet Switches, Release 10.4: Ethernet

Switching

Junos®OS for EX Series Ethernet Switches, Release 10.4: Fibre Channel

over Ethernet

Junos®OS for EX Series Ethernet Switches,Release 10.4: High Availability

Junos®OS for EX Series Ethernet Switches, Release 10.4: Interfaces

Copyright © 2010, Juniper Networks, Inc.xvi

Page 17

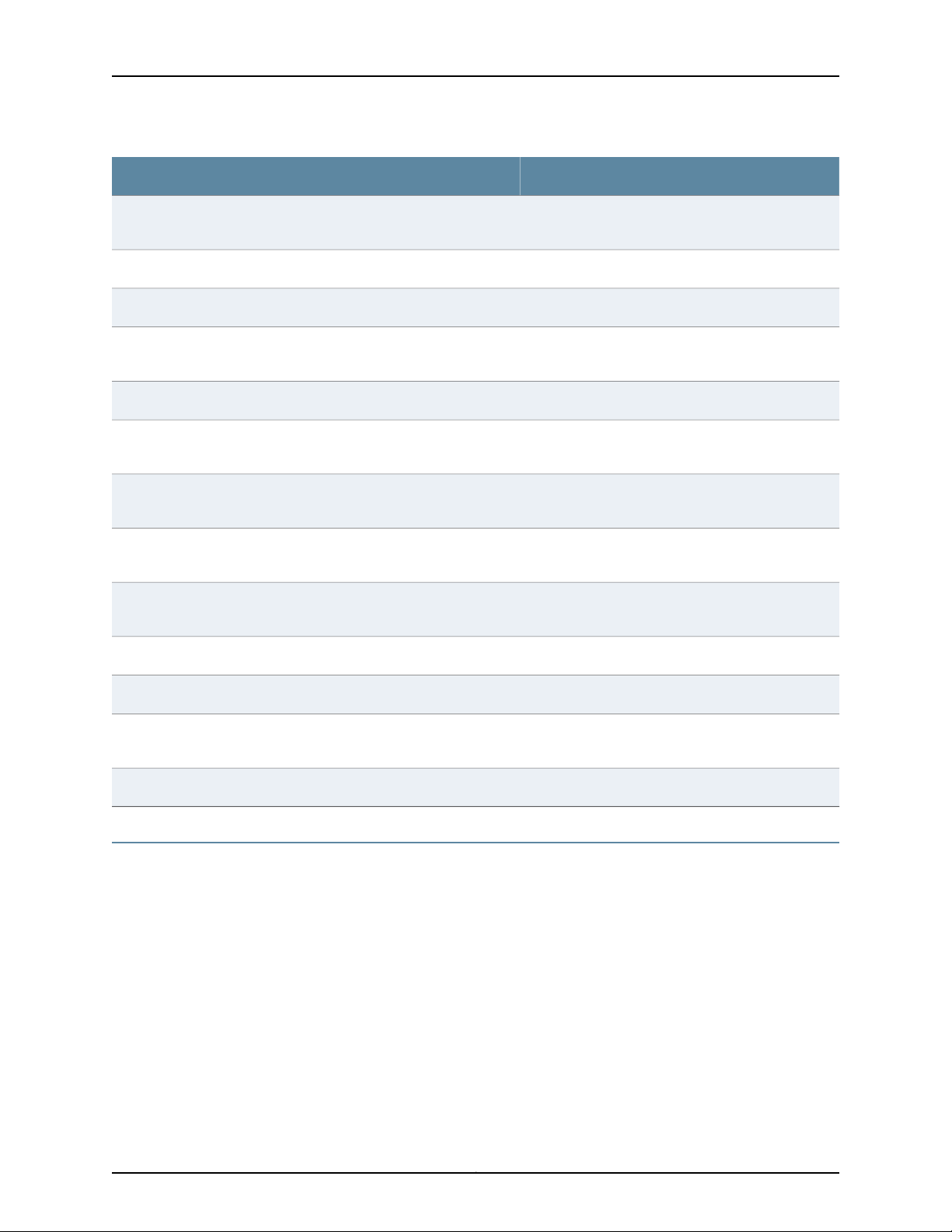

Junos®OS for EX Series Ethernet Switches, Release 10.4: Layer 3

Protocols

Junos®OS for EX Series Ethernet Switches, Release 10.4: MPLS

Junos®OS for EX Series Ethernet Switches, Release 10.4: Multicast

Junos®OS for EX Series Switches, Release 10.4: Network Management

and Monitoring

Junos®OS for EX Series Switches, Release 10.4: Port Security

Junos®OS for EX Series Ethernet Switches, Release 10.4: Routing Policy

and Packet Filtering

Junos®OS for EX Series Ethernet Switches, Release 10.4: Software

Installation

About This Topic Collection

DescriptionTitle

Junos®OS for EX Series Ethernet Switches, Release 10.4: Spanning-Tree

Protocols

Junos®OS for EX Series Ethernet Switches, Release 10.4: System

Monitoring

Junos®OS for EX Series Ethernet Switches, Release 10.4: System Services

Junos®OS for EX Series Ethernet Switches, Release 10.4: System Setup

Junos®OS for EX Series Ethernet Switches, Release 10.4: User and Access

Management

Junos®OS for EX Series Ethernet Switches, Release10.4: User Interfaces

Downloading Software

You can download Junos OS for EX Series switches from the Download Software area

at http://www.juniper.net/customers/support/ . To download the software, you must

have a Juniper Networks user account. For information about obtaining an account, see

http://www.juniper.net/entitlement/setupAccountInfo.do.

xviiCopyright © 2010, Juniper Networks, Inc.

Page 18

Complete Hardware Guide for EX2200 Ethernet Switches

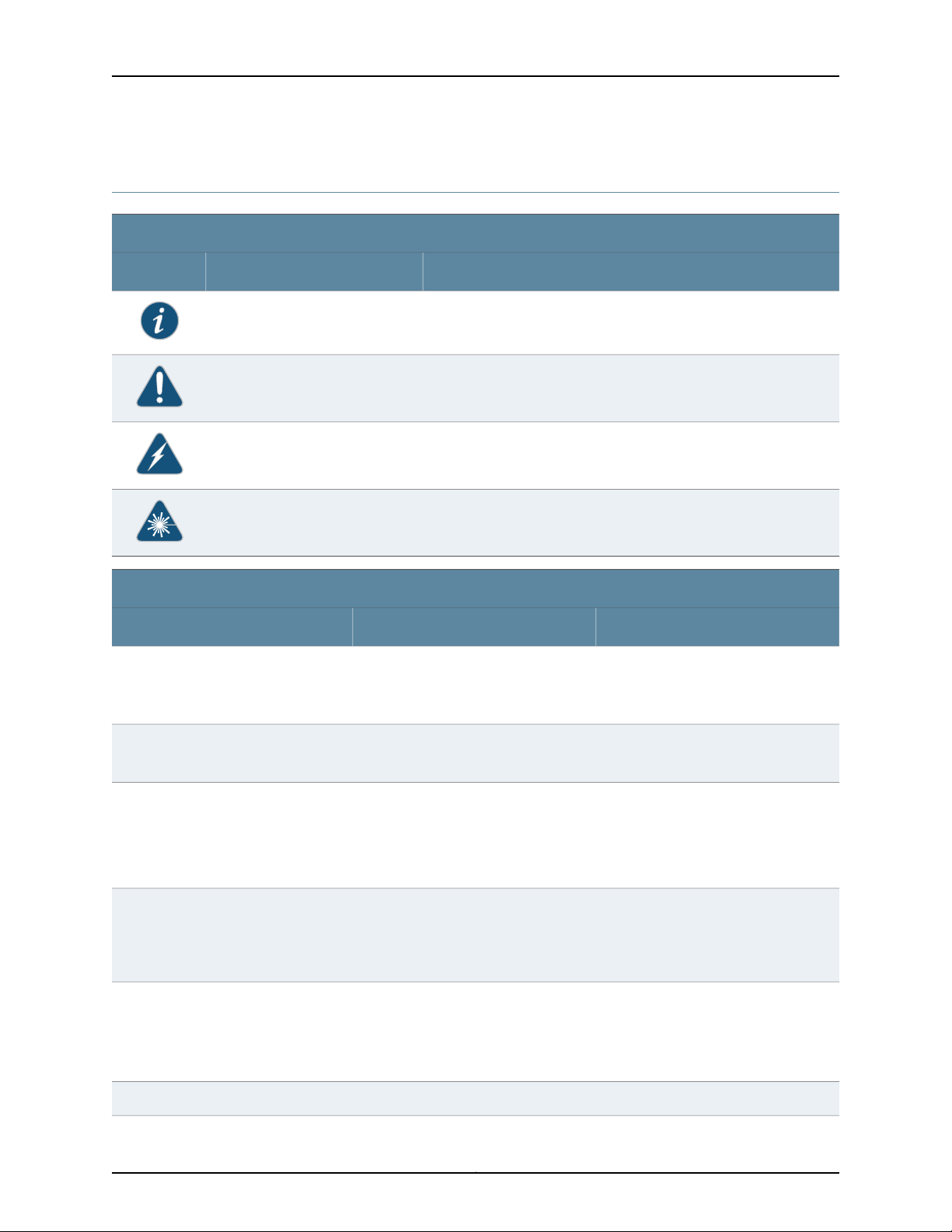

Documentation Symbols Key

Notice Icons

DescriptionMeaningIcon

Indicates important features or instructions.Informational note

Caution

Text and Syntax Conventions

Fixed-width text like this

Italic text like this

Indicates a situation that might result in loss of data or hardware

damage.

Alerts you to the risk of personal injury or death.Warning

Alerts you to the risk of personal injury from a laser.Laser warning

Represents text that you type.Bold text like this

Represents output that appears on the

terminal screen.

•

Introduces important new terms.

•

Identifies book names.

•

Identifies RFC and Internet drafttitles.

ExamplesDescriptionConvention

To enter configuration mode, type the

configure command:

user@host> configure

user@host> show chassis alarms

No alarms currently active

•

A policy term is a named structurethat

defines match conditions and actions.

•

Junos OS System Basics Configuration

Guide

•

RFC 1997, BGP Communities Attribute

Italic text like this

Plain text like this

Represents variables (options for which

you substitute a value) in commands or

configuration statements.

Represents names of configuration

statements, commands, files, and

directories; IP addresses; configuration

hierarchy levels; or labels on routing

platform components.

Configure the machine’s domain name:

[edit]

root@# set system domain-name

domain-name

•

To configure a stub area, include the

stub statement at the [edit protocols

ospf area area-id] hierarchy level.

•

The console port is labeled CONSOLE.

stub <default-metric metric>;Enclose optional keywords or variables.< > (angle brackets)

Copyright © 2010, Juniper Networks, Inc.xviii

Page 19

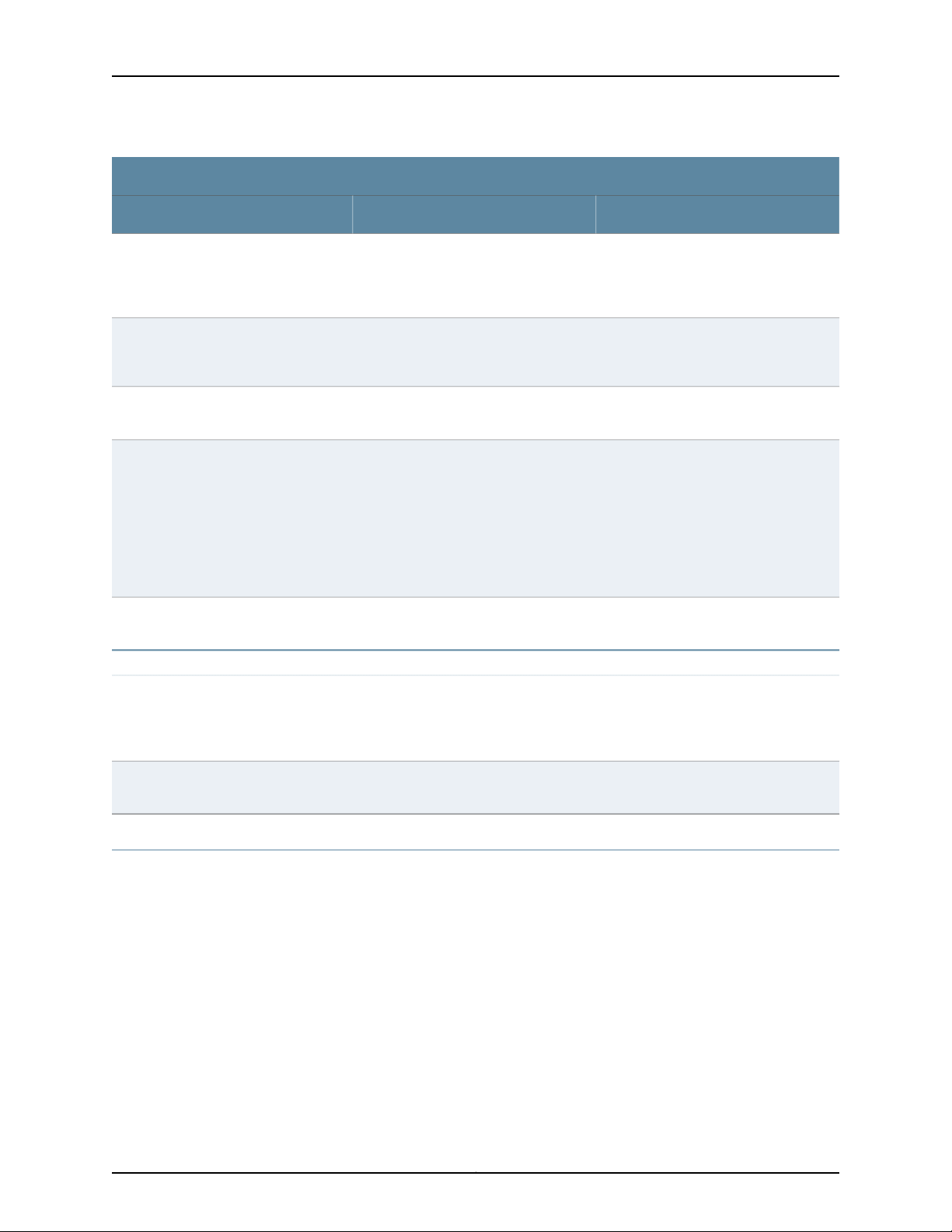

Text and Syntax Conventions

About This Topic Collection

ExamplesDescriptionConvention

| (pipe symbol)

# (pound sign)

[ ] (square brackets)

Indention and braces ( { } )

; (semicolon)

J-Web GUI Conventions

Bold text like this

Indicatesa choice between the mutually

exclusivekeywordsor variableson either

side of the symbol. The set of choices is

often enclosed in parentheses for clarity.

same line as the configurationstatement

to which it applies.

Enclose a variable for which you can

substitute one or more values.

Identify a level in the configuration

hierarchy.

Identifies a leaf statement at a

configuration hierarchy level.

Represents J-Web graphical user

interface (GUI) items you click or select.

broadcast | multicast

(string1 | string2 | string3)

rsvp { # Required for dynamic MPLS onlyIndicates a comment specified on the

community name members [

community-ids ]

[edit]

routing-options {

static {

route default {

nexthop address;

retain;

}

}

}

•

In the Logical Interfaces box, selectAll

Interfaces.

•

To cancel the configuration, click

Cancel.

> (bold right angle bracket)

Documentation Feedback

We encourage you to provide feedback, comments, and suggestions so that we can

improve the documentation. Send e-mail to techpubs-comments@juniper.net with the

following:

•

Document URL or title

•

Page number if applicable

•

Software version

•

Your name and company

Separates levels in a hierarchy of J-Web

selections.

In the configuration editor hierarchy,

select Protocols>Ospf.

xixCopyright © 2010, Juniper Networks, Inc.

Page 20

Complete Hardware Guide for EX2200 Ethernet Switches

Requesting Technical Support

Technicalproduct support is availablethrough the Juniper Networks Technical Assistance

Center (JTAC). If you are a customer with an active J-Care or JNASC support contract,

or are covered under warranty, and need post-sales technical support, you can access

our tools and resources online or open a case with JTAC.

•

JTAC policies—For a complete understanding of our JTAC procedures and policies,

review the JTAC User Guide located at

http://www.juniper.net/us/en/local/pdf/resource-guides/7100059-en.pdf .

•

Product warranties—For product warranty information, visit

http://www.juniper.net/support/warranty/ .

•

JTAC hours of operation—The JTAC centers have resources available 24 hours a day,

7 days a week, 365 days a year.

Self-Help Online Tools and Resources

For quick and easy problem resolution, Juniper Networks has designed an online

self-service portal called the Customer Support Center (CSC) that provides you with the

following features:

•

Find CSC offerings: http://www.juniper.net/customers/support/

•

Search for known bugs: http://www2.juniper.net/kb/

•

Find product documentation: http://www.juniper.net/techpubs/

•

Find solutions and answer questions using our Knowledge Base: http://kb.juniper.net/

•

Download the latest versions of software and review release notes:

http://www.juniper.net/customers/csc/software/

•

Search technical bulletins for relevant hardware and software notifications:

https://www.juniper.net/alerts/

•

Join and participate in the Juniper Networks Community Forum:

http://www.juniper.net/company/communities/

•

Open a case online in the CSC Case Management tool: http://www.juniper.net/cm/

To verify service entitlement by product serial number,use our Serial Number Entitlement

(SNE) Tool: https://tools.juniper.net/SerialNumberEntitlementSearch/

Opening a Case with JTAC

You can open a case with JTAC on the Web or by telephone.

•

Use the Case Management tool in the CSC at http://www.juniper.net/cm/ .

•

Call 1-888-314-JTAC (1-888-314-5822 toll-free in the USA, Canada, and Mexico).

For international or direct-dial options in countries without toll-free numbers, see

http://www.juniper.net/support/requesting-support.html .

Copyright © 2010, Juniper Networks, Inc.xx

Page 21

PART 1

Switch and Components Overview and

Specifications

•

EX2200 Switch Overview on page 3

•

Component Descriptions on page 11

•

Component Specifications on page 19

1Copyright © 2010, Juniper Networks, Inc.

Page 22

Complete Hardware Guide for EX2200 Ethernet Switches

Copyright © 2010, Juniper Networks, Inc.2

Page 23

CHAPTER 1

EX2200 Switch Overview

•

EX2200 Switches Hardware Overview on page 3

•

EX2200 Switch Models on page 4

•

Chassis Physical Specifications for EX2200 Switches on page 5

•

Front Panel of an EX2200 Switch on page 5

•

Rear Panel of an EX2200 Switch on page 6

•

EX2200 Switch Hardware and CLI Terminology Mapping on page 7

EX2200 Switches Hardware Overview

Juniper Networks EX Series Ethernet Switches provide scalable connectivity for the

enterprise market, including branch offices, campus locations, and data centers. The

switches run under the Juniper Networks Junos operating system (Junos OS), which

provides Layer 2 and Layer 3 switching, routing, and security services. The same Junos

OS code base that runs on EX Series switches also runs on all Juniper Networks J Series,

M Series, MX Series, and T Series routers.

EX2200 Switches

Uplink Ports

•

EX2200 Switches on page 3

•

Uplink Ports on page 3

•

Power over Ethernet (PoE) Ports on page 4

Juniper Networks EX2200 Ethernet switches provide connectivity for low-density

environments.

EX2200 switches are available in models with either 24 or 48 built-in network ports and

four uplink ports, with Power over Ethernet (PoE) either available in all built-in network

ports or not available in any built-in network port. All models provide network ports that

have 10/100/1000Base-T Gigabit Ethernet connectors and four uplink ports. These

switches run under Junos OS for EX Series switches.

Each EX2200 switch has four uplink ports that support 1-gigabit small form-factor

pluggable (SFP) transceivers for use with fiber connections and copper connections.

See “Optical Interface Support in EX2200 Switches” on page 22.

3Copyright © 2010, Juniper Networks, Inc.

Page 24

Complete Hardware Guide for EX2200 Ethernet Switches

Power over Ethernet (PoE) Ports

PoEports provide electrical current to devices through the network cables so that separate

power cords for devices such as IP phones, wireless access points, and security cameras

are unnecessary. EX2200 switches are available with full (all 24 or 48 built-in network

ports) or no PoE capability. Full PoE models are primarily used in IP telephony

environments.

EX2200 switches running Junos OS Release 10.3 or later can supply up to 30 W to

individual PoE ports, supporting powered devices that comply with IEEE 802.3af (PoE)

and IEEE 802.3at (PoE+).

NOTE: IEEE 802.3at class 4 powered devices require category 5 or higher

Ethernet cables.

EX2200 switches running Junos OS Release 10.2 or earlier can supply up to 15.4 W to

individual PoE ports, supporting powered devices that comply with IEEE 802.3af (PoE).

Related

Documentation

EX2200 Switch Models on page 4•

• Site Preparation Checklist for EX2200 Switches on page 33

EX2200 Switch Models

The EX2200 switch is available with 24 or 48 built-in network ports with full (all 24 or

48 built-in network ports) or no Power over Ethernet (PoE) capability. Table 1 on page 4

lists the EX2200 switch models.

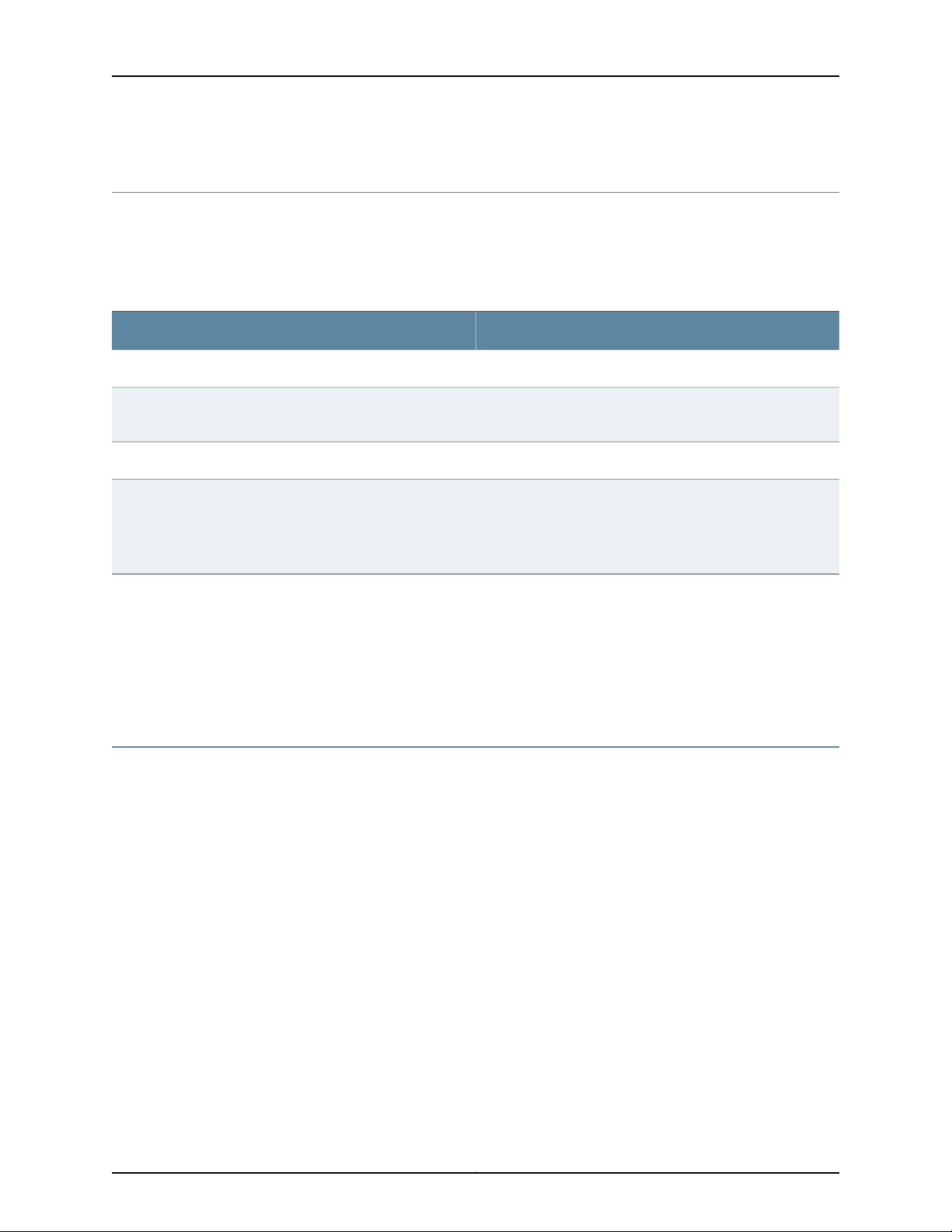

Table 1: EX2200 Switch Models

Related

Documentation

Front Panel of an EX2200 Switch on page 5•

• EX2200 Switches Hardware Overview on page 3

Maximum PoE Power

AvailablePorts in Which PoE Is AvailableAccess PortsModel

––24 Gigabit EthernetEX2200-24T-4G

405 WAll 24 ports24 Gigabit EthernetEX2200-24P-4G

––48 Gigabit EthernetEX2200-48T-4G

405 WAll 48 ports48 Gigabit EthernetEX2200-48P-4G

Copyright © 2010, Juniper Networks, Inc.4

Page 25

Chassis Physical Specifications for EX2200 Switches

The EX2200 switch chassis is a rigid sheet-metal structure that houses the hardware

components. Table 2 on page 5 summarizes the physical specifications of the EX2200

switch chassis.

Table 2: Physical Specifications of the EX2200 Switch Chassis

ValueDescription

1.75 in. (4.45 cm)Chassis height

•

Chassis width

Weight

17.5 in. (44.5 cm)

•

19 in. (48.2 cm) with mounting brackets attached

10.5 in. (26.7 cm)Chassis depth

•

EX2200-24T: 6 lb (2.7 kg)

•

EX2200-24P: 8 lb (3.6 kg)

•

EX2200-48T: 8 lb (3.6 kg)

•

EX2200-48P: 10 lb (4.5 kg)

Chapter 1: EX2200 Switch Overview

Related

Documentation

Rack Requirements for EX2200 Switches on page 39•

• Cabinet Requirements for EX2200 Switches on page 40

• Mounting an EX2200 Switch on page 53

• Installing and Connecting an EX2200 Switch on page 51

Front Panel of an EX2200 Switch

The front panel of an EX2200 switch consists of the following components:

•

Network ports—depending on the switch model, either of:

•

24 or 48 10/100/1000Base-T Gigabit Ethernet ports, with Powerover Ethernet (PoE)

not available in EX2200-24T and EX2200-48T

•

24 or 48 10/100/1000Base-T Gigabit Ethernet ports, with Powerover Ethernet (PoE)

available in EX2200-24P and EX2200-48P

•

4 built-in SFP uplink ports

•

2 chassis status LEDs

•

4 port status mode LEDs

•

Mode button

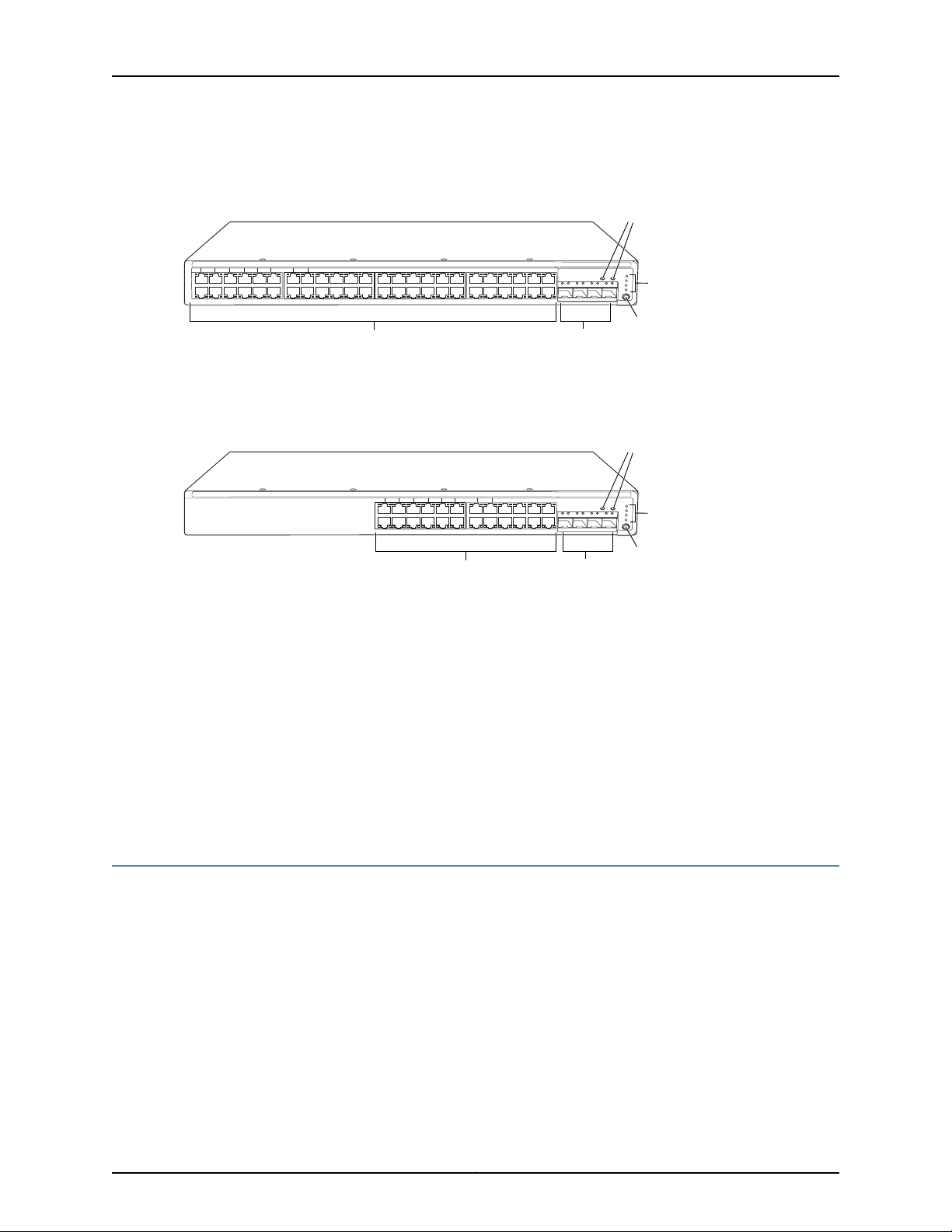

Figure 1 on page 6 shows the front panel of an EX2200 switch with 48 Gigabit Ethernet

ports. Figure 2 on page 6 shows the front panel of an EX2200 switch with 24 Gigabit

Ethernet ports.

5Copyright © 2010, Juniper Networks, Inc.

Page 26

01234567891011121314151617181920212223242526272829303132333435363738394041424344

45

0 1 2

SYS

ALM

SPD

DX

EN

POE

3

46

47

Network

ports

Port status mode LEDs

Mode

button

SFP

uplink

ports

Chassis

status

LEDs

g027000

012345678910111213141516171819202122

23

0 1 2

SYS

ALM

SPD

DX

EN

POE

3

Network

ports

Chassis

status

LEDs

g027002

SFP

uplink

ports

Port status mode LEDs

Mode

button

Complete Hardware Guide for EX2200 Ethernet Switches

Figure 1: Front Panel of an EX2200 Switch with 48 Gigabit Ethernet Ports

Figure 2: Front Panel of an EX2200 Switchwith 24 Gigabit Ethernet Ports

Related

Documentation

Chassis Status LEDs in EX2200 Switches on page 11•

• Network Port and Uplink Port LEDs in EX2200 Switches on page 12

• Network Port Connector Pinout Information for an EX2200 Switch on page 20

• Rear Panel of an EX2200 Switch on page 6

• Installing a Transceiver in an EX Series Switch on page 65

• Removing a Transceiver from an EX Series Switch on page 95

• Installing and Connecting an EX2200 Switch on page 51

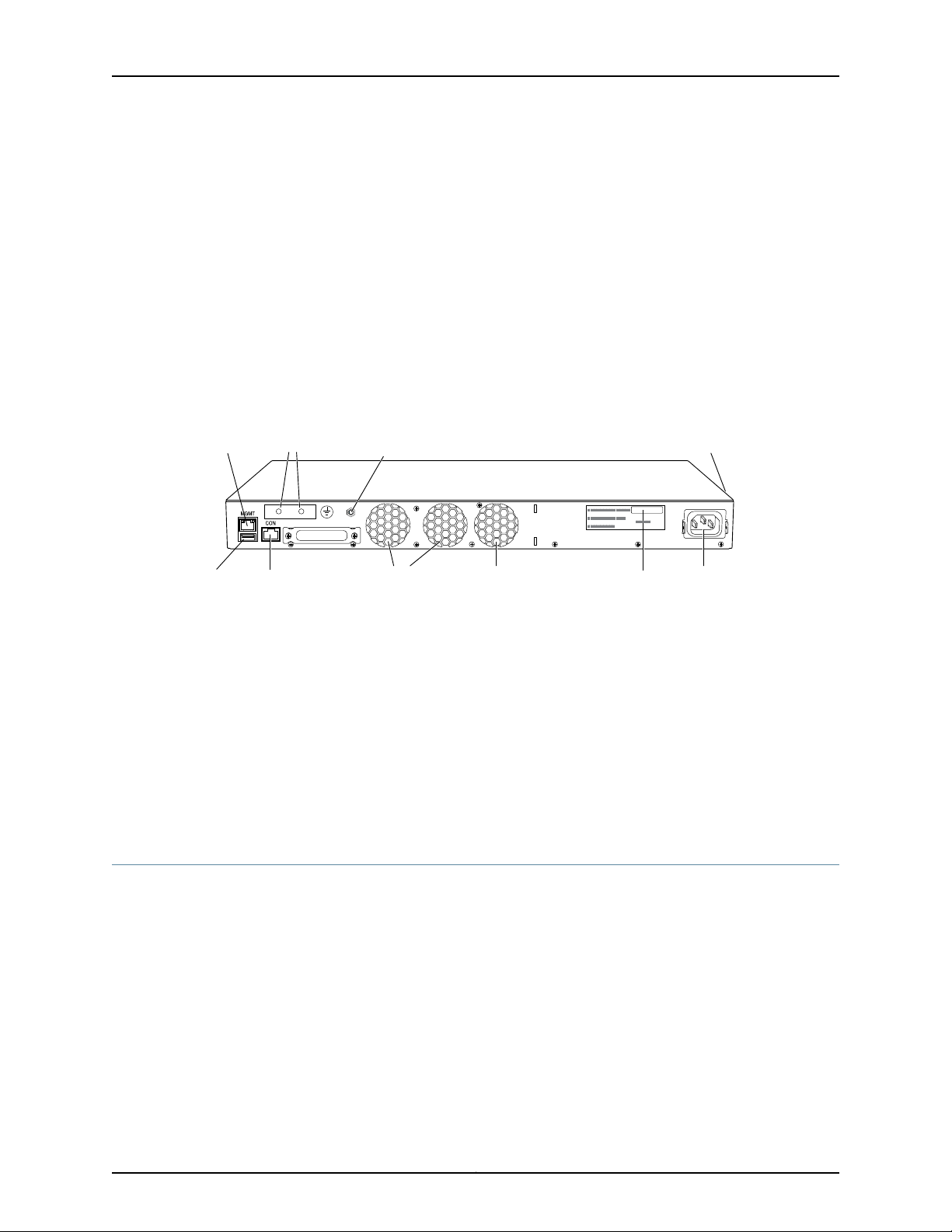

Rear Panel of an EX2200 Switch

The rear panel of the EX2200 switch consists of the following components:

•

Management Ethernet port

•

USB port

•

Console port

•

Protective earthing terminal

•

ESD point

•

Air exhaust

Copyright © 2010, Juniper Networks, Inc.6

Page 27

g027001

USB

port

Management

Ethernet port

Console

port

Protective

earthing terminal

Air exhaust without fan

(closed on non-PoE models)

Air exhaust

with fan

AC power

cord inlet

ESD

point

EX2200-24-4G REV: X1

750-026464 REV: X3

MAC:00:23:9C:oE:19:00

Mfg.Date

20090227

MADEIN CHINA

Serial number

ID label

Air intake with fan for power supply

(fan on PoE models only)

Chapter 1: EX2200 Switch Overview

•

Serial number ID label

•

AC power cord inlet

Figure 3 on page 7 shows the rear panel of an EX2200 switch.

All EX2200 switches have three exhaust openings on the rear panel. The two leftmost

exhaust openings have fans behind them and are open. The rightmost exhaust opening

is open on Power over Ethernet (PoE) models and closed on non-PoE models. On PoE

models, this opening exhausts the air from the fan at the air intake for the power supply

on the side panel.

The power cord retainer clips extend out of the chassis by 3 in.

Figure 3: Rear Panel of an EX2200 Switch

Related

Documentation

Front Panel of an EX2200 Switch on page 5•

• USB Port Specifications for an EX Series Switch on page 19

• Cooling System and Airflow in an EX2200 Switch on page 15

• Power Supply in EX2200 Switches on page 14

• Prevention of Electrostatic Discharge Damage on EX Series Switches on page 142

• Connecting Earth Ground to an EX Series Switch on page 67

• Installing and Connecting an EX2200 Switch on page 51

EX2200 Switch Hardware and CLI Terminology Mapping

This topic describes the hardware terms used in EX2200 switch documentation and the

corresponding terms used in the Junos OS command line interface (CLI). See Table 3 on

page 8.

7Copyright © 2010, Juniper Networks, Inc.

Page 28

Complete Hardware Guide for EX2200 Ethernet Switches

Table 3: CLI Equivalents of Terms Used in Documentation for EX2200 Switches

Chassis

FPC (n)

PIC (n)

•

EX2200-24T-4G

•

EX2200-24P-4G

•

EX2200-48T-4G

•

EX2200-48P-4G

the Flexible PIC

Concentrator (FPC)

One of the following:

•

EX2200-24T-4G

•

EX2200-24P-4G

•

EX2200-48T-4G

•

EX2200-48P-4G

Abbreviated name of

the Physical Interface

Card (PIC)

Value of n is always 0.Abbreviated name of

n is a value in the range

of 0-1.

Item in

DocumentationValue (CLI)Description (CLI)Hardware Item (CLI)

Switch chassis–One of the following:

The switch does not

have actual FPCs. In

this case, FPC refers to

the switch itself.

The switch does not

have actual PIC

devices; see entries for

PIC 0 through PIC 1 for

the equivalent item on

the switch.

Additional

Information

“Chassis Physical

Specifications for

EX2200 Switches” on

page 5

Understanding

Interface Naming

Conventions on EX

Series Switches

Understanding

Interface Naming

Conventions on EX

Series Switches

Xcvr (n)

•

24x 10/100/1000

Base-T

•

48x 10/100/1000

Base-T

Abbreviated name of

the transceiver

PIC 0One of the following:

PIC 14x GE SFP

to the number of the

port in which the

transceiver is installed.

Built-in network ports

on the front panel of

the switch

Built-in uplink ports on

the front panel of the

switch

Optical transceiversn is a value equivalent

AC power supplyValue of n is always 0.Built-in power supplyPower supply (n)

Fan tray–Fan trayFan tray

“Front Panel of an

EX2200 Switch” on

page 5

“Front Panel of an

EX2200 Switch” on

page 5

“Optical Interface

Support in EX2200

Switches” on page 22

“Power Supply in

EX2200 Switches” on

page 14

“Cooling System and

Airflow in an EX2200

Switch” on page 15

Copyright © 2010, Juniper Networks, Inc.8

Page 29

Chapter 1: EX2200 Switch Overview

Related

Documentation

• EX Series Switches Hardware and CLI Terminology Mapping

• EX2200 Switches Hardware Overview on page 3

9Copyright © 2010, Juniper Networks, Inc.

Page 30

Complete Hardware Guide for EX2200 Ethernet Switches

Copyright © 2010, Juniper Networks, Inc.10

Page 31

CHAPTER 2

g027003

0 1 2

SYS

ALM

SPD

DX

EN

POE

3

Chassis

status LEDs

Component Descriptions

•

Chassis Status LEDs in EX2200 Switches on page 11

•

Network Port and Uplink Port LEDs in EX2200 Switches on page 12

•

Management Port LEDs in EX2200 Switches on page 14

•

Power Supply in EX2200 Switches on page 14

•

Cooling System and Airflow in an EX2200 Switch on page 15

Chassis Status LEDs in EX2200 Switches

The front panel of an EX2200 switch has two chassis status LEDs labeled SYS and ALM

on the far right side of the panel, above the uplink ports (see Figure 4 on page 11).

Figure 4: Chassis Status LEDs in an EX2200 Switch

Table 4 on page 11 describes the chassis status LEDs in an EX2200 switch, their colors

and states, and the status they indicate.

Table 4: Chassis Status LEDs in an EX2200 Switch

State and DescriptionColorLED Label

There is no alarm.UnlitALM

There is a minor alarm.Amber

There is a major alarm.Red

GreenSYS

A major alarm (red) indicates a critical error condition that requires immediate action.

•

•

•

On steadily—The switch is functioning normally.

Blinking—The switch is booting.

Off—The switch is off.

11Copyright © 2010, Juniper Networks, Inc.

Page 32

012345678910111213141516171819202122

23

g027005

0

1

Link/Activity LED Status LED

g027007

0 1 2

SYS

ALM

SPD

DX

EN

POE

3

Port 1 Port 2 Port 3

Mode

button

Link/Activity

LED

Status

LED

Port 0

Port status

mode LEDs

Complete Hardware Guide for EX2200 Ethernet Switches

A minor alarm (amber) indicates a noncritical condition that requires monitoring or

maintenance. A minor alarm that is left unchecked might cause interruption in service or

performance degradation.

Both LEDs can be lit simultaneously.

You can view the colors of the two LEDs remotely through the CLI by issuing the

operational mode command show chassis led.

Related

Documentation

Front Panel of an EX2200 Switch on page 5•

• Checking Active Alarms with the J-Web Interface

• Understanding Alarm Types and Severity Levels on EX Series Switches

Network Port and Uplink Port LEDs in EX2200 Switches

Each network port and uplink port on the front panel of an EX2200 switch has two LEDs

that indicate link/activity and port status. See Figure 5 on page 12 and Figure 6 on page 12.

Figure 5: LEDs on the Network Ports on the Front Panel

Figure 6: LEDs on the Uplink Ports and Port Status Mode LEDs

Table 5: Link/Activity LED on the Network Ports and Uplink Ports in EX2200 Switches

Table 5 on page 12 describes the Link/Activity LED.

State and DescriptionColorLED

•

GreenLink/Activity

Blinking—The port and the link are active, and there is link activity.

•

On steadily—The port and the link are active, but there is no link activity.

•

Off—The port is not active.

Copyright © 2010, Juniper Networks, Inc.12

Page 33

Chapter 2: Component Descriptions

The LEDs labeled Status LED in Figure 5 on page 12 and Figure 6 on page 12 indicate the

status of one of the four port parameters—speed, duplex mode, administrative status,

and Power over Ethernet (PoE) status. Use the mode button below the POE LED on the

far right side of the front panel to toggle the Status LED to show the different port

parameters. You can tell which port parameter is indicated by the Status LED by seeing

which port status mode LED (SPD, DX, EN, and POE) is lit. (See Figure 6 on page 12).

Table 6 on page 13 describes the Status LED.

Table 6: Status LED on the Network Ports and Uplink Ports in EX2200 Switches

State and DescriptionPort Parameters

Speed

Duplex mode

Administrative status

PoE status

Indicates the speed. The speed indicators for network ports are:

•

One blink per second—10 Mbps

•

Two blinks per second—100 Mbps

•

Three blinks per second—1000 Mbps

The speed indicators for uplink ports are:

•

On steadily—1000 Mbps

•

Off—10/100 Mbps

Indicates the duplex mode. The status indicators are:

•

On steadily—Port is set to full-duplex mode.

•

Off—Port is set to half-duplex mode.

Indicates the administrative status. The status indicators are:

•

On steadily—Port is administratively enabled.

•

Off—Port is administratively disabled.

Indicates the PoE status. The status indicators for network ports are:

•

On steadily—PoE is availableon the port, a device that draws power from the port

is connected to the port, and the device is drawing power from the port.

•

Blinking—PoEis availableon the port, but no power is drawn from the port because

of one of the following:

•

No device that draws power from the port is connected to the port.

•

A device that draws power from the port is connectedto the port, but the device

is not drawing any power from the port.

•

Off—PoE is not available on the port.

PoE is not available on uplink ports; therefore,the LED for those ports is always unlit.

Related

Documentation

You can tell which port parameter is indicated by the Status LED on network ports and

uplink ports by issuing the operational mode command show chassis led.

Front Panel of an EX2200 Switch on page 5•

• Configuring Gigabit Ethernet Interfaces (CLI Procedure)

• Configuring Gigabit Ethernet Interfaces (J-Web Procedure)

13Copyright © 2010, Juniper Networks, Inc.

Page 34

g027006

Link/Activity

LED

Status

LED

Complete Hardware Guide for EX2200 Ethernet Switches

Management Port LEDs in EX2200 Switches

The management port on the rear panel of an EX2200 switch has two LEDs that indicate

link/activity and port status (see Figure 7 on page 14).