Page 1

E-Series Routers

Installation and User Guide

Release 5.1.x

Juniper Networks, Inc.

1194 North Mathilda Avenue

Sunnyvale, CA 94089

USA

408-745-2000

www.juniper.net

Part No. 162-00730-00 Rev. A00

Page 2

Juniper Networks is registered in the U.S. Patent and Trademark Office and in other countries as a

trademark of Juniper Networks, Inc. Broadband Cable Processor, ERX, ESP, E-series, G1, G10,

G-series, Internet Processor, J-Protect, Juniper Your Net, JUNOS, JUNOScript, JUNOSe, M5, M10,

M20, M40, M40e, M160, M-series, NMC-RX, SDX, ServiceGuard, T320, T640, T-series, UMC, and

Unison are trademarks of Juniper Networks, Inc. All other trademarks, service marks, registered

trademarks, or registered service marks are the property of their respective owners. All specifications

are subject to change without notice.

Products made or sold by Juniper Networks (including the G1 and G10 CMTSs, ERX-310, ERX-705,

ERX-710, ERX-1410, ERX-1440, M5, M10, M20, M40, M40e, M160, and T320 routers, T640 routing

node, and the JUNOS, SDX-300, and ServiceGuard software) or components thereof might be

covered by one or more of the following patents that are owned by or licensed to Juniper Networks:

U.S. Patent Nos. 5,473,599, 5,905,725, 5,909,440, 6,333,650, 6,359,479, and 6,406,312.

E-Series Routers Installation and User Guide, Release 5.1.x

Copyright © 2003, Juniper Networks, Inc.

All rights reserved. Printed in USA.

Writers: John Borelli, Fran Singer

Editor: Fran Mues

Revision History

August 2003

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks

reserves the right to change, modify, transfer, or otherwise revise this publication without notice.

Federal Communications Commission (FCC) Statement

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

This equipment is designed for use with properly shielded and terminated cables. Refer to the

installation sections of this manual before operation.

Reference: CFR 47, Part 15J, Sect 15.105 April 18, 1989

Caution: Changes or Modifications to this equipment not expressly approved by the party

responsible for compliance could void the user’s authority to operate the equipment.

FCC Requirements For Consumer Products

This equipment complies with FCC rules, Part 68. On the back side of this equipment is a label that

contains, among other information, the FCC Registration Number and Ringer Equivalence Number

(REN) for this equipment. If requested, provide this information to your telephone company.

If this equipment causes harm to the telephone network, the Telephone Company may discontinue

your service temporarily. If possible, they will notify you in advance. But if advance notice isn't

practical, you will be notified as soon as possible. You will be advised of your right to file a complaint

with the FCC.

Your telephone company may make changes in its facilities, equipment, operations, or procedures

that could affect the proper operation of your equipment. If they do, you will be given advance notice

so as to give you an opportunity to maintain uninterrupted service.

If you experience trouble with this equipment, please contact the manufacturer for warranty/repair

information. The telephone company may ask that you disconnect this equipment from the network

until the problem has been corrected or until you are sure that the equipment is not malfunctioning.

Food and Drug Administration, Center for Devices and Radiological

Health

This equipment complies with 21 CFR 1040.10 and 1040.11 for the safe use of lasers.

Page 3

Canadian Department Of Communications Radio Interference

Regulations

This Class B (or Class A, if so indicated on the registration label) digital apparatus meets the

requirements of the Canadian Interference-Causing Equipment Regulations.

Réglement sur le brouillage radioélectrique du ministère des

communications

Cet appareil numérique de la Classe B (ou Classe A, si ainsi indiqué sur l’étiquette d’enregistration)

respecte toutes les exigences du Reglement sur le Materiel Brouilleur du Canada.

Industry Canada Notice CS-03

The Industry Canada label identifies certified equipment. This certification means that the equipment

meets certain telecommunications network protective, operation and safety requirements as

prescribed in the appropriate Terminal Equipment Technical Requirements document(s). The

Department does not guarantee the equipment will operate to the user's satisfaction. Before

installing this equipment, users should ensure that it is permissible to be connected to the facilities of

the local telecommunications company. The equipment must also be installed using and acceptable

method of connection. The customer should be aware that compliance with the above conditions

may not prevent degradation of service in some situations.

Repairs to certified equipment should be coordinated by a representative designated by the supplier.

Any repairs or alterations made by the user to this equipment, or equipment malfunctions, may give

the telecommunications company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of the power

utility, telephone lines and internal metallic water pipe system, if present, are connected together.

This precaution may be particularly important in rural areas.

Caution: Users should not attempt to make such connections themselves, but should contact the

appropriate electric inspection authority, or electrician, as appropriate.

Notice: The Ringer Equivalence Number (REN) assigned to each terminal device provides an

indication of the maximum number of terminals allowed to be connected to a telephone interface.

The termination on an interface may consist of any combination of devices subject only to the

requirement that the sum of the Ringer Equivalence Numbers of all the devices does not exceed 5.

Avis CS-03 d’Industrie Canada

L’étiquette du ministère des Communications du Canada indique que l’appareillage est certifié,

c’est-à-dire qu’il respecte certaines exigences de sécurité et de fonctionnement visant les réseaux

de télécommunications. Le ministère ne garantit pas que l’appareillage fonctionnera à la satisfaction

de l’utilisateur. Avant d’installer l’appareillage, s’assurer qu’il peut être branché aux installations du

service de télécommunications local. L’appareillage doit aussi être raccordé selon des méthodes

acceptées. Le client doit toutefois prendre note qu’une telle installation n’assure pas un service

parfait en tout temps.

Les réparations de l’appareillage certifié devraient être confiées à un service d’entretien canadien

désigné par lefournisseur. En cas de réparation ou de modification effectuées par l’utilisateur ou de

mauvais fonctionnement del’appareillage, le service de télécommunications peut demander le

débranchment de l’appareillage.

Pour leur propre sécurité, les utilisateurs devraient s’assurer que les mises à la terre des lignes de

distribution d’électricité, des lignes téléphoniques et de la tuyauterie métallique interne sont

raccordées ensemble. Cette mesure de sécurité est particulièrement importante en milieu rural.

Attention: Les utilisateurs ne doivent pas procéder à ces raccordements eux-mêmes mais doivent

plutôt faire appel aux pouvoirs de réglementation en cause ou à un électricien, selon le cas.

Avis: Veuillez prendre note que pour tout appareillage supportant des lignes de type “loopstart,”

l'indice d'équivalence de la sonnerie (IES) assigné à chaque dispositif terminal indique le nombre

maximal de terminaux qui peuvent être raccordés à une interface. La terminaison d'une interface

téléphonique peut consister en une combinaison de quelques dispositifs, à la seule condition que la

somme d'indices d'équivalence de la sonnerie de tous les dispositifs n'excède pas 5. Le REN figure

sur l’étiquette “FCC Rules Part 68” située sur le support du module ou à l’arrière de l’unité.

D.O.C. Explanatory Notes: Equipment Attachment Limitations

The Canadian Department of Communications label identifies certified equipment. This certification

meets certain telecommunication network protective, operational and safety requirements. The

department does not guarantee the equipment will operate to the users satisfaction.

Page 4

Before installing the equipment, users should ensure that it is permissible to be connected to the

facilities of the local telecommunications company. The equipment must also be installed using an

acceptable method of connection. In some cases, the company’s inside wiring associated with a

single line individual service may be extended by means of a certified connector assembly

(telephone extension cord). The customer should be aware that compliance with the above condition

may not prevent degradation of service in some situations.

Repairs to certified equipment should be made by an authorized Canadian maintenance facility

designated by the supplier. Any repairs or alterations made by the user to this equipment, or

equipment malfunctions, may give the telecommunications company cause to request the user to

disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of the power

utility, telephone lines and internal metallic water pipe system, if present, are connected together.

This precaution may be particularly important in rural areas.

Caution: Users should not attempt to make such connections themselves, but should contact the

appropriate electrical inspection authority, or electrician, as appropriate.

Notes explicatives du ministère des Communications: limites visant

les accessoires

L’étiquette du ministère des Communications du Canada indique que l’appareillage est certifié,

c’est-à-dire qu’il respecte certaines exigences de sécurité et de fonctionnement visant les réseaux

de télécommunications. Le ministère ne garantit pas que l’appareillage fonctionnera à la satisfaction

de l’utilisateur.

Avant d’installer l’appareillage, s’assurer qu’il peut être branché aux installations du service de

télécommunications local. L’appareillage doit aussi être raccordé selon des méthodes acceptées.

Dans certains cas, le câblage interne du service de télécommunications utilisé pour une ligne

individuelle peut être allongé au moyen d’un connecteur certifié (prolongateur téléphonique). Le

client doit toutefois prendre note qu’une telle installation n’assure pas un service parfait en tout

temps.

Les réparations de l’appareillage certifié devraient être confiées à un service d’entretien canadien

désigné par le fournisseur. En cas de réparation ou de modification effectuées par l’utilisateur ou de

mauvais fonctionnement de l’appareillage, le service de télécommunications peut demander le

débranchment de l’appareillage.

Pour leur propre sécurité, les utilisateurs devraient s’assurer que les mises à la terre des lignes de

distribution d’électricité, des lignes téléphoniques et de la tuyauterie métallique interne sont

raccordées ensemble. Cette mesure de sécurité est particulièrement importante en milieu rural.

Attention: Les utilisateurs ne doivent pas procéder à ces raccordements eux-mêmes mais doivent

plutôt faire appel aux pouvoirs de réglementation en cause ou à un électricien, selon le cas.

EC Declaration of Conformity

The EC Declaration of Conformity is available at the end of this manual.

Voluntary Control Council for Interference (VCCI) Statement for Japan

Page 5

SOFTWARE LICENSE AGREEMENT

JUNIPER NETWORKS, INC. IS WILLING TO LICENSE THE ENCLOSED SOFTWARE AND

ACCOMPANYING USER DOCUMENTATION (COLLECTIVELY, THE “PROGRAM”) TO YOU ONLY

UPON THE CONDITION THAT YOU ACCEPT ALL OF THE TERMS AND CONDITIONS OF THIS

LICENSE AGREEMENT. PLEASE READ THESE TERMS AND CONDITIONS CAREFULLY

BEFORE COPYING OR USING THE ACCOMPANYING SOFTWARE OR INSTALLING THE

HARDWARE UNIT WITH PRE-ENABLED SOFTWARE OR USING THE ACCOMPANYING USER

a

DOCUMENTATION.

BY USING THE ACCOMPANYING SOFTWARE OR INSTALLING THE HARDWARE UNIT WITH

PRE-ENABLED SOFTWARE, YOU AGREE TO BE BOUND BY THE TERMS AND CONDITIONS

OF THIS LICENSE AGREEMENT. IF YOU DO NOT AGREE TO BE BOUND BY THE TERMS OF

THIS LICENSE AGREEMENT, JUNIPER NETWORKS IS UNWILLING TO LICENSE THE

PROGRAM TO YOU, IN WHICH EVENT YOU SHOULD PROMPTLY WITHIN TEN (10) DAYS

FROM SHIPMENT RETURN THE UNUSED SOFTWARE, USER DOCUMENTATION, AND

RELATED EQUIPMENT AND HARDWARE TO THE PLACE OF PURCHASE AND YOU WILL

RECEIVE A FULL REFUND OF YOUR LICENSE FEE. THIS LICENSE AGREEMENT

REPRESENTS THE ENTIRE AGREEMENT CONCERNING THE PROGRAM BETWEEN YOU AND

JUNIPER NETWORKS, AND IT SUPERSEDES ANY PRIOR PROPOSAL, REPRESENTATION OR

UNDERSTANDING BETWEEN THE PARTIES.

1. License Grant. Juniper Networks, Inc. (“Juniper Networks”) and its suppliers and licensors

hereby grant to you and you hereby accept a nonexclusive, personal and nontransferable license to

use the computer software and/or hardware unit with pre-enabled software, including all patches,

error corrections, updates, and revisions thereto in machine-readable, object code form only (the

“Software”), and the accompanying User Documentation on the Juniper Networks product owned by

you and only as authorized in this License Agreement. You may make one (1) archival copy of the

Software for backup purposes provided you affix to such copy all copyright, confidentiality, and

proprietary notices that appear on the original. Except as authorized under this paragraph, no copies

of the Program or any portions thereof may be made, in whole or in part, by you or any person under

your authority or control.

The Software and User Documentation are protected under copyright laws. The title to Software and

User Documentation shall remain solely with Juniper Networks and its suppliers.

Except as authorized above, you shall not: copy, in whole or in part, the Software or the related User

Documentation; modify, reverse assemble, reverse compile, or otherwise translate, dissemble, or

obtain source code for the Software or User Documentation, in whole or in part, or permit a third party

to do so; rent, lease, distribute, sell, or create derivative works of the Software; pledge, lease, rent,

sublicense or share its rights under this License Agreement; or, without Juniper Networks’ prior

written consent, assign or transfer its rights hereunder.

2. Juniper Networks' Rights. You agree that the Software, including the User Documentation,

embodies Juniper Networks' and its suppliers' and licensors' confidential and proprietary intellectual

property protected under U.S. copyright law and you will use your best efforts to maintain their

confidentiality. You further acknowledge and agree that Juniper Networks or its suppliers and

licensors own all right, title, and interest in and to the Software, including all intellectual property

rights therein. You shall take no action inconsistent with Juniper Networks' or its suppliers' ownership

of such Software. You shall not sublicense, assign, or otherwise disclose to any third party the

Software or any information about the operation, design, performance, or implementation of the

Software and User Documentation without prior written consent of Juniper Networks. You agree to

implement reasonable security measures to protect such confidential and proprietary information and

copyrighted material. This License Agreement does not convey to you an interest in or to the

Program, but only the limited right of use revocable in accordance with the terms of this License

Agreement.

3. License Fees. The license fees paid by you are paid in consideration of the license granted under

this License Agreement.

4. Term. This license is effective upon opening of the package(s) or use of the hardware containing

the Software, and shall continue until terminated. You may terminate this License at any time by

returning the Software, including any User Documentation, and all copies or portions thereof to

Juniper Networks. This License will terminate immediately without notice from Juniper Networks if

you breach any term or provision of this License. Upon such termination by Juniper Networks, you

a. If you and Juniper Networks, Inc., have executed another license agreement for the Program which

is now in effect, then such agreement (“Negotiated Agreement”) shall supersede this Software

License Agreement and shall exclusively govern the use and license terms of the Program.

Page 6

must return the Software, including any User Documentation, and all copies or portions thereof to

Juniper Networks. Termination of this License Agreement shall not prejudice Juniper Networks' rights

to damages or other available remedy.

5. Limited Software Warranty: Juniper Networks warrants, for your benefit alone, that for a period

of ninety (90) days from the date of shipment from Juniper Networks that the Software substantially

conforms to its published specifications.

The limited warranty extends only to you as the original licensee. Your exclusive remedy and the

entire liability of Juniper Networks and its suppliers under this limited warranty will be, at Juniper

Networks' option, repair or replacement of the Software, or refund of the amounts paid by you under

this License Agreement. You agree that this is your sole and exclusive remedy for breach by Juniper

Networks, its suppliers or its licensors of any warranties made under this License Agreement.

In no event does Juniper Networks warrant that the Software is error free or that you will be able to

operate the Software without problems or interruptions. Juniper Networks does not warrant: 1) that

the functions contained in the software will meet your requirements; 2) that the Software will operate

in the hardware or software combination that you may select; 3) that the operation of the Software

will be uninterrupted or error free; or 4) that all defects in the operation of the Software will be

corrected.

This warranty does not apply if the product: 1) has been altered, except by Juniper Networks; 2) has

not been installed, operated, repaired, or maintained in accordance with instruction supplied by

Juniper Networks; or 3) has been subjected to or damaged by improper environment, abuse, misuse,

accident, or negligence.

EXCEPT FOR THE WARRANTIES SET FORTH ABOVE, THE SOFTWARE IS LICENSED “AS IS,”

AND JUNIPER NETWORKS DISCLAIMS ANY AND ALL OTHER REPRESENTATIONS,

CONDITIONS, AND WARRANTIES, WHETHER EXPRESS, IMPLIED, OR STATUTORY,

INCLUDING, WITHOUT LIMITATION, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE OR ANY WARRANTIES FOR NONINFRINGEMENT OR

ARISING FROM A COURSE OF DEALING, USAGE, OR TRADE PRACTICE. ANY AND ALL SUCH

WARRANTIES ARE HEREBY EXCLUDED TO THE EXTENT ALLOWED BY APPLICABLE LAW.

JUNIPER NETWORKS' SUPPLIERS AND LICENSORS DO NOT MAKE OR PASS ON TO YO U OR

ANY THIRD PARTY ANY EXPRESS, IMPLIED, OR STATUTORY WARRANTY OR

REPRESENTATION, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY WARRANTIES FOR

NONINFRINGEMENT.

6. Proprietary Rights Indemnification. Juniper Networks shall at its expense defend you against

and, subject to the limitations set forth elsewhere herein, pay all costs and damages made in

settlement or awarded against you resulting from a claim that the Program as supplied by Juniper

Networks infringes a United States copyright or a United States patent, or misappropriates a United

States trade secret, provided that you: (a) provide prompt written notice of any such claim, (b) allow

Juniper Networks to direct the defense and settlement of the claim, and (c) provide Juniper Networks

with the authority, information, and assistance that Juniper Networks reasonably deems necessary

for the defense and settlement of the claim. You shall not consent to any judgment or decree or do

any other act in compromise of any such claim without first obtaining Juniper Networks’ written

consent. In any action based on such a claim, Juniper Networks may, at its sole option, either: (1)

obtain for you the right to continue using the Program, (2) replace or modify the Program to avoid the

claim, or (3) if neither (1) nor (2) can reasonably be effected by Juniper Networks, terminate the

license granted hereunder and give you a pro rata refund of the license fee paid for such Program,

calculated on the basis of straight-line depreciation over a five-year useful life. Notwithstanding the

preceding sentence, Juniper Networks will have no liability for any infringement or misappropriation

claim of any kind if such claim is based on: (i) the use of other than the current unaltered release of

the Program and Juniper Networks has provided or offers to provide such release to you for its then

current license fee, or (ii) use or combination of the Program with programs or data not supplied or

approved by Juniper Networks if such use or combination caused the claim.

7. Limitation of Liability. IN NO EVENT WILL JUNIPER NETWORKS OR ITS SUPPLIERS OR

LICENSORS BE LIABLE FOR ANY COST FOR SUBSTITUTE PROCUREMENT; SPECIAL,

INDIRECT, INCIDENTAL, PUNITIVE, EXEMPLARY, OR CONSEQUENTIAL DAMAGES; OR ANY

DAMAGES RESULTING FROM INACCURATE OR LOST DATA OR LOSS OF USE OR PROFITS

ARISING OUT OF OR IN CONNECTION WITH THE PERFORMANCE OF THE SOFTWARE, EVEN

IF JUNIPER NETWORKS HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

Juniper Networks' cumulative liability to you or any other party for any loss or damages resulting from

any claims, demands, or actions arising out of or relating to this License Agreement shall not exceed

the total fees paid to Juniper Networks for the Software.

8. Export Control. Software, including technical data, is subject to U.S. export control laws,

including the U.S. Export Administration Act and its associated regulations, and may be subject to

Page 7

export or import regulations in other countries. You agree to comply strictly with all such regulations

and acknowledge that you have the responsibility to obtain licenses to export, re-export, or import

Software.

9. Government Licensees: If any Software or associated documentation is acquired by or on

behalf of a unit or agency of the United States government, the government agrees that such

Software or documentation is a “commercial item” as that term is defined in 48 C.F.R. 2.101,

consisting of “commercial computer software” or “commercial computer software documentation” as

such terms are used in 48 C.F.R. 12.212 of the Federal Acquisition Regulations and its successors

and 48 C.F.R. 227.7202-1 through 227.7202-4 of the DoD FAR Supplement and its successors. The

use, duplication, or disclosure by the United States government of technical, data, computer software

and documentation is subject to the restrictions set forth in FAR section 12.212(a), FAR section

52.227-14(g)(2), FAR section 52.227-19, DFARS section 252.227-7015(b), DFARS section

227.7202-1(a), and DFARS section 227.7202-3(a), as applicable. All United States government end

users acquire the Software with only the rights set forth in this License Agreement.

10. General: This License shall be governed by and construed in accordance with the laws of the

Commonwealth of Massachusetts, United States of America, as if performed wholly within the state

and without giving effect to the principles of conflict of law. Any dispute arising out of this Agreement

shall be referred to an arbitration proceeding in Boston, Massachusetts, in accordance with the

commercial arbitration rules of the American Arbitration Association (the “AAA”). If the parties cannot

agree upon an arbitrator, arbitration shall be conducted by a neutral arbitrator selected by the AAA

who is knowledgeable in electronics equipment manufacturing and software licensing. The parties

shall share the procedural costs of arbitration equally, and each party shall pay its own attorneys'

fees and other costs and expenses associated with the arbitration, unless the arbitrator decides

otherwise. The arbitrator's award shall be in writing and shall include a statement of reasons, but the

arbitrator shall not be permitted to award punitive or indirect damages. The arbitrator's decision and

award shall be final and binding and may be entered in any court having jurisdiction. The terms of

this section shall not prevent any party from seeking injunctive relief in any court of competent

jurisdiction in order to protect its proprietary and confidential information. If any term or provision

hereof is found to be void or unenforceable by a court of competent jurisdiction, the remaining

provisions of this License Agreement shall remain in full force and effect. This License Agreement

constitutes the entire agreement between the parties with respect to the use of the Software and

User Documentation and supersedes any and all prior oral or written agreements, discussions,

negotiations, commitments, or understandings. No amendment, modification, or waiver of any

provision of this License Agreement will be valid unless in writing and signed by the authorized

representative of the party against which such amendment, modification, or waiver is sought to be

enforced. The waiver by either party of any default or breach of this License Agreement shall not

constitute a waiver of any other or subsequent default or breach. This License Agreement shall be

binding upon the parties and their respective successors and permitted assigns.

Should you have any questions about this agreement, please contact:

Juniper Networks, Inc.

1194 North Mathilda Avenue

Sunnyvale, CA 94089

Attn: Contracts Administrator

Page 8

Page 9

Contents

About This Guide

E-Series Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Comments About the Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

Contacting Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

Part 1. Installing and Using E-Series Routers

MIBS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

Release Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

Web Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

Chapter 1 E-Series Overview

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Where E-Series Routers Fit In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

E-Series Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

ERX-14xx Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

ERX-7xx Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

ERX-310 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

E-Series Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

SRP Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Module Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

SRP Module Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Nonvolatile Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

SRP I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Module Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Line Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Packet Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Network Management Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Page 10

x

Contents

CLI Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

SNMP MIB Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

NMC-RX Device Management System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Redundancy Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

SRP Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

NVS Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Line Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Chapter 2

Chapter 3

Chapter 4

Unpacking and Inspecting E-Series Routers

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Unpacking ERX-14xx Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Unpacking ERX-7xx Models and ERX-310 Routers . . . . . . . . . . . . . . . . . . . . . . . 2-3

Inspecting E-Series Router Components and Accessories . . . . . . . . . . . . . . . . . . . 2-3

If You Detect or Suspect Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Contacting Juniper Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

The Next Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Installation Guidelines and Requirements

Your Preinstallation Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Regulatory Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

ERX-310 Power Cord Warnings (AC Model) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Equipment Rack Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Mechanical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Proper Rack Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Cabling Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Installing E-Series Routers

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Freestanding Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Rack-Mounted Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Preparing the Equipment Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Installing the Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

The Next Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Chapter 5

Installing Modules

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Slot Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Slot Groups for the ERX-1410 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Slot Groups for the ERX-7xx Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Page 11

E-Series Routers

Combinations of Line Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

OC48 Line Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Replacing and Managing Modules Using the Software . . . . . . . . . . . . . . . . . . 5-5

Hot-Swapping Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Protecting Modules and Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Order of Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Required Tools and Safety Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Installing SRP I/O and SRP Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Installing an SRP I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Installing an SRP Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Installing Line and I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Installing a Line Module or an I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Removing a Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Installing Components for Line Module Redundancy . . . . . . . . . . . . . . . . . . . . . 5-13

Installing the Line Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Installing the Redundancy Midplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Installing the I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Verifying the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Configuring Line Module Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

The Next Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

xi

Chapter 6

Cabling E-Series Routers

Cabling Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Required Tools, Wires, and Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Cabling the SRP I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

External Timing Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Console Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Connecting to the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Connecting to a Console Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Cabling the E-Series Router for Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Task 1: Turn Off All E-Series Router Power . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Task 2: Connect the Grounding Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Task 3: Connect the Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

ERX-7xx models, ERX-14xx models, ERX-310 router (DC model) . . . . 6-11

ERX-310 router (AC model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Cabling I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

BNC Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

HSSI Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

RJ-45 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

RJ-48C Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

LC Duplex Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

SC Duplex Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

SMB Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Cabling X.21/V.35 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Redundant Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

The Next Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Page 12

xii

Contents

Chapter 7 Powering Up E-Series Routers

Before You Power Up the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Initialization Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Powering Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

The Next Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Chapter 8

Chapter 9

Accessing E-Series Routers

Setting Up Management Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Console Port Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Using HyperTerminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Connecting Directly to the E-Series Router . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Assigning an IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Telnet Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

SNMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

The Next Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Maintaining E-Series Routers

Required Tools and Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Storing Modules and Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Cleaning the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Upgrading NVS Cards on SRP Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Upgrading a System That Contains One SRP Module . . . . . . . . . . . . . . . . . . 9-3

Upgrading a System That Contains Two SRP Modules . . . . . . . . . . . . . . . . . 9-4

Replacing an NVS Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Upgrading Memory on SRP Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Checking the Memory Installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Removing SODIMMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Adding New SODIMMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Verifying the Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Replacing SFPs on GE I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Removing SFPs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Installing SFPs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Verifying the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Replacing Fan Trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

Removing the Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

Installing the Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

Installing a Cable-Management Bracket on ERX-7xx Models . . . . . . . . . . . . . . 9-16

Chapter 10

Troubleshooting

Diagnosing Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Initialization Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Troubleshooting Power Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Understanding Status LEDs to Troubleshoot . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

LED Activity During Booting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

LED Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Page 13

LED Activity During Booting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

Abnormal LED Activity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

Redundancy Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

Monitoring Temperatures of Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

Resetting Line Modules and SRP Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

Double-Bit Errors on SRP Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

Detecting Double-Bit Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Fixing Double-Bit Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Part 2. System and Module Specifications

Chapter 11 System Specifications

ERX-14xx Models Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

ERX-7xx Models Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

ERX-310 Router Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

xiii

E-Series Routers

Chapter 12

Chapter 13

Module Specifications

Module Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

I/O Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-16

Cable Lengths for X.21/V.35 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-39

Protocol Support

Channelized OCx/STMx Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

Channelized T1 and E1 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-3

Channelized T3 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-4

Ethernet Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-6

HSSI Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-7

OCx/STMx ATM Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-9

OCx/STMx POS and OC48 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-10

Tunnel Service Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-12

Unchannelized E3 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-13

Unchannelized T3 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-15

X.21/V.35 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-17

Part 3. Appendixes

Appendix A Cable Pinouts

SRP I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

CT1 and CE1 I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Page 14

xiv

Contents

Appendix B Installing JUNOSe Software

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Identifying the Software Release File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Installing Software When a Firewall Exists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Task 1: Obtain the Required Information . . . . . . . . . . . . . . . . . . . . . . . . B-3

Task 2: Divert Network Traffic to Another Router . . . . . . . . . . . . . . . . . B-3

Task 3: Access Privileged Exec Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Task 4: Configure IP on an Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Task 5: Mount the CD on the Network Host . . . . . . . . . . . . . . . . . . . . . . B-4

Task 6: Configure Access to the Network Host . . . . . . . . . . . . . . . . . . . . B-5

Task 7: Enable the FTP Server on the E-Series Router . . . . . . . . . . . . . . B-6

Task 8: Identify the Files to Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Task 9: Transfer Files to the User Space . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Task 10: Install Files on the System Space . . . . . . . . . . . . . . . . . . . . . . . . B-6

Task 11: Save the Current Conf iguration . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Task 12: Reboot the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Installing Software When a Firewall Does Not Exist . . . . . . . . . . . . . . . . . . . . . . B-8

Installing Software in Normal Operational Mode . . . . . . . . . . . . . . . . . . . . . B-8

Task 1: Obtain the Required Information . . . . . . . . . . . . . . . . . . . . . . . . B-9

Task 2: Divert Network Traffic to Another Router . . . . . . . . . . . . . . . . . B-9

Task 3: Access Privileged Exec Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Task 4: Configure IP on an Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Task 5: Configure Access to the Network Host . . . . . . . . . . . . . . . . . . . B-10

Task 6: Mount the CD on the Network Host . . . . . . . . . . . . . . . . . . . . . . B-11

Task 7: Copy the Software Release File . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

Task 8: Save the Current Configuration . . . . . . . . . . . . . . . . . . . . . . . . . B-11

Task 9: Reboot the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-12

Installing Software in Boot Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-13

Task 1: Obtain the Required Information . . . . . . . . . . . . . . . . . . . . . . . B-13

Task 2: Divert Network Traffic to Another System . . . . . . . . . . . . . . . . B-13

Task 3: Access the Boot Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-13

Task 4: Assign an IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-14

Task 5: Configure Access to the Network Host . . . . . . . . . . . . . . . . . . . . B-14

Task 6: Mount the CD on the Network Host . . . . . . . . . . . . . . . . . . . . . . B-14

Task 7: Copy the Software Release File . . . . . . . . . . . . . . . . . . . . . . . . . . B-14

Task 8: Reboot the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-15

Copying Release Files from One E-Series Router to Another . . . . . . . . . . . . . . B-15

Upgrading Systems That Are Operating with Two SRP Modules . . . . . . . . . . . B-16

Appendix C

Appendix D

Customer Support

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Information You Need to Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Returning Products for Repair or Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Declaration of Conformity

Index

Page 15

About This Guide

This E-Series Installation and User Guide provides the information you

need to install and start the E-series router.

Note: If the information in the latest E-series Release Notes differs from the

information in this guide, follow the E-series Release Notes.

The E-series router is shipped with the latest system software installed. If

you need to install a future release or reinstall the system software, refer to

the procedures in Appendix B, Installing JUNOSe Software.

E-Series Routers

Five models of E-series routers are available:

• ERX-1440 router

• ERX-1410 router

• ERX-710 router

• ERX-705 router

• ERX-310 router

All models use the same software. For information about the differences

between the models, see Chapter 1, E-Series Overview.

In the E-series documentation, the term ERX-14xx models refers to both

the ERX-1440 router and the ERX-1410 router. Similarly, the term

ERX-7xx models refers to both the ERX-710 router and the ERX-705

router. The terms ERX-1440 router, ERX-1410 router, ERX-710 router,

ERX-705 router, and ERX-310 router refer to the specific models.

Page 16

xvi

About This Guide

Audience

This guide is intended for experienced system and network specialists

working with E-series routers in an Internet access environment.

Conventions

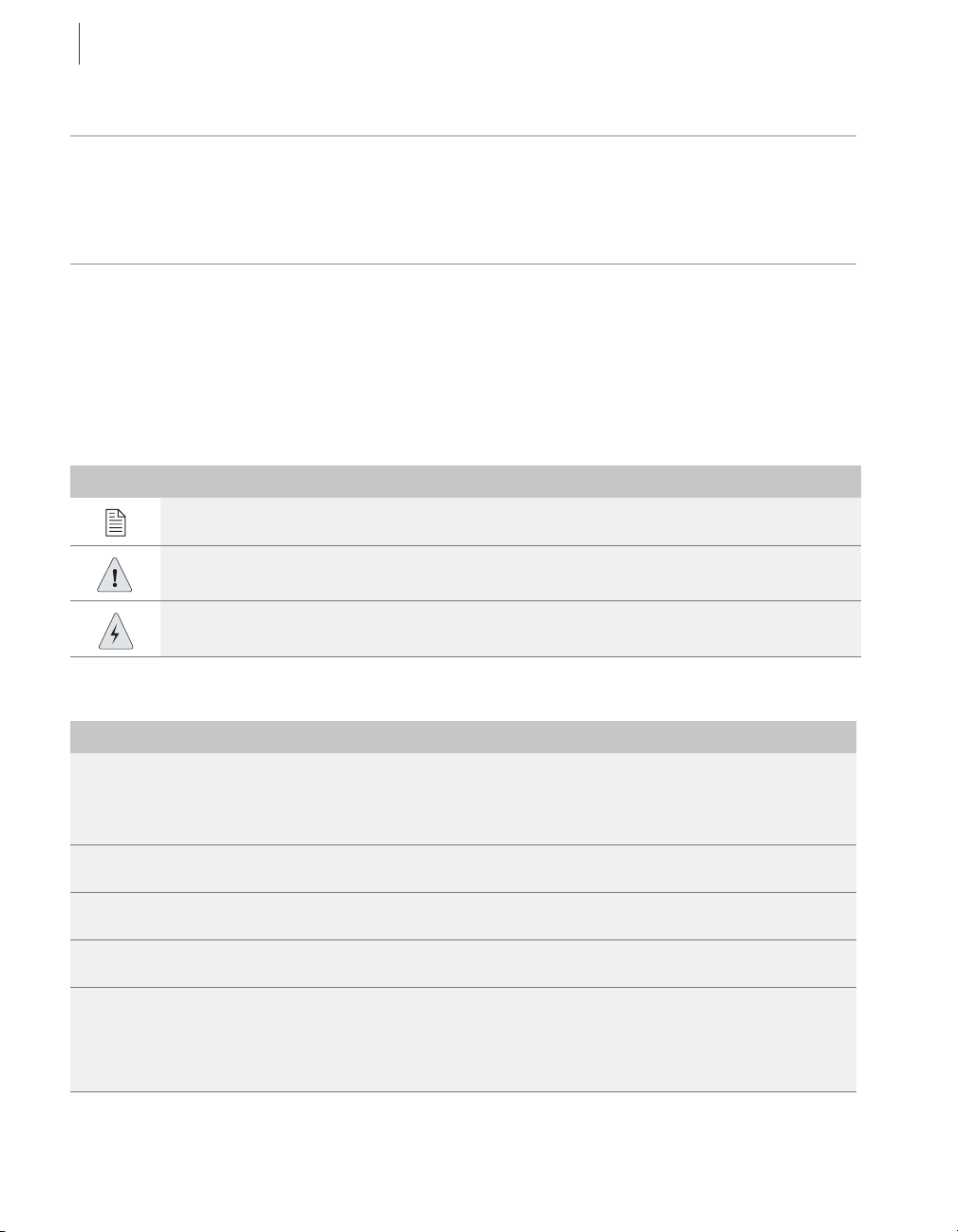

Table 1 defines notice icons used in this guide, and Tab le 2 def ines text

conventions used throughout the book, except for command syntax.

Table 3 provides command syntax conventions used primarily in the

E-Series Command Reference Guide. For more information about

command syntax, see E-Series System Basics Configuration Guide,

Chapter 1, Planning Your Network.

Tab l e 1 Notice icons

Icon Meaning Description

Informational note Indicates important features or instructions.

Caution Indicates that you may risk losing data or damaging your hardware.

Warning Alerts you to the risk of personal injury.

Tab l e 2 Text conventions (except for command syntax)

Convention Description Examples

Bold typeface Represents commands and

Bold Courier typeface Represents text that the user must

Key name in angle brackets Indicates the name of a key on the

Key names linked with a plus sign

(+) in angle brackets.

Plain Courier typeface Represents information as displayed

keywords in text.

type.

keyboard.

Indicates that you must press two or

more keys simultaneously.

on your terminal’s screen.

• Command example:

Issue the clock source command.

• Keyword example:

Specify the keyword exp-msg.

user input

Press <Enter>.

Press <Ctrl+B>.

host1#show ip ospf 2

Routing Process OSPF 2 with

Router ID 5.5.0.250

Router is an Area Border

Router (ABR)

Page 17

Tab l e 2 Text conventions (except for command syntax) (continued)

Convention Description Examples

Italics • Emphasize words.

• Identify variables.

• Identify chapter, appendix, and

book names.

Tab l e 3 Syntax conventions in Command Reference Guide

Convention Description Examples

Words in plain text Represent keywords. terminal length

Words in italics Represent variables. mask, accessListName

Words separated by the | symbol Represent a choice to select one

keyword or variable to the left or

right of this symbol. (The keyword or

variable may be either optional or

required.)

Words enclosed in [ brackets ] Represent optional keywords or

variables.

Words enclosed in [ brackets ]* Represent optional keywords or

variables that can be entered more

than once.

Words enclosed in { braces } Represent required keywords or

variables.

• There are two levels of access,

user and privileged.

• clusterId, ipAddress.

• Appendix A, System Specifications.

diagnostic | line

[ internal | external ]

[ level1 | level2 | l1 ]*

{ permit | deny } { in | out }

{ clusterId | ipAddress }

Documentation

E-Series Routers

xvii

Documentation

The E-Series Installation Quick Start poster is shipped in the box with all

new routers. This poster provides the basic procedures to help you get the

router up and running quickly.

With each software release, we provide the E-Series Routers

Documentation CD (formerly ERX Edge Routers Documentation CD).

The documentation CD contains the document set in PDF format and

HTML format (with and without frames). From the HTML f iles, you can

also access PDF files of individual chapters and appendixes.

The documentation is also available on the Web. You can order a set of

printed documents from your Juniper Networks sales representative.

The document set comprises the following books:

• E-Series Installation and User Guide – Provides the necessary

procedures for getting the router operational, including information on

installing, cabling, powering up, configuring the router for

Page 18

xviii

About This Guide

management access, and general troubleshooting. Describes SRP

modules, line modules, and I/O modules available for the E-series

routers, and provides information about the compatibility of line

modules and I/O modules with software releases. Lists the layer 2

protocols, layer 3 protocols, and applications that line modules and

their corresponding I/O modules support.

• E-Series System Basics Configuration Guide – Describes planning and

configuring your network, managing the router, configuring passwords

and security, configuring the router clock, and configuring virtual

routers. Includes a list of references that provide information on the

protocols and features supported by the router.

• E-Series Physical Layer Configuration Guide – Describes configuring

physical layer interfaces.

• E-Series Link Layer Configuration Guide – Describes configuring link

layer interfaces.

• E-Series Routing Protocols Configuration Guide, Vol. 1 – Provides

information about configuring routing policy and configuring IP, IP

routing, and IP security.

• E-Series Routing Protocols Configuration Guide, Vol. 2 – Describes

BGP routing, MPLS, BGP-MPLS VPNs, and encapsulation of layer 2

services.

• E-Series Policy and QoS Configuration Guide – Provides information

about configuring policy management and quality of service (QoS).

• E-Series Broadband Access Configuration Guide – Provides

information about configuring remote access.

• E-Series Command Reference Guide A to M; E-Series Command

Reference Guide N to Z – Together comprise the E-Series Command

Reference Guide. Contain important information about commands

implemented in the system software. Use to look up command

descriptions, command syntax, a command’s related mode, or a

description of a command’s parameters. Use with the E-series

configuration guides.

• E-Series Product Overview Guide – Gives a thorough overview of the

router from a software and hardware perspective. It provides

illustrations and configuration examples that present the “big picture.”

Page 19

MIBS

Release Notes

Abbreviations

Comments About the Documentation

E-Series Routers

Copies of the MIBs available in a software release are included on the

JUNOSe Software CD (formerly ERX Edge Routers Software CD) and

on the Web.

Release notes are included on the corresponding software CD and are

available on the Web.

In the Release Notes, you will find the latest information about features,

changes, known problems, resolved problems, and system maximum

values. If the information in the Release Notes differs from the

information found in the documentation set, follow the Release Notes.

A complete list of abbreviations used in this document set, along with

their spelled-out terms, is provided in the E-Series System Basics

Configuration Guide, Appendix A, Abbreviations and Acronyms.

xix

Web Access

To view the documentation on the Web, go to:

http://www.juniper.net/techpubs/

Comments About the Documentation

We encourage you to provide feedback, comments, and suggestions so

that we can improve the documentation to better meet your needs. Please

e-mail your comments to:

• techpubs-comments@juniper.net

Along with your comments, be sure to indicate:

• Document name

• Document part number

• Page number

• Software release version

Page 20

xx

About This Guide

Contacting Customer Support

For technical support, contact Juniper Networks at support@juniper.net,

or at 1-888-314-JTAC (within the United States) or 408-745-9500 (from

outside the United States).

Page 21

Part 1

Installing and Using E-Series Routers

Page 22

Page 23

E-Series Overview

This chapter provides introductory information about the E-series

routers.

Top ic Page

Overview 1-1

Where E-Series Routers Fit In 1-2

E-Series Routers 1-3

ERX-14xx Models 1-4

ERX-7xx Models 1-6

ERX-310 Router 1-8

E-Series Modules 1-10

Network Management Tools 1-15

Redundancy Features 1-16

1

Overview

E-series routers are modular, carrier-class networking devices that deliver

performance, reliability, and service differentiation to both business and

consumer Internet users. The ERX-7xx/14xx models offer high port

density, low power consumption, and fully redundant Internet access

routing and edge aggregation. The ERX-310 router supports the same

services, but with smaller capacity and scaling capabilities. E-series

routers offer the complete edge solution for IP-optimized carriers.

Page 24

CHAPTER 1

1-2

E-Series Overview

Where E-Series Routers Fit In

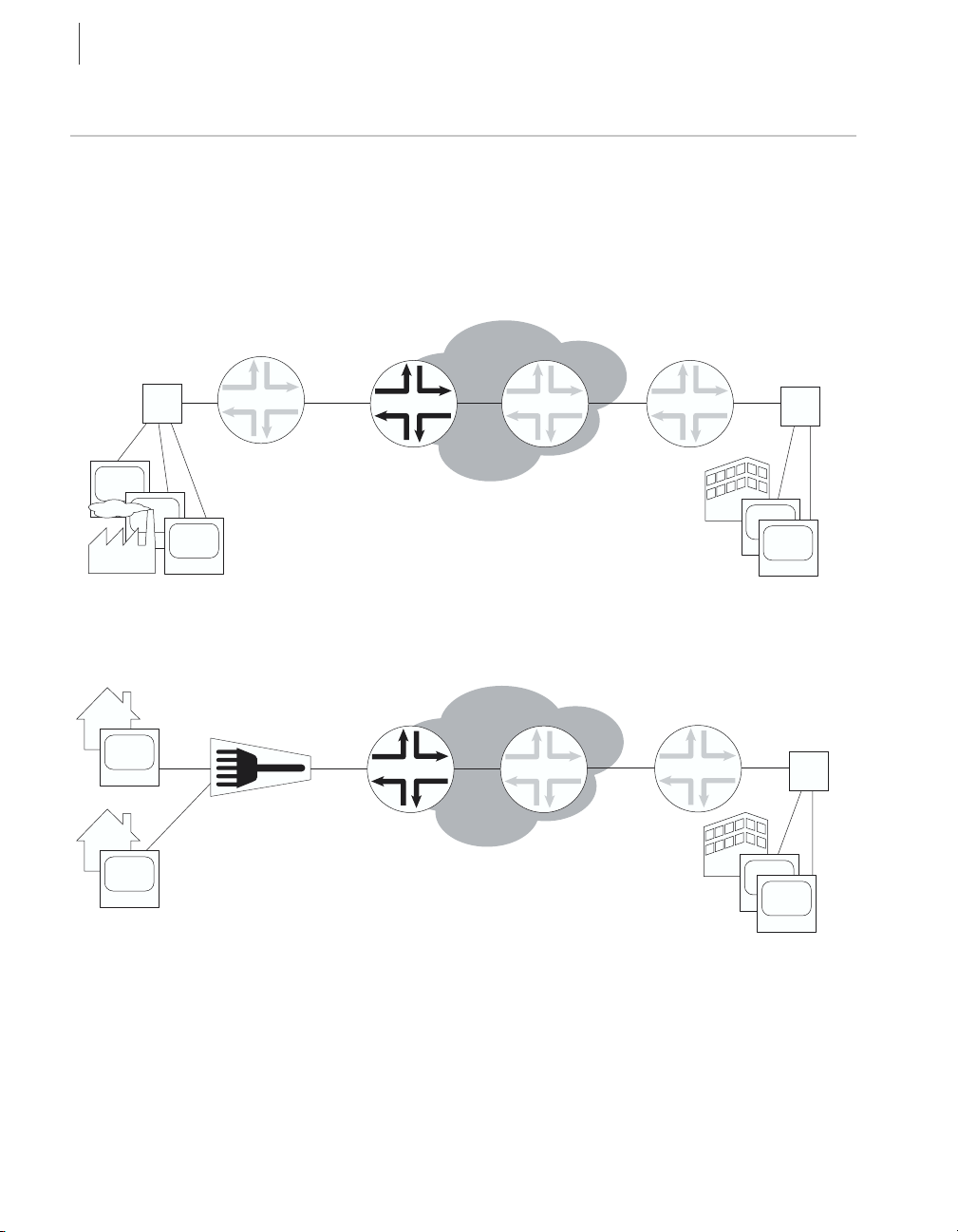

Communications with the router can take place over a variety of media.

Figure 1-1 and Figure 1-2 illustrate the location of E-series routers as an

edge router in an end-to-end Internet network. In Figure 1-1, the

customers are businesses using T1/T3 communication lines. In

Figure 1-2, the customers are using digital subscriber lines (DSLs) with a

DSL access multiplexer (DSLAM).

Internet

Hub

PC

Home office

PC

Home office

PC

Desktop

Remote

access

router

DSLAM

T1/T3

Figure 1-1 E-series router communicating over T1/T3 lines

DS3 OC3

ERX

ERX

OC3

Core

router

Internet

Core

router

Remote

access

router

Remote

access

router

Hub

PC

g013033

Desktop

Hub

PC

g013034

Desktop

Figure 1-2 E-series router communicating over DSL lines

Page 25

CPE

CPE

E-Series Routers

E-Series Routers

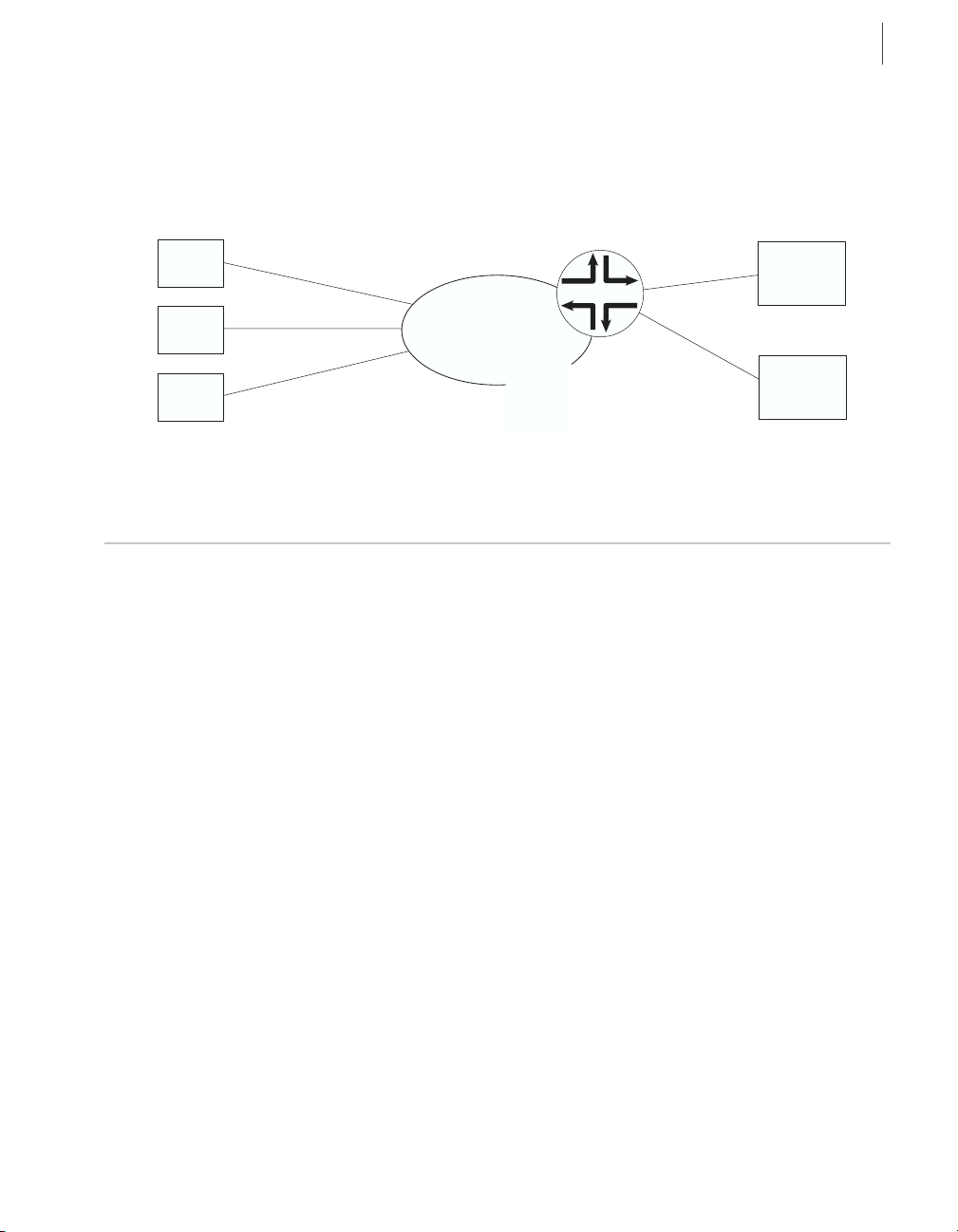

In Figure 1-3, the ERX-310 router is being used as an access router in a

small POP location. The router is deployed by the service provider at the

customer site as a CPE (customer premises equipment).

xDSL

T1/E1

T3/E3

GE

ERX

SONET or ATM

infrastructure

GE

OC3

VPN

1-3

CPE

E-Series Routers

GE

OC3/12

cOC3

cOC12

Figure 1-3 ERX-310 router deployed in a small POP

ISP

Five models of E-series routers are available:

• ERX-1440 router

• ERX-1410 router

• ERX-710 router

• ERX-705 router

• ERX-310 router

All models use the same software. However, the specific model

determines the:

• Combination of line modules supported

• Conditions for line rate performance of line modules

• Type, capacity, and number of SRP modules used

g013726

Page 26

CHAPTER 1

1-4

E-Series Overview

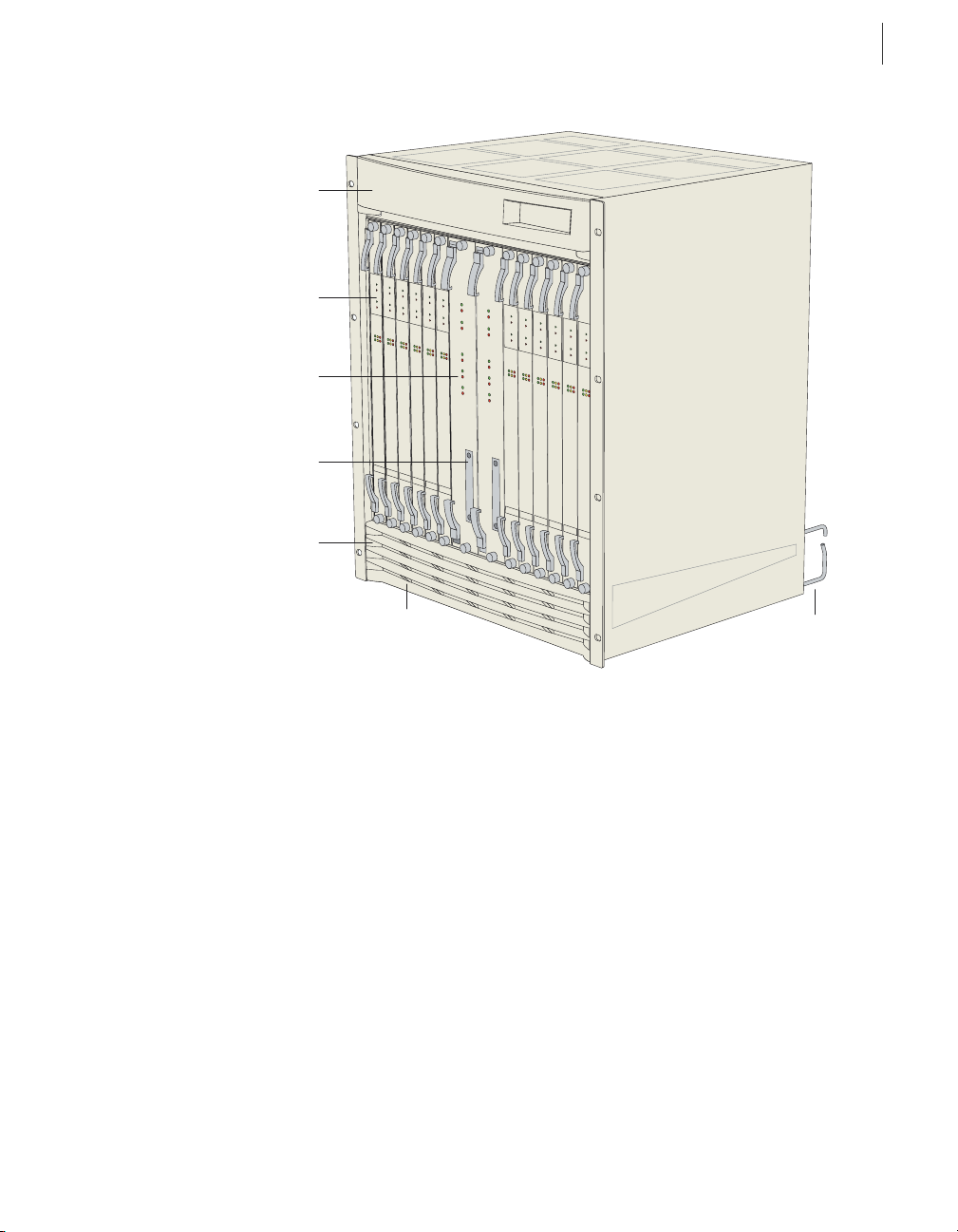

ERX-14xx Models

Note: In the E-series documentation, the term ERX-14xx models refers to both the

ERX-1440 router and the ERX-1410 router. The terms ERX-1440 router and

ERX-1410 router refer to the specific models. See Figure 1-4 and Figure 1-5.

The ERX-1440 router manages an extremely high volume of network

traffic, and uses a 40-Gbps switch route processor (SRP) module, either

the SRP-40G or SRP-40G+ module. (The SRP-40G+ module obsoletes

the SRP-40G module; however, the software continues to support both

modules.) In this model, all line modules operate at full wire speed

simultaneously.

The ERX-1410 router manages high levels of network traffic, and uses the

10-Gbps SRP module (SRP-10G). You can configure the ERX-1410

router to enable the line modules either to operate at full line rate

performance or to allow line modules to operate at a rate dependent on

the resources available. The former option restricts the allowed

combinations of line modules. For information on configuring

performance of line modules, see E-Series System Basics Configuration

Guide, Chapter 5, Managing Line Modules and SRP Modules.

Note: The 10-Gbps SRP module used in the ERX-310 router is different from the

10-Gbps SRP module used in the ERX-1410 router. See section SRP Module,

later in this chapter, for more information.

Externally, the ERX-1440 chassis is the same as the ERX-1410 chassis

(see Figure 1-4 and Figure 1-5). Both routers contain 14 vertical slots to

accommodate modules.

Internally, the ERX-1440 chassis differs from the ERX-1410 chassis, and

includes a special midplane for the 40-Gbps SRP module.

Installation procedures and operating procedures are identical for both

systems. All ERX-7xx/14xx models use the same SRP I/O module, but

different power input modules are used.

Note: The router may look different from the routers shown in the figures in this

chapter, depending on the line modules in the slots.

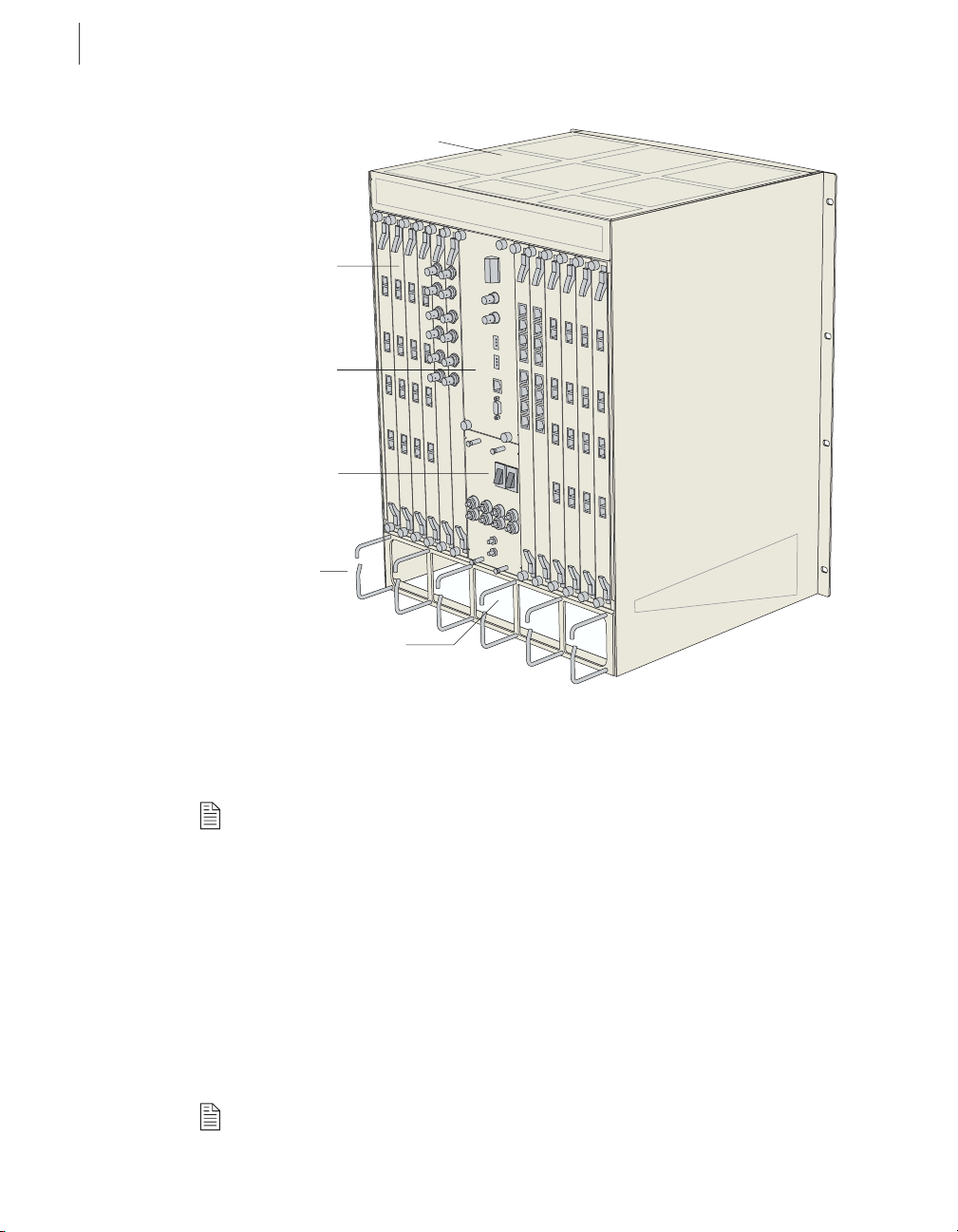

Page 27

Fan tray

behind bezel

Line module

SRP module

PCMCIA slot

Air filter (optional)

behind bezel

E-Series Routers

E-Series Routers

1-5

Bezel

Figure 1-4 ERX-14xx model, front view

g013727

Cable

management

bracket

Page 28

CHAPTER 1

1-6

E-Series Overview

Fan tray

I/O

module

SRP I/O

module

Power input

module

Cable

management

bracket

ERX-7xx Models

Plenum

g013727

Figure 1-5 ERX-14xx model, rear view

Note: In the E-series documentation, the term ERX-7xx models refers to both the

ERX-705 router and the ERX-710 router. The terms ERX-705 router and ERX-710

router refer to the specific models. See Figure 1-6 and Figure 1-7.

The ERX-7xx models are robust, high-density routers with less capacity

than the ERX-14xx models. The ERX-7xx models use either the

SRP-10G module or the SRP-5G module.

You can configure the ERX-7xx models to enable the line modules to

operate either at full line rate performance or at a rate dependent on the

resources available. For information about configuring performance of

line modules, see E-Series System Basics Configuration Guide,

Chapter 5, Managing Line Modules and SRP Modules.

Note: The 10-Gbps SRP module used in the ERX-310 router is different from the

10-Gbps SRP module used in the ERX-710 router. See section SRP Module, later

in this chapter, for more information.

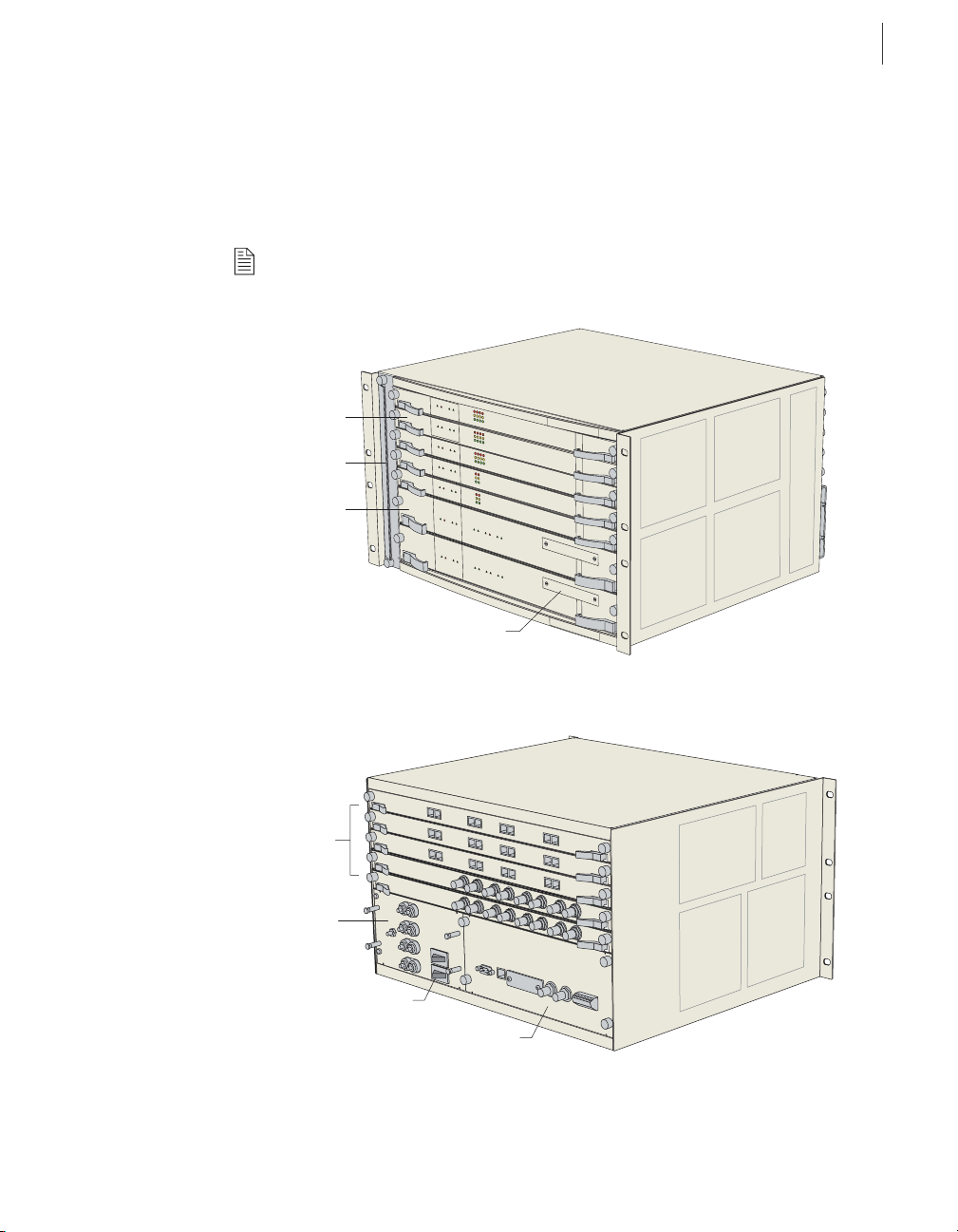

Page 29

E-Series Routers

E-Series Routers

The ERX-705 chassis is the same as the ERX-710 chassis (see Figure 1-6

and Figure 1-7). The chassis contains seven slots to accommodate

modules. Installation procedures and operating procedures are identical

for both systems. All ERX-7xx/14xx models use the same SRP I/O

module, but different power input modules are used.

Note: The router may look different from the routers shown in the figures in this

chapter, depending on the line modules in the slots.

Line module

Fan tray

SRP module

1-7

PCMCIA slot

Figure 1-6 ERX-7xx model, front view

I/O

modules

Power input

module

Power switches

SRP I/O module

Figure 1-7 ERX-7xx model, rear view

g013729

g013730

Page 30

CHAPTER 1

1-8

E-Series Overview

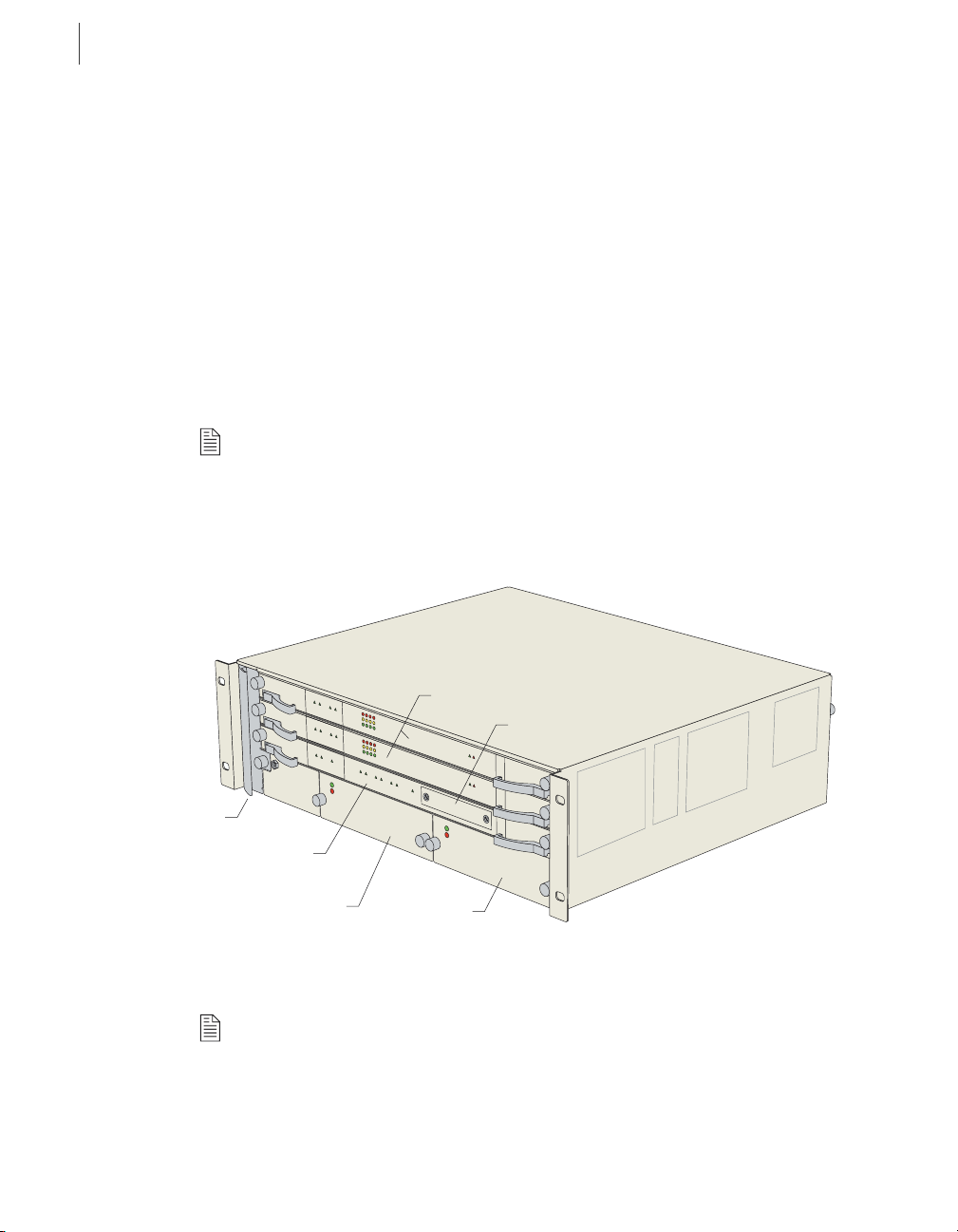

ERX-310 Router

The ERX-310 router is a low-end platform that supports all of the same

services as the ERX-7xx/14xx models, but with smaller capacity and

scaling capabilities. Like the ERX-7xx/14xx models, the ERX-310 router

uses the same software architecture, providing a single IP entry point into

the network with the same IP-based protocols and services that are

available on other E-series routers. The ERX-310 router is designed to be

used as a small distributed POP router as well as a high-end CPE router.

The ERX-310 router is a three-slot chassis with a midplane architecture.

One slot supports one nonredundant 10-Gbps SRP module, while the

other two slots support line modules. The router supports existing E-series

ASIC-based line modules (except the OC48/STM16 line module).

Note: The 10-Gbps SRP module used in the ERX-310 router is different from the

10-Gbps SRP module used in the ERX-7xx/14xx models. See section SRP

Module, later in this chapter, for more information.

The ERX-310 router is available in either redundant AC- or DC-powered

models.

Fan tray

Line modules

PCMCIA slot

SRP module

AC power

supply A

Figure 1-8 ERX-310 router, front view (AC model)

Note: DC model has blank filler panels in power supply slots.

AC power

supply B

g013731

Page 31

g013732

AC power inputs and

switches A and B

Grounding posts

Figure 1-9 ERX-310 router, rear view (AC model)

E-Series Routers

E-Series Routers

I/O module

SRP I/O

module

ESD grounding jack

1-9

g013733

I/O

module

SRP I/O

module

ESD grounding jack

DC power inputs

and switches A and B

Grounding posts

Figure 1-10 ERX-310 router, rear view (DC model)

Page 32

CHAPTER 1

1-10

E-Series Overview

E-Series Modules

The system supports an SRP module and a selection of line modules. You

can use any line module for access or uplink. Access line modules receive

traffic from low-speed circuits, and the system routes the traffic onto

higher-speed uplink line modules and then to the core of the network.

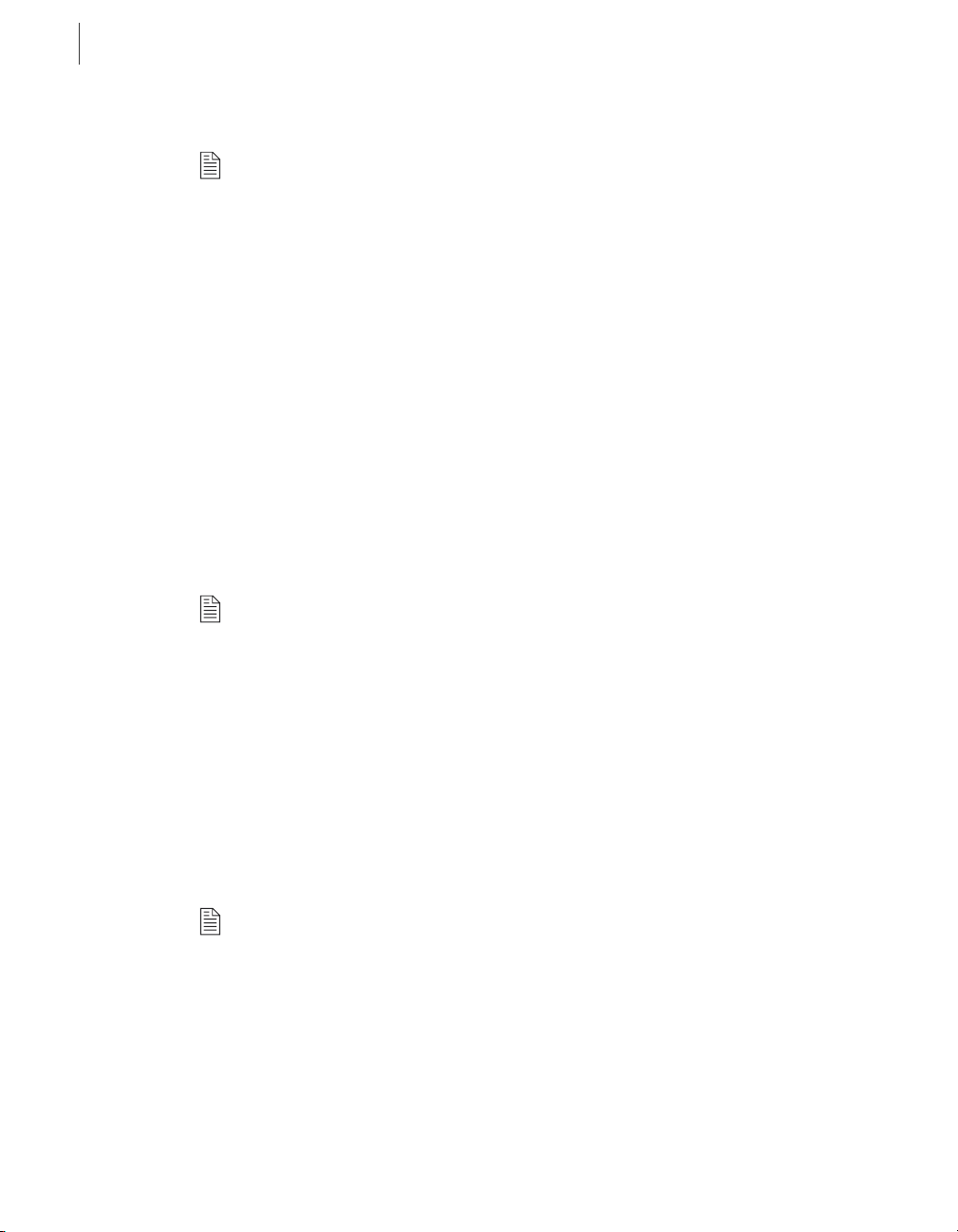

Each module connects to a corresponding I/O module via a passive

midplane. See Figure 1-11.

The front panel of each module contains a collection of status LEDs

(light-emitting diodes). For information about how to interpret the LEDs,

see Chapter 10, Troubleshooting.

Line modules

SRP modules

Line modules

I/O modules

SRP I/O

module

I/O modules

Connection via

passive midplane

g013734

Figure 1-11 Modules in ERX-14xx model

Page 33

SRP Module

E-Series Modules

E-Series Routers

Switch route processor (SRP) modules perform system management,

routing table calculations and maintenance, forwarding table

computations, statistics processing, configuration storage, and other

control plane functions. Each SRP module is a PowerPC-based system

with its own memory, nonvolatile disk storage, and power supply (see

Figure 1-12 and Figure 1-13).

Fabric board

Ejector

Midplane

connectors

Status LEDs

1-11

Board reset

button

NMI button

PCMCIA

NVS card

Figure 1-12 ERX-7xx/14xx SRP module

System

processor board

g013735

Page 34

CHAPTER 1

1-12

E-Series Overview

g013736

Ejector

Midplane

connectors

Status

LEDs

PCMCIA

NVS card

Board reset

button

NMI button

Figure 1-13 ERX-310 SRP module

Integrated fabric system

processor board

Module Details

ERX-7xx/14xx models use up to two redundant SRP modules operating

in an active/standby conf iguration. ERX-310 routers use only one SRP

module. An SRP module must be present for any system to boot.

SRP modules ranging from 5 Gbps to 40 Gbps can be used in

ERX-7xx/14xx models. Only a 10-Gbps SRP module (SRP-SE10G) can

be used in ERX-310 routers. See Chapter 12, Module Specifications for

complete information.

Note: Because of different physical dimensions and switch fabric capabilities, SRP

modules are not interchangeable between systems. For example, the 10-Gbps

SRP module used in ERX-7xx/14xx models cannot be used in the ERX-310 router,

and vice versa.

Page 35

SRP I/O Module

E-Series Modules

E-Series Routers

Caution: Do not remove the SRP module while the system is running.

For details about installing SRP modules, see Chapter 5, Installing

Modules.

SRP Module Redundancy

SRP module redundancy is available only for ERX-7xx/14xx models. See

Redundancy Features, later in this chapter, for more information.

Nonvolatile Storage

The PCMCIA slot on the front of the SRP module holds a Type II

PCMCIA nonvolatile storage (NVS) card (see Figure 1-12 and

Figure 1-13). This card is loaded with the system’s software and

configuration files. The PCMCIA card is factory installed.

The SRP I/O module is a single corresponding input/output module that

interfaces with the SRP module(s) through the system’s midplane. The

same SRP I/O module works with all SRP modules, but is router specific.

The I/O module used in ERX-7xx/14x models cannot be used in the

ERX-310 router, and vice versa. See Figure 1-5, Figure 1-7, and

Figure 1-9 for locations.

1-13

Module Details

The SRP module provides standard craft management interfaces,

including:

• 10/100Base-T – Enables access to the E-series router for Ethernet

management functions via CLI or SNMP, for example.

• RS-232 – Provides a serial connection for monitoring the system’s

hardware configuration through a PC (running terminal emulation

software) or ASCII terminal. Allows direct CLI access.

• Alarm contacts – Provide for remote indication of critical, major, and

minor E-series router alarms (ERX-7xx/14xx models only; currently

not implemented)

• External timing inputs – Provide a method of ensuring that the clock

timing used by the E-series router remains synchronized with the

network’s system clock. BNC connectors and wire wraps are available

for ERX-7xx/14xx models only.

Page 36

CHAPTER 1

1-14

E-Series Overview

Line Modules

For details about installing the SRP I/O module, see Chapter 5, Installing

Modules.

Line modules process data from different types of network connections.

For information about available line modules and which SRP modules

support specific line modules, see Chapter 12, Module Specifications.

Figure 1-14 shows a representative line module. For details about

installing line modules, see Chapter 5, Installing Modules.

Ejector

Status LEDs

Board reset

button

NMI button

Figure 1-14 Representative line module

Midplane

connectors

g013737

Page 37

I/O Modules

Network Management Tools

E-Series Routers

Packet Classification

Most line modules support packet classification on ingress (some

non-ASIC line modules do not). A classification engine on the line

module matches specific f ields (such as source and destination IP address,

source and destination port, and protocol), the ingress IP interface, layer

2 fields, or some combination of these against user-configured filters at

wire speed.

Most line modules have a corresponding input/output (I/O) module that

provides the physical interconnection to the network. Insert each I/O

module into the back of the system, directly behind its corresponding line

module.

For information about which line modules pair with which I/O modules,

see Chapter 12, Module Specifications. See Figure 1-5, Figure 1-7, and