Page 1

E Series™ Broadband Services Routers

ERX™ Hardware Guide

Release 11.1.x

Juniper Networks, Inc.

1194 North Mathilda Avenue

Sunnyvale, California 94089

USA

408-745-2000

www.juniper.net

Published: 2010-03-23

Page 2

Juniper Networks, the Juniper Networks logo, JUNOS, NetScreen, ScreenOS, and Steel-Belted Radius are registered trademarks of Juniper Networks, Inc. in

the United States and other countries. JUNOSe is a trademark of Juniper Networks, Inc. All other trademarks, service marks, registered trademarks, or

registered service marks are the property of their respective owners.

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right to change, modify, transfer, or

otherwise revise this publication without notice.

Products made or sold by Juniper Networks or components thereof might be covered by one or more of the following patents that are owned by or licensed

to Juniper Networks: U.S. Patent Nos. 5,473,599, 5,905,725, 5,909,440, 6,192,051, 6,333,650, 6,359,479, 6,406,312, 6,429,706, 6,459,579, 6,493,347,

6,538,518, 6,538,899, 6,552,918, 6,567,902, 6,578,186, and 6,590,785.

E Series™ Broadband Services Routers ERX™ Hardware Guide, Release 11.1.x

Copyright © 2010, Juniper Networks, Inc.

All rights reserved. Printed in USA.

Writing: John Borelli, Helen Shaw, Krupa Chandrashekar

Editing: Ben Mann

Illustration: John Borelli

Cover Design: Edmonds Design

Revision History

April 2010—FRS JUNOSe 11.1.x

The information in this document is current as of the date listed in the revision history.

SOFTWARE LICENSE

The terms and conditions for using this software are described in the software license contained in the acknowledgment to your purchase order or, to the

extent applicable, to any reseller agreement or end-user purchase agreement executed between you and Juniper Networks. By using this software, you

indicate that you understand and agree to be bound by those terms and conditions.

Generally speaking, the software license restricts the manner in which you are permitted to use the software and may contain prohibitions against certain

uses. The software license may state conditions under which the license is automatically terminated. You should consult the license for further details.

For complete product documentation, please see the Juniper Networks Web site at www.juniper.net/techpubs.

ii ■

Page 3

END USER LICENSE AGREEMENT

READ THIS END USER LICENSE AGREEMENT (“AGREEMENT”) BEFORE DOWNLOADING, INSTALLING, OR USING THE SOFTWARE. BY DOWNLOADING,

INSTALLING, OR USING THE SOFTWARE OR OTHERWISE EXPRESSING YOUR AGREEMENT TO THE TERMS CONTAINED HEREIN, YOU (AS CUSTOMER

OR IF YOU ARE NOT THE CUSTOMER, AS A REPRESENTATIVE/AGENT AUTHORIZED TO BIND THE CUSTOMER) CONSENT TO BE BOUND BY THIS

AGREEMENT. IF YOU DO NOT OR CANNOT AGREE TO THE TERMS CONTAINED HEREIN, THEN (A) DO NOT DOWNLOAD, INSTALL, OR USE THE SOFTWARE,

AND (B) YOU MAY CONTACT JUNIPER NETWORKS REGARDING LICENSE TERMS.

1. The Parties. The parties to this Agreement are (i) Juniper Networks, Inc. (if the Customer’s principal office is located in the Americas) or Juniper Networks

(Cayman) Limited (if the Customer’s principal office is located outside the Americas) (such applicable entity being referred to herein as “Juniper”), and (ii)

the person or organization that originally purchased from Juniper or an authorized Juniper reseller the applicable license(s) for use of the Software (“Customer”)

(collectively, the “Parties”).

2. The Software. In this Agreement, “Software” means the program modules and features of the Juniper or Juniper-supplied software, for which Customer

has paid the applicable license or support fees to Juniper or an authorized Juniper reseller, or which was embedded by Juniper in equipment which Customer

purchased from Juniper or an authorized Juniper reseller. “Software” also includes updates, upgrades and new releases of such software. “Embedded

Software” means Software which Juniper has embedded in or loaded onto the Juniper equipment and any updates, upgrades, additions or replacements

which are subsequently embedded in or loaded onto the equipment.

3. License Grant. Subject to payment of the applicable fees and the limitations and restrictions set forth herein, Juniper grants to Customer a non-exclusive

and non-transferable license, without right to sublicense, to use the Software, in executable form only, subject to the following use restrictions:

a. Customer shall use Embedded Software solely as embedded in, and for execution on, Juniper equipment originally purchased by Customer from Juniper

or an authorized Juniper reseller.

b. Customer shall use the Software on a single hardware chassis having a single processing unit, or as many chassis or processing units for which Customer

has paid the applicable license fees; provided, however, with respect to the Steel-Belted Radius or Odyssey Access Client software only, Customer shall use

such Software on a single computer containing a single physical random access memory space and containing any number of processors. Use of the

Steel-Belted Radius or IMS AAA software on multiple computers or virtual machines (e.g., Solaris zones) requires multiple licenses, regardless of whether

such computers or virtualizations are physically contained on a single chassis.

c. Product purchase documents, paper or electronic user documentation, and/or the particular licenses purchased by Customer may specify limits to

Customer’s use of the Software. Such limits may restrict use to a maximum number of seats, registered endpoints, concurrent users, sessions, calls,

connections, subscribers, clusters, nodes, realms, devices, links, ports or transactions, or require the purchase of separate licenses to use particular features,

functionalities, services, applications, operations, or capabilities, or provide throughput, performance, configuration, bandwidth, interface, processing,

temporal, or geographical limits. In addition, such limits may restrict the use of the Software to managing certain kinds of networks or require the Software

to be used only in conjunction with other specific Software. Customer’s use of the Software shall be subject to all such limitations and purchase of all applicable

licenses.

d. For any trial copy of the Software, Customer’s right to use the Software expires 30 days after download, installation or use of the Software. Customer

may operate the Software after the 30-day trial period only if Customer pays for a license to do so. Customer may not extend or create an additional trial

period by re-installing the Software after the 30-day trial period.

e. The Global Enterprise Edition of the Steel-Belted Radius software may be used by Customer only to manage access to Customer’s enterprise network.

Specifically, service provider customers are expressly prohibited from using the Global Enterprise Edition of the Steel-Belted Radius software to support any

commercial network access services.

The foregoing license is not transferable or assignable by Customer. No license is granted herein to any user who did not originally purchase the applicable

license(s) for the Software from Juniper or an authorized Juniper reseller.

4. Use Prohibitions. Notwithstanding the foregoing, the license provided herein does not permit the Customer to, and Customer agrees not to and shall

not: (a) modify, unbundle, reverse engineer, or create derivative works based on the Software; (b) make unauthorized copies of the Software (except as

necessary for backup purposes); (c) rent, sell, transfer, or grant any rights in and to any copy of the Software, in any form, to any third party; (d) remove

any proprietary notices, labels, or marks on or in any copy of the Software or any product in which the Software is embedded; (e) distribute any copy of

the Software to any third party, including as may be embedded in Juniper equipment sold in the secondhand market; (f) use any ‘locked’ or key-restricted

feature, function, service, application, operation, or capability without first purchasing the applicable license(s) and obtaining a valid key from Juniper, even

if such feature, function, service, application, operation, or capability is enabled without a key; (g) distribute any key for the Software provided by Juniper

to any third party; (h) use the Software in any manner that extends or is broader than the uses purchased by Customer from Juniper or an authorized Juniper

reseller; (i) use Embedded Software on non-Juniper equipment; (j) use Embedded Software (or make it available for use) on Juniper equipment that the

Customer did not originally purchase from Juniper or an authorized Juniper reseller; (k) disclose the results of testing or benchmarking of the Software to

any third party without the prior written consent of Juniper; or (l) use the Software in any manner other than as expressly provided herein.

5. Audit. Customer shall maintain accurate records as necessary to verify compliance with this Agreement. Upon request by Juniper, Customer shall furnish

such records to Juniper and certify its compliance with this Agreement.

■ iii

Page 4

6. Confidentiality. The Parties agree that aspects of the Software and associated documentation are the confidential property of Juniper. As such, Customer

shall exercise all reasonable commercial efforts to maintain the Software and associated documentation in confidence, which at a minimum includes

restricting access to the Software to Customer employees and contractors having a need to use the Software for Customer’s internal business purposes.

7. Ownership. Juniper and Juniper’s licensors, respectively, retain ownership of all right, title, and interest (including copyright) in and to the Software,

associated documentation, and all copies of the Software. Nothing in this Agreement constitutes a transfer or conveyance of any right, title, or interest in

the Software or associated documentation, or a sale of the Software, associated documentation, or copies of the Software.

8. Warranty, Limitation of Liability, Disclaimer of Warranty. The warranty applicable to the Software shall be as set forth in the warranty statement that

accompanies the Software (the “Warranty Statement”). Nothing in this Agreement shall give rise to any obligation to support the Software. Support services

may be purchased separately. Any such support shall be governed by a separate, written support services agreement. TO THE MAXIMUM EXTENT PERMITTED

BY LAW, JUNIPER SHALL NOT BE LIABLE FOR ANY LOST PROFITS, LOSS OF DATA, OR COSTS OR PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES,

OR FOR ANY SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES ARISING OUT OF THIS AGREEMENT, THE SOFTWARE, OR ANY JUNIPER OR

JUNIPER-SUPPLIED SOFTWARE. IN NO EVENT SHALL JUNIPER BE LIABLE FOR DAMAGES ARISING FROM UNAUTHORIZED OR IMPROPER USE OF ANY

JUNIPER OR JUNIPER-SUPPLIED SOFTWARE. EXCEPT AS EXPRESSLY PROVIDED IN THE WARRANTY STATEMENT TO THE EXTENT PERMITTED BY LAW,

JUNIPER DISCLAIMS ANY AND ALL WARRANTIES IN AND TO THE SOFTWARE (WHETHER EXPRESS, IMPLIED, STATUTORY, OR OTHERWISE), INCLUDING

ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR NONINFRINGEMENT. IN NO EVENT DOES JUNIPER

WARRANT THAT THE SOFTWARE, OR ANY EQUIPMENT OR NETWORK RUNNING THE SOFTWARE, WILL OPERATE WITHOUT ERROR OR INTERRUPTION,

OR WILL BE FREE OF VULNERABILITY TO INTRUSION OR ATTACK. In no event shall Juniper’s or its suppliers’ or licensors’ liability to Customer, whether

in contract, tort (including negligence), breach of warranty, or otherwise, exceed the price paid by Customer for the Software that gave rise to the claim, or

if the Software is embedded in another Juniper product, the price paid by Customer for such other product. Customer acknowledges and agrees that Juniper

has set its prices and entered into this Agreement in reliance upon the disclaimers of warranty and the limitations of liability set forth herein, that the same

reflect an allocation of risk between the Parties (including the risk that a contract remedy may fail of its essential purpose and cause consequential loss),

and that the same form an essential basis of the bargain between the Parties.

9. Termination. Any breach of this Agreement or failure by Customer to pay any applicable fees due shall result in automatic termination of the license

granted herein. Upon such termination, Customer shall destroy or return to Juniper all copies of the Software and related documentation in Customer’s

possession or control.

10. Taxes. All license fees payable under this agreement are exclusive of tax. Customer shall be responsible for paying Taxes arising from the purchase of

the license, or importation or use of the Software. If applicable, valid exemption documentation for each taxing jurisdiction shall be provided to Juniper prior

to invoicing, and Customer shall promptly notify Juniper if their exemption is revoked or modified. All payments made by Customer shall be net of any

applicable withholding tax. Customer will provide reasonable assistance to Juniper in connection with such withholding taxes by promptly: providing Juniper

with valid tax receipts and other required documentation showing Customer’s payment of any withholding taxes; completing appropriate applications that

would reduce the amount of withholding tax to be paid; and notifying and assisting Juniper in any audit or tax proceeding related to transactions hereunder.

Customer shall comply with all applicable tax laws and regulations, and Customer will promptly pay or reimburse Juniper for all costs and damages related

to any liability incurred by Juniper as a result of Customer’s non-compliance or delay with its responsibilities herein. Customer’s obligations under this

Section shall survive termination or expiration of this Agreement.

11. Export. Customer agrees to comply with all applicable export laws and restrictions and regulations of any United States and any applicable foreign

agency or authority, and not to export or re-export the Software or any direct product thereof in violation of any such restrictions, laws or regulations, or

without all necessary approvals. Customer shall be liable for any such violations. The version of the Software supplied to Customer may contain encryption

or other capabilities restricting Customer’s ability to export the Software without an export license.

12. Commercial Computer Software. The Software is “commercial computer software” and is provided with restricted rights. Use, duplication, or disclosure

by the United States government is subject to restrictions set forth in this Agreement and as provided in DFARS 227.7201 through 227.7202-4, FAR 12.212,

FAR 27.405(b)(2), FAR 52.227-19, or FAR 52.227-14(ALT III) as applicable.

13. Interface Information. To the extent required by applicable law, and at Customer's written request, Juniper shall provide Customer with the interface

information needed to achieve interoperability between the Software and another independently created program, on payment of applicable fee, if any.

Customer shall observe strict obligations of confidentiality with respect to such information and shall use such information in compliance with any applicable

terms and conditions upon which Juniper makes such information available.

14. Third Party Software. Any licensor of Juniper whose software is embedded in the Software and any supplier of Juniper whose products or technology

are embedded in (or services are accessed by) the Software shall be a third party beneficiary with respect to this Agreement, and such licensor or vendor

shall have the right to enforce this Agreement in its own name as if it were Juniper. In addition, certain third party software may be provided with the

Software and is subject to the accompanying license(s), if any, of its respective owner(s). To the extent portions of the Software are distributed under and

subject to open source licenses obligating Juniper to make the source code for such portions publicly available (such as the GNU General Public License

(“GPL”) or the GNU Library General Public License (“LGPL”)), Juniper will make such source code portions (including Juniper modifications, as appropriate)

available upon request for a period of up to three years from the date of distribution. Such request can be made in writing to Juniper Networks, Inc., 1194

N. Mathilda Ave., Sunnyvale, CA 94089, ATTN: General Counsel. You may obtain a copy of the GPL at http://www.gnu.org/licenses/gpl.html, and

a copy of the LGPL at http://www.gnu.org/licenses/lgpl.html.

15. Miscellaneous. This Agreement shall be governed by the laws of the State of California without reference to its conflicts of laws principles. The provisions

of the U.N. Convention for the International Sale of Goods shall not apply to this Agreement. For any disputes arising under this Agreement, the Parties

hereby consent to the personal and exclusive jurisdiction of, and venue in, the state and federal courts within Santa Clara County, California. This Agreement

constitutes the entire and sole agreement between Juniper and the Customer with respect to the Software, and supersedes all prior and contemporaneous

iv ■

Page 5

agreements relating to the Software, whether oral or written (including any inconsistent terms contained in a purchase order), except that the terms of a

separate written agreement executed by an authorized Juniper representative and Customer shall govern to the extent such terms are inconsistent or conflict

with terms contained herein. No modification to this Agreement nor any waiver of any rights hereunder shall be effective unless expressly assented to in

writing by the party to be charged. If any portion of this Agreement is held invalid, the Parties agree that such invalidity shall not affect the validity of the

remainder of this Agreement. This Agreement and associated documentation has been written in the English language, and the Parties agree that the English

version will govern. (For Canada: Les parties aux présentés confirment leur volonté que cette convention de même que tous les documents y compris tout

avis qui s'y rattaché, soient redigés en langue anglaise. (Translation: The parties confirm that this Agreement and all related documentation is and will be

in the English language)).

■ v

Page 6

vi ■

Page 7

Table of Contents

About the Documentation xiii

E Series and JUNOSe Documentation and Release Notes ..............................xiii

Audience ......................................................................................................xiii

E Series and JUNOSe Text and Syntax Conventions ......................................xiii

Obtaining Documentation .............................................................................xv

Documentation Feedback ..............................................................................xv

Requesting Technical Support ........................................................................xv

Self-Help Online Tools and Resources ....................................................xvi

Opening a Case with JTAC ......................................................................xvi

Part 1 Product Overview

Chapter 1 ERX Overview 3

Overview .........................................................................................................3

ERX Routers ....................................................................................................3

ERX14xx Models ......................................................................................4

ERX7xx Models ........................................................................................6

ERX310 Broadband Services Router .........................................................7

ERX Modules ...................................................................................................9

SRP Module ..............................................................................................9

Module Details ..................................................................................11

SRP Module Redundancy .................................................................12

Nonvolatile Storage ..........................................................................12

SRP I/O Module .......................................................................................12

Module Details ..................................................................................12

Line Modules ..........................................................................................13

Packet Classification .........................................................................13

I/O Modules ............................................................................................14

Network Management Tools ..........................................................................14

CLI Management .....................................................................................14

SNMP MIB Management .........................................................................14

NMC-RX Device Management System .....................................................14

Redundancy Features ....................................................................................14

SRP Modules ...........................................................................................14

NVS Cards ........................................................................................15

Line Modules ..........................................................................................16

Power .....................................................................................................17

Fans ........................................................................................................17

Table of Contents ■ vii

Page 8

ERX 11.1.x Hardware Guide

Part 2 Initial Installation

Chapter 2 Unpacking and Inspecting ERX Routers 21

Before You Begin ...........................................................................................21

Unpacking ERX14xx Models .........................................................................21

Unpacking ERX7xx Models and ERX310 Broadband Services Routers ..........22

Inspecting Router Components and Accessories ...........................................22

If You Detect or Suspect Damage ..................................................................23

Contacting Juniper Networks .........................................................................23

The Next Step ................................................................................................23

Chapter 3 Installing ERX Routers 25

Before You Begin ...........................................................................................25

Freestanding Installation ...............................................................................25

Rack-Mounted Installation .............................................................................26

Installation Guidelines .............................................................................26

Safety Guidelines ....................................................................................27

Preparing the Equipment Racks ..............................................................28

Installing the Router ................................................................................29

The Next Step ................................................................................................29

Chapter 4 Installing Modules 31

Overview .......................................................................................................31

Slot Groups .............................................................................................32

Slot Groups for the ERX1410 Router ................................................32

Slot Groups for the ERX7xx Models ..................................................33

Combinations of Line Modules In Slot Groups .........................................33

OC48 Line Modules .................................................................................34

GE-2 Line Modules ..................................................................................34

Managing Modules Using the Software ...................................................34

Hot-Swapping Modules ...........................................................................34

Protecting Modules and Slots ..................................................................34

Order of Installation ................................................................................36

Required Tools and Safety Items .............................................................36

Safety Guidelines ...........................................................................................36

Installing SRP I/O and SRP Modules ..............................................................37

Installing an SRP I/O Module ...................................................................37

Installing an SRP Module ........................................................................38

Installing Line and I/O Modules .....................................................................40

Installing a Line Module or an I/O Module ...............................................40

Removing a Line Module, SRP Module, or SRP I/O Module ............................41

Installing Components for Line Module Redundancy .....................................42

Installing the Line Modules .....................................................................43

Installing the Redundancy Midplane .......................................................43

Installing the I/O Modules .......................................................................45

Verifying the Installation .........................................................................45

viii ■ Table of Contents

Page 9

Table of Contents

Configuring Line Module Redundancy ...........................................................46

The Next Step ................................................................................................46

Chapter 5 Cabling ERX Routers 47

Cabling Overview ..........................................................................................47

Required Tools, Wires, and Cables ................................................................48

Cabling the SRP I/O Module ...........................................................................49

External Timing Ports .............................................................................50

Management Ports ..................................................................................52

Connecting to the Network ...............................................................52

Connecting to a Console Terminal ....................................................52

Cabling the Router for Power ........................................................................53

Task 1: Turn Off All Router Power ..........................................................55

Task 2: Connect the Grounding Cables ....................................................55

Task 3: Connect the Power Cables ..........................................................56

ERX7xx Models, ERX14xx Models, ERX310 Router (DC Model) .......56

ERX310 Router (AC Model) ..............................................................57

Cabling I/O Modules ......................................................................................58

BNC Connectors ......................................................................................58

HSSI Connectors .....................................................................................58

RJ-45 Connectors ....................................................................................59

RJ-48C Connectors ..................................................................................59

LC Duplex Connectors ............................................................................60

SC Duplex Connectors ............................................................................60

SMB Connectors .....................................................................................61

X.21/V.35 Connectors .............................................................................62

Redundant Ports .....................................................................................63

The Next Step ................................................................................................63

Chapter 6 Powering Up ERX Routers 65

Before You Power Up the System ..................................................................65

Powering Up .................................................................................................65

Initialization Sequence ............................................................................66

Status LEDs ...................................................................................................66

Powering Down .............................................................................................67

The Next Step ................................................................................................67

Chapter 7 Accessing ERX Routers 69

Setting Up Management Access .....................................................................69

Console Port Setup ........................................................................................69

Using HyperTerminal ..............................................................................70

Connecting Directly to the Router ...........................................................70

Assigning an IP Address ..........................................................................71

Telnet Setup ..................................................................................................72

SNMP ............................................................................................................73

The Next Step ................................................................................................73

Table of Contents ■ ix

Page 10

ERX 11.1.x Hardware Guide

Part 3 Hardware Maintenance, Replacement, and Troubleshooting

Procedures

Chapter 8 Maintaining ERX Routers 77

Required Tools and Items ..............................................................................77

Storing Modules and Components .................................................................78

Cleaning the System ......................................................................................78

Upgrading from Release 5.1.1 or Lower-Numbered Releases to Release 6.x.x

or Higher-Numbered Releases ................................................................78

Upgrading NVS Cards on SRP Modules ..........................................................79

Upgrading a System That Contains One SRP Module ..............................79

Upgrading a System That Contains Two SRP Modules ............................80

Replacing an NVS Card ..................................................................................81

Upgrading Memory on SRP Modules .............................................................82

Displaying the Memory Installed .............................................................83

Removing SODIMMs ...............................................................................83

Adding New SODIMMs ...........................................................................83

Verifying the Upgrade .............................................................................85

Replacing SFPs on I/O Modules .....................................................................85

Removing SFPs .......................................................................................85

Installing SFPs .........................................................................................86

Verifying the Installation .........................................................................88

Replacing Fan Trays ......................................................................................88

Removing the Fan Tray ...........................................................................90

Installing the Fan Tray ............................................................................90

Installing a ERX14xx Model Air Filter ............................................................91

Installing a Cable-Management Bracket on ERX7xx Models ..........................92

Replacing a Power Input Module ...................................................................93

Chapter 9 Troubleshooting 95

Diagnosing Problems ....................................................................................95

Initialization Sequence ............................................................................95

Troubleshooting Power Failures ....................................................................96

Understanding Status LEDs to Troubleshoot ..................................................96

LED Identification ...................................................................................96

LED Activity ..........................................................................................100

Redundancy Status ...............................................................................103

Monitoring Temperatures of Modules ..........................................................103

Resetting Line Modules and SRP Modules ...................................................104

Double-Bit Errors on SRP Modules ...............................................................104

Detecting Double-Bit Errors ..................................................................104

Fixing Double-Bit Errors ........................................................................105

x ■ Table of Contents

Page 11

Table of Contents

Part 4 Appendixes

Appendix A System Specifications 109

ERX14xx Models Specifications ...................................................................109

ERX7xx Models Specifications .....................................................................111

ERX310 Broadband Specifications ..............................................................113

Appendix B Installation Guidelines and Requirements 117

Your Preinstallation Responsibilities ............................................................117

Environmental Requirements ......................................................................117

Regulatory Compliances ..............................................................................118

Safety Guidelines .........................................................................................118

ERX310 Broadband Services Router Warnings (AC Model) ...................120

ERX310 Power Cord Warnings (AC Model) .....................................120

Power Cable Warning (Japanese) ....................................................121

Equipment Rack Requirements ...................................................................121

Mechanical Requirements .....................................................................122

Space Requirements .............................................................................123

Proper Rack Installation ........................................................................123

Cabling Recommendations ..........................................................................124

Product Reclamation and Recycling Program ..............................................125

Hardware Compliance .................................................................................126

Federal Communications Commission (FCC) Statement .......................126

FCC Requirements for Consumer Products ...........................................126

Food and Drug Administration, Center for Devices and Radiological

Health ............................................................................................127

Canadian Department Of Communications Radio Interference

Regulations .....................................................................................127

Réglement sur le brouillage radioélectrique du ministère des

communications .............................................................................127

Industry Canada Notice CS-03 ..............................................................127

Avis CS-03 d'Industrie Canada ..............................................................127

D.O.C. Explanatory Notes: Equipment Attachment Limitations ............128

Notes explicatives du ministère des Communications: limites visant les

accessoires .....................................................................................129

EC Declaration of Conformity ...............................................................129

Voluntary Control Council for Interference (VCCI) Statement for

Japan ..............................................................................................129

Appendix C Cable Pinouts 131

SRP I/O Module ...........................................................................................131

CT1 and CE1 I/O Modules ...........................................................................134

Table of Contents ■ xi

Page 12

ERX 11.1.x Hardware Guide

Appendix D Contacting Customer Support and Returning Hardware 139

Contacting Customer Support ......................................................................139

Return Procedure ........................................................................................139

Locating Component Serial Numbers ..........................................................140

Information You Might Need to Supply to JTAC ...........................................141

Tools and Parts Required ............................................................................142

Returning Products for Repair or Replacement ...........................................142

Packing Instructions for Returning a Chassis .........................................142

Appendix E Declaration of Conformity 145

Declaration of Conformity ...........................................................................145

Part 5 Index

Index ...........................................................................................................149

xii ■ Table of Contents

Page 13

About the Documentation

■ E Series and JUNOSe Documentation and Release Notes on page xiii

■ Audience on page xiii

■ E Series and JUNOSe Text and Syntax Conventions on page xiii

■ Obtaining Documentation on page xv

■ Documentation Feedback on page xv

■ Requesting Technical Support on page xv

E Series and JUNOSe Documentation and Release Notes

For a list of related JUNOSe documentation, see

http://www.juniper.net/techpubs/software/index.html .

If the information in the latest release notes differs from the information in the

documentation, follow the JUNOSe Release Notes.

To obtain the most current version of all Juniper Networks® technical documentation,

see the product documentation page on the Juniper Networks website at

http://www.juniper.net/techpubs/.

Audience

This guide is intended for experienced system and network specialists working with

Juniper Networks E Series Broadband Services Routers in an Internet access

environment.

E Series and JUNOSe Text and Syntax Conventions

Table 1 on page xiv defines notice icons used in this documentation.

E Series and JUNOSe Documentation and Release Notes ■ xiii

Page 14

ERX 11.1.x Hardware Guide

Table 1: Notice Icons

DescriptionMeaningIcon

Indicates important features or instructions.Informational note

Indicates a situation that might result in loss of data or hardware damage.Caution

Alerts you to the risk of personal injury or death.Warning

Alerts you to the risk of personal injury from a laser.Laser warning

Table 2 on page xiv defines text and syntax conventions that we use throughout the

E Series and JUNOSe documentation.

Table 2: Text and Syntax Conventions

Represents commands and keywords in text.Bold text like this

Bold text like this

Fixed-width text like this

Represents text that the user must type.

Represents information as displayed on your

terminal’s screen.

Italic text like this

Emphasizes words.

■

Identifies variables.

■

Identifies chapter, appendix, and book

■

names.

Plus sign (+) linking key names

keys simultaneously.

Syntax Conventions in the Command Reference Guide

ExamplesDescriptionConvention

Issue the clock source command.

■

Specify the keyword exp-msg.

■

host1(config)#traffic class low-loss1

host1#show ip ospf 2

Routing Process OSPF 2 with Router

ID 5.5.0.250

Router is an Area Border Router

(ABR)

There are two levels of access: user and

■

privileged.

clusterId, ipAddress.

■

Appendix A, System Specifications

■

Press Ctrl + b.Indicates that you must press two or more

terminal lengthRepresents keywords.Plain text like this

| (pipe symbol)

or variable to the left or to the right of this

symbol. (The keyword or variable can be

either optional or required.)

xiv ■ E Series and JUNOSe Text and Syntax Conventions

mask, accessListNameRepresents variables.Italic text like this

diagnostic | lineRepresents a choice to select one keyword

Page 15

Table 2: Text and Syntax Conventions (continued)

About the Documentation

ExamplesDescriptionConvention

[ internal | external ]Represent optional keywords or variables.[ ] (brackets)

[ ]* (brackets and asterisk)

that can be entered more than once.

Represent required keywords or variables.{ } (braces)

Obtaining Documentation

To obtain the most current version of all Juniper Networks technical documentation,

see the Technical Documentation page on the Juniper Networks Web site at

http://www.juniper.net/.

To download complete sets of technical documentation to create your own

documentation CD-ROMs or DVD-ROMs, see the Offline Documentation page at

http://www.juniper.net/techpubs/resources/cdrom.html

Copies of the Management Information Bases (MIBs) for a particular software release

are available for download in the software image bundle from the Juniper Networks

Web site athttp://www.juniper.net/.

Documentation Feedback

[ level1 | level2 | l1 ]*Represent optional keywords or variables

{ permit | deny } { in | out }

{ clusterId | ipAddress }

We encourage you to provide feedback, comments, and suggestions so that we can

improve the documentation to better meet your needs. Send your comments to

techpubs-comments@juniper.net, or fill out the documentation feedback form at

https://www.juniper.net/cgi-bin/docbugreport/. If you are using e-mail, be sure to include

the following information with your comments:

■ Document or topic name

■ URL or page number

■ Software release version

Requesting Technical Support

Technical product support is available through the Juniper Networks Technical

Assistance Center (JTAC). If you are a customer with an active J-Care or JNASC support

contract, or are covered under warranty, and need post-sales technical support, you

can access our tools and resources online or open a case with JTAC.

■ JTAC policies—For a complete understanding of our JTAC procedures and policies,

review the JTAC User Guide located at

http://www.juniper.net/customers/support/downloads/7100059-EN.pdf .

Obtaining Documentation ■ xv

Page 16

ERX 11.1.x Hardware Guide

■ Product warranties—For product warranty information, visit

http://www.juniper.net/support/warranty/ .

■ JTAC hours of operation—The JTAC centers have resources available 24 hours a

day, 7 days a week, 365 days a year.

Self-Help Online Tools and Resources

For quick and easy problem resolution, Juniper Networks has designed an online

self-service portal called the Customer Support Center (CSC) that provides you with

the following features:

■

Find CSC offerings: http://www.juniper.net/customers/support/

■

Search for known bugs: http://www2.juniper.net/kb/

■

Find product documentation: http://www.juniper.net/techpubs/

■ Find solutions and answer questions using our Knowledge Base:

http://kb.juniper.net/

■ Download the latest versions of software and review release notes:

http://www.juniper.net/customers/csc/software/

■ Search technical bulletins for relevant hardware and software notifications:

https://www.juniper.net/alerts/

■ Join and participate in the Juniper Networks Community Forum:

http://www.juniper.net/company/communities/

■

Open a case online in the CSC Case Management tool: http://www.juniper.net/cm/

To verify service entitlement by product serial number, use our Serial Number

Entitlement (SNE) Tool: https://tools.juniper.net/SerialNumberEntitlementSearch/

Opening a Case with JTAC

You can open a case with JTAC on the Web or by telephone.

■

Use the Case Management tool in the CSC at http://www.juniper.net/cm/ .

■ Call 1-888-314-JTAC (1-888-314-5822 toll-free in the USA, Canada, and Mexico).

For international or direct-dial options in countries without toll-free numbers, see

http://www.juniper.net/support/requesting support.html .

xvi ■ Requesting Technical Support

Page 17

Part 1

Product Overview

■ ERX Overview on page 3

Product Overview ■ 1

Page 18

ERX 11.1.x Hardware Guide

2 ■ Product Overview

Page 19

Chapter 1

ERX Overview

This chapter provides introductory information about the ERX routers. It contains

the following sections:

■ Overview on page 3

■ ERX Routers on page 3

■ ERX Modules on page 9

■ Network Management Tools on page 14

■ Redundancy Features on page 14

Overview

ERX routers are modular, carrier-class networking devices that deliver performance,

reliability, and service differentiation to both business and consumer Internet users.

The ERX7xx and ERX14xx models offer high port density, low power consumption,

and fully redundant Internet access routing and edge aggregation. The Juniper

Networks ERX310 Broadband Services Router supports the same services, but with

smaller capacity and scaling capabilities. ERX routers offer the complete edge solution

for IP-optimized carriers.

ERX Routers

Five models of ERX routers are available:

■ Juniper Networks ERX1440 Broadband Services Router

■ Juniper Networks ERX1410 Broadband Services Router

■ Juniper Networks ERX710 Broadband Services Router

■ Juniper Networks ERX705 Broadband Services Router

■ Juniper Networks ERX310 Broadband Services Router

All models use the same software. However, the specific model determines the:

■ Combination of line modules supported

■ Conditions for line rate performance of line modules

■ Type, capacity, and number of SRP modules used

Overview ■ 3

Page 20

ERX 11.1.x Hardware Guide

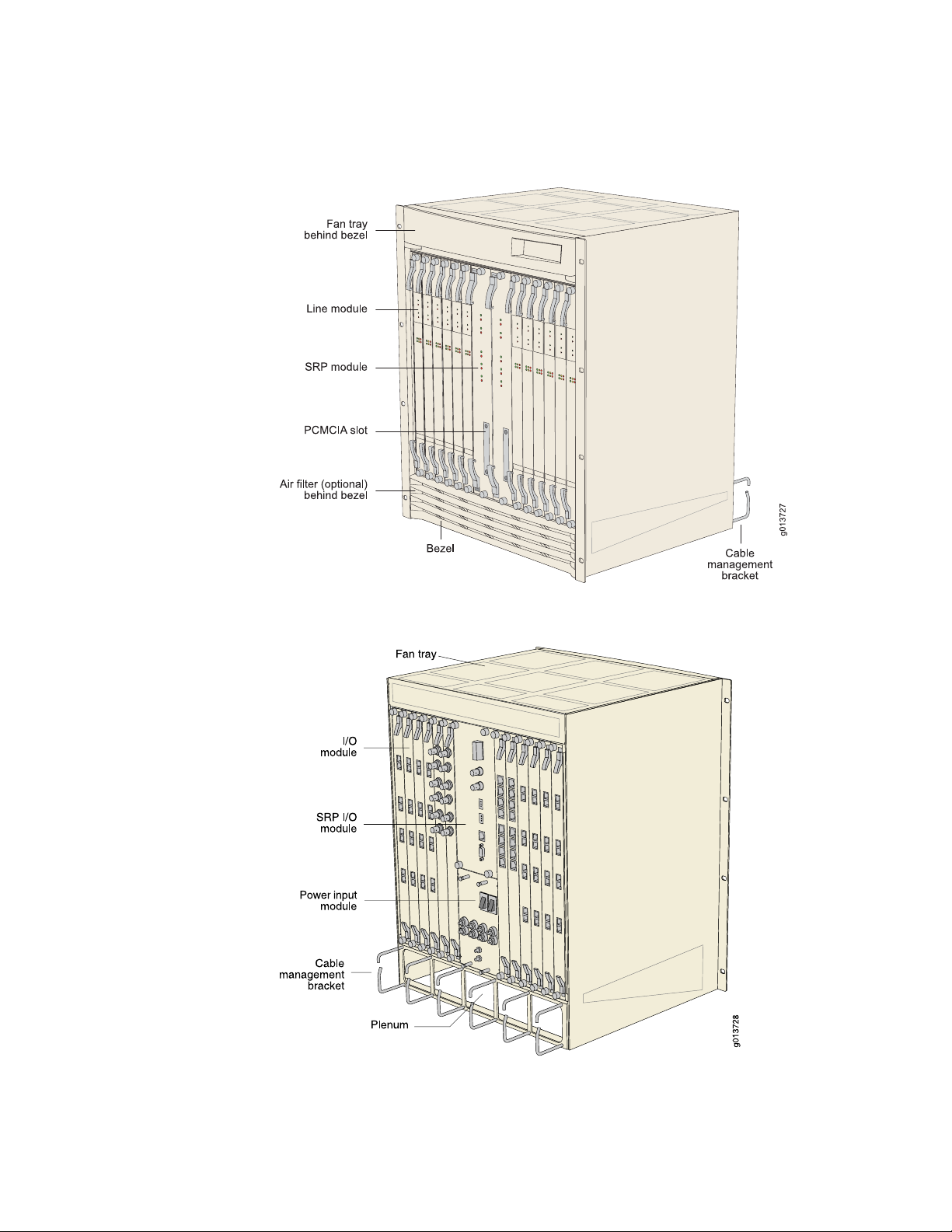

ERX14xx Models

NOTE: In the E Series documentation, the term ERX14xx models refers to both the

ERX1440 and ERX1410 routers. The terms ERX1440 and ERX1410 routers refer to

the specific models. See Figure 1 on page 5 and Figure 2 on page 5.

The ERX1440 router manages an extremely high volume of network traffic, and uses

a 40-Gbps switch route processor (SRP) module, either the SRP-40G or SRP-40G+

module. (The SRP-40G+ module obsoletes the SRP-40G module; however, the

software continues to support both modules.) In this model, all line modules operate

at full wire speed simultaneously.

The ERX1410 router manages high levels of network traffic, and uses the 10-Gbps

SRP module (SRP-10G). You can configure the ERX1410 router to enable the line

modules either to operate at full line rate performance or to allow line modules to

operate at a rate dependent on the resources available. The former option restricts

the allowed combinations of line modules. For information on configuring

performance of line modules, see JUNOSe System Basics Configuration Guide, Chapter 6,

Managing Modules.

NOTE: The 10-Gbps SRP module used in the ERX310 router is different from the

10-Gbps SRP module used in the ERX1410 router. See “SRP Module” on page 9 for

more information.

Externally, the ERX1440 chassis is the same as the ERX1410 chassis. (See Figure 1

on page 5 and Figure 2 on page 5.) Both routers contain 14 vertical slots to

accommodate modules.

Internally, the ERX1440 chassis differs from the ERX1410 chassis, and includes a

special midplane for the 40-Gbps SRP module.

Installation procedures and operating procedures are identical for both systems. All

ERX7xx and ERX14xx models use the same SRP I/O module, but different power

input modules are used.

NOTE: The router may look different from the routers shown in the figures in this

chapter, depending on the line modules in the slots.

4 ■ ERX Routers

Page 21

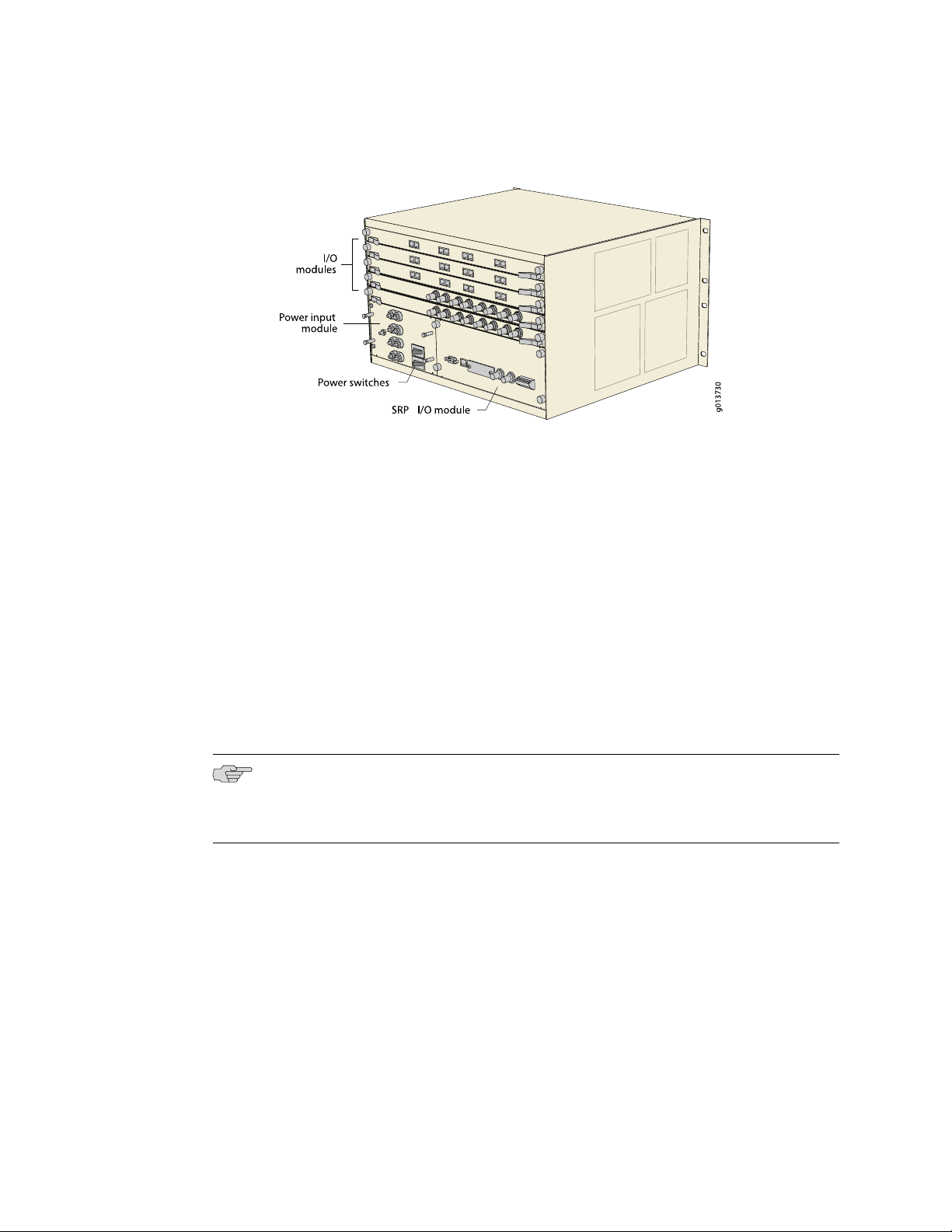

Figure 1: ERX14xx Models, Front View

Chapter 1: ERX Overview

Figure 2: ERX14xx Models, Rear View

ERX Routers ■ 5

Page 22

ERX 11.1.x Hardware Guide

ERX7xx Models

NOTE: In the E Series documentation, the term ERX7xx models refers to both the

ERX705 and ERX710 routers. The terms ERX705 and ERX710 routers refer to the

specific models. See Figure 3 on page 6 and Figure 4 on page 7.

The ERX7xx models are robust, high-density routers with less capacity than the

ERX14xx models. The ERX7xx models use either the SRP-10G module or the SRP-5G

module.

You can configure the ERX7xx models to enable the line modules (LM) to operate

either at full line rate performance or at a rate dependent on the resources available.

For information about configuring performance of line modules, see JUNOSe System

Basics Configuration Guide, Chapter 6, Managing Modules.

NOTE: The 10-Gbps SRP module used in the ERX310 router is different from the

10-Gbps SRP module used in the ERX710 router. See “SRP Module” on page 9 for

more information.

The ERX705 chassis is the same as the ERX710 chassis. (See Figure 3 on page 6

and Figure 4 on page 7.) The chassis contains seven slots to accommodate modules.

Installation procedures and operating procedures are identical for both systems. All

ERX7xx and ERX14xx models use the same SRP I/O module, but different power

input modules are used.

NOTE: The router may look different from the routers shown in the figures in this

chapter, depending on the line modules in the slots.

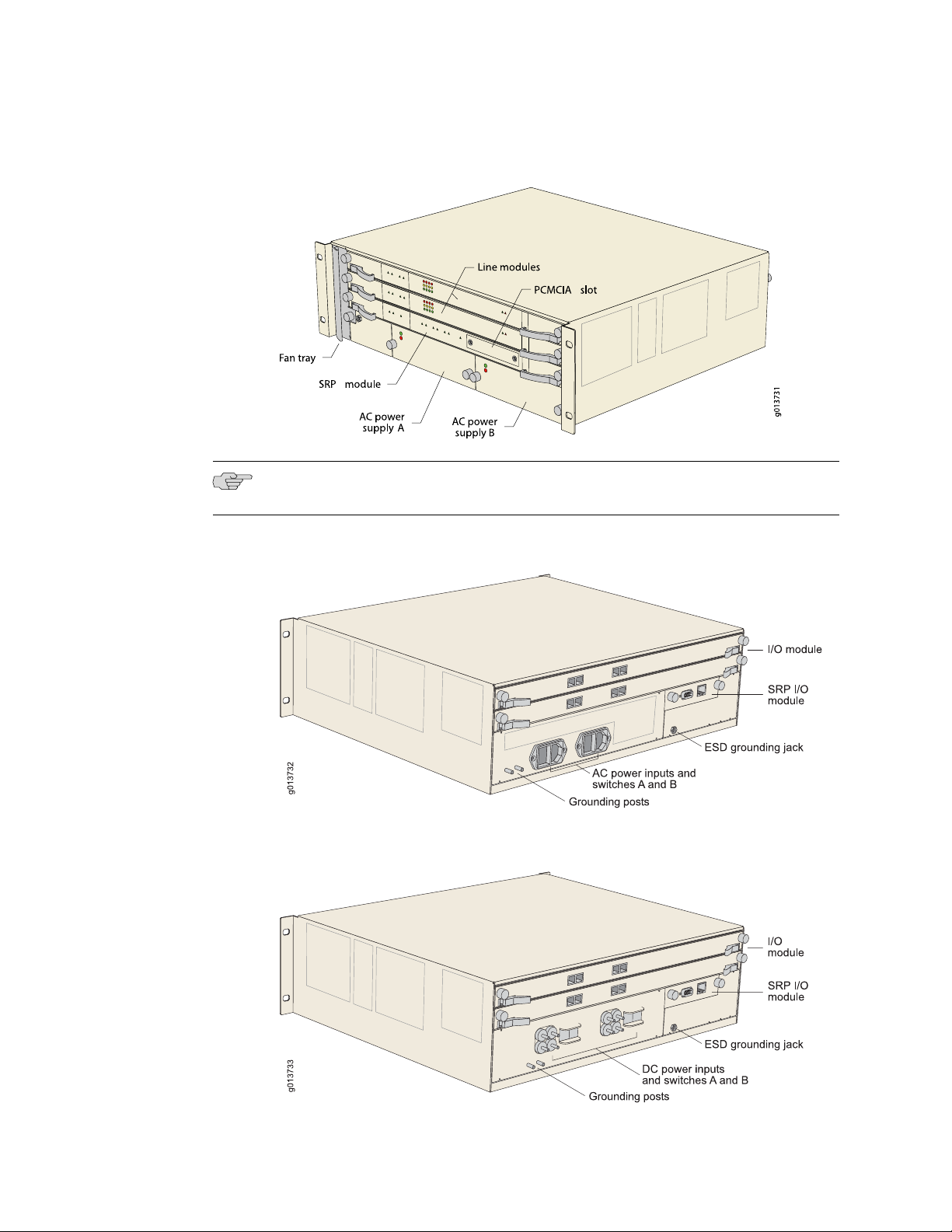

Figure 3: ERX7xx Models, Front View

6 ■ ERX Routers

Page 23

Figure 4: ERX7xx Models, Rear View

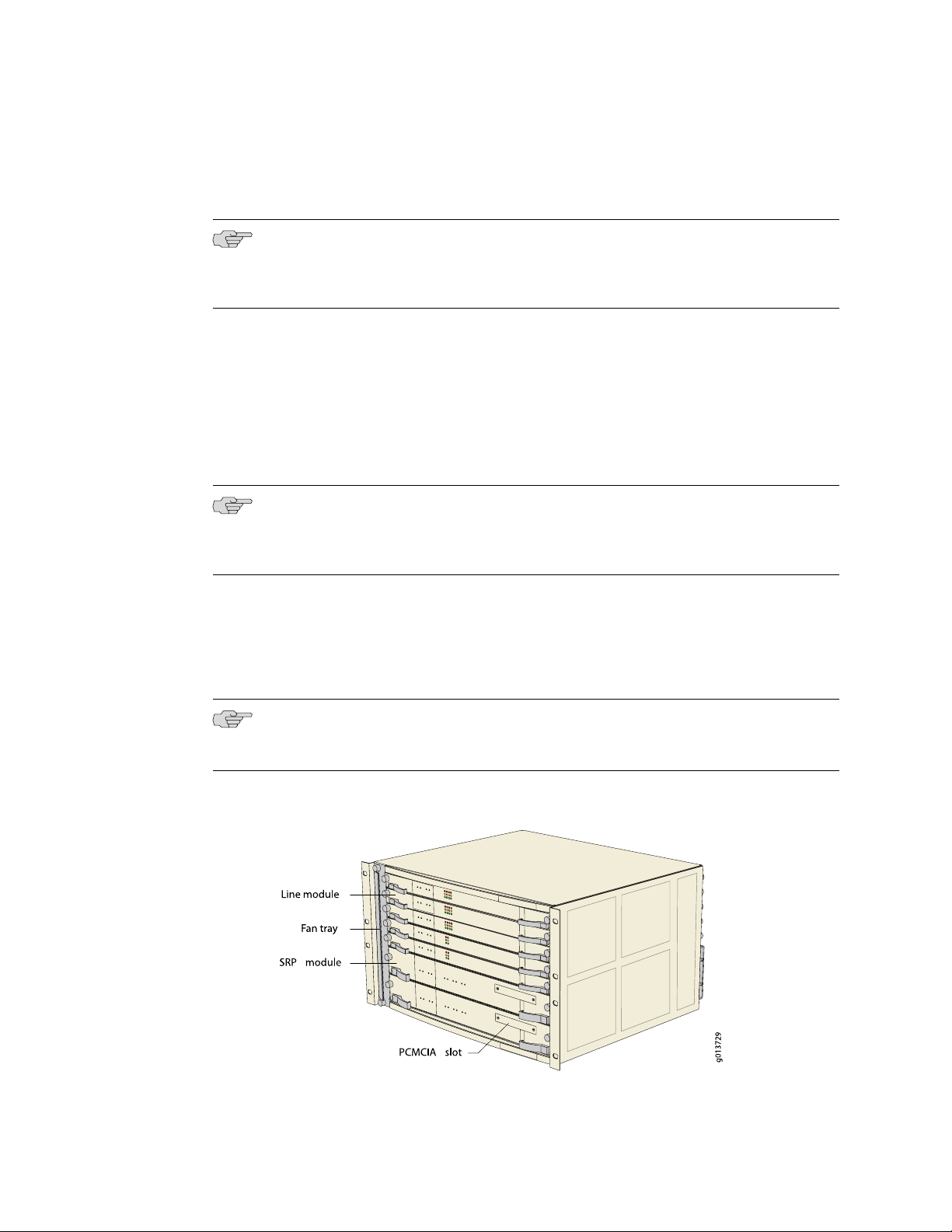

ERX310 Broadband Services Router

Chapter 1: ERX Overview

The ERX310 router is a low-end platform that supports all of the same services as

the ERX7xx and ERX14xx models, but with smaller capacity and scaling capabilities.

Like the ERX7xx and ERX14xx models, the ERX310 router uses the same software

architecture, providing a single IP entry point into the network with the same IP-based

protocols and services that are available on other ERX routers. The ERX310 router

is designed to be used as a small distributed POP router as well as a high-end CPE

router.

The ERX310 router is a three-slot chassis with a midplane architecture. One slot

supports one nonredundant 10-Gbps SRP module, while the other two slots support

line modules. The router supports existing E Series ASIC-based line modules (except

the OC48/STM16 line module), as well as a select number of combination cards. The

combination cards provide a fixed combination of interfaces on the I/O module so

that a single slot can support multiple interfaces (ATM OC3 and GE, for example).

NOTE: The 10-Gbps SRP module used in the ERX310 router is different from the

10-Gbps SRP module used in the ERX7xx and ERX14xx models. See “SRP Module”

on page 9 for more information.

The ERX310 router is available in either redundant AC- or DC-powered models.

ERX Routers ■ 7

Page 24

ERX 11.1.x Hardware Guide

Figure 5: ERX310 Router, Front View (AC Model)

NOTE: The DC model has blank filler panels in power supply slots.

Figure 6: ERX310 Router, Rear View (AC Model)

Figure 7: ERX310 Router, Rear View (DC Model)

8 ■ ERX Routers

Page 25

ERX Modules

Chapter 1: ERX Overview

Each system supports an SRP module and a selection of line modules. You can use

any line module for access or uplink. Access line modules receive traffic from

low-speed circuits, and the system routes the traffic onto higher-speed uplink line

modules and then to the core of the network.

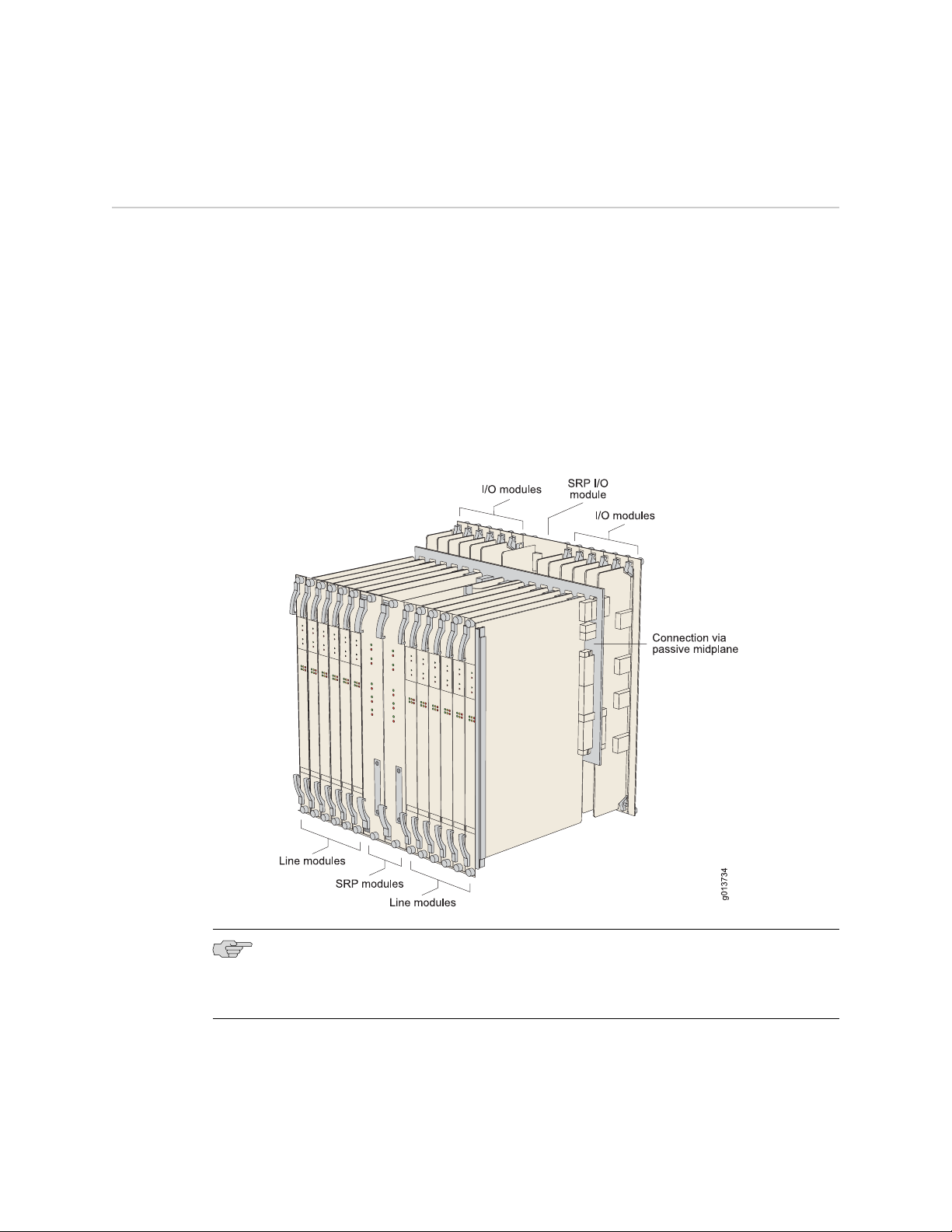

Each module connects to a corresponding I/O module via a passive midplane. See

Figure 8 on page 9.

The front panel of each module contains a collection of status LEDs (light-emitting

diodes). For information about how to interpret the LEDs, see “Troubleshooting” on

page 95.

Figure 8: Modules in ERX14xx Models

SRP Module

NOTE: Some line modules require a minimum amount of memory to be used with

JUNOSe Release 5.3.0 or a higher-numbered release. See the ERX Module Guide for

line module specifications.

Switch route processor (SRP) modules perform system management, routing table

calculations and maintenance, forwarding table computations, statistics processing,

ERX Modules ■ 9

Page 26

ERX 11.1.x Hardware Guide

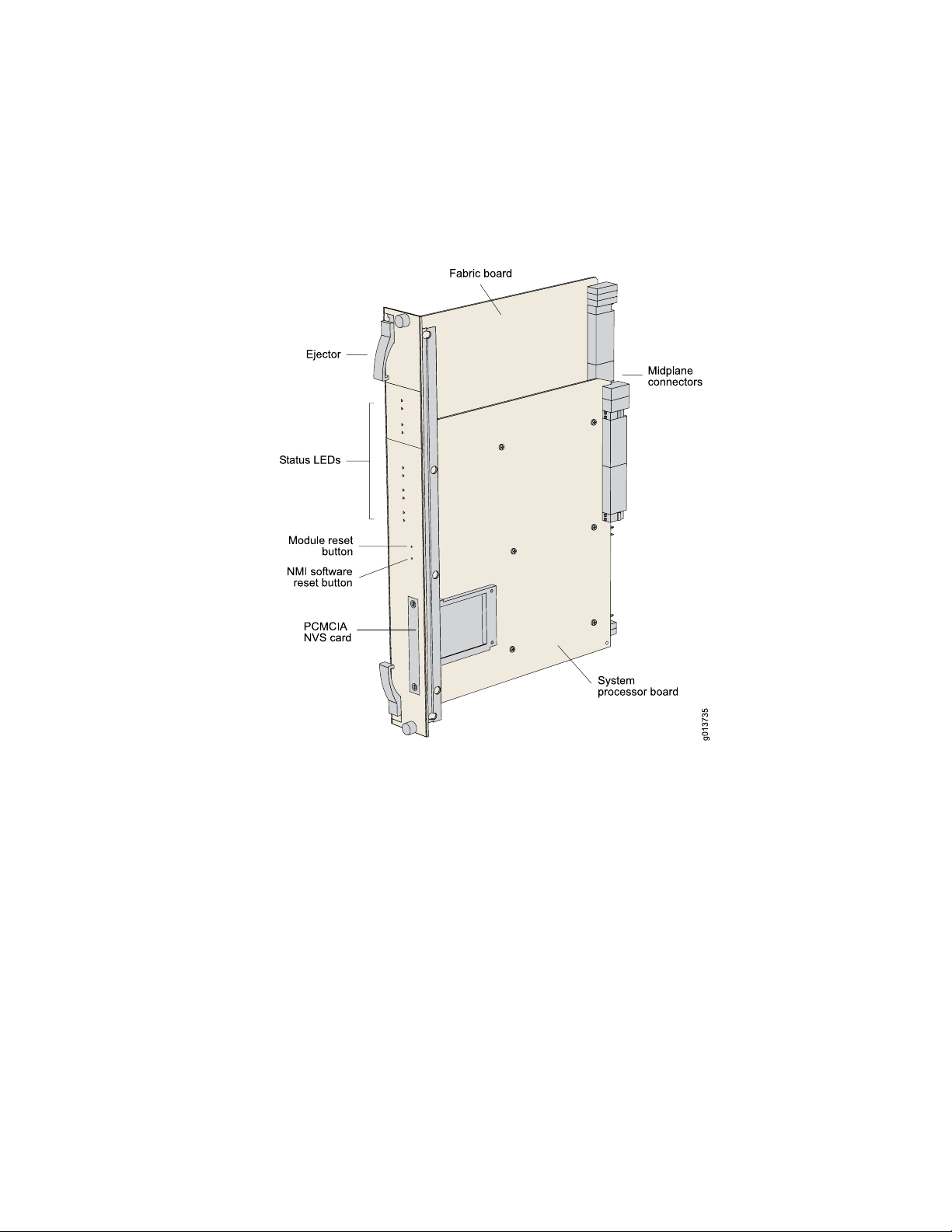

configuration storage, and other control plane functions. Each SRP module is a

PowerPC-based system with its own memory, nonvolatile disk storage, and power

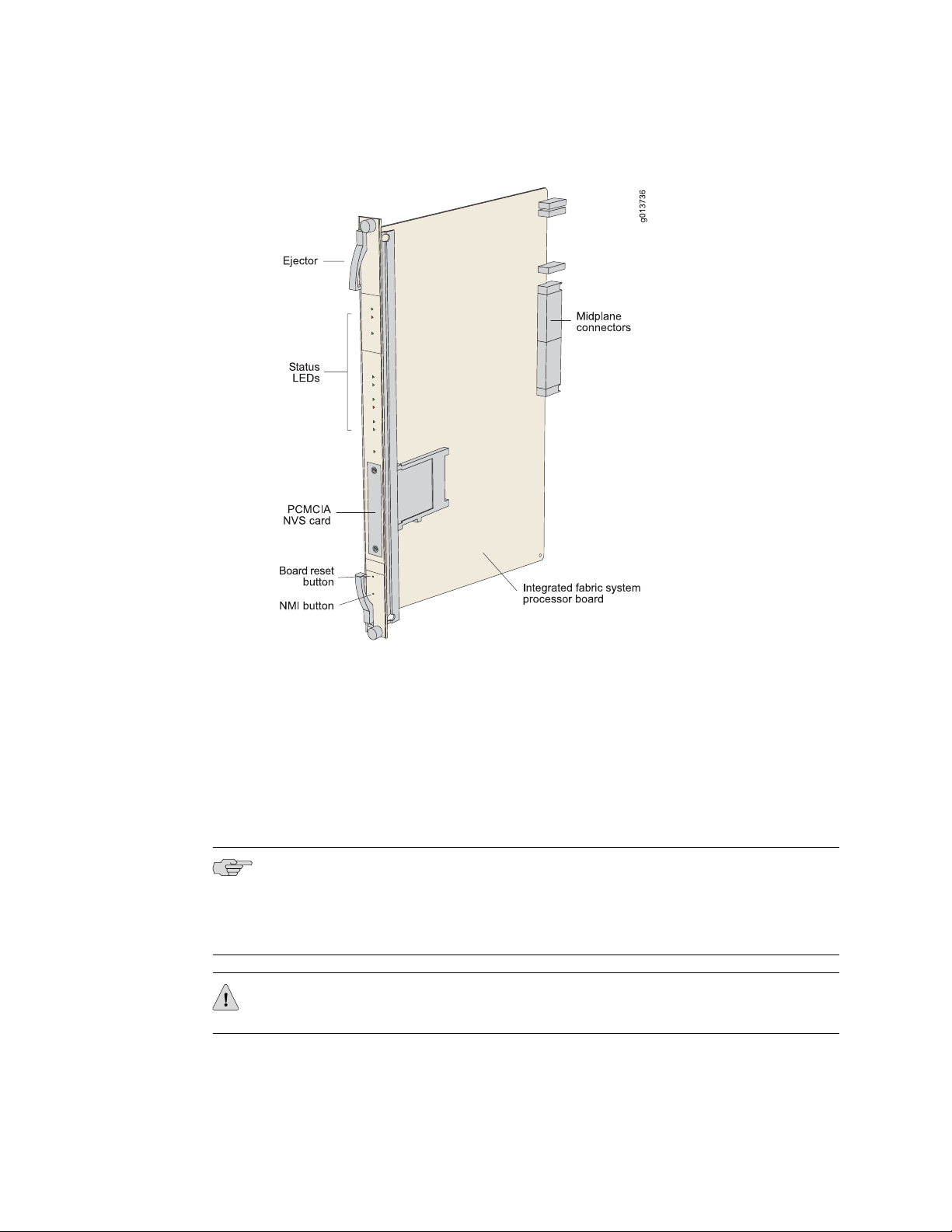

supply. (See Figure 9 on page 10 and Figure 10 on page 11.)

Figure 9: SRP Module for ERX7xx and ERX14xx Models

10 ■ ERX Modules

Page 27

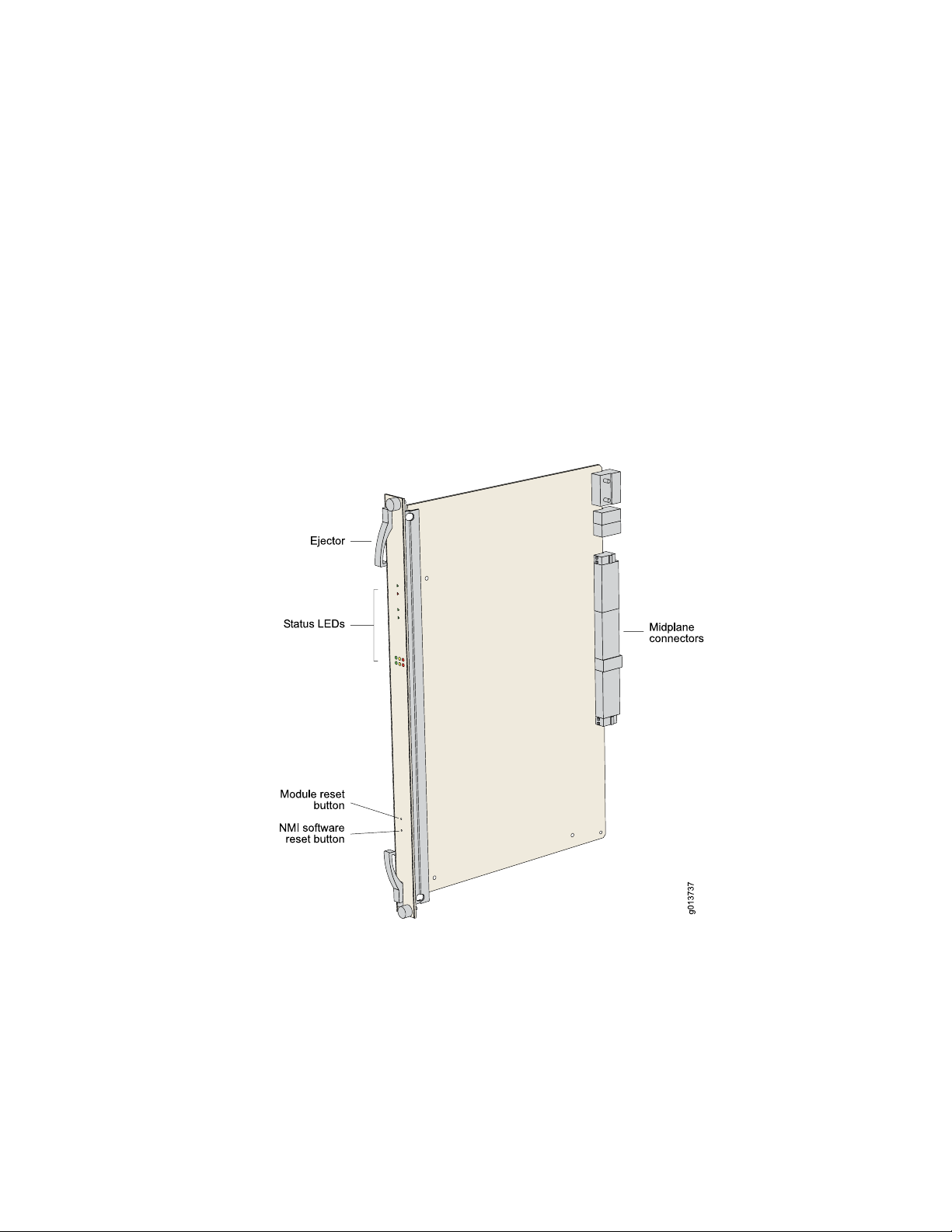

Figure 10: SRP Module for ERX310 Router

Chapter 1: ERX Overview

Module Details

ERX7xx and ERX14xx models use up to two redundant SRP modules operating in

an active/standby configuration. ERX310 router use only one SRP module. An SRP

module must be present for any system to boot.

SRP modules ranging from 5 Gbps to 40 Gbps can be used in ERX7xx and ERX14xx

models. Only a 10-Gbps SRP module (SRP-SE10G) can be used in ERX310 router.

See the ERX Module Guide for complete information.

NOTE: Because of different physical dimensions and switch fabric capabilities, SRP

modules are not interchangeable between systems. For example, the 10-Gbps SRP

module used in ERX7xx and ERX14xx models cannot be used in the ERX310 router,

and vice versa.

CAUTION: Do not remove the SRP module while the system is running.

ERX Modules ■ 11

Page 28

ERX 11.1.x Hardware Guide

NOTE: Some SRP modules require a minimum amount of memory to be used with

JUNOSe Release 5.3.0 or a higher-numbered release. See the ERX Module Guide for

module specifications.

For details about installing SRP modules, see “Installing Modules” on page 31.

SRP Module Redundancy

SRP module redundancy is available only for ERX7xx and ERX14xx models. See

“Redundancy Features” on page 14

Nonvolatile Storage

The PCMCIA slot on the front of the SRP module holds a Type II PCMCIA nonvolatile

storage (NVS) card. (See Figure 9 on page 10 and Figure 10 on page 11.) This card

is loaded with the system's software and configuration files. The PCMCIA card is

factory installed.

SRP I/O Module

CAUTION: Although you can remove PCMCIA NVS (Flash) cards from a running

router, we recommend that you do not do so. If you remove the card while data is

being written to or copied from the NVS card, data can be lost or corrupted. Therefore,

we strongly recommend that you shut down the router before removing a PCMCIA

NVS card.

The SRP I/O module is a single corresponding input/output module that interfaces

with the SRP modules through the system's midplane. The same SRP I/O module

works with all SRP modules, but is router specific. The I/O module used in ERX7xx

and ERX14xx models cannot be used in the ERX310 router, and vice versa. See

Figure 2 on page 5, Figure 4 on page 7, and Figure 6 on page 8 for locations.

Module Details

The SRP I/O module provides standard craft management interfaces, including:

■ 10/100Base-T—The port enables access to the ERX router for Ethernet

management functions via CLI or SNMP, for example.

■ RS-232—The port provides a serial connection for monitoring the system's

hardware configuration through a PC (running terminal emulation software) or

ASCII terminal. Allows direct CLI access.

12 ■ ERX Modules

■ Alarm contacts—The contacts provide for remote indication of critical, major,

and minor router alarms (ERX7xx and ERX14xx models only; currently not

implemented)

■ External timing inputs—The inputs provide a method of ensuring that the clock

timing used by the router remains synchronized with the network's system clock.

Page 29

Line Modules

Chapter 1: ERX Overview

BNC connectors and wire wraps are available for ERX7xx and ERX14xx models

only.

For details about installing the SRP I/O module, see “Installing Modules” on page 31.

Line modules (LM) process data from different types of network connections. For

information about available line modules and which SRP modules support specific

line modules, see the ERX Module Guide.

Figure 11 on page 13 shows a representative line module. For details about installing

line modules, see “Installing Modules” on page 31.

Figure 11: Representative Line Module

Packet Classification

Most line modules support packet classification on ingress; some non-ASIC line

modules do not. A classification engine on the line module matches specific fields

(such as source and destination IP address, source and destination port, and protocol),

the ingress IP interface, layer 2 fields, or some combination of these against

user-configured filters at wire speed.

ERX Modules ■ 13

Page 30

ERX 11.1.x Hardware Guide

I/O Modules

Most line modules have a corresponding input/output (I/O) module that provides the

physical interconnection to the network. Insert each I/O module into the back of the

system, directly behind its corresponding line module.

For information about which line modules pair with which I/O modules, see the ERX

Module Guide. See Figure 2 on page 5, Figure 4 on page 7, and Figure 6 on page 8

for locations. For details about installing I/O modules, see “Installing Modules” on

page 31.

Network Management Tools

You can use different management tools to configure the system to meet the specific

networking requirements.

CLI Management

The CLI provides fully developed and automated configuration and status functionality

through a local RS-232 port, Telnet, or SSH via any reachable network. For a full

discussion of the CLI, see JUNOSe System Basics Configuration Guide, Chapter 2,

Command-Line Interface.

SNMP MIB Management

The system offers a complete SNMP interface for configuration, status, and alarm

reporting. The system supports both Standard and Enterprise MIBs (Management

Information Bases). The Juniper Networks E Series Enterprise MIB is ASN.1 notated

for easy importing into third-party SNMP management applications. For more

information, see JUNOSe System Basics Configuration Guide, Chapter 4, Configuring

SNMP.

NMC-RX Device Management System

The NMC-RX application provides a global method of managing all routers, line

modules, and ports through a graphical user interface.

Redundancy Features

This section describes system redundancy features.

SRP Modules

NOTE: This section applies to ERX7xx and ERX14xx models only. ERX310 routers

contain one SRP module and therefore do not offer SRP module redundancy.

14 ■ Network Management Tools

Page 31

Chapter 1: ERX Overview

ERX7xx and ERX14xx models use a 1:1 redundancy scheme for the SRP module.

When two SRP modules of the same type are installed in the chassis, one acts as a

primary (active) and the second as a redundant (standby) module. Both SRP modules

share a single SRP I/O module located in the rear of the chassis.

If the standby SRP module detects that the primary SRP module is not active (and

high-availability mode is not enabled), it reboots the system and takes control. If

high-availability mode has been enabled, automatic switchover occurs with near

hitless failover. If you upgrade software, you must copy the software to the redundant

SRP and reboot it. For information about configuring and managing SRP module

redundancy, see JUNOSe System Basics Configuration Guide, Chapter 6, Managing

Modules.

After you install two SRP modules, the modules negotiate for the primary role. A

number of factors determine which module becomes the primary; however,

preference is given to the module in the lower-numbered slot. The SRP modules

record their latest roles and retain them the next time you switch on the system. For

information about installing SRP modules, see “Installing Modules” on page 31.

NVS Cards

If you have two SRP modules installed in a system, you can use NVS cards of different

capacities on the SRP modules. The effective capacity of the higher-capacity NVS

card will equal that of the lower-capacity NVS card. For information about installing

NVS cards, see “Installing Modules” on page 31.

When you install new NVS cards or SRP modules, you must issue the synchronize

command to match the file system of the NVS card on the redundant SRP module

with the file system of the NVS card on the primary SRP module. (The NVS card on

the redundant SRP module will hereafter be referred to as the redundant NVS card;

the NVS card on the primary SRP module will hereafter be referred to as the primary

NVS card.)

If the capacity of the primary NVS card is equal to or smaller than that of the

redundant NVS card, the system copies all the files from the primary NVS card to

the redundant NVS card. However, if the capacity of the primary NVS card exceeds

that of the redundant NVS card, the system creates an invisible synchronization

reserve file on the primary NVS card, provided that there is enough space for the

file.

The purpose of the synchronization file is to prevent the creation of data that cannot

fit on the redundant NVS card. The file contains no useful data, and is not visible

when you view the files in NVS. The size of the file is equal to the difference in

capacities of the two NVS cards. For example, if the primary NVS card has a capacity

of 224 MB and the redundant NVS card has a capacity of 220 MB, the size of the

synchronization file is 4 MB, and only 220 MB of space is available on the primary

NVS card.

If the primary NVS card does not have enough space to create the synchronization

reserve file, the synchronize command fails, and a warning message is displayed

on the console. To resolve this issue, either delete unwanted files from the primary

NVS card or replace the redundant NVS card with a higher-capacity NVS card.

Redundancy Features ■ 15

Page 32

ERX 11.1.x Hardware Guide

Line Modules

NOTE: This section applies to ERX7xx and ERX14xx models only. ERX310 routers

do not offer line module redundancy.

ERX7xx and ERX14xx models support line module redundancy for several line

modules. For details about which line modules support redundancy, see the ERX

Module Guide. In this scheme, an extra line module in a group of identical line modules

provides redundancy in case of line module failure. To use this feature, you need a:

■ Spare line module

■ Redundancy midplane

■ Redundancy I/O module

A redundancy midplane can cover 3–6 slots. It provides additional connectivity that

enables the spare line module to take control of the I/O module associated with any

failed line module in the redundancy group. The spare I/O module provides

connectivity from the spare line module to the redundancy midplane.

The process by which the system switches to the spare line module is called

switchover. When switchover occurs, the system:

1. Breaks the connection between the primary I/O module and the primary line

module.

2. Connects the primary I/O module to the spare line module via the redundancy

midplane and redundancy I/O module.

Protocol processing then takes place on the spare line module.

Figure 12 on page 17 shows the data flow when a spare line module becomes active.

16 ■ Redundancy Features

Page 33

Figure 12: Data Flow When a Spare Line Module Is Active

Chapter 1: ERX Overview

Power

Fans

For information about installing modules for line module redundancy, see “Installing

Modules” on page 31. For information about configuring and managing SRP module

redundancy, see JUNOSe System Basics Configuration Guide, Chapter 6, Managing

Modules.

All E Series routers provide a power architecture that distributes redundant –48 VDC

feeds through the router to each line module, SRP module, and fan module where

DC-to-DC converters provide local conversion to the required secondary voltages.

The ERX310 router is available with either DC or AC power inputs. The AC-powered

version can be configured with one or two hot-swappable power supplies for optional

redundancy. (See Figure 5 on page 8 and Figure 6 on page 8.) The power supplies

convert AC power to internal –48 V redundant DC feeds that are then distributed

through the router.

Forced air-cooling keeps the temperature of the E Series modules and components

within normal operating limits. In ERX14xx models, six cooling fans are located in

a tray at the top of the router (Figure 1 on page 5). In ERX7xx models, four cooling

fans are located in a tray on one side of the router (Figure 3 on page 6). In the

Redundancy Features ■ 17

Page 34

ERX 11.1.x Hardware Guide

ERX310 router, two cooling fans are located in a tray on one side of the router (Figure

5 on page 8).

The system monitors the temperature of each module. If the temperature of a module

exceeds the maximum limit, the system immediately goes into thermal protection

mode and the modules are powered off. The ERX system controller enters a low

power mode, keeps the modules in a power-off condition, and does not respond to

any management interface commands. For information about troubleshooting high

operating temperatures, see “Troubleshooting” on page 95.

In ERX7xx and ERX14xx models, the fan tray has two redundant converters that

power the fans (for the ERX14xx models, a –24 V, 50 W converter; for the ERX7xx

models, a –12 V, 15 W converter). If one converter fails, the other takes over. The

ERX310 router does not have redundant converters.

For all E Series routers, the system software reports an alarm if any of the fans or

converters fail.

18 ■ Redundancy Features

Page 35

Part 2

Initial Installation

■ Unpacking and Inspecting ERX Routers on page 21

■ Installing ERX Routers on page 25

■ Installing Modules on page 31

■ Cabling ERX Routers on page 47

■ Powering Up ERX Routers on page 65

■ Accessing ERX Routers on page 69

Initial Installation ■ 19

Page 36

ERX 11.1.x Hardware Guide

20 ■ Initial Installation

Page 37

Chapter 2

Unpacking and Inspecting ERX Routers

This chapter reviews shipping contents and unpacking procedures for ERX routers.

It contains the following sections:

■ Before You Begin on page 21

■ Unpacking ERX14xx Models on page 21

■ Unpacking ERX7xx Models and ERX310 Broadband Services Routers on page 22

■ Inspecting Router Components and Accessories on page 22

■ If You Detect or Suspect Damage on page 23

■ Contacting Juniper Networks on page 23

■ The Next Step on page 23

Before You Begin

Before you begin unpacking the router, be sure you have the following tools:

■ A No. 2 Phillips screwdriver

■ A utility knife

■ A mechanical lift, or at least two people to assist in lifting

Unpacking ERX14xx Models

ERX14xx models come boxed, bolted, and strapped to a skid. For your convenience,

we recommend that you unpack the router in the location where you want to install

it.

WARNING: Three people are required to install the router in a rack: two to lift the

system into position and one to screw it to the rack.

To unpack ERX14xx models:

1. Cut the two straps that secure the carton to the skid, open the carton from the

top, and remove the box of accessories that sits on top of the router.

2. Unlock the four plastic clips that hold the box to the skid by squeezing them in

their center and pulling out, and then lift the carton off the router.

Before You Begin ■ 21

Page 38

ERX 11.1.x Hardware Guide

3. Remove the three screws that attach each of the two L-brackets to the router.

4. To avoid scratching the router when removing it from the skid, detach one of

the L-brackets from the skid by removing the three screws. See Figure 13 on

page 22.

Figure 13: Removing an L-Bracket

Unpacking ERX7xx Models and ERX310 Broadband Services Routers

ERX7xx models and ERX310 routers are shipped boxed, but not attached to a skid.

For your convenience, we recommend that you unpack the router in the location

where you want to install it.

To unpack an ERX7xx model or an ERX310 router:

1. Open the carton from the top.

2. Remove the box of accessories that sits on top of the system.

3. Remove the router from the box.

WARNING: Three people are required to install the router in a rack: two to lift the

system into position and one to screw it to the rack.

Inspecting Router Components and Accessories

After you remove the equipment from the shipping containers:

22 ■ Unpacking ERX7xx Models and ERX310 Broadband Services Routers

Page 39

■ Confirm the contents of each container.

■ Inspect all external surfaces and external connectors for visible signs of damage.

■ Inspect all accessories shipped with each unit.

■ Document any damage noted during your inspection.

■ Confirm that the router has the correct number and type of modules for your

ordered configuration.

If You Detect or Suspect Damage

If you detect or suspect damage to any equipment:

■ Contact the shipper responsible for delivery, and formally report the damage.

■ Contact your Juniper Networks sales representative or reseller.

Chapter 2: Unpacking and Inspecting ERX Routers

Contacting Juniper Networks

Please contact Juniper Networks at 1-888-314-JTAC (from the United States, Canada,

or Mexico) or 408-745-9500 (from elsewhere), or contact your sales representative

if you have any questions or concerns. See “Contacting Customer Support and

Returning Hardware” on page 139 for complete contact information.

The Next Step

■ To familiarize yourself with the electrical, environmental, and other guidelines

and requirements for installing ERX routers, turn to “Installation Guidelines and

Requirements” on page 117.

■ If you are familiar with these guidelines and requirements, turn to “Installing

ERX Routers” on page 25.

If You Detect or Suspect Damage ■ 23

Page 40

ERX 11.1.x Hardware Guide

24 ■ The Next Step

Page 41

Chapter 3

Installing ERX Routers

This chapter describes how to install ERX routers in a rack. It contains the following

sections:

■ Before You Begin on page 25

■ Freestanding Installation on page 25

■ Rack-Mounted Installation on page 26

■ The Next Step on page 29

Before You Begin

Before installing E Series routers, be sure you:

■ Have a plan for installing the routers that takes into consideration future

expansion of your system.

■ Have the tools and accessories needed to complete the installation.

■ Read and understand the clearance requirements for the front and back of the

chassis for cable routing and other unit access. See “Environmental

Requirements” on page 117 for more information.

■ Read and understand the clearance requirements for the chassis to ensure

adequate ventilation.

■ Prepare the equipment racks by measuring and marking space for each router

and plenum you plan to install.

Freestanding Installation

When installing the system on a table top or in any other freestanding mode, be sure

to leave enough space around the system for adequate ventilation. Position the router

with easy access to the connections that it needs for power, local communications,

and remote communications.

See “Installation Guidelines and Requirements” on page 117, and “System

Specifications” on page 109, for more information.

WARNING: Two people are required to lift an E Series router.

Before You Begin ■ 25

Page 42

ERX 11.1.x Hardware Guide

CAUTION: To prevent electrostatic damage to the system and its components, make

sure persons handling the router wear an antistatic device.

Connectors are located on the I/O modules and the power input module. These

modules are installed from the rear of the router. (See Figure 14 on page 26.) See

“Cabling ERX Routers” on page 47 for cabling installation procedures.

Figure 14: ERX7xx Models, Rear View

Rack-Mounted Installation

We recommend that you use a standard EIA distribution rack. See “Equipment Rack

Requirements” on page 121 for detailed rack information.

Installation Guidelines

Before installing the systems in a rack, consider the following guidelines and refer

to Figure 15 on page 27:

■ You can install up to 3 ERX14xx models, 6 ERX7xx models, or 14 ERX310 routers

in a single 7-ft. (2.1 m) rack.

Installing multiple systems in a single rack enables you to maximize your available

space.

■ You can install an ERX14xx model, an ERX7xx model, and an ERX310 router

together in the same rack. (See Figure 15 on page 27.)

CAUTION: If you install an ERX7xx model or ERX310 router directly above an

ERX14xx model in the same rack, you must install a plenum between the ERX7xx

model or ERX310 router and the ERX14xx model so that the air can circulate between

the systems. (See Figure 53 on page 124.) This plenum is available from Juniper

Networks.

26 ■ Rack-Mounted Installation

Page 43

ERX310 router

ERX7xx model

Plenum

ERX14xx model

Chapter 3: Installing ERX Routers

If you install an ERX14xx model above an ERX7xx model or ERX310 router,

there is no need to install a plenum between the units because the ERX7xx

models and ERX310 routers vent air out the side of the chassis.

■ Install heavier systems, such as an ERX14xx model, on the bottom of the rack.

Mount lighter systems, such as the ERX310 router, higher in the rack.

Figure 15: ERX Routers Installed in Recommended Order

Safety Guidelines

Observe the following safety guidelines when mounting the router in a rack.

WARNING: Install equipment in the rack from the bottom upward. This helps to