Page 1

CSE2000

Hardware Installation Guide

Published: 2015-03-23

Copyright © 2015, Juniper Networks, Inc.

Page 2

Juniper Networks, Inc.

1133 Innovation Way

Sunnyvale, California 94089

USA

408-745-2000

www.juniper.net

Juniper Networks, Junos, Steel-Belted Radius, NetScreen, and ScreenOS are registered trademarks of Juniper Networks, Inc. in the United

States and other countries. The Juniper Networks Logo, the Junos logo, and JunosE are trademarks of Juniper Networks, Inc. All other

trademarks, service marks, registered trademarks, or registered service marks are the property of their respective owners.

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right to change, modify,

transfer, or otherwise revise this publication without notice.

CSE2000 Carrier-Grade Service Engine Hardware Installation Guide

Copyright © 2015, Juniper Networks, Inc.

All rights reserved.

Revision History

January 2014—Initial release.

The information in this document is current as of the date on the title page.

YEAR 2000 NOTICE

Juniper Networks hardware and software products are Year 2000 compliant. Junos OS has no known time-related limitations through the

year 2038. However, the NTP application is known to have some difficulty in the year 2036.

END USER LICENSE AGREEMENT

The Juniper Networks product that is the subject of this technical documentation consists of (or is intended for use with) Juniper Networks

software. Use of such software is subject to the terms and conditions of the End User License Agreement (“EULA”) posted at

http://www.juniper.net/support/eula.html. By downloading, installing or using such software, you agree to the terms and conditions of

that EULA.

Copyright © 2015, Juniper Networks, Inc.ii

Page 3

Table of Contents

About the Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Junos OS Documentation and Release Notes . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Documentation Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Requesting Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Self-Help Online Tools and Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Opening a Case with JTAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Part 1 Carrier-Grade Service Engine CSE2000 Overview

Chapter 1 CSE2000 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Carrier-Grade Service Engine and Active Flow Monitoring Overview . . . . . . . . . . . . 3

CSE2000 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2 Device Features and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CSE2000 Chassis Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CSE2000 Front Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CSE2000 Rear Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CSE2000 Chassis Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Part 2 Planning

Chapter 3 Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Environmental Requirements and Specifications for CSE2000 . . . . . . . . . . . . . . . 13

Rack Requirements for CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Clearance Requirements for Airflow and Hardware Maintenance for the

CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

CSE2000 Chassis Grounding Cable and Lug Specifications . . . . . . . . . . . . . . . . . 15

Chapter 4 Cable and Pinout Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

RJ-45 Console Connector Pinout for the CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . 17

AC Power Cord Specifications for the CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 5 Planning Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Power Specifications for the CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 6 Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Agency Approvals for CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

CSE2000 Compliance Statements for NEBS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

iiiCopyright © 2015, Juniper Networks, Inc.

Page 4

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

Part 3 Safety

Chapter 7 General Safety Guidelines and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Definition of Safety Warning Levels for CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . 27

General Safety Guidelines and Warnings for CSE2000 . . . . . . . . . . . . . . . . . . . . . 29

Chapter 8 Electrical Safety Guidelines and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

General Electrical Safety Guidelines and Warnings for CSE2000 . . . . . . . . . . . . . 31

AC Power Electrical Safety Guidelines for CSE2000 . . . . . . . . . . . . . . . . . . . . . . . 32

DC Power Electrical Safety Guidelines for CSE2000 . . . . . . . . . . . . . . . . . . . . . . . 33

Prevention of Electrostatic Discharge Damage on CSE2000 . . . . . . . . . . . . . . . . 34

Part 4 Installation

Chapter 9 Preparing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Unpacking and Inspecting the CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Before You Install the CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Chapter 10 Installing the CS2000 Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Installing the CSE2000 Chassis in a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Installing the CSE2000 in a Two-Post Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Installing the CSE2000 in a Four-Post Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Chapter 11 Grounding the CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Tools and Parts Required to Ground the CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . 45

Connecting the CSE2000 Grounding Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Chapter 12 Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Connecting Power to AC-Powered CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Connecting Power to a DC-Powered CSE2000 Device . . . . . . . . . . . . . . . . . . . . . 48

Connecting a Console Server to the CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chapter 13 Powering On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Powering On the CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Powering Off the CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Part 5 Configuration

Chapter 14 Connecting CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Connecting the CSE2000 to a PTX5000 Router . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Downloading and Upgrading the CSE2000 Software Package . . . . . . . . . . . . . . . 57

Activating the LOCATOR LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Part 6 Maintenance

Chapter 15 Maintaining Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Replacing a Service Card on the CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Replacing a Hard Disk Drive on the CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Replacing an AC Power Supply on the CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Replacing a DC Power Supply on the CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Replacing a Cooling Fan on the CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Copyright © 2015, Juniper Networks, Inc.iv

Page 5

Table of Contents

Chapter 16 Packing and Returning Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Returning CSE2000 Hardware for Repair or Replacement . . . . . . . . . . . . . . . . . . 73

Locating CSE2000 Component Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Chapter 17 Product Reclamation and Recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Product Reclamation and Recycling Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Part 7 Troubleshooting

Chapter 18 Contacting Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Information You Might Need to Supply to JTAC . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Contacting Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Part 8 Index

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

vCopyright © 2015, Juniper Networks, Inc.

Page 6

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

Copyright © 2015, Juniper Networks, Inc.vi

Page 7

List of Figures

Part 1 Carrier-Grade Service Engine CSE2000 Overview

Chapter 2 Device Features and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 1: CSE2000 Front Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2: CSE2000 Rear Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 3: CSE2000 DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Part 2 Planning

Chapter 3 Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 4: Grounding Cable Lug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Part 4 Installation

Chapter 10 Installing the CS2000 Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 5: Install CSE2000 in a Two-Post Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 6: Fixing Chassis Rack Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 7: Installing the Chassis in a Four-Post Rack . . . . . . . . . . . . . . . . . . . . . . . . 43

Chapter 11 Grounding the CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 8: Connecting the Grounding Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chapter 12 Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 9: Connecting AC Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 10: Connecting DC Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 11: Console Cable Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Part 5 Configuration

Chapter 14 Connecting CSE2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 12: Control Plane Connection between CSE2000 and PTX5000 . . . . . . . 56

Part 6 Maintenance

Chapter 15 Maintaining Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 13: Removing a Service Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 14: Replacing a Service Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 15: Removing a Hard Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 16: Replacing a Hard Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 17: Removing an AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 18: Replacing an AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 19: Removing a DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 20: Replacing a DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

viiCopyright © 2015, Juniper Networks, Inc.

Page 8

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

Figure 21: Removing a Cooling Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 22: Replacing a Cooling Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Chapter 16 Packing and Returning Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Figure 23: Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Copyright © 2015, Juniper Networks, Inc.viii

Page 9

List of Tables

About the Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Table 1: Notice Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Part 1 Carrier-Grade Service Engine CSE2000 Overview

Chapter 2 Device Features and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 2: CSE2000 Chassis Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 3: CSE2000 Front Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 4: CSE2000 Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 5: CSE2000 Connectivity Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 6: CSE2000 Rear Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 7: CSE2000 DC Power Supply LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 8: Physical Specifications of the CSE2000 Chassis . . . . . . . . . . . . . . . . . . . 10

Part 2 Planning

Chapter 3 Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 9: CSE2000 Environmental Tolerances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 4 Cable and Pinout Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 10: RJ-45 Console Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 11: AC Power Cord Specifications for the CSE2000 . . . . . . . . . . . . . . . . . . . . 18

Chapter 5 Planning Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 12: AC Power Supply Electrical Specifications for CSE2000 . . . . . . . . . . . . . 21

Table 13: DC Power Supply Electrical Specifications for CSE2000 . . . . . . . . . . . . . 21

Part 4 Installation

Chapter 12 Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 14: CSE2000 DC Power System Input Voltage . . . . . . . . . . . . . . . . . . . . . . . 48

ixCopyright © 2015, Juniper Networks, Inc.

Page 10

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

Copyright © 2015, Juniper Networks, Inc.x

Page 11

About the Documentation

•

Junos OS Documentation and Release Notes on page xi

•

Documentation Conventions on page xi

•

Requesting Technical Support on page xii

Junos OS Documentation and Release Notes

For a list of related Junos OS documentation, see

http://www.juniper.net/techpubs/software/junos/.

If the information in the latest release notes differs from the information in the

documentation, follow the Junos OS Release Notes.

To obtain the most current version of all Juniper Networks®technical documentation,

see the product documentation page on the Juniper Networks website at

http://www.juniper.net/techpubs/.

Documentation Conventions

Table 1 on page xii defines the notice icons used in this guide.

xiCopyright © 2015, Juniper Networks, Inc.

Page 12

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

Table 1: Notice Icons

DescriptionMeaningIcon

Indicates important features or instructions.Informational note

Indicates a situation that might result in loss of data or hardware damage.Caution

Alerts you to the risk of personal injury or death.Warning

Alerts you to the risk of personal injury from a laser.Laser warning

Indicates helpful information.Tip

Requesting Technical Support

Technical productsupportisavailable through theJuniper Networks TechnicalAssistance

Center (JTAC). If you are a customer with an active J-Care or Partner Support Service

support contract, or are covered under warranty, and need post-sales technical support,

you can access our tools and resources online or open a case with JTAC.

•

JTAC policies—For a complete understanding of our JTAC procedures and policies,

review the JTAC User Guide located at

http://www.juniper.net/us/en/local/pdf/resource-guides/7100059-en.pdf.

•

Product warranties—For product warranty information, visit

http://www.juniper.net/support/warranty/.

•

JTAC hours of operation—The JTAC centers have resources available 24 hours a day,

7 days a week, 365 days a year.

Self-Help Online Tools and Resources

For quick and easy problem resolution, Juniper Networks has designed an online

self-service portal called the Customer Support Center (CSC) that provides you with the

following features:

Alerts you to a recommended use or implementation.Best practice

•

Find CSC offerings: http://www.juniper.net/customers/support/

•

Search for known bugs: http://www2.juniper.net/kb/

Copyright © 2015, Juniper Networks, Inc.xii

Page 13

•

Find product documentation: http://www.juniper.net/techpubs/

•

Find solutions and answer questions using our Knowledge Base: http://kb.juniper.net/

•

Download the latest versions of software and review release notes:

http://www.juniper.net/customers/csc/software/

•

Search technical bulletins for relevant hardware and software notifications:

http://kb.juniper.net/InfoCenter/

•

Join and participate in the Juniper Networks Community Forum:

http://www.juniper.net/company/communities/

•

Open a case online in the CSC Case Management tool: http://www.juniper.net/cm/

To verifyservice entitlement byproduct serial number, use ourSerial Number Entitlement

(SNE) Tool: https://tools.juniper.net/SerialNumberEntitlementSearch/

Opening a Case with JTAC

You can open a case with JTAC on the Web or by telephone.

About the Documentation

•

Use the Case Management tool in the CSC at http://www.juniper.net/cm/.

•

Call 1-888-314-JTAC (1-888-314-5822 toll-free in the USA, Canada, and Mexico).

For international or direct-dial options in countries without toll-free numbers, see

http://www.juniper.net/support/requesting-support.html.

xiiiCopyright © 2015, Juniper Networks, Inc.

Page 14

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

Copyright © 2015, Juniper Networks, Inc.xiv

Page 15

PART 1

Carrier-Grade Service Engine CSE2000

Overview

•

CSE2000 Description on page 3

•

Device Features and Specifications on page 5

1Copyright © 2015, Juniper Networks, Inc.

Page 16

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

Copyright © 2015, Juniper Networks, Inc.2

Page 17

CHAPTER 1

CSE2000 Description

•

Carrier-Grade Service Engine and Active Flow Monitoring Overview on page 3

Carrier-Grade Service Engine and Active Flow Monitoring Overview

Carrier-Grade Service Engine (CSE) is a solution that enables Juniper Networks PTX

Series Packet Transport Routers to improve performance and provide flow monitoring

and accounting services. The CSE2000 device is tethered to a PTX5000 router and

provides support for active flow monitoring version 9. CSE2000 allows scaling of control

plane and service plane, without adding components to the existing PTX routers.

After you connect theCSE2000 to aPTX5000 router, packets matchingthe policy criteria

set for the ingress or egress interfaces on the PTX5000 router are sent to the CSE2000

device for flow monitoring.

Flow monitoring andaccounting services providethe operator information about network

traffic and aid in tasks such as billing, traffic engineering, capacity planning, and traffic

analysis. For more information about active flow monitoring, see the Flow Monitoring

Feature Guide for CSE2000.

CSE2000 Features

CSE2000 is a 2-U device with the following features:

•

Pluggable x86 blades, one or two depending on the configuration, that can be

independently serviced, replaced, and upgraded without affecting the operation of the

other blade.

NOTE: The two x86 blades in the CSE2000 are referredto as service cards

in this documentation.

•

ETSI/NEBS Level 3 compliant

•

Dual CPUs with multicore and multithread computing platform

•

AC and DC power supply support

•

Upgradeable and replaceable hard disks

•

Field-replaceable, hot-swappable, and redundant fans and power supplies

3Copyright © 2015, Juniper Networks, Inc.

Page 18

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

•

One USB port for each service card

•

Two 10-Gigabit Ethernet with SFP+ ports

Related

Documentation

• CSE2000 Chassis Physical Specifications on page 10

• Environmental Requirements and Specifications for CSE2000 on page 13

Copyright © 2015, Juniper Networks, Inc.4

Page 19

CHAPTER 2

Device Features and Specifications

•

CSE2000 Chassis Overview on page 5

•

CSE2000 Front Panel Features on page 6

•

CSE2000 Rear Panel Features on page 9

•

CSE2000 Chassis Physical Specifications on page 10

CSE2000 Chassis Overview

The Carrier-Grade Service Engine is available in one model: CSE2000. Table 2 on page 5

provides an overview of the chassis features of the CSE2000.

Table 2: CSE2000 Chassis Features

SpecificationCategory

Rack mountable

Traffic interfaces

x86-based service cards

Storage

Fans

There are two mounting mechanisms: four-post rack mount with the sliding rail and

two-post rack mount with four mid-mount brackets.

Four 1-Gigabit Ethernet RJ-45 ports for data traffic and two 10-Gigabit Ethernet ports

for control traffic for each service card.

One RJ-45 serial console port for each service card.Console interface

The CSE2000 can have one or two service cards, depending on requirement and

configuration.

Two USB ports, one for each service card, for software installation or reinstallation.USB interface

Dual-quad core IntelProcessor

32 GB (16 GB per CPU)RAM

Four hard disk drive slots for each service card; eight hard disk drives for the device, if

two service cards are used. Each service card has four 2.5-inch hard disk drives and is

shipped with one SAS 1 TB hard disk.

Twelve 40 mm hot-swappable and redundant fans; six fans at the rear of the chassis

for each service card.

5Copyright © 2015, Juniper Networks, Inc.

Page 20

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

Table 2: CSE2000 Chassis Features (continued)

SpecificationCategory

When thedevice iscool, thefans spinat a slowerspeed to reduce noise and saveenergy.

As the device heats up, the fans run at a faster speed. In the event of fan failure, the

fault LED blinks and the remaining fan or fans run at full speed.

Power supplies

Removable AC power supply standard: 100 VAC to 240 VAC, 47––63 Hz, 15.0 amperes

(A)maximum. Standard IEC power cord is provided for AC power supply.

Removable DCpowersupply isan availableoption: –45VDC to –60VDC, 35 Amaximum.

NOTE: AC and DC power supplies are not supported simultaneously.

CAUTION: The CSE2000 is NEBS compliant and the fan speed is optimized

for balancing acoustic and cooling conditions based on the system

configurations. Removing any dummy cover or removable component, such

as tray or redundant power supply, changes the system air flow and might

cause overheating of certain components.

Related

Documentation

CSE2000 Front Panel Features on page 6•

• CSE2000 Rear Panel Features on page 9

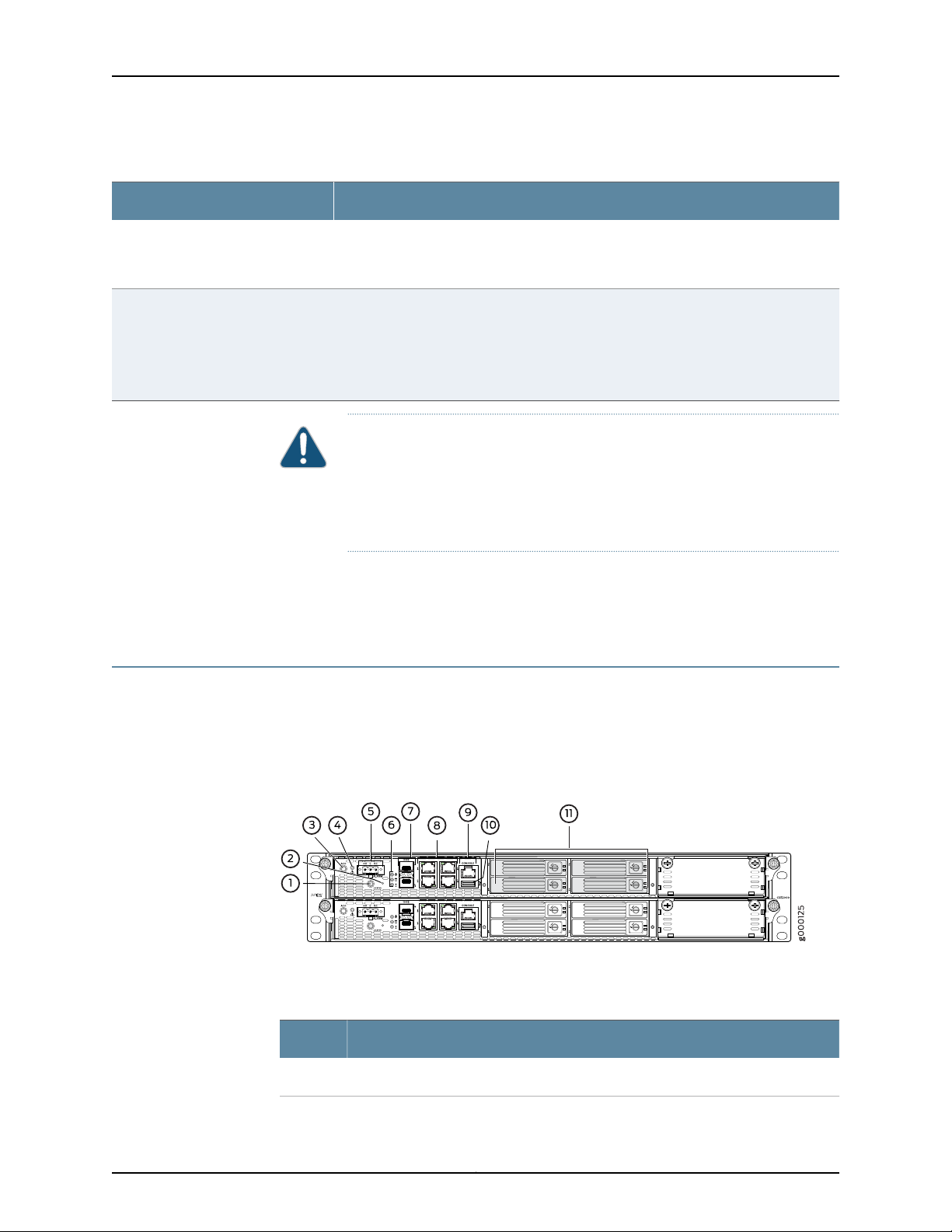

CSE2000 Front Panel Features

Figure 1 on page 6 shows the CSE2000 front panel features. Table 4 on page 7 describes

the front panel LEDs. Table 4 on page 7 describes the front panel LEDs.

describes the connectivity ports on the CSE2000.

Figure 1: CSE2000 Front Panel Features

Table 3 on page 6 lists the front panel features of CSE2000.

Table 3: CSE2000 Front Panel Features

ComponentNumber

LOCATOR LED and button. The LED can be turned off by pressing the button.1

Copyright © 2015, Juniper Networks, Inc.6

Page 21

Chapter 2: Device Features and Specifications

Table 3: CSE2000 Front Panel Features (continued)

ComponentNumber

2

3

4

5

Power button. This is a recessed button located behind a pinhole to prevent the

CSE2000 from getting powered off accidentally.

Alarm cut off (ACO) button to deactivate alarms from the alarm relay, and this turns

off the Alarm LED.

NOTE: This feature is currently not supported.

Alarm LED, which indicates Telcoalarm trigger. This LED glows whenthe telco function

is enabled and a monitored sensor threshold is reached. Pressing the alarm cut off

button turns off the Telco LED.

NOTE: This feature is currently not supported.

3-pin alarm relay contact to connect to an external alarm bell. Whenever a system

condition triggers either the red or yellow alarm, the alarm relay contacts are also

activated. Use the gauge ofwire appropriatefor theexternaldevice you are connecting.

The alarm relay can beused to monitortemperature, fans, voltage,and power supplies.

NOTE: This feature is currently not supported.

Power LED (green), hard disk access LED (amber), and system warning LED (red)6

10-Gigabit Ethernet ports and LEDs.7

1-Gigabit Ethernet ports and LEDs.8

Serial console port.9

USB port.10

11

Four hard disk drives numbered 0, 1, 2, and 3 on each service card. Shipped with one

SAS 1 TB 2.5-inch hard disk. SAS drives are supported.

Table 4 on page 7 describes the front panel LEDs.

Table 4: CSE2000 Front Panel LEDs

DescriptionLEDs

LOCATOR

Telco

Helps to locate a service card on the rack. The LED is lit blue to identify

the service card. Pressing the button turns off the LED. To active the

Locator LED, see “Activating the LOCATOR LED” on page 58.

Telco LED (red), indicates Telco alarm trigger. This LED glows when the

telco function is enabled and a monitored sensor threshold is reached.

Pressing the alarm cut off button turns off the Telco LED. Telco can

monitor temperature, fans, voltage, and power supplies, and provide

alarms.

7Copyright © 2015, Juniper Networks, Inc.

Page 22

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

Table 4: CSE2000 Front Panel LEDs (continued)

DescriptionLEDs

Power

Hard disk activityLED

System alarm LED

The power LED (green) glows when the device is powered on and it is off

when the device is powered off.

Hard disk activity LED (amber) glows when the service card is accessing

the hard disk;it blinks momentarily when there is access to the hard disk.

This LED is turned off when there is no access to the hard disk.

The system warning LED (red) blinks slowly to indicate power supply

failure, blinks fast for fan failure, and glows solid when temperature is

above the maximum limit.

Table 5: CSE2000 Connectivity Ports

DescriptionPorts

Console

USB

10-Gigabit Ethernet ports

One RJ-45 serial console port for each service card

to connect to a console server.

One USB port, per service card, for software

installation or reinstallation.

The two 10-Gigabit Ethernet ports are numbered 0

and 1, on each service card. These ports are used to

connect to the10-Gigabit Ethernet PICson PTX5000

routers for data traffic.

NOTE: The 10-GigabitEthernet ports inthe CSE2000

can be connected to 10-Gigabit Ethernet PICs with

10GBASE-SR (model number SFPP-10GE-SR) or

10GBASE-LR (model number SFPP-10GE-LR)

transceivers.

Related

Documentation

1-Gigabit Ethernet ports

The four RJ45 1-Gigabit Ethernet ports for traffic

control are numbered 0, 1, 2, and 3, on each service

card:

•

•

CSE2000 Chassis Overview on page 5•

• CSE2000 Rear Panel Features on page 9

Port 0: For the service card in slot 0, connects to

port X(GE)2 of CB0 (control board) in PTX5000.

For the service card in slot 1, connects to port

X(GE)3 of CB0 in PTX5000.

Port 1: For the service card in slot 0, connects to

port X(GE)2 of CB1 in PTX5000. For the service

card in slot 1, connects to port X(GE)3 of CB1 in

PTX5000. See “Connecting the CSE2000 to a

PTX5000 Router” on page 55.

Copyright © 2015, Juniper Networks, Inc.8

Page 23

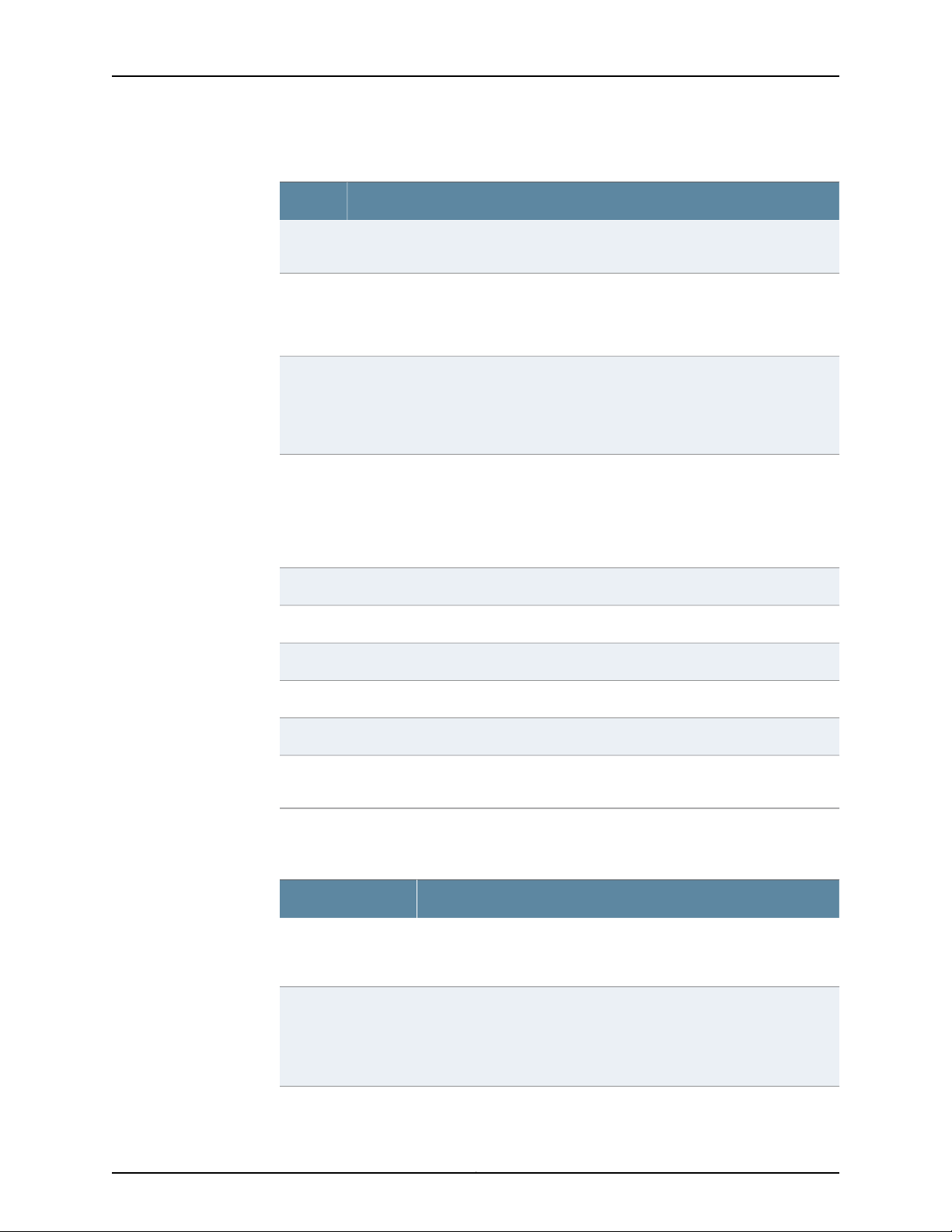

CSE2000 Rear Panel Features

See Figure 2 on page 9 for rear panel features of the CSE2000. This figure shows the

rear panel with AC power supplies.Table 6 on page 9 describes the CSE2000 rear panel

components.

Figure 2: CSE2000 Rear Panel Features

Chapter 2: Device Features and Specifications

Table 6 on page 9 lists rear panel features of the CSE2000.

Table 6: CSE2000 Rear Panel Features

ComponentNumber

1

3

Figure 3 on page 10 shows the DC power supply for the CSE2000 and Table 7 on page 10

describes the LED.

Removable cooling fans. Each service card has six fans numbered 1, 2, 3, 4, 5, and 6

from right to left. The cooling fans draw air through the air inlet on the chassis front

panel and exhaust it through the fan vents on the chassis rear panel. Fans are

redundant and hot-replaceable.

NOTE: When a fan is removed or in case of afan failure, rest of the fans in the service

card operate at full speed.

ESD point to attach the ESD strap.2

Removable AC or DC power supplies with LEDs. Figure 2 on page 9 shows AC power

supplies. There are two AC or DC power supplies for each CSE2000.

Chassis grounding studs to connect the grounding lug and cable.4

9Copyright © 2015, Juniper Networks, Inc.

Page 24

g000148

1

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

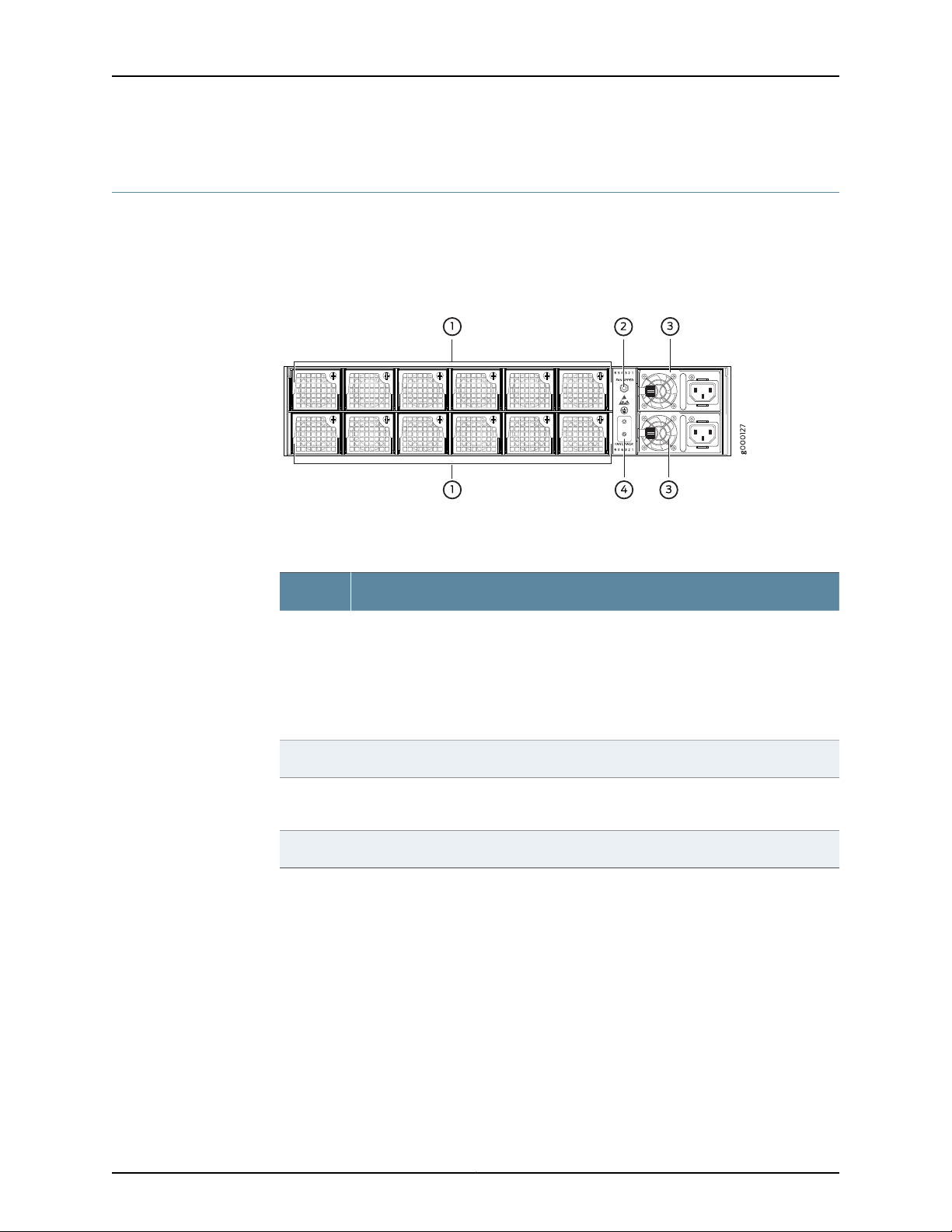

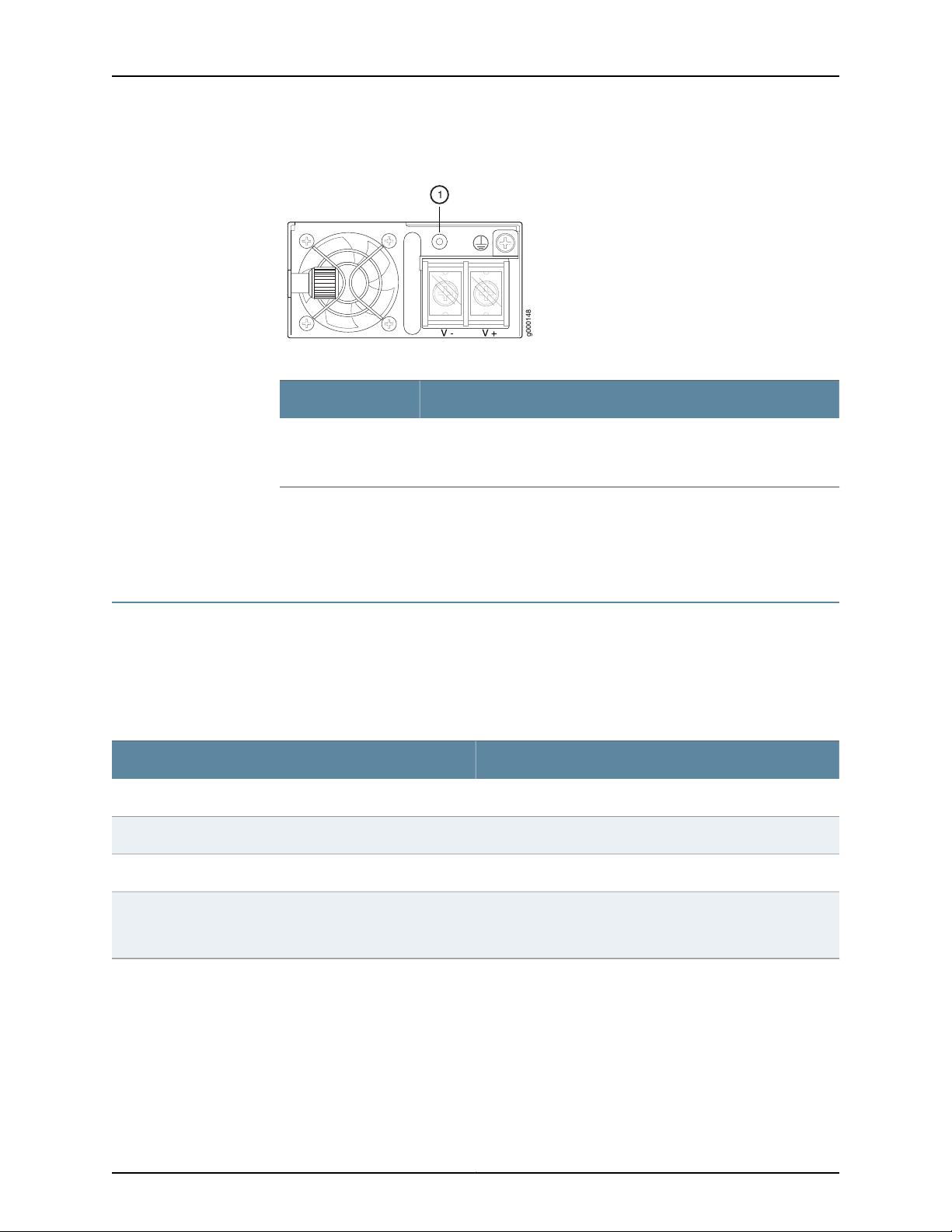

Figure 3: CSE2000 DC Power Supply

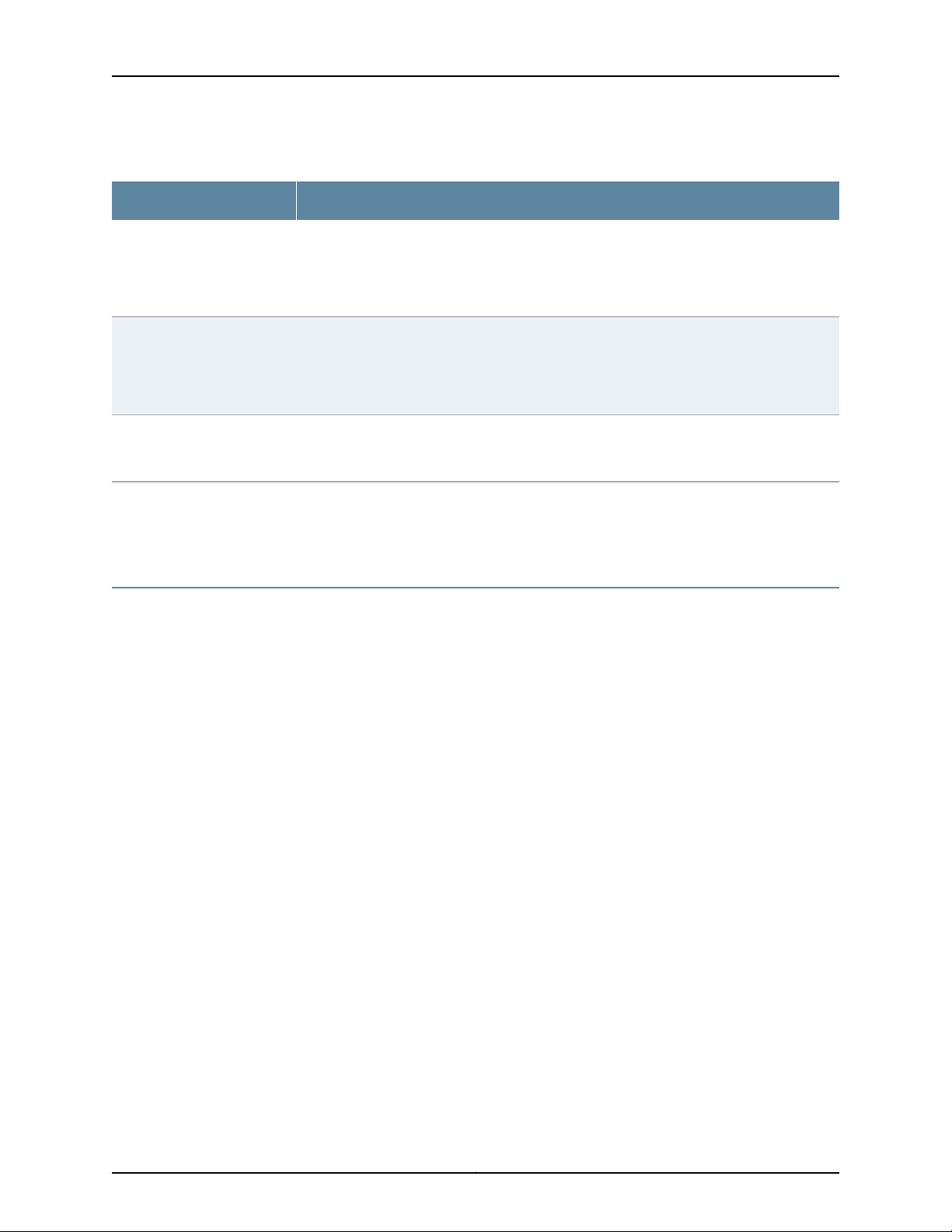

Table 7: CSE2000 DC Power Supply LED

DescriptionComponent

The power supply status LED is green when the power supplyis receiving

power and is powering the device. The LED is amber when the power

supply is receiving power but is not powering the device.

Related

Documentation

1

CSE2000 Chassis Overview on page 5•

• CSE2000 Front Panel Features on page 6

CSE2000 Chassis Physical Specifications

The CSE2000 chassis is a rigid sheet-metal structure that houses the hardware

components. Supports mounting in 19 inch rack; the CSE2000 can be mounted on a

four-post rack or a two-post rack. Table 8 on page 10 summarizes the physical

specifications of the CSE2000 chassis.

Table 8: Physical Specifications of the CSE2000 Chassis

ValueDescription

3.46 in. (88 mm)Chassis height

17.27 in. (438.8 mm)Chassis width

20 in. (508 mm)Chassis depth

Weight

Documentation

Related

Fully loaded chassis with two service cards—60 lbs (27.2 kg)

Fully loaded chassis with one service card—44 lbs (20 kg)

• Installing the CSE2000 Chassis in a Rack on page 41

• Rack Requirements for CSE2000 on page 14

Copyright © 2015, Juniper Networks, Inc.10

Page 25

PART 2

Planning

•

Site Preparation on page 13

•

Cable and Pinout Specifications on page 17

•

Planning Power Requirements on page 21

•

Compliance on page 23

11Copyright © 2015, Juniper Networks, Inc.

Page 26

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

Copyright © 2015, Juniper Networks, Inc.12

Page 27

CHAPTER 3

Site Preparation

•

Environmental Requirements and Specifications for CSE2000 on page 13

•

Rack Requirements for CSE2000 on page 14

•

Clearance Requirements for Airflow and Hardware Maintenance for the

CSE2000 on page 15

•

CSE2000 Chassis Grounding Cable and Lug Specifications on page 15

Environmental Requirements and Specifications for CSE2000

The device must be installed in a rack housed in a dry, clean, well-ventilated, and

temperature-controlled environment.

Ensure that these environmental guidelines are followed:

•

The site must be as dust-free as possible, because dust can clog air intake vents and

filters, reducing the efficiency of the device cooling system.

•

Maintain ambient airflow for normal device operation. If the airflow is blocked or

restricted, or if the intake air is too warm, the device might overheat, causing the device

temperature monitor to power off the device to protect the hardware components.

Table 9 on page14 liststhe required environmental conditions fornormal device operation.

13Copyright © 2015, Juniper Networks, Inc.

Page 28

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

Table 9: CSE2000 Environmental Tolerances

SpecificationCategory

Ambient temperature

Ambient humidity

Altitude

Related

Documentation

Normal operation: 41°F to 104°F (5°C to 40°C)

Short-term operation: 23°F to 131°F (–5°C to 55°C)

Storage: –40°F to 158°F (–40°C to 70°C)

Relative humidity (operating): Normal—8% to 90% noncondensing; short-term relative

humidity—5% to 90% non-condensing, but not to exceed 0.024 kg water/kg dry air (0.053

lb. water/2.205 lbs. dry air).

Relative humidity (storage): 5% to 95% noncondensing

Operating: 10,000 ft (3048 m) maximum

Storage: 40,000 ft (12,192 m) maximum

Clearance Requirements for Airflow and Hardware Maintenance for the CSE2000 on

•

page 15

Rack Requirements for CSE2000

Before you install a CSE2000 in a rack, you must ensure that the rack complies with a

standard 19-in. (48.26 cm) rack as defined in Cabinets, Racks, Panels, and Associated

Equipment (document number EIA-310-D) published by the Electronics Industry

Association (http://www.eia.org). Refer to this standard for details on rack size and

mounting hole spacing.

When selecting a rack, ensure that the physical characteristics of the rack comply with

the following specifications:

•

You can install the CSE2000 in a four-post rack or a two-post rack.

•

The rack rails must be spaced widely enough to accommodate external dimensions

of the chassis: 3.46 in. (8.8 cm) high, 20 in. (50.8 cm) deep, and 17.27 in. (43.8 cm)

wide. The outer edges of the mounting brackets extend the width to 19.2 in. (48.7 cm).

•

For service personnel to remove and install hardware components, there must be

adequate space at the front and back of the device. Allow at least 30 in. (76.2 cm) in

front of the device and 24 in. (61 cm) behind the device.

•

The rack must be strong enough tosupport the weight ofthe fullyconfigured CSE2000,

up to 60 lb (27.2 kg).

•

The CSE2000 must be installed into a rack that is secured to the building structure.

•

Mount the CSE2000 at the bottom of the rack if it is the only unit in the rack.

•

For the cooling system to function properly, the airflow around the chassis must be

unrestricted. The airflow for the CSE2000 is from front to back.

•

The rack or cabinet must have an adequate supply of cooling air.

Copyright © 2015, Juniper Networks, Inc.14

Page 29

Chapter 3: Site Preparation

•

Ensure that the cabinet allows the hot exhaust air to exit from the cabinet without

recirculating into the device.

•

When mounting the device in a partially filled rack, load the rack from the bottom to

the top with the heaviest component at the bottom of the rack.

•

Use a four-post rack or a two-post rack. The rack must have sufficient vertical usable

space to accommodate the height of the device: 3.46 in (88 mm), or 2 U.

NOTE: A U is the standard rack unit defined in Cabinets, Racks, Panels, and

Associated Equipment (document number EIA-310-D) published by the

Electronics Industry Association.

•

You must use only copper grounding conductors.

Related

Documentation

General Safety Guidelines and Warnings for CSE2000 on page 29•

• CSE2000 Chassis Physical Specifications on page 10

• Clearance Requirements for Airflow and Hardware Maintenance for the CSE2000 on

page 15

Clearance Requirements for Airflow and Hardware Maintenance for the CSE2000

When planning the installation site, allow sufficient clearance around the rack.

•

For the cooling system to function properly, the airflow around the chassis must be

unrestricted:

•

Allow at least 6 in. (15.2 cm) of clearance on the side between devices that have

fans or blowers installed.

•

Allow 2.8 in. (7 cm) between the side of the chassis and any non-heat-producing

surface such as a wall.

•

Ensure that the airflow vents remain open and uncovered for proper cooling.

•

For service personnel to remove and install hardware components, there must be

adequate space at the front and back of the device. At least 24 in. (61.0 cm) is required

both in front of and behind the chassis. The front ofthe chassis extends approximately

0.5 in. (1.27 cm) beyond the mounting ears.

Related

Rack Requirements for CSE2000 on page 14•

Documentation

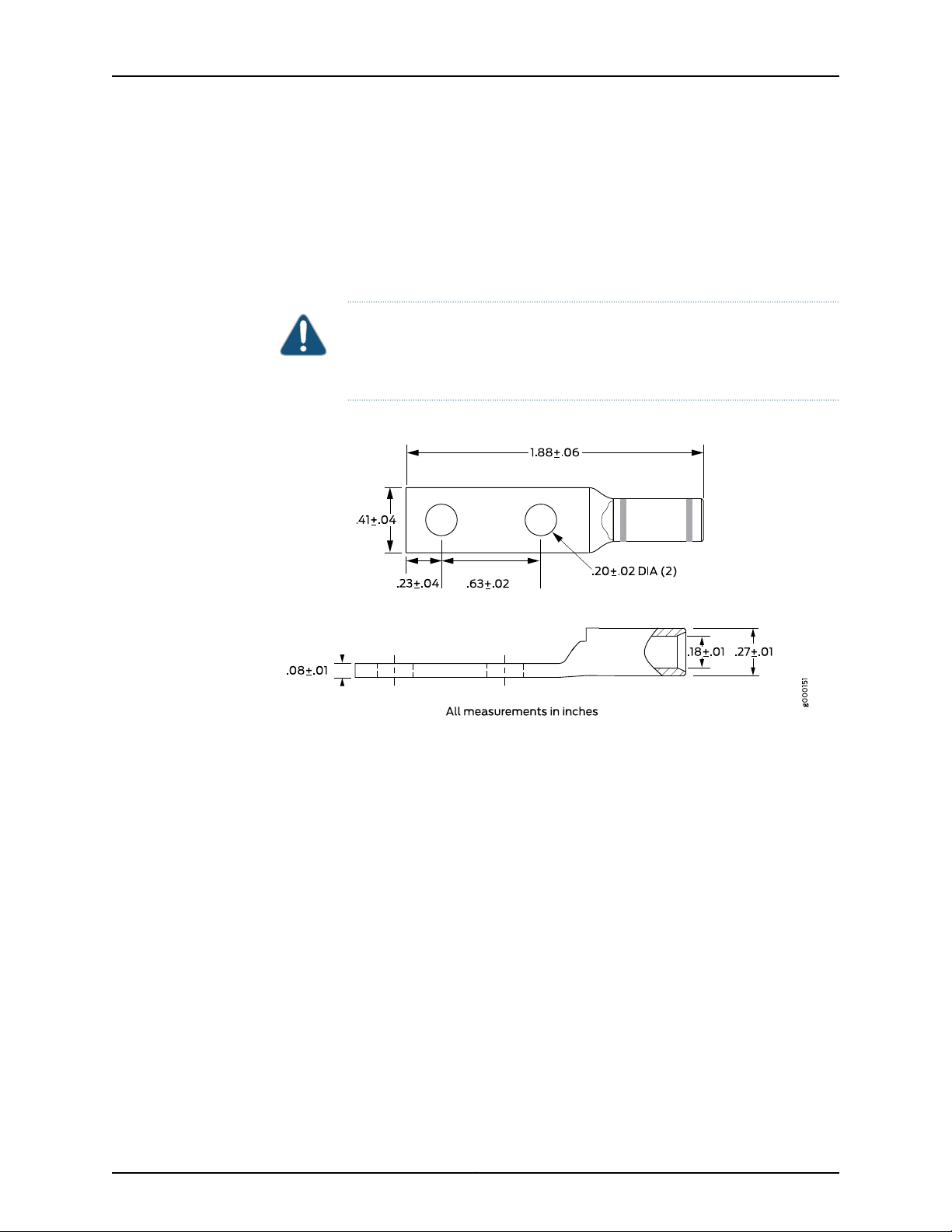

CSE2000 Chassis Grounding Cable and Lug Specifications

NOTE: The grounding lug, cable, screws, and nuts are provided by Juniper

Networks.

15Copyright © 2015, Juniper Networks, Inc.

Page 30

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

To meet safety and electromagnetic interference (EMI) requirements and to ensure

proper operation, theCSE2000 mustbe adequately groundedbefore power isconnected.

Two bolts areprovided at therear ofthe chassis for connecting the routerto earth ground.

Four 8-32 nuts are provided to secure the grounding lug to the bolts.

The grounding cable must be 6-AWG (13.3 mm2) or higher. Figure 4 on page 16 shows

the grounding lug that attaches to the grounding cable.

CAUTION: Before you begin installation of the CSE2000, a licensed electrician

must attach a cable lug to the grounding cable. A cable with an incorrectly

attached lug can damage the device.

Figure 4: Grounding Cable Lug

Related

Documentation

• Tools and Parts Required to Ground the CSE2000 on page 45

• Connecting the CSE2000 Grounding Cable on page 45

Copyright © 2015, Juniper Networks, Inc.16

Page 31

CHAPTER 4

Cable and Pinout Specifications

•

RJ-45 Console Connector Pinout for the CSE2000 on page 17

•

AC Power Cord Specifications for the CSE2000 on page 17

RJ-45 Console Connector Pinout for the CSE2000

Table 10 on page 17 describes the pinout for the RJ-45 console port connector.

Table 10: RJ-45 Console Connector Pinout

DescriptionSignalPin

Request to SendRTS Output1

Data Terminal ReadyDTR Output2

Transmit DataTxD Output3

Related

Documentation

Connecting a Console Server to the CSE2000 on page 49•

AC Power Cord Specifications for the CSE2000

Detachable AC power cords are supplied with the AC-powered CSE2000. The coupler

is type C13 as described by International Electrotechnical Commission (IEC) standard

60320. The plug at the male end of the power cord fits into the power source outlet that

is standard for your geographical location.

Chassis GroundGND4

Chassis GroundGND5

Receive DataRxD Input6

Data Set ReadyDSR Input7

Clear to SendCTS Input8

17Copyright © 2015, Juniper Networks, Inc.

Page 32

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

CAUTION: The AC power cord supplied with the device is intended for use

with that device only and not for any other use.

Power Cable Warning (Japanese)

WARNING: The attached power cable is only for this product. Do not use the cable for another

product.

NOTE: In North America, AC power cords must not exceed 4.5 meters

(approximately 14.75feet) in length, to comply with National ElectricalCode

(NEC) Sections 400-8 (NFPA 75, 5-2.2) and 210-52 and Canadian Electrical

Code (CEC) Section 4-010(3). The cords supplied with the device are in

compliance.

Table 11 on page 18 lists AC power cord specifications provided foreach country or region.

Table 11: AC Power Cord Specifications for the CSE2000

United Kingdom)

Plug StandardsElectrical SpecificationsCountry/Region

AS/NZ 3112250 VAC, 10 A, 50 HzAustralia

GB2099 and GB1002250 VAC, 10 A, 50 HzChina

CEE (7) VII250 VAC, 10 A, 50 HzEurope (except Italy, Switzerland, and

CEI 23-16250 VAC, 10 A, 50 HzItaly

JIS C8303125 VAC, 12 A, 50 or 60 HzJapan

NEMA 5-15125 VAC, 13 A, 60 HzNorth America

Related

Documentation

SEV 1011 SEV 6534/2250 VAC, 10 A, 50 HzSwitzerland

BS 1363/A250 VAC, 10 A, 50 HzUnited Kingdom

• Connecting Power to AC-Powered CSE2000 on page 47

• General Safety Guidelines and Warnings for CSE2000 on page 29

Copyright © 2015, Juniper Networks, Inc.18

Page 33

Chapter 4: Cable and Pinout Specifications

• General Electrical Safety Guidelines and Warnings for CSE2000 on page 31

• AC Power Electrical Safety Guidelines for CSE2000 on page 32

• Prevention of Electrostatic Discharge Damage on CSE2000 on page 34

19Copyright © 2015, Juniper Networks, Inc.

Page 34

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

Copyright © 2015, Juniper Networks, Inc.20

Page 35

CHAPTER 5

Planning Power Requirements

•

Power Specifications for the CSE2000 on page 21

Power Specifications for the CSE2000

This topic describes the power supply electrical specifications for the CSE2000. An AC

power supply is standard, while a DC power supply is an available option.

Table 12 on page 21 lists the AC power supply and Table 13 on page 21 lists the DC power

supply electrical specifications for the CSE2000.

Table 12: AC Power Supply Electrical Specifications for CSE2000

SpecificationItem

100 VAC through 240 VACAC input voltage

50 or 60 HzAC input line frequency

8 A through 4 A (nominal) per power supplyAC system current rating

80+%AC minimum efficiency

Table 13: DC Power Supply Electrical Specifications for CSE2000

SpecificationItem

–48 VDC through –60 VDCDC input voltage

16 A (maximum) per power supplyDC system current rating

80+%DC minimum efficiency

Related

Documentation

• General Electrical Safety Guidelines and Warnings for CSE2000 on page 31

• AC Power Cord Specifications for the CSE2000 on page 17

• Connecting Power to AC-Powered CSE2000 on page 47

• Connecting Power to a DC-Powered CSE2000 Device on page 48

21Copyright © 2015, Juniper Networks, Inc.

Page 36

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

Copyright © 2015, Juniper Networks, Inc.22

Page 37

CHAPTER 6

Compliance

•

Agency Approvals for CSE2000 on page 23

•

CSE2000 Compliance Statements for NEBS on page 23

Agency Approvals for CSE2000

The CSE2000 device complies with the following standards:

•

Safety

•

CAN/CSA-C22.2 No. 60950-1

•

EN 60950

•

IEC 60950-1

•

UL 60950-1

•

EMC

•

FCC Class A

•

EN 55022 Class A

•

EN 55024 Immunity

•

EN 61000-3-2

•

VCCI Class A

Related

Documentation

CSE2000 Compliance Statements for NEBS

•

The equipment is suitable for installation as part of the Common Bonding Network

(CBN).

•

The equipment is suitable for installation in locations where the National Electrical

Code (NEC) applies.

•

The battery return connection is to be treated as an isolated DC return (i.e. DC-I), as

defined in GR-1089-CORE.

23Copyright © 2015, Juniper Networks, Inc.

Page 38

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

Related

Documentation

• Agency Approvals for CSE2000 on page 23

Copyright © 2015, Juniper Networks, Inc.24

Page 39

PART 3

Safety

•

General Safety Guidelines and Warnings on page 27

•

Electrical Safety Guidelines and Warnings on page 31

25Copyright © 2015, Juniper Networks, Inc.

Page 40

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

Copyright © 2015, Juniper Networks, Inc.26

Page 41

CHAPTER 7

General Safety Guidelines and Warnings

•

Definition of Safety Warning Levels for CSE2000 on page 27

•

General Safety Guidelines and Warnings for CSE2000 on page 29

Definition of Safety Warning Levels for CSE2000

The CSE2000 documentation uses the following levels of safety warnings:

NOTE: You might find this information helpful in a particular situation or

might otherwise overlook it.

CAUTION: You must observe the specified guidelines to avoid minor injury

or discomfort to you or severe damage to the equipment.

WARNING: This symbol means danger.You are in a situation that couldcause

bodily injury. Before you work on any equipment, be aware of the hazards

involved with electrical circuitry and be familiar with standard practices for

preventing accidents.

Waarschuwing Dit waarschuwingssymbool betekent gevaar. U verkeert in

een situatie die lichamelijk letsel kan veroorzaken. Voordat u aan enige

apparatuur gaat werken, dient u zich bewust te zijn van de bij elektrische

schakelingen betrokken risico's en dient u op de hoogte te zijn van standaard

maatregelen om ongelukken te voorkomen.

Varoitus Tämä varoitusmerkki merkitsee vaaraa. Olet tilanteessa, joka voi

johtaa ruumiinvammaan. Ennen kuin työskenteletminkään laitteistonparissa,

ota selvää sähkökytkentöihin liittyvistä vaaroista ja tavanomaisista

onnettomuuksien ehkäisykeinoista.

Attention Ce symbole d'avertissement indique un danger. Vous vous trouvez

dans une situation pouvant causer des blessures ou des dommages corporels.

Avant de travailler sur un équipement, soyez conscient des dangers posés

27Copyright © 2015, Juniper Networks, Inc.

Page 42

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

par les circuits électriques et familiarisez-vous avec les procédures

couramment utilisées pour éviter les accidents.

Warnung Dieses Warnsymbol bedeutet Gefahr. Sie befinden sich in einer

Situation, die zu einer Körperverletzung führen könnte. Bevor Sie mit der

Arbeit an irgendeinem Gerät beginnen, seien Sie sich der mit elektrischen

Stromkreisen verbundenen Gefahren und der Standardpraktiken zur

Vermeidung von Unfällen bewußt.

Avvertenza Questo simbolo di avvertenza indica un pericolo. La situazione

potrebbe causare infortuni alle persone. Prima di lavorare su qualsiasi

apparecchiatura, occorre conoscere i pericoli relativi ai circuiti elettrici ed

essere al corrente delle pratiche standard per la prevenzione di incidenti.

Advarsel Dette varselsymbolet betyr fare. Du befinner deg i en situasjon som

kan føre til personskade. Før du utfører arbeid på utstyr, må du vare

oppmerksom på de faremomentene som elektriske kretser innebærer, samt

gjøre deg kjent med vanlig praksis når det gjelder å unngå ulykker.

Related

Documentation

Aviso Este símbolo de aviso indica perigo. Encontra-se numa situação que

lhe poderá causar danos físicos. Antes de começar a trabalhar com qualquer

equipamento, familiarize-se com os perigos relacionados com circuitos

eléctricos, e com quaisquer práticas comuns que possam prevenir possíveis

acidentes.

¡Atención! Este símbolo de aviso significa peligro. Existe riesgo para su

integridad física. Antes de manipular cualquier equipo, considerar los riesgos

que entraña la corriente eléctrica y familiarizarse con los procedimientos

estándar de prevención de accidentes.

Varning!Denna varningssymbol signalerar fara. Du befinner dig i en situation

som kan leda till personskada. Innan du utför arbete på någon utrustning

måste du vara medveten om farorna med elkretsar och känna till vanligt

förfarande för att förebygga skador.

General Safety Guidelines and Warnings for CSE2000 on page 29•

• General Electrical Safety Guidelines and Warnings for CSE2000 on page 31

• AC Power Electrical Safety Guidelines for CSE2000 on page 32

• DC Power Electrical Safety Guidelines for CSE2000 on page 33

Copyright © 2015, Juniper Networks, Inc.28

Page 43

General Safety Guidelines and Warnings for CSE2000

The following guidelines help ensure your safety and protect the CSE2000 device from

damage. The list of guidelines might not address all potentially hazardous situations in

your working environment, so be alert and exercise good judgment at all times.

WARNING: WARNING: Certain ports on the device are designed for use as

intrabuilding (within-the-building) interfaces only (Type 2 or Type 4 ports as

described in GR-1089-CORE) and require isolation from the exposed outside

plant (OSP) cabling. To comply with NEBS requirements and protect against

lightning surges and commercial power disturbances, the intrabuilding ports

must not be metallically connected to interfaces that connect to the OSP or

its wiring. The intrabuilding ports on the device are suitable for connection

to intrabuilding or unexposed wiring or cabling only. The addition of primary

protectors is not sufficient protection for connecting these interfaces

metallically to OSP wiring.

Chapter 7: General Safety Guidelines and Warnings

WARNING: The intra-building port(s) (including the following ports, when

present: DAC, External Clock, Internal Clock, T1/E1, POE Ethernet) of the

equipment or subassembly must use shielded intra-building cabling/wiring

that is grounded at both ends.

•

Perform only the procedures explicitly described in the hardware documentation for

this product. Make sure that only authorized service personnel perform other system

services.

•

Keep the area around the chassis clear and free from dust before, during, and after

installation.

•

Keep tools away from areas where people could trip over them while walking.

•

Do not wear loose clothing or jewelry, such as rings, bracelets, or chains, which could

become caught in the chassis.

•

Wear safety glasses if you are working under any conditions that could be hazardous

to your eyes.

•

Do not perform any actions that create a potential hazard to people or make the

equipment unsafe.

•

Never attempt to lift an object that is too heavy for one person to handle.

•

Never install or manipulate wiring during electrical storms.

•

Never install electrical jacks in wet locations unless the jacks are specifically designed

for wet environments.

•

Operate the device only when it is properly grounded.

29Copyright © 2015, Juniper Networks, Inc.

Page 44

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

•

Ensure that a reliable, low-resistance ground bond exists between the chassis and the

rack, and that the rack is permanently connected to earth.

•

Use only copper grounding conductors.

•

Ensure that the separate protective earthing terminal on this product, if provided, is

permanently connected to earth.

•

Do not open or remove chassis covers or sheet-metal parts unless instructions are

provided in the hardware documentation for this product. Such an action could cause

severe electrical shock.

•

Do not push or force any objects through any opening in the chassis frame. Such an

action could result in electrical shock or fire.

•

Avoid spilling liquid onto the chassis or onto any component. Such an action could

cause electrical shock or damage the device.

•

Avoid touching uninsulated electrical wires or terminals that have not been

disconnected from their power source. Such an action could cause electrical shock.

•

Always ensure that all modules, power supplies, and cover panels are fully inserted

and that the installation screws are fully tightened.

Related

Documentation

• Definition of Safety Warning Levels for CSE2000 on page 27

• General Electrical Safety Guidelines and Warnings for CSE2000 on page 31

• AC Power Electrical Safety Guidelines for CSE2000 on page 32

• DC Power Electrical Safety Guidelines for CSE2000 on page 33

Copyright © 2015, Juniper Networks, Inc.30

Page 45

CHAPTER 8

Electrical Safety Guidelines and Warnings

•

General Electrical Safety Guidelines and Warnings for CSE2000 on page 31

•

AC Power Electrical Safety Guidelines for CSE2000 on page 32

•

DC Power Electrical Safety Guidelines for CSE2000 on page 33

•

Prevention of Electrostatic Discharge Damage on CSE2000 on page 34

General Electrical Safety Guidelines and Warnings for CSE2000

CAUTION: Certain ports on the device are designed for use as intrabuilding

(within-the-building) interfaces only (Type 2 or Type 4 ports as described in

GR-1089-CORE,Issue 4) and requireisolation from the exposed outside plant

(OSP) cabling. To comply with NEBS requirements and protect against

lightning surges and commercial power disturbances, the intrabuilding ports

must not be metallically connected to interfaces that connect to the OSP or

its wiring. The intrabuilding ports on the device are suitable for connection

to intrabuilding or unexposed wiring or cabling only. The addition of primary

protectors is not sufficient protection for connecting these interfaces

metallically to OSP wiring.

CAUTION: Before removing or installing device components, attach an ESD

strap to an ESD point, and place the other end of the strap around your bare

wrist. Failure to use an ESD strap could result in damage to the device.

•

Install the CSE2000 in compliance with thefollowing local, national,and international

electrical codes:

•

United States—National Fire Protection Association (NFPA 70), United States

National Electrical Code.

•

Other countries—International Electromechanical Commission (IEC) 60364, Part 1

through Part 7.

31Copyright © 2015, Juniper Networks, Inc.

Page 46

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

•

Evaluated to the TN power system.

•

Canada—Canadian Electrical Code, Part 1, CSA C22.1.

•

Note the following warning printed on the chassis:

The equipment must be connected to an earthed mains socket-outlet.

•

Locate the emergency power-off switch for the room in which you are working so that

if an electrical accident occurs, you can quickly turn off the power.

•

Make sure thatgrounding surfaces are cleaned before you make groundingconnections.

•

Do notwork alone ifpotentially hazardous conditionsexist anywhere in your workspace.

•

Never assume thatpower is disconnectedfrom acircuit. Always check the circuit before

starting to work.

•

Carefully look for possible hazards in your work area, such as moist floors, ungrounded

power extension cords, and missing safety grounds.

•

Operatethe CSE2000within markedelectrical ratings andproduct usage instructions.

•

To ensure that the CSE2000 and peripheral equipment function safely and correctly,

use the cables and connectors specified for the attached peripheral equipment, and

make certain they are in good condition.

You can remove and replace some components without powering off or disconnecting

power to the device, as detailed elsewhere in the hardware documentation for this

product. Never install equipment if it appears damaged.

Related

Documentation

Definition of Safety Warning Levels for CSE2000 on page 27•

• General Safety Guidelines and Warnings for CSE2000 on page 29

• AC Power Electrical Safety Guidelines for CSE2000 on page 32

• DC Power Electrical Safety Guidelines for CSE2000 on page 33

AC Power Electrical Safety Guidelines for CSE2000

The following electrical safety guidelines apply to AC-powered devices:

•

AC-powered devices are shipped with a three-wire electrical cord with agrounding-type

plug that fits only agrounding-type power outlet. Do not circumventthis safety feature.

Equipment grounding must comply with local and national electrical codes.

•

The power cord serves as the main disconnecting device for the device. The socket

outlet must be near the device and be easily accessible.

•

For CSE2000 devices that have more than one power supply connection, you must

ensure that all power connections are fully disconnected so that power to the device

is completely removed to avoid electric shock. To disconnect power, unplug all power

cords (one for each power supply).

Copyright © 2015, Juniper Networks, Inc.32

Page 47

Chapter 8: Electrical Safety Guidelines and Warnings

CAUTION: The AC power cord for the devices is intended for use with that

device only and not for any other use.

Power Cable Warning (Japanese)

WARNING: The attached power cable is only for this product. Do not use the cable for another

product.

Related

Documentation

Definition of Safety Warning Levels for CSE2000 on page 27•

• General Safety Guidelines and Warnings for CSE2000 on page 29

• General Electrical Safety Guidelines and Warnings for CSE2000 on page 31

• Connecting Power to AC-Powered CSE2000 on page 47

DC Power Electrical Safety Guidelines for CSE2000

The following electrical safety guidelines apply to a DC-powered device:

•

A DC-powered device is equipped with a DC terminal block that is rated for the power

requirements of a maximally configured device.

NOTE: To supply sufficient power, terminate the DC input wiring on a facility

DC source capable of supplying at least 25 A at –48 VDC (minimum

–45VDC and maximum –60VDC).

Incorporate an easily accessible disconnect device into the facility wiring. Be sure to

connect the ground wire or conduit to a solid office earth ground. We recommend a

closed loop ring for terminating the ground conductor at the ground stud.

•

You must use only copper grounding conductors.

•

Run two wires from the circuit breaker box to a source of 48 VDC.

•

You must provide anexternal certified circuitbreaker rated minimum 25 A in thebuilding

installation.

•

A DC-powered device that is equipped with a DC terminal block is intended only for

installation in a restricted access location. In the United States, a restricted access

area is one inaccordancewith Articles 110-16,110-17, and 110-18 of the National Electrical

Code ANSI/NFPA 70.

33Copyright © 2015, Juniper Networks, Inc.

Page 48

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

CAUTION: Primary overcurrentprotectionis providedby the building circuit

breaker. This breaker must protect against excess currents, short circuits,

and earth-grounding faults in accordance with NEC ANSI/NFPA 70.

•

Ensure that the polarity of the DC input wiring is correct. Under certain conditions,

connections with reversed polarity might trip the primary circuit breaker or damage

the equipment.

•

For personal safety, connect a wire for earth ground at both the device and the supply

side of the DC wiring.

•

The marked input voltage of –48 VDC for a DC-powered device is the nominal voltage

associated with the battery circuit, and any higher voltages are to be associated only

with float voltages for the charging function.

•

Because the device is a positive ground system, you must connect the positive lead to

the terminal labeled RTN, the negative lead to the terminal labeled –48 VDC, and the

earth ground to the chassis grounding points.

Related

Documentation

Definition of Safety Warning Levels for CSE2000 on page 27•

• General Safety Guidelines and Warnings for CSE2000 on page 29

• Connecting Power to a DC-Powered CSE2000 Device on page 48

Prevention of Electrostatic Discharge Damage on CSE2000

The CSE2000 components that are shipped in antistatic bags are sensitive to damage

from static electricity. Some components can be impaired by voltages as low as 30 V.

You can easilygeneratepotentially damaging staticvoltages whenever you handle plastic

or foam packing material or if you move components across plastic or carpets. Observe

the following guidelines to minimize the potential for electrostatic discharge (ESD)

damage, which can cause intermittent or complete component failures:

•

Always usean ESDgrounding strap when you are handling components thatare subject

to ESD damage, and make sure that it is in direct contact with your skin.

If a grounding strap is not available, hold the component in its antistatic bag in one

hand, and touch the exposed,bare metal ofthe device withthe other hand immediately

before inserting the component into the device.

CAUTION: For safety, periodically check the resistance value of the ESD

strap. The measurement must be in the range of 1 through 10 Mohms.

•

Avoidcontact between thecomponent that is subjectto ESD damage andyour clothing.

ESD voltages emitted from clothing can damage components.

•

When removing orinstalling a component that is subject to ESD damage, always place

it component-side up on an antistatic surface, in an antistatic card rack, or in an

Copyright © 2015, Juniper Networks, Inc.34

Page 49

Chapter 8: Electrical Safety Guidelines and Warnings

antistatic bag. If you are returning a component, place it in an antistatic bag before

packing it.

CAUTION: ANSI/TIA/EIA-568 cables such as category 5e and category 6

can get electrostatically charged. To dissipate this charge, always ground

the cables to a suitable and safe earth ground before connecting them to the

system.

Related

Documentation

• Definition of Safety Warning Levels for CSE2000 on page 27

• General Safety Guidelines and Warnings for CSE2000 on page 29

• Connecting the CSE2000 Grounding Cable on page 45

35Copyright © 2015, Juniper Networks, Inc.

Page 50

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

Copyright © 2015, Juniper Networks, Inc.36

Page 51

PART 4

Installation

•

Preparing the Installation on page 39

•

Installing the CS2000 Device on page 41

•

Grounding the CSE2000 on page 45

•

Cabling on page 47

•

Powering On on page 51

37Copyright © 2015, Juniper Networks, Inc.

Page 52

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

Copyright © 2015, Juniper Networks, Inc.38

Page 53

CHAPTER 9

Preparing the Installation

•

Unpacking and Inspecting the CSE2000 on page 39

•

Before You Install the CSE2000 on page 40

Unpacking and Inspecting the CSE2000

The CSE2000 is shipped in a box. Quick Start installation instructions and a cardboard

accessory box are also included in the shipping box.

NOTE: The device is maximally protected inside the shipping box. Do not

unpack it until you are ready to begin installation.

Before you begin unpacking the device, be sure you have the following tools and parts:

•

Phillips (+) screwdriver, number 2 (not provided)

•

Electrostatic discharge (ESD) grounding wrist strap (not provided)

•

Mid-mount brackets for two-post mount

•

Sliding rails and rail assembly for four-post mount

To unpack the device:

1. Move the shipping box to a staging area as close to the installation site as possible,

where you have enough room to maneuver.

2. Position the shipping box with the arrows pointing up.

3. Open the shipping box.

4. Remove the accessory box and the Quick Start installation instructions.

5. Verify the parts received.

6. Save the shipping box and packing materials in case you need to move or ship the

device at a later time.

39Copyright © 2015, Juniper Networks, Inc.

Page 54

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

After you remove the equipment from the shipping boxes:

•

Confirm the contents of each box.

•

Inspect all external surfaces and external connectors for visible signs of damage.

•

Inspect all accessories in the accessory box.

•

Document any damage noted during your inspection.

•

Confirm that theplatformhas the correctnumber andtype ofmodules for your ordered

configuration.

If you detect or suspect damage to any equipment:

•

Contact the shipper responsible for delivery, and formally report the damage.

•

Contact Juniper Networks at 1-888-314-JTAC (from the United States, Canada, or

Mexico) or 1-408-745-9500 (from elsewhere), or contact your sales representative

or reseller if you have any questions or concerns.

Related

Returning CSE2000 Hardware for Repair or Replacement on page 73•

Documentation

Before You Install the CSE2000

Before installing the CSE2000:

•

Verify that the site meets all environment specifications. See “Environmental

Requirements and Specifications for CSE2000” on page 13.

•

Read and understand the clearance requirements for the device to ensure adequate

ventilation and enable access to the device for maintenance. See “Clearance

Requirements for Airflow and Hardware Maintenance for the CSE2000” on page 15.

•

Have the tools and accessories needed to complete the installation. See “Unpacking

and Inspecting the CSE2000” on page 39.

•

Verify that the cables you plan to use meet the specifications, and review the cabling

recommendations. See “AC Power Cord Specifications for the CSE2000” on page 17.

Have plastic cable ties or other means to secure traffic and power cables safely out

of the way.

•

Verify that the electrical supply meets all AC or DC power requirements. See “Power

Specifications for the CSE2000” on page 21.

Related

Documentation

• Installing the CSE2000 Chassis in a Rack on page 41

Copyright © 2015, Juniper Networks, Inc.40

Page 55

CHAPTER 10

Installing the CS2000 Device

•

Installing the CSE2000 Chassis in a Rack on page 41

•

Installing the CSE2000 in a Two-Post Rack on page 42

•

Installing the CSE2000 in a Four-Post Rack on page 42

Installing the CSE2000 Chassis in a Rack

To install the CSE2000:

1. Place the shipping container on a flat surface, and remove the hardware components

with care.

CAUTION: Place the shipping container on a flat surface, and remove the

hardware components with care.

2. The CSE2000 can be installed in a two-post rack or a four-post rack. For two-post

rack installations, see “Installing the CSE2000 in a Two-Post Rack” on page 42. For

four-post rack installation, see “Installing the CSE2000 in a Four-Post Rack” on

page 42.

3. Secure the device to the rack with thread-forming screws, and place external-tooth,

paint-piercing lock washers between the screw head and the mounting bracket to

create a reliable low-resistance ground bond between the chassis and the rack.

4. Connect power to the device.

For a standard, AC-power-equipped CSE2000, plug the supplied AC power cord into

the receptacle on the rear panel. See

If you have a DC-power-equipped CSE2000, see

5. To connect to a console terminal, plug the supplied Ethernet cable into the console

port on the front panel.

6. Power on the device. See

When you turn on the power, the power LED (green) glows. See LED details.

7. To connect to your management network, plug an RJ-45 cable to 1-Gigabit Ethernet

port 2 on the front panel.

41Copyright © 2015, Juniper Networks, Inc.

Page 56

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

Related

Before You Install the CSE2000 on page 40•

Documentation

Installing the CSE2000 in a Two-Post Rack

CAUTION: Due to the size and weight of CSE2000—up to 60 lb (27.2 kg)

with two service cards and 44 lb (20 kg) with one service card—we

recommend that you install the device with two people (one to lift and one

to secure the device to the rack).

To install the CSE2000 in a two-post rack:

1. Attach the ESD grounding strap to your bare wrist and to a site ESD point.

2. Fix one mid-mount bracket with screws on either side of the chassis.

3. Fix the chassis to the equipment rack with mounting screws in the two slots. Fix the

other two mid-mountbracketson eitherside of the systemand thensecure the chassis

to the backs of the posts (see Figure 5 on page 42).

Figure 5: Install CSE2000 in a Two-Post Rack

Related

Documentation

Before You Install the CSE2000 on page 40•

• Rack Requirements for CSE2000 on page 14

• Clearance Requirements for Airflow and Hardware Maintenance for the CSE2000 on

page 15

Installing the CSE2000 in a Four-Post Rack

CAUTION: Due to the size and weight of CSE2000—up to 60 lb (27.2 kg)

with two service cards and 44 lb (20 kg) with one service card—we

recommend that you install the device with two people (one to lift and one

to secure the device to the rack).

Copyright © 2015, Juniper Networks, Inc.42

Page 57

g000145

Chapter 10: Installing the CS2000 Device

To install the CSE2000 in a four-post rack:

1. Attach the ESD grounding strap to your bare wrist and to a site ESD point.

2. Remove theslide railsfrom theslide railassembly. You have to push the stopper down

to remove the rails.

3. Insert four screws and fix the slide rails on each side of the device. See

Figure 6 on page 43

4. Adjust the length of the two rack assemblies and fix them to your equipment rack.

Ensure that you identify the left and right rack assemblies, as marked on the

assemblies, and install accordingly.

5. Align the slide rails on either side of the chassis with the rack assemblies, push the

stopper down and slide the chassis fully into the rack enclosure. See

Figure 7 on page 43.

6. Insert two rack mount screws eachin tothe twomount brackets infront of the chassis

to secure the chassis to the equipment rack. See Figure 7 on page 43.

7. Verify that the mounting screws on one side of the rack are aligned with the mounting

screws on the opposite side and that the appliance is level.

Related

Documentation

Figure 6: Fixing Chassis Rack Rail

Figure 7: Installing the Chassis in a Four-Post Rack

• Before You Install the CSE2000 on page 40

• Rack Requirements for CSE2000 on page 14

• Clearance Requirements for Airflow and Hardware Maintenance for the CSE2000 on

page 15

43Copyright © 2015, Juniper Networks, Inc.

Page 58

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

Copyright © 2015, Juniper Networks, Inc.44

Page 59

CHAPTER 11

Grounding the CSE2000

•

Tools and Parts Required to Ground the CSE2000 on page 45

•

Connecting the CSE2000 Grounding Cable on page 45

Tools and Parts Required to Ground the CSE2000

To ground the CSE2000, you need the following tools and parts:

•

ESD grounding wrist strap (not provided)

•

Four 8-32 nuts—two nuts each are fastened to the two earthing bolts on the rear panel

of the chassis when shipped

•

Grounding lug

•

Grounding cable

Related

Documentation

CSE2000 Rear Panel Features on page 9•

• CSE2000 Chassis Grounding Cable and Lug Specifications on page 15

• Prevention of Electrostatic Discharge Damage on CSE2000 on page 34

Connecting the CSE2000 Grounding Cable

BEST PRACTICE: The grounding points for the CSE2000 are at the rear of

the chassis. See “CSE2000 Rear Panel Features” on page 9.

To connect the grounding cable:

1. Make sure that grounding surfaces are clean before grounding connections are made.

2. Connect the grounding cable to a proper earth ground.

3. Verify that a licensed electrician has attached the cablelug provided with the CSE2000

device to the grounding cable.

4. Attach an electrostaticdischarge (ESD) groundingstrap to yourbare wrist,and connect

the strap to an approved ESD grounding point.

45Copyright © 2015, Juniper Networks, Inc.

Page 60

Carrier-Grade Service Engine CSE2000 Hardware Installation Guide

5. Remove the four 8-32 nuts from the two earthing bolts at the rear of the chassis.

6. Insert the grounding cable lug on grounding bolts.

7. Secure the grounding cable lug to the grounding bolts, by fastening two nuts on each

bolt. See Figure 8 on page 46

8. Verify that the grounding cable does not touch or block access to the CSE2000

components, and that it does not drape where people could trip on it.

Figure 8: Connecting the Grounding Cable

Related

Documentation

• Tools and Parts Required to Ground the CSE2000 on page 45