Page 1

C-series Platforms

C2000 and C4000 Hardware Guide

Release 1.0.x

Juniper Networks, Inc.

1194 North Mathilda Avenue

Sunnyvale, California 94089

USA

408-745-2000

www.juniper.net

Part Number: 530–020353–01, Revision A00

Page 2

This product includes the Envoy SNMP Engine, developed by Epilogue Technology, an Integrated Systems Company. Copyright © 1986-1997, Epilogue

Technology Corporation. All rights reserved. This program and its documentation were developed at private expense, and no part of them is in the public

domain.

This product includes memory allocation software developed by Mark Moraes, copyright © 1988, 1989, 1993, University of Toronto.

This product includes FreeBSD software developed by the University of California, Berkeley, and its contributors. All of the documentation and software

included in the 4.4BSD and 4.4BSD-Lite Releases is copyrighted by the Regents of the University of California. Copyright © 1979, 1980, 1983, 1986, 1988,

1989, 1991, 1992, 1993, 1994. The Regents of the University of California. All rights reserved.

GateD software copyright © 1995, the Regents of the University. All rights reserved. Gate Daemon was originated and developed through release 3.0 by

Cornell University and its collaborators. Gated is based on Kirton’s EGP, UC Berkeley’s routing daemon (routed), and DCN’s HELLO routing protocol.

Development of Gated has been supported in part by the National Science Foundation. Portions of the GateD software copyright © 1988, Regents of the

University of California. All rights reserved. Portions of the GateD software copyright © 1991, D. L. S. Associates.

This product includes software developed by Maker Communications, Inc., copyright © 1996, 1997, Maker Communications, Inc.

Juniper Networks, the Juniper Networks logo, NetScreen, and ScreenOS are registered trademarks of Juniper Networks, Inc. in the United States and other

countries. JUNOS and JUNOSe are trademarks of Juniper Networks, Inc. All other trademarks, service marks, registered trademarks, or registered service

marks are the property of their respective owners.

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right to change, modify, transfer, or

otherwise revise this publication without notice.

Products made or sold by Juniper Networks or components thereof might be covered by one or more of the following patents that are owned by or licensed

to Juniper Networks: U.S. Patent Nos. 5,473,599, 5,905,725, 5,909,440, 6,192,051, 6,333,650, 6,359,479, 6,406,312, 6,429,706, 6,459,579, 6,493,347,

6,538,518, 6,538,899, 6,552,918, 6,567,902, 6,578,186, and 6,590,785.

Copyright © 2007, Juniper Networks, Inc. All rights reserved.

C-series Platforms Hardware Guide

Release 1.0.x

Copyright © 2007, Juniper Networks, Inc.

All rights reserved. Printed in USA.

Writing: John Borelli

Editing: Fran Mues

Illustration: John Borelli

Cover Design: Edmonds Design

Revision History

6 April 2007—Revision 1

The information in this document is current as of the date listed in the revision history.

SOFTWARE LICENSE

The terms and conditions for using this software are described in the software license contained in the acknowledgment to your purchase order or, to the

extent applicable, to any reseller agreement or end-user purchase agreement executed between you and Juniper Networks. By using this software, you

indicate that you understand and agree to be bound by those terms and conditions.

Generally speaking, the software license restricts the manner in which you are permitted to use the software and may contain prohibitions against certain

uses. The software license may state conditions under which the license is automatically terminated. You should consult the license for further details.

For complete product documentation, please see the Juniper Networks Web site at www.juniper.net/techpubs.

ii ■

Page 3

End User License Agreement

READ THIS END USER LICENSE AGREEMENT (“AGREEMENT”) BEFORE DOWNLOADING, INSTALLING, OR USING THE SOFTWARE. BY DOWNLOADING,

INSTALLING, OR USING THE SOFTWARE OR OTHERWISE EXPRESSING YOUR AGREEMENT TO THE TERMS CONTAINED HEREIN, YOU (AS CUSTOMER

OR IF YOU ARE NOT THE CUSTOMER, AS A REPRESENTATIVE/AGENT AUTHORIZED TO BIND THE CUSTOMER) CONSENT TO BE BOUND BY THIS

AGREEMENT. IF YOU DO NOT OR CANNOT AGREE TO THE TERMS CONTAINED HEREIN, THEN (A) DO NOT DOWNLOAD, INSTALL, OR USE THE SOFTWARE,

AND (B) YOU MAY CONTACT JUNIPER NETWORKS REGARDING LICENSE TERMS.

1. The Parties. The parties to this Agreement are Juniper Networks, Inc. and its subsidiaries (collectively “Juniper”), and the person or organization that

originally purchased from Juniper or an authorized Juniper reseller the applicable license(s) for use of the Software (“Customer”) (collectively, the “Parties”).

2. The Software. In this Agreement, “Software” means the program modules and features of the Juniper or Juniper-supplied software, and updates and

releases of such software, for which Customer has paid the applicable license or support fees to Juniper or an authorized Juniper reseller. “Embedded

Software” means Software which Juniper has embedded in the Juniper equipment.

3. License Grant. Subject to payment of the applicable fees and the limitations and restrictions set forth herein, Juniper grants to Customer a non-exclusive

and non-transferable license, without right to sublicense, to use the Software, in executable form only, subject to the following use restrictions:

a. Customer shall use the Embedded Software solely as embedded in, and for execution on, Juniper equipment originally purchased by Customer from

Juniper or an authorized Juniper reseller.

b. Customer shall use the Software on a single hardware chassis having a single processing unit, or as many chassis or processing units for which Customer

has paid the applicable license fees; provided, however, with respect to the Steel-Belted Radius or Odyssey Access Client software only, Customer shall use

such Software on a single computer containing a single physical random access memory space and containing any number of processors. Use of the

Steel-Belted Radius software on multiple computers requires multiple licenses, regardless of whether such computers are physically contained on a single

chassis.

c. Product purchase documents, paper or electronic user documentation, and/or the particular licenses purchased by Customer may specify limits to

Customer’s use of the Software. Such limits may restrict use to a maximum number of seats, registered endpoints, concurrent users, sessions, calls,

connections, subscribers, clusters, nodes, realms, devices, links, ports or transactions, or require the purchase of separate licenses to use particular features,

functionalities, services, applications, operations, or capabilities, or provide throughput, performance, configuration, bandwidth, interface, processing,

temporal, or geographical limits. In addition, such limits may restrict the use of the Software to managing certain kinds of networks or require the Software

to be used only in conjunction with other specific Software. Customer’s use of the Software shall be subject to all such limitations and purchase of all applicable

licenses.

d. For any trial copy of the Software, Customer’s right to use the Software expires 30 days after download, installation or use of the Software. Customer

may operate the Software after the 30-day trial period only if Customer pays for a license to do so. Customer may not extend or create an additional trial

period by re-installing the Software after the 30-day trial period.

e. The Global Enterprise Edition of the Steel-Belted Radius software may be used by Customer only to manage access to Customer’s enterprise network.

Specifically, service provider customers are expressly prohibited from using the Global Enterprise Edition of the Steel-Belted Radius software to support any

commercial network access services.

The foregoing license is not transferable or assignable by Customer. No license is granted herein to any user who did not originally purchase the applicable

license(s) for the Software from Juniper or an authorized Juniper reseller.

4. Use Prohibitions. Notwithstanding the foregoing, the license provided herein does not permit the Customer to, and Customer agrees not to and shall

not: (a) modify, unbundle, reverse engineer, or create derivative works based on the Software; (b) make unauthorized copies of the Software (except as

necessary for backup purposes); (c) rent, sell, transfer, or grant any rights in and to any copy of the Software, in any form, to any third party; (d) remove

any proprietary notices, labels, or marks on or in any copy of the Software or any product in which the Software is embedded; (e) distribute any copy of

the Software to any third party, including as may be embedded in Juniper equipment sold in the secondhand market; (f) use any ‘locked’ or key-restricted

feature, function, service, application, operation, or capability without first purchasing the applicable license(s) and obtaining a valid key from Juniper, even

if such feature, function, service, application, operation, or capability is enabled without a key; (g) distribute any key for the Software provided by Juniper

to any third party; (h) use the Software in any manner that extends or is broader than the uses purchased by Customer from Juniper or an authorized Juniper

reseller; (i) use the Embedded Software on non-Juniper equipment; (j) use the Software (or make it available for use) on Juniper equipment that the Customer

did not originally purchase from Juniper or an authorized Juniper reseller; (k) disclose the results of testing or benchmarking of the Software to any third

party without the prior written consent of Juniper; or (l) use the Software in any manner other than as expressly provided herein.

5. Audit. Customer shall maintain accurate records as necessary to verify compliance with this Agreement. Upon request by Juniper, Customer shall furnish

such records to Juniper and certify its compliance with this Agreement.

6. Confidentiality. The Parties agree that aspects of the Software and associated documentation are the confidential property of Juniper. As such, Customer

shall exercise all reasonable commercial efforts to maintain the Software and associated documentation in confidence, which at a minimum includes

restricting access to the Software to Customer employees and contractors having a need to use the Software for Customer’s internal business purposes.

■ iii

Page 4

7. Ownership. Juniper and Juniper's licensors, respectively, retain ownership of all right, title, and interest (including copyright) in and to the Software,

associated documentation, and all copies of the Software. Nothing in this Agreement constitutes a transfer or conveyance of any right, title, or interest in

the Software or associated documentation, or a sale of the Software, associated documentation, or copies of the Software.

8. Warranty, Limitation of Liability, Disclaimer of Warranty. The warranty applicable to the Software shall be as set forth in the warranty statement that

accompanies the Software (the “Warranty Statement”). Nothing in this Agreement shall give rise to any obligation to support the Software. Support services

may be purchased separately. Any such support shall be governed by a separate, written support services agreement. TO THE MAXIMUM EXTENT PERMITTED

BY LAW, JUNIPER SHALL NOT BE LIABLE FOR ANY LOST PROFITS, LOSS OF DATA, OR COSTS OR PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES,

OR FOR ANY SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES ARISING OUT OF THIS AGREEMENT, THE SOFTWARE, OR ANY JUNIPER OR

JUNIPER-SUPPLIED SOFTWARE. IN NO EVENT SHALL JUNIPER BE LIABLE FOR DAMAGES ARISING FROM UNAUTHORIZED OR IMPROPER USE OF ANY

JUNIPER OR JUNIPER-SUPPLIED SOFTWARE. EXCEPT AS EXPRESSLY PROVIDED IN THE WARRANTY STATEMENT TO THE EXTENT PERMITTED BY LAW,

JUNIPER DISCLAIMS ANY AND ALL WARRANTIES IN AND TO THE SOFTWARE (WHETHER EXPRESS, IMPLIED, STATUTORY, OR OTHERWISE), INCLUDING

ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR NONINFRINGEMENT. IN NO EVENT DOES JUNIPER

WARRANT THAT THE SOFTWARE, OR ANY EQUIPMENT OR NETWORK RUNNING THE SOFTWARE, WILL OPERATE WITHOUT ERROR OR INTERRUPTION,

OR WILL BE FREE OF VULNERABILITY TO INTRUSION OR ATTACK. In no event shall Juniper’s or its suppliers’ or licensors’ liability to Customer, whether

in contract, tort (including negligence), breach of warranty, or otherwise, exceed the price paid by Customer for the Software that gave rise to the claim, or

if the Software is embedded in another Juniper product, the price paid by Customer for such other product. Customer acknowledges and agrees that Juniper

has set its prices and entered into this Agreement in reliance upon the disclaimers of warranty and the limitations of liability set forth herein, that the same

reflect an allocation of risk between the Parties (including the risk that a contract remedy may fail of its essential purpose and cause consequential loss),

and that the same form an essential basis of the bargain between the Parties.

9. Termination. Any breach of this Agreement or failure by Customer to pay any applicable fees due shall result in automatic termination of the license

granted herein. Upon such termination, Customer shall destroy or return to Juniper all copies of the Software and related documentation in Customer’s

possession or control.

10. Taxes. All license fees for the Software are exclusive of taxes, withholdings, duties, or levies (collectively “Taxes”). Customer shall be responsible for

paying Taxes arising from the purchase of the license, or importation or use of the Software.

11. Export. Customer agrees to comply with all applicable export laws and restrictions and regulations of any United States and any applicable foreign

agency or authority, and not to export or re-export the Software or any direct product thereof in violation of any such restrictions, laws or regulations, or

without all necessary approvals. Customer shall be liable for any such violations. The version of the Software supplied to Customer may contain encryption

or other capabilities restricting Customer’s ability to export the Software without an export license.

12. Commercial Computer Software. The Software is “commercial computer software” and is provided with restricted rights. Use, duplication, or disclosure

by the United States government is subject to restrictions set forth in this Agreement and as provided in DFARS 227.7201 through 227.7202-4, FAR 12.212,

FAR 27.405(b)(2), FAR 52.227-19, or FAR 52.227-14(ALT III) as applicable.

13. Interface Information.To the extent required by applicable law, and at Customer's written request, Juniper shall provide Customer with the interface

information needed to achieve interoperability between the Software and another independently created program, on payment of applicable fee, if any.

Customer shall observe strict obligations of confidentiality with respect to such information and shall use such information in compliance with any applicable

terms and conditions upon which Juniper makes such information available.

14. Third Party Software.Any licensor of Juniper whose software is embedded in the Software and any supplier of Juniper whose products or technology

are embedded in (or services are accessed by) the Software shall be a third party beneficiary with respect to this Agreement, and such licensor or vendor

shall have the right to enforce this Agreement in its own name as if it were Juniper. In addition, certain third party software may be provided with the

Software and is subject to the accompanying license(s), if any, of its respective owner(s). To the extent portions of the Software are distributed under and

subject to open source licenses obligating Juniper to make the source code for such portions publicly available (such as the GNU General Public License

(“GPL”) or the GNU Library General Public License (“LGPL”)), Juniper will make such source code portions (including Juniper modifications, as appropriate)

available upon request for a period of up to three years from the date of distribution. Such request can be made in writing to Juniper Networks, Inc., 1194

N. Mathilda Ave., Sunnyvale, CA 94089, ATTN: General Counsel. You may obtain a copy of the GPL at http://www.gnu.org/licenses/gpl.html, and a copy of

the LGPL at http://www.gnu.org/licenses/lgpl.html.

15. Miscellaneous. This Agreement shall be governed by the laws of the State of California without reference to its conflicts of laws principles. The provisions

of the U.N. Convention for the International Sale of Goods shall not apply to this Agreement. For any disputes arising under this Agreement, the Parties

hereby consent to the personal and exclusive jurisdiction of, and venue in, the state and federal courts within Santa Clara County, California. This Agreement

constitutes the entire and sole agreement between Juniper and the Customer with respect to the Software, and supersedes all prior and contemporaneous

agreements relating to the Software, whether oral or written (including any inconsistent terms contained in a purchase order), except that the terms of a

separate written agreement executed by an authorized Juniper representative and Customer shall govern to the extent such terms are inconsistent or conflict

with terms contained herein. No modification to this Agreement nor any waiver of any rights hereunder shall be effective unless expressly assented to in

writing by the party to be charged. If any portion of this Agreement is held invalid, the Parties agree that such invalidity shall not affect the validity of the

remainder of this Agreement. This Agreement and associated documentation has been written in the English language, and the Parties agree that the English

version will govern. (For Canada: Les parties aux présentés confirment leur volonté que cette convention de même que tous les documents y compris tout

avis qui s'y rattaché, soient redigés en langue anglaise. (Translation: The parties confirm that this Agreement and all related documentation is and will be

in the English language)).

iv ■

Page 5

Table of Contents

About This Guide ix

Objectives ......................................................................................................ix

Audience ........................................................................................................ix

Documentation Conventions ...........................................................................x

Related Juniper Networks Documentation ......................................................xi

Obtaining Documentation ............................................................................xiii

Documentation Feedback .............................................................................xiii

Requesting Support ......................................................................................xiv

Part 1 Product Overview

Chapter 1 C-series Platform Overview 3

System Description .........................................................................................3

C-series Platform Models .................................................................................3

C-series Model Components ............................................................................5

Network Management Tools ............................................................................6

CLI Management .......................................................................................6

SNMP MIB Management ...........................................................................7

Part 2 Initial Installation

Chapter 2 Unpacking and Inspecting the C-series Platform 11

Before You Begin ...........................................................................................11

Unpacking the Units ......................................................................................12

Inspecting System Components and Accessories ..........................................12

If You Detect or Suspect Damage ..................................................................12

Contacting Juniper Networks .........................................................................12

The Next Step ................................................................................................12

Chapter 3 Installing and Cabling the C-series Platform 13

Before You Begin ...........................................................................................13

Freestanding Installation ...............................................................................13

Table of Contents ■ v

Page 6

C2000 and C4000 1.0.x Hardware Guide

Rack-Mounted Installation .............................................................................14

Installation Guidelines .............................................................................14

Preparing the Equipment Racks ..............................................................14

Installing the System ...............................................................................14

Cabling the System ........................................................................................15

Cabling the Management Console ...........................................................15

Management Ports ...........................................................................15

Cabling Ethernet Interfaces .....................................................................16

Cabling the System for Power .................................................................16

The Next Step ................................................................................................18

Chapter 4 Powering Up the C-series Platform 19

Powering Up .................................................................................................19

Status LEDs ...................................................................................................20

The Next Step ................................................................................................20

Chapter 5 Setting the Initial Configuration 21

Configuration Overview ................................................................................21

Setting Up Management Access and Logging In ............................................21

Configuring the Juniper Networks Database ..................................................22

Configuring Hostname and Domain Parameters ...........................................23

Configuring the System for Remote Access ...................................................24

Configuring the System to Accept SSH and Telnet Connections ....................25

Adding an Admin User Account ....................................................................26

The Next Step ................................................................................................27

Part 3 Hardware Maintenance Procedures and Specifications

Chapter 6 Maintaining the System 31

Required Tools and Items ..............................................................................31

Storing Modules and Components .................................................................32

Cleaning the System ......................................................................................32

Removing and Installing a Fan ......................................................................32

Removing and Installing a Power Supply Module ..........................................33

Removing and Installing a Hard Drive ...........................................................34

Chapter 7 System Specifications 35

C2000 Model Specifications ..........................................................................35

C4000 Model Specifications ..........................................................................36

vi ■ Table of Contents

Page 7

Table of Contents

Chapter 8 Managing RAID Disks on a C-series Platform 39

C-series Platform Data Storage ......................................................................39

Managing Disks in a C-series Platform ...........................................................40

Replacing a Disk .....................................................................................40

Reinitializing an Active Disk ....................................................................41

Viewing Information About Disks on a C-series Platform ........................41

Chapter 9 Installation Guidelines and Requirements 43

Your Preinstallation Responsibilities ..............................................................43

Environmental Requirements ........................................................................44

Regulatory Compliances ................................................................................44

Safety Guidelines ...........................................................................................45

Equipment Rack Requirements .....................................................................46

Mechanical Requirements .......................................................................46

Space Requirements ...............................................................................47

Proper Rack Installation ..........................................................................47

Cabling Recommendations ............................................................................47

Product Reclamation and Recycling Program ................................................48

Hardware Compliance ...................................................................................49

Federal Communications Commission (FCC) Statement .........................49

FCC Requirements for Consumer Products .............................................49

Food and Drug Administration, Center for Devices and Radiological

Health ..............................................................................................49

Canadian Department of Communications Radio Interference

Regulations .......................................................................................50

Réglement sur le brouillage radioélectrique du ministère des

communications ...............................................................................50

Industry Canada Notice CS-03 ................................................................50

Avis CS-03 d'Industrie Canada ................................................................50

D.O.C. Explanatory Notes: Equipment Attachment Limitations ..............51

Notes explicatives du ministère des Communications: limites visant les

accessoires .......................................................................................52

EC Declaration of Conformity .................................................................52

Voluntary Control Council for Interference (VCCI) Statement for

Japan ................................................................................................52

Chapter 10 Contacting Customer Support and Returning Hardware 53

Contacting Customer Support ........................................................................53

Return Procedure ..........................................................................................53

Locating Component Serial Numbers ............................................................54

Information You Might Need to Supply to JTAC .............................................54

Tools and Parts Required ..............................................................................55

Returning Products for Repair or Replacement .............................................55

Packing Instructions for Returning a Chassis ...........................................55

Table of Contents ■ vii

Page 8

C2000 and C4000 1.0.x Hardware Guide

Chapter 11 Declaration of Conformity 57

Declaration of Conformity .............................................................................57

Part 4 Index

Index .............................................................................................................61

viii ■ Table of Contents

Page 9

About This Guide

This preface provides the following guidelines for using the Hardware Guide:

■ Objectives on page ix

■ Audience on page ix

■ Documentation Conventions on page x

■ Related Juniper Networks Documentation on page xi

■ Obtaining Documentation on page xiii

■ Documentation Feedback on page xiii

■ Requesting Support on page xiv

Objectives

This guide provides the information you need to install, start, maintain, and

troubleshoot a C-series Controller.

NOTE: If the information in the latest SRC Release Notes differs from the information

in this guide, follow the SRC Release Notes.

Audience

This guide is intended for experienced system and network specialists working with

JUNOSe routers and JUNOS routing platforms in an Internet access environment.

We assume that readers know how to use the routing platforms, directories, and

RADIUS servers that they will deploy in their SRC networks. For users who deploy

the SRC software on a Solaris platform, we also assume that readers are familiar

with the Lightweight Directory Access Protocol (LDAP) and the UNIX operating system.

If you are using the SRC software in a cable network environment, we assume that

you are familiar with the PacketCable Multimedia Specification (PCMM) as defined

by Cable Television Laboratories, Inc. (CableLabs) and with the Data-over-Cable

Service Interface Specifications (DOCSIS) 1.1 protocol. We also assume that you are

familiar with operating a multiple service operator (MSO) multimedia-managed IP

network.

Objectives ■ ix

Page 10

C2000 and C4000 1.0.x Hardware Guide

Documentation Conventions

Table 1 on page x defines the notice icons used in this guide. Table 2 on page

x defines text conventions used throughout the documentation.

Table 1: Notice Icons

DescriptionMeaningIcon

Indicates important features or instructions.Informational note

Indicates a situation that might result in loss of data or hardware damage.Caution

Alerts you to the risk of personal injury or death.Warning

Table 2: Text Conventions

Bold typeface

Bold sans serif typeface

Monospace sans serif typeface

Regular sans serif typeface

Represents keywords, scripts, and

■

tools in text.

Represents a GUI element hat the

■

user selects, clicks, checks, or

clears.

Represents text that you must type.

Represents information as displayed on

your terminal’s screen, such as CLI

commands in output displays.

Represents configuration

■

statements.

Indicates SRC CLI commands and

■

options in text.

Represents examples in

■

procedures.

ExamplesDescriptionConvention

Specify the keyword exp-msg.

■

Run the install.sh script.

■

Use the pkgadd tool.

■

To cancel the configuration, click

■

Cancel.

user@host# set cache-entry-age

cache-entry-age

nic-locators {

login {

resolution {

resolver-name /realms/login/A1;

key-type LoginName;

value-type SaeId;

}

■

system ldap server {

stand-alone;

■

Use the request sae device failover

command with the force option.

■

user@host# . . .

x ■ Documentation Conventions

Represents URLs.

■

■

http://www.juniper.net/techpubs/software/

management/sdx/api-index.html

Page 11

Table 2: Text Conventions (continued)

About This Guide

ExamplesDescriptionConvention

Italic sans serif typeface

Angle brackets

Key name

Key names linked with a plus sign (+)

Italic typeface

Backslash

Words separated by the | symbol

Represents variables in SRC CLI

commands.

keywords or variables.

keyboard.

more keys simultaneously

Emphasizes words.

■

Identifies chapter, appendix, and

■

book names.

Identifies distinguished names.

■

Identifies files, directories, and

■

paths in text but not in command

examples.

At the end of a line, indicates that the

text wraps to the next line.

keyword or variable to the left or right

of this symbol. (The keyword or variable

may be either optional or required.)

user@host# set local-address

local-address

Another runtime variable is <gfwif>.In text descriptions, indicate optional

Press Enter.Indicates the name of a key on the

Press Ctrl+b.Indicates that you must press two or

There are two levels of access: user

■

and privileged.

Chapter 2, Services.

■

o=Users, o=UMC

■

The /etc/default.properties file

■

Plugin.radiusAcct-1.class=\

net.juniper.smgt.sae.plugin\

RadiusTrackingPluginEvent

diagnostic | lineRepresent a choice to select one

Related Juniper Networks Documentation

With each SRC software release, we provide the SRC Documentation CD, which

contains the documentation described in Table 3 on page xii.

With each SRC Application Library release, we provide the SRC Application Library

CD. This CD contains both the software applications and the SRC Application Library

Guide.

The C-Web interface, which is based on the J-Web interface, is available for monitoring

the C-series platforms and the SRC software. For general information about the J-Web

interface, see the J-Web Interface User Guide.

A complete list of abbreviations used in this document set, along with their spelled-out

terms, is provided in the SRC Getting Started Guide.

Related Juniper Networks Documentation ■ xi

Page 12

C2000 and C4000 1.0.x Hardware Guide

Table 3: Juniper Networks C-series and SRC Technical Publications

DescriptionDocument

Core Documentation Set

C-series Hardware Guide

Describes the hardware platforms and how to install, maintain, replace,

and troubleshoot them. The guide also includes specifications.

SRC-PE Getting Started Guide

SRC-PE CLI User Guide

SRC-PE Network Guide: SAE, Juniper Networks Routers,

and NIC

SRC-PE Integration Guide: Network Devices, Directories,

and RADIUS Servers

SRC-PE Services and Policies Guide

SRC-PE Subscribers and Subscriptions Guide

Describes the SRC software and explains how to set up an initial

configuration and manage a C-series platform. The guide describes how

to set up and start the SRC CLI and C-Web, as well as other SRC

configurations. It provides information about setting up an initial SRC

configuration on a Solaris platform. The guide also describes how to

upgrade the SRC software and how to use the SRC configuration tools.

It includes reference material for the SRC documentation.

Describes how to use the SRC CLI, configure and monitor the platform

with the CLI, and control the CLI environment. The guide also describes

how to manage SRC components with the CLI.

Describes how to use and configure the SAE and the NIC. This guide

also provides detailed information for using JUNOSe routers and JUNOS

routing platforms in the SRC network.

Describes how to integrate external components—network devices,

directories, and RADIUS servers—into the SRC network. The guide

provides detailed information about integrating specific models of the

external components.

Describes how to work with services and policies. The guide provides

an overview, configuration procedures, and management information.

The guide also provides information about the SRC tools for configuring

policies.

Describes how to work with residential and enterprise subscribers and

subscriptions. The guide provides an overview, configuration procedures,

and management information. This guide also provides information

about the sample residential portals and enterprise service portals,

including the Enterprise Manager Portal.

SRC-PE Monitoring and Troubleshooting Guide

SRC-PE Solutions Guide

SRC-PE CLI Command Reference, Volume 1

SRC-PE CLI Command Reference, Volume 2

xii ■ Related Juniper Networks Documentation

Describes how to use logging, the SNMP agent, the SRC CLI, and the

C-Web interface to monitor and troubleshoot SRC components. This

guide also describes the SNMP traps.

Provides high-level instructions for SRC implementations. The guide

documents the following scenarios: managing QoS services on JUNOSe

routers; managing subscribers in a wireless roaming environment;

providing voice over IP (VoIP) services; integrating the SRC software in

a PCMM environment, including the use of the Juniper Policy Server

(JPS); mirroring subscriber traffic on JUNOSe routers; demonstrating

network resource management features in a sample IP television (IPTV)

application; and demonstrating the integration of prepaid services in

a sample application.

Together provide information about command and statement syntax;

descriptions of commands, configuration statements, and options;

editing level of statement options; and a history of when a command

was added to the documentation.

Page 13

Table 3: Juniper Networks C-series and SRC Technical Publications (continued)

DescriptionDocument

About This Guide

SRC-PE Comprehensive Index

Application Library

SRC Application Library Guide

Release Notes

SRC-PE Release Notes

SRC Application Library Release Notes

Provides a complete index of the SRC guides, excluding the C-series

Hardware Guide and the SRC-PE Command Reference.

Provides general information about the J-Web interface.J-Web User Interface Guide

Describes how to install and work with applications that you can use

to extend the capabilities of the SRC software. The guide documents

the following applications: SRC-SG (SOAP Gateway) Web applications,

applications to integrate the Juniper Networks Intrusion Detection and

Protection (IDP) software into an SRC-managed environment, an

application to provide endpoint security by integrating Juniper Networks

Instant Virtual Extranet (IVE) Host Checker, a traffic-mirroring Web

application, an application to integrate IP address managers with the

SAE, an application to provide tracking and QoS control at the

application level by integrating the SRC software with the Ellacoya deep

packet inspection (DPI) platform, an application to control volume

usage, and the SRC-ACP (Admission Control Plug-In) application.

In the Release Notes, you will find the latest information about features,

changes, known problems, resolved problems, supported platforms

and network devices (such as Juniper Networks routers and CMTS

devices), and third-party software. If the information in the Release

Notes differs from the information found in the documentation set,

follow the Release Notes.

Release notes are included in the corresponding software distribution

and are available on the Web.

Obtaining Documentation

To obtain the most current version of all Juniper Networks technical documentation,

see the products documentation page on the Juniper Networks Web site at

http://www.juniper.net/.

To order printed copies of this guide and other Juniper Networks technical documents,

or to order a documentation CD, which contains this guide, contact your sales

representative.

Copies of the Management Information Bases (MIBs) available in a software release

are included on the documentation CDs and at http://www.juniper.net/.

Documentation Feedback

We encourage you to provide feedback, comments, and suggestions so that we can

improve the documentation. You can send your comments to

techpubs-comments@juniper.net, or fill out the documentation feedback form at

Obtaining Documentation ■ xiii

Page 14

C2000 and C4000 1.0.x Hardware Guide

http://www.juniper.net/techpubs/docbug/docbugreport.html. If you are using e-mail, be

sure to include the following information with your comments:

■ Document name

■ Document part number

■ Page number

■ Software release version

Requesting Support

For technical support, open a support case with the Case Manager link at

http://www.juniper.net/support/ or call 1-888-314-JTAC (from the United States, Canada,

or Mexico) or 1-408-745-9500 (from elsewhere).

xiv ■ Requesting Support

Page 15

Part 1

Product Overview

■ C-series Platform Overview on page 3

Product Overview ■ 1

Page 16

C2000 and C4000 1.0.x Hardware Guide

2 ■ Product Overview

Page 17

Chapter 1

C-series Platform Overview

This chapter provides introductory information about the C-series platform. It contains

the following topics:

■ System Description on page 3

■ C-series Platform Models on page 3

■ C-series Model Components on page 5

■ Network Management Tools on page 6

System Description

The C-series platform enables you to easily install, configure, and support Juniper

Networks Session and Resource Control-Policy Engine (SRC-PE) software. It provides

easy access to troubleshooting information, such as reporting events, logs, and system

dumps while providing session resource controller functionality.

There are two C-series platform models: the C2000 model and the C4000 model.

Each model is composed of two hard drives, fans, redundant power supplies, two

USB ports, a console management port, and four Ethernet ports. The main difference

between the two models is the number of service session licenses and concurrent

subscribers allowed on each unit.

C-series Platform Models

Two C-series platform models are available:

■ C2000

■ C4000

Both models use the same software. However, the specific model determines the

number of service session licenses and concurrent subscribers allowed on each unit.

(See Table 4 on page 4.)

System Description ■ 3

Page 18

C2000 and C4000 1.0.x Hardware Guide

Table 4: C-series Model Differences

NOTE: The models illustrated in this book might look different from your model

because of configuration variations.

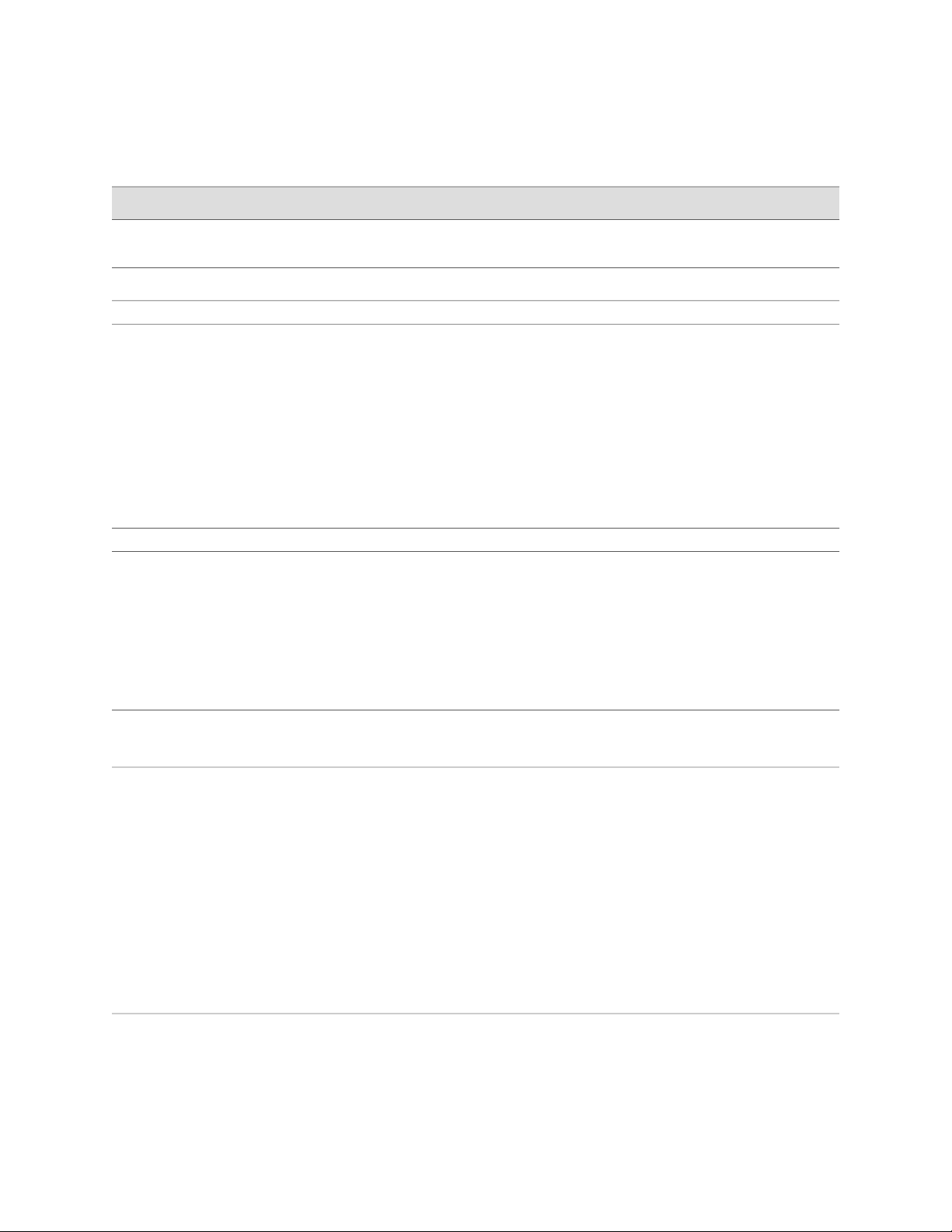

Figure 1: C2000, Front View

Concurrent SubscribersService Session LicensesModel

200,00050,000C2000

500,000100,000C4000

Figure 2: C2000, Rear View

Figure 3: C4000, Front View

4 ■ C-series Platform Models

Page 19

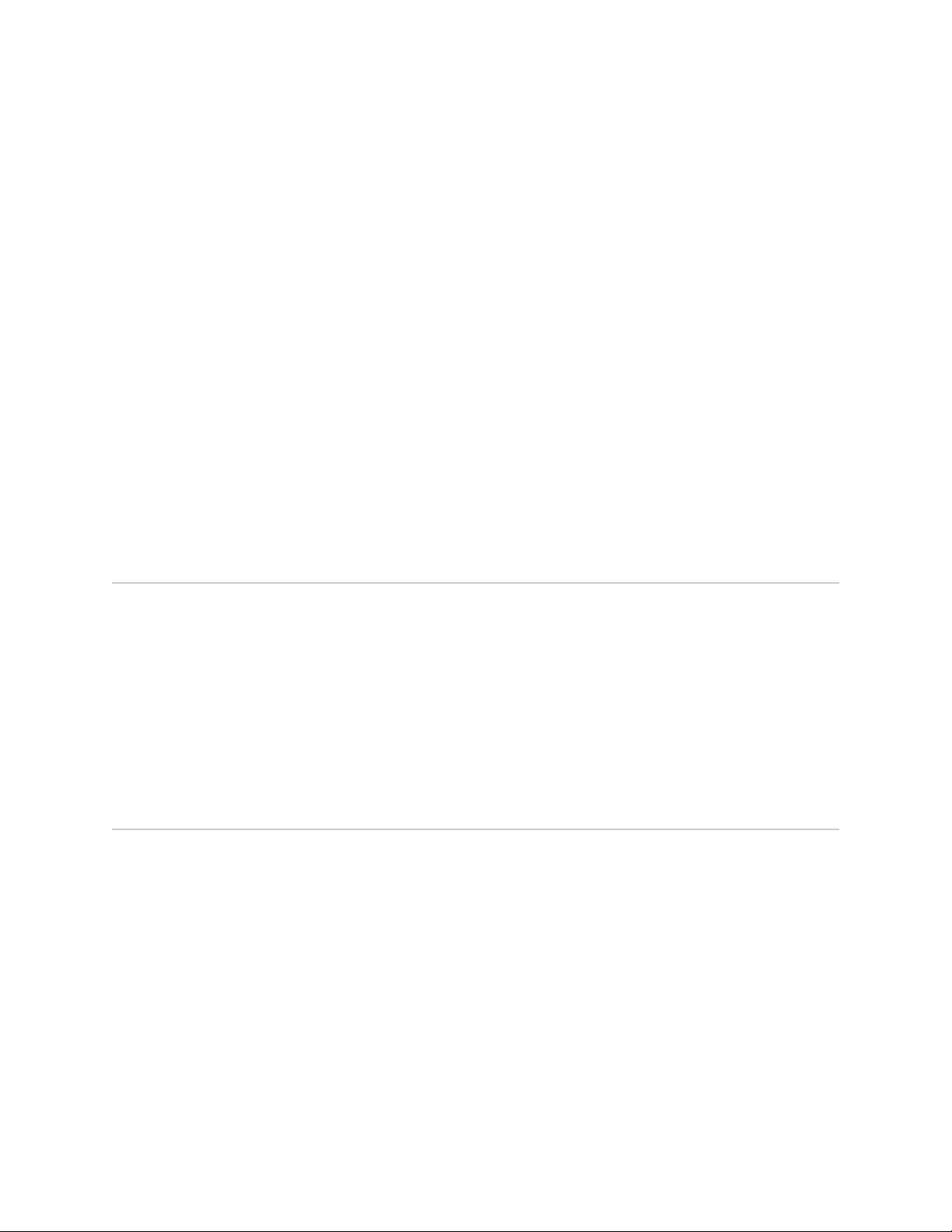

Figure 4: C4000, Rear View

C-series Model Components

The C2000 model and C4000 model contain the following components:

■ Internal memory

Chapter 1: C-series Platform Overview

■ CPU

■ Hard drive—Each model has two hot-swappable, redundant drives in a redundant

array of independent disks (RAID) 1 (mirror) configuration. The C2000 model

has two hard drives located in the front, and the C4000 model has two hard

drives located in the rear.

■ Fans—The C2000 model has two hot-swappable fans located in the rear. The

C4000 model has two hot-swappable fan trays located in the rear. Each fan tray

contains three fans.

■ Power supply—Each model has two hot-swappable, redundant AC-power supplies

located in the rear. Depending on the model, each power supply module has

either two (C2000 model) or one (C4000 model) associated fan.

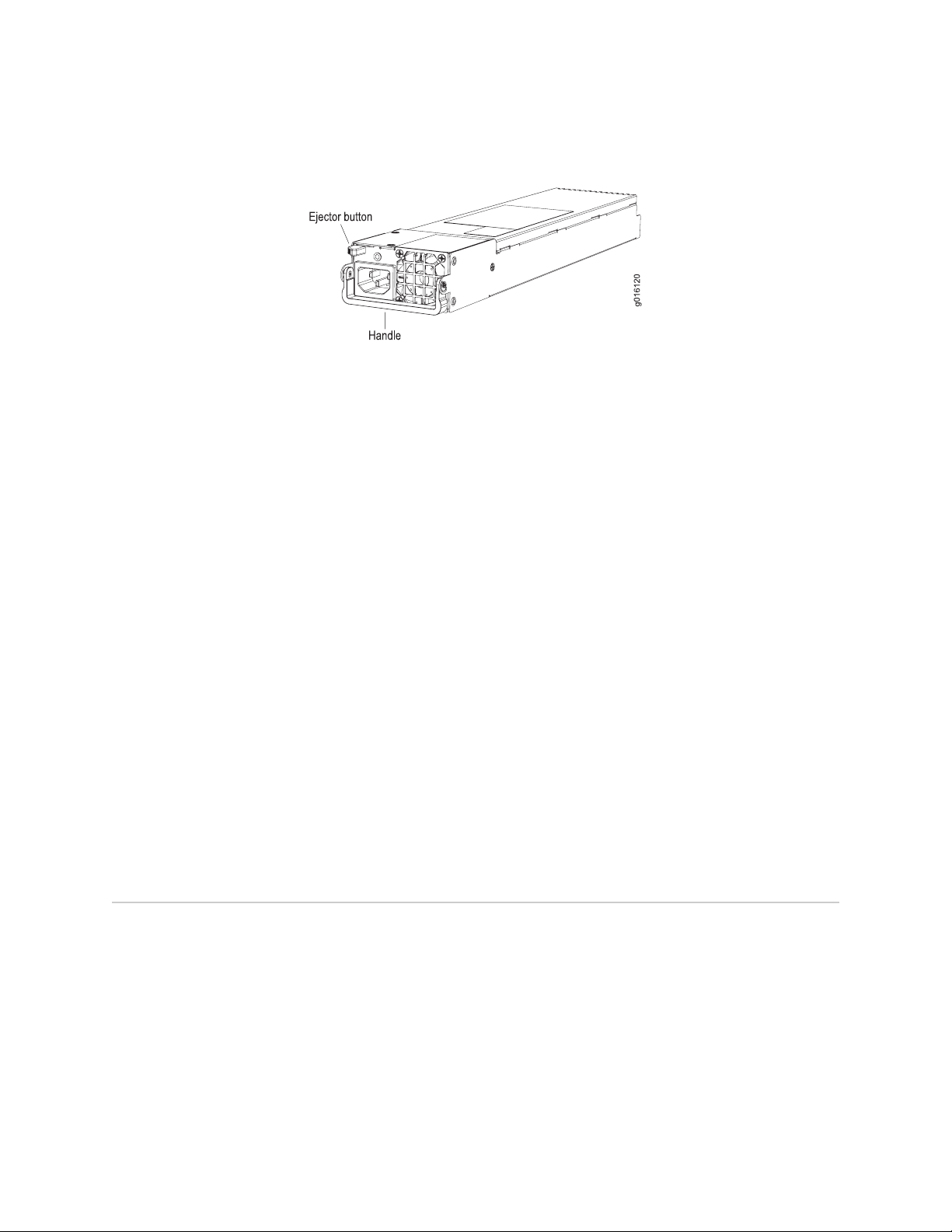

Figure 5: C2000 Power Supply

C-series Model Components ■ 5

Page 20

C2000 and C4000 1.0.x Hardware Guide

Figure 6: C4000 Power Supply

■ Console management port—Each model has one RS-232 port that accepts a

DB-9 (female) connector for direct CLI access from a console terminal.

■ USB port—Each model has two ports that can be used for memory storage

devices.

■ Ethernet interfaces—Each model has two 10/100/1000Base-T Ethernet ports

(ETH0 and ETH1) that accept an RJ-45 (male) connector, providing an out-of-band

connection for LAN access through a Telnet session, SSH, or SNMP. ETH0 provides

access from a network that is behind a firewall. ETH1 provides access for

applications on an external network, such as the Internet.

■ Generic interfaces—Each model has two generic ports (ETH2 and ETH3) that

enable you to use standard connectors, such as small form-factor pluggable

transceivers (SFPs), to create fiber-optic or Gigabit Ethernet connections and

provide additional LAN connectivity.

■ Status LEDs—Each model has LEDs that provide information about hard drive,

power supply, and interface status.

■ USB storage device—Contains the latest system software, including the operating

system for the C-series platform. The device is read-only and should be used to

recover from a major software failure. See the SRC Release Notes for more

information about recovering from a software failure.

■ Rack-mount and rail kit.

Network Management Tools

You can use different management tools to configure the system to meet the specific

networking requirements.

CLI Management

The command-line interface (CLI) provides fully developed and automated

configuration and status functionality through a local RS-232 port, Telnet, or SSH

over any reachable network. For a full discussion of the CLI, see the SRC–PE CLI User

Guide.

6 ■ Network Management Tools

Page 21

SNMP MIB Management

The system offers a complete SNMP interface for configuration, status, and alarm

reporting. For more information, see SRC–PE Monitoring and Troubleshooting Guide.

Chapter 1: C-series Platform Overview

Network Management Tools ■ 7

Page 22

C2000 and C4000 1.0.x Hardware Guide

8 ■ Network Management Tools

Page 23

Part 2

Initial Installation

■ Unpacking and Inspecting the C-series Platform on page 11

■ Installing and Cabling the C-series Platform on page 13

■ Powering Up the C-series Platform on page 19

■ Setting the Initial Configuration on page 21

Initial Installation ■ 9

Page 24

C2000 and C4000 1.0.x Hardware Guide

10 ■ Initial Installation

Page 25

Chapter 2

Unpacking and Inspecting the C-series Platform

This chapter reviews shipping contents and unpacking procedures for the C-series

platform. It contains the following topics:

■ Before You Begin on page 11

■ Unpacking the Units on page 12

■ Inspecting System Components and Accessories on page 12

■ If You Detect or Suspect Damage on page 12

■ Contacting Juniper Networks on page 12

■ The Next Step on page 12

Before You Begin

Before you begin unpacking the item, be sure you have the following tools:

■ A No. 2 Phillips screwdriver

■ A utility knife

■ A mechanical lift, or at least one person to assist in lifting

Before You Begin ■ 11

Page 26

C2000 and C4000 1.0.x Hardware Guide

Unpacking the Units

The systems are delivered boxed. For your convenience, we recommend that you

unpack the system in the location where you want to install it.

WARNING: Three people are required to install the system in a rack: two to lift it

into position and one to screw it to the rack.

Inspecting System Components and Accessories

After you remove the equipment from the shipping containers:

■ Confirm the contents of each container.

■ Inspect all external surfaces and external connectors for visible signs of damage.

■ Inspect all accessories shipped with each unit.

■ Document any damage noted during your inspection.

■ Confirm that the system has the correct number and type of components for

your ordered configuration.

If You Detect or Suspect Damage

If you detect or suspect damage to any equipment:

■ Contact the shipper responsible for delivery, and formally report the damage.

■ Contact your Juniper Networks sales representative or reseller.

Contacting Juniper Networks

Please contact Juniper Networks at 1-888-314-JTAC (from the United States, Canada,

or Mexico) or 1-408-745-9500 (from elsewhere), or contact your sales representative

if you have any questions or concerns. See “Contacting Customer Support and Returning

Hardware” on page 53 for complete contact information.

The Next Step

12 ■ Unpacking the Units

■ To familiarize yourself with the electrical, environmental, and other guidelines

and requirements for installing the system, see Installation Guidelines and

Requirements on page 43.

■ If you are familiar with these guidelines and requirements, see Installing and

Cabling the C-series Platform on page 13.

Page 27

Chapter 3

Installing and Cabling the C-series Platform

This chapter describes how to install the C-series platform and attach cables. It

contains the following topics:

■ Before You Begin on page 13

■ Freestanding Installation on page 13

■ Rack-Mounted Installation on page 14

■ Cabling the System on page 15

■ The Next Step on page 18

Before You Begin

Before installing the system, be sure you:

■ Have a plan for installing the system that takes into consideration future

expansion.

■ Have the tools and accessories needed to complete the installation.

■ Read and understand the clearance requirements for the front and back of the

chassis for cable routing and other unit access. See Environmental

Requirements on page 44 for more information.

■ Read and understand the clearance requirements for the top and bottom of the

chassis to ensure adequate ventilation.

■ Prepare the equipment racks by measuring and marking space for each system

you plan to install.

Freestanding Installation

When installing the system on a table top or in any other freestanding mode, be sure

to leave enough space around the system for adequate ventilation. Position the

Before You Begin ■ 13

Page 28

C2000 and C4000 1.0.x Hardware Guide

system with easy access to the connections that it needs for power, local

communications, and remote communications.

WARNING: Two people are required to lift the system.

CAUTION: To prevent electrostatic damage to the system and its components, make

sure persons handling the system wear an antistatic device.

Rack-Mounted Installation

We recommend that you use a standard EIA distribution rack. See “Equipment Rack

Requirements” on page 46 for rack information.

Installation Guidelines

Before installing the systems in a rack, consider the following guidelines:

■ You can install several models in a single 7-ft. (2.1-m) rack. Installing multiple

systems in a single rack enables you to maximize your available space.

■ Install heavier systems on the bottom of the rack. Mount lighter systems higher

in the rack.

Preparing the Equipment Racks

Following your installation plan, use a tape measure and marking pen to measure

and mark space on each equipment rack for each system component. For horizontal

spacing follow Network Equipment Building System (NEBS) requirements.

Installing the System

To complete the installation of the system in a rack, you need:

■ A Phillips screwdriver

■ Eight 10-32 x 3/8 Phillips screws (provided) for each model to be installed

To install the system in the rack:

14 ■ Rack-Mounted Installation

Page 29

Cabling the System

Chapter 3: Installing and Cabling the C-series Platform

1. With one person standing on the left side of the chassis and another standing

on the right side, lift the unit into the rack.

2. Position the system in its designated location in the equipment rack. Make sure

the holes of the mounting brackets align evenly with the holes of the equipment

rack on both sides.

3. Starting at the bottom of the system, have the third person secure the system

in the equipment rack by using the 10-32 x 3/8 Phillips screws.

4. Connect the necessary cables.

Cabling the system requires the following main tasks:

1. Familiarize yourself with the ports, and ensure that you have the cables and

wires needed to complete each cabling procedure.

2. Read and understand all safety warnings. (See “Installation Guidelines and

Requirements” on page 43.)

3. Connect the system to the network and to a management console.

4. Connect the other interfaces to their appropriate network interface.

5. Connect the power cables from the power source to the system's power supply.

NOTE: We recommend that you use shielded cables where appropriate.

See “System Specifications” on page 35 for more information about system

specifications.

Cabling the Management Console

Before powering up the system, you must set up a management console. The console

enables you to communicate with your system during the power-up process and to

manage your system using the command-line interface (CLI).

When connecting a console directly to the system, use a cable appropriate for your

terminal connector. The cable must have a female DB-9 connector to attach to the

RS-232 port on the system.

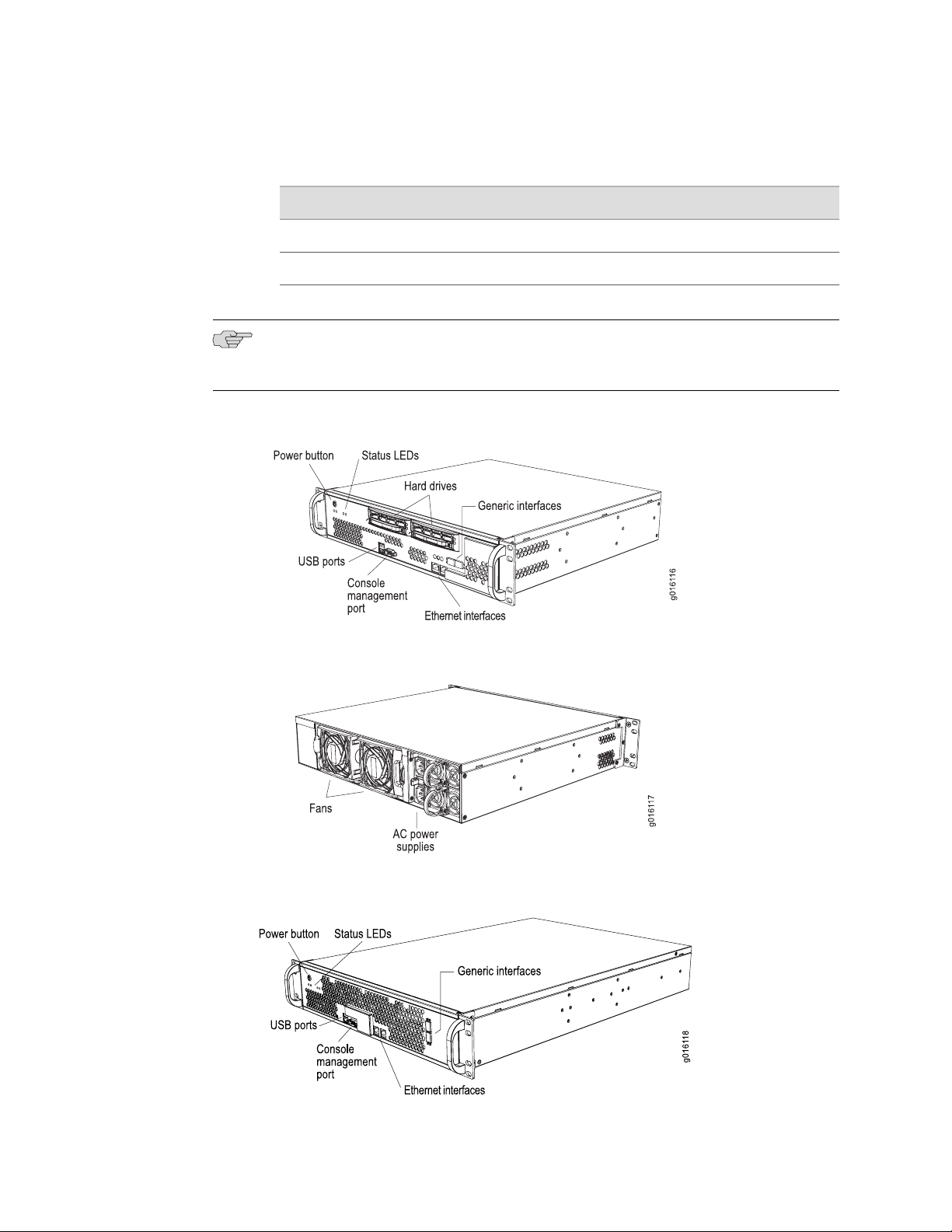

Management Ports

The management section of the system has three ports for management access (see

Figure 7 and Figure 9):

Cabling the System ■ 15

Page 30

C2000 and C4000 1.0.x Hardware Guide

■ Two 10/100Base-T Ethernet ports—Each accepts an RJ-45 (male) connector,

providing an out-of-band connection for LAN access through a Telnet session,

SSH, or SNMP.

■ One RS-232 management port—Accepts a DB-9 (female) connector. This port

provides direct CLI access from a console terminal.

The management port is considered a data terminal equipment (DTE) interface.

Direct connection to a terminal or PC (which also has DTE interfaces) requires a

crossover cable.

See “Setting the Initial Configuration” on page 21 for more information about

management access.

Connecting to the Network

To connect the system to the network:

1. Insert an Ethernet cable (RJ-45) connector into the 10/100Base-T (RJ-45) port on

the system until it clicks into place.

2. Connect the other end of the cable to the appropriate Ethernet network for an

out-of-band connection.

Connecting to a Console Terminal

When you connect a console directly to the system, use a cable appropriate for your

terminal connector. The cable must have a female DB-9 connector to attach to the

RS-232 port on the system.

To connect the console:

1. Insert the female DB-9 connector into the RS-232 port, and tighten the screws.

2. Connect the other end of the cable to your terminal's serial port (VT100/ANSI).

Cabling Ethernet Interfaces

Port ETH0 and ETH1 on the C2000 model and the C4000 model accept RJ-45

10/100/1000Base-T Ethernet (copper) interfaces. Port ETH2 and port ETH3 on the

C2000 model and the C4000 model accept SFPs.

Cabling the System for Power

After you have correctly cabled the system, you can then attach the power cord. See

Figure 8 and Figure 10. See “System Specifications” on page 35 for the power

requirements for the system.

To cable the system for power:

1. Insert the power cord into the AC power IEC receptacle.

16 ■ Cabling the System

Page 31

Chapter 3: Installing and Cabling the C-series Platform

2. Insert the other end of the power cord into an appropriate AC power source.

NOTE: To provide redundancy, do not terminate Power A and Power B leads at the

same power source.

Figure 7: C2000, Front View

Figure 8: C2000, Rear View

Figure 9: C4000, Front View

Cabling the System ■ 17

Page 32

C2000 and C4000 1.0.x Hardware Guide

Figure 10: C4000, Rear View

The Next Step

After you finish installing and cabling the system:

■ See Powering Up the C-series Platform on page 19.

18 ■ The Next Step

Page 33

Chapter 4

Powering Up the C-series Platform

This chapter describes how to power up the C-series platform. It contains the following

topics:

■ Powering Up on page 19

■ Status LEDs on page 20

■ The Next Step on page 20

Powering Up

NOTE: In this procedure we assume that the system is already connected to a power

source.

For specifications of the electrical requirements for the system, see “System

Specifications” on page 35.

CAUTION: Evaluate the overall loading of the branch circuit before you install any

equipment into a rack.

To power up the system:

1. Verify that the power source is operational and turned on.

2. Inspect all grounding and power connections to the system.

3. Confirm that all connections are secure.

4. Push the PWR button.

5. Monitor the LEDs to verify that the system is booting properly.

When the prompt appears on the system console, you can log in and configure

the system.

See the “Setting the Initial Configuration” on page 21 and SRC–PE CLI User Guide for

more information.

Powering Up ■ 19

Page 34

C2000 and C4000 1.0.x Hardware Guide

Status LEDs

The LEDs listed in Table 5 on page 20 are used on both models.

Table 5: Model LEDs

ON to OFFOFF to ONLED ColorLED IndicatorLED Label

Power offPower onGreenPowerPWR

The Next Step

Hard driveHD

RedTemperatureTEMP

PS FAIL

failure

GreenEthernetTX/RX

See “Setting the Initial Configuration” on page 21.

Hard drive is

functioning

error exists; fan

failure

Ethernet link upGreenEthernetLINK

Blinks when

Ethernet traffic

on link

Hard drive

failure detected

Fan okayTemperature

Fan okayFailure detectedRedPower supply

Ethernet link

down

No Ethernet

traffic on link

20 ■ Status LEDs

Page 35

Chapter 5

Setting the Initial Configuration

This chapter discusses how to set up the C-series platform after powering it on. For

basic information on the management of the system, see the SRC–PE Getting Started

Guide.

This chapter contains the following topics:

■ Configuration Overview on page 21

■ Setting Up Management Access and Logging In on page 21

■ Configuring the Juniper Networks Database on page 22

■ Configuring Hostname and Domain Parameters on page 23

■ Configuring the System for Remote Access on page 24

■ Configuring the System to Accept SSH and Telnet Connections on page 25

■ Adding an Admin User Account on page 26

■ The Next Step on page 27

Configuration Overview

After powering on the system, there are six main steps required to get it ready to

work with:

1. Connect a management console to the system, configure it, and log in.

2. Configure the Juniper Networks Database.

3. Configure hostname and domain information.

4. Configure the system for remote access.

5. Configure the system to accept SSH and Telnet connections.

6. Add an Admin user account.

Setting Up Management Access and Logging In

Before you power up the system, you must set up a management console. (See

“Connecting to a Console Terminal” on page 16.)

Configuration Overview ■ 21

Page 36

C2000 and C4000 1.0.x Hardware Guide

You can monitor and manage the system through either of these methods:

■ Console terminal—Connect a console (PC, Macintosh, or UNIX workstation)

directly to the system's RS-232 serial port.

■ Remote console—Connect 10/100Base-T port (ETH0) to an Ethernet network,

and run SSH or Telnet from a remote console.

For initial access to the system, you need to physically connect your console directly

to the system's RS-232 port. Through this connection you use the SRC command-line

interface (CLI) to set the hostname and domain information. You can then access

the system remotely (for example, by means of SSH).

To communicate with the system, you must have a terminal emulation program

running on your PC or Macintosh. You can use any terminal emulation program,

such as HyperTerminal. A UNIX workstation can use the emulator TIP.

To log in to the system:

1. Start your terminal emulation program using the following settings:

■ Bits per second: 9600

■ Data bits: 8

■ Parity: None

■ Stop bits: 1

■ Flow control: none

2. Enter the username.

SRC-PE Release 7.0 [B.7.0.0-12]

localhost login:root

3. Enter the password.

localhost password:password

--- SRC CLI 7.0 build CLI.B.7.0.0.012

(c) 2005-2007 Juniper Networks Inc.

root@localhost>

You are now logged in as root user.

Configuring the Juniper Networks Database

Each C-series platform contains a Juniper Networks database. The database stores

SRC data, sample data, configuration information, and user profiles. You must enable

the Juniper Networks database the first time you power on the system. It can operate

as a standalone database or as a member of a community of Juniper Networks

databases.

22 ■ Configuring the Juniper Networks Database

Page 37

Chapter 5: Setting the Initial Configuration

NOTE: The Juniper Networks database must be running before you start configuring

the SRC software.

Typically, you run the database in standalone mode only in testing environments.

In standalone mode, the database does not communicate with other Juniper Networks

databases; there is no data distribution and no redundancy. In community mode,

databases distribute data changes among specified databases. When you have two

or more C-series platforms, enable the Juniper Networks database to run in community

mode, and assign a role to each database:

■ Primary role—A database that provides read and write access to client

applications. It replicates its data and distributes changes to any Juniper Networks

databases configured as neighbors.

■ Secondary role—A database that provides read access to client applications. If

client applications try to write data to this database, the database refers the client

to a primary database.

In the following example, a standalone database is enabled. For more information

about community mode, see SRC–PE Getting Starting Guide, Chapter 10, Managing

the Juniper Networks Database.

To enable a Juniper Networks database to run in standalone mode:

1. From configuration mode, access the configuration statement that configures

the Juniper Networks database.

user@host# edit system ldap server

2. Enable standalone mode.

[edit system ldap server]

user@host# set stand-alone

Configuring Hostname and Domain Parameters

To set hostname and domain parameters:

1. Enter configuration mode.

root@host> edit

2. Configure the hostname.

[edit]

root@host# set system host-name host-name

For example:

[edit]

root@host# set system host-name my-hostname

Configuring Hostname and Domain Parameters ■ 23

Page 38

C2000 and C4000 1.0.x Hardware Guide

3. Configure either a list of domain names to search, or create the domain name.

We recommend configuring a list of domain names to search.

To configure a list of domain names to search:

[edit]

root@host# set system domain-search [domain-name1, domain-name2, ...]

For example:

[edit]

root@host# set system domain-search [my-domain.juniper.net

domain.juniper2.net]

To configure the domain name:

[edit]

root@host# set system domain-name domain-name

For example:

[edit]

root@host# set system domain-name my-domain.juniper.net

Configuring the System for Remote Access

To allow remote access to the system, you must configure the generic interfaces.

You can specify an IP address with mask or a broadcast address with mask for an

interface. For more information, see SRC–PE Getting Starting Guide, Chapter 7,

Configuring Remote Access to an SRC Platform.

To configure the generic interfaces:

1. From configuration mode, access the configuration statement that configures

the interface.

user@host# edit interfaces eth0

2. Specify the unit, family, and IP address for the interface.

[edit interfaces eth0]

user@host# set unit number family inet address address

For example, to configure an interface with only an IP address:

[edit interfaces eth0]

user@host# set unit 0 family inet address 192.2.0.10/24

3. (Optional) Specify the broadcast address for the interface.

[edit interfaces eth0]

user@host# set unit number family inet broadcast broadcast

For example, to configure an interface with only a broadcast address:

24 ■ Configuring the System for Remote Access

Page 39

Chapter 5: Setting the Initial Configuration

[edit interfaces eth0]

user@host# set unit 0 family inet broadcast 192.2.0.255

4. Verify the interface configuration.

[edit interfaces eth0]

user@host# show

unit 0 {

family {

inet {

broadcast 192.2.0.255;

}

}

}

Configuring the System to Accept SSH and Telnet Connections

You can enable SSH and Telnet to let users who have the appropriate privileges

connect to the system. For security reasons, we recommend that you do not allow

remote users to access the CLI as root. The system does not allow root access over

a Telnet connection. For more information, see SRC–PE Getting Starting Guide, Chapter

7, Configuring Remote Access to a C–series Platform.

To configure the system to accept SSH connections:

1.

From configuration mode, access the [edit system services ssh] hierarchy level.

2. (Optional) Specify whether or not to allow root login through SSH.

[edit system services ssh]

user@host> set root-login (allow | deny | deny-password)

where:

■

allow— Allow users to log in to the C-series platform as root through SSH.

■

deny— Disable users from logging in to the system as root through SSH.

■

deny-password— Allow users to log in to the system as root through SSH

when the authentication method (for example, RSA authentication) does not

require a password. (Default)

Configuring the System to Accept SSH and Telnet Connections ■ 25

Page 40

C2000 and C4000 1.0.x Hardware Guide

To configure the system to accept Telnet connections:

■ In edit mode, type the following command.

[edit]

user@host# set system services telnet

Adding an Admin User Account

Although root access is used for initial configuration of the system, user accounts are

used to enter commands and statements at the CLI. Therefore, you must set up an

admin account to allow further configuration. You can use a built-in class, such as

super-user.

To configure an account for an administrative user:

1. Create an account for an administrative user.

[edit]

user@host # edit system login user user

For example:

[edit]

user@host # edit system login user myadmin

2. Set the class for the administrative user to the login class that you created.

[edit system login user myadmin]

user@host # set class class

For example:

[edit system login user myadmin]

user@host # set class super-user

3. Specify the name of the administrative user.

[edit system login user myadmin]

user@host # set full-name “John Doe”

4. Set the CLI editing level to expert.

[edit system login user myadmin]

user@host# set level expert

5. (Optional) Specify that a space be used for command completion.

[edit system login user myadmin]

user@host # set complete-on-space on

6. Verify that the configuration for the administrative user is correct.

[edit system login user myadmin]

26 ■ Adding an Admin User Account

Page 41

The Next Step

Chapter 5: Setting the Initial Configuration

user@host# show

class super-user;

full-name "John Doe";

uid 506;

gid 100;

level expert;

complete-on-space on;

7. Set the password of the user.

[edit]

user@host# edit system login user myadmin authentication

[edit system login user myadmin authentication]

user@host# set plain-text-password

See “Maintaining the System” on page 31.

The Next Step ■ 27

Page 42

C2000 and C4000 1.0.x Hardware Guide

28 ■ The Next Step

Page 43

Part 3

Hardware Maintenance Procedures and Specifications

■ Maintaining the System on page 31

■ System Specifications on page 35

■ Managing RAID Disks on a C-series Platform on page 39

■ Installation Guidelines and Requirements on page 43

■ Contacting Customer Support and Returning Hardware on page 53

■ Declaration of Conformity on page 57

Hardware Maintenance Procedures and Specifications ■ 29

Page 44

C2000 and C4000 1.0.x Hardware Guide

30 ■ Hardware Maintenance Procedures and Specifications

Page 45

Chapter 6

Maintaining the System

This chapter lists the tools, items, and steps needed for installing and uninstalling

components. Other maintenance procedures must be performed by an authorized

Juniper Networks technician.

This chapter contains the following sections:

■ Required Tools and Items on page 31

■ Storing Modules and Components on page 32

■ Cleaning the System on page 32

■ Removing and Installing a Fan on page 32

■ Removing and Installing a Power Supply Module on page 33

■ Removing and Installing a Hard Drive on page 34

Required Tools and Items

You need the following tools and other items to replace components:

■ Flathead and Phillips screwdrivers

■ Insulated adjustable wrench

■ Antistatic wrist strap

■ Antistatic bags (or other protective packaging to hold components)

■ Plastic boots or other protective covers for fiber-optic connectors

Required Tools and Items ■ 31

Page 46

C2000 and C4000 1.0.x Hardware Guide

Storing Modules and Components

Retain the packaging in which a component was shipped, and use this packaging to

store the item.

CAUTION: Failure to store electronic components correctly can lead to damage of

these items.

Follow these guidelines for storing components:

■ Store each component in a separate antistatic bag.

■ Store components in an antistatic plastic container. Some of these containers

can accommodate several components in separate compartments.

■ Do not store multiple components in an antistatic bag or container where they

■ (Optional) Store the item in its antistatic bag or container within the protective

Cleaning the System

Clean the system with a dry cloth every few weeks to prevent excessive dust

accumulation. This cleaning helps to maintain the efficiency of the cooling system

and to prevent damage to electronic components.

WARNING: Do not insert any metal object, such as a screwdriver, or place your hand

into an open slot when the system is on. Remove jewelry (including rings, necklaces,

and watches) before working on equipment that is connected to power lines. These

actions prevent electric shock and serious burns.

CAUTION: When cleaning the system, wear an antistatic device. This action helps

to protect components from damage by electrostatic discharge.

can touch other items.

packaging or padded box that the item was shipped in.

Removing and Installing a Fan

Both C-series models have two cooling fans that provide forced air cooling for

components in the system. Each fan is hot-swappable; you can replace it without

powering down the system. You can monitor fan status by observing the TEMP LED.

32 ■ Storing Modules and Components

Page 47

Chapter 6: Maintaining the System

NOTE: If the red TEMP LED is illuminated, either a critical or noncritical failure exists.

CAUTION: If the TEMP LED is illuminated and none of the fans is spinning, quickly

power down the system until a new set of fans is available. Operating a system with

inadequate air circulation can damage the components.

To remove a fan:

1. Unlock or loosen the fan from the system.

■ For the C2000 model, press the locking tab and rotate the fan away from

the system.

■ For the C4000 model, loosen the thumb screw in the top-left and lower-right

of the fan.

2. Pull the fan out and remove it from the system.

Use two hands to hold the fan after it comes out of the chassis.

WARNING: Do not place your fingers near the fans when removing the unit. The

blades might still be moving.

CAUTION: Do not use the fan tray handle to carry the fan. Use the handle only to

push the tray into the chassis or pull it out.

To install a fan, reverse the steps taken to remove the fan.

Removing and Installing a Power Supply Module

NOTE: If your system is powered on, see the SRC–PE CLI User Guide, Chapter 5, Using

CLI Operational Commands to Monitor the SRC Software for commands to run before

performing these steps.

To remove a power supply module:

1. Unplug the power cord.

Removing and Installing a Power Supply Module ■ 33

Page 48

C2000 and C4000 1.0.x Hardware Guide

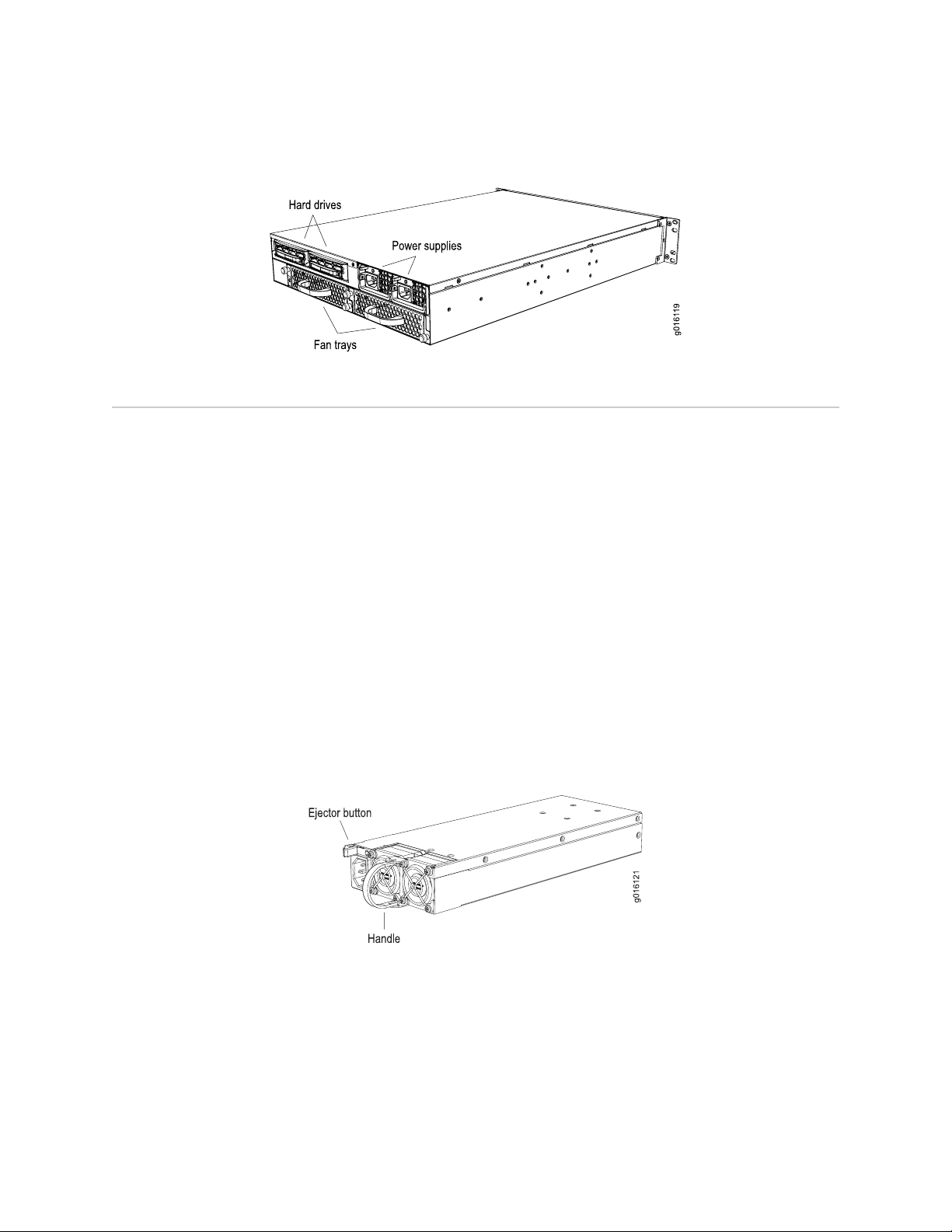

2. Slide the locking tab (ejector button) to the left to release the module. See

Figure 11 and Figure 12.

3. Hold the tab to the left, and using the handle, slowly pull the power supply module

out.

To install a power supply module:

1. Hold the locking tab (ejector button) to the left, and slowly slide the module into

the chassis until it clicks into place.

2. Insert the power cord into the AC power IEC receptacle.

Figure 11: C2000 Power Supply

Figure 12: C4000 Power Supply

Removing and Installing a Hard Drive

NOTE: If your system is powered on, see the SRC–PE Getting Started User Guide for

commands to run before performing these steps.

To remove a hard drive:

1. Slide the locking tab in the bottom-right corner to the right to release the hard

drive.

2. Hold the tab to the right and slowly pull the unit out.

To install a hard drive, hold the locking tab to the right and slowly slide the unit into

the chassis until it clicks into place.

34 ■ Removing and Installing a Hard Drive

Page 49

Chapter 7

System Specifications

This chapter lists the system specifications, requirements, and certifications for the

system. Topics include:

■ C2000 Model Specifications on page 35

■ C4000 Model Specifications on page 36

C2000 Model Specifications

Table 6: C2000 Model Specifications

SpecificationCategory

Weight

Dimensions

Environmental Requirements

Temperature

Relative humidity

Heat Dissipation

AC Input

Space Requirements

33 lb (15 kg)

3.5 (H) x 16.7 (W) x 16.2 (D) inches

8.89 (H) x 42.42 (W) x 41.15 (D) cm

Operating: 50° to 104° F (10° to 40° C)

■

Storage: –40° to 158° F (–40° ˚ to 70° C)

■

Operating: 8% to 90% (noncondensing)

■

Storage: 5% to 95% (noncondensing)

■

500 W, 1706 BTU/hour maximum

100-240 VAC @ –5 APower required

50-60 HzAC line frequency

500 WPower

3 feet (90 cm) behind system or rack.

■

Do not block air vents on front or back of the system.

■

Safety Agency Certification

■

Pending

C2000 Model Specifications ■ 35

Page 50

C2000 and C4000 1.0.x Hardware Guide

Table 6: C2000 Model Specifications (continued)

SpecificationCategory