Page 1

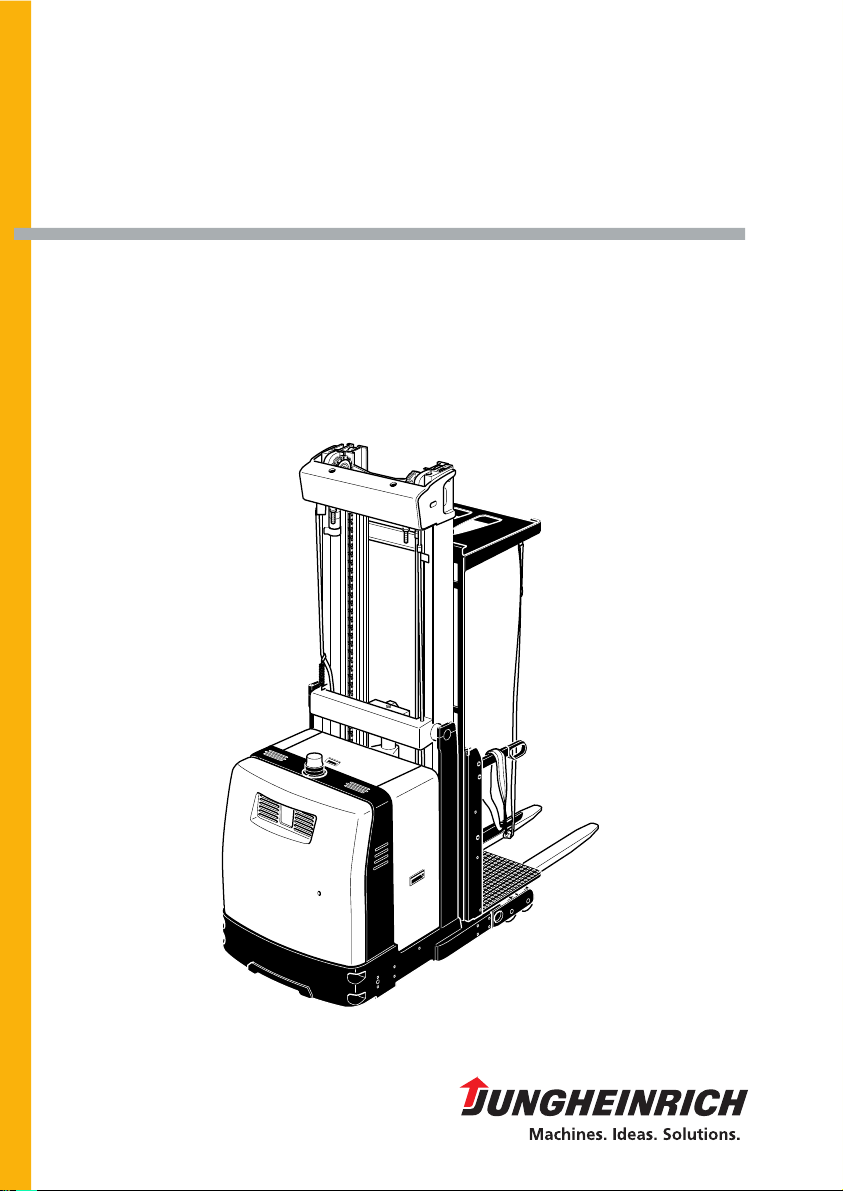

EKS 314

05.05 -

Operating manual

Manual de instrucciones

52032020

07.08

u

E

Page 2

0108.USA

Foreword

Safe operation of the industrial truck requires specialist knowledge, which is acquired

from this Operating Manual, from the training required by OSHA under 29 CFR

1910.178, and by training operators in factory installations and their functions. Safe

operation of the industrial truck requires knowledge that can be acquired from this

ORIGINAL OPERATING MANUAL. The information is set out concisely and in a clear

format. The chapters are organized alphabetically, each starting at page 1. The page

identifier consists of the chapter letter and page number.

For example: Page B2 is the second page of Chapter B.

Various types of industrial trucks are described in this Operating Manual. When

operating the truck and carrying out maintenance work, make certain you use the

description corresponding to your vehicle type.

Safety instructions and important information, and their relative importance, are

indicated by the following safety warning symbols and indicator words:

QwD This message indicates a hazardous situation that, if not avoided, will result

in death or serious injury. The instructions, safety precautions, actions, or

procedures relating to this message must be observed to avoid the risk of

death or serious injury.

QwW This message indicates a hazardous situation that, if not avoided, could

result in death or serious injury. The instructions, safety precautions, actions,

or procedures relating to this message must be observed to avoid the

potential risk of death or serious injury.

QwK This message indicates a situation that may lead to minor or moderate injury

if disregarded. The instructions, safety precautions, actions, or procedures

relating to this message must be observed to avoid the risk of minor or

moderate injury.

IMPORTANT This message appears if special precautionary measures are needed to

ensure that the correct action is taken or to prevent damage to or malfunction

of the industrial truck or a component.

NOTICE This message appears if special information, instructions, or indications are

needed with regard to procedures, equipment, tools, pressures, loads, and

other special data.

t Indicates component fitted as standard.

o Indicates optional extra.

0108.USA

Foreword

Safe operation of the industrial truck requires specialist knowledge, which is acquired

from this Operating Manual, from the training required by OSHA under 29 CFR

1910.178, and by training operators in factory installations and their functions. Safe

operation of the industrial truck requires knowledge that can be acquired from this

ORIGINAL OPERATING MANUAL. The information is set out concisely and in a clear

format. The chapters are organized alphabetically, each starting at page 1. The page

identifier consists of the chapter letter and page number.

For example: Page B2 is the second page of Chapter B.

Various types of industrial trucks are described in this Operating Manual. When

operating the truck and carrying out maintenance work, make certain you use the

description corresponding to your vehicle type.

Safety instructions and important information, and their relative importance, are

indicated by the following safety warning symbols and indicator words:

QwD This message indicates a hazardous situation that, if not avoided, will result

in death or serious injury. The instructions, safety precautions, actions, or

procedures relating to this message must be observed to avoid the risk of

death or serious injury.

QwW This message indicates a hazardous situation that, if not avoided, could

result in death or serious injury. The instructions, safety precautions, actions,

or procedures relating to this message must be observed to avoid the

potential risk of death or serious injury.

QwK This message indicates a situation that may lead to minor or moderate injury

if disregarded. The instructions, safety precautions, actions, or procedures

relating to this message must be observed to avoid the risk of minor or

moderate injury.

IMPORTANT This message appears if special precautionary measures are needed to

ensure that the correct action is taken or to prevent damage to or malfunction

of the industrial truck or a component.

NOTICE This message appears if special information, instructions, or indications are

needed with regard to procedures, equipment, tools, pressures, loads, and

other special data.

t Indicates component fitted as standard.

o Indicates optional extra.

Page 3

0108.USA

It is impossible for the manufacturer to foresee every possible operational

circumstance that could involve a potential danger. For that reason, the warnings in

this manual and on the equipment itself do not encompass all possible

circumstances. If you use a tool, procedure, working method, or operating technique

not expressly recommended by the manufacturer, you must make sure yourself that

it does not present a safety risk to you or to anyone else. You must also ensure that

the product will not be damaged or made unsafe through operation, lubrication,

maintenance, or the chosen repair measures.

The information, technical data, and illustrations contained in this document are

based on the information available at the time of publication. Specifications, torques,

pressures, measurements, settings, illustrations, and all other data are subject to

change at any time. These changes relate to the performance of the product. Before

executing a task, you should request the most up-to-date and comprehensive

information from the manufacturer / dealer. You can also obtain additional copies of

the manual from your dealer.

In the interests of technical advancement, the manufacturer reserves the right to

make changes, while retaining the essential features of the type of vehicle described,

without correcting this Operating Manual at the same time.

Copyright

Copyright of this operating manual remains with JUNGHEINRICH AG.

Jungheinrich Aktiengesellschaft

Am Stadtrand 35

22047 Hamburg - GERMANY

Phone: +49 (0) 40/6948-0

www.jungheinrich.com

0108.USA

It is impossible for the manufacturer to foresee every possible operational

circumstance that could involve a potential danger. For that reason, the warnings in

this manual and on the equipment itself do not encompass all possible

circumstances. If you use a tool, procedure, working method, or operating technique

not expressly recommended by the manufacturer, you must make sure yourself that

it does not present a safety risk to you or to anyone else. You must also ensure that

the product will not be damaged or made unsafe through operation, lubrication,

maintenance, or the chosen repair measures.

The information, technical data, and illustrations contained in this document are

based on the information available at the time of publication. Specifications, torques,

pressures, measurements, settings, illustrations, and all other data are subject to

change at any time. These changes relate to the performance of the product. Before

executing a task, you should request the most up-to-date and comprehensive

information from the manufacturer / dealer. You can also obtain additional copies of

the manual from your dealer.

In the interests of technical advancement, the manufacturer reserves the right to

make changes, while retaining the essential features of the type of vehicle described,

without correcting this Operating Manual at the same time.

Copyright

Copyright of this operating manual remains with JUNGHEINRICH AG.

Jungheinrich Aktiengesellschaft

Am Stadtrand 35

22047 Hamburg - GERMANY

Phone: +49 (0) 40/6948-0

www.jungheinrich.com

Page 4

I 1

0708.USA

Table of Contents

A Following the rules- common sense and the law

B Recognize and avoid the hazards

C Correct use and application of the truck

D Truck Description

1 Application ........................................................................................... D 1

2 Assemblies and Functional Description ..............................................D 3

2.1 Truck ................................................................................................... D 4

3 Standard Version Specifications ......................................................... D 5

3.1 Performance data ................................................................................ D 5

3.2 Dimensions (as per data plate) ........................................................... D 7

3.3 Mast version ........................................................................................ D 8

3.4 US Standards ...................................................................................... D 8

3.5 Conditions for application .................................................................... D 9

4 Identification points, warning labels and data plates ........................... D 10

4.1 Truck data plate .................................................................................. D 12

4.2 Capacity .............................................................................................. D 12

I 1

0708.USA

Table of Contents

A Following the rules- common sense and the law

B Recognize and avoid the hazards

C Correct use and application of the truck

D Truck Description

1 Application ........................................................................................... D 1

2 Assemblies and Functional Description ..............................................D 3

2.1 Truck ................................................................................................... D 4

3 Standard Version Specifications ......................................................... D 5

3.1 Performance data ................................................................................ D 5

3.2 Dimensions (as per data plate) ........................................................... D 7

3.3 Mast version ........................................................................................ D 8

3.4 US Standards ...................................................................................... D 8

3.5 Conditions for application .................................................................... D 9

4 Identification points, warning labels and data plates ........................... D 10

4.1 Truck data plate .................................................................................. D 12

4.2 Capacity .............................................................................................. D 12

Page 5

0708.USA

I 2

E Operation

1 Controls and Displays ......................................................................... E 1

1.1 Operating and display equipment on control panel ............................. E 1

1.2 Display unit controls and displays ....................................................... E 2

1.3 Truck operational status symbols ........................................................ E 6

2 Starting up the truck ............................................................................ E 7

2.1 Attaching the safety restraint belt ........................................................ E 8

2.2 t To prepare the truck for operation .................................................. E 9

2.3 o Preparing the truck for operation with an additional access code ... E 10

2.4 Setting the time ................................................................................... E 11

2.5 Operator specific settings .................................................................... E 12

3 Travelling, Steering, Braking ............................................................... E 13

3.1 Travelling ............................................................................................. E 13

3.2 Steering ............................................................................................... E 14

3.3 Braking ................................................................................................ E 14

3.4 Negotiating narrow aisles .................................................................... E 15

3.5 Lifting – Lowering – outside and inside the rack lanes ........................ E 19

3.6 Diagonal travel .................................................................................... E 19

3.7 Order picking and stacking .................................................................. E 20

3.8 Park the truck securely ........................................................................ E 22

4 Important general issues affecting safe operation

and use of the industrial truck ............................................................. E 23

4.1 Training, certification and permission to operate the truck .................. E 23

4.2 Truck damage and repair .................................................................... E 25

4.3 Load Issues ......................................................................................... E 26

4.4 Work environment ............................................................................... E 27

4.5 Safety devices and warning labels ...................................................... E 29

4.6 Lifting of persons ................................................................................. E 30

4.7 Emergency stop device ....................................................................... E 32

4.8 Driver's cab emergency lowering ........................................................ E 32

5 Operation of the truck .......................................................................... E 33

5.1 Safety regulations for the truck operator ............................................. E 33

5.2 General operation of the truck ............................................................. E 33

5.3 Make sure your truck is properly equipped ......................................... E 36

5.4 Load and transport safety ................................................................... E 37

5.5 Avoid overturn and tipover .................................................................. E 38

5.6 Attend and secure your truck .............................................................. E 39

5.7 Lifting of persons ................................................................................. E 39

5.8 Slack chain safety device override ...................................................... E 41

5.9 Travel cutout override (o) ................................................................... E 41

5.10 Lift limit override (o) ......................................................................... E 41

5.11 Aisle end safety device (o) ................................................................. E 42

5.12 Wire Guidance emergency operation (Error 144) ............................... E 43

5.13 Recovering the truck from a narrow aisle / Moving the truck

without a battery .................................................................................. E 44

0708.USA

I 2

E Operation

1 Controls and Displays ......................................................................... E 1

1.1 Operating and display equipment on control panel ............................. E 1

1.2 Display unit controls and displays ....................................................... E 2

1.3 Truck operational status symbols ........................................................ E 6

2 Starting up the truck ............................................................................ E 7

2.1 Attaching the safety restraint belt ........................................................ E 8

2.2 t To prepare the truck for operation .................................................. E 9

2.3 o Preparing the truck for operation with an additional access code ... E 10

2.4 Setting the time ................................................................................... E 11

2.5 Operator specific settings .................................................................... E 12

3 Travelling, Steering, Braking ............................................................... E 13

3.1 Travelling ............................................................................................. E 13

3.2 Steering ............................................................................................... E 14

3.3 Braking ................................................................................................ E 14

3.4 Negotiating narrow aisles .................................................................... E 15

3.5 Lifting – Lowering – outside and inside the rack lanes ........................ E 19

3.6 Diagonal travel .................................................................................... E 19

3.7 Order picking and stacking .................................................................. E 20

3.8 Park the truck securely ........................................................................ E 22

4 Important general issues affecting safe operation

and use of the industrial truck ............................................................. E 23

4.1 Training, certification and permission to operate the truck .................. E 23

4.2 Truck damage and repair .................................................................... E 25

4.3 Load Issues ......................................................................................... E 26

4.4 Work environment ............................................................................... E 27

4.5 Safety devices and warning labels ...................................................... E 29

4.6 Lifting of persons ................................................................................. E 30

4.7 Emergency stop device ....................................................................... E 32

4.8 Driver's cab emergency lowering ........................................................ E 32

5 Operation of the truck .......................................................................... E 33

5.1 Safety regulations for the truck operator ............................................. E 33

5.2 General operation of the truck ............................................................. E 33

5.3 Make sure your truck is properly equipped ......................................... E 36

5.4 Load and transport safety ................................................................... E 37

5.5 Avoid overturn and tipover .................................................................. E 38

5.6 Attend and secure your truck .............................................................. E 39

5.7 Lifting of persons ................................................................................. E 39

5.8 Slack chain safety device override ...................................................... E 41

5.9 Travel cutout override (o) ................................................................... E 41

5.10 Lift limit override (o) ......................................................................... E 41

5.11 Aisle end safety device (o) ................................................................. E 42

5.12 Wire Guidance emergency operation (Error 144) ............................... E 43

5.13 Recovering the truck from a narrow aisle / Moving the truck

without a battery .................................................................................. E 44

Page 6

I 3

0708.USA

F Battery - Servicing, recharging, replacement

1 Safety regulations governing the handling of lead-acid batteries ........ F 1

2 Battery type ......................................................................................... F 2

3 Charge the battery .............................................................................. F 3

4 Battery removal and installation .......................................................... F 4

5 Check the battery condition, the acid level and acid density ............... F 6

6 Battery discharge indicator .................................................................. F 6

G Truck Maintenance + Troubleshooting

1 Operational safety and environmental protection ................................ G 1

2 Safety regulations applicable to truck maintenance ............................ G 1

3 Servicing and inspection ..................................................................... G 6

4 EKS 314 maintenance checklist .......................................................... G 7

5 Lubrication schedule ........................................................................... G 10

5.1 Fuels, coolants and lubricants ............................................................. G 11

6 Maintenance and Repairs ................................................................... G 12

6.1 Preparing the truck for maintenance and repairs ................................ G 12

6.2 Securing the driver’s position carriage and mast ................................ G 13

6.3 Lift Chain Servicing ............................................................................. G 13

6.4 Inspecting the lift chains ...................................................................... G 13

6.5 Hydraulic oil ......................................................................................... G 14

6.6 Hydraulic hoses ................................................................................... G 14

6.7 Checking electrical fuses .................................................................... G 15

6.8 Recommissioning the truck after cleaning or maintenance work ........ G 16

7 Decommissioning the industrial truck .................................................. G 16

7.1 Operations to be performed prior to decommissioning ....................... G 16

7.2 Measures to be taken during decommissioning .................................. G 17

7.3 Recommissioning the truck after decommissioning ............................ G 17

8 Safety inspections at regular intervals and after exceptional events .. G 18

9 Final de-commissioning, disposal ....................................................... G 18

10 Troubleshooting .................................................................................. G 19

I 3

0708.USA

F Battery - Servicing, recharging, replacement

1 Safety regulations governing the handling of lead-acid batteries ........ F 1

2 Battery type ......................................................................................... F 2

3 Charge the battery .............................................................................. F 3

4 Battery removal and installation .......................................................... F 4

5 Check the battery condition, the acid level and acid density ............... F 6

6 Battery discharge indicator .................................................................. F 6

G Truck Maintenance + Troubleshooting

1 Operational safety and environmental protection ................................ G 1

2 Safety regulations applicable to truck maintenance ............................ G 1

3 Servicing and inspection ..................................................................... G 6

4 EKS 314 maintenance checklist .......................................................... G 7

5 Lubrication schedule ........................................................................... G 10

5.1 Fuels, coolants and lubricants ............................................................. G 11

6 Maintenance and Repairs ................................................................... G 12

6.1 Preparing the truck for maintenance and repairs ................................ G 12

6.2 Securing the driver’s position carriage and mast ................................ G 13

6.3 Lift Chain Servicing ............................................................................. G 13

6.4 Inspecting the lift chains ...................................................................... G 13

6.5 Hydraulic oil ......................................................................................... G 14

6.6 Hydraulic hoses ................................................................................... G 14

6.7 Checking electrical fuses .................................................................... G 15

6.8 Recommissioning the truck after cleaning or maintenance work ........ G 16

7 Decommissioning the industrial truck .................................................. G 16

7.1 Operations to be performed prior to decommissioning ....................... G 16

7.2 Measures to be taken during decommissioning .................................. G 17

7.3 Recommissioning the truck after decommissioning ............................ G 17

8 Safety inspections at regular intervals and after exceptional events .. G 18

9 Final de-commissioning, disposal ....................................................... G 18

10 Troubleshooting .................................................................................. G 19

Page 7

0708.USA

I 4

H Transport and Commissioning

1 Transport ............................................................................................. H 1

2 Lifting by crane .................................................................................... H 1

2.1 Crane points ........................................................................................H 3

2.2 Lifting the battery by crane .................................................................. H 3

2.3 Securing the truck during transport ..................................................... H 3

2.4 Basic truck transport safety ................................................................. H 4

2.5 Mast transport safety ........................................................................... H 5

2.6 Mast assembled .................................................................................. H 5

3 Commissioning .................................................................................... H 7

3.1 Moving the truck without a battery ...................................................... H 7

3.2 Installing/removing or erecting/folding the mast .................................. H 7

4 Commissioning .................................................................................... H 7

0708.USA

I 4

H Transport and Commissioning

1 Transport ............................................................................................. H 1

2 Lifting by crane .................................................................................... H 1

2.1 Crane points ........................................................................................H 3

2.2 Lifting the battery by crane .................................................................. H 3

2.3 Securing the truck during transport ..................................................... H 3

2.4 Basic truck transport safety ................................................................. H 4

2.5 Mast transport safety ........................................................................... H 5

2.6 Mast assembled .................................................................................. H 5

3 Commissioning .................................................................................... H 7

3.1 Moving the truck without a battery ...................................................... H 7

3.2 Installing/removing or erecting/folding the mast .................................. H 7

4 Commissioning .................................................................................... H 7

Page 8

A 1

0505.USA

A Following the rules- common sense and

the law

In 1998, OSHA reported on its thorough study of industrial truck use. This report may

be found at Federal Register/ Vol. 63, No. 230. In its report, OSHA explained its

many reasons for carefully defining the duties of employers to train their employees

in the use of industrial trucks, and the duty of untrained persons not to operate industrial trucks except in controlled, training circumstances. The report addresses how

critically important the training required by the OSHA regulations is for the safety of

people and things wherever industrial trucks are operated. 29 CFR sec. 1910.178. In

simple terms, careful training before operation of an industrial truck is critical and

must occur before truck operation because accidents resulting in injury, death or

property damage almost always result from disregard of the basic risks inherent in

truck use or disregard of safety rules and procedures created to reduce or eliminate

those risks. The training required by OSHA is designed to address those risks. The

evidence provided by OSHA in its report reveals that the law’s operator training requirements for employers and operators are grounded in experience and goog judgment.

Jungheinrich has provided an industrial truck which complies with 29 CFR 1910.178,

and ASME B56.1. Jungheinrich representatives are available to assist and answer

any questions which may arise concerning the capacities, operation, use and maintenance of the truck.

According to OSHA, people do not start out with the knowledge and skills they need

to safely operate a powered industrial truck, and therefore, they need formal training

and practice to gain the knowledge and to master the skills they need to safely operate an industrial truck. Consequently, having an industrial truck which complies with

the law and standards fulfills only one half of the safety equation. It is, therefore, up

to you, the operator, and your employer, to fulfill your responsibilities by obeying all

national, state and local laws and regulations concerning training and the safe operation of industrial trucks - not just because it is the law, but because it also makes

common safety sense.

Only trained and certified persons may operate an industrial truck.

Training programs must comply with OSHA requirements and address, at least,

all of the topics listed there.

The user portion of ASME B56.1 is recommended to employers and operators

for careful review and observance.

“Safe operation is the responsibility of the operator“ ASME B56.1-2003, Part II

sec. 5.1.1.

A 1

0505.USA

A Following the rules- common sense and

the law

In 1998, OSHA reported on its thorough study of industrial truck use. This report may

be found at Federal Register/ Vol. 63, No. 230. In its report, OSHA explained its

many reasons for carefully defining the duties of employers to train their employees

in the use of industrial trucks, and the duty of untrained persons not to operate indus-

trial trucks except in controlled, training circumstances. The report addresses how

critically important the training required by the OSHA regulations is for the safety of

people and things wherever industrial trucks are operated. 29 CFR sec. 1910.178. In

simple terms, careful training before operation of an industrial truck is critical and

must occur before truck operation because accidents resulting in injury, death or

property damage almost always result from disregard of the basic risks inherent in

truck use or disregard of safety rules and procedures created to reduce or eliminate

those risks. The training required by OSHA is designed to address those risks. The

evidence provided by OSHA in its report reveals that the law’s operator training re-

quirements for employers and operators are grounded in experience and goog judg-

ment.

Jungheinrich has provided an industrial truck which complies with 29 CFR 1910.178,

and ASME B56.1. Jungheinrich representatives are available to assist and answer

any questions which may arise concerning the capacities, operation, use and main-

tenance of the truck.

According to OSHA, people do not start out with the knowledge and skills they need

to safely operate a powered industrial truck, and therefore, they need formal training

and practice to gain the knowledge and to master the skills they need to safely oper-

ate an industrial truck. Consequently, having an industrial truck which complies with

the law and standards fulfills only one half of the safety equation. It is, therefore, up

to you, the operator, and your employer, to fulfill your responsibilities by obeying all

national, state and local laws and regulations concerning training and the safe oper-

ation of industrial trucks - not just because it is the law, but because it also makes

common safety sense.

Only trained and certified persons may operate an industrial truck.

Training programs must comply with OSHA requirements and address, at least,

all of the topics listed there.

The user portion of ASME B56.1 is recommended to employers and operators

for careful review and observance.

“Safe operation is the responsibility of the operator“ ASME B56.1-2003, Part II

sec. 5.1.1.

Page 9

0505.USA

A 2

0505.USA

A 2

Page 10

B 1

0505.USA

B Recognize and avoid the hazards

In its 1998 study of industrial truck use, OSHA identified a nummber of ways accidents regularly occur and described why they occur. OSHA concluded that untrained

and poorly trained operators pose significant risks to themselves and those working

in their vicinity. According to OSHA, the major cause of accidents with industrial

trucks and their resulting injuries and deaths is improper or unsafe operation. It is no

surprise, therefore, that when OSHA reviewed its files, it discovered that accidents

almost always occur as a result of situations or actions the operator, or the employer

and the operator, were in a position to influence or control for the better. A simple review of the accident causes identified by OSHA proves this observation. Out of 208

industrial truck accidents studied, which involved 184 deaths or serious injuries, fully

50% were caused by a load problem, including overload, instability, falling load or improper lifting of load. Similarly, 25% involved overturn/tipover of the truck. Falls of the

truck from a platform or trailer, or of lifted persons from the truck, accounted for another 20% of accidents. Although ’no training’ accounted for about 4% of the accidents,

OSHA properly noted that many of the accidents could have been equally caused by

improper training - for example, an overturn accident may also have been the result

of no, or poor, training of the operator about load balance. Other less frequent, but

equally employer and operator - controllable accident causes include speeding and

use of improper equipent.

It is therefore critically important to:

– Complete the training and operator certification process before beginning work with

an industrial truck.

– Always be in competent physical, mental and emotional condition before operating

an industrial truck.

– Understand and observe safe loading and handling practices- know your machine

capacities and work within them.

– Avoid circumstances which can lead to overturn or tipover- this includes, for ex-

ample, understanding center of gravity and following sound loading and load movement practices, and constant area awareness of edges, curbs, dropoffs and

other surface details.

– Never carry passengers or lift people without specific training, the correct truck,

equipment and procedures.

– Always follow traffic rules and always be aware of the location of co-workers, other

trucks and your physical surroundings.

The manufacturer declines all responsibility for the consequences of dismantling the

truck or making any modification which is outside the manufacturer’s control.

The manufacturer’s responsibility is limited to the configuration of the equipment described in the conformance certificate. The manufacturer is absolved from their responsibility if there are modifications, additions or use of equipment from another supplier, in which case the user assumes the manufacturer’s responsibility.

These operating instructions become invalid if the machine is modified by a company

which is not part of our company group, even if original spare parts are used and our

company logo remains displayed on the equipment.

B 1

0505.USA

B Recognize and avoid the hazards

In its 1998 study of industrial truck use, OSHA identified a nummber of ways acci-

dents regularly occur and described why they occur. OSHA concluded that untrained

and poorly trained operators pose significant risks to themselves and those working

in their vicinity. According to OSHA, the major cause of accidents with industrial

trucks and their resulting injuries and deaths is improper or unsafe operation. It is no

surprise, therefore, that when OSHA reviewed its files, it discovered that accidents

almost always occur as a result of situations or actions the operator, or the employer

and the operator, were in a position to influence or control for the better. A simple re-

view of the accident causes identified by OSHA proves this observation. Out of 208

industrial truck accidents studied, which involved 184 deaths or serious injuries, fully

50% were caused by a load problem, including overload, instability, falling load or im-

proper lifting of load. Similarly, 25% involved overturn/tipover of the truck. Falls of the

truck from a platform or trailer, or of lifted persons from the truck, accounted for ano-

ther 20% of accidents. Although ’no training’ accounted for about 4% of the accidents,

OSHA properly noted that many of the accidents could have been equally caused by

improper training - for example, an overturn accident may also have been the result

of no, or poor, training of the operator about load balance. Other less frequent, but

equally employer and operator - controllable accident causes include speeding and

use of improper equipent.

It is therefore critically important to:

– Complete the training and operator certification process before beginning work with

an industrial truck.

– Always be in competent physical, mental and emotional condition before operating

an industrial truck.

– Understand and observe safe loading and handling practices- know your machine

capacities and work within them.

– Avoid circumstances which can lead to overturn or tipover- this includes, for ex-

ample, understanding center of gravity and following sound loading and load mo-

vement practices, and constant area awareness of edges, curbs, dropoffs and

other surface details.

– Never carry passengers or lift people without specific training, the correct truck,

equipment and procedures.

– Always follow traffic rules and always be aware of the location of co-workers, other

trucks and your physical surroundings.

The manufacturer declines all responsibility for the consequences of dismantling the

truck or making any modification which is outside the manufacturer’s control.

The manufacturer’s responsibility is limited to the configuration of the equipment de-

scribed in the conformance certificate. The manufacturer is absolved from their re-

sponsibility if there are modifications, additions or use of equipment from another sup-

plier, in which case the user assumes the manufacturer’s responsibility.

These operating instructions become invalid if the machine is modified by a company

which is not part of our company group, even if original spare parts are used and our

company logo remains displayed on the equipment.

Page 11

0505.USA

B 2

0505.USA

B 2

Page 12

C 1

0108.USA

C Correct use and application of the truck

NOTICE These operating instructions include all the information needed for transport,

first start-up, normal use, servicing and maintenance of the described

industrial truck, in accordance with ASME B56.1-2003, UL 583 and ANSI

Z535.4-2002. Read these instructions carefully to ensure proper and safe

use of the truck.

The industrial truck described in these operating instructions is suitable for lifting and

transporting loads and must be used, operated and maintained according to the law

and the information provided in these operating instructions. Any use of the truck not

authorized by law or these instructions is a misuse of the truck and beyond the intended design of the truck. Such misuse can lead to death and/or serious injury to persons and damage to equipment and property. Overloading caused by excessively

heavy or unbalanced loads is an example of misuse of the truck which must be avoided. The maximum allowable load is indicated on the identification plate and load diagram label shown on the truck. The industrial truck must not be operated in spaces

subject to fire or explosion hazards, or in spaces where corrosive or very dusty atmospheres prevail.

These operating instructions must be kept as long as the vehicle is in use.

Duties of the user:

A user of an industrial truck may be one of several persons depending on the context

referred to in these operating instructions- it includes the truck owner, any person leasing or renting the truck and the operator, as referred to in ASME B56.1- 2003. Users

will usually be employers, and the truck operators will often be their employees for

purposes of OSHA regulations. Every user must know and follow the applicable rules

and regulations concerning industrial truck use and operation. The operator instructions are for all users, and are directed toward and should be provided to the persons

who will actually operate the industrial truck.

The user and operator must ensure that the truck is not abused and used only within

its design limits so that all danger to life and limb of the operator, and third parties, is

avoided. The user and operator must also ensure that the accident prevention regulations and other safety-related provisions, as well as the operating, servicing and

maintenance guidelines, are observed. The user must ensure that all who will operate

this truck have read and understood these operating instructions and have fulfilled all

training and certification required by law before performing any work with the truck.

The user and operator are advised that when functions on industrial trucks are automated (for example rail-guided or inductively-guided trucks), the operation of the vehicle is changed which may result in modified performance characteristics, maintenance procedures, and additional safety precautions.

The addition of any automatic function to a manned industrial vehicle requires the

evaluation of the impact of the automation on all other functions. It maybe necessary

to automate other functions to some degree.

NOTICE If these Operating Instruction are not observed the warranty becomes void.

The same applies if improper work is carried out on the device by the

customer and/or third parties.

C 1

0108.USA

C Correct use and application of the truck

NOTICE These operating instructions include all the information needed for transport,

first start-up, normal use, servicing and maintenance of the described

industrial truck, in accordance with ASME B56.1-2003, UL 583 and ANSI

Z535.4-2002. Read these instructions carefully to ensure proper and safe

use of the truck.

The industrial truck described in these operating instructions is suitable for lifting and

transporting loads and must be used, operated and maintained according to the law

and the information provided in these operating instructions. Any use of the truck not

authorized by law or these instructions is a misuse of the truck and beyond the inten-

ded design of the truck. Such misuse can lead to death and/or serious injury to per-

sons and damage to equipment and property. Overloading caused by excessively

heavy or unbalanced loads is an example of misuse of the truck which must be avo-

ided. The maximum allowable load is indicated on the identification plate and load di-

agram label shown on the truck. The industrial truck must not be operated in spaces

subject to fire or explosion hazards, or in spaces where corrosive or very dusty at-

mospheres prevail.

These operating instructions must be kept as long as the vehicle is in use.

Duties of the user:

A user of an industrial truck may be one of several persons depending on the context

referred to in these operating instructions- it includes the truck owner, any person lea-

sing or renting the truck and the operator, as referred to in ASME B56.1- 2003. Users

will usually be employers, and the truck operators will often be their employees for

purposes of OSHA regulations. Every user must know and follow the applicable rules

and regulations concerning industrial truck use and operation. The operator instruc-

tions are for all users, and are directed toward and should be provided to the persons

who will actually operate the industrial truck.

The user and operator must ensure that the truck is not abused and used only within

its design limits so that all danger to life and limb of the operator, and third parties, is

avoided. The user and operator must also ensure that the accident prevention regu-

lations and other safety-related provisions, as well as the operating, servicing and

maintenance guidelines, are observed. The user must ensure that all who will operate

this truck have read and understood these operating instructions and have fulfilled all

training and certification required by law before performing any work with the truck.

The user and operator are advised that when functions on industrial trucks are auto-

mated (for example rail-guided or inductively-guided trucks), the operation of the ve-

hicle is changed which may result in modified performance characteristics, mainte-

nance procedures, and additional safety precautions.

The addition of any automatic function to a manned industrial vehicle requires the

evaluation of the impact of the automation on all other functions. It maybe necessary

to automate other functions to some degree.

NOTICE If these Operating Instruction are not observed the warranty becomes void.

The same applies if improper work is carried out on the device by the

customer and/or third parties.

Page 13

0108.USA

C 2

Mounting of attachments:

The mounting or installation of any attachments and modifications and/or additions to

hardware or software which will interfere with, or supplement, rated capacity, safe operation, any emergency control or device, or any other function of the truck is only permitted with approval of the proposed modifications or additions by the manufacturer.

When such approval is granted, capacity, operation, and maintenance instruction plates, tags, or decals must be changed accordingly.

If necessary, the approval of local authorities must also be obtained.

Approval obtained from local authorities does not render manufacturer approval of

the modifications or additions unnecessary.

If the truck is equipped with attachment(s) including fork extensions, the user shall

see that the truck is marked to identify the attachment(s), show the approximate

weight of the truck and attachment combination, and show the capacity of the truck

with attachment(s) at maximum elevation with load laterally centered.

When modifications involve rebuild and repair of the basic unit, they shall be made in

accordance with the manufacturer‘s established criteria and procedures.

The basic functions of the truck are:

– steering (guidance)

– travel

– control and sensing

– lifting/load manipulation

0108.USA

C 2

Mounting of attachments:

The mounting or installation of any attachments and modifications and/or additions to

hardware or software which will interfere with, or supplement, rated capacity, safe op-

eration, any emergency control or device, or any other function of the truck is only per-

mitted with approval of the proposed modifications or additions by the manufacturer.

When such approval is granted, capacity, operation, and maintenance instruction pla-

tes, tags, or decals must be changed accordingly.

If necessary, the approval of local authorities must also be obtained.

Approval obtained from local authorities does not render manufacturer approval of

the modifications or additions unnecessary.

If the truck is equipped with attachment(s) including fork extensions, the user shall

see that the truck is marked to identify the attachment(s), show the approximate

weight of the truck and attachment combination, and show the capacity of the truck

with attachment(s) at maximum elevation with load laterally centered.

When modifications involve rebuild and repair of the basic unit, they shall be made in

accordance with the manufacturer‘s established criteria and procedures.

The basic functions of the truck are:

– steering (guidance)

– travel

– control and sensing

– lifting/load manipulation

Page 14

C 3

0108.USA

Identification plate:

We highly recommend that the data from the identification plate be copied onto the

diagram below to ensure that this important data is available to the operator and that

these instructions are not inadvertently used with any other product.

The user is responsible for confirming that all identification plates and caution and instruction markings are in place and legible (refer to section “Identification points and

data plates“ in chapter D).

QwW Industrial truck use is subject to certain hazards that cannot be completely

eliminated by mechanical means. Those risks can, however, be minimized by

the exercise of intelligence, care and common sense. Operators must,

therefore, be competent, careful, physically and mentally fit, and thoroughly

trained in the safe operation of the equipment and load handling.

for type "E" industrial trucks with type "E" battery

Built in compliance with ASME B 56.1

C 3

0108.USA

Identification plate:

We highly recommend that the data from the identification plate be copied onto the

diagram below to ensure that this important data is available to the operator and that

these instructions are not inadvertently used with any other product.

The user is responsible for confirming that all identification plates and caution and in-

struction markings are in place and legible (refer to section “Identification points and

data plates“ in chapter D).

QwW Industrial truck use is subject to certain hazards that cannot be completely

eliminated by mechanical means. Those risks can, however, be minimized by

the exercise of intelligence, care and common sense. Operators must,

therefore, be competent, careful, physically and mentally fit, and thoroughly

trained in the safe operation of the equipment and load handling.

for type "E" industrial trucks with type "E" battery

Built in compliance with ASME B 56.1

Page 15

0108.USA

C 4

General instructions for Users and Operators

QwW The following are general instructions which apply to all users, including

company management, department heads, operators, transporters and

employees who work in the vicinity of industrial trucks. The user is

responsible for safe operation of this truck, and both employer and operator

must work together to enforce and follow the safety regulations which apply

to use of the truck.

1. These instructions must be read before using the truck and followed when the

truck is in use

2. The user and operator must ensure that the truck is used only for the purpose for

which it has been designed. The user and operator must NOT:

– allow abnormal use of the truck

– disable the safety devices

– overload or operate the truck outside the load graph

(refer to section “Capacity“ in chapter D)

– use the truck as a crane

– use the truck to lift or carry people

– lock a control in position

– ignore standard practices for handling and manipulating loads

– transport loads over people’s head

– push or pull loads with the truck

– engage in games or horseplay with the truck such as racing, or ’chicken’

– carry unbalanced loads

3. The user and operator must check the strength of the floors (to avoid damaging

them), the racks, and in general all the corridors and areas where the truck will or

may be used.

4. Read the instructions on the plates attached to the truck and make sure that they

remain legible

5. Keep these instructions available for all operators in an accessible location on

the truck

6. Make sure that only trained, certified and responsible persons, capable of safe

operation of the truck, are allowed to operate the truck.

7. Make sure that the truck cannot be tampered with when it is not in use

8. Never use a truck which does not appear to be in good working condition

9. Never use the truck to carry a load or apply a force which exceeds its maximum

operating load

10. Never use the truck for a purpose for which it is not intended

11. Read the truck safety regulations and apply them rigorously

0108.USA

C 4

General instructions for Users and Operators

QwW The following are general instructions which apply to all users, including

company management, department heads, operators, transporters and

employees who work in the vicinity of industrial trucks. The user is

responsible for safe operation of this truck, and both employer and operator

must work together to enforce and follow the safety regulations which apply

to use of the truck.

1. These instructions must be read before using the truck and followed when the

truck is in use

2. The user and operator must ensure that the truck is used only for the purpose for

which it has been designed. The user and operator must NOT:

– allow abnormal use of the truck

– disable the safety devices

– overload or operate the truck outside the load graph

(refer to section “Capacity“ in chapter D)

– use the truck as a crane

– use the truck to lift or carry people

– lock a control in position

– ignore standard practices for handling and manipulating loads

– transport loads over people’s head

– push or pull loads with the truck

– engage in games or horseplay with the truck such as racing, or ’chicken’

– carry unbalanced loads

3. The user and operator must check the strength of the floors (to avoid damaging

them), the racks, and in general all the corridors and areas where the truck will or

may be used.

4. Read the instructions on the plates attached to the truck and make sure that they

remain legible

5. Keep these instructions available for all operators in an accessible location on

the truck

6. Make sure that only trained, certified and responsible persons, capable of safe

operation of the truck, are allowed to operate the truck.

7. Make sure that the truck cannot be tampered with when it is not in use

8. Never use a truck which does not appear to be in good working condition

9. Never use the truck to carry a load or apply a force which exceeds its maximum

operating load

10. Never use the truck for a purpose for which it is not intended

11. Read the truck safety regulations and apply them rigorously

Page 16

C 5

0108.USA

12. The manufacturer declines all responsibility for the consequences of dismantling

the truck or making any modification which is outside the manufacturer’s control

13. The manufacturer’s responsibility is limited to the configuration of the equipment

described in the conformance certificate. The manufacturer is absolved from

their responsibility if there are modifications, additions or use of equipment from

another supplier, in which case the user assumes the manufacturer’s responsibility

14. These operating instructions become invalid if the machine is modified by a company which is not part of our company group, even if original spare parts are

used and our company logo remains displayed on the equipment

15. The conditions of your workplace, and other unusual operating conditions may

require additional safety precautions and special operating instructions

16. Supervision is an essential element in the safe operation of powered industrial

trucks

17. Batteries must comply with the minimum/maximum battery weight range shown

on the truck identification plate

18. Floor and wheel locks (if provided) are intended only to hold the truck in a desired position on a level surface

QwW Serious hazards are overloading, load instability, obstruction to the free

passage of the load, collision with objects or pedestrians, poor maintenance,

and use of equipment for purposes it was not intended or designed. Changes

in load(s), dimension(s), coupling types(s) and/or position(s), and floor

surface condition(s) or battery weights may affect rated capacities and safe

operation. Only stable or safely arranged loads shall be handled.

The operator is responsible for proper loading, load stability and securement. The

operator shall, as necessary, verify that the load remains stable and secure.

C 5

0108.USA

12. The manufacturer declines all responsibility for the consequences of dismantling

the truck or making any modification which is outside the manufacturer’s control

13. The manufacturer’s responsibility is limited to the configuration of the equipment

described in the conformance certificate. The manufacturer is absolved from

their responsibility if there are modifications, additions or use of equipment from

another supplier, in which case the user assumes the manufacturer’s responsibi-

lity

14. These operating instructions become invalid if the machine is modified by a com-

pany which is not part of our company group, even if original spare parts are

used and our company logo remains displayed on the equipment

15. The conditions of your workplace, and other unusual operating conditions may

require additional safety precautions and special operating instructions

16. Supervision is an essential element in the safe operation of powered industrial

trucks

17. Batteries must comply with the minimum/maximum battery weight range shown

on the truck identification plate

18. Floor and wheel locks (if provided) are intended only to hold the truck in a desi-

red position on a level surface

QwW Serious hazards are overloading, load instability, obstruction to the free

passage of the load, collision with objects or pedestrians, poor maintenance,

and use of equipment for purposes it was not intended or designed. Changes

in load(s), dimension(s), coupling types(s) and/or position(s), and floor

surface condition(s) or battery weights may affect rated capacities and safe

operation. Only stable or safely arranged loads shall be handled.

The operator is responsible for proper loading, load stability and securement. The

operator shall, as necessary, verify that the load remains stable and secure.

Page 17

0108.USA

C 6

0108.USA

C 6

Page 18

D 1

0108.USA

D Truck Description

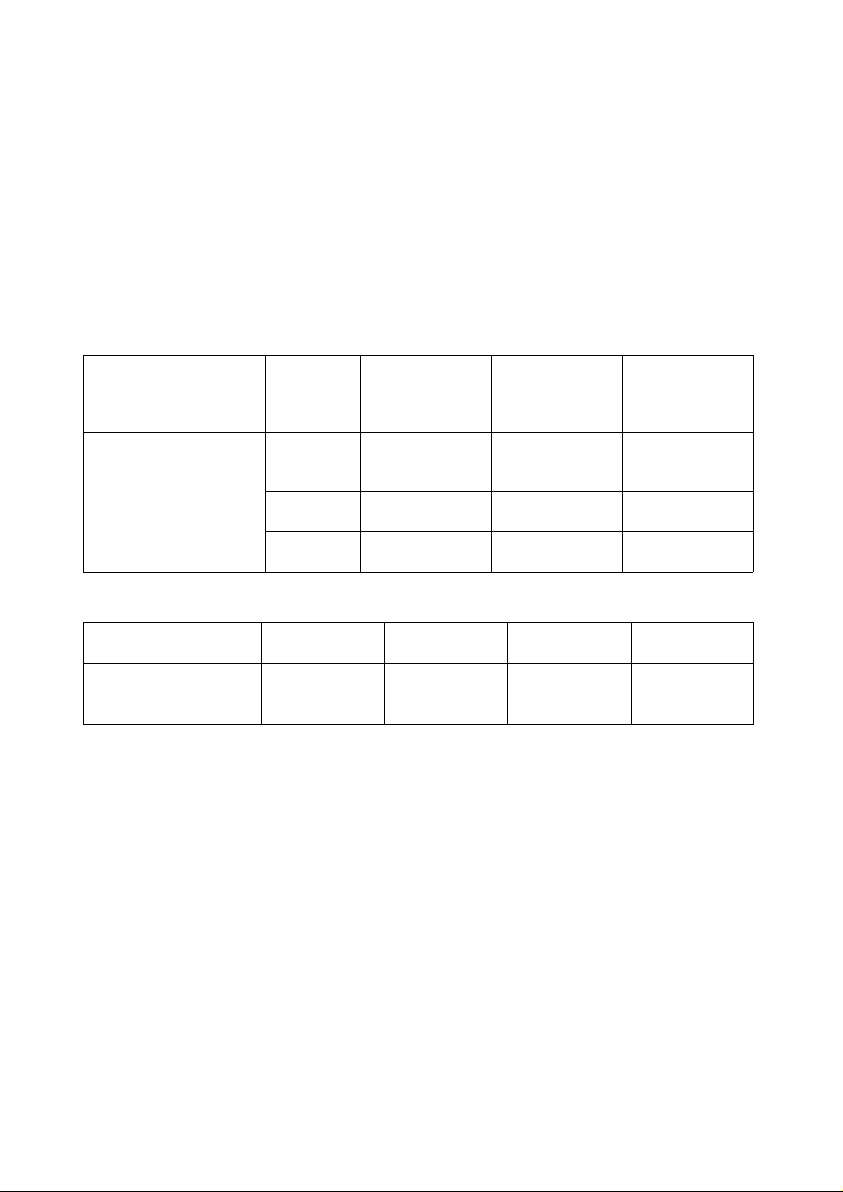

1 Application

The EKS 314 is an electric stockpicker. It is designed to be used on level surfaces to

transport and pick goods. The floor surface must comply with the following requirements:

Floor specifications

QwW In order to prevent accidents due to operation on uneven floor surfaces the

following floor surface tolerances must not be exceeded.

Max. permitted height differences (h) across the aisle:

Floor planeness / tolerances lengthwise to the tracks for both height classes

– Floor has to be oil and grease resistant.

– Floor leakage resistance RE is not permitted to pass 10

6

Ω.

– Floor surface must be carefully finished to eliminate all short floor waves.

Axle width (S)

up to 1 m

up to 40 inch

more than 1,0 m

up to 1,5 m

more than 40 inch

up to 59 inch

more than 1,5 m

up to 2,0 m

more than 59 inch

up to 79 inch

more than 2,0 m

up to 2,5 m

more than 59 inch

up to 98 inch

Max. permitted

height difference

between outer tracks (SP)

VNA truck lift height

</= 6 m / </= 236 inch

VNA truck lift height

> 6,01 m / > 236 inch

2,0 mm

0.08 inch

2,5 mm

0.10 inch

3,0 mm

0.12 inch

3,5 mm

0.14 inch

1,5 mm

0.06 inch

2,0 mm

0.08 inch

2,5 mm

0.10 inch

3,0 mm

0.12 inch

Distance of

measuring points

1,0 m /

39.34 inch

2,0 m /

78.68 inch

3,0 m /

118.02 inch

4,0 m /

157.36 inch

Max. permitted tolerance/

planeness

Bulk sample as limit value

2,0 mm

0.08 inch

3,0 mm

0.12 inch

4,0 mm

0.16 inch

5,0 mm

0.20 inch

D 1

0108.USA

D Truck Description

1 Application

The EKS 314 is an electric stockpicker. It is designed to be used on level surfaces to

transport and pick goods. The floor surface must comply with the following require-

ments:

Floor specifications

QwW In order to prevent accidents due to operation on uneven floor surfaces the

following floor surface tolerances must not be exceeded.

Max. permitted height differences (h) across the aisle:

Floor planeness / tolerances lengthwise to the tracks for both height classes

– Floor has to be oil and grease resistant.

– Floor leakage resistance RE is not permitted to pass 10

6

Ω.

– Floor surface must be carefully finished to eliminate all short floor waves.

Axle width (S)

up to 1 m

up to 40 inch

more than 1,0 m

up to 1,5 m

more than 40 inch

up to 59 inch

more than 1,5 m

up to 2,0 m

more than 59 inch

up to 79 inch

more than 2,0 m

up to 2,5 m

more than 59 inch

up to 98 inch

Max. permitted

height difference

between outer tracks (SP)

VNA truck lift height

</= 6 m / </= 236 inch

VNA truck lift height

> 6,01 m / > 236 inch

2,0 mm

0.08 inch

2,5 mm

0.10 inch

3,0 mm

0.12 inch

3,5 mm

0.14 inch

1,5 mm

0.06 inch

2,0 mm

0.08 inch

2,5 mm

0.10 inch

3,0 mm

0.12 inch

Distance of

measuring points

1,0 m /

39.34 inch

2,0 m /

78.68 inch

3,0 m /

118.02 inch

4,0 m /

157.36 inch

Max. permitted tolerance/

planeness

Bulk sample as limit value

2,0 mm

0.08 inch

3,0 mm

0.12 inch

4,0 mm

0.16 inch

5,0 mm

0.20 inch

Page 19

0108.USA

D 2

Open bottom pallets or pallets with transverse boards can be lifted inside or outside

the area of the load wheels or roll cage.

Loads can be stacked and unstacked and transported over long distances.

The driver's cab is raised together with the load lifting device to provide excellent visibility and easy access to the rack levels to be operated.

The racks must be suitable for the EKS 314. The following safety distances specified

by the manufacturer must be observed:

QwW In order to prevent accidents, whenever a truck is used in rack system aisles

(rail guided) a safety distance of at least 3.54 inch / 90 mm between either

side of the truck and the racks must be maintained.

In case of inductively / wire guided trucks a safety distance of at least

4.92 inch/ 125 mm is recommended.

The ground surface must comply with the floor specifications mentioned above.

Guide rails must be provided in the narrow aisles for the rail guidance system.

Vulkollan guide rollers attached to the truck chassis guide the truck between the

guide rails.

A guidance wire must be routed in the ground for the inductive / wire guidance (WG)

system. The signals from the wire are received on the chassis and processed in the

on-board computer.

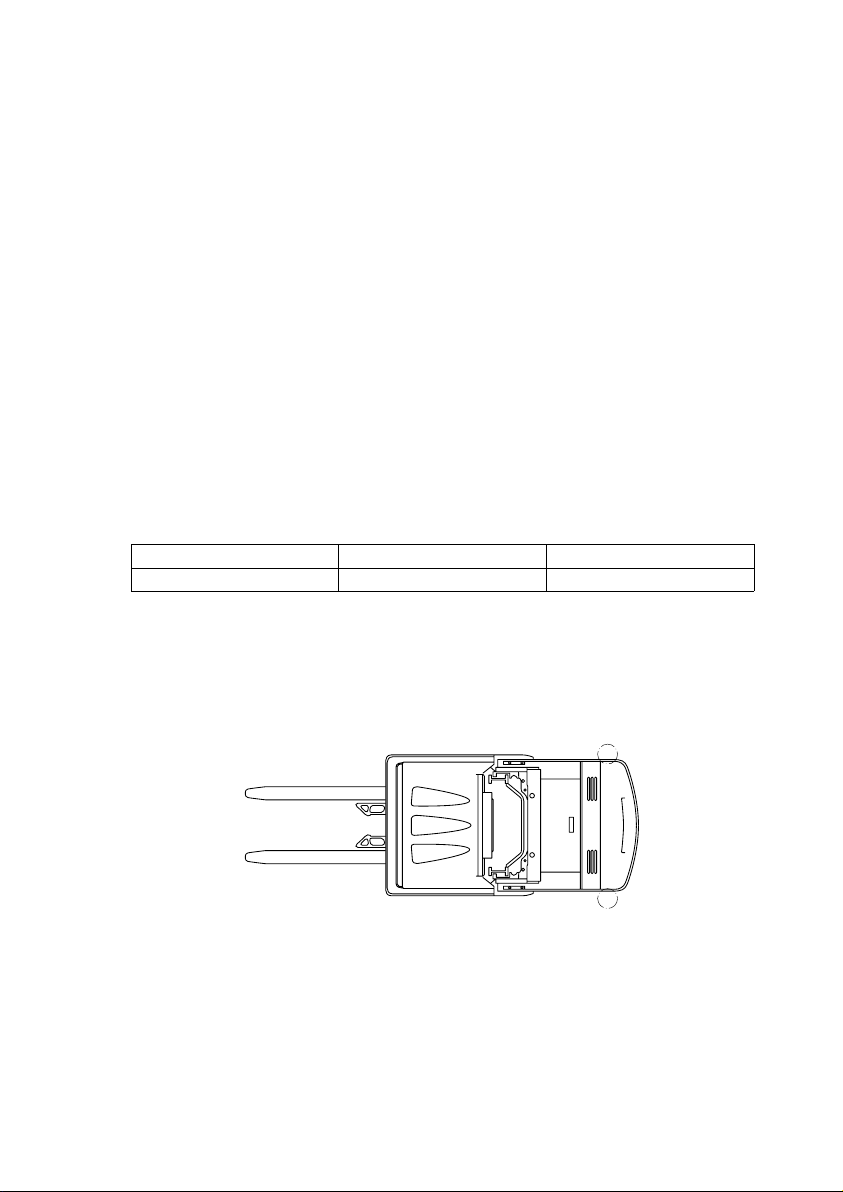

The capacity is shown on the data plate, for example:

Travel direction definition:

To indicate travel directions, the following orientations will be used in this manual:

Type Capacity Load center of gravity

EKS 314 3000 lbs / 1360 kg 23.6 inch / 600 mm

Left

Right

Drive

direction

Load

direction

0108.USA

D 2

Open bottom pallets or pallets with transverse boards can be lifted inside or outside

the area of the load wheels or roll cage.

Loads can be stacked and unstacked and transported over long distances.

The driver's cab is raised together with the load lifting device to provide excellent vis-

ibility and easy access to the rack levels to be operated.

The racks must be suitable for the EKS 314. The following safety distances specified

by the manufacturer must be observed:

QwW In order to prevent accidents, whenever a truck is used in rack system aisles

(rail guided) a safety distance of at least 3.54 inch / 90 mm between either

side of the truck and the racks must be maintained.

In case of inductively / wire guided trucks a safety distance of at least

4.92 inch/ 125 mm is recommended.

The ground surface must comply with the floor specifications mentioned above.

Guide rails must be provided in the narrow aisles for the rail guidance system.

Vulkollan guide rollers attached to the truck chassis guide the truck between the

guide rails.

A guidance wire must be routed in the ground for the inductive / wire guidance (WG)

system. The signals from the wire are received on the chassis and processed in the

on-board computer.

The capacity is shown on the data plate, for example:

Travel direction definition:

To indicate travel directions, the following orientations will be used in this manual:

Type Capacity Load center of gravity

EKS 314 3000 lbs / 1360 kg 23.6 inch / 600 mm

Left

Right

Drive

direction

Load

direction

Page 20

D 3

0108.USA

2 Assemblies and Functional Description

Item Description

1 t Mast

2 t Overhead guard

3 t Safety gates

4 t Safety restraint belt

5 t Control panel

6 t Height-adjustable driver’s position

7 t Chassis

8 t Foot switch/deadman switch

9 t Pallet clamp

t = Standard equipment o = Optional Equipment

1

2

4

3

6

7

5

8

9

D 3

0108.USA

2 Assemblies and Functional Description

Item Description

1 t Mast

2 t Overhead guard

3 t Safety gates

4 t Safety restraint belt

5 t Control panel

6 t Height-adjustable driver’s position

7 t Chassis

8 t Foot switch/deadman switch

9 t Pallet clamp

t = Standard equipment o = Optional Equipment

1

2

4

3

6

7

5

8

9

Page 21

0108.USA

D 4

2.1 Truck

Safety mechanisms: Side mounted safety gates (3). The driver is also secured by a

safety restraint belt (4). The overhead guard (2) protects the driver from falling objects.

The Emergency Disconnect switch immediately cuts out all truck movements in hazardous situations. Safety gates (3) on either side of the cab disable all truck movements as soon as they are opened.

Travelling, lifting and lowering can only be activated when the foot switch (8) is

pressed.

Drive:

Vertical, heavy-duty threephase motor (asynchronous), hence easy and rapid maintenance. The motor is mounted directly onto the single-wheel driving gear

Brake system:

The truck can be braked gently and wear-free by pulling back the travel control button

or steering in the opposite direction. This feeds energy into the battery (operating

brake).

The electromagnetic spring pressure brake acting on the drive motor serves as a

parking brake and handbrake.

Steering:

Particularly smooth steering with threephase drive system. The handy steering

wheel is integrated within the control panel. The position of the steered drive wheel

is shown in the display unit. The steering angle is +/- 90°, offering maximum

maneuverability in narrow aisles.

With the mechanical rail guidance (RG) system the drive wheel is set to the forward

position at the press of a button.

In wire guidance (WG) mode, steering is automatically assumed by the truck controller when it detects the guidance wire, and manual steering is deactivated.

Controls and displays:

The functions are activated via ergonomic thumb and finger movement to ensure fatigue-free operation without straining the wrists; sensitive application of travel and hydraulic movements to spare and position the goods exactly.

Integrated information display unit for all important driver information such as steering

wheel position, overall lift, truck status reports (e. g. faults), service hours, battery capacity, time and wire guidance status etc.

Hydraulic system:

All hydraulic movements are controlled by a maintenance-free AC motor with a flanged low emission gear pump. Oil is distributed via magnetic switch valves. The varying

oil requirements are controlled by the speed of the motor. During a lowering operation

the hydraulic pump drives the motor which then acts as a generator (regenerative

lowering). The energy produced is then fed back to the battery.

0108.USA

D 4

2.1 Truck

Safety mechanisms: Side mounted safety gates (3). The driver is also secured by a

safety restraint belt (4). The overhead guard (2) protects the driver from falling ob-

jects.

The Emergency Disconnect switch immediately cuts out all truck movements in haz-

ardous situations. Safety gates (3) on either side of the cab disable all truck move-

ments as soon as they are opened.

Travelling, lifting and lowering can only be activated when the foot switch (8) is

pressed.

Drive:

Vertical, heavy-duty threephase motor (asynchronous), hence easy and rapid main-

tenance. The motor is mounted directly onto the single-wheel driving gear

Brake system:

The truck can be braked gently and wear-free by pulling back the travel control button

or steering in the opposite direction. This feeds energy into the battery (operating

brake).

The electromagnetic spring pressure brake acting on the drive motor serves as a

parking brake and handbrake.

Steering:

Particularly smooth steering with threephase drive system. The handy steering

wheel is integrated within the control panel. The position of the steered drive wheel

is shown in the display unit. The steering angle is +/- 90°, offering maximum

maneuverability in narrow aisles.

With the mechanical rail guidance (RG) system the drive wheel is set to the forward

position at the press of a button.

In wire guidance (WG) mode, steering is automatically assumed by the truck control-

ler when it detects the guidance wire, and manual steering is deactivated.

Controls and displays:

The functions are activated via ergonomic thumb and finger movement to ensure fa-

tigue-free operation without straining the wrists; sensitive application of travel and hy-

draulic movements to spare and position the goods exactly.

Integrated information display unit for all important driver information such as steering

wheel position, overall lift, truck status reports (e. g. faults), service hours, battery ca-

pacity, time and wire guidance status etc.

Hydraulic system:

All hydraulic movements are controlled by a maintenance-free AC motor with a flang-

ed low emission gear pump. Oil is distributed via magnetic switch valves. The varying

oil requirements are controlled by the speed of the motor. During a lowering operation

the hydraulic pump drives the motor which then acts as a generator (regenerative

lowering). The energy produced is then fed back to the battery.

Page 22

D 5

0108.USA

Electrical System:

Service laptop connection interface:

– To configure all the key truck data (limit position damping, lift cutout, retardation

and acceleration patterns, cut-outs etc.) rapidly and reliably.

– To read out the error log to analyse fault causes.

– To simulate and analyse program operations.

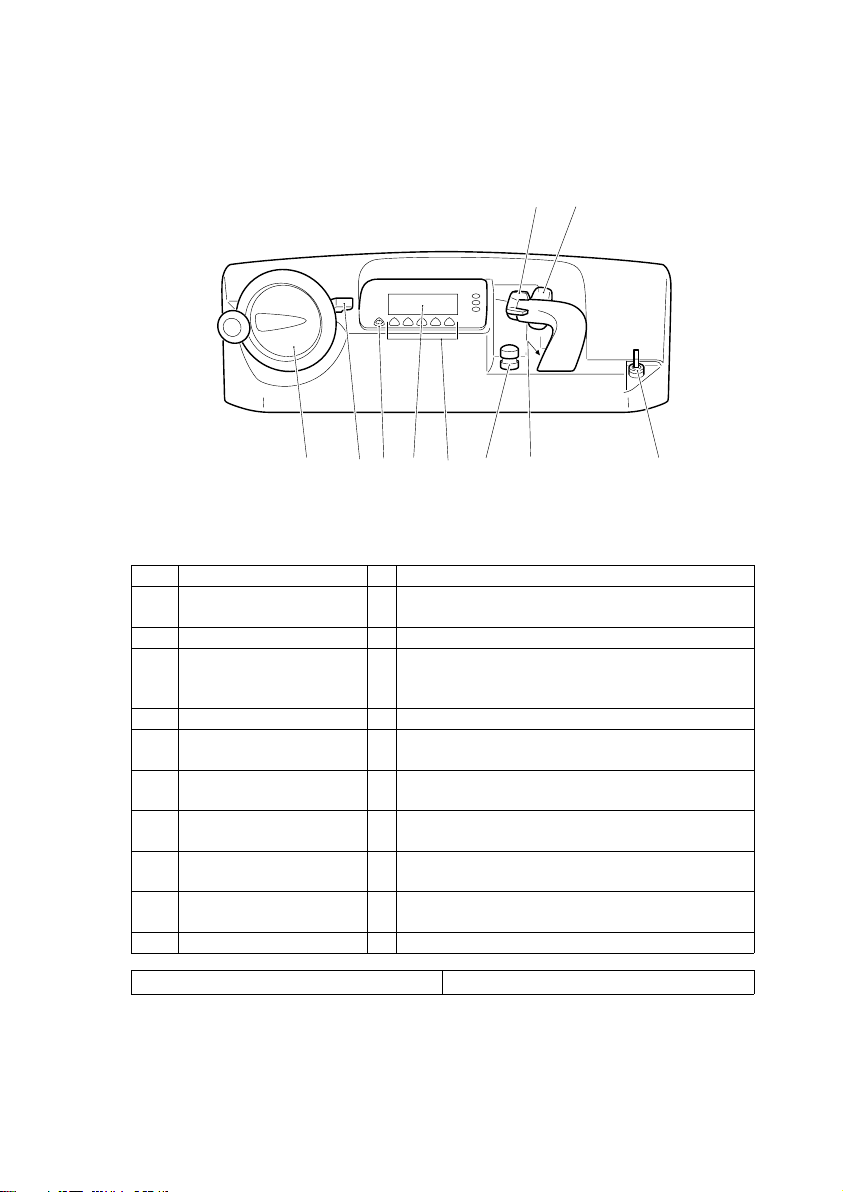

– Provides simple functional extension by releasing code numbers.

The controller is fitted with a CAN Bus and a continually measuring sensor system.

The controller provides smooth start-up and braking of the load in all limit positions

through limit position and intermediate cushioning.

Highly efficient threephase technology with energy retention for the drive and lift motors provides high travel and lift speeds and better use of energy.

The MOSFET threephase controller provides smooth starting for all movements.

For drive battery options see section “Battery type“ in chapter F.

3 Standard Version Specifications

NOTICE Technical data specified in accordance with the german standart „Type

sheets for industrial trucks“.

Technical modifications and additions reserved.

3.1 Performance data

RG: Rail Guidance

WG: Wire Guidance

FR: Free Range

Description EKS 314

Q Capacity (where c= 23.6 inch (600 mm)) 3000 lbs 1360 kg

c Load center of gravity distance 23.6 inch 600 mm

Travel speed without load (RG) 6.0 mph 9.6 km/h

Travel speed with load (RG) 6.0 mph 9.6 km/h

Travel speed without load (WG) 4.7 mph 7.5 km/h

Travel speed with load (WG) 4.7 mph 7.5 km/h

Travel speed without load (FR) 6.0 mph 9.6 km/h

Travel speed with load (FR) 6.0 mph 9.6 km/h

Lift speed without load 1.21 ft/s 0.37 m/s

Lift speed with load 1.21 ft/s 0.37 m/s

Lowering speed with load 1.15 ft/s 0.35 m/s

Lowering speed without load 1.12 ft/s 0.34 m/s

D 5

0108.USA

Electrical System:

Service laptop connection interface:

– To configure all the key truck data (limit position damping, lift cutout, retardation

and acceleration patterns, cut-outs etc.) rapidly and reliably.

– To read out the error log to analyse fault causes.

– To simulate and analyse program operations.

– Provides simple functional extension by releasing code numbers.

The controller is fitted with a CAN Bus and a continually measuring sensor system.

The controller provides smooth start-up and braking of the load in all limit positions

through limit position and intermediate cushioning.

Highly efficient threephase technology with energy retention for the drive and lift mo-

tors provides high travel and lift speeds and better use of energy.

The MOSFET threephase controller provides smooth starting for all movements.

For drive battery options see section “Battery type“ in chapter F.

3 Standard Version Specifications

NOTICE Technical data specified in accordance with the german standart „Type

sheets for industrial trucks“.

Technical modifications and additions reserved.

3.1 Performance data

RG: Rail Guidance

WG: Wire Guidance

FR: Free Range