Page 1

48 V 3-phase AC technology

giving powerful torque

and dynamic movement

Up to two shifts without

changing the battery due to

energy recovery and eective

energy management

Modules for process

integration: RFID technology,

redundant height and

weight measurement,

Logistics Interface

Up to 25 percent greater

performance due to

warehouse navigation

with semi-automatic

approach (optional)

High flexibility due to modular

design and RFID special build

solutions from the factory

EKS 210/312

Vertical order picker (1,000/1,200 kg)

The EKS 210/312 order pickers oer highest picking performance in the high-rack warehouse. Both truck concepts are

optimised for their respective application. The EKS 210 with

1000 kg load capacity and order picking heights up to 7845

mm is specially designed for manoeuvrability in wide aisles.

Its narrow chassis size of just 900 mm oers the maximum

turning capability. The EKS 312 with 1200 kg load capacity and

order picking heights up to 11,345 mm oers high throughput

performance. Both order pickers set new standards in respect

of flexibility, economic eciency and ergonomics:

• The Jungheinrich modular system oers flexibility and a

multitude of options for future customisation. These include

modular loadbearing components such as platforms, walkon

load sections or auxiliary masts. Further options include an

“adaptor system” for flexible choice of cabin widths and electronic height limitations for the masts.

• With the integrated warehouse navigation system (optional),

the control computer on the EKS communicates directly with

the Warehouse Management System (WMS). The truck can be

driven to the destination under semi-automatic control. The

operation is comfortable for the operator, movement errors

are avoided, productivity and picking quality are significantly

improved. The 48 Volt 3-phase technology ensures strong

acceleration and high lifting speeds with unrivalled low power

consumption. The advantage: full availability over 2 shifts in

normal operation without the need to change the battery.

• The EKS operator can easily attain access to this performance.

The cabin oers a generously sized workplace with outstanding vision. At the centre of the control concept, is the

twopiece console for the operator and the large information

display.

Page 2

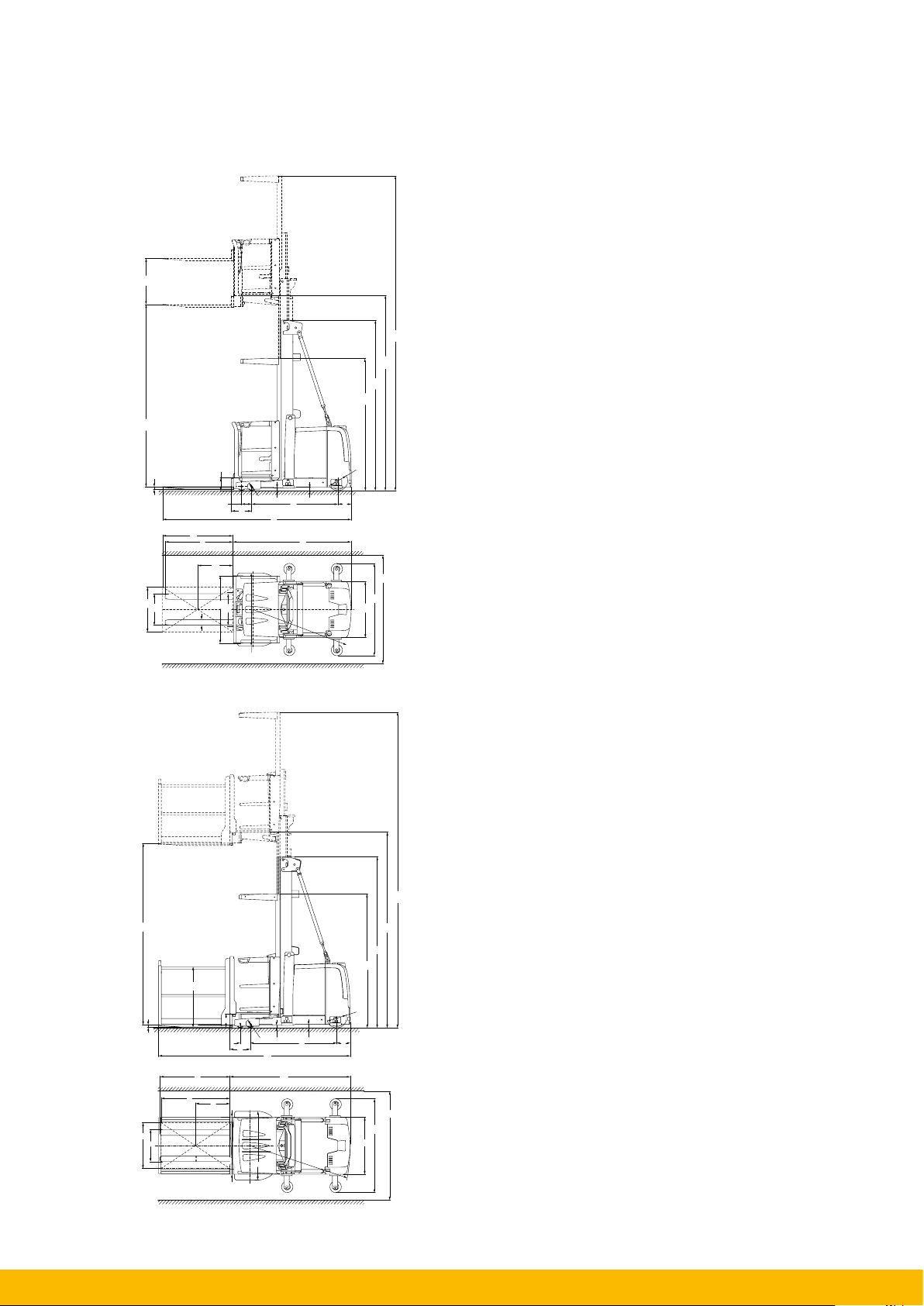

EKS 210/312

h

9

h

3

h

s

b

12

b

5

7

d

1

350

x

l

6

l

c

b

9

b

3

e

m

1m2

l

1

h

4

h

12

h

1

h

6

2

d

y

z

l

2

Ast

b

6

b

1

Wa

b

2

h

4

h

3

h

12

h

1

h

6

EKS Z-Version

1090

d

s

b

12

b

5

h

7

d

m1m

1

350

x

l

l

6

c

e

b

9

y

l

1

l

2

b

2

Wa

2

2

z

Ast

b

6

b

1

EKS L-Version

Page 3

Issue: 03/2014

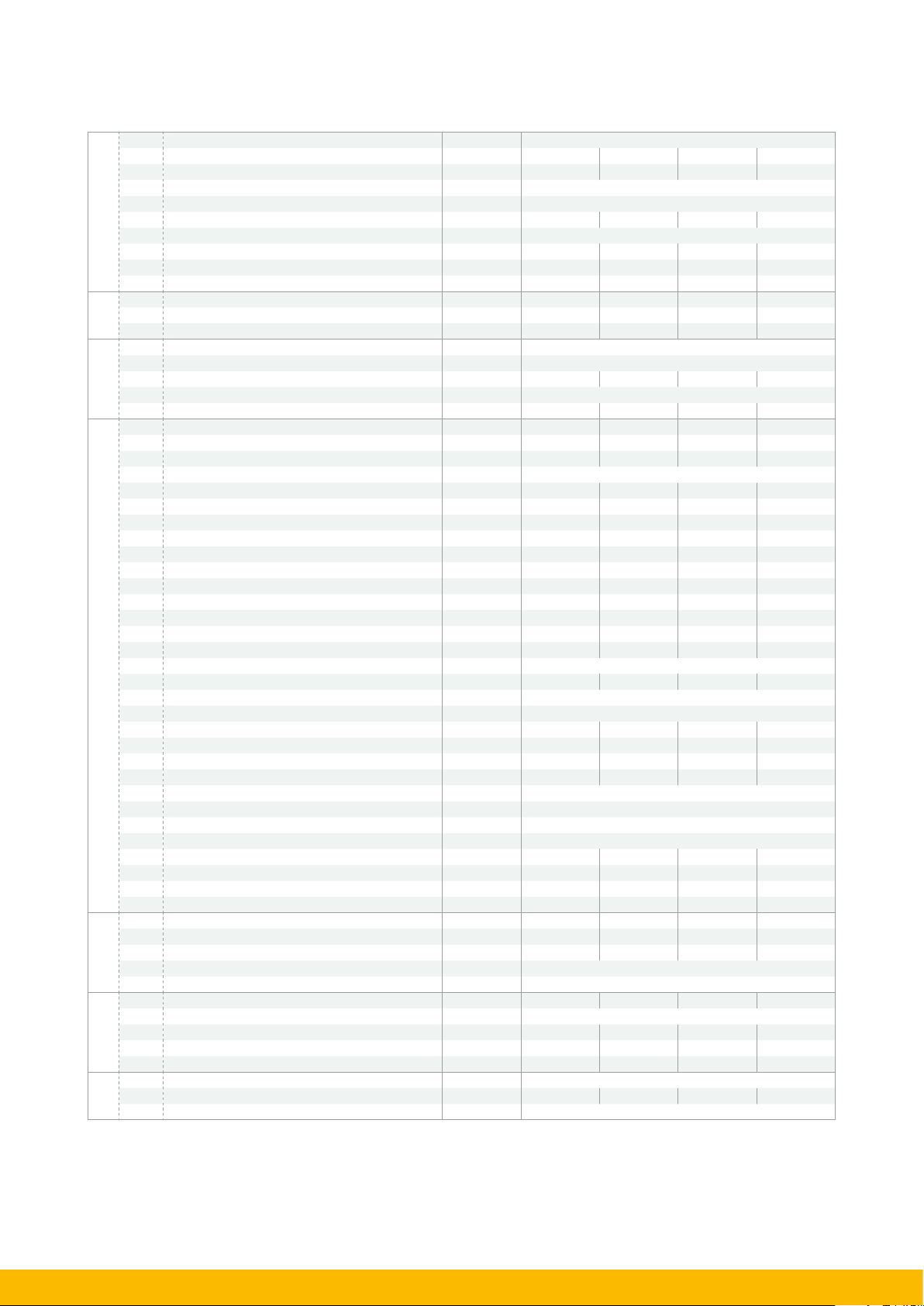

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model EKS 210 EKS 210 EKS 312 EKS 312

Z L Z L

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation order picker

1.5 Load capacity/rated load Q t 1 1 1.2

1.6 Load centre distance c mm 400

Identification

1.8 Load distance x mm 350 350 325 325

1.9 Wheelbase y mm 1325 1325 1515 1515

1.10 Centre of drive wheel/counterweight z mm 210 210 235 235

2.1 Service weight kg 2850 2950 3650 3750

2.2 Axle load, w. load, front / rear kg 3066 / 864 3116 / 914 3574 / 1157 3624 / 1207

2.3 Axle load, w.o. load, front / rear kg 1390 / 1460 1440 / 1510 1840 / 1810 1890 / 1860

Weights

3.1 Tyres Vulkollan

3.2 Tyre size, at front mm Ø 150 x 95

3.3 Tyre size, at rear mm Ø 250 x 80 Ø 250 x 80 Ø 343 x 110 Ø 343 x 110

chassis

3.5 Wheels, number front/rear (× = driven wheels) 2 / 1 x

Wheels /

3.6 Track width, front b

4.2 Mast height (lowered) h1 mm 2330

4.4 Lift h

4.5 Extended mast height h

4.7 Height of overhead guard h

4.8 Seat height/stand height h7 mm

4.8.1 Standing height h

mm 775 775 875 875

10

mm 3000 3000 5000 5000

3

mm 5320

4

mm 2320

6

mm 245 245

7

1)

1)

1) 1)

2330

5320

1)

1)

4.11 auxiliary lift h9 mm 810 810

4.14 Standing height raised h

mm 3245

12

1)

3245

1)

4.16.1 platform length l3 mm 1250

4.19.2 total length (without load) mm 3085 3135

4.19.4 Total length including fork length l

4.20 Length incl. back of forks l

4.21 Total width b

mm 3275 3325

1

mm 1885 1885 2075 2075

2

mm 900 / 900 900 / 1000 1000 / 1000 1000 / 1000

1/b2

4.22 Fork dimensions s/e/l mm 40 / 100 / 1200 40 / 100 / 1250 40 / 100 / 1200 40 / 100 / 1250

4.24 Fork carriage width b

4.25 Width over forks b

mm 600 600

3

mm 560

5

4.27 width over guide rollers mm 1100 1200 1200 1200

4.31 Floor clearance with load under mast m

Basic dimensions

4.32 Floor clearance centre wheelbase m

mm 50

1

mm 60

2

4.33.16 Working aisle width for 1200 x 800 pallet Ast mm 1100 1200 1200 1200

4.35 Turning radius W

mm 1550 1550 1760 1760

a

4.38.1 total lift mm 3810 5810

4.38.2 Order picking height mm 4845 4845 6845 6845

4.38.4 pallet width mm 800

4.38.5 pallet length mm 1200

4.38.6 clear width of operator entrance mm 585

4.38.7 inner clear height of operator compartment mm 2050

4.38.8 outer width of operator compartment mm 900 1000 1000 1000

4.38.12 platform length mm 1250

4.38.12.1 height of protection device mm 1090

4.38.12.2 platform width mm 1000 800

5.1 Travel speed, w. / w.o. load km/h 9 / 9 9 / 9 10.5 / 10.5 10.5 / 10.5

5.2 Lift speed, w. / w.o. load m/s 0.29 / 0.31 0.29 / 0.31 0.35 / 0.39 0.35 / 0.39

5.3 Lower speed, w. / w.o. load m/s 0.34 / 0.31 0.34 / 0.31 0.39 / 0.37 0.39 / 0.37

data

5.10 Service brake reverse current/generated

Performance

5.11 Parking brake electric spring-loaded

6.1 Drive motor rating S2 60 min. kW 3.0 3.0 6.9 6.9

6.2 Lift motor rating at S3 25% kW 9.5

6.3 Battery according to DIN 43531/35/36 A,B,C, no 3 PzS 465 3 PzS 465 4 PzS 620 4 PzS 620

6.4 Battery voltage/nominal capacity K5 V/Ah 48 / 465 48 / 465 48 / 620 48 / 620

Electrics

6.5 Battery weight kg 740 740 930 930

8.1 Type of drive control AC Control

8.4 Sound pressure level at operator’s ear according to EN 12053 dB (A) 62 62 69 69

Misc.

8.6 Steering electric

2)

1)

3330

1)

7320

1)

1)

245

1)

5245

1.2

3330

7320

245

5245

2)

1)

1)

1)

1)

1)

+30 mm with mobile personal safety system (PSS)

2)

1.0 t where c = 600 mm

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

EKS 210/312

Standard values for working aisle widths (mm)

with rail guidance

Pallet size Stacking depth Ast Ast

L design EKS 210 L EKS 312 L EKS 210 L EKS 312 L

800 x 1200 800 1600 1600 3139 3328 +500

1200 x 1200 1200 1600 1600 3496 3684 +500

1200 x 800 1200 1200 1200 3426 3612 +500

Z design EKS 210 Z

800 x 1200 800

1200 x 1200 1200 1400 1400 3412 3599 +500

1200 x 800 1200 1100 1200 3351 3537 +500

Pallet size Stacking depth Ast Ast

L design EKS 210 L EKS 312 L EKS 210 L EKS 312 L

800 x 1200 800

1200 x 1200 1200 1650 1650 3496 3684 + 1000

1200 x 800 1200

Z design EKS 210 Z

800 x 1200 800

1200 x 1200 1200

1200 x 800 1200 1150 1250 3351 3537 + 1000

1400 1400 3047 3235 +500

1650 1650 3139 3328 + 1000

1250 1250 3426 3612 + 1000

1450 1450 3047 3235 + 1000

1450 1450 3412 3599 + 1000

EKS 312 Z EKS 210 Z

with wire guidance

EKS 312 Z EKS 210 Z

/VDI theoretical Ast3 practical

3

/VDI theoretical Ast3 practical

3

EKS 312 Z

EKS 312 Z

Page 5

EKS 210/312

Lowered mast height

Lift

h

3

(mm) (mm) (mm) (mm) (mm) (mm)

ZT

3000 2330 - - - 5320 - 3810 - 4845 -

3500 2580 - - - 5820 - 4310 - 5345 4250 2960 - - - 6570 - 5060 - 6095 -

5000 - 3330 - - - 7320 - 5810 - 6845

5500 - 3600 - - - 7820 - 6310 - 7345

6500 - 4125 - - - 8820 - 7310 - 8345

7500 - 4650 - - - 9820 - 8310 - 9345

8500 - 5150 - - - 10820 - 9310 - 10345

DZ

4750 2330 2330 10 10 7070 7070 5560 5560 6595 6595

5500 2580 2580 260 260 7820 7820 6310 6310 7345 7345

6000 2770 2770 450 450 8320 8320 6810 6810 7845 7845

6500 - 2950 - 630 - 8820 - 7310 - 8345

7500 - 3330 - 1010 - 9820 - 8310 - 9345

8300 - 3600 - 1280 - 10620 - 9110 - 10145

9250 - 4125 - 1805 - 11570 - 10060 - 11095

9500 - 4125 - 1805 - 11820 - 10310 - 11345

1)

+30 mm with mobile personal safety system (PSS)

h

1

EKS 210 EKS 312 EKS 210 EKS 312 EKS 210 EKS 312 EKS 210 EKS 312 EKS 210 EKS 312

Standard mast types EKS 210/312

1)

Free lift

h

2

Extended mast height

h

4

1)

Overall height

h3 + h9

Order picking height

h15

1)

Page 6

EKS 210/312

EKS 210 and EKS 312 standard

equipment

• Energy recovery during lowering and

braking.

• Active energy and battery management.

• Redundant AC drive control with adjustable drive and hydraulic functions.

• TÜV-certified CAN-Bus system.

• Maintenance-free drives for travel,

lifting and steering.

• Wear-free inversion brake.

• Spring-loaded discs as parking brake.

• End position and transfer cushioning of

all hydraulic functions.

• Integrated diagnostic system with service interface.

• Travel direction and height dependent

diagonal travel speed.

• Jungheinrich Curve Control operator assistance system (steering-angle

dependent speed control).

• Stepless speed control of all drives for

gentle movement at best eciency.

• Load wheels in tandem design.

• Ergonomic cab with low entry/exit step

and very roomy.

• Modular, height-adjustable controls

with integrated compartments.

• Graphics-compatible colour display

with soft keys.

• Electronic power-assisted steering for

eortless, precise manoeuvring.

• Battery roller conveyor for lateral

battery exchange.

• Auxiliary lift for ergonomic order

picking.

EKS 210 and EKS 312 optional

equipment

• 24 volt version (EKS 210).

• Stationary or mobile battery changing

stations.

• Walk-on pallet with guard.

• Picking platforms in dierent designs.

• Fork carriage with adjustable and

removable forks.

• Mechanical rail guidance in dierent

designs.

• Wire guidance for precise control in

the aisle with no mechanical loading of

components.

• End of aisle control with speed

reduction.

• Access via PIN code (option for

individual travel programs).

• Truck positioning in narrow aisles via

RFID reader and transponder system.

• Warehouse navigation for semi-automatic approach within the aisle.

• Jungheinrich Logistics Interface (connection to warehouse management).

• Two picking spotlights ‘pick by light’

with display of the picking direction.

• Integrated Jungheinrich personal

protection system (PPS optional), factory-fitted integration into the safety

computer.

• Impact protection (mixed operation of

two trucks in the aisle).

• Workstation comfort package (LED

working lights, LED interior lighting,

fan).

• Radio with CD player and MP3 interface.

• Control panel layout: Load side, drive

side, both sides.

• Button for pedestrian mode incl. 2°

steering.

• Dierent designs of converter (e.g.

power supply terminals, printer etc.).

• Jungheinrich radio data terminals with

mechanical and electrical interfaces for

material flow management systems.

• Laser scanner including holder on the

railing or overhead guard.

• Jungheinrich Information System for

Truck management (ISM).

Page 7

EKS 210/312

Page 8

Benefit from the advantages

Pioneering 3-phase AC technology

More than 150,000 Jungheinrich

3-phase AC trucks are in use all over the

world. This expertise is reflected in our

current drive and control technology:

• High order-picking eciency.

• Low energy consumption.

• Eective thermal economy.

• Reduced maintenance and wear.

High throughput and order-picking

• 3-phase motors with high torque.

• High acceleration for driving and lifting.

• Quick main and auxiliary masts.

Modular design

High flexibility through modular design:

• Range of chassis and cabin width

options.

• Flexible operating console concept.

• Load-bearing components: auxiliary

masts, walk-on pallets or platforms.

• Free ranging.

• Mechanical rail guidance or inductive

guidance (both optional).

Future compatibility:

• Adaptor system for customising the

cab width to new operating requirements.

• Electronic height limitations for the

masts.

• TÜV-certified control system (CANBus) for maximum reliability.

Economic energy management

• Double energy-saving benefits through

regenerative braking and load lowering.

• Workplace lighting using energy-saving

LED spotlights.

• Activation of the LED work spotlights

upon reaching the destination

(optional).

• Longer operating times on a single

battery charge (up to 2 shifts).

• Active energy and battery management

• Longer battery lifetime.

• Battery rollers for quick battery exchange.

RFID floor control (optional)

• Truck control by transponder technology.

• Continuous travel distance measurement for precise recognition of all

warehouse areas.

• High flexibility for switching / safety

functions (aisle end recognition, lift /

drive cut-outs, speed reduction).

• Drive speeds optimised according to

the floor topology.

Jungheinrich warehouse navigation

• Linking the EKS to a Warehouse Management System (WMS) using a radio

data terminal and/or scanner.

• Direct loading of the destination within

the narrow aisle through the truck

computer.

• Automatic vertical positioning under

operator control.

• Automatic horizontal positioning under

operator control.

• High degree of automation.

• Improved order-picking performance.

• Optimised movements and dual

cycling possibilities.

• Elimination of incorrect positioning by

RFID location detection.

• High flexibility in the warehouse, as the

existing WMS can be modified to cater

for warehouse extensions.

Integral Jungheinrich personnel

• Factory-based integration into the

safety computer.

• Configuration, commissioning and

maintenance by Jungheinrich.

Ergonomic benefits and comfort

• Lower cabin platform height – only

245 mm.

• Large headroom.

• Flat surrounding barrier for easy access

to the pallet.

• Outstanding field of view over the load

and the aisle.

• Height-adjustable operating consoles

with integral shelf.

• Configurable membrane keyboard with

numeric pad.

• Switchless two-hand operation concept.

• Drive control by thumb movement.

• Travel limit and damping of all hydraulic functions.

Control system (CAN-Bus)

• All movements can be set and adjusted

via parameter.

• Electronically controlled drive wheel

braking.

Commissioning and maintenance

• Quick and reliable commissioning

using “teach-in” principles.

• Integral diagnostic system for remote

maintenance using a modem.

• 1000 operating hours maintenance

interval.

• Electronics with wear-free sensor

system.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_EKS 210/312_052014_en_UK_000

Loading...

Loading...