Page 1

3-phase AC drive system

Ergonomic workstation

for optimal handling

Excellent cost-eectiveness

thanks to high rate of

order picking with low

energy consumption

Optionally with walk-on load

section (L) or auxiliary mast (Z)

EKS 110

Vertical order picker (1,000 kg)

The EKS 110 is the ideal truck for order

picking from the first to the third levels.

The platform and load section are raised

together up to a lift height of 3000 mm.

This allows operators to pick up to a

reach height of 4600 mm.

The counterbalance design allows a wide

range of load storage units to be raised

o the ground both longitudinally and

crosswise. The load section is optionally

available in either a walk-on design (with

guard) or with an additional lift (without

reducing residual capacity). The additional lift ensures that the picked goods

can be stored at an accessible height.

This truck also features numerous other

ergonomic and technical innovations,

all of which make order picking faster,

easier and more cost-eective:

• There are large storage areas on the

battery lid (optional) and below the

control unit.

• Extended stand-on platform (optional).

• Precise control of travel speed.

• A choice of travel programs.

• Clear operator display.

• 3-phase AC drive system (24 V).

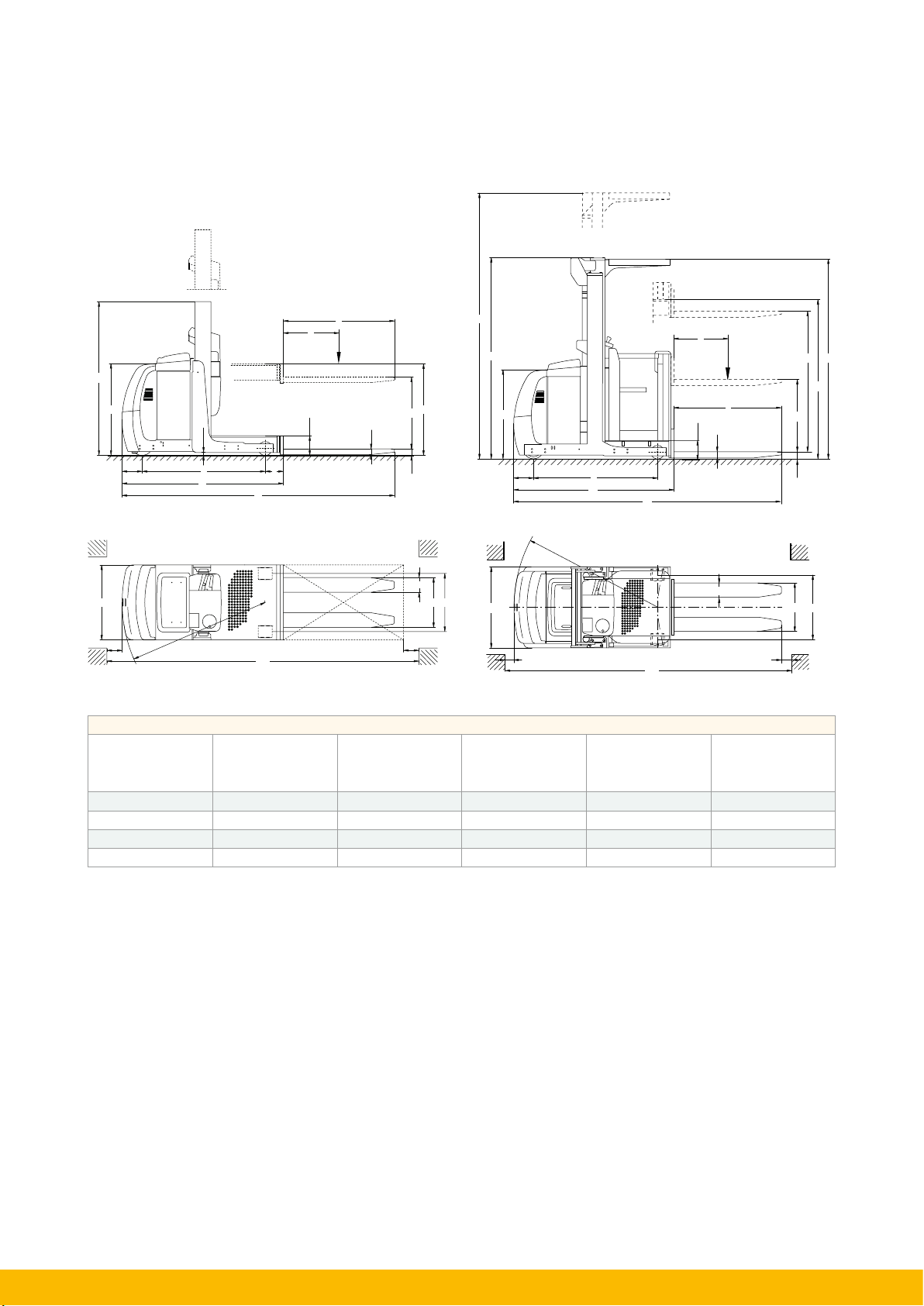

Page 2

EKS 110

EKS 110

h

1

990

b

1

EKS 110

h

l

C

Q

h

12

h

h

35

217

y

l

2

l

1

7

x

3

S

h

e

4

c

h

1

990

217

Wa

b11b

5

b

1

y

l

2

l

1

Q

l

h

7

s

e

h

h

3

6

h

12

h

9

h

13

b

b

11

5

a

Wa

2

Figure shows EKS 110 L 100 E

Ast

a

2

a

2

Figure shows EKS 100 Z 280 ZZ view shown without guard

EKS 110 standard mast designs

Mast lift height

h

3

mm

Standing height

h

12

mm

Order picking height

h12+1600

mm

100 E 1000 1200 2800 2230

160 E 1600 1800 3400 2260

190 E 1900 2100 3700 2560

280 ZZ 2800 3000 4600 2250

1)

without overhead guard: Height reduced by 570 mm, highest point is mast

2)

Mast is highest point

3)

Overhead guard is highest point

Ast

Lowered mast height

with overhead guard

h

1

mm

1), 3)

2)

2)

3)

a

2

Extended mast height

with overhead guard

h

4

mm

1), 3)

3230

3)

3830

3)

4130

3)

5030

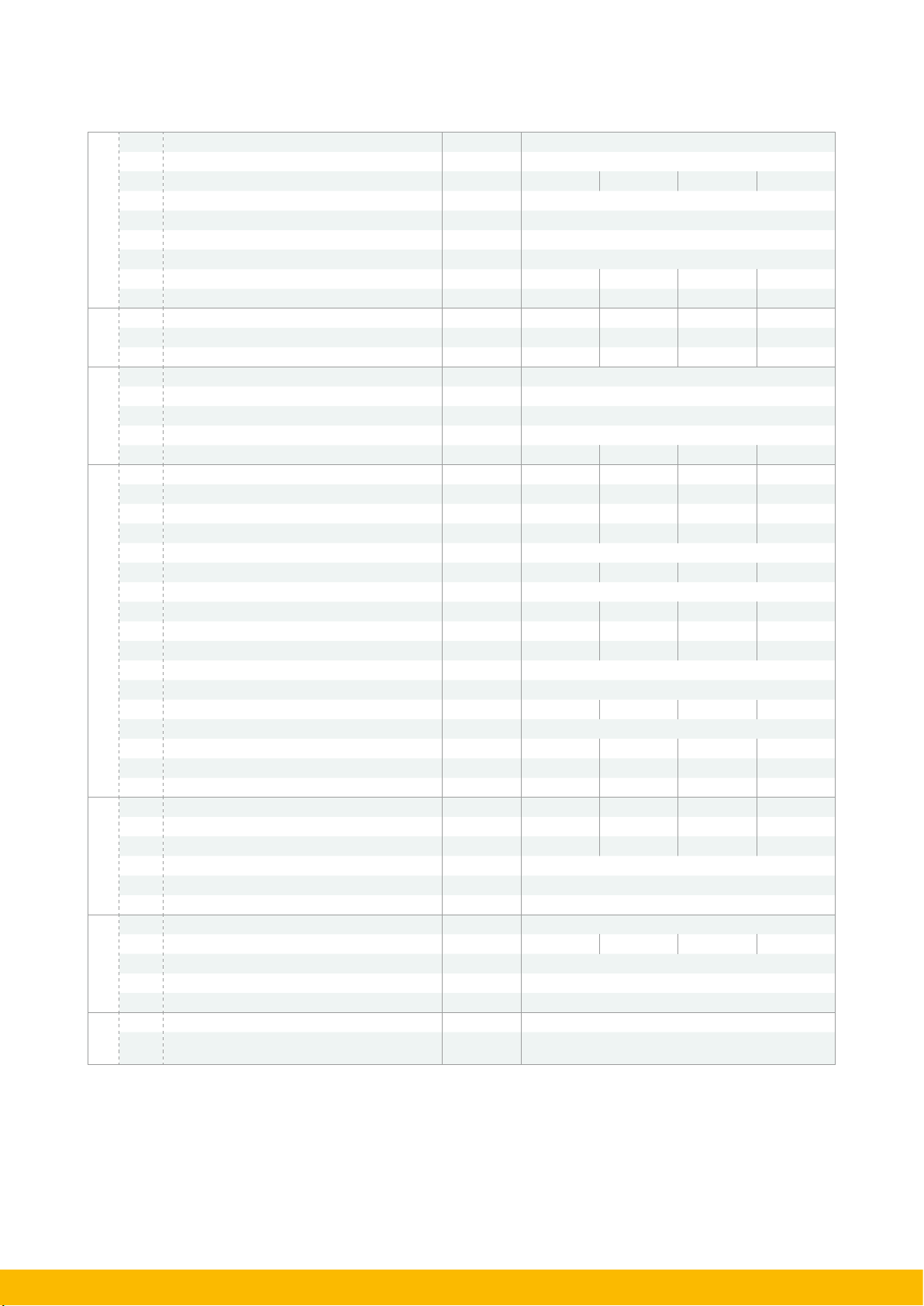

Page 3

Issue: 08/2009

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model EKS 110

100 E 160 E 190 E 280 ZZ

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation order picker

1.5 Load capacity/rated load Q t 1

Identification

1.6 Load centre distance c mm 600

1.8 Load distance x mm 143

6)

1.9 Wheelbase y mm 1330 1330 1330 1385

2.1.1 Net weight incl. battery (see row 6.5) kg 1661

2.2 Axle load, w. load, front / rear kg 491 / 2170

2.3 Axle load, w.o. load, front / rear kg 1053 / 608

Weights

1)

4)

4)

3.1 Tyres Vulkollan

3.2 Tyre size, at front mm Ø 230 x 80

3.3 Tyre size, at rear mm Ø 150 x 130

3.5 Wheels, number front/rear (× = driven wheels) 1x / 2

3.7 Track width, rear b

Wheels / chassis

4.2 Mast height (lowered) h1 mm 1650

4.4 Lift h

4.5 Extended mast height h

4.7 Height of overhead guard h

4.8.1 Standing height h

4.14 Standing height raised h

4.15 Lowered height h

4.19 Overall length l

4.20 Length incl. back of forks l2 mm 1690

mm 630 630 630 720

11

mm 1000 1600 1900 2800

3

mm 2650

4

mm 2230

6

mm 200

7

mm 1200 1800 2100 3000

12

mm 80

13

mm 2890

1

9)

8)

7)

6)

6)

4.21 Total width b1/b2 mm 810 810 810 900

4.22 Fork dimensions s/e/l mm 60 / 160 / 1200

Basic dimensions

4.25 Width over forks b5 mm 540

4.26 Width between support arms/loading surfaces b

4.31 Floor clearance with load under mast m

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 3039

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 3149

mm 430 430 430 520

4

mm 35

1

6)

6)

4.35 Turning radius Wa mm 1548 1548 1548 1603

5.1 Travel speed, w. / w.o. load km/h 9.8 / 10.1 9 / 9 9 / 9 9 / 9

5.2 Lift speed, w. / w.o. load m/s 0.19 / 0.26 0.15 / 0.2 0.15 / 0.2 0.23 / 0.31

5.3 Lower speed, w. / w.o. load m/s 0.24 / 0.24 0.23 / 0.22 0.23 / 0.22 0.28 / 0.26

5.7 Gradeability laden/unladen % 5 / 10

5.10 Service brake reverse current/generated

Performance data

5.11 parking brake electromagnetic

6.1 Drive motor rating S2 60 min. kW 2.8

6.2 Lift motor rating at S3 15% kW 3.0

5)

6.3 Battery according to DIN 43531/35/36 A,B,C, no B 43535

6.4 Battery voltage/nominal capacity K5 V/Ah 24 / 620

Electrics

6.5 Battery weight kg 480

8.1 Type of drive control AC SpeedControl

8.4

Misc.

Sound pressure level at operator’s ear according to EN

12053

dB (A) 61

143

1785

6)

1)

143

1813

6)

1)

516 / 22694)506 / 23074)762 / 2506

1093 / 6924)1084 / 7294)1336 / 932

2260 2560 2250

3830 4130 5030

2230 2230 2230

2890

1690

3039

3149

3.0

6)

6)

6)

6)

5)

2890

1690

3)

3039

3149

3.0

6)

6)

6)

6)

5)

180

2268

2985

1780

3127

3240

6.0

6)

1)

4)

4)

6)

6)

6)

6)

5)10)

1)

For aux. lift Z: + 120 kg

2)

For aux. lift Z: - 65 mm

3)

For aux. lift Z: 65x160x1200 mm

4)

For aux. lift Z: approx. + 20 / + 100 kg

5)

for auxiliary lift Z: +2.2 kW with S3=5%

6)

for auxiliary lift Z: +5 mm

7)

Overhead guard optional

8)

With 3230 mm OHG

9)

with OHG 2230 mm

10)

with S3=20%

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may result in different values.

Page 4

Benefit from the advantages

Controls Operators display Comfortable floor covering all over

Innovative 3-phase AC technology

Jungheinrich 3-phase AC motors oer

greater performance whilst at the same

time reducing the operating costs over

the entire working life of the truck. Make

the most of these advantages:

• High level of eciency with excellent

energy management.

• Powerful acceleration.

• Rapid reversing without ‘needing to

think’.

• No carbon brushes - maintenance-free

drive motor.

• Two-year warranty on the drive motor.

• The speed indicated by the travel

switch is maintained in every situation.

By programming the traction controller to suit the application at hand,

sensitive shunting is possible even at

low speeds.

• Adjustable travel parameters (e.g. acceleration, limit speed, motor brake)

allow you to tailor the truck to your

individual requirements.

• The operator can choose from 3 different travel programs.

• Very low noise levels when lifting and

travelling.

the stand-on platform

passive features provide the necessary

degree of safety:

• Stable cornering thanks to low centre

of gravity.

• Steel supports provide extra tip over

protection in extreme situations.

• Optimum use of maximum permissible

travel speed through a combination of

lift height and steering angle dependent speed reduction.

Less maintenance

Service-friendly components ensure that

running costs are considerably reduced

over the long term:

Smooth lifting and lowering

Through special control of the hydraulic

pump and the valves, even and smooth

movement is ensured when the standon platform is lifted and lowered. A

rubber mat provides additional operating

comfort. Advantages:

• Tangible comfort for the operator.

• Additional protection for sensitive

loads.

• Minimised wear through reduced

dynamic stress.

Travel in comfort

The Jungheinrich SpeedControl system

provides comfortable, precise control of

the travel speed:

Operator display

High-quality control instruments displaying the most important operating data.

• Travel direction and steer angle display.

• Battery status with residual time display.

• Selected travel program with performance features.

• Operating hours/time.

Comfortable control unit

• The tilted steering wheel supports

natural hand movement and avoids

placing strain on the operator’s wrists.

• Easily accessible buttons and switches

allow comfort operation of the truck

with minimum hand movements.

• Maintenance-free AC drive motors

without carbon brushes.

• Easy access to all units through easy

opening front/side panels and optimised layout of auxiliary hydraulics.

Additional equipment

• Provision for radio data.

• Pallet protection for walk-on load

handlers.

• Guidance controls, aisle recognition

and end of aisle control for use in

narrow aisle warehouses.

• Platform extensions.

• Second operator position in fork direction.

• Cold store equipment.

• Working lights on overhead guard.

High levels of eciency and safety

• Beacon on overhead guard.

High acceleration levels and fast travel

/ lift speeds provide the best conditions

for order picking. A range of active and

for new entry click here

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_EKS 110 _042014_en_UK_000

Loading...

Loading...