Page 1

The Jungheinrich EJG is a pedestrian controlled counterbalance truck which can be

used wherever support arm stacker trucks

cannot operate (e.g. lifting perimeter based

pallets directly from the floor, special load

sizes, racking with collision protection). With

an overall width of just 910 mm and a high

degree of manoeuvrability, the truck can also

be operated with ease in confined warehouse areas.

As a flexible truck the EJG offers many advantages:

쐍

Extremely sturdy chassis and load section.

쐍

High ground clearance and large load

wheels for comfortable travel on uneven

ground.

쐍

Sensitive lifting and lowering.

쐍

Excellent energy management.

Also there are ergonomic benefits:

쐍

The bottom mounted, long tiller ensures

a safe clearance from the chassis for the

operator.

쐍

The crawl button assists in extremely confined areas. It allows the truck to travel at

an automatically reduced speed with the

tiller upright.

The EJG draws the required energy from batteries with up to 375 Ah capacity.

EJG 106–112

Pedestrian controlled counterbalance truck (600–1200 kg)

Pedestrian controlled

counterbalance truck

Compact and manoeuvrable

High performance

with maintenance-free

AC drive motor

Sensitive tiller operated

lifting and lowering

through speed-controlled

hydraulic motor

Page 2

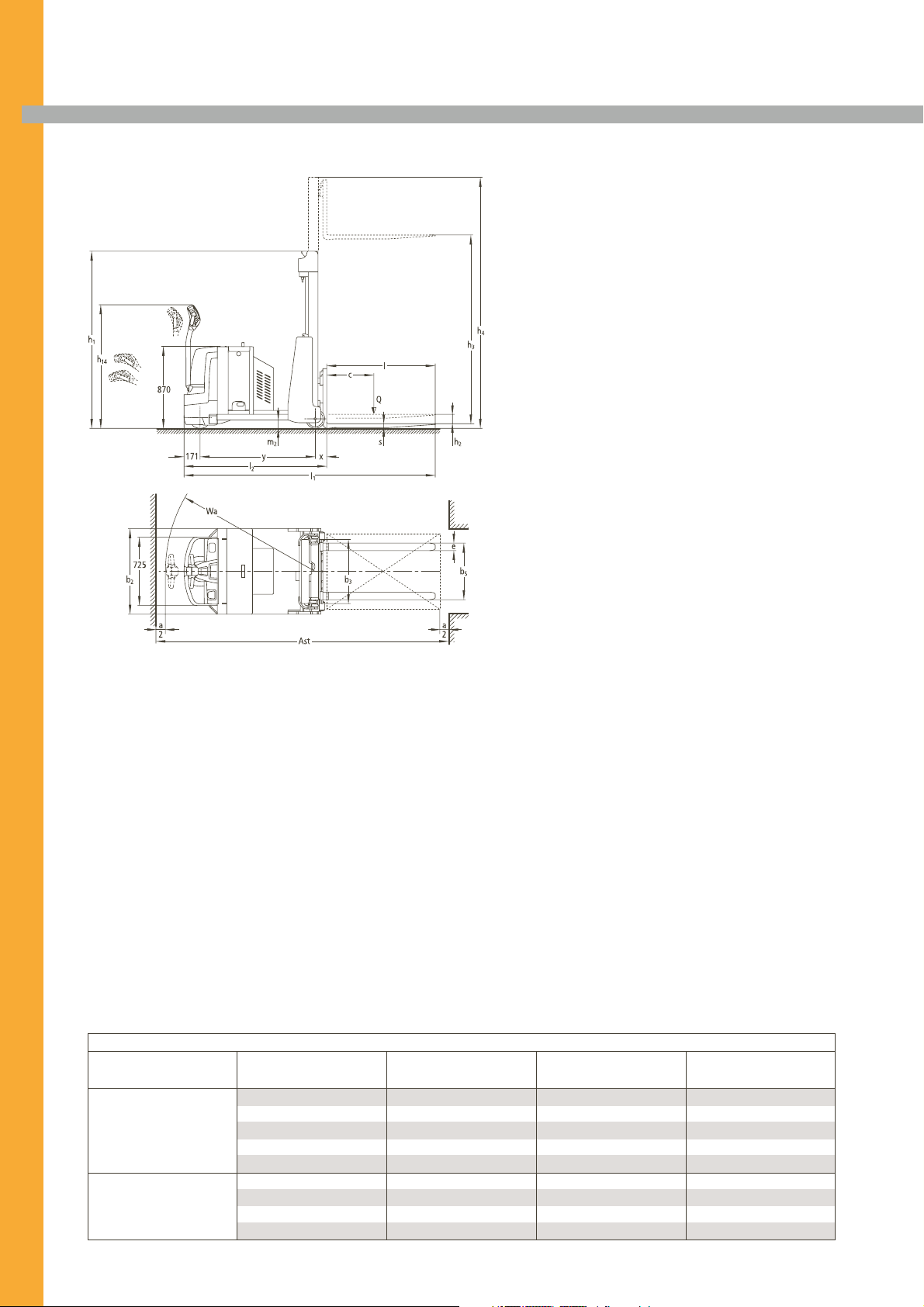

EJG 106–112

Mast table EJG (mm)

Designation Closed height Free lift Lift height Extended height

h

1

h

2

h

3

h

4

Two-stage mast ZT 1930 100 2500 3153

2030 100 2700 3480

2130 100 2900 3553

2280 100 3200 3853

2480 100 3600 4380

Two-stage mast ZZ 1880 1227 2500 3153

2080 1427 2900 3553

2230 1577 3200 3853

2480 1777 3600 4380

Page 3

Technical data in line with VDI 2198 as at: 08/2010

1.1 Manufacturer (abbreviation) Jungheinrich Jungheinrich Jungheinrich Jungheinrich 1.1

1.2 Manufacturer’s type designation EJG 106 EJG 108 EJG 110 EJG 112 1.2

1.3 Drive electric electric electric electric 1.3

1.4 Operator type pedestrian pedestrian pedestrian pedestrian 1.4

1.5 Load capacity /rated load Q (t) 0.6 0.8 1.0 1.2 1.5

1.6 Load centre distance c (mm) 500 500 500 500 1.6

1.8 Load distance, centre of drive axle to fork x (mm) 120 120 120 120 1.8

1.9 Wheelbase y (mm) 960 1090 1220 1350 1.9

2.1 Service weight incl. battery (see line 6.5) kg 1980 2045 2110 2175 2.1

2.2 Axle loading, laden front/rear kg 550 /2030 550 /2295 550 /2560 550 /2825 2.2

2.3 Axle loading, unladen front/rear kg 1000 / 980 1030 /1015 1070 /1040 1100 /1075 2.3

3.1 Tyres PU /Vulkollan

®

PU /Vulkollan

®

PU /Vulkollan

®

PU /Vulkollan®3.1

3.2 Tyre size, front mm ⭋ 230x70 ⭋ 230 x 70 ⭋ 230 x 70 ⭋ 230 x70 3.2

3.3 Tyre size, rear mm ⭋ 200 x100 ⭋ 200 x100 ⭋ 200 x 100 ⭋ 200 x100 3.3

3.5 Wheels, number front rear (x = driven wheels) 1x /2 1x /2 1x/2 1x/2 3.5

4.2 Closed mast height h

1

(mm) 1880 1880 1880 1880 4.2

4.3 Free lift h

2

(mm) 100 100 100 100 4.3

4.4 Lift h3(mm) 2500 2500 2500 2500 4.4

4.9 Height of tiller in drive position min. /max. h

14

(mm) 865 /1320 865 /1320 865 /1320 865 /1320 4.9

4.15 Height, lowered h

13

(mm) 50 50 50 50 4.15

4.19 Overall length l

1

(mm) 2400 2530 2660 2790 4.19

4.20 Length to face of forks l

2

(mm) 1250 1380 1510 1640 4.20

4.21 Overall width b

1/b2

(mm) 910 /– 910 /– 910 /– 910 /– 4.21

4.22 Fork dimensions s/e/ l (mm) 40 /80/ 1150 40 /80/ 1150 40 /80/ 1150 40 /80/ 1150 4.22

4.24 Fork-carriage width b

3

(mm) 680 680 680 680 4.24

4.31 Ground clearance, laden, below mast m

1

(mm) 60 60 60 60 4.31

4.32 Ground clearance, centre of wheelbase m

2

(mm) 90 90 90 90 4.32

4.34

Aisle width for pallets 800 x1200 lengthways

Ast (mm) 2730 2860 2990 3120 4.34

4.35 Turning radius Wa (mm) 1180 1310 1440 1570 4.35

5.1 Travel speed, laden /unladen km/h 4.6/ 5.2 4.6/5.2 4.6 /5.2 4.6/ 5.2 5.1

5.2 Lift speed, laden /unladen m/s 0.13/ 0.20 0.13 /0.20 0.13 /0.20 0.13 /0.20 5.2

5.3 Lowering speed, laden /unladen m/s 0.43 /0.40 0.43 /0.40 0.43 /0.40 0.43 /0.40 5.3

5.10 Service brake electric electric electric electric 5.10

6.1 Drive motor rating S

2

60 min. kW 11116.1

6.2 Lift motor rating at S

3

10% kW 1.7 1.7 1.7 1.7 6.2

6.3 Battery acc. to DIN 43531 /35/ 36 A, B, C, no A A A A 6.3

6.4 Battery voltage, nominal capacityt K

5

V/Ah 24/ 375 24 / 375 24 /375 24/375 6.4

6.5 Battery weight kg 306 306 306 306 6.5

8.1 Type of drive control AC SpeedControl AC SpeedControl AC SpeedControl AC SpeedControl 8.1

IdentificationWeightsWheels, ChassisBasic Dimensions

Performance Data

E-MotorOthers

This specification sheet according to VDI regulation 2198 only provides technical values for the standard truck. Non-standard tyres, different masts, additional equipment, etc. could produce

other values. Right reserved for technical changes and improvements.

Page 4

Make use of the advantages

Innovative AC technology

Jungheinrich AC motors offer higher perform

-

ance and reduce running costs:

쐍

High efficiency levels with excellent energy

management.

쐍 Rapid and smooth acceleration.

쐍 Fast change of direction.

쐍 No carbon brushes – the drive motor is

maintenance-free.

쐍 Two-year warranty on the drive motor.

Counterbalanced stacking

쐍 The counterbalance design without inter-

ference from support arms enables perimeter based pallets and special load sizes

to be used.

쐍 The generous ground clearance with

200 mm load wheels allows the truck to

travel over uneven ground and low thresholds.

쐍 The short overall length helps operation in

confined areas.

쐍 Precise, gentle load lowering through

speed-controlled hydraulic motor.

쐍

Gentle load lowering through proportional

hydraulic system.

Work ergonomically

The newly designed tiller head is ideally suited

to the ergonomic needs of the operator.

쐍 A clear colour coding system and buttons

with non-marking symbols for intuitive

operation.

쐍 Grip angle to suit the hand position of the

operator.

쐍

Mechanical steering with bottom mounted

tiller.

Batteries

쐍 3 EPzS 375 Ah.

쐍 3 PzB 300 Ah.

Readily available information

Extensive controls and setting options allow

the operator to check at a glance:

쐍 Combined discharge indicator (3 colour

LED) with lift cutout and charge status display (for on-board charger).

쐍 “CanDis” information display (optional)

with additional hourmeter display and error

code logging.

쐍 PIN activation of truck and choice of 3

travel programmes through “CanCode”

(optional).

쐍 Adjustable travel parameters through

CanDis and CanCode (optional).

Reduced maintenance

AC systems provide a clear, long-term reduction in running costs:

쐍 Maintenance-free drive motor with no

carbon brushes.

쐍 Easy access to all components.

쐍 Solid protection against dust and humidity

for example through IP 54 enclosure of the

control system and connectors.

Lifting perimeter based pallets directly from the

floor – no problem for the EJG

Excellent visibility through the mast

Ergonomic tiller head

Sideways battery exit (optional) and compact

hydraulic unit

1447.GB.08.2010.r.s.

Jungheinrich trucks

conform to the European

Safety Requirements.

Jungheinrich UK Ltd.

Head Office:

Sherbourne House · Sherbourne Drive

Tilbrook · Milton Keynes MK7 8HX

Phone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

Jungheinrich

Plants, Sales and

Services Europe

ISO 9001/ ISO14001

Loading...

Loading...