Page 1

Cleaning-friendly

construction makes it

corrosion-proof and

resistant to jets of water

Hygienic and food-neutral

due to smooth and

abrasion-proof surface

Ergonomic and IP 65 sealed

multifunction tiller arm

Powerful thanks to

maintenance-free 3-phase

AC drive motor

Outstanding cornering

thanks to ProTracLink

stainless steel coupling unit

Long service life in

harsh environments

EJE i20

Stainless steel electric pedestrian pallet truck (2,000 kg)

The Jungheinrich EJE i20 stainless steel

pallet truck combines the advantages

of a stainless steel frame with proven

Jungheinrich drive and control technology. The truck is designed for demanding

transport operations up to 2000 kg.

The EJE i20 is best suited for operation

in corrosive and damp environments

and satisfies the most stringent hygienic

regulations. With these specifications,

the truck is ideal for use in the food,

chemical and pharmaceutical industries.

High-quality V2A stainless steel also

oers an abrasion-resistant and smooth

surface, even with intensive use: This

prevents dirt deposits, thus preventing

the spread of germs and bacteria.

The rugged vehicle design is designed to

withstand regular high-pressure cleaning

and disinfection. Water can flow freely

over the continuous bevelled surfaces;

special seals inhibit the ingress of fluids

into the drive compartment.

The design of the multifunctional tiller

arm uses encapsulated sensor technology (IP 65) that guarantees maximum

protection against breakdown. Contactfree electronic rocker switches as well as

an easily accessed crawl speed button

allow for ergonomically perfect oper-

ation with every tiller position.

High acceleration, speed and ecient

braking are the strengths of the powerful drive motor, achievable by the

application of innovative 3-phase AC

technology. The centrally driven EJE i20

achieves the necessary cornering stability

via the Jungheinrich ProTracLink torsion

bar made from high-grade stainless steel.

Lateral exchange of the battery further

ensures the ecient application of the

truck in shift operations. All of the above

points add to the ecient, safe and fast

handling of goods.

Page 2

EJE i20

Page 3

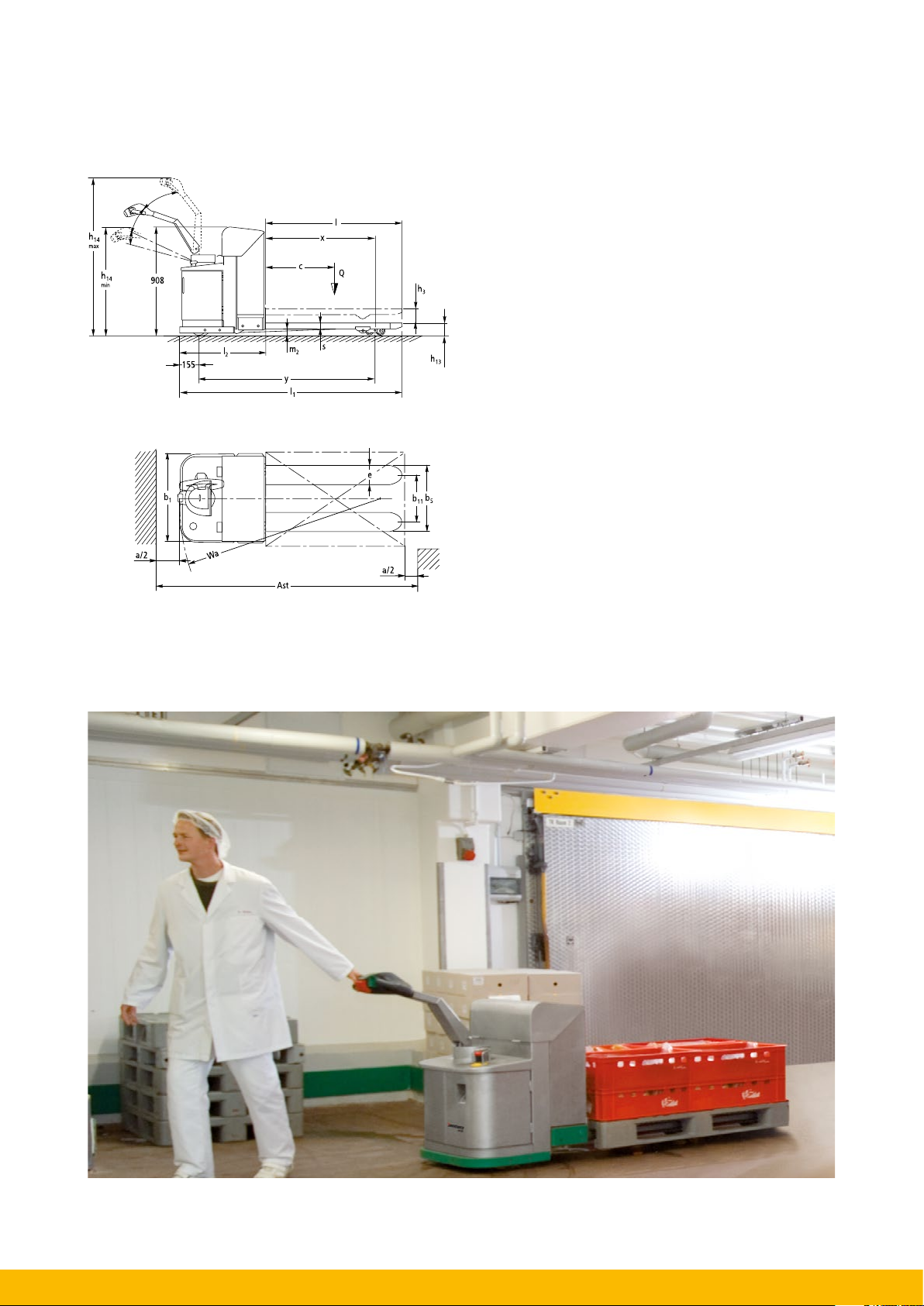

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model EJE i20

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation pedestrian

1.5 Load capacity/rated load Q t 2

1.6 Load centre distance c mm 600

Identification

1.8 Load distance x mm 913

1.9 Wheelbase y mm 1385

2.1.1 Net weight incl. battery (see row 6.5) kg 719

2.2 Axle load, w. load, front / rear kg 1074 / 1645

2.3 Axle load, w.o. load, front / rear kg 574 / 145

Weights

3.1 Tyres Vulkollan

3.2 Tyre size, at front mm Ø 230 x 65

3.3 Tyre size, at rear mm Ø 82 x 66

3.4 Additional wheels (dimensions) mm Ø 125 x 54

3.5 Wheels, number front/rear (× = driven wheels) 3-1x/4

3.7 Track width, rear b

Wheels / chassis

4.4 Lift h3 mm 125

4.9 Height of tiller in drive position min. / max. h

4.15 Lowered height h

4.19 Overall length l

4.20 Length incl. back of forks l

4.21 Total width b

4.22 Fork dimensions s/e/l mm 56 / 160 / 1150

4.25 Width over forks b

Basic dimensions

4.32 Floor clearance centre wheelbase m

4.35 Turning radius W

5.1 Travel speed, w. / w.o. load km/h 5.3 / 5.3

5.2 Lift speed, w. / w.o. load m/s 0.046 / 0.06

5.3 Lower speed, w. / w.o. load m/s 0.059 / 0.053

5.7 Gradeability laden/unladen % 8 / 15

data

5.8 Max. gradeability, laden/unladen % 12 / 15

Performance

5.10 Service brake generated

6.1 Drive motor rating S2 60 min. kW 1.6

6.2 Lift motor kW rating at S3 7% kW 2.2

6.3 Battery according to DIN 43531/35/36 A,B,C, no B

6.4 Battery voltage/nominal capacity K5 V/Ah 24 / 230

Electrics

6.5 Battery weight kg 220

6.6 Energy consumption according to VDI cycle kWh/h 0.5

8.1 Type of drive control AC SpeedControl

Misc.

mm 390

11

mm 810 / 1124

14

mm 85

13

mm 1850

1

mm 711

2

mm 740 / 540

1/b2

mm 540

5

mm 35

2

mm 1685

a

Issue: 07/2008

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

Ready for battery changing: open

battery cover and removed side

panel

Ergonomic tiller with intuitive

buttons

‘Hygienic design’

• Smooth and corrosion-free surface is

food-neutral due to dirt resistance and

the spread of germs and bacteria.

• Stainless steel surfaces oer no risk of

material abrasion during production.

• Closed fork section ensures hygienic

separation of the load wheels and the

goods to be carried.

• Conforms to the EU directive for foodstu hygiene.

Easy clean design

The whole truck is extremely easy to

clean and is designed for daily operation

in damp and wet areas:

• Bevelled surfaces allow water to flow

over them with ease.

• Encapsulated multi-function tiller arm

control head (IP 65) with encapsulated

contactless sensor technology safeguards against high pressure cleaning

and disinfection.

• Robust seals protect drive and control

components.

• Strong overlapping battery compartment hood protects the battery against

the penetration of cleaning fluids.

Excellent service access

High quality materials for demanding

applications

The use of material suited to the application guarantees a high reliability and

long life:

• Surfaces made from high quality stainless steel reliably prevent corrosion.

• Battery in plastic protective carrier, installed on slide rails.

• All controls are sealed and corrosion

proof.

Work ergonomically

The new-generation multifunctional

tiller arm perfectly meets the ergonomic

demands of the operator.

• Clear colour coding and buttons with

countersunk/raised designs for intuitive

operation.

• Grip angle to suit the hand position of

the operator.

• Crawl speed button underneath the

tiller arm for easy access and travelling

with the tiller upright.

• Rocker switch for consistent operation

in all tiller positions.

• Centrally positioned large emergency

stop button with safety guard.

• 3-colour LED battery monitor shows

the battery discharge status at all times.

• Battery exchange from above or side

with plastic sliders.

Optimal cornering

The spring mounted and damped support wheels connected by the torsion

bar suspension system “ProTracLink”

made from stainless steel, ensure safe

operation, a reduction in wear and high

stability in every travel situation. Support

is automatically distributed equally over

all wheels during straight travel or concentrated on the outer support wheel

during cornering.

Innovative 3rd Generation AC technology

Jungheinrich 3rd Generation AC technology motors oer high performance

and at the same time, reduce operating

costs:

• Powerful acceleration.

• Higher eciency with excellent energy

consumption.

• Faster travel direction change without

delay.

• No carbon brushes – the drive motor is

maintenance free.

• 2 year guarantee on the drive motor.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_EJE i20_042014_en_UK_000

Loading...

Loading...