Page 1

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Mineral-Insulated Thermocouples

According to DIN 43710

and DIN EN 60584

• For temperatures between -200 to +1200 °C

• Flexible sheath cable with vibration-resistant measuring insert

• Protection tube diameter as of 0.5 mm

•Quick response time

• Application-specific insertion length

Due to their specific features, mineral-insulated thermocouples are used in chemical plants,

power plants, pipelines, engine building, and test rigs. Inside the flexible and thin-walled

sheathed cable, the thermowires are embedded in compressed and fire-resistant magnesium

oxide.

The good thermal transfer between the sheath and the thermocouple enables short response

times (t

guarantees a long operating life. The smallest bending radius is 5 times the outer diameter. With

a diameter of 0.5 to 2.0 mm, the minimum insertion length (EL) is ≥ 50 mm; with a diameter of

3.0 to 6.0 mm the EL is ≥ 100 mm.

The thermocouples are designed to be insulated from the sheath as standard. The measuring

insert is equipped with thermocouples (elements) according to DIN EN 60584 and/or DIN

43710. Versions with two thermocouples are also possible.

Test pressure: check for leaks at the measuring point at 40 bar (helium).

Leakage resistance: thermocouple against sheath at room temperature and lengths < 1 m

200 MΩ, with lengths ≥ 1 m 200 MΩ ×m.

as of 0.15 s) and excellent measuring accuracy. The vibration-resistant construction

0.5

Data Sheet 901210 Page 1/11

Technical data

Terminal head Form B, diecast aluminum, M20 × 1.5; IP65, ambient temperature -40 to +100 °C

Connection Cable ends stripped bare; alternatively available with ferrules, plug-in sleeves, or multi-pole electrical

Compensating cable Silicone, ambient temperature -50 to +180 °C

Process connection Thread, stainless steel 1.4571

Protection tube Stainless steel 1.4541, thermocouple type "L" and "J"

Adapter sleeve (end closure) As standard, the adapter sleeve (end closure) is designed up to 120 °C; it is available up to 300 °C upon

Measuring insert Insulated construction:

Response times In water with 0.4 m/s / in air with 2 m/s

Transmitter Programmable transmitter, 4 to 20 mA / 20 to 4 mA output, data sheet 707010

2013-01-21/00073440

Form BUZ, diecast aluminum, M20 × 1.5; IP65, ambient temperature -40 to +100 °C

Form J, diecast aluminum, M16 × 1.5; IP65, ambient temperature -40 to +100 °C

Caution: reduced ambient temperature when using transmitters

connectors (e.g. thermal-voltage-free connector)

PTFE, ambient temperature 190 to +260 °C

Metal braiding, ambient temperature -20 to +350 °C

Inconel 2.4816 (Inconel 600), thermocouple type "K" and "N"

request.

1× Fe-CuNi "J", DIN EN 60584, class 2, operating temperature -200 to +800 °C

1× Fe-CuNi "L", DIN 43710, class 2, operating temperature -200 to +800 °C

1× NiCr-Ni "K", DIN EN 60584, class 2, operating temperature -200 to +1200 °C

1× NiCrSi-NiSi "N", DIN EN 60584, class 2, operating temperature -200 to +1200 °C

2× Fe-CuNi "L", DIN 43710, class 2, operating temperature -200 to +800 °C

2× NiCr-Ni "K", DIN EN 60584, class 2, operating temperature -200 to +1200 °C

2× NiCrSi-NiSi "N", DIN EN 60584, class 2, operating temperature -200 to +1200 °C

Ø 0.5 mm: water t

Ø 1.0 mm: water t

Ø 1.5 mm: water t

Ø 2.0 mm: water t

Ø 3.0 mm: water t

Ø 4.5 mm: water t

Ø 6.0 mm: water t

programmable transmitter, 4 to 20 mA / 20 to 4 mA and HART

= 0.15 s, t

0.5

= 0.20 s, t

0.5

= 0.40 s, t

0.5

= 0.80 s, t

0.5

= 1.00 s, t

0.5

= 2.50 s, t

0.5

= 3.00 s, t

0.5

= 0.30 s/air t

0.9

= 0.60 s/air t

0.9

= 0.90 s/air t

0.9

= 2.60 s/air t

0.9

= 2.80 s/air t

0.9

= 6.50 s/air t

0.9

= 9.00 s/air t

0.9

= 3.5 s, t

0.5

= 7.5 s, t

0.5

= 10.0 s, t

0.5

= 13.0 s, t

0.5

= 22.0 s, t

0.5

= 34.0 s, t

0.5

= 55.0 s, t

0.5

= 8.0 s

0.9

= 17.0 s

0.9

= 25.0 s

0.9

= 34.0 s

0.9

= 64.0 s

0.9

= 113.0 s

0.9

= 170.0 s

0.9

®

interface output, data sheet 707010

Page 2

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Lead wire resistance in Ω/m at 20 °C for mineral-insulated thermocouples

Data Sheet 901210 Page 2/11

Diameter

D in mm

1 element

resistance in Ω/m

2 elements

resistance in Ω/m

Thermocouple Fe-CuNi "L"

6.0 0.66 0.85

4.5 1.40 1.80

3.0 2.70 3.50

2.0 5.00 -

1.5 12.00 -

1.0 21.50 -

Thermocouple Fe-CuNi "J"

6.0 0.54 -

3.0 2.10 -

2.0 8.60 -

1.5 15.00 -

1.0 34.00 -

Thermocouple NiCr-Ni "K"

6.0 0.88 2.70

4.5 1.56 4.80

3.0 3.50 11.00

2.0 7.90 25.00

1.5 14.00 -

1.0 32.00 -

0.5 126.00 -

Thermocouple NiCrSi-NiSi "N"

6.0 1.81 1.68

3.0 5.98 7.00

2013-01-21/00073440

Page 3

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

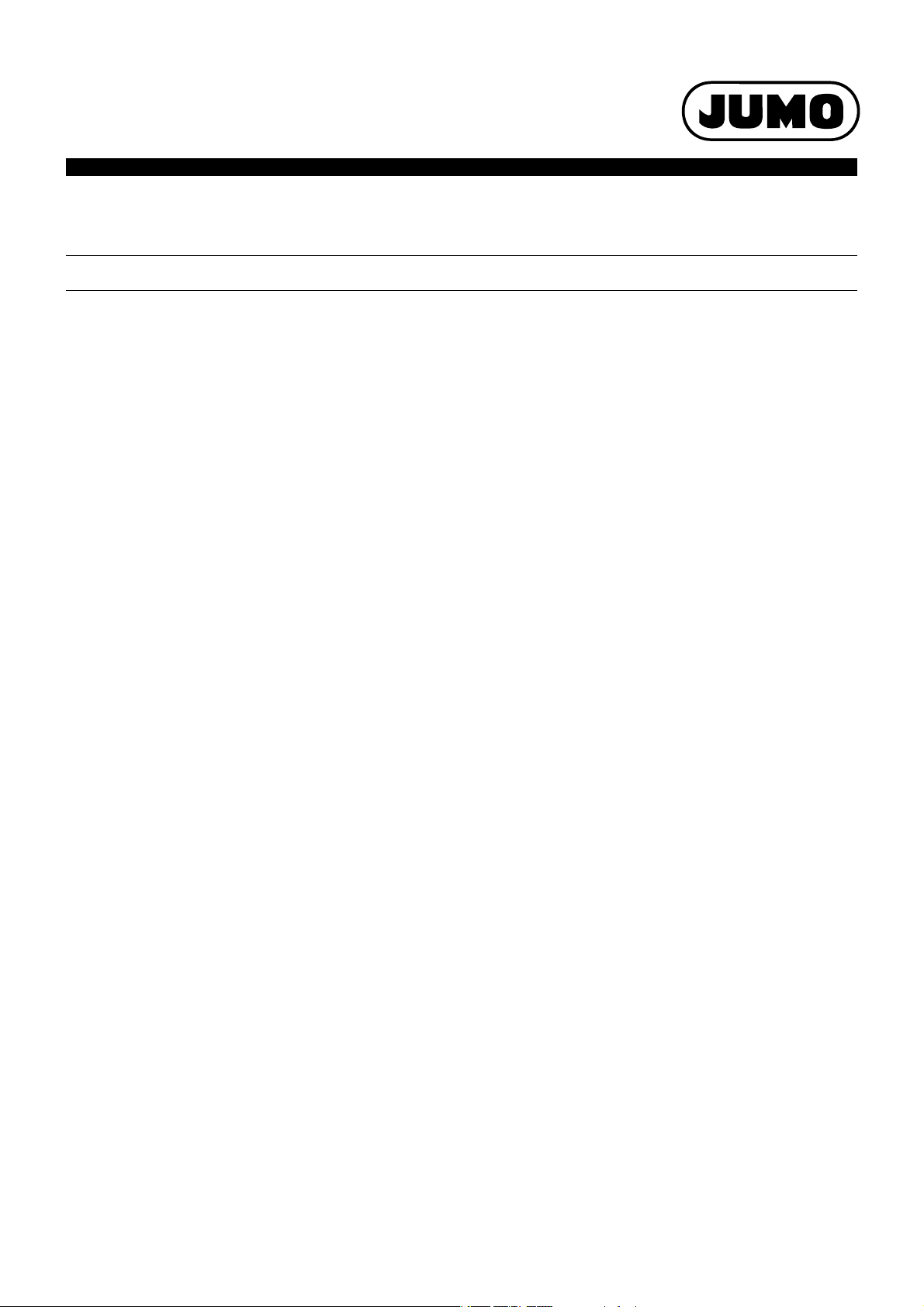

Dimensions

Data Sheet 901210 Page 3/11

Basic type 901210/10 Basic type 901220/40 Basic type 901220/41

Basic type 901230/40 Basic type 901230/41 Basic type 901240/20

2013-01-21/00073440

Page 4

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

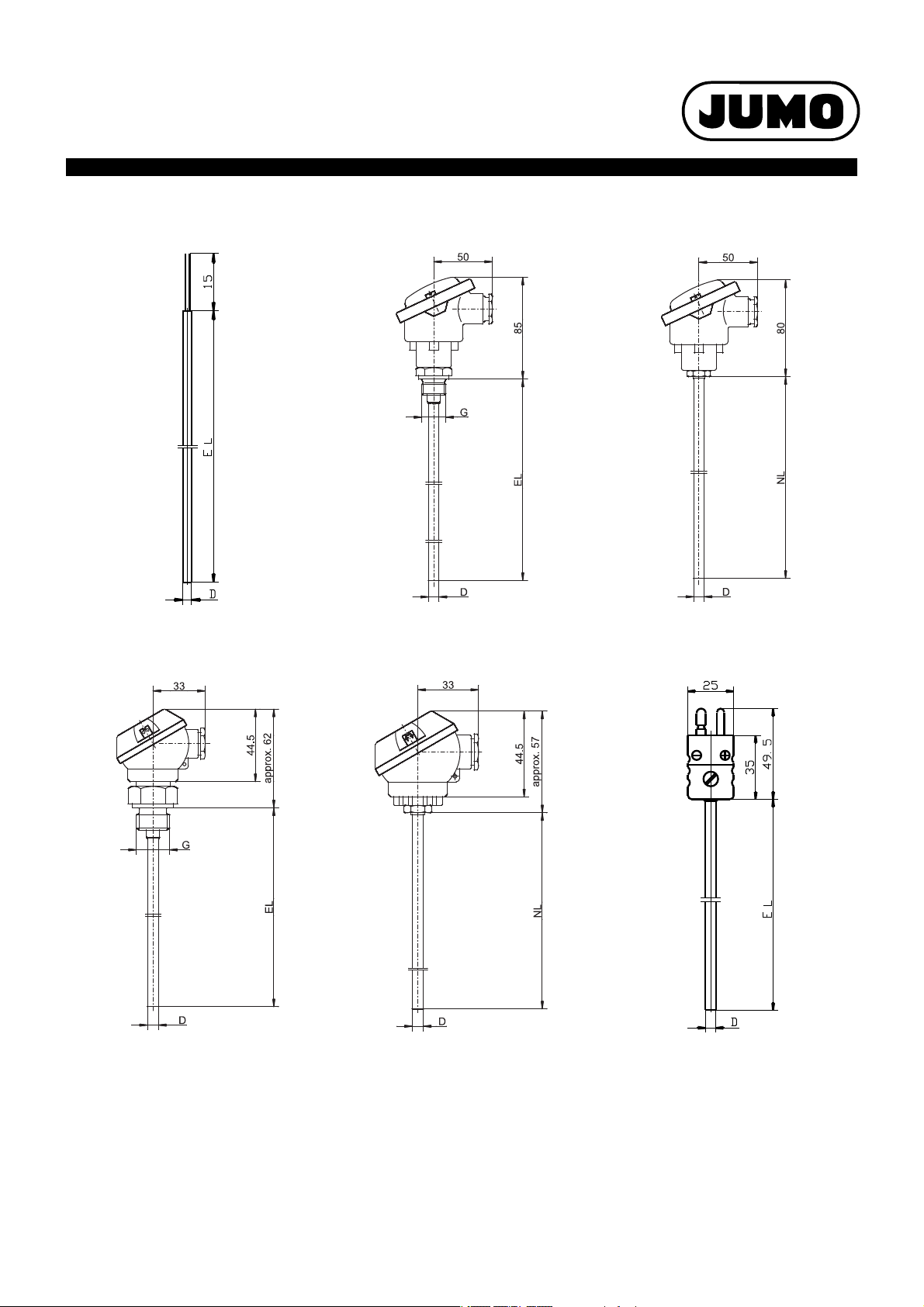

Basic type 901250/3x Terminal head form BUZ

extra code 320

Data Sheet 901210 Page 4/11

2013-01-21/00073440

Page 5

Data Sheet 901210 Page 5/11

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Order details: Mineral-insulated thermocouples according to DIN 43710 and DIN EN 60584

(1) Basic type

901210/10

901240/20

Mineral-insulated thermocouples

with bare connection wires

Mineral-insulated thermocouple

with thermal-voltage-free standard tab-connector

(2) Measuring insert / operating temperature in °C

x x 1040 1× Fe-CuNi "J", operating temperature -200 to +800 °C, sheath material no. 1.4541

x x 1042 1× Fe-CuNi "L", operating temperature -200 to +800 °C, sheath material no. 1.4541

x x 1043 1× NiCr-Ni "K", operating temperature -200 to +1200 °C, sheath material no. 2.4816

x 1048 1× NiCrSi-NiSi "N", operating temperature -200 to +1200 °C, sheath material no. 2.4816, D = 3 and 6 mm

x 2042 2× Fe-CuNi "L", operating temperature -200 to +800 °C, sheath material no. 1.4541

x 2043 2× NiCr-Ni "K", operating temperature -200 to +1200 °C, sheath material no. 2.4816

x 2048 2× NiCrSi-NiSi "N", operating temperature -200 to +1200 °C, sheath material 2.4816, D = 3 and 6 mm

(3) Protection tube diameter D in mm

x 0.5 Ø 0.5 mm, only in connection with measuring insert 1× NiCr-Ni "K"

xx 1 Ø1mm

x x 1.5 Ø 1.5 mm

xx 2 Ø2mm

xx 3 Ø3mm

x x 4.5 Ø 4.5 mm

xx 6 Ø6mm

(4) Insertion length EL in mm (50 to 50000 mm)

x x 100 100 mm

x x 200 200 mm

x x 300 300 mm

x x 400 400 mm

x x 500 500 mm

x x ... Please specify in plain text (50 mm steps)

(5) Extra codes

x x 000 Without

x x 309 Uninsulated construction (element welded to the base)

(1) (2) (3) (4) (5)

Order code ---/

Order example 901210/10 - 1042 - 3 - 200 / 000

2013-01-21/00073440

Page 6

Data Sheet 901210 Page 6/11

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Order details: Mineral-insulated thermocouples according to DIN 43710 and DIN EN 60584

(1) Basic type

901220/40

901220/41

Screw-in mineral-insulated thermocouple

with terminal head, form B

Push-in mineral-insulated thermocouple

with terminal head, form B

(2) Measuring insert / operating temperature in °C

x x 1040 1× Fe-CuNi "J", operating temperature -200 to +800 °C, sheath material no. 1.4541

x x 1042 1× Fe-CuNi "L", operating temperature -200 to +800 °C, sheath material no. 1.4541

x x 1043 1× NiCr-Ni "K", operating temperature -200 to +1200 °C, sheath material no. 2.4816

x x 1048 1× NiCrSi-NiSi "N", operating temperature -200 to +1200 °C, sheath material no. 2.4816

x x 2042 2× Fe-CuNi "L", operating temperature -200 to +800 °C, sheath material no. 1.4541

x x 2043 2× NiCr-Ni "K", operating temperature -200 to +1200 °C, sheath material no. 2.4816

x x 2048 2× NiCrSi-NiSi "N", operating temperature -200 to +1200 °C, sheath material no. 2.4816

(3) Protection tube diameter D in mm

xx 3 Ø3mm

x x 4.5 Ø 4.5 mm (not for measuring insert type "N")

xx 6 Ø6mm

(4) Insertion length EL/NL in mm (50 to 50000 mm)

x x 100 100 mm

x x 200 200 mm

x x 300 300 mm

x x 400 400 mm

x x 500 500 mm

x x ... Please specify in plain text (50 mm steps)

(5) Process connection

x 000 Without

x 103 Screw connection G 3/8

x 104 Screw connection G 1/2

(6) Extra codes

x x 000 Without

x x 309 Uninsulated construction (element welded to the base)

x x 320 Terminal head form BUZ

x x 331 1× programmable transmitter, 4 to 20 mA / 20 to 4 mA output, data sheet 707010

x x 336

1× programmable transmitter, 4 to 20 mA / 20 to 4 mA and HART

®

interface output, data sheet 707010

(1) (2) (3) (4) (5) (6)

Order code ----/, ...

a

Order example 901220/40 - 1040 - 3 - 100 - 104 / 000

a

List extra codes in sequence, separated by commas.

2013-01-21/00073440

Page 7

Data Sheet 901210 Page 7/11

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Accessories

Article Part no.

Pipe screw connection M8 × 1 stainless steel, clamping ring stainless steel for protection tube diameter D = 3 mm 00080810

Pipe screw connection M8 × 1 stainless steel, clamping ring PTFE for protection tube diameter D = 3 mm 00049709

Pipe screw connection M8 × 1 steel, clamping ring PTFE for protection tube diameter D = 4.5 mm 00049704

Pipe screw connection M8 × 1 stainless steel, clamping ring PTFE for protection tube diameter D = 4.5 mm 00049710

Pipe screw connection M10 × 1 stainless steel, clamping ring stainless steel for protection tube diameter D = 6 mm 00065416

Pipe screw connection G 1/4 stainless steel, clamping ring stainless steel for protection tube diameter D = 6 mm 00080811

Pipe screw connection G 3/8 steel, clamping ring steel for protection tube diameter D = 6 mm 00057945

Pipe screw connection G 3/8 stainless steel, clamping ring stainless steel for protection tube diameter D = 6 mm 00317966

Pipe screw connection G 1/2 stainless steel, clamping ring stainless steel for protection tube diameter D = 6 mm 00305445

Pipe screw connection 1/2-14NPT stainless steel, clamping ring stainless steel for protection tube diameter D = 6 mm 00444210

Sheet steel flange for protection tube diameter D = 6 mm 00065042

2013-01-21/00073440

Page 8

Data Sheet 901210 Page 8/11

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Order details: Mineral-insulated thermocouples according to DIN 43710 and DIN EN 60584

(1) Basic type

901230/40

901230/41

Screw-in mineral-insulated thermocouple

with terminal head, form J

Push-in mineral-insulated thermocouple

with terminal head, form J

(2) Measuring insert / operating temperature in °C

x x 1040 1× Fe-CuNi "J", operating temperature -200 to +800 °C, sheath material no. 1.4541

x x 1042 1× Fe-CuNi "L", operating temperature -200 to +800 °C, sheath material no. 1.4541

x x 1043 1× NiCr-Ni "K", operating temperature -200 to +1200 °C, sheath material no. 2.4816

x x 1048 1× NiCrSi-NiSi "N", operating temperature -200 to +1200 °C, sheath material no. 2.4816

x x 2042 2× Fe-CuNi "L", operating temperature -200 to +800 °C, sheath material no. 1.4541

x x 2043 2× NiCr-Ni "K", operating temperature -200 to +1200 °C, sheath material no. 2.4816

x x 2048 2× NiCrSi-NiSi "N", operating temperature -200 to +1200 °C, sheath material no. 2.4816

(3) Protection tube diameter D in mm

xx 3 Ø3mm

x x 4.5 Ø 4.5 mm (not for measuring insert type "N")

xx 6 Ø6mm

(4) Insertion length EL/NL in mm (50 to 50000 mm)

x x 100 100 mm

x x 200 200 mm

x x 300 300 mm

x x 400 400 mm

x x 500 500 mm

x x ... Please specify in plain text (50 mm steps)

(5) Process connection

x 000 Without

x 103 Screw connection G 3/8

x 104 Screw connection G 1/2

(6) Extra codes

x x 000 Without

x x 309 Uninsulated construction (element welded to the base)

(1) (2) (3) (4) (5) (6)

Order code ----/

Order example 901230/40 - 1040 - 3 - 100 - 104 / 000

2013-01-21/00073440

Page 9

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Data Sheet 901210 Page 9/11

Accessories

Article Part no.

Pipe screw connection M8 × 1 stainless steel, clamping ring stainless steel for protection tube diameter D = 3 mm 00080810

Pipe screw connection M8 × 1 stainless steel, clamping ring PTFE for protection tube diameter D = 3 mm 00049709

Pipe screw connection M8 × 1 steel, clamping ring PTFE for protection tube diameter D = 4.5 mm 00049704

Pipe screw connection M8 × 1 stainless steel, clamping ring PTFE for protection tube diameter D = 4.5 mm 00049710

Pipe screw connection M10 × 1 stainless steel, clamping ring stainless steel for protection tube diameter D = 6 mm 00065416

Pipe screw connection G 1/4 stainless steel, clamping ring stainless steel for protection tube diameter D = 6 mm 00080811

Pipe screw connection G 3/8 steel, clamping ring steel for protection tube diameter D = 6 mm 00057945

Pipe screw connection G 3/8 stainless steel, clamping ring stainless steel for protection tube diameter D = 6 mm 00317966

Pipe screw connection G 1/2 stainless steel, clamping ring stainless steel for protection tube diameter D = 6 mm 00305445

Pipe screw connection 1/2-14NPT stainless steel, clamping ring stainless steel for protection tube diameter D = 6 mm 00444210

Sheet steel flange for protection tube diameter D = 6 mm 00065042

2013-01-21/00073440

Page 10

Data Sheet 901210 Page 10/11

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Order details: Mineral-insulated thermocouples according to DIN 43710 and DIN EN 60584

(1) Basic type

901250/32

901250/33

901250/34

Mineral-insulated thermocouple

with silicone-insulated compensating cable

Mineral-insulated thermocouple

with PTFE-insulated compensating cable

Mineral-insulated thermocouple

with compensation cable

that is metal-braided and insulated with glass-fiber

(2) Measuring insert / operating temperature in °C

x x x 1040 1× Fe-CuNi "J", operating temperature -200 to +800 °C, sheath material no. 1.4541

x x x 1042 1× Fe-CuNi "L", operating temperature -200 to +800 °C, sheath material no. 1.4541

x x x 1043 1× NiCr-Ni "K", operating temperature -200 to +1200 °C, sheath material no. 2.4816

x x 2042 2× Fe-CuNi "L", operating temperature -200 to +800 °C, sheath material no. 1.4541

x x 2043 2× NiCr-Ni "K", operating temperature -200 to +1200 °C, sheath material no. 2.4816

(3) Protection tube diameter D in mm

x x x 0.5 Ø 0.5 mm

xxx 1 Ø1mm

x x x 1.5 Ø 1.5 mm

xxx 2 Ø2mm

xxx 3 Ø3mm

x x x 4.5 Ø 4.5 mm

xxx 6 Ø6mm

(4) Insertion length EL in mm (50 to 50000 mm)

x x x 100 100 mm

x x x 200 200 mm

x x x 300 300 mm

x x x 400 400 mm

x x x 500 500 mm

x x x ... Please specify in plain text (50 mm steps)

(5) Compensating cable end

x x x 11 Ferrules according to DIN 46228 part 4 (standard)

x x x 80 Multi-pole electrical connector (specify type in plain text)

(6) Compensating cable length AL in mm (500 to 500000 mm)

x x x 2500 2500 mm (standard)

x x x ... Please specify in plain text (500 mm steps)

(7) Extra codes

x x 000 Without

x x 309 Uninsulated construction (element welded to the base)

x x 317 Compensating cable shielded

x x 855 Adapter sleeve (end closure) 300 °C

(1) (2) (3) (4) (5) (6) (7)

Order code -----/, ...

a

Order example 901250/32 - 1042 - 3 - 200 - 11 - 2500 / 000

a

List extra codes in sequence, separated by commas.

2013-01-21/00073440

Page 11

Data Sheet 901210 Page 11/11

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Stock versions

(1) (2) (3) (4) (5) (6) (7) Part no.

901250/32 - 1042 - 3 - 100 - 11 - 2500 / 000 00056809

901250/32 - 1042 - 3 - 200 - 11 - 2500 / 000 00068433

901250/32 - 1042 - 1.5 - 100 - 11 - 2500 / 000 00056811

901250/32 - 1042 - 1.5 - 200 - 11 - 2500 / 000 00068438

901250/32 - 1043 - 6 - 100 - 11 - 2500 / 000 00056812

901250/32 - 1043 - 6 - 200 - 11 - 2500 / 000 00068427

901250/32 - 1043 - 3 - 100 - 11 - 2500 / 000 00056813

901250/32 - 1043 - 3 - 200 - 11 - 2500 / 000 00068441

901250/32 - 1043 - 3 - 300 - 11 - 2500 / 000 00068442

901250/32 - 1043 - 3 - 500 - 11 - 2500 / 000 00068443

901250/32 - 1043 - 1.5 - 100 - 11 - 2500 / 000 00049205

901250/32 - 1043 - 1.5 - 200 - 11 - 2500 / 000 00068436

901250/32 - 1043 - 1.5 - 500 - 11 - 2500 / 000 00068437

901250/32 - 1043 - 0.5 - 100 - 11 - 2500 / 000 00066345

Stock versions

(1) (2) (3) (4) (5) (6) Part no.

901230/40 - 1043 - 6 - 200 - 104 / 000 00068430

901230/40 - 1043 - 6 - 300 - 104 / 000 00068431

2013-01-21/00073440

Loading...

Loading...