Page 1

English

www.julabo.de

Operating Manual

Heating Circulators

HE-4

SE-6

SE-12

SE-26

Bridge Mounted

Circulator

SE-Z

1.951.2442-V2 06/13

19512442-V2.doc 22.09.14

JULABO GmbH

77960 Seelbach / Germany

Tel. +49 (0) 7823 / 51-0

Fax +49 (0) 7823 / 24 91

info@julabo.de

Page 2

Temperature control devices for research and industry are developed,

Congratulations!

You have made an excellent choice.

JULABO thanks you for the trust you have placed in us.

This operating manual has been designed to help you gain an unders tandin g o f the operation and

possibl e ap pl i cat ions of our ci r cul at or s . F or optimal utilization o f all funct ions, we rec ommend that you

thoroughly study this manual prior to beginning operation.

The JULABO Quality Management System

produced, and distributed according to the requirements of ISO 9001 and

ISO 14001. Certificate Registration No. 01 100044846

Unpacking and inspecting

Unpack the circulator and accessories and inspect them for possible transport damage. Damage

should be reported to the responsible carrier, railway, or postal authority, and a damage report should

be request ed. These ins t r uctions must be followed full y for us to guarantee our full support of your

claim for pr ot ec ti n g against loss fr om c onc ealed dam ag e. T he for m req ui r ed for fil i n g suc h a clai m w i ll

be provided by the carrier.

Printed in Germany Changes without prior notification reserved

Important: keep operating manual for futur e us e

2

Page 3

TABLE OF CONTENTS

Operating manual ................................................................................................................ 5

1. Intended use ................................................................................................................. 5

1.1. Description ............................................................................................................... 5

2. Operator responsibility – Safety recommendations ....................................................... 6

2.1. Disposal ................................................................................................................... 7

2.2. EC Conformity .......................................................................................................... 8

2.3. Warranty con ditions ................................................................................................. 9

2.4. Technical specifications ......................................................................................... 10

Operating instructions ....................................................................................................... 12

3. Safety no tes for the user ............................................................................................. 12

3.1. Expl anation of safety notes .................................................................................... 12

3.2. Expl anation of other notes ...................................................................................... 12

HE / SE

3.3. Safety recommendations ........................................................................................ 13

4. Operating controls and functional elements ................................................................ 15

5. Preparations ............................................................................................................... 18

5.1. Installation .............................................................................................................. 18

5.2. Bath fluids .............................................................................................................. 19

5.3. Temperature application to external systems ......................................................... 20

5.3.1. Tubing ............................................................................................................... 21

5.4. Filli ng / drai ning ...................................................................................................... 22

5.5. Countercooling ....................................................................................................... 23

6. Operating procedures ................................................................................................. 24

6.1. Power connection ................................................................................................... 24

6.2. Switching on / Start - Stop ......................................................................................

24

6.2.1. Switchin g on the circul ator ................................................................................. 24

7.

7.1. Using the pre-settings in the

Setting of temperatures ................................................................................. 25

menu ........................................................... 25

7.2. Direct setting of temperatures ................................................................................ 26

8.

Safety installations, warning functions ........................................................... 27

8.1. Excess temperature protection ............................................................................... 27

8.1.1. Early warning system, low level protection ......................................................... 28

8.2. Switch-over from warning to shutdown funct i o n ...................................................... 29

8.3. Over and Sub temperature warning function .......................................................... 30

9.

Menu func ti ons.............................................................................................. 31

9.1. MENU PROGRAM – START.................................................................................. 32

9.2. MENU PROGRAM – creatio n, adm i ni stratio n ......................................................... 35

3

Page 4

9.3. MENU PUMP - Setting of pump pressure ...............................................................37

9.4. MENU CONFIG - Configur at ion of unit ....................................................................38

9.4.1. Remote control via the serial interface ................................................................39

9.4.2. Keypad control or setpoint setting via the analog input .......................................40

9.4.3. AUTOSTART ......................................................................................................40

9.4.4. OFF-MODE ........................................................................................................41

9.4.5. ACTVAR - actuating variable ..............................................................................41

9.4.6. Setting of clock and date ....................................................................................42

9.4.7. RESET – Factory settings...................................................................................42

9.5. MENU CONTROL – Control char acteris ti cs an d p ar am eters...................................42

9.5.1. CONTROL – Control INTERNAL / EXTERNAL ...................................................44

9.5.2. SELFTUNING .....................................................................................................45

9.5.3. Dynamic internal .................................................................................................45

9.5.4. Control parameters– XP-, TN-, TV- INTERNAL ..................................................46

9.5.5. COSPEED - external ..........................................................................................47

9.5.6. Control parameters – XPU-, XP-, TN-, TV- EXTERNAL ......................................47

9.6. MENU SERIAL - BAUDRATE, HANDSHAKE, PARITY ...........................................48

9.7. MENU ATC - Absolut Temperature Calibration .......................................................49

9.7.1. ATC SENSOR - INTERNAL / EXTERNAL ..........................................................51

9.7.2. ATC STATUS - YES / NO ...................................................................................51

9.7.3. CALIBRATION TYPE: 1 -/ 2 -/ 3 POINT..............................................................52

9.7.4. Exampl e: 3-point calibration for internal control .................................................53

9.8. MENU LIMITS - Begrenzungen ...............................................................................

55

9.8.1. Limits for internal control .....................................................................................56

9.8.2. Limits for external contr ol ....................................................................................56

9.9. MENU IN/OUT – Analog inputs/outputs (Option) .....................................................58

9.9.1. Outputs of the connector - REG+E-PROG ..........................................................61

9.9.2. Input of the c on nector - REG+E-PROG ..............................................................62

9.9.3. ALARM-out put / Stand-by-input ..........................................................................64

10. Troubleshooting guide / error messages ......................................................................66

11. Electrical connections ..................................................................................................69

12. Remote control ............................................................................................................71

12.1. Setup for remote control ..........................................................................................71

12.2. Communication with a PC or a superordinated data system ...................................71

12.3. List of commands ....................................................................................................72

12.4. Status messages ....................................................................................................75

12.5. E rror messages .......................................................................................................75

13. Installati o n o f elec tronic mod ul e ...................................................................................76

14. JULABO Service – Online remote diagnosis ................................................................77

15. Cleaning / re pair i n g t he unit .........................................................................................78

4

Page 5

HE / SE

JULABO cir c ulators are n ot sui table for dir ec t temperat ur e cont r ol of foods, semi -

medium ( bat h fl ui d) .

1x10

TCF

ATC

3

RS232

Pt100

PUMP

SMART

depen de nt pr ocesses can be s tor e d and execut ed us i n g the

temperature control parameters. This means full control of the control behavior at all

temperatures to ensure an accurate temperature pattern at the selected spot in the

Intelligent pump system: The pump capacity (electronically adjustable via the motor

Operating manual

1. Intended use

JULABO circulators have been designed to control the temperature of specific fluids in a bath tank.

The units f eat ur e pump connections for temperature control o f external systems (loop circuit).

luxury foo ds an d tobacco, or phar m aceutical and medical pr oducts.

Direct temperature control means unprotected con t act of the objec t with the bath

1.1. Description

The circulators are operated via the splash-proof keypad. The implemented

microprocessor technology allows to set and to store different values that can be

indicated on the VFD COMFORT-DISPLAY. Three menu keys facilitate adjusting

setpoints, warning and safety func tions and m en u functions .

Temperature- and t im e-

integrated progr am m er.

The control electronics including “ICC - Intelligent Cascade Control” automatically

adjust the heat supply to the thermal requirements of the bath.

The TCF - Temperature Control Features give the user access to all important

ICC

times and the ability to manually adjust or adapt the controls to the specific

application.

Absolute Temperature Calibration (ATC3) provides high temperature stability at all

points in the bath. With the 3-point calibratio n, an offset is adjusted at t hr e e

bath over the entire temperature range.

Electrical connections:

The serial interface, switchable from RS232 to RS485, allows modern process

technology without additional interface.

Connection for Pt1 00 ext er n al sensor for ext er n al tem p er ature meas ur em e nt an d

control.

Alarm output for external alarm message or control of JULABO refrigerating baths

or solenoid valve (cooling water).

The electr oni c m od ul e ( option) provi d es 3 fur ther anal og connections ( al ar m in put,

standby input, recorder output, programmer input).

The excess temperature protection conforming to IEC 61010-2-010 is a safety

installation independent from the control circuit. This protection can be indicated

and set on the VFD COMFORT -DISPLAY.

The early warning system for low level signals that bath fluid needs to be refilled

before th e low l ev el pr otecti on co nforming t o IEC 61 01 0-2-010 causes a complete

shutdown of the main functional elements.

speed) enables to adapt to varying conditions for internal and external temperature

applications.

5

Page 6

Operator responsibility – Safety recommendation s

2. Operator responsibility – Safety recommendations

The products of JULABO ensure safe operation when installed, operated, and maintained according to

common safety regulations. This section explains the potential dangers that may arise when operating

the circulator and also specifies the most important safety precautions to preclude these dangers as

far as possible.

The operator is responsible for the qualification of the personnel operating the units.

The personnel operating the units should be regularly instructed about the dangers involved with

their job activities as well as measures to avert these dangers.

Make sure all persons tasked with operating, installing, and maintaining the unit have read and

understand the safety information and operating instructions.

When using hazardous materials or materials that could become hazardous, the circulator may be

operated only by persons who are absolutely familiar with these materials and the cir c ulator.

These persons must be fully aware of possible risks.

If you have any questions concerning the operation of your unit or the information in this manual,

please contact us!

Contact

Safety instructions for the operator:

You have received a product designed for industrial use. Nevertheless, avoid strikes to the

housing, vibrations, damage to the operating-element panel (keypad, display), and contamination.

Make sure the product is checked for proper condition regularly (depending on the conditions of

use). Regularly check (at least every 2 years) the proper condition of the mandatory, warning,

prohibition and safety labels.

Make sure that the mains power supply has low impedance to avoid any negative effects on

instruments being operated on the same mains.

This unit is designed for operation in a controlled electromagnetic environment. This means that

transmitting devices (e.g., cellular phones) should not be used in the immediate vicinity.

Magnetic radiation may affect other devices with components sensitive to magnetic fields

(e.g., monitors). We recommend maintaining a minimum distance of 1 m.

Permissible ambient tem perature: ma x . 40 °C, min. 5 °C.

Permissible relative humidity: 50% (40 °C).

Do not store the uni t in an aggressi ve atmos ph er e .

Protect the unit from contamination.

Do not expose the unit to sunlight.

JULABO GmbH

Eisenbahnstraße 45

77960 Seelbach / Germany

Tel. +49 (0) 7823 / 51-0

Fax +49 (0) 7823 / 24 91

info@julabo.de

www.julabo.de

Appropriate operation

Only qual ified personnel is authorized to perform configuration, installation, maintenance and repairs of

the circulator.

Routine op er at ion can als o be car r i ed out by untrained personn el wh o sh ould however be i nst r uc t e d by

trained per sonnel.

6

Page 7

HE / SE

Valid in EU countries

waste is not permitted!

Use:

The bath can be fil led with flammable materials. Fire hazard!

There might be chemical dangers depending on the bath medium used.

Observe all warnings for the used materials (bath fluids) and the respective instructions (safety data

sheets).

Insufficient ventilation may result in the format ion of explo si ve mi xtures. Only use the unit in well

ventil ate d ar eas.

Only use recommended materials (bath fluids). O nly use non-acid and non corroding materials.

When using hazardous materials or materials that could become hazardous, the opera to r must affix

the enclosed safety labels (1 + 2) to the front of the unit so they are highly visible:

1

2

or

2

Particular care and attention is necessary because of the wide operating range.

There are thermal dangers: Burn, scald, hot steam, hot parts and surfaces that can be touched.

Observe the instructions in the manuals for instruments of a different make that you connect to the

circulator, particularly the respective safety recommendations. Also observe the pin assignment of

plugs and technical specifications of the p r oducts .

Warning label W00: Colors: yellow, black

Danger area. Attention! Observe instructions.

(operating manual, safety data sheet)

Mandatory label M018: Colors: bl ue , whi te

Carefully read the user information prior to beginning operation.

Scope: EU

Semi S1-0701 Table A1-2 #9

Carefully read the user information prior to beginning operation.

Scope: USA, NAFTA

Warning label W26: Colors: yellow, black

Hot surface warning.

(The label is put on by JULABO)

2.1. Disposal

The circul ator cont ains a back -up battery that supplies voltage to memory chips when the unit is

switched off. Do not dispose of the battery with household waste!

Depending on battery regulations in your country, you might be obliged to give back used or defect

batteries to gathering places.

The product may be used with oil as bath fluid. These oils fully or partially consist of mineral oil or

synthetic oil. For disposal, observe the instructions in the safety data sheets.

See the current official journal of the European Union – WEEE directive.

Directi v e o f the E ur op ea n Par l i am e nt and of the Cou nc i l on waste elec tr i cal and

electro ni c eq ui pm e nt (WEEE).

This direc ti v e r eq ui r es el ec tr i cal a nd electronic equipment marked with a crossedout trash can to be disposed of separately in an environmentally friendly manner.

Contact an authorized waste management company in your country.

Disposal with household waste (unsorted waste) or similar collections of municipal

7

Page 8

Operator responsibility – Safety recommendation s

2.2. EC Conformity

8

Page 9

HE / SE

2.3. Warranty conditi ons

JULABO GmbH warrants its products against defects in material or in workmanship, when used under

appropriate conditions and in accordance with appropriate operating instructions

for a period of ONE YEAR.

Extension of the warr a nty per i o d – fre e of charge

With the ‘1PLUS warranty’ the user receives a free of charge extension to the warranty of up to 24

months, limited to a maximum of 10 000 worki ng hours.

To apply for thi s extended war r a nty the user mus t r egi s ter th e uni t on the JULABO web s i te

www.julabo.de, indicating the serial no. The extended warranty will apply from the date of JULABO

GmbH’s original invoice.

JULABO GmbH reserves the right t o decide the val i dit y of any warran ty cl ai m . In cas e of faults ari s i ng

either due to faulty materials or workmanship, parts will be repaired or replaced free of charge, or a

new replacement unit will be supplied.

Any other c om p ensation clai m s ar e exc luded from this guar a ntee.

9

Page 10

Operator responsibility – Safety recommendation s

20 ... 300

20 ... 300

20 ... 300

±0.01

±0.01

±0.01

±0.01

Bridge mounted circulator

SE-Z

Working temperature range

°C

20 ... 300

Temperature stability

°C

±0.01

Immersion depth max./min.

cm

18/9

Overall di m ens ions (WxDx H)

cm

32x17x33

Weight

kg

7 HE

SE

Mains power c o nn ec ti o n 230 V/50-60 Hz

V/Hz

190-253 / 50-60

190-253 / 50-60

Current dr aw (at 208 V / 230 V)

A

8 / 9

12 / 13

Mains power c o nn ec ti o n 115 V/50-60 Hz

V/ Hz

90-127 / 50-60

Current dr aw (at 100 V / 115 V)

A

9 / 10

HE

SE

Temperature selection

digital

via keypad

indication on VF D COMFORT-DISPLAY

remote control via PC

indication on monitor

Temperature indication

VFD COMFORT-DISPLAY

Resolution

°C

0.01

0.01

Temperature control

ICC - Intelligent Cascade Control

Heater wattage (at 230 V)

kW

2,0

3,0

Heater wattage (at 115 V)

kW

1,0

---

Electronically adj. pump capacity stages

1 ... 4

1 ... 4

Flow rate at 0 bar

l/min

22 ... 26

22 ... 26

Max. pressure at 0 liters

bar

0.7

0.7

Max. suction at 0 liter s

bar

0.4

0.4

Electrical connections:

See pa ge 11

Ambient temperature

°C

5 … 40

5 ... 40

2.4. Technical specifications

Heating circulators

Working temperature range °C

Temperature stability °C

Bath openi n g (WxL) cm

Bath depth cm

Filling volume liters

Overall di m ens ions (WxDx H) cm

Weight kg

HE-4 SE-6 SE-12 SE-26

20 … 250

13x15 13x15 22x15 22x30

15 20 20 20

3 ... 4,5 4,5 ... 6 7,5 ... 12 18 ... 26

21x42x40 21x43x44 30x43x47 36x61x47

11 13,5 14,0 27,0

All measurements have been carried out at: rated voltage and frequency

ambient temperature: 20 °C bath fluid: water operating temperature: 70 °C

Technical changes without prior notification reserved.

ATC3 INT/EXT °C ±3 / ±9 ±3 / ±9

10

Page 11

HE / SE

Caution:

Electrical connections:

External alarm devi c e 24-0 V DC / max. 25 mA

Computer interface RS232 or RS485

External Pt100 se nsor

Optio nal for HE, SE

(Order No. 8900100 Electronic module with analog connections)

Programmer input -100 °C to 400 °C = 0 - 10 V or 0 - 20 mA or 4 - 20 mA

Input for the signal of a flow meter or external manipulated variable

Temperature recorder outputs 0 - 10 V (0 V = -100 °C, 10 V = 400 °C)

0 - 20 mA (0 mA = -100 °C, 20 mA = 400 °C)

4 - 20 mA (4 mA = -100 °C, 20 mA = 400 °C)

Standby input for external emergency switch-off

Alarm output for external alarm signal

Safety installations according to IEC 61010-2-010:

Excess temperature protection adjustable from 0 °C ... 320 °C

Low liquid level protection float switch

Classification according to DIN 12876-1 class III

Supplementary safety installations

Early warning system for low level float switch

High temperature warning function optical + audible (in intervals)

Low temperature warning function optical + audible (in intervals)

Supervision of working sensor plausibility control

Reciprocal sensor monitoring between

working and safety sensors difference >35 K

Alarm message optical + audible (permanent)

Warning message optical + audible (in intervals)

Environmental conditions according to IEC 61 010-1:

Use indoors only.

Altitude up to 2000 m - normal zero.

Ambient temperature: see Technical specifications

Humidity:

Max. relative humidity 80% for temperatures up to +31 °C,

linear decrease dow n to 50% relative humidity at a temperature of +40 °C

Max. mains voltage fluctuations of ±10% are permissible.

Protection class according to IEC 60 529 IP21

The unit corresponds to Class I

Overvoltage category II

Polluti on d egr ee 2

The unit is not suitable for use in explosive environment

EMC requirements according to EN 61326-1

This unit is an ISM device classified in Group 1 (using high frequency for internal purposes), Class A

(industrial and commercial range).

11

Page 12

Operating instructions

In addition to the safety warnings listed, warnings are posted throughout the operating

Read and follow these important instructions for averting dangers.

Warning:

Caution:

sible property damage may also be contained in

Notice:

This icon is used in the operating instructions to indicate flashing values or parameters

which hav e to be s et or confirme d.

Operating instructions

3. Safety notes for the user

3.1. Explanation of safety notes

manual. T hese warnin gs ar e desi g nated by an ex c l am ati o n mark inside an eq ui l at er al

triangle. “Warning of a dangerous situation (Attention! Please follow the

documentation).”

The danger is classified using a signal word.

Describes a possibly highly dang er o us situation. If these ins t r uctions are n ot

followed, serious injury and danger to life could result.

Describes a possibly dangerous situation. If this is not avoided, slight or minor

injuries could result. A warning of pos

the text.

Describes a possibly harmful situation. If this is not avoided, the product or anything

in its surroundings can be damaged.

3.2. Explanation of other notes

Note!

Draws attention to something special.

Important!

Indicate s usage tips and ot h er useful infor m ation.

12

Page 13

Follow the safety instructions to avoid personal injury and property damage. Also, the

• Only connect the unit to a power socket with an earthing contact (PE – protective

stand all instructions and safety precautions listed in

Check the temperature of the bath fluid prior to draining (e.g., by switching the unit

e bath tank and the pump connections may become extremely hot

during continuous operation. Therefore, exercise particular caution when touching

these parts.

3.3. Safety recommendations

valid safety instructions for workplaces must be followed.

earth)!

• The power supply plug serves as a safe disconnecting device from the line and

must alway s be easily acc es si ble.

• Place the unit on an even surface on a base made of nonflammable material.

• Do not stay in the area below the unit.

• Make sure you read and under

this manual before installing or operating your unit.

• Set the excess temperature safety installation at least 25 °C below th e fir e p oi nt o f

the bath fluid.

• Observe the limited working temperature range when using plastic bath tanks.

• Never operate the unit without bath fluid in the bath.

• Pay atten ti on to the t h er m al expansion o f ba th oi l dur i n g heating to av oi d

overflowing of the fl ui d.

• Prevent w at er from enterin g the ho t bath oil.

• Do not drain the bath fluid while it is hot!

HE / SE

on for a short m om en t) .

• Use suitable connecting tubing.

• Avoid sharp bends in the tubing, and maintain a sufficient distance from

surrounding walls.

• Make sure that the tubing is securely attached.

• Regularly check the tubing for material defects (e.g., for cracks).

• Never operate damaged or leaking units.

• Always turn off the unit and disconnect the mains cable from the power source

• Always turn off the unit and disconnect the mains cable from the power source

• Always empty the bath before moving the unit.

• Transport the unit with care.

• Sudden jolts or drops may cause damage in the interior of the unit.

• Observe all warning labels.

• Never remove warning labels.

• Never operate units with damaged mains power cables.

• Repairs are to be carried out only by qualified service personnel.

Some parts of th

before performing any service or maintenance procedures, or before moving the

unit.

before cleaning the unit.

13

Page 14

Safety no tes for the user

Caution:

determi ne the method o f deco nt amination.

With a screwdriver turn back the adjustable excess temperature protection until the

of the float, it can be manually lowered with a screwdriver for

example.

The temperature controlling i.e. of fluids in a reactor constitutes normal circulator

practice.

We do not know which substances are contained within these vessels.

Many substances are:

• inflamm a bl e, e as i l y ignited or expl os i ve

• hazardo us to he al th

• enviro nmentally unsafe

i.e.: dangerous

The user alone is responsible for the handling of these substances!

The following questions shall help to recognize possible dangers and to reduce the

risks to a min imum.

• Are all tubes and electrical cables connected and installed?

Note:

sharp edges, hot surfaces in operation, moving machine parts, etc.

• Do danger ous s te am s or ga ses ar is e w he n he at ing?

Is an exhaust needed when working?

• What to do when a dangerous substance was spilled on or in the unit?

Before starting to work, obtain information concerning the substance and

Notice: Check the safety installations at least twice a year!

• Excess temperature protection according to IEC 61010-2-010.

shut-down point (actual temperature).

• Low level pr ot ec ti o n according to IEC 61010-2-010.

To check th e function

14

Page 15

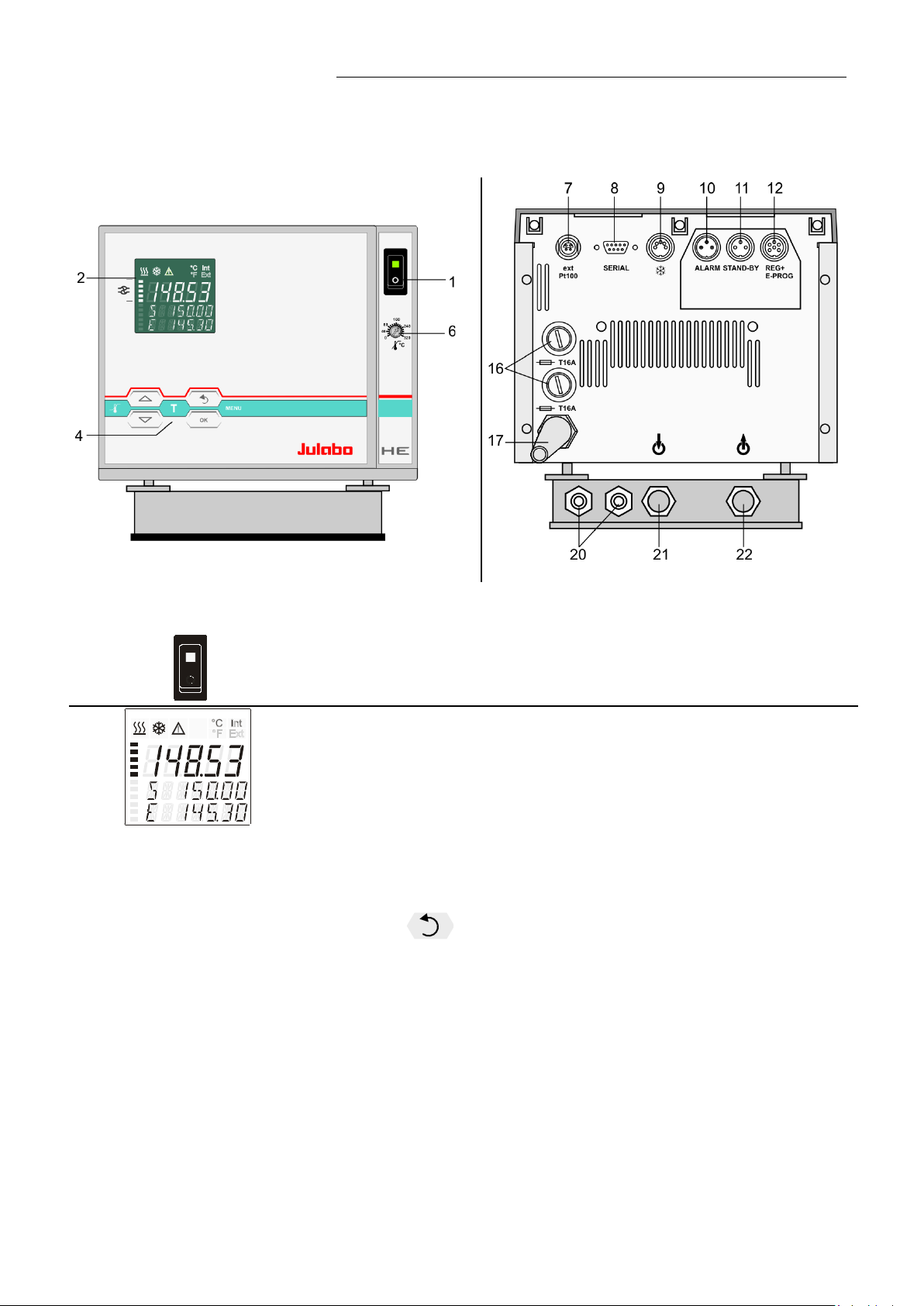

4. Operating controls and functional elements

*refer to >MENU/CONFIG< >CONFIG / ACTVAR>

Front view Rear view

HE / SE

1

2

Mains power switch, illuminated

VFD COMFORT-DISPLAY

Header: Control indicators

Line 1: Actual value internal or external

The displ ay is de pe nding on the sel ected contr ol m ode in th e

menu > Control < (internal or external).

Line 2: Working temp. setpo int, constantly S xxx.xx

Line 3: Actual value (E = external or I = internal)

Alternating with the display in line 1

Use the keys

PI Capacit y in % - with manipul at ed v ar i a bl e set t o > c ontrol<*

PS Capacity in % - with ma ni p ul ated varia bl e set to > s er i al <* or

>eprog<*

H Heater capacity in Watts

U Mains voltage Volts

F Flow rate in liters/minute

(providing EPROG input set to >Flowrate<)

to indicate further values in line 3

15

Page 16

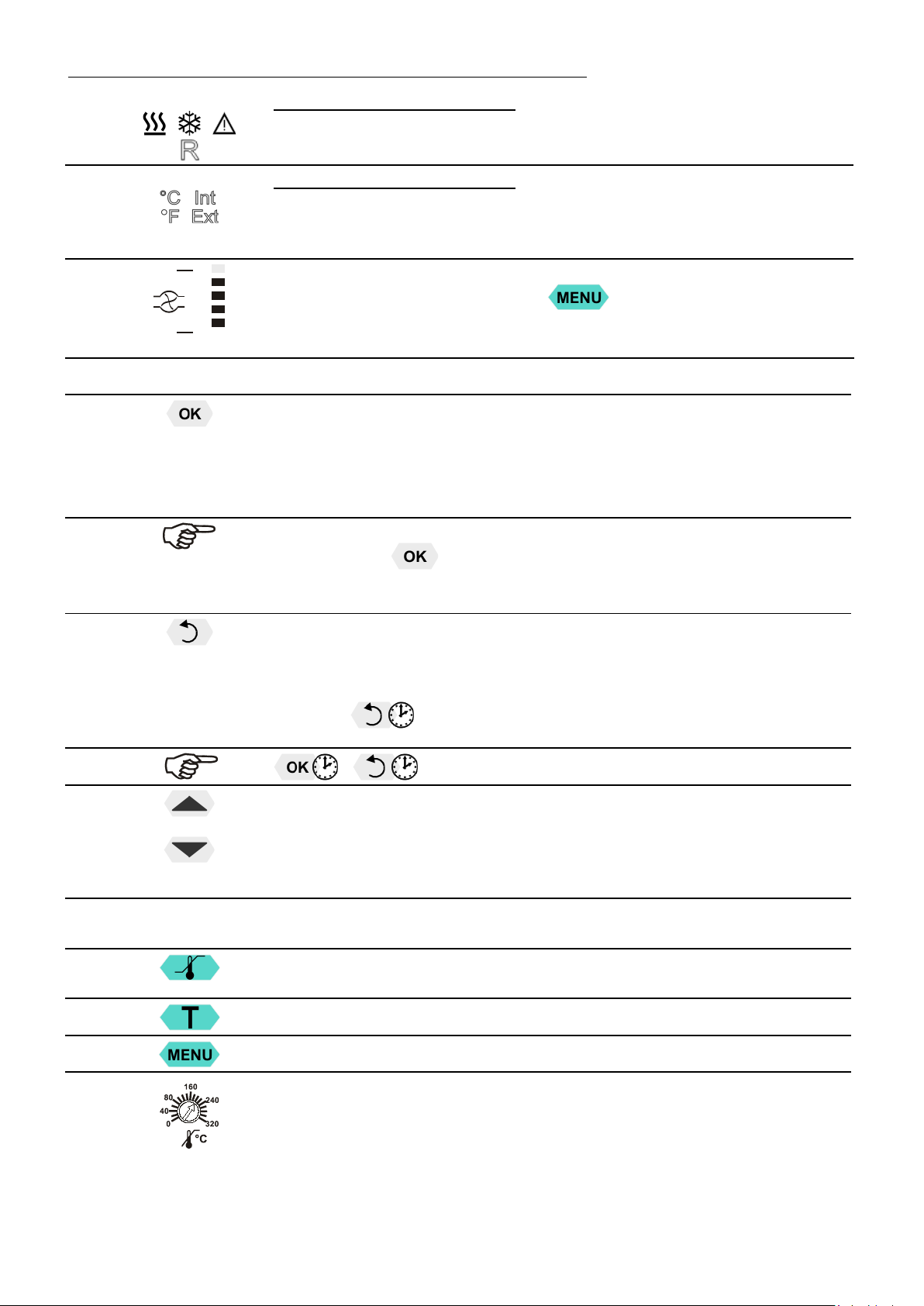

Operating controls and functional elements

2.1

R

2.2

A beep signals the end o f setting

2.3

4

4.1

Control indicators in th e header:

Heating / Cooling / Alarm /

emote control

Control indicators in the header:

Temperature indication Internal or External actual value

Temperature indication in °C (°F not possible on thi s uni t)

Display of set pump pressure stage

Four stages, can be set via the key

Navigation keys

1. Key: >OK< Start / Stop (pump / heater )

2. >OK< in the menu Menu item / sel ec t s u bm en u for s etti ng

Save set value

Save selec t ed paramet er

After the ac ti o ns S tar t , Sto p and ch an ge from VFD Dis pl ay t o standard

display the key

The above graph “front side” shows an example for standard display.

is locked for a s hor t ti m e.

, under >MENU - PUMP<.

4.2

4.3

4.4

4.5

4.6

1. Key: >Return< Stop (pump / heater )

2. >Return< in the menu one menu level down

Correcti on function for param et er s or val u es (pr i or to OK)

- icon for „ke ep k ey pr es sed down“.

1. Key: >Up / Down <temperature – increase/decrease setpoint

Push key quickly for single steps,

Keep key pres sed for fast ch an ge .

2. >Up/Down< in the menu selection of menu items / parameters

Menu keys

Key: start the menu > warning and safety values<

Key: start the menu >temperature setpoints<

Key: display of MENU structure

immediately bac k t o standard di splay

6

16

Adjusta bl e ex ce s s t em p er at ur e pr otectio n acc ording to IEC 61 01 0-2-010

Page 17

7

8

SERIAL

9

10

ALARM

11

STAND-BY

12

REG+E-PROG

16

17

20

21

ext Pt100

HE / SE

Socket for external measurement and control sensor

or external setpoint programming

Interface RS232: remote control via personal computer

Socket: control cable of JULABO refrigerated circulator

or output for alar m messages

Option: Electronic module Order No. 8 900 100

Alarm output (for external alarm signal)

Standby input (for external emergency switch-off)

Programmer input and temperature recorder output

Mains fuses, T16A

Mains power cable with plug

Cooling coil connectors

Pump connectors suction pump pressure pum p

17

Page 18

Preparations

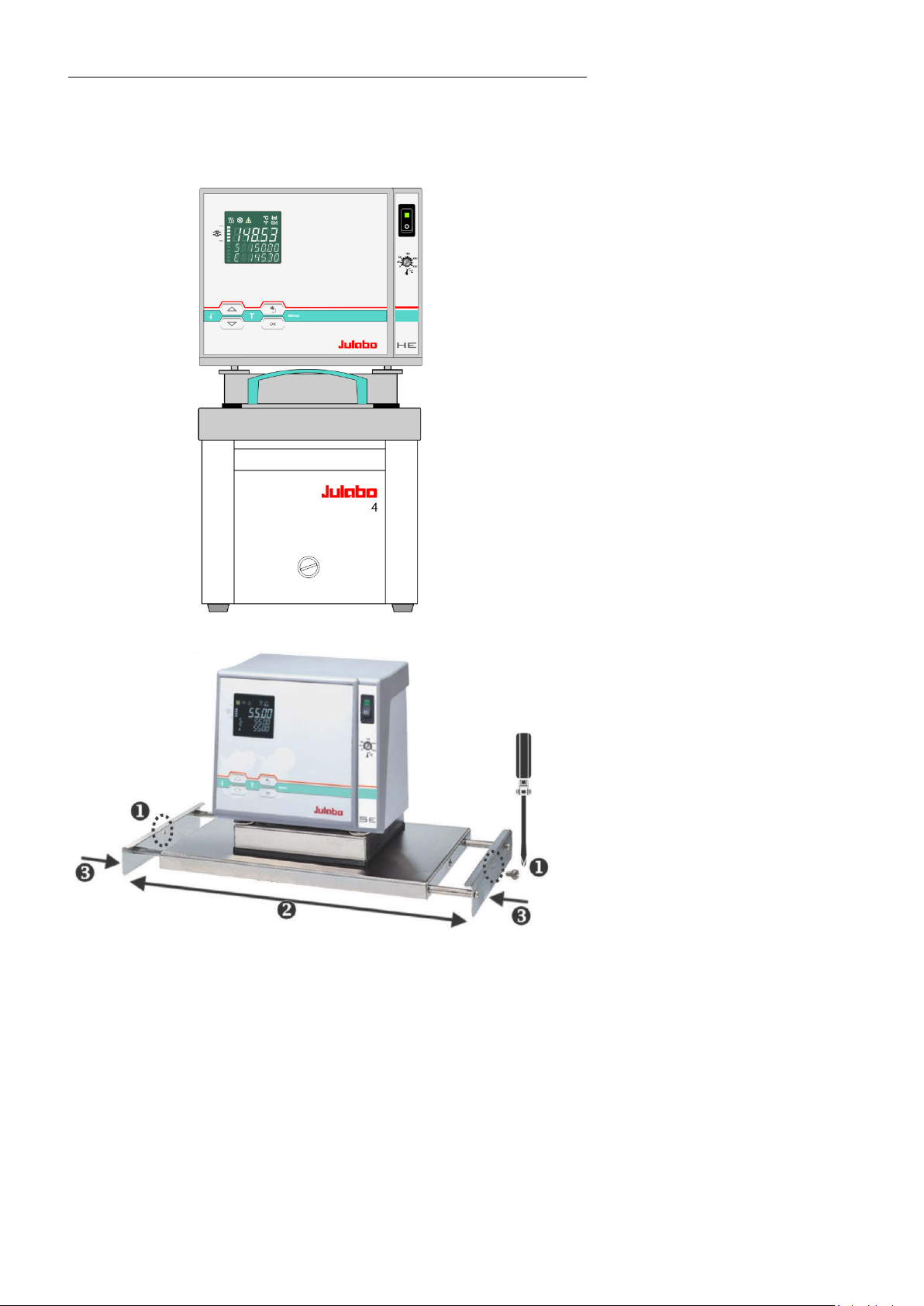

Heating circulators

Place the unit on an even surface

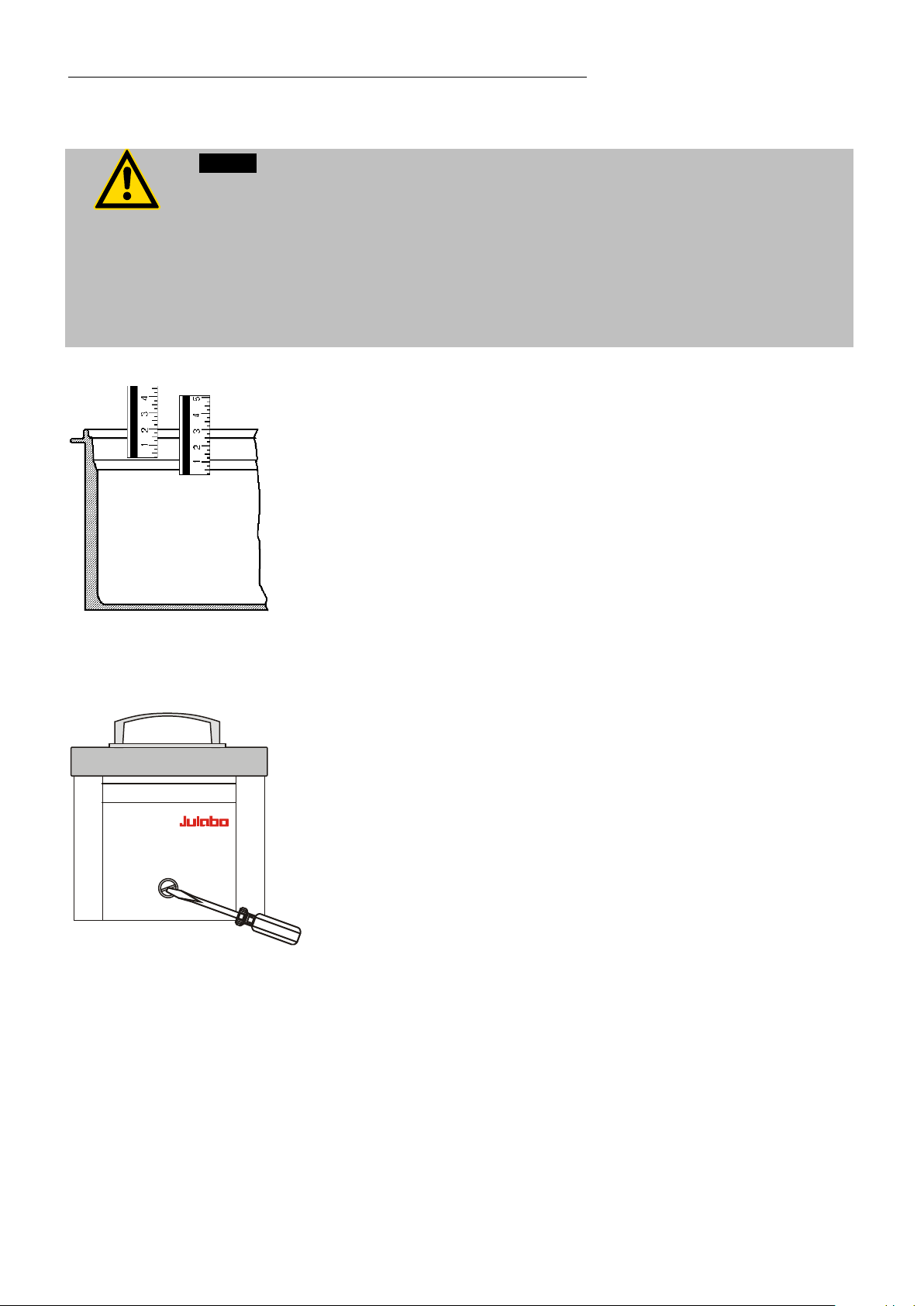

Bridge mounted circulator SE-Z

5. Preparations

5.1. Installation

•

on a base made of

nonflammable material.

• Place the bath tank in an upright

position.

1. Remove screw on both sides (transportation safety devi ce in

the middle).

2. Extend the bridge and place it on the bath tank.

The bridge is extendable from 310 mm to 660 mm.

3. Adjust the brid ge to t h e width of the bat h tank.

18

Page 19

5.2. Bath fluids

Caution:

corrosion in the bath, even in stainless steel.

Bath fluid

Temperature range

soft/decalcified water

5 °C to 80 °C

JULABO

Description

Thermal

G

Thermal

M

Thermal

HS

Order Number

10 liters

8 940 124

8 940 100

8 940 102

5 liters

8 940 125

8 940 101

8 940 103

Temperature range

°C

-30 ... 80

40 ... 170

20 ...250

Flash poi nt

°C

--

284

270

Fire point

°C

--

306

>360

Color

light yellow

clear

light brow n

JULABO

Description

Thermal

H10

Thermal

H20S

Thermal

H200

Order Number

10 liters

8 940 114

8 940 108

8 940 134

5 liters

8 940 115

8 940 109

8 940 135

Temperature range

°C

-20 ... 180

0 ... 220

60 ...200

Flash poi nt

°C

190

230

292

Fire point

°C

216

274

334

Color

clear

light brow n

clear

(much higher than recommended at the respective working temperature)

Carefully read the safety data sheet of the bath fluid used, particularly with regard to

the fire poi nt!

If a bath fluid with a fire point of ≤6 5 °C is used, only supervised operation is possible.

Water: The quality of water depends on local conditions.

• Due to the high concentration of lime, hard water is not suitable for temperature

control because it leads to calcification in the bath.

• Ferrous water can cause corrosion - even on stainless steel.

• Chloric water can cause pitting corrosion.

• Distilled and deionized water is unsuitable. Their special properties cause

Recommended bath fluids:

JULABO bath fluids

HE / SE

See websi te for list of recommen de d bat h fl ui ds .

ATTENTION: The maximum permissible viscosity is 70 mm

Caution:

Fire or other dangers when using bath fluids that are not recommended:

Please contact JULABO before using other than recommended bath fluids.

Use only no naci di c and nonc or r osi v e ba th fl ui ds.

JULABO assumes no liability for damage caused by the selection of an unsuitable

bath liquid.

Unsuit able bath flui ds are fluids whic h , e. g. ,

• are highly vis cous

2

/s.

19

Page 20

Preparations

No liability for use of other bath fluids!

with the cap nut.

21 22

Unscrew the M16x1 collar nuts on the pump connectors with

H = Height adjustment

• have a low viscosity and have creep characteristics

• have corrosive characteristics or

• tend to crack.

•

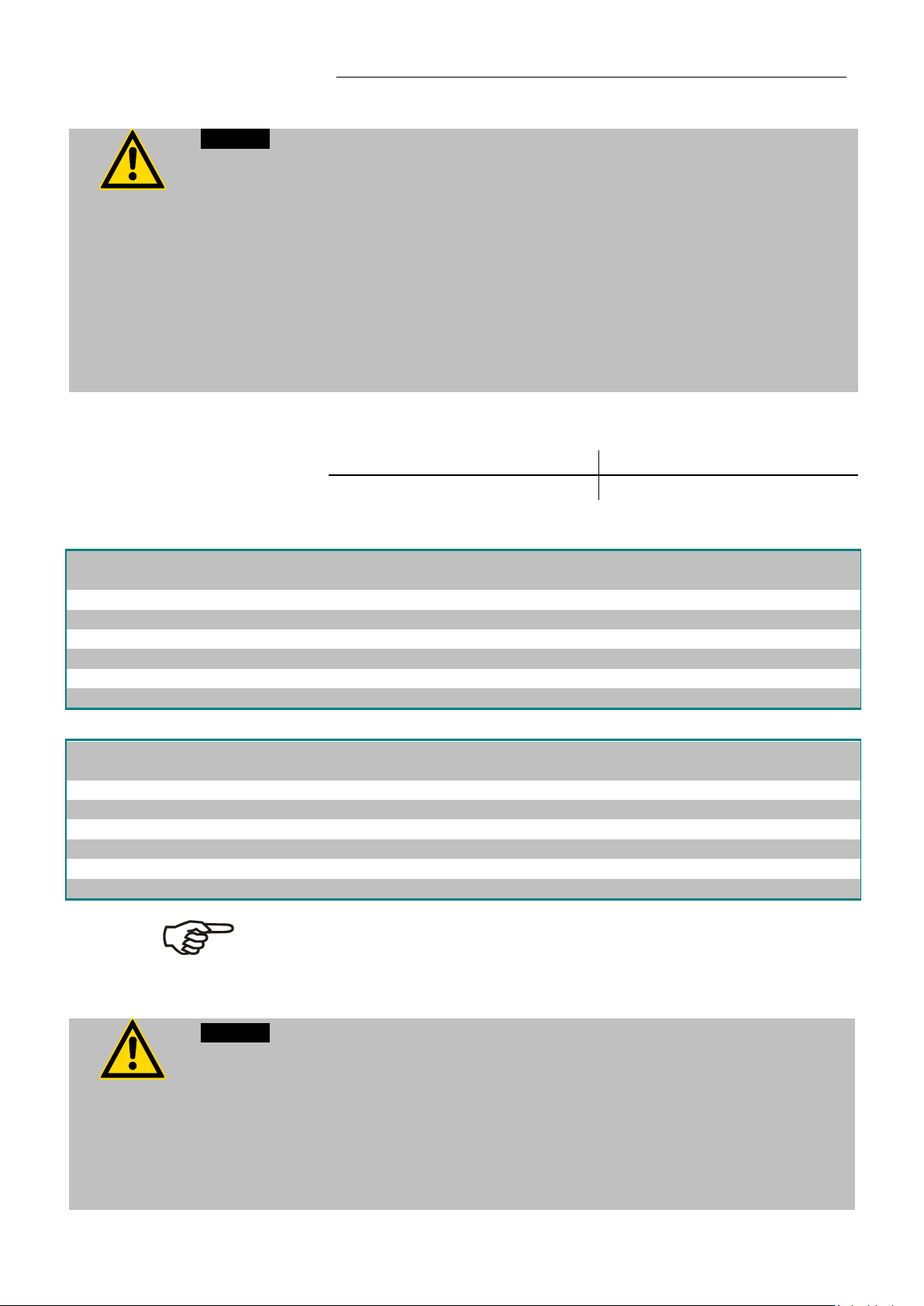

5.3. Temperature application to external systems

Caution: Securely attach all tubing to prevent slipping.

If the circulator is operated without external system, close the pump connector (22)

Temperature application to external, closed systems

The circulator is used for temperature application to external,

closed systems (loop circuit) with simultaneous temperature

application in the circulator bath.

•

a 19 mm (3/4“) wrench and remove the sealing disks. Using

the collar nuts, screw on the tubing connection fittings (for

tubing 8 mm or 12 mm in diameter) delivered with the unit

and tight en fi r mly. (Pressure pump: 22, suction pump: 21)

Pt100

T16A

T16A

ext

SERIAL

ALARM

STAND-BY

REG+

E-PROG

• Push on the tubings, and secure with tube clamps.

• Attach the tubings to the connectors of the external closed

system, e.g., an instrument with a pressure-resistant

temperature jacket or a temperature coil, and fasten with

tube clamps to prevent slipping.

Temperature application to external, open systems

The circulator is equipped with both a pressure and suction pump

for external temperature application in open systems.

Differing flo w rates of the pressure and suction pumps should be

compensated. To maintain a constant liquid level, the JULABO

„D+S“ Level Adapter is recommended for the external bath tank.

The flow rate of the pressure pump will be then regulated by a

built-in float device. The liquid level may be changed by a height

adjustm e nt on t h e „D+ S“ Level Adapter.

Accessor y : „D +S“ L ev el Ad apter Order No. 8 970 410

Important:

The liquid level should be equal in the internal and external

S = Suction pump connection

D = Pressure pump connection

K = Float

20

baths (absolute height).

If you take out samples (for exam pl e Erl e nm eyer flask s) from

the external bath, turn the circulator off with the Start/Stop key.

Page 21

Order No. Length

Temperature range

8930008 1 m

CR® tubing 8 mm inner dia.

-20 °C to 120 °C

8930012 1 m

CR® tubing 12 mm inner dia.

-20 °C to 120 °C

8930108 1 m

Viton tubing 8 mm inner dia.

-50 °C to 200 °C

8930112 1 m

Viton tubing 12 mm inner dia.

-50 °C to 200 °C

8930410 1 m

Insulati o n for t ubing 8 mm inner dia.

-50 °C to 100 °C

8930412 1 m

Insulati o n for t ubing 12 mm inner dia.

-50 °C to 100 °C

8 930 209 0.5 m

8 930 214 3.0 m

Metal tubing, triple insulated, M16x1

-100 °C to +350 °C

8 930 220 0.5 m

8 930 223 3.0 m

Metal tubing, insulated, M16x1

-50 °C to +200 °C

Warning: Tubing:

At high working temperatures the tubing used for temperature application and cooling

A damaged tubing line may cause hot bath fluid to be pumped out within a short time.

Preventive maintenance: Replace the tubing from time to time.

Return flow safety device

If the liquid levels in the circulator bath and the external system are at

5.3.1. Tubing

Recommended tubing:

HE / SE

different heights, overflowing must be prevented after the power has

been turn ed off .

Flood hazard!

For this reason, shut-off valves can be integrated in the loop circuit.

Order No. Description

8 970 456 Shut-off valve (sui ta bl e up to + 9 0 °C)

8 970 457 Shut-off valve (sui t a bl e up to +200 °C)

8 930 210 1.0 m

8 930 211 1.5 m

8 930 221 1.0 m

8 930 222 1.5 m

water supply represents a danger source.

This may result in:

• Burning o f skin

• Difficul t ies i n br ea thi n g due to hot atmos p here

Safety recommendations

• Employ suitable conn ec ting tubing.

• Make sure that the tubing is securely attached.

• Avoid sharp bends in the tubing, and maintain a sufficient distance from

surrounding walls.

• Regularly check the tubing for material defects (e.g. for cracks).

•

21

Page 22

Preparations

Check the temperature of the bath fluid prior to draining (by switching the unit on

protection.

5.4. Filling / draining

Notice:

• Pay attention to the thermal ex pa ns ion of bath oil dur i n g heating to avoid

overflowing of the liquid.

• Do not drain the bath fluid while it is hot!

Recommendation: Temperature range 5 °C to 40 °C

for a short moment, for example).

• Store and dispose the used bath fluid according to the laws for environmental

Filling

Take care that no liquid enters the interior of the circulator.

• Recommended maximum filling level with water as bath fluid:

30 mm bel ow t he ta nk rim

• Recommended maximum filling level with bath oils:

40 mm below the tank rim

After filling, immerse the samples in the bath or place the lid on

the bath, in case the opening is not to be used.

The circulator provides an early warning system for low level

(description – pl e as e r e fer to page 28) that may be triggered when

changin g sam ples in the bat h.

Draining

• Turn the unit off with the mains switch.

• Place the he ati n g cir c ulator near the rim of the table. Use a

suitable vessel as recipient for the bath fluid.

• Unscrew the drain plug on the front of the bath tank to drain the

bath.

22

Page 23

5.5. Countercooling

location where the unit is operated.

T16A

T16A

ext

Pt100

SERIAL

ALARM

REG+

E-PROG

STAND-BY

20

ambient temperature (20 °C), the cooling

FD200 Flow-through cooler

Caution:

Securely attach all tubing to prevent slipping.

Observe the laws and regulations of the water distribution company valid in the

HE / SE

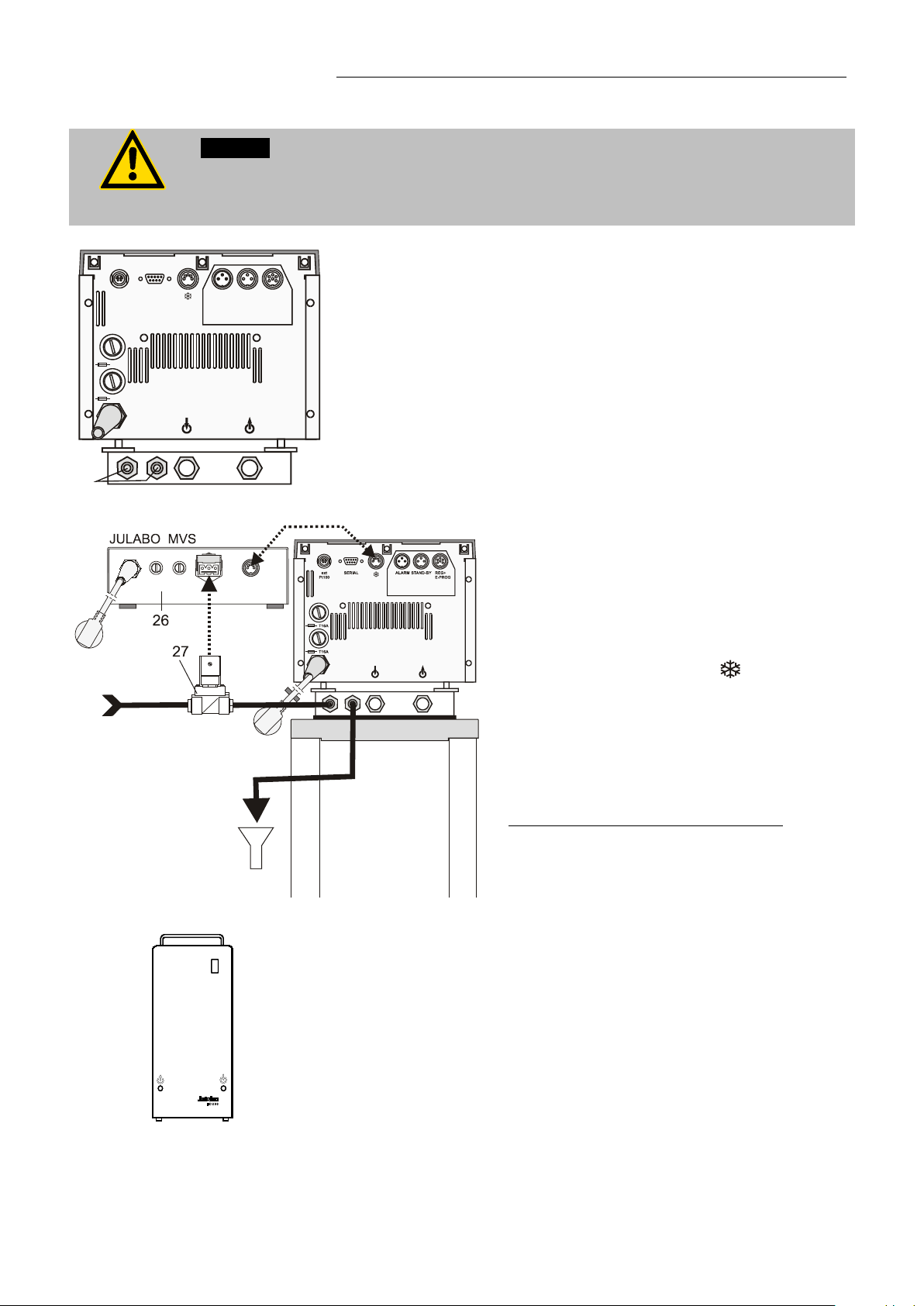

For applications near the ambient temperature, the cooling coil

(20) must be connected to the water mains.

• Using tubing, connect the cooling coil to the tap water supply,

and lead the tap water in a sink through the return connector.

A specific water flow rate of 750 ml/minute (15 °C) is sufficient

to compensate for th e char acteristi c tem p er ature.

For applications near

water temperature should at least be 5 °C below the working

temperature.

Controlled countercooling

Use the MVS solenoid valve controller

(26) and a solenoid valve (27) for

controlled countercooling to reduce tap

water consumption.

The circulator recognizes the MVS

controller via the socket

automatically adjusts the necesssary

parameters.

Accessory:

Order No. Description

9 790 000 MVS controller for

cooling water

8 980 700 Solenoid valve

for cooling water

Order No. 9 655 825

The FD200 is suitable as cooling device for liquids in closed circuits

(loops).

This unit is integrated in the return flow circuit from the external

system connected to a circulator, and continuously withdraws heat

from the liquid.

(10) and

23

Page 24

Operating procedures

Caution:

The power supply plug serves as safe disconnecting device from the line and must

We disclaim all li abil i ty for damage caused by inco r rec t li ne volt ages!

Check to make sure that the line voltage matches the supply voltage

specified on the identification plate. Deviations of ±10 % are permissible.

The VFD COMFORT-DISPLAY indicates the message "OFF".

6. Operating procedures

6.1. Power connection

• Only connect the unit to a power socket with earthing contact (PE – protective

6.2. Switching on / Start - Stop

6.2.1. Switching on the circulator

earth)!

•

be always easily accessible.

• Never operate equipment with damaged mains power cables.

• Regular l y ch eck th e mains power cables for material defects (e.g. for cracks).

•

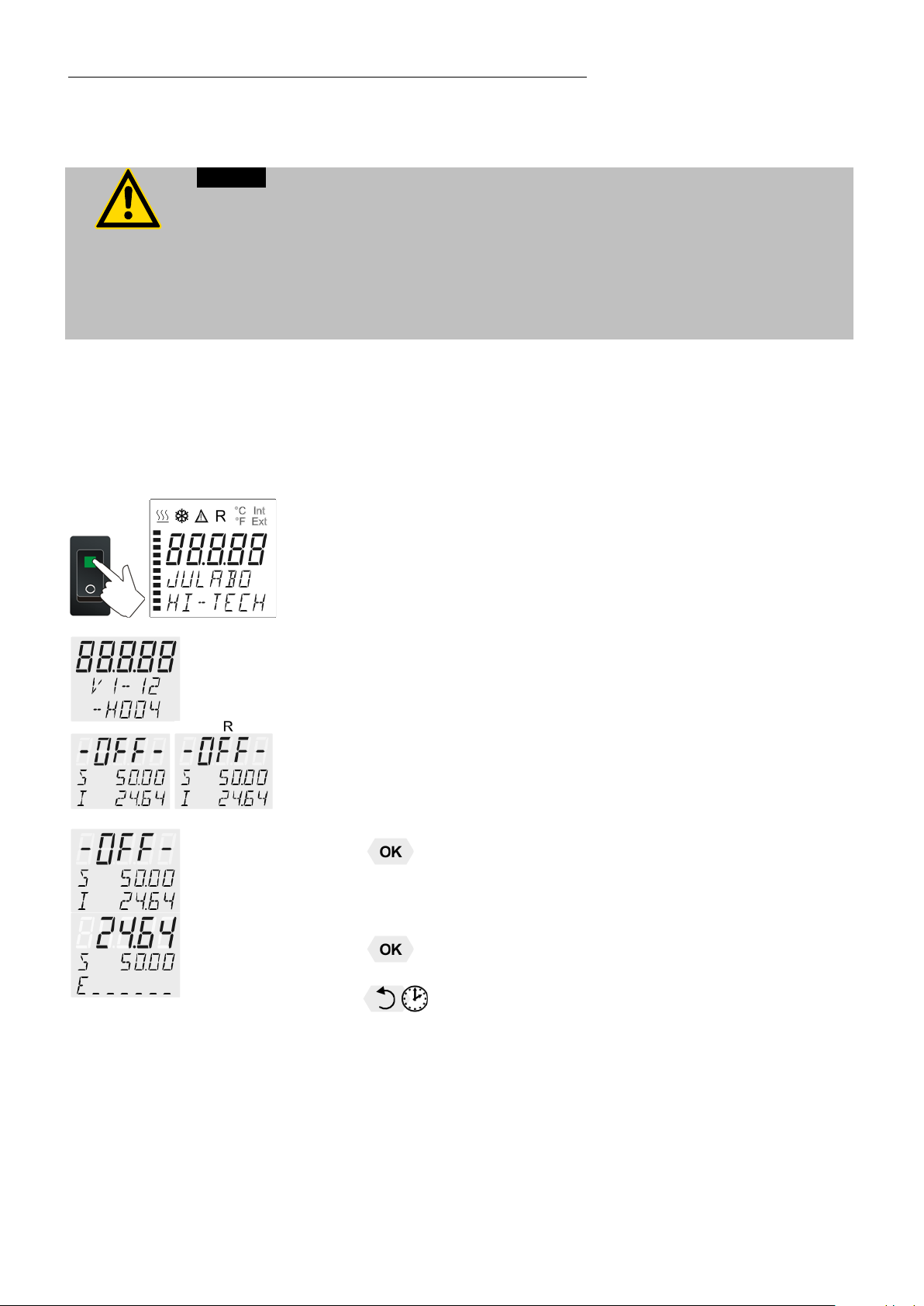

Switching on:

• Turn on the mains power switch (1).

The unit per form s a self-test.

Then the software version (example: V 1.xx) appears. The display

„OFF“ or „R OFF“ indicates the unit is ready to operate.

The circulator enters the operating mode activated before switching

the circulator off:

keypad control mode (manual operati o n)

or

remote control mode (operation via personal computer).

Start:

• Press

The actual bath temper ature is displayed on the VFD COMFORTDISPLAY. The circulating pump starts with a slight delay.

Stop:

key.

Press key.

or

Keep

key press ed .

24

Page 25

7. Setti n g of tempera t ures

7.1. Using the pre-settings in the menu

HE / SE

Werkseinstellungen:

SETPNT 1 25 °C

SETPNT 2 37 °C

SETPNT 3 70 °C

Press the

3 different working temperatures can be adjusted. Their values are freely

selectable within the operating temperature range.

key to call up the menu for temperature selection.

The temperatures can be set in start or stop mode.

Press key if a value is to be retained

Setting of working temperature in the

1. Press the key

2. Select SETPOINT 1 or 2 or 3 using the key

3. Confirm by pressing the

. The value flas h es

key.

menu

or .

The circulator uses the new working temperature value for temperature

control.

Example: Adjustment/modification of the pre-setting of "SETPOINT 3"

1. Press the

2. Select SETPOINT 3 by pressing the

Example: SETP NT 3 / 70.00 °C

key.

key.

3. Kee p th e

(example: <70>)

4. Adjust value by pressing the

and confirm by pressing the

The decim al di gi ts fl as h

Confirm once more by pressing the

Example on the left: SET PN T 3 / 85.00 .

key pressed until the integer digits flash .

key and the

key.

and can be adjusted if desired.

key.

key to 85.00 °C

If the active setpoint (SETPNT) is changed, the new value is

immediately used for the control of the working temperature.

The heater co ntr ol i ndicator flashes.

If the other two setpoints (not activated for control) are changed the

MENU has to be le ft by pr ess ing the key after the decimal

digits hav e be en confirm ed

Notice: Refer to SETPOINT MAX / MIN in chapter >MENU LIMITS<

25

Page 26

Setting of temperatures

7.2. Direct setting of temperatures

The circulator uses the setpoint of SETPNT 1 or 2 or 3 for temperature

control

The indicated setpoint temperature can be changed directly any time.

Example: change 25.00 °C to 50.00 °C

1. By pressing the key

SETPOINT< example on the left: >SETPNT / 1 25.00°C<.

The integer di git s flash

2. By pressing the keys

50.00 °C and

is confirm e d by pr es si n g t he

The decim al di gi ts fl as h an d c an be adjusted if desired.

Confirm once more by pressing the

the circul at or swi tches to the acti v e

(example: <25>).

and

the value is changed to

key.

key.

The circulator uses the new working temperature value for temperature

control.

The temperatures can be set in start or stop mode.

26

Page 27

Warning:

Set the excess temperature protection at 5 °C to 10 °C above the working

8. Safet y inst alla ti on s, war ni n g fu nctions

Check the safety installations at least twice a year! Refer to ( page 14)

HE / SE

SECVAL

(Securit y Values)

SAFETMP

AL-TYPE

OVERTMP

SUBTEMP

Settings for t h e exc ess temperature pr ote c ti o n > SAFETMP<

and for the warning functions for high > OVERTMP< and low >

SUBTEMP< temperature are made in a menu which is called up by

pressing the key

Menu item > AL-TYPE< allows choosing between a warning and

an alarm cut-off for the menu items > OVERTMP< and > SUBTEMP<.

8.1. Excess temperature protection

The excess tem p er ature prot ec ti o n must be set at least 25 °C below the fire point of

the bath fluid used!

In case of wrong setting there is a fire hazard!

We disclaim all liability for damage caused by wrong settings!

This excess temperature protection is independent of the control circuit.

When activated heater and circulating pump are completely shut down.

The alarm is indicated by optical and audible signals (continuou s tone)

and the error message "ALARM-CODE 14" appears on the VFD

COMFORT-DISPLAY together with the ticker:

> EXCESS TEMPERATURE PROTECTOR ALARM-CHECK

ADJUSTMENT <

Setting range: 20 °C ... 320 °C

.

Rough setting can be effect ed by usi ng the temperature scale.

Exact setting:

1. Press the key

2. Press the

3. Set th e new shutdown val u e wi t hi n 30 s econds usi ng a screwdriver .

The value is indicated on the VFD COMFORT-DISPLAY

Example: SAFETMP / 100 °C

Recommendation:

temperature setpoint.

to display menu >SAFETMP<.

key and the set shutdown value is indicated.

27

Page 28

Safety installations, warning functions

An audible warning sounds (interval tone) and together with the

Warning:

8.1.1. Early war ning system, low level protection

This low level protection is independent of the control circuit and is

divided into two sections:

1. Swi tc h in st ag e 1 recognizes a de fi ned fluid lev el .

ticker: > LOW LEVE L WAR N ING-FILL MEDIUM < a message

appears on the VFD COMFORT-DISPLAY:

Refill the bath fluid!

2. Switch in stage 2 recognizes a low fluid level

If stage 2 of the low level protection according to IEC 61010-2-

010 is triggered, a complete, all-pole shutdown of heater and

circulating pump is effected

A continuous alarm sounds and together with the ticker: > LOW

LEVEL ALARM-FILL MEDIUM < a message appears on the

VFD COMFORT-DISPLAY:

.

When adding bath fluid, always us the type of fluid which is identi cal with th e fl ui d in

the ba th.

Bath oils must not contain any water and should be pre-he at ed ap pr ox i m a tel y to th e

current bath temperature! Explosion hazard at high temperatures!

Turn off the unit with the mains switch, refill bath fluid and turn

the un i t on again!

3. Float

4. Circulating pump

5. Heater

28

Page 29

Factory setting:

A mere warning function with optical and audible warning signal (interval

8.2. Switch-over from warning to shutdown function

If a shutdown of functional elements (e.g. heater, circulating pump) is

required when the limit values are exceeded or undercut the circulator can

be changed over from warning function >WARNING< to shutdown function

>ALARM<.

HE / SE

>WARNING<

1. Press the key

2. Select the menu >SECVAL -AL-TYPE< by pressing the

3. Press the

(Example: WARNING)

4. Change the parameter by pressing the

pressing the

or

press the

key if the parameter is to retained.

.

key.

key and the set parameter will flash .

key and confirm by

key.

Setting >WARNING<

tone) A message appears on the VFD COMFORT-DISPLAY:

or

OVERTMP SUBTEMP

• Setting >ALARM<

Temperature limit with shutdown of heater and circulating pump.

An audible alarm sounds (continuous tone) and a message appears on

the VFD COMFORT-DISPLAY:

or

OVERTMP SUBTEMP

29

Page 30

Safety installations, warning functions

the set limit values. The resulting reaction is defined in a further menu item.

Set the over temperature warning value >OVERTMP< 5 °C to 10 °C above

Set the sub temperature warning value >SUBTMP< 5 °C to 10 °C below the

8.3. Over and Sub temperature warning function

Over temperature

Sub temperature

If the observance of a working temperature value >SETP< has to be

supervised for a sensitive temperature application, then set over and sub

temperature warning values. In the example below the SETPOINT 85 °C is

surrounded by the values OVERTMP 87 °C and SUBTEMP 83 °C. The

electronics immediately register if the actual temperature breaches one of

(See chapt er 8.2. )

1. Press the key

.

2. By pressing the

>SUBTEMP<.

or

key select the menu >OVERTMP< or

1. Press the key . Th e int e ger di gi ts f lash

2. Change the values to 87. °C and/or 83. °C by pressing the and

key and confirm with the key.

The decimal digits flash and can be adjusted if desired.

Confirm once more by pressing the

See above ex amples.

• The warning functions are only activated if the actual bath temperature

remains within the set limit values for 3 seconds after switch-on.

Recommendation:

the working temperature setpoint.

working tem peratur e set point.

key.

30

Page 31

9. Menu functions

HE / SE

Menu level 1

1. Ope n the me nu by pr ess ing the

2. Use the

3. Press the

Press the

The term „Menu functions“ refers to settings such as

Start pro gr am Page 32

Administration and creation of programs Page 35

Electronically adjustable pump capacity Page 37

Configuration of the unit Page 38

REMOTE – on / off (remote control via RS232)

AUTOST – AUTOSTART on / off

OFF-MODE – pump on / off

TIME / DATE – setting ti m e an d date

RESET – factory settings

keys to scroll in menu level 1.

key to change to menu level 2.

key if settings are to be retained.

key.

Control characteristics and parameters Page 42

C-TYPE – Internal or external control

DYNAMICS - internal

Control parameter - XP-, TN-, TV- INTERNAL

Control parameter - XP-, TN-, TV- XPU-, EXTERNAL

Adjustable interface parameters Page 48

BAUD RATE, PARITY, HANDSHAKE

ATC - Absolute Temperature Calibration, Page 49

Sensor calibration INTERNAL SENSOR,

Sensor calibration EXTERNAL SENSOR

3-point calibration

Limitati o ns o f temp er ature and capacity Page 55

SETPOINT MAX / MIN - Maximum and minimum setpoint

HEAT MAX – Set maximum heating

COOLING MAX – Set maximum c ooling

INTERN MAX / MIN – Limitation o f th e tem p er at ur e ra nge

BAND HIGH / LOW – Band limit

31

Page 32

Menu functions

Analog inputs/outputs Page 58

This menu will start a previously set program.

Correcti o n function for paramet er s or val u es ( pr i or to OK)

Menu level 1

Recorder output – CHANNEL 1, 2, 3

EPROG – External programmer input

EX-STBY - STAND-BY input

ALARM - output

9.1. MENU PROGRAM – START

Start-Menu

Requirements:

1. Create a program. (refer to next chapter)

2. Return to the Start-MENU and confirm the desired setting of each

MENU item with the key

3. Set a start time (>TIME< >DATE< >YEAR<) if the program is to be

started by the internal timer.

Menu level 1

Level 2 Parameter level

Press the key if a param eter is to be ret ained.

> STEP< Program start at section 1 … 10

> RUNS < Number of rep et it i o ns 1 .. . 99

> END< Status at en d o f pro gr am (ST D BY /SETPNT)

Standby or last setpoint

> GO < Time of start (NOW/TIMER)

• Set program step with

example: STEP 1

and

• Set number o f runs with

example: 1 ru n

and

• Set desi r ed parameter s with

32

or

(STDBY / SETPNT)

Parameter STanDBY: the circulator switches to –

OFF-.

Parameter SETPoiNT: the circulator const antly

keeps the temperature at the value of the last step.

and .

Page 33

HE / SE

Submenu TIMER

Level 2 Parameter level

oer

Parameter level

• Confirm >NOW< with the key and the program

will start immed iately

or

start at the set time under paramet er (TIMER ).

Set time in the ex ample bel ow :

09. August 20 09, 11:15 hrs

set the time for the start of the program in the

submenu >TIMER<.

>TIME< hours/minutes (hh:mm ) , s et bot h v al u es one

after the other and confirm

• hours flas h, set by pressi ng

+

minutes flash, set by pressing

+

>DATE< day/months (TT/MM), set both values one after

the other and confirm.

• day flashes, set by pressing

+

month flas h es , s et by pr es sing

>YEAR< year

• Set the year with

+

and .

The program starts at the set time.

Display of time until start:

In line 3 the notice >TIMER< and the set values for „TIME“ and

„DATE/Y EAR “ ar e al ter n ately indi cated

Check the correct setting of the internal real time clock if required

(see MENU CONFIG)

33

Page 34

Menu functions

The started program

D2

After the start the program will indicate the currently calculated setpoint in line

Termination / Interruption of a program

2

S XX.XX. The value increases within the time period >TSLICE< until the

target temperature >SETPNT< of the section is reached.

If the time per iod in a section is set to „0“, the next section will not begin until

the target temperature has been reached.

A

B

C1

C2

D1

Use the edit keys

approximately every 4 seconds between the current section (STEP XX) and

the

A remaining time of the section

B remaining time of the program

C current bath temperature

I xxx.xx - inter nal actual valu e or

E xxx.xx – external actual value

D RUN – the program has started or

PAUSE – the progress of the program has been interrupted by pressing

the

remain at the last calculated setpoint

Continue with the

key. While the time is stopped the temperature will constantly

to scroll to line 3. The display changes

key.

The program can be terminated any time by pr essing the key .

In case of power fai lur e t h e pr ogram is inter r up ted.

The circulator switches to –OFF- .

If the AUTOSTART-function is activated the programmer starts again at

the point in time approx. 5 minutes prior to the interruption. However, an

uncontrolled change of the bath temp er ature has occ ur red.

34

Page 35

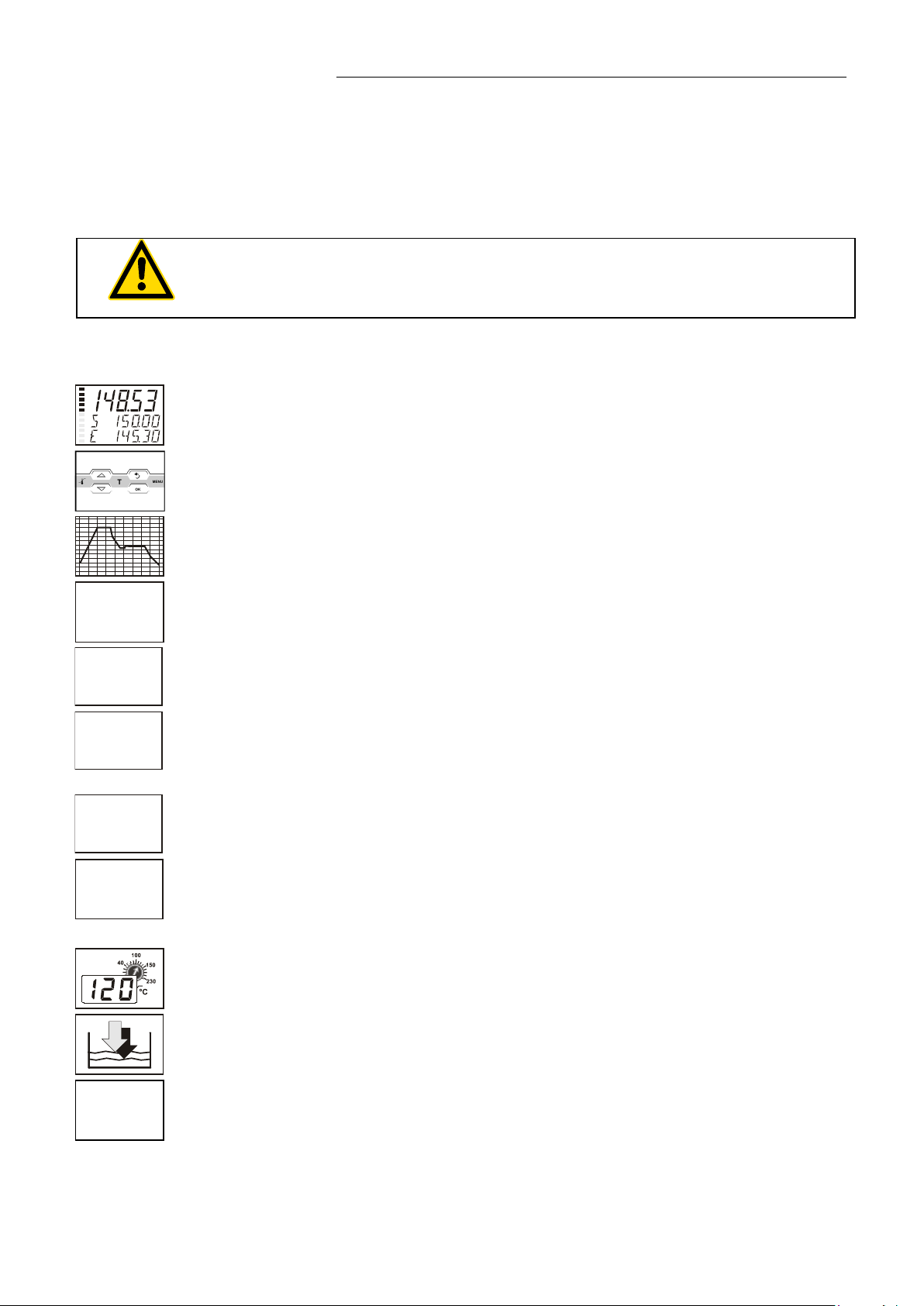

9.2. MENU PROGRAM – creation, administration

The integrated programmer permits fast and easy programming of setpoint

setpoint (SETPNT), which is achieved at the end of a section. The programmer

25

50

10 20 30 40 50 60 10 20 30 40 50 60 10

[min]

75

100

150

200

°C

t

Step 1 2 4

6 8

retroac ti vel y an d the integra te d in to the progr am .

HE / SE

Menu level 1

1 program

10 sections

temperature sequences. This temperature sequence is called progr am . A

program is composed of individual sections (STEP). The sections are defined

by duration (TSLICE) and target temperature. The target temperature is the

calculates the temper at ur e ramp from the differen ce in ti m e an d tem peratur e.

STEP (Nr.) 1 2 4 6 8

SETPNT (°C) 100 180 180 75 75

TIME (hh.mm) 00:20 00.10 00:20 00:50 00:20

Graph1

Sections without set value and time are skipped. They can be defined

35

Page 36

Menu functions

Level 2

Level 3

Parameter level

Menu level 1

>EDIT< Create , adm i ni ster progr am

> STEP< Program step (1 ... 10)

>SETPNT < Temperature setpoint of step ...

>TSLICE< Duration of step ...

> DELETE< delete program step (01 … 10, ALL)

Press key, if a parameter is to be retained.

Correcti o n function for paramet er s or val u es ( pr i or to OK)

• Set program step with

(Example: EDIT STEP 01)

For STEP 01 the values for SETPOINT 01 and

TSLICE 01 ar e s et on e a ft er the other

and

(STEP 1 … 10)

• Integer digits flash, set by pressing

(values within working temp. range)

+

• Decimal digits flash, set by pressing

+

(time slice)

• Set durati o n by pr es si ng and

Delete program

Program steps can be deleted individually or

entirely. (STEP 01, 02,… 10, ALL).

• Set parameters by pressing and

36

Page 37

9.3. MENU PUMP - Setting of pump pressure

The pressure of the circulating pump is adjustable in four stages. After

setting, the VFD COMFORT-DISPLAY indicates the corresponding value.

Adjusta bl e pump capaci t y stage 1 ... 4

Examples:

Soll Ist

Illuminated display:

for pump pressure

Adjusted:Display for the adj usted pump pressure stage in t he –OFF-

mode.

Effective: Display for th e ef fe c ti ve p um p pr es sure stage (rotation

Factory setting:

stage 1

speed) a ft er st ar t.

For protecting the pump motor, the rotation speed (i.e. the pump pressure

stage) changes with the load applied.

Example: The viscosity of the bath fluid (i.e. the load applied to the pump

motor) changes with the working temperature in the bath.

Flow rate: 22 ... 26 l/min

Pump capacity stage 1 2 3 4

Pump pressure [bar] 0.4 0.5 0.6 0.7

Suction pump [bar] 0.2 0.26 0.33 0.4

Total capacity [bar] 0.6 0.76 0.93 1.1

in a loop circuit

1. Press the

2. Select the menu >PUMP< pressing the

pressing the

The set par am et er flashes (example: >LEVEL 2<)

key.

key

HE / SE

key and confirm by

3. Change the parameter by pressing

key.

or

Press the

key if the parameter is to be retained.

and confirm b y press ing the

37

Page 38

Menu functions

9.4. MENU CONFIG - Configuration of unit

Menu level 1

A RESET can be effected only in the >OFF< mode.

Switch off circulator by pressing the

CONFIGURATION.

key and call up the menu

or

or

or

Level 2 Parameter level

Press the key if a parameter is to be

retained. Correc ti o n func tion for par am eters and

values (prior to OK).

• Switch on and off remote control by pressing

and

Control display in the topline

for Remote

For remote control refer to 71

Connect RS232 with PC.

• Switch over s et point setti ng by pr ess ing

and

OFF –Setpoint setting with the navigation keys

or

Setpoint setting via the analog socket „ext. Pt100

or

analog socket >REG+EPROG<

• Switch on and off autostart by pressing

or

AUTOSTART on = on

AUTOSTART off = off

See WARNING page 40

and

• Switch on and off OFFMODE by pressing

or

PUMP ON continuous operation of circulating pump

PUMP OFF circulating pump is linked to Start/Stop

and

• Switch over the input variable by pressing

or

and

Programmin g o f vari ables for the p ar am eters >

or

SERIAL < or > EPROG < is only accepted, if the

unit is in Start mode

38

Page 39

HE / SE

Level 2

Level 3

Parameter level

• Hours flash, set by pressing

• Minutes flash, set by pressing

• Day flashe s , s et by pr es si n g

• Month fl ash es , s et by pr es sing

• Year flashes, set by pressing

+

+

+

+

+

• Return to factory settings by pressing

RESET returns all set values to the factory setting

except for dat e and time.

A RESET can be effected only in the –OFF- mode.

During the mess age –RUN- all parameters are

9.4.1. Remote control via the serial interface

Factory setting : OFF

The control electronics offer two ways of adjusting a setpoint.

1. Adjustment of setpoint using the keypad

or the integrated programmer.

2. Adjustment of setpoint via the serial interface RS232 using a PC or a

superordinated process control system.

The topline of the VFD-DISPLAY shows a br i ght „R“ for remote

control; - remote co ntr ol di sc o nti n ued.

RS232

IMPORTANT: additional measures for remote control

Connect the circulator to the PC using an interface cable.

Check the int erface par am et er s of bot h in terfaces ( ci r c ul ator an d PC)

and make sure they match.

(refer to 12.1. Setup for remote controll page 71)

reset to fac tor y sett ings.

39

Page 40

Menu functions

Notice:

accordance with the NAMUR recommendations. This means for the start

The values set on the circulator remain saved and the unit is restarted by

start of the circulator by pressing the mains switch or using a timer.

9.4.2. Keypad control or setpoint setting via the analog input

Factory setting:: OF F

The selected mode is

indicated on the VFD

COMFORT-DISPLAY

OFF

PT100

EPROG

>

>

In addition to the serial interface via remote control the new circulator

offers the possibility to adjust the setpoint via analog interface >ext.

Pt100< or >R EG+E-PROG<.

OFF - Setpoint setting with the navigation keys

o r the integrated programmer.

PT100 - Setpoint setting via the analog socket „ext. Pt100“ using an

external temperature sensor or an appropriate voltage/current

source.

EPROG - Ca n onl y be adjusted w he n an el ectroni c mod ule wi t h analog

connections is used (option).

Setpoint setting via the analog interface REG+E-PROG connection

with an external voltage or current sour c e or a pr o gr am m er .

Important:

Connect the external voltage or current source or a programmer to

the circulator via the socket REG+E-PROG (see page 62).

In the menu >MENU IN/OUT< set the par ameter >EPR O G INPUT< and the input variables >EPROG-SIGN A L< (see page 62).

The E-Prog input can only be used either under menu item >SP

EXT < or under menu item >ACTVAR<

(see page 41).

9.4.3. AUTOSTART

Warning:

For superv is e d or uns u per vi sed operation with the “AUTOSTART“ funct ion avoid any

hazardous situation to persons or property

Take care to fully observe the safety and warning functions of the circulator.

Factory settings : OFF

The circulator has been configured and delivered by JULABO in

mode that th e uni t m us t en t er a s a fe oper a ti n g st a tus a ft er a pow er

failure. This safe operating status is indicated by the message „OFF“ or

„R OFF“ on the VFD COMFORT-DISPLAY.

A complet e, al l -pole shutdown of the main functional elements such as

heater an d pump motor is e ff ected.

pressing the start/stop key in manual control.

In remote control mode the values need to be resent by the PC via the

interface.

If such a safety standard is not required, the NAMUR recommendations

can be bypassed with the AU TO START func ti on thus allow ing a direct

40

Page 41

9.4.4. OFF-MODE

The heater or the connected cooling unit receives the control

control. The permissible maximum temperature can be exceeded. The user has to take

ch as gaskets or ins ulat ions for example, may be damaged or destroyed, i f

HE / SE

Factory setting:

PMP OFF

Usually the circulating pump is controlled with the key

start/stop command. If the circulating pump is to work in the –OFFmode, the adjustment can be set in a sub-menu.

The pump motor will be shutdown in case of alarm anyhow.

9.4.5. ACTVAR - actuating variable

Factory setting:

CONTROL

The variable (ACTuating VARiable) corresponds to the extent to which

the heater or cooling unit of the circulator is controlled. Heat or cold is

applied to the bath according to this variable. If this happens with the

control electronics of the circulator, called > CONTROL < in this

particular case, the bath temperature is exactly heated and maintained

constant at the adjusted setpoint.

Programming of variables for the parameters > SERIAL < or >

EPROG < is only accepted, if the unit is in Start mode.

Possibl e par ameters :

CONTROL – The internal control electronics of the circulator controls

the heater und the connected cooling unit. Self-tuning is possible.

SERIAL –

signal via the serial interface. Self-tuning is not possible.

or the

Warning:

The working temperature range of the circulator is determined during configuration. If

set to >CONTROL<, this range cannot be exceeded.

If se t to > SERIAL < and > EPROG <, heat or cold is applied to the bath without

adequat e pr ec a utions for tem p er ature contr ol .

Materials, su

the permissible maximum temperature is exceeded.

The safety and warnin g f unc t ions > < of the instrument must always be used to

their full est capacit y .

EPROG - Th e he at er or t he connected cooling unit receives the control

signal via the E-Prog input. Self-tuning is not possible.

Important:

Under

(refer to pa ge 62).

Note:

The E-Prog input can only be used either under menu item

>SP EXT< (refer t o page 40) or under menu item > ACTVAR <.

set the input variable >EPROG U/I< to

41

Page 42

Menu functions

The internal real time clock allows starting a program any time. The clock

Level 2

Parameter level

9.4.6. Setting of clock and date

is set to the local mean time (MEZ) at the factory.

If the unit is operated in a different time zone, the clock can be

adjusted in this menu.

9.4.7. RESET – Factory settings

Change summer/winter time in this menu

A Reset will ret ur n al l values to fact or y s et ti ng except for da te and time.

A RESET ca n be effected in the >OFF < mode on ly.

9.5. MENU CONTROL – Control characteristics and parameters

Menu level 1

The circulator is qualified for internal and external temperature control

The switchover is carried out in the menu >C-TYPE< .(INT or EXT).

Switch off the circulator by pressing the key

menu CONFIGURATION.

For external temperature control and measurement connect a Pt100

external sensor to the socket at the rear of the circulator.

Press the key if a parameter is to be retained. Correc ti on fu nc ti o n

for parameters or values (prior to OK)

and call up the

The parameter flashes, swit c h by pr ess i n g

or

The control type can be adjusted in the -OFF-

mode only.

Depending on the adjustment only the active

parameter s ar e displayed.

and

The parameter flashes, switch by pressing

or

and

OFF - no selftuning.

or

ONCE - single selftuning (factory setting)

ALWAYS - continual selftuning.

42

Page 43

HE / SE

Level 2

Parameter level

C-TYPE INTER NAL

C-TYPE EXTERNAL

0.1 … 99.9

• The param et er flashes, swi tch by pressi n g

or

This parameter affects the temperature sequence

in case of internal control.

and

• The param et er flashes, set by pr es si n g

0.1 … 99.9

+

• The param et er flashes, set by pr es si n g

3 … 9999

+

• The param et er flashes, set by pressing

0 … 999

+

• The param et er flashes, set by pr es si n g

0.1 … 99.9

+

• The param et er flashes, set by pr es si n g

3 … 9999

+

• The param et er flashes, set by pr es si n g

0 … 999

+

• The param et er flashes, set by pr es si n g

+

43

Page 44

Menu functions

(See pag e 49).

Attention:

circuit

9.5.1. CONTROL – Contr o l INTERNAL / EXTERNAL

Switchover can only be effected if a Pt100 external sensor is

connected.

Pt100

Factory setting: I NT

IMPORTANT: Additional measures for external temperature control

Suggested settings for external temperature control:

BAND HIGH / LOW and INTERN MAX / MIN

see chapter >MENU LIMITS<

Sensor calibration of the Pt100 external sensor is carried out in the

menu >ADJUST<, submenu >ATC SENOR - EXT<; set ATC

STATUS< to >OFF<

Place the external sensor into the temperature-controlled medium and securely fix the

sensor.

Accessory: Pt100 external sen s or

Order No. Description Material Cable

8981003 200x6 mm Ø, stainless steel 1.5 m

8981005 200x6 mm Ø, glass 1.5 m

8981006 20x2 mm Ø, stainless steel 1.5 m

8981010 300x6 mm Ø, stainless steel 1.5 m

8981015 300x6 mm Ø, stainl ess steel / PTFE coated 3 m

8981013 600x6 mm Ø, stainless steel / PTFE coated 3 m

8981016 900x6 mm Ø, stainless steel / PTFE coated 3 m

8981014 1200x6 mm Ø, stainless steel / PTFE coated 3 m

8981103 Extension cable for Pt100 sensor 3.5 m

8981020 M+R in-line Pt100 sensor

Pt100 M+R

The M+R in-line Pt100 sensor is a flow sensor and can be installed loop

44

Page 45

9.5.2. SELFTUNING

The control parameters ascertained during the last identification are

he instrument performs a single selftuning of the controlled system

t

APER

NORM

Setpoint

t

APER

NORM

temperature ramp

temp. stability

Setpoint change: The temperature increases at

HE / SE

Selftuning:

When performing a selftuning for the controlled system (temperature

applicat ion system) , th e control parameters Xp, Tn and Tv are

automatically determined and stored.

Possibl e par ameters :

OFF - no selftuning

used for cont r ol purposes .

ONCE - single selftuning (factory setting)

T

after each s tar t wi th the key or after receiving a start

command via the interface.

ALWAYS - continual selftuning

The instrument performs a selftuning of the controlled system

whenever a new setpoint is to be reached.

Use this setting only when the temperature application system

changes per manently.

9.5.3. Dynamic internal

This parameter affects the temperature sequence onl y i n

case of int er nal c o ntr ol .

Factory setting: APER (aperiodic)

°C

temp. stability

°C

Possibl e par ameters :

NORM Allows for reaching the setpoint faster – with

setpoint change or ramp function – but

overshooting of up to 5 % is possible.

APER Ramp function: the increase of temperature

occurs tem p or al l y o f fset an d achieves the

target temperature without overshooting.

the same rate, the target temperature is

achieved without overshooting.

With both settings constant temperature is achieved

after approximately the same time.

45

Page 46

Menu functions

The differential component reduces the transient time. An insufficient lead

Optimum setting

Control parameters XP-, TN-, TV - INTERNAL as well as

Xp too low