Page 1

Proj. 1716 24.01.2013

Operating Manual

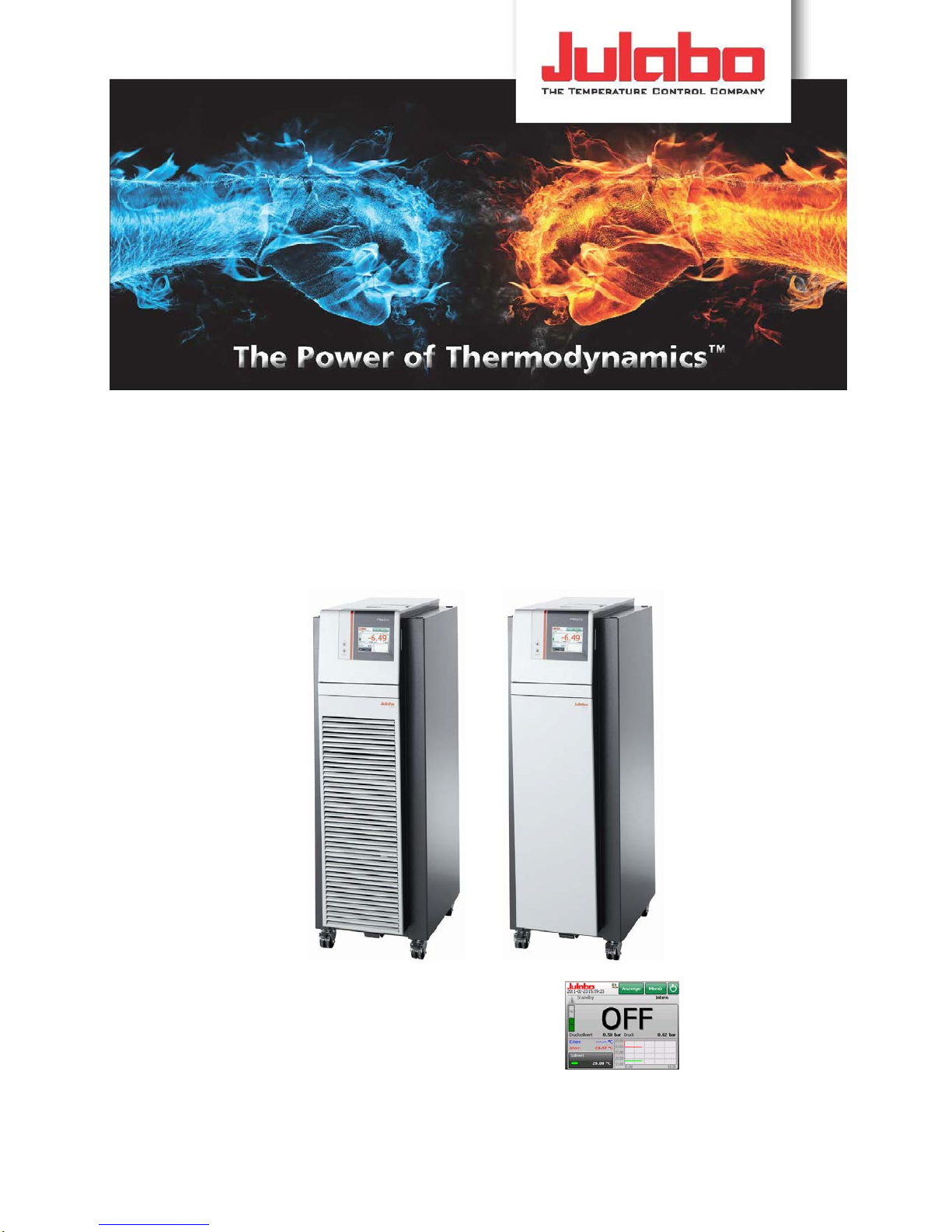

PRESTO®

Highly Dynamic Temperature Control S ystem

A80, A80t, W80, W80t

1.953.3044-V1 us 12/12

See Operati ng

instructions „User

Interface“, 1953.3041,

for additional

information.

JULABO USA, Inc.

884 Marcon Boulevard Allentown, PA 18109

Phone: +1(610) 231-0250 Fax: +1(610) 231-0260 i nfo@j ulabo.com www.julabo.com

Page 2

Table of Contents

2 01.24.2013

Congratulations!

You have made an excellent choice.

JULABO would like to thank you for the trust you have placed in our company and products.

This Operating Manual will help you become acquainted with the use of our temperature control

systems. Read this manual carefully before bringing the unit into operation!

The JULABO Quality Management System

Temperature control devices for research and industry are developed,

produced, and distributed according to the requirements of

ISO 9001 . Certificate Registration No. 01 100044846

Unpacking and Inspection

After unpacking the units and accessories, carefully inspect them for any damage. If the packaging

has been damaged, you must notify the freight forwarder, railway company, or postal service so they

can file a damage report.

Printed in Germany Changes without prior notification reserved

Important: keep operating manuals for future use

Page 3

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 3

Table of Contents

Table of Contents ....................................................................................................................... 3

1. Proper Use ........................................................................................................................ 6

1.1. Description .................................................................................................................... 6

2. Operator Responsibilities - General Safety Notices .......................................................... 7

2.1. Personnel ..................................................................................................................... 7

2.2. Handling guidelines ...................................................................................................... 7

2.3. Operation ...................................................................................................................... 8

2.4. Disposal ........................................................................................................................ 9

3. Safety Notices ................................................................................................................. 10

3.1. Explanation of safety notices ...................................................................................... 10

3.2. Descriptions of other notices ...................................................................................... 10

3.3. Safety instructions for operation ................................................................................. 10

3.4. Safety instructions for properly locating and installing the device ............................... 12

3.5. Transporting and properly locating the device ............................................................ 13

3.5.1. Transport ................................................................................................................ 13

3.5.2. Properly locating the device ................................................................................... 14

3.6. Connecting to power supply ....................................................................................... 15

4. Operating and functional elements ................................................................................. 16

4.1. Front side of the unit ................................................................................................... 16

4.1.1. Electrical connections on the front side of the device (upper section) ................... 17

4.1.2. Drain elements on the front side of the device (lower section) ............................... 18

4.2. Rear of unit ................................................................................................................. 19

4.2.1. A80, air-cooled ....................................................................................................... 19

4.2.2. W80, water-cooled ................................................................................................. 20

5. Preparations .................................................................................................................... 21

5.1. Cooling water connections.......................................................................................... 21

5.2. Bath fluids ................................................................................................................... 23

5.3. Temperature control tubing......................................................................................... 24

5.4. Connecting an external vessel.................................................................................... 26

5.5. Diagram: Device structure and mechanical connections ............................................ 27

Page 4

Table of Contents

4 01.24.2013

5.6. Accessories ................................................................................................................ 27

5.6.1. Connectors, Valves, Adapters, etc. ........................................................................ 27

5.7. Filling .......................................................................................................................... 28

5.7.1. Sample Calculation: D e termining whether an exte rna l expansion reserv o ir is needed

28

5.7.2. Filling a closed, external system ............................................................................ 29

5.8. “Empty the unit” menu ................................................................................................ 30

5.9. Additional thermal adjustment and electrical connection elements............................. 34

5.9.1. Adjustable high temperature cut-off ....................................................................... 34

5.9.2. Electrical connections ............................................................................................ 35

6. Electrical connection pin assignments ................................................................................. 37

6.1. Accessories ................................................................................................................ 37

6.1.1. Alarm output........................................................................................................... 37

6.1.2. Connection for the external Pt100 sensor .............................................................. 38

6.2. Options (on the rear side) ........................................................................................... 38

6.2.1. Analog module ....................................................................................................... 39

6.2.2. Module with Pt100 connector ................................................................................. 39

6.2.3. Connecting to the STAND-BY socket..................................................................... 40

6.2.4. Connecting to the REG+E-PROG socket ............................................................... 41

6.2.5. Connecting to the JULABO Pressure / Flow Sensor socket................................... 42

7. Remote operation, laboratory automation ....................................................................... 43

7.1. Preparing for remote control ....................................................................................... 43

7.2. Communication with PC or higher priority data system .............................................. 43

7.3. Status messages / Error messages ............................................................................ 44

7.3.1. Alarms .................................................................................................................... 44

7.3.2. Warnings................................................................................................................ 44

8. Technical Data ................................................................................................................ 45

8.1. Cooling water connection, cooling water quantity ....................................................... 49

8.2. Connections ............................................................................................................... 49

8.3. Safety ......................................................................................................................... 50

8.4. Ambient conditions for proper operation according to EN 61 010-1 ........................... 50

8.5. Materials of Construction of the wetted Parts ............................................................. 51

9. Pump characteristic curves (using water) ........................................................................ 52

9.1. Medium with a density of 1 kg/dm3 [8.35 lb/gal] ......................................................... 52

10. Cleaning the unit ............................................................................................................. 53

Page 5

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 5

10.1. External cleaning ........................................................................................................ 53

10.2. Internal cleaning ......................................................................................................... 53

10.3. Cleaning the reservoir, tubing system and heat exchanger: ....................................... 54

10.4. Removing residual cleaning liquid: ............................................................................. 55

11. Maintenance/repair of the unit ........................................................................................ 56

11.1. Repair service ............................................................................................................. 56

11.2. Warranty ..................................................................................................................... 57

Page 6

Proper Use

6 01.24.2013

1. Proper Use

PRESTO

®

is a highly dynamic temperature control system designed for

controlling the temperature of certain liquids in a closed, external

system. The temperature-controlled external system is attached to the

protruding pump connections on the rear of the PRESTO

®

.

JULABO temperature control systems are not suitable for direct

temperature control of food or other items intended for human

consumption, pharmaceutical products, or medical products.

Direct temperature control means: The temperature-controlled object

has unprotected contact with the bath fluid.

1.1. Description

• In addition to the refrigeration unit, the main functional elements are

the heater, circulation pump, and control electronics. When used

with an external Pt100 control sensor, the auto-optimizing electronic

PID controller will automatically adjust to the requirements of the

external vessel.

• The pump’s powerful output can be reduced for use with pressure-

sensitive vessels by altering the motor speed in four stages or by

controlling via pressure.

• The refrigeration systems are cooled

- A80, A80t with air from the ambient surroundings

- W80, W80t with water.

• The unit is operated via the TFT user interface.

• Remote control through the digital RS232, USB, and ethernet

interfaces according to NAMUR enable advanced process control

without an additional interface card.

• The high temperature cut-off is a safety device that is independent

from the control circuit. The cut-off temperature is adjustable and is

displayed on the TFT user interface.

• The integrated programmer lets you store and retrieve setpoints

and times for eight different temperature profiles.

• Interfaces available on the right side of the housing:

- SD card for datalogging

- USB host interface.

• Analog interfaces:

- Alarm output for an external signal

- Ext. Pt100 connection for an external control

- Connection for JULABO pressure or flow sensor

• An analog module is optionally available, it consists of:

A STAND-BY input for remote shutoff with an external switch.

REG+E-PROG connection for specifying the setpoint with an

external analog setpoint device or programmer. Three analog

outputs for datalogging are also integrated.

Page 7

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 7

2. Operator Responsibilities - G e neral Safety Notices

Products from JULABO are safe when installed, operated, and

maintained according to generally accepted rules of safety. This chapter

explains the potential hazards that can arise in conjunction with

operation of the temperature control system and describes safety

measures for eliminating these hazards when possible.

2.1. Personnel

• The owner/operator is responsible for the qualifications of the

operating personnel.

• Make sure that anyone who will operate the temperature control

system has been instructed regarding the relevant tasks.

• The operators must be trained on a regular basis on the hazards

that may occur during their activities and on measures for mitigating

these hazards.

• Make sure that anyone entrusted with operation, maintenance, and

installation has read and understood the safety information and the

operating manual.

• When using hazardous materials or materials that may become

hazardous, allow only persons with complete knowledge of the

materials and the circulator to bring the unit into operation. These

persons must have the ability to evaluate potential dangers in their

entirety.

2.2. Handling guidelines

• Avoid impacts to the housing, vibrations, damage to the keypad

(keys, display), or heavy soiling.

• Regularly check, at least once every two years, to ensure proper

condition of the safety, warning, and prohibition symbols.

• Ensure that the mains power network exhibits low impedance in

order to avoid influencing units that are operated on the same

network.

• Magnetic radiation may affect other devices that contain

components that are sensitive to magnetic fields, such as a monitor.

We advise maintaining a min. distance of 1 m from such devices.

• The ambient temperature may not exceed 40 °C [104 °F], nor fall

below 5 °C [41 °F].

• Rel. humidity should not exceed 50% at 40 °C, [104 °F].

• Do not store or use the unit in aggressive (corrosive) atmospheres.

Protect the unit from contamination.

• Do not place the device in direct sunlight.

Page 8

Operator Responsibilities - General Safety Notices

8 01.24.2013

2.3. Operation

The unit may only be configured, installed, maintained, and repaired by

qualified personnel.

Persons who operate the circulator must be trained in the particular

tasks by qualified personnel. Please call us if you have any questions

about operating the unit or the operating manual.

Contact:

JULABO USA, Inc.

884 Marcon Boulevard

Allentown, PA 18109

Phone: +1(610) 231-0250

Fax: +1(610) 231-0260

info @ julabo.com

www.julabo.com

The bath may be filled with flammable liquids. Fire hazard!

Some bath fluids may represent a chemical hazard.

Observe all warning notices on the materials used (bath fluids) and in

their associated instructions (safety data sheets).

Potentially explosive mixtures may be formed if adequate ventilation is

not provided. Use the units only in well ventilated areas. The units are

not suitable for use in potentially explosive atmospheres.

Proper use includes limitations on the types of materials (bath fluids)

used. Do not use toxic, acidic, or corrosive bath fluids.

If using hazardous materials or materials that may become hazardous,

the operator must apply the enclosed safety labels to the front side of

the unit where they are easily visible:

Warns against a dangerous condition. Important! Please observe the

documentation. (operating instructions, safety data sheet).

You must read the operating manual before switching on the unit.

Valid in: EU

You must read the operating manual before switching on the unit.

Valid in: USA, NAFTA

Page 9

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 9

Special diligence and care are essential due to the wide operating

temperature range.

There are heat- and cold-related hazards: burns, scalding, superheated

steam, frostbite.

Hot and cold parts and surfaces that could cause burns or frostbite

when touched.

Warns against hot or cold surfaces.

Disconnect the unit from the power supply prior to opening.

Dangerous electrical voltage. Discharging of internal capacitors.

Observe the notices in the instructions for third-party units that you

attach to the JULABO unit, especially any safety notices.

The pin assignment of the plugs and the technical data of the products

must be observed of all times.

2.4. Disposal

This product contains oils used as bath fluids that must be disposed and

consist partially or entirely of petroleum or synthetic oil. Observe

regulations for disposal provided in the safety data sheets.

These units contains refrigerants– at this time considered not to have

any negative effects on the ozone layer. However, during the long

operating period of the unit, disposal prescriptions may change. For this

reason, disposal should be performed by qualified personnel only.

Observe all disposal regulations applicable in your country or region.

This symbol on the product or its packaging indicates that it may not be

disposed with household waste. Proper disposal avoids negative

impacts on people and the environment and enables reuse of valuable

raw materials.

Information about collection centers for old units is available from your

city or community or an authorized disposal company.

Page 10

Operator Responsibilities - General Safety Notices

10 01.24.2013

3. Safety Notices

3.1. Explanation of safety notices

The Operating Manual contains additional safety notices. They are

identified by a triangle with exclamation point.

"Caution, warning of a dangerous condition."

The significance of the danger is categorized in conjunction with a

signal word. Carefully read and observe the instructions!

Danger:

Designates a potentially threatening danger to life and health. Failure

to observe these notices can result in serious health consequences,

including life-threatening injuries.

Warning:

Designates a potentially hazardous situation. If not avoided, they may

result in slight or minor injuries. The text may also warn against

potential property damages.

Caution:

Designates the potential for property damage. If not avoided, the

product or something in its vicinity may be damaged.

3.2. Descriptions of other notices

Note!

This symbol draws attention to important information.

Important!

Refers to usage tips and other useful information.

3.3. Safety instructions for operation

It is important that you follow all safety instructions in order to avoid

personal injury and property damage. These instructions supplement

workplace safety regulations.

Safety instructions

• This device may be connected to grounded (protected earth, PE)

mains power outlets only!

• These tasks may be performed by properly trained personnel only.

• The mains plug serves as a reliable way to disconnect the unit

from its power supply for safety reasons and must be readily

accessible at all times.

• Install the unit on a level, noncombustible surface

• It is essential that you read the operating manuals before initial

operation.

• Adjust the high temperature cut-off before operating the unit.

•

Never operate the unit without bath fluid!

Page 11

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 11

• Observe expansion of the bath oil as the bath temperature rises.

• Do not allow water to enter hot bath oil.

• Do not drain bath fluid while it is hot!

Check the temperature of the bath fluid before draining; this may

be done by briefly switching on the unit.

• Use tubing suitable for temperature-control purposes.

• Avoid kinking the external tubing.

• Secure tubing connections to prevent slipping.

• Regularly check tubing for material fatigue, such as cracks.

• Never operate a damaged or leaking unit.

• Do not attempt to use the unit if the power cable is damaged!

• Before performing service or repair tasks or moving the unit, switch

the unit off and remove the power plug from the socket.

• Allow only authorized technicians to perform service and repair

tasks.

• Always switch off the device and disconnect it from its power

supply before attempting to clean it.

• Completely drain the unit before moving it.

• Transport the unit carefully.

• Do not tilt or lay the unit during transport.

• Shaking or falls may damage the inside of the unit.

• Observe all safety labels!

•

Do not remove safety labels!

Warning

Hot or cold parts.

Risk of burns or frostbite.

Use gloves.

Caution

Dangerous electrical voltage

Discharging of internal capacitors takes 5 sec. Do not touch plug pins

for 5 sec. after pulling the power plug.

Page 12

Operator Responsibilities - General Safety Notices

12 01.24.2013

3.4. Safety instructions for properly locating and installing the device

Warning:

Proper use of the temperature control system includes controlling the

temperature of a liquid in a reactor or similar vessel.

We do not know which substances you will need to use.

Many substances are:

• combustible, flammable, or explosive

• hazardous to health

• hazardous to the environment

• in other words: dangerous.

The user bears sole responsibility for handling these materials!

The following questions are meant to help recognize potential

hazards and minimize risks.

• Are all tubes and electrical cables securely attached and laid?

Watch for:

sharp edges, hot surfaces during operation, moving mechanical

parts, etc.

• Will hazardous vapors or gases be produced during heat-up?

Is it necessary to work under a fume hood?

• What must be done if a hazardous substance is spilled onto or into

the unit?

Obtain information about the substance before beginning work and

define decontamination methods.

Warning: E scaping vapors/gases

• Vapors/gases may develop, especially at higher working

temperatures. The unit will vent these vapors/gases to ensure

optimum performance. Operation under a fume hood is

recommended.

Ensure good ventilation and airflow at the place of installation.

Caution:

It is advisable to continue circulation for a certain amount of time after

you are finished working with the temperature control system. You

should also set the working temperature to approximately 20 °C [68

°F] in order to uniformly drop the temperature in the closed loop. This

will avoid overheating of the bath fluid and dangerous draining

conditions.

Caution: Inspect safety devices at least twice per year:

• High temperature cut-off device.

Use a screwdriver to turn the adjustable high temperature cut-off

down to the current bath temperature (this will shut off the unit).

• Low-level safety

The float switch on this unit cannot be activated manually for the

purpose of checking functionality. Therefore, you should observe

the five-stage level indicator each time you refill the unit.

If the bath fluid becomes thick or cracks during operation, the

temperature control system must be cleaned by qualified personnel.

This can be avoided by changing the fluid regularly. Refer to

chapter 5.8. “Empty the unit” menu.

Page 13

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 13

3.5. Transporting a nd properly locating the device

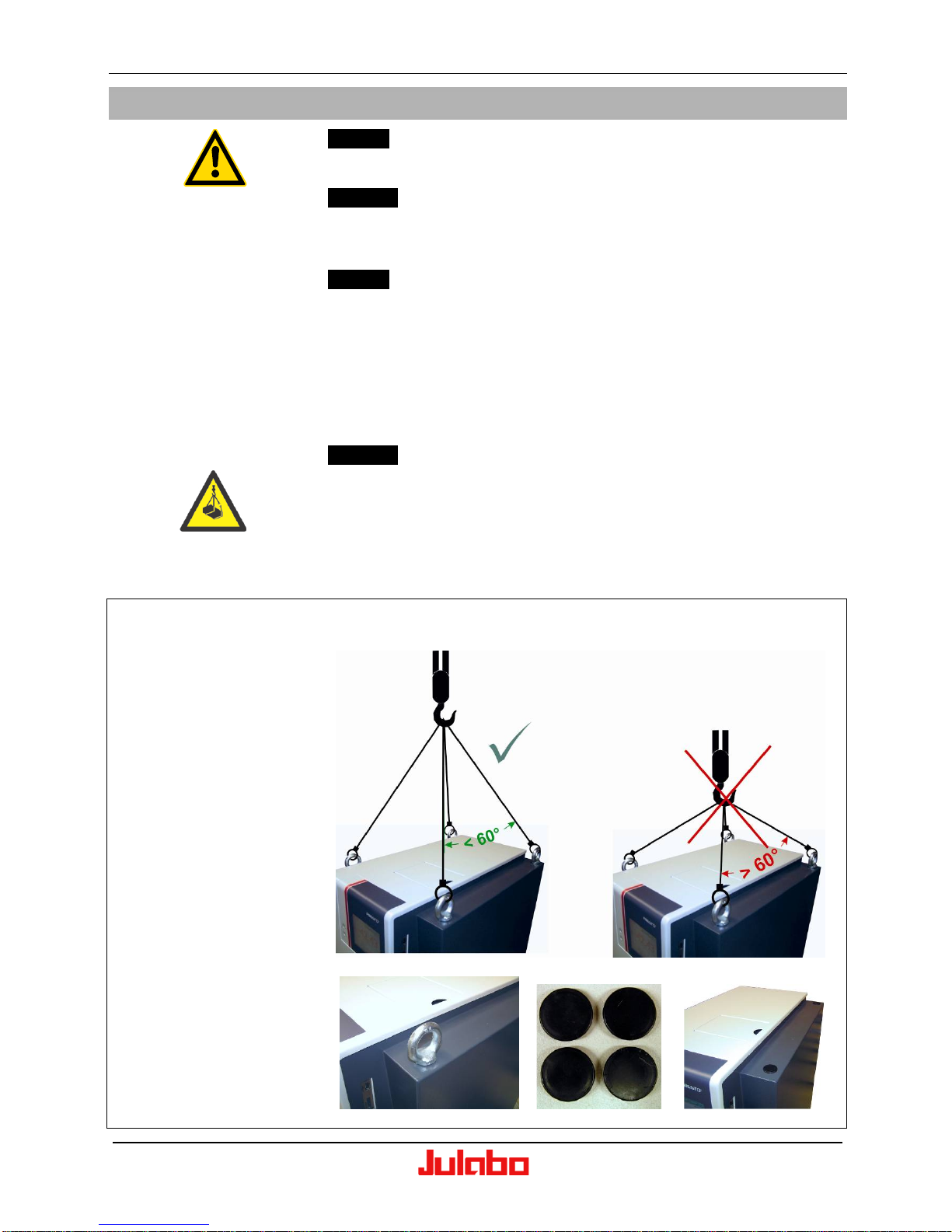

Danger:

The unit is not suitable for use in potentially explosive atmospheres

Warning:

Tipping hazard!

Unit may tip if pushed from the side with more than 180 N of force.

Danger:

Incorrect lifting techniques and/or lifting equipment can lead to

overloading of one or more of the eye bolts (pictured below), which

could destroy it/them. As a result, all of the support points used for

lifting could become overloaded, leading to a drop that could cause

harm to bystanders and/or damage to the device.

When selecting lifting equipment, please take into account the weight

of the temperature control system.

Warning:

Danger of suspended loads

Risk of impact and crushing

- Do not step beneath the suspended unit.

- Wear personal protective equipment e.g.

safety shoes, safety helmet.

3.5.1. Transport

• Fasten lifting gear to

the four eye bolts.

• Transport unit to

installation site and

place in position.

• Remove lifting gear.

• Remove eye bolts and

retain.

• Suggestion: Close the

tapped bores with the

plastic caps included in

delivery.

To transport and position the unit with lifting gear there are four lifting

points with eye bolts.

Page 14

Operator Responsibilities - General Safety Notices

14 01.24.2013

3.5.2. Properly locating the device

• Transport the unit on a

firm, level surface.

Avoid shocks, e.g. floor

grates.

• For longer distances,

securely strap the unit

to a trolley or cart

before transport.

• Using the retractable

handle, position the unit

at the desired location

and lock the castors.

• Install the unit on a

level, noncombustible

surface.

• Do not install the unit in

the immediate vicinity of

a heat source and do

not place it in direct

sunlight.

• Keep the ventilation

grids clear (front and

rear)! Maintain

clearance of at least 8

inches (20 cm) from

objects, walls, etc. in

both the front and rear

of the unit.

• Clean the ventilation

grids (front and rear) at

least once every 2-3

weeks. In dirty

environments, clean the

ventilation grids more

often.

• When using an external

reservoir, additional

space is needed at the

rear.

Ensure adequate air conditioning at the installation location.

The installation location should be air conditioned to prevent the

exhaust heat of the unit from increasing the ambient temperature too

much (maximum ambient temperature 40 °C [104 °F]). Furthermore,

standard EN 378 requires a minimum room size for each kilogram of

refrigerant in the event of a leak in the refrigeration circuit. Refer to the

type label for the refrigerant volume.

0.49 kg of refrigerant R507 requires 1 m

3

of space.

0.68 kg of refrigerant R23 requires 1 m3 of space.

Page 15

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 15

3.6. Connecting to power supply

Danger:

• This device may be attached to grounded (protected earth, PE)

mains power outlets only!

• The mains plug serves as a reliable way to disconnect the unit

from its power supply for safety reasons and must be readily

accessible at all times.

• Do not attempt to use the unit if the power cable is damaged!

• Regularly inspect the power cable for damage.

• JULABO assumes no liability for improper power connection!

Compare the available mains voltage and mains frequency with the

specifications on the type label.

See technical data section for information on allowable voltage

tolerances.

Connect the mains plug to a grounded (protected earth, PE) power

supply socket!

3.6.1. Unit for hard-wired installa tion

Units for hard-wiring are delivered with a mains power cable but without

a plug. These units are A80t and W80t units with the voltage

3x208 V / 60 Hz.

When installed in a building, provisions must be made for a circuit

breaker of 32-A as separator.

In addition it is recommended to fuse the unit in the building installation

with 32-A-with C-characteristic.

Page 16

Operating and functional elements

16 01.24.2013

4. Operating and f unct ional element s

4.1. Front side of the unit

1 User Interface

2 Retractable handle

3 Removable ventilation

grid

4 High temperature cut-

off adjustment

5 Power switch (at the

side of the housing)

6 USB Host (Type A)

connection and SD

Card slot.

Operation of the user

interface is described in a

separate document (see

page 1).

Fig.: A80

Page 17

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 17

4.1.1. Electrical connections on the front side of the device (upper section)

Remove the ventilation

grid as follows in order to

access the electrical

connections:

• Pull out the handle.

• Grasp the bottom

edge of the ventilation

grid, lif t slightly, and tilt

it forwards.

• Remove the

ventilation grid from

the housing frame.

Included connections:

1 Ethernet connection.

2 USB device (Type B

plug).

3 RS232 interface

4 Alarm socket for ext.

alarm signal.

5 Socket for external

measurement and

control sensor

(Pt100).

6 Connection for

draining residual bath

fluid.

7 Sensor for ambient

temperature

measurement.

Using tubing and a

suitable vessel, open the

connection (6), about

every 2-3 weeks, to

release any built-up

deposits

Page 18

Operating and functional elements

18 01.24.2013

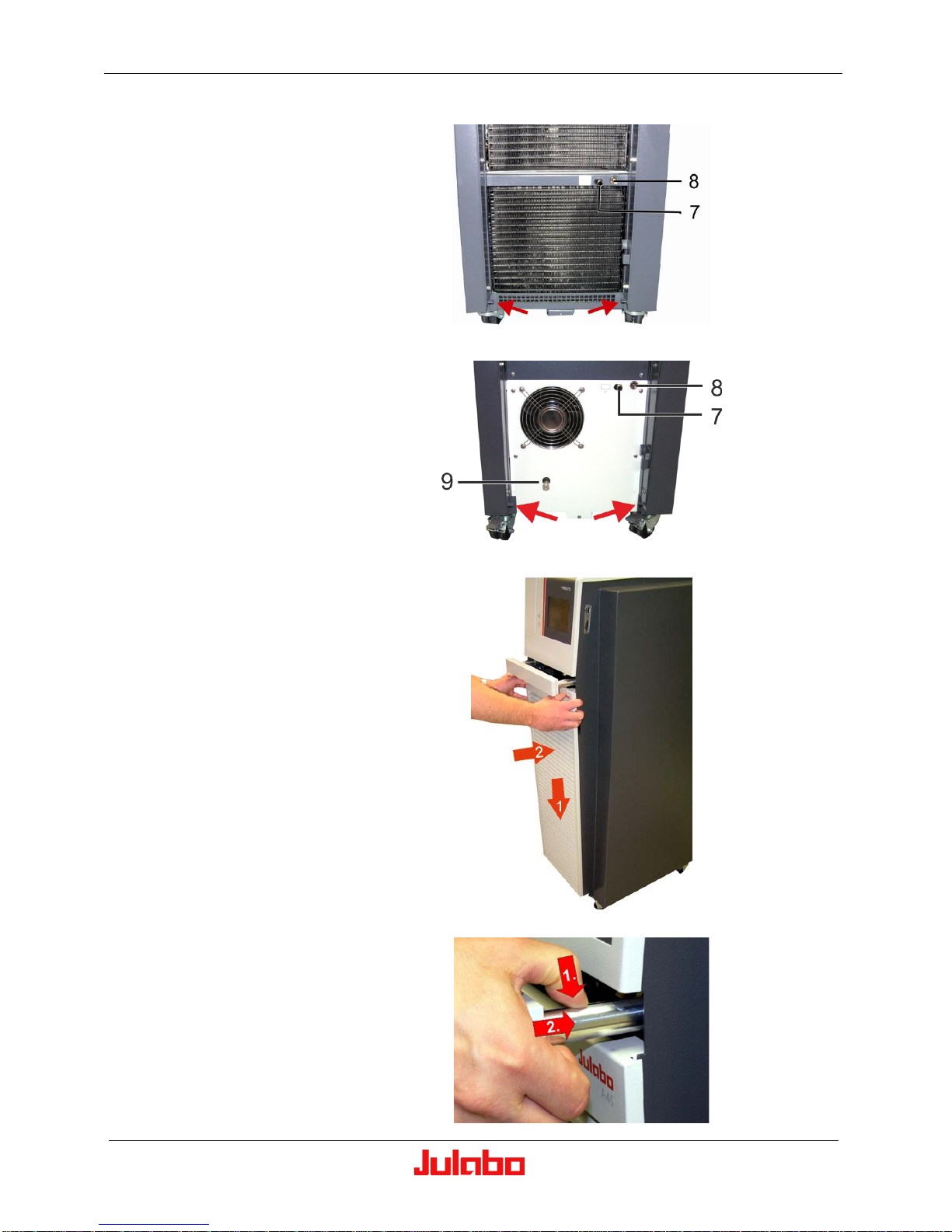

4.1.2. Drain elements on the front side of the device (lower section)

The drain nozzle (7) with

outer diameter ∅12 mm and

the drain screw (8) are

located near the bottom of

the unit behind the

ventilation grid.

On the W80 it is possible to

completely drain the cooling

water system via the sealing

plug M10x1 (9).

Details are given in chapter

5.8. “Empty the unit”

menu.

A80

W80

Replace the ventilation grid

as follows:

• Set the ventilation grid

onto the angled metal

piece at the bottom of

the unit.

• Tilt the ventilation grid

towards the unit until it

touches the mounting

pins.

• Lift the grid slightly and

onto the mounting pins.

• Slide the ventilation grid

downward.

•

To retract the handle,

press down on the

locking tab, located on

the right rail.

Page 19

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 19

4.2. Rear o f unit

4.2.1. A80, A80t, air-cooled

1 Circuit breakers for

mains supply

1a at A80t

2 Mains cable with plug

2a at A80t

3 Overflow connection,

M16x1 male

4 Pump connection

(supply

),

M24x1.5 male

5 Pump connection,

(return IN

),

M24x1.5 male

6 Connection for external

expansion reservoir,

M16x1 male

Options

7 Socket for connection

of optional accessory

analog connections

(Order No. 8900105).

8 Socket for connection

of Pt100 module with

connector (Order No.

8900106).

9 JULABO Pressure /

Flow Sensor socket.

More information regarding

these connections can be

found in chapter 6.

Electrical connection pin

assignments, page 37

Safety cutouts and mains cable at A80t

Page 20

Preparations

20 01.24.2013

4.2.2. W80, W80t, water-cooled

1 Circuit breakers for main s

supply

1a at W80t

2 Mains cable with plug

2a at W80t

3 Overflow connection,

M16x1 male

4 Pump connection

(supply

),

M24x1.5 male

5 Pump connection

(return,

),

M24x1.5; male

6 Cooling water outlet,

(OUT

) G3/4“ barbed

fittings for ½” inner diameter

7 Cooling water inlet,

(IN

) G3/4“ barbed fittings

for ½” inner diameter

8 Connection for external

expansion reservoir, M16x1

male

Options

9 Socket for connection of

optional accessory analog

connections (Order No.

8900105).

10 Socket for connection of

Pt100 module with

connector (Order No.

8900106)

11 JULABO Pressure / Flow

Sensor socket

More information reg. these

connections can be found in

chapter 6. Electrical connection

pin assignments, page 37

Safety coutouts and mains cable at W80t

Page 21

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 21

5. Preparations

5.1. Cooling water connections at W80 and W80t

Even high quality heat exchangers, like those installed in our equipment,

can be damaged by unsuitable cooling water.

Cooling water quality can vary based on local conditions.

The heat exchanger may become leaky due to corrosion, or it may

become clogged due to particulates building up inside.

Cooling water pressure (IN / OUT) max. 6 bar

Differential pressure (IN - OUT) 0.5 bar

Cooling water temperature < 30 °C [ < 86 °F]

Cooling water quantity see technical data.

Notice:

Danger of corrosion of heat excha nger due to unsuitable quality

of cooling water.

• Due to its high lime content, hard water is not suitable for cooling.

It will cause scale formation in the heat exchanger.

• W ater containing high amounts of iron will cause rusting even in

heat exchangers made of stainless steel.

• Chlorinated water will cause pitting corrosion in heat exchangers

made of stainless steel.

• Due to their corrosive characteristics, distilled water and deionized

water are unsuitable and will cause corrosion of the bath.

• Due to its corrosive characteristics, sea water is not suitable.

• Due to their microbial (bacterial) components which settle in the

heat exchanger, untreated and unpurified water from rivers and/or

cooling towers is unsuitable.

• Avoid particulate matter in cooling water.

• Avoid putrid water.

Page 22

Preparations

22 01.24.2013

5.1.1. Recommended quality of cooling water:

pH

7.5 to 9.0

Sulfate [SO4 2- ]

< 100 ppm

Hydrocarbonate [HCO 3-]/sulphate

[SO4 2-]

> 1 ppm

Hardness [Ca 2+, Mg 2+]/[HCO 3-]

> 0.5 °dH

Alkalinity

60 ppm < [HCO 3-] < 300 ppm

Conductivity

< 500 μs/cm

Chloride (Cl -)

< 50 ppm

Phosphate (PO4 3-)

< 2 ppm

Ammonia (NH3)

< 0.5 ppm

Free chlorine

< 0.5 ppm

Trivalent iron ions (Fe 3+)

< 0.5 ppm

Manganese ions (Mn 2+) < 0.05 ppm

Carbon dioxide (CO2)

< 10 ppm

Hydrogen sulfide (H2S)

< 50 ppm

Oxygen content

< 0.1 ppm

Algae growth

Not permitted

Suspended solids

Not permitted

Notice:

Cooling wate r circuit

There is a risk that oil could leak from the refrigeration system

(compressor) of the temperature control system into the cooling water

in case of a fault in the cooling water circuit!

Obey the laws and regulations of the water distribution company.in the

region where the unit is operated.

Connect cooling water:

• Cooling water connectors G3/4" female / Barbed fittings ½” inner

diameter.

• The used cooling water will exit via the outlet (OUT

). Plumb this

connection to the respective drain or return flo w c ircuit.

• Supply cooling water via the inlet (IN

).

5.1.2. Accessories

Order No.:

Description

8 930 312

Reinforced tubing (pressure resistant) 1/2“ inner

dia.

8 970 482

2 Tube clamps

8 920 000

Particle filter for cooling water circuit

Page 23

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 23

5.2. Bath f luids

Warning:

Observe the safety data sheet of the bath fluid, especially the fire

point!

The unit must be supervised at all times if using a bath fluid with a fire

point of ≤ 65 °C [≤ 149 °F].

Recommended bath fluids for closed, external systems

• A list of recommended bath fluids is available on our website.

Find it at: www.julabo.com

Warning

Use of non-recommended bath fluids may result in a fire hazard or

other hazard:

JULABO will assume no liability for damages resulting from use of an

unsuitable bath liquid.

Unsuitable bath liquids include substances with the following

characteristics:

• highly viscous

(significantly higher than 50 cSt (50 mm

2

/s) at the relevant working

temperature)

• low viscosity, but with creep properties

• corrosive properties

• liquids that tend to crack.

JULABO assumes no liability if unsuitable liquids are used!

Page 24

Preparations

24 01.24.2013

Caution!

Maximum viscosity must not exceed 50 cSt (50 mm2/s) at working

temperature.

Caution!

Use of purified or unpurified water is not permitted.

Examples:

tap water, distilled water, deionized water, water/glycol mixtures, CaCl

2

solutions

Important notice about recommended Bath fluids:

Wh y is the operational range above the bath fluid's fire point?

This temperature control system is operated in a closed, external

temperature loop. As a result, the bath fluid only comes into contact

with oxygen in the internal filling reservoir, which is not located directly

in the temperature control loop.

A safety device monitors and controls the temperature in the internal

reservoir.

• The temperature of the bath fluid is held steady at approximately

25 °C [77 °F].

• A safety device with an adjustable temperature value

>RESERVOIR< protects against dangerous conditions, independent

of the control loop. When this safety device triggers (e.g. if

excessively hot liquid flows into the internal reservoir), the

temperature control system is completely shut down and will not

restart without manual intervention.

Set the >RESERVOIR< safety temperature at least 25 °C below the

fire point of the bath fluid.

5.3. Temperature control tubing

The following tubing is recommended:

Triple-insulated metal tubing, each with two end connections M24x1.5

female, temperature range to

-100 °C ... +350 °C [-148 °F to 662 °F].

Order No. Length

8.930.261

8.930.262

8.930.263

8.930.264

1.0 m

1.5 m

2.0 m

3.0 m

Maximum pressure 6.0 bar at +20 °C [ 68 °F]

4.6 bar at +200 °C [392 °F]

3.8 bar at +350 °C [662 °F]

Page 25

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 25

Warning:

Tubing:

Temperature control tubing is a potential source of danger at high

working temperatures. If one or more temperature control tubes are

damaged, a large volume of hot bath fluid can be pumped out of the

unit in a short period of time.

Potential consequences include:

• Fire hazard

• Explosion hazard

• Severe burns to persons or property

• Difficulty breathing caused by a hot atmosphere

Safety instructions

• Use tubing suitable for temperature control purposes.

• Secure tubing connections against slipping.

• Avoid kinking the tubes.

• Regularly check tubes for material fatigue, such as cracks.

Page 26

Preparations

26 01.24.2013

5.4. Connecting an external vessel

This temperature control system is designed to control the temperature

of an external, closed-loop vessel (temperature loop).

The tubing connections between the temperature control system and

the attached external vessel should be as short as possible. This is the

only way to fully utilize one of the main advantages of this system (its

speed!).

Caution:

Secure tubing connections against slipping.

• Remove the screw

caps from the pump

connections (4, 5)

and use appropriate

tubing to connect the

unit to the external

system (M24x1.5 /

27mm wrench).

The pressure line (4,

OUT) must be

attached to the

lowest fluid

connection point of

the external vessel to

prevent air from

becoming trapped.

•

Connect one end of

an appropriate tube

to the overflow (3)

adapter and place

the other end into a

suitable container.

The container must

always be lower than

the "overflow" outlet

(M16x1 / 19mm

wrench).

The below picture shows the W80, but the A80 connects to the

external vessel in the same way.

Important notice:

If bath fluid drains out through the overflow (3) at your highest working

temperature, direct the liquid into a suitable container. If the unit also

triggers a low fluid-level alarm at the lowest working temperature, then

you should use an external expansion vessel to avoid this problem.

Page 27

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 27

5.5. Diagram: Device structure and mechanical connections

5.6. Accessories

5.6.1. Connectors, Valves, Adapters, etc.

Various accessories can be found at our homepage, www.julabo.com.

Page 28

Preparations

28 01.24.2013

5.7. Filling

Caution:

Be aware of how the bath fluid changes volume within the

temperature control system's working temperature range.

Rule of thumb:

Expect about 12% volume change for every 100 °C [212 °F]

temperature change.

Attention:

Connect the external vessel first!

See chapter 5.4. Connecting an external consumer, page 26.

Note:

Always check to make sure the drain screw is closed before filling.

Recommendation:

• Use a 2-liter measuring cup or similar f or filling.

• Use a heat transfer fluid that is appropriate for your application.

5.7.1.

Sample Calc u lation: Det e rmining whet her a n ex ternal expansion reservoir is needed

Assumption:

The external vessel for this example is a reactor with capacity 5 l.

The length of the connection tube is 6 m, the inner diameter is 10 mm.

The bath fluid has a thermal expansion coefficient (γ) of 1.1 • 10-3 K-1

The temperature difference (∆ϑ) is 280 °C.

The change in volume (∆V) οf the bath fluid can be calculated as follows:

ϑγ

∆⋅⋅=∆

ges

VV

In which V

ges

= VM + VS + V

G

V

M

= Jacket volume (approx. 1/3 of external reactor volume) = 0.33 • 5 l = approx. 1.65 l

V

S

= Volume of the tubes (A • l) = 78.5 mm2 • 6 m = 0.47 l

V

G

= Volume of the active heat exchanger volume = 1.7 l

V

ges

= 1.65 + 0.47 + 1.7 = 3.82 l

∆V = 3.82 l • 1.1•10-3 K

-1

• 280 K = 1.18 • 20 % safety factor = approx. 1.4 l.

In this case, the internal usable expansion volume (please see technical data) would be sufficient.

With a reactor volume of 50 l in this example, the external expansion reservoir, offered by JULABO

(Order No. 8970833), would be necessary.

Page 29

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 29

5.7.2. Filling a closed, external system

(Also refer to the "User Interface" operating manual, 1.953.3041)

Connect the unit to the

mains power supply and

switch on the unit at the

mains switch .

After the self-test is

completed, the unit will be

in the "OFF" state and will

emit an audible signal.

To mute the audible

alarm, touch the alarm

notice's red box.

The fill level indicator on

the left side of the display

shows that the unit is

empty.

To continue,

press the

button.

You will see a message

instructing how to fill the

unit. Press the button

labeled “Fill unit” and

follow t he instructions

displayed on the User

Interface.

Filling the unit:

• Open the cover on top

of the housing

• Remove the plug (not

pictured).

• Slowly pour heat

transfer liquid into the

round opening (Use a

funnel or a container

designed for pouring,

for best results).

The area around the filling

opening is sealed from

the housing, but you

should avoid spilling large

amounts of bath fluid.

Clean up any spilled fluid

with a towel or similar.

Page 30

Preparations

30 01.24.2013

Watch the level indicator.

As soon as the minimum

filling level has been

reached the fill lev el

indicator will turn green.

Switch the unit off and

switch it back on again.

You may now continue

filling up to the desired

level.

Return to standard display

by pressing

.

If there is too much bath

fluid or if the bath fluid

expands due to heating

during operation, a high

fluid level warning is

activated.

In this case, use the

residual fluid drain (6) to

remove some bath fluid.

See the next chapter for

draining instructions..

Ticker text:

The early warning system for high fluid level reports a critical fluid

level. Please drain some bath fluid.

5.8. “Empty the unit” menu

• Caution:

• Do not drain the bath fluid while it is hot!

Check the temperature of the bath fluid before draining; this may

be done by briefly switching on the unit.

• Always store and dispose of old bath fluid in an environmentally

friendly way.

Always observe the applicable disposal regulations in your

region.

Page 31

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 31

After removing the

ventilation grid, the drain

nozzle (7) and the drain

screw (8) can be operated.

For draining:

• Attach a tube (outer

diameter 12 mm) to the

drain port (7).

• Place a suitable

container for holding or

storing the liquid under

the unit.

A80

W80

The draining operation is menu-driven on the user interface, but it also

requires some mechanical operations.

Call up the main menu,

then press

Page 32

Preparations

32 01.24.2013

Press

The ticker in the display

reports the start of the

automatic draining mode.

The setpoint is

automatically changed to

20.00°C. As soon as the

temperature reaches

20 °C (± 10 K), the ticker

text will change and

prompts you to drain the

unit.

• Unscrew the drain

screw (8) by a few

turns.

• To drain excess or

stagnant cooling water

from the W80 before

transportation, use the

M10x1 drain screw (9)

Ticker text:

Automatic draining mode active. Wait until the medium temperature

has reached the adjusted setpoint.

Automatic draining mode finished. You can drain the unit now.

A80

W80

Page 33

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 33

As the liquid drains, the

fluid level will decrease.

The low-level warning

(warning 40) and then the

low-level alarm (alarm 1,

red) will eventually occur

when the level drops to

the two trigger points.

Warnings are displayed as

a ticker in the status line.

Mute the audible signal by

pressing the yellow

symbol.

Mute the audible signal

by touching the red box.

In order to completely drain

the bath fluid, it is

necessary to also empty

the filling reservoir.

Connect a piece of tubing

(diam. 11.5 mm), and flip

the ball valve’s handle (6)

to empty the filling

reservoir.

Page 34

Preparations

34 01.24.2013

5.9. Additional thermal adjustment and electrical connection elements

5.9.1. Adjustable high temperature cut-off

Two circular potentiometers for setting the high temperature cut-off

are located on the front of the unit. Use a screwdriver to turn these

dials.

On the TFT you will find

the continuous display of

important values and

functions.

Warning

The >TANK< high

temperature cut-off

(complies with DIN

standard 12876-1-2000)

should be set to 15 °C

above the highest

working temperature

setpoint. Make sure that

the fluid is rated for use

at this temperature, first!

The >RESERVOIR< high

temperature cut-off must

be set to at least 25 °C

below the bath fluid's fire

point.

Adjust the high

temperature cut-off by

slowly turning the dial

with a screwdriver. The

exact value will appear

on the display.

1 Date / time

2 Status: On/Standby

3 Fill level indica tor

4 External temperature sensor value

5 Current power output (X% heating, -X% cooling)

6 Selected temperature control mode (internal/external)

7 Current liquid temperature

8 Selected max. pump pressure and current pump pressure

9 Selected high temperature warning setpoint

10 Selected low temperature warning setpoint

11 High temperature cut-off setting (TANK)

12 High temperature cut-off setting (RES)

Cooling indicator icon - Blinking or continuous

Heating indicator icon - Blinking or continuous

Page 35

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 35

5.9.2. Electrical connections

Electrical connections (behind the ventilation grid on the front of the unit, see Chapter 4.1.1)

Ethernet-based network

connection

1 ETHERNET

USB device interface

2

USB DEVICE

Interface RS232C

For controlling the unit via a

PC or a higher priority

process control system.

3 SERIAL

Connector: ALARM output

(for external alarm signal)

4 ALARM

Connection socket: External

measurement and control

sensor

Connect the external Pt100

sensor to the socket,

calibrate with the "ATC Ext"

function, and then use a

suitable device to secure the

sensor inside the external

vessel.

5

EXT Pt100

There are cable guides at

the side for a neat and easy

installation of the connection

cables.

Page 36

Preparations

36 01.24.2013

USB HOST and SD-Card slot are located on the right side of the housing:

USB HOST for configuring

the unit from a USB stick, or

datalogging.

SD Card for datalogging

Page 37

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 37

6.Electrical connect ion pin assignments

Important:

Use shielded cables only.

The shield should be continuous, and should be electrically

connected to the plug’s housing.

When working with the SERIAL interface, use a null modem cable.

Normal operation can be ensured only if cables no longer than 3m

(9.85 ft.) are used. The use of longer cables does not itself affect

proper performance of the unit, however external interference (e.g.

cellular phones) may have a negative impact on performance in this

configuration.

SERIAL interface

Use this socket to connect

a PC via null modem cable

to PRESTO

®

in order to

remotely control the

temperature control

system.

9 6

5

1

RS232 pin assignments

Pin 2

RxD

Receive Data

Pin 3

TxD

Transmit Data

Pin 5

0 V

Signal GND

Pin 7

RTS

Request to send

Pin 8

CTS

Clear to send

Pin 1; 4; 6, 9 Reserved - do not use!

6.1. Accessories

Order No.:

Description

8 980 073 RS232 interface cable 9 pole/9 pole, 2.5 m

(8.2 ft) long.

8 900 110

USB interface adapter cable

6.1.1. Alarm output

This socket is a voltage-free change-over contact. With the options in

the menu item > AL-OUT Function< (see operating instructions for the

user interface), all possible operating conditions can be signalled as

desired, without having to change the wiring of the cable. Normally

during an alarm, pins 2 and 3 are connected.

Alarm output

This output can be used to

alert the user when the

unit enters an alarm

condition, from a distance.

Check the operating

condition of the plug

regularly (about every 2-3

days).

13

2

ALARM

Breaking capacity

max. 30 W / 40 VA

with turn-on voltage

max. 125 V∼/−

with switching current

max. 1 A

Page 38

Electrical connection pin assignments

38 01.24.2013

6.1.2. Connection for the external Pt100 sensor

The cable's shield must be electrically connected to both the sensor’s

sheath as well as the housing of the connector plug.

External sensor

connection for external

temperature measurement

and control. Only use

shielded sensors.

Check the plausibility of

the external temperature

measurement regularly

(about every 2-3 days), by

placing the Pt100 in a

state where the

temperature is already

known (e.g. in ambient air,

or a container of ice

water).

4

1

3

2

ext. Pt100

1

4

2

3

Shield Plug

Look on

soldering side.

Pt100

Pin

Signal

1

I+ 2 U+ 3 U- 4 I-

6.2. Options (on the rear side)

Caution

Danger: electricity.

During assembly conductive objects may drop into the unit and cause

a short circuit.

Disconnect the unit from the power supply prior to opening.

Installation and maintenance may be performed only by authorized,

qualified personnel.

7 Socket for connection of

optional accessory

analog connections

(Order No. 8900105).

8 Socket for connection of

Pt100 module with

connector (Order No.

8900106).

9 JULABO Pressure /

Flow Sensor socket.

Page 39

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 39

6.2.1. Analog module

Order No.: 8900105

7a 7b

The analog module has two circular female connectors.

7a Female connector STAND-BY input (can be used for an

external "on/off" switch).

7b Female connector REG+E-PROG with three analog

datalogger outputs, and one input for an external programmer

or other voltage and/or current sources.

Information regarding labeling:

test For service purposes only. This button has no function during

regular operation.

reset The module can be „reset“ with this key. This may be necessary

in case of an error, for example if the red LED (error) lights up.

on

If the Green LED is blinking

Blinking indicates that the module is receiving information

(CAN-Messages) and is working correctly.

If the Green L ED is illuminated

The module is powered on, but is not receiving any information

(CAN-Messages).

If the Green LED is not illuminated

The unit is turned off, or the module is damaged, or the power

supply to the module is not working.

error

If the Red LED is not illuminated

If the unit is operating and this LED is not illuminated, the

module is working properly.

If the Red LED blinks

An unknown error has occurred while this module was

communicating on the CAN-Bus. The CAN-Bus has deactivated

itself for safety reasons. Turn the unit off via the power switch,

wait a few seconds, and turn it back on again. If the error

occurs again, please contact JULABO service

(Service@julabo.com).

If the Red LED is illu minated

A fault has occurred with the module. The TFT display will show

the type of error (Alarm code) and troubleshooting steps, if

applicable.

6.2.2. Module with Pt100 connector

Order No.: 8900106

The module with a Pt100 connector is intended for the connection of a

second Pt100 external sensor. The sensor is connected at the back of

the JULABO temperature control system. It will measure a second

temperature at any point in an application.

In connection with the VFC (Volume Flow Control) unit, it is possible to

determine the calorimetric power and performance. The value (external

2) can be displayed on the user interface. For setup use the path >

Menu Customize Home display <. For description see the operating

manual “User Interface”, 1.953.3041 of the JULABO temperature

control system.

Page 40

Electrical connection pin assignments

40 01.24.2013

6.2.3. Connecting to the STAND-BY socket

The STAND-BY-socket can be enabled or disabled via the TFT user

interface.

When the STAND-BY socket is activated, a connected switch must be

closed to start the device. If this function is activated, but an external

switch is not connected and properly closed, the TFT will display the

message "E-OFF." When you see this message, it means that the

external switch must be closed to start the device.

Stand-BY

Socket for connecting an

external on/off switch.

Warning: This

feature does not turn off

the power to the

instrument

1

2

3

AK

STAND-BY

Pin

Signal

1

Not used

2

5 VDC

3

0 V

Page 41

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 41

6.2.4. Connecting to the REG+E-PROG socket

The programmer input and all of the datalogger outputs are configurable

via the TFT user-interface.

Channel 1 Voltage output, e.g. for datalogger (V)

Channel 2 Voltage output, e.g. for datalogger (V)

Channel 3 Current output, e.g. for datalogger (mA)

E-PROG Input for external programmer

With the E-PROG - input, you can use either a voltage source or a

current source to change the unit’s setpoint temperature.

REG+E-PROG

The programmer input (EPROG, pin 4) can be

configured as a voltage or

current input via the TFT

user interface.

Pin

Signal

1 Voltage output*, channel 1

0 ... 10 V

2 Voltage output*, channel 2

0 ... 10 V

3 Gnd for outputs

0 V

4 Programmer input, EPROG

0 ... 10 V or 0 ... 20 mA

5 Current ouput**, channel 3

0 ... 20 mA or 4 ... 20 mA

6 Gnd for programmer

0 V

* The resistance of any load placed on either of the voltage

outputs must be, at minimum, 10 kΩ.

** The resistance of any load placed on the current output must

be, at minimum, 400 Ω.

Page 42

Electrical connection pin assignments

42 01.24.2013

6.2.5. Connecting to the JULABO Pressure / Flow Sensor socket

Signal input for the connection of an external pressure sensor or flow-

through sensor. These two sensors are available as accessories.

Please note that only the JULABO accessory sensors will work with

this socket.

Julabo Sensor

Pressure / Flow

Pin

Signal

1

24 V

2

5 V

3

4…20 mA

4

GND (0 V)

Flow Control Units in JULABO program

Order No. Description

8980762 VFCpro Volume Flow Control unit, M24x1.5 male, (-100…300 °C) [-148…572 °F]

8980782 VFC Volume Flow Control assembly unit, (-100…300°C) [-148…572 °F]

For further i nf or mation, r efer to t he inst r uct ion manual flow control unit, 1.950.0133.

Pressu re sen sors for PRESTO® in JULABO program

Order No. Description

8980771 Pressure sensor M24x1.5 male

Caution:

Possible incorrect measurement when connecting a JULABO

pressure sensor!

• If the customer's application is positioned higher or lower than

the PRESTO

®

Temperature Control System, the height

difference will affect the measurement and cause incorrect

results.

Remedy:

Position the PRESTO

®

Temperature Control System and the

application at the same height level.

Check the plausibility of the sensor measurement regularly (about every 2-3 days).

Page 43

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 43

7. Remote operation, laboratory autom at ion

7.1. Preparing for remote control

RS232, serial interface.

Refer to the "User

Interface" operating

instructions (1.953.3041).

9 6

5

1

SERIAL

BAUD RATE

4800 Baud

PARITY

Even parity

HANDSHAKE

RTS/CTS Protocol (Hardware handshake)

Data bits

7

Stop bits

1

7.2. Communication with PC or higher priority data system

When the PRESTO® temperature control system is in remote control

mode, the following symbol appears on the TFT display:

"R " = REMOTE

In most cases, commands are sent from the computer (“master

device”) to the temperature control system (“slave device”). The

temperature control system will also send error messages to the

computer, if the computer requests to know the current status of the

instrument.

If there is a power failure during remote control operation, the

computer must resend the start command and all other settings

through the RS232 or USB interface.

The instrument will not automatically restart when power is restored!

Signals are transferred in accordance with DIN standard 66022 and

DIN standard 66003, code table 1.

A transmission sequence consists of:

• Command

• Space (⇔; Hex: 20)

• Parameter (if applicable; period (“dot”) character used for

decimal point)

• Termination (↵; Hex: 0D)

Commands are divided into in and out commands.

In commands: retrieve parameters from the instrument

out commands: set parameters on the instrument

out commands can only be used while remote control mode is

active.

For more information, see the "User Interface" manual, 1.953.3041.

Page 44

Remote operation, laboratory automation

44 01.24.2013

7.3. Status messages / Error messages

7.3.1. Alarms

Alarm messages are

displayed in a flashing red

box, and are accompanied

by a loud beeping tone.

Example: Error 14

Touch the red box to mute

the alarm.

The unit switches to

“Standby“. The heater,

refrigeration unit and

circulation pump are all

switched off.

Press <

> button for

help text.

7.3.2. Warnings

Warnings are displayed in

a ticker on the status line

Example: Warning 40

Touch the icon to mute the

beeping tone.

Help is alway s accessible

through the icons

or .

Touch the icon and the

error history is displayed.

ALARMS are shown in

Red >

WARNINGS are shown in

Yellow >

The dates and times when each error occurred are also displayed.

If possible, this data will also be recorded when the error is cleared.

Examples: codes , .

For more information, including a list of alarm and warning codes with explanations, please see the

separate User Interface manual, 1.953.3041.

Page 45

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 45

8. Technical Data

PRESTO

®

A80

Order No.

9420801.14

9420801.03

9420801.04

Mains connection (nom. volt.)

Nominal frequency

Tolerance of the nom.voltage

Max . current consumption

Max. heating capacity at 200 V

at 208 V

at 220 V

at 230 V

V

Hz

%

A

kW

kW

kW

kW

208

60

+ 10

15.0

1.3

1.5

1.76

-

230

50

+ 10

16.0

-

-

-

1.8

230

50

+ 10

13.0

-

-

-

1.05

Working temperature range °C [°F] -80…250 [-112…482]

Temperature stability K ± 0.01…± 0.05

Cooling capacity

Liquid: Silicon Oil//Ethanol*

°C

kW

200 100 20 0 -10 -20 -30 -40 -60 -80

1.2

1.2

1.2

1.2

1.2

1.1

1.1

1.1

0.65

0.1

Refrigeration compressor dual

stage

air-cooled

Refrigerant First stage: R507; Second Stage: R23

Pump capacity

Pressure, max.

Flow rate, max. at 0 bar

bar [psi]

l/min

[gal/min]

1.3 [18.85]

1.7 [24.66]

38

[10.04]

40

[10.57]

Viscosity not to exceed max. 50 mm2/s (50 cSt)

Noise level, 1 m distance dBA 68

Ambient temperature °C [°F] 5…40 [41…104]

Rel. Humidity %

< 80 (at <31 °C) up to < 50 (at 40 °C)

Process volume, min.

Active heat exchanger vol.

Internal usable expansion vol.

l [gal]

l [gal]

l [gal]

3.9 [1.04]

1.7 [0.45]

5.6 [1.48]

Overall dimensions (WxDxH) mm

[inch]

430 x (650 + (Stud 35)) x 1258

[16.9 x (25.6 + Stud 1.38)] x 49.5]

Weight, approx. Kg [lbs] 164 [361.6]

* at 200 °C [392 °F] and 100 °C [212 °F] : measured using Thermal HL45

All data provided in this operating manual assumes use at the rated nominal voltage and rated

nominal frequency and with ambient temperature of 20 °C [68 °F].

Information subject to technical changes without notice.

Page 46

Technical Data

46 01.24.2013

PRESTO

®

A80t

Order No.

9420801.06.T

9420801.16.T

9420801.07.T

Mains connection (nom. volt.)

Nominal frequency

Tolerance of the nom.voltage

Max. current consumption

Max. heating capacity

at 200 V

at 208 V

at 220 V

at 230 V

at 400 V

V

Hz

%

A

kW

kW

kW

kW

kW

230/3PPE

50

+ 10

16.0

-

-

-

3.4

208-220/3PPE

60

+ 10

20.0

2.6

2.8

3.1

-

-

400/3PNPE

50

+ 10

20.0

-

-

-

3.4

Working temperature range °C [°F] -80…250 [-112…482]

Temperature stability K ± 0.01…± 0.05

Cooling capacity

Liquid: Silicon Oil//Ethanol*

°C

kW

200

100

20 0 -10

-20

-30

-40

-60

-80

1.2

1.2

1.2

1.2

1.2

1.1

1.1

1.1

0.65

0.1

Refrigeration compressor dual

stage

air-cooled

Refrigerant First stage: R507; Second Stage: R23

Pump capacity

Pressure, max.

Flow rate, max. at 0 bar

bar

[psi]

l/min

[gal/min]

1.7

[24.66]

40

[10.57]

Viscosity not to exceed max. 50 mm2/s (50 cSt)

Noise level, 1 m distance dBA 69 74

Ambient temperature °C [°F] 5…40 [41…104]

Rel. Humidity %

< 80 (at <31 °C) up to < 50 (at 40 °C)

Process volume, min.

Active heat exchanger vol.

Internal usable expansion vol.

l [gal]

l [gal]

l [gal]

3.9 [1.04]

1.7 [0.45]

5.6 [1.48]

Overall dimensions (WxDxH) mm

[inch]

430 x (650 + (Stud 35)) x 1258

[16.9 x (25.6 + Stud 1.38)] x 49.5]

Weight, approx. Kg

[lbs]

165 [361.6]

* at 200 °C [392 °F] and 100 °C [212 °F] : measured using Thermal HL45

All data provided in this operating manual assumes use at the rated nominal voltage and rated

nominal frequency and with ambient temperature of 20 °C [68 °F].

Information subject to technical changes without notice.

Page 47

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 47

PRESTO

®

W80

Order No.

9421801.14

9421801.03

9421801.04

Mains connection (nom. volt.)

Nominal frequency

Tolerance of the nom. voltage

Max . current consumption

Max. heating capacity at 200 V

at 208 V

at 220 V

at 230 V

V

Hz

%

A

kW

kW

kW

kW

208

60

+ 10

15.0

1.3

1.5

1.76

-

230

50

+ 10

16.0

-

-

-

1.8

230

50

+ 10

13.0

-

-

-

1.05

Working temperature range °C [°F] -80…250 [-112…482]

Temperature stability K ± 0.01…± 0.05

Cooling capacity

Liquid: Silicon Oil//Ethanol

°C

kW

200

100

20 0 -10

-20

-30

-40

-60

-80

1.2 1.2 1.2 1.2 1.2 1.1 1.1 1.1 0.65 0.1

Refrigeration compressor dual

stage

water-cooled

Refrigerant First stage: R507; Second stage: R23

Pump capacity

Pressure, max.

Flow rate, max. at 0 bar

bar [psi]

l[gal]/min

1.3 [18.85]

1.7 [24.66]

38 [10.04]

40 [10.57]

Viscosity not to exceed max. 50 mm2/s (50 cSt)

Pump connection M24x1.5

Cooling water connection G3/4 / barbed fitting ½“ inner diameter.

Noise level, 1 m distance dBA 64

Ambient temperature range °C [°F] 5…40 [41…104]

Rel. Humidity %

< 80 (at <31 °C) up to < 50 (at 40 °C)

Process volume, min.

active heat exchanger

volume

Internal usable expans. vol.

l [gal]

l [gal]

l [gal]

3.9 [1.04]

1.7 [0.45]

5.6 [1.48]

Dimensions (WxDx H) mm

[inches]

430 x (650 + (stud 35)) x 1258

[16.9 x (25.6 + Stud 1.38)] x 49.5]

Weight, approx. kg [lbs] 159 [350]

* at 200 °C [392 °F] and 100 °C [212 °F] : measured using Thermal HL45

All data provided in this operating manual assumes use at the rated nominal voltage and rated

nominal frequency and with ambient temperature of 20 °C [68 °F].

Information subject to technical changes without notice.

Page 48

Technical Data

48 01.24.2013

PRESTO

®

W80t

Order No.

9421801.06.T

9421801.16.T

9421801.07.T

Mains connection (nom. volt.)

Nominal frequency

Tolerance of the nom. voltage

Max. current consumption

Max. heating capacity at 200 V

at 208 V

at 220 V

at 230 V

at 400 V

V

Hz

%

A

kW

kW

kW

kW

kW

230/3PPE

50

+ 10

16.0

-

-

-

3.4

208-220/3PPE

60

+ 10

20.0

2.6

2.8

3.1

-

-

400/3PNPE

50

+ 10

20.0

-

-

-

-

3.4

Working temperature range °C [°F] -80…250 [-112…482]

Temperature stability K ± 0.01…± 0.05

Cooling capacity

Liquid: Silicon Oil//Ethanol

°C

kW

200

100

20 0 -10

-20

-30

-40

-60

-80

1.2

1.2

1.2

1.2

1.2

1.1

1.1

1.1

0.65

0.1

Refrigeration compressor dual

stage

water-cooled

Refrigerant First stage: R507; Second stage: R23

Pump capacity

Pressure, max.

Flow rate, max. at 0 bar

bar [psi]

l/min [gal]

1.7 [24.66]

40 [10.57]

1,3 [18.85]

38 [10.04]

1.7 [24.66]

40 [10.57]

Viscosity not to exceed max. 50 mm2/s (50 cSt)

Pump connection M24x1.5

Cooling water connection G3/4 / barbed fitting ½“ inner diameter.

Noise level, 1 m distance dBA

66

64

Ambient temperature range °C [°F] 5…40 [41…104]

Rel. Humidity %

< 80 (at <31 °C) up to < 50 (at 40 °C)

Process volume, min.

active heat exchanger

volume

Internal usable expans. vol.

l [gal]

l [gal]

l [gal]

3.9 [1.04]

1.7 [0.45]

5.6 [1.48]

Dimensions (WxDx H) mm

[inches

]

430 x (650 + (stud 35)) x 1258

[16.9 x (25.6 + Stud 1.38)] x 49.5]

Weight, approx. kg [lbs] 162 [357]

* at 200 °C [392 °F] and 100 °C [212 °F] : measured using Thermal HL45

All data provided in this operating manual assumes use at the rated nominal voltage and rated

nominal frequency and with ambient temperature of 20 °C [68 °F].

Information subject to technical changes without notice.

All pump data is based on use with liquids having a specific density of

1 kg/dm

3

[8.35 lb/gal]

Page 49

PRESTO® A80, A80t, W80, W80t Operating Manual

24.01.2013 49

Temperature setting

Digital

Local / Remote

Control type displayed on TFT User Interface

Remote Control from PC

Displayed on TFT User Interface

Temperature display

Displayed on TFT User Interface

Resolution

°C

0.01

ATC function (ATC3) internal

(ATC2) extern.

K

± 3

± 10

Temperature control

ICC – Intelligent Cascade Control

Cascade, parameters may be retrieved and modified

Working temperature sensor

Pt 100 1/3 DIN

Safety temperature sensor

Pt 100

8.1. Cooling water connection, cooling water quantity

Cooling water connections

G3/4 male / barbed fittings for ½“ I.D. tubing

Maximum water pressure bar [psi] 6 [87]

Min. water pressure at 30 °C bar [psi] 0.5 [7.25]

Necessary pressure difference bar [psi] 0.5 [7.25]

Cooling water quantity

l/min

2.0 (at 1.2 kW cooling capacity)

Max. cooling water temperature

°C [°F]

30 [86]

8.2. Connections

Computer interfaces RS232,

USB-Device V2.0 /

Ethernet

USB-Host V2.0

SD Card

USB-Stick

SD-card – up to 2 GB

Alarm output

for external alarm signal

External measurement and control sensor

Pt100

Optional Accessories: (Rear side)

Analog module

REG+E-PROG

Programmer input -100 °C - 400 °C

0 - 10 V or 0 - 20 mA or 4 - 20 mA

Temperature recorder outputs

0 - 10 V (0 V = -100 °C, 10 V = 400 °C)

0 - 20 mA (0 mA = -100 °C, 20 mA = 400 °C)

4 - 20 mA (4 mA = -100 °C, 20 mA = 400 °C)

Stand-By-input

for external switch on/off

JULABO Pressure / Flow Sensor

for pressure sensor / flow sensor

Module with Pt100 connection socket

for connection of a further Pt100

Page 50

Technical Data

50 01.24.2013

8.3. Safety

High temp. cut-off >TANK<, adj u stable setting

0 °C ... 320 °C [32 °F …608 °F]

High temp. cut-off >RESERVOIR<, adjustable

setting

0 °C ... 100 °C [32 °F …428 °F]

Low fluid protection

float s witch

Fluid level display

represented on TFT in 7 stages

Classification according to DIN 12876-1

Clas s III (FL)

Additional safety devices