Page 1

Product data sheet 1/4

PRESTO W50

temperature control system / process system

Reactor temperature control, tests for all kinds of substances or temperature

simulation – the new PRESTO are made for highly precise temperature

control and rapid temperature changes.

PRESTO provide large heating and cooling capacities covering a working

temperature range from -92 °C to +250 °C. Highly efficient components allow

extremely fast compensation of exothermic and endothermic reactions.

Lab users benefit from high flow rates, constant pressure, and a controlled

build-up of pump pressure. Changes in the temperature-control liquid’s

viscosity are balanced dynamically. Permanent internal monitoring and

self-lubricating pumps contribute to the new PRESTO®’s long service life. A

special feature of the new PRESTO is the integrated 5.7’’ industrial touch

screen.

All important information is displayed clearly and concisely enhancing ease

of use considerably.

The new PRESTO can be operated intuitively with the tip of your finger. As

the new PRESTO operate whisper quiet, you will hardly hear them in your

laboratory. Even high room temperatures of up to +40 °C will not make the

new PRESTO sweat. Maintenance-free pumps and drives guarantee

operational readiness. Multiple interfaces permit remote control of the

PRESTO® across networks and in superordinated control systems. The

Design does away with venting slots at the sides. The required installation

space is reduced to an absolute minimum.

PRESTO W50

Your advantages

For highly precise, external temperature applications

Rapid heating and cooling

Fast compensation of exothermic reaction

Wide working temperature ranges without changing fluids

Highest performance with small footprint

Space-saving design optimizes space utilization in your lab

NEW 5,7” industrial color TFT touch screen

well-organized view of important information with unmatched,

intuitive user friendliness

Up to 3 user level with password management

NEW USB (Host und Device)

NEW Ethernet

NEW SD-Card slot

RS232 / optional RS485 / optional Profibus DP

Stand-by input

Filling system accessible from the top

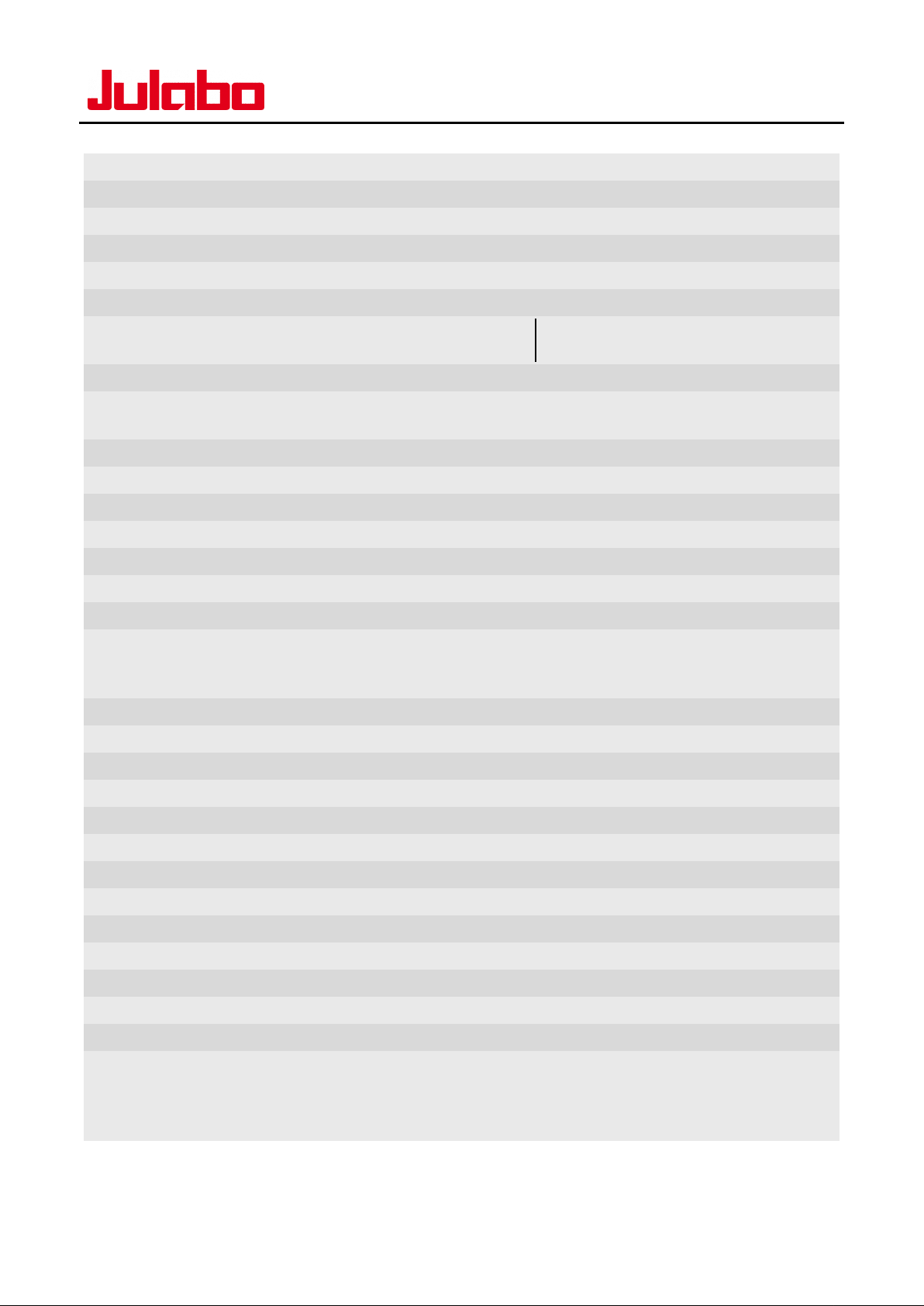

Technical Data

Order No. 9421502

Category Temperature Control PRESTO

Working temperature range (°C) -50 ... +250

Page 2

Product data sheet 2/4

Temperature control ICC

Temperature stability (°C) ±0.05 ... ±0.1

Setting / display resolution 0.01 °C

Integrated programmer 8x60 steps

Temperature Display TFT Touchscreen

Heating capacity (kW) 6 @ 400V; 6 @ 230V; 5.5 @ 208V

Cooling capacity (Medium: JULABO Thermal | Ethanol) °C 200 20 0 -10 -20 -30 -40

kW 7 7.5 6.5 5 3 1.8 0.6

Pump capacity flow rate (l/min) 35 ... 76

Pump capacity flow pressure (psi) 6.74 ... 43.5 @ 208V; 6.74 ... 46.4 @ 230V; 6.74 ... 46.4 @

400V

Viscosity max. (cSt) 50

Pump connections M30x1.5

Refrigerant stage 1 R507

Filling volume refrigerant stage 1 (g) 1000

PRESTO W50

Global Warming Potential for 3985

Carbon dioxide equivalent stage 1 (t) 3.985

External Pt100 sensor connection integrated

Digital interface RS232, SD memory card, USB, Ethernet, Modbus,

Alarm-out

Optional: RS485, Profibus

Analog connection input / output Optional

Ambient temperature 5 ... 40 °C

Dimensions W x L x H (inch) 20.9 x 26.2 x 49.6

Weight (LBS) 463

Sound pressure level (distance 1 m) max. (dBA) 65

Process volume min. (active heat exchanger volume) liters 7.5 (3.5)

Internal usable expansion vol. (liters) 7.5

Classification according to DIN12876-1 Classification III (FL)

Cooling of compressor 1-stage Water

Cooling water connection G ¾‘‘ male with barbed fittings for tubing ½’’ lD

Cooling water consumption (l/min) 8…12

Cooling water temperature (°C) <30

Cooling water differential pressure (bar) 0.5

Available voltage versions 3 x 208-230V/60Hz (+/- 5%) / 25A @ 208V, 27A @ 230V /

Without Plug

3 x 230V/50Hz (+/- 10%) / 27A / Plug 32A CEE

3 x 400V/50Hz (+/- 10%) / 16A / Plug 16A CEE

Page 3

Product data sheet 3/4

PRESTO W50

Tip: Counter-cooling your PRESTO with a Recirculating Cooler

If there is no cooling water, the PRESTO W50 can be cooled down with a recirculating cooler with a cooling capacity

of 13 kW at a flow temperature of 15°C. The required circulating pump has to ensure a flow rate of 13 l/min at a

counter-pressure of 0.5 bar. The recommended minimum tank volume is 50 liters.

Characteristics

Display

State-of-the-art display

technology

TFT Display for comfortable user

guidance, colored display of

measurement values, graphs and

control options, user-defined views

Operation

Optimal ease of use

Touch screen for direct operation via

display

Instructions inside

Help menus and explanations in

plain text for all control options, help

messages and warning messages

Multilingual user guidance

Language selection for display of

control options, notifications and

warning messages via touchscreen

Convenience for several users

Administrator level for customizing

instrument settings, user levels with

limited permissions for fast and safe

defined access, password

protection, all levels adjustable

Temperature Control

For perfect results

‘Intelligent Cascade Control’,

automatic & self optimizing

adjustment of PID control

parameters, temperature stability

±0.01 °C ... <±0.2 °C

Full control

‘Temperature Control Features’, for

individual optimization, access to all

important control parameters,

additional settings for band limit,

limits, co-speedfactor etc.

Control from the external

application

External Pt100 sensor connection

for precise measurement and

control directly in the external

application

Highest measuring accuracy

‘Absolute Temperature Calibration’

for manual compensation of a

temperature difference, 3-point

calibration

Refrigeration Technology

Consistent cooling capacity

Easily removable venting grid for

quick and easy cleaning

100 % Cooling capacity

‘Active Cooling Control’ for cooling

available throughout the entire

working temperature range, fast

cool-down even at higher

temperatures

Energy saving cooling

Proportional cooling control for

automatic adjustment of cooling

power or temporary switch-off of

compressor as needed to save up to

90 % energy in comparison to

unregulated cooling machines

Technical Features

Intelligent pump system

Reliable and consistent pump

capacity, electronically adjustable

pump stages or pressure value,

automatic adjustment of pump

capacity to viscosity

Communication via networks

For the remote control of

instruments via Ethernet networks,

full access to all functions of the unit

via a networkcapable PC

Intelligent communication

USB connection for data exchange

(e.g. service data) or for wireless

remote control via WirelessTEMP®

Data exchange via SD-Card

For data exchange (e.g. service

data) via SD memory card

Connections according to

standard

RS232/RS485 dual-interface for

serial data transmission according to

EIA-485 industry standard (2-wire

bus technology), upgradable with

Profibus DP

Comfortable program control

Integrated programmer for the

execution of time and temperature

dependant profiles, 8 temperature

profiles with 60 steps max., with real

time clock

Quiet as a whisper

Efficient components produce only a

minimal sound decibel level

Space-saving footprint

All connections as well supply and

exhaust air are located at the front

or rear, no venting grids on the

sides, units can be placed close to

each other or the application

Continuous operation up to +40

°C

Robust temperature control

instrument, continuous operation

even at ambient temperatures of up

to +40 °C

Easy transport by one person

Ergonomic design facilitates moving

and positioning by one person

Filling level at a glance

Backlit indicator for selected pump

stages and filling volume

Page 4

Warning & Safety Functions

Early warning system for high/low

temperature limits

Maximum safety for applications,

optical and audible signal when

limits are exceeded.

Duplicate safety

Adjustable high temperature cut-off

for internal tank and for integrated

expansion vessel

For flammable bath fluid

Classification III (FL) according to

DIN 12876-1

Quick support

If an error occurs, the integrated

Black-Box function permits fast

diagnosis by the JULABO service

team

Product data sheet 4/4

PRESTO W50

Powered by TCPDF (www.tcpdf.org)

Refer to www.julabo.us for more information regarding the entire JULABO product portfolio.

Technical changes without prior notification. Images may deviate from the original.

Loading...

Loading...