Page 1

Operating Manual

Highly Dynamic Temperature Control Systems

with integrated programmer

LH 47

air cooled

LH 50

water cooled

Version: V45D-01

1.951.2790-V2 06/13

JULABO GmbH

77960 Seelbach / Germany

Tel. +49 (0) 7823 / 51-0

Fax +49 (0) 7823 / 24 91

info@julabo.de

www.julabo.de

19512790-V2.doc Print date: 29.07.13

Page 2

Congratulations!

You have made an excellent choice.

JULABO thanks you for the trust you have placed in us.

This operating manual has been designed to help you gain an understanding of the operation and

possible applications of our circulators. For optimal utilization of all functions, we recommend that you

thoroughly study this manual prior to beginning operation.

Printed in Germany Changes without prior notification reserved

Important: keep operating manual for future use

The JULABO Quality Management System

Temperature control devices for research and industry are developed,

produced, and distributed according to the requirements of ISO 9001 and

ISO 14001. Certificate Registration No. 01 100044846

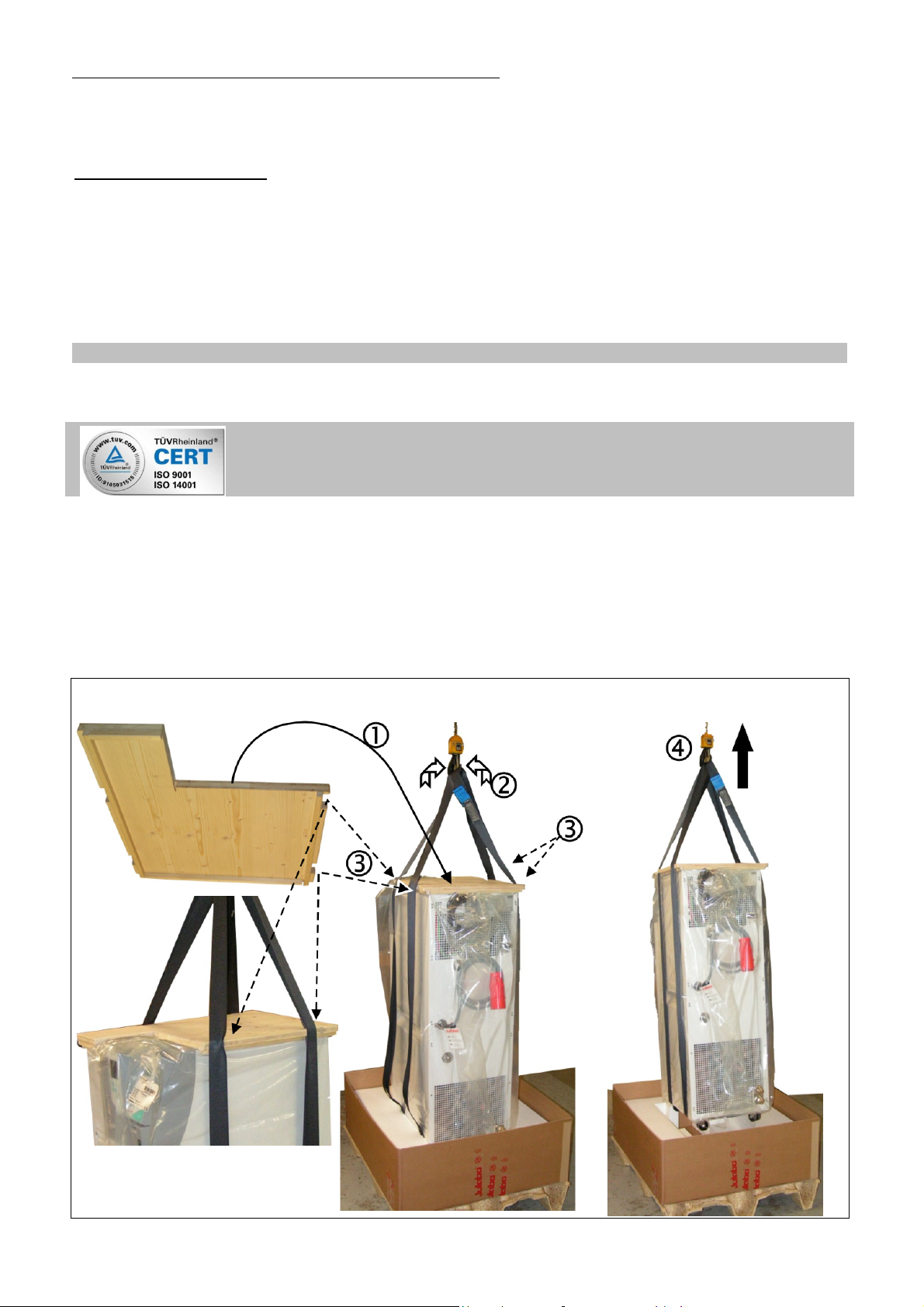

Unpacking and inspecting

Unpack the unit and accessories and inspect them for possible transport damage. Damage should be

reported to the responsible carrier, railway, or postal authority, and a damage report should be

requested. These instructions must be followed fully for us to guarantee our full support of your claim

for protecting against loss from concealed damage. The form required for filing such a claim will be

provided by the carrier.

Lift the unit only with a crane (see pictures) using the lifting strands and the wooden crate .

The recessed grips on the side are not suited for this purpose!

2

Page 3

TABLE OF CONTENTS

OPERATING MANUAL ....................................................................................................... 5

1. INTENDED USE .................................................................................................... 5

1.1. Description ............................................................................................................. 5

2. OPERATOR RESPONSIBILITY – SAFETY INSTRUCTIONS .............................. 6

2.1. Disposal ................................................................................................................. 8

2.2. EC Conformity ....................................................................................................... 8

2.3. Warranty conditions ............................................................................................... 9

2.4. Technical specifications ....................................................................................... 10

2.5. Cooling water connection .................................................................................... 14

OPERATING INSTRUCTIONS ......................................................................................... 15

3. SAFETY NOTES FOR THE USER ...................................................................... 15

3.1. Explanation of safety notes ................................................................................. 15

3.2. Explanation of other notes ................................................................................... 15

3.3. Safety instructions ............................................................................................... 15

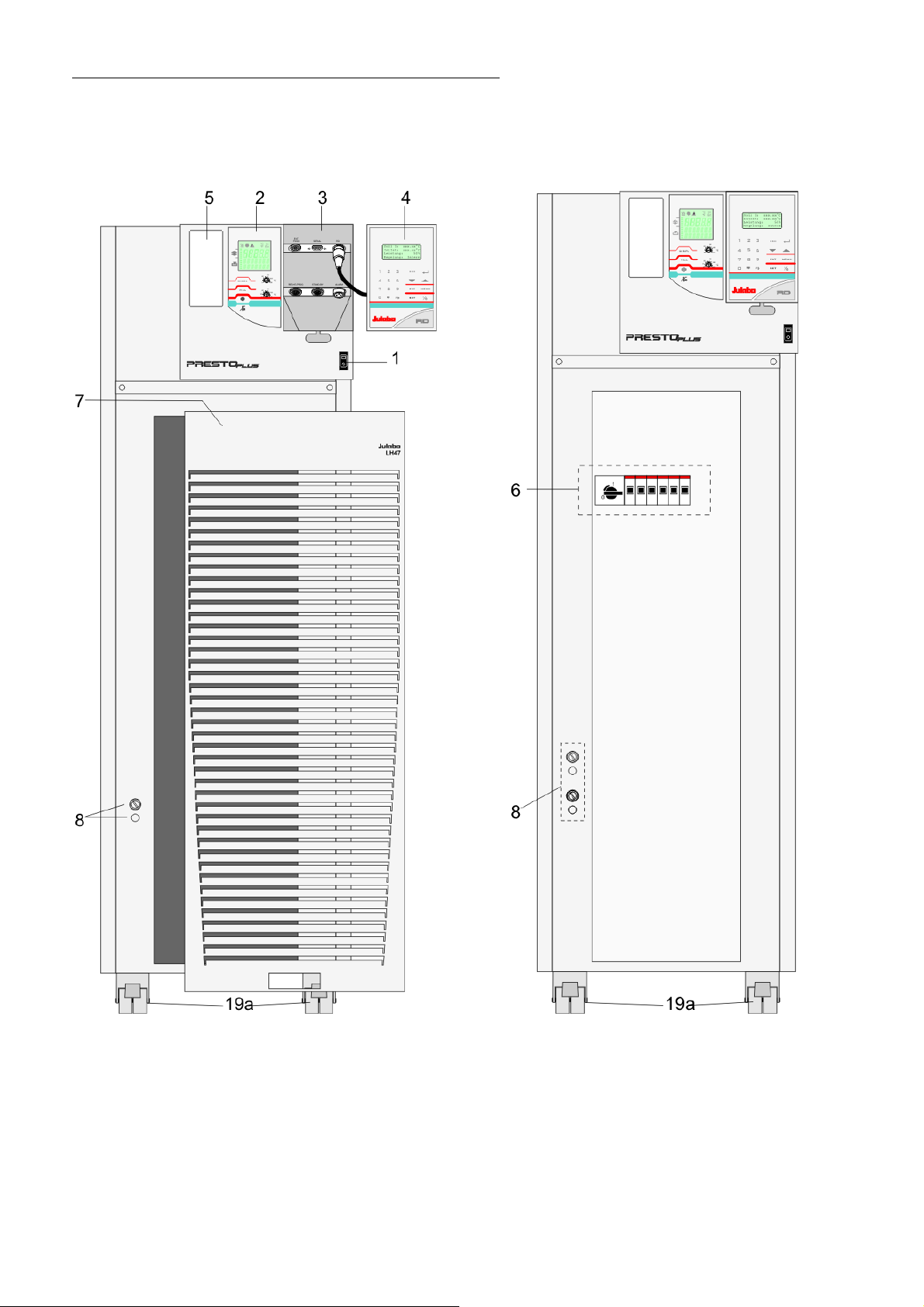

4. OPERATING CONTROLS AND FUNCTIONAL ELEMENTS .............................. 18

4.1. The Presto Plus

principle with closed external system ........................................ 24

5. PREPARATIONS ................................................................................................ 25

5.1. Bath fluids ............................................................................................................ 25

5.2. Tubing .................................................................................................................. 27

5.3. Installation ........................................................................................................... 28

5.4. Connect the external system ............................................................................... 28

5.5. Cooling water connection LH 50 .......................................................................... 30

5.6. Power connection ................................................................................................ 31

5.7. Filling ................................................................................................................... 31

5.7.1. Filling of external, closed systems ................................................................ 32

5.8. Degasifying .......................................................................................................... 34

5.9. Draining ............................................................................................................... 35

6. OPERATING PROCEDURES ............................................................................. 36

6.1. Switching on / Selecting the language ................................................................. 36

7. MANUAL OPERATION ........................................................................................ 37

7.1. Start - Stop .......................................................................................................... 37

7.2. Direct setting of the working temperature ............................................................ 38

7.3. Settings in the SET menu .................................................................................... 38

7.3.1. Setting the working temperature ................................................................... 38

7.3.2. Warning functions ......................................................................................... 39

7.3.3. Setting the pump pressure stage .................................................................. 40

7.4. Setting the safety temperature (with shutdown function) ..................................... 40

3

Page 4

7.5. Internal / external control ..................................................................................... 42

8. MENU FUNCTIONS ............................................................................................ 42

8.1. Configuration ....................................................................................................... 44

8.2. Control parameters .............................................................................................. 47

8.3. Start of a profile ................................................................................................... 49

8.3.1. Interrupting a profile ...................................................................................... 51

8.4. Integrated programmer ........................................................................................ 52

8.5. Analog inputs/outputs .......................................................................................... 55

8.6. Limits ................................................................................................................... 58

8.7. Interface............................................................................................................... 58

8.8. Sensors ............................................................................................................... 59

8.9. Pump ................................................................................................................... 60

9. TROUBLESHOOTING GUIDE / ERROR MESSAGES ....................................... 61

10. ELECTRICAL CONNECTIONS ........................................................................... 63

11. REMOTE CONTROL ........................................................................................... 66

11.1. Setup for remote control ...................................................................................... 66

11.2. Communication with a PC or a superordinated data system ............................... 67

11.3. List of commands ................................................................................................ 68

11.4. Status messages / error messages ..................................................................... 71

12. CLEANING THE UNIT ......................................................................................... 72

13. MAINTAINING / REPAIRING THE UNIT ............................................................. 75

4

Page 5

Operating manual

1. Intended use

JULABO Temperature Systems have been designed for temperature application to specific fluids in a

external closed system (oop circuit). The units feature pump connections for temperature control of

external systems (loop circuit).

JULABO circulators are not suitable for direct temperature control of foods, semi-luxury

foods and tobacco, or pharmaceutical and medical products. Direct temperature control

means unprotected contact of the object with the bath medium (bath fluid).

1.1. Description

Besides the cooling unit, the main functional elements are the heater, circulation pump and control

electronics. Via an external Pt100 control sensor, a self-optimizing, electronic proportional

temperature control (PID characteristic) adapts the heat supplied to the thermal requirements of

the external system.

The high pump capacity can be reduced by regulating the motor speed in five grades. It may thus

be adapted to sensitive vessels.

LH47: The cooling unit may be cooled with air.

LH50: The cooling unit may be cooled with water.

Setting is rapid and simple using the splash-proof keypads. The operating elements consist of the

local operating board with a bright VFD-Info-Display, as well as the removable control module RD

connected with a cable.

The microprocessor technology allows four temperature values to be stored and indicated on the

DIALOG-DISPLAY (LCD) of the control module RD: working temperature, high and low

temperature warning limits as well as pump pressure stage.

The digital RS232 / RS485 port permits modern process engineering without additional interface.

The excess temperature protection (safety temperature), a safety feature functioning independent

of the regulator circuit, is adjusted and indicated via the VFD-Info-Display.

The integrated programmer allows programming of setpoint and time values for six temperature

profiles.

The following analog sockets are available:

- The REG+E-PROG socket for setpoint selection via an external, analog programmer.

At the same time, this socket provides three analog outputs for temperature recorders.

- The external Pt100 socket for external control.

- The alarm output for an external signal.

- The stand-by input for external emergency switch-off.

5

Page 6

Operator responsibility – Safety instructions

2. Operator responsibility – Safety instructions

The products of JULABO ensure safe operation when installed, operated, and maintained according

to common safety regulations. This section explains the potential dangers that may arise when

operating the circulator and also specifies the most important safety precautions to preclude these

dangers as far as possible.

The operator is responsible for the qualification of the personnel operating the units.

The personnel operating the units should be regularly instructed about the dangers involved with

their job activities as well as measures to avert these dangers.

Make sure all persons tasked with operating, installing, and maintaining the unit have read and

understand the safety information and operating instructions.

When using hazardous materials or materials that could become hazardous, the circulator may be

operated only by persons who are absolutely familiar with these materials and the unit. These

persons must be fully aware of possible risks.

If you have any questions concerning the operation of your unit or the information in this manual,

please contact us!

Contact:

Safety instructions for the operator:

Avoid strikes to the housing, vibrations, damage to the operating-element panel (keypad, display),

and contamination.

Make sure the product is checked for proper condition regularly (depending on the conditions of

use). Regularly check (at least every 2 years) the proper condition of the mandatory, warning,

prohibition and safety labels.

Make sure that the mains power supply has low impedance to avoid any negative effects on the

instruments being operated on the same mains.

This unit is designed for operation in a controlled electromagnetic environment. This means that

transmitting devices (e.g., cellular phones) should not be used in the immediate vicinity.

Magnetic radiation may affect other devices with components sensitive to magnetic fields (e.g.,

monitors). We recommend maintaining a minimum distance of 1 m.

Permissible ambient temperature: max. 40 °C, min. 5 °C.

Permissible relative humidity: 50 % (40 °C).

JULABO GmbH

Eisenbahnstraße 45

77960 Seelbach / Germany

Tel. +49 (0) 7823 / 51-0 info@julabo.de

Fax +49 (0) 7823 / 24 91 www.julabo.de

Do not store the unit in an aggressive atmosphere. Protect the unit from contamination.

Do not expose the unit to sunlight.

Appropriate operation

Only qualified personnel is authorized to configure, install, maintain, or repair the unit.

Persons who operate the circulator must be trained in the particular tasks by qualified personnel. The

summarized user guidance (short manual) and the specification table with information on individual

parameters are sufficient for this.

6

Page 7

Use

The bath can be filled with flammable materials. Fire hazard!

There might be chemical dangers depending on the bath medium used.

Observe all warnings for the used materials (bath fluids) and the respective instructions (safety data

sheets).

Insufficient ventilation may result in the formation of explosive mixtures. Only use the unit in well

ventilated areas.

Only use recommended materials (bath fluids). Do not use poisonous, vitriolic or corrosive bath

fluids..

When using hazardous materials or materials that could become hazardous, the operator must affix

the enclosed safety labels (1 + 2) to the front of the unit so they are highly visible:

1

2

or

2

Particular care and attention is necessary because of the wide operating range.

There are thermal dangers: Burn, scald, hot steam, hot parts and surfaces that can be touched.

Warning label W00: Colors: yellow, black

Danger area. Attention! Observe instructions.

(operating manual, safety data sheet)

Mandatory label M018: Colors: blue, white

Carefully read the user information prior to beginning operation.

Scope: EU

Semi S1-0701 Table A1-2 #9

Carefully read the user information prior to beginning operation.

Scope: USA, NAFTA

Warning label W26: Colors: yellow, black

Hot surface warning.

(The label is put on by JULABO)

Observe the instructions in the manuals for instruments of a different make that you connect to the

circulator, particularly the corresponding safety instructions. Also observe the pin assignment of plugs

and technical specifications of the products.

7

Page 8

Operator responsibility – Safety instructions

2.1. Disposal

The product may be used with oil as bath fluid. These oils fully or partially consist of mineral oil or

synthetic oil. For disposal, follow the instructions in the material safety data sheets.

This unit contains the refrigerants R-404A and R-23, which at this time are not considered harmful to

the ozone layer. However, over the long operating period of the unit, disposal rules may change.

Therefore, only qualified personnel should handle the disposal.

Valid in EU countries

See the current official journal of the European Union – WEEE directive.

Directive of the European Parliament and of the Council on waste electrical and

electronic equipment (WEEE).

This directive requires electrical and electronic equipment marked with a crossedout trash can to be disposed of separately in an environmentally friendly manner.

Contact an authorized waste management company in your country.

Disposal with household waste (unsorted waste) or similar collections of municipal

waste is not permitted!

2.2. EC Conformity

The products described in the operating instructions conform to the requirements

of the following European guidelines:

Directive of the European Parliament and of the Council on the approximation of the laws of the

Member States relating to machinery.

Low voltage regulations with respect to legal harmonization of the member countries concerning

electric devices for use within certain voltage limits.

EMC guideline with respect to legal harmonization of the member countries concerning

electromagnetic compatibility.

JULABO GmbH

Eisenbahnstr. 45

77960 Seelbach / Germany

8

Page 9

2.3. Warranty conditions

JULABO GmbH warrants its products against defects in material or in workmanship, when used under

appropriate conditions and in accordance with appropriate operating instructions

for a period of ONE YEAR.

Extension of the warranty period – free of charge

With the ‘1PLUS warranty’ the user receives a free of charge extension to the warranty of up to 24

months, limited to a maximum of 10 000 working hours.

To apply for this extended warranty the user must register the unit on the JULABO web site

www.julabo.de

GmbH’s original invoice.

JULABO GmbH reserves the right to decide the validity of any warranty claim. In case of faults

arising either due to faulty materials or workmanship, parts will be repaired or replaced free of charge,

or a new replacement unit will be supplied.

Any other compensation claims are excluded from this guarantee.

, indicating the serial no. The extended warranty will apply from the date of JULABO

9

Page 10

Operator responsibility – Safety instructions

2.4. Technical specifications

Mains power connection

400 V/3P/50 Hz

LH 47 LH 50

V /

360-440 V/3PNPE/50 Hz 360-440 V/3PNPE/50 Hz

Hz

Current input (at 230 V) A 12 20

Working temperature range °C -47 ... 250 -50 ... 250

Temperature stability K ±0.01 ... ±0.05 ±0.01 ... ±0.05

Cooling capacity

pump pressure stage 1

pump pressure stage 5

(bath liquid: Thermal / Ethanol)

Cooling compressor 1-stage

°C

kW

kW

200 100// 20 0 -20 -40

3.7 3.1 // 3.07 2.0 0.99 0.27

3.5 3.0 // 2.9 1.9 0.90 0.07

air-cooled

200 // 20 0 -20 -40

5.5 // 7.3 4.6 2.3 0.45

5.5 // 7.2 5.1 2.3 0.19

1-stage

water-cooled

Refrigerant R404A R404A

Cooling water : Flow rate

l/h ----- 390

at 20 °C inlet temperature

Heater capacity kW

1.8 6.0

Pressure pump, adjustable

pressure min ... max. at 0 liter

discharge, max. at 0 bar

Pressure pump, adjustable

pressure min ... max. at 0 liter

discharge, max. at 0 bar

grade

bar

l/min

grade

bar

l/min

1

2

3

4

5

0.5

0.7

1.1

1.3

1.7

16

19

23

26

30

1

0.7

17

2

0.9

19

3

1.4

24

Viscosity, max. 50 mm²/s (50 cSt)

Noise level, 1 m distance dBA 72 ----Ambient temperature °C 5 ... 40 5 ... 40

Filling volume Heat exchanger

Reservoir

liters

liters

2.5

3.2 … 8.4

10

3.2 … 8.4

Overall dimensions (WxDxH) cm 40x55x127 40x55x127

Weight kg 150 182

All measurements have been carried out at: rated voltage and frequency

ambient temperature: 20 °C Technical changes without prior notification reserved.

Pump data in relation to fluids with a specific density of 1 kg/dm3

4

1.8

27

5

2.3

31

10

Page 11

Mains power connection

LH 47 LH 50

V / Hz 207-253 V/3PPE/60 Hz 207-253 V/3PPE/60 Hz

230 V/3P/60 Hz

Current input (at 230 V) A 13 27

Working temperature range °C -47 ... 250 -50 ... 250

Temperature stability K ±0.01 ... ±0.05 ±0.01 ... ±0.05

Cooling capacity

pump pressure stage 1

pump pressure stage 5

(bath liquid: Thermal / Ethanol)

Cooling compressor 1-stage

°C

kW

kW

200 100// 20 0 -20 -40

3.8 3.3 // 3.2 2.1 1.1 0.32

3.7 3.2 // 3.1 2.0 1.0 0.12

air-cooled

200 // 20 0 -20 -40

5.5 // 7.3 4.9 2.6 0.5

5.5 // 7.2 4.6 2.1 0.4

1-stage

water-cooled

Refrigerant R404A R404A

Cooling water : Flow rate

l/h ----- 330

at 20 °C inlet temperature

Heater capacity kW

1.8 6.0

Pressure pump, adjustable

pressure min ... max. at 0 liter

discharge, max. at 0 bar

Pressure pump, adjustable

pressure min ... max. at 0 liter

discharge, max. at 0 bar

grade

bar

l/min

grade

bar

l/min

1

2

3

4

5

0.5

0.7

1.1

1.3

1.7

16

19

23

26

30

1

0.7

17

2

0.9

19

3

1.4

24

Viscosity, max. 50 mm²/s (50 cSt)

Noise level, 1 m distance dBA 72 ----Ambient temperature °C 5 ... 40 5 ... 40

Filling volume Heat exchanger

Reservoir

liters

liters

2.5

3.2 … 8.4

10

3.2 … 8.4

Overall dimensions (WxDxH) cm 40x55x127 40x55x127

Weight kg 150 182

All measurements have been carried out at: rated voltage and frequency

ambient temperature: 20 °C Technical changes without prior notification reserved.

Pump data in relation to fluids with a specific density of 1 kg/dm3

4

1.8

27

5

2.3

31

11

Page 12

Operator responsibility – Safety instructions

Temperature selection digital

via Removable control module RD indication on DIALOG-Display (LCD)

remote control via personal computer indication on monitor

Temperature indication VFD-Info-Display

DIALOG-DISPLAY (LCD)

Resolution K 0.01 from -9.99 °C to +249.99 °C

Pump pressure display on VFD-Info-Display in five grades

Liquid level display on VFD-Info-Display in five grades

Absolute Temperature Calibration

(ATC1) K ±3

(ATC2) K ±9

Temperature control ICC - Intelligent Cascade Control, self-optimizing

Cascade, parameter can be called-in and modified

Working temperature sensor Pt 100

Safety temperature sensor Pt 100

Electrical connections:

Computer interface RS232 or RS485

Programmer input -100 °C to 400 °C = 0 to 10 V or 0 to 20 mA or 4 to 20 mA

Temperature recorder outputs 0 to 10 V (0 V = -100 °C, 10 V = 400 °C)

0 to 20 mA (0 mA = -100 °C, 20 mA = 400 °C)

4 to 20 mA (4 mA = -100 °C, 20 mA = 400 °C)

Stand-by input

External alarm device 24-0 V DC / max. 25 mA

External measurement and control sensor Pt100, 4-lead technique

Control connector (10) Output voltage: 230 V / max. 0.1 A

Safety installations according to IEC 61010-2-010:

Excess temperature protection >TANK< adjustable from 0 °C ... 320 °C

Excess temperature protection >RES< adjustable from 0 °C ... 220 °C

Low level protection float switch

Liquid level display optical, 5-graded

Classification according to DIN 12876-1 class III FL

Supplementary safety installations

High temperature warning function optical + audible (in intervals)

Low temperature warning function optical + audible (in intervals)

Supervision of the working sensor plausibility control

Reciprocal sensor monitoring between

working and safety sensors difference >50 K

Alarm indication optical + audible (permanent)

12

Page 13

Environmental conditions according to IEC 61 010-1:

Use only indoor.

Altitude up to 2000 m - normal zero.

Ambient temperature: see Technical specifications

Air humidity:

Max. rel. humidity 80 % for temperatures up to +31 °C,

linear decrease down to 50 % relative humidity at a temperature of +40 °C

Max. mains fluctuations of ±10 % are permissible.

Overvoltage category II

Pollution degree 2

Caution:

The unit is not suitable for use in explosive atmosphere

Protection class according to IEC 60 529: IP31

The unit corresponds to Class I

Standards for interference resistance according to EN 61326-1

This unit is an ISM device classified in Group 1 (using high frequency for internal purposes) Class A

(industrial and commercial range).

13

Page 14

Operator responsibility – Safety instructions

2.5. Cooling water connection

Cooling water pressure (IN / OUT ) max. 6 bar

Difference pressure (IN - OUT ) 3.5 to 6 bar

Cooling water temperature <20 °C

Notice: Cooling water circuit

Risk of oil leaking from the refrigeration system (compressor) of the recirculating

cooler into the cooling water in case of a fault in the cooling water circuit!

Observe the laws and regulations of the water distribution company valid in the

location where the unit is operated.

Notice:

Danger of corrosion of heat exchanger due to unsuitable quality of cooling

water.

Due to its high content of lime, hard water is not suitable for cooling and causes

scale in the heat exchanger.

Ferrous water or water containing ferrous particles will cause formation of rust

even in heat exchangers made of stainless steel.

Chlorinated water will cause pitting corrosion in heat exchangers made of

stainless steel.

Due to their corrosive characteristics, distilled water and deionized water are

unsuitable and will cause corrosion of the bath.

Due to its corrosive characteristics, sea water is not suitable.

Due to its microbiological (bacterial) components, which settle in the heat

exchanger, untreated and unpurified river water and water from cooling towers is

unsuitable.

Avoid particulate matter in cooling water.

Avoid putrid water.

Recommended quality of cooling water:

pH

Sulfate [SO4 2- ]

Hydrocarbonate [HCO 3-]/sulfate [SO4 2-]

Hardness [Ca 2+, Mg 2+]/[HCO 3-]

Alkalinity

Conductivity

Chloride (Cl -)

Phosphate (PO4 3-)

Ammonia (NH3)

Free chlorine

Trivalent iron ions (Fe 3+)

Manganese ions (Mn 2+)

Carbon dioxide (CO2)

Hydrogen sulfide (H2S)

Content of oxygen

Algae growth

Suspended solids impermissible

7.5 to 9.0

< 100 ppm

> 1 ppm

> 0.5

60 ppm < [HCO 3-] < 300 ppm

< 500 μS/cm

< 50 ppm

< 2 ppm

< 0.5 ppm

< 0.5 ppm

< 0.5 ppm

< 0.05 ppm

< 10 ppm

< 50 ppm

< 0.1 ppm

impermissible

dH

14

Page 15

Operating instructions

3. Safety notes for the user

3.1. Explanation of safety notes

In addition to the safety warnings listed above, warnings are posted throughout the

manual. These warnings are designated by an exclamation mark inside an equilateral

triangle. “Warning of a dangerous situation (Attention! Please follow the

documentation).”

The danger is classified using a signal word.

Read and follow these important instructions.

Warning:

Describes a possibly highly dangerous situation. If these instructions are not followed,

serious injury and danger to life could result.

Caution:

Describes a possibly dangerous situation. If this is not avoided, slight or minor injuries

could result. A warning of possible property damage may also be contained in the

text.

Notice:

Describes a possibly harmful situation. If this is not avoided, the product or anything in

its surroundings can be damaged.

3.2. Explanation of other notes

Note!

Draws attention to something special.

Important!

Indicates usage tips and other useful information.

3.3. Safety instructions

Follow the safety recommendations to prevent damage to persons or property.

Further, the valid safety instructions for working places must be followed.

Only connect the unit to a power socket with earthing contact (PE – protective

earth)!

The power supply plug serves as safe disconnecting device from the line and

must be always freely accessible.

Place the instrument on an even surface on a pad made of non-inflammable

material.

Do not stay in the area below the unit.

Make sure you read and understand all instructions and safety precautions listed

in this manual before installing or operating your unit.

Set the safety temperature.

Never operate the unit without bath fluid in the bath.

15

Page 16

Safety notes for the user

Pay attention to the thermal expansion of bath oil during heating to avoid

overflowing of the fluid.

Prevent water from penetrating into the hot bath oil.

Do not drain the bath fluid while it is hot!

Check the temperature of the bath fluid prior to draining (by switching the unit on

for a short moment for example).

Employ suitable connecting tubing.

Avoid sharp bends in the tubing, and maintain a sufficient distance from

surrounding walls.

Make sure that the tubing is securely attached.

Regularly check the tubing for material defects (e.g. for cracks).

Never operate damaged or leaking equipment.

Always turn off the unit and disconnect the mains cable from the power source

before performing any service or maintenance procedures, or before moving the

unit.

Always turn off the unit and disconnect the mains cable from the power source

before cleaning the unit.

Always empty the bath before moving the unit.

Transport the unit with care.

Sudden jolts or drops may cause damages in the interior of the unit.

Observe all warning labels.

Never remove warning labels.

Never operate equipment with damaged mains power cables.

Repairs are to be carried out only by qualified service personnel.

Some parts of the bath cover and the pump connections may become extremely

warm during continuous operation. Therefore, exercise particular caution when

touching these parts.

Caution:

The temperature controlling i.e. of fluids in a reactor constitutes normal temperature

system practice.

We do not know which substances are contained within these vessels.

Many substances are:

inflammable, easily ignited or explosive

hazardous to health

environmentally unsafe

i.e.: dangerous

The user alone is responsible for the handling of these substances!

16

Page 17

The following questions shall help to recognize possible dangers and to reduce the

risks to a minimum.

Are all tubes and electrical cables connected and installed?

Note:

sharp edges, hot surfaces in operation, moving machine parts, etc.

Do dangerous steams or gases arise when heating?

Is an exhaust needed when working?

What to do when a dangerous substance was spilled on or in the unit?

Before starting to work, obtain information concerning the substance and

determine the method of decontamination.

Caution: Escape of vapors / gas

The necessity of degassing requires that a closed system is not entirely sealed.

Especially at increased working temperatures vapor / gas may escape.

Ensure sufficient ventilation at the place of installation!

Notice:

When you have finished the application, it is recommended to keep on circulating the

liquid in the bath or the external system for some time. Simultaneously set the

working temperature to +20 °C to allow the temperature in the system to decrease

slowly.

Thus fractional over-heating of the bath liquid is prevented.

Notice:

Please check the safety device from time to time.

Excess temperature protection according to IEC 61010-2-010

With a screw driver turn back the adjustable excess temperature protection until

the shut-down point (actual temperature).

Low level protection

To check the function of the float of this unit it cannot be operated manually.

The 5-graded level display should therefore be observed whenever refilling.

If the bath liquid thickens or cracks, the instrument should be cleaned and

checked by qualified personnel.

17

Page 18

Operating controls and functional elements

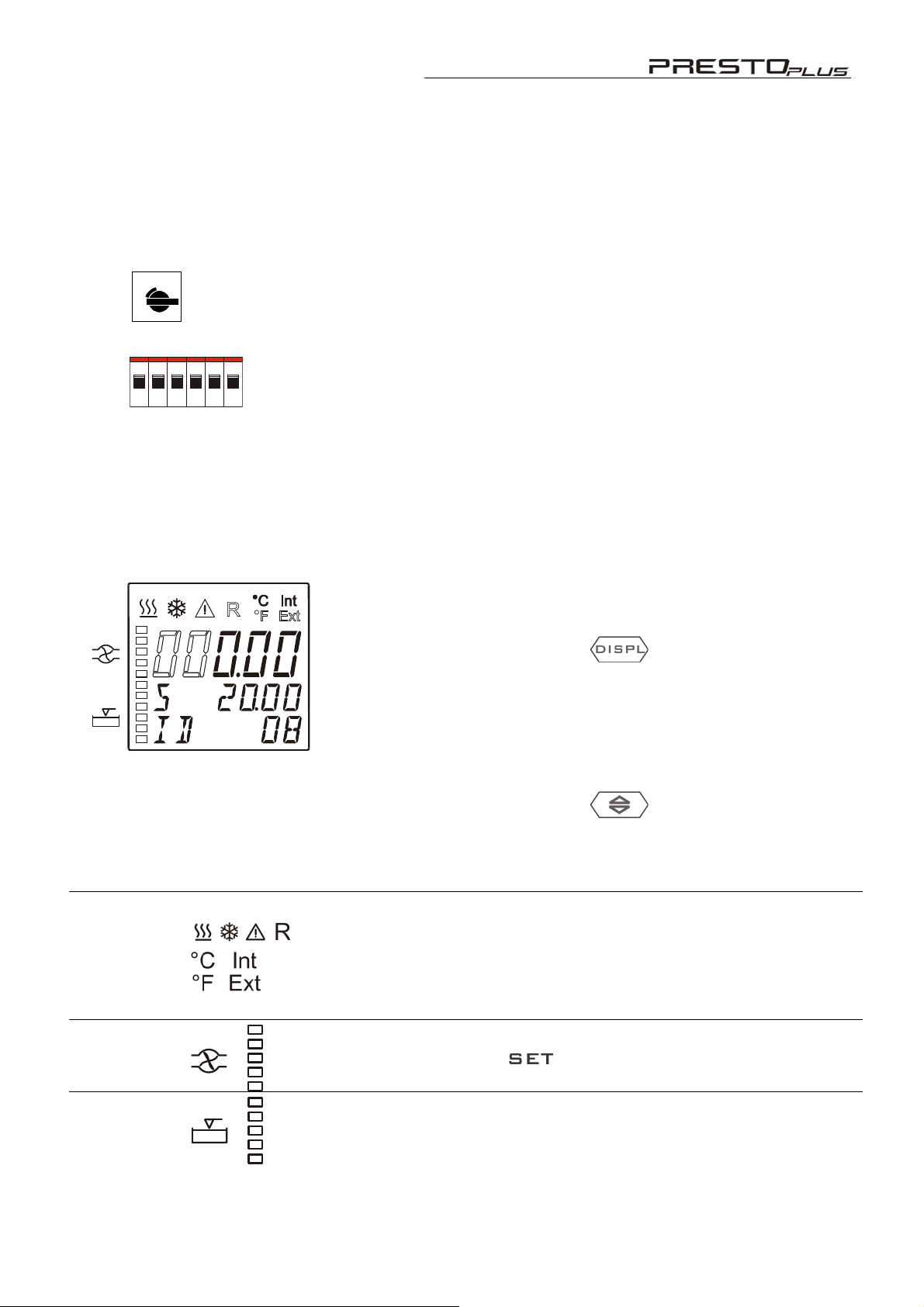

4. Operating controls and functional elements

Front view LH47 LH50

air-cooled water-cooled

18

Page 19

1 Mains power switch, illuminated

2 Local operating board

3 Socket board - description see page 20

4 Removable control module RD

5 Filling funnel (hinged)

1

6

7 Venting grid, removable

8 Drain with drain port

2 Local operating board

2.1

0

Motor protection circuit breaker for compressor motor

2 Mains circuit breakers (resettable) 10 A for the pump-motor

4 Mains circuit breakers (resettable) 16 A

VFD-Info-Display

Header: Control indicators see section 2.2

Line 1: Actual value Int or Ext

To swap, press the key

Line 2: Working temp. setpoint, constantly S xxx.xx

or indication of the safety temperature (TANK)

(see below)

2.2

Line 3: Miscellaneous values

To swap, press the key

or indication of the safety temperature (RES)

Control indicators in the header:

Heating / Cooling / Alarm / Remote control

Temperature indication Internal or External actual value

Temperature indication in °C or °F

Display for the adjusted pump pressure stage (five grades),

adjustable via the key

Liquid level display (five grades)

for the reservoir.

.

(see below)

19

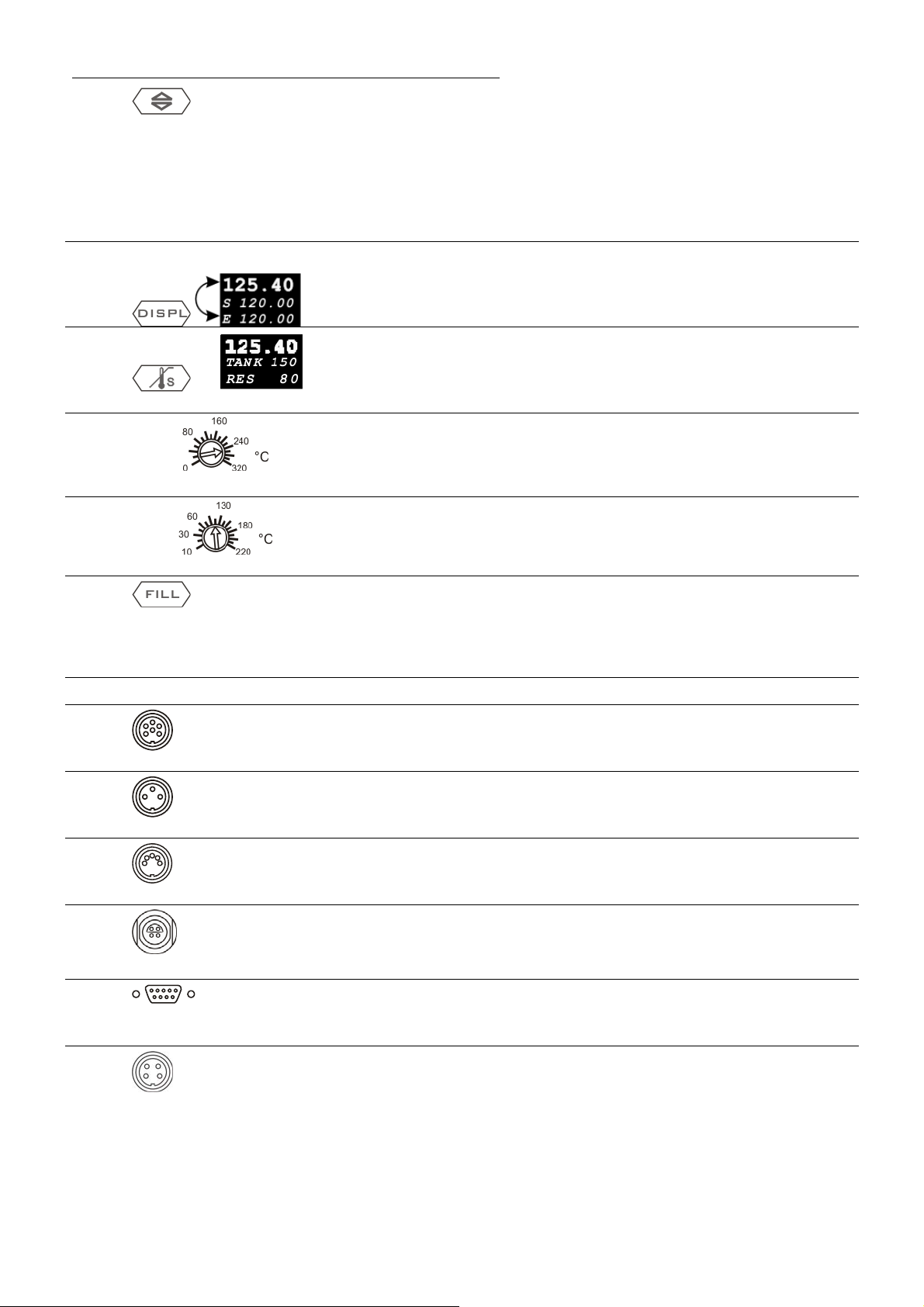

Page 20

Operating controls and functional elements

2.3

2.4

2.5

2.6

2.7

Int

Key to swap line 3 on the VFD

ID xx Identification no. of control module RD

L xx Capacity in %

E xxx.xx or I xxx.xx Actual value (external or internal)

P x.xx Pump pressure in bar

Key to swap line 1 on the VFD

Actual value Int or Ext alternating with line 3

Key to indicate the safety temperature on the VFD

Line 2: TANK - Safety temperature in internal bath

Line 3: RES - Safety temperature in internal reservoir

Adjustable excess temperature protection (safety temperature)

Used for setting the safety temperature in the internal bath, called

"TANK" on the display

Adjustable safety temperature.

Used for setting the safety temperature in the internal reservoir,

called "RES" on the display

2.8

3 Socket board

3.1

3.2

3.3

3.4

3.5

REG+E-PROG

STAND-BY

ALARM

EXT. Pt100

SERIAL

Key for automatic filling and air purge of the unit as well as the

connected external system.

Programmer input and temperature recorder output

Stand-by input (for external emergency switch-off)

Alarm output (for external alarm signal)

Connector for external measurement and control sensor

Interface RS232/RS485

3.6

20

Connector: control cable of control module RD

RD

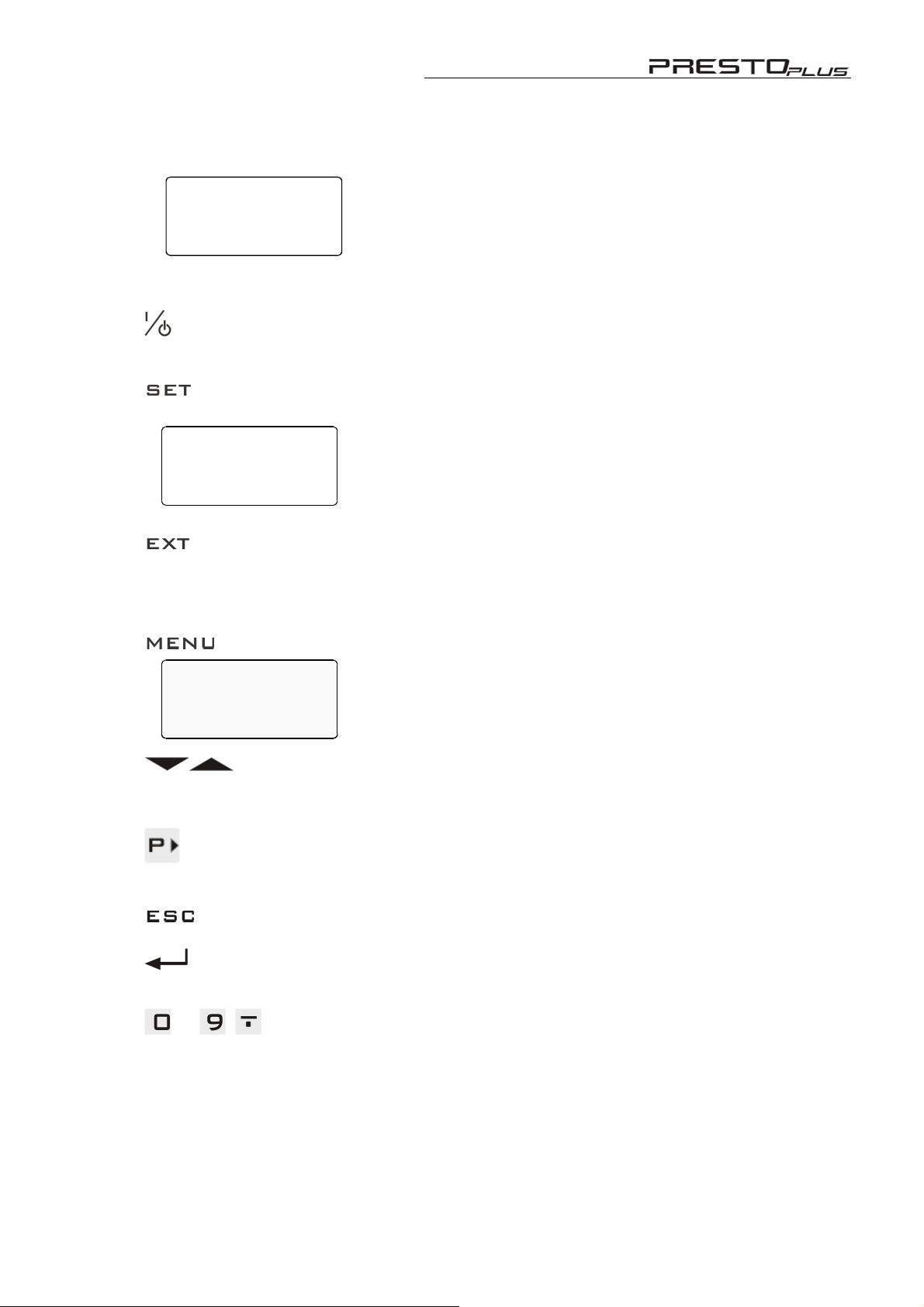

Page 21

4

4.0

Control module RD

Setp: 120. 00 °C

IntAct 21.00°C

ExtAct : 20. 00 °C

Contro l: Intern

DIALOG-DISPLAY (LCD) Standard indication

Line 1: Setpoint in °C

Line 2: Internal actual value in °C

Line 3: External actual value in °C

Line 4: Control type: internal / external control

Indicating messages (e. g. warnings)

4.1

4.2

4.3

4.4

4.5

>Setp. : 12 0. 00 °C

Overt.:255.00°C

Subtmp:-55.00°C

St.Pump: 2

>Configuration

Control param.

Profile Start

Int. Programmer

Start / stop key

To switch the circulation pump, heating element and cooling unit.

SET Menu Key - Indicating and setting setpoint values

Set the following values:

in Line 1: the working temperature Setp.:

Line 2: the high temperature limit Overt.:

Line 3: the low temperature limit Subtmp:

Line 4: the pump pressure stage St.Pump:

Control type: internal / external control

To swap, the unit has to be in the STOP MODE.

Indicated in line 4 on the DIALOG-DISPLAY (LCD)

MENU key - for selecting the menu functions

(Menu see page 42)

Cursor keys - Select menu items

4.6

4.7

4.8

4.9

....

P-key Selecting parameters

Escape key 1) Cancel entries

2) Return to a higher menu level

Enter key 1) Store value / parameter

2) Next lower menu level

Numeric keypad: numerals 0 to 9; minus / decimal point

21

Page 22

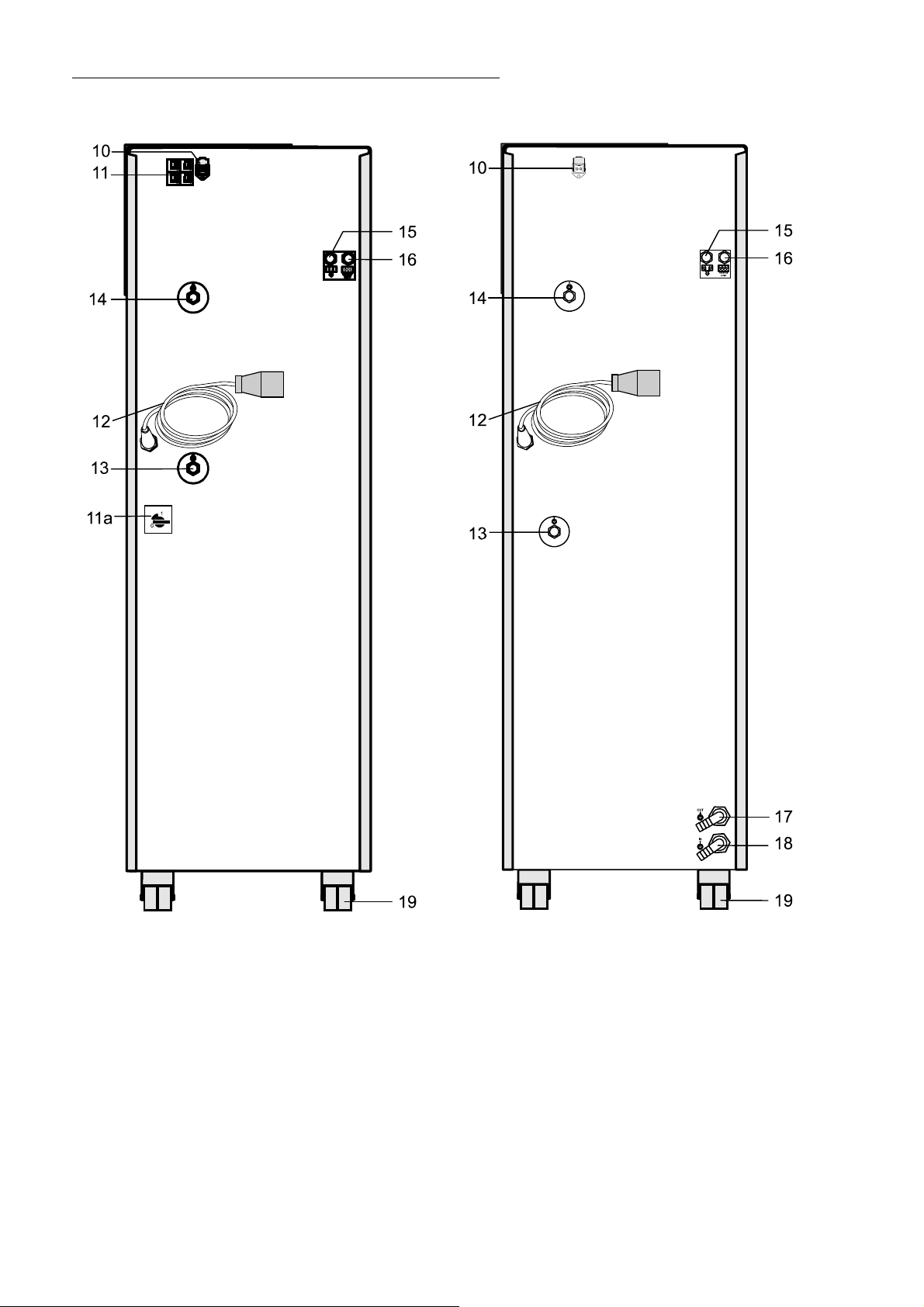

Operating controls and functional elements

Rear

22

Page 23

A

A M P

A M P

10

11

Si1

Control connector

230 V / max. 0.1 A

Si3

16

A

M

P

16

M

P

Si4 Si2

4 Mains circuit breakers (resettable) 16 A

16

F1 and F3 Compressor

16

F2 and F4 Heater, Pump

11a

1

0

12

13 + 14

15

16

17 + 18

19

19a

Motor protection circuit breaker for compressor motor

Mains power cable with plug

Pump connectors

Return Feed M16x1

Overflow connector M16x1

Connector for expansion vessel M16x1

Cooling water connectors LH41 G3/4" external thread

IN - inlet OUT - outlet

Castor without brake (at the back)

Castor with brake (at the front)

23

Page 24

Operating controls and functional elements

4.1. The Presto Plus principle with closed external system

Operating:

The operation of the temperature

system and the indication is

effected via the local control panel

(2) and the removable operating

device RD(4).

Filling :

First connect the external

consumer. The menu option

>Mode< is set on >Fill<. The unit

is filled at the hinged filling funnel

(5) via the internal reservoir (5a).

The bath liquid spreads from here

into the external reservoir (16a)

and into the heat exchanger (20).

The filling pipe (25) represents narrows. Therefore the filling should be done slowly. The air from the

heat exchanger (20) escapes via the venting valve. In a first step approximately 2,6 liters of bath liquid

is filled in until the level indication

e.g. LH47; double-sided glass vessel

indicates 3 or 4 batons (see –Filling volume- page 31). Then, by

pressing the key

(23) is started. In intervals the tempering liquid is pumped via connection (13) into the external system

(33) and led back into the heat exchanger (20) via connection (14). At the end of the filling process the

menu option >Mode< has to be set on >Sys close<.

Working:

In case of a closed external system the filling pipe (25) remains open and allows a change in volume

of the bath liquid caused by temperature during operation. In case of emergency it has to be possible

that the expanding bath liquid can drain off at the overflow (15) into a suitable vessel. If necessary the

external reservoir (16a) can be mounted at connection (16).

The temperature system can be cooled with air (32 / LH47) or water (LH50). Connect the cooling

water to the lead in for cooling water (18). Lead the outflow for cooling water (17) into the locally

provided drain respectively backflow.

The temperature system is started with the key

the circulating pump (23) start according to the desired adjustments at the operating device RD (4). In

the line to the pump exit (14) the pump pressure (29) and the actual temperature of the internal control

sensor (28a) is permanently measured. If the temperature control has to be effected externally a

Pt100 external sensor (28b) has to be connected and switched over to external control at the

operating device RD(4).

Safety:

In the internal reservoir (5a) there are the level sensor (26) as well as a safety sensor (27b).

The safety sensor (27a) as high temperature protection is located directly at the heater (21).

If the external circuit is interrupted (e.g. with a shut-off valve), an emergency circuit is maintained via

an internal Bypass (30).

an automatic filling and venting mode with activation of the circulating pump

. The heating (21), the cooling aggregate (22) and

24

Page 25

5. Preparations

5.1. Bath fluids

Caution:

Carefully read the safety data sheet of the bath liquid used, particularly with regard

Recommended bath liquids for external, c l osed systems:

to the fire point!

If a bath fluid with a fire point of 65 °C is used, only supervised operation is

possible.

Caution:

Fire or other dangers when using bath fluids that are not recommended:

ATTENTION: The maximum permissible viscosity is 50 mm2 / S

Please contact JULABO before using other than recommended bath liquids.

JULABO assumes no liability for damage caused by the selection of an unsuitable

bath fluid.

Unsuitable bath fluids are fluids which, e.g.,

are highly viscous

(much higher than 50 mm2 / S at the respective working temperature)

have a low viscosity and have creep characteristics

have corrosive characteristics or

tend to crack.

Caution:

See website for list of recommended bath fluids.

Contact: see page 6

No liability for use of other bath fluids!

.

The use of water in purified or unpurified form is not allowed.

Examples: Tap water, distilled water, water-glycol mixture, CaCl2-brine

Important notice concerning the recommended bath liquids:

Bath liquids with a range of application above the fire point ?

This temperature system is mainly operated in a closed external system (loop

circuit). The contact of the bath liquid with atmospheric oxygen only takes place in

the internal reservoir, which is not located directly in the termperature circuit.

A safety device supervises and controls the the temperature in the internal

reservoir.

The temperature of the bath liquid is maintained constant at approx. +20°C

The safety device with an adjustable temperature value >RES< works

independently from the control circuit. When actuating this safety device (too

much hot fluid streams into the internal reservoir) the temperature system is

switched off all-polo and permanently.

Adjust the safety temperature >RES< at at least 20 K below the fire point of

the bath liquid.

25

Page 26

Preparations

Diagram 1: JULABO Thermal oils

Change in volume in dependence on the temperature of bath liquid.

Example A: Filling quantity at ambient temperature 5 liters

Intended working temperature range -40 °C bis +250 °C

Change in volume caused by temperature 1,75 liters

Here an external expansion vessel is required (Order no.: 8 970 830)

Example B: Filling quantity at ambient temperature 5 liters

Intended working temperature range +20 °C bis +200 °C

Change in volume caused by temperature 1,2 liters

Here no external expansion vessel is required

(see table „Filling volume“ Page 31).

26

Page 27

5.2. Tubing

Recommended tubing:

Metal tubing, triple insulated, M16x1, Temperature range -100 °C ... +350 °C

Order No. Length

8 930 209

8 930 210

8 930 211

8 930 214

Metal tubing, insulated, M16x1, Temperature range -50 °C ... +200 °C

Order No. Length

8 930 220

8 930 221

8 930 222

8 930 223

Pressure max. 6.0 bar at +20 °C

4.6 bar at +200 °C

3.8 bar at +350 °C

Warning:

0.5 m

1.0 m

1.5 m

3.0 m

0.5 m

1.0 m

1.5 m

3.0 m

Tubing:

At high working temperatures the tubing used for temperature application and

cooling water supply represents a danger source.

A damaged tubing line may cause hot bath liquid to be pumped out within a short

time.

This may result in:

Fire hazard

Explosion hazard

Burning of skin

Difficulties in breathing due to hot atmosphere

Safety recommendations

Employ suitable connecting tubing.

Make sure that the tubing is securely attached.

Avoid sharp bends in the tubing, and maintain a sufficient distance from

surrounding walls.

Regularly check the tubing for material defects (e.g. for cracks).

27

Page 28

Preparations

5.3. Installation

Caution:

Danger of tipping

Lift the unit only with a crane using the lifting strands and the wooden crate (see

The recessed grips on the side are not suited for lifting the unit!

Max. permissible application of force to the upper side 220 N.

The unit is not suitable for use in explosive environment

pictures on page 2)

Careful positioning of the unit on its rollers is permitted.

Danger of tipping if larger force is applied.

Place the unit on an even surface on a base made of

nonflammable material. Lift the handle (6) and using the

castor (19) move the unit to the intended location.

Keep at least 20 cm of open space on the front and rear

venting grids.

Do not install the unit in the immediate vicinity of heat

sources and do not expose it to sunlight.

Before operating the unit after transport, wait about one

hour after setting it up. This will allow any oil that has

accumulated laterally during transport to flow back down

thus ensuring maximum cooling performance of the

compressor.

5.4. Connect the external system

The temperature systems are designed for temperature

application to closed, external systems (loop circuits). To profit

from the system's rapid performance, ensure the tubing line

between the temperature system and the connected external

system is as short as only possible.

The place of installation should be large enough and

provide sufficient air ventilation to ensure the room does

not warm up excessively because of the heat the

instrument rejects to the environment. (Max. permissible

ambient temperature: 40 °C).

For a fault (leakage) in the refrigeration system, the

standard EN 378 prescribes a certain room space to be

available for each kg of refrigerant.

The refrigerant quantity is specified on the type plate.

3

> For 0.52 kg of refrigerant R404A, 1 m

of space is

required.

28

Page 29

Caution:

Securely attach all tubing to prevent slipping.

Connecting the external system:

Remove the cap nuts from the pump connectors

(13, 14) and using tubing connect the external

system (M16x1 / wrench 19 mm).

To prevent the formation of bubbles in the loop

circuit, the pressure line (13) is to be connected

to the lower nozzle of the external system.

Also see the description on page 24

Connect a piece of tubing to the overflow

connector (15) and drain into a suitable vessel.

(M16x1 / wrench 19 mm), which always has to

be placed lower than the exit „Overflow“.

If required, the connector (16) may be used for

connecting an expansion vessel. (M16x1 /

wrench 19 mm)

The use of an expansion vessel is depending on

the highest temperature and the volume of the

bath liquid in the loop circuit.

(see diagram 1 page 26).

Close the expansion vessel with the cover Das

Order No. 8 970 831 Expansion vessel 5 liters

Warning:

An external expansion vessel is heated up by the wam outgoing air, especially in

small rooms or if there is not enough distance between the wall and the unit.

In this case only bath liquids with a fire point of 100 °C are allowed to be used.

Note:

At the desired highest temperature, drain overflowing bath liquid into a

suitable vessel via the connector (15). If at the desired lowest

temperature, low liquid level alarm is not triggered, there is no need to

use an external expansion vessel.

Important: Leakage on shaft sealing

The shaft sealings of the pump are never absolutely tight. But this does

not have an impact on the proper functioning of the instrument. The

slight leakage that appears ensures good sliding properties of the

sealing. Any excess fluid is drained via the overflow connector (15).

29

Page 30

Preparations

Notice:

If an expansion vessel is not used, make sure the connector (16) is closed with a cap

nut.

If an external expansion vessel is mounted later, a part of the bath liquid should be

drained before (see chapter Emptying on page 35). It might be helpful to put the

castors at the back on a base which is approximately 10-15 mm high. So the bath

fluid can be collected in the front part of the internal reservoir.

5.5. Cooling water connection LH 50

OUT

Notice: Cooling water circuit

Risk of oil leaking from the refrigeration system (compressor) of the recirculating

cooler into the cooling water in case of a fault in the cooling water circuit!

Observe the laws and regulations of the water distribution company valid in the

location where the unit is operated.

Even high quality heat exchangers as they are installed in our

equipment can be damaged by unsuitable cooling water.

The quality of the cooling water depends on the local conditions.

The heat exchanger may become leaky due to corrosion or it may

become clogged due to particulate matter

Caution:

Securely attach all tubing to prevent slipping.

Supply cooling water via the inlet (18).

Conduct the cooling water via the outlet (17) in the

Example:

PVC-tubing

respective sink or return flow circuit.

Cooling water connectors G3/4" external thread

Tubing 12 mm inner dia. tubing

IN

30

12 mm inner dia.

Cooling water see page 14

Page 31

5.6. Power connection

Check to make sure that the line voltage matches the supply

Caution:

Only connect the unit to a power socket with earthing contact (PE – protective

earth)!

The power supply plug serves as a safe disconnecting device from the line and

must be always easily accessible.

Never operate equipment with damaged mains power cables.

Regularly check the mains power cables for material defects (e.g. for cracks).

We disclaim all liability for damage caused by incorrect line voltages!

voltage specified on the identification plate.

Deviations of ±10 % are permissible

Connect the mains plug (12) to a power socket with earthing

contact (PE – protective earth)!

5.7. Filling

Caution:

Take care of the bath liquid's changing volume varying with the working

temperature of the Presto temperature system.

Guideline:

A volume change of 12 % per 100 °C temperature variation is to be considered..

The maximum change in volume in the internal reservoir for the different models is

included in the table below.

Filling is performed in two sections.

In section 2, the temperature system starts an automatic filling

process enabling convenient filling.

Indication max:

11 liters (LH 47)

18.5 liters (LH 50)

Indication min:

3.0 liters (LH 47)

10.5 liters (LH 50)

Notice:

First connect the external system! (see page 28)

Take care no bath liquid enters the interior of the unit.

Filling volume LH47 LH50

(without external approx. liters approx. liters

system connected) 2.5 10

- in the heat exchanger 2.5 10

- in the internal reservoir 8.4 8.4

Recommendation:

For filling, use for example an approx. 2 liters measuring jug.

Select the bath liquid suitable for the temperature application task.

(see also diagram 1 page 26).

For temperature applications to +250 °C fill up to marker "HT", for

applications to for example –50 °C fill up to marker "TT".

31

Page 32

Preparations

5.7.1. Filling of external, closed systems

Section 1

ALARM

CODE 14

Section 2

Turn the unit off and on again with the mains power switch (1). Wait

Press the key

The liquid level in the unit falls.

If the liquid level display remains unchanged after some minutes,

Connect the unit to a mains power socket (see page 31) and

turn on the unit with the mains power switch (1).

until the self-test is completed.

As soon as the pump pressure indication in the 3

Info-Display

(„P X.XX“) has scaled up to at least 0.1 bar, the tempering liquid is

pumped into the external system. In intervals of 10 seconds bath

liquid is pumped into the external system - air purge is carried out in

the breaks.

Notice: The filling mode has to stay activated for at least 5 minutes in

order to fully de-air the system.

In case of a WARNING >CODE 40< again slowly fill in tempering

liquid into the opening (5.2).

In case of a ALARM >CODE 14< return to the final condition of

section 1 and restart section 2.

complete filling according to the application task.

See page 31 - marker "HT" or "TT".

During the self-test all segments of the VFD-Info-Display, all

control indicators and the DIALOG-DISPLAY light up.

After the self-test, the VFD-Info-Display signals low liquid level

alarm. >CODE 14< and a signal tone sounds.

Press (5.1) to open the filling funnel (5). Slowly pour in bath

liquid into the opening (5.2) and observe the liquid level

display.

Watch the level indication

procedure 3 or 4 steps of the level indication can light-up, in

the end they should light-up.

to start the automatic filling process.

. During the filling

rd

line of the VFD-

Pump

>Pump OFF

Mode:Sys close

32

Press

The message >SELECT SYSTEM<is a demand to make now an

adjustment in the menu >Pump<.

In the sub >Pump< the unit has to be set on >Mode:< >sys close< .

(see page 33 Adjusting Mode: )

The unit is now ready for operation .

to finish the automatic filling process.

Page 33

Notice:

In the >Mode< > fill < or. >drain<>SELECT SYSTEM< is shown when starting.

The message >SELECT SYSTEM<is a demand to make an adjustment in the menu

>Pump<.

The insertion is effected cyclicly until the adjustment has been made.

Adjusting Mode:

Notice concerning the filling

The temperature system was emptied last, therefore the menu option >Mode< now still

stands on >drain<. In the configuration of this unit the >Mode< >fill< means the same as

>drain< and therefore does not have to be adjusted.

Explanation of terms:

>Mode: sys close< stands for closed, external system (Presto principle page 24)

Press the respective keys in the following order:

1. MENUE key

2. Cursor key

3. Enter key

4. Cursor key

5. P- key

6. Enter key

7. Escape key

The DIALOG-DISPLAY (LCD) helps to follow up the individual settings.

The VFD-Info Display shows the recently chosen operating status for approx. 3 seconds.

Switch over to > sys close < CLOSED SYSTEM

Switch over to > fill < FILL SYSTEM

Switch over to >drain< DRAIN SYSTEM

1x

up to Submenu "Pump"

1x

1x up to "Pump"

sys close / fill / drain

1x

2x

33

Page 34

Preparations

5.8. Degasifying

S 180.00

-DEGAS-

Setp: 180.00°C

IntAct 78.00°C

ExtAct: --.--°C

Control: Intern

degasing activ

If the temperature system is operated an automatic degasifying is

carried out after the start.

During the degasifying unwelcome components of the bath liquid

are are drawn off .

Examples:

Air bubbles which were enclosed in the bath liquid during the

filling for the unit.

Slightly volutile components which are eventually in the fluid.

Eventually existing water components, which reached the bath

liquid during the storage.

The automatic degasifying is a part of the program in the unit,

which is always active in the background. Experience shows that

the activity is only noticed after a first or new filling of the unit.

During the heating-up phase, e.g. to a working temperature of

180°C, the VFD-Info-Display shows >DEGAS<.

Parallely to this, in line 4 in the DIALOG-DISPLAY the message

>Degasifying active< is inserted. In this phase the temperature rise

is stopped, the pump motor and the ventilation valve are activated

alternately (audible). During the heating-up phase this degasifying

mode can be repeated with the most different temperatures.

The automatic degasifying can be stopped by :

Operating the key

or

adjusting the set temperature on at least 50°C lower than the

Caution: Escape of vapors / gas

The necessity of degassing requires that a closed system is not entirely sealed.

Especially at increased working temperatures vapor / gas may escape.

Ensure sufficient ventilation at the place of installation!

With different substances the change-over to the steam phase and therefore also

an enormous change of volume is carried out very quickly. The fluid, for which

there is no more room in the internal reservoir, now has to drain off controlled via

the overflow.

Important:

Connect a piece of tubing to the overflow connector (15) and drain into a suitable

vessel. (min. 2 liters) (M16x1 / wrench 19 mm), which always has to be

placed lower than the exit „Overflow“

current set temperature.

34

Page 35

5.9. Draining

Notice:

Do not drain the bath fluid while it is hot or cold !

S 20.00

P x.xx

Pump

>Pump OFF

Mode: drain

ALARM

CODE 14

Check the temperature of the bath fluid prior to draining (by switching the unit on

for a short moment, for example).

Store and dispose the used bath fluid according to the laws for environmental

protection.

Turn on the temperature system with the mains power

switch or

press the stop key

MODE.

In the submenu >Pump<, set the menu items >Mode< to

>drain<.

(see page 33 Adjusting Mode: )

The reset to another mode can only take place after the

next filling.

Reason: During the >ALARM – CODE 14< there is no

possibility for access to the menu functions !

to make the unit enter the STOP-

Pull the venting grid (8.1) to the front and remove.

Place a suitable vessel (8.2) for accepting the used bath

liquid underneath the drain.

Slide a short piece of tubing onto the drain port and hold

the end into the vessel.

Unscrew the drain screw by some turns.

The LH50 has two drain screws. Both have to be used.

The liquid level in the unit falls.

Now the VFD-Display of the unit should show low level,

WARNING >CODE 40< and then ALARM >CODE 14<.

Press enter

to quit the audible signal.

Drain the external system:

At the upper nozzle of the external system, disconnect the

tubing to the pump connector "return" (14) until an air

stream moves in.

(see sketch on page 28)

Tighten the drain screw after draining the unit.

The internal reservoir should additionally be emptied via the

connection for the expansion vessel (16) on the rear side of

the temperature system.

(Cleaning the unit see page 72)

35

Page 36

Operating procedures

6. Operating procedures

6.1. Switching on / Selecting the language

Switching on:

The unit is operated by pressing the mains power switch (1).

The integrated pilot lamp illuminates.

JULABO

P R E S T O

V1.45-1

During the self-test all segments of the VFD-Info-Display, all

control indicators and the DIALOG-DISPLAY light up.

Then the software version number (example: V1.45-1)

appears for a short moment and the message "OFF" indicates

the unit is ready to operate.

Message >WAIT< when adjusting >Mode: sys close<:.

During the message >WAIT< the ventilation valve is opened for

10 seconds. So, the air which has eventually been collected

during the standstill, can escape.

Soll: 20.00°C

IntIst xxx.00°C

>Konfiguration

ExtIst:

Regelparameter

Konfiguration

Regelung:

Identif. xxxxx

Sollwert xxxxx

Autostart xxx

Standby xxxx

>Sprache xxxxxxx

Setp.: 20.00°C

IntAct xxx.xx°C

ExtAct: xx x. xx °C

Control: intern

The unit returns to the previous operating mode that was

active before it was turned off:

keypad control mode

(manual operation via the unit itself/RD)

or

remote control mode

(operation via PC).

Selecting the language:

There are two options for the language of the DIALOG-DISPLAY

(LCD): German or English. Select the desired language in the

MENU level under the submenu >Configuration.

Press the respective keys in the following order:

1. MENU key

2. Enter key

3. Cursor key

4. P-key

5. Enter key

6. Escape key

The DIALOG-DISPLAY (LCD) helps to follow up the individual

settings (example: swap the language from German to English).

1x

1x

up to Submenu "Sprache/Language"

1x

1x

2x

36

Page 37

7. Manual operation

7.1. Start - Stop

Setp.: 20.00°C

IntAct 21.00°C

ExtAct : --. -- °C

Control: Intern

S 20.00

P x.xx

Setp.: 20.00°C

IntAct 21.00°C

ExtAct : --. -- °C

Control: Intern

Stop-Mode

Notice:

The message >SELECT SYSTEM<is a demand to make an adjustment in the menu

>Pump< according to the connected system. The insertion is effected cyclicly until

the adjustment has been made

(see page 33 Adjusting Mode: )

In the >Mode< > fill < or. >drain<>SELECT SYSTEM< is shown when starting.

Start:

Press the start/stop key

The actual bath temperature is displayed.

For approx. 3 seconds the VFD-Info-Display shows the

adjusted >Mode< .

Adjustment > sys close < CLOSED SYSTEM

The temperature system runs.

Notic:

For physical reasons, refrigeration units provide full cooling

performance only after some minutes. After the start up to 5

minutes can go by, until the cooling capacity is given.

Stop:

Press the start/stop key

The VFD indicates "OFF" and the message STOP-MODE

flashes in line 4 on the LCD.

.

.

S 20.00

ID 0

The unit also enters the safe operating state "OFF" after a mains

power interruption. The temperature values entered via the

keypad remain in memory. With the temperature system in

keypad control mode, press the start/stop key to restart operation.

With the instrument in remote control mode, the personal

computer must first resend the parameters set via the interface

before the temperature system may be restarted.

37

Page 38

Manual operation

7.2. Direct setting of the working temperature

Setp.: 20.00°C

IntAct 21.00°C

ExtAct : --. -- °C

Control: Intern

7.3. Settings in the SET menu

This setting may be carried out with the temperature system being

in operating state Start or Stop!

The value previously set appears on the DIALOG-DISPLAY

(LCD) (example: 20.00 °C).

A flashing segment indicates that a value needs to be entered.

Use the keypad to enter the new value and press enter

to store the selected value.

(examples: 120.00 °C; 228.50 °C; -15.00 °C).

Press the key

indicated on the DIALOG-DISPLAY (LCD).

Set the following values:

in Line 1: the working temperature in °C Setp.:

Line 2: the high temperature limit in °C Overt.:

Line 3: the low temperature limit in °C Subtmp:

Line 4: the pump pressure stage St.Pump:

to call up the SET menu. It is then

Enter the desired values via the keypad. Settings may be

carried out with the temperature system being in operating

state Start or Stop!

Use the cursors

Press escape

7.3.1. Setting the working temperature

>Setp. : 200 .0 0° C

Overt.: 255.00°C

Suptmp: -55.00°C

St.Pump: 2

>Setp: Setting the working temperature

Setting in line 1.

>Setp. : 12 0. 00 °C

Overt.:255.00°C

Subtmp:-55.00°C

St.Pump: 2

The value previously set appears on the DIALOG-DISPLAY

(LCD) (example: 100.00 °C).

A flashing segment indicates that a value needs to be

entered.

Use the keypad to enter the new value

(examples: 120.00 °C; 228.50 °C; -15.00 °C).

Press enter to store the selected value.

to swap the lines.

to quit the SET menu.

38

Page 39

7.3.2. Warning functions

The high and low temperature warning functions accompany the

working temperature value. An audible signal sounds in intervals

when the actual temperature exceeds one of the set limits

(patented).

The corresponding message appears in line 4 on the DIALOGDISPLAY (LCD).

Setp.: 120.00°C

>Overt.:130.00°C

Subtmp:-55.00°C

St.Pump: 2

Setp.: 120.00°C

Overt.:130.00°C

>Subtmp:110.00°C

St.Pump: 2

>Overt: Setting the high temperature limit

Setting in line 2.

The value previously set appears on the DIALOG-DISPLAY

(LCD).

A flashing segment indicates that a value needs to be

entered.

Use the keypad to enter the new value

(examples: 130.00 °C; -13.00 °C).

Press enter to store the selected value.

>Subtmp: Setting the low temperature limit

Setting in line 3.

The value previously set appears on the DIALOG-DISPLAY

(LCD).

A flashing segment indicates that a value needs to be

entered.

Use the keypad to enter the new value

(examples: 110.00 °C; -17.00 °C).

Press enter to store the selected value.

Example:

Setp: 120. 00 °C

IntAct 130.50°C

ExtAct : --. -- °C

Control: Intern

Excess temp.

Note:

The warning functions will only be triggered when the actual bath

temperature, after start from the "OFF" or "rOFF" mode, lies within

the set limits for 3 seconds.

The corresponding message appears in line 4 on the DIALOGDISPLAY (LCD).

39

Page 40

Manual operation

7.3.3. Setting the pump pressure stage

The pressure of the circulation pump is adjustable in five grades.

After setting, the VFD-Info-Display indicates the corresponding

value.

>St.Pump: Setting the pump pressure stage

Setp.: 120.00°C

Overt.:130.00°C

Subtmp:110.00°C

>St.Pu mp : 4

Setting in line 4.

The value previously set appears on the DIALOG-DISPLAY

(LCD).

A flashing segment indicates that a value needs to be

entered.

Use the keypad to enter the new value

Note:

The mechanical rotation of the circulation pump produces heat that is

radiated into the bath liquid. The lowest working temperature may thus only

be reached if the pump pressure is set to grade 1.

7.4. Setting the safety temperature (with shutdown function)

Check the safety installations at least twice a year! See page 17.

TANK 150

RES 100

160

80

40

0

60

30

10

ALARM

CODE 14

ALARM!

IntAct : xx. xx °C

ExtAct : --. -- °C

Temp/level alarm

320

°C

130

220

°C

240

180

This safety feature functions independent of the regulator circuit.

When the temperature of the bath liquid has reached the safety

temperature, a complete shutdown of the heater and pump is

effected.

Safety temperature in the heat exchanger >TANK<

(excess temperature protection)

Press the key

Setting range: 0 °C to 320 °C

in 2 °C steps

The alarm is indicated by optical and audible signals (continuous

tone).

The error messages opposite appear on the DIALOG-DISPLAY

(LCD) and VFD-Info-Display.

(example: 4).

Press enter to store the selected value.

to indicate the safety temperature value in

line 2 >TANK< on the VFD-Info-Display and using a screwdriver

simultaneously turn the setting screw to the desired value

(example: 150 °C).

40

Page 41

ALARM

CODE 13

ALARM!

IntAct : xx. xx °C

ExtAct : --. -- °C

RESERVOIR

Safety temperature in the internal reservoir >RES<

This supplementary safety installation supervises and controls the

temperature of the bath liquid in the internal reservoir.

Press the key

line 3 >RES< on the VFD-Info-Display and using a screwdriver

simultaneously turn the setting screw to the desired value

(example: 100 °C).

Setting range: 10 °C to 220 °C

in 2 °C steps

The alarm is indicated by optical and audible signals (continuous

tone).

The error messages opposite appear on the DIALOG-DISPLAY

(LCD) and VFD-Info-Display.

to indicate the safety temperature value in

Press enter

After eliminating the malfunction, press the mains power switch

off and on again to cancel the alarm state.

Warning:

Set the safety temperature >TANK< 15 °C above the working temperature

setpoint.

The safety temperature value >RES<should be set at least 25 °C below the fire

point of the bath liquid used.

to quit the audible signal.

41

Page 42

Menu functions

7.5. Internal / external control

ext. Pt100

S xx.xx

ID 0

Setp: 120. 00 °C

IntAct 21.00°C

ExtAct : 20. 00 °C

Contro l: Intern

Setp: 120. 00 °C

IntAct 21.00°C

ExtAct : 20. 00 °C

Contro l: Extern

Int

S 120.00

E 20.00

The temperature system offers the possibility of internal

temperature control in the internal bath or external control directly

in an external system.

Setup for external control:

Connect a Pt100 sensor to the socket "EXT" of the Presto

temperature system, if necessary perform a calibration using the

"ATC Ext:" function (see page 59) and then securely fix the sensor

in the external system.

To swap internal to external control:

Press the key

control type.

The DIALOG-DISPLAY (LCD) indicates the effective control

type in line 4

>Control: intern< or > Control: extern<

Press the start/stop key

Temperature indication:

The DIALOG-DISPLAY (LCD)

simultaneously indicates both actual temperatures.

The VFD-Info-Display

indicates the actual temperature in line 1. In the header the

corresponding symbol >Int< or >Ext< is illuminated.

Press the key

It is useful, to set line 3 to show the actual temperature

in operating state "OFF" to select the

.

to swap the display.

®

Caution:

Place the external sensor into the bath medium and securely fix the sensor.

8. Menu functions

42

Press the MENU key

Use the up/down cursor keys

submenu and press enter

Press escape

>E xx.xx°C< by pressing the key

to enter the menu level.

.

to return to the previous menu level.

.

to select the desired

Page 43

43

Page 44

Menu functions

8.1. Configuration

By means of the configuration functions, operation of the

instrument can be optimized for the current application.

Press enter

Use the up/down cursor keys

option. A flashing line indicates that a value needs to be

entered.

Press the P-key

.

Press escape

> Identification

When performing an identification for the controlled system

(temperature application system), the control parameters Xp, Tn

and Tv will be automatically determined and stored.

Possible parameters:

to select the configuration submenu.

to select the desired

to select the parameter and press enter

to return the previous menu level.

off - no identification.

The control parameters ascertained during the last

identification are used for control purposes.

once - single identification

The instrument performs a single identification of the

controlled system after start.

After the identification process the parameter is automatically

set to "off".

always - continual identification

The instrument performs an identification of the controlled

system whenever a new setpoint is to be reached.

NOTE: Use this setting only when the temperature application

system changes permanently.

Important:

For physical reasons, refrigeration units provide full cooling

performance only after some minutes. During identification this is

given consideration by waiting for 5 minutes after switch-on.

44

Page 45

Setp.: 50.00°C

IntAct: 50.00°C

Eprog: 50.00°C

ExtAct: 50.00°C

IntAct: 50.00°C

Rs232: 50.00°C

Control: intern

Power: 50 %

IntAct: 50.00°C

Control: intern

Power: 50 %

Control: intern

R

S xx.xx

ID 0

REG+E-PROG

SERIAL

Note:

Requirement for an identification of the controlled system:

The temperature system must heat to a setpoint temperature

at least 10 °C above the previous setpoint using the adjusted

heating power.

When the adjusted control parameters Xp, Tn and Tv are too

high, this requirement may not be given with respect to on

how much the setpoint temperature has to change. In this

case, prior to carrying out an identification in the "OFF" state,

set the control parameters to lower values.

Recommended setting for internal control:

Xp = 1.0 °C

Tn = 80 s

Tv = 8 s

> Setpoint

The instrument provides three possibilities for setpoint selection.

The active mode is indicated on the DIALOG-DISPLAY (LCD).

The control indicator >R< (REMOTE) is illuminated in the header

of the VFD-Info-Display if setpoint selection is effected via the

EPROG or SERIAL input.

Possible parameters:

keyb- Setpoint setting via keypad (Setp.:) or via the integrated

programmer.

eprog - Setpoint setting via the analog interface REG+E-PROG

(3.1) connection with an external voltage or current source or

a programmer. (see page 55)

RS232 - Setpoint setting via the serial RS232/RS485 interface

(3.5) through a PC or superordinated data system.

>Autostart

Note:

The temperature system has been configured and supplied by

JULABO according to N.A.M.U.R. recommendations. This

means for the start mode, that the unit must enter a safe

operating state after a power failure (non-automatic start mode).

This safe operating state is indicated by "OFF", resp. on the

VFD-Info-Display. A complete shutdown of the main functional

elements such as heater and circulation pump is effected

simultaneously.

Only with setpoint adjustment the AUTOSTART-function can be

executed via >Taste< and >EPROG< (see above).

45

Page 46

Menu functions

Should such a safety standard not be required, the AUTOSTART

function (automatic start mode) may be activated, thus allowing