Page 1

English

Operating manual

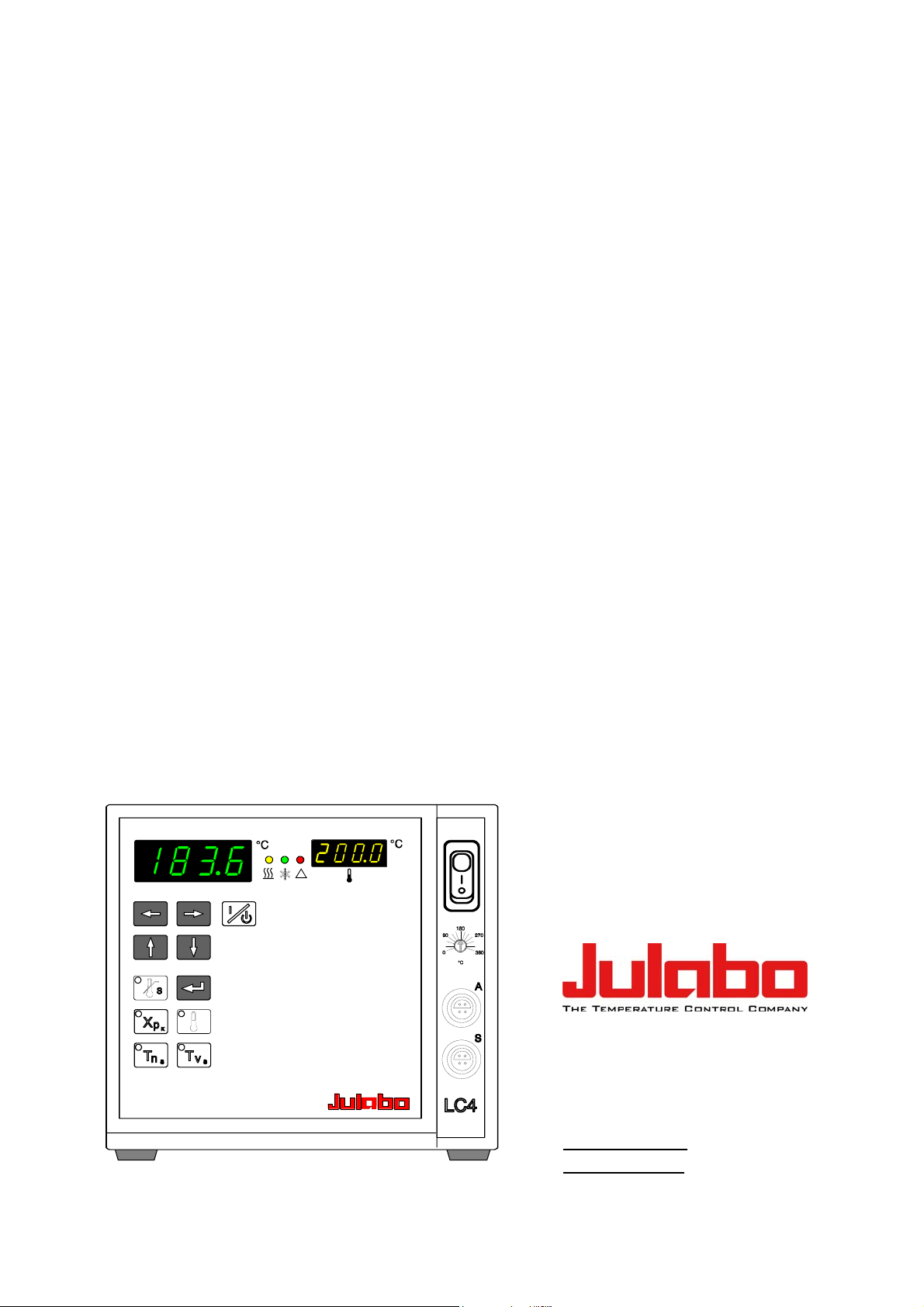

Temperature controller

LC4

!

JULABO GmbH

77960 Seelbach / Germany

Tel. +49 (0) 7823 / 51-0

Fax +49 (0) 7823 / 24 91

1.951.5200-V2 06/13

19515200-V2.doc 26.07.2013

info@julabo.de

www.julabo.de

Page 2

Congratulations!

You have made an excellent choice.

JULABO thanks you for the trust you have placed in us.

This operating manual has been designed to help you gain an understanding of the operation

and possible applications of our circulators. For optimal utilization of all functions, we

recommend that you thoroughly study this manual prior to beginning operation.

The JULABO Quality Management System

Temperature control devices for research and industry are developed,

produced, and distributed according to the requirements of ISO 9001

and ISO 14001. Certificate Registration No. 01 100044846

Unpacking and inspecting

Unpack the circulator and accessories and inspect them for possible transport damage.

Damage should be reported to the responsible carrier, railway, or postal authority, and a

damage report should be requested. These instructions must be followed fully for us to

guarantee our full support of your claim for protecting against loss from concealed damage.

The form required for filing such a claim will be provided by the carrier.

Printed in Germany Changes without prior notification reserved

Important: keep operating manual for future use

2

Page 3

INDEX

OPERATING MANUAL ..................................................................................................... 4

1. INTENDED USE ........................................................................................................ 4

1.1. Description ........................................................................................................ 4

2. OPERATOR RESPONSIBILITY – SAFETY RECOMMENDATIONS ........................ 4

2.1. Disposal ............................................................................................................ 6

2.2. EC Conformity ................................................................................................... 7

2.3. Warranty conditions .......................................................................................... 7

2.4. Technical specifications .................................................................................... 8

OPERATING INSTRUCTIONS ....................................................................................... 10

3. SAFETY NOTES FOR THE USER ......................................................................... 10

3.1. Explanation of safety notes ............................................................................. 10

3.2. Explanation of other notes .............................................................................. 10

3.3. Safety recommendations ................................................................................ 10

4. OPERATING CONTROLS AND FUNCTIONAL ELEMENTS .................................. 12

LC4

5. OPERATING PROCEDURES ................................................................................. 14

5.1. Installation ....................................................................................................... 14

5.2. Power connection ........................................................................................... 14

5.3. Connecting a heating device ........................................................................... 15

5.4. Connecting the temperature sensors .............................................................. 15

5.5. Applications ..................................................................................................... 16

5.6. Switching on / Start - Stop ............................................................................... 17

5.7. Setting the temperatures ................................................................................. 19

5.8. Setting the PID control parameters Xp, Tn and Tv .......................................... 19

5.8.1. Optimization instructions for the PID control parameters ........................ 21

5.9. Setting the safety temperature (with shutdown function) ................................ 22

6. MENU FUNCTIONS ................................................................................................ 23

6.1. Sensor calibration - ATC function ................................................................... 23

6.2. Temperature range: HL / LL ............................................................................ 24

6.3. Parameter sets for control: PA ........................................................................ 24

6.4. Active countercooling: Pc ................................................................................ 26

6.5. Controlling the heater capacity: h .................................................................... 26

6.6. Interface parameters: r - br - P - H .................................................................. 27

7. TROUBLESHOOTING GUIDE / ERROR MESSAGES ........................................... 28

8. ELECTRICAL CONNECTIONS ............................................................................... 29

9. REMOTE CONTROL............................................................................................... 31

9.1. Communication with a PC or a superordinated data system........................... 31

9.2. List of commands ............................................................................................ 32

9.3. Status messages ............................................................................................ 34

9.4. Error messages ............................................................................................... 34

10. CLEANING / REPAIRING THE UNIT ...................................................................... 35

3

Page 4

Operating manual

Operating manual

1. Intended use

Fulfilling its principle task, reliable temperature control and measurement, the LC4 temperature

controller also implements safety and monitoring functions, particularly in the areas of chemical

research and quality control. The sophisticated capabilities of the unit allow wide application

with electrical heating devices such as

heating hoods, heating baths,

heating pads and bandages,

water and oil baths.

JULABO Temperature controllers are not suitable for direct temperature

control of foods, semi-luxury foods and tobacco, or pharmaceutical and

medical products. Direct temperature control means unprotected contact of the

object with the bath medium (bath fluid).

1.1. Description

Setting is rapid and simple using the keypad with its easy to learn symbols. Keypad is splashproof, easily cleaned and ergonomically designed. The microprocessor technology allows the

working temperature setpoint and five parameter sets to be stored and indicated on the

MULTI-DISPLAY (LED).

The safety value for excess temperature protection, a safety installation independent from the

control circuit, is adjustable on the front and visible on the MULTI-DISPLAY (LED).

The RS232C port permits modern process engineering without additional interface, directly online from the controller to your application equipment.

2. Operator responsibility – Safety recommendations

The products of JULABO ensure safe operation when installed, operated, and maintained

according to common safety regulations. This section explains the potential dangers that may

arise when operating the circulator and also specifies the most important safety precautions to

preclude these dangers as far as possible.

The operator is responsible for the qualification of the personnel operating the units.

The personnel operating the units should be regularly instructed about the dangers involved

with their job activities as well as measures to avert these dangers.

Make sure all persons tasked with operating, installing, and maintaining the unit have read

and understand the safety information and operating instructions.

When using hazardous materials or materials that could become hazardous, the circulator

may be operated only by persons who are absolutely familiar with these materials and the

circulator. These persons must be fully aware of possible risks.

4

Page 5

If you have any questions concerning the operation of your unit or the information in this

manual, please contact us!

LC4

Contact:

Safety instructions for the operator:

You have received a product designed for industrial use. Nevertheless, avoid strikes to the

housing, vibrations, damage to the operating-element panel (keypad, display), and

contamination.

Make sure the product is checked for proper condition regularly (depending on the

conditions of use). Regularly check (at least every 2 years) the proper condition of the

mandatory, warning, prohibition and safety labels.

Make sure that the mains power supply has low impedance to avoid any negative effects on

instruments being operated on the same mains.

This unit is designed for operation in a controlled electromagnetic environment. This means

that transmitting devices (e.g., cellular phones) should not be used in the immediate

vicinity.Magnetic radiation may affect other devices with components sensitive to magnetic

fields (e.g., monitors). We recommend maintaining a minimum distance of 1 m.

Permissible ambient temperature: max. 40 °C, min. 5 °C.

Permissible relative humidity: 50% (40 °C).

Do not store the unit in an aggressive atmosphere.

Protect the unit from contamination.

Do not expose the unit to sunlight.

Appropriate operation

Only qualified personnel is authorized to perform configuration, installation, maintenance and

repairs of the circulator.

Routine operation can also be carried out by untrained personnel who should however be

instructed by trained personnel.

Use:

The bath can be filled with flammable materials. Fire hazard!

There might be chemical dangers depending on the bath medium used.

Observe all warnings for the used materials (bath fluids) and the respective instructions (safety

data sheets).

Insufficient ventilation may result in the formation of explosive mixtures. Only use the unit in well

ventilated areas. The unit is not for use in explosive atmosphere.

Only use recommended materials (bath fluids). Only use non-acid and non corroding materials.

JULABO GmbH

Eisenbahnstraße 45

77960 Seelbach / Germany

Tel. +49 (0) 7823 / 51-0 info@julabo.de

Fax +49 (0) 7823 / 24 91 www.julabo.de

5

Page 6

Operator responsibility – Safety recommendations

When using hazardous materials or materials that could become hazardous, the operator

must affix the enclosed safety labels (1 + 2) to the front of the unit so they are highly visible:

1

2

or

2

Particular care and attention is necessary because of the wide operating range.

There are thermal dangers:

Burn, scald, hot steam, hot parts and surfaces that can be touched.

Observe the instructions in the manuals for instruments of a different make that you connect to

the circulator, particularly the respective safety recommendations. Also observe the pin

assignment of plugs and technical specifications of the products.

Warning label W00: Colors: yellow, black

Danger area. Attention! Observe instructions.

(operating manual, safety data sheet)

Mandatory label M018: Colors: blue, white

Carefully read the user information prior to beginning operation.

Scope: EU

Semi S1-0701 Table A1-2 #9

Carefully read the user information prior to beginning operation.

Scope: USA, NAFTA

Warning label W26: Colors: yellow, black

Hot surface warning.

(The label is put on by JULABO)

2.1. Disposal

Valid in EU countries

See the current official journal of the European Union – WEEE directive.

Directive of the European Parliament and of the Council on waste electrical

and electronic equipment (WEEE).

This directive requires electrical and electronic equipment marked with a

crossed-out trash can to be disposed of separately in an environmentally

friendly manner.

Contact an authorized waste management company in your country.

Disposal with household waste (unsorted waste) or similar collections of

municipal waste is not permitted!

6

Page 7

2.2. EC Conformity

LC4

The products described in the operating instructions conform to the

requirements of the following European guidelines:

Low voltage regulations with respect to legal harmonization of the member countries

concerning electric devices for use within certain voltage limits.

EMC guideline with respect to legal harmonization of the member countries

concerning electromagnetic compatibility.

JULABO GmbH

Eisenbahnstr. 45

77960 Seelbach / Germany

2.3. Warranty conditions

JULABO GmbH warrants its products against defects in material or in workmanship, when

used under appropriate conditions and in accordance with appropriate operating instructions

Extension of the warranty period – free of charge

for a period of ONE YEAR.

With the ‘1PLUS warranty’ the user receives a free of charge extension to the warranty of up to

24 months, limited to a maximum of 10 000 working hours.

To apply for this extended warranty the user must register the unit on the JULABO web site

www.julabo.de, indicating the serial no. The extended warranty will apply from the date of

JULABO GmbH’s original invoice.

JULABO GmbH reserves the right to decide the validity of any warranty claim. In case of faults

arising either due to faulty materials or workmanship, parts will be repaired or replaced free of

charge, or a new replacement unit will be supplied.

Any other compensation claims are excluded from this guarantee.

7

Page 8

Operator responsibility – Safety recommendations

2.4. Technical specifications

LC4

Adjustable temperature range °C -50 .... 350

Display accuracy % ±0.5 ± 1 Digit

Temperature stability

(depending on substances in the bath)

Temperature selection digital

via keypad indication on MULTI-DISPLAY (LED)

remote control via computer indication on monitor

Temperature display MULTI-DISPLAY (LED): 4-digit

Resolution °C 0.1

ATC function °C ±9.99

Temperature control PID

with 5 parameter sets freely selectable

°C >±0.05

Working temperature: 4-digit

Working temperature sensor Pt100, 4-lead technique

Safety temperature sensor Pt100, 4-lead technique

Electrical connections:

External alarm 24-0 V DC / max. 25 mA

Interface RS232C

Mains power socket

for heating device (at 115 V) W max. 1000; resistive load

or (at 230 V) W max. 2000; resistive load

Overall dimensions (WxDxH) cm 17 x 17 x 16

Weight kg 3

Ambient temperature °C 5 ... 40

Mains power connection ±10% V/Hz 230 / 50-60

Mains power connection ±10% V/Hz 115 / 50-60

Current draw A 10

Total power consumption W max. 1050 (at 115 V)

Total power consumption W max. 2050 (at 230 V)

All measurements have been carried out at

rated voltage and frequency

ambient temperature 20 °C

Technical changes without prior notification reserved.

8

Page 9

Safety installations according to IEC 61010-2-010:

Excess temperature protection 0 °C ... 350 °C

Supplementary safety installations:

Supervision of the working sensor plausibility control

Alarm indication optical + audible (continuous tone)

LC4

Environmental conditions according to EN 61 010, part 1:

Use only indoor.

Altitude up to 2000 m - normal zero.

Ambient temperature: +5 ... +40 °C (for storage and transportation)

Air humidity:

Max. rel. humidity 80 % for temperatures up to +31 °C,

linear decrease down to 50 % relative humidity at a temperature of +40 °C

Max. mains fluctuation of ±10 % are permissible.

Protection class according to EN 60 529 IP31

The unit corresponds to Class I

Overvoltage category II

Pollution degree 2

Caution:

The unit is not for use in explosive environment.

Standards for interference resistance according to EN 61326-1

This unit is an ISM device classified in Group 1 (using high frequency for internal purposes)

Class A (industrial and commercial range).

9

Page 10

Operating instructions

Operating instructions

3. Safety notes for the user

3.1. Explanation of safety notes

In addition to the safety warnings listed, warnings are posted throughout the

operating manual. These warnings are designated by an exclamation mark

inside an equilateral triangle. “Warning of a dangerous situation (Attention!

Please follow the documentation).”

The danger is classified using a signal word.

Read and follow these important instructions for averting dangers.

Warning:

Describes a possibly highly dangerous situation. If these instructions are not

followed, serious injury and danger to life could result.

Caution:

Describes a possibly dangerous situation. If this is not avoided, slight or

minor injuries could result. A warning of possible property damage may also

be contained in the text.

Notice:

Describes a possibly harmful situation. If this is not avoided, the product or

anything in its surroundings can be damaged.

3.2. Explanation of other notes

Note!

Draws attention to something special.

3.3. Safety recommendations

Follow the safety recommendations to prevent damage to persons or property.

Important!

Indicates usage tips and other useful information.

Further, the valid safety instructions for working places must be followed.

ConnOnly connect the unit to a power socket with earthing contact

(PE – protective earth)!

The power supply plug serves as a safe disconnecting device from the line

and must always be easily accessible.

Place the instrument on an even surface on a pad made of non-inflammable

material.

10

Do not stay in the area below the unit.

Make sure you read and understand all instructions and safety precautions

Page 11

LC4

listed in this manual before installing or operating your unit.

Never operate the unit without bath fluid in the bath.

Observe the flash point of the bath medium used. The excess temperature

protection should be set at least 25 °C below the fire point.

Set up the heating device according to the instructions prior to connection to

the controller and ensure secure attachment to the bath.

Danger of burning and fire!

Immerse both temperature sensors in the bath medium and ensure secure

attachment.

Check the filling level of the bath fluid from time to time. The heater must

always be fully covered with the bath fluid!

Never operate damaged or leaking equipment.

Always turn off the unit and disconnect the mains cable from the power

source before performing any service or maintenance procedures, or before

moving the unit.

Sudden jolts or drops may cause damage in the interior of the unit.

Always empty the bath before moving the unit.

Transport the unit with care.

Never operate equipment with damaged mains power cables.

Observe all warning labels.

Never remove warning labels.

Always turn off the unit and disconnect the mains cable from the power

source before cleaning the unit.

Repairs are to be carried out only by qualified service personnel.

Some parts of the bath cover may become extremely warm during

continuous operation. Therefore, exercise particular caution when touching

these parts. Use safety glasses!

11

Page 12

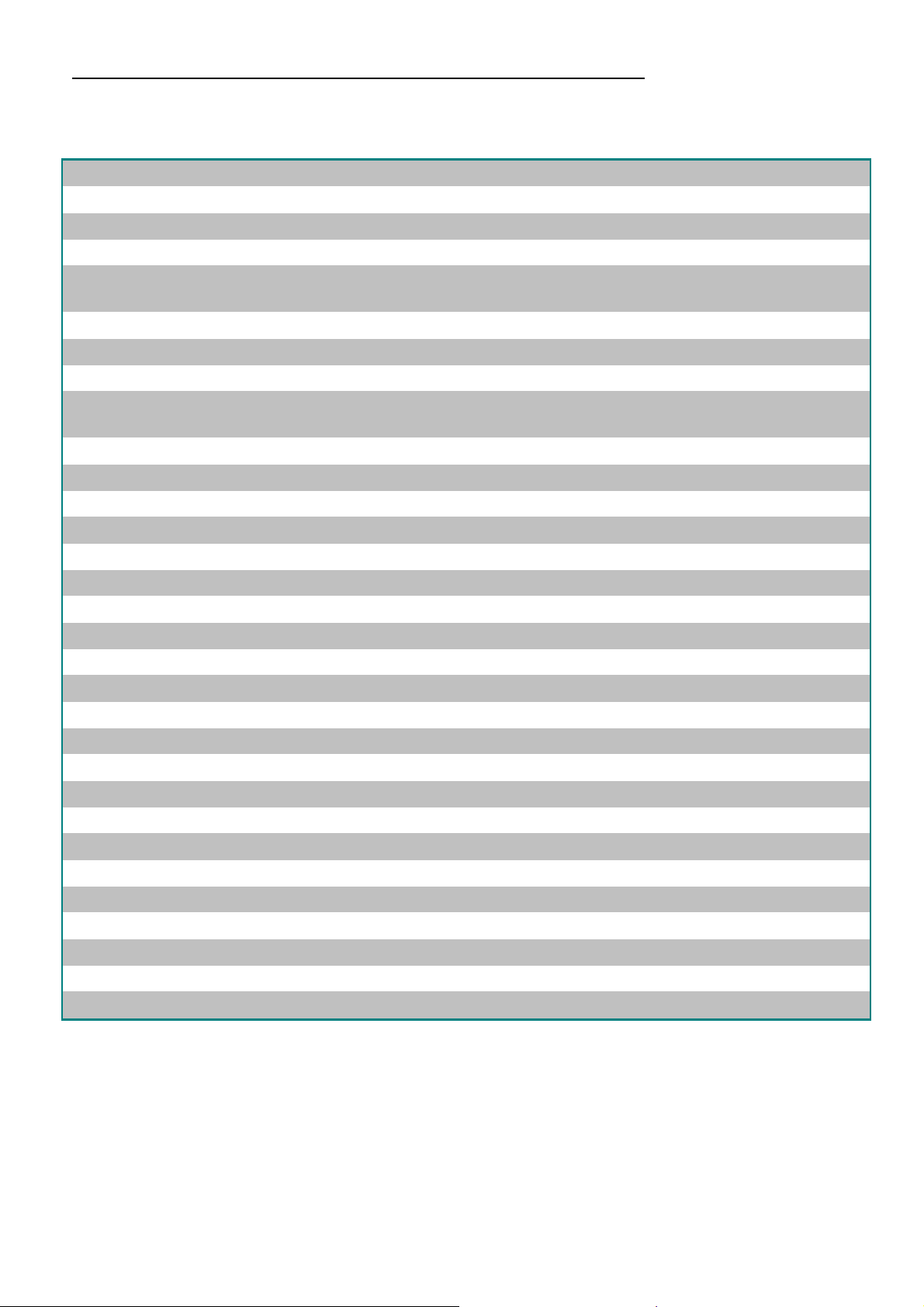

Operating controls and functional elements

4. Operating controls and functional elements

10

11

12

13

7

6

5

4

3

9

!

1

8

2

14

15

21

16

17

20

19

18

12

Rear view

Page 13

LC4

1

2

3

4

5

6

7

8

9

10

Mains power switch, illuminated

Start / stop key

Working temperature setpoint

Control parameter Tv (lead time)

Control parameter Tn (resetting time)

Control parameter Xp (proportional range)

Safety temperature

Adjustable excess temperature protection(safety temperature)

Indication of working temperature

MULTI-DISPLAY (LED) temperature indication

11

12

13

14

15

16

17

18 Grounded mains socket for heating device

19 Threaded fitting (10 mm) for stand rod attachment

Indicator light - Alarm

Indicator light - Cooling

Indicator light - Heating

Cursors left/right

Edit keys (increase/decrease setting)

Enter key (store)

Connector: Working sensor A

Connector: Safety sensor S

Connector: / alarm output

RS232C interface

20 Mains fuses, fuse holders

21 Mains power cable with plug

13

Page 14

Operating procedures

5. Operating procedures

5.1. Installation

The unit should be set up at a dry location.

5.2. Power connection

Caution:

Only connect the unit to a power socket with earthing contact (PE –

protective earth)!

Place the unit in an upright position and do not obstruct the

ventilation.

A wall distance of at least 10 cm must be maintained for

ventilation, allowing internal heat

to be conducted away from the unit.

If one or more temperature controllers are set up in a

cabinet for example, take care of good ventilation (waste

heat per unit = approx. 60 Watts).

The ambient temperature must not exceed 35 °C. Ambient

temperatures above 35 °C result in a failure of the unit.

Do not set up the unit in the immediate vicinity of heat

sources and do not expose to sun light.

The power supply plug serves as safe disconnecting device from the line and

must be always easily accessible.

Never operate equipment with damaged mains power cables.

Regularly check the mains power cables for material defects (e.g. for cracks).

We disclaim all liability for damage caused by incorrect line voltages!

Make sure that the line voltage and frequency match the

supply voltage specified on the type plate.

Deviations of ±10 % are permissible.

14

Page 15

5.3. Connecting a heating device

Caution:

Set up the heating device according to the instructions or securely fix the unit in

the bath tank using appropriate means. Danger of burning and fire!

Connect the power plug to the grounded mains socket (18) on

the rear of the controller.

Caution:

Max. resistive load 1000 W at 115 V / 2000 W at 230 V.

Max. current 5 A at 115 V / 10 A at 230 V.

LC4

5.4. Connecting the temperature sensors

Connect both sensors prior to

alarm shutoff will be effected if the sensors are not connected

(see page 28).

Connect the working sensor to the socket “A” (14) and

the safety sensor to socket “S” (15) .

Sensor calibration:

When the controller is first placed into operation or whenever

Caution:

Place both sensors into the bath medium and securely fix the sensors.

a sensor is replaced, a working sensor calibration must be

carried out (ATC - see page 23).

turning the unit on since an

15

Page 16

Operating procedures

5.5. Applications

Directly heated bath liquid:

The bath liquid is directly heated via the heating device.

Working and safety sensors must both be immersed in the bath liquid.

Whenever countercooling is necessary (in case of temperature application near the

ambient temperature), cooling in the bath is performed through a cooling coil connected to

a solenoid valve and the MVS controller.

!

14

30

15

16a

JULABO MVS

16

15a

18a

18

28

26

25

29

14a

27

14 Connector: Working sensor 14a Working sensor

15 Connector: Safety sensor 15a Safety sensor

16 Connector for control cable 16a Control cable for MVS

18 Mains socket for heating device 18a Heating device / heating hood

25 MVS solenoid valve controller (order no. 9 790 000)

26 Solenoid valve 220 Volts (order no. 8 980 700)

27 Cooling coil

28 Tap water connection

29 Cooling water drain

30 Stirrer motor for bath circulation

31 Bath tank / round bottom flask with bath liquid

31

16

Page 17

Indirectly heated bath liquid:

The bath liquid is indirectly heated.

Working and safety sensors must both be immersed in the bath liquid.

!

LC4

14

14a

30

15

15a

18

31

18a

5.6. Switching on / Start - Stop

Switching on:

Turn on the mains power switch.

The unit performs a self-test. A signal sounds, and all

segments of the two 4-digit displays as well as all indicator

lights will illuminate.

Then the software version (example: n 1.0) and the model

description "LC 4" appear.

17

Page 18

Operating procedures

The display "OFF" or "r OFF" indicates the controller is ready to

operate. Also the effective working temperature setpoint is

indicated

(example: 20.0 °C).

The controller enters the operating mode activated before

switching the controller off,

keypad control mode (manual operation) or

remote control mode (operation via personal computer).

Start:

Press the start/stop key.

- The MULTI-DISPLAY (LED) indicates the actual bath

temperature. (example: 21.0 °C)

- The indicator light in the setpoint key illuminates.

Temperature control is carried out according to the parameter

set last effective (see page 24).

Stop:

Press the start/stop key.

The MULTI-DISPLAY (LED) indicates the message "OFF".

The unit also enters the safe operating state "OFF" or "r OFF"

after a mains power interruptance. The temperature values

entered via the keypad remain in memory. With the controller

in keypad control mode, press the start/stop key to restart

operation.

With the controller in remote control mode, the personal

computer must first resend the parameters set via the interface

before operation of the controller may be restarted.

18

Page 19

5.7. Setting the temperatures

LC4

Setting the working temperature:

1. Press the setpoint key .

The indicator light blinks and the effective value appears

on the MULTI-DISPLAY (LED).

2. Use the cursor keys to move left or right on the

display until the numeral you wish to change is blinking.

3. Use the increase/decrease arrows to change the

selected numeral (-, 0, 1, 2, 3, ... 9).

4. Press enter to store the selected value (example: 37.0

°C).

The working temperature is maintained constant after a short

heat-up time (example: 37.0 °C).

5.8. Setting the PID control parameters Xp, Tn and Tv

Setting the Xp (proportional range)

1. Press the key .

The indicator light blinks and the effective Xp value

appears on the MULTI-DISPLAY (LED).

2. Use the cursor keys to move left or right on the

display until the numeral you wish to change is blinking.

3. Use the increase/decrease arrows to change

the selected numeral (-, 0, 1, 2, 3, ... 9).

4. Press enter to store the selected value (example: 12

°C).

Setting range for the Xp parameter: 0.1 to 50 °C

19

Page 20

Operating procedures

Setting the Tn (resetting time)

1. Press the key .

The indicator light blinks and the effective value for Tn

appears on the MULTI-DISPLAY (LED).

2. Follow the instructions

3. for

4. (example: 1200 s).

Setting range for Tn: 1 to 9998 s.

With Tn set to 9999, the integral part of the controller is

deactivated (use of a P or PD type controller).

Setting the Tv (lead time)

1. Press the key .

The indicator light blinks and the effective value for Tv

appears on the MULTI-DISPLAY (LED).

2. Follow the instructions

3. for

4. (example: 120 s).

Setting range for Tv: 0 to 1000 s.

With Tv set to 0 eingestellt, the differential part of the

controller is deactivated (use of a P or PI type controller).

20

Page 21

5.8.1. Optimization instructions for the PID control parameters

The heat-up curve reveals inappropriate control settings.

°C

optimum setting

t

Inappropriate settings may produce the following heatup curves:

°C

Xp too low

LC4

°C

°C

°C

t

Tv/Tn too low

t

Xp or Tv too high

t

Tv/Tn or Xp too high

t

21

Page 22

Operating procedures

5.9. Setting the safety temperature (with shutdown function)

!

+

(excess temperature protection)

Press the key to indicate the safety temperature value on

the MULTI-DISPLAY and using a screwdriver

simultaneously turn the setting screw to the desired

value (example: 50 °C).

Setting range: 0 °C to 360 °C

in 2 °C steps

This safety installation is independent of the control circuit.

As soon as this safety installation is triggered, a complete

The excess temperature protection should be set at least 25 °C below the fire

point of the bath liquid used!

In the event of wrong setting there is a fire hazard!

We disclaim all liability for damage caused by wrong settings!

shutdown of the connected heating device is effected.

The alarm is indicated by optical and audible signals

(continuous tone)

and

on the MULTI-DISPLAY (LED) appears the error message

"Error 01".

Recommendation:

Set the safety temperature at 5 to 10 °C above the working

temperature setpoint.

22

Page 23

6. Menu functions

LC4

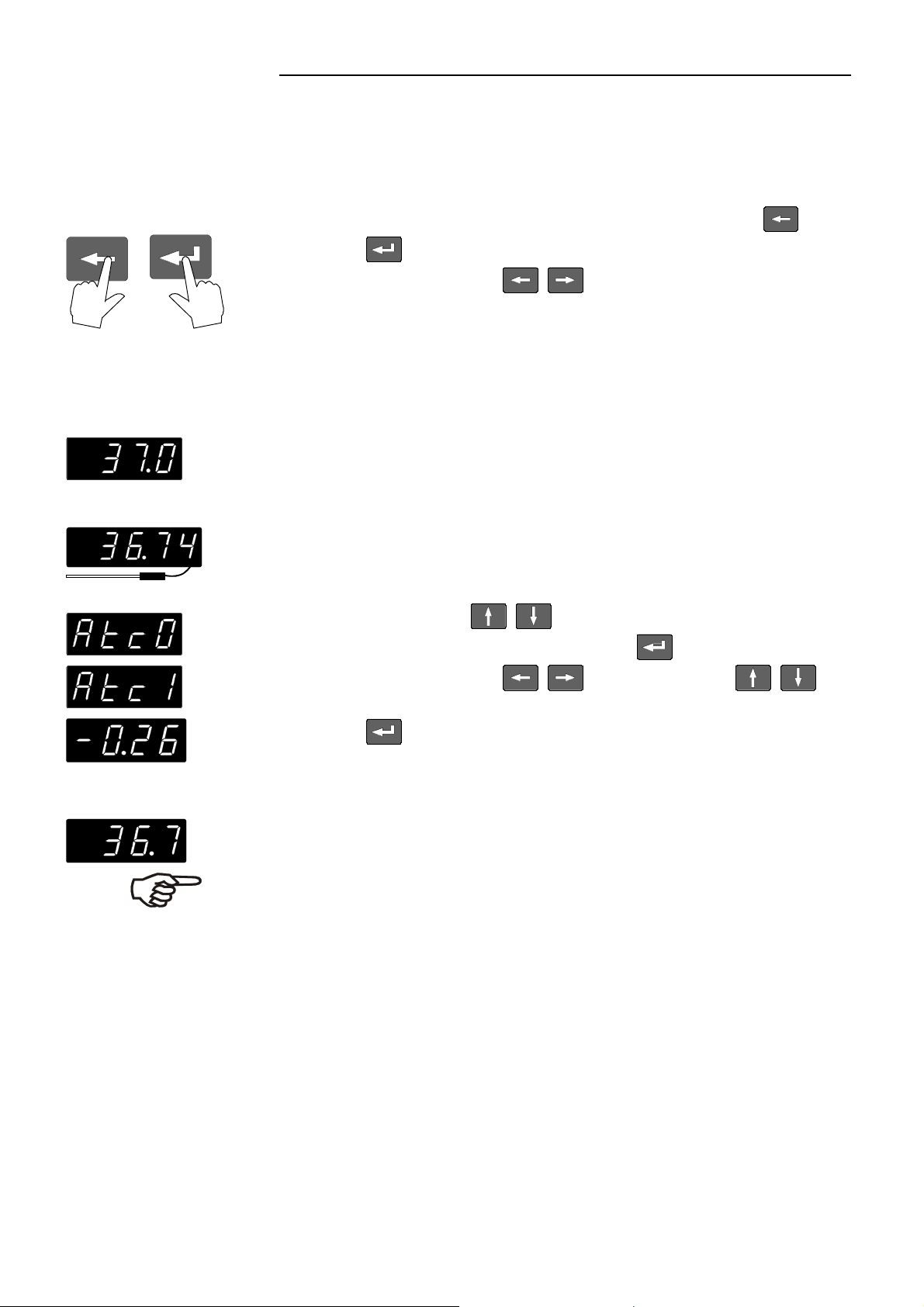

6.1. Sensor calibration - ATC function

Controller (TT)

Calibration bath (TM)

Parameters and values are set via the menu level that may be

selected at any time.

Enter or exit the menu level by pressing the left arrow and

enter at the same time.

Using the cursor keys select the menu functions one

by one.

The ATC (Absolute Temperature Calibration) function serves to

calibrate the working sensor.

Place the working sensor "A" and the temperature sensor of a

thermometer in the calibration bath.

Determine the difference temperature (∆T=TM - TT)

and store as correcting factor (example ∆T = -0.26 °C) as

follows:

With the edit keys

"Atc 0" to "Atc 1" and then press enter .

Using the cursor keys and the edit keys

set the correcting factor (example -0.26 °C) and then press

enter .

After exiting the menu level, the corrected value (example: 36.7

°C) is indicated on the MULTI-DISPLAY (LED).

Recommendation:

In case a calibrated temperature measuring instrument is used, the

ATC function allows the controller to be used as testing instrument

according to ISO 9000.

change the menu function from

23

Page 24

Menu functions

6.2. Temperature range: HL / LL

The laboratory controller LC4 features the possibility to limit the

working temperature range to protect thermally sensitive

substances.

Setting the upper limit

With the edit keys change the menu function from

6.3. Parameter sets for control: PA

“HL 0” to "HL 1" and then press enter .

Using the cursor keys and the edit keys set

the upper limit (example: 250.0 °C) and then press enter .

HL (High Limit) factory-setting: 350.0 °C

Setting the lower limit

With the edit keys

0” to "LL 1" and then press enter .

Using the cursor keys and the edit keys set

the lower limit (example: -40.0 °C) and then press enter .

LL (Low Limit) factory-setting: -50.0 °C

The LC4 provides 5 different parameter sets for controlled

processes.

Selecting a parameter set for control:

Press the edit keys to select the desired parameter

set (1 to 5) and then press enter .

(example: parameter set 3).

change the menu function from “LL

24

Page 25

Set 1: Xp = 4 °C

Set 2 Xp = 10 °C

Set 3 Xp = 20 °C

Set 4 Xp = 35 °C

Set 5 Xp = 15 °C

Tn = 150 s

Tv = 10 s

Tn = 300 s

Tv = 25 s

Tn = 1800 s

Tv = 165 s

Tn = 1800 s

Tv = 130 s

Tn = 1550 s

Tv = 120 s

LC4

For each parameter set, the control parameters Xp, Tn and Tv

may be individually modified and stored (see page 19).

Preference:

Quick access to parameters determined during previous

applications.

Factory-preset parameter sets for the following

controlled processes:

Directly heated liquid bath

Filling volume: 4.5 litres of water

Setpoint temperature: 70 °C

Heater capacity: 2000 W

Directly heated liquid bath

Filling volume: 4 litres of Thermal H

Setpoint temperature: 150 °C

Heater capacity: 2000 W

Heating hood model JH2000 with 2000 ml round bottom

flask

Filling volume: 2 litres of water

Setpoint temperature: 70 °C

Heater capacity: 480 W (stage III)

Heating hood JM500 with 500 ml round bottom flask

Filling volume: 0.5 litres of water

Setpoint temperature: 70 °C

Heater capacity: 150 W (stage II)

Heating hood JM500 with 500 ml round bottom flask

Filling volume: 0.5 litres of Thermal H

Setpoint temperature: 100 °C

Heater capacity: 150 W (stage II)

25

Page 26

Menu functions

6.4. Active countercooling: Pc

6.5. Controlling the heater capacity: h

For applications near the ambient temperature, countercooling

might become necessary.

For this purpose, connect the JULABO MVS solenoid valve

controller to the / alarm socket (application example see page

16). The supply of a cooling pulse "Pc" must be activated on the

controller.

Activating the supply of a cooling pulse:

With the edit keys change the menu function from

“Pc 0” to "Pc 1" and then press enter .

Factory setting: "Pc 0" (no countercooling).

Whenever countercooling is not necessary, reset the “Pc”

parameter to 0.

This control allows the maximum effective heater capacity of the

connected heating device to be adjusted in 10 % steps between 10

% and 100 %. The gradient of the temperature rise function may

thus be controlled to permit gentle warming of thermally sensitive

substances and to prevent over-shooting.

Controlling the heater capacity:

Using the edit keys

capacity and then press enter .

(example: 70 %).

Factory setting: 100 %

set the desired maximum heater

26

Page 27

6.6. Interface parameters: r - br - P - H

LC4

RS232C

Whenever the parameter setting of the controller is not conform to

those of the connected personal computer, a modification is

necessary.

Factory setting of the RS232 interface:

Baudrate: 4800 Bauds

Parity: 2 (even)

Handshake: 1 (Hardware handshake)

Data bits: 7

Stop bits: 1

Press the cursor key until the desired parameter appears on

the MULTI-DISPLAY (LED).

Use the edit keys to set the desired parameter and

then press enter .

Adjustable interface parameters

REMOTE 0 = keypad control mode

1 = remote control mode via RS232C

BAUDRATE 12 = 1200 bauds

24 = 2400 bauds

48 = 4800 bauds

96 = 9600 bauds

PARITY 0 = no parity

1 = odd

2 = even

HANDSHAKE

0 = Protocol Xon/Xoff (software handshake)

1 = Protocol RTS/CTS (hardware handshake)

Like all parametes which can be entered through the keypad,

interface parameters are stored in memory even after the controller

is turned off.

27

Page 28

Troubleshooting guide / Error messages

7. Troubleshooting guide / Error messages

!

+

Cause Remedy

A sudden temperature increase,

Whenever the microprocessor electronics registers a failure, a

complete shutdown of the heating device connected to the controller

is performed. The alarm light " " illuminates and a continuous

signal tone sounds.

Press enter to turn off the signal tone.

The safety temperature value lies

below the working temperature

setpoint.

e.g. caused by the immersion of

preheated samples.

After eliminating the malfunction, press the mains power switch off

and on again to cancel the alarm state.

The wires of the working temperature sensor are interrupted or

short-circuited.

Set the safety temperature to

a higher value.

Set the safety temperature to

a higher value.

Warning:

Before exchanging the fuses, turn off the mains power switch and disconnect

the power plug from the mains socket!

Use only fine fuses with the specified nominal value.

other errors

After eliminating the malfunction, press the mains power switch off

and on again to cancel the alarm state.

If the error reappears, contact an authorized JULABO service station.

If necessary have the unit checked by a JULABO service technician.

Mains fuses

The mains fuses on the rear of the unit may easily be

exchanged as shown on the left.

(Fine fuse T 10.0 A, dia. 5 x 20 mm)

28

Page 29

S

g

8. Electrical connections

Grounded mains socket

Connector for heating device

Maximum 1000 W resistive load at 115 V.

Maximum current 5 A.

Maximum 2000 W resistive load at 230 V.

Maximum current 10 A.

Notice:

LC4

2

3

Pt100

1

4

hield Plug

Use shielded cables only.

The shield of the connecting cable is electrically connected to the plug

housing.

Connectors for temperature sensors

Pin assignment:

Pin 1 Current +

Pin 2 Voltage +

Pin 3 Voltage -

2

3

Look on

solderin

1

4

side.

Pin 4 Current -

/ ALARM - connector

The "

messages.

ALARM" connector may be used as output for alarm

Circuit: Operation = relay powered

Alarm = relay not powered

Pin assignment:

Pin 1: +24 V (max. current 25 mA)

Pin 2: 0 V

Pin 3: 0 V / alarm relay

Pin 4: Reserved - do not use!

Pin 5: Cooling pulse

29

Page 30

Electrical connections

9

5

1

6

RS232C

Accessories: Order No. Description

RS232C serial interface

This port can be used to connect a computer with an RS232C

cable for remote control of the controller.

RS232 serial interface

This port can be used to connect a computer with an RS232 cable

for remote control of the circulator.

Pin assignments RS232:

Pin 2 RxD Receive Data

Pin 3 TxD Transmit Data

Pin 5 0 V Signal GND

Pin 7 RTS Request to send

Pin 8 CTS Clear to send

Pin 1; 4; 6, 9 Reserved - do not use!

RS232 interface cable

Circulator (9-pol) PC (9-pol)

Pin 2 RxD Pin 3 TxD

Pin 3 TxD Pin 2 RxD

Pin 5 GND Pin 5 GND

Pin 7 RTS Pin 8 CTS

Pin 8 CTS Pin 7 RTS

8 980 073 RS232 interface cable 9-pol./9-pol. , 2,5 m

8 900 110 USB interface adapter cable

30

Page 31

9. Remote control

9.1. Communication with a PC or a superordinated data system

Suitable terminal programs for communicating with a PC are:

MS-Windows - TERMINAL.EXE (included with MS-Windows).

If the controller is put into remote control mode via the configuration

level, the display will read "r OFF" = REMOTE STOP. The controller is

now operated via the computer.

In general, the computer (master) sends commands to the controller

(slave). The controller sends data (including error messages) only

when the computer asks for it.

A transfer sequence consists of:

Command

space (; Hex: 20)

LC4

parameter (the character separating decimals in a

group is the period) End of file (; Hex: 0D)

The commands are divided into in and out commands.

in commands: asking for parameters to be displayed

out commands: setting parameters

The out commands are valid only in remote control mode.

Examples:

Command to set the working temperature to 55.5 °C:

out_sp_00 55.5

Command to ask for the working temperature:

in_sp_00

Response from the controller:

55.5

31

Page 32

Remote control

9.2. List of commands

Befehl Parameter Description

version none Number of software version (V X.xx)

status none Status message, error message (see page 34)

out_mode_05 0 Stop the controller = r OFF

out_mode_05 1 Start the controller

out_mode_02 1 Parameter set 1 effective for control

out_mode_02 2 Parameter set 2 effective for control

out_mode_02 3 Parameter set 3 effective for control

out_mode_02 4 Parameter set 4 effective for control

out_mode_02 5 Parameter set 5 effective for control

in_mode_02 none Ask for effective parameter set

out_sp_00 xxx.x Set working temperature

in_sp_00 none Ask for working temperature

in_pv_00 none Ask for effective value registered by working sensor

in_pv_01 none Ask for effective heater capacity

out_par_00 xxx.x Set Xp of parameter set 1

in_par_00 none Ask for Xp of parameter set 1

out_par_01 xxx.x Set Tn of parameter set 1

in_par_01 none Ask for Tn of parameter set 1

out_par_02 xxxx.x Set Tv of parameter set 1

in_par_02 none Ask for Tv of parameter set 1

out_par_03 xxx.x Set Xp of parameter set 2

in_par_03 none Ask for Xp of parameter set 2

32

Page 33

Command Parameter Description

out_par_04 xxx.x Set Tn of parameter set 2

in_par_04 none Ask for Tn of parameter set 2

out_par_05 xxxx.x Set Tv of parameter set 2

in_par_05 none Ask for Tv of parameter set 2

out_par_06 xxx.x Set Xp of parameter set 3

in_par_06 none Ask for Xp of parameter set 3

out_par_07 xxx.x Set Tn of parameter set 3

in_par_07 none Ask for Tn of parameter set 3

out_par_08 xxxx.x Set Tv of parameter set 3

LC4

in_par_08 none Ask for Tv of parameter set 3

out_par_09 xxx.x Set Xp of parameter set 4

in_par_09 none Ask for Xp of parameter set 4

out_par_10 xxx.x Set Tn of parameter set 4

in_par_10 none Ask for Tn of parameter set 4

out_par_11 xxxx.x Set Tv of parameter set 4

in_par_11 none Ask for Tv of parameter set 4

out_par_12 xxx.x Set Xp of parameter set 5

in_par_12 none Ask for Xp of parameter set 5

out_par_13 xxxx.x Set Tn of parameter set 5

in_par_13 none Ask for Tn of parameter set 5

out_par_14 xxxx.x Set Tv of parameter set 5

in_par_14 none Ask for Tv of parameter set 5

33

Page 34

Remote control

9.3. Status messages

Message Description

00 MANUAL STOP Controller in "OFF" state

01 MANUAL START Controller in keypad control mode

02 REMOTE STOP Controller in "r OFF" state

03 REMOTE START Controller in remote control mode

9.4. Error messages

Message

-01 SAFETY-TEMP ALARM

-05 TEMPERATURE MEASUREMENT

ALARM

-07 I2C-BUS WRITE ERROR

-07 I2C-BUS READ ERROR

-07 I2C-BUS READ/WRITE ERROR

-08 INVALID COMMAND

-10 VALUE TOO SMALL

-11 VALUE TOO LARGE

-12 VALUE NOT VALID

-13 COMMAND NOT ALLOWED IN

CURRENT OPERATING MODE

Description

Safety temperature alarm

Error in measuring system.

Internal errors

Invalid command

Entered value too small

Entered value too large

Value not valid

Invalid command in current operating mode

34

Page 35

10. Cleaning / repairing the unit

Caution:

Improper maintenance or repair can result in electric shock or damage to the

unit.

Repairs and any other work are to be carried out only by qualified service

Always turn off the unit and disconnect the mains cable from the power

Prevent humidity from entering into the water bath.

Cleaning:

personnel authorized by JULABO.

source before performing any service or maintenance procedures, or

before moving the unit.

The controller is designed for continuous operation under normal

conditions. Periodic maintenance is not required.

Clean the outside of the unit using a wet cloth and low surface

tension water.

LC4

Repairs:

Returning a unit:

Before asking for a service technician or returning a JULABO

instrument for repair, please contact an authorized JULABO service

station.

When returning the unit:

Clean the unit and, if necessary, decontaminate the unit in order

to avoid endangering service personnel.

Attach a short fault description.

During transport the unit has to stand upright. Mark the packing

correspondingly.

When returning a unit, take care of careful and adequate

packing.

JULABO is not responsible for damages that might occur from

insufficient packing.

JULABO reserves the right to carry out technical modifications with

repairs for providing improved performance of a unit.

35

Loading...

Loading...