Page 1

40033638

No.E368-00

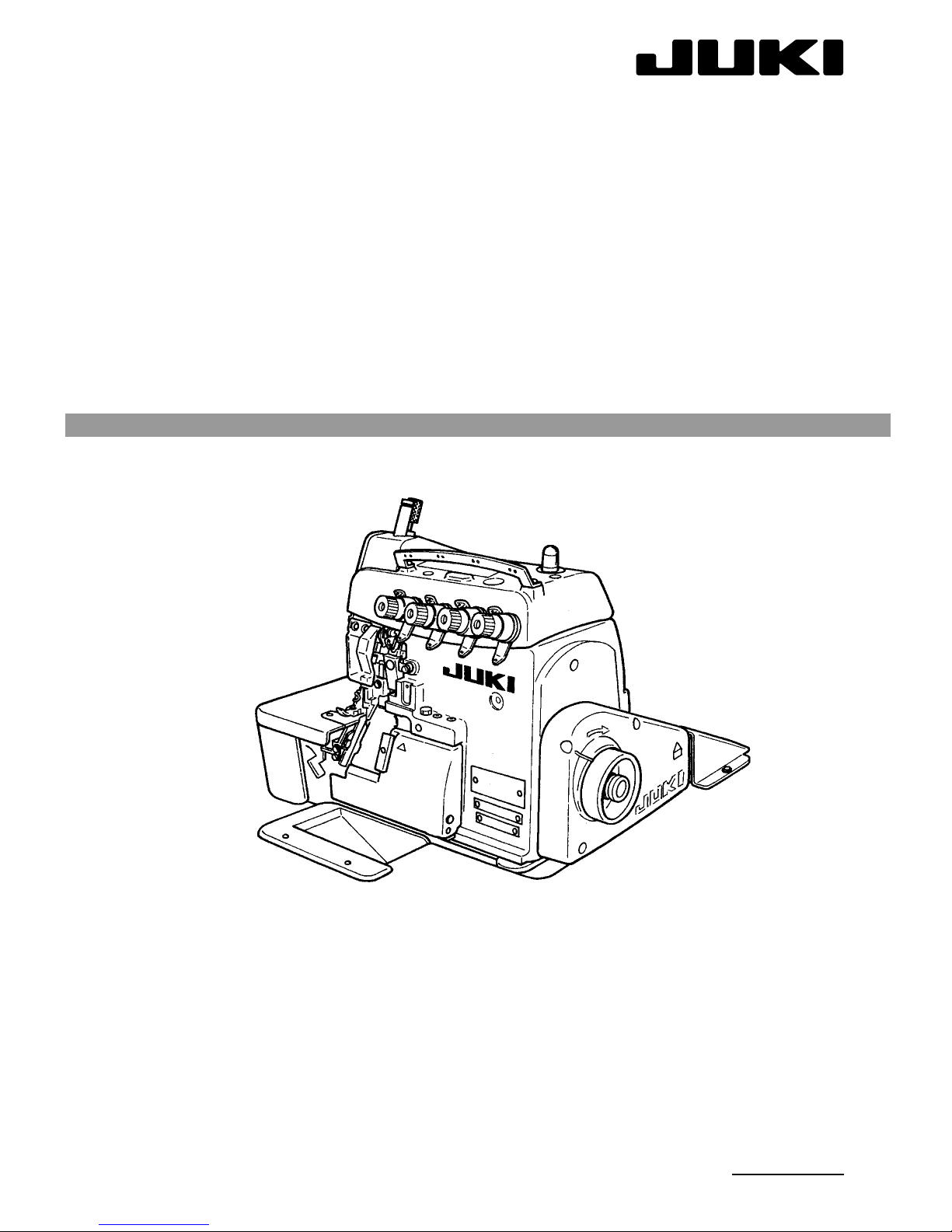

ENGINEER’S MANUAL

HIGH SPEED SEMI-DRY HEAD OVERLOCK/INTERLOCK/

SEWING MACHINE

MO-6700D Series

®

Page 2

PREFACE

This Engineer’s Manual is written for the technical personnel who are responsible for the service and maintenance

of the machine.

The Instruction Manual for these machines intended for the maintenance personnel and operators at an apparel

factory contains operating instructions in detail. And this manual describes “Standard Adjustment”, “Adjustment

Procedures”, “Results of Improper Adjustment”, and other important information which are not covered by the

Instruction Manual.

It is advisable to use the relevant Instruction Manual and Parts List together with this Engineer’s Manual when

carrying out the maintenance of these machines.

In addition, for the motor for the sewing machine with thread trimmer, refer to the separate Instruction Manual or

Engineer’s Manual for the motor. And for the control panel, refer to the Instruction Manual for the control panel.

This manual gives the “Standard Adjustment” on the former page under which the most basic adjustment value is

described, and on the latter page “Results of Improper Adjustment” under which stitching errors and troubles

arising from mechanical failures are described together with the “Adjustment Procedures”.

Page 3

CONTENTS

1. SPECIFICATIONS.......................................................................................... 1

(1) MO-6700D SERIES ......................................................................................................1

2. MODEL NUMBERING SYSTEM.................................................................... 2

3. ST ANDARD ADJUSTMENT .......................................................................... 4

(1) Adjusting the needle height.......................................................................................4

(2) Positioning the throat plate .......................................................................................4

(3) Installing position of the needle clamp ....................................................................6

(4) Adjusting the length of the lower looper holder

(Applicable only to MO-6716D series) ......................................................................6

(5) Adjusting the lower looper ........................................................................................8

1) Returning amount of the lower looper ..................................................................................................8

2) Clearance between the lower looper and the needle...........................................................................8

(6) Position of the upper looper guide .........................................................................10

(7) Positioning the upper looper holder.......................................................................12

(8) Positioning the upper looper...................................................................................14

1) Height of the upper looper..................................................................................................................14

2) Longitudinal position of the upper looper ...........................................................................................14

(9) Adjusting the double chain looper (Applicable only to MO-6716D series) .........16

1) Returning amount of the double chain looper ....................................................................................16

2) Longitudinal motion (Avoid motion)....................................................................................................16

3) Clearance between the double chain looper and the needle .............................................................16

(10) Adjusting the height and clearance of the needle guard......................................18

1) For 1-needle or 2-needle overlock machine.......................................................................................18

2) For safely stitch machine ...................................................................................................................18

(11) Adjusting the height of the feed dog ......................................................................20

(12) Adjusting the tilt of the feed dog.............................................................................20

(13) Adjusting the differential feed ratio ........................................................................22

(14) Longitudinal position of the feed dog ....................................................................22

(15) Adjusting the presser foot.......................................................................................24

1) Adjusting the tilt of the presser foo....................................................................................................24

2) Adjusting the micro-lifting mechanism of the presser foot.................................................................24

(16) Positioning the upper knife arm shaft ....................................................................26

(17) Positioning the upper and lower knives, and available overedge widths...........26

1) Lower knife.........................................................................................................................................26

2) Upper knife.........................................................................................................................................26

3) Overdging width .................................................................................................................................26

(18) Resharpening of the knife........................................................................................28

(19) Position of the thread cam (Applicable only to MO-6716D series) ......................28

1) Adjustment of the thread cam ............................................................................................................28

2) Adjusting looper thread cam thread guides A and B and the looper thread cam nail.........................28

3) Adjusting looper thread auxiliary thread take-up lever (Exclusive for 30P)........................................30

(20) Adjusting the throat plate support..........................................................................32

(21) Adjusting the feed mechanism cover presser.......................................................32

(22) Adjusting the looper cover ......................................................................................34

(23) Adjusting the cloth chip cover ................................................................................34

(24) Position of the thread guides and the looper thread take-ups.............................36

Page 4

(25) Adjusting soft chain making mechanism...............................................................38

1) Replacing the parts with those exclusively designed for making soft chains .....................................38

2) Adjustment value................................................................................................................................38

3) Important points in adjustment ...........................................................................................................39

4. ADDITIONAL INFORMATION AND PRECAUTIONS.................................. 40

(1) Thread tension............................................................................................................40

1) Strength of tension spring ..................................................................................................................40

2) Springs used for each model .............................................................................................................40

(2) Upper looper .............................................................................................................40

(3) Center-to-center distance of the upper looper holder ..........................................41

(4) Caution in assembly.................................................................................................41

1) Application of sealant .........................................................................................................................41

2) Precautions to be taken with respect to the lubricating components .................................................43

3) Applying the exclusive grease............................................................................................................44

(5) Kinds of motor pulleys, belts and frame support plate bolts...............................46

1) Motor pulleys and belts ......................................................................................................................46

2) Pat No. of frame support plate bolt ....................................................................................................46

5. ADJUSTMENT VALUES OF THE NEEDLE HEIGHT

AND LOOPER TIMING ................................................................................ 47

(1) MO-6700D SERIES ....................................................................................................47

6. TROUBLES AND CORRECTIVE MEASURES ........................................... 48

7. DIMENSIONS OF TABLE ............................................................................ 60

(1) Semi-sunken type .....................................................................................................60

(2) Semi-sunken type (synchronizer is used)..............................................................61

(3) Fully-sunken type .....................................................................................................62

Page 5

– 1 –

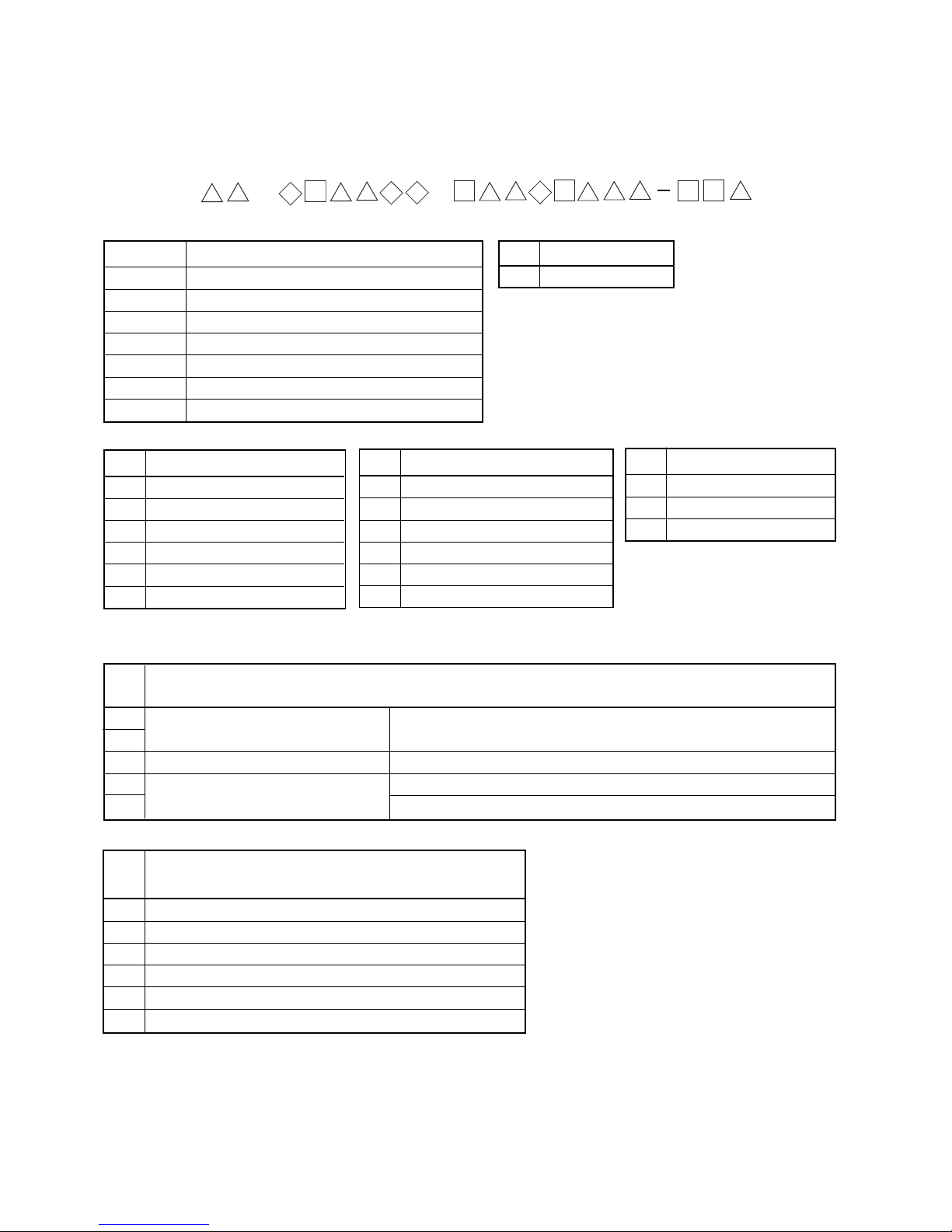

1. SPECIFICATIONS

(1) MO-6700D SERIES

No. Item Specifications

1 Model MO-6704D MO-6714D MO-6716D

2 Description 1-needle Overlock 2-needle Overlock 2-needle Safety stitch

machine machine machine

3 Stitch type F. S. T. JIS E13 JIS E24 JIS E13+D12

(USA standard : 504) (USA standard : 514) (USA standard : 516)

4 Sewing speed 6000rpm

5 Stitch length 0.8 to 4mm 1.5 to 4mm

6Needle gauge 2.0, 3.2mm 3.2, 4.8mm

7Overedging width 1.6, 3.2, 4, 4.8mm 2.0, 3.2, 4mm 3.2, 4, 4.8, 6.4mm

8 Differential feed ratio Gathering 1 : 2 (Max.1 : 4), Stretching 1 : 0.7 (Max.1 : 0.6)

9 Needle bar stroke 24.5 mm (30P for light to medium-weight materials),

25.5 mm (40H for medium to heavy-weight materials)

10 Needle tilt angle 20°

11

Needle bar mechanism

Upper and lower needle bar bushing type

12 Needle ORGAN DC X 27 (Standard) (DC X 1 can be used as well.)

13 Presser lifting amount 7.0mm 6.5mm 7.0mm

14 Presser foot pressure 49N (5kg)

15

Stitch adjusting method

By pushbutton

16 Upper knife Flat knife

17

Differential feed adjustment

By lever with micro adjustment mechanism

18 Weight 28kg

19 Lubrication Automatic geared lubrication system and grease charge

20 Lubricating oil JUKI MACHINE OIL 18 (Equivalent to ISO VG 18) Product No.: MML018900CA

21 Grease Exclusive grease (Part No. 23640204)

22 Needle cooler Optional

23 Needle thread cooler Optional

24

Micro presser lifting device

Provided as standard

25 Motor 2P 400W

*1. Grease should be supplied to the needle bar system and upper looper system.

Page 6

– 2 –

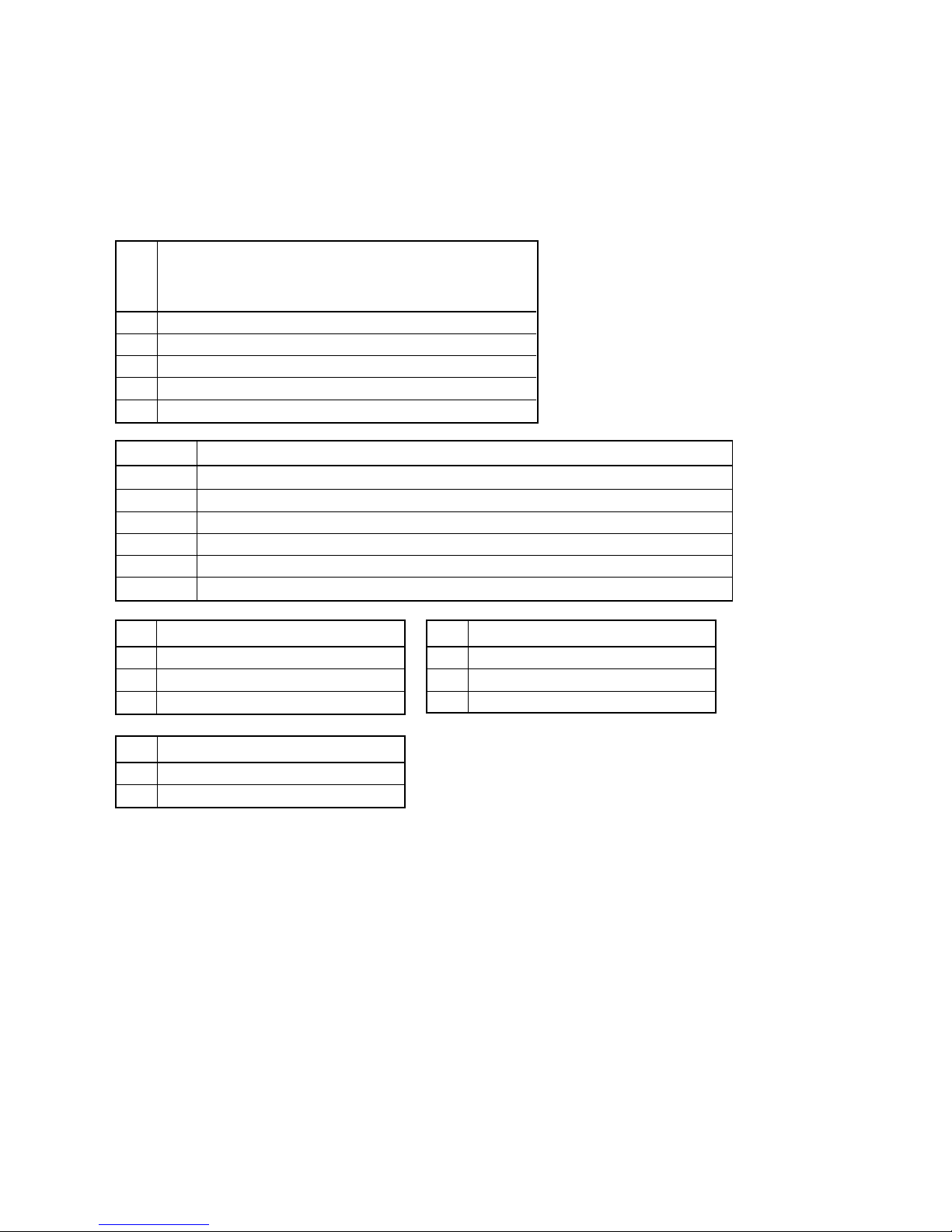

2. MODEL NUMBERING SYSTEM

MO-6700D SERIES MODEL NUMBERING SYSTEM

1 2345678910111213 14 15 16 17 18 19 20 21 22 23 24 25 26

MO67 D /

3 to 6 Model classification

6704 1-needle 3-thread overlock

6705 Blind-hemming

6712 2-needle, 4-thread imitation safety stitch

6714 2-needle 4-thread overlock

6716 2-needle 5-thread safety stitch

6743 3-needle 6-thread safety stitch

6745 2-needle double chain stitch

7Type classification

D Semi-dry head

8 Needle gauge classification

0 1-needle

B 2.0mm

D 3.2mm

F 4.8mm

1 4.8+2.0mm

2 3.2+2.0mm

9 Overedging width classification

A 1.6mm

B 2.0mm

D 3.2mm

E 4.0mm

F 4.8mm

H 6.4mm

10 Feed dog classification

42-row

51-row

63-row

11 Material classification

(classification applied to handling material and cloth)

1 Extra light- to right-weight material Light weight material such as dress shirt

2

3Light- to medium-weight materials General fabrics

4 Meduim- to heavy-weight materials Exclusive for knit such as sweater

5Medium weight material such as denim to heavy weight material

12 Application classification

(classification of application based on work and process)

0 Standard

1 For blind hemming

2 For ruffling

4 For tape attaching

5 For rolled hemming

6 For tape feeding

*

*

The asterisk (*) indicates 3-needle type.

Page 7

– 3 –

13 Special machine classification

(special classification of machine,

structure and specs. other than gauge set)

0 Standard

7 Upper looper high throw

F Swim suits

H Upper looper extra high lift

P Puckering prevention

15 to 22 Device and attachment classfication

G39/Q141 Presser for tape attaching (for sharp curve)/tape guide

L121 Blind stitch hemming attachment

S159 Swing-type gathering device (interlocked with pedal, for safety stitch machine)

S162 Swing-type gathering device (manual lever operated, for overlock machine)

N077 Clean finish top and bottom

E35 Overedging lug replace type throat plate

24 Place of destination

A Standard

DU.S.A and Japan

G China (in China)

25 Accessories type

A Standard

B Eouropa and U.S.A

G China (in China)

26 Table type

0 Fully sunken type

1 Semi sunken type

Page 8

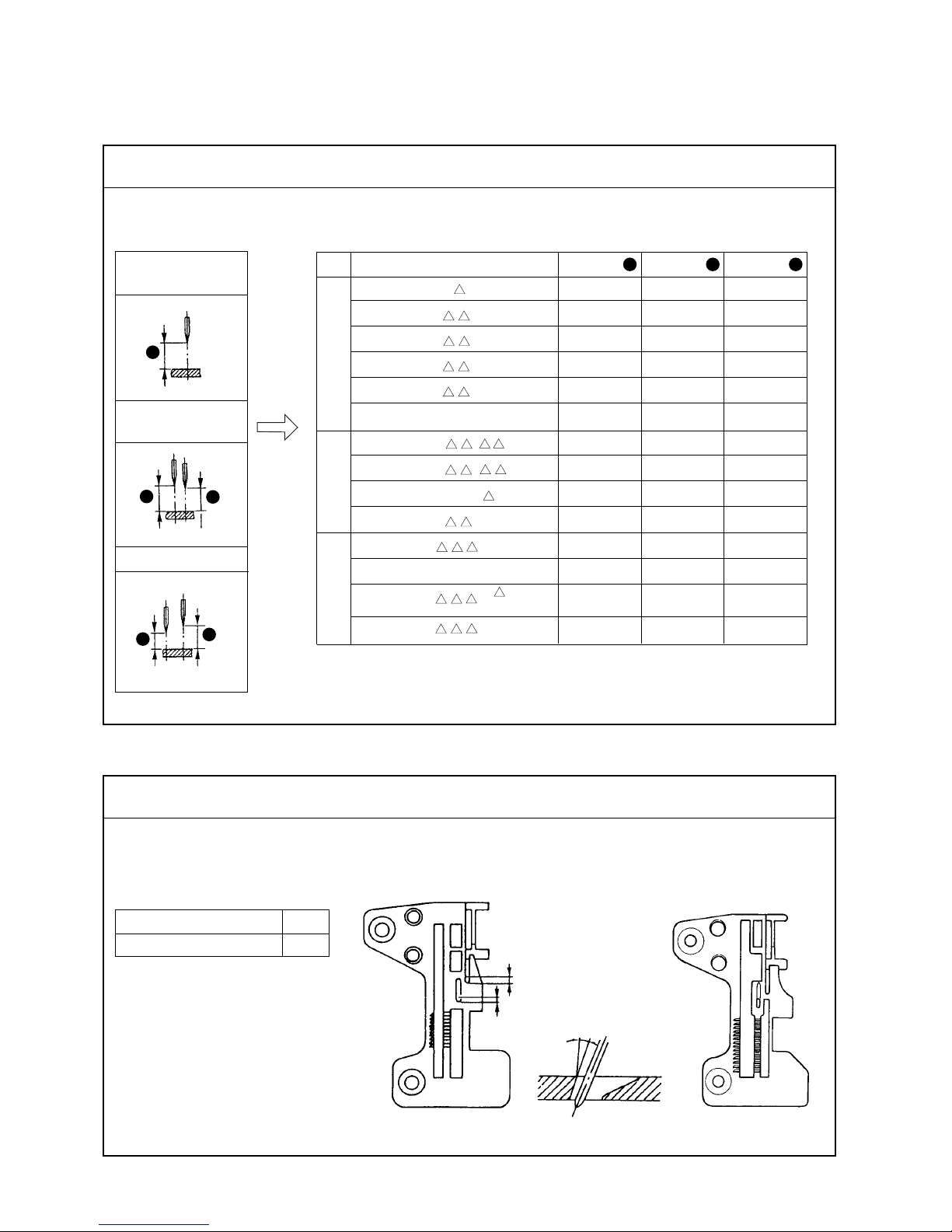

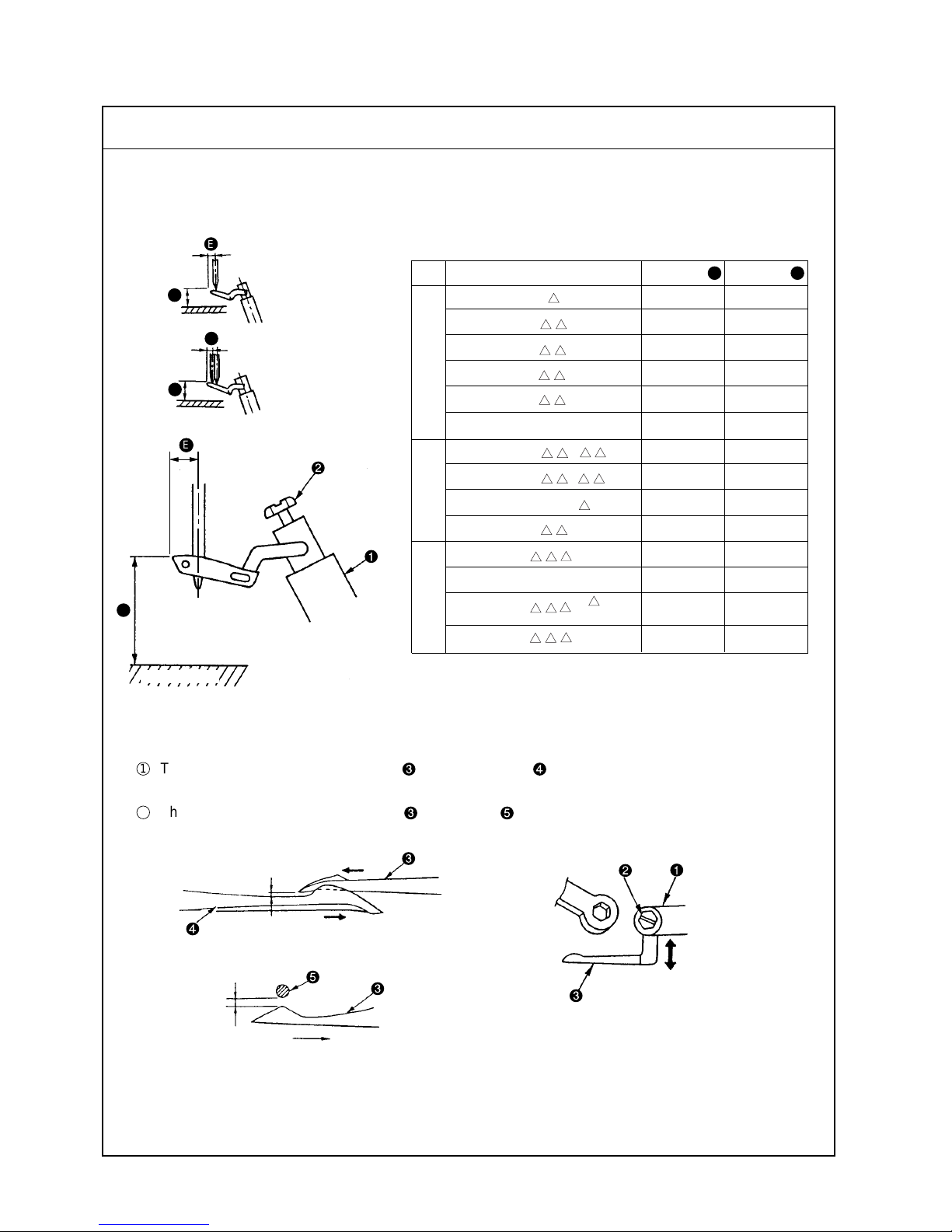

– 4 –

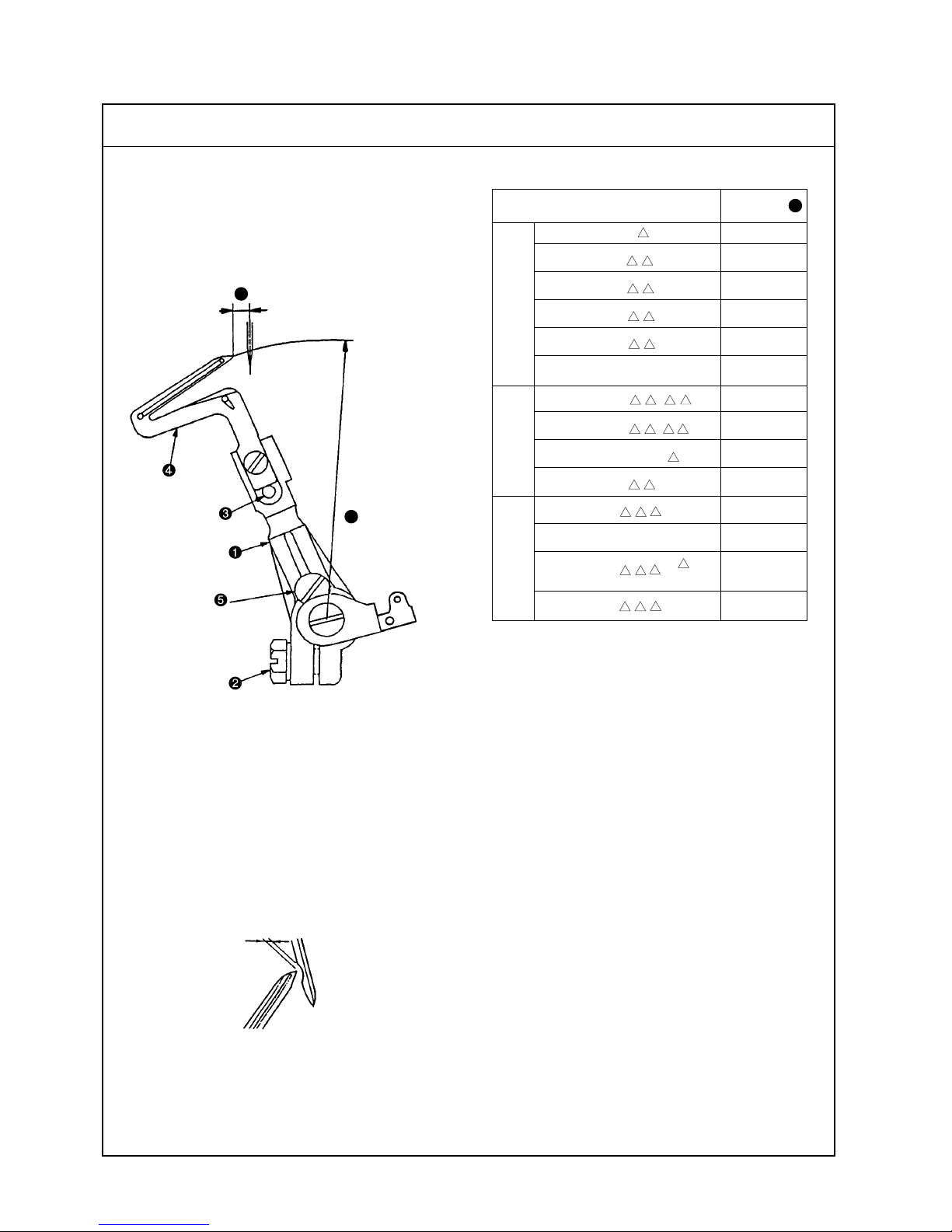

Model

DimensionADimensionBDimension

C

MO-6704D-0A -150 10.5 — —

MO-6705D-0 -210 10.5 — —

MO-6704D-0 -300 10.5 — —

MO-6704D-0 -307 10.5 — —

MO-6704D-0 -40H 11.3 — —

MO-6704D-0F6-50H 11.3 — —

MO-6714D-B - 7 10.5 9.1 —

MO-6714D-B - H 11.3 9.9 —

MO-6712D-DF6-50 11.0 9.4 —

MO-6714D-B -30P 10.5 9.1 —

MO-6716D- -300 10.5 — 9.8

MO-6716D-FF6-307 10.5 — 9.8

MO-6716D- - 11.3 — 10.6

MO-6716D- -30P 10.5 — 9.8

A

B

10

°

6704D

6705D

6712D

6714D

6716D

When the needle(s) is in the highest position, the needle height from the throat plate surface should be as

shown below.

3. STANDARD ADJUSTMENT

(1) Adjusting the needle height

The needle entry point should be such that the distances listed below are provided between the needle slot

edge of the throat plate and the center of needle.

(2) Positioning the throat plate

(Unit : mm)

The adjustment of needle height for the 2-needle overlock machine should be

made in reference to the left needle.

(Unit : mm)

Overlock side A 1.3

Double-chainstitch side B 1.0

For 30P

(Safety stitch machine)

4 H

50H

A

A

B

C

A

Standard Adjustment

Standard Adjustment

1-needle overlock

machine

2-needle overlock

machine

Safety stitch

machine

Page 9

– 5 –

Needle driving shaft

1) Take off the upper cover, loosen setscrew of needle driving forked

crank and move needle driving forked crank up or down to adjust

the needle height.

(Caution) Do not fully loosen the setscrew of the needle driving

forked crank .

If the needle driving forked crank has got out of position

laterally when its setscrew was loosened, fully loosen the

setscrew and turn pulley to allow the forked crank to turn

until it settles by itself. Then tighten the setscrew to fix

the forked crank at that position.

o Any other needle height than

specified here will badly affect the

action of the lower looper, the

timing for catching the upper

looper thread, etc.

o Improper lateral position of the

needle driving forked crank will

cause seizure, play, or other

troubles.

o Improperly positioned throat plate

with cause needle breakage,

contact of the needles will the

throat plate, or other troubles.

1) Loosen setscrews of throat plate base and move throat plate

base back and forth to adjust dimension A or B.

Adjustment Procedure Results of Improper Adjustment

Adjustment Procedure Results of Improper Adjustment

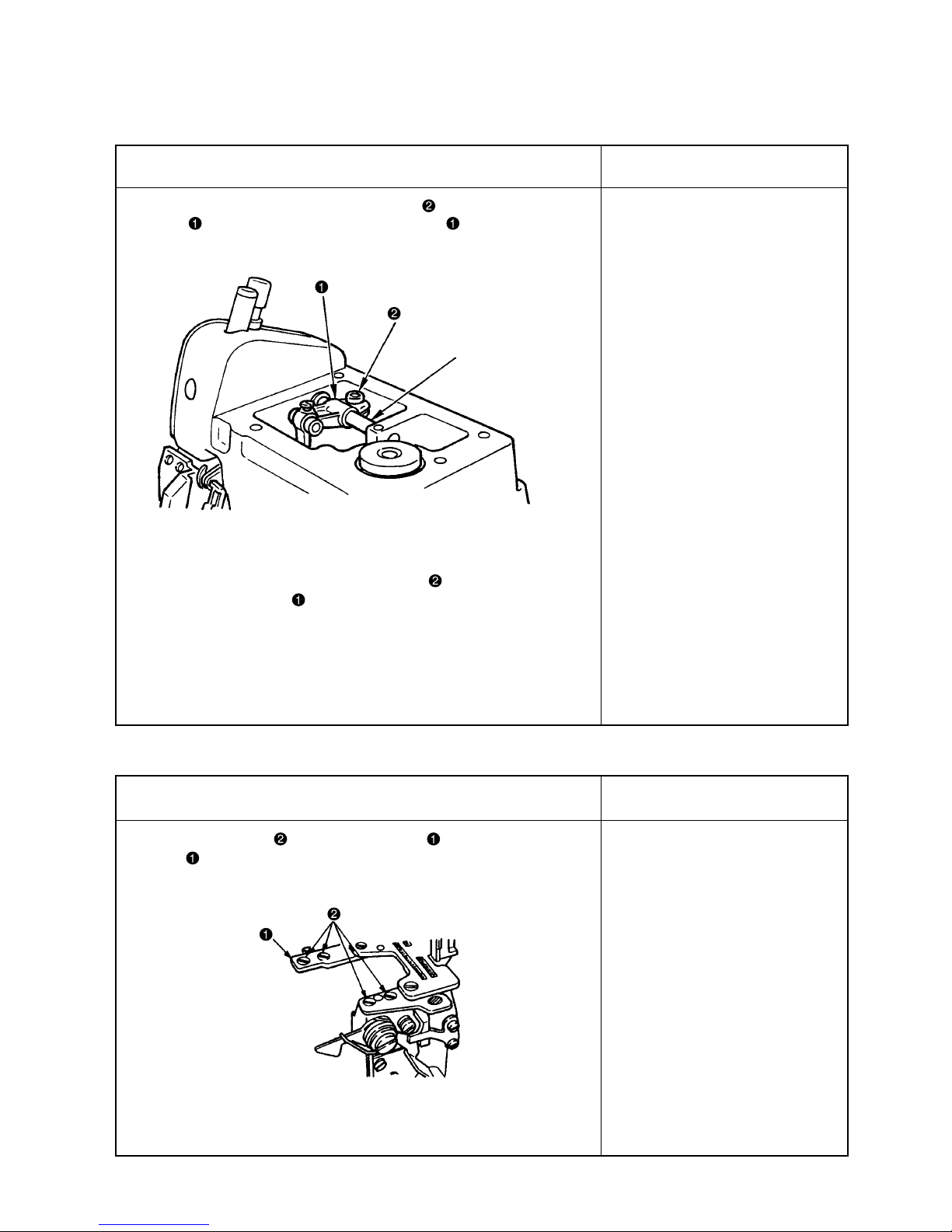

Page 10

– 6 –

(3) Installing position of the needle clamp

Needle clamp connecting stud should fit with the bottom end of needle bar or be spaced within 0 to 0.5

mm.

(4) Adjusting the length of the lower looper holder (Applicable only to MO-6716D series)

The center-to-center distance should be 26 mm.

At this time, the clearance between the end surface of the arm and the neck of the ball should be 3.5mm.

26mm

3.5mm

Butt the needle clamp with the

bottom end of the needle bar.

0 to 0.5mm

Standard Adjustment

Standard Adjustment

Page 11

– 7 –

1) Loosen setscrew and adjust, by slightly turning needle clamp ,

the clearance provided between the right-hand side needle and the

lower looper (for 2-needle overlock machine) and the clearance

provided between the needle hole in the throat plate and the needle

(for safety stitch machine).

o If the clearance provided

between the needle and the

looper is excessive, the needle

thread will be likely to skip at the

time of tucking.

o If the clearance provided

between the needle and the

looper is insufficient, the needle

will break or the looper blade

point will be damaged causing

thread breakage.

1) Loosen setscrew of the lower looper holder from the rear of the

frame.

Since it is difficult to accurately measure the center-to-center distance,

perform adjustment to provide a 3.5 mm distance between the end

surface of the arm and the neck of the ball as illustrated.

o Increasing the center-to-center

distance will give a smaller stroke

of the double chain looper or

lower looper, and decreasing the

distance will give larger stroke.

Adjustment Procedure Results of Improper Adjustment

Adjustment Procedure Results of Improper Adjustment

Page 12

– 8 –

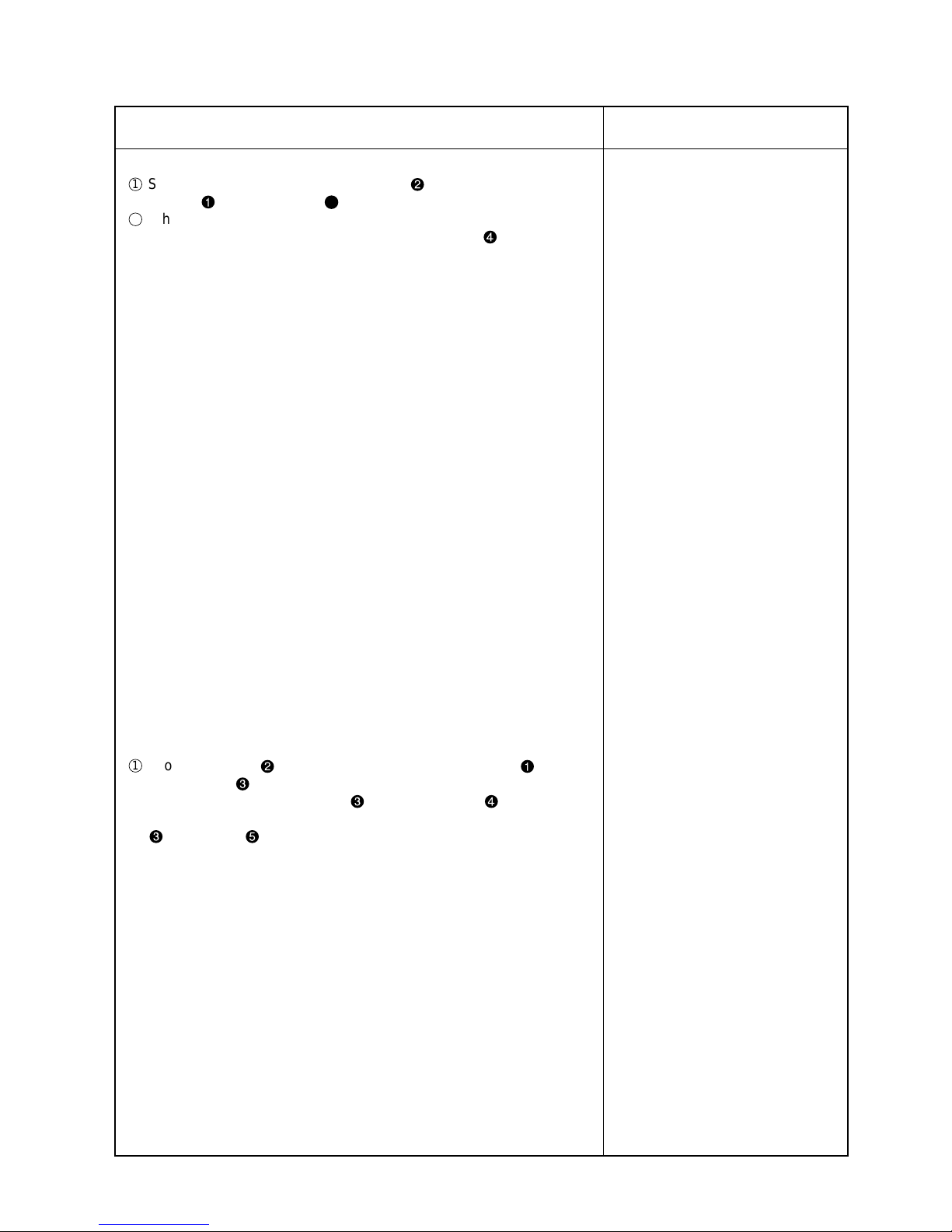

1) Returning amount of the lower looper

The distance between the blade point of the lower

looper and the center of the needle should be as

follows when the lower looper is at the extreme

left of its stroke.

(5) Adjusting the lower looper

Model

MO-6704D-0A -150 4.0

MO-6705D-0 -210 4.0

MO-6704D-0 -300 3.8

MO-6704D-0 -307 3.8

MO-6704D-0 -40H 3.8

MO-6704D-0F6-50H 3.8

MO-6714D-B - 7 3.8

MO-6714D-B - H 4.0

MO-6712D-DF6-50 2.2

MO-6714D-B -30P 3.8

MO-6716D- -300 3.8

MO-6716D-FF6-307 3.8

MO-6716D- - 3.8

MO-6716D- -30P 3.8

(Unit : mm)

0.01 to 0.1 mm

Dimension

J

J

K

(66.9±0.2mm)

Standard Adjustment

1-needle overlock

machine

2-needle overlock

machine

Safety stitch

machine

2) Clearance between the lower looper and the needle

The clearance should be 0.01 to 0.1 mm.

4 H

50H

Page 13

– 9 –

o Excessive return of the lower

looper tends to cause stitch

skipping when filament thread is

used.

o Insufficient return of the lower

lopper tends to cause needle

thread stitch skipping when spun

thread is used.

o Excessive clearance will often

cause needle thread stitch

skipping.

o Insufficient clearance will cause

needle breakage due to the contact of the looper with the needle,

or produce scratches on the

blade point of the looper, leading to needle thread breakage or

other troubles.

1) Returning amount of the lower looper

1

Loosen setscrew of lower looper support arm and adjust lower

looper to make adjustment of the returning amount.

(Referential information)

1. Radius K of lower looper will be 66.9 mm when the lower

looper is inserted into lower looper support arm until it contacts with stopper pin and then is fixed.

2. The rocking angle of the lower looper will be 26°.

2) Clearance between the lower looper and the needle

1

Loosen setscrew of lower looper support arm to the extent that

it is temporarily tightened. Then finely adjust the longitudinal position

of the looper using fine adjustment screw .

2

Turn fine adjustment screw clockwise to move lower looper away

from the needle.

Turn the screw counterclockwise to move lower looper closer to it.

Adjustment Procedure Results of Improper Adjustment

Page 14

– 10 –

MO- 6704D - 0E to 0F - 4 H

MO- 6714D - BB6 to BE6- 30P

BD4 to BE4

BD6 to BE6

MO- 6716D - - 30P

D

F

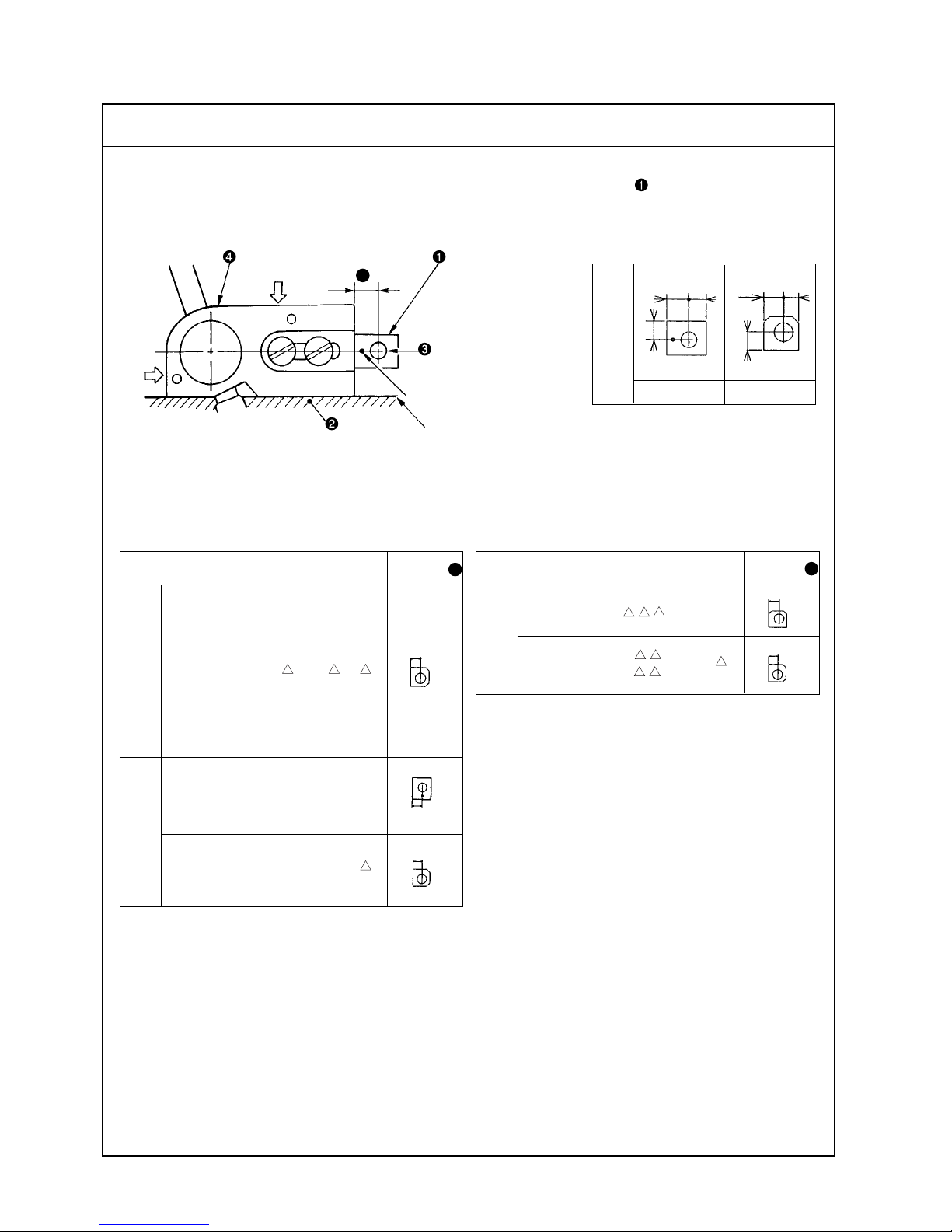

(6) Position of the upper looper guide

Vertical position : To be in close contact with the frame guide surface.

Laternal position : To be pressed against the upper looper guide support gauge .

13131909 13132006

Model

Dimension

G

MO- 6714D - - 4 H

(Unit : mm)

(Unit : mm)

Model

Dimension

G

(Unit : mm)

7 5.5

6

6.3 4.7

5.8

5.8

6.3

5.8

5.8

6

G

Marker dot

Frame guide surface

MO- 6716D - - 4 H

Standard Adjustment

Upper looper guide

support gauge

1-needle overlock

machine

2-needle overlock

machine

Safety stitch

machine

Page 15

– 11 –

1) Fit upper looper guide support gauge over gauge fixing pin which

has been driven in frame and secure the gauge with an O ring.

Then position the gauge taking the marker dot engraved on it or the

chamfering direction as reference.

2) When installing upper looper guide support , press it against the

gauge while keeping the upper looper guide support into close contact with the frame guide surface, then tighten the screws.

(Caution) Refer to “4- (4) -1) – 7 Various sealantsî for the various

sealants.

o If the upper looper guide has

improperly positioned vertically,

it will cause oil leakage or

disturbed path of the upper

looper with resultant stitch

skipping.

o If the upper looper guide has

been inaccurately positioned laterally , it will cause stitch skipping,

or contact with the looper.

Adjustment Procedure Results of Improper Adjustment

Page 16

– 12 –

(7) Positioning the upper looper holder

Model

MO- 6704D - 0E to 0F - 4 H 48.2

MO- 6714D - BB6 to BE6 - 30P 47.3

BD4to BE4

BD6 to BE6

MO- 6716D - - 30P 46.2

D

F

MO- 6714D - - 4 H 48.4

Dimension

F

The distance between the bottom surface of the frame and the upper end of the upper looper holder pin

should be as shown below when the upper looper holder is at the highest point of its stroke.

(Unit : mm)

Bottom surface of frame

53mm

F

0.2mm

0.2mm

MO- 6716D - - 4 H 48.2

Standard Adjustment

1-needle overlock

machine

2-needle overlock

machine

Safety stitch

machine

Page 17

– 13 –

1) Loosen the setscrew of upper looper ball arm and setscrew of

the upper looper holder.

2) Adjust the clearances between upper looper bracket and upper

looper holder to approximately 0.2 mm respectively, and tighten

setscrew of the upper looper holder.

(Make sure that the upper looper holder smoothly moves together

with upper looper shaft .)

3) Then determine dimension F from the bottom surface of the frame to

the top surface of upper looper holder pin before tightening the

setscrew of upper looper ball arm .

(Caution) Replace upper looper holder according to the needle

gauge size.

o Inaccurately positioned upper

looper holder will cause

excessive projection of the upper

looper, resulting in stitch

skipping, or contact.

(Caution) To adjust the upper

looper ball arm, take

dimension

FF

FF

F

as stan-

dard.

Remember that the

projecting amount

and the height of the

upper looper should

eventually be properly adjusted. So,

confirm the dimensions related to the

upper looper.

Adjustment Procedure Results of Improper Adjustment

Page 18

– 14 –

(8) Positioning the upper looper

1) Height of the upper looper

The distance between the throat plate surface and the blade point of the looper should be as follows when

the upper looper is at the extreme left of its travel.

2) Longitudinal position of the upper looper

1

The clearance between upper looper

and lower looper should be 0.05 to 0.2 mm when they cross

with each other.

2

The clearance between upper looper and needle should be 0.01 to 0.2 mm.

D

0.05 to 0.2 mm

0.01 to 0.2 mm

Model

DimensionDDimension

E

MO-6704D-0A -150 11.0 4.0

MO-6705D-0 -210 11.0 4.0

MO-6704D-0 -300 11.0 4.0

MO-6704D-0 -307 10.3 4.4

MO-6704D-0 -40H 11.3 4.4

MO-6704D-0F6-50H 11.3 4.4

MO-6714D-B - 7 10.3 4.4

MO-6714D-B - H 10.5 4.8

MO-6712D-DF6-50 11.0 3.6

MO-6714D-B -30P 10.3 4.4

MO-6716D- -300 11.0 4.0

MO-6716D-FF6-307 10.3 4.4

MO-6716D- - 11.3 4.4

MO-6716D- -30P 11.0 4.0

(Unit : mm)

EE

EE

E

E

D

E

D

Standard Adjustment

Throat plate

1-needle overlock

machine

2-needle overlock

machine

Safety stitch

machine

4 H

50H

Page 19

– 15 –

1) Height of the upper looper

1

Set a hexagon wrench key onto setscrew at the end of upper looper

bracket to adjust height D.

2

When adjusting the height, pay attention also to the clearance produced between the upper looper and lower looper at the time of

their crossing.

2) Longitudinal position of the upper looper

1

Loosen setscrew at the top end of upper looper bracket to move

upper looper back or forth for positioning the clearance of 0.05 to

0.2 mm between upper looper and lower looper at the time of

their crossing or the clearance of 0.01 to 0.2 mm between upper looper

and needle .

o If the upper looper has been

positioned too high, an excessive

clearance will be produced

between the upper looper and

the needle. As the result, the

upper looper thread will fail to

catch the needle thread, and

stitch skipping occurs.

o On the contrary, if the upper

looper has been positioned too

low, the needle point will hit the

looper, causing needle breakage. Also the looper will touch

other component when the

presser foot goes up.

o Excessive clearance will cause

stitch skipping.

o Insufficient clearance will cause

the upper looper to come in contact with the lower looper.

Adjustment Procedure Results of Improper Adjustment

Page 20

– 16 –

1.5 to 1.7 mm

(63.4 mm)

M

1) Returning amount of the double chain looper

The distance between the needle center and the blade point of the double chain looper should be 1.5 to 1.7

mm when the looper is at the extreme left of its travel.

2) Longitudinal motion (Avoid motion)

The standard minor axis of the elliptical motion should be :

3.0 mm.

Note : The avoid motion should be adjusted in accordance with Needle No.

3) Clearance between the double chain looper and the needle

The clearance should be 0.05 to 0.1 mm.

(9) Adjusting the double chain looper (Applicable only to MO-6716D series)

3.0 to 3.6 mm

0.05 to 0.1 mm

Standard Adjustment

Marker

Hole

Marker

A

B

Page 21

– 17 –

1) Returning amount of the double chain looper

1

Loosen setscrew of double chain lopper driving arm to make

this adjustment.

2

Radius Mof the double chain looper driving arm will be 63.4 mm

when it is lowered until it comes in contact with stopper pin .

2) Longitudinal motion (Avoid motion)

1

Open the cover of the adjusting hole on the rear of the frame, loosen

setscrew , and put a Ø2 rod in the hole. Now, make the adjustment

by turning the rod back and forth.

Marker : This side

..... Minimum (for standard to thin needle)

A

Marker : Far side

..... Maximum (for thick needles)

B

3) Clearance between the double chain looper and the needle

1

Temporarily tighten setscrew in the double chain looper, and finely

adjust the longitudinal position of the double chain looper. Adjust the

clearance to 0.05 to 0.1 mm.

o Excessive return of the double

chain looper will cause frequent

stitch skipping when filament

thread is used.

o Insufficient return of the double

chain looper will cause frequent

thread stitch skipping when a

spun thread is used.

o If the avoid motion is too large,

triangle stitch skipping will often

occur.

o Insufficient avoid motion will

cause the needle point to hit the

looper, producing scratches on

the needle point or looper.

o Excessive clearance will cause

frequent needle thread stitch

skipping.

o Insufficient clearance will cause

to looper to hit the needle, leading to needle breakage or

scratches on the looper blade

point with consequent thread

breakage.

As observed

from this side

Adjustment Procedure Results of Improper Adjustment

Bad needle

entry

Good needle

entry

Page 22

– 18 –

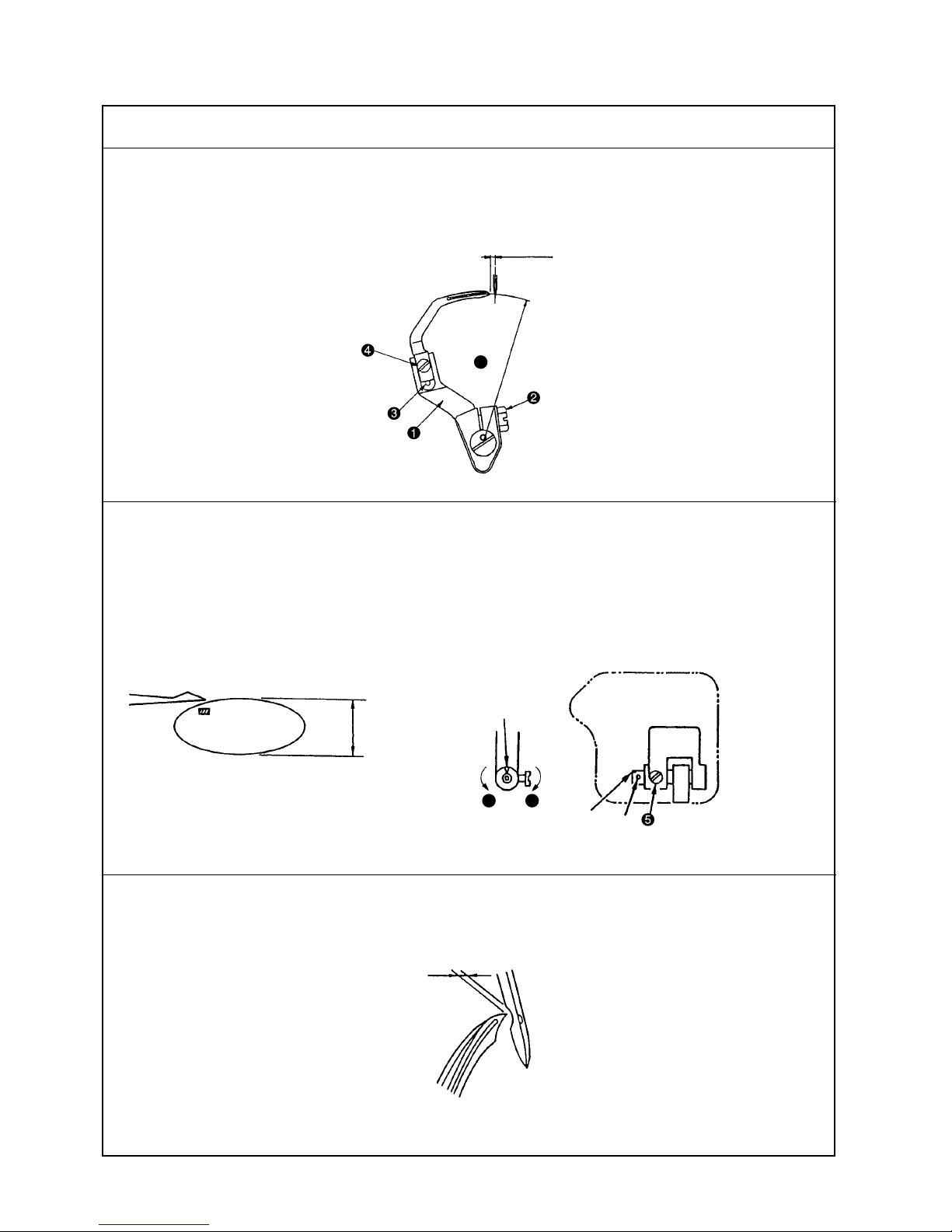

(10) Adjusting the height and clearance of the needle guard

1) For 1-needle or 2-needle overlock machine

The overlock machine has two needle guards, A and B.

The needle guard B should be located 1 mm below the throat plate bottom surface.

2) For safely stitch machine

The safely stitch machine has four needle guards, A, B, C and D. The needle guards A and B are

positioned in the same manner as those for the overlock machine.

The needle guard C should be positioned 5 mm below the throat plate bottom surface.

Needle guard

A

Needle guard

B

Throat plate

1 mm

0.1 mm

B

Throat plate

5 mm

B

0.1 m

m

D

C

(Traveling needle guard)

A

Standard Adjustment

Light

touch

the

needle

guard

Lightly touches

Page 23

– 19 –

1) For 1-needle or 2-needle overlock machine

1

Adjust needle guard A with setscrews in the needle guard so that

it lightly comes in contact with the needle when the blade point of the

lower looper reaches the needle center.

2

To adjust the clearance provided between needle guard B and the

needle when the needle bar is at the lowest point of its stroke, loosen

setscrews in the needle guard support and turn needle guard B to

adjust the clearance to 0.1 mm.

3

Adjust the height of needle guard B to 1 mm from the throat plate

bottom surface with setscrew in the needle guard.

2) For safety stitch machine

1

Loosen setscrews in the needle guard, and adjust the clearance

provided between needle guard C and the needle so that it lightly

comes in contact with the needle.

2

Adjust the installing height of needle guard C to 5 mm with setscrew

in the needle guard.

3

Adjust the clearance provided between needle guard D and the needle

to 0.1 mm with setscrews .

(Caution) Check again the clearance provided between needle guard

B

and the needle after adjusting the height of needle

guard C.

o Excessively close contact

between the needle guard

A

and the needles will lead to

needle bend or stitch skipping.

oA clearance left between the needle

guard A and the needles will cause

the looper blade point to come in

contact with the needles, leading to

needle or blade point breakage, or

other troubles.

o If the needle guard B is too high,

thread loops will be damaged

with resultant stitch skipping.

Also, double chain loops will be

affected, causing double chain

stitch skipping.

o If the needle guard B is too low,

the needle cooling felt will be lowered, resulting in deteriorated effect

of the cooling and needle guard.

oExcessive clearance between

the needle guard Band the

needle will cause stitch skipping

due to needle shake. On the contrary, insufficient clearance will

cause the needle guards to catch

the needles between them, leading to wear on the needle guards

and scratches on the needles.

o If the needle guard C is too high,

the needle thread loops will be

damaged, and stitch skipping

occurs. If it is too low, the needle

points will be crushed.

o If the clearance between the

needle guard C and the needles

is too large, the double chain

looper blade point will come in

contact with the needles, causing

the breakage of the needles,

causing the breakage of the

needles or looper blade point.

No clearance left between them

will cause them to come in excessively close contact with each other,

and bend of needle, wear on the

needle guard and scratches on the

needles will occur.

o Excessive clearance left be-

tween the needle guard D and

the needles will cause stitch skipping due to needle shake, and

insufficient clearance will cause

the needle guards to catch the

needles between them, leading

to wear on the needle guards

and scratches on the needles.

Adjustment Procedure Results of Improper Adjustment

Page 24

– 20 –

(11) Adjusting the height of the feed dog

The height of main feed dog from the top surface of the throat plate should be as follows when it is at its

highest position.

[Standard]

Auxiliary feed dog is 0.5 mm lower than main feed dog .

B = 0.5 mm

[30P]

Auxiliary feed dog is as high as main feed dog .

B = 0 mm

Model Dimension A

MO-6700D series (30P excluded) 1.0

MO-67 D- -30P 0.8

(12) Adjusting the tilt of the feed dog

Tilt of the feed dogs when

the feed dogs have come

up most.

Model Dimension A Dimension B

MO-6700D series (30P excluded) 1.0 (1.2)

MO-67 D- -30P 0.8 (0.9)

(Unit : mm)

When the feed dog juts

out the top surface of

the throat plate

Top surface of

the throat plate

Feed dog is leveled.

B

Needle

entry

A

B

Front up

(Unit : mm)

In case of 30P type

15

°

Standard Adjustment

Standard Adjustment

A

Needle

entry

Page 25

– 21 –

o If the feed dogs are too high, the

needles will be deflected and

broken when sewing heavyweight

materials. The feed dogs will tend

to suffer scratches when sewing

light-weight materials. Puckering

will frequently occur.

o If the feed dogs are too low, in-

sufficient feed power will result.

o If the auxiliary feed dog is too

high, chain-off thread will be often jammed.

o If the main feed dog and differ-

ential feed dog are set at different heights, proper differential

feeding action will be hindered.

1) Adjust the height of main feed dog to dimension A with setscrew

.

2) Adjust the height of differential feed dog with setscrew so that

there is no difference in level between main feed dog and differential feed dog .

3) Adjust the height of auxiliary feed dog with setscrew so that it is

0.5 mm lower than main feed dog .

o When tilted with the front up

Good material catching will be

obtained.

oWhen tilted with the front down

Uneven feed and puckering will

be effectively prevented.

1) Use the tilt of the feed dog when it is in its highest position as a

reference and adjust so that the feed dog is flush with the throat plate

when the feed dog juts out the throat plate.

2) Feed bar shaft consists of an eccentric shaft. Loosen setscrew

to perform adjustment.

When the marker line is set at middle

.....The feed dog will be flat.

When the marker line is set at bottom

.....The feed dog will be tilted with its front up (in the arrowed direc-

tion).

When the marker line is set at top

.....The feed dog will be tilted with its front down.

(Caution) The marker line should be used just as the reference since

it slightly differs with that of each machine due to the

disparity of the components.

Confirm the accurate tilt of the feed dog by observing

the feed dog itself.

Adjustment Procedure Results of Improper Adjustment

Adjustment Procedure Results of Improper Adjustment

Page 26

– 22 –

(13) Adjusting the differential feed ratio

(Standard)

Gathering: 1: 2

Stretching: 1: 0.7

(Max, stretching)

Gathering: 1:1.6

Stretching: 1:0.6

(Max, gathering)

Gathering: 1: 4

Stretching: 1: 1.3

Pin at its highest

position

Washer

Pin at its lowest

position

(14) Longitudinal position of the feed dog

When the feed pitch is maximized and the differential feed ratio is also maximized, the clearances of the front

and rear ends of the feed dog, and the throat plate should be spaced approximately 0.5 mm respectively.

0.5mm

0.5mm

Standard Adjustment

Standard Adjustment

Center of

nut Lower

marker line

Page 27

– 23 –

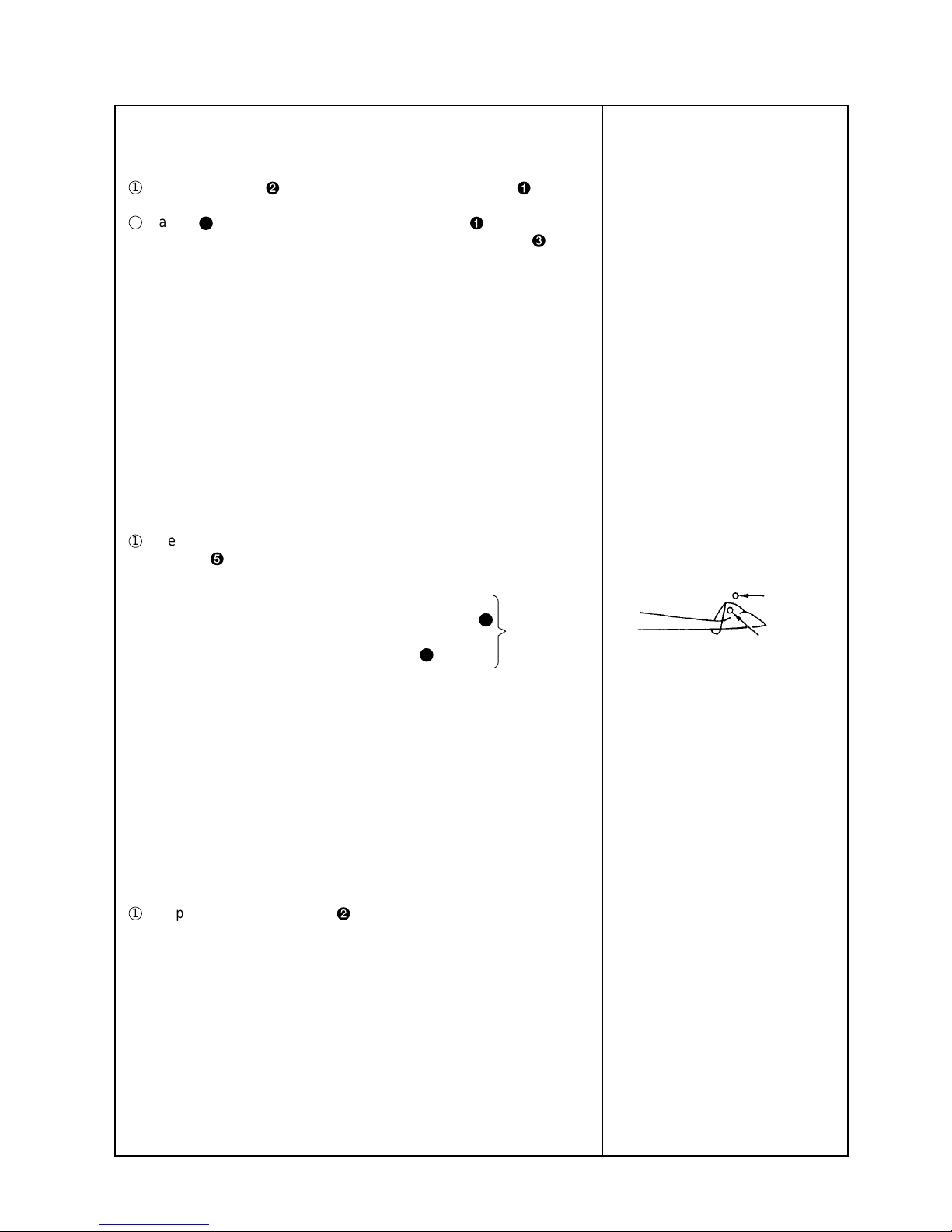

1) Remove cover on the rear of the frame and loosen main feed pin

and nut .

2) Move main feed pin up or down to adjust the differential feed ratio.

3) Adjust so that the lower engraved marker line on main feed rocker

aligns with the center of nut . (Standard)

4) When adjusting the maximum stretching, adjust main feed pin to

the highest position.

5) When adjusting the maximum gathering, adjust main feed pin to

the lowest position.

6) After performing adjustment, tighten the main feed pin and nut ,

and install cover .

o If the clearance provided

between the throat plate and the

feed dog is too small, they will

come in contact with each other

when the sewing machine runs

at high speed

1) Remove the cover on the rear of the frame, loosen main feed bracket

clamping screw and differential feed bracket clamping screw ,

and adjust the clearances provided between the front and rear ends

of the feed dogs and the slots in the throat plates to approximately

0.5 mm. Then tighten main feed bracket clamping screw and

differential feed bracket clamping screw .

Adjustment Procedure Results of Improper Adjustment

Adjustment Procedure Results of Improper Adjustment

Page 28

– 24 –

(15) Adjusting the presser foot

1) Adjusting the tilt of the presser foot

The presser foot should be positioned so that the feed dogs go down under the specified presser foot

pressure, and the presser foot sole comes in contact evenly with the throat plate surface.

2) Adjusting the micro-lifting mechanism of the presser foot

Throat plate

Standard Adjustment

Page 29

– 25 –

o Uneven contact will result in bad

straight material feed and weak

feed force. Puckering is apt to

occur as well.

1) Adjusting the tilt of the presser foot

1

Turn the handwheel and place the feed dog in the position where the

feed dog does not jut out the top surface of the throat plate.

2

Loosen setscrew and adjust so that the presser foot sole comes in

contact evenly with the throat plate top surface. Then tighten setscrew .

(Reference) Accurate adjustment can be made by using two pieces

of thin paper to check for even drawing-out tension.

In addition, even contact of the presser foot with the

throat plate top surface is achieved rather easily by

tightening the screw while pushing the right side of

the presser foot.

2) Adjusting the micro-lifting mechanism of the presser foot

1

When moving presser lifting lever just a little, perform it with fine

adjustment screw .

Adjustment Procedure Results of Improper Adjustment

Page 30

– 26 –

1) Lower knife

2) Upper knife

3) Overedging width

Overedging width can be adjusted from 1.6 to 6.4 mm.

(16) Positioning the upper knife arm shaft

(17) Positioning the upper and lower knives, and available overedge widths

The upper knife shaft should be positioned 34 mm above the top surface of the throat plate when it is at its

highest position.

34mm

Lower knife

Throat plate

Standard Adjustment

Standard Adjustment

Upper knife

0.5 to 1 mm

Page 31

– 27 –

oImproperly positioned upper

knife arm shaft will come in

contact with the frame.

If it is moved with the position of

the upper knife unchanged,

proper engagement of the knives

will be disturbed, prohibiting

sharp cutting of the knives.

1) Remove the upper cover, loosen setscrew in upper knife driving

arm , and turn upper knife shaft to adjust the position from the

top surface of the throat plate to 34 mm.

(Caution) Be sure to fully tighten the setscrew since upper knife

shaft is subjected to high load.

o The lower knife, if positioned too

high, will catch materials or

cause no contact of the presser

foot with the throat plate top surface.

o If the lower knife is positioned too

low, the cutting width will be

changed or materials will be

caught by the lower knife.

o The upper knife, if positioned too

high, will fail to cut materials.

o Failure of cutting or abnormal

wear on the knives will result

unless the lower knife is laterally

positioned and fixed at a position

where it has settled by itself under the upper knife spring.

1) Lower knife

1

Adjust the vertical position of the lower knife by screw so that the

blade top aligns with the top surface of the throat plate.

2

Tighten screw after bringing the upper knife to its lowest position

of its stroke.

2) Upper knife

1

Adjust the position of the upper knife by screw so that the engagement with the lower knife is 0.5 to 1 mm when the upper knife is in the

lowest position of its stroke.

(Caution) Adjust the lateral position of the lower knife by screw .

Adjust the lateral position of the upper knife by screw .

After performing adjustment, be sure to fix the knife. Otherwise, the durability of the knife will be affected.

3) Overedging width

1

Adjust the overedging width in the following way :

Laterally position the upper knife before loosening screw .

Tighten screw when the upper knife has settled by itself under the

pressure applied by the spring. Repeat this adjustment procedure to

obtain desired overedging width.

Adjustment Procedure Results of Improper Adjustment

Adjustment Procedure Results of Improper Adjustment

Page 32

– 28 –

(18) Resharpening of the knife

(19) Position of the thread cam (Applicable only to MO-6716D series)

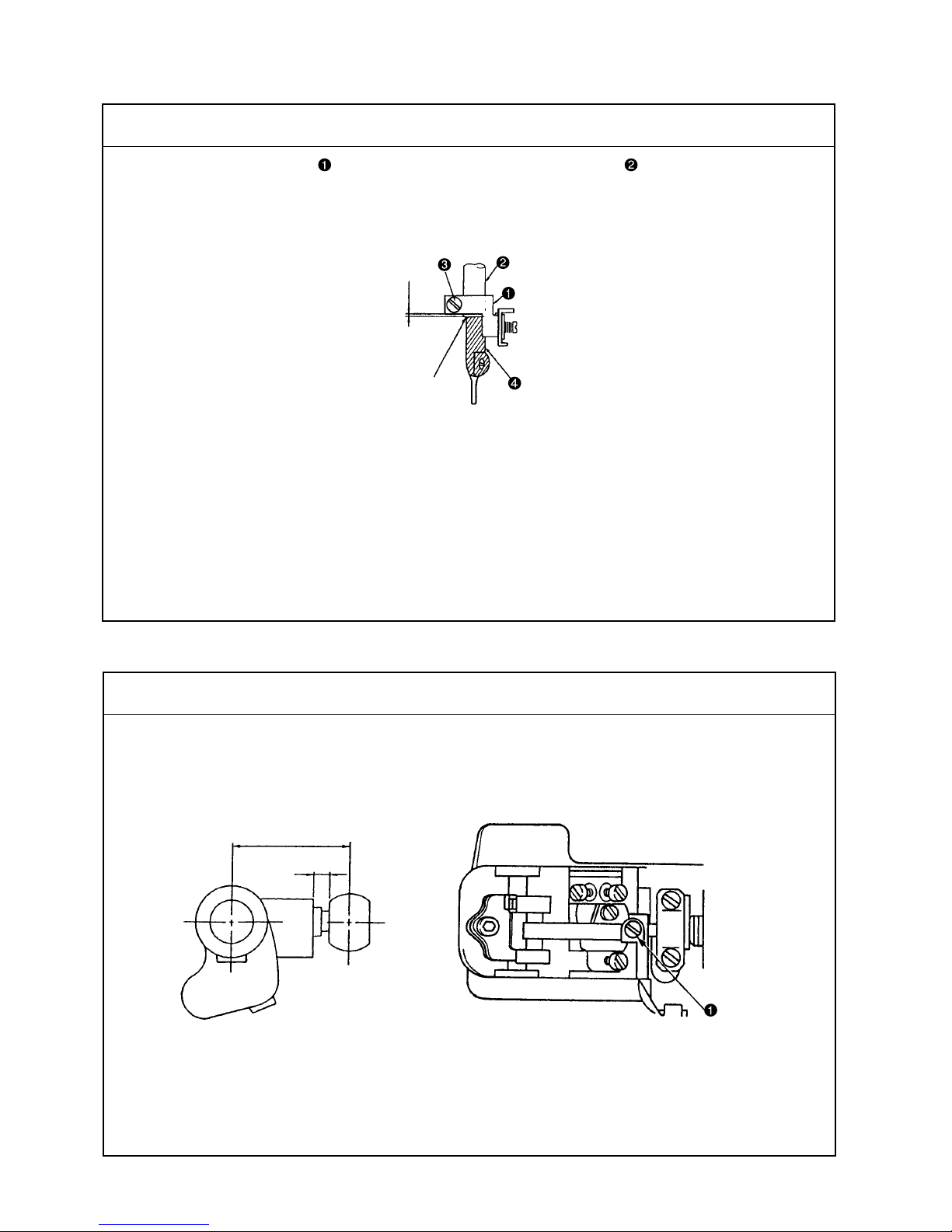

1) Adjustment of the thread cam

2) Adjusting looper thread cam thread guides A and B and the looper thread cam nail

10°

55°

Standard Adjustment

Standard Adjustment

Level

Level

Page 33

– 29 –

1) Adjusting the thread cam

1

Adjust the position of the thread cam by its setscrew with the

needles at their upper dead point so that the straight section of the

thread cam is leveled.

2

Laterally position the thread cam so that the looper thread cam nail is

located at the center of the thread cam groove.

[How to check for proper positioning]

Check that the thread cam releases the looper thread when the needle

tip begins to come out of the bottom surface of the throat plate by 0 to 1

mm.

2) Adjusting the looper thread cam thread guides A and B and the

looper thread cam nail

1

Install looper thread cam thread guides A and B at the center of

the slots with setscrews A and B .

2

Install looper thread cam nail with setscrew so that the straight

section of the forked portion is leveled.

o If the 10∞ angle of the lower knife

is exceeded, the durability of the

knife will be deteriorated, often

resulting in blade chipping.

o If the angle is smaller than 10°,

the knife will be dull.

o If the 55° angle is not observed,

the knife may catch materials.

1) When the knives have become dull, fully resharpen lower knife

until the contact mark of it disappears.

2) When the upper knife has become dull, replace it with a new one.

(This is because the upper knife is a serrated carbide knife.)

o If the timing of the thread cam is

too early, the needle point will fail

to enter a thread triangle,

resulting in looper thread stitch

skipping.

o If the timing of the thread cam is

too late, puckering and loose

looper thread stitches will results.

o If the chain looper thread guide

is moved away from you, the

take-up amount of the lower

looper thread will decrease. In

this case, puckering may result

there by impairing the feeling of

the finished product.

Throat plate

0 to 1 mm

Thread

Adjustment Procedure Results of Improper Adjustment

Adjustment Procedure Results of Improper Adjustment

Page 34

– 30 –

(19) Position of the thread cam (Applicable only to MO-6716D series)

3) Adjusting looper thread auxiliary thread take-up lever (Exclusive for 30P)

When lopper thread auxiliary thread take-up lever is in its lower dead point, the thred hole should align

with the hole in lopper thread auxiliary thread take-up lever guide .

The holes should align

with each other at the

lower dead point.

Standard Adjustment

Page 35

– 31 –

1) Open the cloth base cover and loosen setscrew .

2) When looper thread auxiliary thread take-up lever is in its lower

dead point (when the feed dog goes back to the end), tighten setscrew so that the thread hole in looper thread auxiliary thread

take-up lever aligns with the thread hole in looper thread auxiliary

thread take-up lever guide .

(Caution) 1. When the feed pitch is changed, perform re-adjustment.

2. Confirm that looper thread auxiliary thread take-up le-

ver does not come in contact with the cloth base

cover.

Adjustment Procedure Results of Improper Adjustment

Page 36

– 32 –

(20) Adjusting the throat plate support

(21) Adjusting the feed mechanism cover presser

Standard Adjustment

Standard Adjustment

Uniform contact

Page 37

– 33 –

oIf the throat plate support comes

in single sided contact with the

throat plate or does not come in

contact with it, the throat plate will

vibrate severely.

1) Loosen setscrews and adjust so that throat plate support should

not come in single-sided contact but come in uniform contact with

throat plate using setscrews .

o If the feed mechanism cover is

not fully pressed and the cover

rises, oil leakage will be caused.

1) Loosen setscrew and press feed mechanism cover presser in

the direction of arrow.

2) Press feed mechanism cover and tighten setscrew so that the

feed mechanism cover should not rise.

(Caution) Check that feed mechanism cover is pressed so that it

should not rise.

Adjustment Procedure Results of Improper Adjustment

Adjustment Procedure Results of Improper Adjustment

Page 38

– 34 –

(22) Adjusting the looper cover

o The looper cover should smoothly close without coming in contact with upper knife when slowly closing

looper cover with upper knife in its lowest position of its troke.

(23) Adjusting the cloth chip cover

o When cloth chip cover is pressed away from you, it should not rattle.

In addition, the cloth chip cover should not come in contact with upper knife and lower looper .

(There are 2 pcs. inside.)

Frame

Cloth chip

cover

Standard Adjustment

Standard Adjustment

Page 39

– 35 –

1) Close looper cover , loosen setscrew , and move looper cover

guide plate back and forth until the looper cover is brought to a

position where the cover smoothly closes.

2) Move looper cover guide plate until it slightly comes in contact

with looper cover receiving bracket . Now, fix the guide plate by

tightening setscrew .

1) Loosen setscrew and temporarily tighten the setscrew with cloth

chip cover stopper raised.

2) Loosen setscrews in the cloth chip cover , and adjust the longitudinal position of cloth chip cover .

3) Loosen setscrew in the cloth chip cover stopper again, and press

cloth chip cover stopper downward until the stopper slightly comes

in contact with looper cover . Now, tighten setscrew .

4) Finally , confirm that cloth chip cover comes in contact with neither

upper knife nor lower looper .

Adjustment Procedure Results of Improper Adjustment

Adjustment Procedure Results of Improper Adjustment

Page 40

– 36 –

(Caution) The needle thread take-up shall be positioned at the lower dead point.

B

A

C

D

Needle thread guide

Needle thread take-up guide

of double-chainstitch machine

P

Needle thread takeup lever of doublechainstitch machine

(24) Position of the thread guides and the looper thread take-ups

MO-6704D MO-6714D MO-6716D

Needle thread

take-up

B

Needle thread

guide

A

B

A

Needle thread take-up lever of

2-needle machine

Needle thread guide of

2-needle machine

The thread hole in the needle thread

guide and the hooked portion of the

needle thread take-up are in the position where 2/3 of the hole in the needle

thread guide can be observed.

The thread hole in the needle thread guide and

the hooked portion of the needle thread take-up

are in the position where 2/3 of the hole in the

needle thread guide can be observed.

The thread hole in the double-chainstitch needle

thread guide and the hooked portion of the needle

thread take-up are in the position where the entire

hole in the needle thread guide can be observed.

The thread hole in the needle thread

guide and the hooked portion of the

needle thread take-up are in the position where 2/3 of the hole in the needle

thread guide can be observed.

Upper looper thread guide (upper)

Upper looper thread guide (middle)

Looper thread take-up (left)

Looper thread t

ake-up (right)

Lower looper thread take-up

E

N

M

J

H

F

K

G

Upper looper thread guide (right)

Lower looper thread guide

I

L

MO-6 04D MO-6 14D MO-6 16D MO-6 16D MO-6 05D MO-6 04D

(Standard) (Standard) (Standard) (50H) (Blind-hemming) (Soft chain)

General thread Wooly thread General thread Wooly thread General thread Wooly thread General thread General thread Wooly thread General thread

15.8 ←←←←← ← ← ← 13.5

3.4 ←←←1.8 ← 2.6 3.4 ← 2.1

————21.5 ← 2.3 — — —

————30.5 ← 24.5 — — —

22 ←←←←← ← ← ← ←

65 ←←←←← ← ← ← ←

17.5 ←←←←← ← ← ← ←

43.5 ←←←←← ← 40.5 ← 43.5

26.5 ←←←←← ← 24 ← 26.5

38 41 38 ← 34 36 34 38 42 43.5

15 ← 12 15 12 15 12 12 ← 14

6.5 ← 10 ← 6.5 ←← 24 34 ←

29 ←←←27.5 ←← 29 ← 26.5

27 21 23 ← 20 ← 19 24 ← 19

11 ←←←←← ← 12 ← 9.5

————16← 12.8 — — —

Symbol

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

(Unit : mm)

Standard Adjustment

Page 41

– 37 –

1) Perform the adjustment by the setscrews. Position of the needle thread

guide and needle thread take up lever is a very important decisive

factor when making soft chains since the needle thread take-up

amount is increased in this case. So, carefully position these parts.

2) Set distance I a little smaller when using

synthetic thread or the like which tends to form

stitches swelling out of the cloth edge.

A smaller I is effective for preventing stitch skipping.

3) Distance J is related to the vertical knotting point

of the upper and lower looper threads.

Set this distance larger for wooly thread, and set it smaller for thin

thread which is likely to cause stitch skipping.

4) It is desirable to set distance K larger for stretchy threads such as

wooly thread.

5) Set distance L a little larger when making blind hemming soft chain

stitches.

6) Set distance N a little smaller for blind hemming or making soft chain

stitches.

7) Set distance O larger if stitch skipping occurs due to looper thread

slack.

Set it smaller for better appearance and touch of produced stitches

when wooly thread is used.

o Distance

a

When set smaller, better tightness of needle thread stitches

will be obtained.

When set larger, loose needle

thread stitches will result.

o Distance E, F and H exert least

influence on stitch formation,

however, improper setting of

these distances will cause contact between the moving parts.

o Distance J

When set larger, the amount of

the upper looper thread will be

increased.

When set smaller, the amount of

the upper looper thread will be

decreased.

oDistance K

When set larger, the amount of

the upper looper thread will be

increased.

When set smaller, the amount of

the upper looper thread will be

decreased.

o Distance L

When set larger, the amount of

the upper looper thread will be

increased.

When set smaller, the amount of

the upper looper thread will be

decreased.

o Distance N

When set larger, the amount of

the upper looper thread will be

increased.

When set smaller, the amount of

the upper looper thread will be

decreased.

o Distance I

When set larger, the amount of

the upper and lower looper

threads will be increased.

When set smaller, the amount of

the upper and lower looper

threads will be decreased.

o Distance O

When set larger, the amount of

the upper and lower looper

threads will be decreased.

When set smaller, the amount of

the upper and lower looper

threads will be increased.

Swell out

Adjustment Procedure Results of Improper Adjustment

Needle thread take-up amount

a

Large

Small

Lower looper

Thread slack

Upper looper

Upper looper

Needle

Thread slack

Page 42

– 38 –

1) Replacing the parts with those exclusively designed for making soft chains

Needle thread presser plate C .......12112504

Driving cam .................................... 12112603

Needle thread presser spring B ..... 12112702

Throat plate ....................................(only for 1-needle

overlock machine)

0D4-300 ......................................... R4200J6DD0A

2) Adjustment value

1

Needle thread guide and needle thread take-up lever

Adjust the needle thread guide to increase the needle thread feeding amount when the needle bar is in

the lowest dead point of its stroke.

(04 1-needle overlock machine) (16 Safely stitch machine)

2

Adjust the rising amount of needle thread presser plate C.

Adjust the rising amount of needle thread presser plate C to 0.6 to 1 mm (max.) by moving driving

cam to the right and left within the slot.

Rising amount : 0.6 to 1 mm (max.)

(25) Adjusting soft chain making mechanism

Max. slot of the needle

thread guide

3.1 to 3.6mm

Max. slot of the needle

thread guide

Needle thread takeup amount when the

needle bar is in its

lowest dead point

2.5 to 3mm

Standard Adjustment

Cam face

Needle thread take-up

amount when the needle

bar is in its lowest dead

point

Rising amount

Cam face

Page 43

– 39 –

3) Important points in adjustment

1

Increase the thread take-up amount of the needle thread take-up lever.

Refer to the adjustment values related to the needle thread guide and needle thread take-up lever.

2

Reduce the feed of the looper threads. (Mainly lower looper thread)

Set J, K, L and M for the soft chain distances.

Fine adjustment of J and M is required to produce even stitches.

3

Adjsut the thread tension while checking the appearance and touch of the stitches produced.

1) Minimize the needle thread tension as far as satisfactory tightness of needle thread stitches is obtained.

2) Increase the upper looper thread tension as much as possible.

4

If the chain-off thread does not stretch satisfactorily, and if it is not satisfied, proceed with the following.

1) Increase the upper looper thread tension.

2) Further increase distances J and K.

3) Further increase the upper looper thread tension.

4) Increase the lower looper thread tension to a maximum as far as good tightness of needle thread

stitches is maintained.

5) Increase the thread take-up amount. If the needle thread is poorly tensed, increase the needle thread

tension.

5

Fine adjustment for producing stitches with better appearance and touch

1) If the knotting point varies at high or low sewing speed, slightly reduce L, and increase the lower looper

thread tension.

2) If a knot is made at a high point, increase J and I.

3) If the needle thread is likely to break, decrease the thread take-up amount and lower the needle thread

tension.

6

Pay attention to the following

1) Minimize the needle thread tension as far as satisfactory tightness of needle thread stitches is obtained.

2) The knot of upper and lower looper threads should be made near the upper edge of a material.

3) Minimize the lower looper thread tension as far as even stitches are maintained.

4) For a safety stitch machine, adjust the soft chain making mechanism so that uniform chain-off thread

is produced during double-chain stitching and overlocking.

Soft chain stitches

Standard stitches

The value given in ( ) parentheses is

the adjustment value for the safety

stitch machine. (Unit : mm)

Looper thread

take-up (left)

Looper thread

take-up (right)

Lower looper

thread take-up

Lower looper

thread guide

Upper looper thread

guide (middle)

Upper looper thread guide (upper)

Upper looper thread guide (right)

O

11

M

29 (27.5)

N

27 (20)

G

17.5

K

15 (12)

E

22

I

26.5

F

65

H

43.5

J

38

(34)

L

6.5

Looper thread should not be

loosened and stretch well

The looper thread loosens

When the chain-off

thread is pulled.

When the chain-off

thread is pulled.

Page 44

– 40 –

(2) Upper looper

Use a proper upper looper in accordance with the needle No. When ordering, refer to the Parts List. The

numbers shown in frame in the table below are engraved markers. In addition, the letters in ( )

parentheses are the kinds of the needles.

Parts Nos. with an asterisk * are factory-installed on the standard machine heads at the time of delivery.

Model Nos. engraved on Needle No.

upper looper (kind)

MO-6704D series *1188 81 #9 #11 #14

MO-6716D series

MO-6714D series *1217 60

Part No. Color Natural length Operating length Weight required to compress

(mm) (mm) spring to working length

13137807 Red 19.5mm 11.5mm 4.21±0.49N (430±50g)

13138508 Yellow 17.8mm 9.8mm 3.14±0.34N(320±35g)

13138805 Blue 17.3mm 9.3mm 1.47±0.20N(150±20g)

4. ADDITIONAL INFORMATION AND PRECAUTIONS

2) Springs used for each model.

Needle thread Double-chainstitch Upper looper Lower looper

needle thread thread thread

MO-6704D series Red — Yellow Blue

MO-6714D series Red • Yellow — Blue Yellow

MO-6716D series (30P included) Red Yellow Yellow Blue

MO-6716D- -4 H, -50H Red Red Blue Yellow

Model

Where to use

(1) Thread tension

1) Strength of tension spring

Page 45

– 41 –

(3) Center-to-center distance of the upper looper holder

The center-to-center distance of upper looper holder 1.

Be careful not to allow the

sealant to run to the rear.

Apply the sealant to the

bottom surface.

Apply the sealant to the

bottom surface.

H

(4) Caution in assembly

1) Application of sealant

1

Setscrew of the throat plate base (B) retainer (JUKI seal)

Apply the sealant only to the right setscrew.

2

Bottom surface of the upper looper guide support (Three-bond 1104)

Apply the sealant to the bottom surface of the upper looper guide support , which contacts with the

frame surface.

3

After assembling the front edge of the upper looper guide support (JUKI seal), apply the sealant to

the gap of the contact surface between the frame and the upper looper guide support ( section

in the illustration).

Frame

Apply only to the right setscrew

Model

MO-6704D - MO-6705D - - 0

MO-6704D - 0E4 40H

0F6 50H

MO-6712D -D MO-6714D - MO-6716D - - 0

MO-6716D -DE to FF MO-6743D - - 40H

(Unit : mm)

38

39

39

39

38

39

39

4 H

5 H

-

Center-to-center

distance

H

Page 46

– 42 –

Apply the sealant to the frame.

Apply the sealant to the oil shield rubber support

plate and the top surface of the oil shield case.

Be careful that the sealant should not overflow on

the side of the oil shield rubber.

Feed mechanism

cover (rear face)

Lightly apply the sealant to the rear

face of the feed mechanism cover

and the top surface of the feed bar

presser.

7

Various sealants

Maker’s name Part No.

Three Bond 1104D

Three Bond 1104

Three Bond 1212

* * : It is commonly called “JUKI seal”.

JUKI exclusive part Nos. of the above 3 kinds of the sealants are not set.

4

Portion of the setscrews of the dust-proof rubber case (JUKI seal)

Apply the sealant to the oil shield case setscrew (1 pc.) and the dust-proof rubber case setscrews

(4 pcs.)

5

Oil shield plate assembly (JUKI seal)

Apply the sealant to the inside of the oil shield plate .

6

Portion of the feed mechanism cover (Three-bond 1212)

Apply the sealant to the rear face of the feed mechanism cover, the top surface of the oil shield plate,

the oil shield rubber support plate , the top surface of the oil shield case, and the hatched parts on the

top surface of the feed bar presser.

Apply the sealant to

the hatched parts.

Inside contact surface

Apply the sealant to the

top surface of the oil

shield plate.

Page 47

– 43 –

2) Precautions to be taken with respect to the lubricating components

1

Feed bar components

o Be careful of the orientation of the oil shield rubber and the dust-proof rubber .

* Assembling as shown in the illustration

will result in oil leakage. So, be careful.

2

Portion converted to dry-head type

Forced lubrication room

[Wet portion]

3. Upper looper mechanism portion

[Dry portion]

1. Needle bar mechanism portion

[Dry portion]

2. Feed mechanism portion

[Wet portion]

o Assemble the feed bar presser and the dust-

proof rubber case so that their top faces are

flush with the frame plane on which the feed

mechanism cover is installed.

o Do not loosen the screws in feed bar presser

unless it is necessary. The clearance between

the feed bar presser and the feed bar and the

contact with each other are important.

Do not loosen the screws.

Page 48

– 44 –

3) Applying the exclusive grease

o The exclusive grease (23640204) is applied to the necessary components other than the lubricating com-

ponents. Never use any grease other than the exclusive one.

It is not necessary to additionally apply grease to the components when the sewing machine is used under

the normal condition.

When the machine is used under the specially severe condition, it is effective to periodically (once a year

or every other year) fill up the exclusive grease.

* : Apply the exclusive grease.

1

Needle bar components

*

*

*

*

*

*

*

(Caution) There are grease grooves on the inside

of needle bar upper metal (No. 19) and

needle bar lower metal (No. 18). Fill up

the exclusive grease to the groove portion when drawing out the needle bar.

Page 49

– 45 –

2

Upper looper components

*

*

*

*

*

*

*

*

Page 50

– 46 –

2) Pat No. of frame support plate bolt

1

Semi-sunken type

Support plate bolt (A) 13155007 x 4

Locknut NS6240630SE x 4

Washer WP1002036SE x 4

Spring washer WS1002560KR x 4

2

Fully-sunken type

Support plate bolt (C) 13155106 x 2

Support plate bolt (D) 13155205 x 2

Locknut NS6240630SE x 12

Washer WP1002036SE x 12

Spring washer WS1002560KR x 4

Difference of support plate bolts (A), (C) and (D)

Entire length under the neck and length of threaded part

Entire length Length of threaded part

(mm) (mm)

Support plate bolt (A) 69 39

Support plate bolt (C) 137 107

Support plate bolt (D) 149 119

(5) Kinds of motor pulleys, belts and frame support plate bolts

1) Motor pulleys and belts

50Hz 60Hz

V-belt V-belt

Semi-sunken type Fully-sunken type Semi-sunken type Fully-sunken type

mm (inch) mm (inch) mm (inch) mm (inch)

6000 110 (105) 914 (36) 813 (32) 95 (90) 889 (35) 762 (30)

5500 100 (95) 914 (36) 813 (32) 85 (80) 889 (35) 762 (30)

5000 90 (85) 889 (35) 762 (30) 80 (75) 864 (34) 762 (30)

4500 85 (80) 889 (35) 762 (30) 70 (65) 864 (34) 762 (30)

4000 75 (70) 864 (34) 762 (30) 60 (55) 864 (34) 737 (29)

Sewing

speed of

sewing

machine

(rpm)

* A motor with 1/2 horsepower (400 W) or more shall be used.

(Caution) If a motor of less than 400W is used, in the low temperature area, viscosity of oil increases

and the sewing speed may not increase or the sewing machine may fail to run in some cases.

* Part No. of motor pulley

MTKP0xxx000 (Enter the effective diameter to “xxx.”)

If the outside diameter of the motor pulley is 90 mm, the effective pulley will be 085.

.....So, the part No. will be MTKP0085000.

* Part No. of belt

MTJVM00xx00 (Enter a number that shows the belt length to “xx”)

If the belt length is 889 mm (35 inches), enter “35” to “xx.”

.....So, the part No. will be MTJVM003500.

Outside diameter

of motor pulley mm

(effective diameter

mm)

Outside diameter

of motor pulley mm

(effective diameter

mm)

Support plate bolt (A) Support plate bolt (C) Support plate bolt (D)

69mm

39mm

137mm

107mm

149mm

119mm

Page 51

0A5 to 0F5 15

MO- - 0A4 to 0E4 - 210

0D6 3

MO-6704D - 0F4 -30

0D4 to 0E4

MO- 6704D- 0F6 - 4 H

50H

MO- 6714D- BD6 to BE6- 7

MO-6714D - B 6 - 30P

MO- 6714D- BD to BE - H

MO- 6712D- DF6 -50F

MO- 6716D- -30

MO- 6716D-

D

to F

-4

H

50H

MO- 6743D- 2D6 - 40H

MO- 6745D- FF4 - 360

13131008 13131107

13131909 13132006

Needle height Upper looper components

Lower looper components

Double-chain looper

1-needle 2-needle Upper looper Projection of Upper looper Marker of Position of

Guide support

Center-to- Marker of Feed amount Radius of Feed amount Radius of

2-needle (right) height upper looper

holder height

guide support guide support

cover

center of upper

upper looper of lower lower looer of double- double-chain

(left) of pin looper holder holder chain looper looper

10.5±0.1 — 11.0±0.3 4.0±0.3 (45.0) A 38 4.0 66.9 — —

10.5±0.1 — 11.0±0.3 4.0±0.3 (46.2) A 38 3.7 66.9 — —

11.3±0.1 — 11.3±0.3 4.4±0.3 (48.2) A 39 3.8 66.9 — —

10.5±0.1 (9.1) 10.3±0.3 4.4±0.3 (47.3) B 39 3.8 66.9 — —

10.5±0.1 (9.1) 10.3±0.5 4.4±0.3 (47.3) B 39 3.8 66.9 — —

11.3±0.1 (9.9) 11.0±0.5 4.8±0.3 (48.4) A 39 3.8 66.9 — —

11.0±0.3 (9.4) 11.0±0.5 (46.9) B 39 2.2±0.3 66.9 — —

10.5±0.1 — 11.0±0.3 4.0±0.3 (46.2) A 38 3.7 66.9 1.5 to 2.0 63.4

1.3±0.1 — 11.3±0.3 4.4±0.3 (48.2) A 39 3.8 66.9 1.5 to 2.0 63.4

11.3±0.1 (9.9) 11.0±0.3 4.8±0.3 (48.4) A 39 3.8 66.9 1.5 to 2.0 63.4

9.8±0.1 — — — — — — — — — — — 2.0 to 2.5 63.6

5.8

39

– 47 –

Description

Subclass

6704D

6705D

5. ADJUSTMENT VALUES OF THE NEEDLE HEIGHT AND LOOPER TIMING

(1) MO-6700D SERIES

#81

(11888609)

7

40004713

Marker A

+0.5

–0.8

+0.5

–0.7

#81

(11888609)

6.3

40004713

A

+0.5

–0.8

#19

(11991908)

5.8

40004713

A

+0.5

–0.8

#60

(12176004)

6

40004714

B

+0.5

–0.8

#61

(12176103)

5.8

+0.5

–0.8

40004713

A

#60

(12176004)

40004714

B

#66

(11996600)

5.5

40004714

B

3.6±0.3

(Right side)

#81

(11888609)

6.3

40004713

A

+0.5

–0.7

+0.5

–0.8

#19

(11991908)

5.8

40004713

A

#61

(12176103)

40004713

A

1- needle overlock

macine/safety

stitch machine

3- needle

safety stitch

A

B

B

C

C

D

E

F

H

G

D

E

2- needle overlock

macine

3- needle

safety stitch

J

K

J

2- needle overlock

macine

3- needle

safety stitch

L

M

6

7 5.5

5.8

6.3 4.7

38

A

B

C

D

E

F

G

H

J

K

L

M

+0.5

–0.8

(Unit : mm)

Needle height

Upper looper components

Lower looper components

Double-chain looper components

2- needle overlock

macine

1-needle overlock machine

2-needle overlock machine

Safety stitch machine

Classification

Upper looper

guide support

gauge

Upper looper

holder

1D6

6

Page 52

1. Needle thread breakage Threading The thread is entangled with the thread Refer to the threading diagram.

guide, or the machine head has been (Refer to the Instruction Manual)

incorrectly threaded.

Thread path Scratches, burrs or rust on the pawls Remove such scratches, burrs, etc. and

or needle holes of the throat plate,

perform thread path finishing. Replace major

stitch tongue, lower looper, double chain

components such as looper, which have

looper, needle thread take-up, needle been deformed, causing thread breakage.

thread presser spring, thread guide,

or tension discs causes friction.

Needle guard The needle hits the needle guard intensely, Replace the needle and needle guard if 18

and sharp edges are produced on them, they have worn,

causing thread breakage.

Needle The needle is too thin for the thread. Replace the needle by a proper one.

Needle heat The needle gets very hot, depending on Use a thinner needle. Reduce the sewing

the type of materials, number of plies and speed. Use the needle cooler. Use an S-point

sewing speed, and causes the thread to needle or needle for synthetic thread.

burn and break.

Thread

The thread is weak because of its poor quality.

Replace the thread by one with good quality.

Thread tension The thread tension is too high. Reduce the thread tension. Check whether the

needle thread take-up guide and needle thread

guide are positioned too high, causing such

excessive thread tension.

Contact The double chain looper or lower looper Properly position the double chain looper or 8, 16

has been improperly positioned and strikes lower looper.

the feed dog or throat plate.

Double thread hooking Poor drawing up of the needle thread Increase the needle thread tension. Properly 28

(only for double chain stitch) causes the looper to catch it again. position the thread cam. Properly position the

double chainstitch thread guide.

Defective double chain-off thread Refer to the clause referring to defective

(only for double chain stitch) double chain-off thread.

6. TROUBLES AND CORRECTIVE MEASURES

Trouble Case (1) Case (2) Check and Corrective measures Page

– 48 –

Page 53

2. Looper thread breakage Thread path Scratches, burrs, rust, etc, on the paw of Remove such scratches, burrs, etc. and carry

the throat plate, stitch tongue, looper, out thread path finishing. Replace loopers or

looper thread take-up, thread guide, other components which have been deformed,

or tension discs causes friction. causing thread breakage.

Adjustment of the looper thread take-up The looper thread take-up or thread guide Refer to the pertinent Standard Adjustment. 36

has been improperly positioned, causing

excessive thread tension.

Thread tension The looper thread tension is too high. Reduce the tension while checking the tension

balance other looper thread.

Thread The thread is weak because of its poor Replace the thread by one with good quality.

quality.

Position of the thread guides The upper looper thread guide is too high, Refer to the pertinent Standard Adjustment. 36

(only for double chain stitch) and the thread taking balance is disturbed,

resulting in the thread breakage.

Double chain looper avoid The double chain looper strikes the needle Correct the longitudinal motion of the double 16

at the back, causing the thread breakage. chain looper so as not to cause the looper to

strike the needle.

Needle heat The needle gets hot, and the looper thread Refer to the clause relating to the needle heat

breaks when it comes in contact with the causing needle thread breakage.

hot needle at the time of needle stop.