Page 1

I

Instruction

Manuel

manual

d'instructions

Brugsanvisning

Bedienungsanleitung

Page 2

Contents

1

Safety

regulations

5

Contents

7

Detailsofthe

7

-Detailsofthe

9

Preparing

9

-Accessories

9 -Accessory Box

9

-Looper

9 -Cloth plate cover

11 -Attaching the foot control

11 -Sewing

11 -Assembling

11

-Thread

11 -Power/light switch

13. Using (he machine

13.-Haadwheel

13.-Presser

13. >Changingthe ]nesser foot

15. - Inserting needles

15. - Raisingthe upperknife

17. Threading

17. -Threading/Preparation

17. -

Upper

19. -

Lower

21. - Right needle (Blue)

23. - Left needle(Yellow)

23. > After threading

25 Trial

sewing,

25 -Sewing

25 -Check your trial run

machine

machine

the

machine

cover

speed

the

cones

foot

lifter

looper

(Green)

looper(Red)

thread

test

thread

tension

stand

27

Adjusting

27 -Adjusting

29. Adjustments

29. -

the

the

Ac^'ustment

thread

and

of stitch length

29. - Cuttingwidth

29. - Stitch plate

31

Differential

31

-Differential

31 -Gathering *

33

Automatic

33

auto

35

Practical

-3

thread

-3

thread

-Unpicking

37

Maintenance

-Changing light bulb

-Cleaning

39

Trouble

43

Technical

switch

overlock

rolled

shooting

feed

feed

threadev

sewing

seams

and

lubricating

data

thread

settings

*

*

off

hem

guide

tension

tension

Page 3

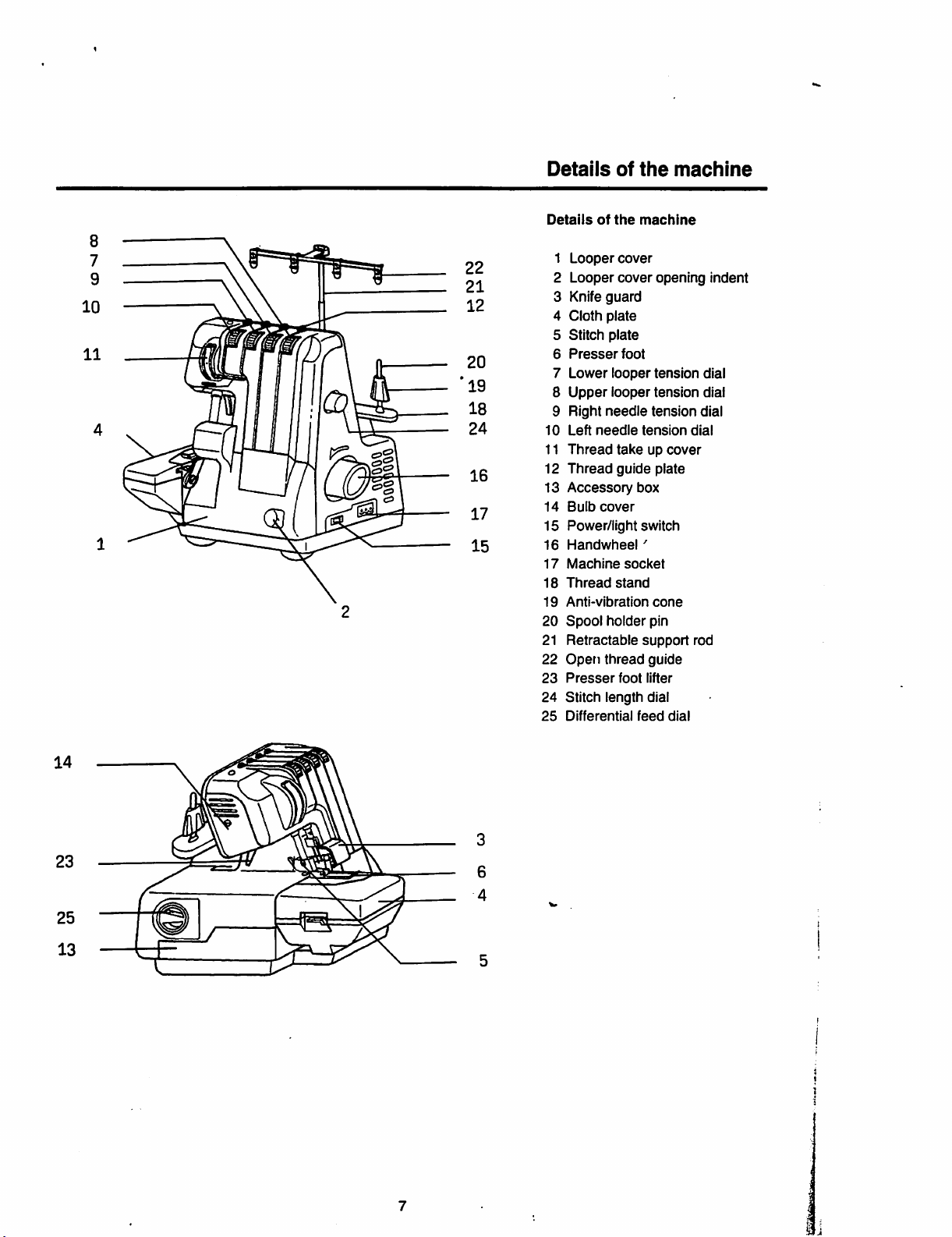

Details

of

the

machine

10

11

Detailsofthe

machine

8

1

7

9

22

21

12

20

19

18

24

16

17

15

Looper

2 Looper

3 Knife

4 Cloth

5 Stitch

Presser

6

7

Lower

Upper

8

9 Right

10

Left

11

Thread

12

Thread

Accessory

13

14

Bulb

15

Power/light switch

Handwheel'

16

17

Machine

Thread

18

Anti-vibration

19

20

Spool

21

Retractable

Open

22

Presser

23

24

Stitch length dial

Differential

25

cover

cover

guard

plate

plate

foot

looper

looper

needle

needle

tension

takeupcover

guide

box

cover

socket

stand

holder

support

thread

guide

foot

lifter

feed

opening indent

tension

tension

dial

dial

tension dial

dial

plate

cone

pin

rod

dial

14

23

25

13

Page 4

Preparing

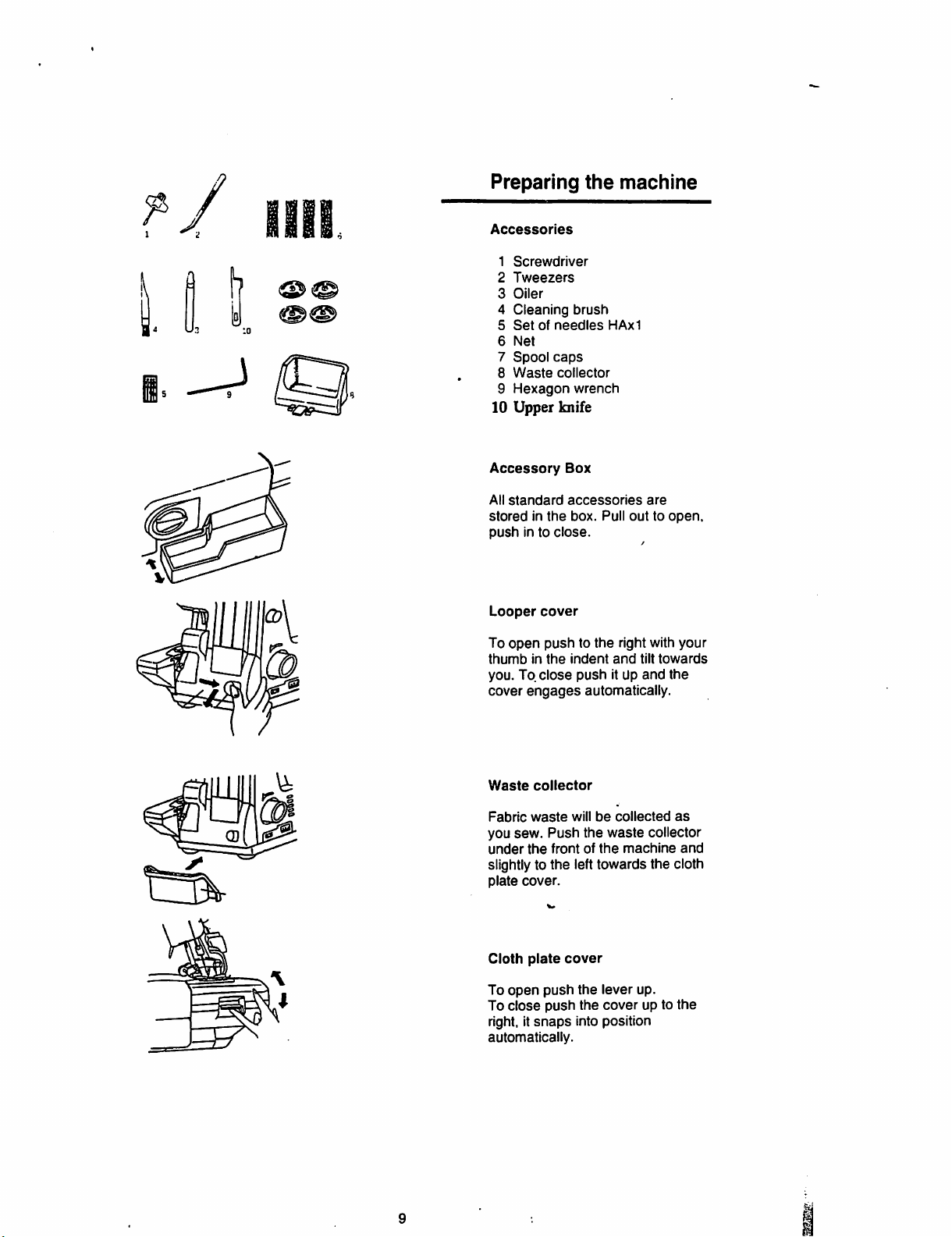

Accessories

1

Screwdriver

2

h

Tweezers

3

Oiler

4 Cleaning

5

Setofneedles

6

Net

7

Spool

8

Waste

9

Hexagon

brush

caps

collector

wrench

the

HAx1

machine

10 Upper knife

I

Accessory

All

standard

storedinthe

push

Looper

To

open

thumbinthe

you. To

cover

Waste

Fabric

you

sew.

under

in to

close.

cover

pushtothe

close

engages

collector

waste

Push

the

frontofthe

Box

accessories

box.

Pull

outtoopen,

right with your

indent

and

push

it Up

automatically.

willbecollected

the

waste

machine

are

tilt

towards

and

the

collector

as

and

slightlyto the lefttowards the cloth

plate

cover.

Cloth

plate

cover

To

open

push

the

To

close

push

right, it

snaps

automatically.

lever up.

the

cover

into position

up to

the

Page 5

Preparing

the

machine

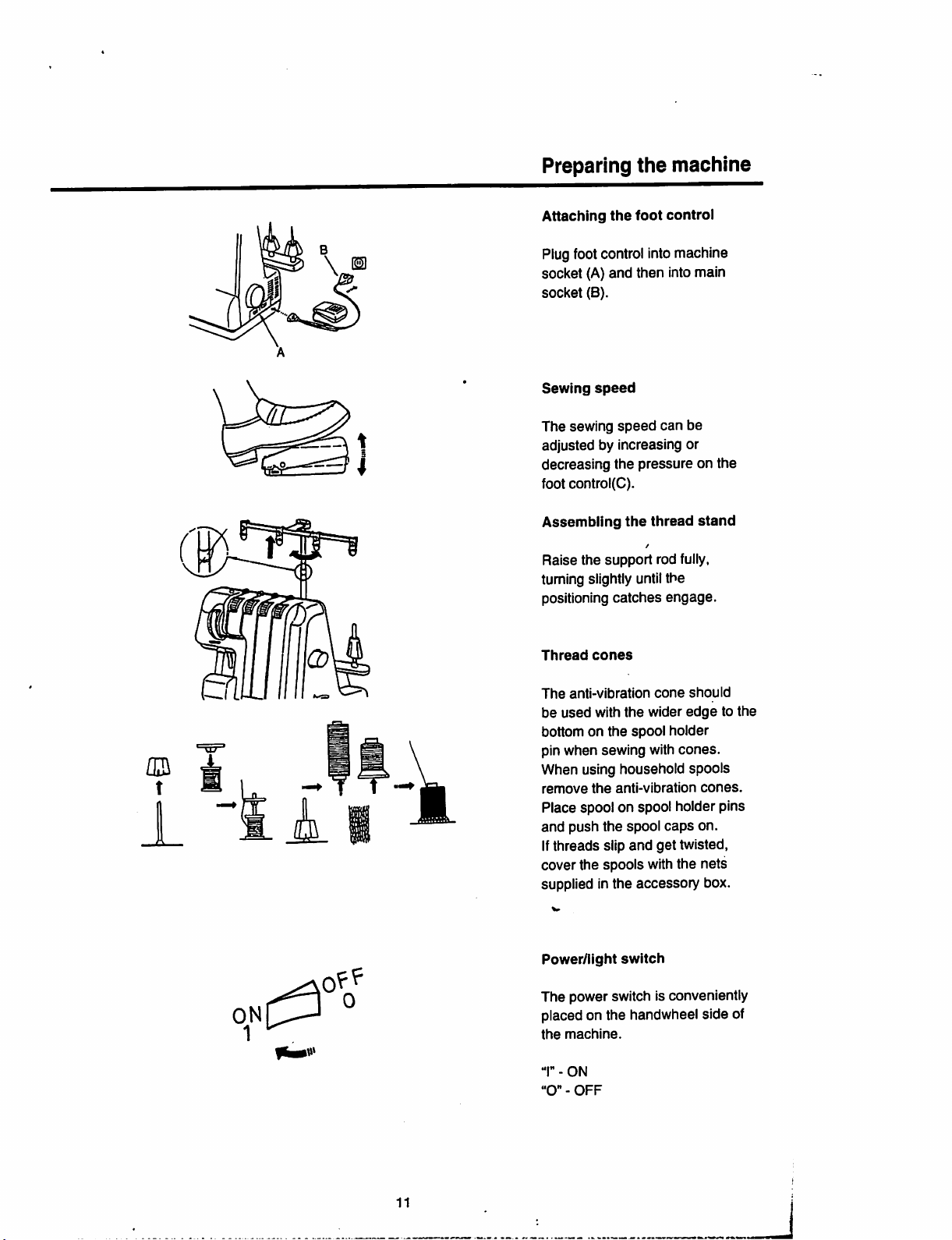

Attaching

the

foot

control

Plugfootcontrol into machine

socket (A)and then into main

socket

(B).

Sewing

The

adjusted by increasing or

speed

sewing

speed

can

be

decreasing the pressure on the

foot control(C).

Assembling

Raise

tuming slightly until the

positioning

Thread

the

the

support rod fully,

catches

cones

thread

engage.

stand

onC^

The

anti-vibration

be

used

with

bottomonthe

pin when sewing with

the

spool

cone

wider

holder

should

edgetothe

cones.

When using household spools

remove

the

anti-vibration

cones.

Place spool on spool holder pins

and

push

the

spool

caps

on.

Ifthreads slip and get twisted,

cover the

supplied in

Power/light

spools

the

switch

with the

accessory

nets

box.

The power switch is conveniently

placed on the handwheel side of

the

machine.

"I" -

ON

"0"-OFF

11

Page 6

Using

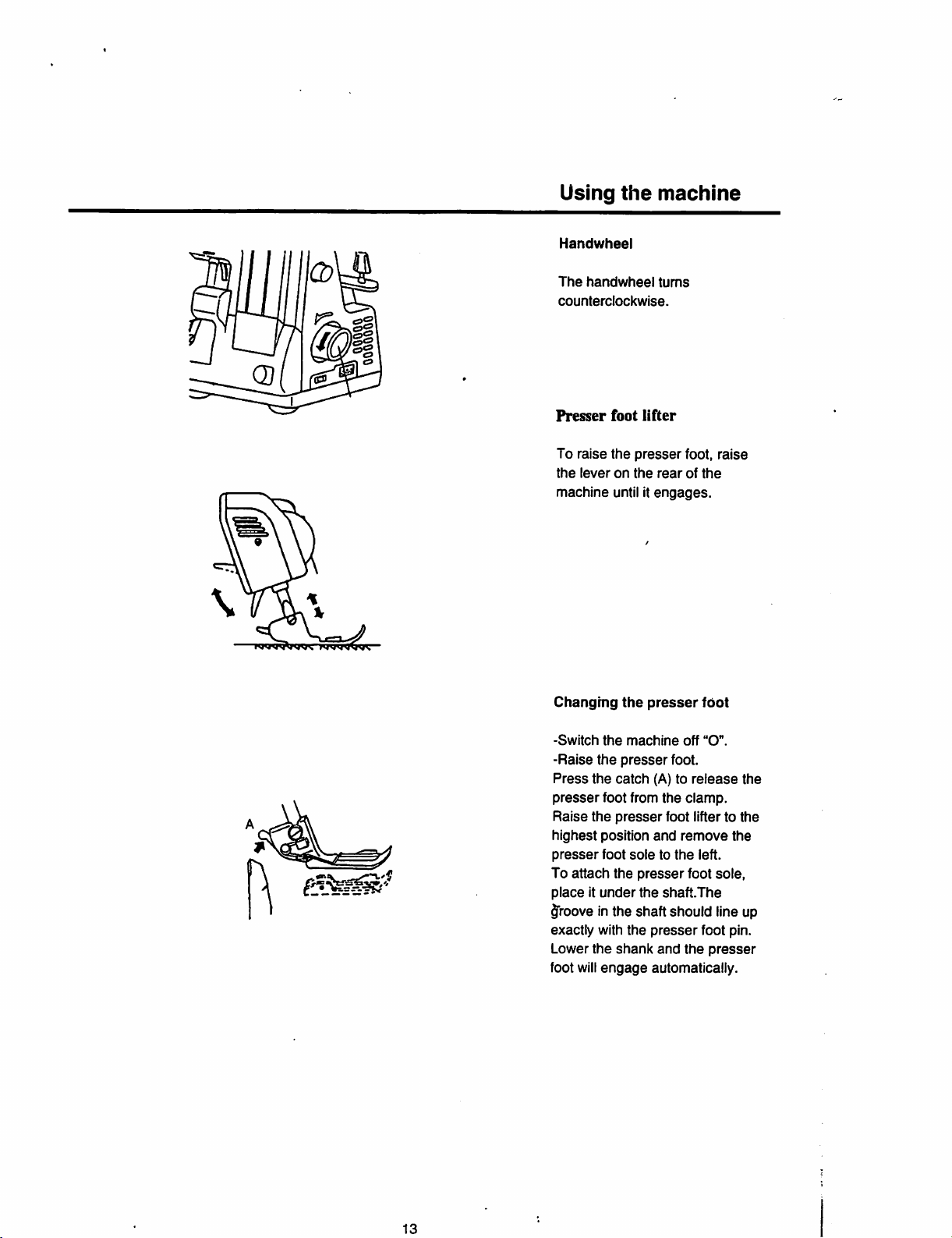

Handwheel

the

machine

0)

The

handwheel

counterclockwise.

Presser

To

the

machine

Changing

foot

raise

the

leveronthe

until it

the

turns

lifter

presser

rearofthe

engages.

presser

foot,

raise

foot

-Switch

-Raise

Press

presser

Raise

highest

presser

To

placeitunder

the

the

attach

the

machine

the

presser

catch

foot from

presser

position

foot

soletothe

the

(A) to

the

foot lifter to

and

presser

the

shaft.The

off

foot.

release

clamp.

remove

foot

"O".

the

the

the

left.

sole,

groove inthe shaft should lineup

exactly with

Lower

foot will

the

engage

the

presser

shank

automatically.

and

foot pin.

the

presser

13

Page 7

Using

the

machine

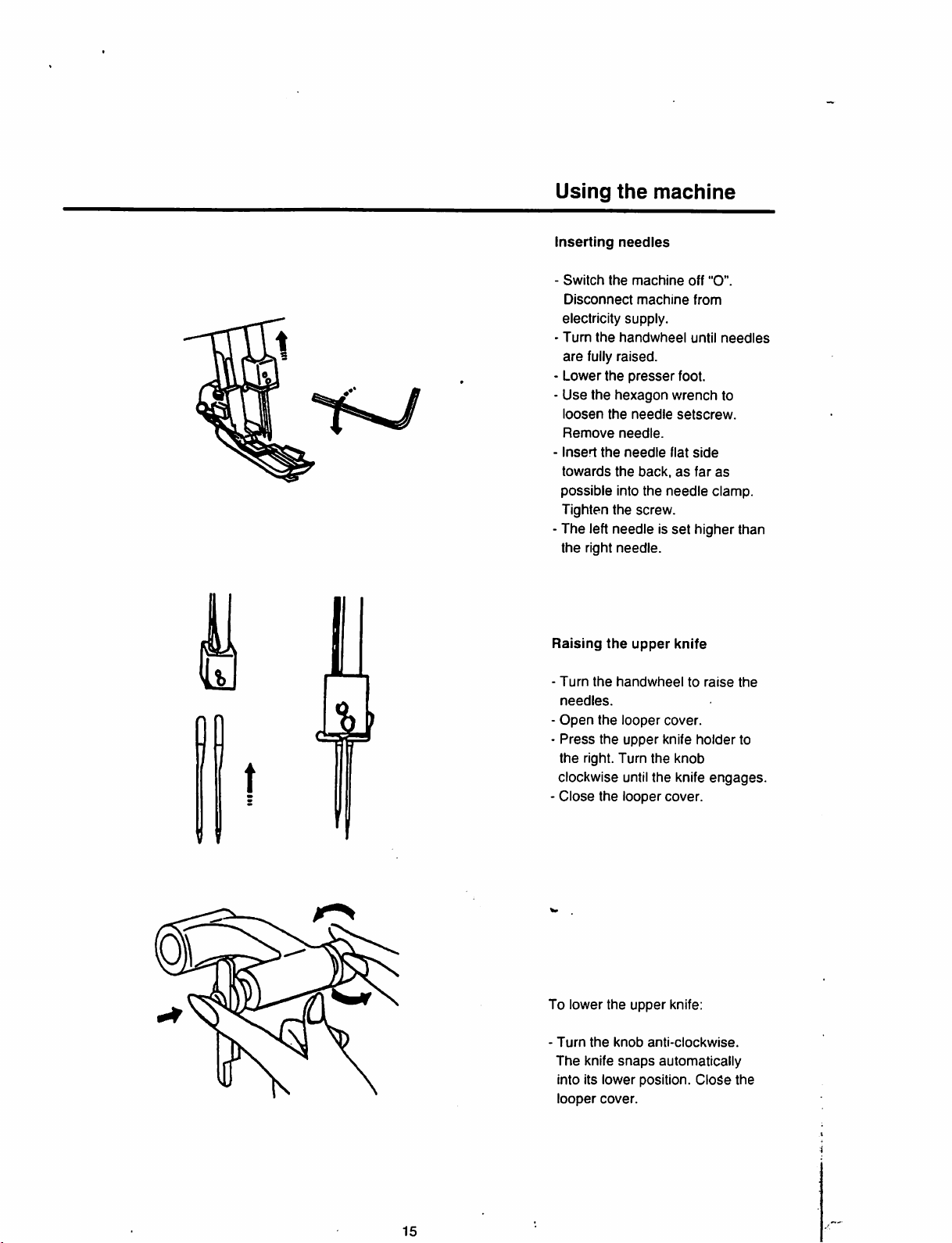

inserting

•

Switch

Disconnect

needles

the

machine

machine

off

from

"O".

electricity supply.

•

Turn

the

are

fully raised.

Lower

Use

the

loosen

Remove

Insed

towards

possible

handwheel

the

hexagon

the

needle.

the

needle

the

into

presser

needle

back,asfar

the

until

foot.

wrench

setscrew.

flat

needle

needles

to

side

as

clamp.

Tighten the screw.

The left needle is

the

right

needle.

Raising

-

Turn

needles.

-

Open

-

Press

the

t

clockwise until the knife

-

Close

the

the

handwheel

the

looper

the

upper

right. Turn

the

looper

upper

the

set

knife

cover.

knife

knob

cover.

higher than

to

raise

holder

engages.

the

to

To

lower

the

upper

-

Turn

the

knob

anti-clockwise.

The

knife

snaps

into its

lower

position.

looper

cover.

15

knife:

automatically

Close

the

Page 8

® (D ® ©

If

u =

Threading

Threading/Preparation

-

Disconnect

electricity

-

Support

mustbefully

-

Open

cloth

-

Turn

until

-

Thread

correct

Upper looper (Green)

rod with

the

plate

the

handwheel

needles

the

sequence.

machine

supply.

raised.

looper

cover.

are

machine

thread

cover

fully

from

guide

and

towards

raised.

in

the

the

you

> Place the spool on the spool holder

pin.

- Bring thread up from back to front

through guide (1).

- Make s-loop through holes in thread

guide bar (2).

- Thread guide (3,4,5)

- Thread looper eye (6)

>

- For Certain modelsonly

- Pourun certain

-

Kun

for

visse

- Nur fur gewisse

modules

modeller

Modelle

uniquement

17

Page 9

Threading

Lower

looper

(red)

-

Place

the

spoolonthe

holder

pin.

- Bring

thread

up from

through

- Make

thread

-Threadguide

FOR

♦If

guide

S-loop

guide

CERTAIN

machine

(1).

through

bar

(3,4,5)

attached

lower looper automatic

threader, then please reter to

page 33 continuously and

disregard the following

instruction.

Turn

the

handwheel

until

the

loweK

looper

left-most

tweezers

(not

left.

on the

handweel

lower

position.

thread

Insert

lower

looper

position.

to pull a

end)

the

thread

looper(6) Turnthe

towards

is in

- Thread the looper eye

that

the

thread

lies in

grooveonthe

•

Place

thread

lower

under

back

holes

(2).

MODEL

with

towards

is in

Use

the

thread

from right

into

you

until

(he

rightmost

(7)

the

looper.

presser

spool

ONLY

the

loop

the

long

to front

in

the

you

side

slit

the

so

foot..

to

- For Certain models only

- Pour un

-

Kun

for

colain

visse

- Nur fur gewisse

19

modules uniquemei

modeller

Modelle

1^-

Page 10

Threading

Right

needle

- Place the spool on the

spoolholderpin.

-

Bring

guide (1).

-

Make

in threadguidebar(2).

- Thread guide (3,4)

-

Thread

- Place thread under

foot.

(Blue)

threadupthrough

S-loop

right

through

needle

eye (5)

presser

holes

f

For Certain

Pourimcertain

Kun

for

V.

21

Nur fur gewisse

models

visse

only

modules

nndeUer

Modelle

uniquement

Page 11

iMf

Threading

Left

needle

(Yellow)

- Place the spool on the

spool holder pin.

- Bring

- MakeS-loop through holes

- Thread guide(3,4)

-

- Place thread under presser

After

When

the

looper cover

thread

through

(1).

in threadguide bar (2).

TTiread

foot.

presser

left needle eye (5)

threading

threading is

foot

and

and

complete,

close

cloth

plate.

guide

the

lower

Note:

If

the

lower

looper

threaded.

off at

surplus

the

re-thread

For Certain

the

looper

cut

needle

thread

and

the

both

eye

from

then

needles.

models

Pouruncertain

Kun

for

visse

Nur fiir gewisse

23

hastobe

needle

and

below.

only

modules

modeller

Modelle

re-

threads

remove

Thread

uniquement

J-S:.

Page 12

Trial

tension

sewing,

thread

Sewing

After threading

Always

test

make

useadouble

a trial run.

layer

of fabric

in order to be able to check tfie

stitch

formation

properly.

-

Switch

-

Set

all

tension

-

Raise

the

foot slightly with your

position

just

up to

-

Sew.

- At

the

endofthe

sewing a

chain.

-

Cut

the

remove

the

front of

the

the

8cm

thread

work.

and

machine

dialsto4.

fabric

knife.

(4") long

chain

the

under

seam

thread

on

presser

thumb

and

tension

"1".

the

continue

thread

and

foot

Check

your

trial

run

1

Upper

looper

thread

2

Lower

looper

thread

3 Right

4 Left

Perfect

both

fabric

needle

needle

stitch

looper

edge.

thread (green)

thread

(yellow)

formationiswhen

threads

The

meetatthe

needle

(grm straight stitches for a

stretchy

Thread

be

of fabric

and

tension

required

and

durable

seam.

adjustments

dependingonthe

thread

being

(blue)

(red)

threads

may

type

used.

25

Page 13

Adjusting

tension

the

thread

Adjusting

The

on

the

Tighten

tension (yeilow).

The right needle thread forms

loopsonthe

Tighten the right needle thread

tension

the

left

needle thread

underside:

the

left

underside:

(green)/

thread

needle

tension

forms

thread

loops

f

1

I

HL

^0\

The

looper loops

the

underside:

Tighten the upper looper tension

(blue), or loosen the lower looper

tension (red).

The

looper loops

the

upper

side:

Tighten the iower looper tension

(red), or loosen the upper looper

tension

(blue).

are

are

formed on

formed on

27

fi

Page 14

Adjustments

and

settings

stitch

length

- Thestitchlengthcan be adjusted

from1to4mm.

- Highernumber = longer stitch,

lower

number=shorter

- Basic stitch length = N.

stitch.

Cutting

The cutting width should be

width

adjusted accordingto the type of

fabric being sewn. Check the

seam

each

time and adjust the

cutting widthaccordingly.

Adjusting

- Open cloth plate cover

- Turn cutting width dial:

- Clockwise to

left (forheavier fabrics).

- Counter-clockwise to

knife

fabrics).

the

butting

width:

move

knife to

move

to the right(foriighter

the

the

I

How to use the needle plate

ueve?

Switch

regular or rolled hem

R-

hem sewing. "N" for regular sew

ing.

the

levertoselect

and

the

narrow

"R"

for

rolled

and

sewing.

Level

R-

29

narrow

hem

Page 15

Differential

feed'

Differential

There

and

one

move

distance

during

feed*

are

two feed

rear.

independently

each

one

complete

canbeadjusted.

Stretching effect

To

stretch

the

number

section"

This

or

prevents

closely

fromNto

[Xl

woven

puckering.

Pushing

To

selectanumber

section"

This

prevent

prevents

effect

waving or to

knitsorpuckers

fabrics.Italso

gather

single

layers

fabric.

dogs:

one

front

The

two

feed

dogs

and

the

feed

dog

travels

movement

fabric

select

a

5 in

the

fine nylon

fabrics

jerseys

from

gather

fromNto

"

8 in

waving or fluting in

in fine

woven

canbeused

of fine

to

woven

the

Note:

When

feed

sewing

the

without differential

dial

should

position N.

Gathering*

Use

the

differential

a

single

layer

of fabric.

ple

sleeve

heads,

ing or frills.

be

on

feedtogather

For

exam

yokes,

lace

edg

Page 16

Threading

AUTOMATIC LOWER LOOPER

THREADER

1.passing the thread through

the hole on lower looper

thread

2.Turn

toward

looper extending out

5-10mm

piate

S.Pull

with tweezers to pass the

lower looper

4.Draw

left hand tightly.

5.Use your finger to push the

automatic

the

thread goes through the

lower

automatically.

(FOR

CERTAIN

guide

(5).

the

balance

you

from

until

the

wheel

the

needle

edge.

the

thread

hole(A),

the therad with your

threader(B)

topmost,

looper(C)

and

then

TYPE

lower

up to

ONLY)

C€:Security "auto switch off"

T)Wien

you open

infront of the loopers

machine stops automatically

-FINGERPROTECHTION.

33

the

panel

the

Page 17

Practical

3

thread

overlock

sewing

Fora3-5

overlock,

Thread

right

Fora5-7

mm

remove

both

needle.

mm

wide3thread

the

left

loopers

and

wide3thread

needle.

then

the

overlock. remove the right needle.

Thread both loopers

left

needle.

3

thread

Switch

29.

Note:

The

adjusted

roll

the

leverto"R".

tensions

may

dependingonthe

hem

and

then

See

needtobe

the

page

type of

fabric or thread being used.

Setting:

Stitch:

Needle:

Tensions:

Needle:

Lfpper

looper

Lower

looper

Stitch length

3-5

1.5-2

Differential feed N (depending on

fabric)

Unpicking

Cut

Pull

stitches

35

the

the

seams

loops with

needle

thread

will

come

3

thread

right

3-5

7-9

sharp

undone.

overlock

scissors.

and

the

Page 18

Maintenance

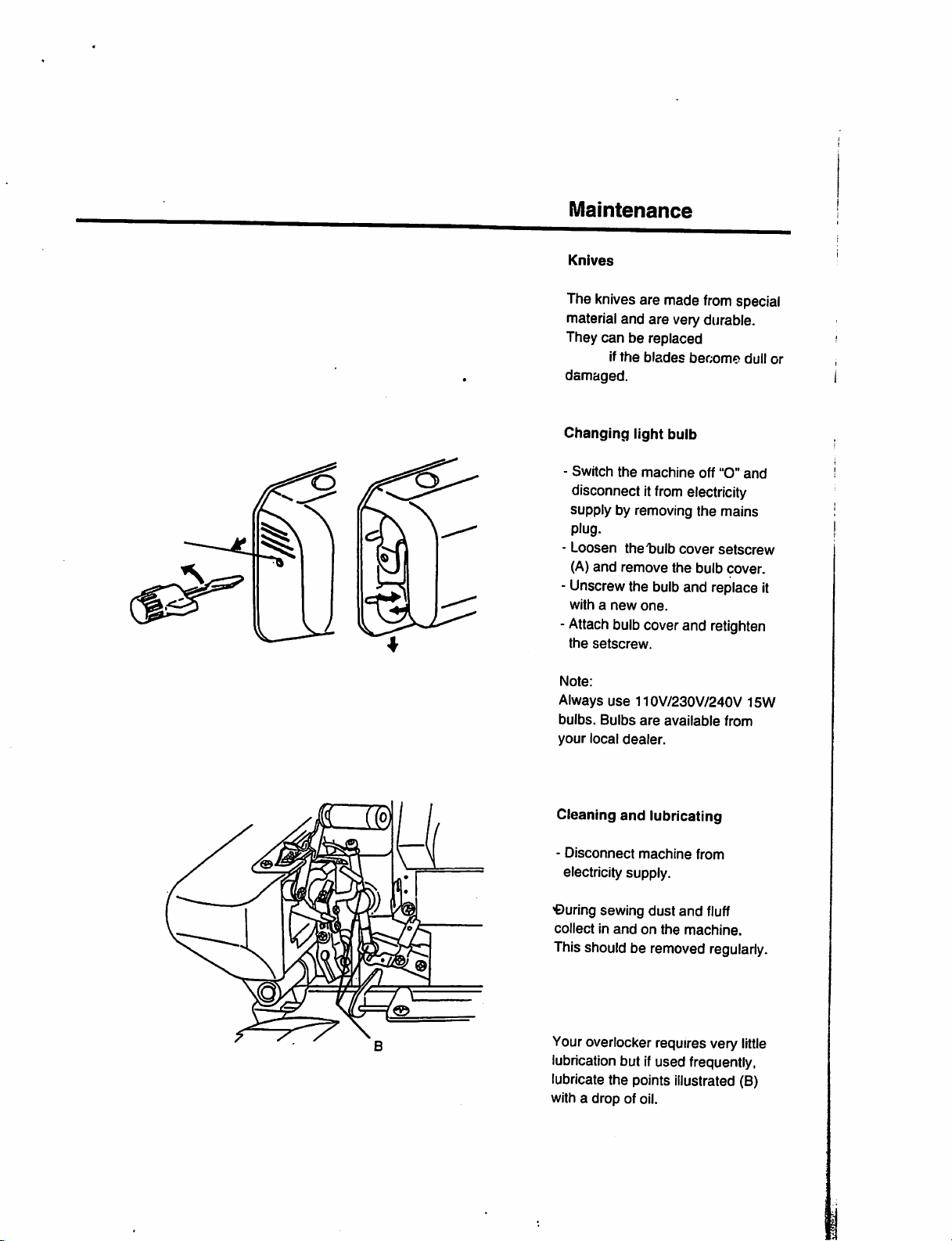

Knives

The

knives

are made

material

They

damaQed.

and

can

be replaced

If

the

are

blades

from

special

very durable.

become

dull

or

Changing

-

Switch

disconnect it

light buib

the

machine

from

off "O"

electricity

supply by removing the mains

plug.

-

Loosen

(A)

and

thet»ulb

remove

cover

the

bulb

setscrew

cover.

- Unscrewthe bulband replace

withanew

-

Attach

the

setscrew.

Note:

Always

bulbs.

your

local

Cleaning

-

Disconnect

electricity supply.

one.

bulbcoverand

use

110V/230V/240V

Bulbs

are

available

dealer.

and

lubricating

machine

retlghten

from

from

and

It

15W

'During sewing

collectinandonthe

dust

Thisshould be removed regularly.

Youroverlooker requires very

lubrication but ifused frequently,

lubricate the points illustrated (B)

with a drop of oil.

and

fluff

machine.

little

Page 19

Trouble

Thread

breaks

Needles

Skipped stitches

Poor

Seams

Seams

Fabric

Thread

Machine

stitch

flute or

pucker

edges

loops

break

formation

does

shooting

wave

(knits)

curl

are

loose

not

sew

guide

Thread tension is too tight forthread

used.

The machine is not threaded correctly.

Needles are incorrectly inserted.

Needles

are

Needles not inserted correctly.

Fabric

Needles

Wrong

Thread

tension

Differential feed is

Fabric

Differential

Too

formation.

Too

Cord not plugged in correctly.

Main

are

bent, blunt or

damaged.

was

pulled while sewing.

are

bentorblunt.

needles

used.

is not wound correctly round

dials.

set

incorrectly.

was

pulled while sewing.

much

little

switch

feedisset

fabricinthe

fabricinthe

not

incorrectly.

stitch

stitch

on.

the

points .

formation.

Reduce

thread

tension.

Check the threading.

Insert needles

flat

sidetothe

Replace

Insert

needles

flat

sidetothe

Guide

Replace

Use

system

Check

Adjust differential

••

Adjust

differential

fully

back.

the

needles.

fully into

back.

fabric gently with both hands.

the

needles.

HAxI (130/705H)

threading.

feed

feed

CX]

Reduce

cutting width, knife to the left.

Increase

Check

Switch

the cutting width, knife to the right.

plug.

machineon" 1

into needle clamp with

needle

clamp with

needles.

betweenNand

betweenNand

8

5

27

17/19

21/23

15

15

15

25

15

17/19

21/23

31

31

29

29

11

39

Page 20

Technical

stitch

types:

•2 needles. 4

seam

•1

needle.

Needle

system:

data

thread

3-thread

HAxI (130/705H)

Seam

width:

3-7

mm

Stitch

length;.

1-4

mm

Presser

max.

Handwheel:

rotates

Sewing

up to

foot

lift:

6mm

counter-clockwise

speed:

1300

s.p.m.

Weight:

7.3

kg

Dimensions:

340W*370DX350H

overtook with integrated safety

overlook,3thread

mm

rollhem,

Donnees

Points

rdallsables:

- 2 aiguilles, surjet d 4 fils

techniques

avec

point de

sdcuritd intdgrd

• 1 aiguille, surjet a 3 fils

Outlet

rould

k 3 fils

Syst6me

d'algullle:

HAxI (130/705 H)

Largeurdecouture:

3-7

mrn

Longueurdepoint:

1-4mm

EHvatenr de pied-de biche

6mmau

Rotation

En

Vitesse

Jusqu'd 1300 points,omite/mi

Polds:

73

Dimensions:

sens

leg.

max.

du

volant:

inverse

de

travalll

des

aiguilles

d'une

montre

- 340 (L) X370 (P) X350 (H) mm.

Standard

Dust

cover

accessory:

Special

Blind

Elasticator

Shirring

accessories

stitch

foot

foot

foot

Bead/sequin foot

Cording

foot

Accessoires

Moussedepiotection

standard

Pied

Pied

Accessoires

pour

points invisibles

pour

poser

w.

spdclaux:

des

elastiques

Taping

foot

Les

Special

from

accessories

your

dealer

are

available

accessoires

disponibles

ad

speclaux

aupr^sdeIdgent:

sont

Page 21

English

The product in this manual fulfil the demands in below norms:

Please

pay

attentiononthe

totally protection will

Greatcautionshould be

nectthe

overlook

machinebyremove

spoil

shown

needle

the

fimdemental

when

area:

working

plug

72/23

89/336

89/392

The

EEC

needle

fimction

in the

from

outlet

EEC

EEC

area

of the

needle

when

can

notbecompletely

overlook

area.

machine.

It is

recommendedtodiscon-*

changing

needle,

other work in the needlearea is required.

The light to

Dansk

Produktet i denne betjeningsvejledning opfylder kravene i nedenstSende noimer:

change

in construction and spefication

reserved.

proteced,asa

bulborwhen

72/23

89/336

89/392

Dog henledes

beskyttes fiildt ud, idet en total beskyttelse af

grundlsggende fiinktion. Der bor derfor udvises stor forsigtighed ved arbejde i n^eomrMet,

og det anbefales derfor at overlook maskinen afbrydes pS net-stikket ved udskiftning af nSl

eller ved andet arbejde i nSleomrldet.

Ret til aendringi konstruktion og specifikatioii forbeholdes.

opmaerksomheden

pS,

at nilens arbejdsomride pSoverlook maskinen ikke kan

EEC

EEC

EEC

n§leomr&det

vil

odelaegge

overlookmaskinens

45

Loading...

Loading...