Page 1

Portable Zigzag Sewing Machine

HZL-30Z / HZL-60

INSTRUCTION MANUAL

®

Page 2

“IMPORTANT SAFETY INSTRUCTIONS”

“When using an electrical appliance, basic safety precautions should always be followed, including the following:”

“Read all instructions before using this sewing machine.”

“DANGER_____To reduce the risk of electric shock:”

1. “An appliance should never be left unattended when plugged in. Always unplug this appliance from the electric

outlet immediately after using and before cleaning.”

2. “Always unplug before relamping. Replace bulb with same type rated 15 Watts.”

“W ARNING_____To reduce the risk of burns, fire, electric shock, or injury to persons:”

1. “Do not allow to be used as a toy. Close attention is necessary when this appliance is used by or near children.”

2. “Use this appliance only for its intended use as described in this manual. Use only attachments recommended

by the manufacturer as contained in this manual.”

3. “Never operate this appliance if it has a damaged cord or plug, if it is not working properly , if it has been dropped

or damaged, or dropped into water. Return the appliance to the nearest authorized dealer or service center for

examination, repair, electrical or mechanical adjustment.”

4. “Never operate the appliance with any air openings blocked. Keep ventilation openings of the sewing machine

and foot controller free from the accumulation of lint, dust and loose cloth.”

5. “Keep fingers away from all moving parts. Special care is required around the sewing machine needle.”

6. “Always use the proper needle plate. The wrong plate can cause the needle to break.”

7. “Do not use bent needles.”

8. “Do not pull or push fabric while stitching. It may deflect the needle causing it to break.”

9. “Switch the sewing machine off ("O") when making any adjustments in the needle area, such as threading

needle, changing needle, threading bobbin, or changing presser foot and the like.”

10. “Always unplug sewing machine from the electrical outlet when removing covers, lubricating, or when making

any other user servicing adjustments mentioned in the instruction manual.”

11. “Never drop or insert any object into any opening.”

12. “Do not use outdoors.”

13. “Do not operate where aerosol (spray) products are being used or where oxygen is being administered.”

14. “To disconnect, turn all controls to the off (“O”) position, then remove plug from outlet.”

15. “Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.”

“SAVE THESE INSTRUCTIONS”

“This sewing machine is intended for household use only.”

Use only foot controller

Be sure to turn power switch OFF and disconnect

the plug from the wall outlet before replacing the

sewing machine needle or lubricating the machine.

Do not use thinner or other similar solvents to clean

the machine.

1

with your HZL-30Z/HZL-60.

When not in use, be sure to turn power switch

OFF and unplug the machine.

Do not expose the machine to direct sunlight or

humid atmosphere.

Page 3

CONTENTS

Important safeguards ··········································· 1

Accessories ·························································· 2

Principal parts ······················································ 3,4

Major functions ···················································· 5,6

Winding the bobbin ············································· 7,8

Threading the machine ······································ 9,10

Changing the presser feet ··································· 1 1

How to remove and insert the needle ················· 11

Types of feet and their application ····················· 12

How to adjust thread tension ····························· 13

Stitch length of each stitch pattern ····················· 13

Fabric, thread and needle table ·························· 13

Straight stitch ··················································· 14,15

Reverse stitch ······················································ 15

Zigzag stitch ························································· 16

Stitch width vs stitch length

Overcasting ························································· 16

Buttonholes ······················································ 17,18

Corded Buttonholes ············································· 18

Inserting zippers ··················································· 19

Blind stitch ···························································· 20

Reinforcing stretch stitch ····································· 21

Patch work ··························································· 21

Optional parts ················································ 22~24

Invisible zipper foot / Even feed foot

Rolled hemming foot / Quilting attachment

Teflon-coated presser foot

How to replace light bulb ····································· 25

Cleaning ······························································· 25

Performance checklist ········································ 26

Specification table ················································ 26

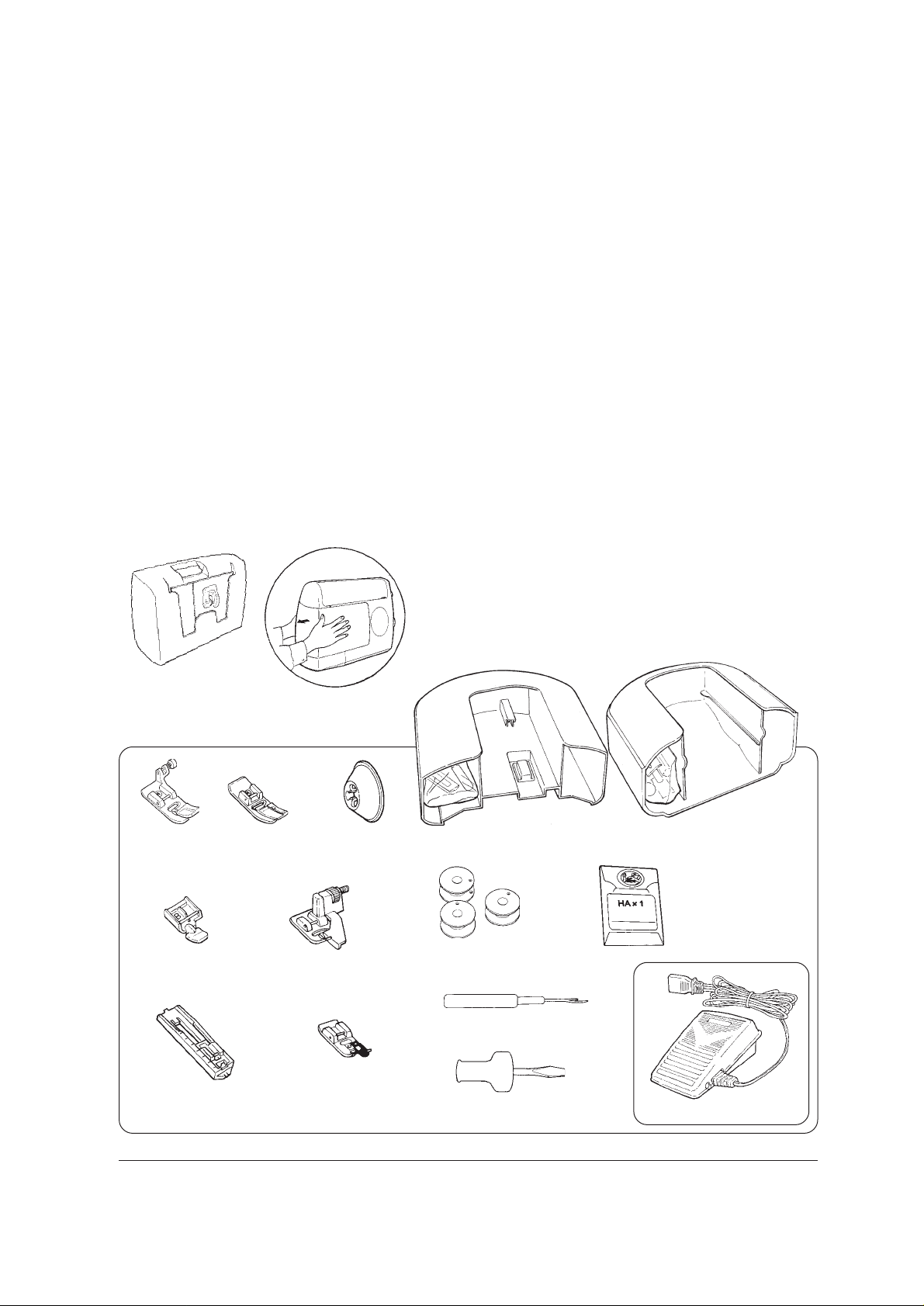

HZL-30Z

Y ou can keep instruction

manual at hard case.

Accessories

HZL-30Z

Standard presser foot (A)

Zipper foot (B)

Buttonhole foot (E)

HZL-60

HZL-60

Blindstitch presser foot (D)

HZL-30Z

Spool cap (small)

Overcasting foot (C)

HZL-30Z

Bobbins (3)

Seam ripper

Screwdriver

Auxiliary Bed

HZL-60

Needle pack

HAx1 No.11 2P

( )

No.14 1P

Speed controller

* Standard presser foot (A) is equipped with machine.

2

Page 4

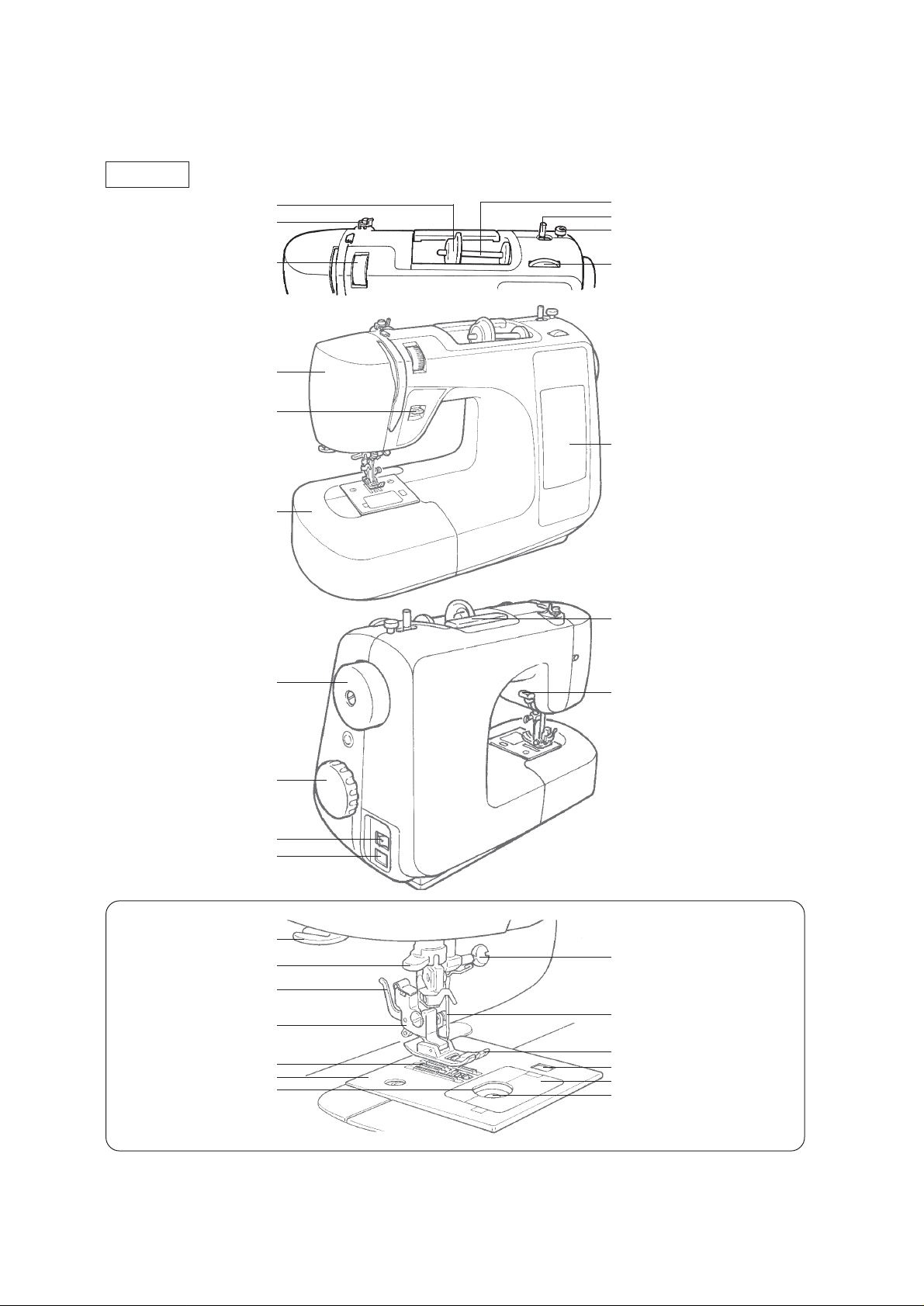

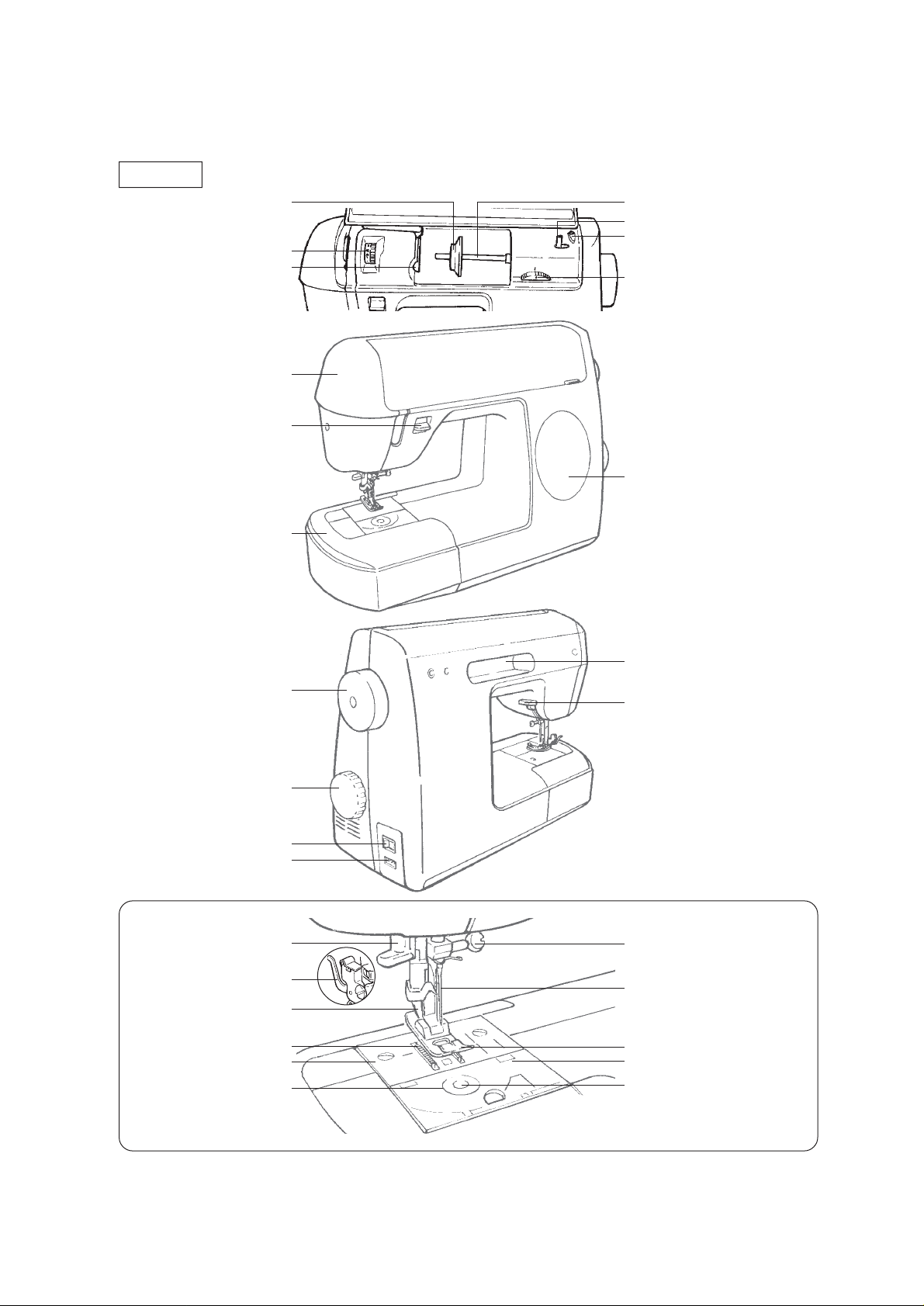

Principal Parts

HZL-30Z

Thread spool cap

Bobbin thread guide

Spool pin

Bobbin winder

Bobbin winding regulator

Thread tension dial

Face cover

Reverse stitch lever

Auxiliary bed

Handwheel

Stitch length dial

Pattern display panel

Handle

Presser foot lever

Stitch pattern dial

Light switch

Speed controller receptacle

Thread Cutter

Needle threader

Presser foot release lever

Presser foot holder

Feed dog

Needle plate

Bobbin case

3

Needle clamp

Needle

Presser foot

Hook cover release button

Hook cover

Bobbin

Page 5

HZL-60

Thread spool cap

Thread tension dial

Reverse stitch lever

Thread guide

Face cover

Auxiliary bed

Spool pin

Bobbin winder

Bobbin winding regulator

Stitch length dial

Pattern display panel

Handwheel

Stitch pattern dial

Light switch

Speed controller receptacle

Needle threader

Presser foot release lever

Presser foot holder

Feed dog

Needle plate

Bobbin case

Handle

Presser foot lever

Needle clamp

Needle

Presser foot

Hook cover

Bobbin

4

Page 6

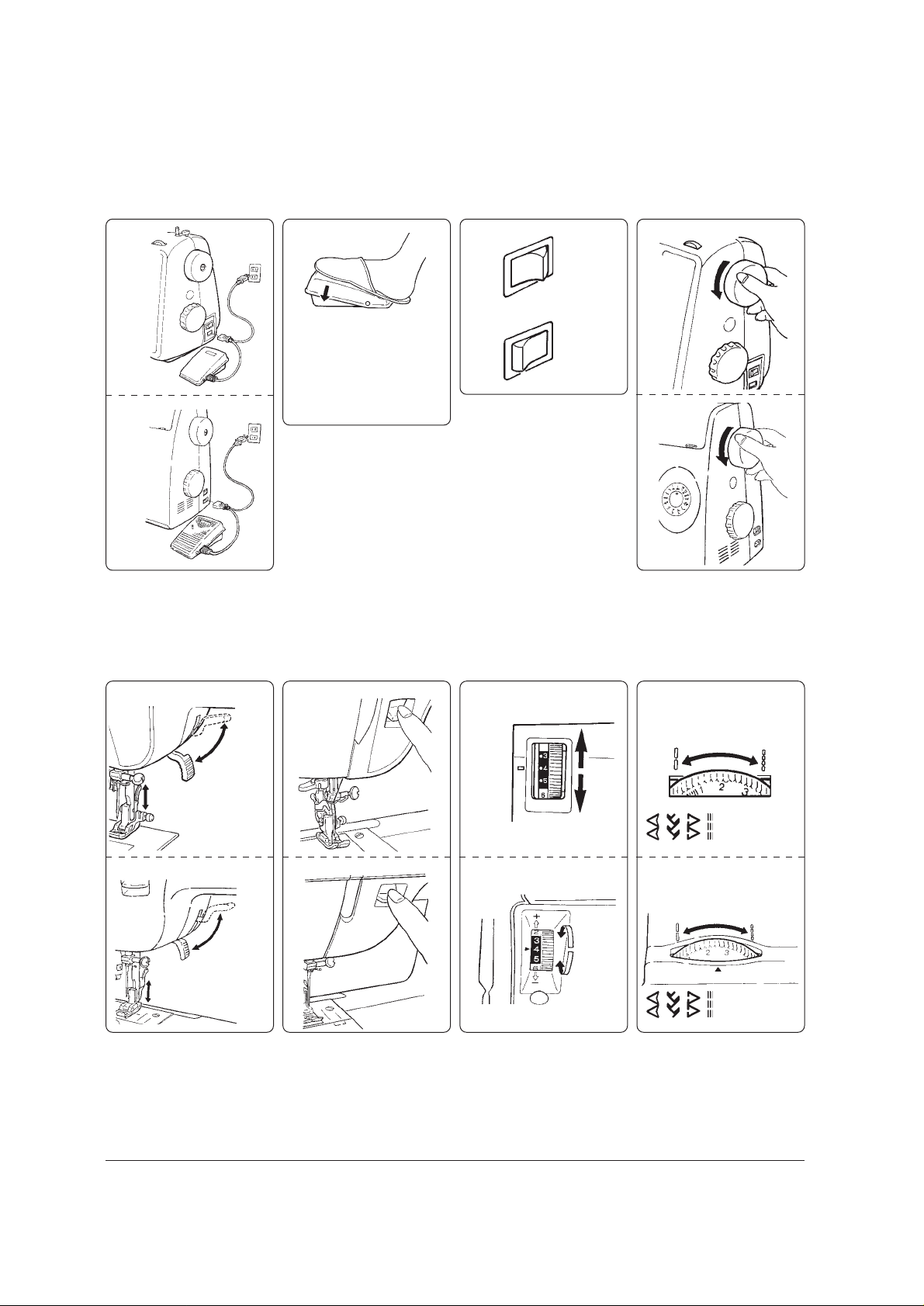

Major Functions

HZL-30Z

HZL-60

To run the machine press

foot speed controller. The

harder you press, the faster

machine will sew. To stop

machine, remove foot from

controller.

Push speed controller plug into

receptable at right end of the

machine. Plug power cord into

electric outlet.

Light switch

HandwheelSpeed controller

HZL-30Z

ON

OFF

HZL-60

Presser foot lever

HZL-30Z

Presser foot

comes down.

HZL-60

Presser foot

comes down.

Presser

foot

goes up.

Presser

foot

goes up.

Reverse stitch lever

HZL-30Z

HZL-60

The reverse stitch is used at

the beginning and end of a

seam to secure it.

Thread tension dial

HZL-30Z

To increase the needle thread

tension

To decrease the needle thread

tension

HZL-60

To increase the needle thread

tension

To decrease the needle thread

tension

Stitch length dial

HZL-30Z

T o increase the

stitch length

T o decrease the

stitch length

Automatic

stitch length

HZL-60

T o increase the

stitch length

T o decrease the

stitch length

Automatic

stitch length

5

Page 7

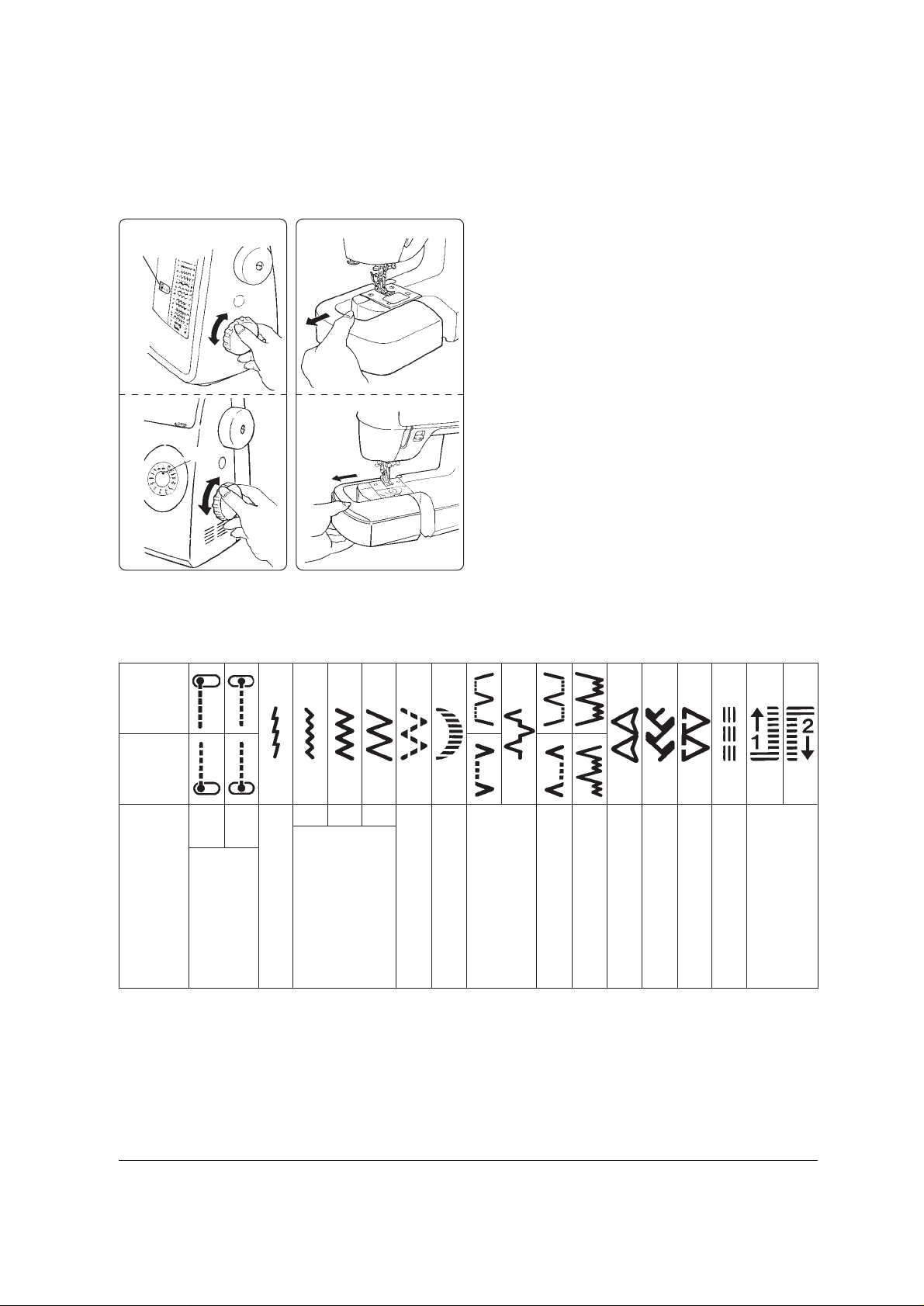

Stitch pattern dial Free arm

HZL-30Z

Pointer

HZL-30Z

HZL-60

Pointer

Stitch pattern

HZL-30Z

HZL-60

Left

side

position

Center

position

HZL-60

Draw the auxiliary bed to the

left side.

(S)

(L)(M)

Straight stitch

Straight stitch for elastic

Zigzag stitch

3-step zigzag stitch

Scallop stitch

Pattern stitch

Blindstitch

Blindstitch for elastic

Arrowhead

Overcasting

Patchwork

Stretch reinforcing stitch

Buttonholing

6

Page 8

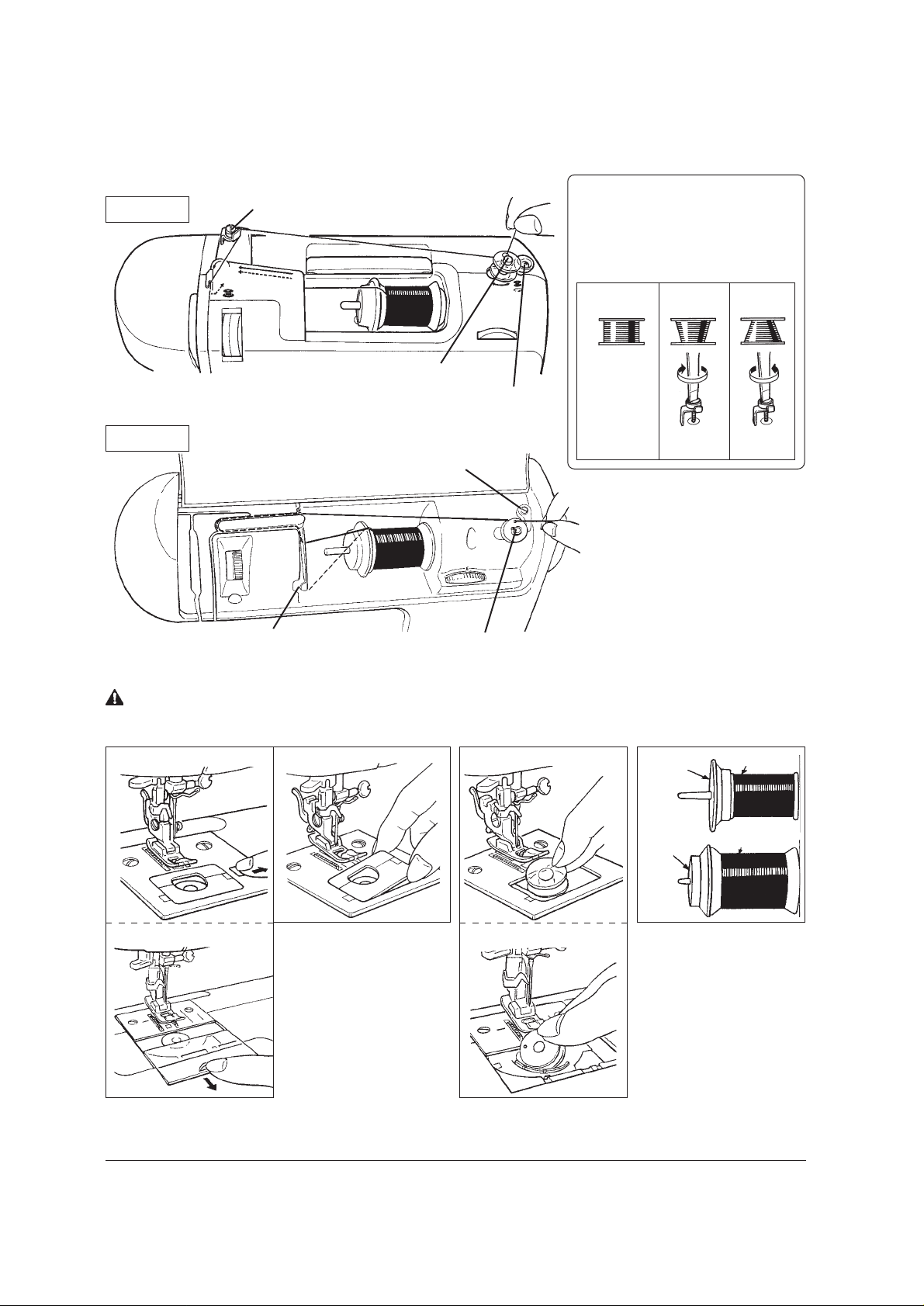

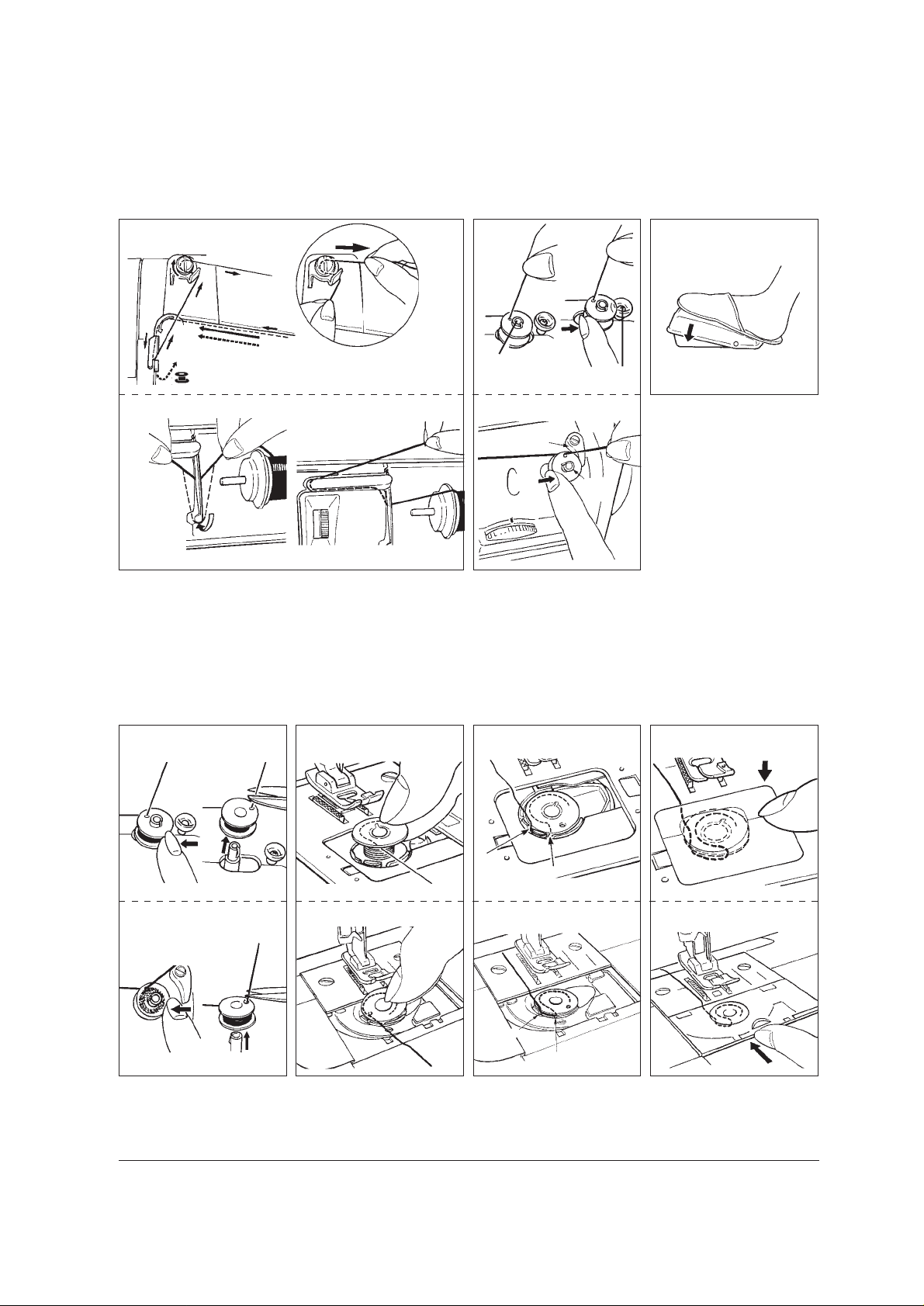

Winding The Bobbin

Threading for winding the bobbin

HZL-30Z

HZL-60

Thread guide

Bobbin winder

Bobbin winding regulator

Bobbin winding regulator

[HZL-30Z]

Adjusting the bobbin thread guide

In the case where the bobbin is unevenly

wound with thread according to the type of

thread, the bobbin thread guide has to be

adjusted.

•~•› •~

Move the bobbin thread

guide up or

down to adjust

so that the

bobbin is

evenly wound

with thread.

Thread guide

Caution:

Turn off the machine before opening the hook cover.

HZL-30Z

HZL-60

Bobbin winder

2. T ake out the bobbin.1. Open the hook cover .

HZL-30Z

HZL-60

3. Place the thread spool

and cap onto the spool

pin.

Thread

spool

cap

Thread

spool

cap

Small spool

Large spool

7

Page 9

4. Follow threading path into the bobbin winder thread

guide.

HZL-30Z

5. Place the bobbin on the

bobbin winding shaft.

HZL-30Z

6. Depress speed

controller to wind bobbin.

HZL-60

Hook the

thread into

the thread

guide.

7. Push the bobbin back

to the left.

HZL-30Z

Hook the thread into

the thread guide.

8. Place the bobbin in

case with thread pulling

off as illustrated.

HZL-30Z

Bobbin

winder

HZL-60

Bobbin winding

regulator

Press the bobbin against the

bobbin winding regulator.

Bobbin winding

regulator

Bobbin

winder

9. Pull the thread into the

groove of the bobbin

case.

HZL-30Z

10. Close the hook cover.

HZL-30Z

HZL-60

Cut the thread and take the

bobbin off the shaft.

HZL-60

[2]

[1]

HZL-60

[2]

[1]

Thread [1], place the thread on

the groove [2] and draw thread

to rear of machine.

HZL-60

8

Page 10

Threading The Machine

HZL-30Z

CAUTION:

* Be sure to raise the presser foot before threading the machine head.

Be sure to turn off the machine before threading.

[4]

Take-up

HZL-60

[4]

[7]

[8]

[2]

[7]

[3]

[8]

[5]

[2]

[3]

1. Raise the presser foot

lever.

HZL-30Z

[1]

HZL-60

[1]

2. Hook the thread into the

thread guide.

HZL-30Z

[2]

HZL-60

[2]

3. To thread the machine

follow steps.

HZL-30Z

HZL-60

[4]

[2]

[3]

9

4. 5. 6.

HZL-30Z

[3]

HZL-60

[5]

HZL-30Z

[4]

Take-up

HZL-60

[6]

Turn the handwheel to place

the take-up in the highest position.

Hook the thread in thread

guide from the right.

HZL-30Z

[5]

HZL-60

[7]

Page 11

Automatic Needle Threading

2. Push the threading lever

all the way down and a hook

1. Push the threading lever

down.

HZL-30Z

(A)

will go through the eye of the

needle.

HZL-30Z

* Check to be sure that the needle is in its highest position.

3. Slowly release the needle

threader and it will return to

its original position.

HZL-30Z

Hook

4. Pull the loop of thread

that is at the back of the

needle out about 4”.

HZL-30Z

HZL-60

HZL-60

(A)

Lower the threading lever

and place the thread onto

(A).

Pass the thread in front of the

needle and below the hook.

Pulling Up The Bobbin Thread

1. Hold the needle thread lightly with

the left hand and turn the handwheel

toward you until the needle enters the

needle plate.

HZL-30Z

HZL-60

Hook

2. Turn the handwheel

toward you.

HZL-30Z

HZL-60

3. Pull both the needle and bobbin

threads out by 10 cm.

HZL-30Z

HZL-60

Continue turning the handwheel while

holding the needle thread until the needle

rises.

HZL-60

Undo the loop with your finger.

HZL-60

10

Page 12

Changing The Presser Feet

2. Push the presser foot

1. Raise the presser foot.

HZL-30Z

release lever.

HZL-30Z

Push

CAUTION:

Make sure to disconnect the plug from the wall

outlet before changing the presser foot.

3. Align the presser foot

pin with the marker line on

needle plate.

HZL-30Z

Pin

Marker line

4. Lower the presser foot.

HZL-30Z

HZL-60

HZL-60

How T o Remove And Insert The Needle

2. Attaching the needle.

1. Removing the needle.

Needle clamp

screw

(The needle cannot be inserted unless it is correctly positioned.)

The flat

part should

face away

from you.

HZL-60

Stopper pin

CAUTION:

HZL-60

Make sure to disconnect plug from wall

outlet before inserting needle.

Screwdriver

(1) Turn the handwheel toward you to until

the needle bar reaches its highest

position.

(2) Loosen the needle clamp screw.

Needle to be purchased

When purchasing spare needles,

specify HAx1 (130/705H) for

household sewing machine or

HAx1SP (needle for knits).

11

Hold the needle with its flat part facing

away from you, and insert it fully until it

touches the stopper pin.

Checking the needle

Needle size

The larger the number,

the thicker the needle.

Parallel

Level plate

Securely tighten the needle clamp screw,

using the screwdriver furnished with the

machine.

* Check the needle for its

straightness occasionally .

Any bent needle would

cause stitch skipping,

thread breakage or damage

to materials.

Page 13

T ypes of Feet and Their Application

Feet

HZL-30Z

Stitch pattern

HZL-60

Typical applications

Straight stitch

standard presser foot (A)

HZL-30Z HZL-60

Straight stitch for elastic

Zigzag stitch

Scallop stitch

3-step zigzag stitch

Pattern stitch

Zipper foot (B)

Patchwork

Stretch reinforcing stitch

Setting zipper

Overcasting foot

(C)

Overcasting

(Overlocking)

Blindstitch

presser foot (D)

Feet

Stitch pattern

HZL-60 HZL-30Z

Typical applications

Blindstitch

Buttonhole foot (E)

Blindstitch for elastic

Buttonholing

12

Page 14

How T o Adjust Thread Tension

Correct the thread tension

Upper thread (Needle thread)

Fabric (right side)

Middle

of fabric

thickness

Fabric (wrong side)

Bobbin thread

The upper thread tension is too low.

Upper thread (Needle thread)

Bobbin thread

The upper thread tension is too high.

Normally, well-tensed seam is obtained when the

needle thread and bobbin thread interlace with

each other at the middle of the fabric thickness.

Bobbin thread

Stitch Length Of Each Stitch Pattern

Stitch

Best adjustment

Possible

adjustment scope

Adjustment

example

Straight stitch

HZL-60 HZL-30Z

2 ~ 2.5

0 ~ 4

for elastic

0 ~ 2.5

0.5 2.5

fabric

2.5

Zigzag stitch

1 1.4 2

0 ~ 4

Blindstitch

for elastic

fabric

2 1.5

0 ~ 4 0 ~ 4

Upper thread (Needle thread)

3-step

zigzag stitch

1

0 ~ 4 0 ~ 4 0 ~ 4 0 ~ 4

Pattern stitch Buttonholing

2 2.5 Automatic

HZL-30Z HZL-60

To increase upper

thread tension.

HZL-30Z

To decrease upper

thread tension.

Scallop stitch

0.5 0.4 ~ 0.6

Automatic

stitch

length

HZL-60

(0.2) (1)

Fabric, Thread And Needle Table

Light-weight

Medium-weight

Heavy-weight

Fabric

Lawn # 80~100 (No.9)

Georgette

Tricot

Wool and synthetic

fiber cloth

General cotton

and synthetic cloth

Light-weight jersey

General wool and

synthetic cloth

Jersey

Coating

Thread Needles

Silk

Synthetic thread/

Fine thread

Synthetic

Silk

Synthetic

Cotton

Synthetic

Silk

Synthetic

Cotton

Synthetic

Silk

Synthetic

Silk

# 90, 100

# 60~100

# 80

# 60~100

# 50~80

# 50~60

# 50

# 50~60

# 30~50

# 30~50

# 50

# 50~60

# 50

HA x 1

(130/705H)

No.1 1

Knitting needle

No.11

No.1 1

No.11~14

Knitting needle

No.11

No.11~14

No.14~16Denim

Knitting needle

No.11

No.11~14

Stitch length

HZL-30Z

HZL-60

Straight Zigzag

1 ~ 3 1 ~ 4

1.5 ~ 3 0.5 ~ 4

2 ~ 4 0.5 ~ 4

Thread

tension

dial

HZL-30Z HZL-60

HZL-30Z HZL-60

HZL-30Z HZL-60

* The knitting needles (HAx1sp) effectively prevent from stitch skipping, and ideal for sewing stretchy fabrics.

13

Page 15

Straight Stitch

The straight stitch is the basic stitch.

CAUTION: Turn off the machine before changing the presser foot.

1. Select a stitch pattern.

HZL-30Z

For

elastic

fabric

stitch

HZL-60

For

elastic

fabric

stitch

2. Make sure that the

presser foot is correct.

HZL-30Z

Standard presser

foot (A)

HZL-60

Standard presser

foot (A)

3. Set the fabric and lower

the presser foot.

HZL-30Z

HZL-60

Place the fabric under the

presser foot so the needle will

enter the sewing start point of the

fabric.

Pull both the needle and bobbin

threads to the rear of the machine and lower the presser foot.

4. Select the stitch length

range.

HZL-30Z

HZL-60

5. Begin sewing.

6. Lightly hold the fabric

with your hands.

HZL-30Z

HZL-60

Be careful not to apply excessive pulling force to the fabric

while sewing.

7. Adjust the sewing

speed.

8. Stop sewing.

14

Page 16

9. Remove the fabric from

the machine.

HZL-30Z

10. Cut the threads, using

the thread cutting groove.

HZL-30Z

Thread cutter

11. Knot the threads on the

wrong side of the fabric.

For elastic fabric

straight stitch

Finished seams are

elastic.

This stitch system

can be used for producing straight

stitches on elastic

fabrics such as knits

and jersey .

HZL-60

After finishing a seam, raise the

needle and the presser foot,

and slowly pull the fabric from

under the presser foot.

Reverse stitch

1. Press the reverse

[2]

[1]

Fabric

stitch button. Begin

sewing.

HZL-30Z

HZL-60

Thread

cutting

groove

Hold the upper and bobbin

threads together, pull them out

about 4” and cut them with the

thread cutting groove located

at the rear of the presser foot.

2. Detach the finger

from the reverse

stitch button, sew

the straight stitch.

HZL-30Z

Pull the upper thread to the

wrong side of the fabric, and

knot the upper and bobbin

threads. Cut the threads as

close to the knot as possible.

This technique is useful for

securing the pattern stitches.

Beginning of sewing heavy-weight fabric

[HZL-30Z]

Pressing the button (spring) that is

mounted on the presser foot into

the groove in the presser foot

holder, lower the presser foot.

To start sewing from the

multi-layer material edge,

use the button mounted on

the presser foot to make the

presser foot parallel to the

fabric, thereby ensuring

smooth sewing.

3. Press the reverse

stitch button.

HZL-30Z

4. Stop sewing.

[3]

The reverse stitch is

used at the beginning

and end of a seam to

secure it.

15

HZL-60

HZL-60

HZL-60

Page 17

Zigzag Stitch

1. Select a stitch pattern.

HZL-30Z

(S)

(M)

CAUTION: Make sure to turn off the machine before changing the presser foot.

2. Make sure that the

presser foot is correct.

HZL-30Z

Standard presser

foot (A)

Stitch width vs.stitch length

Pattern

(L)

HZL-60

(S)

(M)

(L)

HZL-60

Overcasting

Used to prevent fabric from fraying.

2. Replace the presser foot.1. Select a stitch pattern.

HZL-30Z

(L)

HZL-30Z

(S) 1.5

(M) 3.3 (L) 5

~~~

Standard presser

foot (A)

Stitch length Stitch width

0.5 4 0.5 4 0.5 4

CAUTION: Make sure to turn off the machine before changing the presser foot.

4. In case of the overcasting

3. Set the stitch length.

HZL-30Z

1 ~ 2

presser foot.

HZL-30Z

HZL-60

(L)

There are three stitch types

that can be used for overcasting.

Standard presser foot (A)

(L)

HZL-60

(L)

Overcasting foot (C)

Standard presser foot (A)

Overcasting foot (C)

Automatic

stitch length

HZL-60

1 ~ 2

Automatic

stitch length

Guide

HZL-60

Guide

Place the fabric against the foot

guide so that the needle sews

close to the edge.

16

Page 18

Buttonholes

CAUTION:

Make sure to turn off the machine before changing the presser foot.

1. Install the presser foot

for buttonholing.

HZL-30Z

HZL-60

Install it so that its scale comes

to the left-hand side.

2. Set the stitch length.

HZL-30Z

0.2 ~ 1

HZL-60

0.2 ~ 1

3. Mark the fabric.

Mark

Mark the fabric to indicate

the buttonhole placement.

4. Push the slide and set the

mark.

HZL-30Z

Mark

The slide

HZL-60

Mark

Lower the buttonhole foot so that the

mark is at the center of the needle

hole in the foot.

Push

Push

5. Select a buttonhole that matches your

purpose.

HZL-30Z

HZL-60

Step of procedure for making a choice of pattern to be

sewn.

Adjusting stitch

balance of

buttonhole stitching.

The adjusting screw is

located on the under

handwheel and can be

turned with a screwdriver

through the hole.

Incorrect Adjustment Correct

17

Page 19

6. Open the completed

buttonhole, using the

seam ripper.

Stopper pin

In the eventof buttonholing failure

In the case where a buttonholing

failure has arisen when the machine

has been sewing the right-parallel

seam of the buttonhole.

1. Lift the presser foot and undo the seam.

2. Select the “ ” using the pattern

selector dial.

3. Run the machine idle by approximately

10 stitches.

4. Select the “ ” using the pattern

selector dial.

Then, perform the buttonholing again from the

sewing start position.

In the case where a buttonholing

failure has arisen when the machine

has been sewing the left-parallel

seam of the buttonhole.

1. Lift the presser foot and undo the seam.

2. Select the “ ” using the pattern

selector dial.

Then, perform the buttonholing again from the

sewing start position.

Corded Buttonholes

Sewing a cord into the buttonholes will

prevent them from becoming loose and

they will last longer. Buttonhole twist

thread may be used for cording.

How to set the cord.

Cord

(Front)

(back)

CAUTION: Make sure to turn off the machine before

changing the presser foot.

When you sew buttonholes with cording, pass the cord through the end of the

buttonhole foot and knot the ends of the threads at the front. Then, attach the

buttonhole foot to the presser bar and sew the buttonhole. Pull the cording tight

into the sewn buttonhole and cut off the excess cord.

18

Page 20

Inserting Zippers

CAUTION: Make sure to turn off the machine before changing the presser foot.

Zippers may be inserted in several ways.

The type and location of the zipper will help you choose the right method.

1. Select a stitch pattern. 3. Change the presser foot.

HZL-30Z

Left

side

position

HZL-60

Left

side

position

2.

Seam...Stitch length [2]

Machine-baste...Stitch length [4]

Reverse stitch

(1 cm)

Fabric

(wrong side)

A zipper is lapped when one edge of the fabric opening overlaps and conceals it, allowing only one stitching line to show.

· Machine-baste the zipper opening together on the

seamline, and press open the seam allowance.

Zipper foot (B)

(Left)

(Right)

· If the zippers is left of the needle, the left

side of the zipper foot goes on the shank.

· If the zippers is right of the needle, the

right side of the zipper foot goes on the

shank.

Lapped Insertion

1. Lapped: Zippers usually are inserted

in the side seam of the garment.

3mm

Teeth

Fabric

(wrong side)

Slider

1cm

2. 3.

Attach the

right side

Fabric

(wrong side)

Zipper opening size

Stitch length [2]

Slider

Attach the

left side

Reverse

stitch

Stitch length [2]

Machine-baste

Fabric

(right side)

· The edge of the teeth following the seam line.

· Stitch the zipper to the seam allowance from

bottom to top.

Centered Insertion

1. Lapped: Zippers usually are inserted

in the side seam of the garment.

Seamline Slider

Machine-baste

Zipper

(wrong side)

Teeth

Fabric

(wrong side)

· Machine-baste the zipper opening to the

seamline, and press open the seam allowance.

Fabric

(wrong side)

19

· Smooth back the seam allowance at the edge

of the zipper.

· Stitch the zipper from bottom to top, as shown,

near the seam allowance folded edge.

· Pin or machine-baste the zipper to the garment

from the wrong side, through zipper tape, the

seam allowance, and the front of the garment.

· Turn the garment right side out.

· Stitch across the lower end of the zipper and up

to the waistline. Use the basting stitches as a

guide.

· Remove the basting and press.

2. 3.

Attach the

right side

Reverse

stitch

Fabric

(wrong side)

Stitch length [2]

· Baste through the zipper tape, seam allowance

and garment exterior .

· Turn the garment left side up and top-stitch it to

the zipper, sewing through all layers.

Machine-baste

· Right side sewing through all layers.

· Remove the basting and press.

Attach the

left side

Reverse

stitch

Fabric

(right side)

Stitch length [2]

Page 21

Blindstitch

CAUTION: Make sure to turn off the machine before changing the presser foot.

Blind stitching provides a durable way to finish a hem and is

presented as an instantly selectable pattern as a convenience.

It takes practice, however, so a test sample is suggested.

1. Overcast the fabric,

and fold the edge.

1. Fold the fabric and then baste it.

0.5~0.6 cm

Fabric

(wrong

side)

2. Fold the fabric at

the basting stitch seam.

Fabric

(wrong

side)

3.

Fabric

(wrong

side)

Refer to page 16 for overcasting.

Finished

hem

Basting

2. Select the blindhem

stitch pattern.

HZL-30Z

For

elastic

fabric

stitch

HZL-60

For

elastic

fabric

stitch

* Set the stitch length.

HZL-

30Z

HZL-

60

:2~4

:1.5~3

3. Change the presser

foot.

HZL-30Z

Blindstitch presser foot (D)

HZL-60

Blindstitch presser foot (D)

4. Position the folded

edge against the guide.

Fabric

(wrong

side)

Guide

Place the folded edge

against the presser foot

guide, and sew the fabric.

5. Turn the fabric over.

Fabric

(wrong side)

Finished hem

After sewing the seam, turn the

fabric over.

Fabric

(right side)

How to adjust stitch width

If the stitches fail to reach the folded edge:

HZL-30Z HZL-60

If the stitches reach too far beyond the folded edge:

HZL-30Z HZL-60

Turn the screw

toward you.

This will move the

guide to the right.

Place the foded

edge sungly

against the repositioned guide.

Turn the screw

away from you.

This will move the

guide to the left.

Place the foded

edge sungly

against the repositioned guide.

20

Page 22

Reinforcing stretch stitch

Stretch stitching reinforces the seam on elastic fabric

or sections that are likely to after overdged.

2. Make sure that the

1. Select the pattern.

HZL-30Z

presser foot is correct.

HZL-30Z

Standard presser

foot (A)

3.

CAUTION:

Automatic

stitch

length

Make sure to turn off the machine

before changing the presser foot.

Application examples

Sewing sleeve to armhole

Back body

HZL-60

Patch Work

1. Running stitch.

1 cm

Runstitch

Fabric

(wrong

side)

Outlet

seam

Fabric

(wrong

side)

HZL-60

Standard presser

foot (A)

CAUTION:

Make sure to turn off the machine before changing the presser foot.

2. Select the pattern.

HZL-30Z

3. Check that the

presser foot is the

correct one.

HZL-30Z

Standard

presser

foot (A)

Side

Open patch Overlapping patch

Fabric

(right

side)

Press the seam open.

Reinforcing stitch

Patch pocket

Attaching handles to bags

Fabric

(right

side)

Press the seam open.

21

HZL-60

HZL-60

Standard

presser

foot (A)

Page 23

Optional parts

Invisible zipper foot

Pattern to be used

HZL-30Z HZL-60

Since a seam does

not appear on the

right side of fabric,

opening can be finished with fabric

edges neatly butted.

CAUTION:

Make sure to turn

off the machine

before changing

the presser foot.

1. Check the zipper opening size. Install

the standard presser foot (A).

Basting

Opening end

Opening size

Fabric

(wrong side)

Runstitch

Reverse stitch (1 cm)

Place two pieces of fabric face to face. Baste the

fabric from the edge of fabric to the opening end.

At the opening end, change the stitch length to

[2.0] and sew reverse stitches by 1 cm and sew

until the predetermined position is reached.

Neatly open the seam allowance.

Zipper size

2.5 cm

3. 4.

2.

Basting

Basting

Fabric

(wrong side)

Cardboard

Put the invisible zipper on the fabric so that its

center meets the seam line. Place a cardboard

between the seam allowance and front fabric.

Manually baste both sides of seam allowances

and zipper tapes.

Upon completion of basting, remove the cardboard.

(only zipper tape and

seam allowance)

Invisible zipper

(wrong side)

Invisible

Tape

zipper foot

Undo the basting stitch seam to the bottom of opening as shown in the sketch

given in step 1. Then, open the zipper.

5.

Invisible

zipper foot

Teeth

Seam

Aligning the teeth of either zipper tape with the groove

on the zipper foot, sew the zipper at the very edge of

the teeth from the end of opening while raising the teeth

with fingers.

Teeth

Fabric

6.

Seam

Tape

Fabric

Slider

Sew the remaining zipper tape on the other side of seam

allowance in the same procedure. (The lower portion of

zipper tape located below the bottom of the opening will

remain loose without sewn on the seam allowance.)

Take out the slider and pull it out to appear on the right side of the fabric.

22

Page 24

Even feed foot

Pattern to be used

HZL-30Z

HZL-60

1. Remove presser foot holder . 2. Attach even feed foot to machine.

Actuating lever

Presser bar

Presser foot

clamp screw

Needle

clamp screw

Presser foot clamp screw

This even feed foot is generally used for fabrics (such

as knits, jersey, vinyl cloth,

artificial leather and leather)

that are difficult to be fed by

sewing machine. It ensures

smooth feed of fabric while

preventing fabric slippage

to achieve neatly finished

seams.

CAUTION:

Make sure to turn off the machine

before changing the presser foot.

Rolled hemming foot

Pattern to be used

Lift presser bar, remove presser foot clamp

screw and presser foot holder.

Put forked section of actuating lever around

needle clamp, attach to presser bar and securely tighten presser foot clamp screw.

* Sewing speed should be set at low to medium.

1. Remove presser foot holder . 2. Attach even feed foot to machine.

0.5cm

0.8cm

10cm

Groove

Fabric

HZL-30Z HZL-60

Fabric edge is hemmed

while rolling it under .

Used for finishing bottom

of shirts and blouses and

edges of frills and handkerchiefs.

CAUTION:

Make sure to turn

off the machine

before changing

the presser foot.

23

Cut away a corner of fabric in order to make

work easier.

Insert fabric into spiral groove in hemmer foot

until needle position is reached.

Drawing ends of needle and bobbin threads,

turn handwheel 3 or 4 turns by hand to guide

fabric to hemmer foot.

Page 25

Quilting attachment

Pattern to be used

HZL-30Z

HZL-60

Two piles of fabric are

stitched together with batting placed between them

to produce quilt with your

original design.

CAUTION:

Make sure to turn off the machine

before changing the presser foot.

1. Remove presser foot

holder.

Presser bar

Presser foot clamp screw

Lift presser bar, remove

presser foot clamp screw and

presser foot holder.

2. Attach throat plate

cover over throat plate.

3. Install the quilting foot.

T eflon-coated presser foot

Teflon coating provides

smooth surface.

T eflon presser foot is suitable for hard-to-feed fabrics (jersey, vinyl cloth or

leather).

CAUTION:

Make sure to turn

off the machine

before changing

the presser foot.

24

Page 26

How To Replace Light Bulb (How To Remove The Face Cover)

1. 2.

HZL-30Z

HZL-30Z

CAUTION:

Be sure to disconnect the plug from the wall outlet

before replacing light bulb.

Contact the dealer in your area for the correct light bulb

replacement.

Light bulb is hot after usage of the machine.

HZL-60

Loosen setscrew located on

rear face of machine. Slide

cover straight in a lateral direction until it comes off.

HZL-60

Increase

Decrease

The power consumption of the

light is 15 watts.

Maintenance of the sewing machine (cleaning)

3. Clean the area between

1. Remove the needle plate.

HZL-30Z

2. Take out the bobbin

case.

HZL-30Z

the feed dog teeth and in

the hook.

HZL-30Z

CAUTION:

Be sure to disconnect the plug

from wall outlet before cleaning and lubricating machine.

4. After cleaning machine,

reinstall bobbin case and

needle plate.

HZL-30Z

HZL-60

25

HZL-60

HZL-60

Fitting projection of bobbin case

holder with part marked with arrow , drop holder in place.

HZL-60

Page 27

Performance Checklist

If sewing difficulties occur, make sure the instructions are correctly followed.

If a problem still exists, the reminders below may help solve it.

Problem Cause (Reason) Action to be taken

The machine does

not feed the fabric.

The needle breaks.

The thread breaks.

The bobbin thread

breaks.

Skipped stitches.

Loud noise is head.

Fabric puckers.

The sewing

machine will not run.

The needle threading lever cannot be

done.

* The machine runs idle.

* The stitch length has been set to zero.

* The needle has been inserted wrong.

* The needle is bent or is blunt.

* The presser foot is not the correct one.

* The needle and the threads do not match.

* Threading is not correct.

* The thread has a knot in it.

* The thread tension is not correct.

* The needle is bent.

* The needle has been inserted wrong.

* The needle is bent.

* Threading is not correct.

* Dust has accumulated on the feed dog. * Clean the machine.

* The fabric, the needle and the thread do

not match.

* The bobbin winder was left in winding

position.

* Dropping the needle in the needle plate.

* The needle is not in the highest position.

* The needle has not been fully inserted into

the needle bar.

* The machine starts when the needle

threader is pushed down.

* Return bobbin winder to the left.

* Set the stitch length “ 1 - 4 ”.

* Properly insert the needle.

* Replace the needle with a new one.

* Use the correct presser foot.

* Use proper thread or needle.

* Correctly thread the machine.

* Remove the knot.

* Correct the thread tension.

* Replace the needle.

* Properly insert the needle.

* Replace the needle

* Correctly thread the machine.

* Use the correct size needle and the thread.

* Move the bobbin winder back fully to the left.

* Remove the needle.

* Turn the handwheel until the needle reaches

its highest position.

* Properly insert the needle.

* Turn the handwheel toward the back side a

little.

Page

7,8

13

11

11

12

13

9,10

-

13

11

11

11

9,10

25

13

7,8

-

9,10

11

-

The stitch pattern

dial cannot be

turned.

Specification table

Item Specification (HZL-30Z)

Dimensions 410 (W) x 300 (H) x 180 (D) mm

Dimensions when

attached with case

Weight

Rated voltage /

Power consumption

Power consumption

of lamp

440 (W) x 305 (H) x 215 (D) mm

6.6 kg (when attached with case: 7.7 kg)

120V / 1.0A 60Hz (USA and Canada only)

220-230V / 85W 50 / 60Hz

120V / 15W (USA and Canada only)

240V / 15W

* Raise the presser foot lever, turning the

handweel toward you.

Specification (HZL-60)

384 (W) x 292 (H) x 166 (D) mm

384 (W) x 292 (H) x 166 (D) mm

6.5 kg (when attached with case: 6.8 kg)

120V / 1.0A 60Hz (USA and Canada only)

220-230V / 85W 50 / 60Hz

120V / 15W (USA and Canada only)

240V / 15W

-

26

Page 28

®

8-2-1, KOKURYO-CHO,

CHOFU-SHI, TOKYO 182-8655, JAPA N

PHONE: 03(3480)5034

FAX: 03(3480)5037

E-mail: hsm@juki.co.jp

http:// www.juki.co.jp

Copyright © 2003 JUKI CORPORATION.

All rights reserved throughout the world.

000903•iJ•jA9250 30Z 000

Loading...

Loading...